Page 1

Operator´s Manual

RO MEDICAL

Description: NRO-MED-IFU-1001

Date: 06.10.2021 | Version: 12

Written by: Nipro Pure Water

Page 2

Page 3

Version 12| 06.10.2021 | Page 3

Table of Contents

1 General .............................................................................................. 6

1.1 Scope of supply ................................................................................... 6

1.2 Unit combinations ................................................................................ 6

1.3 Notes for the Operator.......................................................................... 6

1.4 Laws and Standards ............................................................................. 6

1.5 Symbols used in this Manual ................................................................. 7

1.6 Transport and Storage .......................................................................... 7

1.7 Model Plate ......................................................................................... 8

1.8 Warning on the Unit. ............................................................................ 8

1.9 Shutdown ........................................................................................... 8

1.10 Disposal.............................................................................................. 9

1.11 Instruction / Further Documentation ...................................................... 9

1.12 Duration of usage ................................................................................ 9

2 Intended operation ............................................................................. 10

2.1 Contraindications / side effects ............................................................. 11

3 Safety ............................................................................................... 11

3.1 Risk Assessment ................................................................................. 11

3.2 EMC .................................................................................................. 11

3.3 Emissions .......................................................................................... 11

4 Technical Data .................................................................................... 12

5 Description of the device ..................................................................... 13

5.1 Flow-Chart ......................................................................................... 13

5.2 Functional sequence ............................................................................ 14

5.3 Safety devices / Components ............................................................... 15

6 Installation......................................................................................... 16

6.1 Environmental Condition ...................................................................... 16

6.2 Assembly ........................................................................................... 16

6.3 Electrical installation ........................................................................... 17

6.4 Prefiltration (Example) ........................................................................ 18

6.5 Commissioning ................................................................................... 19

6.6 Initial commissioning ........................................................................... 20

7 Operation .......................................................................................... 21

7.1 Control Panel ..................................................................................... 21

7.2 System on / off without permeate tank .................................................. 22

Page 4

Version 12| 06.10.2021 | Page 4

7.3 Device on / off with permeate tank ....................................................... 23

7.4 Emergency operation .......................................................................... 24

7.5 Operating displays .............................................................................. 25

8 Error messages / troubleshooting ......................................................... 26

8.1 Error messages .................................................................................. 26

8.2 Clear alarms....................................................................................... 26

9 Maintenance and cleaning .................................................................... 27

9.1 External Cleaning ................................................................................ 27

9.2 Maintenance Intervals ......................................................................... 28

9.3 Chemical Disinfection .......................................................................... 29

9.4 Microbiological Inspection .................................................................... 30

10 Display / Parameter ............................................................................ 31

10.1 Retrieval of the operating hours / conductivities ..................................... 31

10.2 Change the conductivity parameter ....................................................... 32

10.3 Change parameter temperature ............................................................ 33

Technical appendix ........................................................................................ 34

11 Replacement of the reverse osmosis membrane ..................................... 35

12 Service Parameters ............................................................................. 36

12.1 Adjustment of the conductivity ............................................................. 37

12.2 Setting date and time .......................................................................... 37

12.3 Summer / winter time ......................................................................... 37

12.4 Auto Start (Timer) .............................................................................. 38

12.5 Service point ...................................................................................... 39

13 Disinfection ........................................................................................ 40

13.1 Disinfection Protocol ............................................................................ 43

14 EMC manufacturer's declaration ............................................................ 44

Page 5

Version 12| 06.10.2021 | Page 5

0297

Foreword

For the reverse osmosis type RO medical, conformity according to

EC directives is declared

This Operator’s Manual includes all information required for the installation and operation for the

reverse osmosis model RO medical.

Please keep this Operator’s Manual readily available and near the unit.

This Operator’s Manual applies for the units with the serial number:

© Copyright 2021

Nipro Pure Water GmbH

Werner-von-Siemens-Str.2-6

76646 Bruchsal –

Tel.: 0049 7251-32 19 7810

Rev# Date / Name Description

1 16.05.11 / N.Bürkle First edition

2 07.07.11 / N.Bürkle Disposal added

3 31.08.11 / N.Bürkle Disinfection added

4 28.02.12 / N.Bürkle Limit values added

5 28.02.14 / N.Bürkle Company name

6 20.12.19 / N.Bürkle New Design / EMC

7 10.01.20 / N.Bürkle Air pressure added

8 29.06.20 / N.Bürkle Changes accord. EN 60601

9 29.06.20 / N.Bürkle LOGO Control

10 24.02.21 / T. Barretto Cosmetic corrections

11 03.03.21/ R.Tille Water pressure input

12 06.10.21/G.Biscardi Information Service point

Page 6

1 General

1.1 Scope of supply

The scope of delivery includes the following parts:

1 reverse osmosis

1 connection set

1.2 Unit combinations

The unit model RO may be combined with the following devices:

* Permeate tank

* City water tank

Version 12| 06.10.2021 | Page 6

1.3 Notes for the Operator

The operator is responsible for:

Competent and intended operation

Compliance with work safety and accident prevention provisions

Technical instruction of operating personnel

1.4 Laws and Standards

The following laws and standards are adhered to:

Council Directive 93/42 EEC Medical Devices

EN 60601

DIN EN 1717 Protection of potable water against contamination

Page 7

1.5 Symbols used in this Manual

Stands for a dangerous situation. Disregard can result in personal injury or

material damage.

Stands for information and valuable tips.

1.6 Transport and Storage

Protect unit against frost and moisture

Version 12| 06.10.2021 | Page 7

Protect against strong jolting and collisions.

Only move unit upright and with an appropriate lift.

The system may be stored for a maximum of 1 year.

Page 8

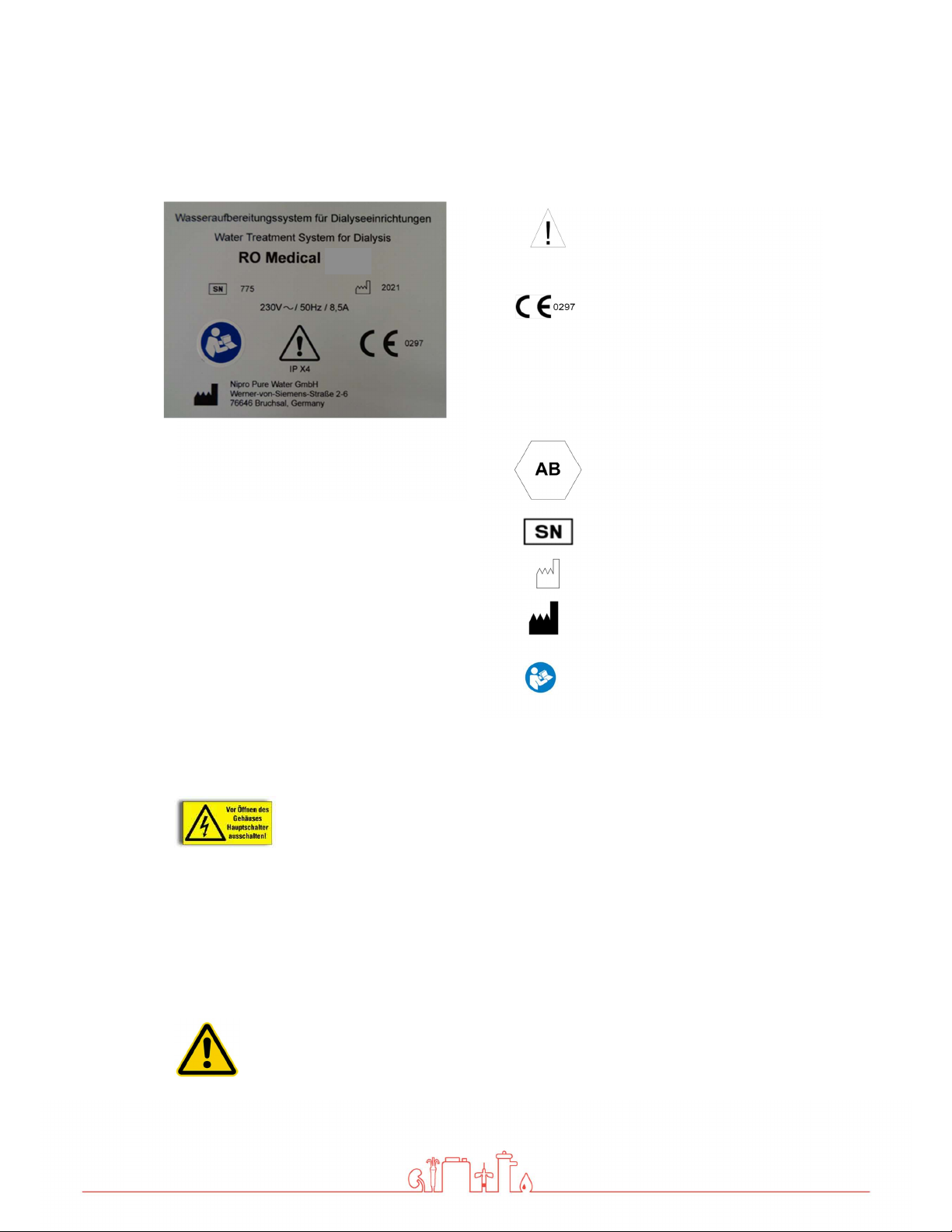

1.7 Model Plate

Version 12| 06.10.2021 | Page 8

IPX 4

Manufacturer

Attention, take note of

accompanying documents

CE mark with the number of

the notified body. Here DQS

Protection against the

ingress of liquids. Here

splash-water protection

Protection Scheme according

to EN 1717. Here free outlet

Serial number

Year of construction

Pay attention to manual

1.8 Warning on the Unit.

Caution voltage. Turn mains switch off before opening housing. Fixed on

control cabinet.

1.9 Shutdown

If a unit is shutdown for more than 5 days, conservation will be necessary.

Please contact Nipro Pure Water before performing conservation.

Page 9

Version 12| 06.10.2021 | Page 9

1.10 Disposal

Regarding the WEEE guidelines of the European Union, the disposal of electronic devices and

electronic sub-assemblies and parts into the general garbage is not lawful. These parts must be

disposed environmentally appropriate:

If not appointed otherwise and no private disposal management is available, these devices or

possibly other environmental hazardous items can be sent back.

The filters and membrane can be disposed via the general garbage

1.11 Instruction / Further Documentation

The using personnel must be warned against the hazards during operation and must be warned

against the hazards of misusing the product.

The personnel gets the instruction of operation and the specialties of usage. Instructed adult only

are allowed to operate this device.

This instruction by the manufacturer or authorized personnel takes place during the

commissioning of the device.

Further trainings are not necessary for this device.

For qualified personnel the following documents can be made available upon request.

Circuit diagrams

Spare parts list

1.12 Duration of usage

The device is designed for a use of 10 years

Page 10

Version 12| 06.10.2021 | Page 10

Serious soiling

2 Intended operation

The unit is designed for the treatment of potable water. The pure water (permeate) thus

produced may be used for dialysis treatment.

Other applications are only possible after consulting the manufacturer and receiving their

approval.

The unit can only be maintained by the manufacturer or technicians trained by

the manufacturer.

Only original replacement parts may be used for maintenance and repairs.

Installation operations, modifications or reparations, are only allowed to be

performed by persons authorised by the manufacturer and may only be done with

original replacement parts. Improper performed reparations or modifications can

lead to hazards to the user and/or may damage the device.

The device may only be operated in perfect condition.

Before operating, check the following:

Lose or defect parts

Defect cables and/or isolations

The device may only be operated with the appropriate ring line.

The device does not produce water for injections.

The device has pressurized parts.

If the temperature sensor fails, the temperature in the permeate can increase.

(Max 60°C)

The water treatment system RO medical may only be used for permeate supply

of dialysis devices, which have a temperature measurement (permeate

temperature).

The device has no direct patient contact and no patient application part.

Page 11

Version 12| 06.10.2021 | Page 11

2.1 Contraindications / side effects

None

3 Safety

3.1 Risk Assessment

There will be no dangers associated with the reverse osmosis model RO medical D if the

operating instructions are followed.

The device can automatically start by way of an auto-start.

3.2 EMC

The device was developed and tested in accordance with current standards. Nevertheless,

influence through electromagnetic fields cannot be completely excluded.

3.3 Emissions

The device does not produce dust or vibrations.

The noise level is under 609 dB (A).

Page 12

4 Technical Data

Temperature

1 Membrane

2 Membranes

3 Membranes

4 Membranes

15° C

350 l/h

700 l/h

1050 l/h

1400 l/h

Quality

Potable Water

Hardness

< 1 °dH

Silicate

< 25 mg/l

Chlorine

< 0,1 ppm (mg/l)

Iron < 0,1 ppm (mg/l)

Fouling Index (S.D.I)

< 3 Temperature

5-25°C Pressure

1-

3 bar

Water feed

1”

internal thread

Pure water connection

Hose nozzle d20

Drain

HT 4

0

Supply voltage

220-230 V, 1 Phase,

50/60 Hz

Fuse

Automat 16 A

-K,

Fi ΔI 30mA

Current consumption

9,9 A

x 60 Hz

Degree of pollution

1

Storage / transport

3-

40°C

Operation

10-

35°C

Air pressure

795-1062 hPa

Conductivity

0-

1000 µS/cm ±5%

100-1000 l/h

RO Medical

1000x500x1

64

0

Permeate performance

Inlet water

Version 12| 06.10.2021 | Page 12

Connections

Electrical data

Ambient temperature

Display system

pressure switch 0-10 bar ±5%

Flow (sight glass) 300-3000 l/h ±5%

Size

Page 13

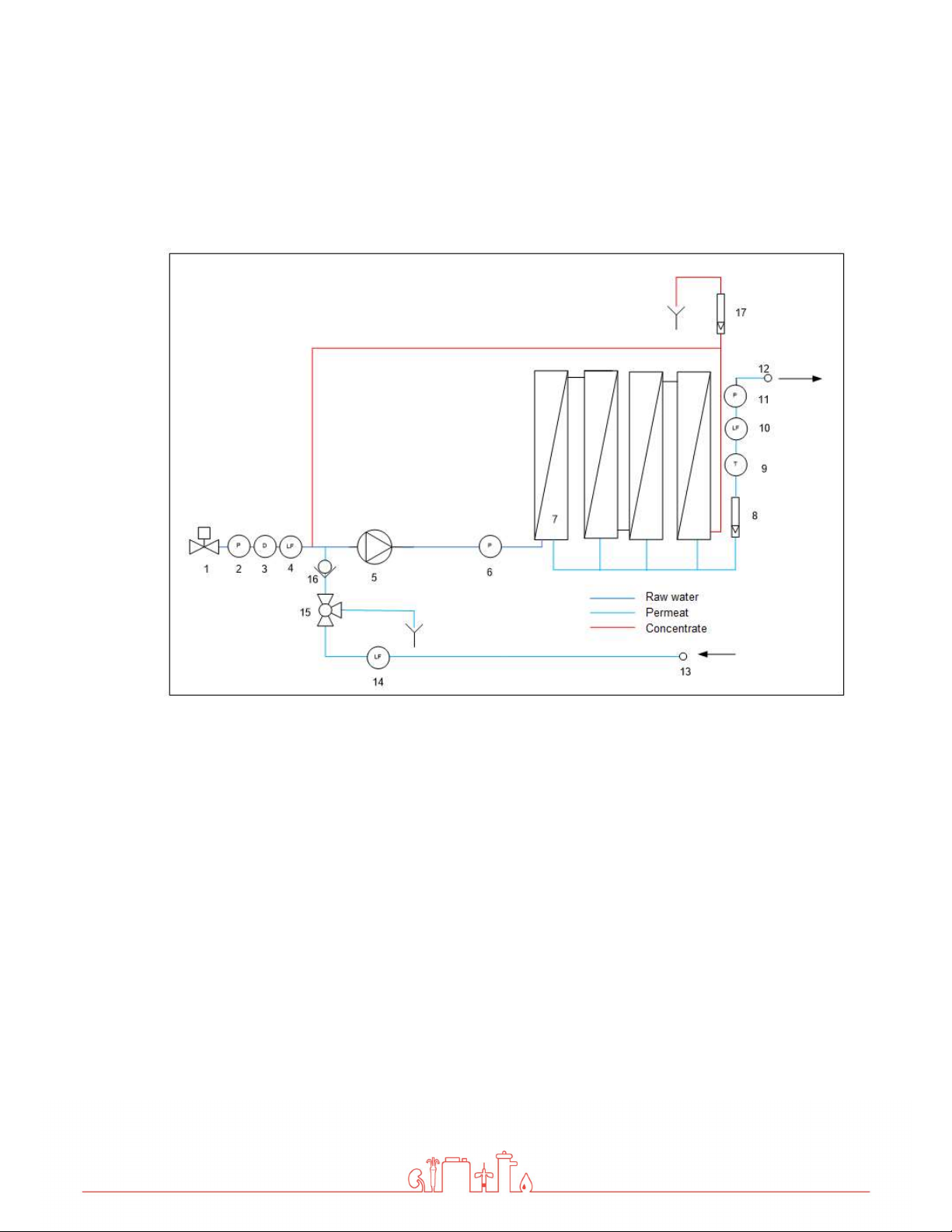

5 Description of the device

5.1 Flow-Chart

Version 12| 06.10.2021 | Page 13

1. Magnetic valve inlet

2. Pressure switch input

3. Disinfection point

4. Conductivity input

5. Pump (pressure 10-13bar)

6. Manometer (pressure 10-13 bar)

7. Reverse osmosis membrane (1-4

pieces)

8. Permeate flow rate indicator

9. Temperature sensor

10. Conductivity probe permeate flow

11. Permeate pressure switch

12. Connection back flow hose nozzle d20

13. Connection back flow hose nozzle d20

14. Conductivity ring back flow

15. Discard three-way ball valve permeate

16. Check valve

17. Flow indicator concentrate outflow

Page 14

Version 12| 06.10.2021 | Page 14

5.2 Functional sequence

If the toggle switch is turned to the ‘On‘ position, the magnetic valve (1) opens and water flows

into the system. After a short delay, the pump (4) will start.

Now the water is pressed into the reverse osmosis membrane at a pressure of 10-15 bar. The

flow is divided into a permeate and a concentrate part. The permeate content flows through the

flow indicator (7), the temperature sensor (8), the conductivity probe (9) and the pressure switch

(10) into the ring line. The unused permeate flows back into the RO medical via the connection

(12).

To save water, the concentrate portion is divided up again, one portion is given into the drain via

the flow indicator (17), the other is fed back in front of the pump.

Page 15

5.3 Safety devices / Components

Inlet

Mode switch

Connection

Turn on key

Pressure switch

Permeat Flow

Pressure Switch

Inlet

Pressure tube with

membrane

Version 12| 06.10.2021 | Page 15

Display

Main switch

Service Point

Flow Display

Concentrate

Flow Display

Permeat

Raw water

connection

Magnetic valve

Conductivity Probe

Inlet

Disinfection port

Emergency

Fault signal lamp

Manometer

Pump pressure

Pressure pump

Page 16

6 Installation

The installation must be conducted by the manufacturer or by personnel trained

and authorized by the manufacturer.

6.1 Environmental Condition

Conditions for the osmosis room:

Relative air moisture < 90% at 20°C

Room temperature between +10°C and +35°C (frost proof)

Equipped with floor drain, water supply and electrical supply

Version 12| 06.10.2021 | Page 16

6.2 Assembly

Bring the device into the appropriate position

Adjust machine feet until the device stands level and secure on the floor.

Do not store easily flammable materials in the vicinity of the device.

Do not store chemicals in the vicinity of the device.

Only operate the device with the necessary water pre-treatment.

Room of osmosis may not be freely accessible. (Access for instructed personnel

only)

Page 17

6.3 Electrical installation

The installation may only be performed by a qualified electrician.

The device must be supplied by a permanent connection, connectors are not

valid. The disconnection via the main switch at the control cabinet. The power

cord must be provided with a strain relief.

Version 12| 06.10.2021 | Page 17

Connection cable RO Medical

For protection against a re-start of the unit, the main switch

can be locked with a padlock.

Safety class I

The device is equipped with a Protective earth terminal for

prevention against high touch current

For prevention of the hazard of an electric shock, this device

may only be connected to a power supply with protective

earth.

The power cord is fixed to the device and cannot be replaced.

Page 18

6.4 Prefiltration (Example)

Install the necessary water pre-treatment equipment first!

Only then connect the RO medical and start up

Version 12| 06.10.2021 | Page 18

Local water works regulations and DIN EN 1717 must be followed.

The water pre-treatment must be adapted to the local potable water quality.

Page 19

6.5 Commissioning

filter and a softening system

HT 40

Hose nozzle d20

Caution, device damage!

The device must be preconnected by a suitable preas well as a pressure reducer.

Permeat Flow Connection (2)

Hose nozzle d20

Version 12| 06.10.2021 | Page 19

Permeat back flow (3)

Drain water

connection (4)

Raw water connection (1)

1“ Internal thread

Page 20

Version 12| 06.10.2021 | Page 20

water (4)

Now water is running into

the device

.

water outlet can be seen.

6.6 Initial commissioning

1. Connect and check the raw water connection (1),

permeate flow (2), permeate back flow (3) and waste

2. Open the inlet valve manually. To do this, turn the white

magnet coil 45° counter clockwise.

3. Carefully open the screw for the pump venting until a

Then close the screw again and

reset the solenoid.

4. Make sure that the wall-mounted taps at the start and end

of the ring are open.

5.

Start the device using the toggle switch.

6.

Check all connections for leaks.

7.

Open the three-way valve permeate to the drain.

8.

Allow the device to discard permeate for at least 30

minutes.

Page 21

7 Operation

and off

emergency operation here.

operation (4)

Toggle switch (1)

Fault light (2)

Display (3)

Version 12| 06.10.2021 | Page 21

7.1 Control Panel

Right Side

Main Switch (5)

Key switch

emergency

1. Toggle switch system on

This is used to switch the device on

4. Key switch emergency operation

The device can be switched to

Page 22

Version 12| 06.10.2021 | Page 22

completely

2. Fault light

Lights up when there is a fault

3. Display

Display of conductivity and faults

5. Main switch

With this the device can be switched off

7.2 System on / off without permeate tank

System on

To start the device, turn the toggle switch to the right (on

position).

The green lamp lights up.

The pump starts after a short delay

System off

Reset toggle switch (position 0)

The green lamp goes out.

Pump stops.

If the device is switched off using the toggle switch, the rinse intervals are

carried out as programmed. If no rinsing is to take place, the device must be

switched off completely at the main switch. However, this is only

recommended for decommissioning.

Page 23

7.3 Device on / off with permeate tank

is connected to a permeate tank, the toggle switch must be

full, it is not necessary to reset it to position 0.

If the tank is already full, the osmosis waits to start until the level

If the RO medical

set to "Auto". Since the device switches off automatically when the tank is

Caution, danger of overflow!

If the RO medical is operated with a permeate tank, the system may only be

started via "Auto". In the "On" position there is a risk of overflow.

Device on

To start the system, turn the knob switch to the right.

If the permeate tank is empty, the system starts automatically.

Version 12| 06.10.2021 | Page 23

in the tank drops.

Page 24

7.4 Emergency operation

Caution!

If the HC Medical hot cleaning system is connected, the following steps

must be carried out before emergency operation:

1. Check HC Medical for pending alarms.

2. Carefully touch the lines of the HC Medical and check whether

they are warm.

Do not carry out emergency operation when the lines are warm !!

Only use emergency operation if the automatic function fails. Have device

repaired as soon as possible.

Version 12| 06.10.2021 | Page 24

Attention!

There is no monitoring of the water inflow during the emergency operation.

Therefore a continuous water inflow has to be guaranteed.

Absent water causes the destruction of the pump.

1. Open the inlet valve manually. To do this, turn the white

magnet coil 45° counter clockwise.

To turn off the device, turn switch to position 0.

Now water runs into the device.

2. Set the key switch to position 1. Pump starts up

In emergency operation all automatic functions are turned off. No cleaning cycle

and no automatic start and/or stop will be conducted.

Page 25

7.5 Operating displays

System Off

Set: 90:00

Actual: 25:22

Until rinsing

Device is off.

Rinsing interval (target) is set to 90 minutes.

25:22 min have already passed.

If the actual value reaches the set point, the system goes into rinsing.

Version 12| 06.10.2021 | Page 25

System On

LF Flow 008

LF Backflow 008

Microsiemens

Rinsing

LF Flow 008

LF Backflow 008

Microsiemens

Device is on.

The current conductivities are displayed.

Device is being rinsed.

The current conductivity is displayed.

Page 26

8 Error messages / troubleshooting

The temperature of the permeate has reached

Check the start and end of the

Call service.

8.1 Error messages

Display

Error

Motor protection triggered

Check 1Q5

Error

Over temperature

Check 16S12

Error

Over pressure

Check 16S08

Error

Inlet water missing

Check 16S6

Error

Conductivity

Error Description

The motor protection switch of the pump has

triggered. Check motor protection switch. If

this alarm occurs frequently, the pump must

be checked.

to 38 °C. The system switches off to protect

the membranes.

The permeate pressure has exceeded 6 bar.

The pressure switch 1 has responded.

The conductivity has exceeded the limit of

100µS/cm.

Version 12| 06.10.2021 | Page 26

Troubleshooting

Turn the motor protection

switch back to position 1.

The system must be cooled

(see next page).

ring taps. Check setting of

permeate pressure retention

valve.

Check water inlet.

There is probably a defect in

the membranes.

8.2 Clear alarms

Correct the error

Follow the notes in Display.

Clear the alarm by pressing the F3 key

Page 27

Version 12| 06.10.2021 | Page 27

9 Maintenance and cleaning

9.1 External Cleaning

Stains and dust can be removed with a cloth and a commercially available cleaner.

Do not clean the device with solvents.

Stains from softening salts or disinfectants must be removed immediately.

Page 28

Version 12| 06.10.2021 | Page 28

Measure

period

Notes

user

9.2 Maintenance Intervals

Fill salt at softener Daily user

Chemical disinfection If needed Manufacturer or

persons authorized by

manufacturer

Maintenance Yearly Manufacturer or

persons authorized by

manufacturer

Safety related check Every 2 years Manufacturer or

persons authorized by

manufacturer

Microbiological analysis Every 3 months User

Chemical analysis

Every 12 months User

Not replacing the filter or replacing it too late can lead to damaging of the reverse

osmosis.

Page 29

9.3 Chemical Disinfection

high pathogen values are encountered

guidelines

before handling.

A chemical disinfection should only be performed upon new installation or when

Disinfection may only be performed by Nipro Pure Water or by instructed

persons.

Caution when handling disinfectants!

Per acetic acids can cause damage to your health. Always read safety

Before the next dialysis each consumption point must be tested for disinfectant

traces.

Version 12| 06.10.2021 | Page 29

Page 30

Version 12| 06.10.2021 | Page 30

9.4 Microbiological Inspection

Necessary Values1

Pathogens < 100 CFU/ml no traces of Pseud. aeruginosa and E. coli

Endotoxins < 0,25 EU/ml

Inspection Interval 2

Inspection of permeate every 3 months.

Inspection method 2

Pathogen count determination:

Nutrient medium: TGEA (OXID Nr.CM 127), R2A

Incubation temperature: 22°C ± 2°C

Endotoxins determination:

Method: GEL-Clot; Cromogen; Turbid metric

_________________________

1

According to the European Pharmacopoeia

² Recommendations according to the guideline for the practice of applied hygiene in treatment units for dialysis

Page 31

Version 12| 06.10.2021 | Page 31

back to the

The X indicates which key can be used to switch back to the

If the key is pressed again, the display changes back to the

10 Display / Parameter

10.1 Retrieval of the operating hours / conductivities

Press the F1 key. The operating hours are displayed.

If the key is pressed again, the display changes

standard display.

X

standard display.

Press the F2 key. The conductivities are displayed.

standard display.

To view the time and date, press the down arrow.

Page 32

10.2 Change the conductivity parameter

Press the F4 key and F2 key simultaneously.

The conductivity in the return is displayed.

Press the ESC key for 3 seconds, the first value is marked.

Press enter

Set the value with the arrow keys (up / down). Complete the

entry with ENTER.

Press the ESC key.

Press the F4 and F2 keys simultaneously to return to the

standard display

Both parameters (MAX1 and MAX2) must be set to the same value.

Version 12| 06.10.2021 | Page 32

Standard value = 100 µS / cm

If the conductivity in the back flow reaches the value set here, the conductivity

alarm is activated.

Page 33

10.3 Change parameter temperature

M

ax. 40°C

is allowed,

higher temperatures damage the membranes

.

Press the F4 key and F3 key simultaneously.

The temperature is displayed.

Press the ESC key for 3 seconds, the first value is marked.

Select corresponding value with the arrow keys.

Press enter

Set the value with the arrow keys (up / down). Complete the

entry with ENTER.

Press the ESC key.

Press the F4 and F3 keys simultaneously to return to the

standard display

Version 12| 06.10.2021 | Page 33

Both parameters (MAX1 and MAX2) must be set to the same value.

Default value = 38°C

If the temperature reaches the value set here, the over temperature alarm is

activated.

CAUTION!

Page 34

Version 12| 06.10.2021 | Page 34

Technical appendix

The settings and functions described below may only be carried out by technically

trained personnel.

ATTENTION. DANGER TO PERSONS AND SYSTEM TECHNOLOGY!

Incorrect settings can lead to hazards.

No service or maintenance work may be carried out during treatment.

Page 35

Version 12| 06.10.2021 | Page 35

1.

Switch off the system at the main switch

.

11 Replacement of the reverse osmosis

membrane

Caution pressure!

Membrane tubes are under pressure. Please open carefully.

The settings and functions described below may only be carried out by technically

trained personnel.

2. Open wing screw and take off the clip

3. Lift module cover by using a screwdriver.

4. Take off cover.

5. Take the end plug out of the module.

6. Pull out the membrane by using a tong.

7. Reinstall the new membrane in reverse order.

Take care of the flow direction and

position of the gasket

Page 36

Rinse membrane!

B001

3sec

B002

60m

B003

10m

B005

5sec

B019

30sec

B034

30sec

B036

B040

After the new membrane has been installed the mode “drain permeate”

has to be started for 20 minutes.

12 Service Parameters

The settings and functions described below may only be carried out by technically

trained personnel.

ATTENTION, SYSTEM DAMAGE!

Incorrect settings can lead to damage.

Version 12| 06.10.2021 | Page 36

Arrow key down and then press the ESC key. (Service mode)

Then Logo settings> ENTER> Program> ENTER> Set

parameters> ENTER> select the appropriate parameter (B001-

Parameter Function

B021

B037

B040)

Pump start time delay

Rinse waiting time

Rinse time

Dry flow alarm delay

Conductivity alarm delay

Adjustment of conductivity

(permeate)

Alarm delay temperature

Calibration of conductivity (inflow)

Adjustment of conductivity

(permeate back flow)

Timer (auto start)

default value

Page 37

12.1 Adjustment of the conductivity

saving time (summertime) in the

- Call up parameters B21, B36 or B37.

- "Ax" value = displayed conductivity

- Select value "B" and confirm with Enter.

- Change the value with the arrow keys. (+00001 = current value +1)

- press enter

- Press ESC several times (until time is displayed), then arrow key up.

12.2 Setting date and time

Version 12| 06.10.2021 | Page 37

- Call up service mode

- LOGO Settings <ENTER> Setup <ENTER> Clock <ENTER> Set Clock <ENTER>

- Set the time and date with the arrow keys <ENTER

12.3 Summer / winter time

- Call up service mode

- Setup <ENTER> Clock<ENTER>S/W Time – Select the S/W Time

– "④": disables automatic S/W time conversion.

– "⑤" represents the start and end of European summertime.

– "⑥" represents the start and end of summertime in the United Kingdom.

– "⑦" represents the start and end of daylightUnited States prior to 2007.

– "⑧" represents the start and end of daylight-saving time (summertime) in the

United States in 2007 and later years.

– "⑨" represents the start and end of Australian summertime.

– "⑩" represents the start and end of Australian/ Tasmanian summertime.

– "⑪" represents the start and end of New Zealand summertime.

– "⑫": Here you can enter any month, day and time zone difference.

Page 38

Version 12| 06.10.2021 | Page 38

-Press right arrow key to move the cursor to the first position of the

Press right arrow key to move the cursor to the first position of the

12.4 Auto Start (Timer)

Call up service mode

Logo settings < ENTER > Program < ENTER > Set parameters

< ENTER > Select parameter B040<ENTER>

To set the on-/off-times:

-Move the cursor to one of the parameters of the timer.

-Press ENTER. The cursor is positioned on the day of the week.

-Press up and down key to select one or several days of the week.

on-time.

-Set the on-time.

Modify the value at the respective position, using the up and down

keys and move to the cursor to the various positions, using the

right and left arrow keys.

At the first position, you can only select the value - -:- - (- -:- means: No on-/off-times set).

off-time.

-Set the off-time

-Confirm your entries with ENTER

The prefix "D=" (Day) has the following meaning:

Thursday

● F: Friday ● S: Saturday ● S: Sunday

Uppercase letters indicate a specific day of the week. A "-" indicates no selection for the day of the week.

● M: Monday ● T: Tuesday ● W: Wednesday ● T:

Page 39

Version 12| 06.10.2021 | Page 39

only be operated by

technically trained personnel

.

12.5 Service point

The service point can be used for water withdrawal to check water temperature and conductivity.

Service point may only be opened, if operating pressure in the system is

reached.

Service point must be closed prior to each system start. Service point may

Page 40

13 Disinfection

Disinfection may only be performed by Nipro Pure Water or by instructed

persons.

Caution when handling disinfectants!

Per acetic acids can cause damage to your health. Always read safety

guidelines before handling.

To be performed precisely!

Danger!

Ensure that no dialysis can be performed while disinfecting. Only approve

thoroughly rinsed system for treatment use.

CAUTION!

While using chemicals.

Wear safety gloves and safety goggles during the

here described jobs.

Version 12| 06.10.2021 | Page 40

ATTENTION!

Do not eat, drink or smoke during work.

Disinfectant: MINNCARE® Cold Sterilant (Artikelnr.:489)

Detection method: MINNCARE® Test Strips Residual (Artikelnr.:490)

MINNCARE® Test Strips 1 Indication (Artikelnr.:491)

Page 41

Version 12| 06.10.2021 | Page 41

2.

8.

1. Connect the disinfection pump to the disinfection point.

3.

4.

5.

6.

7.

Open the three-way valve permeate to the drain.

Start the device

Start the disinfectant pump.

Check for correct disinfectant concentration at the

permeate outlet with test strips. Use Minncare Test Strips

Indication 1% for this.

Let the disinfectant pump run until sufficient disinfectant is

detected.

Close the three-way valve permeate to the drain.

Switch off the system

9.

Restart the system after 20 minutes.

Page 42

Version 12| 06.10.2021 | Page 42

13.

that it is free from disinfectants.

10.

11.

12.

Open the three-way valve permeate to the drain.

Let the system run until no more disinfectant can be

detected at the permeate drain. Use Minncare residual

test strips for this.

Close the three-way valve permeate to the drain.

Check that all dialysis stations are free from disinfectants.

Switches the system off during disinfection with a conductivity alarm,

clear the alarm and restart the system.

RISK OF DEATH !

Before the next dialysis, each sampling point must be tested again to ensure

* Free of disinfection means 0ppm- no discoloration of the test strip.

See the colour scale on the packaging of the test strip Residual.

Page 43

13.1 Disinfection Protocol

Disinfectant type

Inoculated amount in litres

Wash time in minutes

Wait time in minutes

stations and results were negative?

disinfectant

Date

Signature

Dialysis centre

Section

Contact person

Function

Street / Bldg. No.

Postcode / City

Unit model : RO Medical

Serial number:

Ring line length

Version 12| 06.10.2021 | Page 43

Rinse time in minutes

If disinfection was performed the operator is obligated by its signature to re-test all dialysis stations

for

. This test must be conducted before the dialyses are performed

______________________

Tested for disinfectant at all dialysis

yes

____________________________

Page 44

Version 12| 06.10.2021 | Page 44

Voltage fluctuations / flickers in

14 EMC manufacturer's declaration

Electromagnetic emissions and electromagnetic immunity

The RO device is intended for use in electromagnetic environments as described below.

The customer or the operator of the RO should ensure that the device is only used in such an

environment.

This EMC manufacturer's declaration is based on the use of the power supply unit from Phoenix

Contact.

The power supply is installed in the control cabinet.

The cable length between the power supply unit and the cable entry through the housing wall is

150 cm.

Warning

The use of other accessories, other power supply units and cables than specified can lead to

increased emissions and/or reduced interference immunity of the RO.

Requirements

During the interference immunity tests, the temperature accuracy and conductivity accuracy

were checked.

Emission measurement Compliance

RF emission in accordance with

CISPR 11 / EN 5511

RF emission in accordance with

CISPR 11 / EN 55011

Harmonics in accordance with

IEC 61000-3-2

accordance with IEC 61000-3-3

Group 1 The device only uses RF

Class B The device is suitable for use

Class A

Fulfilled

Electromagnetic

environment - Guidelines

energy for its internal

function. Its RF emissions are

therefore very low and

interference to nearby

electronic devices is unlikely.

at any location, including

residential areas and facilities

directly connected to the

public low-voltage grid for

residential buildings.

Page 45

Immunity test

Discharge of

static electricity

(ESD) in

accordance with

EIC 61000-4-2

Electrical fast

transient

burst/immunity

test in

accordance with

IEC 61000-4-4

Surge voltage in

accordance with

IEC 61000-4-5

Voltage drops,

short

interruptions,

and fluctuations

in supply voltage

in accordance

with IEC 610004-11

Magnetic field at

supply frequency

(50/60 Hz)

in accordance

with IEC 610004-8

Conducted RF

disturbances in

accordance with

IEC 61000-4-6

Radiated RF

disturbances in

accordance with

IEC 61000-4-3

Version 12| 06.10.2021 | Page 45

Test level – IEC

60601

± 6 kV contact

discharge

± 8 kV air

discharge

Compliance

level

± 6 kV contact

discharge

± 8 kV air

discharge

Electromagnetic

environment - Guidelines

The floor should be made of

wood, concrete, or of tiles. In

case of synthetic flooring,

relative air humidity should be

at least 30%.

± 2 kV for power

cables

± 1 kV for input

and output cables

± 1 kV outer

conductor-outer

conductor

± 2 kV outer

conductor-ground

95% voltage drop

for ½ period

60% voltage drop

for 5 periods

30% voltage drop

for 25 periods

95% voltage drop

for 5 s

± 2 kV for power

cables

± 1 kV for input

and output cables

± 1 kV outer

conductor-outer

conductor

± 2 kV outer

conductor-ground

95% voltage drop

for ½ period

60% voltage drop

for 5 periods

30% voltage drop

for 25 periods

95% voltage drop

for 5 s

The quality of supply voltage

should comply with that of a

typical commercial or hospital

environment.

The quality of supply voltage

should comply with that of a

typical commercial or hospital

environment.

The quality of supply voltage

should comply with that of a

typical commercial or hospital

environment. If the device is

to continue functioning

uninterruptedly in case of

power interruptions, it is

recommended that the device

be operated via uninterrupted

power supply or a battery.

3 A/m 3 A/m In supply frequency, the

magnetic fields should comply

with the values characteristic

of locations in a typical

commercial or hospital

environment.

3 V rms

150 kHz to 80

MHz

3 V rms

150 kHz to 80

MHz

When operating portable or

mobile RF communication

devices (transmitters), a

safety distance should be

observed to all parts of the

device, including cables,

calculated on the basis of one

of the following equations

depending on the transmission

frequency.

Recommended safety

distance:

3 V/m

80 MHz to 2.5

GHz

3 V/m

80 MHz to 2.5

GHz

d = 1.2P 150 kHz to 80 MHz

d = 1.2P 80 MHz to 800

MHz

Page 46

Version 12| 06.10.2021 | Page 46

he

d = 2.3P 800 MHz to 2.5

GHz

Whereby P is the maximum

nominal output of the

respective transmitter

specified by the manufacturer

in Watts (W), and d is the

recommended safety distance

in meters (m).

The field strength of

stationary RF transmitters,

which is definable via

electromagnetic site survey a,

should be below the

compliance level of the

individual frequency ranges b.

Disturbances are possible near

devices which bear the symbol

below.

Note: These guide values may not apply to all situations. Spreading of electromagnetic

waves is also influenced by absorption and reflection via buildings, items, persons, and

animals.

a. The field strength of stationary transmitters (e.g. base stations of mobile phones

(mobile/cordless) and mobile land mobile radios, amateur radio stations, AM and FM

radio, and TV transmitters), cannot be theoretically calculated in advance. To identify

the electromagnetic environment with regard to stationary RF transmitters, an

electromagnetic site survey should be considered. If the field strength identified at the

location at which the device is used exceeds the RF compliance level specified above, t

device should be closely observed. It may be necessary to take additional measures

(e.g. changing the alignment or transposition of the device).

b. Across the frequency range of 150 kHz to 80 MHz, the field strength should be less

than 3 V/m.

Page 47

Version 12| 06.10.2021 | Page 47

Recommended minimum distances between portable and

mobile RF communication devices and the RO

The RO is intended for use in electromagnetic environments in which radiated RF disturbances are

controlled. The buyer or user of the RO can help prevent electromagnetic interference by maintaining a

minimum distance between portable/mobile RF communications equipment (transmitters) and the RO as

recommended below, according to the maximum output power of the communications equipment

Max. output of the

transmitter

(W)

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters with a maximum output not specified above, the recommended

distance d in meters (m) can be calculated in accordance with the equation appropriate

for the frequency of the transmitter, whereby P is the maximum output of the

transmitter in Watts (W) in accordance with the specifications of the manufacturer.

NOTE 1:

For 80 MHz and 800 MHz, the safety distance applies for the higher frequency range.

NOTE 2:

These guide values may not apply to all situations. Spreading of electromagnetic waves

is also influenced by absorption and reflection via buildings, items, and persons.

Minimum distance in accordance with the frequency of the

transmitter (m)

150 kHz to 80 MHz

d=1.2 √P

80 MHz to 800 MHz

d=1.2 √P

800 MHz to 2.5 GHz

d=2.3 √P

Loading...

Loading...