Nilfisk-ALTO POSEIDON 5-32 PAXT, POSEIDON 5-41 PAXT, POSEIDON 5-47 PA, POSEIDON 5-41 PA, POSEIDON 5-56 PA Service Manual

...Page 1

POSEIDON 5 - NA5

SERVICE MANUAL

ENGLISH

Page 2

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Preface

This service manual contains detailed description of the main repair work on the cold HPW

POSEIDON 5 - NA5.

Repair work requires a suitable testing workplace with the necessary water and power supply.

If operating errors are evident, refer the customer to the operating instructions.

A fault in the cleaner can have several causes as described in the section on troubleshooting.

Refer to the illustrated spare parts lists during repairs. They show the assembly position and the

sequence in which the individual components should be assembled.

See ”Technical Service Bulletin (TSB) sheets. They include information on technical

modifications that have been made after this repair manual was printed.

”Technical Service Bulletin” sheets are also valid as a supplement to the spare parts list until

publication of a new edition.

Repair manuals and ” Technical Service Bulletin” sheets should be available at the site

where repairs are carried out.

It is not permitted to give them to third parties.

Use original Nilfisk-ALTO spare parts only.

Page 3

A.

B.

C.

D.

E.

F.

G.

H.

I.

Special tools /Spare parts

Wiring diagrams

Adjustment / Test

Service / Repair

Troubleshooting

Function

Construction

Technical data

Safety instructions

66

59-65

56-58

47-55

43 -46

36 -42

30 -35

6 -29

5

Page 4

Index

4

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

A. Safety instructions ................................................... 5

B. Technical data .......................................................... 6

C. Constrution

-Overview Unit: .......................................................... 30

- Overview complete motor/pump .............................. 31

D. Function

-Electrical ................................................................... 36

-Funktion PCB ............................................................ 37

-Schematic function .................................................... 39

E. Troubleshooting

-Table ......................................................................... 43

- Failure description .................................................... 45

F. Service / Repair

-Indification ................................................................. 47

-Chassis ..................................................................... 47

-Unloader/ By-pass valve ........................................... 48

-Pump ....................................................................... 50

-Wobble disc / motor ................................................. 54

G. Adjustment / Test

- Torque settings ........................................................ 56

Page 5

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Safety instructions

5

A

For your own safety

ESD measures

(electrostatic discharge)

Observe valid safety regulations

for electrical equipment. In

particular, observe the following

regulations:

IEC 60335-2-79

EN 60335-2-79

Additionally:

Also see national regulations

Before using the cleaner, always

read the operating instructions

and keep them readily available.

Repair work should be carried

out by persons instructed in

electrical installations or by

trained electricians only.

Take the following ESD precautions before carrying out any

repairs to the electronics:

Touch the earth conductor before repairing the cleaner

( to discharge electrostatic charge from your body ).

Wear wrist band if necassary.

Use a conductive floor covering or a conductive table cover.

Never touch the printed circuit board or electronic components

( always hold on to plastic ).

Transport electronic components in conductive packaging

( e.g. ESD bag ).

Page 6

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

6

B

Parent item no: Description:

107146700 POSEIDON 5-32 PA 230/1/50 UK

Service data Unit Value

Model

POSEIDON 5-32 PA

Item no. →

107146700

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

91

Pressure gun outlet @ Qiec bar

82

Retaining pressure* bar

145

Flow. Qiec l/min

9,7

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

Castrol ALPHASyn 150

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420558

Unit Data:

Nozzle size, water

NT 0475

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

82

Impactfactor calculated

2,6

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

68

Size - Machine alone L x W x H mm

735x570x1020

Page 7

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

7

B

Parent item no: Description:

107146701 POSEIDON 5-32 PAXT 230/1/50 UK

Service data Unit Value

Model

POSEIDON 5-32 PAXT

Item no. →

107146701

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

94

Pressure gun outlet @ Qiec bar

82

Retaining pressure* bar

145

Flow. Qiec l/min

9,7

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

Castrol ALPHASyn 150

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420558

Unit Data:

Nozzle size, water

NT 0475

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

DN8 x 15 m

Guarantied sound power

82

Impactfactor calculated

2,6

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

73

Size - Machine alone L x W x H mm

890x570x1020

Page 8

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

8

B

Parent item no: Description:

107146702 POSEIDON 5-47 PA 200/3/50 JP

Service data Unit Value

Model

POSEIDON 5-47 PA

Item no. →

107146702

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

157

Pressure gun outlet @ Qiec bar

141

Retaining pressure* bar

230

Flow. Qiec l/min

13,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420554

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

88

Impactfactor calculated

4,7

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

71

Size - Machine alone L x W x H mm

735x570x1020

Page 9

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

9

B

Parent item no: Description:

107146703 POSEIDON 5-47 PA 200/3/60 JP

Service data Unit Value

Model

POSEIDON 5-47 PA

Item no. →

107146703

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

157

Pressure gun outlet @ Qiec bar

141

Retaining pressure* bar

230

Flow. Qiec l/min

13,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1740

Electrical diagram no.

106420554

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

88

Impactfactor calculated

4,7

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

71

Size - Machine alone L x W x H mm

735x570x1020

Page 10

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

10

B

Parent item no: Description:

107146705 POSEIDON 5-41 PA 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-41 PA

Item no. →

107146705

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

173

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

11,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0400

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

FLEXOPOWER PLUS 1120 BEND W/O NOZZLE

Secondary Lance Type

None

Hose

DN6 x 10m

Guarantied sound power

88

Impactfactor calculated

4,1

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

66

Size - Machine alone L x W x H mm

735x570x1020

Page 11

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

11

B

Parent item no: Description:

107146706 POSEIDON 5-41 PA 220;440/3/60 EXPT

Service data Unit Value

Model

POSEIDON 5-41 PA

Item no. →

107146706

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

171

Pressure gun outlet @ Qiec bar

160

Retaining pressure* bar

230

Flow. Qiec l/min

11,5

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1740

Electrical diagram no.

106420564

Unit Data:

Nozzle size, water

NT 0400

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

FLEXOPOWER PLUS 1120 BEND W/O NOZZLE

Secondary Lance Type

None

Hose

DN6 x 10m

Guarantied sound power

88

Impactfactor calculated

4,1

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

69

Size - Machine alone L x W x H mm

735x570x1020

Page 12

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

12

B

Parent item no: Description:

107146708 POSEIDON 5-41 PAXT 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-41 PAXT

Item no. →

107146708

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

178

Pressure gun outlet @ Qiec bar

161

Retaining pressure* bar

230

Flow. Qiec l/min

11,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0400

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

FLEXOPOWER PLUS 1120 BEND W/O NOZZLE

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

HP-Hose o6x15m Quick 3/8"

Guarantied sound power

88

Impactfactor calculated

4,1

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

72

Size - Machine alone L x W x H mm

890x570x1020

Page 13

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

13

B

Parent item no: Description:

107146710 POSEIDON 5-56 PA 230;400/3/50 NO

Service data Unit Value

Model

POSEIDON 5-56 PA

Item no. →

107146710

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

182

Pressure gun outlet @ Qiec bar

163

Retaining pressure* bar

230

Flow. Qiec l/min

14,7

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420564

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

75

Size - Machine alone L x W x H mm

735x570x1020

Page 14

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

14

B

Parent item no: Description:

107146711 POSEIDON 5-56 PA 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-56 PA

Item no. →

107146711

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

182

Pressure gun outlet @ Qiec bar

163

Retaining pressure* bar

230

Flow. Qiec l/min

14,7

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

73

Size - Machine alone L x W x H mm

735x570x1020

Page 15

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

15

B

Parent item no: Description:

107146713 POSEIDON 5-56 PA 220/440/3/60 EXPT

Service data Unit Value

Model

POSEIDON 5-56 PA

Item no. →

107146713

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

181

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

14,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1740

Electrical diagram no.

106420564

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

74

Size - Machine alone L x W x H mm

735x570x1020

Page 16

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

16

B

Parent item no: Description:

107146714 POSEIDON 5-56 FA 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-56 FA

Item no. →

107146714

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

182

Pressure gun outlet @ Qiec bar

163

Retaining pressure* bar

-

Flow. Qiec l/min

14,7

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v1

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420552

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

73

Size - Machine alone L x W x H mm

735x570x1020

Page 17

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

17

B

Parent item no: Description:

107146715 POSEIDON 5-56 PAXT 230;400/3/50 NO

Service data Unit Value

Model

POSEIDON 5-56 PAXT

Item no. →

107146715

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

188

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

14,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420564

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

DN8 x 15 m

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

80

Size - Machine alone L x W x H mm

890x570x1020

Page 18

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

18

B

Parent item no: Description:

107146716 POSEIDON 5-56 PAXT 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-56 PAXT

Item no. →

107146716

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

188

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

14,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

DN8 x 15 m

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

78

Size - Machine alone L x W x H mm

890x570x1020

Page 19

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

19

B

Parent item no: Description:

107146718 POSEIDON 5-62 PA 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-62 PA

Item no. →

107146718

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

197

Pressure gun outlet @ Qiec bar

174

Retaining pressure* bar

241

Flow. Qiec l/min

16,2

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0530

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

88

Impactfactor calculated

6,2

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

78

Size - Machine alone L x W x H mm

735x570x1020

Page 20

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

20

B

Parent item no: Description:

107146719 POSEIDON 5-62 PA 220;440/3/60 EXPT

Service data Unit Value

Model

POSEIDON 5-62 PA

Item no. →

107146719

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

197

Pressure gun outlet @ Qiec bar

174

Retaining pressure* bar

242

Flow. Qiec l/min

16,2

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1740

Electrical diagram no.

106420564

Unit Data:

Nozzle size, water

NT 0530

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

88

Impactfactor calculated

6,2

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

80

Size - Machine alone L x W x H mm

735x570x1020

Page 21

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

21

B

107146721 POSEIDON 5-62 FA 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-62 FA

Item no. →

107146721

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

197

Pressure gun outlet @ Qiec bar

174

Retaining pressure* bar

-

Flow. Qiec l/min

16,2

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v1

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420552

Unit Data:

Nozzle size, water

NT 0530

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

88

Impactfactor calculated

6,2

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

79

Size - Machine alone L x W x H mm

735x570x1020

Page 22

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

22

B

Parent item no: Description:

107146722 POSEIDON 5-62 PAXT 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-62 PAXT

Item no. →

107146722

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

206

Pressure gun outlet @ Qiec bar

172

Retaining pressure* bar

241

Flow. Qiec l/min

16,2

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0530

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

HP-HOSE DN8X20M 250bar 150°C G3/8

Guarantied sound power

88

Impactfactor calculated

6,2

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

85

Size - Machine alone L x W x H mm

890x570x1020

Page 23

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

23

B

Parent item no: Description:

107146724 POSEIDON 5-52 FA 220-240/1/60 USA

Service data Unit Value

Model

POSEIDON 5-52 FA

Item no. →

107146724

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

148

Pressure gun outlet @ Qiec bar

121

Retaining pressure* bar

210

Flow. Qiec l/min

16,3

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v1

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1740

Electrical diagram no.

106420566

Unit Data:

Nozzle size, water

NT 0650

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

DN8 x 15 m

Guarantied sound power

88

Impactfactor calculated

5,2

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

84

Size - Machine alone L x W x H mm

735x570x1020

Page 24

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

24

B

Parent item no: Description:

107146725 GERNI POSEIDON 5-30 PA 240/1/50 AU

Service data Unit Value

Model

POSEIDON 5-30 PA

Item no. →

107146725

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

105

Pressure gun outlet @ Qiec bar

97

Retaining pressure* bar

145

Flow. Qiec l/min

9,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

Castrol ALPHASyn 150

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420559

Unit Data:

Nozzle size, water

NT 0435

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 ST GUN W. HOSE SWIVEL - GERNI

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

82

Impactfactor calculated

2,7

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

68

Size - Machine alone L x W x H mm

735x570x1020

Page 25

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

25

B

Parent item no: Description:

107146726 GERNI POSEIDON 5-56 PAXT 415/3/50

Service data Unit Value

Model

POSEIDON 5-56 PAXT

Item no. →

107146726

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

188

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

14,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 ST GUN W. HOSE SWIVEL - GERNI

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

HP-Hose O8x15m quick 3/8" nozzle grey

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

78

Size - Machine alone L x W x H mm

890x570x1020

Page 26

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

26

B

Parent item no: Description:

107146727 POSEIDON 5-53 PA 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-53 PA

Item no. →

107146727

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

182

Pressure gun outlet @ Qiec bar

163

Retaining pressure* bar

230

Flow. Qiec l/min

14,7

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

FLEXOPOWER PLUS 1120 BEND W/O NOZZLE

Secondary Lance Type

None

Hose

DN6 x 10m

Guarantied sound power

89

Impactfactor calculated

5,4

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

71

Size - Machine alone L x W x H mm

735x570x1020

Page 27

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

27

B

Parent item no: Description:

107146728 POSEIDON 5-53 PAXT 400/3/50 EU

Service data Unit Value

Model

POSEIDON 5-53 PAXT

Item no. →

107146728

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

190

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

14,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

FLEXOPOWER PLUS 1120 BEND W/O NOZZLE

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

HP-Hose o6x15m Quick 3/8"

Guarantied sound power

89

Impactfactor calculated

5,4

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

76

Size - Machine alone L x W x H mm

890x570x1020

Page 28

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

28

B

Parent item no: Description:

107146734

POSEIDON 5-41 PA 400/3/50 EU Sondi

Line

Service data Unit Value

Model

POSEIDON 5-41 PA

Item no. →

107146734

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

174

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

11,6

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0400

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

FLEXOPOWER PLUS 1120 BEND W/O NOZZLE

Secondary Lance Type

None

Hose

10 M WIRE HOSE 5/16 DN8

Guarantied sound power

88

Impactfactor calculated

4,1

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

68

Size - Machine alone L x W x H mm

735x570x1020

Page 29

Technical data

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

29

B

Parent item no: Description:

107146735

POSEIDON 5-56 PAXT 400/3/50 EU

Sondi Line

Service data Unit Value

Model

POSEIDON 5-56 PAXT

Item no. →

107146735

Technical Data ↓

Pump:

Pump pressure water bar

Pressure pump outlet @ Qiec bar

186

Pressure gun outlet @ Qiec bar

162

Retaining pressure* bar

230

Flow. Qiec l/min

14,7

Suction height dry m

1

Suction height primed m

2,5

Pump type

NA5 v2

Number of pistons

3

Piston type

Full Ceramic

Stroke mm

0

Pump oil type

BP Energol GR-XP220

Pump oil amount l

0,73

Electric:

Electric data

Control voltage V

Highvoltage (HV) test voltage V

1,5

HV Insulation resistance

1

Earth circuit resistance

0,2

Pump revolutions

1450

Electrical diagram no.

106420550

Unit Data:

Nozzle size, water

NT 0500

Max. Inlet temp. (primed) °C

-

Max. Inlet temp. (suction) °C

40

Max. Inlet temp. (pressure fed) °C

60

Gun Type

ERGO 2000 STD INCL. SWIVEL NILFISK

Primary Lance Type

TORNADO PLUS LANCE 1120 BEND

Secondary Lance Type

TURBOHAMMER PLUS 1040 STRAIGHT W/O NOZZ.

Hose

DN10 x 15m - Grey

Guarantied sound power

89

Impactfactor calculated

5,5

Vibration ISO 5349, lance 1 / lance 2

<1,5 ±1

Protection Class

IPX5

Machine incl. standard acc. kg

81

Size - Machine alone L x W x H mm

890x570x1020

Page 30

Construction

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

30

C

Overview Poseidon 5 NA5

Lance

Lance holder top

Water inlet + Filter

ON / OFF switch

Pic. C1: POSEIDON 5 NA5

Lance holder bottom

Water outlet

Pressure gauge

View for oil container

Detergent valve

Detergent Bottles

Cabinet lock

Pic. C2: POSEIDON 5 Cabinet & frame parts

Page 31

Construction

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

31

C

Overview Poseidon 5 NA5

Pic. C3: Poseidon 5 NA5 without cabinet

Pressure gauge

Injector

Unloader valve

Cylinder head

Water outlet

Water inlet

Electrical box

Water regulation

D-bearing cover

Detergent valve

ON-OFF switch

Pump oil lid

Pump oil container

Cylinder block

Page 32

Construction

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

32

C

Micro switch

Unloader piston

Micro switch housing

Water regulation

Unloader spring

Activation arm

Non return valve for

water regulation

By-pass opening valve

Non return valve

Injector nozzle

Unloader housing

Injector valve

Overview Poseidon 5 NA5 unloader- PA Models

Pic. C4: Unloader

Page 33

Construction

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

33

C

Water regulation

Flow piston

By-pass valve

Injector valve

Injector nozzle

Reed contact

Unloader housing

Overview Poseidon 5 NA5 By-pass valve– FA Models

Pic. C5: By-pass valve

Page 34

Construction

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

34

C

Pic. C6: Pump parts

Piston

Washer for spring

Spring

Cylinder block

Thrust collar

Oil seals

Cylinder head

Water inlet

Pressure valve

Secondary seal

Support ring

Back up ring

Primary seal

Header ring

Inlet valve

Overview NA 5 pump unit

Page 35

Construction

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

35

C

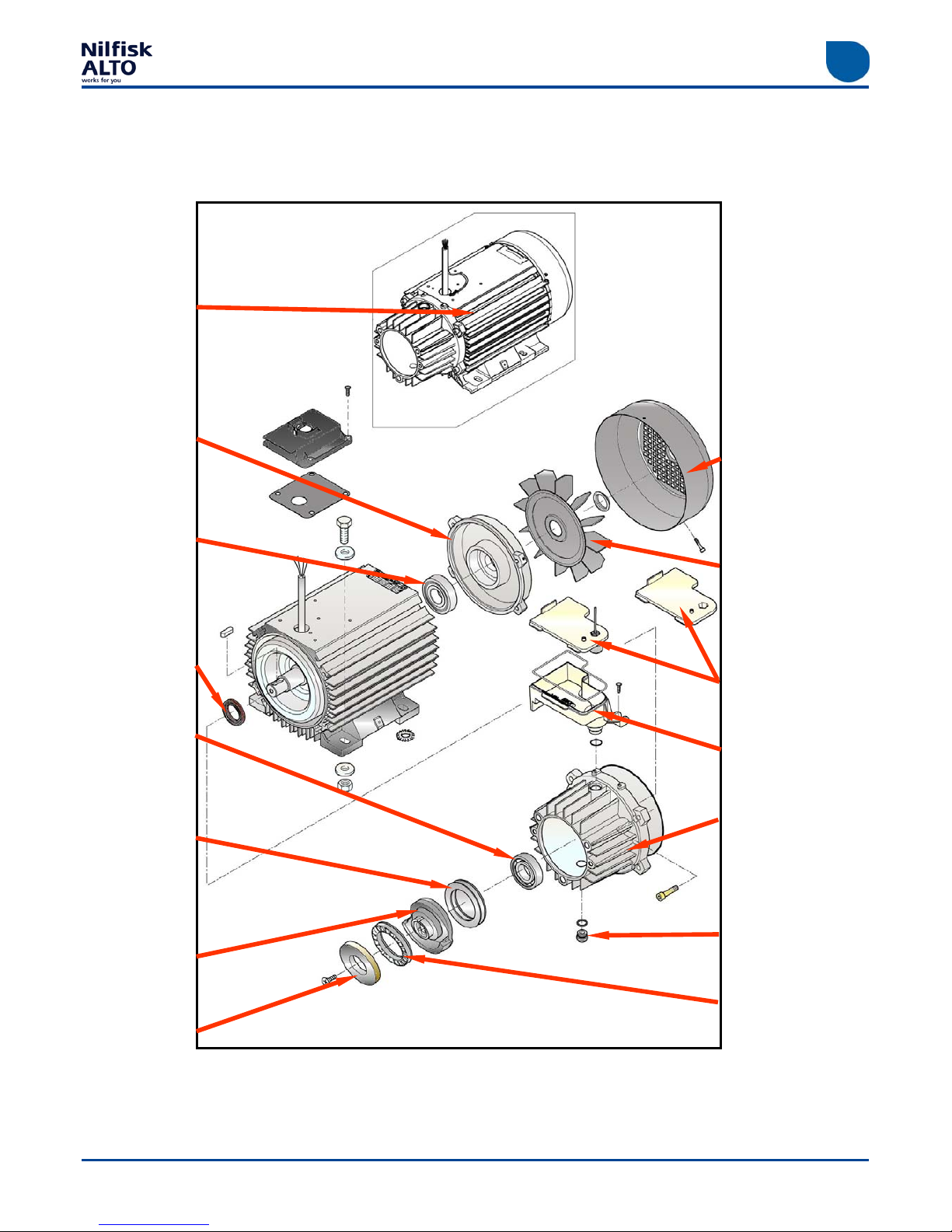

Overview NA 5 Motor/Pump

Motor complete

Fan

Oil Tank

End bearing

cover

D-bearing cover

Lid for oil tank

Oil seal

Oil plug

Pic. C7: Motor/pump unit

Radial

ball bearing

Cylindrical roller

bearing

Pressure disc

Wobble disc/

Radial

ball bearing

Fan cover

Cylindrical roller

bearing

with

Page 36

36

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Function

D

B3 Motor thermal switch.

B4 Micro switch.

K1 Contactor.

M1 Motor.

S1 Main switch ON/OFF.

Pic. D1: Wiring diagram.

Operation of Poseidon PA 5:

Pre-conditions: Machine hooked up to adequate water and power supply. Right Spray gun,

hose and lance/nozzle is used.

Main switch in position ”0” (OFF):

-There is main voltage at the contacts of S1 and K1.

- Machine is still off.

Main switch S1 in position ”1” (ON):

- Spray gun is closed; machine builds up pressure, if B4 (cut off pressure not reached)

and B3 (motor winding temp. Below < 160°C or < 320°F; automatic reset of B3) are closed;

if cut off pressure is reached B4 opens and the machine stops.

-If spray gun is activated pressure in unloader drops, B4 closes and starts the motor, water

flows at working pressure.

- Closing spray gun; working pressure increase in unloader till cut off pressure is reached;

B4 opens, machine stops.

Operation electrical system

Page 37

37

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Function

D

A1 Control PCB

B3 Motor thermal switch.

B4 Reed contact.

K1 Contactor.

M1 Motor.

S1 Main switch ON/OFF.

Operation of Poseidon 5 FA:

The PCB has following functions:

1. To start the motor when starting the machine.

2. To stop the motor when operation of the machine is finished.

3. To run the motor in by-pass for 20 sec. after flow stop was reached and B4 opened.

4. To record and store data concerning the machines work stiuations, operation and by-pass.

The PCB is protected ——————- by a fuse (6.3A—slow) placed on the board.

Pre-conditions: Machine hooked up to adequate water and powerr supply.

Main switch S1 in position ”0” (OFF):

- There is mains voltage at the contacts of S1 and K1, but no power at the PCB

- Machine is still off.

Pic. D2: Wiring diagram.

Operation electrical system

Page 38

38

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Function

D

RUN – Mode

Motor runs — Micro switch closed; water run through the gun..

Closing the gun — Switching to “By-pass” mode.

BYPASS – Mode

Motor runs — Micro switch open; water runs by-pass.

If gun not activated within 20 sec. — Motor stops in “Stand-by” mode.

STAND BY – Mode

Motor is switched off — Micro switch open.

If the gun is activated — The motor starts and goes to “Run mode”

SLEEP – Mode

If the gun isn’t activated within 30 minutes; the unit will not restart automatically. It has to be

restarted at the main switch.

If the micro switch closes in time intervals t < 1,5 sec. it is recognised as a leakage, as an

activation

Pic. D3: PCB.

Function PCB 301001104

Page 39

39

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Function

D

Pressure Activated Unloader— by pass (closed gun)

1. Motor/pump Unit.

2. Micro switch.

3. Activation arm.

4. Unloader spring.

5. Unloader piston.

6, Ball for by-pass.

7. Non return valve.

8. Ergo gun.

The machine is started with closed spray gun (8).

The pressure rises until the cut-off pressure is reached. The unloader piston (5) is pressed

forward caused by the outlet pressure exceeding the pressure from the unloader spring → the Bypass ball (6) is moved forward and opens the connection between the water inlet and the water

outlet (blue arrows). The micro switch (2) is activated by the activation arm (3) and the motor/pump

(1) stops. Now the non return valve piston (7) is pressed against its seat, which keeps the pressure

high in the hose and on the backside of the unloader piston. The pressure in the pump is released to

”0” due to open connection between pump inlet and outlet (blue arrows).

1

2

3

5

4

6

7

8

Pic. D4: Unloader—Closed gun.

Motor/pump

Page 40

40

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Function

D

1. Motor/pump Unit.

2. Micro switch.

3. Activation arm.

4. Unloader spring.

5. Unloader piston.

6, Ball for by-pass.

7. Non return valve.

8. Ergo gun.

Pic. D5: Unloader—Open gun.

Mounted with a lance and high pressure nozzle the spray gun (8) is now activated.

The non return valve (7) opens, the pressure in the hose drops and release the pressure on

the backside of the unloader piston (5). The unloader spring (4) presses the unloader piston (5)

backwards and drags the activation arm (3) away from the micro switch (2) and the motor/

pump (1) starts.

The pressure rises to working pressure and remains constant during operation.

1

2

3

6

4

5

7

8

Motor/pump

Pressure Activated Unloader— working pressure (open gun)

Page 41

41

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Function

D

Pressure Activated Unloader— by pass (closed gun) and reduced water volume

3

2

1

1. Valve for water

reduction open.

2. Water can pass through

non return valve.

3. Water can pass hrough

4. connection from water inlet to

water outlet

Pressure Activated Unloader— working pressure (open gun) and reduced water volume

Pressure Activated Unloader— closing gun and reduced water volume

1

2

3

1

2

3

4

1. Valve for water

reduction open.

2. Water can pass through non

return valve.

3. Water can pass through

water outlet

1. Valve for water

reduction open.

2. Non return valve is closing.

3. Non return valve in outlet is closing.

4. Connection between water inlet

and water outlet is opening.

Pic. D6: Unloader– Closed gun.

Pic. D7: Unloader—Open gun.

Pic. D8: Unloader— Closing gun.

Page 42

42

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Function

D

Water runs under pressure from the

pump through the injector nozzle, where

there is a pressure drop made. Water

also enters the chamber between the bypass pistons. Due to a higher pressure

between the pistons than under the

lower piston, the by-pass valve is closed

and the machine runs in working mode.

When the spray gun is closing the flow

shortly stops and the pressure rises.

The opening pressure valve shortly

opens, the pressure on both sides of the

lower piston equalizes and the lower bypass piston lifts up and open the by-pass

Flow Activated By-pass system— working pressure (open gun)

Pic. D9: — By-pass valve open gun.

Pic. D10: By-pass valve — open gun. Pic. D11: By-pass valve — closed gun.

Page 43

Troubleshooting

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

43

E

Fault Cause Remedy

Pressure drop

- Air in the system.

- High pressure nozzle

blocked / worn.

- Pressure control on the

spray lance is not set

correctly.

- Detergent container empty.

- Water inlet temperature

too high.

Vent the system by

operating the spray gun

several times at short

intervals .If necessarly

operate the cleaner for a

short time without the

High pressure hose

connected.

Clean / replace the high

pressure nozzle.

Set the required working

pressure.

Change container or close

detergent valve.

See technical data part ”B”.

Pressure

fluctuations

- Lack of water

- Water inlet hose is too long

or its cross-section too

small.

- Lack of water caused by

blocked water filter.

- Lack of water because

max. permissible suction

height has not been

heeded.

- Pump sucks in air

(suction mode)

Open water tap.

Use specified water inlet

hose(Refer to user manual).

Clean the water filter in the

water connection.

(Never work without water

filter).

See technical data part ”B”

Check that the suction set

is air tight.

The motor does not start when

the cleaner is switced on.

- The plug is not inserted

properly, i.e. there is no

current.

- The main fuse is switced off.

Check the plug, lead and

switch.If necessary have them

replaced by a trained

electrician.

Switch on the main fuse.

General failures.

Page 44

Troubleshooting

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

44

E

Fault Cause Remedy

When the cleaner is switched

on the motor buzzes without

starting.

The main voltage is too low

or there is a phase failure

(3 ph model).

The pump is blocked or

frozen.

Incorrect cross-section or

lenght of the extension lead.

Have the electrical

connections checked.

Pump needs service

(see part ”F”).

Use lead with correct cross

section and length.

The motor switches off.

The overload protection has

been activated due to

overheating or overloading

of the motor.

High pressure nozzle is

dirty.

Check that the main voltage

and the cleaner voltage are

the same.

Switch off the cleaner and

allow it to cool for at least

3 minutes.

Change the high pressure

Cleaner starts / stops by itself.

Leakage on high pressure

side.

Locate the leak and repair

it. (See next page).

No detergents drawn in.

Injector is dirty or suction

hose is blocked.

Detergent container empty.

The cap on the nozzle is

not set at low pressure.

Clean.

Top up/change the

container.

Turn cap of the

FlexoPower nozzle towards

”CHEM” up to the stop.

Working pressure too low.

Working pressure too low and

loud noise comming from

pump .

- Suction - and pressure

valves leaking.

- Piston U-sleves in pump

worn.

- Piston stocked in pump.

Replace parts.

Check pump for

damaged parts —

demount and

reassemble pump

housing with the right

torque.

General failures.

Page 45

Troubleshooting

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

45

E

Unloader failures.

Symptom: Machine does not stop when releasing the spray gun.

Cause: Defective spring (1), or defective activation arm (3), or defective micro switch housing (4),

or defective micro switch (5).

Remedy: Replace defective parts.

Symptom: Machine does not stop when releasing the spray gun. Pump runs in by-pass mode with

very high pressure — approx 180bar.

Cause: Non return valve piston (12) - O-ring (11) - Seat (13) defective → System leaks internally or

piston (12) closes too slowly caused by dirt/chalk.

Remedy: Replace Non return valve kit or clean dirty parts.

Symptom: Machine starts by itself and stops right away.

Cause: Pressure system leaks between spray gun and pump → Cut-off pressure drops and the

activation arm (3) releases the micro switch (5), or leaks at gaskets 6, 8, 10, 11.

Remedy: Check gaskets in spray gun - Check gaskets 6, 8, 10, 11 and replace if necessary.

Symptom: Working pressure too low.

Cause: Machine by-passes water.

Remedy: Spring (1) tension too low or leakage between ball (16) and seat.

1

2

3

4

5

6

7

8

9

10

16

11

12

15

14

13

Pic. E1: Unloader.

Page 46

Troubleshooting

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

46

E

By-pass valve failures.

1

2

3

4

5

Symptom: Machine doesn’t start when

activating the spray gun.

Cause: Defective reed contact (3) or piston

(2) is stuck.

Remedy: Replace defective parts.

Symptom: Irregular working pressure.

Cause: Injector nozzle (4) is worn.

Remedy: Replace injector nozzle.

Symptom: Low working pressure

Cause: By-pass valve kit worn and leaks

water.

Remedy: Replace By-pass valve kit.

Symptom: Suction inlet for detergent leaks

water.

Cause: Non return valve (5) defective.

Remedy: Replace non return valve.

Pic. E2: By-pass valve..

Page 47

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

47

F

Pic. F4: Oil container

Identify the machine version at the

dataplate.

Find the techincal data for the machine

version in this manual chapter ”A”.

Pic. F1: Data Plate Pic. F2: Cabinet

Pic. F3: E– box

1

1

The lid for the electrical box is fitted with

2 x torx T20 screws.

Remove the screws and push the lid

backwards to open the E-box.

The oil container is fitted to the pump by the 2x

Torx 20 screws.

The cabinet is demounted by turning the two

lock screws (1) on top of the cabinet.

Open the cabinet and pull forward.

Page 48

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

48

F

Water inlet filter is placed in the housing for

hose connector. Remove the circlip and filter

check for impurities.

Pic. F5: Water inlet filter

Unloader.

When the non return valve is defective,

replace the complete repair kit to ensure all

related parts are in a proper condition. When

the non return valve seat is mounted - use

silicon grease to protect the o-rings against

damages.

When the unloader piston is defective, replace

the complete repair kit to ensure all related

parts are in a proper condition. Use silicon

grease to protect gaskets against damages.

Pic. F6: Water outlet/ Injector

The injector nozzle is placed in the water

outlet and is demounted with a 10mm socket

wrench.

Inside the hose tail the seat for injector non

retaining valve is integrated.

Hose tail is demounted with a 14mm spanner.

Pic. F7: Non return valve Pic. F8: Unloader piston

Page 49

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

49

F

Micro switch housing

Pic. F9: Micro switch box

Remove the lid from micro switch housing by

removing 1 x torx 10 screw and flip the three

hinges on the lid.

Micro switch box is fixed to the unloader by 2 x

torx 20 screws.

Unloader housing.

Pic. F11: Unloader housing

Dismount the unloader housing (3) from the valve

housing (1) by the three M6 bolts (4). By

reassembling mount the smallest o-ring (6) in the

unloader (3) and the biggest o-ring (5) in the

water inlet part (2). Use silicone grease and

stretch the o-rings over the parts - do not roll the

o-rings.

Pic. F12: Oil drain/fill

Drain off the oil by dismounting the 14mm oil

plug (1).

After repair refill pump with new oil.

1

2

3

6

5

Oil drain and filling.

4

1

Pic. F10: Micro switch box

Page 50

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

50

F

Valves

Dismount the valve housing from the

cylinder block by the three M12 bolts.

Be aware of the o-rings and valve parts.

Be carefull not to damage the surface

inside when dismounting the thrust collar.

Inspect the thrust collar for damages

before mounting.

Pic. F14: Thrust collar Pic. F13: Valve housing

Pic. F15: Valve housing Pic. F16: Valve housing

Carefully tip out the sleeves with an

adequate puller or screwdriver and replace

them. Be careful not to scratch the surface.

Knock carefully on the back side of the

valve seat to demount it or use an 8mm

threaded pin and pull it out.

Replace with new parts.

Page 51

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

51

F

Overview of the placement of suction valve

parts.

Pic. F.17: Suction valves

Overview of the placement of pressure

valve parts

Pic. F20: Pressure valves

Valves

Assemble header ring in right position. Knob on

header ring must be placed in groove in

cylinderhead. Drop —do not knock it into the

right position.

Pic. F.18: Header ring

If the header ring is mounted wrongly and not

according to instruction, there is a big risk of

damaging the header ring and parts of it will

block pistons and valves in the pump or get

stucked in the non return valve in the unloader.

Pic. F19: Header ring

Page 52

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

52

F

Pic. F21: Pressure valves Pic. F22: Pressure valve seat

Take out the pressure valve seats with

an adequate puller or use an 8mm

threaded pin.

Replace with new parts if necessary.

Picture of piston guides

The pressure valves can easily be taken

out of the cylinder head.

Replace with new parts if necessary.

Pic. F23: Cylinder block

Cylinder Block

Pic. F24: Oil Sleeves

Overview of the placement of the parts in

the cylinder block.

Take out the oil sleeves using an

adequate puller or a screwdriver.

Be careful not to damage the surface of

the cylinder block.

NEW !

Valves

Page 53

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

53

F

Pic. F26: Pistons Pic. F25: Valve Kit 3~ - Exploded View

Oil seal and piston

To make replacement easier moisten the

sleeves with soapy water.

Mount the sleeves using a 19mm box

spanner and a fiber hammer.

Place sleeves, pistons and springs as

shown.

Mount the cylinder block to the D-bearing

cover by the two 6mm mounting screws.

Wobble disc

The cylinder head and the cylinder block

is fastend to the D-bearing cover by two

6mm mounting bolts for the cylinder

block and three 12mm bolts for the

cylinder head.

Pic. F27: Pump head Pic. F28: D-bearing cover and wobble disc

Overview of the parts inside the D-

bearing cover.

Page 54

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

54

F

Pic. F30: Wobble disc removal Pic. F29: Wobble disc

Demount the wobble disc screwing a 1

6mm bolt into the threads. Tighten the

bolt against the motorshaft and pull the

wobble disc out.

The center bolt is fixing the wobble disc

to the motor shaft and ensure the rotor to

be kept in the right position in proportion

to the stator.

Wobble disc

Pic.16. Replace the complete wobble disc system and make sure

parts are assembled according to instructions pic.17. & pic.18. pos.

A & B

B

A

Pic.17. The curved edge (A) of the bearing

tracks must be mounted against the D-bearing

cover and the wobble disc.

Pic.18. The sharpe edge (B) of the bearing

track must be mounted against the bearings

A

B

Pic. F31: Wobble disc

Pic. F32: Bearing track

Page 55

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Service / Repair

55

F

Pic. F35: Electrical Motor

D-bearing cover

Pic. F34: Oil sleeve Pic. F33: D-bearing cover

The D-bearing cover is mounted to the

Motor by four 6mm bolts.

When the bearing is damaged, always

replace the complete D-bearing cover.

Pic. F36: fan

The oil sleeve in the D-bearing cover can

be demounted carefully using a

screwdriver.

Mount the oil sleeve by using an

adequate box spanner and a fiber

Overview of the motor parts. The fan can be demounted by taking off

the lock ring and carefully push the fan

with a screwdriver.

Electrical motor

Page 56

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Adjustment / Test

56

G

Unloader - Retaining pressure settings.

The retaining pressure is adjusted by tightning or loosening the unloader spring.

Follow the pressure values stated in the Technical data sheets in chapter B and read out the

pressure on the pressure gauge with valve mounted on the pump outlet.

Pic. G1: Unloader spring

Pic. G2: Adjustment of unloader spring

Pic. G3: Pressure gauge with valve.

Special tool no. 1206358

Page 57

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Adjustment / Test

57

G

IMPORTANT: When torque settings are made, all parts — Pump, screws etc. must have a temperature at

max. 20°C or as the surroundings.

The only Adjustment to be made on the by-pass system is the opening pressure valve (Safety

valve). Always adjust the pressure to be approx 25 - 30 bar higher than normal pressure.

Pic. G4: Opening pressure valve.

Unloader - Retaining pressure settings.

Page 58

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Adjustment / Test

58

G

Tool & Torque List for NA5 MPU

Pump

Description Tool Torque

Unloader Valve PA

3 M6 screws for unloader valve Unbracho 5 10 Nm

2 M8 screws for outlet fitting Unbracho 6 20 Nm

Lock Nut NV 13 10 Nm

Spring adjustment NV 27 N/A

Plug/Stem assy NV 27 40 Nm

Screws for microswitch box Torx TX10 1 Nm

Seat for holding pressure valve M8 screw N/A

Seat for by pass Mandrel and hammer N/A

Seat for water regulation Unbracho 6 14 Nm

Seat for pressure build up valve Unbracho 4 10 Nm

Test Screw Unbracho 6 14 Nm

M4 pointed screw Unbracho 4 5 Nm

Outlet fitting

Detergent studs NV 17 20 Nm

Venturi NV 8 1,4 Nm

Pump Head

3 M12 screws for pump assy Unbracho 10 65 Nm

Thrust collar Pull out tool N/A

Outlet valves Pull out tool N/A

Inlet valves Mandrel and hammer N/A

Primary seals ø20 seal tool N/A

Cylinderblock

2 M8 service screws Unbracho 6 20 Nm

Oil seals Ring and hammer N/A

Wobble disc assy

M8 Screw Unbracho 6 20 Nm

Wobble disc M16 screw N/A

Bearing washer Pull tool N/A

Motor

D-bearing cover

4 M8 stay-bolt for D-bearing cover NV 13 20 Nm

Oil plug outlet NV 14 10 Nm

Fan

4 screws for fan cover Screw driver * 1 Nm

Lock ring Pliers N/A

Fan N/A

N-bearing cover

4 M8 stay-bolt for N-bearing cover NV13 20 Nm

Page 59

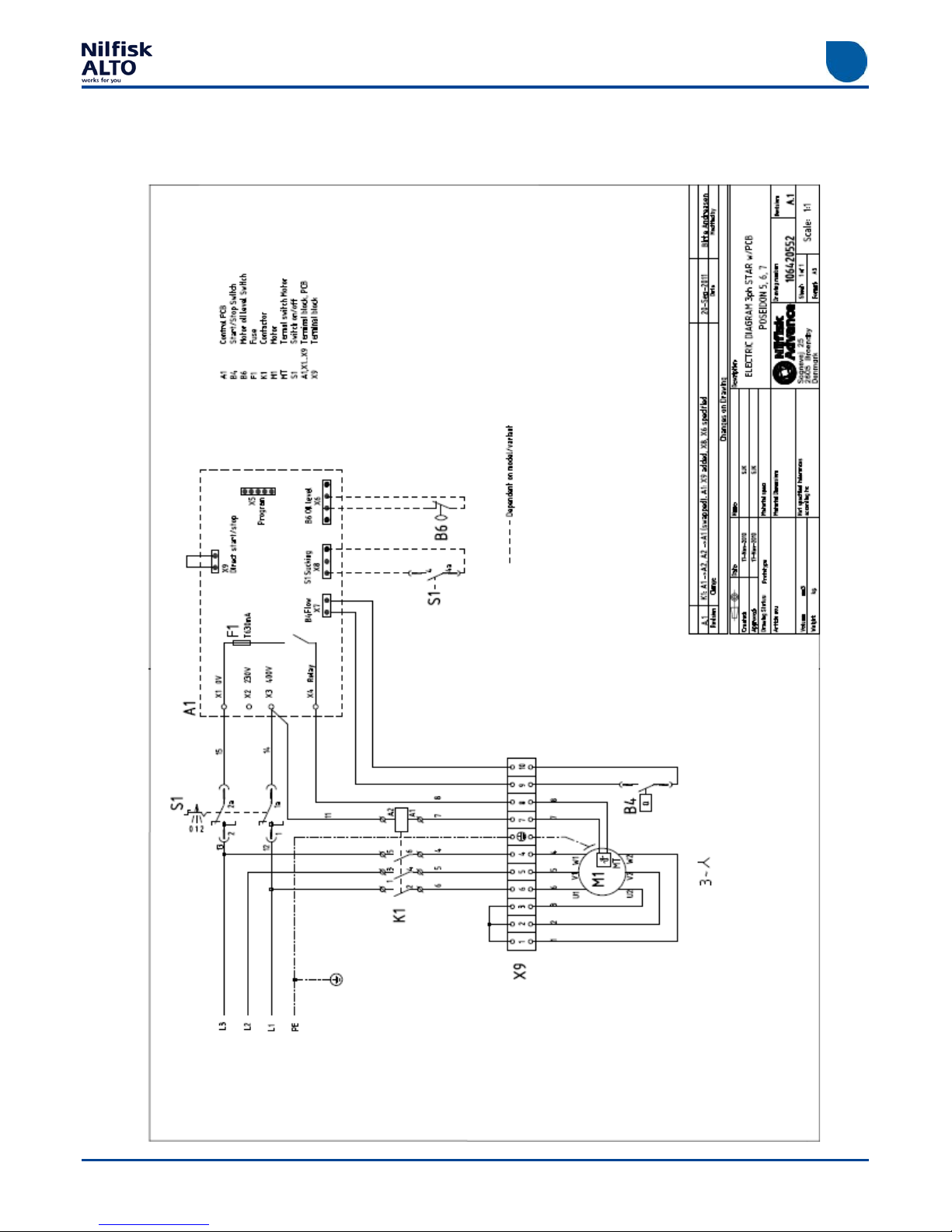

Wiring diagrams

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

59

H

106420550

Page 60

Wiring diagrams

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

60

H

106420552

Page 61

Wiring diagrams

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

61

H

106420554

Page 62

Wiring diagrams

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

62

H

106420558

Page 63

Wiring diagrams

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

63

H

106420559

Page 64

Wiring diagrams

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

64

H

106420564

Page 65

Wiring diagrams

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

65

H

106420566

Page 66

Special Tools / Spare Parts

66

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

I

Part Number Description Remarks

Special Tools

1206358 Test Pressure Gauge Adjustment cut-off pressure

Spare Parts*

Additional Materials***

41455 Grease (-15 C to +130 C) Valve grease

107144146 Pump oil Energol GR-XP 220

* Includes all important repair kits and parts necessary for service and maintenance.

For a detailed view have a look in the Spare Parts List.

Page 67

67

POSEIDON 5 NEW-NA5_en_Ver.1.0_20/12

Notes

Page 68

Nilfisk - ALTO

Division of Nilfisk - Advance A/S

Industrivej 1

9650 Hadsund

Denmark

Loading...

Loading...