Nilfisk DUO BOOSTER EXTENDED, UNO BOOSTER EXTENDED Instruction manual

UNO BOOSTER EXTENDED

DUO BOOSTER EXTENDED

Instruction manual ........................................... 3 - 22

Betriebsanleitung ............................................. 23 - 43

Manuel d’Instructions ....................................... 44 - 66

Gebruikershandleiding ..................................... 67 - 88

Manual de instrucciones .................................. 89 - 111

Manuale di istruzioni ........................................ 112 - 133

Руководство по эксплуатации ....................... 134 - 156

Index

1 Safety Precautions and Warnings ...............................................................................................4

2 Description 2.1 Application ..............................................................................6

2.2 Operation elements ................................................................6

3 Installation 3.1 Temperature conditions ..........................................................7

3.2 Condition of distance ..............................................................7

3.3 Wall mounting .........................................................................8

3.4 Water connection ....................................................................8

3.5 Mains power connection .........................................................9

3.6 High pressure connection .......................................................9

3.7 Venting ...................................................................................9

4 Operation 4.1 Connections .........................................................................10

4.1.1 High pressure hose - directly on the machine ...........10

4.1.2 High pressure hose - to outlet point ...........................10

4.1.3 Spray handle - accessories .......................................11

4.1.4 Selection of spray lance .............................................11

4.1.5 Function (only DUO BOOSTER) ...............................12

4.1.6 Application of detergents (external injector) ..............12

4.1.7 Application of detergents (internal) ............................13

4.2 Starting up ............................................................................13

4.3 Operation - automatic start/stop ...........................................13

4.4 Double spray lance, pressure regulation ..............................14

4.5 Stop ...................................................................................14

4.6 Frost protection .....................................................................14

5 Fields of Application

and Working Methods 5.1 Fields of application ..............................................................16

5.2 Working pressure .................................................................16

5.3 Detergents ............................................................................16

5.4 Working methods .................................................................17

6 Maintenance 6.1 Oil ...................................................................................18

6.2 Water fi lter ............................................................................19

6.3 Cleaning of high pressure nozzle .........................................19

6.4 Disposable waste .................................................................19

7 Trouble Shooting .....................................................................................................20

8 Technical Data .....................................................................................................22

9 Warranty .....................................................................................................22

EC Declaration of Conformity ...................................................................................................157

3

1 Safety Precautions and Warnings

Before starting up your high

pressure washer for the fi rst

time, this instruction manual

must be read through carefully.

Save the instructions for later

use.

Only let instructed people

operate the machine.

General

When using the high pressure

washer all existing national

regulations must be observed.

Beyond the instruction manual

and the current national legal

regulations for prevention of

accidents, also the approved

rules for safe working must be

observed.

Any method of use endangering

the safety of persons or

equipment is forbidden.

Before use

Before starting up your high

pressure washer check that it is

in a regular condition. Electric

plugs and couplings must be

watertight.

Check the electric cables at

regular intervals for damage

and wear. Only use the high

pressure washer if the electric

cable is all right (damaged

electric cables can cause

electric shock!)

Important instructions

Connection to public mains

according to the applicable

regulations in your country.

IMPORTANT: Only use water

without impurities!

Before each use of your high

pressure washer check the

most important visual parts.

High pressure jets can be

dangerous if misused. Never

direct the water jet towards

people, pets, electric wiring, or

the machine itself.

Spray handle and lance are

affected by a thrust during

operation - therefore always

hold the spray lance fi rmly with

both hands.

Never try to clean clothes or

footwear on yourself or other

persons.

Operator and anyone in

immediate vicinity of the site

of cleaning should take action

to protect himself from being

struck by debris dislodged

during operation.

Check that cleaning will not

result in dangerous substances

(e.g. asbestos, oil) being

washed off the object to be

cleaned and harming the

environment.

Do not clean sensitive surfaces

made of rubber, fabrics or

the like with the zero nozzle.

With the fl at jet nozzle keep a

distance of at least 15 cm to the

surface to be cleaned.

Never let children operate the

machine.

Do not use the machine if

the electric cable or the high

pressure hose are damaged.

Do not cover the machine

during operation or use it

in a room without adequate

ventilation !

If the overload protection device

of the motor trips (motor stops),

release the trigger of the spray

handle. Lock the spray handle

with locking device and turn the

start/stop switch to position „0“.

Let the machine cool off for at

least 3 minutes!

The machine must be placed in

a room where it is not exposed

to frost.

Operation

Avoid damage to the electric

cables such as running over

by a car, squeezing, pull, knots

etc. and keep them away from

sharp or hot objects.

Avoid damage to the high

pressure hose such as running

over by a car, squeezing, pull,

knots/kinks etc. and keep it

away from oil and sharp or hot

objects, as such may cause the

hose to burst.

The cleaner can be used in

zones classifi ed as ZONE 2.

Important! Never use the

machine in an environment

where there could be a danger

of explosion (according to EN-

50014).

4

Important! When the system

has been in operation and

thereafter stopped, there will

still be a working pressure in

the pipeline and high pressure

hoses. Therefore you should

pay special attention to the

following:

• Never dismount the high

pressure hose from the

machine during operation.

Disconnect the machine,

close the shut-off cock and

relieve the high pressure

hose of pressure prior to

dismounting.

• Never dismount the high

pressure hose from the outlet

point before it has been

securely closed and the high

pressure hose has been

relieved of pressure.

• Prior to any service

interference in the machine

it should be disconnected

and the system relieved of

pressure by activating the

trigger of the spray handle.

Mains power connection

Check the nominal voltage

of the high pressure washer

before connecting it to the

electricity supply.

Check that the voltage stated

on the model tag corresponds

to your mains voltage.

A circuit breaker must be

placed in the immediate vicinity

of the machine.

We recommend you to connect

the machine to a power source

with a Residual Current Device

(RCD) which will disconnect

the power supply if the leakage

current exceeds 30 mA for 20

milli seconds.

Only connect to an approved

socket with earth connection.

Safety Devices

Safety Valve

The pressure side of the high

pressure pump is fi tted with a

safety valve. This valve leads

the water back to the suction

side of the pump when the

spray handle is closed or if a

nozzle is blocked.

The safety valve is adjusted

and sealed by the producer.

THIS ADJUSTMENT MUST

NOT BE CHANGED !

Motor protection

The motor features an

overcurrent protection and

built-in thermal switches for

protection of motor against

overloading. In the event of

increased power consumption

(maloperation), the current for

the motor will automatically be

cut out.

Repair and Maintenance

Only carry through the

maintenance operations

described in the operating

instructions. Only use original

Nilfi sk-ALTO spare parts.

Do NOT make any technical

modifi cations to the high

pressure washer.

Warning! High pressure

hoses, nozzles and couplings

are important for the safety

when operating the machine.

Only use the high pressure

hoses, nozzles and couplings

prescribed by Nilfi sk-ALTO!

For major repairs, please

contact your nearest Nilfi skALTO service organisation.

Only connect the machine to an

electrical installation made by

an qualifi ed electrician.

The insulation of the electric

cable should be quite faultless

and without any cracks.

If you are in doubt about the

the mains power connection,

please contact a qualifi ed

electrician.

Note: If using another cable it

must be earthed and connected

through the plug to the earth

cable of your supply network

in accordance with prescribed

safety regulations.

Always use a cable similar

to the one mounted on the

machine.

Check cables before usage. Do

not use damaged cables.

Only let a qualifi ed electrician

replace the electric cable.

5

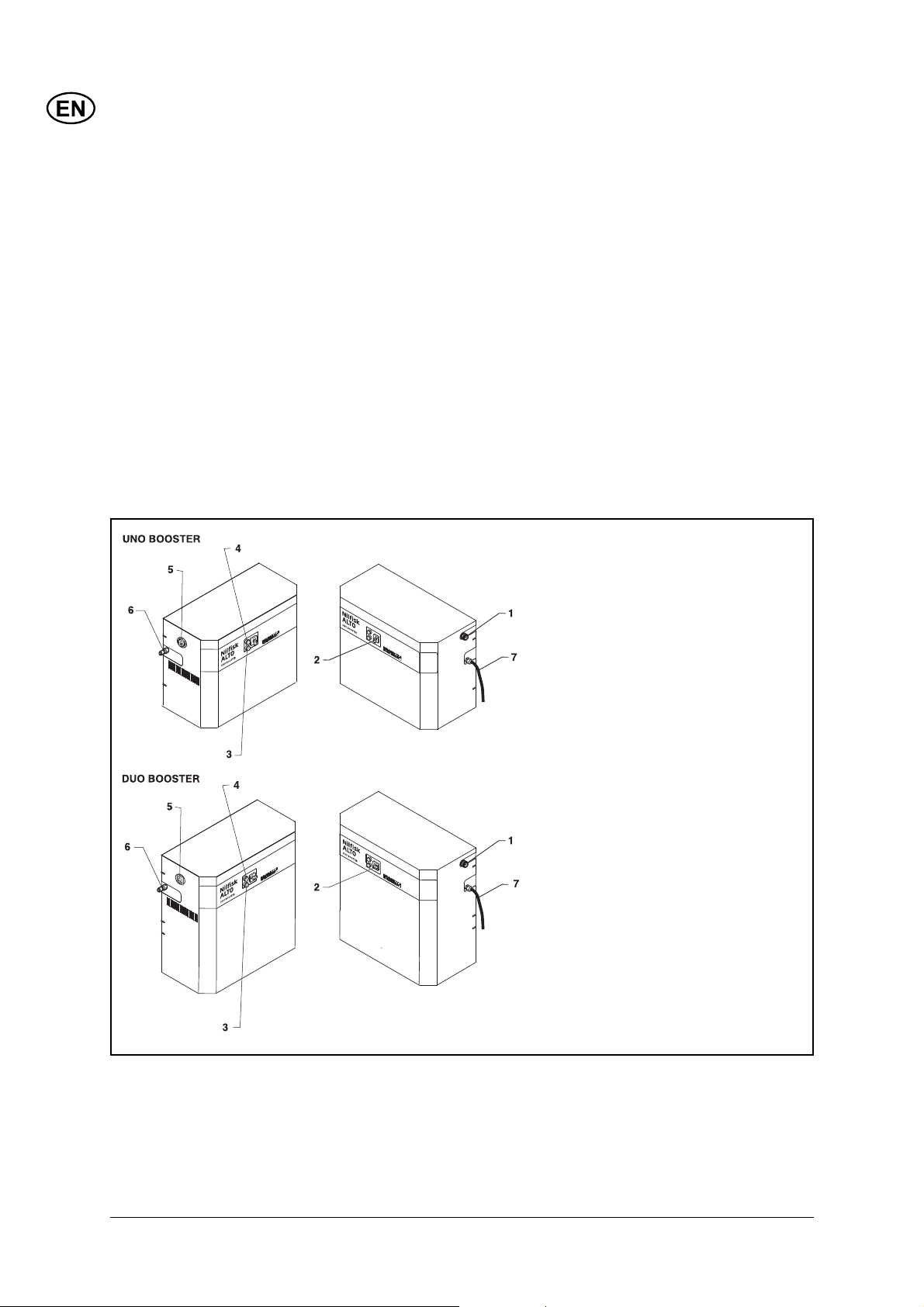

2 Description

2.1 Application

2.2 Operation elements

This high pressure washer has

been developed for professional

use within:

- agriculture

- light industry

- transport

- building and construction

- service

Section 4 describes how to use

the high pressure washer.

Only use the high pressure

washer for purposes described

in this manual.

The safety precautions must be

observed to prevent damage

to the machine, the surface to

be cleaned or severe personal

injuries.

1 Water connection with fi lter

2 Main switch

3 Starter switch

4 Stop switch

5 Pressure gauge

6 Connection of high pressure

hose

7 Electric cable

S

6

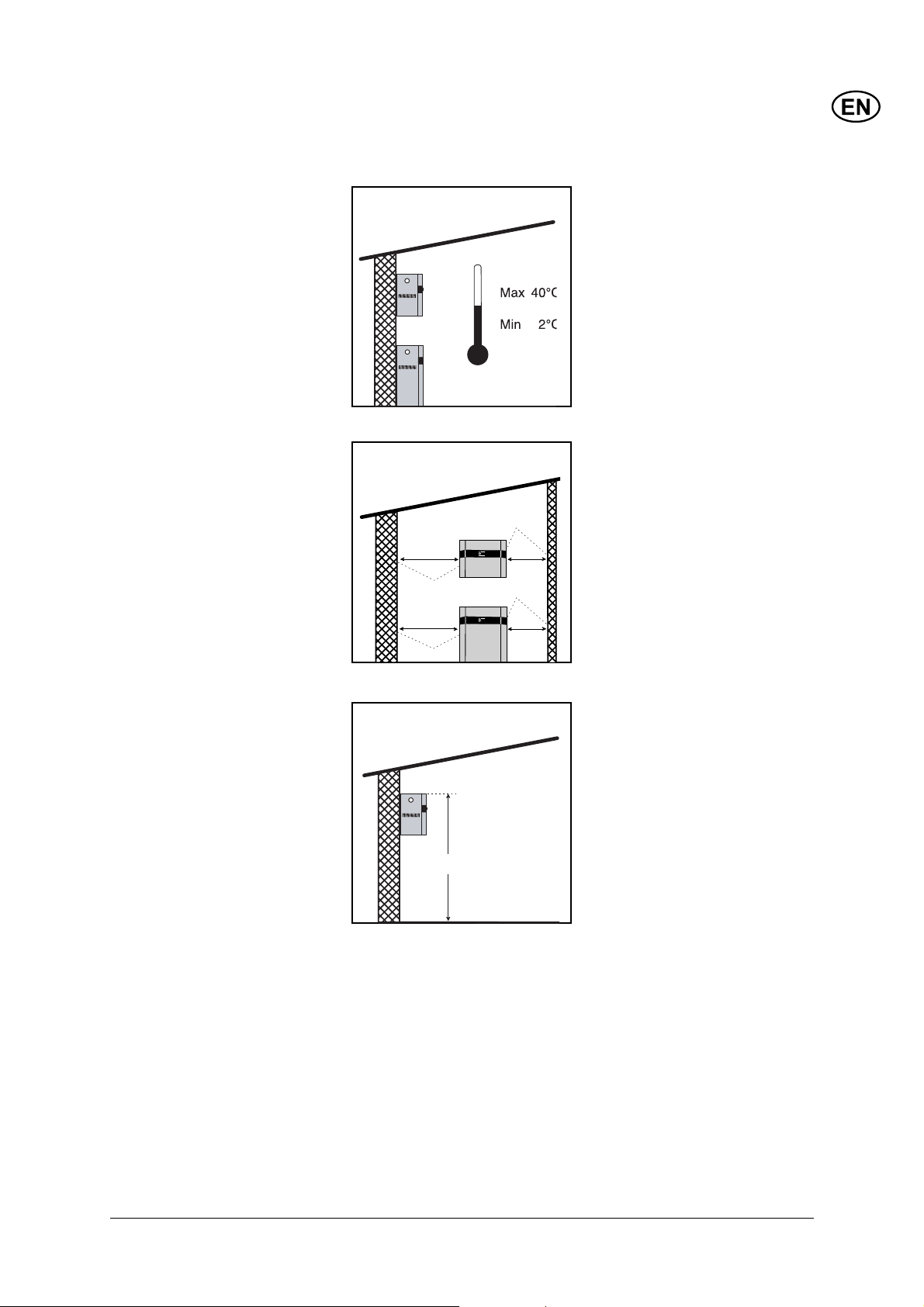

3 Installation

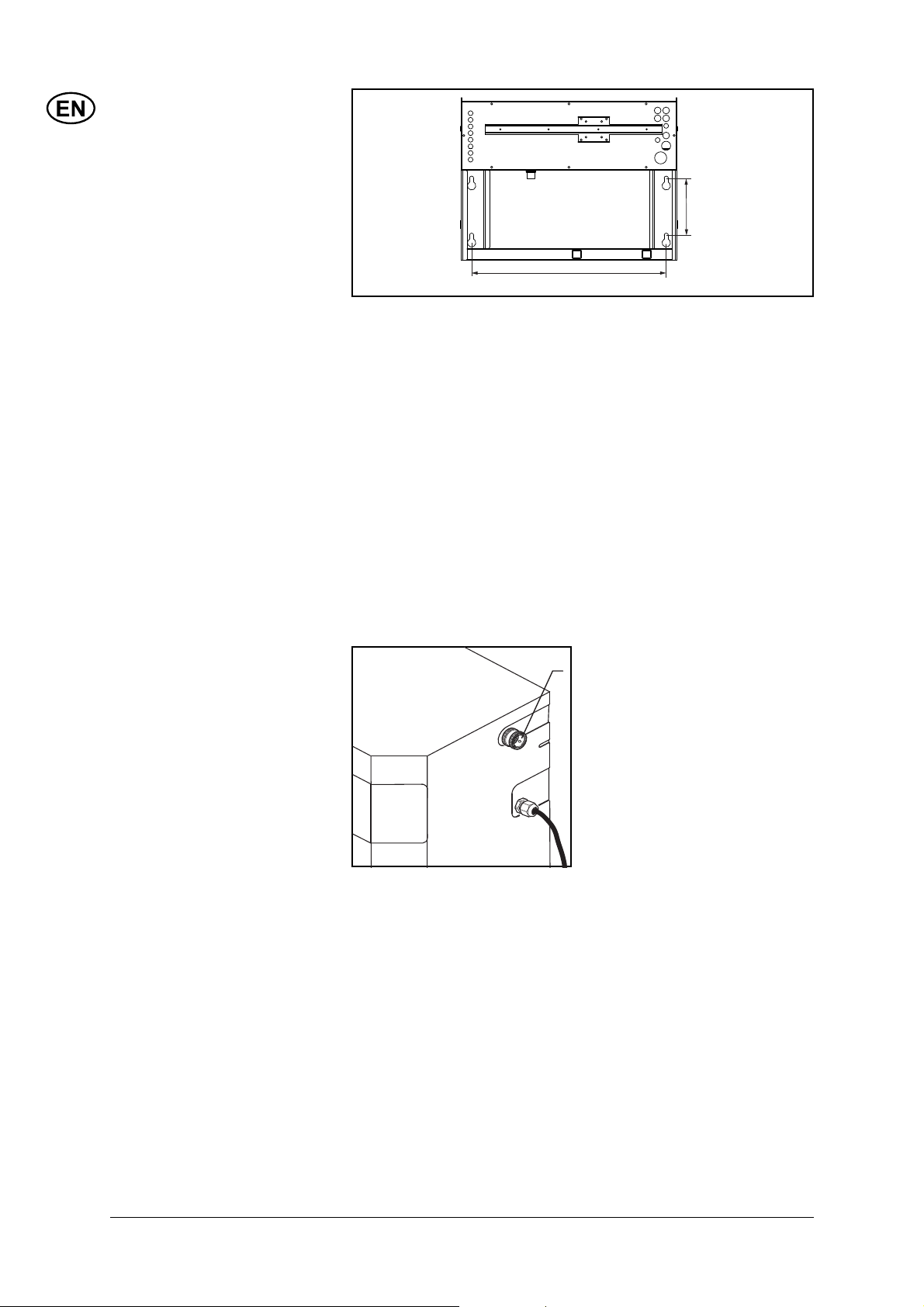

Min 400 mm

Min. 150 mm

1

0

1

0

Min 400 mm

Min. 150 mm

3.1 Temperature conditions

3.2 Condition of distance

The machine should be

installed in a frost-free room.

This applies to pump as well as

pipelines incl. of outlet points.

Con cern ing outdoor outlet

points, it should be possible to

close and emp ty that part of the

line which is exposed to frost.

The maximum ambient

temperature for the machine is

40°C.

In consideration of the cooling

system of the machine and the

accessibility of service, there

must be free wall space on

both sides of the machine. To

the right 150 mm at a min i mum

and to the left 400 mm at a

min i mum.

Max. 1700 mm

Max. 1700 mm

UNO BOOSTER:

The recommended installation

height for the machine is max.

1700 mm measured from the

upper edge of the machine.

7

1

3.3 Wall mounting

253,5

645

3.4 Water connection

UNO BOOSTER:

Only mount the machine on a

solid wall construction suited for

the mounting of a ma chine. I.e.

a concrete or brick wall.

Do not mount the machine

on a wall where it will cause

disturbances in neighbouring

rooms (canteens, offi ces etc.).

DUO BOOSTER:

Place the machine on a plane

fl oor.

Machine feet have been

mounted under the machine.

These must be adjusted so that

the machine stands stable.

The water connection is

made through a fl exible hose

connected to the quick cou pling

on the water inlet (1) of the

machine.

supply network is required. The

machine complies with EN 1717.

If there is a risk of running sands

or other impurities in the inlet

water, a sand fi lter (50 micron)

should be mounted beyond the

internal fi lter of the machine

(for further connection data see

section 8 Tech ni cal data).

If mounting the by-pass hose,

the water inlet temperature can

The connection can be made

to a water supply network or an

internal water sup ply. A shutoff cock should be mounted

be raised to 80°C. ONLY do

this if there is a separate water

supply (contact your Nilfi sk-

ALTO distributor).

on the water supply network

in the immediate vicini ty of the

ma chine.

Clean the water inlet fi lter (1)

once a month.

Max. water pressure: 10 bar

Max. water inlet temp.: 70°C

The machine features a water

tank, and no further protection

against return water into the

8

3.5 Mains power

connection

Connect the machine to an

approved socket.

Check voltage, fuse, and cables

according to section 1 Safety

proceautions and warnings.

Connection data conc. power

consumption can be taken from

the model tag of the machine.

3.6 High pressure

connection

3.7 Venting

)

0

1

MPORTANT: When connecting

to a pipeline always use a

fl exible hose connection from

the outlet of the machine (pos.

6) - order no. 6300843. Contact

your Nilfi sk-ALTO distributor for

further information.

The outlet of the machine can

be connected to a pipeline with

fi xed outlet points, or standard

high pres sure hoses can be

connected directly to the outlet

of the machine.

It is recommended to let a

service tech ni cian authorized

by Nilfi sk-ALTO prepare the

pipeline.

Turn main switch to position

- 1 -. Open the outlet point.

Let the water run until all air has

escaped from the pump (even

water fl ow).

In the case of a recently

installed sys tem, or if the

pipeline and the pump have

been emptied in any other way,

the system should be vented

by starting the pump and then

let the water run at each outlet

point of the pipeline at turns.

When con nect ing the high

pressure hose directly to the

ma chine, the sys tem should

be vented by starting the pump

and ac ti vat ing the trigger of the

spray handle without having

attached the spray lance.

9

Loading...

Loading...