SCRUBTEC R 571SCRUBTEC R 571

SCRUBTEC R 571

SCRUBTEC R 571SCRUBTEC R 571

Operator's

Manual

U.S. Patent No. 6,105,192; No. 6,493,896; No. 6,557,207

READ THIS BOOK

CAUTION: Read the Operator's Manual before using the appliance.

This book has important information for the use and safe operation of this machine. Failure to read this

book prior to operating or attempting any service or maintenance procedure to your ALTO machine could

result in injury to you or to other personnel; damage to the machine or to other property could occur as

well. You must have training in the operation of this machine before using it. If operator(s) cannot read

this manual, have it explained fully before attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

For new books write to: ALTO, 2100 Highway 265, Springdale, Arkansas 72764.

Form No. 70879E 9/05 CLARKE TECHNOLOGY Printed in the U.S.A.

SCRUBTEC R 571 CSCRUBTEC R 571 C

SCRUBTEC R 571 C

SCRUBTEC R 571 CSCRUBTEC R 571 C

SCRUBTEC R 586SCRUBTEC R 586

SCRUBTEC R 586

SCRUBTEC R 586SCRUBTEC R 586

Table of Contents

Operator Safety Instructions .................................................................................................................................................. 3

Introduction & Machine Specifications.................................................................................................................................... 5

Symbols Used on Scrubtec .................................................................................................................................................... 6

Display Screens for Scrubtec ................................................................................................................................................ 7

Machine Control Panel ............................................................................................................................................................. 8

I-Drive Controls ........................................................................................................................................................................ 9

Machine Controls and Features .............................................................................................................................................. 9

How to Prepare the Machine for Operation ........................................................................................................................... 10

How to Operate the Machine .................................................................................................................................................. 15

Maintenance ............................................................................................................................................................................ 25

How to Correct Problems in the Machine ............................................................................................................................... 29

Common Error Codes .............................................................................................................................................................. 30

Accesories and Options ......................................................................................................................................................... 31

SECTION II Parts and Service Manual

Final Assembly Drawing ......................................................................................................................................................... 34

Main Frame Assembly Drawing .............................................................................................................................................. 36

Optional Side Squeegee Lift (571 and 586 Rotary Models) ................................................................................................... 38

Front Wheel Assembly Drawing and Parts List ..................................................................................................................... 40

Squeegee Lift Assembly Drawing and Parts List .................................................................................................................. 41

Recovery Tank Assembly Drawing........................................................................................................................................ 42

Solution Tank Assembly Drawing (View 1) ........................................................................................................................... 44

Solution Tank Assembly Drawing (View 2) ........................................................................................................................... 46

571 Rotary Brush Head Assembly Drawing and Parts List................................................................................................... 48

586 Rotary Brush Head Assembly Drawing and Parts List................................................................................................... 49

571 C Cylindrical Head Assembly Drawing ............................................................................................................................ 50

Squeegee Assembly Drawing ................................................................................................................................................ 52

Front Squeegee Assembly Drawing and Parts List ............................................................................................................... 54

Front Squeegee Arm Assembly Drawing and Parts List ....................................................................................................... 55

Right Arm Control Assembly Drawing and Parts List ............................................................................................................ 56

Left Arm Control Assembly Drawing and Parts List .............................................................................................................. 57

Electrical Panel Assembly Drawing ........................................................................................................................................ 58

Vac Motor Assembly ............................................................................................................................................................... 60

Electrical Connection Diagram................................................................................................................................................. 61

Electrical Schematic ................................................................................................................................................................ 65

How to Handle the Packed Machine....................................................................................................................... 10

How to Unpack the Machine................................................................................................................................... 10

How to Install the Batteries..................................................................................................................................... 10

Battery Maintenance ............................................................................................................................................... 11

How to Charge the Batteries .................................................................................................................................. 12

Recharging the Batteries ........................................................................................................................................ 12

Level Indicators for the Charge on the Batteries ................................................................................................... 12

How to Install the Squeegee................................................................................................................................... 13

How to Adjust the Squeegee ................................................................................................................................. 13

How to Change or Rotate Brushes on Cylindrical Brush Head............................................................................. 14

How to Operate the i-Drive Controls ...................................................................................................................... 15

Horn Operation........................................................................................................................................................ 15

One Touch Operation.............................................................................................................................................. 15

Reprogramming One Touch.................................................................................................................................... 15

How to Return One Touch to Factory Default Settings ......................................................................................... 16

Directional Control ................................................................................................................................................... 16

How to Move Machine ............................................................................................................................................ 16

Seat Adjustment...................................................................................................................................................... 17

How to Read the Battery Meter .............................................................................................................................. 18

How to Change Display Screens on the LCD Module ........................................................................................... 18

How to Operate the Squeegee and the Vacuum Motor ........................................................................................ 19

How to Operate the Solution Flow ......................................................................................................................... 19

How to Operate Brush Pressure ........................................................................................................................... 19

How to Fill the Solution Tank................................................................................................................................... 20

Operating the Machine ............................................................................................................................................ 20

Do These Procedures When You Begin Your Work Period .................................................................................. 21

How to Clean a Floor .............................................................................................................................................. 22

How to Clean a Very Dirty Floor............................................................................................................................. 23

Do These Procedures When You End Your Work Period ..................................................................................... 23

Maintenance to Be Done Every Week .................................................................................................................... 25

Battery Inspection and Cleaning ............................................................................................................................. 25

Cleaning the Recovery Tank and Filter................................................................................................................... 25

Cleaning the Solution Tank and Filter...................................................................................................................... 26

Manually Draining the Solution Tank ....................................................................................................................... 26

Vac Assisted Solution Tank Draining ..................................................................................................................... 26

Squeegee Maintenance .......................................................................................................................................... 26

Front Squeegee Blade Replacement ...................................................................................................................... 26

Rear Squeegee Blade Replacement....................................................................................................................... 27

Parts List ................................................................................................................................................................. 35

Parts List ................................................................................................................................................................. 37

Parts List ................................................................................................................................................................. 39

Parts List ................................................................................................................................................................. 43

Parts List (View 1).................................................................................................................................................. 45

Parts List (View 2).................................................................................................................................................. 47

Parts List ................................................................................................................................................................. 51

Parts List ................................................................................................................................................................. 53

Parts List ................................................................................................................................................................. 59

Page -2- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

OPERATOR SAFETY INSTRUCTIONS

DANGER: Failure to read and observe all DANGER statements could result in severe

bodily injury or death. Read and observe all DANGER statements found in

your Owner's Manual and on your machine.

WARNING: Failure to read and observe all WARNING statements could result in injury

to you or to other personnel; property damage could occur as well. Read

and observe all WARNING statements found in your Owner's Manual and

on your machine.

CAUTION: Failure to read and observe all CAUTION statements could result in

damage to the machine or to other property. Read and observe all

CAUTION statements found in our Owner's Manual and on your machine.

DANGER: Failure to read the Operator’s Manual prior to operating or attempting any service or

DANGER: Operating a machine that is not completely or fully assembled could result in injury or

DANGER: Machines can cause an explosion when operated near flammable materials and

DANGER: Lead acid batteries generate gases which can cause an explosion. Keep sparks and

DANGER: Working with batteries can be dangerous! Always wear eye protection and protective

DANGER: Using the charger with a damaged power cord could result in an electrocution. Do not

maintenance procedure to your ALTO machine could result in injury to you or to other

personnel; damage to the machine or to other property could occur as well. You must

have training in the operation of this machine before using it. If your operator(s) cannot

read English, have this manual explained fully before attempting to operate this

machine.

property damage. Do not operate this machine unless it is completely assembled.

Inspect the machine carefully before operation. Operate only when lids, doors and

access panels are securely closed.

vapors. Do not use this machine with or near fuels, grain dust, solvents, thinners, or

other flammable materials. This machine is not suitable for picking up hazardous dust

or flammable materials. Use only commercially available floor cleaning waxes intended

for machine operation. DO NOT put gasoline, combustible or flammable materials in

the solution or recovery tank.

flames away from batteries. Do not smoke around the machine. Charge the batteries

only in an area with good ventilation.

clothing when working near batteries. Remove all jewelry. Do not put tools or other

metal objects across the battery terminals, or the tops of the batteries.

use the charger if the power cord is damaged.

WARNING: Do not turn the machine on a ramp. Do not use on surfaces having a gradient exceeding that

marked on the appliance.

WARNING: Machines can topple over and cause injury or damage if guided over the edges of stairs or

loading docks. Stop and leave this machine only on a level surface. When you stop the

machine, put all switches into their "OFF" position. Turn the key switch "OFF" and remove the

key.

WARNING: Skidding may occur when traveling at high speeds and attempting sharp turns, especially on

wet surfaces.

WARNING: Do not move machine with forklift. Damage could occur to machine.

WARNING: Maintenance and repairs performed by unauthorized personnel could result in damage or

injury. Maintenance and repairs must be performed by authorized ALTO personnel only.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -3-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

WARNING: Any alterations or modifications of this machine could result in damage to the machine or

injury to the operator or other bystanders. Alterations or modifications not authorized by the

manufacturer voids any and all warranties and liabilities.

WARNING: Electrical components of this machine can "short-out" if exposed to water or moisture. Keep

the electrical components of the machine dry. Wipe the machine down after each use. This

appliance is for dry use only and is not to be used or stored outdoors in wet conditions. For

storage, keep the machine in a building.

WARNING: Operating a machine without observing all labels and instructional information could result in

injury or damage. Read all machine labels before attempting to operate. Make sure all of the

labels and instructional information are attached or fastened to the machine. Do not cover

them for any reason. If labels or decals are missing or become damaged, get replacement

labels and decals from your ALTO distributor immediately.

WARNING: Wet floor surfaces can be slippery. Water solutions or cleaning materials used with this type of

machine can leave wet areas on the floor surface. These areas can cause a dangerous

condition for the operator or other persons. Always put "Caution" signs around/near the area

you are cleaning.

WARNING: Improper discharge of waste water may damage the environment and be illegal.

The United States Environmental Protection Agency has established certain regulations

regarding discharge of waste water. City, state and national regulations regarding this

discharge may also be in effect in your area. Understand and follow the regulations in your

area. Be aware of the environment hazards of chemicals that you dispose.

WARNING: Only use the brushes provided with the appliance or those specified in the Operator's Manual.

The use of other brushes may impair safety.

CAUTION: Use of this machine to move other objects or to climb on could result in injury or damage. Do

not use this machine as a step or furniture.

CAUTION: Your machine warranty will be voided if anything other than genuine ALTO parts are used on

your machine. Always use ALTO parts for replacement.

CAUTION: This machine contains lead acid batteries. The batteries must be disposed of in an environ-

mentally acceptable manner.

WARNING: GENERAL SAFETY RULES

The rules below have to be followed carefully in order to avoid injury to the operator and damage to the

machine:

• During the operation of this machine, pay attention to other people around you, especially children.

• Use care when reversing machine in confined areas.

• Do not mix different kinds of detergents. Avoid harmful odors.

• Do not place any liquid containers on to the machine.

• The recommended operating temperature should be between 32° F and 104° F.

• The humidity for operating this machine should be between 30 and 95%.

• Do not use acid solutions that could damage the machine.

• In order to prevent floor damage, do not leave brushes running when machine is standing still.

• In case of fire, use a powder extinguisher. Do not use water.

• Do not strike shelving or scaffoldings, where there is danger of falling objects.

• Adapt the utilization speed to the adhesion conditions.

• Do not exceed the declared hill climbing capacity, otherwise the machine could become unstable.

• For any maintenance operation take off the power supply from the machine.

• Do not disassemble any parts which require the use of a tool to be removed.

• Do not wash the machine with direct water jets or with high water pressure nor with corrosive material.

• After every 200 working hours have machine checked by an authorized service person.

Page -4- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

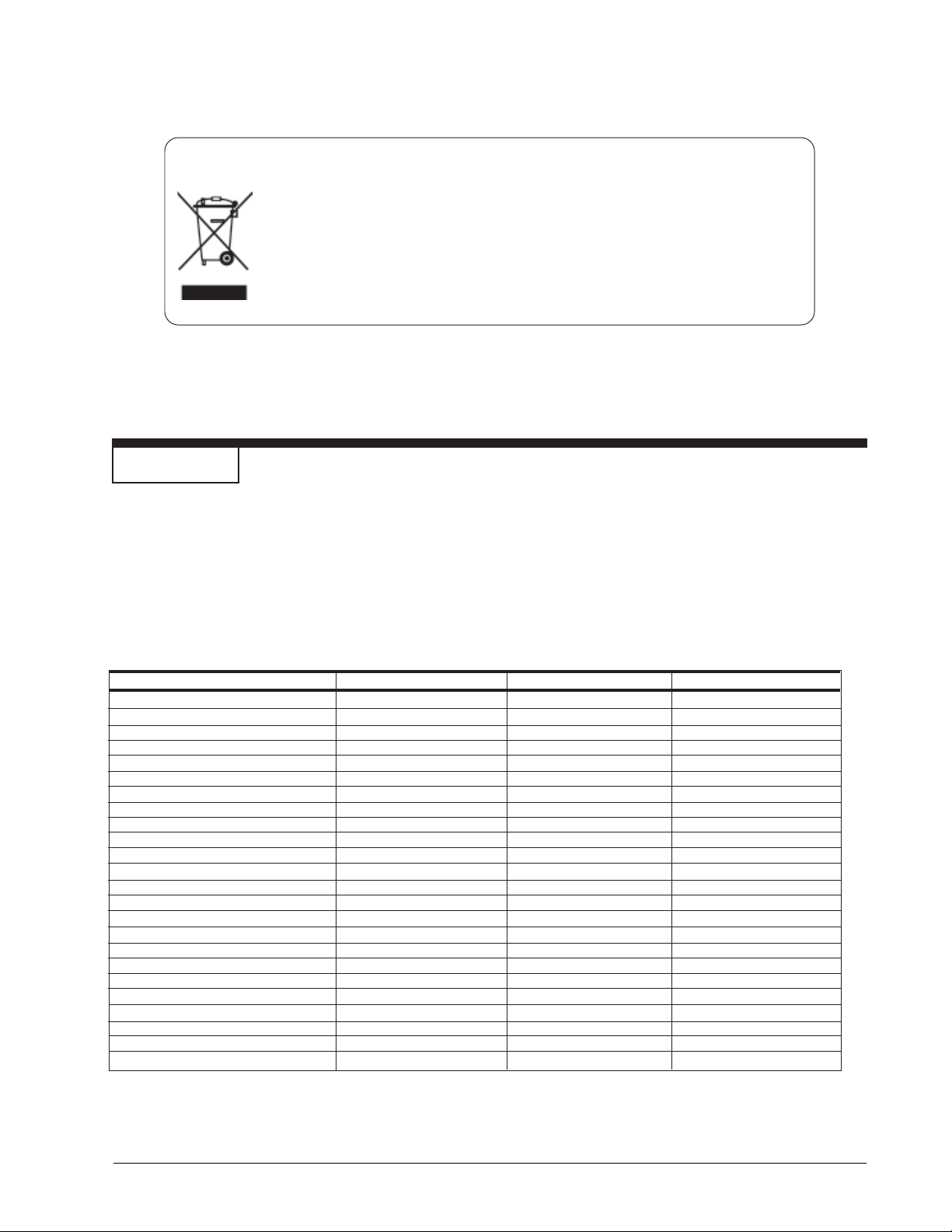

English

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

(Applicable in the European Union and other European countries with separate

collection systems)

This marking shown on the product or its literature, indicates that it should not be disposed with

other household wastes at the end of its working life. To prevent possible harm to the

environment or human health from uncontrolled waste disposal, please separate this from other

types of wastes and recycle it responsibly to promote the sustainable reuse of material resources.

Household users should contact either the retailer where they purchased this product, or their

local government office, for details of where and how they can take this item for environmentally

safe recycling.

Business users should contact their supplier and check the terms and conditions of the purchase

contract. This product should not be mixed with other commercial wastes for disposal.

Introduction

Introduction & Machine Specifications

This is a floor cleaning machine which, using the mechanic abrasive action of two rotary brushes or two cylindrical brushes and the chemical action of a water-detergent solution, is able to clean any type of floor. During its

forward movement, it picks up the removed dirt and the detergent solution which has not been absorbed by the

floor.

SPECIFICATIONS:

Model SCRUBTEC R 571 SCRUBTEC R 586 SCRUBTEC R 571 C

Cleaning Width 28 inch (71 cm) 34 inch (86 cm) 28 inch (71 cm)

Brush Deck Side Movement 2 inch (5 cm) * 2 inch (5 cm) * -------Squeegee Width 33 inch (83.8 cm) 40 inch (101.6 cm) 40 inch (101.6 cm)

Working Capacity 32,000 sq ft/hr

Brushes (2) 14 inch (33 cm) 17 inch (38 cm) 6 inch diameter Cylindrical

Brush Speed 300 rpm 300 rpm 750 rpm

Brush Pressure 0 - 225 lbs. (77 kg)** 0 - 225 lbs. (86 kg)** 90-130 lbs.

Brush Motor 2.0 hp (900 W) 2.5 hp (900 W) .75 hp (2 required)

Traverse Motor 1.5 hp (450 W) 1.5 hp (450 W) 1.5 hp (450 W)

Wheel Diameter 10 inch (24.8 cm) 10 inch (24.8 cm) 10 inch (24.8 cm)

Traverse Speed (Max) 350 ft/min (76 m/min) 350 ft/min (76 m/min) 350 ft/min (76 m/min)

Maximum Cleaning Grade 10% (6 degree) 10% (6 degree) 10% (6 degree)

Vacuum Motor 1 hp (670 W) 1 hp (670 W) 1 hp (670 W)

Solution Tank 30 gallon (110 liter) 30 gallon (110 liter) 30 gallon (110 liter)

Recovery Tank 30 gallon (110 liter) 30 gallon (110 liter) 30 gallon (110 liter)

Base Machine Length 65.5 inch (166.4 cm) 65.5 inch (166.4 cm) 65.5 inch (166.4 cm)

Base Machine Height 49.6 inch (126 cm) 49.6 inch (126 cm) 49.6 inch (126 cm)

Base Machine Width 30.0 inch ( 64.8 cm) 30.0 inch (64.8 cm) 30.0 inch (64.8 cm)

Brush Deck Width 28 inch (74.9 cm) 34 inch (81.3 cm) 28 inch (74.9 cm)

Batteries**** 36 volt 36 volt 36 volt

Machine Weight w/Batteries *** 1425 lbs. (532 kg) 1445 lbs. (540 kg) 1445 lbs. (540 kg)

Shipping Weight w/Batteries 1590 lbs. (594 kg) 1610 lbs. (600 kg) 1610 lbs. (600 kg)

Noise (EN ISO 3744:1995) < 70 dBA < 70 dBA < 70 dBA

Vibration (EN ISO 2631-1:1997 (E) ) < 2.5 m/s

* Movement to left only from R.H. side of machine. ** 125 lbs. to 225 lbs. in 5 - 25 lb. increments.

***330AH ****330, 370

(2970 sq m/hr)

2

36,000 sq ft/hr

< 2.5 m/s

2

(3344 sq m/hr)

32,000 sq ft/hr

< 2.5 m/s

2

(2970 sq m/hr)

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -5-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

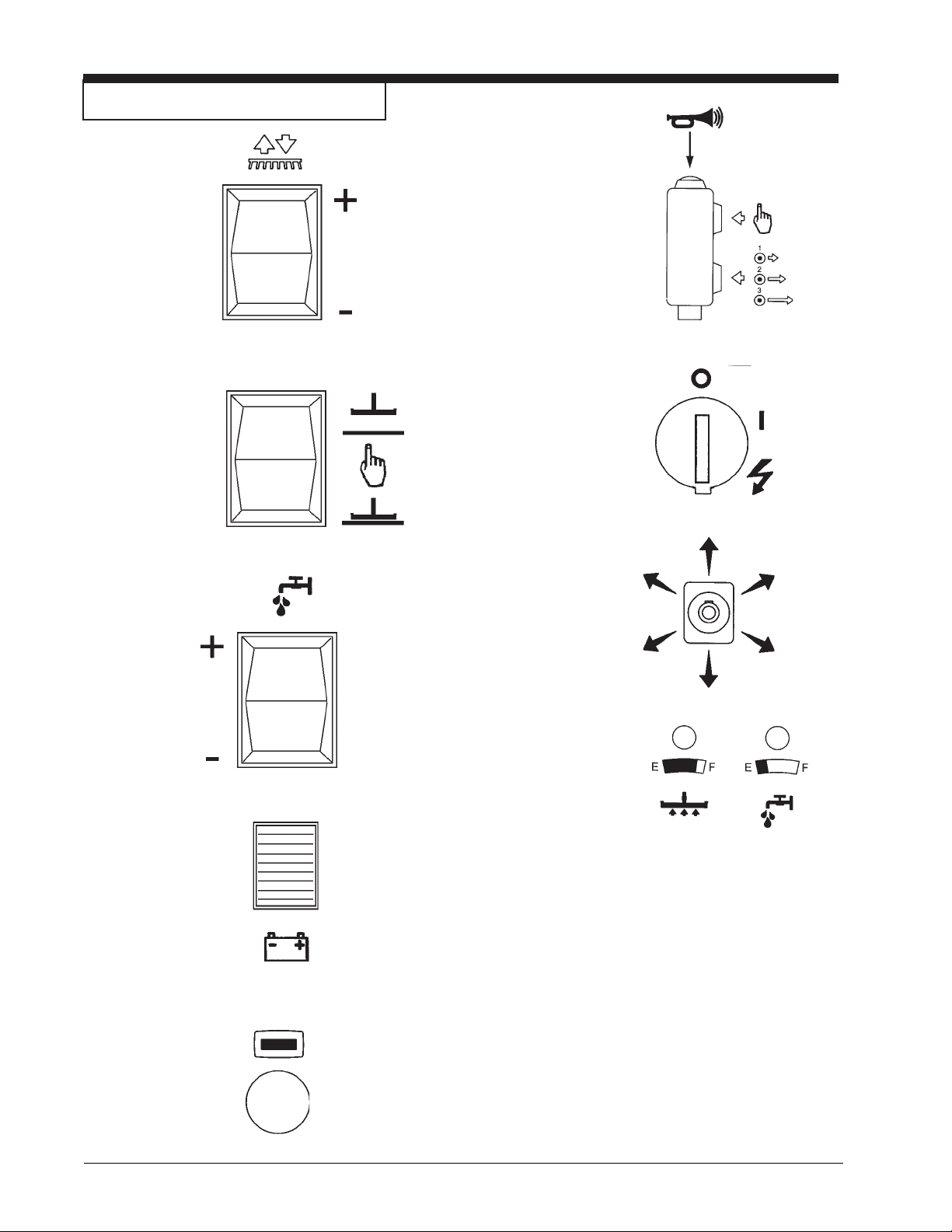

Symbols Used On Scrubtec R

Brush Up/Down

Squeegee

Up/Down

Horn Button

One Touch

Traverse Speed

On/Off Switch

Solution Flow

Switch

Battery Meter

i-Drive

Directional

Guide

Recovery /

Solution LED

LCD Display

Button

Page -6- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

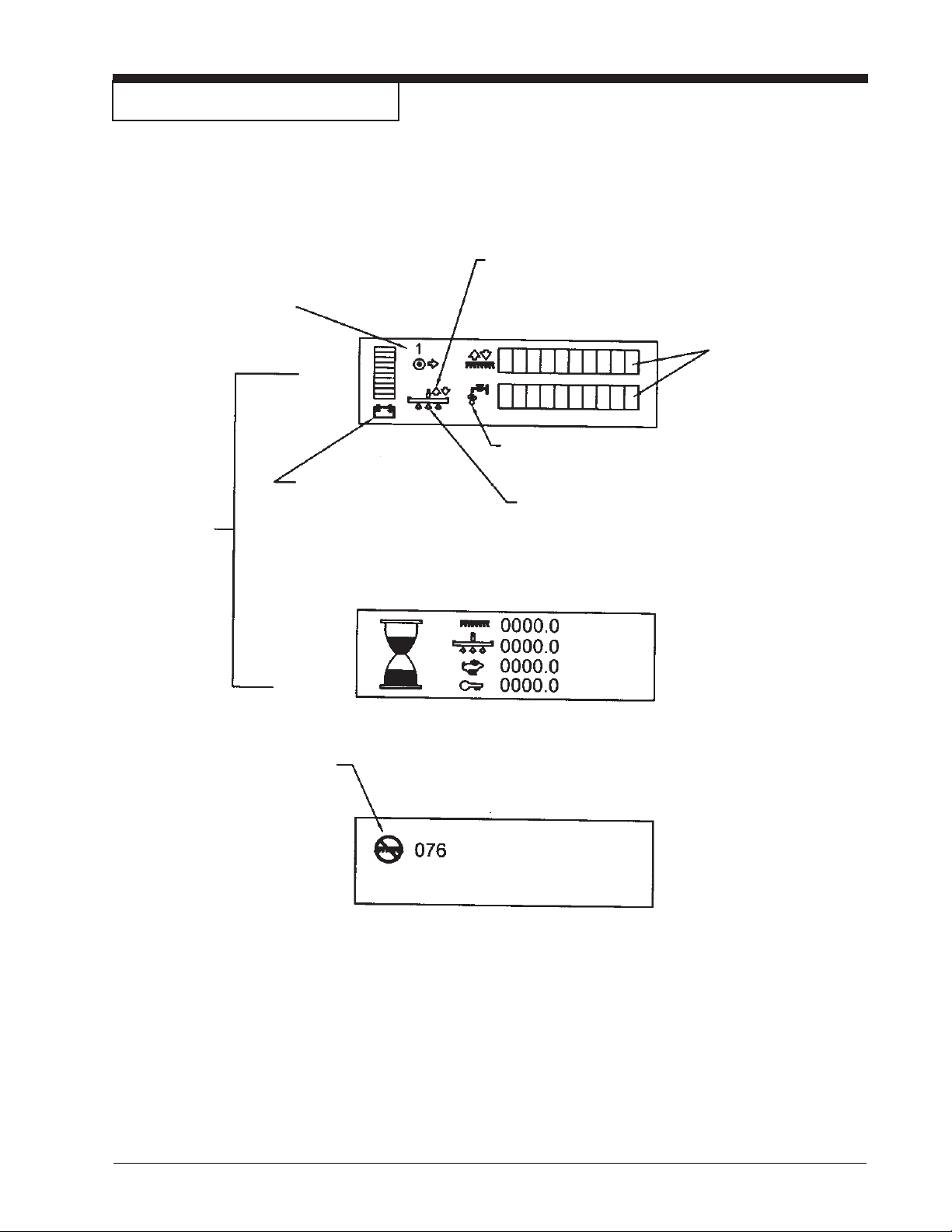

Display Screens For Scrubtec R

Traverse speed indicator

1 = low 0-3 KPH

2 = med 0-5 KPH

3 = high 0-6.4 KPH

SCREEN 1

Screens

Available

to Operator

SCREEN 2

“Battery” blinks when

low voltage occurs.

Position arrow indicating current position

of squeegee (up or down)

Indicators are on,

showing current

settings.

Water “droplets” off when solution is off and

they are flashing when solution is on.

Arrows indicating vacuum status.

They are flashing when vac is on

and off when vac is off.

Example

The Diagnostic only. It will not show unless a fault with

the machine occurs. When the fault happens the icon

and error code will be displayed.

CLARKE TECHNOLOGY Operator's Manual -

SCREEN 3 (Diagnostic)

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -7-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

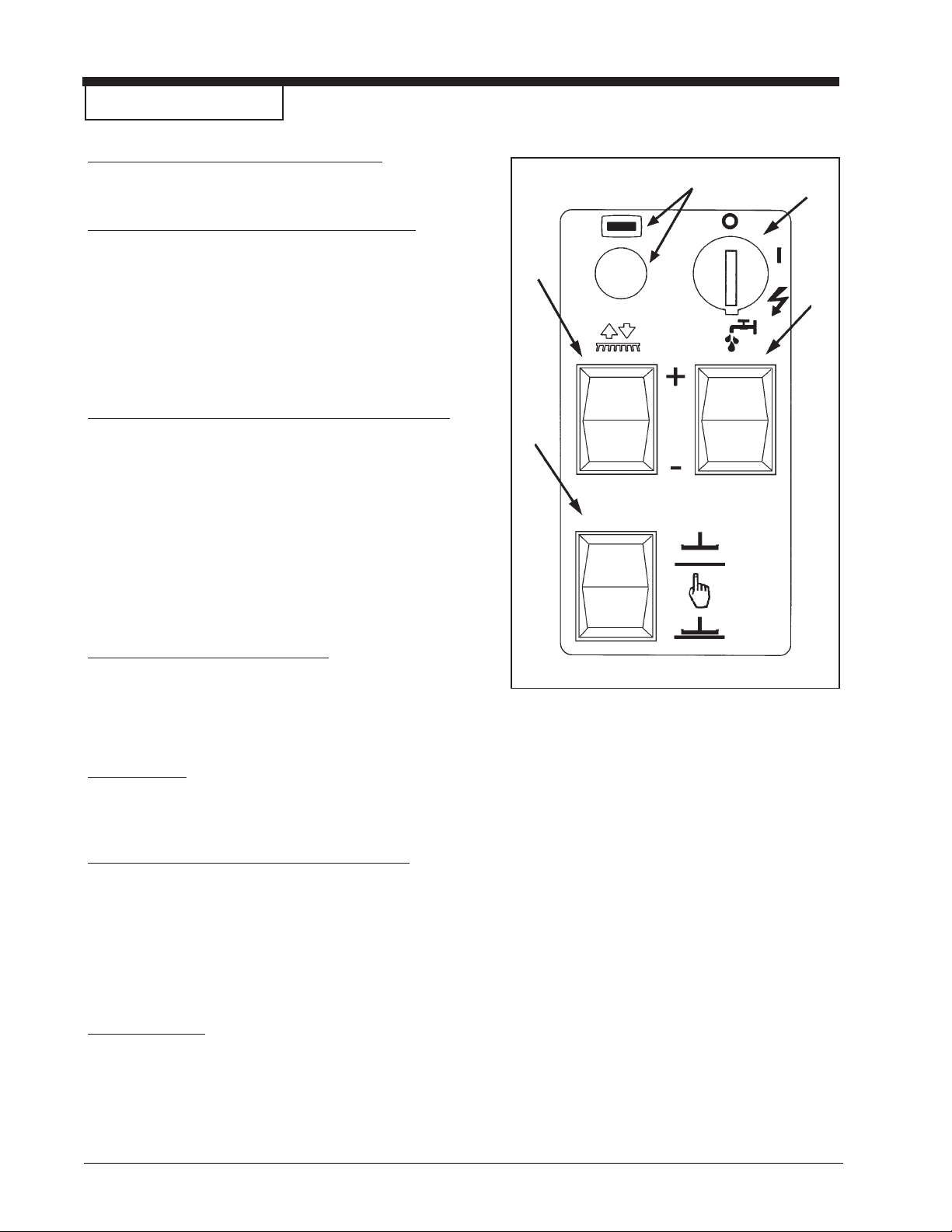

Machine Control Panel

On/Off Key Switch (See figure 1, Item D)

The key switch turns “ON” the power to the control

panel. “O” is the “OFF” and “I” is the “ON”.

Brush Up/Down Switch (See figure 1, Item A)

To lower brush head, push the brush switch in the

down (+) position. To lower the brush head to maximum brush pressure, continue to hold the switch in

the down (+) position until the travel stops. The brush

motors will start and solution will flow (provided the

solution is turned “ON”) when the machine begins to

traverse. To raise the brush head, push the brush

switch in the up (-) position until the brush head travel

stops or desired position is reached.

Squeegee Up/Down Switch (See figure 1, Item B)

The squeegee switch is used to raise and lower the

squeegee and to turn on and off the vacuum motor.

The vacuum motor is turned on when the switch is

placed in the middle or lower position. NOTE: When

the squeegee switch is placed in the lower

position, the vacuum motor will turn on.

To raise the squeegee, place the switch in either the

middle or up position. The middle position is used for

one touch control. The vacuum motor will stop, after a

short delay, when the switch is placed in the up

position.

E

D

A

C

B

Hour Meter (See figure 1, Item E)

The hour meter is located on the front display. You

must toggle screens using LCD display button. The

hour meter indicates the number of hours the machine

has operated. It displays brush motor, vacuum motor,

traverse motor and total key on times.

Battery Meter

The battery meter indicates the relative charge on the

battery pack. The battery meter is located on screen

1 on the front display. See page 7.

Solution Flow Control (See figure 1, Item C)

The solution flow switch regulates the flow of chemical

solution to the floor. To increase the flow, toggle (+).

To decrease the flow, toggle (-). To shut off the

solution, toggle - until no indicators are visible on

display (see figure 2). NOTE: DO NOT run dry!

NOTE: No solution will flow when the machine

does not traverse.

Circuit Breakers

The circuit breaker reset buttons are located on the

back side of the front cover below front display. The

breakers are as follows:

Item A - Main (5 amp)

Item B - Key Switch (5 amp)

Figure 1

Page -8- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

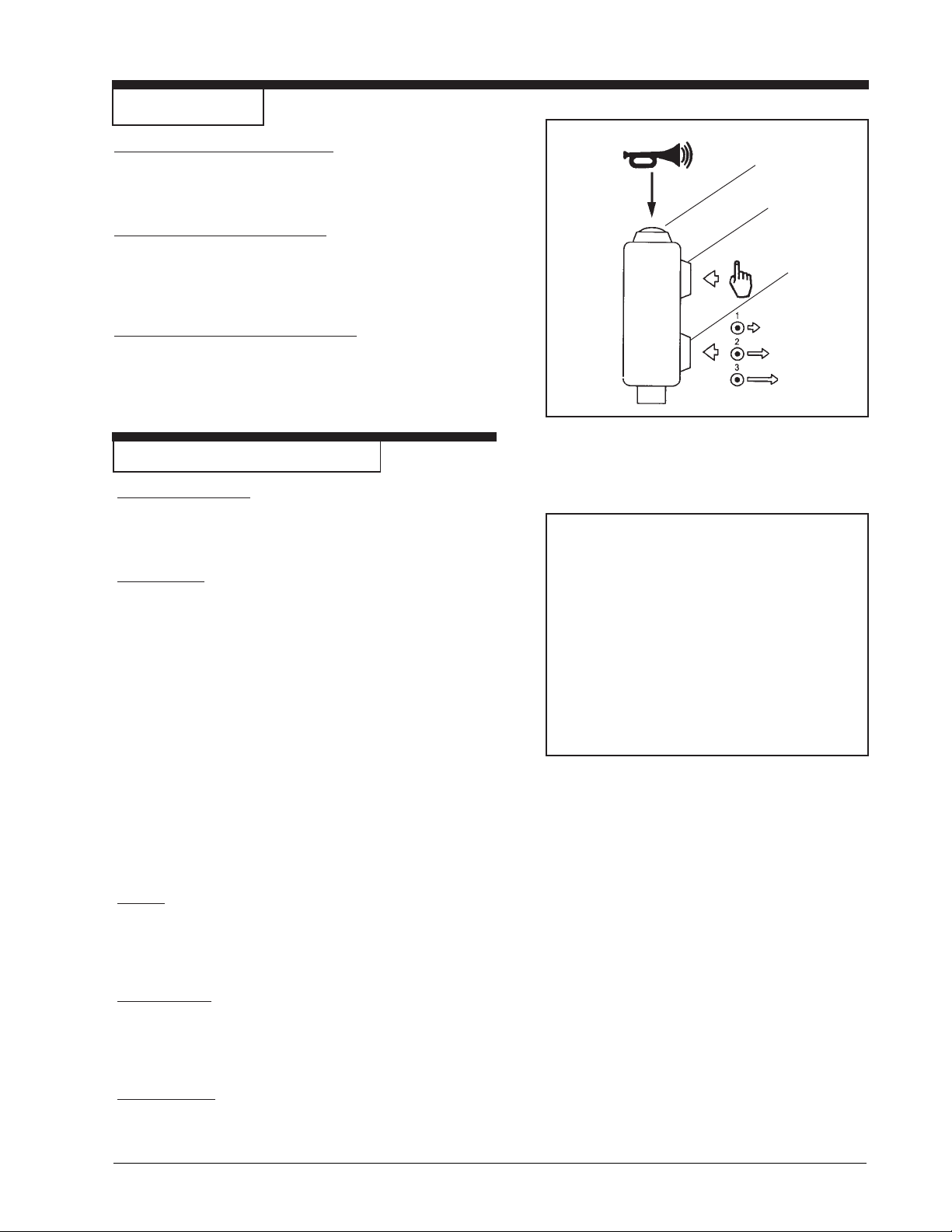

i-Drive Controls

Horn Button (See figure 2, Item A)

The machine is equipped with a horn and is activated by the

red button located on the top of the joystick. The horn will

sound continuously when pressed.

One Touch (See figure 2, Item B)

The one touch button is a green button located on the upper

front of the joystick. NOTE: For more information about the

one touch feature see the section titled “How to Operate the

Machine”.

Speed Selector (See figure 2, Item C)

The speed selector is a black button located on the lower

front of the joystick. Pressing will advance speed range in

the following manner: 1, 2, 3, 2, 1. You may change speeds

while traversing the machine.

Machine Controls and Features

Recovery Tank Float

The Scrubtec R is equipped with a float that shuts the vacuum

off when the recovery tank is full. The squeegee will no longer

pick up water. If this should happen, raise the squeegee and

empty the recovery tank.

A

B

C

Figure 2

The Traverse

The Scrubtec R is equipped with an electronically controlled

traverse system with variable speeds in forward and reverse.

1. To traverse the machine, the power to the machine must

be turned on with the key switch and the operator must

be properly seated. The joystick must be positioned in

either the forward or reverse direction.

2. The traverse speed and direction can be adjusted by

varying the pressure and direction of the joystick.

3. The joystick is very responsive. Simply point it in the

direction you wish to go. NOTE: For initial training, keep

speed setting in 1 and train in an open area.

NOTE: During reverse motion, the squeegee raises and the

solution flow stops automatically. Reverse also reduces

maximum traverse speed.

4. The front wheel always returns to center when you

remove your hand from the joystick.

Brakes

The machine is equipped with an electronic braking system.

The electronic braking is activated automatically when the

operator’s hand is removed from the joystick. NOTE: During

training, you should allow machine to come to a full stop until

you become familiar with stopping distances required.

Parking Brake

The parking brake is activated automatically when the

machine comes to a stop. It disengages automatically when

you begin to traverse. The transaxle is equipped with a

manual brake release. NOTE: Machine will not function when

manual brake release is engaged. See figure 3.

Figure 3

Reverse Alarm

The reverse alarm will sound intermittently and automatically

when the machine is in reverse.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -9-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Prepare the Machine For Operation

How To Handle the Packed Machine

The machine is packed in a specific package provided on

a pallet so that it can be moved with a forklift.

WARNING: The packages cannot be placed on

top of each other.

How to Unpack the Machine

1. Remove the outer package.

2. The machine is fixed on the pallet with banding

straps and wooden blocks to prevent movement

during shipment. Remove the bands and blocks.

3. The machine is shipped with the batteries already

installed. The machine can be driven off of the

pallet if the operator is thoroughly familiar with its

operation.

4. Remove tie down brackets.

5. Lower the ramp. Release the parking brake and

remove the machine. Avoid violent blows to the

base unit.

6. Keep the pallet for future transport necessities.

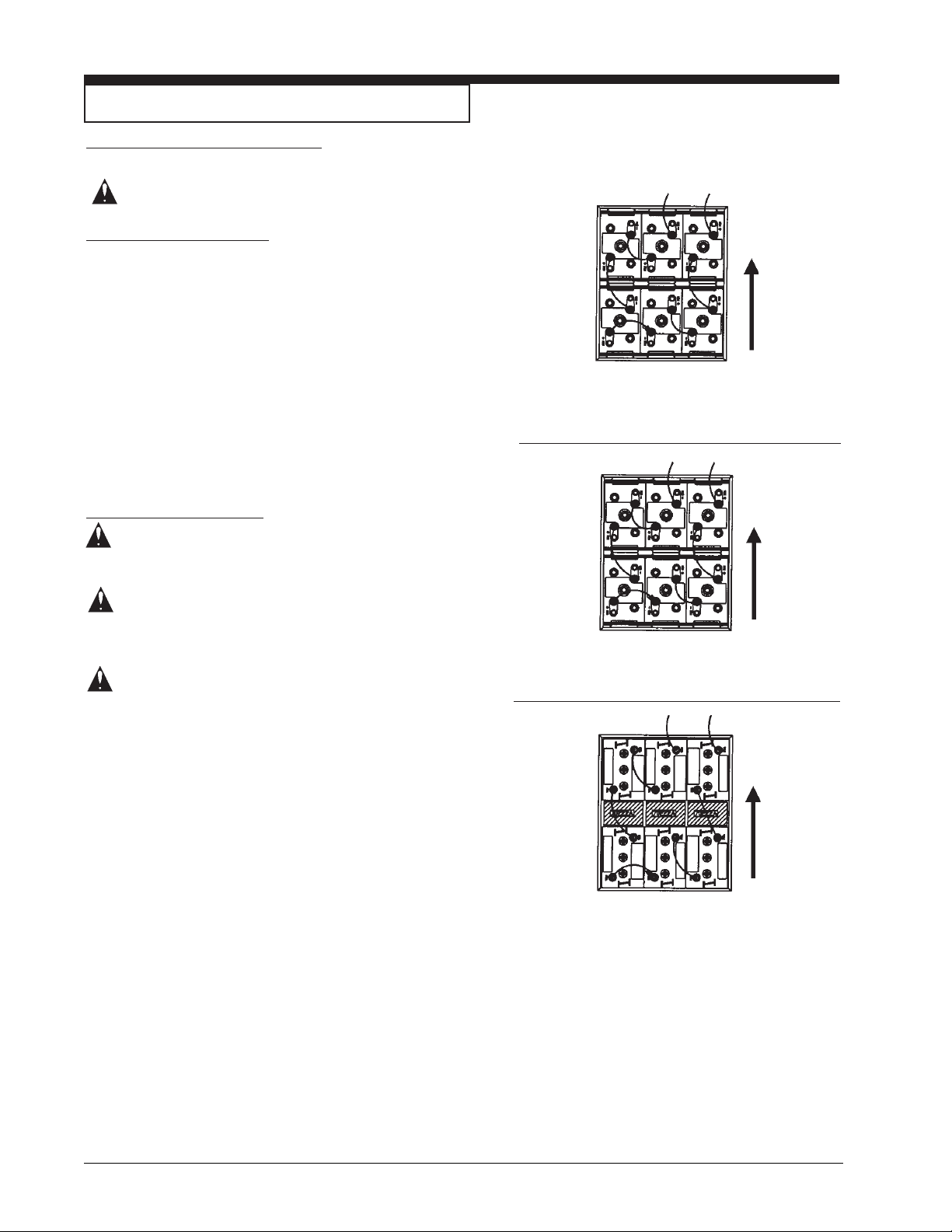

How to Install the Batteries

BA TTERY CONNECTIONS

Front of

machine

370 AH, 6 V olt

(Battery No. 40704A Wet)

(Battery No. 40602A Dry)

Front of

machine

WARNING: The batteries are heavy. Lifting

batteries without help could result in

an injury. Get help to lift the

batteries.

WARNING: Working with batteries can be

dangerous. Always wear eye

protection and protective clothing

when working near batteries. NO

SMOKING!

WARNING: Hydrogen gas is formed during the

charging operation and is explosive.

Only charge batteries in a well

ventilated area with the seat base

lifted.

The batteries are fitted in the battery compartment under

the seat and recovery tank (figure 4). The machine uses

six - 6 volt batteries. They must be handled by using

appropriate lifting equipment suitable for the weight and

for the coupler system. For maintenance and daily

recharge of the batteries, it is necessary to follow all

instructions given by the manufacturer.

For Battery Installation follow these steps (See figure 4):

1. Make sure that the key switch is in the “OFF”

position.

2. Lift and rotate the base support of the seat forward.

3. Lean the seat on it’s restraint cable.

4. Lift the front of the recovery tank and rotate it towards

the rear until it rests on it’s restraint cable.

5. Put the batteries into position and connect the

battery cables as shown in figure 4.

6. Rotate the recovery tank and then carefully rotate it

forward to the normal operating position.

330 AH, 6 V olt

(Battery No. 891384 Wet)

(Battery No. 891385 Dry)

Front of

machine

250 AH, 6 V olt

(Battery No. 881317 Wet)

(Battery No. 881318 Dry)

Three (3) 70222A Spacers

Figure 4

7. Lower the base support of the seat.

NOTE: Charge the batteries before using.

Page -10- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Prepare the Machine For Operation

Battery Maintenance

The electrical power to operate the machine comes from the

storage batteries. Storage batteries need preventative

maintenance.

WARNING: Working with batteries can be

dangerous. Always wear eye

protection and protective clothing

when working near batteries. NO

SMOKING!

To maintain the batteries in good condition, follow these

instructions:

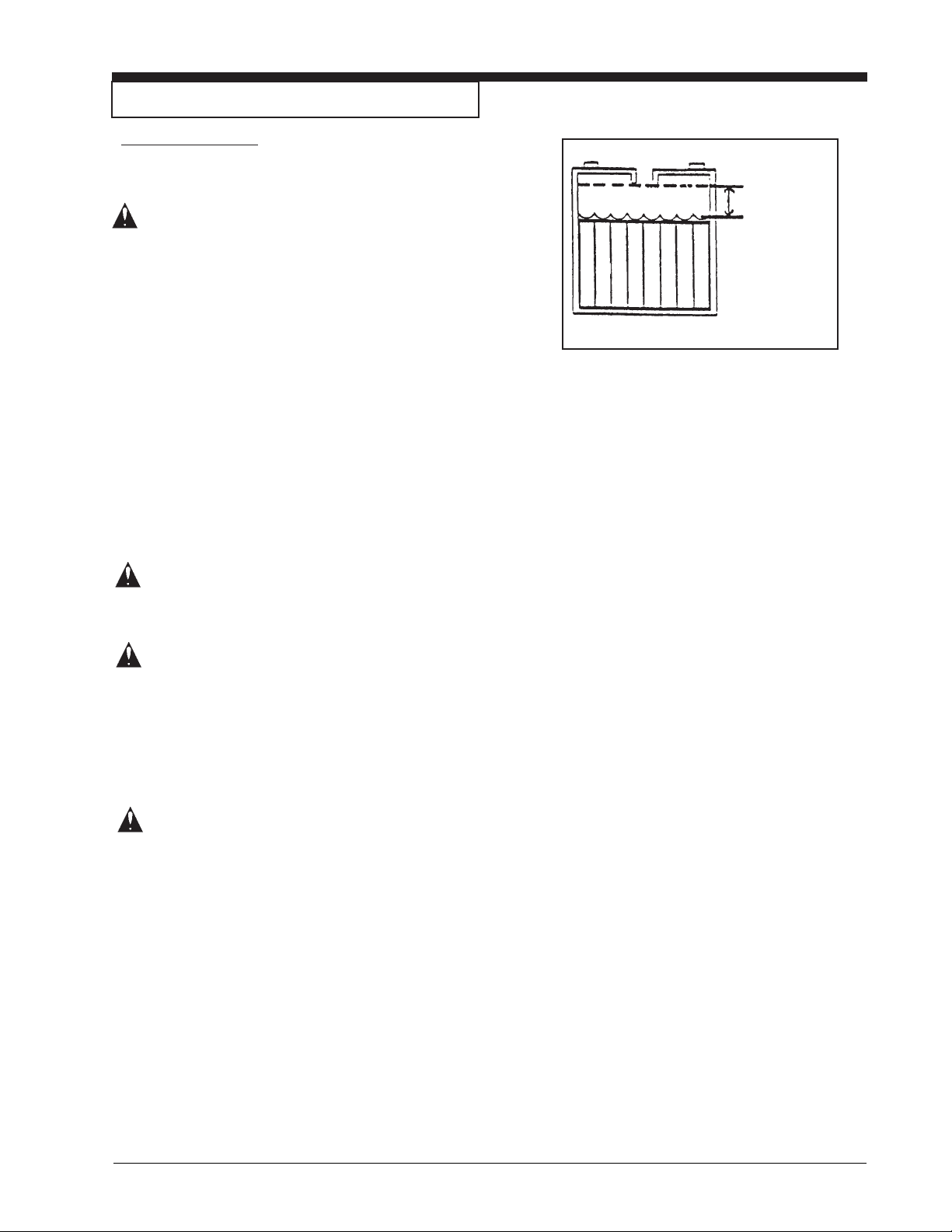

Correct Fill

1. Keep the electrolyte at the correct level. The correct

level is between 1/4” (1/2 cm) below the bottom of the

tube in each cell and above the tops of the plates.

Check the level of the electrolyte each time you charge

the batteries (see figure 5).

NOTE: Check the level of electrolyte prior to charging the

batteries. Be sure the plates in each cell are covered with

electrolyte before charging. Do not top off the cells prior to

charging the battery. Electrolyte expands during charging.

As a result, the electrolyte could overflow from the cells.

Always top off the cells with distilled water after charging.

CAUTION: Irreversible damage will occur to

the batteries if electrolyte does not

cover the plates. Keep the

electrolyte at the correct level.

CAUTION: Machine damage and discharge

across the tops of the batteries can

occur if the batteries are over filled.

Do not fill the batteries up to the

bottom of the tube in each cell.

Wipe any acid from the machine or

the tops of the batteries. Never

add acid to a battery after

installation.

Figure 5

CAUTION: Batteries must be refilled with

distilled water only. Do not use tap

water as it may contain

contaminants that will damage

batteries.

2. Keep the tops of the batteries clean and dry. Keep the

terminals and connectors clean. To clean the top of

the batteries, use a damp cloth with a weak solution of

ammonia or bicarbonate of soda solution. To clean

the terminals and connectors, use a terminal and

connector cleaning tool. Do not allow ammonia or

bicarbonate of soda to get into the batteries.

3. Keep the batteries charged.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -11-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Prepare the Machine For Operation

How to Charge the Batteries

WARNING: Charging the batteries in an area

without adequate ventilation could

result in an explosion. To prevent

an explosion, charge the batteries

only in an area with good

ventilation.

WARNING: Lead acid batteries generate gases

which could explode. Keep sparks

and flames away from batteries.

NO SMOKING!

To charge the batteries, follow this procedure:

1. Make sure the key switch is in the “OFF” position.

2. Raise the seat base support.

3. Connect the battery charger AC cord to a 15 amp

(min) 120V properly grounded wall receptacle.

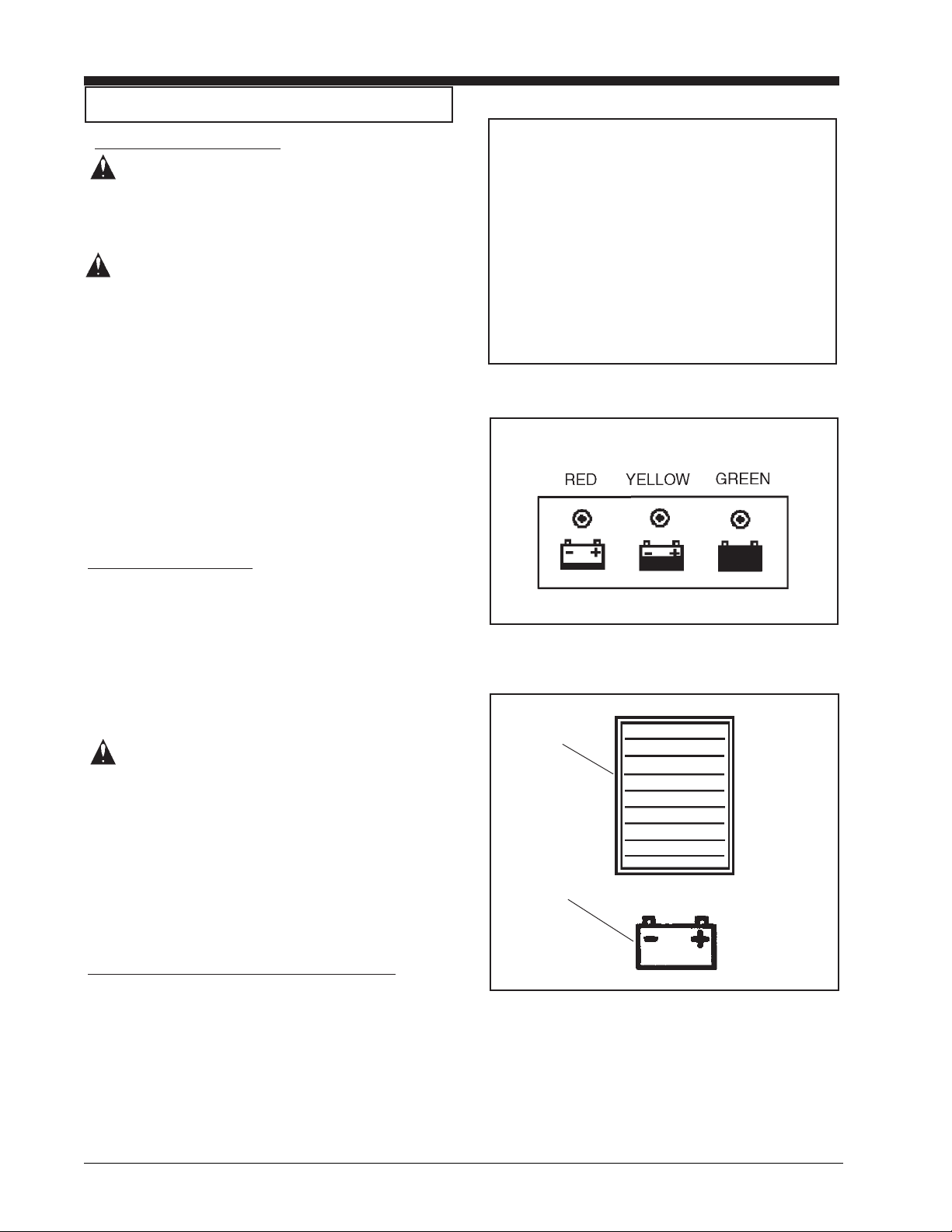

4. Observe indicator light to ensure the charging

process has started (see figure 6, A - Red, B Yellow, C - Green ). For color indications see figure

6A.

Recharging the Batteries

The Scrubtec R comes with an on board charger.

1. Plug into any wall socket and charging is automatic.

A

A

B

Figure 6

B

C

C

2. Observe indicator light to ensure the charging

process has started (see figure 6, A - Red, B Yellow, C - Green ). For color indications see figure

6A.

NOTE: Make sure you plug into a circuit that is not loaded

by other equipment. Wall breakers may be tripped and

no charge will occur.

WARNING: Never charge a GEL battery with an

unsuitable battery charger.

Carefully follow the instructions

given by the manufacturer of the

batteries and battery charger.

NOTE: To prevent permanent damage to the batteries,

avoid their complete discharge. Never leave the batteries

completely discharged, even if the machine is not being

used. When recharging the batteries, keep the base

support of the seat lifted. After every 20 recharging

operations, check the level of the electrolyte and if

necessary top off with distilled water.

Level Indicators for the Charge of the Batteries

The battery meter ( see figure 7) on the control panel has

a digital read out with 10 fixed positions (A) and also a

blinking indicator (B). The bars that appear on the display

show the approximate charge level with icon (blinking)

discharged battery.

NOTE: A few seconds after the voltage reads 32V it will

start blinking. The brush motors will then automatically

switch off.

Figure 6A

A

B

Figure 7

Page -12- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Prepare the Machine For

Operation

How To Install the Squeegee

To install the squeegee onto the machine, follow this

procedure:

1. The squeegee assembly has a break away feature

that is also used for mounting the squeegee. Loosen

the knobs on the squeegee (figure 8). Slide the stud

into the slotted hole in the support frame on the

machine.

2. Attach the vacuum hose cuff to the squeegee hose

fitting (see figure 9).

3. Tighten knobs. NOTE: Do not overtighten or break

away feature is lost and damage may occur.

NOTE: To prevent damage to the squeegee or machine, the

squeegee was designed to break away from the machine.

If the squeegee is impacted and it breaks away from the

machine, simply reinstall it by following step 1-3.

How to Adjust the Squeegee

During operation, the rear squeegee blade should have a

constant 3/16” minimum flare along the entire squeegee

blade (see figure 10).

1. The squeegee body can be tilted to adjust the

squeegee blade flare in the middle to match the flare

on the ends. To adjust the tilt, loosen the adjusting

bolt located on the left and right side of the squeegee

(see figure 9).

2. Press down on the squeegee until both sets of guide

wheels contact floor.

3. After making adjustments, retighten the screw(s).

NOTE: It is important that the right and left wheels are

contacting the floor in order for the squeegee to work.

Figure 8

Figure 9

Figure 10

3

/16” minimum

NOTE: As the rear squeegee blade wears, it can be rotated

and/or flipped to obtain four good edges before having to

change blades.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -13-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Prepare the Machine For

Operation

How To Change or Rotate Brushes on Cylindrical Brush

Head

To install or rotate brushes on the cylindrical brush head:

1. Raise the brush deck and turn the key switch “OFF”.

2. Raise the brush skirt and pull out to remove. See

figure 11.

3. Remove thumb screw from brush door. See figure 12.

4. Lower door approximately 12 mm and slide door and

hub assembly from brush. See figure 13.

5. Slide brush off hub at opposite end. See figure 14.

6. Rotate brush or replace.

7. Slide brush on drive hub and insert door and hub

assembly into brush core.

8. Raise door and install thumb screw.

9. Place side skirt on retainer pins and lower in place.

10. Brushes should be rotated after every 20 hours of use.

Figure 11

Figure 12

Page -14- CLARKE TECHNOLOGY Operator's Manual -

Figure 13

Figure 14

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate The Machine

How to Operate the i-Drive Controls

The following controls are located on the joystick:

1.

Horn : The horn is a red button located on the top of the

joystick (figure 15, item A). NOTE: The horn sounds

continuously when pressed and intermittent and

automatic in reverse.

2.

One Touch: The one touch button is a green button located

on the upper front of the joystick (figure 15, item B). NOTE:

For more information about the one touch control see

below.

3.

Speed Selector: The speed selector is a black button

located on the lower front of the joystick (figure 15, item C).

Horn Operation

The horn is a continuous tone when pressing the horn button. In

reverse the horn pulses automatically.

One Touch Operation

One touch cleaning is a feature on the Scrubtec R. The factory

defaults for this setting are two bars of brush pressure and four

bars for solution flow and squeegee in the down position.

1. Press and release the green button for all cleaning

functions to begin.

A

B

C

Figure 15

2. The squeegee and brush head lower to the floor and the

vacuum starts.

3. The brushes and solution will begin only when you begin to

traverse.

4. The cleaning will be at the factory default settings, however

you can reprogram these settings to your specifications.

See “Reprogramming One Touch” section below.

5. To end cleaning process, press the green button again and

solution will stop; brushes will raise; after a short delay

squeegee will raise; and the vacuum motor will turn off.

NOTE: It is intended that this be done while traversing. If you

stop and do it, some solution can be left on the floor.

Reprogramming One Touch

If you do not want to use the factory default settings, you may

reprogram the setting by following the procedures below:

1. Place the machine in the desired scrub condition by using

the one touch and / or individual switches.

2. Press and hold the green one touch button until you hear a

single beep from the machine then release the button.

NOTE: The time required should be approximately 5

seconds.

3. When you activate or deactivate the one touch, it will now be

set to your preference for cleaning. These settings will

remain until you disconnect power or reprogram them.

NOTE: When programming one touch, be sure squeegee

is in automatic (middle) position, otherwise you may

program squeegee either up or down all the time.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -15-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate The Machine

How to Return One Touch to Factory Default Settings

To restore the factory settings, follow the procedures below:

1. Press and hold the green one touch button (figure 15, B)

until you hear a

The time required for this will be approximately 10

seconds.

2. The settings should be returned to 4 bars of solution and

2 bars of brush pressure. NOTE: The squeegee vac

switch must be in the middle position for default

settings to work.

Directional Control (see figure 16, A and B)

The Scrubtec R is equipped with a joystick for controlling

speed and direction of the machine. Simply point the

joystick in the direction you want the machine to go (figure

16, A). This is true for both forward and reverse directions.

The speed and direction are directly proportional to the

position of the joystick. If you want to go slow and straight,

apply a slight amount of pressure to the joystick in the

forward direction. For more speed, move the joystick

further in direction you wish to travel.

double beep from the machine. NOTE:

Forward Left

(T op V iew)

A

B

Forward Right

NOTE: See example in figure 16, B - the joystick is

positioned to where the machine will go in the forward-right

direction.

How to Move the Machine Without Power (see figure 17)

1. Engage manual override on brake (see page 9, “Parking

Brake”).

2. Remove foot plate and 4 screws.

3. Using the knob, turn shaft on motor in direction you wish

to turn machine.

4. Slowly push machine to desired location. NOTE: If you

attempt to push machine too fast it will limit top speed.

If this happens, stop and restart.

5. After moving machine, disengage manual brake

override. NOTE: Machine will not function if override is

engaged.

Reverse Left Reverse Right

Figure 16

Page -16- CLARKE TECHNOLOGY Operator's Manual -

Figure 17

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate the Machine

Seat Adjustment (Standard)

The seat cannot be adjusted.

Seat Adjustment (Deluxe)

The optional deluxe seat is adjustable in three ways:

1. The seat can be adjusted to the forward/backward

position by using the lever on the lower right side of the

seat . Moving the lever will allow the seat to slide into

the preferred position. See figure 18.

2. To adjust the angle of the back support portion of the

seat, turn the lever located in the middle right position

of the seat. Turning this clockwise will make the seat

more vertical. Turning the knob counterclockwise will

tilt the seat back.

See figure 19, A.

3. To adjust the suspension of the seat for operator

comfort, use the lever on the side of the back support

section of the seat. This has three positions. The

upper position is for light weight operators. The

middle position is for medium weight operators. The

bottom position is for heavy weight operators. See

figure 20, B. NOTE: The lever must be pressed firmly

to change positions.

Figure 18

Figure 19

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -17-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate the Machine

How to Read the Battery Meter (see figure 20, A)

The battery meter is an indicator on the LCD display. This

indicator is on the LCD display on the front of the machine.

It has 10 bars with 10 bars visible indicating a full charge.

As you run the machine the bars will begin to lower. The

“Battery Icon” (B) will begin to flash to indicate you are

reaching the end of charge.

NOTE: If you continue to run the brushes they will shut

down to protect the batteries from over discharging.

NOTE: Run times will vary depending on machine

variables, battery size, brush pressure and floor type,

etc.

How to Change Displays Screens on the LCD Module

The LCD display has three screens. Two of them can be

accessed at any time the key is on. The first screen

shows the machine status and the second screen shows

the four hour meters (figure 20).

The two screens that can be viewed by the operator can be

accessed via the display button (figure 21) on the control

panel to the left of the key switch. Pressing this button

toggles the display between the available screens.

SCREEN 1

A

B

SCREEN 2

Figure 20

The third screen is for diagnostics only. This screen

displays any errors that might occur or if the system

diagnostics finds something wrong. When the diagnostic

screen comes up, refer to the trouble shooting guide for

suitable action to resolve the error code.

Figure 21

Page -18- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate the Machine

How to Operate the Squeegee and the Vacuum

Motor

The squeegee wipes the floor while the vacuum motor

removes the dirty solution from the floor. To operate the

squeegee, follow this procedure:

1. To lower the squeegee and start the vacuum motor,

press the squeegee up/down switch to the down

position (figure 22). NOTE: The vacuum motor

will start immediately when the down position

of the switch is pressed, and the squeegee will

lower.

2. To raise the squeegee, press the squeegee up/

down switch to the up position (figure 22). The

squeegee will then raise and the vacuum motor will

shut off after short delay NOTE: The center

position of the squeegee up/down switch is for

use with one touch control.

NOTE: The squeegee will rise automatically when

traversing in reverse during scrubbing operations.

How to Operate the Solution Flow

The solution is used to loosen and remove dirt from the floor.

The amount of solution applied can be adjusted to five

different levels to accommodate many different floor

conditions. These different levels are shown on the LCD

display on the front of the machine. To adjust the amount

of solution applied, use the Solution Flow Switch (figure 23).

NOTE: There are five different settings on the display

and they come on two bars at a time. See figure

24, A.

Figure 22

To increase solution flow:

1. Press the “ + ” side of the switch (figure 23).

2. Press and hold the “ + ” switch to achieve the desired

level of solution flow.

To decrease solution flow:

.

1. Press the “ - “ side of the switch (figure 23).

2. Press and hold the “ - “ side of the switch to achieve the

desired level of solution flow.

How to Operate the Brush Pressure

The brushes are used to supply agitation for the solution,

which improves the cleaning process. The amount of brush

pressure applied can be adjusted to five different levels to

accommodate many different floor conditions. These

different levels are shown on the LCD display on the front of

the machine (figure 24, B). To adjust the amount of brush

pressure, use the brush up/down switch (figure 25).

To increase brush pressure:

1. Press the “ + ” side of the switch (figure 25).

2. Press and hold the “ + ” switch to achieve the desired

level of pressure.

To decrease brush pressure:

.

1. Press the “ - “ side of the switch (figure 25).

Figure 23

B

A

Figure 24

2. Press and hold the “ - “ side of the switch to achieve the

desired level of pressure.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -19-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

Figure 25

How To Operate the Machine

How to Fill the Solution Tank

The solution tank fill port is located at the left side of the

machine (see figure 26). To fill the solution tank, follow

this procedure:

1. Turn the key switch to the “OFF” position.

2. Remove lid.

3. Add a cleaning chemical to the solution tank. For

the correct amount of chemical, follow the directions

shown on the container. NOTE: Excess foam in

the recovery tank could damage the vacuum

motor, so use only the minimum amount of

detergent necessary.

WARNING: Always use low foam detergent.

To avoid the production of foam,

before starting to clean, put a

minimum quantity of antifoam

liquid into the recovery tank.

NEVER USE PURE ACID.

4. Fill the solution tank with clean water (see figure 26).

5. After filling the solution tank, replace the solution

tank lid.

WARNING: Water solutions or cleaning

materials used with this type of

machine can leave wet areas on

the floor surface. These areas

can cause a dangerous condition

for the operator or other persons.

Always put CAUTION signs near

the area you are cleaning.

WARNING: Machines can ignite flammable

materials and vapors. Do not use

with or near flammables such as

gasoline, grain dust, solvents and

thinners. Only use a cleaning

concentration recommended by

the chemical manufacturer.

WARNING: ALTO recommends a maximum

water temperature of 120°F

(49°C).

Figure 26

Operating the Machine

NOTE: Before scrubbing with the machine, become

familiar with the operations and handling of the machine.

Run the machine at the lowest traverse speed. Use the

machine in an area that has no furniture or objects until

you can do the following:

1. Traverse the machine in a straight direction, forward

and backward.

2. Stop the machine safely.

3. Turn the machine both left and right and return to a

straight direction.

o

4. Turn a 180

Page -20- CLARKE TECHNOLOGY Operator's Manual -

turn where one rear wheel just pivots.

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate the Machine (cont.)

To traverse the machine follow this procedure:

1. Sit on the driver seat.

traverse if the operator is not properly seated.

NOTE: The machine will not

2. Turn the key switch to the “ON” position.

3. Raise the brush to the highest position.

4. Raise the squeegee.

6. Gently press on the joystick in the direction you

want to travel. The machine will begin to move.

7. To change the speed of the machine move the

joystick. Move it in the direction you want to travel.

8. To stop, release pressure on the joystick and allow

it to re-center.

9. To travel in reverse, move the joystick in the reverse

position. NOTE: Keep the joystick pointed in

the direction you wish to go.

10. To stop, release the joystick.

11. To turn the machine, move the joystick in the

direction you want to turn.

12. When you stop the machine, turn the key switch

“OFF” and remove the key.

Figure 27

Do These Procedures When You Begin Your Work

Period

1. Make sure the key switch is in the “OFF” position.

2. Disconnect AC power from battery charger (follow

charger instructions).

3. Make sure the filter screen (1) to the vacuum motor

is clean and installed properly in the recovery tank

(see figure 27).

4. Make sure the recovery tank lid is in place and has

been tightened (see figure 28).

5. Close and secure the lower cleaning port cover on

the recovery tank.

6. Make sure that the plug in the recovery drain hose

is in place and has been tightened (see figure 29).

7. Make sure that the brushes/pads are in position

and installed correctly.

8. Make sure the brush housings are in position on

the brush head.

9. Check the installation of the squeegee and

squeegee hose.

Figure 28

Figure 29

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -21-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate the Machine

How to Clean a Floor

WARNING: Water solutions or cleaning materials

For one touch automatic cleaning follow this procedure:

1. Turn the key switch to the “OFF” position.

2. Put the water and a cleaning chemical in the solution

tank.

3. Sit on the driver seat. NOTE: The machine will not

traverse if the operator is not properly seated.

4. Turn the key switch “ON”. NOTE: The key switch turns

on the battery and LED screen displays, which shows

the machines condition.

5. The machine has a one touch button on the joystick

(see figure 30) that is preset for brush pressure and

solution flow. Momentarily depress the one touch

button if you wish to use these settings. NOTE: If this is

not the settings that you desire see page 15 or one

touch operation.

For manual control of cleaning process, follow these

procedures:

1. Turn the key switch to the “OFF” position.

2. Put the water and a cleaning chemical in the solution

tank.

3. Sit on the driver seat. NOTE: The machine will not

traverse if the operator is not properly seated.

4. Turn the key switch “ON”. NOTE: The key switch turns

on the battery and LED screen displays, which shows

the machines condition.

5. Lower the squeegee. NOTE: The vacuum motor will

turn on when the squeegee up/down switch is placed

in the lower position.

6. Lower the brush head until it reaches the full stroke

down. NOTE: The brushes will start rotating only

when the machine begins to traverse.

7. Reset the solution flow valve by using the + / - solution

switch. NOTE: The solution will flow only if the

machine is moving forward.

8. Press the joystick in the desired direction/position.

After the joystick is pressed the machine will begin to

move and the brushes will start to rotate and solution

will begin to flow.

9. After a few feet of scrubbing, check to see that the

amount of solution being applied is correct and that the

squeegee is picking up water and drying the floor.

Make adjustments as required.

10. Once the machine is set properly continue to scrub until

the solution low indicator comes on or until you run out

of solution.

WARNING: If the machine develops operating

NOTE: When making multiple passes across the floor,

overlap the brush cleaning path approximately 2 inches (5

cm) of the area already cleaned by the brush.

NOTE: During most cleaning procedures, apply and remove

the solution in one operation.

used with this type of machine can

leave wet areas on the floor surface.

These areas can cause a dangerous

condition for the operator or other

persons. Always put CAUTION signs

near the area you are cleaning.

problems while working, remove your

hand from the joystick. After

resolving the problem, continue

working.

Figure 30

Page -22- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate the Machine

How to Clean a Very Dirty Floor

To clean a very dirty floor, follow this procedure:

1. Apply solution to the floor.

2. Do not lower the squeegee. This will keep the vacuum

motor off.

3. Lower the brush or pad and scrub the floor.

4. Scrub the floor again with additional solution and

lower the squeegee.

5. Pick up all the solution with the squeegee.

Do These Procedures When You End Your Work Period

Having finished the job and before any type of maintenance

is done, follow these procedures:

For one touch cleaning shut down process, press and

release the one touch button.

For manual shut down follow these procedures:

1. Turn the solution flow off by decreasing the flow to its

minimum position.

2. Press the brush up/down switch to the up position

until the brush head has reached its up most position.

3. Place the squeegee up/down switch in the up position

to raise the squeegee and allow the vacuum motor to

continue to run. The vacuum motor will run for another

20 seconds and then place the squeegee up/down

switch to the up position. This will shut the vacuum

motor off.

4. Take the machine to a water drain.

5. Turn the key switch “OFF”.

6. Remove the drain hose from the holding hook.

Figure 31

7. Put the end of the hose over a drain or bucket.

8. Turn the valve housing to the left (see figure 31).

9. To open the valve completely, turn the housing fully to

the left. Pull the housing off of the valve.

10. Empty the recovery tank. NOTE: When hose is

lowered below water level, water will flow.

WARNING: Use gloves to protect your hands

from contact with dangerous

solutions when preforming the steps

listed above.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -23-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

How To Operate the Machine

11. Rinse the tank. Put clean water in the tank through

the opening at the top. Be careful not to allow

water into the vacuum intake tube (with screen).

12. If the tank or drain hose has an obstruction, use

water pressure to flush the tank or hose. Put the

water hose into the drain hose.

13. Leave the tank and drain plug removed to air dry.

14. Check the squeegee blade. Use a cloth to clean

the squeegee blade. If the squeegee blade is

damaged or worn, turn or replace the blade.

NOTE: To avoid damage to the squeegee, the

squeegee must be lifted when the machine is not in

operation.

15. Take off the brushes and clean them with a jet

stream of water.

16. Use a clean cloth and wipe the surface of the

machine.

17. Check the batteries and add distilled water as

needed. The correct level is between ¼” (½ cm)

below the bottom of the tube in each cell and above

the tops of the plates. See the instructions in the

section of this book called “Battery Maintenance”.

CAUTION: Tap water may contain

contaminants that will damage

batteries. Batteries must be

refilled with distilled water only.

WARNING: Lead acid batteries generate

gases which can cause an

explosion. NO SMOKING.

Always wear eye protection and

protection clothing when

working near batteries.

18. Charge the batteries. See the instructions in the

section of this book called “How to Charge the

Batteries”.

Page -24- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

Maintenance

Maintenance To Be Done Every Week

WARNING: Maintenance and repairs must be

done by authorized personnel

only. Always empty the solution

tank and the recovery tank before

doing any maintenance. Keep all

fasteners tight.

WARNING: Always wear eye protection and

protective clothing when working

near batteries. NO SMOKING! Do

not put tools or other metal

objects across the battery

terminals or the tops of the

batteries.

CAUTION: To prevent damage to the

machine, and discharge across

the tops of the batteries, do not fill

the batteries above the bottom of

the tube in each cell. Wipe any

acid from the machine or the tops

of the batteries. Do not add acid

to batteries after installation.

Battery Inspection and Cleaning

1. Turn the key switch to the “OFF” position.

2. To inspect batteries, rotate seat support forward.

Lift and rotate recovery tank. Be sure the recovery

tank is empty before lifting.

Figure 32

3. Disconnect the batteries. Use a cloth and a solution

of ammonia or bicarbonate of soda to wipe the top of

the batteries. Clean the battery terminals. Reconnect

the batteries. See the instructions in the section of

this book called “Battery Maintenance”.

4. When battery inspection is completed, close the

recovery tank. Rotate the seat support back to the

operating position.

Cleaning the Recovery Tank and Filter

1. Turn the key switch to the “OFF” position and set the

parking brake.

2. Empty the recovery tank using the flexible drain

hose by unscrewing the knob and taking off the

plug (see figure 32).

3. If the machine is equipped with the optional cleanout port, open the lower cleaning port cover by

unscrewing the four knobs (see figure 33). NOTE:

Make sure that the tank is empty first.

4. Rinse the tank and clean the drain plug.

Figure 33

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -25-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

Maintenance

5. Clean the hose fitting in the recovery tank and

spray water down the squeegee hose to clean

out debris.

6. Reattach the squeegee hose.

Cleaning the Solution Tank and Filter

1. Move the machine so that the solution tank filter

assembly is located directly over a floor drain.

2. Turn the key switch to the “OFF” position.

3. Clean inside the solution tank with a jet stream

of water.

7. Close the solution flow valve.

8. Clean the filter inside the housing and reinstall on

machine.

Manually Draining the Solution Tank

1. Remove sight gauge hose from top connector

(see figure 34).

Figure 34

2. Rotate lower fitting to allow drain hose to rest

over drain.

3. Drain solution tank (see figure 35).

Vac Assisted Solution Tank Drain

1. Remove vacuum hose from squeegee plate.

2. Turn vac on.

3. Remove and place solution hose into vac hose

until washer rest against hose cuff.

NOTE: Using vac assist will help to rinse recovery

tank. This will help to reduce cleanup and

maintenance times.

Squeegee Maintenance

Clean the squeegee with a jet stream of water and a

damp cloth. Inspect the front and rear squeegee

blades for wear. Readjust or replace if necessary.

Front Squeegee Blade Replacement

To replace the front squeegee blade, follow this

procedure:

1. Remove the squeegee assembly from the

machine.

Figure 35

2. Remove clamp and front squeegee blade.

3. Install new front squeegee blade and reinstall

clamp.

4. Replace squeegee on machine.

Page -26- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

Maintenance

Rear Squeegee Blade Replacement

If the rear squeegee blade is worn and does not dry

the floor well, follow this procedure:

1. Remove the squeegee assembly from the

machine.

2. Remove the squeegee blade and inspect it.

3. Rotate the squeegee blade to obtain a new

cleaning edge. Replace if necessary.

4. Reinstall the squeegee blade.

5. Reinstall the squeegee assembly on the

machine.

6. Readjust the settings on the squeegee as

required (see “How to Adjust Squeegee”).

Squeegee Maintenance

The squeegee blade may be rotated for longer life.

Keep sharp corner on floor for best cleaning

results. See figure 36. To rotate follow this

procedure:

Figure 36

1. Remove Clamp.

2. Remove blade and rotate to new edge.

3. Replace squeegee.

4. Replace clamp.

Cleaning the Vacuum Hoses

Make sure the squeegee is over a suitable drain.

1. Use a garden hose to flush through the

recovery hoses.

2. Side Squeegee - Position garden hose to the

squeegee side of the hose and flush

thoroughly.

3. Recovery Hose - Position garden hose

inside recovery tank. NOTE: Do not place

hose in vacuum intake (see figure 37),

damage will occur.

Re-center Front Wheel

If the front wheel gets out of adjustment and the

machine does not drive straight when the joystick

is pointed forward, follow this procedure:

Figure 37

Figure 38

1. Remove 4 screws holding foot plate to solution

tank (see figure 38).

2. Locate two black wires tied together and

marked “reset sw” (see figure 39).

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -27-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

Figure 39

Maintenance

3. Using the joystick, position the front wheel

straight by doing one of the following:

a) Using black indicator marks on steering

system, realign front wheel (see figure 40).

b) Place front wheel straight by visually

estimating it’s position (see figure 41).

4. Hold joystick in corrected position and

connect black wires together and key off the

machine (see figure 42).

5. Disconnect black wires.

6. Key machine on. If machine drives straight,

then proceed to step 7. If not, then repeat

steps 2-5.

7. Replace foot plate and screws.

8. Key machine on.

Figure 40

Figure 41

Page -28- CLARKE TECHNOLOGY Operator's Manual -

Figure 42

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

HOW TO CORRECT PROBLEMS IN THE MACHINE

PROBLEM CAUSE ACTION

Insufficient water onto the brushes

The machine does not clean

satisfactorily

The squeegee does not dry the floor

The solution flow is not set

There is no water in the solution tank.

The solution filter is dirty.

A circuit breaker has tripped.

Insufficient flow.

The brushes are worn.

Need to use a different kind of brush/pad

The squeegee is dirty.

Recovery drain hose is not closed.

The suction hoses need to be cleaned.

The squeegee blades are worn.

Make sure the solution flow is set.

Fill the solution tank.

Clean the solution filter.

Reset the circuit breaker.

Increase flow with solution switch.

Check the brushes and replace if necessary.

(the brushes have to be replaced when the

bristles reach approximately .59 inches (15mm

height.)

Use a different kind of brush. For cleaning

operations on floors where the dirt proves to be

particularly resistant, we recommend using special brushes. See Accessories page.

Clean the squeegee.

Close the drain plug.

Clean the vacuum hoses. See “Routine Maintenance” section.

Replace/ or rotate the squeegee blades. See

“Routine Maintenance” section.

The vacuum motor does not function

The machine does not start

The brush motors do not work

WARNING: To avoid damage to the

floor, the motor starts only when the

machine is traversing.

The recovery tank is full.

The squeegee up/down switch in not in the

low or middle position.

The operator is not properly seated.

The key is not in the “ON position”.

The charger is still connected.

The batteries are not charged or not con-

nected properly.

The circuit breaker has tripped.

The brush head unit is not down.

The batteries are not charged or not con-

nected properly.

Poor electrical connection at the brush head

unit.

Drain recovery tank.

Put the squeegee in the low or middle position

or reprogram “one touch”.

The operator must be properly seated in the

driving position.

Turn the key to the “ON” position.

Remove the A/C cord from the wall.

Check to make sure the batteries are con-

nected properly and charge if necessary.

Reset the circuit breaker.

Put the brush head unit down.

Check to make sure the batteries are con-

nected properly and charge if necessary.

Connect the electrical connection at the brush

head unit.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

SCRUBTEC R 571 / 571 C / 586 Page -29-

SCRUBTEC R 571 / 571 C / 586SCRUBTEC R 571 / 571 C / 586

Scrubtec R

Common Error Codes

ERROR

CODE

1500

1501

1507

1600

3100

3101

3102

3103

3104

3105

7600

7602

7603

CAUSE

Check brake and wiring for

short circuit.

High battery voltage.

Probable short circuit of