Page 1

Dynamics 440

Betriebsanleitung ...........................2

Operating Instructions ....................8

Notice d'utilisation ....................... 14

Gebruiksaanwijzing ...................... 20

Istruzioni sull'uso ......................... 26

Driftsinstruks ............................... 32

Bruksanvisning ............................. 38

Driftsvejledning............................ 44

Käyttöohje ................................... 50

Navodilo za uporabo ................... 56

Uputstvo za rad ............................ 62

Prevádzkový návod ..................... 68

Provozní návod ............................ 74

Instrukcja obsługi........................ 80

Kezelési utasítás.......................... 86

Instrucciones de manejo............... 92

Instruções de operação................. 98

Οδηγίες λειτουργίας ................104

65318 - 020500

Page 2

EG - Konformitätserklärung

Déclaration de conformité CE

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Erzeugnis:

Typ:

Beschreibung:

Die Bauart des Gerätes entspricht

folgenden einschlägigen

Bestimmungen:

Angewendete harmonisierte

Normen:

Angewendete nationale Normen

und technische Spezifikationen:

ppa. Rau, Dipl. Ing. (FH)

Leitung Forschung und Entwicklung

EU Declaration of Conformity Dichiarazione di conformità CE

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Product:

Type:

Description:

The design of the unit corresponds

to the following pertinent

regulations:

Applied harmonised standards:

Applied national standards and

technical specifications:

ppa. Rau, Dipl. Ing. (FH)

Head of Research and Development

Schmutzsauger

Dynamics 440

400 V 3~, 4000 W

EG-Maschinenrichtlinie 89/392/EWG

EG-Niederspannungsrichtlinie 73/23/EWG

EG-Richtlinie EMV 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

Vacuum Cleaner

Dynamics 440

400 V 3~, 4000 W

EC Machine Directive 89/392/EWG

EC Low-voltage Directive 73/23/EWG

EC EMV Directive 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produit:

Type:

Description:

La construction de l’appareil est

conforme aux réglementations

afférentes suivantes:

Normes harmonisées appliquées:

Normes nationales et spécifications

techniques appliquées:

ppa. Rau, Dipl. Ing. (FH)

Direction Recherche et

Développement

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Prodotto:

Tipo:

Descrizione:

La costruzione dell' apparecchio è

conforme alle seguenti direttive

specifiche:

Norme armonizzate applicate:

Norme nazionali applicate e

specifiche tecniche:

ppa. Rau, Dipl. Ing. (FH)

Direttore Ricerca e Sviluppo

Aspirateurs de saletés

Dynamics 440

400 V 3~, 4000 W

Directive CE relative aux machines 89/392/EWG

Directive CE relative à basse tension 73/23/EWG

Directive CE EMV 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

Aspiratore per sostanze sporche

Dynamics 440

400 V 3~, 4000 W

Direttiva CE sulle macchine 89/392/EWG

Direttiva CE sulla bassa tensione 73/23/EWG

Direttiva CE sulla compatibilità

elektromagnetica 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

EG-Verklaring van overeenstemming

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beschrijving:

De constructie van het apparaat

voldoet aan de volgende van

toepassing zijnde voorschriften:

Toegepaste geharmoniseerde

normen:

Toegepaste nationale normen en

technische specificaties:

ppa. Rau, Dipl. Ing. (FH)

Chef onderzoek en ontwikkeling

Vuilzuiger

Dynamics 440

400 V 3~, 4000 W

EG-machinerichtlijn 89/392/EWG

EG-laagspanningsrichtlijn 73/23/EWG

EG-richtlijn EMV 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

Atestado de conformidad de la UE

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Producto:

Modelo:

Descripción:

La construcción de la máquina

corresponde a las siguientes

normas específicas:

Normas armonizadas aplicadas:

Normas nacionales aplicadas y

especificaciones técnicas:

ppa. Rau, Dipl. Ing. (FH)

Director Investigación y Desarrollo

Aspirador de suciedad

Dynamics 440

400 V 3~, 4000 W

R. de la UE para máquinas 89/392/EWG

R. de la UE para baja tensión 73/23/EWG

R. de la UE para la compatibilidad electromagnética 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

Page 3

Atestado de

conformidade da UE

∆ήλωση ανταπόκρισης ΕΟΚ

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produto:

Modelo:

Descrição:

A construção da máquina

corresponde às seguintes normas

específicas:

Normas harmonizadas aplicadas:

Normas nacionais aplicadas e

especificações técnicas:

ppa. Rau, Dipl. Ing. (FH)

Diretor de Pesquisas e

Desenvolvimento

EF-konformitetserklæring

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beskrivelse:

Apparatets konstruksjonstype er i

samsvar med følgende gjeldende

bestemmelser:

Anvendte harmoniserte

standarder:

Anvendte nasjonale standarder og

tekniske spesifikasjoner:

Aspirador de sujidades

Dynamics 440

400 V 3~, 4000 W

Directiva UE para máquinas 89/392/EWG

Directiva UE para baixa tensão 73/23/EWG

Directiva para a compatibilidade

electromagnética 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

Smussoppsugeren

Dynamics 440

400 V 3~, 4000 W

EF-maskindirektiv 89/392/EEC

EF-lavspenningsdirektiv 73/23/EEC

EF-direktiv elektromagnetisk

kompatibilitet 89/336/EEC

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Προϊόν:

Τύπος:

Περιγραφή:

Ο κατασκευαστικός τύπος της

συσκευής ανταποκρίνεται στους

ακόλουθους σχετικούς

κανονισµούς:

Εφαρµοσθείσες εναρµονισµένες

προδιαγραφές:

Εφαρµοσθείσες εθνικές

προδιαγραφές και τεχνικοί

προσδιορισµοί:

∆ιπλ. µηχ. A. Rau

Υπεύθυνος ερευνητικού τµήµατος

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Typ:

Beskrivning:

Apparatens konstruktion motsvarar

följande tillämpliga bestämmelser:

Tillämpade harmoniserade normer:

Tillämpade nationella normer och

tekniska specifikationer:

µηχανής αναρρόφησης

Dynamics 440

400 V 3~, 4000 W

Οδηγία περί µηχανών ΕΟΚ 89/392/ΕΟΚ

Οδηγία χαµηλών τάσεων ΕΟΚ 73/23/ΕΟΚ

Οδηγία περί ηλεκτροµαγνητικής

συµβατότητας 89/336/ΕΟΚ

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

EG-försäkran om

överensstämmelse

Smutssugaren

Dynamics 440

400 V 3~, 4000 W

EG-maskindirektiv 89/392/EWG

EG-lågspänningsdirektiv 73/23/EWG

EG-direktiv EMK 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

ppa. Rau, Dipl. Ing. (FH)

Leder forskning og utvikling

EF-overensstemmelsesattest

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beskrivelse:

Konstruktionen af dette apparat

opfylder følgende gældende

bestemmelser:

Anvendte harmoniserede

standarder:

Anvendte tyske standarder og

tekniske specifikationer:

ppa. Rau, Dipl. Ing. (FH)

Leder forskning og udvikling

Bellenberg, 03.02.1997

Smudssugeren

Dynamics 440

400 V 3~, 4000 W

EF-maskindirektiv 89/392/EØF

EF-lavspændingsdirektiv 73/23/EØF

EF-direktiv vedr. elektromagnetisk

fordragelighed 89/336/EØF

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

ppa. Rau, Dipl. Ing. (FH)

Ledare för forskning och utveckling

EY-Vaatimustenmukaisuusvakuutus

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Tuote:

Tyyppi:

Kuvaus:

Tämän laitteen rakenne vastaa

seuraavia määräyksiä:

Käytetyt harmonisoidut normit:

Käytetyt kansalliset normit ja

tekniset spesifikaatiot:

ppa. Rau, Dipl. Ing. (FH)

Kehitys- ja tutkimusjohtaja

Bellenberg, 03.02.1997

Likaimurin

Dynamics 440

400 V 3~, 4000 W

EY-konedirektiivi 89/392/EWG

EY-pienjännitedirektiivi 73/23/EWG

EY-direktiivi EMV 89/336/EWG

EN 292

EN 60335-2-2

EN 60335-2-69

EN 50081, EN 50082

DIN EN 60335-1

IEC 335-2-69

DIN VDE 0700 T 205

Bellenberg, 03.02.1997

Page 4

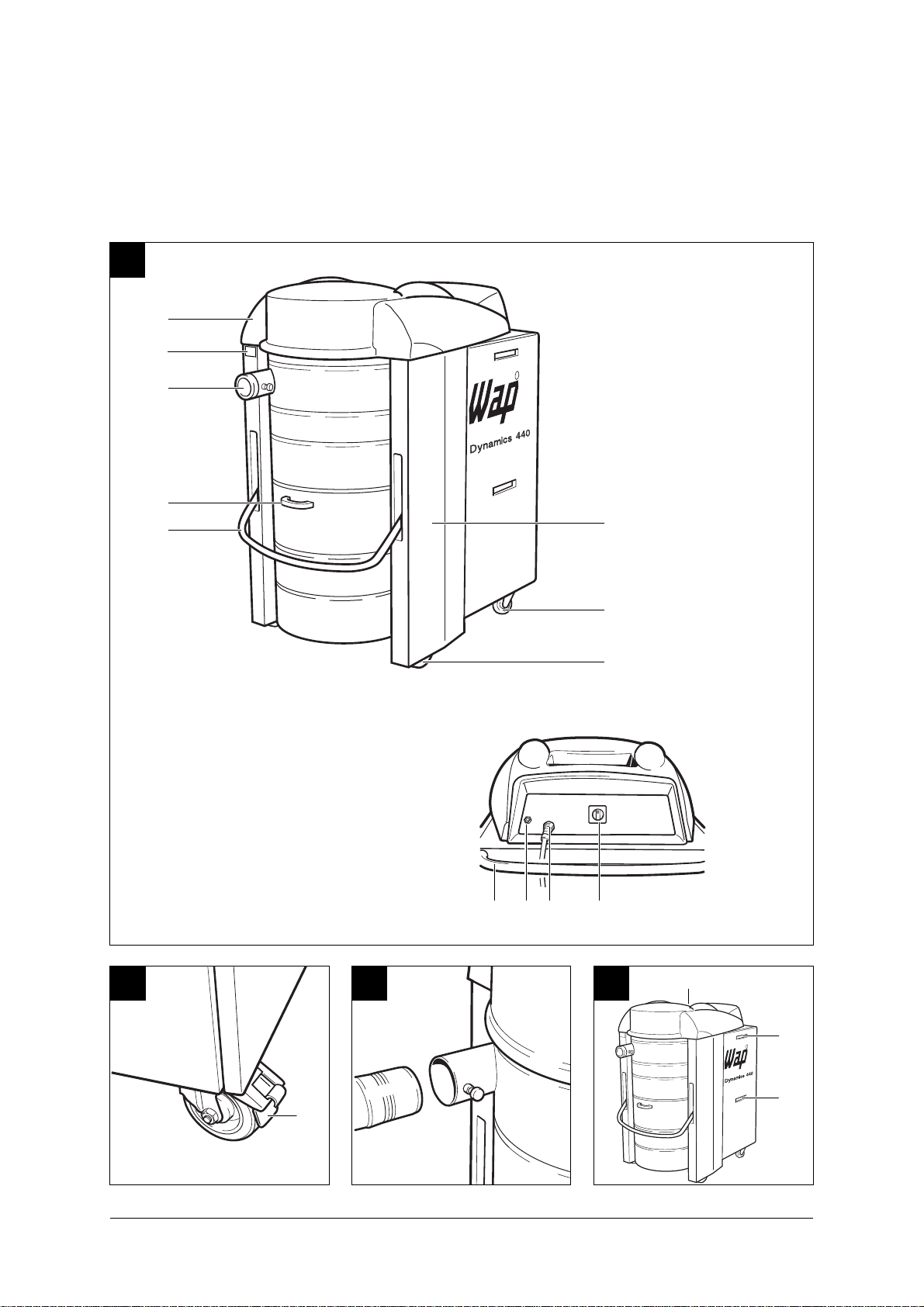

Dynamics 440

1

1

2

R

3

4

5

8

7

6

9

10 11 12

2

3 4

1

1

2

R

2

Page 5

Dynamics 440

R

5

8

6 7

1

9 10

2112 1

1

R

3

2

3

4

11

7

6

5

14

5

6

2

1

12 13

8

15 16

2

10

11

4

3

Page 6

FOR YOUR OWN

SAFETY

Before putting the

cleaner into operation, be

sure to also read the

enclosed operating

instructions thoroughly

and keep them close at

hand for future reference.

The cleaner may only be

used by persons trained in

its use and expressly

authorised to use it.

GENERAL

Operation of this cleaner

is subject to the

applicable national

regulations.

In addition to these

operating instructions and

the binding regu

lations on accident

prevention

applicable in the country

of use, the generally

acknowledged technical

rules for safe and correct

working must also be

observed.

*)

4

For tested safety cleaners of dust clases L,M, H and B1, observe

the instructions in the operating manual.

Any method of work

endangering health or

safety is forbidden!

HEALTH-ENDANGERING

DUSTS

*

)

This cleaner is not suitable

for picking up health-

endangering dusts.

FIRE AND EXPLOSION

HAZARD

The following materials

must not be picked up

with the cleaner:

_ Hot materials (glowing

cigarettes, hot ashes,

etc.)

_ Inflammable, explosive

or aggressive fluids

(e.g. petrol, solvents,

acids, alkalines, etc.)

_ Inflammable, explosive

dusts (e.g. magnesium

or aluminium dust,

etc.).

APPLIANCE PLUG

SOCKET

Before connecting any

appliance to the appliance

plug socket, the cleaner

must always be

switched off.

If appliances are

connected to the

appliance plug socket,

ensure that these

appliances are also

switched off when being

connected to the

appliance plug socket.

CAUTION!

The operating

instructions and the

safety precautions

contained therein must

be observed when

using appliances

connected to the

appliance plug socket

of the cleaner.

USING FOR THE FIRST

TIME

Before using the cleaner

for the first time, check

that it is in a good and

safe condition.

Plugs and connectors of

mains leads must be at

least splash water-proof.

Check the mains

connection and mains

plug.

Inspect the mains lead at

regular intervals for

damage or signs of

ageing. Use the cleaner

only

when the mains lead is in

a good and safe

condition.

(Damaged mains leads

present a danger of

electric shocks!)

Use the cleaner only with

an undamaged filter

element.

Page 7

DURING OPERATION

Take care not to damage

the mains lead (e.g. by

driving over, pinching or

dragging). Pull out the

mains plug only directly at

the plug, i.e. not by

pulling at the mains lead.

Before picking up liquids,

the filter bag must be

removed and the function

of the float switch

checked.

If foaming is observed,

stop work immediately

and empty the tank.

MAINTENANCE AND

REPAIR

CAUTION!

Before cleaning and

servicing the cleaner,

always remove the

mains plug.

Carry out only

maintenance operations

described in these

operating instructions.

Use only original Wap

spare parts.

Do not make any

technical modifications to

the cleaner.

CAUTION!

Your safety could be

endangered as a result!

For all other

maintenance and repair

work, please contact

the Wap Service

department or an

authorised specialist

workshop!

ELECTRICAL

EQUIPMENT

Check the rated voltage

of the cleaner before

connecting it to the mains

power supply. Ensure

that the voltage specified

on the rating plate

corresponds to the local

mains voltage.

When connected to the

mains power supply with

a mains lead of type H 07

RN-F 3G 1.5 mm², the

cleaner may also be used

outdoors.

When using an extension

lead or replacing the

mains lead, the lead type

specified by the

manufacturer must always

be used.

We recommend that the

power supply to the

cleaner be connected via

an earth-leakage circuit

breaker which interrupts

the power supply either if

the earth leakage current

exceeds 30 mA for 30

ms, or it contains an

earthing test current

circuit.

When using an extension

lead, observe the

minimum cross-sections of

the leads:

Cable length Cross-section

m mm²

up to 20 1.5

20 to 50 2.5

Always arrange the

current-carrying parts

(plug sockets, plugs and

connectors) and lay

extension leads so that

the protection class of the

cleaner is maintained.

CAUTION!

Never spray the top

section of the cleaner

with water: Danger for

persons, danger of short

circuits.

The latest edition of the

IEC Regulations must be

observed.

5

Page 8

Dynamics 440

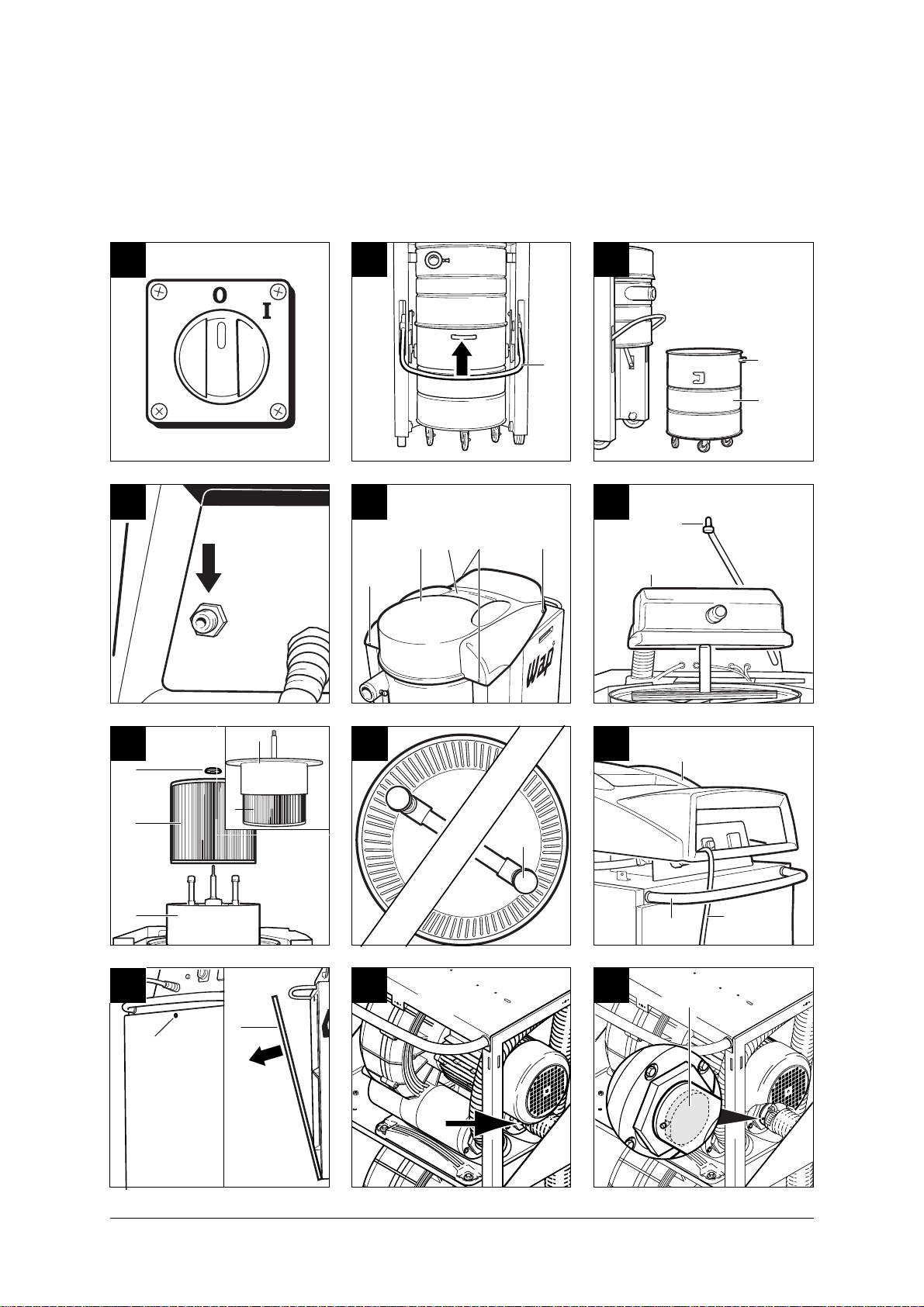

1 Description

1.1 Illustration

(Fig. 1)

1 Cover

2 Rating plate

3 Inlet fitting

4 Tank

5 Tank lock

Description

6 Fixed castors

7 Swivel castors with brake

8 Chassis

9 Handle

10 Compressed-air

connection

11 Power cable

12 Main switch

1.2 Application

The Dynamics 440 is an

industrial vacuum cleaner of the

usage class M and is thus

suitable when used properly for

vacuuming up dry, nonflammable dusts with a lower

toxic limit > 1 mg/m3.

1.3 Inspections and

approvals

Protection class 1

Protection type IP X4

Radio interference

suppression level N

At a filter surface load

< 500 m3 x m-2 x h-1 the vacuum

cleaner has a permeability

< 0.5 % and thus corresponds to

the usage class “M” due to its

other equipment.

The filter paper of the filter

cartridge has been tested by the

German BIA as per ZH 1/487,

Para. 2. The mean permeability

is certainly less than 0.1 % at a

velocity in blower stream of

0.05 m/sec.

Electrotechnical tests must be

conducted as per VDE 0105 in

accordance with the regulations

of the German Accident

Prevention Regulation (VBG4)

and as per DIN VDE 0701 Parts 1

and 3. These tests are required

in accordance with DIN VDE

0702 at regular intervals and

following servicing or changes.

Electrotechnically tested by the

German SEV and TÜV in

accordance with the test

methods/principles

DIN VDE 0700 Part 1

DIN VDE 0700 Part 2

DIN VDE 0700 Part 205.

Based on the test in accordance

with DIN VDE 0700 Part 205,

the vacuum cleaner is suitable

for increased loading during

commercial use.

The test as per DIN VDE 0700

Parts 1 and 205 showed that the

technical safety requirements

with regard to the electrical

safety are also fulfilled when

vacuuming up a water/air

mixture.

8

Page 9

Dynamics 440

1.4 Technical data

Dynamics

440

Voltage volts 400

Frequency Hz 50

Power connection 3-phase w/o neutral,

clockwise phase

sequence

Connected load watts 4000

Max. volume flow (air) max. m3/h 432

max. l/min 7200

Max. vacuum max. hPa 230

Filter surface area m

2

5

Separating capacity % 99,95

Filter blow-off

Compressed air

(oil and water-free) bar 8

Measuring surface sound

pressure level at 1 m

distance as per DIN 45 635,

Part 1 (4/84) in open field

at maximum volume flow dB(A) 70

Description

1.5 Accessories, additional

equipment

Tank volume l 100

Power cable m 5

Suction hose diameter mm 70

Width mm 750

Depth mm 1250

Height mm 1350

Weight kg 195

Protection class 1

Protection type (splash-proof) IP X4

Radio-interference

suppression level EN 50081

Filter element Part No. 34931

“Special” filter element with non-stick

coating Part No. 26736

Please see the “Accessories, Vacuum-Cleaner and Safety VacuumCleaner Systems” chapter of our catalogue for the wide range of

accessories available for this vacuum cleaner.

9

Page 10

Dynamics 440

2 Use/Operation

2.1 Setting up vacuum

cleaner

The vacuum cleaner must be set

up on a firm surface. The

surface must be able to safely

support the weight of the

vacuum cleaner and must be

vibration-free.

CAUTION!

When setting up the vacuum

cleaner, a minimum distance of

500 mm must be maintained to

the surrounding walls or objects.

CAUTION!

At an ambient temperature from

25 °C sufficient air circulation

(cooling) must be provided at the

set-up location.

(Fig. 2)

Use/Operation

l Set up vacuum cleaner at

desired location.

l Lock swivel castors on

vacuum cleaner by pressing

brake (1).

2.4 Vacuuming

Never vacuum up flammable

materials or liquids.

After vacuuming up liquids, the

filter cartridge is damp. A damp

filter cartridge can become

blocked faster when dry

materials are vacuumed up. For

this reason the filter cartridge

should be dried or replaced with

a dry cartridge prior to dry

vacuuming.

2.5 Operating vacuum

cleaner

2.5.1 Before switching on

(Fig. 4)

Before switching the vacuum

cleaner on, check whether the

exhaust air outlet (1) is free and

the cooling air inlet (2) of the

motor is not covered or blocked

and clear if necessary.

2.2 Connecting suction

hose

(Fig. 3)

Pull locking pin to connect or

remove the suction hose.

2.3 Electrical connection

The operating voltage indicated

on the rating plate must

correspond to the mains voltage.

l Insert plug of power cable

into a properly installed CEE

outlet (clockwise phase

sequence, connected load 3 x

16 A) . Make sure vacuum

cleaner is switched off.

10

2.5.2 Switching vacuum

cleaner on/off

(Fig. 5)

Operate unit switch:

Switch position “I”:

Vacuum cleaner runs.

2.6 Following work

Switch position “0”:

Vacuum cleaner is switched off.

If the vacuum cleaner is not

required for a longer period of

time, pull the mains plug out of

the electrical outlet.

Page 11

3 Care/Maintenance

Dynamics 440

3.1 Important safety

precautions

CAUTION!

Always pull out the mains plug

before performing cleaning or

maintenance work on the

vacuum cleaner.

3.2 Maintenance schedule

Activity

3.3 Emptying tank

3.4.1 Blowing off filter

3.4.2 Replacing filter element

Only carry out maintenance

work described in these

operating instructions and use

only genuine WAP spare parts.

Do not make any technical

changes to the vacuum cleaner.

CAUTION!

Changes of this type could

endanger your safety.

As required

Monthly

l

l

l

Please contact Wap Customer

Service or an authorised

workshop for further

maintenance and repair work.

3.3 Emptying tank

(Fig. 6)

l Switch off vacuum cleaner by

setting main switch to “0”

position.

l Swing bar (1) of tank lock

upward; tank is lowered.

l Roll out tank (2).

(Fig. 7)

l Dispose of tank content in

accordance with legal

regulations.

l Roll in tank (2). Handle (3)

must face toward front.

l Swing bar (1) of tank lock

downward; tank is raised and

locked.

3.4 Filter element

3.4.1 Blowing off filter

(Fig. 8)

With vacuum cleaner switched

on:

l Connect compressed-air hose

to connection with quick

coupling and leave connected

for approx. 10 seconds, then

remove compressed-air hose

again.

Compressed air: Maximum

8 bar.

3.4.2 Changing filter element

(Fig. 9)

l Pull mains plug.

l Unlock four quick-lock screws

(1) of cover (2) by turning 90°

and pull off.

l Lift off cover (2) and thread

out power cable.

(Fig. 10)

l Disconnect connection hose

of filter blow-off (3).

l Lift off cover (4) upward and

lay toward rear on vacuum

cleaner.

(Fig.11)

l Pull out filter carrier ring (5)

with filter element (6).

(Fig. 11)

l Lay filter carrier ring (5)

upside down on vacuum

cleaner.

l Screw off hand screw (7).

Care/Maintenance

11

Page 12

Dynamics 440

l Pull off filter element (6)

upward.

l Dispose of used filter element

in accordance with legal

regulations.

Part No. for filter element:

34931.

(Fig. 12)

l Insert new filter element

centred.

l Make sure filter blow-off (8)

turns freely.

l Fit hand screw and tighten.

(Fig. 11)

l Remount filter carrier ring (5)

with filter element (6).

(Fig. 10)

l Fit cover (4), making sure that

notches in cover are located

over supports (9) of filter

carrier ring.

l Screw on connection hose of

filter blow-off (3) and

tighten.

(Fig. 13)

l Fit cover (2).

l Guide power cable (10)

Care/Maintenance

through opening of cover (2)

and under handle (11).

(Fig. 9)

l Move cover (2) into position.

No lines may be visible in area

of exhaust air outlet (12).

3.5 Checking exhaust-air

flap

Exhaust-air flap of stopped

turbine is jammed.

(Fig. 14)

l Release quick-lock screw (1)

of vacuum-cleaner rear panel

by turning 90°.

l Tilt back vacuum-cleaner rear

panel (2) and unhook.

(Fig. 15)

l Check exhaust-air flap (3) of

stopped turbine.

(Fig. 16)

l Bond paper piece onto bolt

(4) of exhaust-air flap.

l Switch vacuum cleaner to

position “I”, then to position

“II”. Flap must move.

l If exhaust-air flap does not

move, switch off vacuum

cleaner and free up exhaustair flap.

l Check for smooth movement

by switching vacuum cleaner

to position “I” first, and then

to position “II”. If exhaust-air

flap still does not move,

switch off vacuum cleaner

and inform Wap Customer

Service.

(Fig. 14)

l Hook in vacuum-cleaner rear

panel (2) and tilt forward.

l Lock cover by pressing in four

quick-lock screws (1).

12

l Lock vacuum-cleaner rear

panel by pressing in quicklock screw (1).

Page 13

3.6 Trouble-shooting

Dynamics 440

Fault

≠ Motor does not run

≠ Reduced suction power

Cause

> Mains plug not plugged in

> Circuit breaker of connection

outlet has been tripped

> Wrong rotating field

> Suction nozzle blocked

> Suction hose blocked

> Filter cartridge dirty

Remedy

• Plug mains plug into outlet,

see Section 2.3

• Reset circuit breaker

• Have connection outlet

connected according to

standard by electrician

• Clean suction nozzle

• Clean suction hose

• Clean filter cartridge (see

Section 3.4.1) or replace (see

Section 3.4.2)

4 Wap Service

4.1 Warranty

Our General Conditions of Sale

and Delivery apply for the

warranty and warranty period.

4.2 Company address

Wap

Reinigungssysteme GmbH & Co

Guido-Oberdorfer-Str. 2-8

89287 Bellenberg

Germany

Care/Maintenance

Wap Service

13

Page 14

www.nilfisk-alto.com

HEADQUARTER

DENMARK

Nilfisk-Advance Group

Sognevej 25

2605 Brøndby

Denmark

Tel.: (+45) 43 23 81 00

Fax: (+45) 43 43 77 00

E-mail: mail@nilfisk-advance.dk

SALES COMPANIES

AUSTRALIA

Nilfisk-ALTO

48 Egerton St.

PO box 6046

Silverwater NSW 2128

Australia

Tel.: (+61) 2 8748 5966

Fax: (+61) 2 8748 5960

AUSTRIA

Nilfisk-Advance GmbH.

Nilfisk-ALTO

Metzgerstrasse 68

A-5101 Bergheim bei Salzburg

Tel.: (+43) 662 456 400-0

Fax: (+43) 662 456 400-34

E-mail: info@nilfisk-alto.at

www.nilfisk-alto.at

BRASIL

Wap do Brasil Ltda.

Rua das Palmeiras, 350

Capela Velha

83.705-500 – Araucária - PR

Brasil

Tel.: (+55) 41 2106 7400

Fax: (+55) 41 2106 7403

E-mail: export@wapdobrasil.com.br

CANADA

ALTO Canada

24 Constellation Road

Rexdale

Ontario M9W 1K1

Canada

Tel.: (+1) 416 675 5830

Fax: (+1) 416 675 6989

CZECH REPUBLIC

ALTO Ceskà republika s.r.o.

Zateckých 9

14000 Praha 4

Czech Republic

Tel.: (+420) 24 14 08 419

Fax: (+420) 24 14 08 439

E-mail: wap_p@mbox.vol.cz

DENMARK

Nilfisk-ALTO

Division of Nilfisk-Advance A/S

Industrivej 1

9560 Hadsund

Denmark

Tel.: (+45) 72 18 21 00

Fax: (+45) 72 18 21 11

E-mail: salg@nilfisk-alto.dk

E-mail: service@nilfisk-alto.dk

www.nilfisk-alto.dk

Nilfisk-ALTO Food Division

Division of Nilfisk-Advance A/S

Blytækkervej 2,

9000 Aalborg

Denmark

Tel.: (+45) 72 18 21 00

Fax: (+45) 72 18 20 99

E-mail: scanio.technology@nilfisk-alto.dk

www.nilfisk-alto.com

FRANCE

Nilfisk-ALTO

ALTO France SA

Aéroparc 1

19 rue Icare

67960 Entzheim

France

Tel.: (+33) 3 88 28 84 00

Fax: (+33) 3 88 30 05 00

E-mail: info@nilfisk-alto-fr

www.nilfisk-alto.com

GERMANY

Nilfisk-Advance AG

Nilfisk-ALTO Business Unit

Guido-Oberdorfer-Str. 10

89287 Bellenberg

Germany

Tel.: (+49) (0) 180 5 37 37 37

Fax: (+49) (0) 180 5 37 37 38

E-mail: info@nilfisk-alto.de

www.nilfisk-alto.de

HOLLAND

Nilfisk-ALTO

Division of Nilfisk-Advance BV

Camerastraat 9

NL-1322 BB Almere

Tel.: (+31) 36 5460 760

Fax: (+31) 36 5460 761

info@nilfisk-alto.nl

E-mail:

www.nilfisk-alto.nl

HONG KONG

Nilfisk-Advance Ltd.

2001 HK Worsted Mills Ind'l Bldg.,

31-39 Wo Tong Tsui St.

Kwai Chung, Hong Kong

Tel.: (+852) 2427 5951

Fax: (+852) 2487 5828

HUNGARY

Kvantor-Itb Kft

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklos-Lakihegy

Hungary

Tel.: (+36) 24 47 55 50

Fax: (+36) 24 47 55 51

E-mail: nilfisk@kvantor-itb.hu

JAPAN

Nilfisk-Advance, Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku,

Yokohama, 223-0059

Japan

Tel.: (+81) 45 548 2571

Fax: (+81) 45 548 2541

MALAYSIA

Nilfisk-Advance Sdn Bhd

No. 1011, Block A4

Leisure Commerce Square

No. 9, Jalan PJS 8/9

46150 Petaling Jaya

Selangor, Malaysia

Tel.: (+60) 3 603 7876 4222

Fax: (+60) 3 603 7876 3878

PEOPLE’S REPUBLIC OF CHINA

Nilfisk-Advance (Shenzhen) Ltd

Blok 3, Unit 130, 1001 Honghua Road

Int. Commercial & Trade Center

Fuitian Free Trade Zone

518038 Shenzhen

P.R. China

Tel.: (+86) 755 8359 7937

Fax: (+86) 755 8359 1063

POLAND

Nilfisk-ALTO

Division of Nilfisk-Advance A/S

05-800 Pruszków

ul. 3-go MAJA 8

Poland

Tel.: (+48) 22 738 37 50

Fax: (+48) 22 738 37 51

info@nilfisk-alto.pl

www.nilfisk-alto.pl

NORWAY

ALTO Norge AS

Bjørnerudveien 24

1266 Oslo

Norway

Tel.: (+47) 22 75 17 70

Fax: (+47) 22 75 17 71

E-mail: info@nilfisk-alto.no

www.nilfisk-alto.no

PORTUGAL

Nilfisk-ALTO

Division of Nilfisk-Advance Lda.

Sintra Business Park

Zona Industrial Da Abrunheira

Edificio 1, 1

P-2710-089 Sintra

Tel.: (+35) 808 200 537

Fax: (+35) 121 911 2679

E-mail: mkt@nilfisk-advance.es

www.nilfisk-alto.com

SINGAPORE

Nilfisk-Advance Pte. Ltd.

Nilfisk-ALTO Division

40 Loyang Drive

Singapore 508961

sales@nilfisk-advance.com.sg

Tel.: (+65) 6 759 9100

Fax: (+65) 6 759 9133

SPAIN

Nilfisk-ALTO

Division of Nilfisk-Advance S.A.

Torre DAra

Paseo del Rengle, 5 Pl. 10

E-08302 Mataró

Tel.: (+34) 902 200 201

Fax: (+34) 93 757 8020

E-mail: mkt@nilfisk-advance.es

www.nilfisk-alto.com

SWEDEN

ALTO Sverige AB

Member of Nilfisk-Advance Group

Aminogatan 18, Box 4029

S-431 04 Mölndal

Sweden

Tel.: (+46) 31 706 73 00

Fax: (+46) 31 706 73 40

E-mail: info@nilfisk-alto.se

www.nilfisk-alto.se

TAIWAN

Nilfisk-Advance Ltd.

Taiwan Branch (H.K.)

1F, No. 193, Sec.2

Xing Long Rd., Taipei

Taiwan, R.O.C.

Tel.: (+886) 2 2239 8812

Fax: (+886) 2 2239 8832

THAILAND

Nilfisk-Advance Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Thailand

Tel.: (+66) 2 275 5630

Fax: (+66) 2 691 4079

UNITED KINGDOM

Nilfisk-ALTO

Division of Nilfisk-Advance Ltd.

Bowerbank Way

Gilwilly Industrial Estate

Penrith Cumbria CA11 9BQ

Great Britain

Tel.: (+44) (0) 1768 868995

Fax: (+44) (0) 1768 864713

E-mail: sales@nilfisk-alto.co.uk

www.nilfisk-alto.co.uk

USA

ALTO Cleaning Systems Inc.

Part of the Nilfisk-Advance Group

12249 Nations Ford Road

Pineville, NC 28134

USA

Tel.: (+1) 704 971 1240

Fax: (+1) 704 971 1241

E-mail: info@nilfisk-advance.us

www.nilfisk-alto.com

o

A

Loading...

Loading...