Page 1

American-Lincoln

®

Operator's

Manual &

Sweeper/Scrubber

Parts List

Beginning with Serial No. 690119

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure

to read this book prior to operating or attempting any service or maintenance procedure to

your machine could result in injury to you or to other personnel; damage to the machine or to

other property could occur as well. you must have training in the operation of this machine

before using it. If you or your operator (s) cannot read English, have this manual explained

fully before attempting to operate this machine.

Si Ud. o sis operadores no pueden leer el Inglés, se hagen explicar este manual completamente

antes de tratar el manejo o servicio de esta máquina.

SMART 2000

ISO 9001

U

®

L

#

FILE A2287

All directions given in this book are as seen from the operator's position at the rear of the machine.

For new books, write to: American-Lincoln., Inc., 1100 Haskins Road, Bowling Green, Ohio 43402

Part No. 2-86-00254 2001 Printed in the American-Lincoln® USA

Page 2

TABLE OF CONTENTS

SPECIFICA TIONS .................................................................................................................................. 1-4

MACHINE DIMENSIONS ........................................................................................................................1-6

ST ANDARD HARDWARE & TORQUE V ALUES...................................................................................... 1-7

HYDRAULIC TORQUE REQUIREMENTS ............................................................................................... 1-8

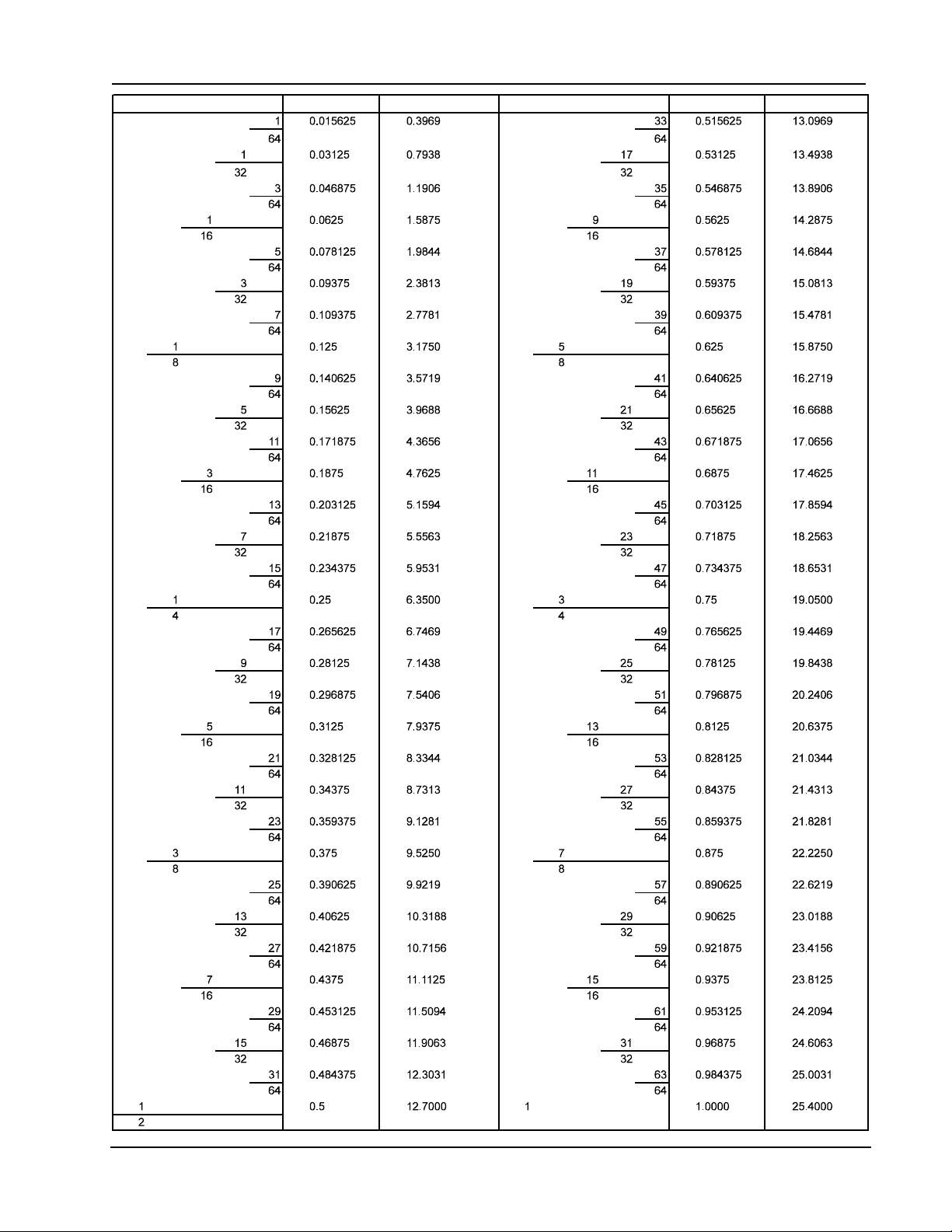

DECIMAL - METRIC CONVERSION T ABLE ...........................................................................................1-9

MACHINE PREP ARA TION ...................................................................................................................... 1-10

PREP ARING THE MACHINE FOR OPERA TION...............................................................................1-10

BA TTERY POWERED MACHINE PREP ARA TION............................................................................1-11

SAFETY INSTRUCTIONS .................................................................................................................1-12

OPERA TION OF CONTROLS AND GAUGES .........................................................................................1-15

LIGHT SWITCH................................................................................................................................. 1-15

HORN BUTTON ................................................................................................................................ 1-15

KEY SWITCH ................................................................................................................................... 1-15

HOUR METER.................................................................................................................................. 1-15

BA TTERY CONDITION METER ........................................................................................................1-16

BA TTERY CONDITION LIGHT...........................................................................................................1-16

SEA T POSITION ADJUSTMENT .......................................................................................................1-16

FIL TER SHAKER SWITCH ............................................................................................................... 1-17

DUST CONTROL SWITCH................................................................................................................1-17

MAIN BROOM AND SIDE BROOM SWITCH .................................................................................... 1-17

SIDE BROOM ADJUSTMENT...........................................................................................................1-17

MAIN BROOM ADJUSTMENT ..........................................................................................................1-17

SCRUB DECK SWITCH ...................................................................................................................1-18

SQUEEGEE SWITCH ......................................................................................................................1-18

SOLUTION CONTROL KNOB ........................................................................................................... 1-18

LOW SOLUTION LIGHT (WARNING LIGHT) ..................................................................................... 1-19

RECOVERY HIGH LIGHT (WARNING LIGHT)................................................................................... 1-19

P ARKING BRAKE ............................................................................................................................ 1-19

TURN SIGNAL (4-W AY) OPTION...................................................................................................... 1-19

HYDRAULIC RESERVOIR LEVEL SIGHT GAUGE...........................................................................1-19

ACCELERA TOR and DIRECTIONAL CONTROL PEDAL ................................................................... 1-20

BACK-UP ALARM SWITCH ..............................................................................................................1-20

FIL TER P ANEL KNOB ......................................................................................................................1-20

MAIN BROOM COMP ARTMENT DOOR ........................................................................................... 1-21

HOPPER LIFT SWITCH....................................................................................................................1-21

ESP SYSTEM OPERA TING INSTRUCTIONS .........................................................................................1-22

THE SCRUBBING SYSTEM - HOW IT WORKS ............................................................................... 1-22

THE NON-RECYCLING OR ST ANDARD SCRUBBING SYSTEM - HOW IT WORKS........................1-22

RECOVERY OR ESP SYSTEM - HOW IT WORKS .........................................................................1-22

OPERA TING INSTRUCTIONS ................................................................................................................. 1-23

BEFORE ST ARTING THE ENGINE...................................................................................................1-23

PRE-ST ART CHECKLIST.................................................................................................................. 1-23

ST ARTING BA TTERY MACHINES ....................................................................................................1-23

POST-OPERA TION CHECKLIST.......................................................................................................1-23

SERVICE CHART ................................................................................................................................... 1-24

HELPFUL HINTS FOR CLEANING OPERA TION ..................................................................................... 1-26

SERVICE PRECAUTIONS ...................................................................................................................... 1-27

SERVICE INSTRUCTIONS ...................................................................................................................... 1-28

MAIN BROOM .................................................................................................................................. 1-28

CHECKING THE MAIN BROOM SWEEP P A TTERN......................................................................... 1-28

ADJUSTING THE MAIN BROOM HEIGHT ........................................................................................ 1-28

REPLACING THE MAIN BROOM ..................................................................................................... 1-28

MAIN BROOM LEVEL ADJUSTMENT ..............................................................................................1-28

SIDE BROOM .................................................................................................................................. 1-29

CHECKING THE SIDE BROOM SWEEP P A TTERN .........................................................................1-29

AMERICAN-LINCOLN TECHNOLOGY 1 - 1

SMART 2000

Page 3

TABLE OF CONTENTS

REPLACING THE SIDE BROOM......................................................................................................1-29

HOPPER .......................................................................................................................................... 1-30

CLEANING THE HOPPER................................................................................................................1-30

ADJUSTING THE HOPPER SWITCH................................................................................................1-30

DUST CONTROL FIL TER..................................................................................................................1-30

CHECKING THE DUST CONTROL FIL TER ....................................................................................... 1-30

CLEANING THE DUST CONTROL FIL TER........................................................................................1-30

REPLACING THE DUST CONTROL FIL TER .....................................................................................1-31

DUST FLAPS ...................................................................................................................................1-31

CHECKING THE DUST FLAPS ........................................................................................................ 1-31

ADJUSTING THE DUST FLAPS ....................................................................................................... 1-31

BRAKES .......................................................................................................................................... 1-32

ADJUSTING THE BRAKE PEDAL ....................................................................................................1-32

ADJUSTING THE BRAKES ..............................................................................................................1-32

ADJUSTING THE FOOT THROTTLE SWITCH...................................................................................1-32

GENERAL MACHINE MAINTENANCE.................................................................................................... 1-33

FILLING THE HYDRAULIC RESERVOIR ..........................................................................................1-33

CLEANING THE HYDRAULIC SYSTEM ...........................................................................................1-33

REPLACING THE RETURN FIL TER ELEMENT ................................................................................ 1-33

REPLACING THE SCRUB BRUSH ................................................................................................... 1-34

ADJUSTING THE SCRUD DECK ......................................................................................................1-34

COVERS AND LATCHES ................................................................................................................. 1-34

SOLUTION LOW WARNING LIGHT ..................................................................................................1-34

RECOVERY HIGH WARNING LIGHT ...............................................................................................1-34

SOLUTION CONTROL ...................................................................................................................... 1-34

RECYCLING PUMP ESP SYSTEM..................................................................................................1-35

RECYCLING PUMP STORAGE........................................................................................................1-35

REAR SQUEEGEE .......................................................................................................................... 1-35

ADJUSTING THE REAR SQUEEGEE LIFT....................................................................................... 1-35

SQUEEGEE CASTER WHEELS......................................................................................................1- 35

ADJUSTING CASTERS ....................................................................................................................1-35

EMPTYING THE RECOVERY T ANK ................................................................................................1-36

P ARTS LIST LEGEND............................................................................................................................ 1-37

HARDWARE LEGEND ............................................................................................................................ 1-38

ORDERING P ARTS ................................................................................................................................ 1-44

ELECTRICAL SCHEMA TIC (BA TTERY) ..................................................................................................1-45

CONNECTION - HARNESS ROUTING (BA TTERY) ................................................................................. 1-46

HYDRAULIC SCHEMA TIC (BATTER Y) ................................................................................................... 1-47

CHAPTER 2 (P ARTS LIST) .....................................................................................................................2-1

MAIN BROOM .................................................................................................................................. 2-2

MAIN BROOM BAFFLE AND FLAPS ............................................................................................... 2- 6

SIDE BROOM (12V & 36V) ..............................................................................................................2-8

HOPPER ASSEMBLY (12V & 36V BA TTERY) ................................................................................. 2-10

SCRUB DECK ACTUA TOR...............................................................................................................2-12

SCRUB DECK ASSEMBL Y (40”) ...................................................................................................... 2-14

SCRUB DECK ASSEMBL Y (46”) ...................................................................................................... 2-17

SIDE SQUEEGEE (40”)....................................................................................................................2-19

SIDE SQUEEGEE (46”)....................................................................................................................2-20

REAR SQUEEGEE (40”) ..................................................................................................................2-22

REAR SQUEEGEE (46”) ..................................................................................................................2-24

REAR SQUEEGEE LIFT SYSTEM (12V AND 36V) .......................................................................... 2-26

SWING SQUEEGEE SUPPORT ......................................................................................................2- 28

SOLUTION TANK ............................................................................................................................. 2-30

SOLUTION CONTROL ...................................................................................................................... 2-32

RECOVERY TANK ........................................................................................................................... 2-34

1 - 2 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 4

TABLE OF CONTENTS

FORWARD AND REVERSE CONTROL (BA TTER Y).........................................................................2-36

BRAKE ASSEMBL Y......................................................................................................................... 2-38

FRONT WHEEL ASSEMBL Y............................................................................................................ 2-40

REAR WHEEL ASSEMBLY.............................................................................................................. 2-42

FRONT COVER AND LA TCH ASSEMBL Y ........................................................................................2-44

SEA T ASSEMBL Y............................................................................................................................2-46

ACCESS PANELS ........................................................................................................................... 2-47

ROLL OUT BA TTER Y ....................................................................................................................... 2-48

DUST CONTROL (BA TTER Y) ........................................................................................................... 2-50

VACUUM MANIFOLD SYSTEM ....................................................................................................... 2-54

HYDRAULIC MOTOR AND PUMP ASSEMBL Y ................................................................................2-56

MOTOR AND PUMP MOUNTING ASSEMBL Y................................................................................. 2-58

HYDRAULIC RESERVOIR ASSEMBLY............................................................................................2-59

HYDRAULIC FILTER AND SOLENOID ASSEMBLY ..........................................................................2-60

HYDRAULIC CONNECTION DIAGRAM ............................................................................................ 2-62

POWER PANEL (36V) .....................................................................................................................2-64

POWER STEERING.........................................................................................................................2-66

ELECTRICAL POWER PANEL (36V) ...............................................................................................2-68

INSTRUMENT PANEL ...................................................................................................................... 2-70

DECALS...........................................................................................................................................2-74

CHAPTER 3 (OPTIONS) ......................................................................................................................... 3-1

BACK-UP ALARM (12V & 36V) ........................................................................................................ 3-2

BA TTERY ST AND.............................................................................................................................3-3

ESP (12V & 36V) .............................................................................................................................3-4

FIRE EXTINGUISHER .......................................................................................................................3-7

LIGHT PACKAGE ............................................................................................................................. 3-8

OVER HE AD GUARD (OHG)............................................................................................................ 3-9

STROBE LIGHT WITHOUT OHG (12 & 36 VDC)...............................................................................3-10

STROBE LIGHT WITH OHG (12 & 36 VDC)......................................................................................3-12

SEA T BELT ASSEMBL Y...................................................................................................................3-14

SQUEEGEE WAND .........................................................................................................................3-15

PAD DRIVER (20”)............................................................................................................................ 3-16

SPRA Y & VAC WAND (12V & 36V) ................................................................................................. 3-17

HYDRAULIC KIT ...............................................................................................................................3-21

INDEX.....................................................................................................................................................3-22

WARRANTY ........................................................................................................................................... 3-25

AMERICAN-LINCOLN TECHNOLOGY 1 - 3

SMART 2000

Page 5

SPECIFICATIONS

CLEANING PA TH

Scrubbing - 40 in. (101 cm)

- 46 in. (1 17 cm)

Sweeping - 46in. (1 17 cm)

Edge Cleaning - 6 in.(15 cm) Right Side 46in. 117 cm) only

TRAVEL SPEED - 0-4 MPH (0 - 6.4kph)

STEERING - Rack & Pinion 90°-90° Hyd. Power Steering

- Adjustable S teering Column

TURNING RADIUS

Left - 59 in. (150 cm)

Right - 59 in. (150 cm)

Aisle “U” Turn - 87 in. (221 cm)

DIMENSIONS

Length - 87 in. (221 cm)

Width - 46 in. (1 16.8 cm)

Height - 52 in. (132 cm)

Height w/Overhead Guard - 79 in. (200.6 cm)

Wheel Base - 37.6 in. (95.5 cm)

WEIGHT

St andard Machine (Battery) - 1700 lbs. (765 kg.) without battery

TIRES

Front (Battery) Solid Urethane - T wo (2)16 in (41cm) x 3.75 in (8.26 cm)

Rear (Battery) Solid Rubber - One (1)16 in (41 cm) x 4.00 in (10.16cm)

RAMP CLIMBING

Transporting - 8° (battery)

MAIN BROOM

One piece plastic core disposable type. Broom position can be set to “restricted down” or

“free floating”.

Length - 36 in (91.4 cm)

Diameter - 10 inches (25.4 cm)

Optional Bristle T ype - Nylon (High density)

SIDE BROOM

Side Broom Size - 16 inches (40.6 cm) Diameter

- 510 Ah battery 1800 lbs. (810 kg)

- 720 Ah battery 1990 lbs. (896 kg)

- Proex

- Nylon Eight (8) Row

1 - 4 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 6

INSTRUMENTS AND CONTROLS

Main/Side Broom Switch Key Switch

(activates immediately when lowered) Rectangular Hour Meter

Headlight/T aillight Switch (option) Battery Rollout

Squeegee Switch Recovery High Light

3 Position Scrub Deck Switch Dust Control Switch(with certain models)

Horn Button Solution Low Light

Solution Control Coolant T emperature Light

Hopper Up/Down Filter Shaker Switch

SCRUBBING SYSTEM

Brush Size-46” (116.84 cm) - Three (3) 16” (40.6cm) Diameter

Brush Size-40” (101.4 cm) - T wo (2) 20” (51cm) Diameter

Brush Drive Lift - Electric Actuator

Scrub Load

40” scrub p ath )(116.84 cm) - From 90 lbs. to 140 lbs. per brush (Battery)

46” scrub path)(101.4 cm) - From 90 lbs. to 140 lbs. per brush (Battery)

SQUEEGEE

Rear - Accu-Trac™ 46 in(1 16.8 cm) Swing, break away ,

Side - 26 in (66 cm) Easy Change

SPECIFICATIONS

w/no tool squeegee replacement

T ANKS

Solution T ank - 55 Gallons (208 liter)Polyethylene

Recovery T ank - 55 Gallons (208liter)Polyethylene

Solution Metering - V ariable to 3.0 GPM (1 1.4 lpm)

Drain Hose - 48 in (122 cm) No Plug required

Clean Out Port - 5.7 in (14.5 cm) heavy debris

HOPPER

Capacity - 2.5 cu.ft.(71liter)

DUMP AND LIFT

Dump Height - 14 in (35.6 cm.)

SYSTEM FLUID CAP ACITIES

Hydraulic System (Battery) - 4.7 Gallons (17.79 Liters)

OPTIONAL EQUIPMENT

Back-Up Alarm Headlight/T aillights

Push Pull Light Switch (Work Light) Strobe Light (Red or Amber)

ESP System w/o Detergent Provisions Overhead Guard

Pad Drivers Arm Rest

Spray and Vac Wand Option Fire Extinguisher

Linatex Squeegee Squeegee Wand

720 Amp Hour Battery 510 Amp Hour Battery

AMERICAN-LINCOLN TECHNOLOGY 1 - 5

SMART 2000

Page 7

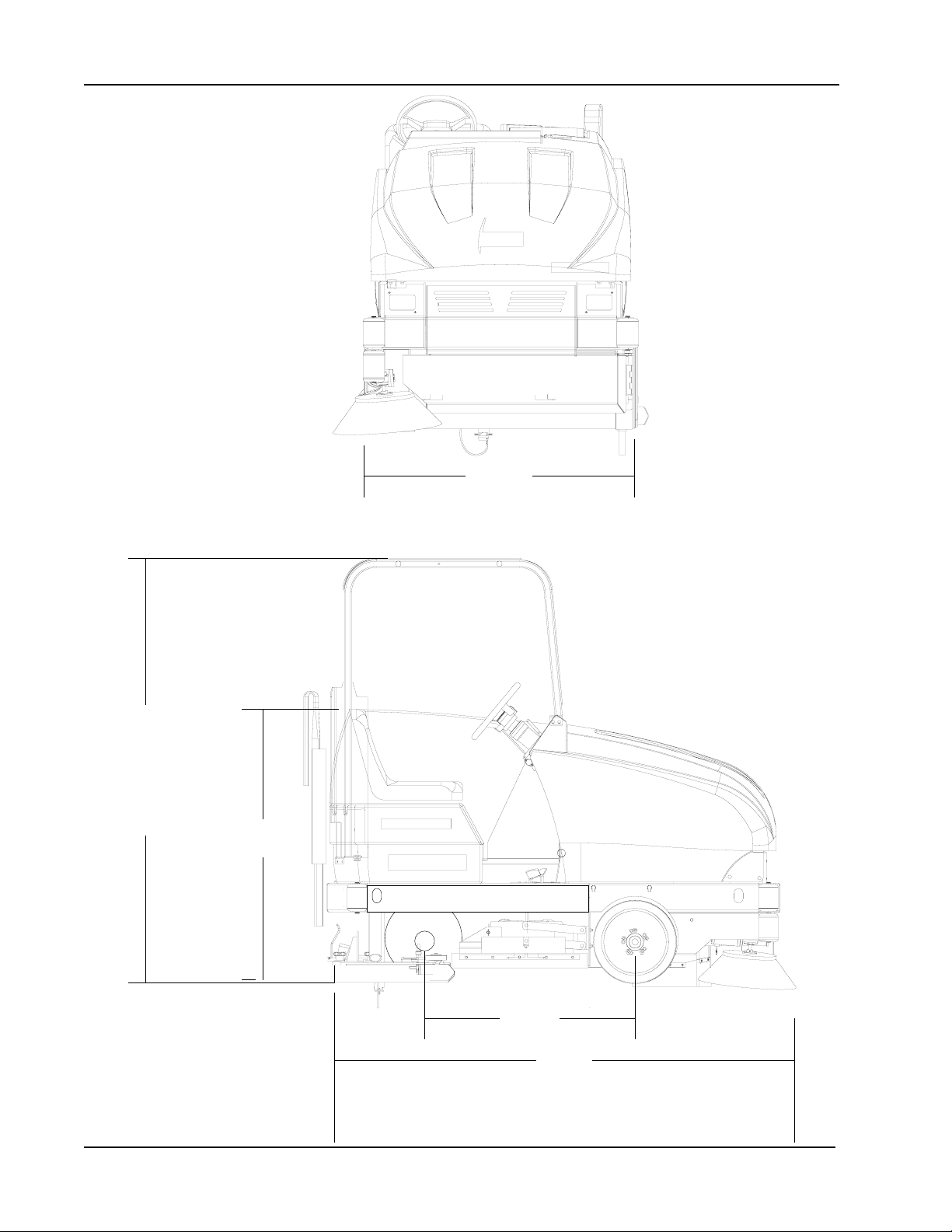

MACHINE DIMENSIONS

46"

(116.8 cm)

79”

(200.6 cm)

52"

(132 cm)

37.6"

c1961/0002

(95.5 cm)

87”

(221 cm)

1 - 6 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 8

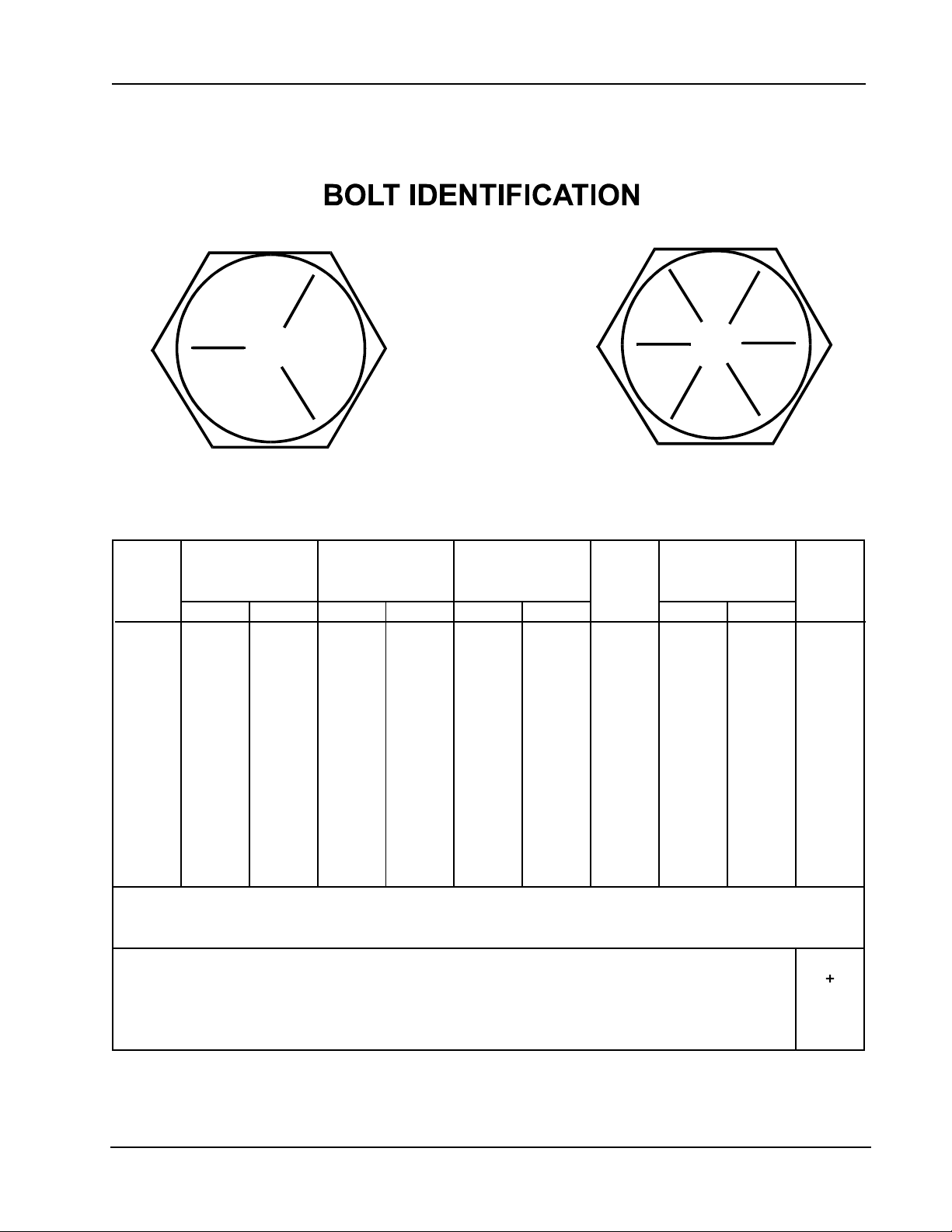

STANDARD HARDWARE & TORQUE VALUES

SAE - Grade 5

C

14

27

39

86

15

28

44

68

98

135

239

387

579

Grade

5

Plated

Grade

8

Plated

FFF

15

28

43

108

17

31

49

76

110

153

267

-

-

C

-

-

-

130

22

40

63

95

138

191

338

545

818

-

-

-

151

24

44

70

108

155

216

378

-

-

410H

Stainless

C

18

33

47

114

19

34

55

85

-

-

-

-

-

20

35

54

132

22

39

62

95

-

-

-

-

-

Screw

Size

*6

*8

*10

*1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

C = Coarse Thread

F = Fine Thread

* = Torque values for #6 through 1/4 are lb./in. All others are lb./ft.

Brass

5

9

13

32

6

10

16

-

-

-

-

-

-

SAE - Grade 8

Type

F&T

&BT

C

20

37

49

120

-

-

-

-

-

-

-

-

-

F

23

41

64

156

-

-

-

-

-

-

-

-

-

Type

B, AB

21

34

49

120

-

-

-

-

-

-

-

-

-

NOTE

Decrease the torque by 20% when using thread lubricant

The torque tolerance is ± on torque values.

C2000/9905

AMERICAN-LINCOLN TECHNOLOGY 1 - 7

SMART 2000

Page 9

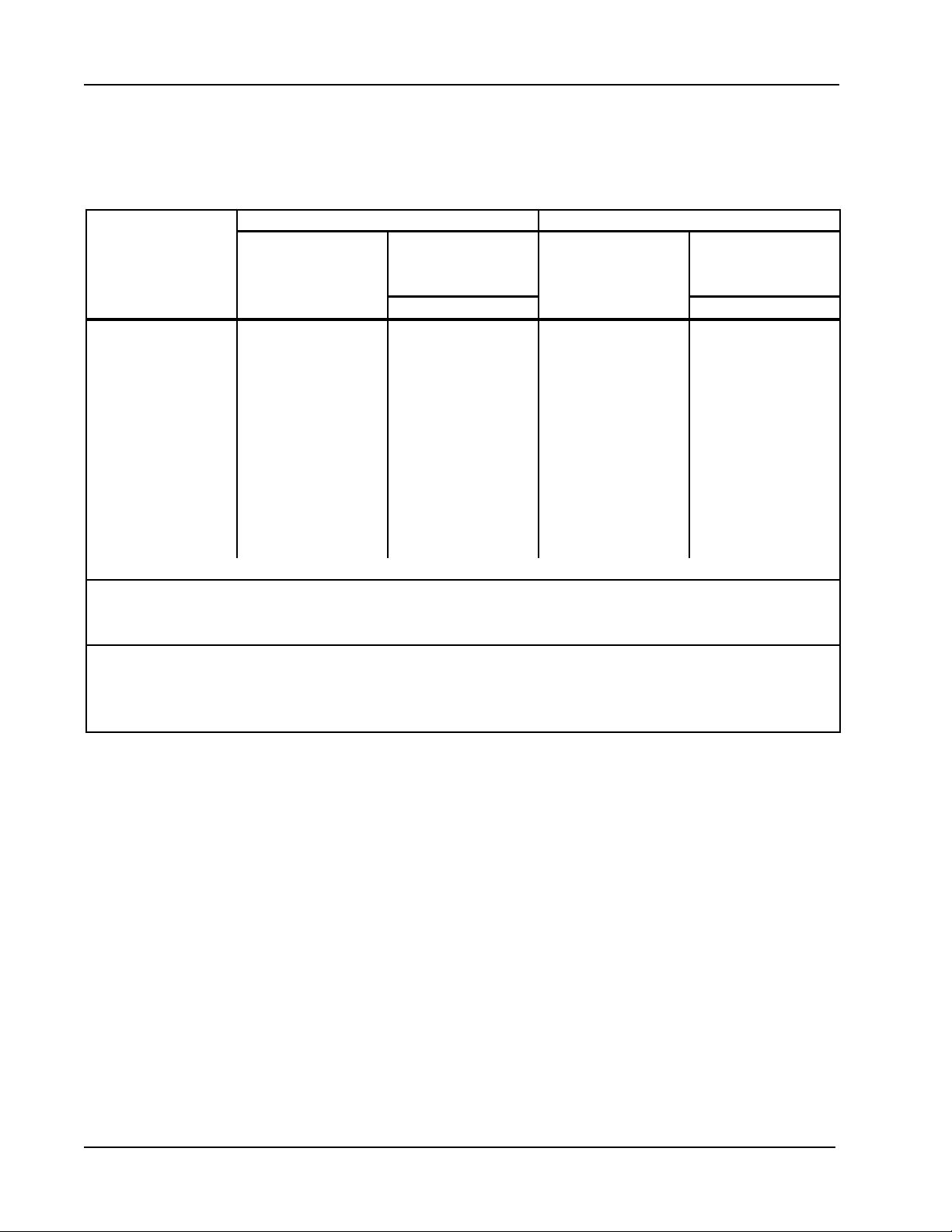

HYDRAULIC TORQUE REQUIREMENTS

HYDRAULIC TORQUE REQUIREMENTS

Refer to the following chart for torque values on all hydraulic hoses and fittings.

Nominal O-Ring Face Seal End SAE O-Ring Boss End

SAE Thread Swivel Thread Str. Fitting

Dash Size Nut Size or Locknut

Size Inch Torque Inch Torque

LB-FT LB-FT

-3 * * 3/8-24 8-10

-4 9/16-18 10-12 7-16-20 14-16

-5 * * 1/2-20 18-20

-6 11/16-16 18-20 9/16-18 24-25

-8 13/16-16 32-35 3/4-16 50-60

-10 1-14 46-50 7/8-14 72-80

-12 1 3/16-12 65-70 1 1/16-12 125-135

-14 1 3/16-12 65-70 1 3/16-12 160-180

-16 1 7-16-12 92-100 1 5/16-12 200-220

-20 1 11/16-12 125-140 1 5/8-12 210-280

-24 2-12 150-165 1 7/8-12 270-360

* O-Ring face seal type end not defined for this tube size.

NOTE

Parts must be lightly oiled with hydraulic fluid.

C-2002

1 - 8 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 10

DECIMAL - METRIC CONVERSION TABLE

FRACTION FRACTION

DECIMAL DECIMAL

MILLIMETER MILLIMETER

C-2001/9907

AMERICAN-LINCOLN TECHNOLOGY 1 - 9

SMART 2000

Page 11

MACHINE PREPARATION

Figure 1

YOUR SMART 2000 MACHINE HAS BEEN SHIPPED COMPLETE, BUT DO NOT A TTEMPT TO OPERA TE

WITHOUT FOLLOWING THESE INSTRUCTIONS.

PREP ARING THE MACHINE FOR OPERA TION (IC Engine Powered)

1. Connect and tighten battery cables.

2. Fill the tank with REGULAR GRADE gasoline. (Diesel fuel if equipped with diesel engine.)

WARNING

Never fill the tank while the engine is running. Always be sure the gasoline container and sweeper are electrically

connected before pouring gasoline. This can easily be done by providing an insulated wire (permanently attached

to container) with a battery clip on the other end.

3. Check engine crankcase oil level. Although properly lubricated at the factory, check before starting the

engine. No special break in oil is used and recommended number of operating hours before the initial oil

change is the same as normal. See Maintenance.

4. Check radiator coolant level. Permanent type antifreeze is added at the factory to provide protection to approximately -35°F (37°C). To retain this protection level, always add ½ part water to ½part

antifreeze.

5. Check oil level in the hydraulic reservoir located at the drivers side of the machine beside the engine. The

oil fill level should be halfway on sight glass. If oil is needed, add Standard, 30 weight, non-detergent motor

oil. Af ter the first 50 operating hours, service must be performed on your engine to ensure future high

performance and trouble free operation. See Maintenance.

1 - 10 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 12

MACHINE PREPARATION - BATTERY

NOTE

After the first 35 operating hours, service must be performed on your engine to ensure future high performance

and trouble free operation. See Maintenance.

BA TTERY POWERED MACHINES

*Uncrate the machine and carefully remove from skid to prevent damage.

*The SMART 2000 machines that are shipped without batteries have the (+) positive drive motor lead

disconnected.

*Open the battery compartment and connect the (+) positive motor lead to the top terminal post

(the wire “P” is also attached to it). Tighten the terminal nut.

*Install the scrub brushes.

*Check the oil level in the hydraulic reservoir

*Install batteries as follows (if not included):

1. Turn the key to the “OFF” position.

2. Raise the Front Cover to the open position.

3. Use a battery lifting device with a 2500 lbs. (1 150 Kg) cap acity hoist to lift the battery. Set up the battery

tray in the center position. Make sure the size of the battery fits into the tray prior to installation

(20.25W x 38.50 x 31.00 L).

4. Using the lifting device, lower the 36 volt battery into the battery tray directly in front of the

driver’s compartment. Orient the cables & plug them in as required.

5. Plug the polarized connector from the battery into the 36 volt plug provided.

WARNING

Hydrogen gas is formed during the charging operation and is explosive! Only charge batteries in a well ventilated

area with the lid open. Avoid any open flame or electrical sparks. Pulling out the charger plug with the timer on

will cause an arc and must be avoided.

AMERICAN-LINCOLN TECHNOLOGY 1 - 11

SMART 2000

Page 13

SAFETY INSTRUCTIONS

THE FOLLOWING ST A TEMENTS ARE USED THROUGHOUT THIS MANUAL AS INDICA TED IN THEIR

DESCRIPTIONS:

DANGER

To warn of immediate hazards which will result in severe personal injury or death.

WARNING

To warn of hazards or unsafe practices which could result in severe personal injury or death.

CAUTION

T o warn of hazards or unsafe practices which could result in minor personal injury .

A TTENTION

T o warn of unsafe practices which could result in extensive equipment damage.

NOTE

To give import ant information or to warn of unsafe practices which could result in equipment damage.

WARNING

THE FOLLOWING INFORMATION SIGNALS POTENTIALL Y DANGEROUS CONDITIONS T O THE OPERATOR OR EQUIPMENT . READ THIS MANUAL CAREFULL Y . KNOW WHEN THESE CONDITIONS CAN EXIST . THEN, T AKE NECESSARY

STEPS TO TRAIN MACHINE OPERA TING PERSONNEL. FOR THE SAFE OPERATION OF THIS MACHINE, READ AND

UNDERST AND ALL WARNINGS, CAUTIONS AND NOTES.

WARNING

Machines can ignite flammable materials and vapors. Do not use with or near flammables such as gasoline, grain

dust, solvents, and thinners.

WARNING

Improper use of heavy machinery can cause personal injury .

WARNING

Operate only when lids, doors, and access panels are securely closed.

WARNING

Use care when reversing machine in confined area.

WARNING

When servicing the machine, disconnect the batteries first to prevent possible injury.

WARNING

When working on the machine, empty hopper, remove batteries, clear area of people and obstructions, use

additional people and proper procedures when lifting the machine.

WARNING

Always empty the hopper and disconnect the battery before doing maintenance.

WARNING

You must have training in the operation of this machine before using it. READ THE INSTRUCTION BOOK.

WARNING

Do not operate this machine unless it is completely assembled.

WARNING

Do not use this machine as a step or furniture.

WARNING

Stop and leave this machine on a level surface. When you stop the machine, put the power switch in the “OFF”

position and engage the Wheel Lock.

1 - 12 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 14

SAFETY INSTRUCTIONS

WARNING

T o prevent injury and damage to the machine, do not lift the machine or move it to an edge of a st air or loading

dock.

WARNING

Lead acid batteries generate gases which can cause an explosion. Keep sparks and flames away from batteries.

NO SMOKING . Charge batteries only in areas with good ventilation.

WARNING

Always wear eye protection and protective clothing when working near batteries. Remove all jewelry . Do not put

tools or other metal objects across the battery terminals or across the tops of batteries.

WARNING

Maintenance and repairs must be done by authorized personnel only . Tighten all fasteners. Maint ain adjustment s

according to the specifications given in the service manual for the machine. Keep the electrical parts of the

machine dry. For storage, keep the machine in a building.

WARNING

Make sure all labels, decals, warnings, cautions and instructions are fastened to the machine. Purchase new

labels and decals from American-Lincoln T echnology .

WARNING

The operator must exhibit extreme caution when negotiating, turning, and traveling across grades or ramps. Start,

stop, change direction, travel and brake smoothly . Slow down when turning.

WARNING

Avoid uneven surfaces and loose materials. Watch for obstructions, especially overhead.

WARNING

Operate only from the designated operator’s position. Stay inside the body of the machine. Keep hands and feet

on the designated controls. Always operate in well lighted areas.

WARNING

Do not carry passengers on the machine. Set the Wheel Lock when leaving the machine. Chock (block) the

wheels if the machine is parked on a grade (ramp), or is being prepared for Maintenance.

WARNING

Never leave the operator’s compartment when the is engine running.

WARNING

Report damage or faulty operation immediately . Do not operate the machine until repairs have been completed.

Maintenance and repairs must be done by authorized

personnel only .

WARNING

To maint ain the stability of this machine in normal operation, the overhead guard, counterweight s, roller bumper

guards, or any similar equipment installed by the manufacturer as original equipment should never be removed. If

it becomes necessary to remove such equipment for repair or maintenance, this equipment must be reinstalled

before the machine is placed back into operation.

WARNING

Electrical hazard. Shocks can cause serious personal injury. Unplug the battery before cleaning or servicing. To

avoid possible injury or property damage, read the Operator’s Manual before servicing the machine. Maintenance

and repair must be done by authorized personnel.

WARNING

Disconnecting the battery connector with the key switch in the “I” position will cause sparks that could ignite

explosive hydrogen gas generated by the batteries. T o prevent serious injury or possible property damage, turn

Key Switch to “O” position before disconnecting the battery cable from the machine for charging or service.

AMERICAN-LINCOLN TECHNOLOGY 1 - 13

SMART 2000

Page 15

SAFETY INSTRUCTIONS

FOR SAFETY , OBSERVE THE FOLLOWING W ARNINGS. FAILURE TO COMPL Y MA Y CREA TE A SERIOUS RISK OF INJURY

TO YOURSELF AND OTHERS. THIS MACHINE SHOULD NOT BE USED IN HAZARDOUS LOCA TIONS INCLUDING AREAS

OF VOLA TILE DUST OR VAPOR CONCENTRA TIONS.

Operators must be trained and qualified to operate this machine. They must also understand the operator’s

manual before starting.

Use caution when mounting or dismounting the machine particularly on wet slippery

surfaces. Do not dump the hopper over an open pit or dock. Do not dump the hopper when positioned on a grade

(ramp). The machine must be level (horizontal).

1 - 14 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 16

Figure 2

OPERA TION OF CONTROLS AND GAUGES

LIGHT SWITCH (See Figure 2)

The light switch is located above the horn button to the left

of the steering wheel. By pressing on the lower part of the

switch, it will work various light options that are available for

this machine, such as:

Headlights

Taillights

HORN BUTTON (See Figure 3)

The horn button is located to the left of the steering column

below the instrument panel. The horn button is always

active.

Figure 3

Figure 4

KEY SWITCH (See Figure 4)

The keyed ignition switch is located on the instrument panel

to the right of the broom lever.

The “OFF” position (O position) will shut off the engine. The

IGN/ON position (I position) provides power to all machine

systems and accessories. The “ST ART” position (one

position clockwise of I position) is momentary and provides

power to the starter motor.

NOTE

To reengage, the key must be returned to the “OFF” position.

HOUR METER (See Figure 5)

The hour meter is located on the instrument panel below the

fuel gauge (gas version), below the battery condition meter

(battery version). The meter is activated when the key

switch is placed in the ignition position. The meter

indicates the actual “run” time of the machine. The meter

can be used to determine when maintenance should be

done on the machine.

Figure 5

AMERICAN-LINCOLN TECHNOLOGY 1 - 15

SMART 2000

Page 17

OPERA TION OF CONTROLS AND GAUGES - Cont.

BA TTERY CONDITION METER (See Figure 6)

The battery condition meter is located on the right side of

the instrument panel. The condition meter indicates the

level of charge in the batteries (inspect underload). The

batteries are sufficiently charged when the needle stays in

the green area on the gauge while the machine is being

operated.

Charge the batteries when the needle drops into the red

zone while operating the machine. Do not operate the

machine if the needle stays in the red area.

Figure 6

BA TTERY CONDITION LIGHT (See Figure 7)

The meter shows the condition of the battery , while the

machine is running, under load. When the battery voltage

falls below 31-32 volts for longer than 2-3 seconds the low

voltage light will come on and the Brush/Water solenoids

will be shut off automatically. This is a permanent lockout

until the power is turned off to module. The low voltage

lock out can be reset almost immediately by turning off all

power to the module for 3-5 seconds. In a permanent low

battery condition, the machine can be functional only for

one minute periods an then only by turning the ignition off

and on.

Figure 7

SEA T POSITION ADJUSTMENT (See Figure 8)

The seat position adjustment lever is located on the front

of the seat to the left. The lever is spring loaded to the

“LOCK” position.

T o adjust the seat, push the lever to the “RIGHT” and

move the seat to the desired position. Then release the

lever to “LOCK” the seat into place.

Figure 8

1 - 16 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 18

Figure 9

OPERA TION OF CONTROLS AND GAUGES - Cont.

FIL TER SHAKER SWITCH (See Figure 9)

The filter shaker switch is located on the top left corner of

the instrument panel . By pressing and holding in the

lower part of the switch, it will activate the filter shaker

motors for 20 to 30 seconds. Upon releasing the switch,

it will return to the off (middle) position.

The Impeller fan will stop when the filter shaker has been

activated. The filter shaker will only operate with the

hopper in the “DOWN” position.

DUST CONTROL SWITCH (See Figure 9)

The Dust Control Switch located on the top left corner of

the instrument panel. To turn on the dust control system

for “NORMAL” sweeping, press in the upper portion of the

switch. To turn off the dust control system for sweeping in

wet conditions, return the switch to the middle position

(wet sweep bypass). This will prevent the filter from being

damaged by water pickup while sweeping.

SIDE BROOM and MAIN BROOM SWITCH (See

Figure 10)

The Side and Main Broom Switch is located to the right of

the steering column. By pressing in the upper portion of

the switch, the side and main broom are raised and

turned off. To lower and turn on both brooms, press the

lower portion of the switch.

Figure 10

MAIN BROOM ADJUSTMENT (See Figure 1 1)

The main broom adjustment knob for changing the sweep

height to compensate for broom wear, is located in front

of the machine to the right of the filter. Turning the knob to

the left (counterclockwise) will lower the main broom.

SIDE BROOM ADJUSTMENT (See figure 1 1)

The side broom adjustment knob for changing the sweep

height to compensate for broom wear, is located in front

of the machine to the right of the filter. Turning the knob to

the left (counterclockwise) will lower the side broom.

Figure 1 1

AMERICAN-LINCOLN TECHNOLOGY 1 - 17

SMART 2000

Page 19

OPERATION OF CONTROLS AND GAUGES - Cont.

SCRUB DECK SWITCH (See Figure 12)

The scrub deck switch is located on the instrument panel

to the left of the solution control knob. Pressing in the

upperportion of th switch raises the scrub deck and turns

the brush. In the middle position, the scrub deck lowers

to the normal down position. Pressing the lower portion of

the switch lowers the scrub deck to the heavy down

position.

In the third position, Scrub Deck Heavy , additional

downward pressure is applied. This will help for extremely

dirty surfaces.

Lowering the scrub deck does not turn on the brushes. The

brushes turn on automatically when the machine moves in

Figure 12

SQUEEGEE SWITCH (See Figure 13)

The squeegee blade switch is located on the console to

the left of the steering wheel.Pressing the lower portion of

the switch will lower the squeegee and activate the

squeegee vacuum. Pressing the upper portion of the

switch will turn off the squeegee vacuum and raise the

squeegee.

NOTE

the forward or reverse direction.

Figure 13

Figure 14

In the middle position the switch will raise the squeegee.

In this position the vacuum remains on to allow vacuuming

the water that is left in the squeegee recovery hose. This

prevents water from dripping on the floor with the

squeegee “UP .”

If the squeegee is lowered and the direction of the

machine is reverse (activated by the FWD/REV pedal) the

squeegee will automatically raise.

Upon moving in the forward position, the squeegee wil

automatically return to the lowered position.

SOLUTIONS CONTROL KNOB (See Figure 14)

The solution control knob is located to the left hand side of

the steering wheel. Turning the knob counterclockwise will

increase the flow of solution and water. The farther the

solution control knob is turned the heavier the flow of water

and solution will be. Turning the knob counterclockwise

will decrease the flow of the water and solution. To turn

the water and solution off turn the knob all the way

counterclockwise.

NOTE

For best results, discontinue application of solution

10 feet before stopping or making a 90° or 180° turn.

1 - 18 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 20

Figure 15

OPERA TION OF CONTROLS AND GAUGES - Cont.

RECOVERY HIGH LIGHT (See Figure 15)

The recovery high warning light will illuminate

approximately 5 minutes before the recovery tank is full,

giving ample time to complete the scrubbing cycle, before

the mechanical float shuts off the vacuum to the recovery

tank.

LOW SOLUTION LIGHT (See Figure 15)

The Low Solution Warning Light is located on the

console. The Solution Warning Light will illuminate when

the solution tank is empty , marking the end of the

scrubbing cycle.

P ARKING BRAKE (See Figure 16)

Never leave operator’s seat without engaging the parking

brake. The parking brake is located on the floor of the

machine left of the directional control pedal. To set the

parking brake, press down on the foot pedal (Item A) and

the press down the lock (Item B). To unlock the parking

B

brake, push down on the upper portion of the foor pedal

and release.

Figure 16

A

TURN SIGNAL - 4-Way (Option)

The turn signal option is located on the steering column

and works as automotive turn signals work, forward on

the lever for right and back on the lever for left. The 4-way

flasher will activate when the turn signal lever is pulled

out.

HYDRAULIC RESERVOIR LEVEL SIGHT GAUGE (See

Figure 17)

The sight gauge is located on the left side of the machine

under the front cover. The sight gauge is used to indicate

the level of fluid in the reservoir. The fluid level must be

visible in the sight gauge when the hopper is in the down

position.

Figure 17

AMERICAN-LINCOLN TECHNOLOGY 1 - 19

SMART 2000

Page 21

OPERA TION OF CONTROLS AND GAUGES - Cont.

ACCELERA TOR and DIRECTIONAL CONTROL PEDAL

- (See Figure 18)

The Accelerator and Directional Control Pedal is located

on the floor of the operator’s area. This pedal controls the

machine direction and travel speed.

1. Put foot pressure on the right side of the pedal. The

machine will move forward.

2. Increase the foot pressure on the right side of the

pedal to increase the forward speed.

3. Put foot pressure on the left side of the pedal. The

machine will move in reverse.

4. Increase the foot pressure on the left side of the pedal

to increase the reverse speed.

5. T o stop the machine, allow directional control pedal to

return to neutral (center position). Pedal will automatically return to neutral when foot pedal is released, or

put light foot pressure on the opposite end of the accelerator and directional control pedal. If the ma chine is moving forward, put light foot pressure on the

left side of the pedal. If the machine is moving in

reverse, put light foot pressure on the

Figure 18

right side of the pedal.

BACK-UP ALARM SWITCH (Option)

The back-up alarm is operated by a switch that is located

under the accelerator and directional control pedal

mounting plate. The alarm makes a loud audible noise

when the machine is being driven in reverse.

FIL TER P ANEL KNOB (See Figure 19)

The filter panel knob is used to hold the dust control filter

down. It is located in the hopper filter compartment and

will need to be removed periodically for cleaning or

replacement. Removal of the filter panel requires no

tools. The hopper cover must be opened to gain access

to the filter compartment. The panel filter is held in place

by a hinged frame and knob.

T o remove the panel filter , turn the knob counterclockwise

and lift the hinged frame. The panel filter can now be lifted

out and cleaned or replaced.

T o inst all the replacement panel filter , place a new filter in

the machine, lower the frame and twist the knob

clockwise to lock the filter in place.

Figure 19

1 - 20 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 22

OPERATION OF CONTROLS AND GAUGES - Cont.

Figure 20

MAIN BROOM COMP ARTMENT DOOR (See Figure 20)

The main broom compartment door is located in front of the left side tire of the machine. The door provide

access to the main broom for service or inspection. The hopper must be raised to access.

Figure 21

WARNING

Engage hopper safety arm while accessing the main

broom.

HOPPER LIFT SWITCH (See Figure 21)

The hopper lift switch is located on the operator’s

compartment console. The switch controls the operation

of the hopper lift system.

T o raise the hopper for dumping, press and hold the

upper portion of the switch until the hopper reaches the

desired height or a ratcheting sound is heard, then

release.

NOTE

While the hopper is open a chime will ring letting the

operator know it is open. The chime will stop when the

hopper is completely closed.

T o close the hopper press in and hold the lower portion of

the switch until the hopper closes completely (chime wil

turn off) then release.

AMERICAN-LINCOLN TECHNOLOGY 1 - 21

SMART 2000

Page 23

ESP SYSTEM OPERATING INSTRUCTIONS

THE SCRUBBING SYSTEM - HOW IT WORKS

There are two scrubbing systems available for the SMART 2000 machine, the non-recycling or standard

scrubbing system and the recycling or ESP scrubbing system.

THE NON-RECYCLING OR ST ANDARD SCRUBBING SYSTEM - HOW IT WORKS

During the scrubbing process, detergent solution water from the solution tank is fed to the solution line.

There it is fed to the floor where three disc scrubbing brushes work to dislodge soil. Af ter scrubbing, the

dirty solution is vacuumed from the floor and discharged into the containment chamber in the forward

portion of the recovery tank, where a system of baffles helps to clarify the solution.

Sensors in each tank will indicate, by lights on the control panel, when the water in the solution tank is too

low or when the water in the recovery tank is too high.

THE ESP RECYCLING SYSTEM ON/OFF SWITCH (Option)

This switch turns the ESP recycling system on and off.

SOLUTION

TANK

P4796/0001

FILTER

SOLUTION

PUMP

FILTER

RECOVERY

TANK

FLOW VALVE

SEPARATOR

SCRUB

BRUSH

SQUEEGEE

FLOOR CONTACT

Figure 22

NOTE

The solution control lever must be on “FULL” for ESP operation.

THE RECOVERY OR ESP SYSTEM - HOW IT WORKS

During the scrubbing process, filtered water from the solution tank is fed to the solution line, where it combines

with detergent . This mixture is then fed to the floor where three disc scrubbing brushes work to dislodge soil.

After scrubbing, the dirty solution is vacuumed from the floor and discharged into the recovery tank. At intervals,

a float switch activates the recycling pump, which sends filtered solution from the recovery tank to the solution

tank.

1 - 22 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 24

OPERATING INSTRUCTIONS

BEFORE ST ARTING THE MACHINE

1. Set parking brake.

2. Make sure all controls are in the “OFF” position.

3. Be sure the directional control pedal is in neutral.

4. Ensure the batteries have been fully charged and serviced (see battery service instructions).

NOTE

Before starting the engine, perform the pre-start checklist.

PRE-ST ART CHECKLIST

1 Clean engine air filter element.

2 Check hydraulic fluid level.

3 Check all systems for leaks.

4 Check brakes and controls for proper operation.

5 Check broom patterns.

6 Check to ensure that all covers, panels and access doors are securely closed.

NOTE

To prevent possible fire, never fill fuel t ank while the engine is running. Always be sure gasoline container and

machine are grounded before dispensing gas. This can be done by permanently attaching an insulated wire with a

battery clip on the end to the gasoline container .

ST ARTING BATTER Y MACHINES

St arting the battery powered models is accomplished by turning the key switch to the “I” (on) position. It is

important to note that the batteries should be fully charged and serviced prior to using the machine.

After turning off the machine, perform these post-operation checks.

POST-OPERA TION CHECKLIST

1. Clean the debris hopper.

2. Check sweeping brooms for wear or damage.

3. Check all flaps for wear, damage and adjustment.

4. Check all systems for leaks.

5. Charge and service motive power batteries.

6. Check squeegees for damage.

NOTE

AMERICAN-LINCOLN TECHNOLOGY 1 - 23

SMART 2000

Page 25

SERVICE CHART

SERVICE CHART

Check items for proper operation. If service is required, please contact an authorized American-Lincoln

T echnology distributor . For best performance, replace worn parts with genuine American-Lincoln Technology

parts.

EVERY eight (8) HOURS or DAILY check and clean/adjust if necessary:

1 Inspect panel filters for damage and clean them.

2 Inspect and clean hopper.

3 Inspect and clean recovery tank screens and filters.

4 Check hydraulic fluid level.

5 Check all flaps for wear or damage.

6 Check brooms for wear or damage, adjust as required.

7 Check brake pedal and parking brake.

8 Check hydraulic oil filter.

9 Check battery electrolyte level.

1 0 Check all fluid system components for leaks.

50 HOUR (WEEKL Y) MAINTENANCE CHECKLIST

11 Check solution tank (recycling or ESP system).

1 2 Check solution filter screen (recycling or ESP system).

13 Check recovery tank.

1 4 Check recovery tank screens and filters.

15 Inspect scrub brushes for wear or damage.

16 Inspect rear and side squeegees for wear or damage.

17 Check battery electrolyte level.

1 8 Check all hydraulic hoses for wear or cuts.

19 Rotate main brush (end over end).

20 Clean or replace panel filters.

21 Lubricate squeegee casters.

22 Clean throttle rod springs

100 HOUR MAINTENANCE CHECKLIST

23 Lubricate drive wheel, swivel wheel bearings, and steering rack guide (engine side above rear wheel).

24 Lubricate front wheel bearings.

25 Lubricate all moving joints.

2 6 Check brake shoes for wear and adjust accordingly .

2 7 Lubricate all bushings with anti-seize lubricant. The bushings are located on the steering,

scrub deck lift, and squeegee lift

250 HOUR MAINTENANCE CHECKLIST

28 Lubricate squeegee casters.

2 9 Clean solution tank and filter screen.

30 Replace hydraulic filter element.

31 Clean hydraulic reservoir.

1 - 24 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 26

1,20

2

3,13,14

4,31

5,16

5,16

5,16

6

6,19

8,18

30,

9,17

10

11,12,29

21,28

21,28

23

27

27

26

24

25

C1960/0102

22

SERVICE CHART DIAGRAM

Figure 23

AMERICAN-LINCOLN TECHNOLOGY 1 - 25

SMART 2000

Page 27

HELPFUL HINTS FOR CLEANING OPERATION

SIDE AISLES

MAIN AISLE

P4134/0001

Do not turn the steering wheel sharply when the machine is in motion. The machine is very responsive to

movement of the steering wheel. Do not make sudden turns. Scrub in straight paths. Do not bump posts. Do

not scrape the sides of the machine.

1. Plan your sweeping and scrubbing in advance. Try to arrange long runs with minimum stopping and

starting. Sweep debris from narrow aisles out into main aisles ahead of time. Do an entire floor or

section at one time.

2. Pick up oversize debris before sweeping.

3. Allow a few inches of overlap of sweep and scrub paths. This will eliminate leaving dirty patches.

4. Do not turn steering wheel too sharply when the machine is in motion. The machine is very responsive

to movement of the steering wheel, so avoid sudden turns.

5. Try to follow as straight a path as possible. Avoid bumping into posts or scraping the sides of the

machine.

6. Always allow the machine to warm up before operating in cold temperatures.

7. Periodically turn the sweeping broom end-over-end to prevent the bristles from “setting” in one direction.

Replace the sweeping broom when the bristles are worn to 3 inch (8 cm) length. Replace disc brushes when

bristles are reduced to ½ inch (1.3 cm) in length. Replace squeegee rubbers when all usable edges have

become rounded with wear, impairing the wiping action.

SIDE AISLES

Figure 24

WARNING

NOTE

1 - 26 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 28

SERVICE PRECAUTIONS

For safety , read and follow the service precautions below. Know the hazards associated with the equip

ment you are working on to prevent personal injury or damage to equipment.

For service assistance, consult you nearest American Lincoln T echnology Dealer . For best performance

replace worn parts with genuine American Lincoln Technology parts.

Refer all Maintenance and Service requirements to Qualified Maintenance Personnel.

WARNING

DO NOT attempt to service this machine until you have read and understand all Safety Warnings associated with

the equipment you are working on.

WARNING

Electrical repairs must be done by authorized personnel only . Consult your American-Lincoln Authorized Service

Person to do service procedures. Use only genuine American-Lincoln parts.

WARNING

Unexpected movement could cause injury. Always p ark on a level surface, turn key off, and engage p arking brake

before working on the machine.

WARNING

Maintenance and repairs must be done by authorized personnel only . Always empty the hopper and disconnect

the batteries before doing any maintenance. Keep all fasteners tight. Keep adjustments according to the specifi-

cations as shown in the Service Manual for this machine.

WARNING

Always wear eye protection and protective clothing when working near batteries. Do not put tools or other metal

objects across the tops of the batteries. NO SMOKING.

WARNING

The hopper could fall and cause serious injury. Always engage the hopper safety arm before working under the

hopper.

WARNING

Moving the fan and belt may cause injury . Stay clear of moving p art s.

WARNING

Pinch points may cause injury . St ay clear of moving p arts.

WARNING

T o maintain the stability of this machine in normal operation, the overhead guard, or any similar equipment

installed by the manufacturer as original equipment should not be removed. If it becomes necessary to remove

such equipment for repair or maintenance, this equipment must be reinstalled before the machine is placed back

in operation.

WARNING

T o prevent injury or engine damage, do not remove the radiator cap under any conditions while the engine is

running or when it is hot. To prevent burns from steam or scalding hot coolant being expelled from the radiator ,

use extreme care when removing the radiator cap. Wait until the engine has cooled.

AMERICAN-LINCOLN TECHNOLOGY 1 - 27

SMART 2000

Page 29

SERVICE INSTRUCTIONS

SWEEPING SYSTEM SERVICE

Figure 25

MAIN BROOM

T o prevent the broom from “setting” in one direction and to

provide the maximum life of the broom it is recommended

that the broom be turned end over end periodically .

ADJUSTING THE MAIN BROOM HEIGHT

When changing the sweep height adjustment it is

recommended that the knob be adjusted 1 turn at a time.

After adjustment, recheck the sweep pattern to determine if

further adjustment is necessary .

Turn the adjustment knob counterclockwise to IN-

CREASE the sweep pattern width.

Turn the adjustment knob clockwise to DECREASE the

sweep pattern width.

Figure 26

REPLACING THE MAIN BROOM

The Main Broom should be replaced when the bristles become

worn to less than 3". The main broom is held in place by the

right side broom door. This feature provides for easy removal

and installation of the main broom without the need for special

tools or equipment. Follow the instructions below for main broom

removal & replacement.

1. Park sweeper on a smooth level surface, engage park ing

brake, turn key switch to “O”, place the main/side broom

switch in the “SWEEP” position.

2. Open the main broom door.

3. Swing the broom drive idler hub out to clear the main

broom.

4. Remove the broom from the broom compartment.

5. Install the replacement broom. Pay special attention to

the slots on the broom, it may be necessary to rotate the

broom so the tabs on the drive hub align with the slots on

the broom.

6. Swing the idler hub to engage the main broom and close

the access door. Check the door latch for proper engage

ment when closed.

7. Check the Main Broom sweep pattern and adjust as

necessary .

1 - 28 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 30

SIDE BROOMS SERVICE

Figure 27

SERVICE INSTRUCTIONS (Cont.)

SIDE BROOM

The Side Broom sweeping angle is not adjustable however

the height of the side brooms can be adjusted to

compensate for wear as the broom becomes worn from

use. Always check and adjust the sweep p attern after

changing the side broom.

ADJUSTING THE SIDE BROOM HEIGHT

Turn the side broom adjustment knob to change the side

broom sweep height. Recheck for proper sweep pattern

after adjustment.

Turn the adjustment knob counterclockwise to IN-

CREASE the sweep pattern width.

Turn the adjustment knob clockwise to DECREASE the

sweep pattern width.

Figure 28

REPLACING THE SIDE BROOM

Change the side brooms when the bristles become worn to

less than 3 inches length.

1. Park the machine on a smooth level surface, turn key

switch to “O” Position and engage parking brake.

2. Place the side brooms switch in the “UP” position.

3. Remove the lock pin that holds the broom flange to the

motor shaft.

4. Disassemble the flange from the broom by removing the

screws that hold the flange to the broom.

5. Assemble the flange to the replacement broom and

fasten using the hardware removed.

6. Install the replacement broom on the shaft and insert

the lock pin.

AMERICAN-LINCOLN TECHNOLOGY 1 - 29

SMART 2000

Page 31

SERVICE INSTRUCTIONS (Cont.)

HOPPER SERVICE

REF

H34

Figure 29

HOPPER

The hopper houses the debris compartment, the dust control filter and the removable dust baffle. For

maximum performance and service life, keep the hopper clean and inspect the seals and flaps daily . Clean

the hopper prior to parking the sweeper at the end of the day . A clean hopper will make inspecting the flaps

and seals much easier and will prevent premature deterioration of hopper components. Do not leave the hopper

full of debris while in storage or when parked for extended periods of time

Figure 30

CLEANING THE HOPPER

Once the hopper has been emptied the insides of the hopper should be rinsed out with water.

AJDUSTING THE HOPPER SWITCH

With hopper fully closed and seated and bolt loose, rotate the bracket clockwise until the switch clicks.

Retighten bolt. (See Figure 30).

DUST CONTROL FIL TER

The dust control filter should be checked daily for damage and cleaned if necessary . A damaged filter must be

replaced to prevent damage to other dust control system components. Inspect the filter for tears in the filter

media or excessive dirt lodged in the pleats. A tear in the filter media will allow dirt to pass through the filter

and can be easily seen as a dirty patch on the top side on the filter . Cleaning of the filter is necessary when

the filter shaker fails to adequately clean the pleats.

CHECKING THE DUST CONTROL FIL TER

1. Park the machine on a smooth level surface, turn the key switch to the “O” position and engage the

parking brake.

2. Raise the hopper lid for access to the filter compartment.

3. Turn the filter latch, lift the filter frame and remove the filter .

4. Inspect the panel filter for tears and clean or replace if necessary .

5. Reinstall the filter , lower the filter frame and engage the filter latch.

6. Close the hopper cover.

CLEANING THE DUST CONTROL FIL TER

Clean the dust control filter when the shaker fails to adequately clear the filter. The filter can be cleaned with

compressed air not to exceed 100 PSI.

To clean the filter with compressed air, apply the compressed air to the top side of the panel to back flush the

lodged dirt from the filter pleats. Be careful to not damage the filter media while cleaning. The filter can be

cleaned with a solution of soap and water. If this cleaning method is used do not use the filter until it has

completely dried.

1 - 30 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 32

HOPPER SERVICE - Cont.

SERVICE INSTRUCTIONS (Cont.)

Figure 31

REPLACING THE DUST CONTROL FIL TER

Change the filter panel when damage is evident.

1. Park the machine on a smooth level surface, turn the key switch to the “O” position and engage the parking

brake.

2. Open the hopper compartment cover to gain access to the filter compartment.

3. Turn the latch on the hinged frame counterclockwise and lift the frame .

4. Remove the filter panel.

5. Install replacement filter , lower the hinged frame and engage the latch.

6. Lower the filter compartment cover.

DUST FLAPS

The dust flaps are very important to sweeping and dust control and are susceptible to damage and should be

inspected daily and maintained in good condition.

CHECKING THE DUST FLAPS

The dust flaps are used on the wheel well, broom chamber and broom door . Inspect the flaps daily and replace

any flap that shows signs of wear or deterioration. All flap s should be replaced when worn or damaged to the

point that they can no longer perform their normal function. The adjustable flaps have slotted mounting holes to

facilitate adjustment.

ADJUSTING THE DUST FLAPS

Adjust the flaps so there is a 1/8" to 1/16" gap between the floor and the bottom edge of the flaps. The rear

flapadjustment is 1/16" (16 cm.) above the floor .

1. Park the machine on a smooth level surface and engage the parking brake.

2. Loosen the flap retaining screws and adjust the flap to clear the floor and leave a 1/16" to 1/8" gap.

3. Tighten flap retaining screws while holding flap in position.

4. Drive the machine on a smooth surface and recheck the flaps for proper floor clearance.

AMERICAN-LINCOLN TECHNOLOGY 1 - 31

SMART 2000

Page 33

SERVICE INSTRUCTIONS (Cont.)

P ARKING BRAKE SERVICE

C1539/0002

.10

Figure 32

Figure 33

P ARKING BRAKES

The parking brakes are located on the front wheels. They are operated by the brake pedal and the lock lever .

Check the parking brakes daily for proper operation and inspect the brake pads for wear every 100 hours of

operation.

ADJUSTING THE BRAKE PEDAL

Perform this adjustment to ensure proper pedal height and linkage operation. The brakes are properly adjusted

when the brakes hold the sweeper on an 8 degree ramp. The brakes need adjusted if the Pedal travels closer

than 1 inch to the floor of the operator’s compartment when the brakes are fully engaged.

WARNING

The hopper could fall and cause serious injury . Always engage the hopper safety arm before working under the

hopper.

WARNING

Always park on a level surface, chock tires and observe safety procedures when adjusting the brakes.

ADJUSTING THE P ARKING BRAKES

When adjusting the brake clevis, follow these steps.

1. Open cover.

2. Roll out battery on service cart

3. Remove Pin from clevis (U-Joint)

4. Adjust clevis clockwise to tighten brakes for maximum engagement.

5. With parking brake “off” rotate wheel with minimum drag (not completely free)

ADJUSTING THE FOOT THROTTLE SWITCH

With the foward/reverse pedal in the neutral position, the switches can be adjusted to .100” of face on the

forward/reverse pedal.

1 - 32 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 34

GENERAL MACHINE MAINTENANCE

FILLING THE HYDRAULIC RESERVOIR (Figure 29)

1. Access to the hydraulic reservoir is located in the engine

compartment.

2. Open the hydraulic reservoir breather filter cap.

3. Remove any debris that is in the breather filter cap

screen.

4. Fill the reservoir until the fluid is at the “FULL” line

on the hydraulic fluid sight gauge. The sight gauge

is located on the center side of the hydraulic res

ervoir.

5. Close the hydraulic reservoir breather filter cap.

6. Close the engine compartment cover .

Figure 34

CLEANING THE HYDRAULIC SYSTEM

1. Put a drop cloth on the floor.

2. Drive the machine onto the drop cloth.

3. Set the parking brake.

4. Open the engine covers.

5. Put a container under the reservoir drain to catch the reservoir fluid. Pivot the reservoir out.

6. Remove the drain plug. The reservoir fluid will drain. Do not use the drained fluid to refill the

hydraulic reservoir. Dispose of the used fluid.

7. Flush the interior of the hydraulic reservoir with clean fluid.

8. Put the reservoir plug, removed in step six, back in the hydraulic tank drain and tighten it. A pipe

thread sealer is required on the plug.

9. Open the breather filter cap.

10. Fill the reservoir with new SAE 30W non detergent automotive transmission fluid. The capacity of the tank is

4.7 gal (17.79 liters). Fill to the “FULL” line on the hydraulic fluid sight gauge.

1 1. Close the breather filter cap. Rotate the reservoir into the engine compartment.

12. Replace the engine covers.

REPLACING THE RETURN FIL TER ELEMENT

1. Replace the return filter element after 250 hours of

machine run time.

2. Unscrew the fasteners from the filter assembly

cover and retain.

3. Remove the cover and the compression spring

and retain.

4. Discard the old filter element.

5. Position the new filter element inside the filter body .

6. Put the compression spring in position. Wipe the

cover magnet free of any metal filings or debris.

7. Place O-ring (moisten with clean hydraulic fluid)

and cover into position.

8. Reattach fasteners to the filter cover .

9. Clean any hydraulic reservoir fluid spills. The fluid

Figure 35

can damage painted surfaces of the machine.

AMERICAN-LINCOLN TECHNOLOGY 1 - 33

SMART 2000

Page 35

GENERAL MACHINE MAINTENANCE (Cont.)

REF ROD END

REF FRAME-

BRUSH DRIVE

Figure 36

REPLACING THE SCRUB BRUSH

1. Raise the scrub brush deck by pressing the “Scrub Brush” switch on the instrument panel.

2. Press the brush latches in to release the scrub brush.

3. Remove the old scrub brush.

4. Snap the new brush into place.

Figure 37

3.5"

ADJUSTING THE SCRUB DECK (See Figure 37)

Adjust the center of the rod end to 3.5” from the frame.

COVERS AND LATCHES

The covers have been designed to allow access, either by hinge or removal, to all areas of the machine. No

maintenance is required.

SOLUTION LOW WARNING LIGHT

The solution low warning light will illuminate when the solution tank is low. This part of the level control system

requires no maintenance. If the system fails to operate, consult the Electrical Troubleshooting Guide.

RECOVERY HIGH W ARNING LIGHT

The recovery high warning will illuminate approximately 5 minutes before loss of vacuum to the recovery tank.

This part of the level control system requires no maintenance, except for daily cleaning of the tank level switch.

If the system fails to operate, consult the Electrical Troubleshooting Guide.

SOLUTION CONTROL (Non-Recycling or Standard)

The solution control knob controls the amount of solution applied to the scrubbing brushes.

The solution control should shut off completely with the knob in the “off” position. If complete shut off does not

occur, the control valve should be adjusted.

SOLUTION CONTROL (Recycling or ESP System)

In the recycling mode, the solution control lever is also used to activate the detergent pump. If the detergent

pump fails to operate (engine running) when the solution control lever is moved into the low to high range, first

check the circuit by manually activating the switch. If the detergent pump does not operate at this time, a

further electrical or mechanical check is required (see Electrical Troubleshooting Guide or Detergent Pump

Troubleshooting).

1 - 34 AMERICAN-LINCOLN TECHNOLOGY

SMART 2000

Page 36

GENERAL MACHINE MAINTENANCE (Cont.)

RECYCLING PUMP ESP SYSTEM

The recycling pump is located under the seat. The pump is electric and except for daily cleaning of the pump

intake screens, it requires no regular maintenance.

RECYCLING PUMP STORAGE

Always drain pump for extended storage, especially when freezing temperatures may be encountered.

REAR SQUEEGEE

The squeegee will require service when the inner edges of the blades become round with wear, imp airing the

wiping action or water pickup. T o service the rear squeegee use the following step s:

1. Loosen the four aluminum knobs

2. Remove the squeegee tool and turn upside down to service the blades or caster wheels. The

squeegee blades are designed to flip over and use another unworn edge.

ADJUSTING THE REAR SQUEEGEE LIFT

1. Loosen nut (2-00-00641).

2. Turn screw (2-00-00087) either counterclockwise (to raise)

or clockwise (to lower) to adjust the position of the

squeegee lift. (The gap between the frame and the

squeegee lift should be .75”).

NOTE

Raising squeegee lift too far will cause the squeegee lift to hit the

EF SCREW

2-00-00087)

REF NUT

(2-00-00641)

C1980

frame and may cause damage.

Figure 38

To service the blades

1. Loosen the clamp bolts which clamp items 8 & 9 together .

2. Loosen far enough to slip the end clamp brackets off the squeegee tool. This will allow flipping the blades or

installing new blades.

3. Install blades so that the outer blade is 3/16” longer than the inner blades. This is achieved by assembling

the top edge of the blade against the squeegee tool weldment.

4. Reinstall the squeegee clamp band and tighten the clamp bolt.

SQUEEGEE CASTER WHEELS

There are 2 grease fittings on each caster wheel. The casters

should be greased each time the blades are serviced.

ADJUSTING CASTERS

Lower the squeegee on a flat surface, making sure the rear

squeegee blade is perpendicular to the surface. Adjust the

caster 3/16” above the flat surface. Lock the jam nuts.

Figure 39

AMERICAN-LINCOLN TECHNOLOGY 1 - 35

SMART 2000

Page 37

GENERAL MACHINE MAINTENANCE (Cont.)

Figure 40

EMPTYING THE RECOVERY T ANK (Figure 36)

Simply lower the drain hose, telescope out to a drain and let the recovery tank drain. The farther you telescope

the hose the faster the water will drain.

When finished draining recovery tank loosen both knobs on the recovery clean out door . The door will pivot on