Page 1

Instruction manual

GB 1133

Categories of application: U, S, C, B1, EOB, K1

ATTENTION

Keep these instructions for future reference!

Page 2

1 Contents

Paragraph Page

1 Contents 2

2 Scope of the instruction manual 3

3 Tests 4

4 Categories of application 5

5 Technical specifications 6

6 General notice on safety 7

7 Filter and emptying systems 8

8 Initial operation 9

9 Adjusting the automatic gear change of the minimum airflow 10,11,12

10 Monitoring the airflow 13

11 Cleaning the filter 14

12 Emptying the container 15

13 Disposal of collected dust 16,17

14 Pre-separator 18

15 Notice on K1 vacuum cleaners used for removing asbestos 19

16 Service 20

Page 3

2 Scope of the instruction manual

This instruction manual is valid for the the following machine types:

GB 1133 – U(L)

GB 1133 – C(M,H)

GB 1133 – S(M) - B1

GB 1133 – C(M,H) - B1

GB 1133 – C(M,H) - EOB/IS

GB 1133 - K1(H)

Meaning of the type name

GB 1033 - series

C(M,H) - category of application (dust class)

EOB - machine type

The machine type “industrial vacuum cleaner (IS)“ is left out. The machine type of

cleaners that have passed the additional “Dust Explosion Protection Test“ is “B1“.

Page 4

3 Tests

All Nilfisk-Advance systems are tested in order to comply with the requirements of

system safety regulations. They have fulfilled the technical safety demands according

to the following special regulations:

- Technical Dust Test

- Mechanical and Electrical Test

- Noise Technology Test

DIN EN ISO 3744

- Additional Dust Explosion Protection Test

Page 5

4 Categories of application

This Nilfisk machine is suitable for removing dusts of the following categories of

application:

“U“ suitable for removing hazardous, dry, not inflammable dusts whose MAK*

limiting value is greater than 1 mg/cm³ (comparable to the new dust class “L“

- light hazard - defined by EN 60335-2-69).

“S“ suitable for removing hazardous, dry, not inflammable dusts whose MAK

limiting value is greater than 0.1 mg/cm³ (comparable to the new dust class

“M“ - medium hazard - defined by EN 60335-2-69).

“C“ suitable for removing hazardous, dry, not inflammable dusts with all MAK

limiting values (comparable to the new dust class “M“) as well as dry, not

inflammable dusts of carcinogenic substances (comparable to the new dust

class “H“ – high hazard – defined by EN 60335-2-69). The cleaned air is fed

back to the workplace atmosphere.

“K1“ suitable for removing hazardous, dry, not inflammable dusts with all MAK

limiting values as well as dry, not inflammable dusts of carcinogenic

substances. The cleaned air is fed back to the workplace atmosphere

(comparable to the new dust class “H“).

*maximale Arbeitsplatz-Konzentration, maximal workplace concentration

Explanation

Since May 1998, Europe has a common norm. Dust removing systems are from now

on divided into three dust classes L, M and H. Older test certificates remain valid until

December 31st, 2002. “Category of application“ is a synonym for “dust class“.

Page 6

5 Technical specifications

Voltage 400 V

Rated power 13,000 W

Vacuum 320 mbar

Connection Ø 70/100 mm

Airflow 750/930 m³/h

Filter area Main filter (U,S,C) 52,000 cm²

Prefilter (K1) 52,000 cm²

Main filter (K1) 60,000 cm²

Minimum airflow 300/580 m³/h

Protection class IP 54

Insulation class F

-1

Noise emission

Sound pressure level measuring as described in DIN EN ISO 3744.

According to the machine guideline Appendix 1, point 1.75 f, the highest sound

pressure level is measured at 1 m distance from the machine at a height of 1.6 m.

The highest value is reached on the right side (view down on the inlet):

77 dB(A).

Page 7

6 General notice on safety

Only original Nilfisk spare parts may be used.

The machine may only be operated by instructed and authorised individuals.

Liquids, aggressive gases, flammable materials or smouldering particles should not

be removed.

The machine may only be used for cleaning dry surfaces and is not suitable for

outdoor use.

The power cord should not be damaged by being driven over, squeezed, pulled tight

or around sharp corners. Keep the power cord away from heated surfaces.

The power cord should be checked at regular intervals for signs of damage or

ageing.

Do not use the machine when the power cord is not in perfect condition.

Only original Nilfisk-Advance spare parts should be used when replacing the power

cord.

When the mains plug is replaced, splash-proof protection and mechanical safety

must be assured.

The replacement of the power cord or the mains plug should be carried out by a

competent person.

After use, before cleaning or any maintenance or adjustment work the mains plug

must be unplugged.

Before connecting the cable, the dust-producing system has to be shut down.

MAINTENANCE

Regular maintenance test: check the bounce separator for damage, the integrity of

the system, the filter and the functioning of the control system. Nilfisk-Advance offers

maintenance contracts which guarantee constant performance and value

preservation of the machines and their technical safety functions by regular checkups.

Page 8

7 Filters and emptying systems

The installed main and exhaust filters are approved by the German Trade

Association Institute for Safety at the Workplace (BIA). The transmission factors are

lower than the limiting values required by relating regulations.

The installed filters normally have a long service life. Exchange of filters should only

be carried out by Nilfisk-Advance Service.

Without the appropriate emptying system, the machine does not match the

requirements specified by relating regulations. In this case, danger to health

cannot be excluded.

Article numbers for filters and emptying systems

Category of application Main filter Disposal system

(dust class) Type A Type B

U (L) 040053

S (M) 040053 027641

C (M, H) 040053 030343 031101

K1 (H) (prefilter) 040053 4 x 02170000 030343 031101

Two different disposal systems are in use:

Type A: Dust bag system

Type B: Disposable container

Page 9

8 Initial operation

Please read these notes of safety before initial operating.

The application scope of the machine is marked on the rating-plate.

Industrial vacuum cleaners are exclusively designed for removing settled dusts.

Extractors are designed for removing dust at that very place where it is produced.

Having removed the system from packaging, check it for completeness and

transportation damage. In case of damage or missing parts please contact NilfiskAdvance immediately. Before connecting the vacuum cleaner to the mains supply,

check that the voltage of the machine specified on the rating-plate corresponds with

the mains voltage.

Switch the motor on to control its direction of rotation.

When it is wrong, a red lamp at the switch housing flashes up.

Extractors: an arrow on the motor housing shows the right direction of rotation.

Working for a long time with the wrong direction of rotation heatens the

vacuum cleaner’s surface up to over 80°C.

When the direction of rotation is wrong two phases in the mains supply (not within the

machine) need to be exchanged. All electrical sockets of the workplace should have

the same phase sequence in order to operate the system in all areas of the

workplace.

Systems with antistatic design (B1)

These machines are not suitable for removing explosive materials, dusts with an

extremely low minimum ignition energy of less than 1 mJ and inflammable liquids.

Do not use others than conductible original Nilfisk-Advance accessories.

Use couplers that only allow connecting and disconnecting the system in voltage-free

condition.

Antistatic systems must be equipped with a protective circuit breaker or a blowout

fuse 16 A (delayed-action fuse).

The use of coupling devices and adapters is not allowed.

The system is ready for use when all equipment has been connected.

Page 10

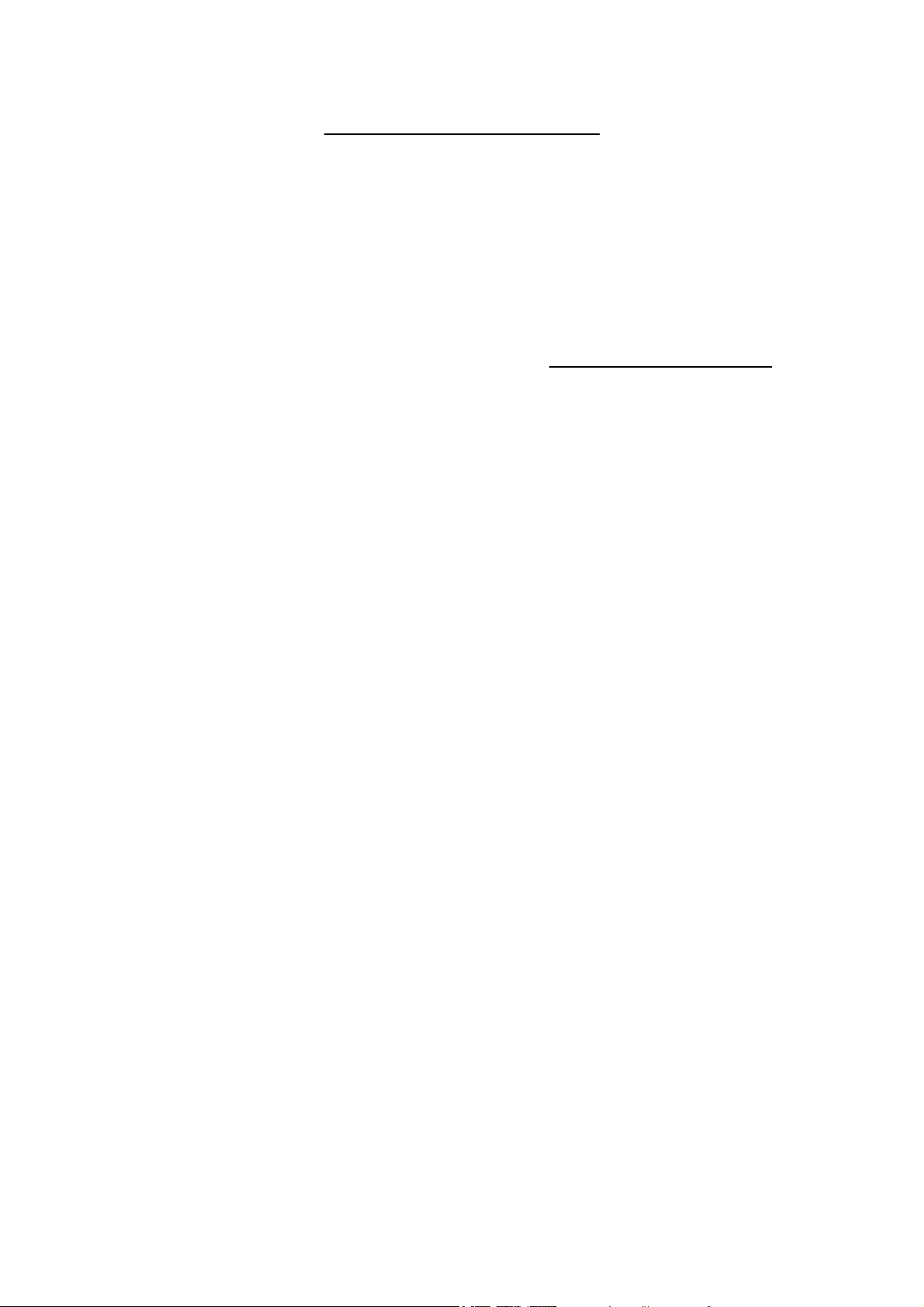

9 Adjusting the automatic gear change of the minimum airflow

Use the performance profile to adjust the cutoff point for the minimum

airflow of extractors. First of all, find out the minimal airflow that ensures

a good operation of the dust-producing system. Mark this value on the xaxis, then draw a vertical line from here to the curve. Now draw a line

parallel to the x-axis from the point of intersection to the y-axis. This

value describes the vacuum that has to be adjusted at the vacuum

switch when the minimal airflow is no longer sufficient.

When adjusting the vacuum, you have to connect an appropriate

measuring device parallel to the vacuum switch. Throttle the airflow at

the suction inlet until the required value is reached. Now calibrate the

cutoff point by the adjusting screw of the vacuum switch.

When the minimal airflow falls short, the following happens after a few

seconds:

- the red warning light flashes up.

- the floating contact in the switch housing switches. This contact (6 A at

a

voltage of 230 V, AC11) manages the connection of the control circuit

of

the dust-producing system to the extractor or to control an external

optical or acoustical signal.

Page 11

The works for configuring an extractor (connecting the cable, adjusting

the cutoff point) may only be carried out by a technician or skilled

personnel using suitable tools.

When using the vacuum cleaner outdoors, use only a type H07RN-F

cable.

Connecting the cable must be carried out according to the manual added

to the machine.

Even when the extractor is switched off, the interlock circuit might still

carry external voltage from the dust-producing system.

When the airflow control has cut off the dust-producing system, the main

switch has to be switched off as well in order to prevent an unintentional

start of the dust-producing system (after a malfunction has been

removed).

The recirculating airflow mustn’t exceed the 50 per cent of the incoming

airflow in order to comply with the required limiting values.

In case of variation (when high-quality separators are used or the

incoming air is very clean), the evidence of complying with the limiting

values has to be proved

.

Page 12

GB 1133 Performance profile

Page 13

10 Monitoring the airflow

All Nilfisk vacuum cleaners - except category of application “U“ are fitted with a manometer that allows you to monitor the

minimum airflow in order to guarantee an optimal air speed

within the suction hose. When you lift the floor nozzle into the

air and the manometer’s pointer turns from the green into the

red zone, the main filter needs to be cleaned or the dust bag

is full and needs to be replaced.

Extractors

When the cutoff point is reached, the dust-producing system is switched off

automatically and the red warning light flashes up. Clean the main filter or replace the

dust bag.

The fill level of the dust bag/dust collecting container has to be checked at regular

intervals. Monitoring the fill level/automatic gear change (extractors) is no guarantee

that the bag is not full.

Page 14

11 Cleaning the filter

Nilfisk-Advance systems are fitted with a device for cleaning the main filter. First of

all, switch the machine off. Then move the shaker handle placed at the container

vigorously with a push-pull movement.

Extractors

When the dust-producing system is shut down automatically, it needs to be switched

off manually before cleaning the filter or replacing the dust bag. Otherwise, an

hazardous situation could occur if after these works, the dust-producing system

restarts automatically.

After the main filter has been cleaned, the manometer’s pointer must return to the

green area or the red warning light has to go out. Otherwise, the main filter has to be

replaced.

K1 vacuum cleaners

When the pointer is still in the red area or the warning light does not go out, the

prefilter has to be replaced as well.

Page 15

12 Emptying the container

Industrial vacuum cleaners with antistatic design need to be emptied after

every single use.

First of all, switch the motor off. Wait a moment until the dust has settled down before

you separate the dust collecting container from the upper part of the machine:

Lower the container by using the lifting mechanism.

Switch the motor on again in order to prevent dust

falling down from the filter.

Move the dust collector forwards.

Replace the disposal system.

Move the dust collector back under the machine.

Switch the motor off.

Push the dust collector upwards by using the lifting

mechanism.

Page 16

13 Disposal of collected dust

Category of application: “U“

The are no particular prescriptions, but take care that no one around you will be

affected by the dust. The disposal of the collected dust has to be carried out

according to local prescriptions.

Category of application: “S“

Type A: Dust bag system Art. 027 641

Having opened the system, remove the plastic

bag’s edge carefully from the container’s edge

that it is covering. Close the bag’s opening and

take it out of the container.

Put a new dust bag into the container. Take care

that it fits the bottom and the walls. Pull the bag’s

edge over the container’s edge and smooth it down.

Machines of this category of application can be used

without a dust bag. In this case please take care that

the removal of the dust takes place in a special area

and use a respiratory protection mask.

Page 17

Category of application: “C“ and “K1“

Type B: Disposable container Art.no. 031 101

When the container has been torn away from the

machine, close it by the lid and fix the lid by the

clamp ring.

Type A: Dust bag system Art.no. 030 343

Leave the hose connected or close by shutter cap!

Having opened the system, carefully remove the

plastic bag which that is covering the container’s

edge. Close the bag’s opening. Now remove the

cornered back part of the bag’s flange carefully

from the inlet. While doing this, hold the fastening

ring placed on the inlet.

The plastic connection gets visible. It can be closed

tight by the binder.

Having assured that the dust cannot escape from the

dust bag, release the fastening ring from the inlet.

The dust bag can now be removed from the container

without any risk.

Put a new dust bag into the container. Its connector

must point at the inlet.

Now push the flange onto the inlet until fits tight.

The plastic bag has to fit well the bottom and walls of

the container. Tear the edge of the bag above the

edge of the container and smooth it down.

Page 18

14 Pre-separator

The system can connect to secondary interceptor

tanks for even greater waste capacity of 200 litres

at a time. The lid fitting both sizes of pre-separators

(125 and 200 litres) and the hose connection have

to be ordered separately.

The separator trolley runs on three wheels. A preseparator fitted with such a trolley can comfortably

be transported by a forklift.

The machine and the pre-separator can easily be

connected by a special connector that makes their

transport more comfortable.

Category of application S: a plastic bag (030 370)

is used for the disposal of collected dust.

Category of application C: the pre-separator’s

container is used as a disposable container. It is

closed by a lid (030 715) and a lock ring (030 717)

before disposal.

Page 19

15 Notice on K1 vacuum cleaners used for removing asbestos

A vacuum cleaner that has been used for removing asbestos in a contaminated area

may no longer be used in a non-contaminated area.

An exception is possible when the vacuum cleaner has been decontaminated

completely, that means not only the outside, but also the inside of the vacuum

cleaner (cooling air passages, the installation space for electrical resources or the

resources themselves). The persons in charge is obliged to write it down and sign a

protocol.

Fixed filters may only be replaced by skilled personnel special areas

(decontamination stations).

For a dust-free transport, the vacuum cleaner has to be emptied, the shutter cap of

the suction inlet has to be mounted, the exhaust outlets have to be closed (e.g. by

adhesive tape) and the lifting mechanism has to be locked.

The accessories in use have to be transported in closed plastic bags.

Use our exhaust air accessory kits to guide the exhaust air outdoors!

Art.no. 021 753 for 70 mm suction inlet

Reduction tube (Ø 100 mm)

5 m exhaust air hose (Ø 100 mm)

Art.no. 021 751 for 100 mm suction inlet

Reduction tube (Ø 150 mm)

5 m hose (Ø 150 mm)

Page 20

16 Service

Nilfisk-Advance Limited

Newmarket Road

Bury St. Edmunds

Suffolk IP33 3SR

Tel: 01284 763163

Fax: 01284 750562

Internet: www.nilfisk-advance.com

__________________________________________________________

Specifications and details are subject to change without prior notice July 1999

Loading...

Loading...