Page 1

CONTRACTOR DIESEL

Instruktionsbog ........................ 1 - 12

Instruksjonsbok ........................ 13 - 24

Instruktionsbok......................... 25 - 36

Instruction manual ................... 37 - 48

Betriebsanleitung ..................... 49 - 60

Manual d’Instructions ............... 61 - 72

Gebruikershandleiding ............. 73 - 84

Page 2

Congratulations!

We’d like to say, “Thank You” for choosing the

CONTRACTOR DIESEL. This instruction ma nu al

is provided with your new High Pressure Washer

to ensure that you obtain the best results, in the

safest manner, with your new machine.

IMPORTANT

This machine is a High Pressure Washer, capable of producing 2600 psi (180 bar). Read this

manual completely, befare operating the machine. A complete understanding of the material

in this manual will help you avoid possible injury

or damage to other objects, as well as damage

to the machine, itself. It’s also important that

you read the Ruggerini engine manual provided,

before you begin to use this machine.

Sincerely,

Nilfi sk-ALTO

Division of Nilfi sk-Advance A/S

Contents EN

1.0 Safety .......................................................38

1.1 Warning Refi lling with diesel ............ 38

1.2 Asbestos ...........................................38

2.0 Motor Protection Device ....................... 39

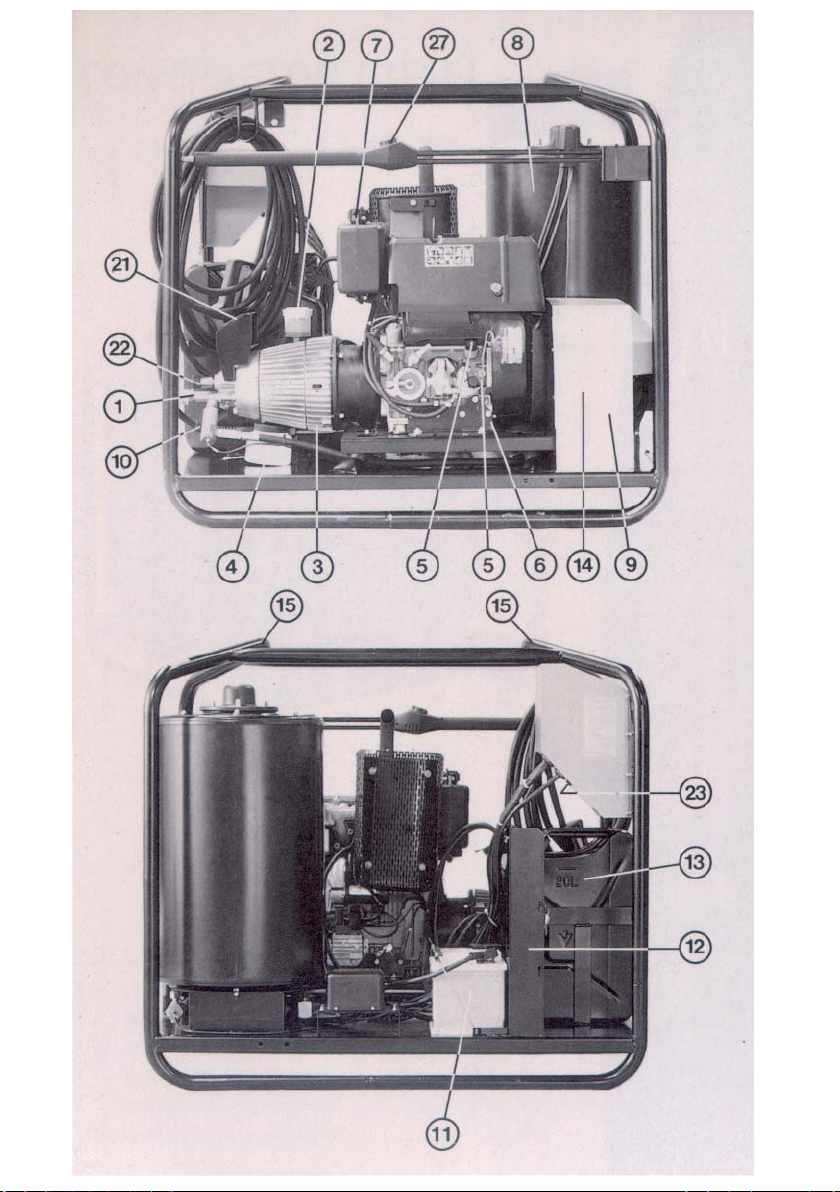

3.0 Key photo’s ............................................39

4.0 Application ..............................................40

4.1 Handling and transport. ....................40

5.0 Standard equipment ............................... 40

6.0 Accessories. ...........................................40

7.0 Functional description ..........................41

7.1 High pressure pump . .......................42

7.2 Burner system ..................................42

7.3 Diesel engine ................................... 42

7.4 Spray lance. ......................................42

8.0 Connections............................................43

8.1 High pressure hose ..........................43

8.2 Spray handle and lance .................... 43

8.3 Water connection ..............................43

8.4 Suction mode ....................................43

8.5 Use of detergents .............................43

8.6 Fuel for burner .................................. 43

8.7 Fuel for engine .................................. 43

9.0 Operating instructions ..........................44

9.1 Start-up procedure ........................... 44

9.2 Cold water operation.........................44

9.3 Hot water/steam operation................44

9.4 Adjustment of pressure and

water volume ....................................44

9.5 Shutdown .........................................44

10.0 Storage/frost proofi ng ..........................45

11.0 Model tag .................................................45

12.0 Maintenance ...........................................46

12.1 Water inlet fi lter .................................46

12.2 Couplings/connectors ....................... 46

12.3 Oil change, pump/engine .................. 46

12.4 Burner fuel fi lter ............................... 46

12.5 Descaling.......................................... 46

12.6 High pressure nozzle care................47

13.0 Warranty ..................................................47

14.0 Troubleshooting ..................................... 48

15.0 Technical data .........................................48

37

Page 3

1.0 Safety EN

I

0

Your CONTRACTOR DIESEL washer has been

developed and manufactured in accordance with

the latest working safety regulations.

Caution! However, to prevent possible per so nal

accidents or damage to any other product, we

advise you to read carefully through this section

on safety precautions before you operate your

washer for the fi rst time.

General safety precautions

1. Always use both hands for operating spray

equipment to maintain complete control of

the lance.

2. Water jets should never be directed towards

people, pets, electrical wiring or the Nilfi skALTO CONTRACTOR DIESEL machine itself.

3. Always switch off engine during work breaks.

11. The machine must not be used in surroundings with risk of fi re or explosion.

12. Exhaust from engine and burner contains

poisonous carbon monoxide gases. Avoid

inhalation of exhaust gases. Never run the

machine in a closed garage or confi ned area.

13. To prevent fi re hazards and to provide adequate ventilation, keep the engine at least

1m/3ft away from buildings and other equipment during operation.

14. Do not place fl ammable objects such as

gasoline, matches, etc., close to the machine

while it is running.

15. Allow only properly instructed personnel to

use the machine.

16. Never let children operate your CONTRACTOR DIESEL at any time.

17. Don’t use the machine if important parts of

the equipment are damaged - i.e. safety

devices, high pressure hoses, spray hand le,

cabinet.

4. Connect or disconnect the high pressure

hose ONLY when the engine is stopped.

5. Use only those hoses and nozzles specifi ed

by Nilfi sk-ALTO.

6. The machine should only run for a maximum

of fi ve minutes once the spray handle has

been released (the pump then circulates the

water internally and the machine will over heat unless stopped after 5 minutes).

7. The pump is equipped with a high pressure

relief safety valve. This adjustment, like any

others that require the use of tools, should

only be made by a trained service technician.

8. Operating the machine when it, or any attachments are frozen, is dangerous. Be sure

everything is thawed before operating the

machine.

9. Manufacturer’s instructions for the use of any

detergents should be carefully observed at

all times.

10. During work breaks, or any time lances or

accessories are changed, the spray handle

must be secured by rotating the safety knob

into position O.

1.1 Warning

Refi lling with diesel:

Always stop the Ruggerini engine and allow it to

cool off for at least two minutes before fi lling with

diesel. Avoid spilling diesel. If diesel nevertheless

is spilled while refi lling, the engine must not be

started before the spilled diesel has been removed. If the machine is located in a trailer, any

diesel spillage must be removed before restarting

the machine. Never use an open fl ame near the

machine. It is forbidden to smoke while refi lling

with diesel. Read the in struc tion manual for the

Ruggerini engine carefully.

NOTE: Never run the machine in a closed room.

The exhaust gases are dangerous

1.2 Asbestos

To avoid release of asbestos fi bers into the environment, Nilfi sk-ALTO strongly recommends that

this machine not be used for cleaning of materials or surfaces of materials containing asbestos.

If this machine is to be used for asbestos removal

do so only in complete compliance with approved

goverment guide li nes and/or procedures.

38

Page 4

2.0 Motor Protection De vice

The diesel engine is equipped with a protection

device called ”Oil Alert”, which stops the engine

if the oil level is insuffi cient. If this occurs, check

the engine for leaks, and after making sure the

machine is level, refi ll it to the proper level. The

engine can then be restarted.

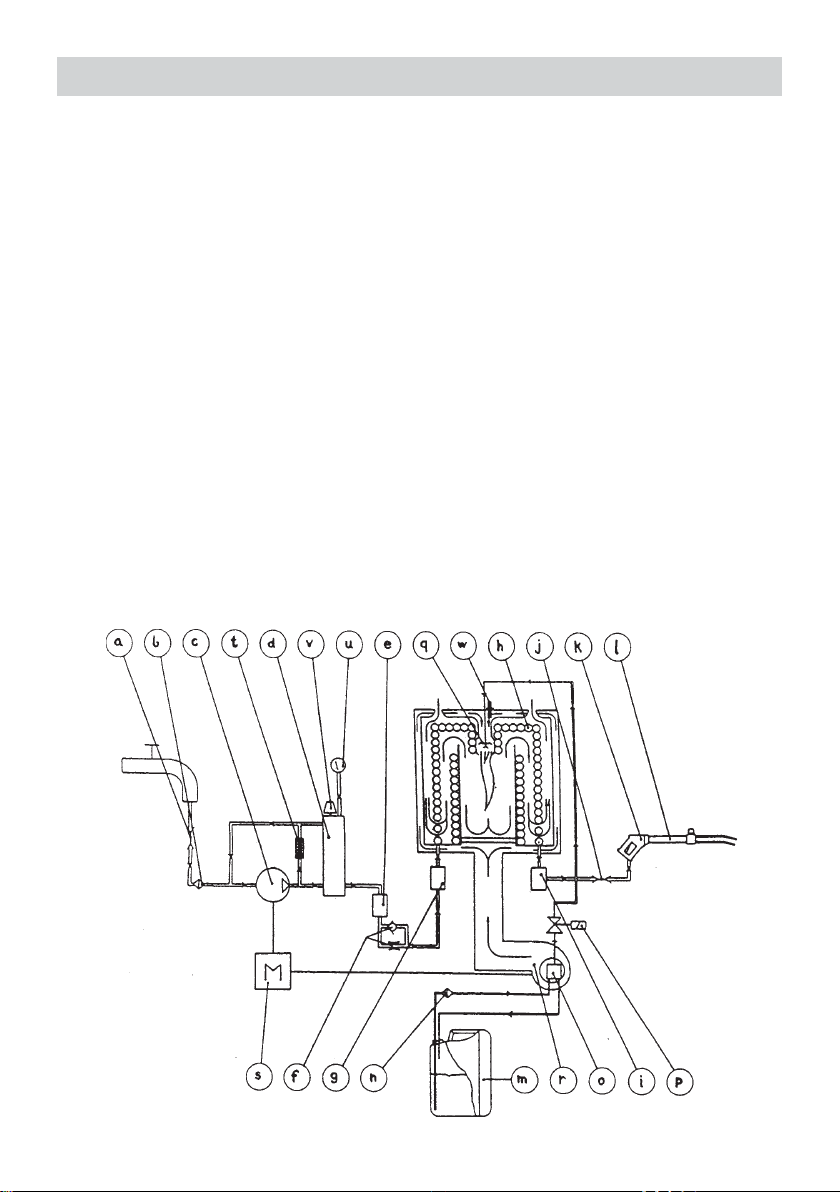

3.0 Key photo’s EN

(See drawing on the cover)

1. Water inlet and fi lter

(quick-coupler for supply hose)

2. Pump oil level inspection and fi ll cup

3. Oil drain plug for pump

4. Sludge container

5. Engine oil dipstick and fi ller tube

6. Oil drain plug for diesel engine

7. Diesel fi lling cap

8. Burner coil

9. Fan for burner

10. High pressure outlet (male quick-connector)

11. Battery

12. Container rack for detergents

13. ”Jerry-can” for heating oil

14. Burner fuel fi lter

15. Frame lift points

16. Thermostat

17. Thermometer

18. Key for electric start

19. Battery charge control

20. »Oil Alert« (see section 2.0)

21. Pressure gauge

22. Knob for adjustment of water volume

23. Fuse (protection of electronic unit)

rating 1.25 AT

Double spray lance with hose

24. High pressure, steam-capable hose

25. Male connector

26. Quick coupler

27. Pressure adjustment

28. Release trigger

29. Standard double spray lance

30. Low pressure nozzle

31. High pressure nozzle

32. Spray handle

33. Trigger safety knob

35. Data plate

36. Inlet hose w. fi lter

39

Page 5

4.0 Application EN 6.0 Accessories EN

Nilfi sk-ALTO’s diesel powered high pressure

washers can be used for all outdoor cleaning

jobs for which steam, hot or cold water is used.

Detergents can be used (see section 8.5)

4.1 Handling and Transport

When handling the machine with a fork lift truck,

be sure the forks extend completely under the

machine to prevent tipping. When lifting the

machine, a sling may be wrapped around the

upper frame tubes for lifting. Ensure that personnel aren’t under or near the machine during

lifting. When transporting the machine in a truck

or trailer, be sure that it is secured against sliding

or tipping.

In order that you may make the most of your high

pressure washer, Nilfi sk-ALTO has produced a

very comprehensive accessory program, including a pneumatic tire kit especially for the CONTRACTOR DIESEL.

Please feel free to contact your Nilfi sk-ALTO supplier for further information.

5.0 Standard equipment

The mac hi ne is delivered with a dou ble lance

and a spray handle with high pres su re steamcapable hose. The low pressure tube (pos. 30)

is fi tted with a fl at jet nozzle 6530* and the high

pres su re tube (pos. 31) with a fl at jet nozzle

1506*.

*) The fi rst two digits of the nozzle number refer

to the spray angle, in degrees. The last two digits

indicate the water fl ow in l/min. at a pres su re of

20 bar and a temperature of 20°C.

The actual nozzle orifi ce size are 0.63” (1.6 mm)

for the nozzle 1506 and 0.142” (3.6 mm) for the

nozzle 6530. NEVER replace the nozzles with

those of a smaller size.

Maximum working pressure and temperature

rating are embossed on the Nilfi sk-ALTO hose.

Use only Nilfi sk-ALTO high pressure, steamcapable hoses. In case of damage to your hose,

DO NOT attempt to repair the hose yourself! The

thrust (backwards turned force) on the nozzle is

approximately 12.5 ft/Ib (55 N).

Since the nozzles are mounted at an angle to the

lance, there will be a torque effect at the handle

when spraying. Always use two hands when

operating the spray equipment.

40

Page 6

7.0 Functional description EN

The water passes from the inlet connector (a)

through a water fi lter (b) and into the high pres su re pump (c). The high pressure water is passed through the regulating unloader (recycling

valve) (d) and the fi rst fl ow control (e) to the

throttle valve (f) and through the second fl ow

control (g) into the burner-coil (h). Here the water

is heated to the required tem pe ra tu re. At the

outlet of the burner-coil the hot high pres su re

water passes the tem pe ra tu re sensor (i) and

proceeds through the outlet connector (j) to the

spray handle (k) and double spray lance (1.) The

fuel is drawn from the fuel tank (m) through the

fuel fi lter (n) by the fuel pump (a). The fuel pump

passes the fuel through the magnetic solenoid

valve (p) to the fuel nozzle (q) where it is ignited.

The combustion in the burner is monitored by

the fl ame sensor (w) and is supplied with air from

the fan (r), which together with the high pres su re

pump (c) are driven by the diesel engine (s).

a Inlet quick-connector

b Water fi lter

c High pressure pump

d Unloader/regulator (recycling valve)

e Flow switch

f Throttle valve

g Flow switch

h Burner coil

i Temperature sensor

j Outlet quick-connector

k Spray handle

I Double spray lance

m Fuel tank ”Jerry-can”

n Burner fuel fi lter

o Fuel pump

p Magnetic solenoid valve

q Fuel nozzle

r Blower for burner

s Diesel engine

t Safety valve (internal)

u Pressure gauge

v Water volume adjustment

w Flame sensor

41

Page 7

Functional description EN

7.1 High pressure pump

An unloader (recycling valve) and a safety valve

are located on the pres su re side of the high pressure pump. The unloader recirculates the water

to the suction side of the pump when the spray

handle is closed or if a nozzle is bloc ked. The safety valve is adjusted to approx. 25 bar (360 psi)

above the working pressure. The high pressure

pump should not run idle for more than 5 min.,

since the water inside the pump gets hot while it

is recirculating. The unloader ens ures there is no

pressure in the pump when the engine is stopped. The unloader and safety valve are adjusted

and sealed at the factory. DO NOT attempt to

change this adjustment.

7.2 Burner system

The burner is controlled by electronic circuits

which include a thermostat, fl ow switches to

evaluate water fl ow and a sensor to monitor the

fl ame. Water temperature is regulated by the

thermostat. Flow switches ensure there is water

fl owing through the machine before allowing the

burner to light. These devices are connected to a

printed circuit board which activates a magnetic

solenoid valve on the fuel pump to supply or stop

fuel fl ow to the burner. There are two fl ow switches installed, for additional safety and protection of the burner coil. The circuit board ensures

that they agree before allowing fuel to fl ow to the

burner. The fl ame sensor is a separate circuit

which stops the machine if there is no fl ame in

the burner in hot water or steam mode.

It is important for the life of the fuel pump, that

the machine is not allowed to run in the hot water

or cold water mode, with empty fuel tank. If the

burner stops working unexpectedly, check the

fuel level in the tank and refi ll it if necessary.

7.4 Spray lance

The double spray lance is fi tted with 2 nozzles, a

high pressure nozzle and a low pressure nozzle.

When the pressure adjustment valve (pos. 27) is

completely closed only the high pressure nozzle

is used. Both the high pres su re nozzle and the

low pressure nozzle are used when the pressure

adjustment valve is opened. Nozzles with smaller

orifi ce size (0) than described in section 5.0 must

not be mounted on the lance.

7.3 Diesel engine

A description and operating/maintenance instructions for the Ruggerini engine will be found

in the Ruggerini manual provided with the CONTRACTOR DIESEL. Please read this before

starting up. The throttle limit of the engine has

been adjusted by Nilfi sk-ALTO, so that the max.

number of revolutions corresponds to the max.

pressure of the pump. The adjustment is sealed.

This adjustment must not be changed.

42

Page 8

8.0 Connections EN

8.1 High pressure Hose

Connect the high pressure, steam-capable hose

(pos. 24), to the outlet quick-coupling (pos. 10)

on the machine front. Use only original Nilfi skALTO high pressure, steam-capable hoses. The

hose should not be exposed to abuse, such as

knots, kinks, contact with sharp objects or external heat sources, as this may cause bur sting.

Only Nilfi sk-ALTO high pressure, steam-capable

hose should be used for extension hoses. The

extension hoses should not exceed a total maximum length of 300 ft (100 m).

8.2 Spray handle and lance

Check the male connector (pos. 25) of the spray

lance for foreign material. With one hand, grasp

the quick coupler fi tting (pos. 26) and pull it

forward. Insert the male connector of the lance

or accessory into the spray handle quick-coupler,

and release the fi tting. Pull the lance or accessory forward to ensure it is correctly and tightly

installed, before operating the machine. NEVER

release a lance or accessory while water or

steam are coming from the nozzles of the lance

or accessory.

8.3 Water connection

The water inlet connection is at the front of the

machine, on the pump (pos. 1). Before connecting the water supply hose, it should be fl ushed

to remove any impurities. The machine can be

connected directly to a pressurized water supply

or a tank. The inlet pressure must not exceed 15

bar (218 psi) and the water tem pe ra tu re must

not exceed 35°C (95F°) . When the mac hi ne

is connected to a water supply with back-fl owpreventer the water supply hose must be at least

6 m (20 ft) in length. If there are impurities in the

water source, it is advisable to provide additional

fi ltration in the inlet line. Ask your Nilfi sk-ALTO

representative about the fi lters and fi lters available for your CONTRACTOR.

8.4 Suction Mode

The machine is self priming, when used from a

tank or stream, etc. The inlet hose must be fi lled

with water before starting up. The self priming

height depends on the water temperature. Max.

self priming height of 5 m (17 ft) is reached with

cold water (up to 8°C/47°F). Foreign material

in the water supply can damage your machine.

If there is a risk of foreign material in the water

source entering the supply hose, a fi lter or fi lter

must be mounted.

8.5 Use of Detergents

The machine is supplied as standard without

detergent injection equipment. In self priming

mode, detergents must not be added to the feed

water (pos. 1), and thereby circulated through the

pump. If your work requires detergents, they may

be added through the optional external (downstream) injector available from your Nilfi sk-ALTO

supplier.

NOTE! Certain organic solvents are aggressive

to rubber and plastics used in high pressure

hoses and must therefore not be used. Using

detergents outside the range from 4.0 - 10.0 pH,

will result in a loss of working life for your high

pressure hose and seals in the spray handle,

lances and other accessory. Follow precisely the

directions printed on the packing when using

detergents.

8.6 Fuel for burner

Use ONLY ”heating oil”, kerosene or diesel fuel

in the ”Jerry-can” fuel tank for the burner. DO

NOT put gasoline in the burner fuel can!

8.7 Fuel for engine

Use only clean auto-diesel for the Ruggerini

engine.

43

Page 9

9.0 Operating instructions EN

9.1 Start-up procedure

1. Check that the pump oil level is between the

MIN. and MAX. marks (pos. 2). Oil type: Nilfi skALTO Pump Oil 100.

2. Check the oil level on the Ruggerini engine.

Oil type: Choose oil type in accordance with

the instructions in the Ruggerini manual.

3. Run water through the inlet hose before con-

necting in order to remove possible impurities

in the hose. Any water supply valve must be

fully open in order to provide suf fi cient water

supply.

4. Open the small venting cap on the ”Jerry-can”

if you intend to operate in hot water or steam

mode.

5. Turn the thermostat (pos. 16) to the blue fi eld.

6. Start the Ruggerini engine as described in the

enclosed operating instructions. The key for

the electric start has the following 3 positions:

1 ”0” off

2 ”I” run

3 the startkey will return to position 2

when released.

7. Turn the trigger safety knob (pos. 33) to po-

sition 0 and squeeze the trigger of the spray

handle (pos. 28) allowing water to fl ow until

the stream is steady.

8. When the engine is warmed up, check that

max. working pressure does NOT exceed the

maximum allowable pump pressure. This can

be taken from the pressure gauge and must

not exceed 180 bar (2600 psi). Over load will

reduce the life of the machine. (See section

14.0).

9.2 Cold water operation

After the starting up procedure the machine is

ready for cleaning with cold water.

d) Start the machine, if stopped, and activate the

spray handle to start the burner.

IMPORTANT: For safety reasons it is important

that instruction (a), above, always be followed!

Note: If the engine stops immediately after

having been started up, it should be checked

whether the throttle control is set at idle speed.

If it is, the throttle control should be adjusted to

full speed.

9.4 Adjustment of pressure and

water volume

High pressure/volume

In order to achieve maximum working pressure the

pressure adjustment knob (pos. 27) on the lance

should be turned all the way in (clockwise until

completely closed) and the volume adjustment

knob (pos. 22) situated on the front of the pump

should be turned all the way out (counterclockwise). The water volume is infi nitely variable up

to the max. capacity of the machine.

Low pressure/volume

To reduce the working pressure, turn the pres su re adjustment knob (pos. 27) on the lance,

counterclockwise until the desired result is achieved. To reduce the water pressure AND volume,

release the trigger (pos. 28) or stop the machine.

Turn the volume adjustment knob on the front

of the pump, clockwise, reducing water fl ow and

volume. Test the results, and repeat the process

until you have achieved the results you wish. By

varying the settings of the pres su re adjustment

knob on the lance, and the volume adjustment

knob on the pump, you may obtain pressures

from 4 bar (60 psi) to 180 bar (2600 psi), and

water fl ows from 6 l/min. (1.6 US gpm) to 20.5

l/min. (5.4 US gpm).

9.3 Hot water/Steam operation

Hot water:

Adjust the thermostat (pos. 16) to the required

temperature, 30-95°C (86-200°F).

Steam:

a) Adjust to temperatures above 95°C (200°F)

ONLY with the trigger on spray handle

released.

b) Turn the water volume adjustment knob (pos.

22) completely in (fully clockwise).

c) Adjust the thermostat to the required tem pe -

ra tu re, 95-150°C (200-302°F).

44

9.5 Shutdown

WARNING: Danger of burn

Do not disconnect the high pressure hose until

you have completed the following steps (risk of

injury):

1. Turn the thermostat (pos. 16) to the blue fi eld.

Spray cold water until the water tem pe ra tu re is

under 50°C (122°F). Disconnect or turn off the

water supply.

2. Squeeze the trigger of the spray handle for a

short time to empty the system of water.

3. Stop the diesel engine. (See instructions for

the Ruggerini engine).

4. Disconnect the high pressure hose.

Page 10

10.0 Storage/frost proofi ng

It is advisable to store the machine in a frost

proof place between operations. If this is not

possible the machine should be protected in the

following way:

1. Disconnect the inlet hose. Remove the lance

(pos. 29) and empty it of water.

2. Ensure that the thermostat is set in the blue

fi eld, and start the machine, allowing it to run

with the spray handle opened until it is empty

of water.

3. Place a suction hose in a bucket with 6-8 l

(1.5-2 gallons) anti-freeze.

4. Place the spray handle (without spray lance)

above the bucket, open the spray handle so

that the antifreeze can circulate. Open and

close the spray handle a few times.

5. Rem ove the suction hose from the bucket and

allow the machine to pump all of the solution

back into the anti-freeze container. The antifreeze can be re-used, but keep in mind that

it is slightly diluted with water each time this

is done.

Important:

To avoid damage always ensure that the washer,

the hoses and the spray lance are unfrozen

before restarting. Place the washer and the accessories in a warm environment for some time

before starting up.

11.0 Model tag

This machine has the model name, ”CONTRACTOR DIESEL”. The model de sig na ti on is printed

on a decal positioned on the control panel and

on the data plate. The data plate provides the

following important information:

1. Model designation

2. Production code (year and week) 3. Serial

number

4. Pump pressure

5. Water volume

6. Max pressure

7. Max temperature

8. Manufacturer

45

Page 11

12.0 Maintenance EN

12.1 Water inlet fi lter

The inlet water connection (pos. 1) contains

a fi lter to prevent impurities entering the highpressure pump. This fi lter must be inspected at

regular intervals, and cleaned as required. The

fi lter can be removed after removing the quick

coupling.

NOTE:

To avoid serious damage to the rubber gasket,

the quick coupling should be tightened only

gently.

12.2 Couplings/connectors

To prevent leakage and damage to connectors/

couplings on hoses, spray handle, machine and

spray lance, these need to be cleaned occasionally and lightly lubricated with oil or grease.

12.3 Oil Change

The oil level must be checked at regular intervals

(see section 9.1). The oil should be changed according to the following guidelines:

1. OIL CHANGE FOR PUMP

Change the oil after 1000 hours of operation, or

when the oil appears ”milk-white”. Take off the

cover of the oil glass (pos. 2). Unscrew the oil

drain plug on the bottom of the pump (pos. 3).

Drain the oil and then clean the dirt off the drain

plug. Screw the plug in and top up the pump with

fresh oil through the oil glass.

The pump holds approximately 1 quart (1 litre)

of zincless hydraulic oil. From Nilfi sk-ALTO the

pump is fi lled with Nilfi sk-ALTO Pump Oil 100.

When refi lling and changing the oil this or a

substitute with the following specifi cations may

be used:

Zincless Hydraulic Oil

ISO no. 100

Viscosity Index (VI) min. 130

Pour Point below -30°C

SLUDGE CONTAINER

It is normal for a small amount of oil and water

to get past their seals. This oil/ water is collected

in a sludge container (pos. 4). Empty the container before it has fi lled completely. This oil/water

mixture must not be re-used in the pump.

2. ENGINE OIL CHANGE

Refer to the Ruggerini engine manual for breakin and normal operating oil change requirements.

Carry out fi rst oil change after i0 hours of operation and then every 100 hours. Not less than

once every six months, however.

NOTE: Protect the environment by properly

disposing of used pump and engine oil.

12.4 Burner fuel fi lter

To prevent foreign material from entering the fuel

pump a fi lter (14) is fi tted between the fuel tank

and the fuel pump. This fi lter must be changed

regularly, the frequency depends on the purity

of the fuel. Replacement of the fi lter each year is

recommended. See also diagnosis of faults and

repair 16.0.

12.5 Descaling

After a period of operation depending on the

hardness of the water, scale deposits will begin

to accumulate in the heating coil. These deposits

will reduce the effect of the water heating system

and increase the fuel consumption. The machine

should therefore be descaled regularly. If the

machine adjusted on maximum water volume will

not heat cold water (8°C/47°F) to 70°C (158°F)

within three minutes, the burner or coil require

servicing or descaling, as follows:

NOTE:

Always carry out the descaling according to the

instructions supplied with the descaling product:

1. Disconnect the high pressure hose

2. Place an inlet hose in a container of at least

10 l (3 gallon) capacity, with a solution of

recognized descaling product (i.e. Nilfi sk-ALTO

STONEX), and water in the recommended

percentage (not normally over 10% of the

descaling product ratio 1:10). Ask your Nilfi skALTO distributor for recommendations.

3. Start the machine.

4. Switch off the machine when the water from

the outlet fi tting is colored by the scale rem over.

WARNING! The solution can be caustic. Note:

Air must in no circumstances get into the sy stem;

therefore the container with scale rem over must

never be emptied completely.

46

Page 12

Maintenance EN 13.0 Warranty EN

5. Leave the machine for 20 minutes.

6. Start the machine and pump the used so lu ti on

into a container for proper disposal.

7. Immediately connect a fresh water supply and

turn it on.

8. Start the machine, let it work for 5-10 minutes,

until all the scale remover is out of the sy stem.

9. If necessary, repeat the procedure from instructions 2 to 8.

12.6 High pressure nozzle care

An obstructed nozzle causes an increase in

pump pressure. Immediate correction is required.

1. Stop the machine and dismount the spray

lance.

2. Clear the nozzle obstruction with a Nilfi skALTO nozzle tool No. 6401654.

WARNING: This operation must be per-formed

ONLY with the lance removed from the mac hi ne.

3. Backfl ush the spray lance with water. Use the

spray handle, pressing it towards the nozzle

protection cap on the front of the spray lance.

4. If the pressure is still too high, repeat items

1-3, or remove the nozzle from the lance for

cleaning.

Nilfi sk-ALTO warrants against defects in the supplied product for a period of 12 months from the

purchase date subject to the following con dit ions:

- that defects are attributable to material or

ma nu fac tu ring fl aws. (Items which require replacement due to normal wear and tear, abuse

or misuse are not included in this limited warranty).

- Repairs required due to improperly performed

service or repairs, are excluded.

- Repairs required due to the use of non-Nilfi skALTO parts or accessories, are excluded.

- Repairs required by operation of the machine

in a manner not prescribed in this Instruction

Manual.

The engine warranty is as described by, and in

accordance with the practices and policies of

Ruggerini Motor Company. See the Ruggerini

documents for details.

47

Page 13

14.0 Troubleshooting EN

Fault Cause Repair

The engine fails to start Insuffi cient diesel supply Refi ll diesel tank.

Battery run down Recharge the battery*)

Fuse blown Exchange fuse. See section 3.0.

The pump is frozen Let the pump thaw.

Working pressure too high Nozzle partly blocked Clean the nozzle. See section 12.6.

Working pressure Valve for regulation of Open fully the valve for regulation of

too low water volume is not water.

adjusted to max pressure Turn counterclockwise.

Nozzle worn Replace nozzle.

Motor speed too low Contact Nilfi sk-ALTO service technician.

Irregular working Air in the pump Repeat the venting procedure.

pressure Inlet fi lter/fi lter blocked Clean the fi lter. See section 12.1.

Insuffi cient water supply Change to a water supply with greater

from the water works output. If this is not possible; turn the

valve for regulation of the water volume

clockwise, until the machine works smoothly.

In suction mode: Excessive suction head Read section on suction mode (8.4).

or excessively hot water

Nozzle partly blocked Clean nozzle. See section 12.6.

No working pressure Nozzle blocked Clean nozzle. See section 12.6.

No water Check the water connection.

Unloader (recycling valve) Allow the machine to thaw.

frozen See section 10.0.

High pressure hose/ Allow the high pressure hose/

spray lance frozen spray lance to thaw.

The burner does not Insuffi cient fuel supply Refuel.

ignite Fuel fi lter blocked Clean the fi lter. See section 12.4

Should faults occur other than those mentioned above, please contact the nearest Nilfi sk-ALTO service

organization *) IMPORTANT NOTE: To avoid damage to the electronic systems, the battery connecting

cables must be removed when recharging the battery.

15.0 Technical data EN

Model CONTRACTOR DIESEL

Pump pressure, max. bar/psi 180/2610

Water volume at min/max pressure l/min-USgpm 20,5/19 - 5.42/5

Max. temperature of inlet water °C/°F 35/95

Heating power kW/Kcal 115/98.200

Nozzle, spray angle degrees (05) 15/65

Self-priming, max. lift m/ft 5/16.5

Engine Ruggerini MD 151

Rated effect kW/hp 12/16.3

Start system Electric start

Battery V/Ah 12/50

Diesel consumption, max. pressure l/h-USgph 3.0-0.79

Fuel consumption at 60°C/140°F 1) l/h-USgph 7.5-1.98

“Jerry-can”, capacity l/Usg 20/5

Sound power level (LWA) of the machine measured in accordance with ISO 3746: 112 dB(A).

Sound pressure level (L

1

) Delta t= 52°C/126°F

This machine has been manufactured in accordance with the EMC directive 89/336/EEC inclusive of subsequent

amendments.

Specifi cations are subject to alterations.

48

) measured in accordance with ISO 11202 [DISTANCE 1m] [FULL LOAD]: 100 dB(A).

PA

Page 14

Page 15

Page 16

http://www.nilfi sk-alto.com

HEAD QUARTER

DENMARK

Nilfi sk-Advance Group

Sognevej 25

DK-2605 Brøndby

Tel.: (+45) 4323 8100

Fax: (+45) 4343 7700

E-mail: mail.com@nilfi sk-advance.com

SALES COMPANIES

ARGENTINA

Nilfi sk-Advance srl.

Edifi cio Central Park

Herrera 1855, Offi ce 604

Ciudad Autónoma de Buenos Aires

Tel.: (+54) 11 6091 1571

Fax:(+54) 11 6091 1575

AUSTRALIA

Nilfi sk-ALTO

48 Egerton St.

P.O. Box 6046

Silverwater, N.S.W. 2128

Tel.: +61 2 8748 5966

Fax: +61 2 8748 5960

E-mail: info@nilfi skalto.com.au

AUSTRIA

Nilfi sk-Advance GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Tel.: 0662 456 400-0

Fax: 0662 456 400-34

E-mail: info.at@nilfi sk-advance.com

BELGIUM

Nilfi sk-ALTO a division of Nilfi sk-Advance n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070 Brussel

Tel.: (+32) 2 467 60 40

Fax: (+32) 02 466 61 50

E-mail: info.be@nilfi sk-alto.com

CANADA

Clarke Canada

Part of the Nilfi sk-Advance Group

4080-B Sladeview Crescent, Unit 1

Mississauga, Ontario L5L 5Y5

Tel.: (+1) 905 569 0266

Fax: (+1) 905 569 8586

CHILE

Nilfi sk-Advance S.A.

San Alfonso 1462

Santiago

Tel.:(+56) 2 684 50 00

E-mail: Pablo.noriega@nilfi sk.com

CHINA

Nilfi sk-Advance (Shenzhen) Ltd.

Blok 3, Unit 130 1001 Honghua Road

Int. Commercial & Trade Center

Fuitian Free Trade Zone

518038 Shenzhen

Tel.: (+86) 755 8359 7937

Fax: (+86) 755 8359 1063

CZECH REPUBLIC

ALTO Ceská Republika s.r.o.

Do Čertous 2658/1

193 00 Praha 9

Tel.: (+420) 24 14 08 419

Fax: (+420) 24 14 08 439

E-mail: info@alto-cz.com

DENMARK

Nilfi sk-Advance A/S

Industrivej 1

9560 Hadsund

Tel.: +45 7218 2100

Fax: +45 7218 2105

E-mail: salg.dk@nilfi sk-alto.com

Nilfi sk-ALTO Food division

Division of Nilfi sk-Advance A/S

Blytækkervej 2

9000 Aalborg

Tel.: +45 7218 2100

Fax: +45 7218 2099

E-mail: food.division@nilfi sk-alto.dk

6229950 a (01.2009)

FINLAND

Nilfi sk-Advance Oy Ab

Piispantilankuja 4

02240 Espoo

Tel.: +358 207 890 600

Fax: +358 207 890 601

E-mail: asiakaspalvelu.fi @nilfi sk.com

FRANCE

Nilfi sk-ALTO

ALTO France SAS

Aéroparc 1

19 rue Icare

67960 Entzheim

Tel.: (+33) 3 88 28 84 00

Fax: (+33) 3 88 30 05 00

E-mail: info.fr@nilfi sk-alto.com

GERMANY

Nilfi sk-ALTO

Division of Nilfi sk Advance

Guido-Oberdorfer-Str. 10

89287 Bellenberg

Tel.: (+49) (0) 180 5 37 37 37

E-mail: info.de@nilfi sk-alto.com

GREECE

Nilfi sk-Advance SA

8, Thoukididou str.

164 52 Argiroupolis

Tel.: +30 210 96 33443

Fax: +30 210 96 52187

E-mail: nilfi sk-advance@clean.gr

HOLLAND

Nilfi sk-ALTO

Division of Nilfi sk-Advance BV

Camerastraat 9

3322 BB Almere

Tel.: (+31) 36 5460 760

Fax: (+31) 36 5460 761

E-mail: info.nl@nilfi sk-alto.com

HONG KONG

Nilfi sk-Advance Ltd.

2001 HK Worsted Mills Ind’l Bldg.

31-39 Wo Tong Tsui St.

Kwai Chung

Tel.: (+852) 2427 5951

Fax: (+852) 2487 5828

HUNGARY

Nilfi sk-Advance Kereskedelmi Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklos-Lakihegy

Tel: (+36) 24475 550

Fax: (+36) 24475 551

E-mail: info@nilfi sk-advance.hu

INDIA

Nilfi sk-Advance India Limited

349, Business Point,

No 201,2nd fl oor, above Popular Car World,

Western Express Highway, Andheri ( East),

Mumbai - 400 069

Tel: (+91) 22 321 74592

ITALY

Nilfi sk-ALTO

Divisione di Nilfi sk-Advance A/S

Località Novella Terza

26862 Guardamiglio (LO)

E-mail: d.puglia@nilfi sk-advance.it

JAPAN

Nilfi sk-Advance Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Tel.: (+81) 45 548 2571

Fax: (+81) 45 548 2541

MALAYSIA

Nillfi sk-Advance Sdn Bhd

Sd 14, Jalan KIP 11

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: (+60) 3 603 6275 3120

Fax: (+60) 3 603 6274 6318

MEXICO

Nilfi sk-Advance de Mexico, S. de R.L. de C.V.

Prol. Paseo de la Reforma 61, 6-A2

Col. Paseo de las Lomas

01330 Mexico, D.F.

Tel: +52 55 2591 1002 (switchboard)

Fax: +52 55 2591 1002 ext. 229

E-mail: info@advance-mx.com

NORWAY

Nilfi sk-Advance AS

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 70

Fax: (+47) 22 75 17 71

E-mail: info.no@nilfi sk-alto.com

POLAND

Nilfi sk-Advance Sp. Z.O.O.

05-800 Pruszków

ul. 3-go MAJA 8

Tel.: +48 22 738 37 50

Fax: +48 22 738 37 51

E-mail: info@nilfi sk-alto.pl

PORTUGAL

Nilfi sk-ALTO

Division of Nilfi sk-Advance Lda.

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: +35 808 200 537

Fax: +35 121 911 2679

E-mail: mkt@nilfi sk-advance.es

RUSSIA

Нилфиск-Эдванс

127015 Москва

Вятская ул. 27, стр. 7

Россия

Tel.: (+7) 495 783 96 02

Fax: (+7) 495 783 96 03

E-mail: info@nilfi sk.ru

SINGAPORE

Nilfi sk-Advance Pte. Ltd.

Nilfi sk-ALTO Division

40 Loyang Drive

Singapore 508961

Tel.: (+65) 6 759 9100

Fax: (+65) 6 759 9133

E-mail: sales@nilfi sk-advance.com.sg

SPAIN

Nilfi sk-ALTO

Division of Nilfi sk-Advance S.A.

Torre D’Ara

Paseo del Rengle, 5 Pl. 10

08302 Mataró

Tel.: (+3) 4 902 200 201

Fax: (+3) 4 93 757 8020

E-mail: mkt.es@nilfi sk-alto.com

SWEDEN

ALTO Sverige AB

Member of Nilfi sk-Advance Group

Aminogatan 18, Box 4029

431 04 Mölndal

Tel.: (+46) 31 706 73 00

Fax: (+46) 31 706 73 40

E-mail: info.se@nilfi sk-alto.com

TAIWAN

Nilfi sk-Advance Taiwan Branch

No. 5, Wan Fang Road

Taipei

Tel.: (+886) 227 002 268

Fax: (+886) 227 840 843

THAILAND

Nilfi sk-Advance Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Tel.: (+66) 2 275 5630

Fax: (+66) 2 691 4079

TURKEY

Nilfi sk-Advance Profesional Temizlik

Ekipmanlari Tic. A/S.

Necla Cad. NI.: 48

Yenisahra / Kadiköy

Istanbul

Tel.: (+90) 216 470 08 - 60

E-mail: info.tr@nilfi sk-advance.com

UNITED KINGDOM

Nilfi sk-ALTO

Division of Nilfi sk-Advance Ltd.

Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BQ

Tel.: (+44) 1 768 86 89 95

Fax: (+44) 1 768 86 47 13

E-mail: sales.uk@nilfi sk-alto.com

USA

Nilfi sk-Advance Inc.

14600 21st Avenue North

Plymouth, MN 55447-3408

Tel.: (+1) 763 745 3500

Fax: (+1) 763 745 3718

E-mail: info@advance-us.com

VIETNAM

Nilfi sk-Advance Representative Offi ce

No. 51 Doc Ngu Str.

Ba Dinh Dist.

Hanoi

Tel.: (+84) 4 761 5642

Fax: (+84) 4 761 5643

E-mail: nilfi sk@vnn.vn

Loading...

Loading...