Page 1

RS 501

ENGLISH SERVICE MANUAL

33015499(3)2008-02

Page 2

Page 3

SERVICE MANUAL

ENGLISH

TABLE OF CONTENTS

GENERAL INFORMATION .............................................................................................................................................. 3

MACHINE LIFTING ......................................................................................................................................................................... 3

MACHINE TRANSPORT ................................................................................................................................................................. 3

PUSHING OR TOWING THE MACHINE ......................................................................................................................................... 3

OTHER AVAILABLE MANUALS ...................................................................................................................................................... 3

SAFETY ........................................................................................................................................................................................... 3

GENERAL SAFETY INSTRUCTIONS ............................................................................................................................................. 4

TECHNICAL DATA ........................................................................................................................................................................... 6

ENVIRONMENTAL CONDITIONS ................................................................................................................................................... 8

MAINTENANCE ............................................................................................................................................................................... 9

SCHEDULED MAINTENANCE TABLE ........................................................................................................................................... 9

MACHINE NOMENCLATURE ........................................................................................................................................................11

SWEEPING SYSTEM .................................................................................................................................................... 17

DESCRIPTION .............................................................................................................................................................................. 17

TROUBLESHOOTING ................................................................................................................................................................... 18

SIDE BROOM POSITION CHECK AND ADJUSTMENT ............................................................................................................... 19

BROOM REPLACEMENT ............................................................................................................................................................. 21

BROOM SPEED ADJUSTMENT ................................................................................................................................................... 22

DUST AND DEBRIS COLLECTION SYSTEM .............................................................................................................. 23

DESCRIPTION .............................................................................................................................................................................. 23

TROUBLESHOOTING ................................................................................................................................................................... 25

HOPPER, FILTER AND SUCTION HOSE CLEANING, AND GASKET CHECK ........................................................................... 26

SUCTION INLET AND SKIRT HEIGHT AND OPERATION CHECK ............................................................................................. 29

SUCTION INLET WHEEL DISASSEMBLY/ASSEMBLY ................................................................................................................ 31

SUCTION INLET SLIDING PANELS DISASSEMBLY/ASSEMBLY ............................................................................................... 32

SUCTION INLET DISASSEMBLY/ASSEMBLY ............................................................................................................................. 33

SKIRT REPLACEMENT ................................................................................................................................................................ 34

HOPPER POSITION ADJUSTMENT ............................................................................................................................................. 35

HOPPER LID CLOSING ACTUATOR ADJUSTMENT ................................................................................................................... 37

MOTOR AND SUCTION FAN DISASSEMBLY/ASSEMBLY .......................................................................................................... 39

SUCTION HOSE DISASSEMBLY/ASSEMBLY ............................................................................................................................. 41

DUST CONTROL SYSTEM ........................................................................................................................................... 43

DESCRIPTION .............................................................................................................................................................................. 43

TROUBLESHOOTING ................................................................................................................................................................... 44

NOZZLE AND FILTER CLEANING ................................................................................................................................................ 45

WATER FILTER CLEANING .......................................................................................................................................................... 47

WATER TANK EMPTYING ............................................................................................................................................................ 48

STEERING SYSTEM ..................................................................................................................................................... 49

DESCRIPTION .............................................................................................................................................................................. 49

TROUBLESHOOTING ................................................................................................................................................................... 50

REAR AXLE TOE-IN ADJUSTMENT ............................................................................................................................................. 51

BRAKE SYSTEM ........................................................................................................................................................... 53

DESCRIPTION .............................................................................................................................................................................. 53

TROUBLESHOOTING ................................................................................................................................................................... 54

BRAKE FLUID LEVEL CHECK ...................................................................................................................................................... 55

PARKING BRAKE CHECK AND ADJUSTMENT ........................................................................................................................... 56

PARKING BRAKE CONTROL CABLE REPLACEMENT............................................................................................................... 57

BRAKE SYSTEM CHECK ............................................................................................................................................................. 59

BRAKING MASSES REPLACEMENT ........................................................................................................................................... 60

BRAKE SYSTEM BLEEDING ........................................................................................................................................................ 61

DRIVE SYSTEM ............................................................................................................................................................. 63

DESCRIPTION .............................................................................................................................................................................. 63

TROUBLESHOOTING ................................................................................................................................................................... 64

TIRE PRESSURE CHECK ............................................................................................................................................................ 65

REVERSE GEAR BUZZER CHECK AND REVERSE GEAR BUZZER ACTIVATION SENSOR ADJUSTMENT ......................... 66

REVERSE GEAR BUZZER SENSOR DISASSEMBLY/ASSEMBLY ............................................................................................. 67

WHEEL REMOVAL/INSTALLATION .............................................................................................................................................. 68

DRIVE SYSTEM MOTOR DISASSEMBLY/ASSEMBLY................................................................................................................ 69

DRIVE PEDAL CHECK AND ADJUSTMENT ................................................................................................................................ 70

RS 501 33015500(3)2008-02

1

Page 4

ENGLISH

SERVICE MANUAL

LDW 1603/B2 ENGINE .................................................................................................................................................. 73

DESCRIPTION .............................................................................................................................................................................. 73

TROUBLESHOOTING ................................................................................................................................................................... 74

ENGINE OIL LEVEL CHECK ......................................................................................................................................................... 75

ENGINE OIL CHANGE .................................................................................................................................................................. 76

ENGINE OIL FILTER CHANGE ..................................................................................................................................................... 77

ENGINE COOLANT LEVEL CHECK ............................................................................................................................................. 78

ENGINE AIR FILTER CLEANING .................................................................................................................................................. 79

FUEL FILTER REPLACEMENT ..................................................................................................................................................... 80

FUEL FITTING AND SCREW CHECK .......................................................................................................................................... 81

ALTERNATOR BELT TENSION CHECK ....................................................................................................................................... 82

ALTERNATOR BELT REPLACEMENT .......................................................................................................................................... 83

RADIATOR FIN CLEANING CHECK ............................................................................................................................................. 84

ENGINE COOLANT LINE SLEEVE CHECK ................................................................................................................................. 85

ENGINE COOLANT CHANGE ...................................................................................................................................................... 86

INJECTOR CALIBRATION AND CLEANING ................................................................................................................................ 87

CLIMATE CONTROL SYSTEM ..................................................................................................................................... 89

DESCRIPTION .............................................................................................................................................................................. 89

TROUBLESHOOTING ................................................................................................................................................................... 90

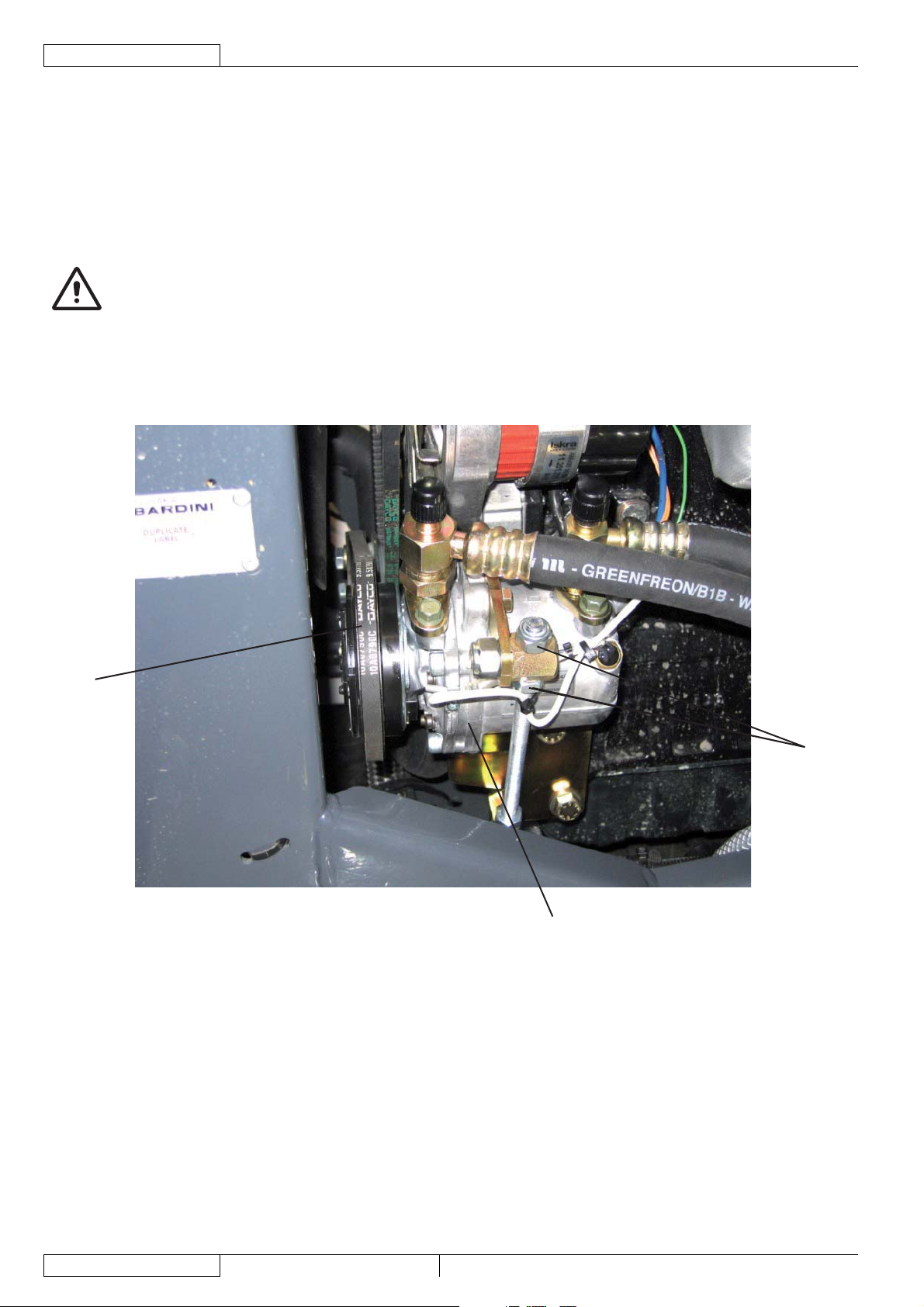

COMPRESSOR BELT TENSION CHECK (LDW 1603/B2 engine) ............................................................................................... 91

COMPRESSOR BELT REPLACEMENT (LDW 1603/B2 engine) .................................................................................................. 92

AIR FILTER REPLACEMENT ........................................................................................................................................................ 93

OTHER SYSTEMS ......................................................................................................................................................... 95

NUT AND SCREW TIGHTENING AND LEAKAGE CHECK .......................................................................................................... 95

LUBRICATION ............................................................................................................................................................................... 96

CHECK AND ADJUSTMENT OF SENSOR FOR ENGINE START-UP INHIBITION WHEN

THE DRIVE PEDAL IS PRESSED ................................................................................................................................................ 97

DISASSEMBLY/ASSEMBLY OF SENSOR FOR ENGINE START-UP INHIBITION WHEN

THE DRIVE PEDAL IS PRESSED ................................................................................................................................................ 98

HYDRAULIC SYSTEM ................................................................................................................................................... 99

DESCRIPTION .............................................................................................................................................................................. 99

COMPONENT LOCATION ............................................................................................................................................................ 99

HYDRAULIC DIAGRAM .............................................................................................................................................................. 101

TROUBLESHOOTING ................................................................................................................................................................. 103

HYDRAULIC SYSTEM OIL LEVEL AND DRAIN FILTER EFFICIENCY CHECK ........................................................................ 104

HYDRAULIC SYSTEM OIL CHANGE ......................................................................................................................................... 105

HYDRAULIC SYSTEM OIL SUCTION FILTER REPLACEMENT ............................................................................................... 107

HYDRAULIC SYSTEM OIL DRAIN FILTER REPLACEMENT .................................................................................................... 108

DRIVE SYSTEM PUMP OIL FILTER REPLACEMENT ............................................................................................................... 109

HYDRAULIC SYSTEM OIL COOLER FIN CLEANING CHECK ...................................................................................................110

REAR WHEEL CONTROL HYDRAULIC CYLINDER DISASSEMBLY/ASSEMBLY.....................................................................111

HYDRAULIC CYLINDERS DISASSEMBLY/ASSEMBLY ............................................................................................................112

SUCTION FAN CONTROL VALVE ASSEMBLY REMOVAL/INSTALLATION ...............................................................................114

ACCESSORY SYSTEM CONTROL VALVE ASSEMBLY REMOVAL/INSTALLATION .................................................................115

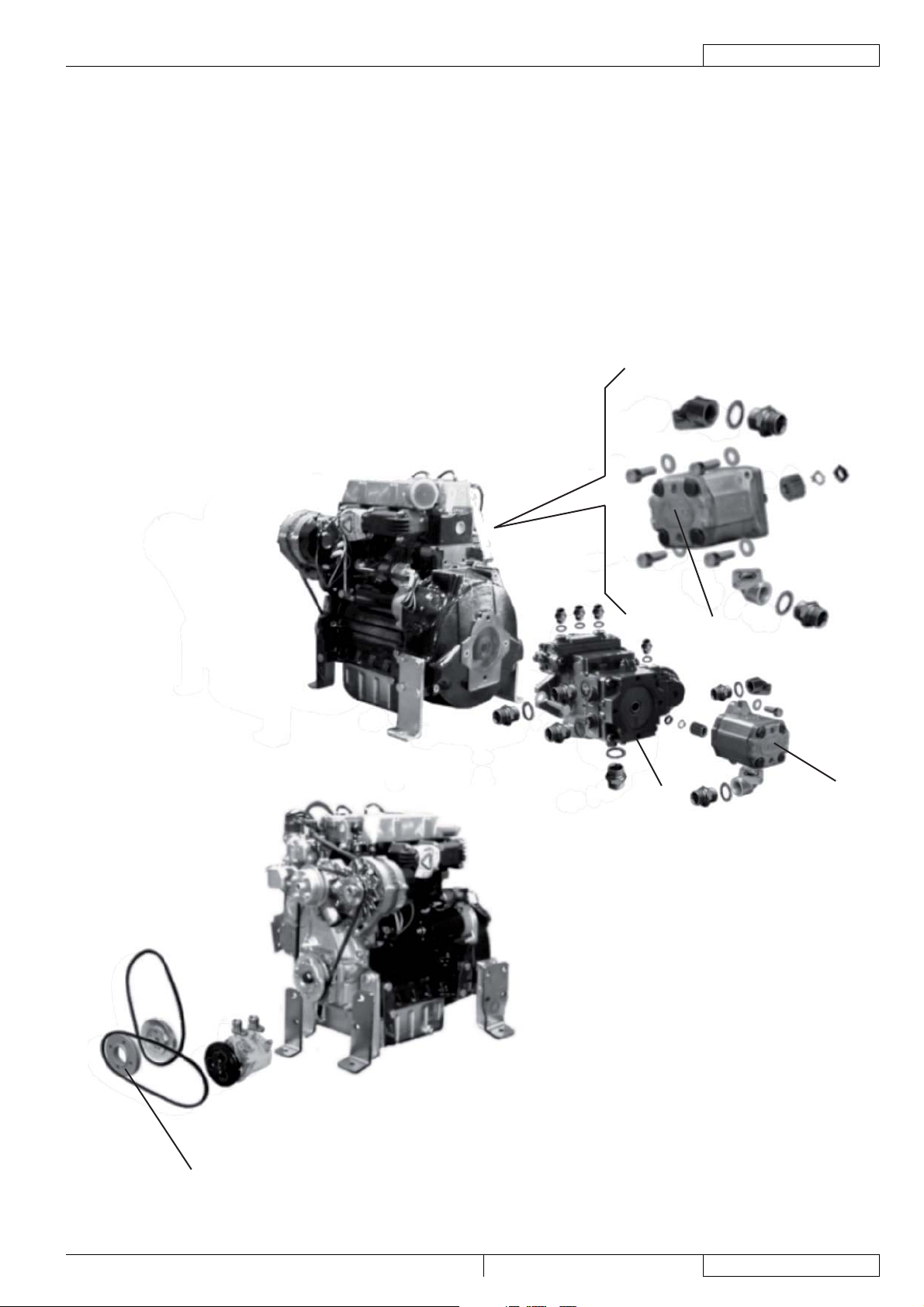

ACCESSORY AND STEERING SYSTEM PUMP DISASSEMBLY/ASSEMBLY (LDW 1603/B2 engine) .....................................116

SUCTION FAN PUMP DISASSEMBLY/ASSEMBLY .................................................................................................................. 120

DRIVE SYSTEM PUMP DISASSEMBLY/ASSEMBLY................................................................................................................. 121

HYDRAULIC SYSTEM OIL PRESSURE CHECK AT THE SUCTION FAN PUMP ..................................................................... 122

HYDRAULIC SYSTEM OIL PRESSURE CHECK AT THE ACCESSORY AND STEERING SYSTEM PUMP ............................ 124

HYDRAULIC SYSTEM OIL PRESSURE CHECK ON DRIVE SYSTEM PUMP .......................................................................... 126

ELECTRICAL SYSTEM ............................................................................................................................................... 129

DESCRIPTION ............................................................................................................................................................................ 129

COMPONENT LOCATION .......................................................................................................................................................... 129

WIRING DIAGRAM ...................................................................................................................................................................... 133

TROUBLESHOOTING ................................................................................................................................................................. 137

BATTERY FLUID LEVEL CHECK ................................................................................................................................................ 138

FUSE REPLACEMENT ............................................................................................................................................................... 139

RELAY REPLACEMENT ............................................................................................................................................................. 140

CONTROL PANEL DISPLAY REPLACEMENT ........................................................................................................................... 141

LOW BEAM AND HIGH BEAM ADJUSTMENT AND BULB REPLACEMENT ............................................................................ 142

2

33015500(3)2008-02 RS 501

Page 5

GENERAL INFORMATION

NOTE

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, while on the driver’s

seat.

MACHINE LIFTING

WARNING!

Do not work under the lifted machine without supporting it with safety stands.

MACHINE TRANSPORT

(See User Manual)

WARNING!

Before transporting the machine, make sure that:

All lids and covers are closed.

–

All moving parts are stopped.

–

The ignition key is removed.

–

The machine is securely fastened to the means of transport.

–

PUSHING OR TOWING THE MACHINE

WARNING!

When pushing or towing the machine, carefully follow the relevant instructions given in the User Manual. Failure

to follow these instructions may cause damage to the machine.

SERVICE MANUAL

GENERAL INFORMATION

ENGLISH

OTHER AVAILABLE MANUALS

The following Manuals are available at Nilfi sk Literature Service Department:

–

RS 501 Spare Parts List – Nilfi sk Form Number 33015502

–

RS 501 User Manual – Nilfi sk Form Number 33015501

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary

precautions to safeguard people and property.

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people or damage to objects.

CAUTION!

It indicates a caution related to important or useful functions.

Pay careful attention to the paragraphs marked by this symbol.

NOTE

It indicates a remark related to important or useful functions.

CONSULTATION

It indicates that it is necessary to consult the User Manual before performing any procedure.

RS 501 33015500(3)2008-02

3

Page 6

ENGLISH

SERVICE MANUAL

GENERAL INFORMATION

GENERAL SAFETY INSTRUCTIONS

Specifi c warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

This machine must be used by properly trained and authorised personnel only.

–

Moreover, the operator must:

–

Be of full age

•

Have a driving license

•

Be in normal psycho-physical conditions

•

Not be under the effect of substances that alters the nervous system (alcohol, psycopharmaceuticals,

•

drugs, etc.)

Before performing any maintenance/repair procedure remove the ignition key, engage the parking brake

–

and disconnect the battery.

Do not wear jewels when working near electrical components.

–

Do not work under the lifted machine without supporting it with safety stands.

–

When working under open hoods/lids, make sure that they cannot be closed by accident.

–

When performing maintenance procedures with the lifted hopper, apply the relevant support rods.

–

Do not operate the machine near toxic, dangerous, fl ammable and/or explosive powders, liquids or vapors.

–

Be careful, fuel is highly fl ammable.

–

Do not smoke or bring naked fl ames in the area where the machine is refuelled or where the fuel is stored.

–

Refuel outdoors or in a well-ventilated area, with the engine off.

–

Do not fi ll the fuel tank to the top, but leave at least 4 cm from the fi ller neck to allow the fuel to expand.

–

After refuelling, check that the fi ller cap is tightly closed.

–

If any fuel is spilled while refuelling, clean up the affected area and allow the vapors to dissipate before

–

starting the engine.

Avoid contact with skin and do not breathe in fuel vapors. Keep out of reach of children.

–

Do not tilt the engine too much to avoid fuel spillage.

–

During machine transportation, the fuel tank must not be full.

–

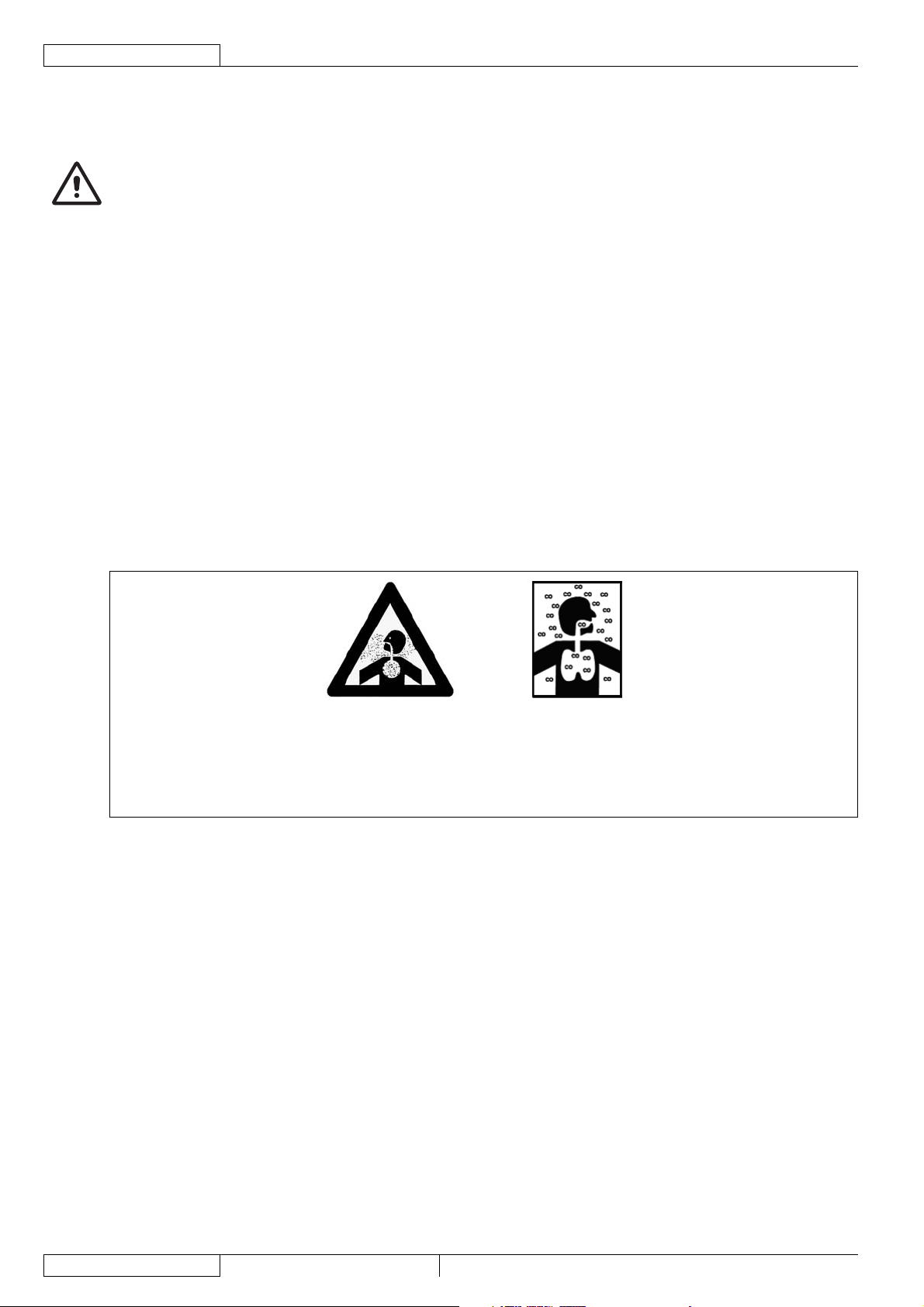

WARNING!

Carbon monoxide (CO) can cause brain damage or death.

The internal combustion engine of this machine can emit carbon monoxide.

Do not inhale exhaust gas fumes.

Only use indoors when adequate ventilation is provided, and when an assistant has been instructed to look

after you.

Do not lay any object on the engine.

–

Before working on the engine turn it off. To prevent the engine from starting accidentally, disconnect the

–

battery negative terminal.

See also the SAFETY RULES in the Diesel Engine Manual, which is to be considered an integral part of this

–

Manual.

4

33015500(3)2008-02 RS 501

Page 7

SERVICE MANUAL

ENGLISH

GENERAL INFORMATION

WARNING!

Carefully read all the instructions before performing any maintenance/repair procedure.

–

Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the machine

–

moving parts.

Protect body parts (eyes, hair, hands, etc.) properly, when performing cleaning procedures using

–

compressed air or water gun.

Avoid contact with battery acid, do not touch hot parts.

–

Do not leave the machine unattended with the ignition key inserted and the parking brake deactivated.

–

Do not remove or modify the plates affi xed to the machine.

–

To drive on public roads, the machine must follow local licensing requirements.

–

The machine has been designed to be used as a sweeper, do not use it for different purposes.

–

In case of part replacement, order ORIGINAL spare parts from an authorised Dealer or Retailer.

–

The machine must be disposed of properly, because of the presence of toxic-harmful materials (batteries,

–

etc.), which are subject to standards that require disposal in special centres (see the Scrapping chapter).

While the engine is running the silencer heats up. Do not touch the silencer to avoid serious scalding or

–

fi re.

Do not run the engine if the oil level is low, to avoid damaging it seriously. Check the oil level with the

–

engine off and the machine on a level surface.

Do not run the engine if the air fi lter is not installed, to avoid damaging it.

–

The coolant line is pressurised; do not perform any check until the engine has cooled down and, even if the

–

engine is cold, the tank plug must be opened with extreme care.

Only use original spare parts or parts of matching quality for the diesel engine. Using spare parts of lower

–

quality can seriously damage the engine.

See also the SAFETY RULES in the Diesel Engine Manual, which is to be considered an integral part of this

–

Manual.

RS 501 33015500(3)2008-02

5

Page 8

ENGLISH

SERVICE MANUAL

GENERAL INFORMATION

TECHNICAL DATA

Dimensions and weights Values

Machine length (broom bristles not included) 3,065 mm

Machine width (broom bristles not included) 1,315 mm

Distance between front and rear wheels 1,475 mm

Front wheel base 930 mm

Rear wheel base 840 mm

Machine height 1,997 mm

Minimum distance from the ground (skirts not included) 90 mm

Maximum front working angle 18°

Maximum dumping height 1,460 mm

Front tires R165/70 R14C 89R

Rear tires R165/70 R14C 89R

Tire pressure 3.75 Bar

Standard side broom diameter 720 mm

Optional side broom diameter 650 mm

Total machine weight, in running condition (without operator) 1,500 Kg

Performance data Values

Maximum forward speed (for transport only) 20 km/h

Maximum working speed 12 km/h

Maximum reverse speed 8 km/h

Gradeability at full load 22% (30% optional)

Minimum inner turning radius 2.46 m

Maximum side broom speed 80 rpm

Collection system Suction

Cleaning width 1,600 mm

Filtering system Metallic net

Sound pressure level at workstation (ISO/EN 3744) at maximum working speed 82 dB(A)

Certifi ed sound power (2000/14/EC) at maximum working speed 108 dB(A)

Measured sound power (ISO/EN 3744) at maximum working speed 106 dB(A)

Hopper capacity 500 liters

Hopper maximum load 380 Kg

Dust control By water

Dust control system tank total capacity (No. 2) 240 liters

Lighting and signalling system Road type

Transmission Hydrostatic servoassisted

Steering system On the rear axle, power assisted

Brake Hydraulic

Parking brake Mechanic

Controls Hydraulic

6

33015500(3)2008-02 RS 501

Page 9

SERVICE MANUAL

ENGLISH

GENERAL INFORMATION

LDW 1603/B2 diesel engine data (*) Values

Make Lombardini

Type LDW 1603/B2

Cylinders 3

Maximum speed 2,600 rpm

Maximum working speed 2,200 rpm

Maximum power at 2,600 rpm 25 kW

Idle speed 900 rpm

Consumption while operating at 2,200 rpm 5.0 L/h

Consumption while operating at 2,600 rpm 5.9 L/h

Engine coolant 50% antifreeze AGIP and 50% water (**)

Engine oil type AGIP Sigma Turbo 15W/40 (***)

(*) For other diesel engine data/values, see the relevant Manual.

(**) See the coolant technical data and reference data tables below.

SPECIFICATIONS REFERENCE DATA

Boiling point °C 170 CUNA NC 956-16 97

Boiling point in solution with 50% water °C 110 FF.SS cat. 002/132

Freezing point in solution with 50% water °C -38 ASTM D 1384

Color /

Density at 15°C kg/l 1.13

(***) See the engine oil technical data and reference data tables below.

Turquoise

blue

SPECIFICATIONS REFERENCE DATA

SAE QUALITY / 15W40 ACEA E3-96

Viscosity at 100°C mm2/s 13.7 API Service CG-4/SG

Viscosity at 40°C mm2/s 100 CCMC D5, PD-2

Viscosity at -15°C mm2/s 3,300 US Department of the Army MIL-L-2104 E

Viscosity index / 138 US Department of the Army MIL-L-46152 E

Flash point COC °C 230 MACK EO-L

Pour point °C -27 MAN M 3275

Density at 15°C kg/l 0.885 Mercedes Benz 228.3

VOLVO VDS2

MTU typ 2

Refuelling data Values

Fuel tank capacity 30 liters

Hydraulic system oil tank capacity 40.6 liters

Hydraulic system capacity 58 liters

Electrical system data Values

System voltage 12 V

Starting battery 12 V – 80 Ah

RS 501 33015500(3)2008-02

7

Page 10

ENGLISH

SERVICE MANUAL

GENERAL INFORMATION

Hydraulic system data Values

Maximum drive system pressure 250 Bar

Maximum accessory system pressure 120/200 Bar

Hydraulic system oil type (at ambient temperature above 10°C) AGIP Arnica 46 (****)

NOTE

If the machine is to be used at ambient temperatures below 10°C, the oil should be replaced with equivalent oil having a

viscosity of 32 cSt. For temperatures below 0°C, use oil with lower viscosity.

(****) See the below hydraulic system oil technical data and reference data tables.

TECHNICAL DATA REFERENCE DATA

AGIP ARNICA 46 32 ISO-L-HV

Viscosity at 40°C mm2/s 45 32 ISO 11158

Viscosity at 100°C mm

Viscosity index / 150 157 AISE 127

Flash point COC °C 215 202 ATOS Tab. P 002-0/I

Pour point °C -36 -36 BS 4231 HSE

Density at 15°C kg/l 0.87 0.865 CETOP RP 91 H HV

2

/s 7.97 6.40 AFNOR NF E 48603 HV

COMMERCIAL HYDRAULICS

Danieli Standard 0.000.001 (AGIP ARNICA

22, 46, 68)

EATON VICKERS I-286-S3

EATON VICKERS M-2950

DIN 51524 t.3 HVLP

LAMB LANDIS-CINCINNATI P68, P69 and

P70

LINDE

PARKER HANNIFIN (DENISON) HF-0

REXROTH RE 90220-1/11.02

SAUER-DANFOSS 520L0463

ENVIRONMENTAL CONDITIONS

In the environment where the machine operates, there must not be any danger of explosion.

To avoid inhaling exhaust gas, the machine must be used only where there is a proper air change.

The machine operates correctly (*) in the following environmental conditions:

Temperature: -10°C to +40°C

–

Humidity: 30% to 95%, not condensed

–

Store the machine indoor, in a clean and dry place, protected from bad weather conditions and with the following values:

Temperature: +1°C to +50°C

–

Humidity: maximum 95%, not condensed

–

(*) When using the sweeper at a temperature between -10°C and 0°C the dust control system cannot be used; moreover the

water tanks and the dust control system itself must be empty.

8

33015500(3)2008-02 RS 501

Page 11

SERVICE MANUAL

ENGLISH

GENERAL INFORMATION

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

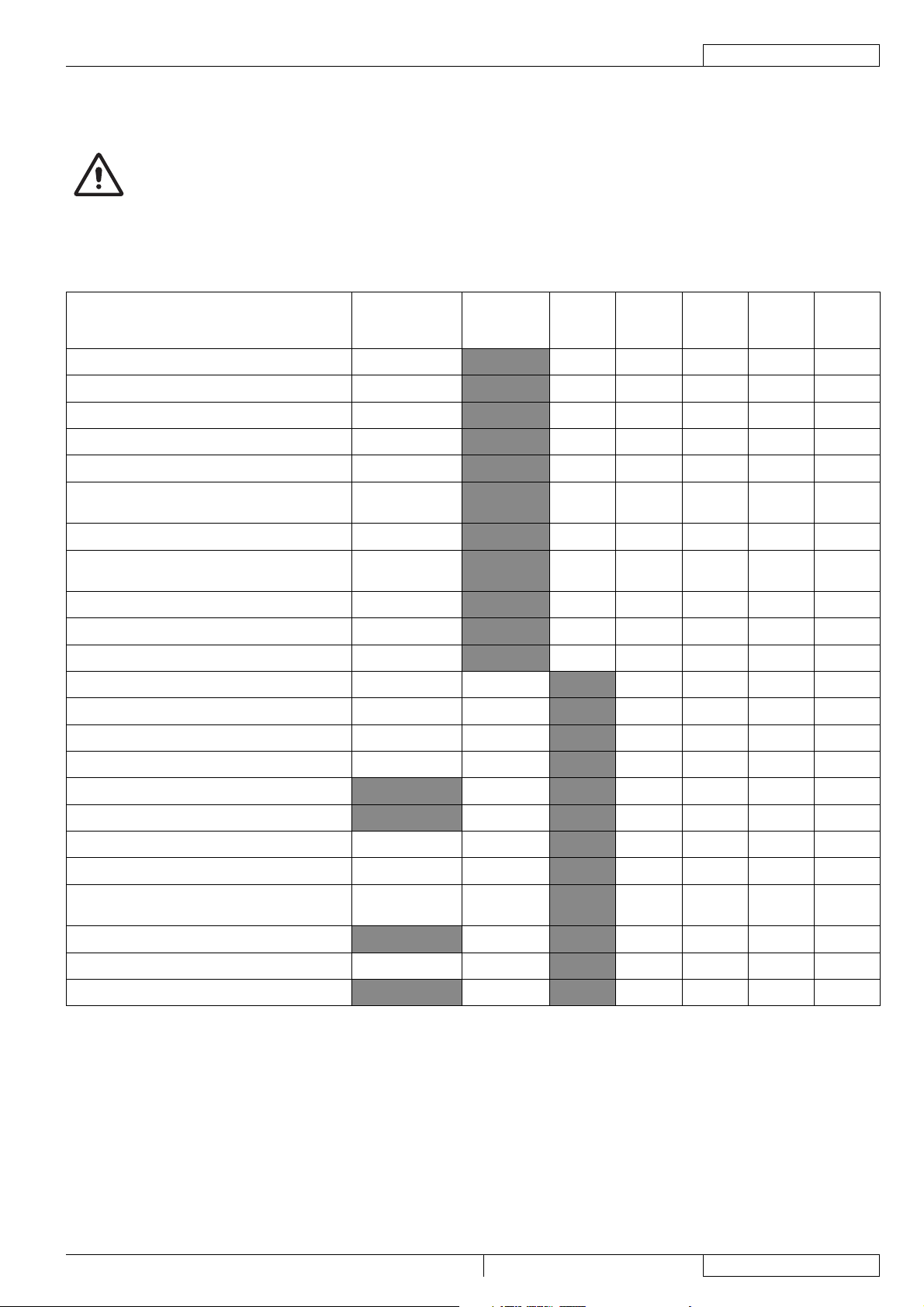

WARNING!

See GENERAL INFORMATION and SAFETY paragraphs.

The following table provides the scheduled maintenance. The intervals shown may vary according to particular working conditions,

which are to be defi ned by the person in charge of the maintenance.

The instructions relating to the maintenance procedures given in the following table are described in the next paragraphs.

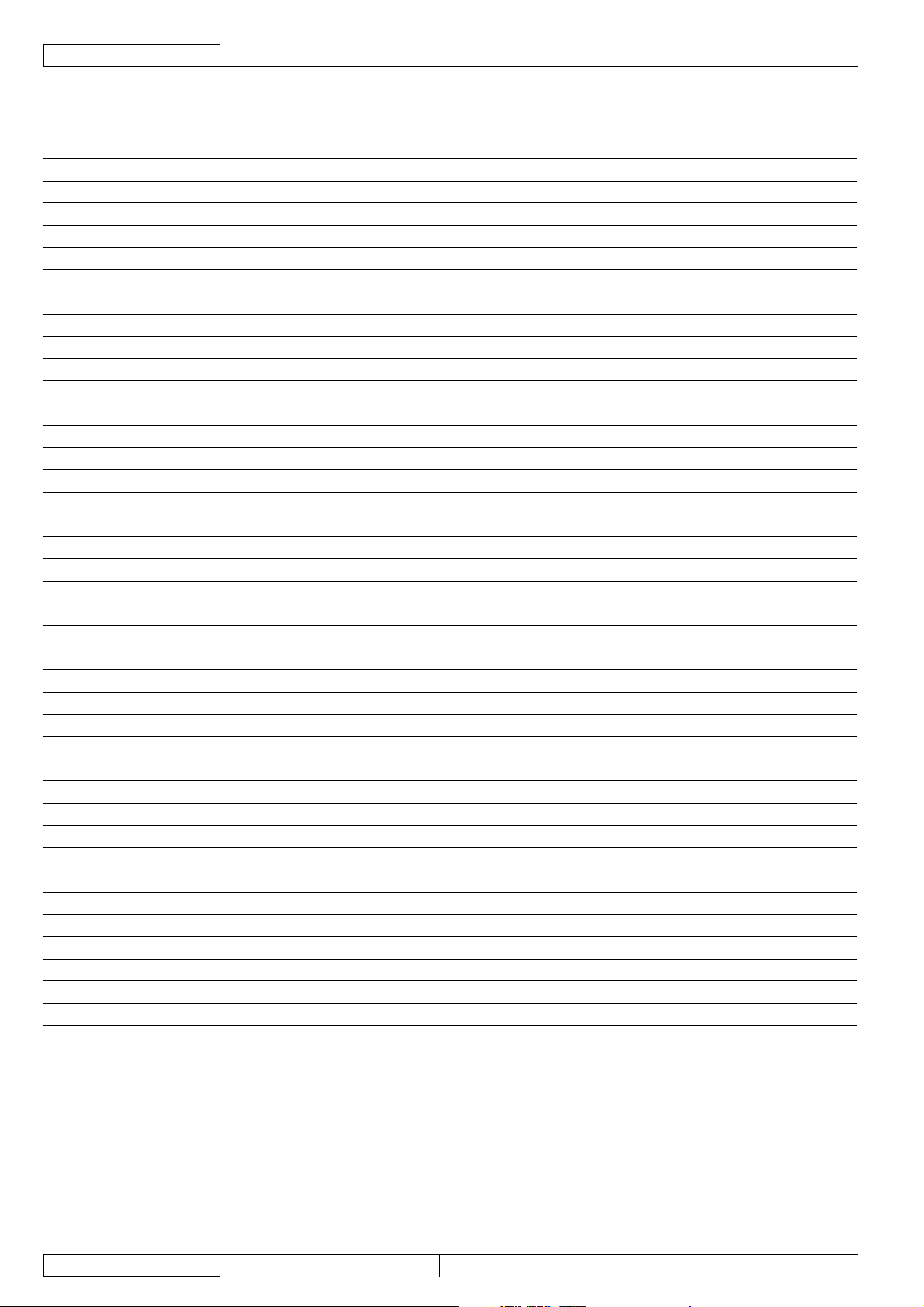

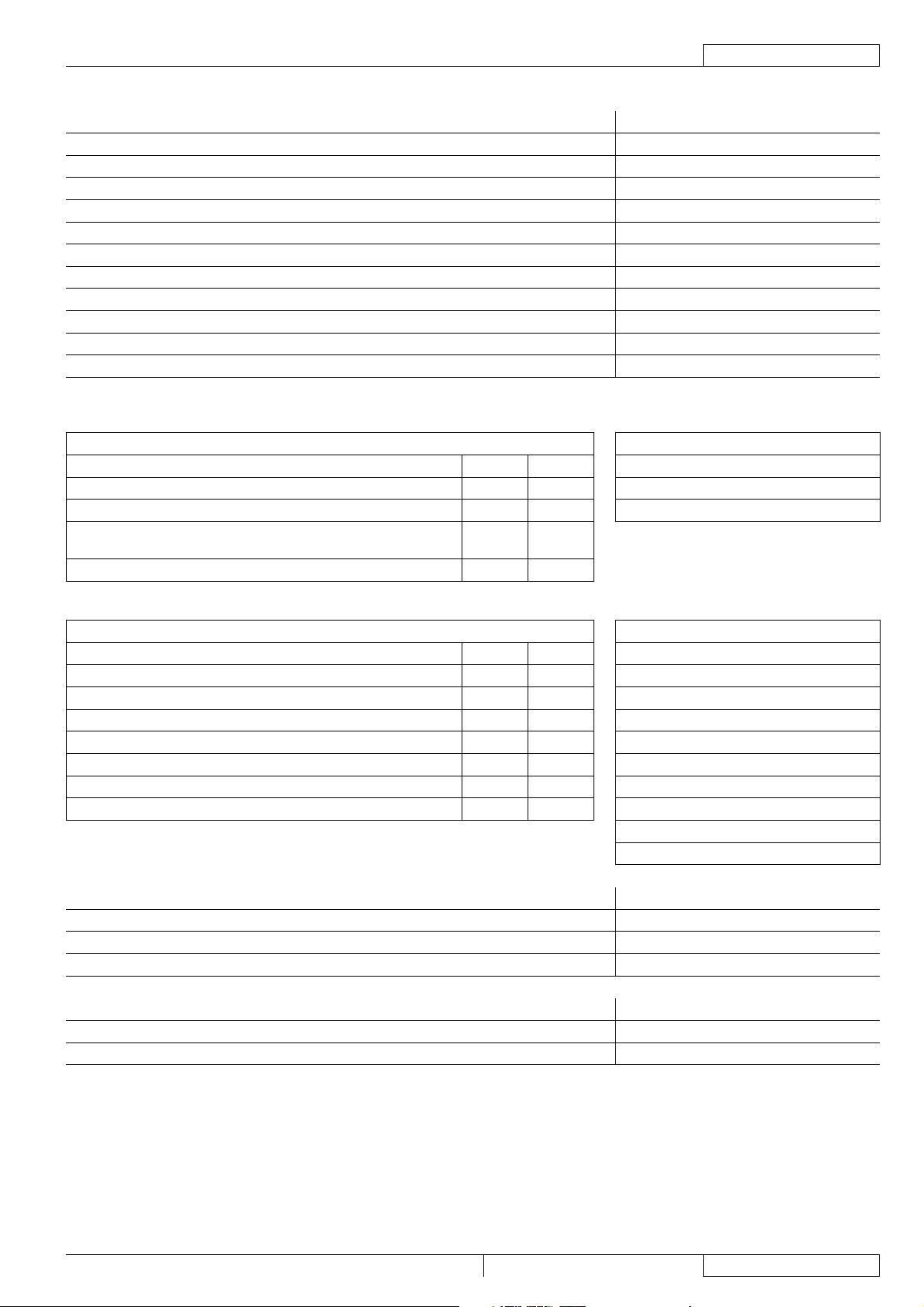

SCHEDULED MAINTENANCE TABLE

Maintenance

Engine oil level check

Engine air fi lter cleaning

Engine radiator fi n cleaning check

Engine coolant level check

Battery fl uid level check

Hydraulic system oil level and drain fi lter effi ciency

check

Hydraulic system oil cooler fi n check and cleaning

Hopper, fi lter and suction hose cleaning, and

gasket check

Dust control system nozzle and fi lter cleaning

Brake fl uid level check

Reverse gear buzzer operation check

Diesel engine start-up safety system check

Tire pressure check

Suction inlet and skirt height and operation check

Running-in

period (after the

fi rst 50 hours)

Every 10

hours or

before use

Every

200

hours

Every

600

hours

Every

1,200

hours

Every

2,400

hours

Long

periods

Side broom position check and adjustment

Engine oil change (7)(8)

Dust control system water fi lter cleaning

Parking brake check

Alternator belt tension check (7)

Climate control system compressor belt tension

check

Diesel engine oil fi lter replacement (7)(8)

Fuel fi lter replacement (7)

Nut and screw tightening and leakage check

RS 501 33015500(3)2008-02

9

Page 12

ENGLISH

SERVICE MANUAL

GENERAL INFORMATION

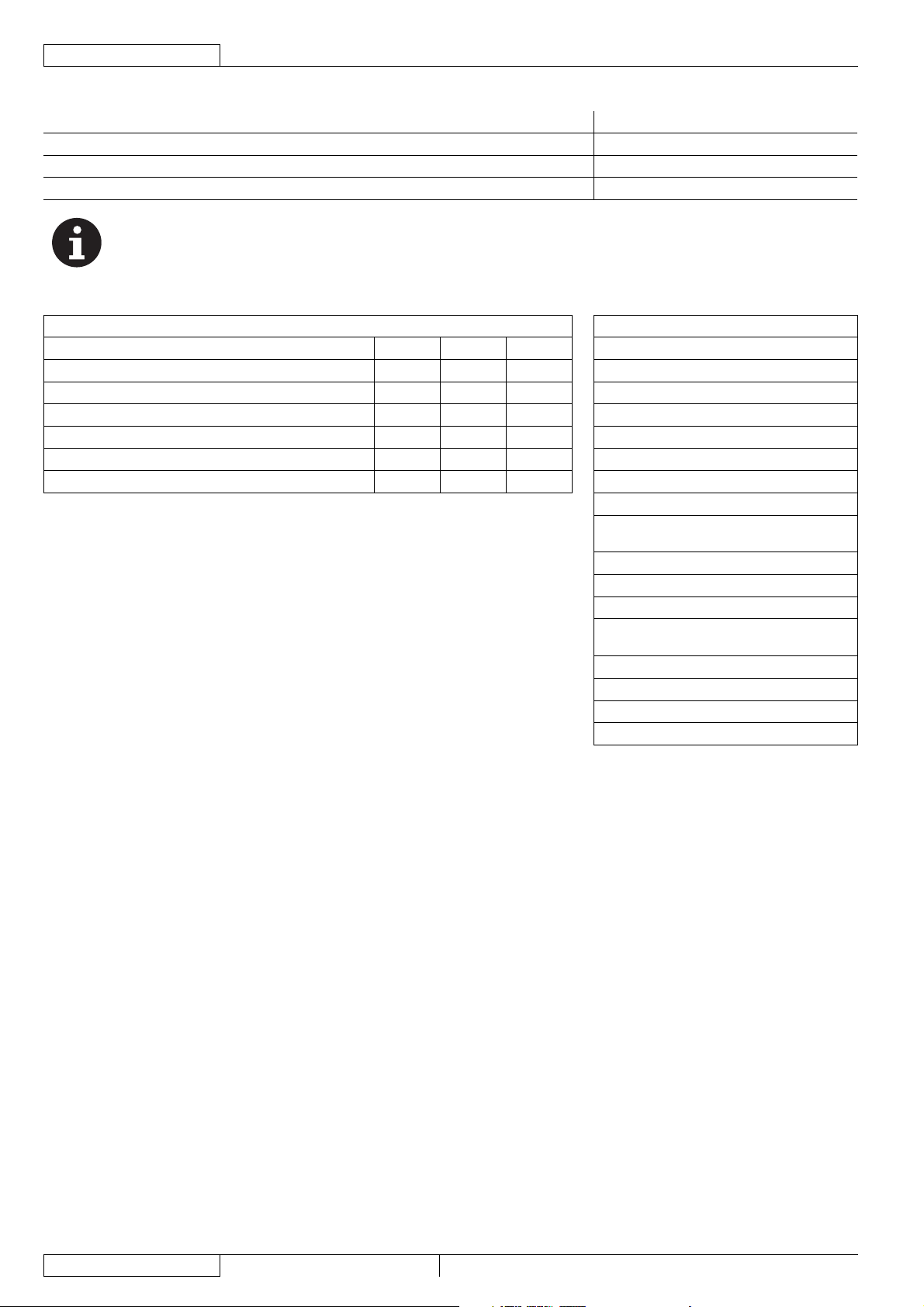

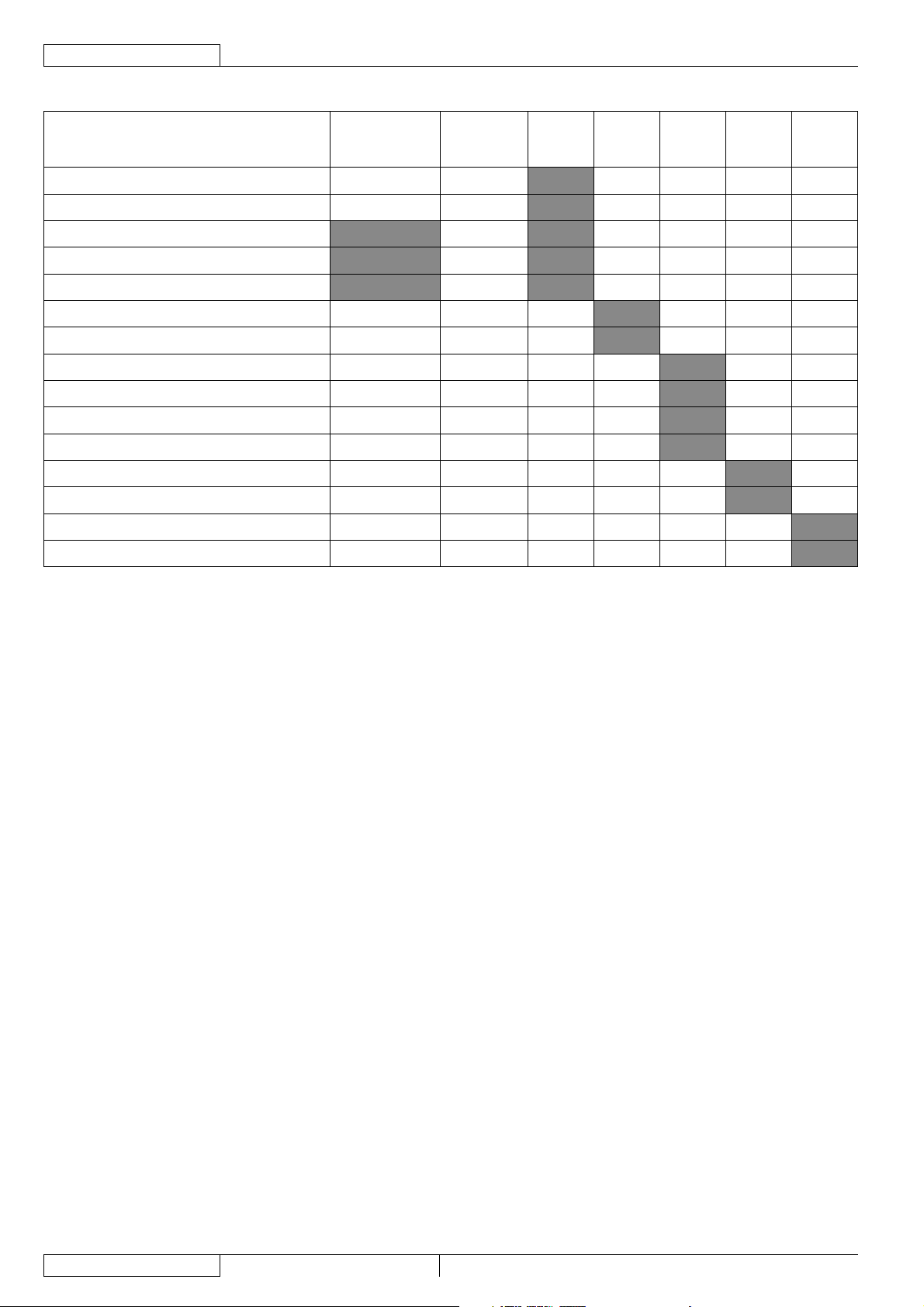

Maintenance

Lubrication

Engine coolant line sleeve check (7)

Drive system pump oil fi lter check

Hydraulic system oil drain fi lter replacement

Hydraulic system oil suction fi lter replacement

Alternator belt replacement (3)

Cab air fi lter replacement (1)

Injector calibration and cleaning (2) (3)

Climate control system belt replacement

Engine coolant change (3)

Hydraulic system oil change (3)

Brake system check

Hydraulic system pump pressure check

Minor engine overhaul (2) (4)

Major engine overhaul (2) (5)

Running-in

period (after the

fi rst 50 hours)

Every 10

hours or

before use

Every

200

hours

Every

600

hours

Every

1,200

hours

Every

2,400

hours

Long

periods

(1) Or every 6 months

(2) Maintenance to be performed by Lombardini authorised Service Center

(3) Or every two years

(4) After 5,000 hours

(5) After 10,000 hours

(7) Every year, if the machine is not frequently used

(8) If a lower-quality oil is used, change it every 125 hours

10

33015500(3)2008-02 RS 501

Page 13

SERVICE MANUAL

ENGLISH

GENERAL INFORMATION

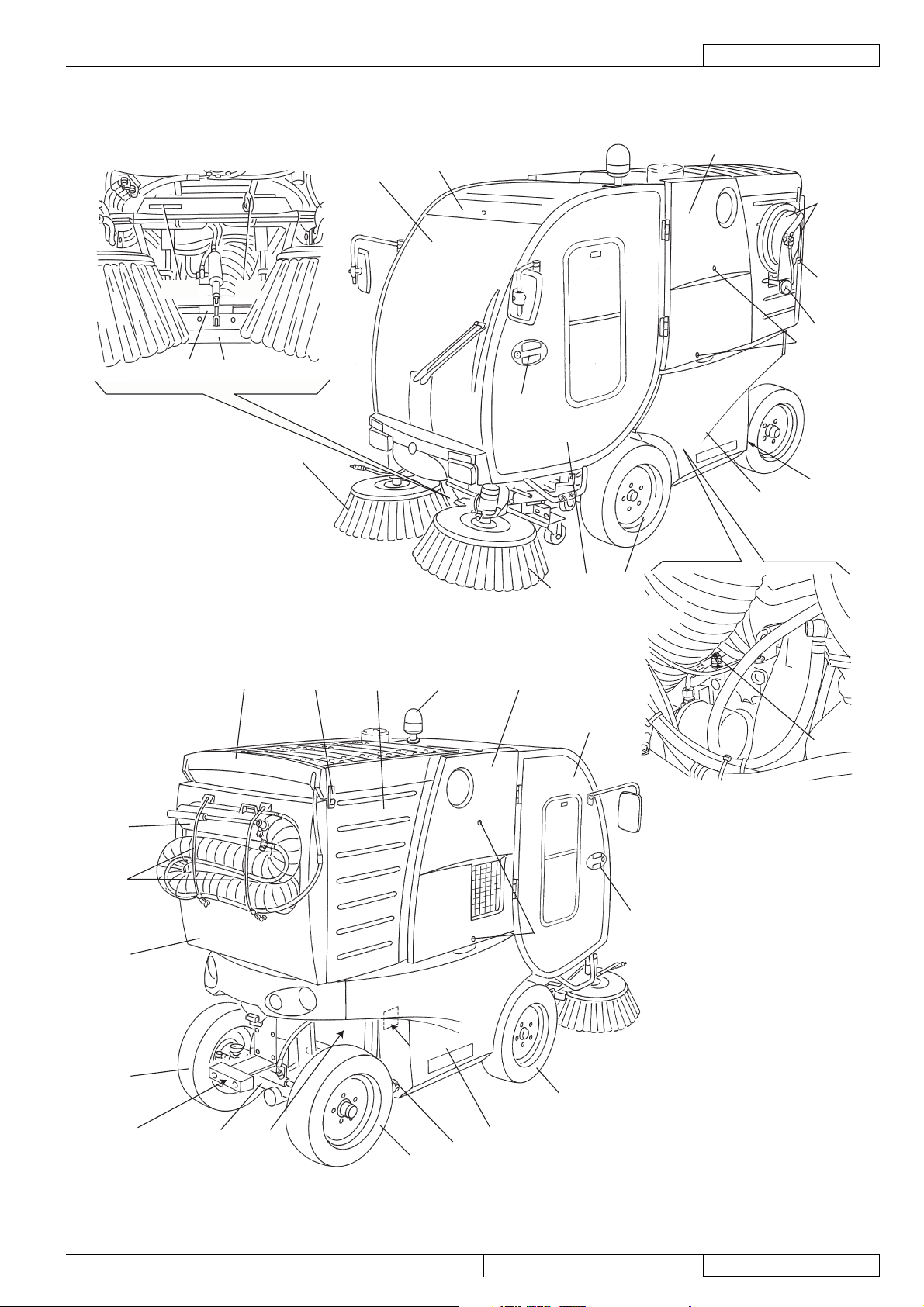

MACHINE NOMENCLATURE

Throughout this Manual you will fi nd numbers in brackets, for example: (2). These numbers refer to the components indicated in

these two nomenclature pages. Refer to these pages whenever it will be necessary to identify a component mentioned in the text.

Cab

1.

Left door

2.

Hopper

3.

Diesel engine

4.

Suction fan

5.

Flashing light

6.

Dust control system left tank

7.

Front fi xed wheels

8.

Rear steering wheels

9.

Right side broom

10.

Left broom

11.

Suction inlet

12.

Right door

13.

Meter and control panel

14.

Rear axle

15.

Dust control system right tank

16.

Rear suction pipe (*)

17.

Left lid

18.

Left lid fasteners

19.

Right lid

20.

Right lid fasteners

21.

Cab right panel

22.

Cab left panel

23.

Right door handle

24.

Left door handle

25.

Hopper lid

26.

Open lid support rod

27.

Lifted hopper locking pins

28.

Lifted hopper locking pins housing

29.

Lifted hopper locking pins holes

30.

Suction fi lter

31.

Drain fi lter

32.

Hydraulic system oil tank

33.

Battery

34.

Hydraulic system oil cooler

35.

Suction inlet-to-hopper pipe

36.

Fuel tank

37.

Hopper manual lifting hand pump (to be used in case of

38.

engine malfunction)

Hydraulic system oil drain fi lter

39.

Hopper lifting device

40.

Dust control system left tank

41.

Left tank mounting screw

42.

Dust control system right tank

43.

Right tank mounting screw

44.

Front towing hook

45.

Engine air fi lter

46.

Fuel tank fi ller neck

47.

Hopper support rods

48.

Left water tank fi ller plug

49.

Right water tank fi ller plug

50.

Brake fl uid tank

51.

Windscreen wiper fl uid tank

52.

Windscreen wiper motor

53.

Combination switch

54.

Steering wheel adjusting lever

55.

Drive pedal

56.

Brake pedal

57.

Steering wheel

58.

Driver’s seat

59.

Suction inlet and brooms control lever

60.

61.

Driver’s seat safety belt (*)

62.

Hopper lifting/lowering lever

63.

Suction activation lever

64.

Cab heater control knob

65.

Diesel engine throttle lever

66.

Parking brake lever

67.

Broom dust control system nozzle valve

68.

Suction inlet dust control system nozzle valve

69.

Skirt lifting switch

70.

Lifted hopper warning light (red)

71.

Hazard warning light switch

72.

Dust control system switch

73.

Cab blower switch

74.

Windscreen wiper/washer switch

75.

Climate control system switch (*)

76.

Ignition key

77.

Dust control system water tank warning light (red)

78.

Warning buzzer (it activates together with the warning

lights 87, 91, 93, 94)

79.

Fuse box B

80.

Fuse box A

81.

Indicators and warning lights

82.

Optional indicator light

83.

Optional indicator light

84.

Engine coolant temperature

85.

High beam indicator light

86.

Running light indicator light

87.

Charged battery indicator light (together with the indicator

light a buzzer activates with intermittent sound)

88.

Parking brake indicator light (together with the indicator

light a buzzer activates with continuous sound)

89.

Glow plug pre-heating warning light

90.

Hour counter/revolution counter display:

•

It displays the hours, when the ignition key (76) is

turned on the fi rst position, before running the engine;

•

It displays the engine speed, when the engine is

running and the charged battery warning light is off.

91.

Low fuel warning light (a buzzer activates together with the

warning light)

92.

Optional indicator light

93.

Engine coolant high temperature warning light (a buzzer

activates together with the warning light)

94.

Engine oil pressure warning light (a buzzer activates

together with the warning light)

95.

Turn signal indicator light

96.

Hopper lid opening/closing switch

97.

Rear bumper

Diesel engine serial number/technical data plate (another

98.

plate showing the same data as the plate affi xed on the

diesel engine)(*)

High-pressure washing system hose with reel (*)

99.

High-pressure water quick coupling (*)

100.

Breather fi lter hood fasteners

101.

Rear suction pipe fastener

102.

Front skirt

103.

Machine serial number

104.

Hopper (dumping position)

105.

Suction hose gasket

106.

RS 501 33015500(3)2008-02

11

Page 14

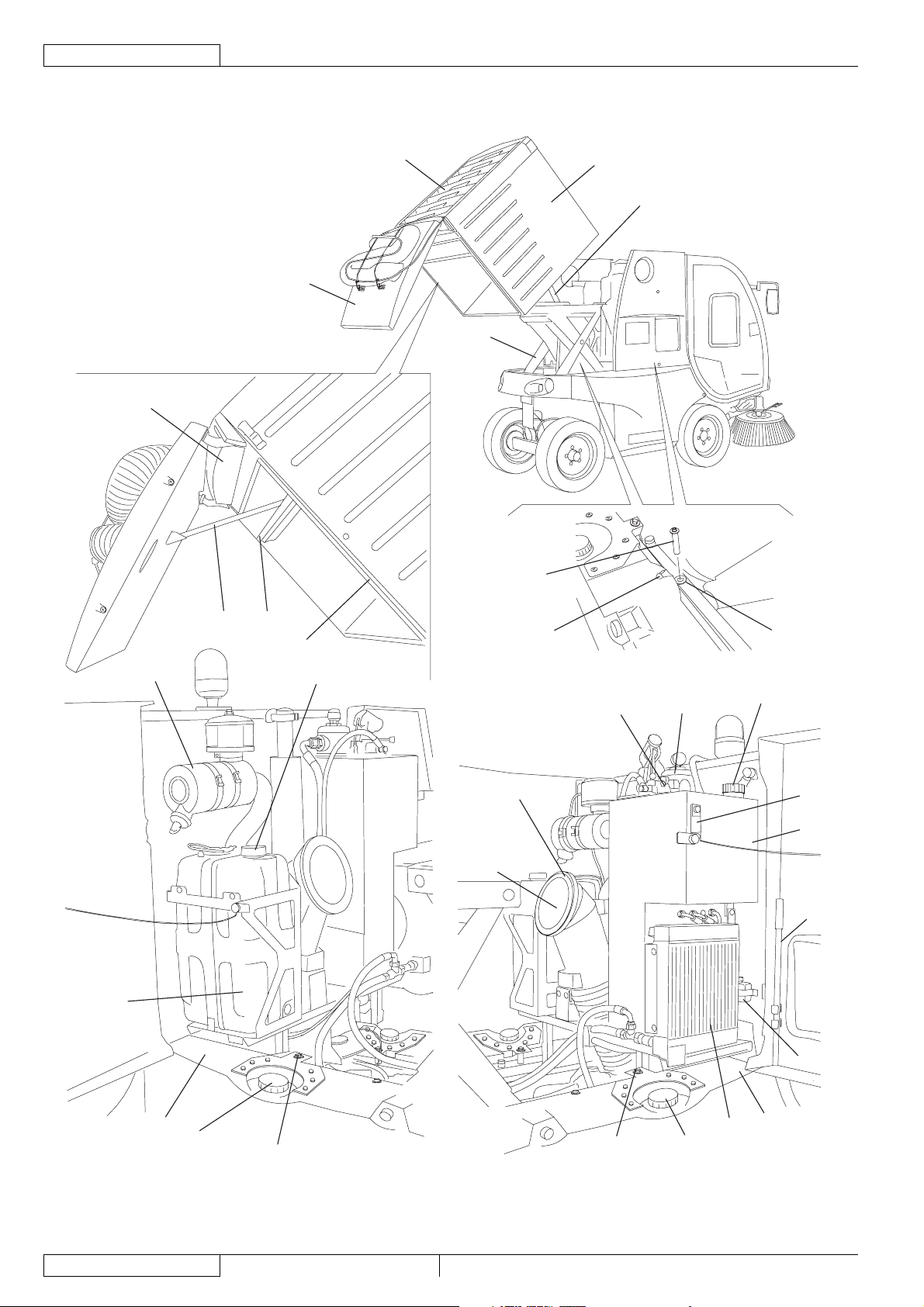

ENGLISH

SERVICE MANUAL

GENERAL INFORMATION

Hopper manual lifting hand pump lever

107.

High-pressure water gun

108.

Serial number plate/technical data/certifi cation marking

109.

Right water tank drain plug

110.

Left water tank drain plug

111.

High-pressure washing system pressure gauge

112.

Breather fi lter hood

113.

Hydraulic system oil fi ller plug

114.

Hydraulic system pressure intake (on drive system pump)

115.

Hydraulic system pressure intake (at suction fan pump)

116.

Hydraulic system pressure intake (at accessory and

117.

steering system pump)

Hopper lid suction sealing gasket

118.

Document holder

119.

Hopper lifting/lowering lever safety fl ange

120.

Suction inlet and broom lifting/lowering lever safety fl ange

121.

Driver’s seat forward/backward adjustment lever

122.

Ashtray

123.

High-pressure water gun sprinkler nozzle

124.

Cigarette lighter

125.

Can holder

126.

Broom speed adjuster (***)

127.

Hydraulic system oil level indicator

128.

(*) Optional for some countries.

12

33015500(3)2008-02 RS 501

Page 15

MACHINE NOMENCLATURE (Continues)

1

14

SERVICE MANUAL

GENERAL INFORMATION

ENGLISH

18

99

104

12

103

45

10

100

112

19

25

111

7

8

2

11

3101113

6

20

13

115

17

102

26

9

97

15

24

21

98

8

4

9

RS 501 33015500(3)2008-02

16

110

S301479

13

Page 16

ENGLISH

SERVICE MANUAL

GENERAL INFORMATION

MACHINE NOMENCLATURE (Continues)

32

26

5

105

48

40

28

37

46

27

31

118

47

36

106

29

38

39

30

114

128

33

107

51

14

41

49

42

33015500(3)2008-02 RS 501

44

50

35

43

S301617

Page 17

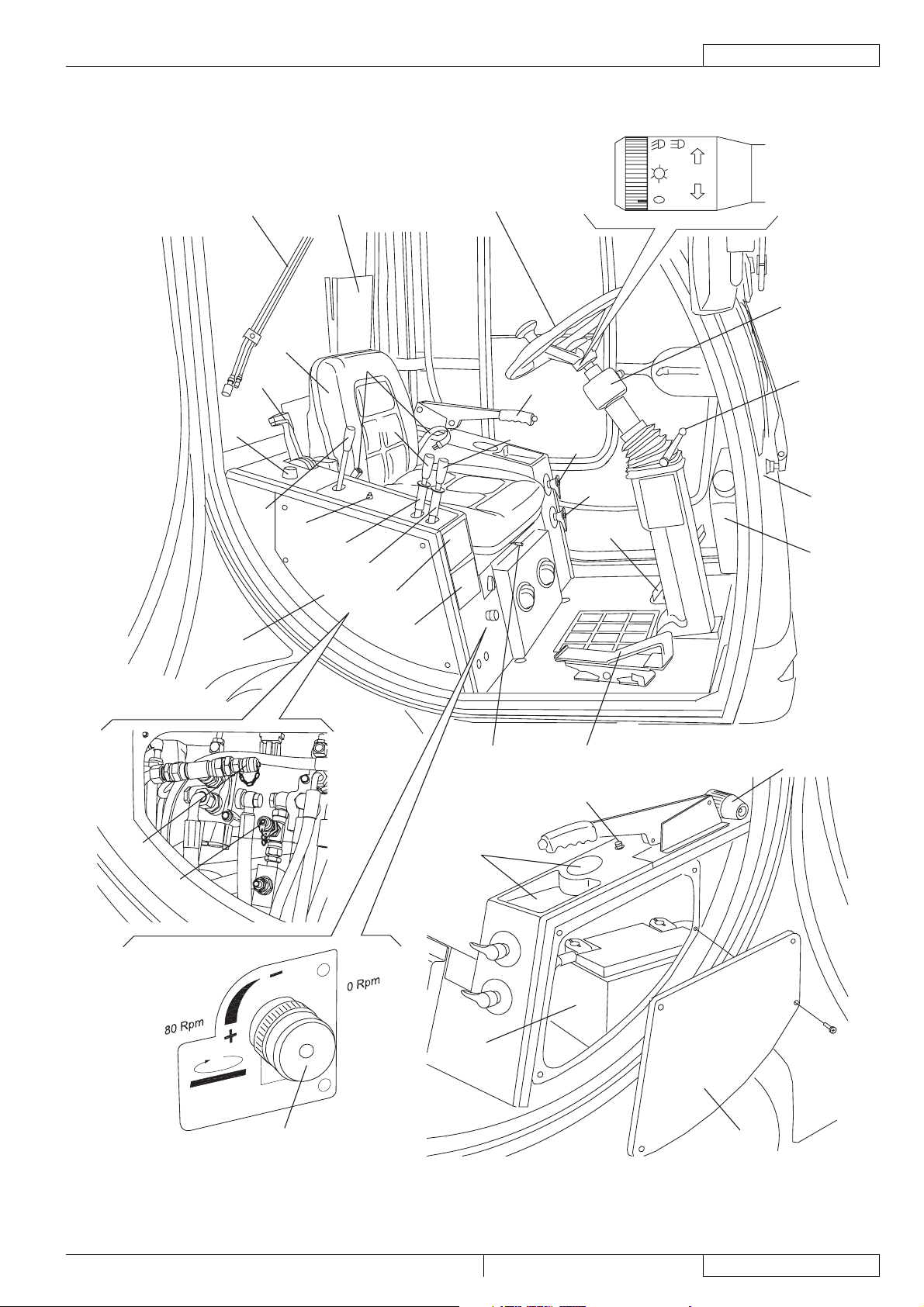

MACHINE NOMENCLATURE (Continues)

SERVICE MANUAL

GENERAL INFORMATION

ENGLISH

64

22

108

65

63

59

69

119

121

61

120

60

123

109

58

62

66

68

67

57

54

55

53

52

116

117

127

126

34

122

56

125

124

23

S301481

RS 501 33015500(3)2008-02

15

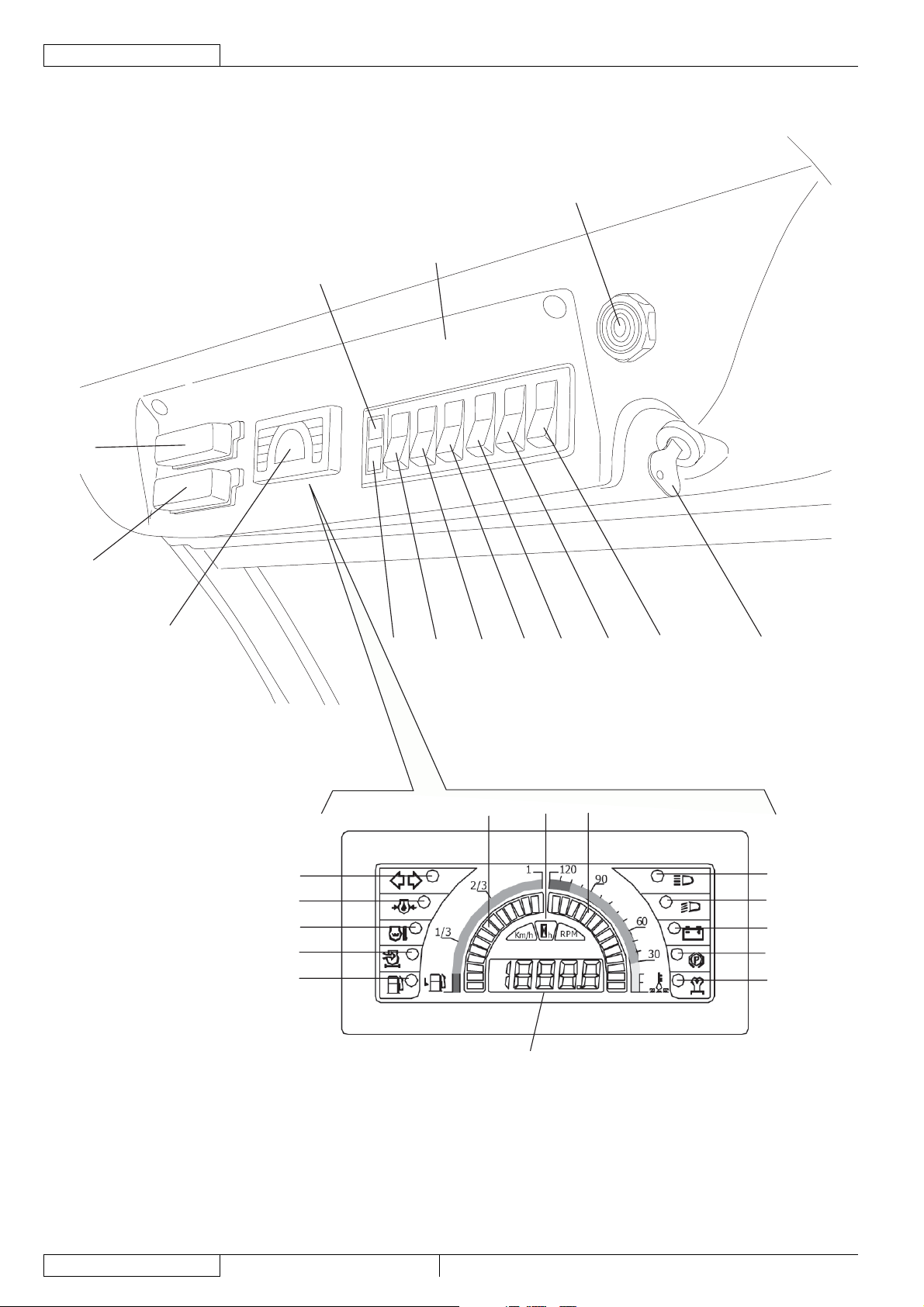

Page 18

ENGLISH

SERVICE MANUAL

GENERAL INFORMATION

MACHINE NOMENCLATURE (Continues)

70

80

78

1

79

81

95

94

93

92

91

77 71

73 74

82

72

83 84

75

96

76

85

86

87

88

89

16

90

S301407

33015500(3)2008-02 RS 501

Page 19

SERVICE MANUAL

SWEEPING SYSTEM

SWEEPING SYSTEM

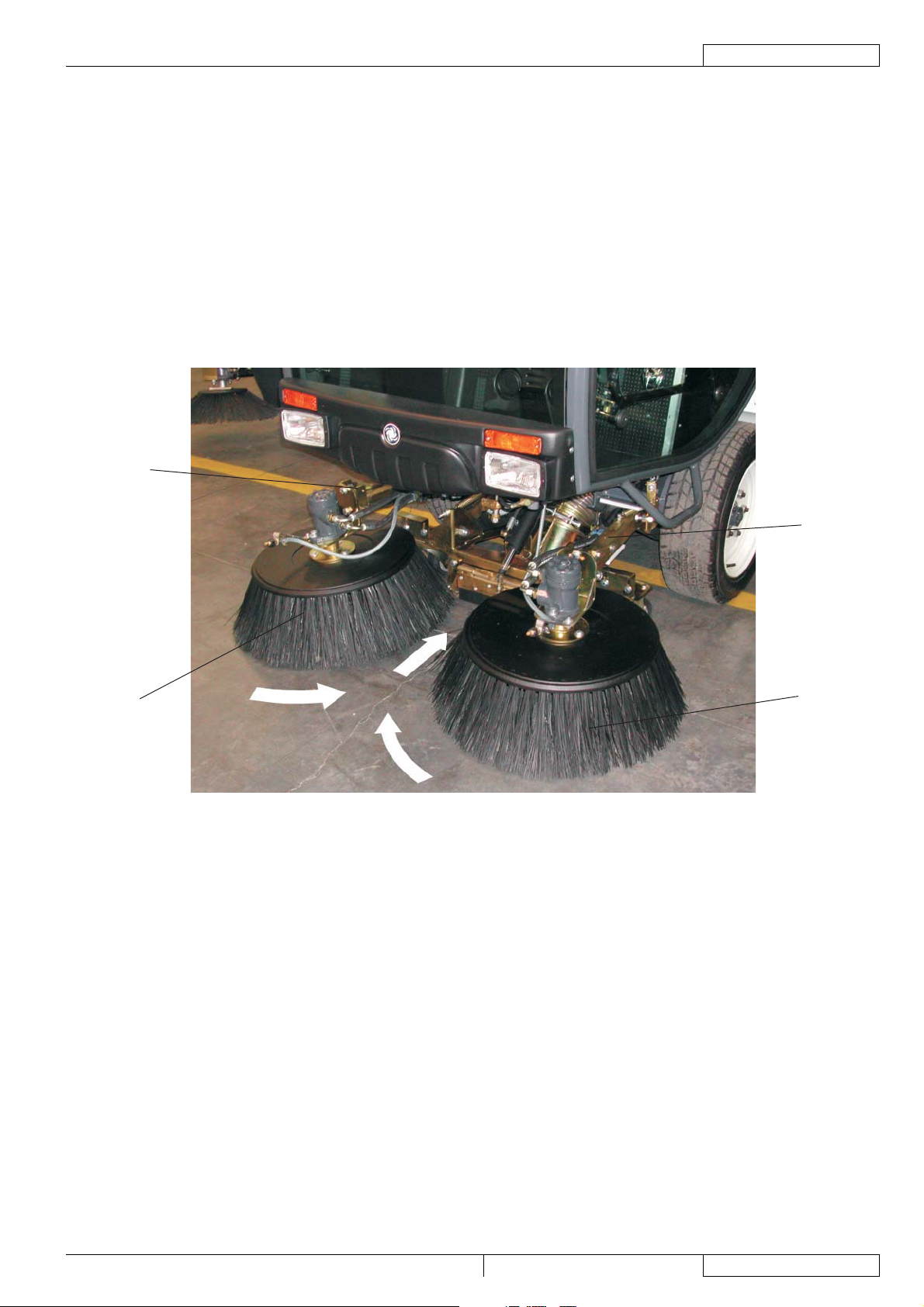

DESCRIPTION

The sweeping system consists of:

A)

Right side broom

B)

Left broom

C)

Broom arms

The brooms (A) and (B) are supported by arms (C) which are fastened to the machine frame.

Broom rotation is activated by hydraulic motors.

For proper sweeping and conveyance of dust and debris towards the suction inlet:

–

Broom height and tilting must be properly adjusted;

–

Proper brooms must be used according to the type of ground to be cleaned. The following types are available:

•

Polypropylene brooms

•

Polypropylene and steel brooms

C

ENGLISH

A

C

B

S300857

RS 501 33015500(3)2008-02

17

Page 20

ENGLISH

SERVICE MANUAL

SWEEPING SYSTEM

TROUBLESHOOTING

The brooms do not clean correctly

Possible causes:

The brooms are not adjusted correctly (adjust).

1.

The broom speed is not correct (adjust).

2.

The brooms do not rotate

Possible causes:

There are oil leaks from the hydraulic system hoses (replace the hoses).

1.

The hydraulic motors are faulty (replace).

2.

The accessory system hydraulic pump does not pressurize the oil in the circuit (check the hydraulic system oil pressure).

3.

18

33015500(3)2008-02 RS 501

Page 21

SERVICE MANUAL

ENGLISH

SWEEPING SYSTEM

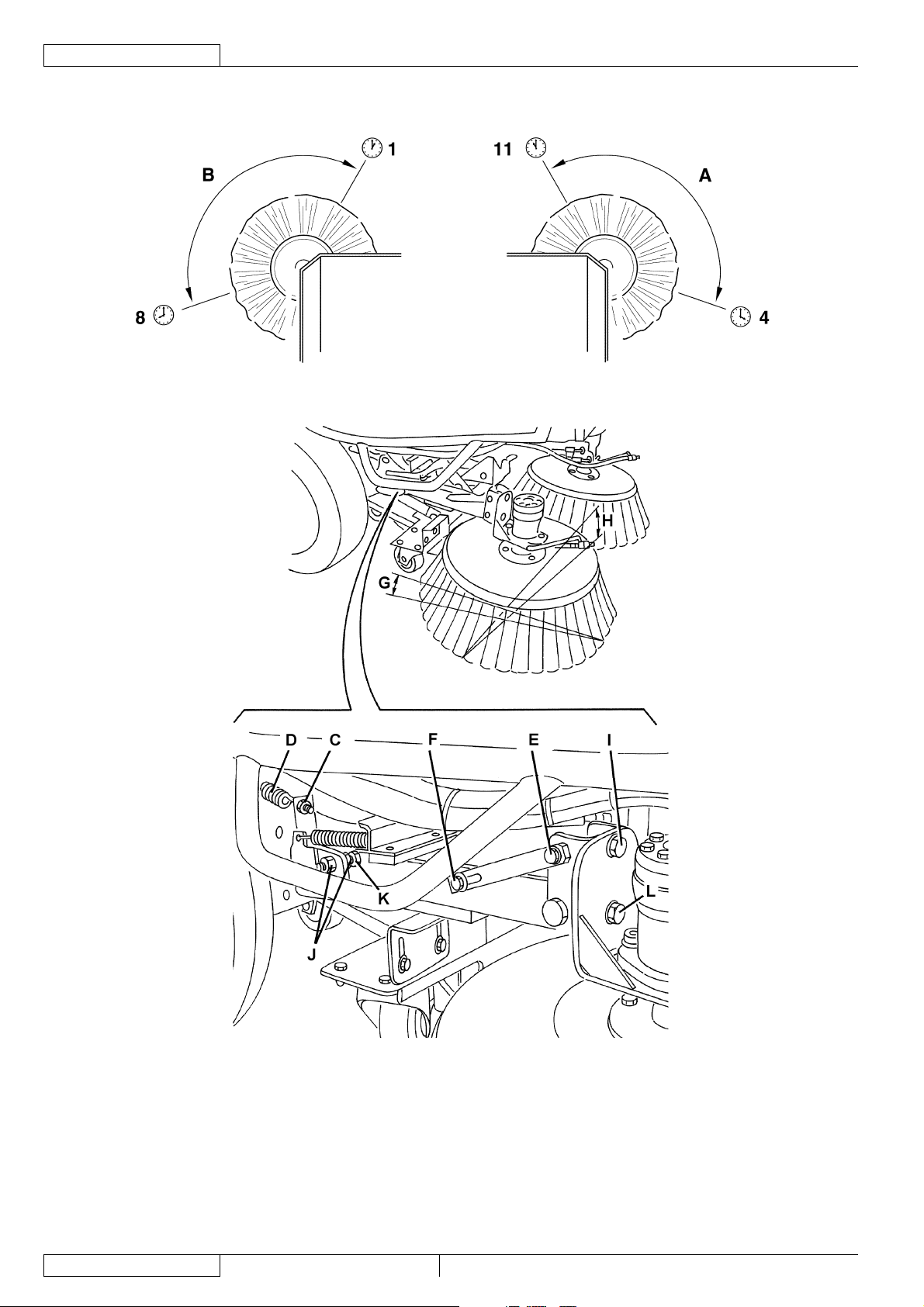

SIDE BROOM POSITION CHECK AND ADJUSTMENT

NOTE

Brooms of various hardness are available. This procedure is applicable to all types of brooms.

Check

Check the side brooms for proper height and tilting, according to the following procedure:

1.

Drive the machine on a level ground.

•

While keeping the machine stationary, fully lower the side brooms and allow them to rotate for a few seconds.

•

Stop and lift the side brooms, then move the machine.

•

Check that the size and orientation of the prints left by the side brooms are as follows:

•

The right side broom must touch the ground along a circle arc (A) ranging from “11 o’clock” position to “4 o’clock” position.

•

The left side broom must touch the ground along a circle arc (B) ranging from “8 o’clock” position to “1 o’clock” position.

•

Adjust the broom height when the prints are out of specifi cation, according to the following procedure.

Engage the parking brake with the lever (66).

2.

Turn the ignition key (76) to OFF position and remove it.

3.

Broom height adjustment

On both sides of the machine, operate on the tensioning self-locking nut (C) of the spring (D) and consider the following:

4.

To lower the broom, the nut (C) must be unscrewed;

•

To lift the broom, the nut (C) must be screwed.

•

Perform step 1 again.

5.

Broom forward tilting angle adjustment

On both sides of the machine, loosen the screws (E) and (F), then adjust the forward tilting angle (G).

6.

When the adjustment is completed, tighten the screws (E) and (F).

Perform step 1 again.

7.

Broom side tilting angle adjustment

On both sides of the machine, loosen the screws (I) and (L), then adjust the side tilting angle (H).

8.

When the adjustment is completed, tighten the screws (I) and (L).

Perform step 1 again.

9.

Broom side position adjustment

The purpose of this adjustment is to improve the side position of the brooms as to the suction inlet (12).

10.

To perform the adjustment, loosen the nuts (J) and operate on the screw (K), thus changing the side position of the brooms.

11.

When the side brooms are too worn out, the adjustment is not possible; replace the brooms according to the instructions in the

12.

relevant paragraph.

RS 501 33015500(3)2008-02

19

Page 22

ENGLISH

SERVICE MANUAL

SWEEPING SYSTEM

SIDE BROOM POSITION CHECK AND ADJUSTMENT (Continues)

20

S301482

33015500(3)2008-02 RS 501

Page 23

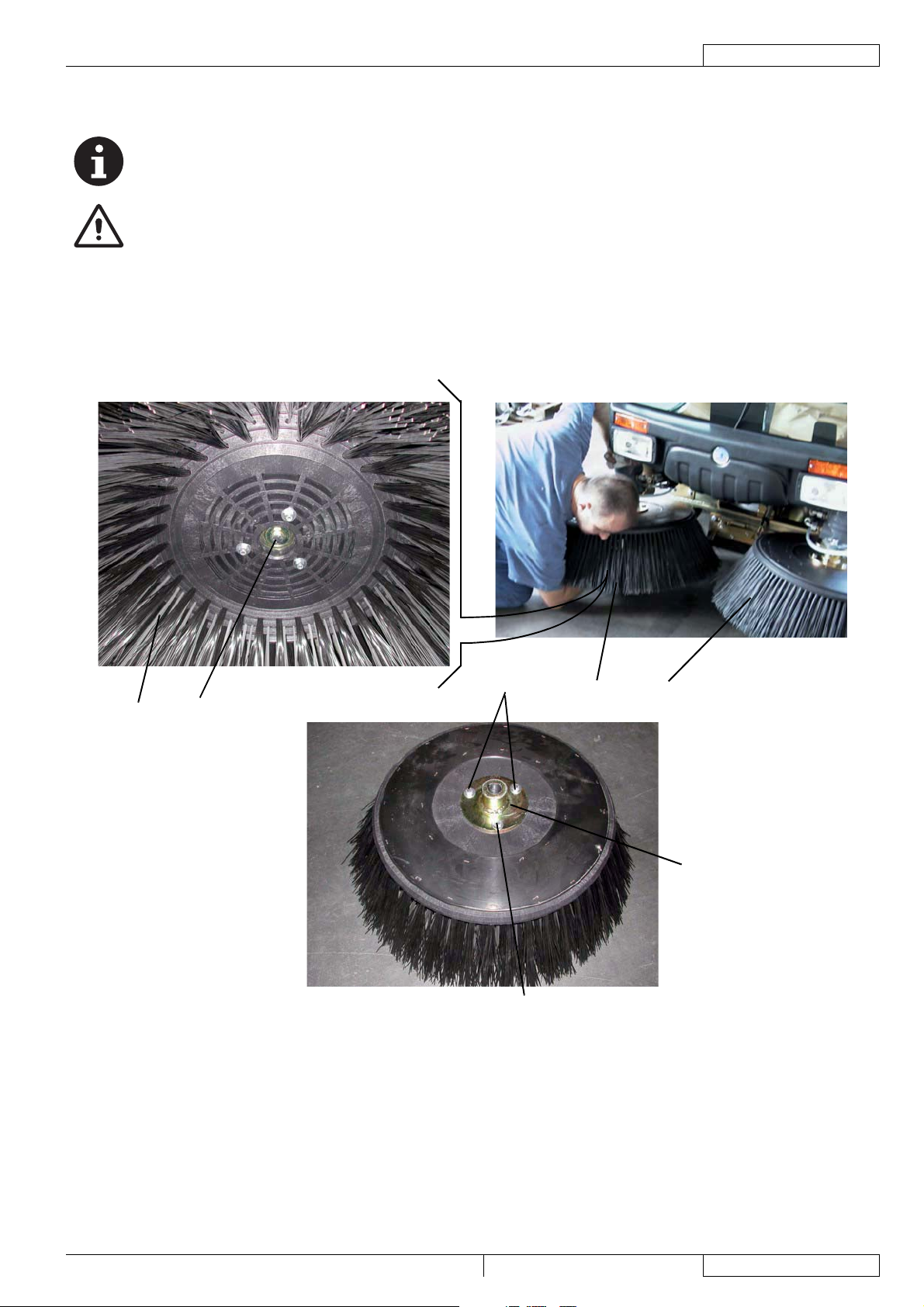

SERVICE MANUAL

BROOM REPLACEMENT

NOTE

Brooms of various hardness are available. This procedure is applicable to all types of brooms.

CAUTION!

It is advisable to use protective gloves when cleaning the side brooms because there can be sharp debris

between the bristles.

1.

Lift the brooms and engage the parking brake with the lever (66).

2.

Turn the ignition key (76) to OFF position and remove it.

3.

Remove the centre screw (A), then remove the broom (B) to be replaced. Recover the key.

4.

Remove the screws (D), then remove the fl ange (E).

5.

Install the fl ange (E) and secure it on the new broom with the screws (D).

6.

Install the new broom (B) with the key, then tighten the centre screw (A).

7.

Adjust the height of the new broom according to the procedure shown in the previous paragraph.

ENGLISH

SWEEPING SYSTEM

B

A

D

D

B

B

E

S300859

RS 501 33015500(3)2008-02

21

Page 24

ENGLISH

SERVICE MANUAL

SWEEPING SYSTEM

BROOM SPEED ADJUSTMENT

Speed measurement

1.

Engage the parking brake with the lever (66).

2.

Turn the ignition key (76) to OFF position and remove it.

Connect a speed measurement indicator with a portable tachometer to the broom (10) or (11).

3.

4.

Start the machine and run the engine at maximum speed and set the broom speed adjuster (127) to maximum speed (as

shown in the User Manual). In this condition, measure the broom speed with the portable tachometer. Turn off the machine.

The broom speed must be: 80 rpm

If necessary, change the broom speed according to the following procedure.

Speed adjustment

5.

Remove the screws and the right panel (22) in the cab.

6.

To change the broom speed, loosen the locknut (A) and turn the screw (B), then tighten the locknut (A).

7.

Perform step 4 again.

22

B

A

S301510

33015500(3)2008-02 RS 501

Page 25

SERVICE MANUAL

ENGLISH

DUST AND DEBRIS COLLECTION SYSTEM

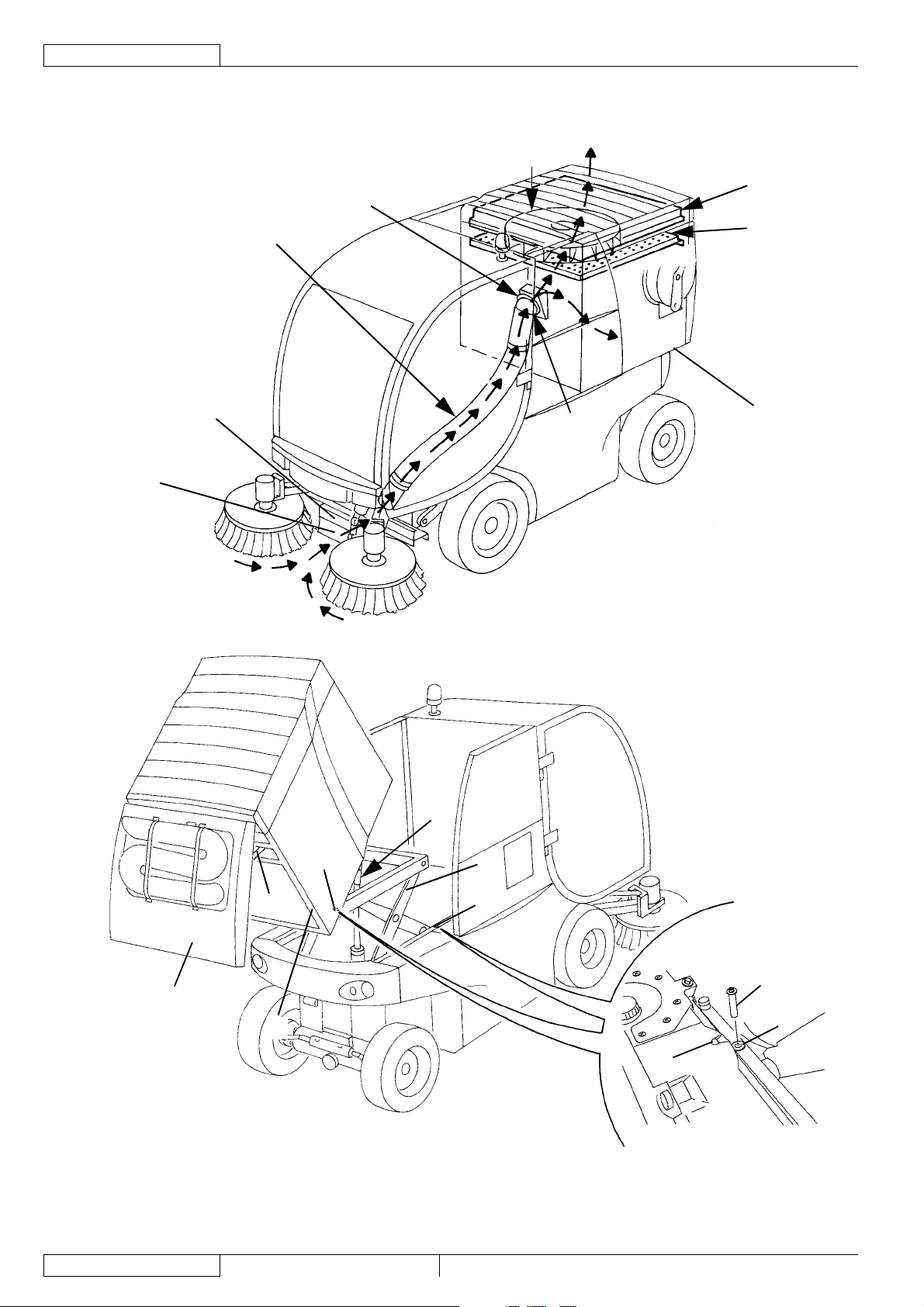

DUST AND DEBRIS COLLECTION SYSTEM

DESCRIPTION

The dust and debris collection system consists of:

Suction fan

A)

Dust and debris suction fi lter

B)

Hopper

C)

Suction hose

D)

Suction inlet

E)

Skirt

F)

Gasket between suction inlet and hopper

G)

Hopper lid

H)

Hopper suction hole

I)

Open lid support rod

J)

Lifted hopper locking pins

K)

Lifted hopper locking pins housing

L)

Lifted hopper locking pins holes

M)

Air breather fi lter

N)

Hopper lid suction sealing gasket

Q)

The suction fan (A), activated by an hydraulic motor, creates vacuum inside the hopper (C). The vacuum determines the suction

capacity of the suction inlet (E) through the suction hose (D).

The hopper (C) is made of steel.

It is fastened with two pins to a mechanic/hydraulic lifting system (O) (for hopper lifting) and to a dumping system (P) (for hopper

tilting). The lid (H), which can be opened with an hydraulic control system, allows for debris discharging.

Both the lid (H) and the suction hole (I) are equipped with gaskets, which allow the suction inlet (E) to reach the maximum suction

capacity.

Inside the hopper there are two stainless steel fi lters having the following functions:

The suction fi lter (B) retains dust and debris during fan suction phase, and makes them settle in the hopper;

–

The breather fi lter (N) retains dust and debris escaped from the suction fi lter, and does not allow them to be discharged

–

externally.

Both fi lters can be easily removed and cleaned.

To perform checks and maintenance procedure safely with the hopper lifted and the lid opened, perform the following procedures:

Turn the rod (J) to lock the lid (H) in open position.

–

Remove the pins (K) from the housings (L) and place them into the holes (M) to lock the hopper (C) in lifted and dumped

–

position.

The suction inlet is made of sheet steel.

It is equipped with three wheels, which allow it to follow the pattern of the surface to be cleaned.

On its front side there is a skirt (F) that must be lifted to collect bulky debris.

RS 501 33015500(3)2008-02

23

Page 26

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

DESCRIPTION (Continues)

G

A

N

D

E

B

C

I

F

H

P

K

J

O

K

K

Q

M

L

S301483

24

33015500(3)2008-02 RS 501

Page 27

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

TROUBLESHOOTING

The suction fan turns but it is not effi cient

Possible causes:

The fi lters are clogged (clean).

1.

The suction hose is clogged (clean).

2.

The suction hose is cut/torn (replace).

3.

The gasket between the suction inlet and the hopper is broken or misadjusted (replace or adjust).

4.

The hopper lid gasket is broken (replace).

5.

There is no pressure at the suction fan motor drive pump (adjust the pump pressure).

6.

The suction fan does not turn

Possible causes:

The motor is faulty (replace).

1.

The control valve assembly is stuck (repair).

2.

The pump is faulty (replace).

3.

The suction inlet does not collect debris effi ciently

Possible causes:

The suction inlet position is incorrect (check the suction inlet and skirt height and effi ciency).

1.

The skirt opening force is not suffi cient

Possible causes:

The skirt opening pressure is incorrect (adjust).

1.

The hopper does not lift/lower

Possible causes:

The control valve assembly is stuck (repair).

1.

The cylinder gaskets are worn (repair the cylinder).

2.

The rear lid does not open/close

Possible causes:

There is no voltage in the actuator (repair the electrical system).

1.

The actuator is faulty (repair/adjust the actuator cams).

2.

ENGLISH

RS 501 33015500(3)2008-02

25

Page 28

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

HOPPER, FILTER AND SUCTION HOSE CLEANING, AND GASKET CHECK

WARNING!

Protect body parts (eyes, hair, hands, etc.) properly, when performing cleaning procedures using compressed

air or water gun.

Preliminary operations

Empty the hopper (3), drive the machine to a cleaning/washing appointed area, then engage the parking brake with the lever

1.

(66).

Lift and dump the hopper (3), according to the procedure shown in the User Manual.

2.

Install the lid support rod (27).

3.

Hopper cleaning

Clean the hopper (H) with pressurised water from a hydrocleaner (G).

4.

Carefully check the suction sealing gasket (U) for integrity, and replace it if necessary.

5.

Suction hose cleaning

Thoroughly clean the suction hose (R) inside, up to the suction inlet, with pressurised water.

6.

Carefully check the suction sealing gasket (V) for integrity, and replace it if necessary.

7.

Suction fi lter cleaning

Inside the hopper, remove the suction fi lter fastener (A).

8.

Remove the suction fi lter (B).

9.

Wash the defl ector (C) and the fan (D) with pressurised water; check that all fan sectors (T) are clean.

10.

Clean the suction fi lter (F) with pressurised water from a hydrocleaner (E).

11.

Install the suction fi lter (B) and secure it with the fastener (A).

12.

Remove the lid support rod (27) and lower the hopper (3) according to the procedure shown in the User Manual.

13.

Turn the ignition key (76) to OFF position and remove it.

14.

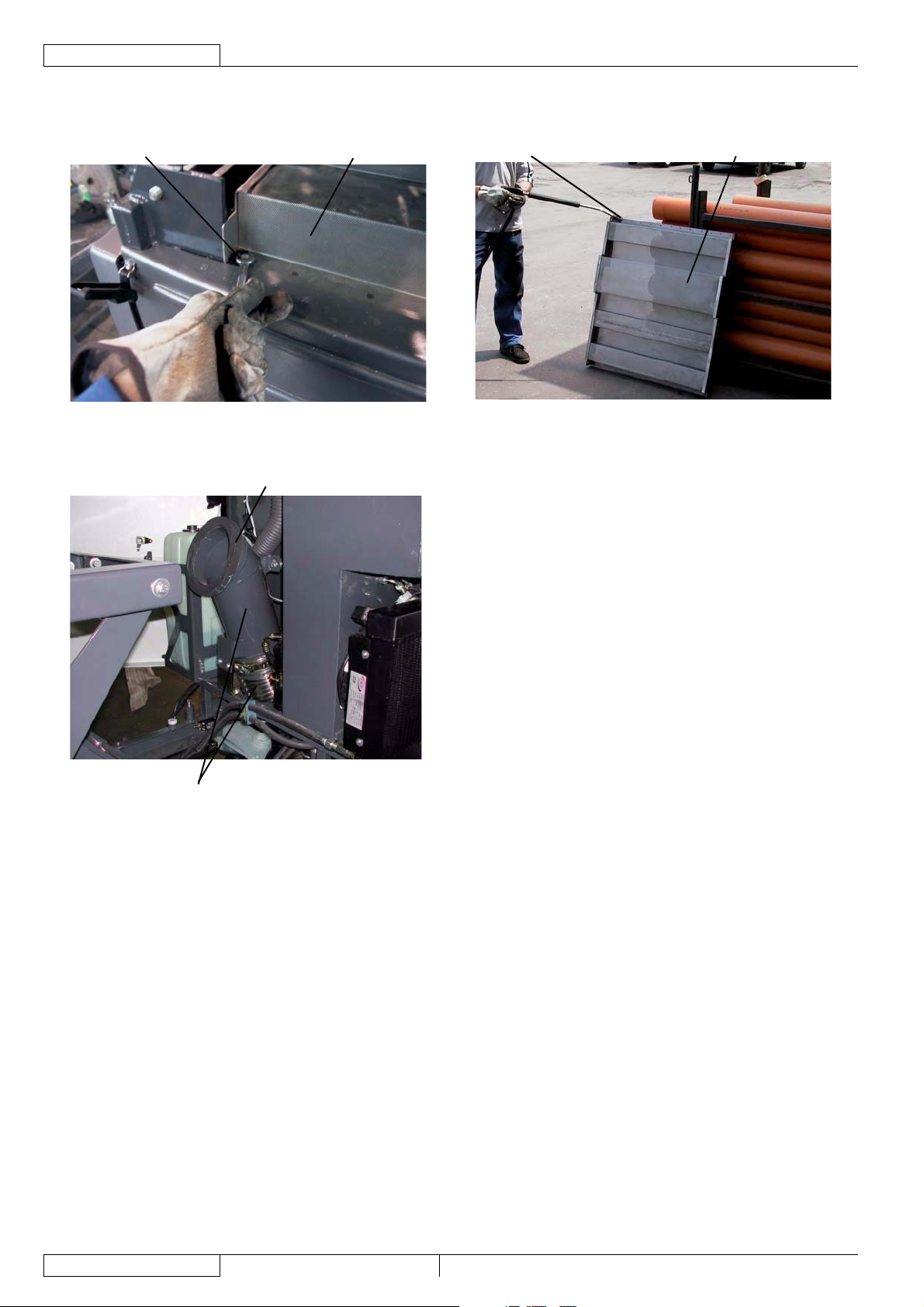

Breather fi lter cleaning

With a ladder and the help of an assistant, disengage the fasteners (I) of the breather fi lter hood (J).

15.

Open the hood (K) and install the safety pin (L).

16.

Remove the mounting screws (M), then remove the breather fi lter (N).

17.

Clean the breather fi lter (P) with pressurised water from a hydrocleaner (O).

18.

Install the breather fi lter and its hood performing steps from 15 to 17 in reverse order.

19.

26

33015500(3)2008-02 RS 501

Page 29

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

HOPPER, FILTER AND SUCTION HOSE CLEANING, AND GASKET CHECK (Continues)

T

A

ENGLISH

D

DCB

F

E

U

H

G

K

L

J

I

S300862

RS 501 33015500(3)2008-02

27

Page 30

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

HOPPER, FILTER AND SUCTION HOSE CLEANING, AND GASKET CHECK (Continues)

NMPO

V

R

S300863

28

33015500(3)2008-02 RS 501

Page 31

SERVICE MANUAL

ENGLISH

DUST AND DEBRIS COLLECTION SYSTEM

SUCTION INLET AND SKIRT HEIGHT AND OPERATION CHECK

Preliminary operations

Engage the parking brake with the lever (66).

1.

Lift the suction inlet (12), according to the procedure shown in the User Manual.

2.

Turn the ignition key (76) to OFF position and remove it.

3.

Suction inlet wheel check

Check that the three wheels (A) of the suction inlet are in good conditions and turn freely (they must not be bent/misshapen

4.

because of bumps or excessive pressure, etc.). Check also that the rubber thickness (B) is not lower than some millimeters.

If necessary replace the wheels (A) (see the procedure in relevant paragraph).

Sliding panel check

Check that the main sliding panel (C) and the front (D) and (E) and rear (H) sliding panels are in good conditions and that their

5.

thickness (F) is not lower than 5 mm, otherwise replace them (see the procedure in the relevant paragraph).

It is important to replace the sliding panels (C), (D), (E), and (H) when they are not completely worn, to avoid damaging the

relevant mounting screws and making them diffi cult to remove.

Replace the sliding panels (C), (D), (E), and (H) as a unit, to avoid steps in the union areas (G), caused by different levels of

wear.

Suction inlet skirt and wheel adjustment check

Check that the skirt (I) is integral and that it does not have excessive tears (J) or lacerations (K), which can affect the suction

6.

inlet operation.

If necessary replace the skirt (I) (see the procedure in the relevant paragraph).

Drive the machine on a level ground and lower the suction inlet (12) according to the procedure shown in the User manual.

7.

Turn the ignition key (76) to OFF position and remove it.

8.

Check that the distance (L) of the skirt from the ground is not bigger than 1 cm. Greater distances can affect the suction inlet

9.

operation.

If necessary replace the skirt (K) (see the procedure in the relevant paragraph).

Also check that, when the three wheels (A) contact the ground, the sliding panels (C), (D), (E), and (H) do not touch the

10.

ground, otherwise the wheels (A) must be replaced to avoid an excessive wear of the sliding panels (for wheel replacement

procedure, see the relevant paragraph).

Start the machine according to the procedure shown in the User Manual, then press the switch (69) and check that the skirt

11.

(I) lifts freely. Check that it lifts also when a force of some kg is applied (simulating to move bottles or other heavy objects that

must then be collected). If necessary, adjust the opening force of the skirt (I) according to the following procedure:

Turn off the machine.

•

Remove the screws and the right panel (22) in the cab.

•

Loosen the control valve locknut (N) and turn the screw (O) as necessary, reminding that:

•

The opening force decreases by loosening the screw;

–

The opening force increases by tightening the screw.

–

When the adjustment is completed, tighten the locknut (N).

•

Install the right panel (22) in the cab and tighten the screws.

•

Reset

Assemble the components in the reverse order of disassembly.

12.

RS 501 33015500(3)2008-02

29

Page 32

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

SUCTION INLET AND SKIRT HEIGHT AND OPERATION CHECK (Continues)

E

A

D

C

G

H

A

G

B

F

F

G

L

J

A

IK

N

O

S301484

30

33015500(3)2008-02 RS 501

Page 33

SERVICE MANUAL

ENGLISH

DUST AND DEBRIS COLLECTION SYSTEM

SUCTION INLET WHEEL DISASSEMBLY/ASSEMBLY

NOTE

To remove the rear wheel (C), the machine must be lifted with an appropriate hoisting system. Otherwise, remove the

suction inlet assembly (D) according to the procedure shown in the relevant paragraph. See the following disassembling

procedures.

Front wheels (A) and (B) removal/installation

Engage the parking brake with the lever (66).

1.

Lift the suction inlet (12), according to the procedure shown in the User Manual.

2.

3.

Turn the ignition key (76) to OFF position and remove it.

4.

On both sides of the machine, loosen the screws (E) and (F), then remove the front wheels (A) and (B).

5.

Install the new front wheels (A) and (B) and fasten them with the screws (E) and (F).

If necessary, perform the suction inlet and skirt height and operation check (see the procedure in the relevant paragraph).

6.

Front wheels (A) and (B), and rear wheel (C) removal/installation

7.

Place the machine on the appropriate hoisting system (if present) and lift it.

If the hoisting system is not available, remove the suction inlet assembly (D) (see the procedure in the relevant paragraph).

8.

Remove the screws (E), (F) and (G), then remove the wheels (A), (B) and (C).

9.

Install the new wheels (A), (B) and (C) and fasten them with the screws (E), (F) and (G).

10.

Perform step 1 again.

11.

If necessary, perform the suction inlet and skirt height and operation check (see the procedure in the relevant paragraph).

A

E

B

D

C

G

F

S301485

RS 501 33015500(3)2008-02

31

Page 34

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

SUCTION INLET SLIDING PANELS DISASSEMBLY/ASSEMBLY

NOTE

To remove the suction inlet sliding panels, the machine must be lifted with an appropriate hoisting system. Otherwise,

remove the suction inlet assembly (D) according to the procedure shown in the relevant paragraph. See the following

disassembling procedures.

Place the machine on the appropriate hoisting system (if present) and lift it.

1.

If the hoisting system is not available, remove the suction inlet assembly (D) (see the procedure in the relevant paragraph).

2.

Remove the mounting screws (A), and (B), then remove the sliding panels (C), (D), and (E).

3.

Install the new sliding panels (C), (D), and (E) and fasten them with the screws (A), and (B).

4.

Also check that, when the wheels (F) contact the ground, the sliding panels (C), (D), and (E) do not touch the ground,

otherwise the wheels (F) must be replaced to avoid an excessive wear of the sliding panels (for wheel replacement procedure,

see the relevant paragraph).

5.

Perform step 1 again.

6.

If necessary, perform the suction inlet and skirt height and operation check (see the procedure in the relevant paragraph).

C

A

F

E

BF

D

C

A

F

S301486

32

33015500(3)2008-02 RS 501

Page 35

SERVICE MANUAL

ENGLISH

DUST AND DEBRIS COLLECTION SYSTEM

SUCTION INLET DISASSEMBLY/ASSEMBLY

Disassembly

1.

Remove the side brooms (see the procedure in the relevant paragraph).

Lower the suction inlet (12), according to the procedure shown in the User Manual.

2.

Engage the parking brake with the lever (66).

3.

Turn the ignition key (76) to OFF position and remove it.

4.

Disconnect the hydraulic system hoses (A) and (B) from the suction inlet (C) and plug them.

5.

Disconnect the dust control system water hose (D).

6.

Remove the nuts (E) and pins (F).

7.

Move the suction inlet (C) forward, and loosen the suction hose clamp (G).

8.

Disconnect the suction hose (H) from the suction inlet.

9.

Remove the suction inlet (C).

10.

Assembly

Assemble the components in the reverse order of disassembly.

11.

If necessary, perform the suction inlet and skirt height and operation check (see the procedure in the relevant paragraph).

F

B

H

A

G

D

E

E

F

C

S301487

RS 501 33015500(3)2008-02

33

Page 36

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

SKIRT REPLACEMENT

Lower the suction inlet (12), according to the procedure shown in the User Manual.

1.

2.

Engage the parking brake with the lever (66).

3.

Turn the ignition key (76) to OFF position and remove it.

4.

Remove the clip (A) and the skirt (B).

5.

Remove the screws (C), then remove the skirt (D).

6.

Install the new skirt (D) and fasten it with the screws (C).

7.

Install the skirt (B) and the clip (A).

8.

Lift the suction inlet (12), according to the procedure shown in the User Manual.

A

B

D

C

S300868

34

33015500(3)2008-02 RS 501

Page 37

SERVICE MANUAL

ENGLISH

DUST AND DEBRIS COLLECTION SYSTEM

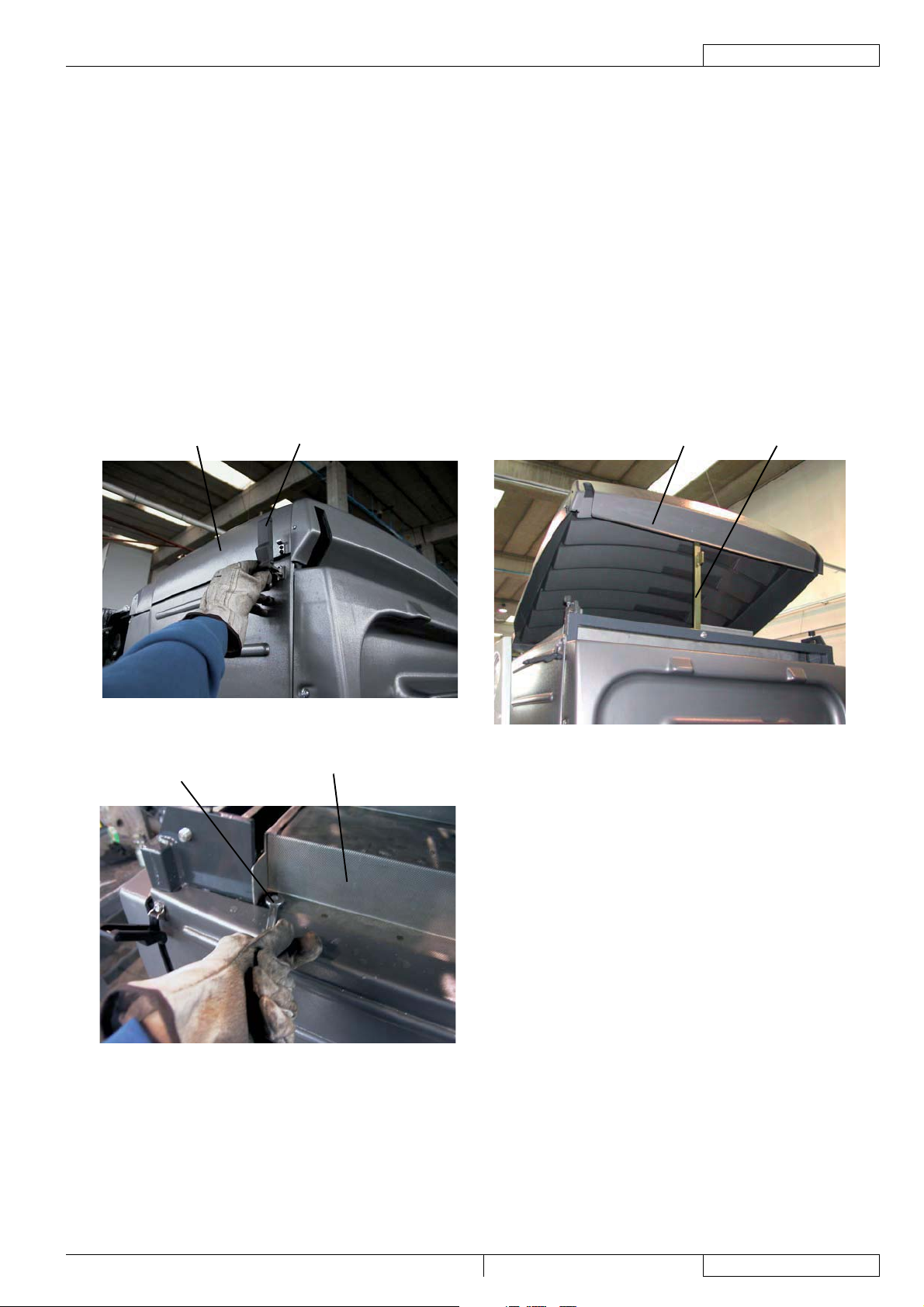

HOPPER POSITION ADJUSTMENT

Empty the hopper (3); if it contains a small quantity of waste, it is not necessary to dump it.

1.

Drive the machine on a solid and level ground, then engage the parking brake with the lever (66).

2.

Open the right and left lids (20) and (18) by releasing the fasteners (21) and (19) with the supplied key.

3.

Lift the hopper (3), according to the procedure shown in the User Manual.

4.

Turn the ignition key (76) to OFF position and remove it.

5.

Remove the locking pins (28) from the housings (29) and place them into the holes (30).

6.

Loosen the locknuts (A).

7.

Insert a lever into the holes (C), then turn the rods (B) as necessary.

8.

Remove the locking pins (28) and place them into the holes (29).

9.

Lower the hopper (3), according to the procedure shown in the User Manual, and check that the profi les (D) match the frame

10.

profi les (E).

If necessary, perform steps 4, 5, 6, 8, 9 and 10 again.

11.

Then perform steps 3, 4, 5 and tighten the locknuts (A).

12.

Lower the hopper (3), according to the procedure shown in the User Manual, and check that the hopper suction hole (F) match

13.

the suction hose gasket (G). If necessary, adjust the position of the suction hose (H) according to the procedure shown in the

following steps.

Perform steps 4, 5 and 6 again.

14.

Loosen the left and right side screws (I) (J) and (L), then adjust the position of the suction hose (H). Tighten the left and right

15.

side screws (I) (J) and (L).

Lower the hopper (3), according to the procedure shown in the User Manual, and check that the hopper suction hole (F) match

16.

the suction hose gasket (G).

Close the right and left lids (20) and (18) by engaging the fasteners (21) and (19) with the supplied key.

17.

RS 501 33015500(3)2008-02

35

Page 38

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

HOPPER POSITION ADJUSTMENT (Continues)

D

A

D

B

A

C

B

C

E

E

F

G

I

H

J

L

S300869

36

33015500(3)2008-02 RS 501

Page 39

SERVICE MANUAL

ENGLISH

DUST AND DEBRIS COLLECTION SYSTEM

HOPPER LID CLOSING ACTUATOR ADJUSTMENT

Preliminary operations

1.

Empty the hopper (3), according to the procedure shown in the User Manual.

Drive the machine on a solid and level ground, then engage the parking brake with the lever (66).

2.

Lift the hopper (3), according to the procedure shown in the User Manual.

3.

Turn the ignition key (76) to OFF position and remove it.

4.

Open the right lid (20) by releasing the fasteners (21) with the supplied key.

5.

Remove the locking pins (28) from the housings (29) and place them into the holes (30).

6.

Remove the screws (A), then remove the cover (B) and the gasket (C) of the actuator (R), under the rear side of the hopper.

7.

Lid safety hook closing

According to the procedure shown in the User Manual, turn the safety hook (D) of the lid (E) to closing position (as shown

8.

in the fi gure); in this condition, loosen the security dowel (F) of the cam (G), and then turn the cam until the microswitch (H)

activates.

Open safety hook warning light adjustment

When the safety hook (D) of the lid (E) is turned to closing position (as shown in the fi gure), loosen the security dowel (I) of the

9.

cam (J), and turn the cam until the corner (K) causes the microswitch (L) to activate and the warning light to turn off.

Lid safety hook opening end-of-stroke adjustment

According to the procedure shown in the User Manual, turn the safety hook (D) of the lid (E) to the opening end-of-stroke; in

10.

this condition, loosen the security dowel of the cam (N), and then turn the cam until the microswitch (O) activates.

NOTE

To maximize cam adjustment consider the following:

The cam turns in the direction shown by the arrow (P) when the hook (D) opens;

–

The cam turns in the direction shown by the arrow (Q) when the hook (D) closes.

–

To check the cam proper adjustment, open and close the hook (D) several times.

11.

Reset

12.

Perform steps 3 to 7 in the reverse order.

B

CR

A

S300964

RS 501 33015500(3)2008-02

37

Page 40

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

HOPPER LID CLOSING ACTUATOR ADJUSTMENT (Continues)

P

G

Q

F

I

NH

L

O

D

E

J

38

K

S300965

33015500(3)2008-02 RS 501

Page 41

SERVICE MANUAL

ENGLISH

DUST AND DEBRIS COLLECTION SYSTEM

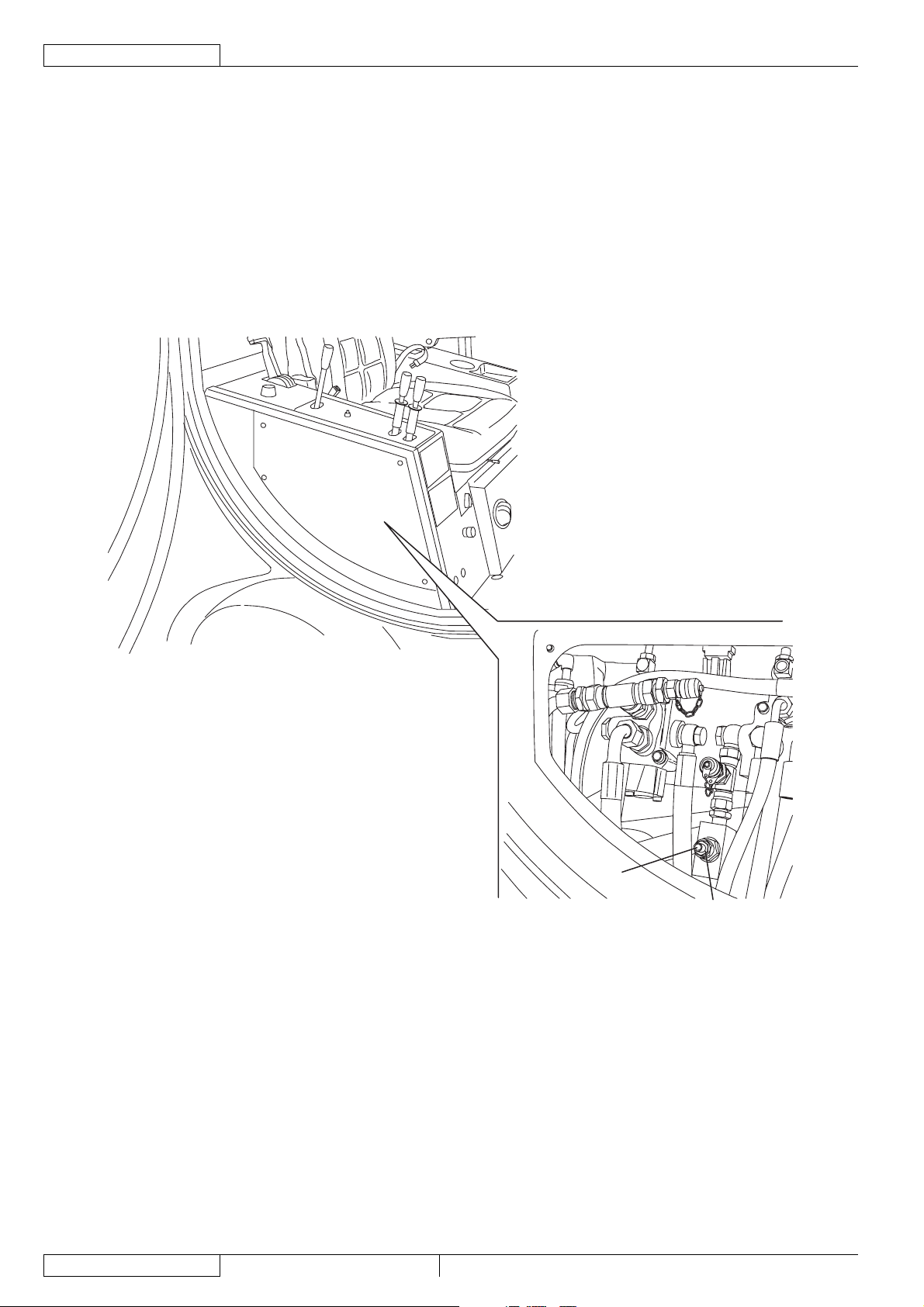

MOTOR AND SUCTION FAN DISASSEMBLY/ASSEMBLY

Disassembly

1.

Engage the parking brake with the lever (66).

Turn the ignition key (76) to OFF position and remove it.

2.

With a ladder and the help of an assistant, disengage the fasteners (A) of the breather fi lter hood (B).

3.

Open the hood (C) and install the safety pin (D).

4.

Remove the mounting screws (E), then remove the breather fi lter (F).

5.

Disconnect the hoses joints (G) and (H) from the suction fan motor (I).

6.

Remove the mounting nuts (J) of the fl ange (M).

7.

With an appropriate hoisting system, remove the suction fan motor assembly (K) by removing the silicone along the perimeter

8.

(L) of the fl ange (M), then sling the assembly (K) by placing a rope around the motor (I) and the fi ttings (N).

At the workbench, remove the screw (O) and the fan (P).

9.

Remove the nuts (Q) from the screws (R).

10.

Remove the motor (I) from the fl ange (M).

11.

Assembly

12.

Assemble the components in the reverse order of disassembly and note the following:

•

Remove the silicone along the perimeter (L) of the fl ange (M) and from the fl ange housing on the hopper.

•

Apply new silicone along the perimeter (L) of the fl ange (M).

B

A

CD

E

F

S300870

RS 501 33015500(3)2008-02

39

Page 42

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

MOTOR AND SUCTION FAN DISASSEMBLY/ASSEMBLY (Continues)

Q

N

H

N

G

J

M

P

K

L

R

O

40

S301488

33015500(3)2008-02 RS 501

Page 43

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

SUCTION HOSE DISASSEMBLY/ASSEMBLY

Preliminary operations

1.

Empty the hopper (3); if it contains a small quantity of waste, it is not necessary to dump it.

Drive the machine on a solid and level ground, then engage the parking brake with the lever (66).

2.

Lift the hopper (3), according to the procedure shown in the User Manual.

3.

Turn the ignition key (76) to OFF position and remove it.

4.

Open the right and left lids (20) and (18) by releasing the fasteners (21) and (19) with the supplied key.

5.

Remove the locking pins (28) from the housings (29) and place them into the holes (30).

6.

Disassembly

Loosen the clamp (A) and disconnect the suction hose (B) from the suction inlet (C).

7.

Loosen the left and right side mounting screws (D) of the suction hose upper end (E).

8.

Remove the suction hose (F) by pulling it upwards.

9.

Assembly

Assemble the components in the reverse order of disassembly and note the following:

10.

For a easier installation of the suction hose (B) into the suction inlet (C), apply a thin coat of grease on the sliding parts.

•

ENGLISH

B

D

F

E

D

D

A

C

S300874

RS 501 33015500(3)2008-02

41

Page 44

ENGLISH

SERVICE MANUAL

DUST AND DEBRIS COLLECTION SYSTEM

42

33016312(0)2007-04 RS 501 UK

Page 45

DUST CONTROL SYSTEM

DESCRIPTION

The dust control system consists of:

A)

Right water tank

B)

Left water tank

Tank fi ller plugs

C)

Broom nozzles

D)

Suction inlet nozzles

E)

Water fi lter

F)

Hose

G)

Water level indicator

H)

Nozzle pump

I)

Taps

J)

Rear suction pipe nozzle

K)

Opening tap

L)

Tank drain plugs

M)

The water gun connected to the dust control system consists of:

Water gun pump

N)

Quick coupling

O)

Water gun

P)

Hose

Q)

Reel

R)

Pressure gauge

S)

QR

SERVICE MANUAL

DUST CONTROL SYSTEM

ENGLISH

D

D

K

G

A

I

J

E

E

C

M

S

P

O

B

B

I

J

F

J

J

N

E

O

C

L

P

K

DD

A

H

N

F

M

RS 501 33015500(3)2008-02

S301489

43

Page 46

ENGLISH

SERVICE MANUAL

DUST CONTROL SYSTEM

TROUBLESHOOTING

No water from the nozzles

Possible causes:

The water fi lter is clogged (clean/replace).

1.

The nozzles are clogged (clean).

2.

No water to the nozzles

Possible causes:

The water pump relay is burned (replace).

1.

The pump does not work (repair/replace).

2.

44

33015500(3)2008-02 RS 501

Page 47

SERVICE MANUAL

ENGLISH

DUST CONTROL SYSTEM

NOZZLE AND FILTER CLEANING

WARNING!

Protect body parts (eyes, hair, hands, etc.) properly, when performing cleaning procedures using compressed

air or water gun.

Preliminary operations

Engage the parking brake with the lever (66).

1.