CONTRACTOR SILENT

NL

FR

DE

EN

Instruction manual........................ 1 - 12

Betriebsanleitung .......................... 13 - 24

Manuel d'Instructions.................... 25 - 36

Gebruikershandleiding.................. 37 - 48

IMPORTANT: Read this instruction manual

before you start up your high pressure washer

for the rst time.

This machine is a high pressure washer producing a water jet under high pressure which is why

severe injuries can occur if the safety precautions

are not observed.

Therefore a complete understanding of the contents of this instruction manual is required in order

to prevent injuries to yourself, objects and persons

nearby, and the machine itself.

Contents 2 - 13 EN

1.0 Survey of models.........................................3

1.1 Model tag................................................ 3

2.0 Instructions for use.....................................4

Safety precautions and warnings

2.1 Unpacking...............................................4

2.2 Operation................................................ 4

2.3 Safety devices on the cleaner.................5

2.4 General................................................... 5

3.0 Operating instructions................................6

3.1 Connections ...........................................6

1. High pressure hose.............................6

2. Water connection................................6

3. Spray handle - accessories ................6

4. Diesel engine...................................... 7

5. Fuel for engine and burner .................7

3.2 Starting-up procedure............................. 7

3.3 Operation................................................ 7

3.4 Spray lance, pressure regulation............ 8

3.5 End of operation ..................................... 8

3.6 Transport and lifting directions................ 9

3.7 Storage...................................................9

4.0 Fields of application and

working methods....................................... 10

4.1 Fields of application.............................. 10

4.2 Working pressure .................................10

4.3 Detergents............................................10

4.4 Working methods..................................11

5.0 Pre-priming ...............................................11

6.0 Maintenance............................................... 12

6.1 Oil ......................................................... 12

6.2 Sludge container ..................................12

6.3 Water lter ............................................ 12

6.4 Cleaning of high pressure nozzle ......... 12

7.0 Trouble shooting and correction..............13

Designations EN

(see drawing inside back cover)

1. Ignition key for electric start

2. Connection of water and water lter

3. Thermometer

4. Pump oil level inspection and ll cup

5. Pressure gauge

6. Thermostat, burner

7. High pressure outlet

8. Spray handle

9. Spray lance

10. Model tag

11. Sludge container

12. High pressure hose

13. Oil drain plug, high pressure pump

14. Air lter, diesel engine

15. Filler hole for diesel (auto diesel)

16. Diesel lter, diesel engine/burner

17. Hour counter

18. Shift lever for hot/cold water

19. Start, oil burner

20. Oil lamp, diesel engine

21. Filament lamp, diesel engine

22. Water temperature lamp, engine

23. Charging lamp for battery

24. Valve for regulation of water volume

25. Oil dip-stick

26. Expansion tank, diesel engine

27. Lifting points on frame

The environmental policy of ALTO

ALTO has made it a natural part of the concept of

the company to reduce the effect on our environment as much as possible. This plan is effected

through a constant development in all branches

of the company so that the greatest number of

elements in our high pressure washers affects the

environment to a minimum.

This product too is characterised by the attitude

of ALTO towards the environment.

For the production of this high pressure washer

the latest technique and technology has been applied. The consumption of unnecessary subsidiary

materials has been minimized, and during the nal

test of the product the test water is recycled.

1

3

1.0 Model survey EN

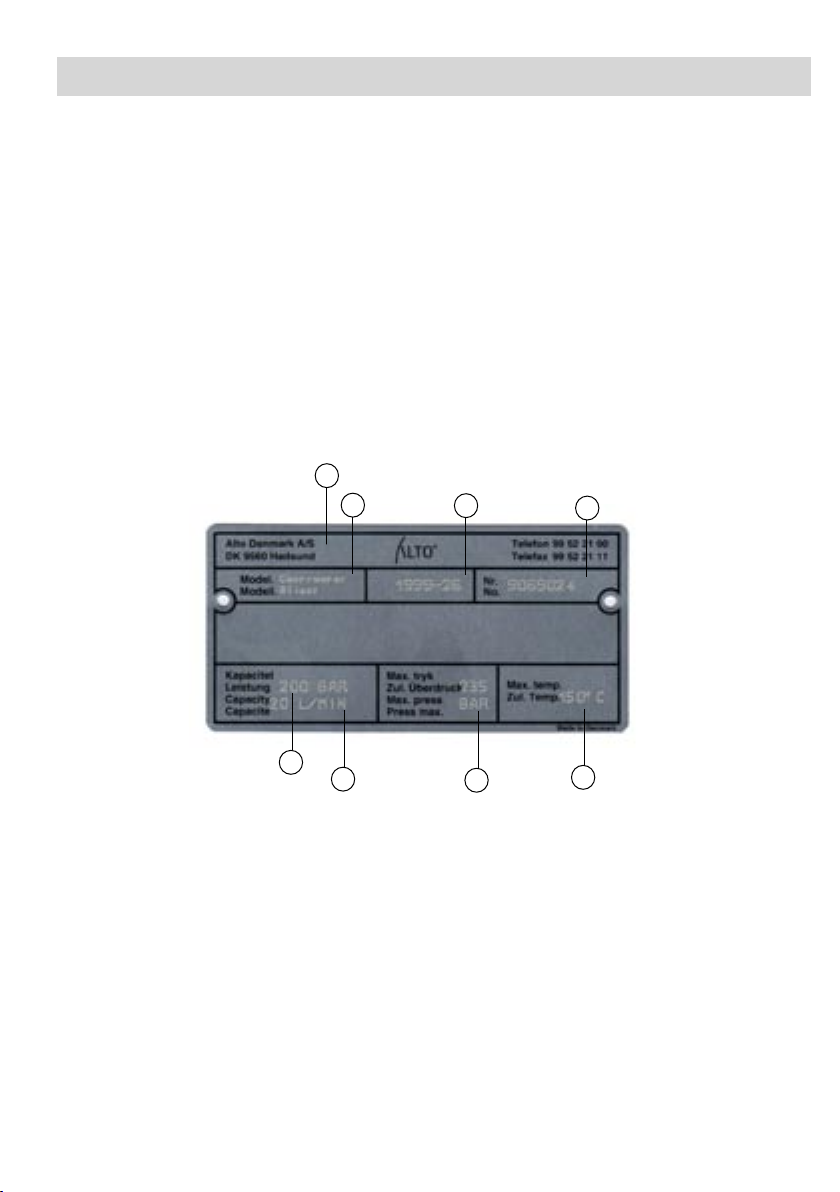

1.1 Model tag

This ALTO high pressure washer has the serial designation CONTRACTOR.

The model designation appears from the text on the cabinet, i.e. CONTRACTOR SILENT

and the model tag (Pos. 10) at the back of the machine.

The model tag provides the following important information:

1. Producer

2. Model designation

3. Production year/week

4. Serial number

5. Pump pressure

6. Water volume

7. Max. pressure

8. Max. temperature

1

2

3

4

5

6

2

7

8

2.0 Instructions for use Safety precautions and warnings EN

Before starting up your high pressure washer for the rst time, we advise you to read through the following

sections: 2.0 Instructions for use and 3.0 Operating instructions and to follow all instructions to ensure the

protection of user, surroundings and machine.

2.1 Unpacking

Upon the unpacking of your machine please check it for any defects. If you nd any, we kindly ask you to

contact your ALTO distributor.

2.2 Operation

This machine produces a high pressure jet and operation contrary to the instructions can cause severe

injuries!

For your own and the safety of others the following precautions should always be observed:

l WARNING! Never direct the water jet towards people, pets, electric wiring, or the machine

itself.

l WARNING! Never try to clean clothes or footwear on yourself or other persons.

l We recommend you to wear goggles during operation.

l Never work barefoot or with sandals.

l Operator and anyone in immediate vicinity of the site of cleaning should take action to pro-

tect himself from being struck by debris dislodged during operation.

l According to regulations persons under the age of 18 must not operate cleaning machines

with a working pressure above 70 bar (applies to this machine).

l The machine should be placed as far away from the cleaning site as possible.

l Only let instructed personnel operate the machine.

l Don’t start the machine until the high pressure hose has been correctly mounted.

l Spray handle and lance are affected by a thrust during operation - therefore always hold the

spray lance rmly with both hands.

l At intervals during operation, the machine should be stopped and the spray handle secured

against inadvertent use by locking trigger with locking device.

l Only activate the trigger by hand. Never tie it up or x it in any other way.

l Avoid damage to the high pressure hose such as running over by a car, squeezing, pull, knots/kinks

etc. and keep it away from oil and sharp or hot objects, as such may cause the hose to burst.

l Danger of scalding! Never dismount the high pressure hose or the water inlet hose while the machine

is in operation. Disconnect the cleaner, shut off the water supply and activate the spray handle before

dismounting the high pressure hose or the water inlet hose.

l According to the legislation in many countries it is forbidden to use the machine in an environment

where there could be a danger of explosion. If any doubt arises, please contact your local authorities.

Important: OFFSHORE

Never use the machine in an environment where there could be a danger of explosion

(according to EN-50014).

l WARNING! High pressure hoses, nozzles and connections are important for safety when operating the

machine. Only use the high pressure hoses, nozzles and connections prescribed by ALTO.

l For safety reasons only use original ALTO accessories and spare parts.

l In icy conditions never start the cleaner until machine, hoses and accessories have thawed. Otherwise

the machine could be damaged.

l The cleaner should not be covered during operation.

WARNING!

Diesel lling

Always stop the engine and let it cool for at least two minutes before lling with fuel.

Avoid spilling diesel. If diesel nevertheless is spilled while relling, the engine must not be started until the

spilled diesel has been removed.

3

5

Safety precautions and warnings EN

If the machine is placed in a trailer, any diesel spillage must be removed before restarting the machine.

Never use an open ame near the machine.

It is forbidden to smoke while relling with diesel.

Also read the instruction manual for the Mitsubishi engine.

NB: Never run the machine in a closed room. The exhaust gases are dangerous.

2.3 Safety devices on the machine

Circulation valve (safety valve)

The pressure side of the high pressure pump is tted with a circulation valve (safety valve). This valve

circulates the water back to the suction side of the pump when the spray handle is closed or if a nozzle

is blocked. The circulation valve has been constructed as a safety function ensuring that the pressure will

never exceed the working pressure by more than 35 bar. At this pressure the circulation valve will automatically switch from high pressure to circulation mode, approx. 15 bar.

Never let the machine run for more than 5 min. upon release of the spray handle trigger as it may be

damaged. The valve has been adjusted and sealed from the factory. This adjustment must not be chan-

ged! The circulation valve ensures that the machine becomes devoid of pressure when it is stopped.

Engine protection

The diesel engine will automatically stop if the oil level is insufcient or if the temperature of the cooling

water is too high. The engine can be restarted when having been relled with oil or dhet water has cooled.

2.4 General

l It is not allowed to clean asbestos-containing surfaces with high pressure, unless using special equip-

ment.

l Persons under the inuence of alcohol, drugs and medicine should not operate the machine.

l WARNING! This machine has been constructed for use with ALTO detergents. The use of other deter-

gents or chemicals may cause problems as to the operation and the safety.

l When using detergents the instructions should always be strictly observed.

l Don’t use the machine if important parts of the equipment are damaged - i.e. safety devices, high pres-

sure hoses, spray handles, cabinet.

l The most efcient cleaning is obtained if you adjust the distance to the surface which is to be cleaned.

Thus you will also avoid damaging the surface.

l Do not let the machine run for more than 5 minutes once the spray handle has been released (the

pump then circulates the water internally and the machine will overheat unless stopped after 5 minutes).

4

3.0 Operating instructions EN

25

26

3.1 Connections

1. High pressure hose

Max. extension hose: 50 m.

Only use ALTO high pressure hose.

Connect the high pressure hose with imprinted max. working pressure and temperature to the quick coupling (1) on the machine front.

1

2. Water connection

Min. length of hose: 6 m. 3/4".

Clean water inter lter (1) at monthly

intervals.

Max. water pressure 10 bar.

Let water run through the inlet hose to remove any impurities.

1

3. Spray handle - accessories

1

Clean nipple of any impurities each time

the spray lance has been detached.

2

1. Pull the blue quick coupling of the spray handle forward and lock it by turning it to the left (1).

2. Insert the nipple of the lance (2) into the quick coupling and turn the blue quick coupling to the right.

3. Pull forward the spray lance or any other accessory to ensure correct mounting before starting the

cleaner.

5

7

Operating instructions EN

28

33

4. Diesel engine

A description and operating / maintenance instructions for the Mitsubishi engine will be found in the

Mitsubishi manual provided with the CONTRACTOR SILENT. Please read this manual before starting up.

The throttle control of the engine has been adjusted by ALTO meaning that the max. number of revolutions

corresponds to the max. pressure of the pump. This adjustment must not be changed.

5. Fuel for engine and burner

Only use pure auto diesel.

3.2 Starting-up procedure

2

1

Check that the oil in the oil reservoir (2) is between the MIN and the MAX markings.

Turn the starting key (1) to the right.

3.3 Operation

2

Always hold the spray lance with both

hands!

Always lock the spray handle when the

cleaner is not in operation.

1

Activate the high pressure washer by releasing the trigger of the spray handle (1). When starting up the

machine the pressure may be unsteady because of air in the pump system. After a short time the air has

escaped from the system and the pressure will become steady. When the cleaner is not in use, secure the

spray handle (2).

6

Operating instructions EN

1

3.4 Spray lance, pressure regulation

Turn pressure reducing valve:

Clockwise (B): high pressure

Counter clockwise (A): low pressure

The spray lance features 2 nozzles, a high pressure nozzle and a low pressure nozzle.

High pressure operation

The max. working pressure of the machine is reached when the pressure reducing valve (1) is completely

closed (B). In this position only the high pressure nozzle is used - high pressure operation.

Low pressure operation

If a completely reduced pressure is required, open the pressure reducing valve (A) completely. The nozzle

pressure will then be approx. 8 bar. In this postion both spray lances are used - low pressure operation.

3.5 End of operation

Turn key (1) to the left - motor stops.

Danger of scalding! Never dismount the

high pressure hose or the water inlet hose

while the machine is in operation.

Disconnect the machine, shut off the water

supply and activate the spray handle

before dismounting the high pressure

hose or the water inlet hose.

Turn off the water supply and activate the trigger of the spray handle.

Dismount the high pressure hose and the water inlet hose.

1

1

7

9

Operating instructions EN

3.6 Transport and lifting instructions

Always secure the machine during

transport

When handling the machine with a fork-lift truck, be sure the forks extend completely under the machine

to balance it. The machine can also be lifted with a tackle/crane by wrapping a sling around the lifting

points on the upper frame parts. Ensure that no persons are under or near the machine during lifting. If the

machine is transported in a truck or trailer, it must be secured against sliding or tipping.

3.7 Storage

Frost-freee room or anti-freeze!

Prior to putting the machine aside for storage, it must be emptied completely of water according to the

following procedure:

1. Dismount the water inlet hose and the high pressure hose and empty them of water.

2. Start the machine to empty the pump system of water.

If the store room is not frost-free, the machine shoud be protected against frost in the following way:

1. Dismount the water inlet hose from the water tap, dismount the spray lance and activate the trigger of

the spray handle until the machine has been emptied of water.

2. Place the water inlet hose in a bucket containing an anti-freeze.

3. Draw in the anti-freeze from the bucket by activating the trigger of the spray handle while placing it

above the bucket with the anti-freeze letting the anti-freeze circulate.

4. Remove the water inlet hose from the bucket, activate the trigger of the spray handle and the rest of the

anti-freeze is lead back into the bucket.

NB! After repeated use the anti-freeze will be diluted with water and thus loose its effect.

8

4.0 Fields of application and working methods EN

4.1 Fields of application

The diesel powered hot water cleaner of ALTO, CONTRACTOR SILENT, is a sturdy machine suitable for

all outdoor cleaning tasks, for which steam, hot or cold water is used with or without the addition of a detergent (see section 4.3).

The most important elds of application for this machine are:

Building & Construction Cleaning of vehicles, equipment, buildings etc.

Building & Construction Removal of grafti

Building & Construction Cleaning of house fronts

4.2 Working pressure

The high pressure washer may be used with high or low pressure at your own option. At the standard

spray lance the working pressure is adjusted by turning the reduction valve.

Low pressure Is rst and foremost used for application of detergents and for washing off.

High pressure Is used for cleaning.

Intermediate pressure As an example it may be used for the cleaning of surfaces, which cannot

stand a too powerful jet, i.e. soft surfaces.

4.3 Detergents

As standard the machine is delivered without a detergent injector.

Detergents should not be added to the inlet water (pos. 2) and thus pass through the pump. If you want to

use detergents, these should be added through an external injector.

The most efcient cleaning is reached with detergents in conjunction with the high pressure cleaning.

For that purpose ALTO can offer you a series of products specially developed for high pressure cleaning,

among other elds within

Cleaning of vehicles, machines, house fronts etc. Disinfection

Degreasing of workpieces Descaling

The products are water-based, without phosphates, and the applied tensides (surface active substances)

comply with the present requirements for easy biodegradability.

Contact your ALTO distributor for directions as to which product will full your requirements.

The method of application and the dosage of the individual products appear from the product labels or the

data sheet.

Change from application of detergent under low pressure to cleaning under high pressure is simply effected by regulating from »low pressure mode« to »high pressure mode« on the spray lance.

For foam cleaning mount the special foam injector between the high pressure washer and the high pressure hose. Insert the suction hose on the injector into the foam detergent. Attach the foam lance to the

spray handle and now foam can be applied. Upon application detach the foam injector and replace the

foam lance by a spray lance and you are ready for cleaning.

9

11

Fields of application and working methods EN

4.4 Working methods

Your high pressure washer has been developed for cleaning according to the so-called »2-step method«. It

requires, however, that the high pressure washer is equipped with an external detergent injector.

STEP 1 Application of detergent

STEP 2 High pressure cleaning

In practice the working process is laid down in accordance with the actual job, but as a starting point the

following working method can be described for a job:

1. Apply detergent under low pressure. The dosage is chosen according to the job, which is to be carried

through, and the adjustment is made on the dosing unit.

2. Await acting time. Let the detergent act on the dirt/surface for a short time prior to pressure cleaning

- usually a few minutes.

3. High pressure cleaning. Clean all surfaces under high pressure.

4. Rinse afterwards, if necessary, to make sure that residual impurities are removed from the surface.

In connection with the working process the optimum cleaning will be reached by following these 3 pieces

of advice:

Advice no. 1

When using a detergent, usually always apply it on a dry surface. If the surface is rinsed with water at rst,

it may be difcult for it to absorb the detergent, and the result is a reduced effect of the detergent.

Advice no. 2

When applying a detergent on large vertical surfaces (i.e. the sides of a truck) work from below and

upwards. Thus you will avoid the detergent running off the surface through grooves and dark streaks appearing on the surface whilst cleaning.

Advice no. 3

During the high pressure cleaning you should work so that the high pressure water does not run over the

surface which has not been cleaned yet. This is to ensure that there is sufcient detergent on the surface

when the high pressure water hits the surface.

5.0 Pre-priming

The pressure washer is pre-priming, and the water can be taken from a tank, a stream or the like. The

suction height depends on the water temperature. Max. suction height of 2 m is reached with cold water

(up to 8°C).

The pump and the water inlet hose must be primed with water before starting up.

If there is a risk of impurities (such as running sands) in the inlet water, an external lter must be mounted

beyond the internal lter of the machine. Please contact your ALTO distributor for further information.

10

6.0 Maintenance EN

It applies to the most exposed components that a minimum of maintenance ensures a prolonged and

problem-free operation. Therefore it will be a good idea to make a habit of the following:

Before mounting the water hose and the high pressure hose clean the couplings of dust and

sand.

Before mounting spray lance or any other accessory on the spray handle start the machine and

clean the couplings of dust and sand.

The machine should be stored in a frost-free room. If by mistake the machine freezes up, it

must not be started. Let machine, hoses and accessories thaw up before starting up. NEVER

START A FROZEN UP MACHINE.

6.1 Oil

Oil change - pump

Change the oil after 1000 hours' operation.

Remove the cover of the oil reservoir (pos. 4). Unscrew the oil drain plug (pos. 13). Let the oil run out and

clean the drain plug of dirt. Screw in the plug and rell the pump with fresh oil through the oil reservoir.

Holds approx. 1 litre per pump. From ALTO the pumps are lled with zincless hydraulic oil - ALTO Pump Oil

100. When relling and changing the oil, this or an oil with the following specications should be used:

ISO no. 100

Viscosity index (VI) min. 130

Pour point below -30°C

6.2 Sludge container

The used oil is caught in a sludge container (pos. 11). Empty the container before it is full. This oil must not

be re-used in the pump.

PROTECT THE ENVIRONMENT

Waste oil and oil sludge must be disposed of as laid down in the instructions.

6.3 Water lter

To avoid debris entering the high pressure pump, at water lter is tted at the water inlet. Dependent on the

purity of the water, this lter must be cleaned at regular intervals.

The lter can be removed when the quick coupling (pos. 2) has been unscrewed.

6.4 Cleaning of high pressure nozzle

A clogging up in the nozzle causes a too high pump pressure, why a cleaning is immediately required.

1. Stop the machine and detach the spray lance.

2. Clean the nozzle.

IMPORTANT: ONLY use the cleaning tool when the spray lance is dismounted!

3. Flush the spray lance backwards with water.

4. If the pressure is still too high, repeat items 1-3.

11

7.0 Trouble shooting chart EN

You have chosen the best quality and therefore deserve the best service. To avoid unnecessary dis-appointments, you should check the following before contacting the nearest ALTO service organisation:

Fault Cause Correction

Machine will not start Insufcient diesel Rell with diesel

Battery run down Recharge battery*)

Pump frozen up Let the pump thaw

Working pressure too Nozzle partly clogged up Clean the nozzle (see section 6.4)

high

Working pressure too Valve for regulation of water Completely open the valve for regulation

low volume not adjusted to max. of water volume (turn counter clockwise).

water volume

Nozzle damaged Replace nozzle

Number of revolutions of the Contact ALTO servicing department

engine too low

Working pressure Air in the pump Repeat venting

uctuating

Water lter clogged up Clean the lter (see section 6.3)

Insufcient water supply Change to a bigger water tap. If this is

from the waterworks not possible: Turn the valve for regula tion of the water volume in the opposite

direction of the arrow, until the machine

operates steady again.

Suction mode Suction height too high or See section 5.0.

water too hot

Water lter clogged up Clean the lter.

No working pressure Nozzle clogged up Clean the nozzle (see section 6.4)

No inlet water Check the water connection.

Hoses/spray lance frozen up Let hoses/spray lance thaw.

Burner does not ignite Lack of fuel Rell with fuel.

Fuel lter clogged up Change the lter.

Should other malfunctions occur than those mentioned above, please contact the nearest ALTO service

organisation.

Customer services (UK only): ALTO Cleaning Systems Ltd. Phone: 01 768 868995

Gilwilly Industrial Estate

Penrith, Cumbria CA11 9BN

*) NB! To avoid damage to the electronic system of the machine, the snap terminals of the battery must be

dismounted prior to recharging the battery.

12

27

8

12

9

19

10

23

5

2

22

13

21

20

1

18

24

3

6

11

7

14

15

16

4

26

25

4809250 a (10.2003)

Printed in Denmark

Copyright © 2003 ALTO Danmark A/S

ALTO Danmark A/S

Industrikvarteret

DK-9560 Hadsund

Tel.: +45 7218 2100

www.alto-online.com

Loading...

Loading...