Nissan Altima 2000 Owner's Manual

MANUAL TRANSAXLE

GI

CONTENTS

PREPARATION...........................................................2

Special Service Tools..............................................2

Commercial Service Tools......................................4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING................................................5

NVH Troubleshooting Chart....................................5

Manual Transaxle...............................................5

DESCRIPTION............................................................6

Cross-sectional View ..............................................6

ON-VEHICLE SERVICE .............................................7

Replacing Oil Seal..................................................7

Position Switch Check............................................8

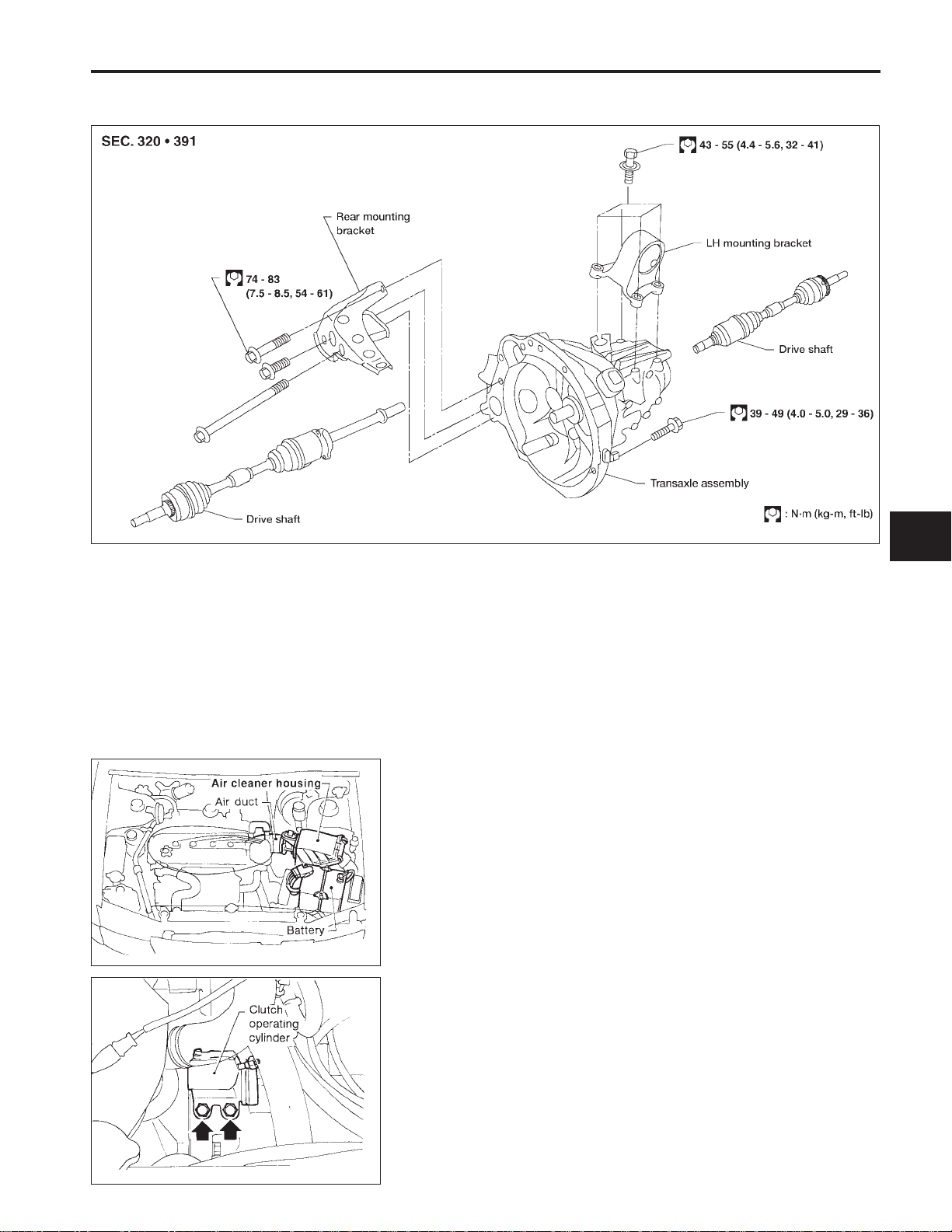

REMOVAL AND INSTALLATION...............................9

Removal..................................................................9

Installation.............................................................12

TRANSAXLE GEAR CONTROL..............................13

MAJOR OVERHAUL................................................14

Case Components................................................14

SECTION MT

Gear Components.................................................15

Shift Control Components.....................................16

DISASSEMBLY.........................................................17

REPAIR FOR COMPONENT PARTS.......................20

Input Shaft and Gears ..........................................20

Mainshaft and Gears ............................................25

Final Drive.............................................................29

Shift Control Components.....................................31

Case Components................................................31

ADJUSTMENT..........................................................33

Input Shaft End Play and Differential Side

Bearing Preload....................................................33

Mainshaft Bearing Preload ...................................34

ASSEMBLY...............................................................37

SERVICE DATA AND SPECIFICATIONS (SDS).....41

General Specifications..........................................41

Inspection and Adjustment....................................42

MA

EM

LC

EC

FE

CL

MT

AT

FA

RA

BR

ST

RS

BT

HA

EL

IDX

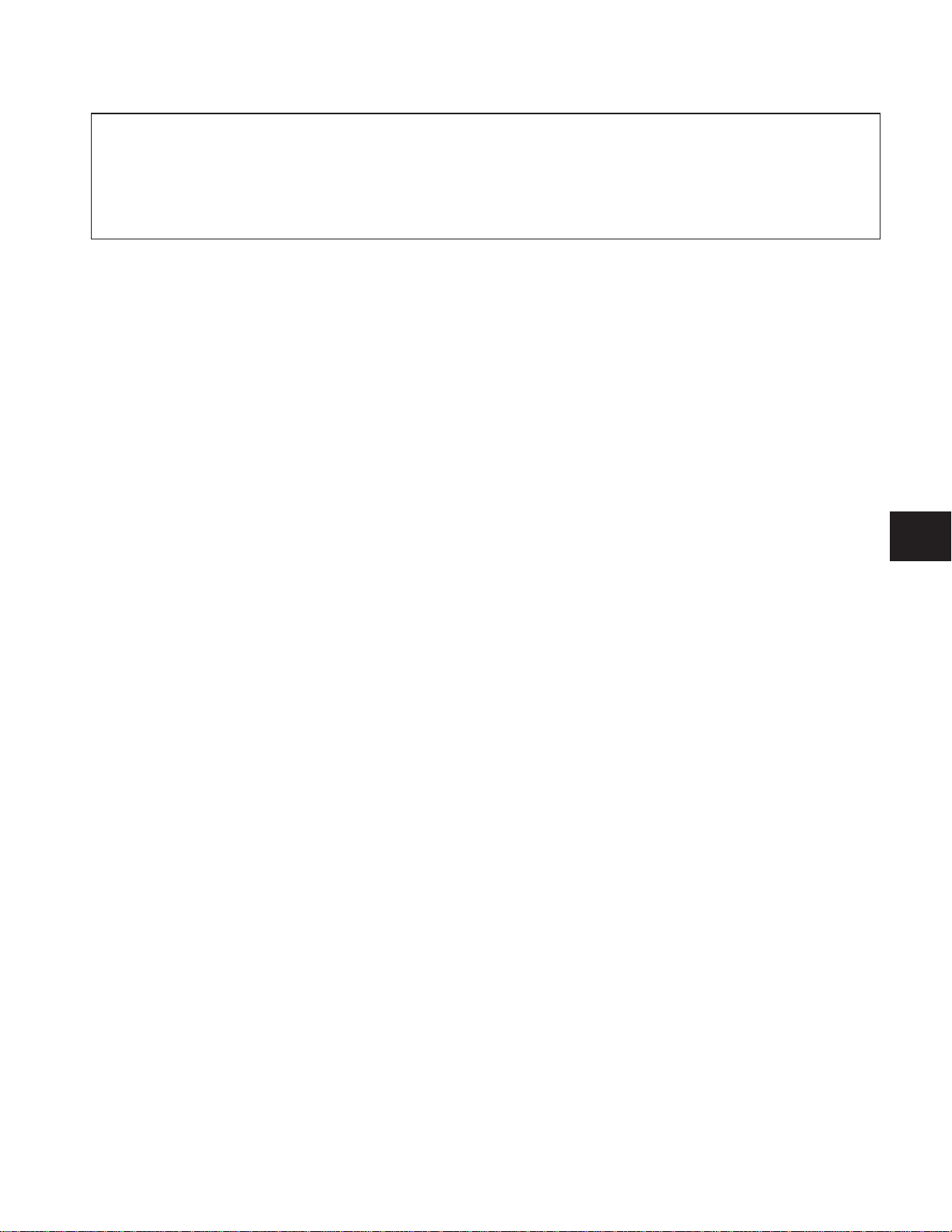

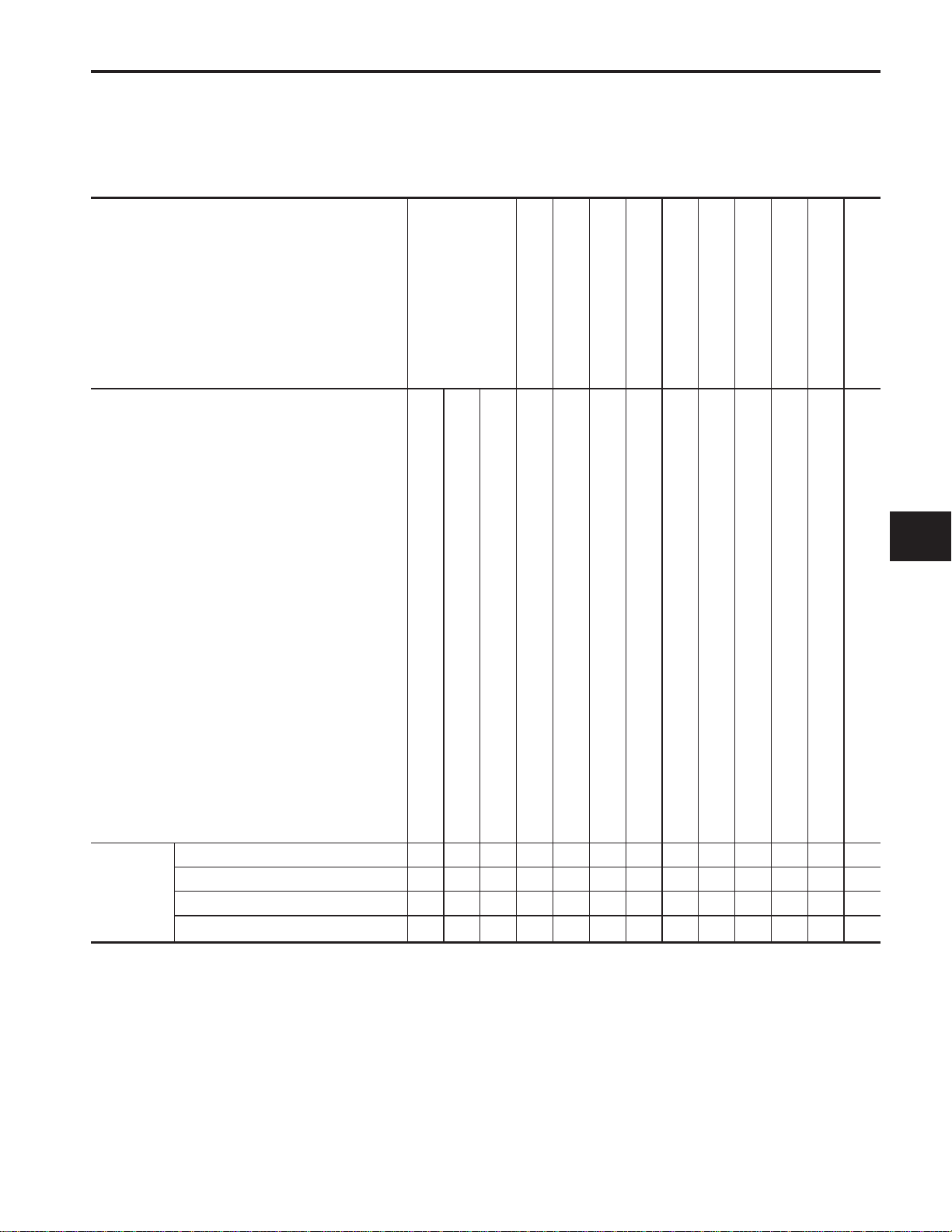

PREPARATION

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

KV38106500

(J34284)

Preload adapter

KV32101000

(J25689-A)

Pin punch

ST22730000

(J25681)

Puller

ST30031000

(J22912-01)

Puller

NT087

NT410

NT411

Measuring turning torque of final drive

assembly

Measuring total turning torque

Measuring clearance between side gear and

differential case with washer

Selecting differential side bearing

adjusting shim

Removing and installing retaining pin

a: 4 mm (0.16 in) dia.

Removing mainshaft front and rear bearing

inner race

a: 82 mm (3.23 in) dia.

b: 30 mm (1.18 in) dia.

Removing input shaft front and rear bearing

Removing 4th & 5th main gear

ST30021000

(J22912-01)

Puller

ST3306S001

(J22888-D)

Differential side bearing

puller set

1

ST33051001

s

(J22888-D)

Puller

2

ST33061000

s

(J8107-2)

Adapter

NT411

NT411

AMT153

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

Removing 5th synchronizer

Removing 3rd & 4th synchronizer

Removing 2nd & 3rd main gear

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

Removing differential side bearing

inner race

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

c: 130 mm (5.12 in)

d: 135 mm (5.31 in)

e: 100 mm (3.94 in)

MT-2

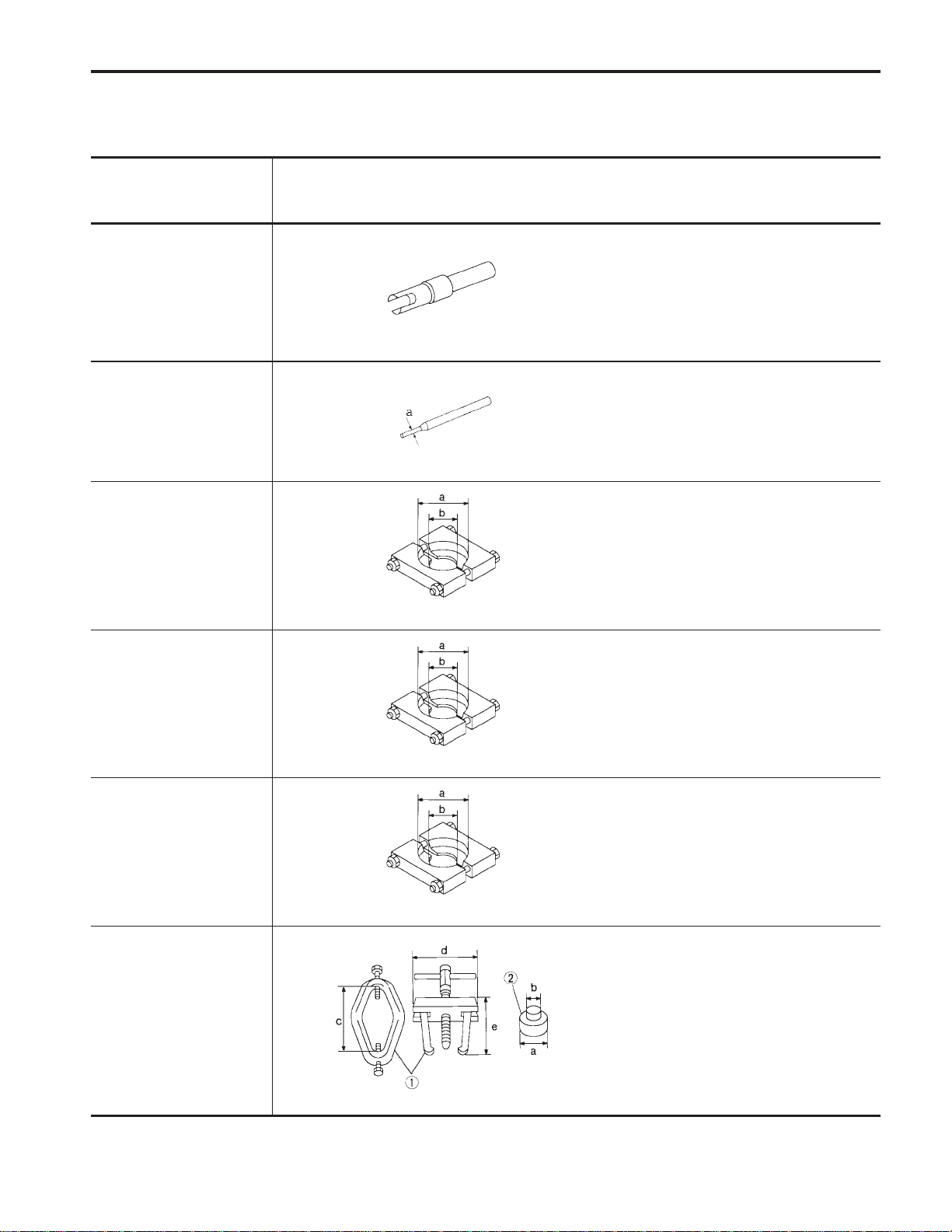

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Special Service Tools (Cont’d)

Description

GI

ST33290001

(J34286)

Puller

ST33400001

(J26082)

Drift

ST30600000

(J25863-01)

Drift

ST22452000

(J34335)

Drift

NT414

NT086

NT065

Removing differential oil seal

Removing mainshaft rear bearing outer race

Removing differential side bearing outer

race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

Installing differential oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing input shaft front bearing

a: 36 mm (1.42 in) dia.

b: 31 mm (1.22 in) dia.

Installing 3rd, 4th and 5th main gear

MA

EM

LC

EC

FE

CL

MT

AT

FA

ST30621000

(J25742-5)

Drift

ST30611000

(J25742-1)

Drift

ST307200000

(J25405)

Drift

NT065

NT073

NT419

NT115

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

Installing mainshaft rear bearing outer race

(Use with ST30611000.)

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

Installing mainshaft rear bearing outer race

(Use with ST30621000.)

a: 15 mm (0.59 in)

b: 335 mm (13.19 in)

c: 25 mm (0.98 in) dia.

d: M12 x 1.5P

Installing differential side bearing outer race

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

RA

BR

ST

RS

BT

HA

EL

IDX

MT-3

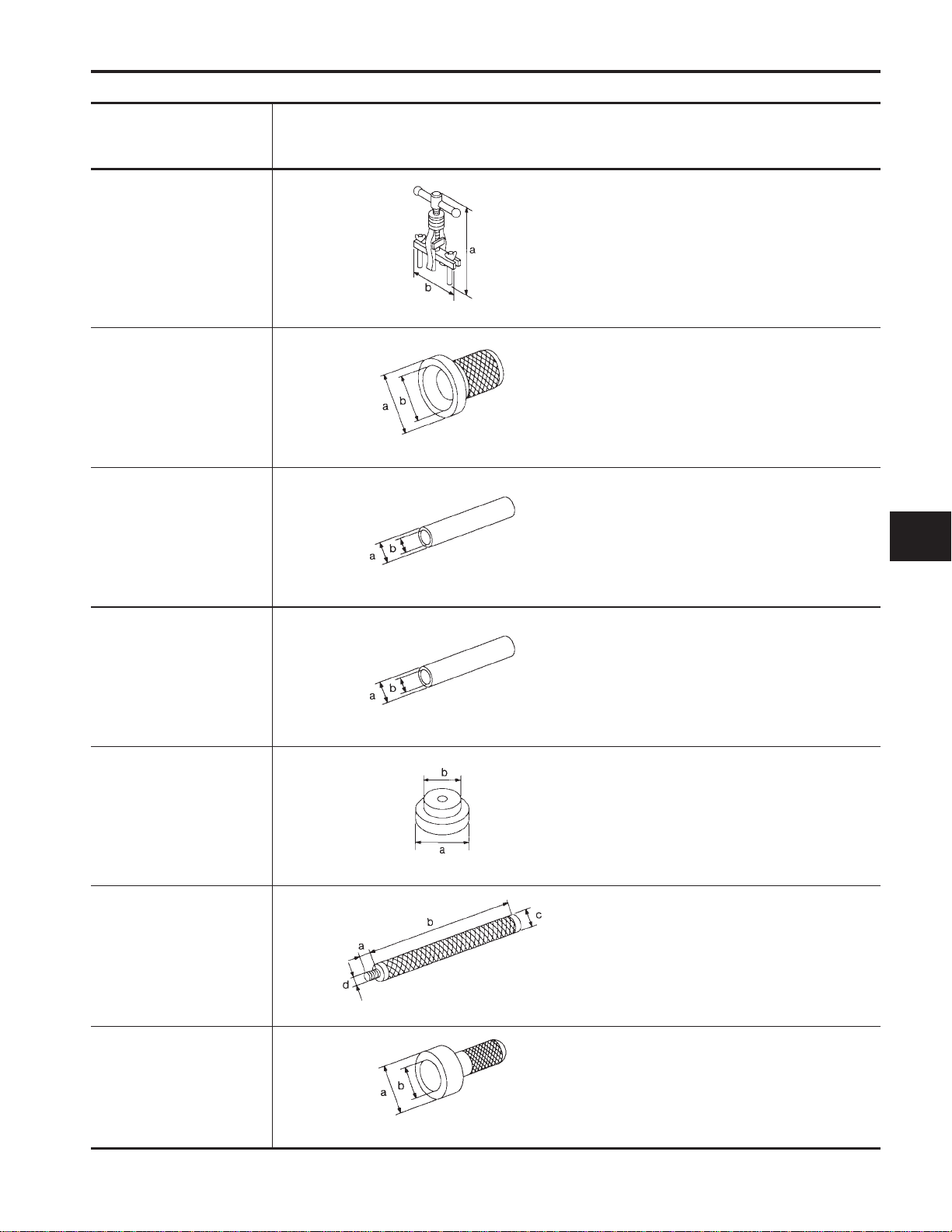

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Special Service Tools (Cont’d)

Description

(J34290)

Shim selecting tool set

(J34305)

Snap ring remover and

installer

(J25407-2)

Selecting differential side bearing adjusting

shim

NT080

Removing and installing stopper ring of shift

fork

NT081

Measuring reverse baulk ring wear

NT082

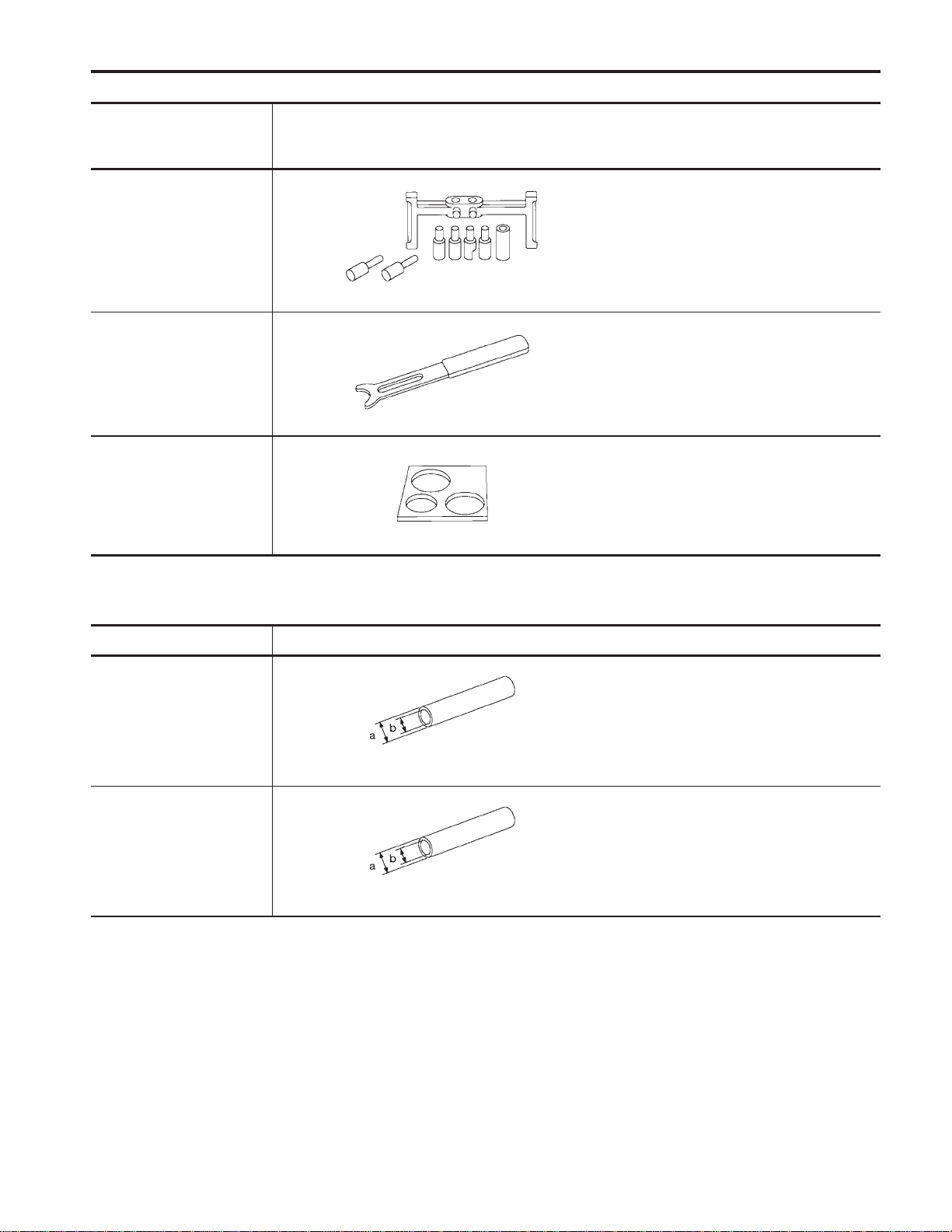

Commercial Service Tools

Tool name Description

Drift

NT065

Drift

NT065

Installing differential side bearing inner race

a: 45 mm (1.77 in) dia.

b: 41 mm (1.61 in) dia.

Installing striking rod oil seal

a: 38 mm (1.50 in) dia.

b: 20 mm (0.79 in) dia.

MT-4

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of

inspection. If necessary, repair or replace these parts.

MANUAL TRANSAXLE

GI

MA

EM

Reference page

SUSPECTED PARTS

(Possible cause)

Refer to MA-17 section

(‘‘Checking M/T Oil’’, ‘‘CHAS-

SIS AND BODY MAINTE-

NANCE’’).

MT-14

MT-14

MT-14

MT-13

MT-16

MT-16

MT-15

MT-15

MT-15

MT-15

LC

EC

FE

CL

MT

AT

FA

RA

Symptom

Oil (Oil level is low.)

Oil (Wrong oil)

Oil (Oil level is too high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

CONTROL ROD (Worn)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

Noise 1 2 3 3

Oil leakage 31222

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear 1233

BR

ST

INSERT SPRING (Damaged)

RS

BT

HA

EL

IDX

MT-5

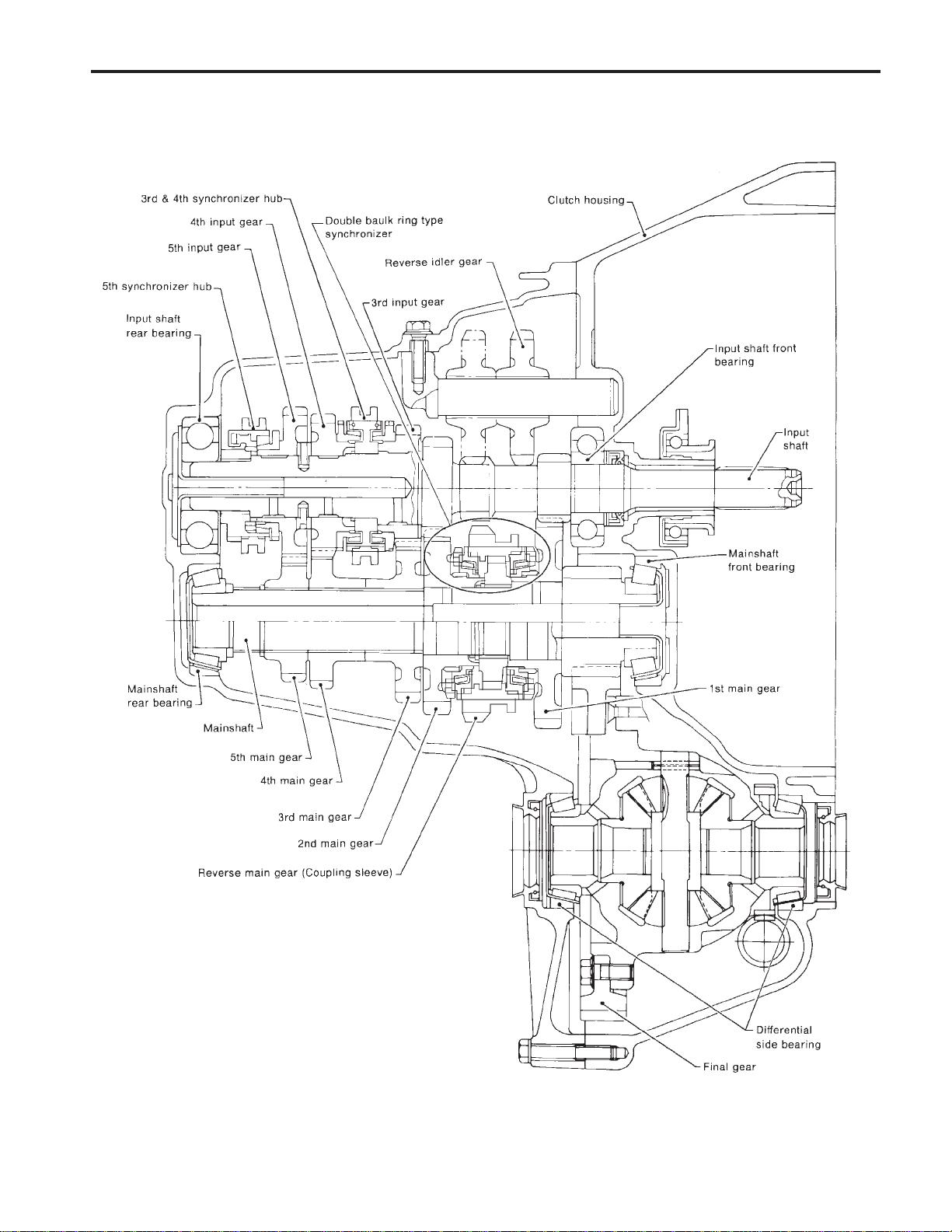

RS5F50A

DESCRIPTION

Cross-sectional View

MT-6

WMT001

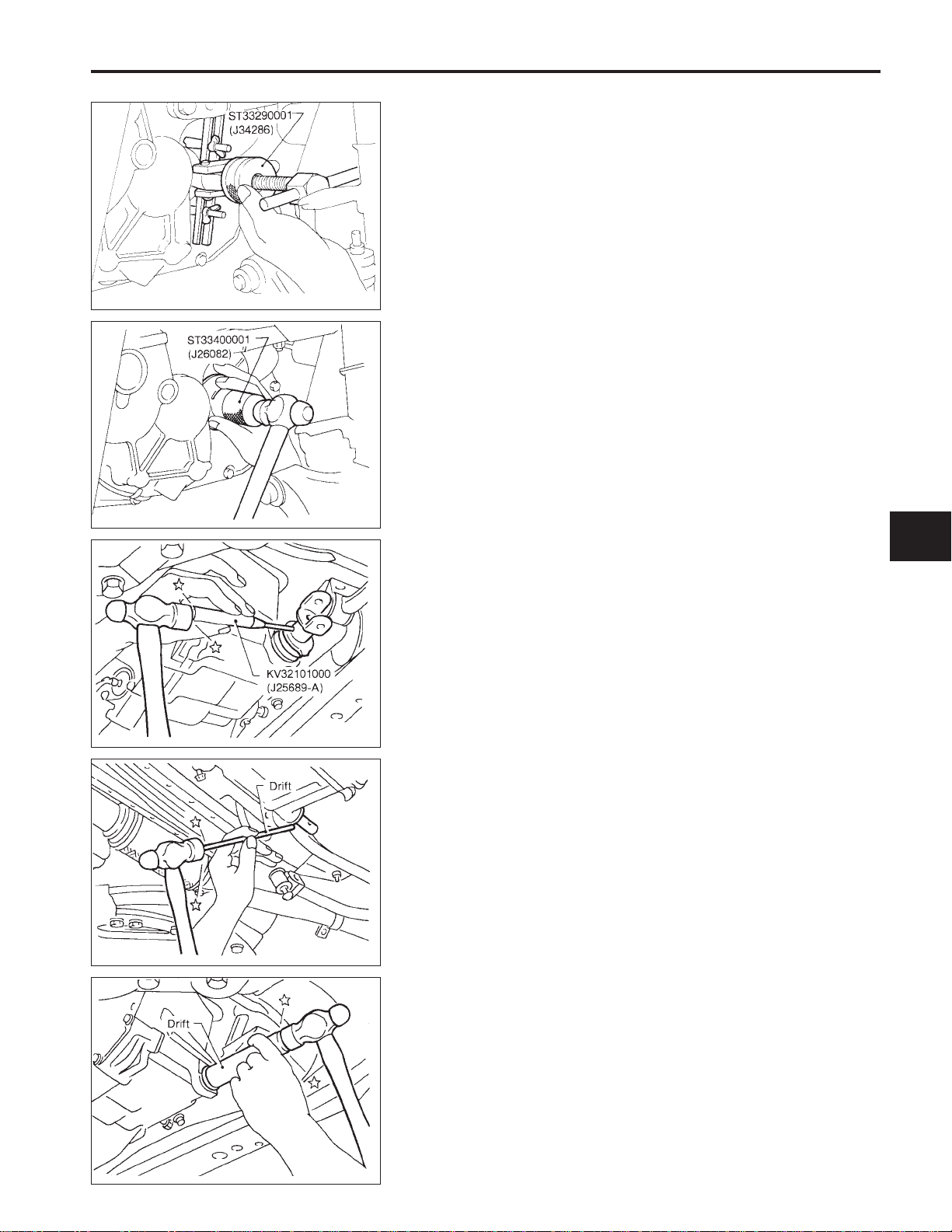

ON-VEHICLE SERVICE

Replacing Oil Seal

SMT563A

SMT564A

DIFFERENTIAL OIL SEAL

1. Drain gear oil from transaxle.

2. Remove drive shafts. Refer to FA-16 section (‘‘REMOVAL’’,

‘‘FRONT AXLE — Drive Shaft’’).

3. Remove differential oil seal with Tool.

●

Always replace with a new seal once it has been removed.

4. Install differential oil seal.

●

Apply multi-purpose grease to seal lip of oil seal before

installing.

5. Install drive shafts. Refer to FA-17 section

(‘‘INSTALLATION’’, ‘‘FRONT AXLE — Drive Shaft’’).

STRIKING ROD OIL SEAL

1. Remove transaxle control rod from yoke.

2. Remove yoke retaining pin with Tool.

●

Be careful not to damage boot.

GI

MA

EM

LC

EC

FE

CL

MT

AT

SMT261C

SMT220C

3. Remove striking rod oil seal.

4. Install striking rod oil seal.

●

Apply multi-purpose grease to seal lip of oil seal before

installing.

FA

RA

BR

ST

RS

BT

HA

EL

IDX

SMT221C

MT-7

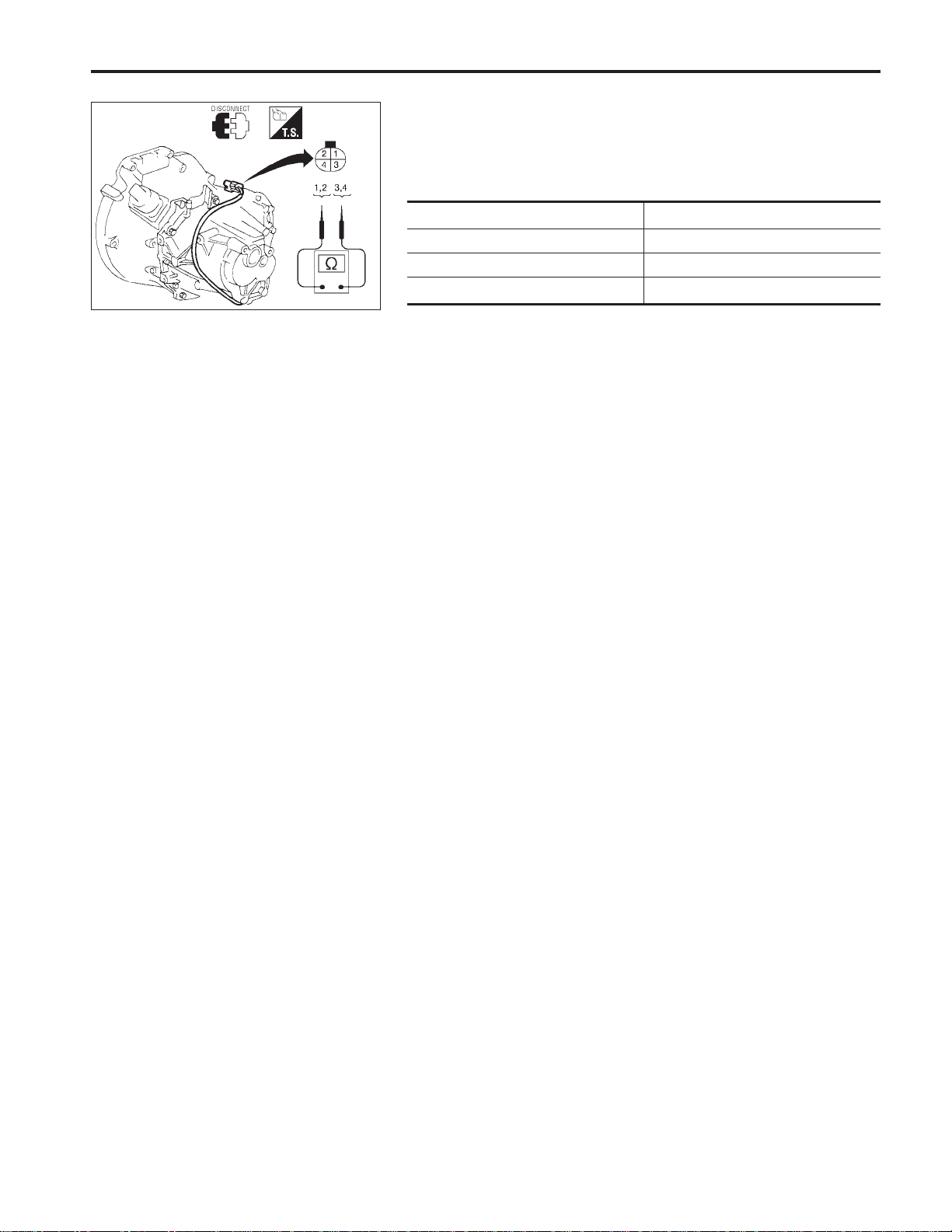

ON-VEHICLE SERVICE

Position Switch Check

BACK-UP LAMP SWITCH AND PARK/NEUTRAL

POSITION (PNP) SWITCH

●

Check continuity.

Gear position Continuity

Reverse

Neutral

AMT119

Except reverse and neutral No

1

s

2

s

—

—

3

s

4

s

MT-8

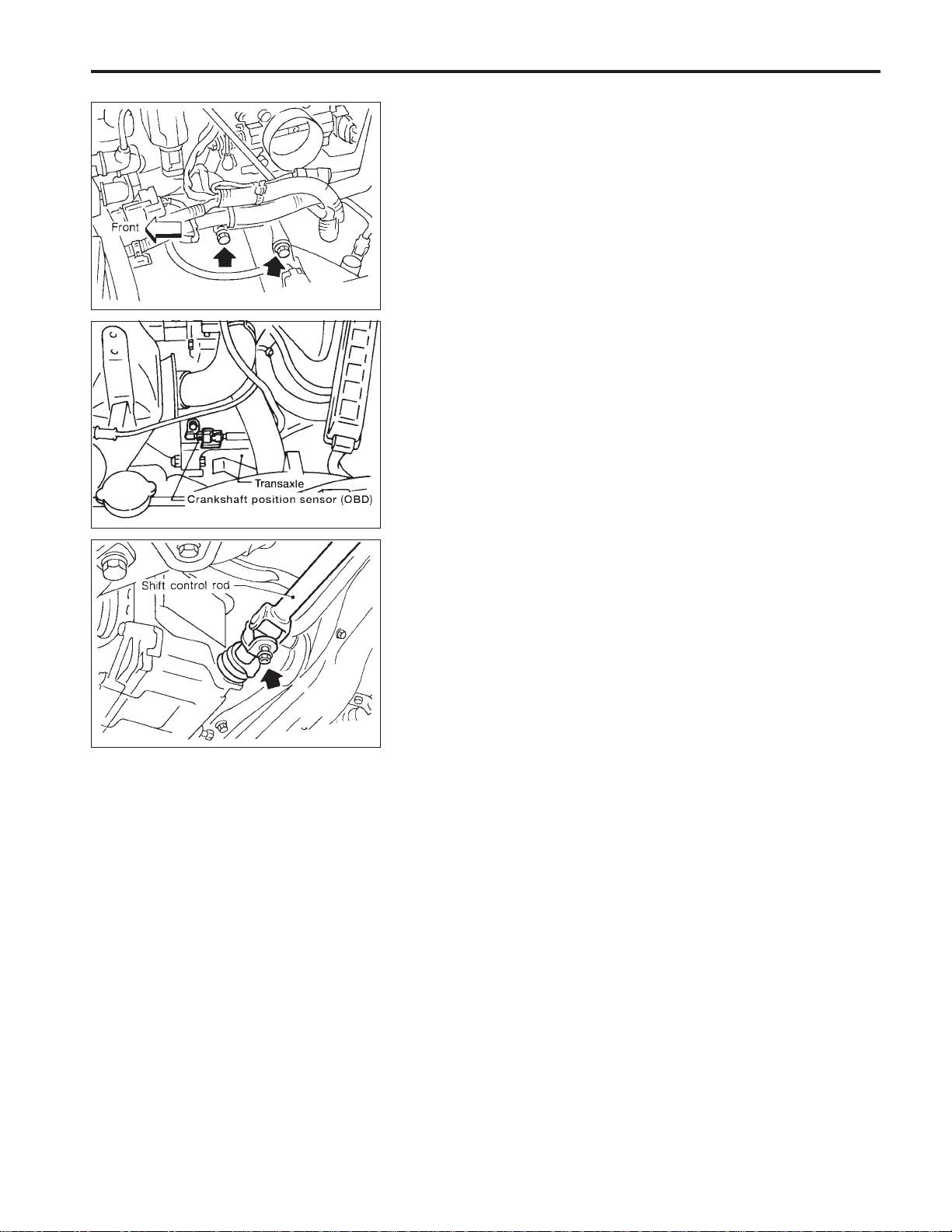

REMOVAL AND INSTALLATION

Removal

GI

MA

EM

LC

EC

FE

CL

AMT068

AMT118

CAUTION:

Before separating transaxle from engine, remove the

crankshaft position sensor (OBD) from transaxle.

Be careful not to damage sensor edge or ring gear teeth.

1. Remove battery and its bracket.

2. Remove air cleaner housing with mass air flow sensor.

3. Remove air duct.

4. Remove clutch operating cylinder from transaxle.

5. Disconnect speedometer pinion, park/neutral position

(PNP) switch and ground harness connectors.

MT

AT

FA

RA

BR

ST

RS

BT

HA

EL

SMT301C

IDX

MT-9

REMOVAL AND INSTALLATION

Removal (Cont’d)

6. Remove starter motor from transaxle.

SMT225C

7. Remove crankshaft position sensor (OBD) from transaxle.

●

Be careful not to damage sensor tip.

AMT064

SMT226C

8. Remove shift control rod from transaxle.

9. Drain gear oil from transaxle.

MT-10

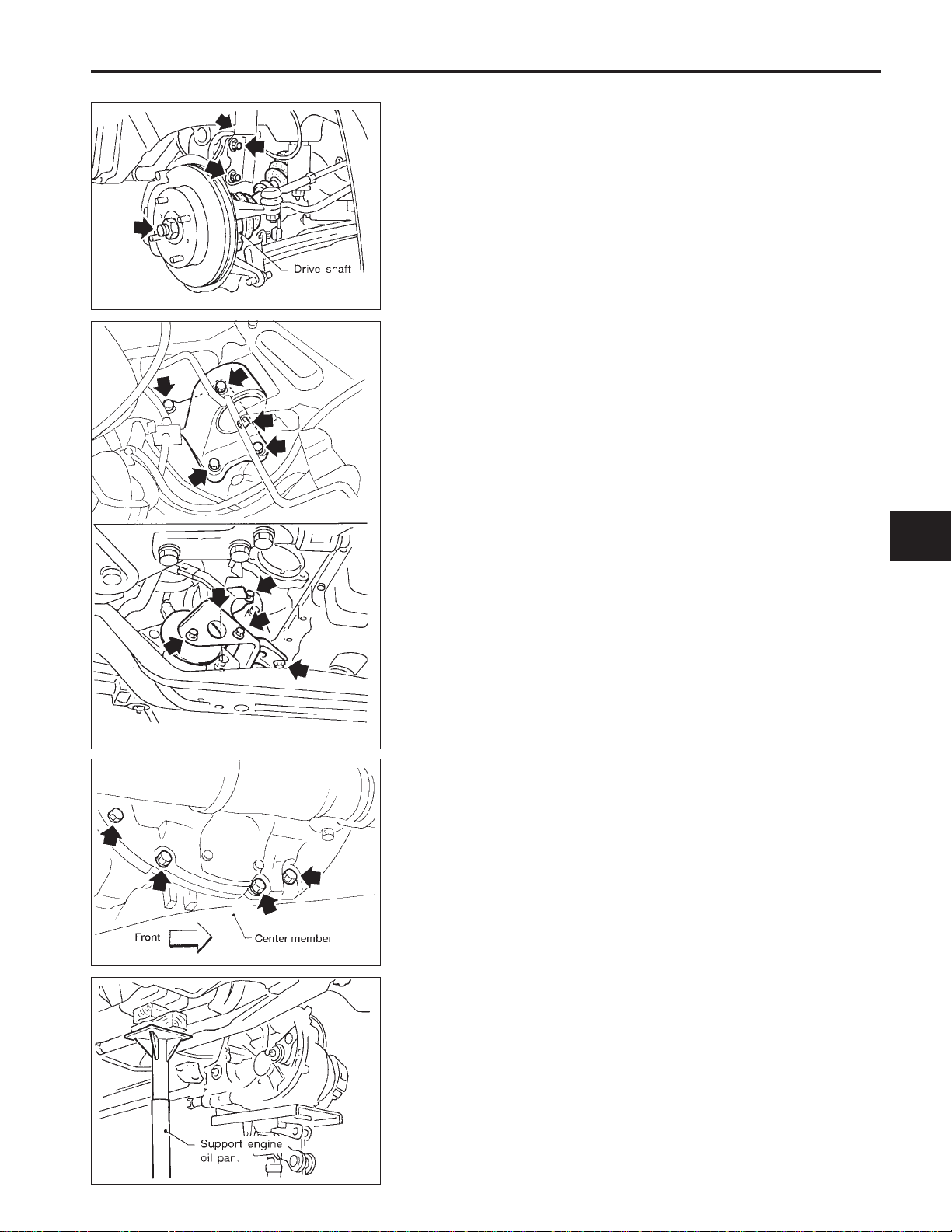

REMOVAL AND INSTALLATION

Removal (Cont’d)

10. Draw out drive shafts from transaxle. Refer to FA-16 section

(‘‘REMOVAL’’, ‘‘FRONT AXLE — Drive Shaft’’).

SMT227C

11. Support engine by placing a jack under oil pan.

CAUTION:

Do not place jack under oil pan drain plug.

12. Remove rear and LH engine mounts.

GI

MA

EM

LC

EC

FE

CL

SMT302C

AMT111

13. Raise jack for access to lower housing bolts. Remove bolts.

Lower jack.

14. Remove bolts securing transaxle.

15. Lower transaxle while supporting it with a jack.

MT

AT

FA

RA

BR

ST

RS

BT

HA

EL

SMT230C

IDX

MT-11

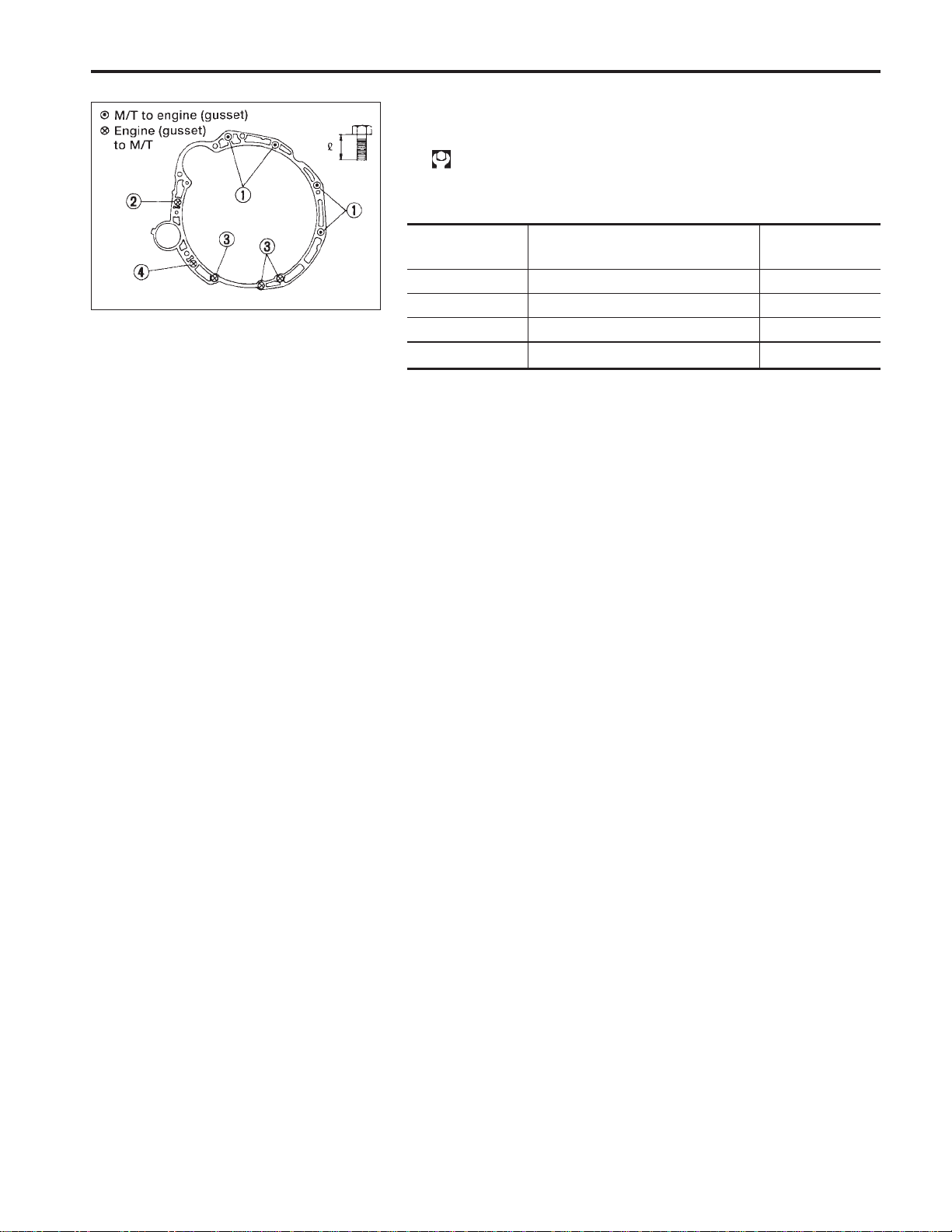

REMOVAL AND INSTALLATION

Installation

●

Tighten starter motor to transaxle.

: 30.40 - 41.29 Nzm (3.1 - 4.2 kg-m, 22.4 - 30.5 ft-lb)

●

Tighten bolts securing transaxle and install any part

removed.

AMT001

Bolt No.

1

s

2

s

3

s

4

s

Tightening torque

Nzm (kg-m, ft-lb)

39 - 49 (4.0 - 5.0, 29 - 36) 45 (1.77)

39 - 49 (4.0 - 5.0, 29 - 36) 48 (1.89)

30 - 40 (3.1 - 4.1, 22 - 30) 30 (1.18)

30 - 40 (3.1 - 4.1, 22 - 30) 40 (1.57)

l mm (in)

MT-12

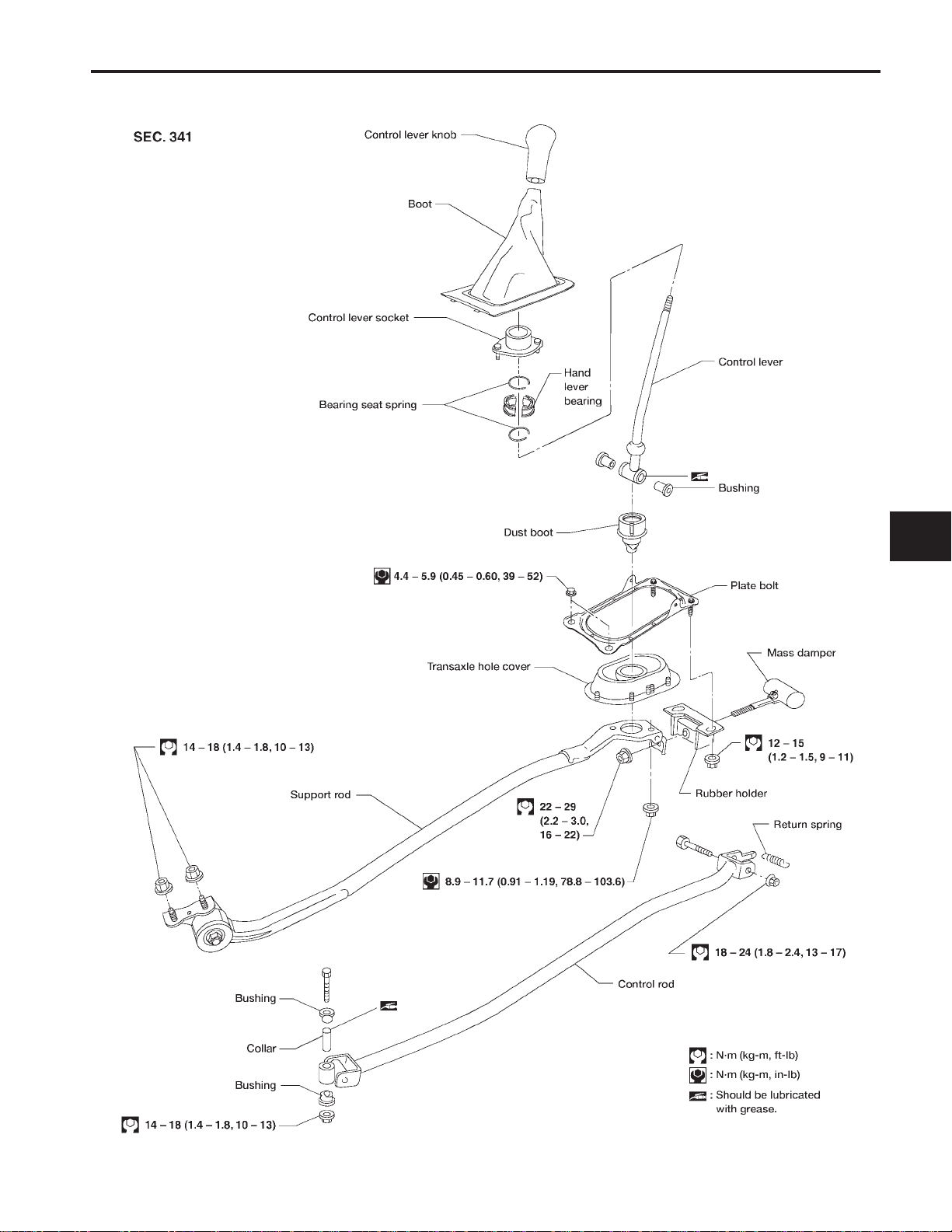

TRANSAXLE GEAR CONTROL

GI

MA

EM

LC

EC

FE

CL

MT

AT

FA

RA

BR

ST

RS

BT

HA

MT-13

EL

IDX

AMT117

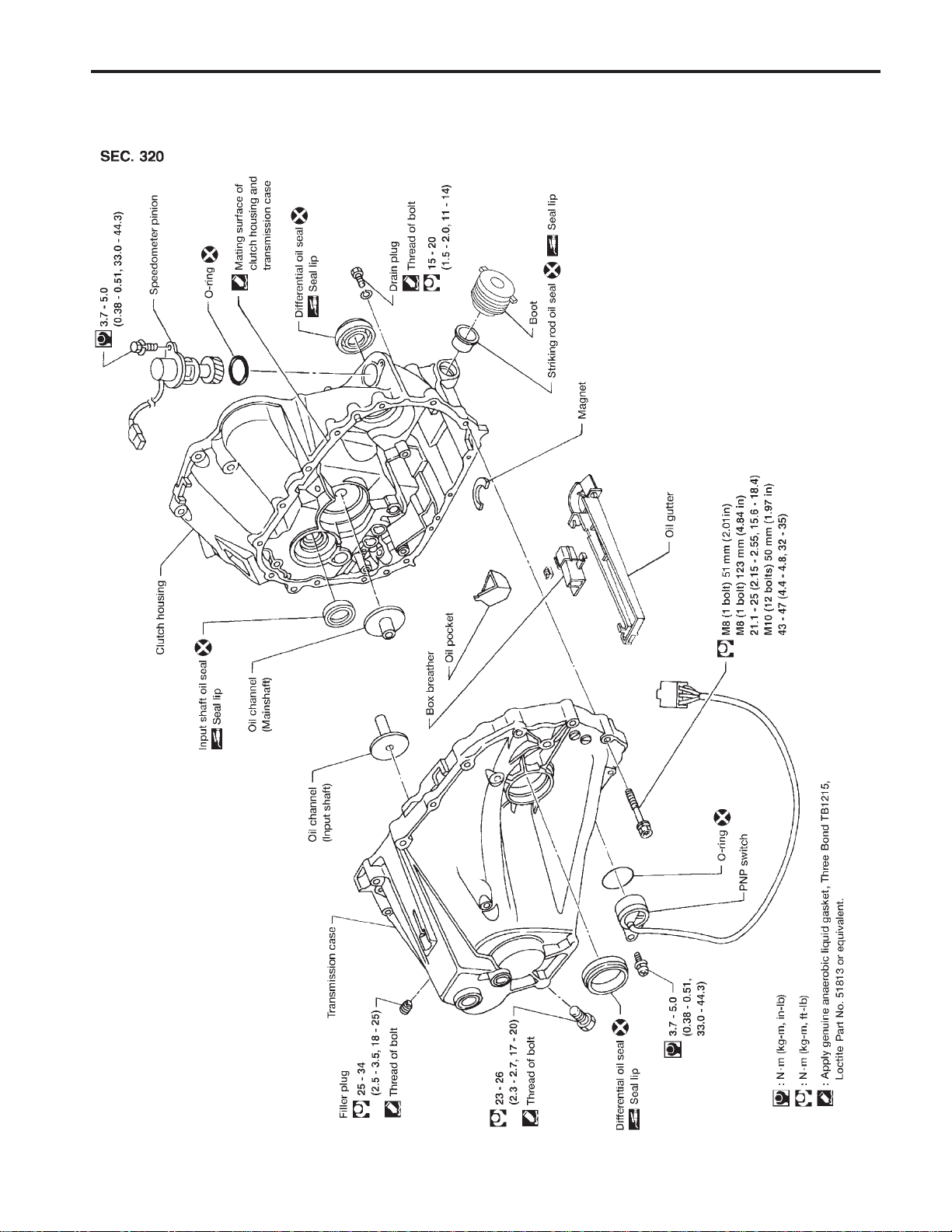

MAJOR OVERHAUL

Case Components

MT-14

WMT002

Loading...

Loading...