BRX 700, BRX 700 EDS

Instructions for Use

Bedienungsanleitung

Mode d’ emploi

Gebruiksaanwijzing

Nilfi sk Models: 56314019, 56316516 (EDS)

2/03 revised 1/09

FORM NO. 56041541

A-English

B-Deutsch

C-Français

D-Nederlands

Printed in USA

A-2 / ENGLISH

TABLE OF CONTENTS

page

Introduction ........................................................................................... A-2

Cautions and Warnings ........................................................................ A-3

Know Your Machine .............................................................................. A-4

Control Panel ........................................................................................ A-5

Prepare the Machine for Use

Description of the Battery Condition Indicators ....................................A-6

Install the Batteries ...............................................................................A-6

Filling the Solution Tank ........................................................................ A-7

Pre-Spraying the Carpet ....................................................................... A-7

Plan for Cleaning ..................................................................................A-7

Detergent (EDS) System Preparation & Use .....................................A-8-9

Operating the Machine ....................................................................... A-10

Using Attachments .............................................................................. A-10

After Use ............................................................................................. A-11

Maintenance Schedule ....................................................................... A-11

Vacuum Shoe Maintenance ................................................................ A-11

Spray Nozzle Maintenance ................................................................. A-11

Lubricating the Machine ..................................................................... A-11

Cleaning the Vacuum Motor Filters .................................................... A-11

Power Brush Maintenance ................................................................. A-11

Removing the Brushes ....................................................................... A-12

Removing the Vacuum Shoes ............................................................A-12

Charging the Batteries ........................................................................ A-12

Check the Battery Electrolyte Level .................................................... A-12

Troubleshooting .................................................................................. A-13

Technical Specifi cations ..................................................................... A-14

INTRODUCTION

This manual will help you get the most from your Nilfi sk Rider Extractor. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages A-4 – A-5.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfi sk Service Center, who employs factory trained service personnel, and maintains an

inventory of Nilfi sk original replacement parts and accessories.

Call the NILFISK DEALER named below for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

(Dealer, affi x service sticker here.)

NAME PLATE

The Model Number and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering repair parts

for the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference.

MODEL NUMBER ______________________________________________

SERIAL NUMBER ______________________________________________

UNCRATE THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping carton (if

applicable) so that it can be inspected. Contact the Nilfi sk Customer Service Department immediately to fi le a freight damage claim. Refer to the unpacking

instruction sheet included with the machine to remove the machine from the pallet.

A-2 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

revised 3/06

ENGLISH / A-3

CAUTIONS AND WARNINGS

SYMBOLS

Nilfi sk uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take the

necessary steps to protect personnel and property.

DANGER !

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING !

Is used to call attention to a situation that could cause severe personal injury.

CAUTION !

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

WARNING !

• This machine shall be used only by properly trained and authorized persons.

• While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean

only while ascending (driving up) the ramp.

• Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

• Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away from

open fl ame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where

fl ammable liquids exist.

• Do not clean this machine with a pressure washer.

CAUTION !

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that function.

• Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and applying the parking

brake.

• Turn the key switch off (O) before changing the brushes, and before opening any access panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery or

detergent tanks or in the hose lines could freeze, causing damage to valves and fi ttings. Flush with windshield washer fl uid.

• The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries should be

safely done in accordance with your local environmental regulations.

SAVE THESE INSTRUCTIONS

FORM NO. 56041541 - BRX 700, BRX 700 EDS - A-3

A-4 / ENGLISH

1

2

3

4

5

6

8

10

11

12

9

13

14

15

16

17

18

20

21

22

23

19

7

24

25

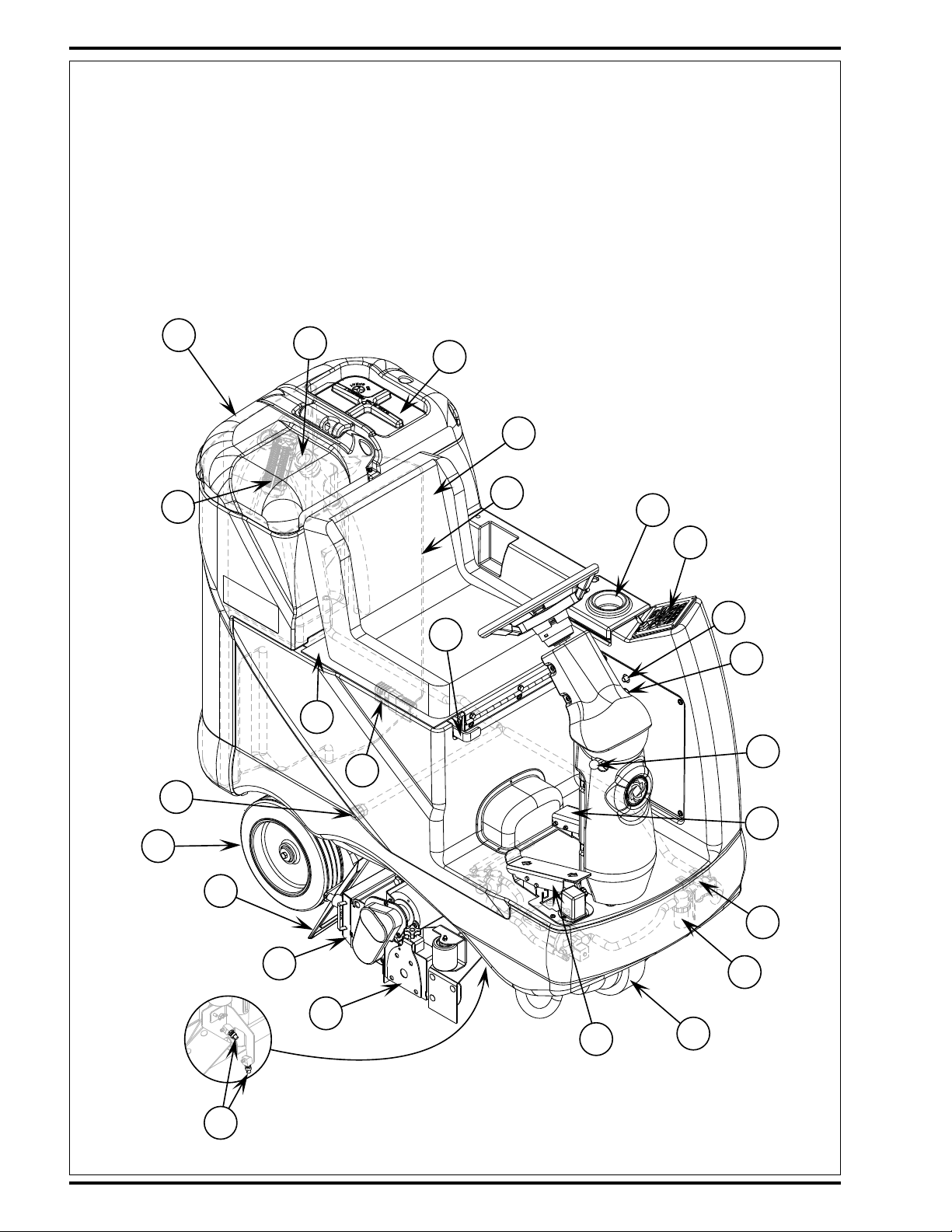

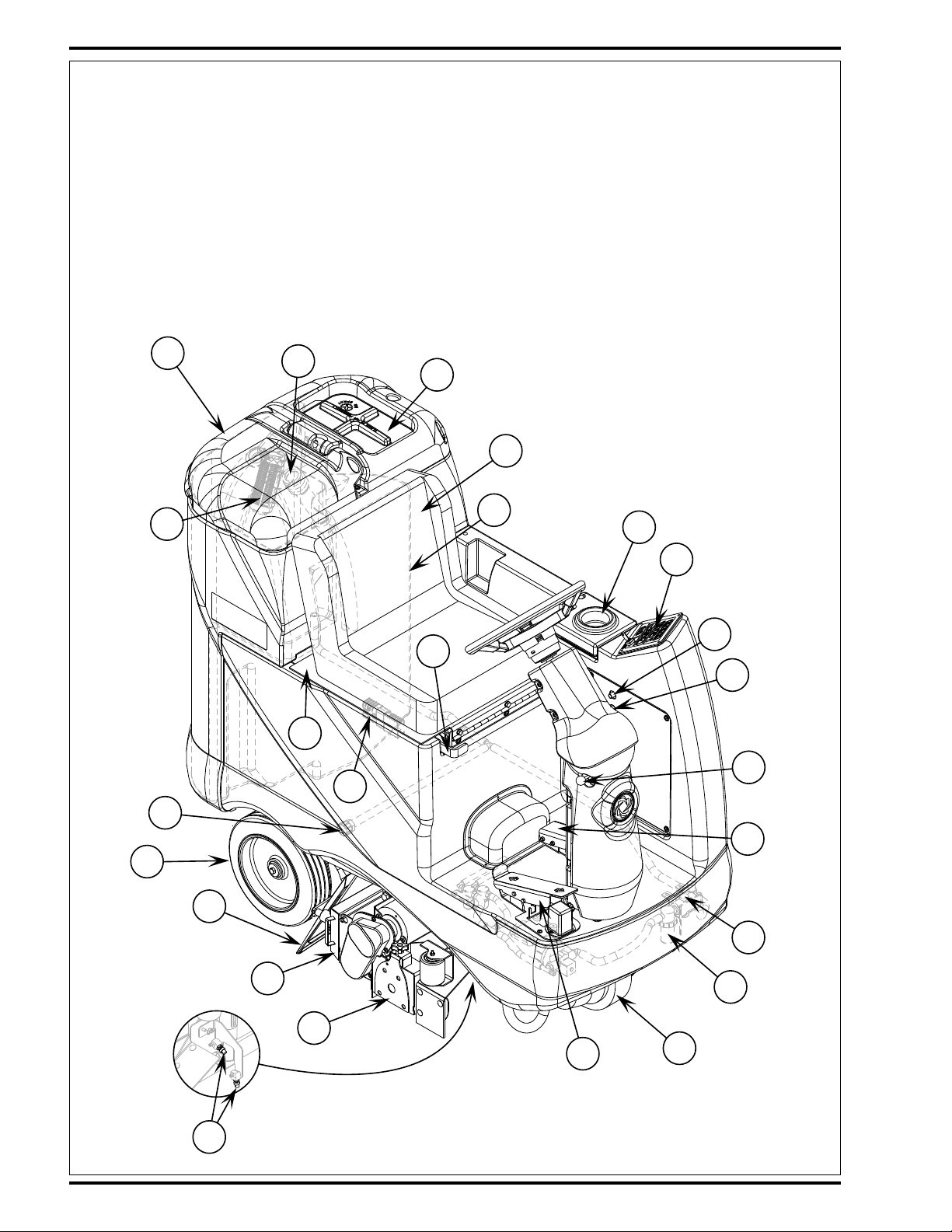

KNOW YOUR MACHINE

1 Recovery Tank Cover

2 Solution Tank Fill Cover

3 Operator’s Seat

4 Solution Tank Drain Hose

5 Steering Wheel Tilt Adjust Knob

6 Brake Pedal / Parking Brake

7 Solution Spray Jets

8 Drive Pedal, Directional/Speed

9 Vacuum Shoes

10 Drive and Steer Wheel

11 Wheel Drive Circuit Breaker

12 Control Circuit Circuit Breaker

13 Emergency Stop Switch / Battery Disconnect

14 Brush Deck

15 Rear Wheel

16 Battery Compartment (under seat)

17 Recovery Bladder Shutoff Float

18 Vacuum Motor Filter Housing

19 Recovery Bladder

20 Solution Filter

21 Recovery Bladder Drain Hose (rear of machine)

22 Machine Battery Connector

23 Control Panel

24 Debris Hopper

25 Solution Control Valve

A-4 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

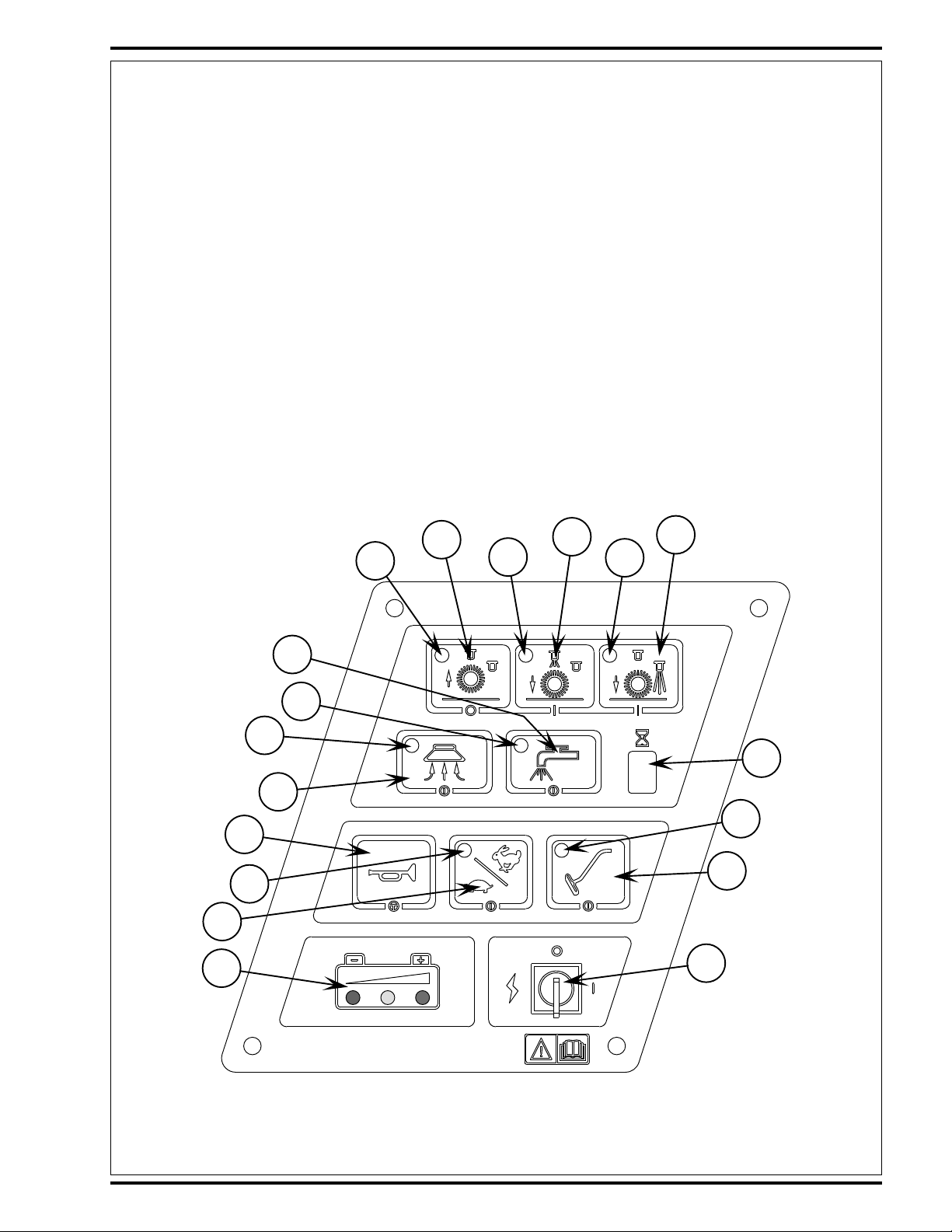

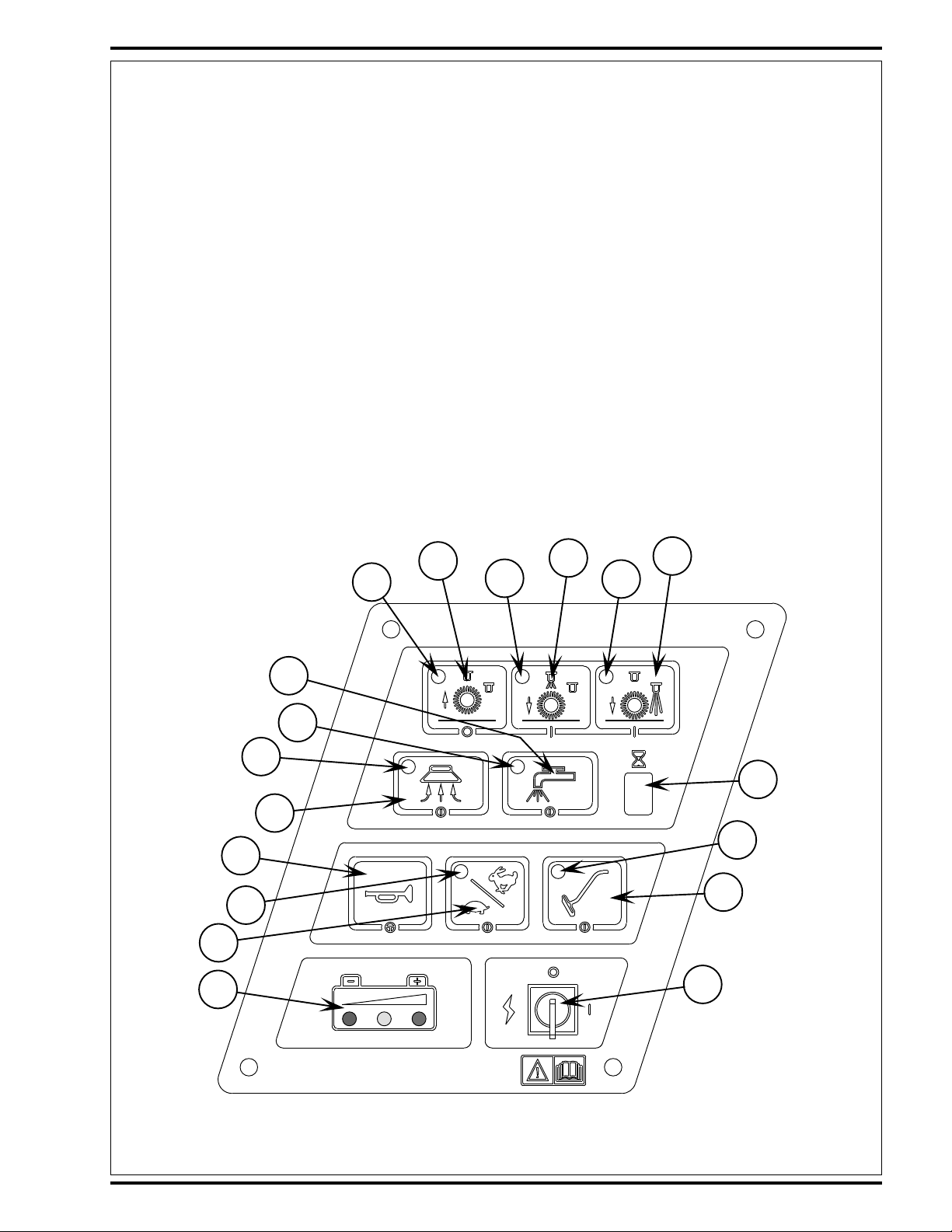

CONTROL PANEL

A Scrub OFF Indicator

B Scrub OFF Switch

C Maintenance Mode Indicator

D Maintenance Mode Switch

E Restoration Mode Indicator

F Restoration Mode Switch

G Hourmeter Display

H Accessory Vacuum Indicator

I Accessory Vacuum ON / OFF Switch

J Key Switch / Main Power

K Battery Condition Indicator

L Speed Select Switch (extract / transport)

M Speed Select Indicator

N Horn Switch

O Vacuum Switch

P Vacuum System Indicator

Q Solution System Indicator

R Solution Switch

ENGLISH / A-5

L

K

N

M

P

O

R

Q

A

B

C

D

F

E

G

H

I

J

FORM NO. 56041541 - BRX 700, BRX 700 EDS - A-5

A-6 / ENGLISH

DESCRIPTION OF THE BATTERY CONDITION INDICATORS

The battery condition indicators give a relative indication of the state of charge of the battery pack. A fully charged battery pack will measure above 37.6 volts

with no load applied (2.09 volts per cell). The BRX 700 is equipped with a low voltage cutout feature that will turn the scrub system off when the batteries

are discharged to their minimum level. There are two different cutout levels to accommodate different battery types. See the service manual for details. The

voltage levels for the various indications are as follows (the voltages shown represent the voltage under load):

INDICATOR VOLTAGE LEVELS FOR STANDARD CUTOUT LEVEL (AS SHIPPED)

Green indicator = full charge down to 34.00 volts

Green & Yellow indicator 33.99 volts down to 33.00 volts

Yellow indicator = 32.99 volts down to 32.00 volts

Yellow & Red indicator = 31.99 volts down to 31.50 volts

Red indicator = 31.49 volts down to 31.00 volts

Flashing Red indicator = less than 31.00 volts – scrub system will shut down.

INDICATOR VOLTAGE LEVELS FOR ALTERNATE CUTOUT LEVEL

Green indicator = full charge down to 34.50 volts

Green & Yellow indicator 34.49 volts down to 34.00 volts

Yellow indicator = 33.99 volts down to 33.50 volts

Yellow & Red indicator = 33.49 volts down to 33.00 volts

Red indicator = 32.99 volts down to 32.5 volts

Flashing Red indicator = less than 32.5 volts – scrub system will shut down.

NOTE: Refer to service manual for selection of alternate cutout level.

NOTE: Once the low voltage cutout level has been reached (fl ashing red indicator) the batteries must be FULLY recharged (37.6 volts) to reset the battery

condition indicator. The scrub system will not function until the indicator has been reset.

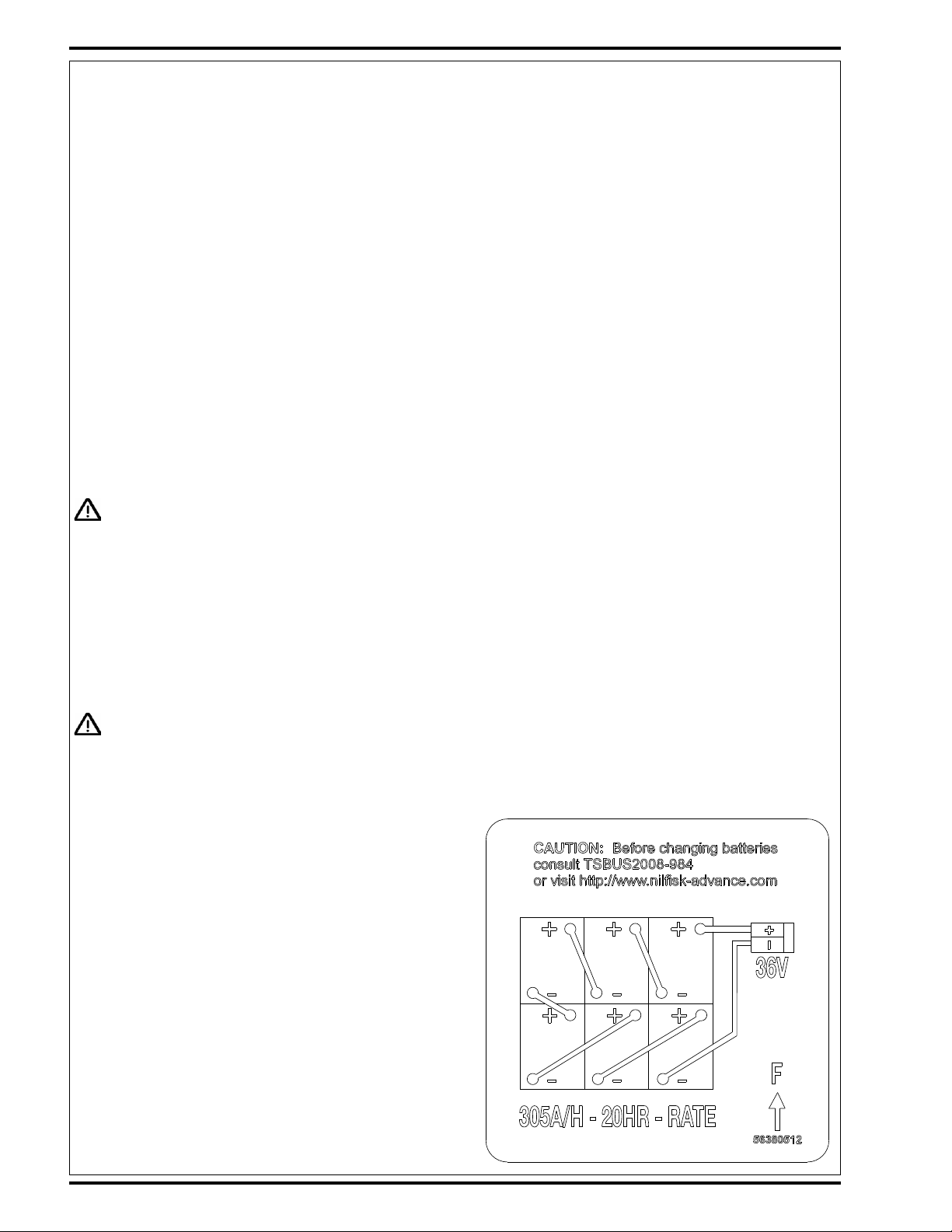

INSTALL THE BATTERIES

WARNING !

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin

or eyes. Explosive hydrogen gas is vented from inside the batteries through openings in the battery caps. This gas can be ignited

by any electrical arc, spark or fl ame.

When Servicing Batteries...

* Remove all jewelry.

* Do not smoke.

* Wear safety glasses, a rubber apron and rubber gloves.

* Work in a well-ventilated area.

* Do not allow tools to touch more than one battery terminal at a time.

CAUTION !

Electrical components in this machine can be severely damaged if the batteries are not installed and connected properly.

Batteries should be installed by Nilfi sk or by a qualifi ed electrician.

1 Turn the Key Switch (J) off (O) and remove the key. Then swing open the Battery Compartment Cover (16).

2 Using (2) people and an appropriate lifting strap, carefully lift the batteries into the compartment tray exactly as shown. Use decal 56380512 battery

cable layout.

3 See Figure 1. Install battery cables as shown and tighten the nuts on the battery terminals.

4 Install the battery boots and secure tightly to the battery cables with the supplied tie straps.

5 Connect the battery pack connector to the machine connector (22) and close the battery compartment cover.

FIGURE 1

A-6 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

revised 1/09

ENGLISH / A-7

FILLING THE SOLUTION TANK

1 Open the Solution Tank Fill Cover (2).

2 Read the dilution instructions on the chemical container. Then fi gure the proper amount of chemical to mix with 40 gallons (151 liters) of water.

3 Pour the proper amount of chemical into the solution tank and fi ll the tank with warm water to 7.62cm (3 inches) from the top of the tank opening.

4 Close the Solution Tank Fill Cover (2).

NOTE: If your machine was factory equipped with a chemical system you DO NOT mix chemical in the solution tank.

CAUTION!

Use low-sudsing, liquid detergents designed for carpet extraction. Water temperature should not exceed 130 degrees

Fahrenheit (54.4 degrees Celsius).

BEFORE USING THE BRX 700

Thorough vacuuming of the carpet to be cleaned is not necessary before using the BRX 700 automatic extractors, due to the on-board sweeping broom and

debris hopper.

PRE-SPRAYING THE CARPET

Pre-spray spots and heavy traffi c areas before extracting. Use a hand-held bottle sprayer or a pressurized “Hudson” type sprayer. Mix the pre-spray

according to the chemical manufacturer’s directions.

PLAN FOR CLEANING

Before you begin extracting, look at the area to be cleaned and plan your work. Divide the space into sections. Overlap each pass 2 inches (5 cm).

FORM NO. 56041541 - BRX 700, BRX 700 EDS - A-7

A-8 / ENGLISH

DETERGENT (EDS) SYSTEM PREPARATION AND USE

COMMON INSTRUCTIONS:

The system should be purged of previous detergent when switching to a different detergent.

SERVICE NOTE: Move machine over fl oor drain before purging because a small amount

of detergent will be dispensed in the process.

To Purge When Changing Chemicals:

1 Disconnect and remove the detergent cartridge.

2 Turn the Key Switch (J) ON. Press and hold the Purge Switch (T) down for at least 3

seconds, then press and hold the Solution Switch (R) (on the main machine’s control

panel) for the duration of the purge cycle. Holding the solution switch is necessary

to open the solution valve and prevent the purged detergent from fl owing back into

the solution tank. NOTE: Once activated the Purge Indicator (U) will begin to scroll

a fl ashing light from left to right and will automatically shut off after 10 seconds.

Normally one purge cycle is adequate to purge the system.

To Purge Weekly:

1 Disconnect and remove the detergent cartridge. Install and connect a Cartridge fi lled

with clean water.

2 Turn the Key Switch (J) ON. Press and hold the Purge Switch (T) down for at least 3

seconds, then press and hold the Solution Switch (R) (on the main machine’s control

panel) for the duration of the purge cycle. Holding the solution switch is necessary

to open the solution valve and prevent the purged detergent from fl owing back into

the solution tank. NOTE: Once activated the Purge Indicator (U) will begin to scroll

a fl ashing light from left to right and will automatically shut off after 10 seconds.

Normally one purge cycle is adequate to purge the system.

The Detergent Box (AA) has a Detergent Level Viewing Slot (BB) for keeping track of

how much detergent is remaining in the cartridge. When the detergent level is nearing the

bottom of this slot it is time to refi ll or replace the cartridge.

General Use:

The detergent injection system is activated when the Key Switch (J) is turned on but no

detergent is dispensed until the scrub system is activated and the Drive Pedal (8) pushed

forward. The solution fl ow rate is determined by the use of “Maintenance” or “Restoration”

mode. The solution fl ow rate can be changed by pressing the Maintenance Extract Mode

Switch (D) for reduced fl ow or the Restoration Extract Mode Switch (F) for increased fl ow.

The detergent fl ow rate increases or decreases with the solution fl ow rate but the detergent

ratio remains the same. During scrubbing, the detergent system can be turned off at any

time by pressing the Detergent ON/OFF Switch (S) to allow scrubbing with water only.

SERVICE NOTE: Follow the “To Purge Weekly” instructions above if the machine is going

to be stored for an extended period of time or if you plan to discontinue use of the detergent

injection system.

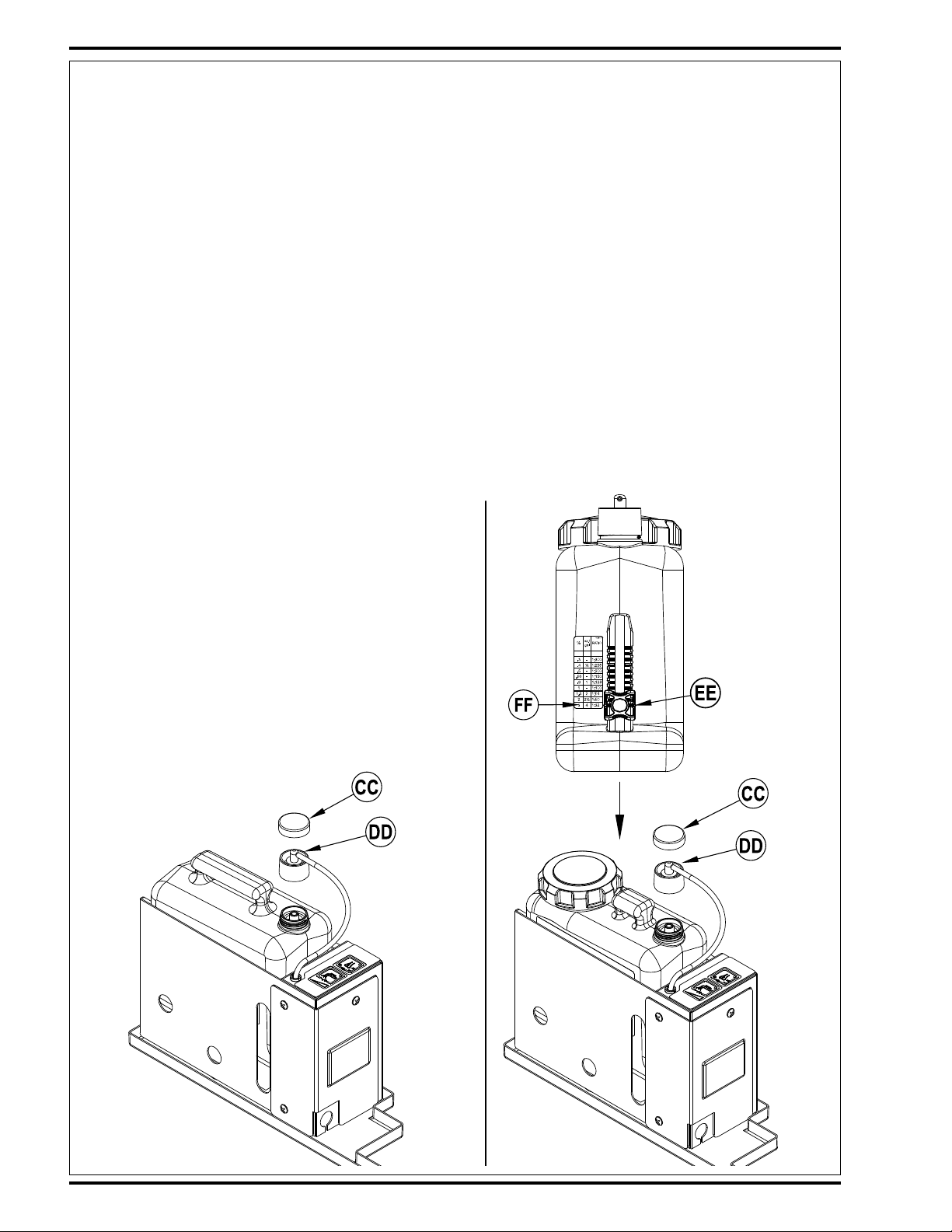

DISPOSABLE CARTRIDGE SPECIFIC INSTRUCTIONS:

Remove the Cap (CC) and place the cartridge in the detergent box. Install the Dry Break

Cap (DD) as shown.

NON-DISPOSABLE CARTRIDGE SPECIFIC INSTRUCTIONS:

Fill the detergent cartridge with a maximum of 1.25 gallons (4.73 Liters) of

detergent. SERVICE NOTE: Remove the detergent cartridge from the detergent

box prior to

It is recommended that a separate cartridge be used for each detergent you plan

to use. The detergent cartridges have a white decal on them so you can write

the detergent name on each cartridge to avoid mixing them up. The detergent

cartridge has a Magnetic Slider (EE) on one end that needs to be set to the proper

dilution ratio according to the dilution instructions on the manufacturer’s bottle.

Slide the Magnet Slider (EE) to the appropriate location on Detergent Dilution

Ratio Decal (FF). When installing a new cartridge, remove the Cap (CC) and

place the cartridge in the detergent box. Install the Dry Break Cap (DD) as shown.

fi lling to avoid spilling detergent on the machine.

A-8 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

revised 3/06

DETERGENT (EDS) SYSTEM PREPARATION AND USE

S

T

ENGLISH / A-9

V

U

revised 3/06

AA

BB

FORM NO. 56041541 - BRX 700, BRX 700 EDS - A-9

A-10 / ENGLISH

OPERATING THE MACHINE

WARNING!

Be sure you understand the operator controls and their functions.

While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only

while ascending (driving up) the ramp.

To Extract...

Follow the instructions in preparing the machine for use section of this manual.

1 While seated on the machine, adjust the steering wheel to a comfortable operating position using the adjustment knob (5).

2 Turn the Master Key Switch (J) ON (I). This will display the control panel indicator lights, reference the Battery Condition Indicator (K) and Hour Meter

(G).

3 Release the Parking Brake (6). To transport the machine to the work area, apply even pressure with your foot on the front of the Drive Pedal (8) to go

forward or the rear of the pedal for reverse. Vary the pressure on the foot pedal to obtain the desired speed.

4 Press either the Maintenance Mode Switch (D) or the Restoration Mode Switch (F) to activate the scrub system. Note: refer to the “Functional

Description of Control Switches” section for a more detailed explanation of these and other control panel functions.

NOTE (EDS Models): The Detergent system is activated by default when the Key Switch (J) is turned ON (I). The Detergent ON/OFF Indicator (V) is lit

when the detergent system is activated. The Detergent system can be turned OFF by pressing the Detergent ON/OFF Switch (S). When the system is

activated detergent fl ows whenever solution fl ows.

5 When either the Maintenance Mode Switch (D) or the Restoration Mode Switch (F) is selected, the brush deck and vacuum shoes are automatically

lowered to the fl oor. The machine’s scrub brush rotation and solution system fl ow starts when the Drive Pedal (8) is activated. NOTE: When operating

the machine in reverse, solution will not be dispensed. The brush deck can be programmed to raise in reverse, have a qualifi ed service technician refer

to the service manual to perform this function.

6 Begin cleaning by driving the machine forward in a straight line at a normal walking speed and overlap each path by 2-3 inches (50-75 mm). Turn the

Solution Switch (R) OFF prior to turns to ensure complete extraction of solution from carpet. Adjust when necessary the machine speed according to

the condition of the carpet.

If there is little or no fl uid entering the recovery bladder, the solution tank may be empty. Refi ll the solution tank with water and the proper ratio of

cleaning chemical.

7 The recovery bladder has an automatic fl oat shut-off to prevent solution from entering the vacuum system when the recovery bladder is full. When

the fl oat shut-off is activated, the control system will shut down the scrub, vacuum, solution and detergent (EDS models) systems. The Hourmeter

Display (G) will display “FULL”. To clear the display, press the Scrub OFF Switch (B), Maintenance Mode Switch (D) or the Restoration Mode Switch

(F). When the fl oat closes, the recovery bladder must be emptied. The machine will not pick up water with the fl oat closed. NOTE: If the control

repeatedly gives a full indication when the tank is not full, the automatic shut-off feature can be disabled, have a qualifi ed service technician refer to the

service manual to perform this function.

8 When the operator wants to stop cleaning or the recovery bladder is full, press the Scrub OFF Switch (B). This will automatically stop the scrub

brushes and solution

to allow any remaining water in the pick up hose to be brought into the recovery bladder.

9 Drive the machine to a designated waste water “DISPOSAL SITE” and empty the recovery bladder. To empty, pull the Drain Hose (21) from its rear

storage area, then remove the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). Refi ll

the solution tank and continue cleaning.

fl ow and the brush deck will raise to the up position. NOTE: The vacuum system will be turned off after a 10 second delay this is

USING ATTACHMENTS

Steps to follow in fi tting the machine with optional attachments for detail or upholstery cleaning.

1 Disconnect the recovery hose connection at the Y-fi tting, which goes to the vacuum shoes. Connect the coupler and hose from suitable wet pick-up

tools to the recovery hose.

2 Attach the solution connection to the accessory port, located at the rear of the machine on the chassis. (An optional Wand Caddy Kit is available from

Nilfi sk).

3 Turn the Master Key Switch (J) ON, next press the Accessory Vacuum Switch (I). The vacuum motor will run continuously until the switch is pressed

again to turn it OFF. NOTE: If the control repeatedly gives a full indication when the tank is not full, the automatic shut-off feature can be disabled, have

a qualifi ed service technician perform this function.

A-10 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

revised 3/06

ENGLISH / A-11

AFTER USE

1 When fi nished cleaning, press the Scrub Off Switch (B), this will automatically raise, retract and stop all the machine systems (brush, vacuum &

solution). Then drive the machine to a service area for daily maintenance and review of other needed service up-keep.

2 To empty the solution tank, remove the Solution Drain Hose (4) from its storage clamp. Direct the hose to a designated “DISPOSAL SITE” and remove

the plug. Rinse the tank with clean water.

3 To empty the recovery bladder, pull the Recovery Bladder Drain Hose (21) from its storage area. Direct the hose to a designated “DISPOSAL SITE”

and remove the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). Rinse the Waste

water Bladder (19) with clean water.

4 Remove the Brushes, rinse with warm water and remove any built-up string, hair or carpet fi bers.

5 Disconnect the Recovery Hose from the Recovery Tank and fl ush with warm water to wash any debris out of the Recovery Hose / Vacuum Shoe

Assembly.

6 Remove the debris hopper and clean thoroughly. Remove from left or right side of machine by lifting hopper up and tilting it forward then pull out.

7 Check the maintenance schedule below and perform any required maintenance before storage.

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries •

Check/Clean Tanks & Hoses •

Check/Clean/ Power Brushes •

Check/Clean Vacuum Shoes •

Check/Clean Vacuum Shut-Off Float •

Check/Clean the vacuum motor foam fi lter(s) •

Empty Debris Hopper •

Clean Spray Nozzles •

Check Each Battery Cell(s) Water Level •

Inspect Brush Deck Skirts •

Inspect and clean Solution Filter •

Check Foot/ Parking Brake for Wear & Adjustment •

Purge the Detergent Injection System (EDS models only) •

Lubrication - Grease Fittings •

* Check Carbon Brushes •

* Have Nilfi sk check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The brush and drive motor carbon brushes check

every 350 hours or once a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

8 Store the machine indoors in a clean dry place. Keep from freezing. Leave the tanks open to air them out.

9 Turn the Master Key Switch (J) OFF (O) and remove the key.

VACUUM SHOE MAINTENANCE

Check the vacuum shoes daily, they can be removed to aid in cleaning, see “Removing the Vacuum Shoes”. Remove any built-up string, hair or carpet

fi bers.

SPRAY NOZZLE MAINTENANCE

Remove the spray nozzles once a week. Soak the nozzles overnight in a vinegar and water solution to remove chemical deposits.

LUBRICATING THE MACHINE

Once a month, pump a small amount of grease into each grease fi tting on the machine until grease seeps out around the bearings.

Grease fi tting locations are:

• Steering Wheel Shaft Universal joint

Once a month, apply light machine oil to lubricate the:

• Steering Chain

• General Pivot Points For the Brush Deck Linkage

CLEANING THE VACUUM MOTOR FILTERS

Clean the vacuum motor fi lters daily with compressed air. For extremely dirty fi lters, wash with warm, soapy water and rinse thoroughly with clean water.

Allow the fi lters to dry completely before re-installing in the machine. MAINTENANCE NOTE: Keep a second set of fi lters on hand to use while fi rst set is

drying.

POWER BRUSH MAINTENANCE

Check the brushes daily. Remove any built-up string, hair or carpet fi bers. Check the bristle length. Have a service technician change the brushes when the

brush bristles are worn to 1/2 inch (12.7 mm).

revised 3/06

FORM NO. 56041541 - BRX 700, BRX 700 EDS - A-11

A-12 / ENGLISH

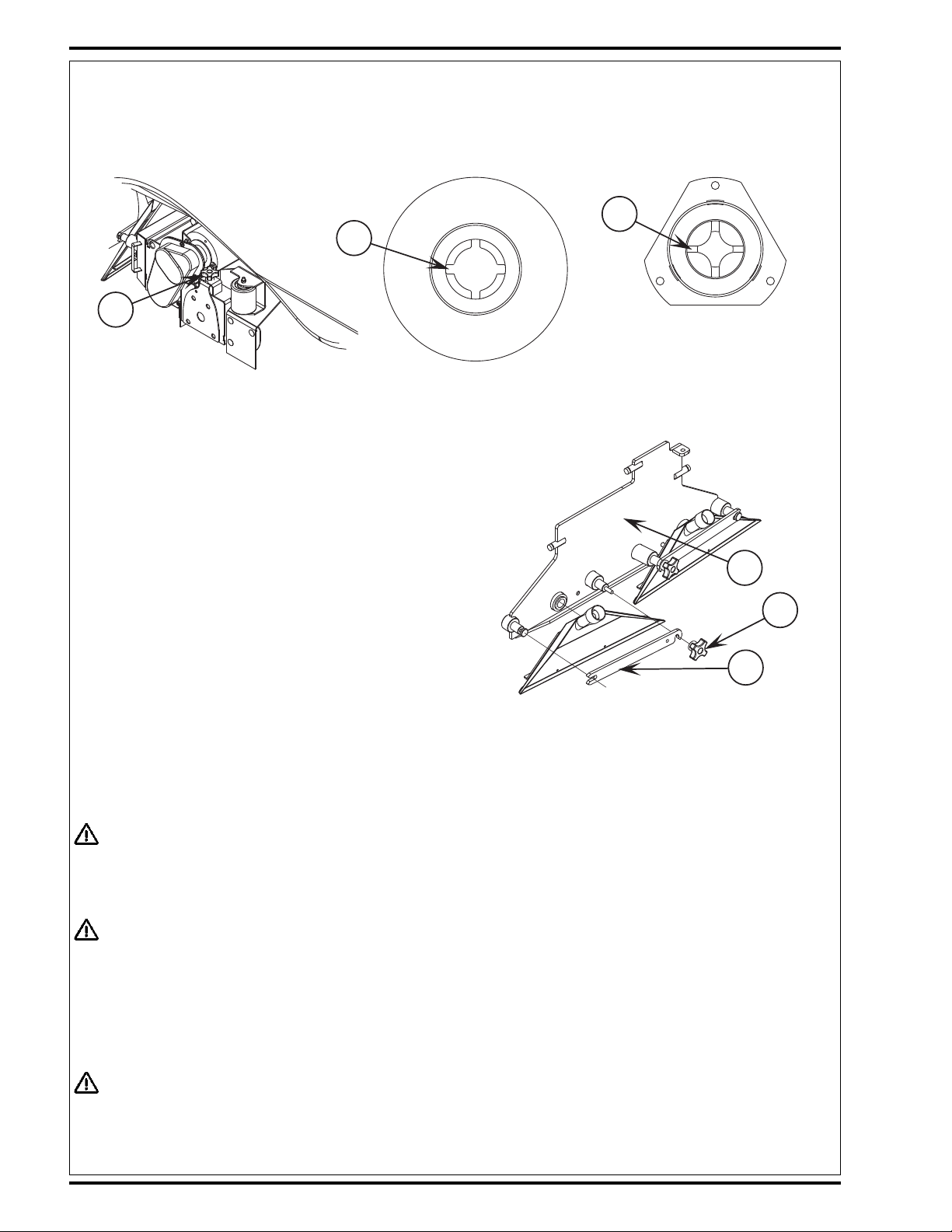

REMOVING THE BRUSHES

1 Turn the Master Key Switch (J) OFF.

2 Loosen the Black Knob (A) on top of the idler assembly and remove the idler assembly. Slide the brush out of the brush deck housing.

3 To reinstall, slide the brush into the housing, lift slightly, push and turn until it seats. NOTE: Make sure Slots (B) in end of Brush line up with and seat

fi rmly on Lugs (C) on the Drive End Assembly. Re-install the idler assembly and tighten Black Knob (A).

+

*

)

Right Side of Machine

Rechte Seite der Maschine

Côté droit de la machine

Rechter kant van machine

End View of Brush

Endansicht der Bürste

Vue latérale de la brosse

Eindaanzicht van borstel

End View of Drive End Assembly

Endansicht der Antriebseinheit

Vue latérale du dispositif d'entraînement

Eindaanzicht van aandrijfuiteinde

REMOVING THE VACUUM SHOES

1 Turn the Master Key Switch (J) OFF.

2 Loosen the Black Knob (D) on the back of the scrub deck. Lift the

Bar (E) up and remove. Slide the vac shoe out of the shoe support

weldment (F). Procedure is the same for both vac shoes.

3 Reinstallation is reverse of removal.

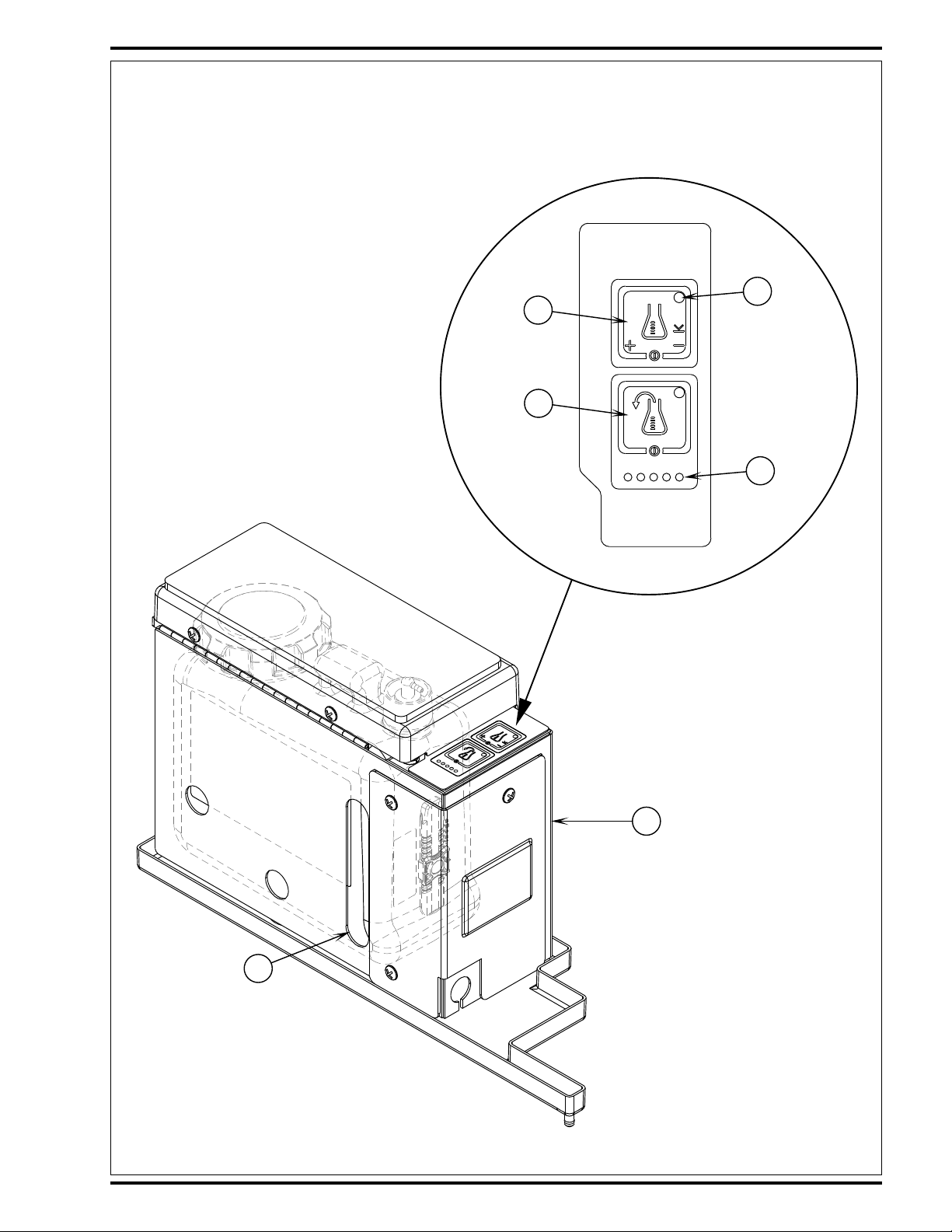

CHARGING THE BATTERIES

Charge the batteries each time the machine is used, or whenever the

Battery Condition Meter (K) is showing a yellow, red or fl ashing red

indicator light(s).

To Charge the Batteries...

1 Depress the Battery Disconnect (13).

2 Open the Battery Compartment Cover (16) to provide proper

ventilation.

3 Push the connector from the charger into the Battery Connector (22).

4 Follow the instructions on the battery charger.

5 Check the fl uid level in all battery cells after charging the batteries. Add distilled water, if necessary, to bring the fl uid level up to the bottom of the fi ller

tubes.

View from left rear of machine

Ansicht der Maschine von links hinten

Vue arrière gauche de la machine

Zicht linker achterkant van machine

.

,

-

WARNING !

Do not fi ll the batteries before charging.

Only charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

CAUTION !

To avoid damage to fl oor surfaces, always wipe water and acid from the top of the batteries after charging.

CHECKING THE BATTERY ELECTROLYTE LEVEL

Check the electrolyte level of the batteries at least once a week.

After charging the batteries, remove the vent caps and check the electrolyte level in each battery cell. Use distilled water to fi ll the batteries to the bottom of

the fi ller tube.

Do not over-fi ll the batteries!

CAUTION !

Acid can spill onto the fl oor if the batteries are overfi lled.

Tighten the vent caps. If there is acid on the batteries, wash the tops of the batteries with a solution of baking soda and water (2 tablespoons of baking soda

to 1 quart of water).

A-12 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

ENGLISH / A-13

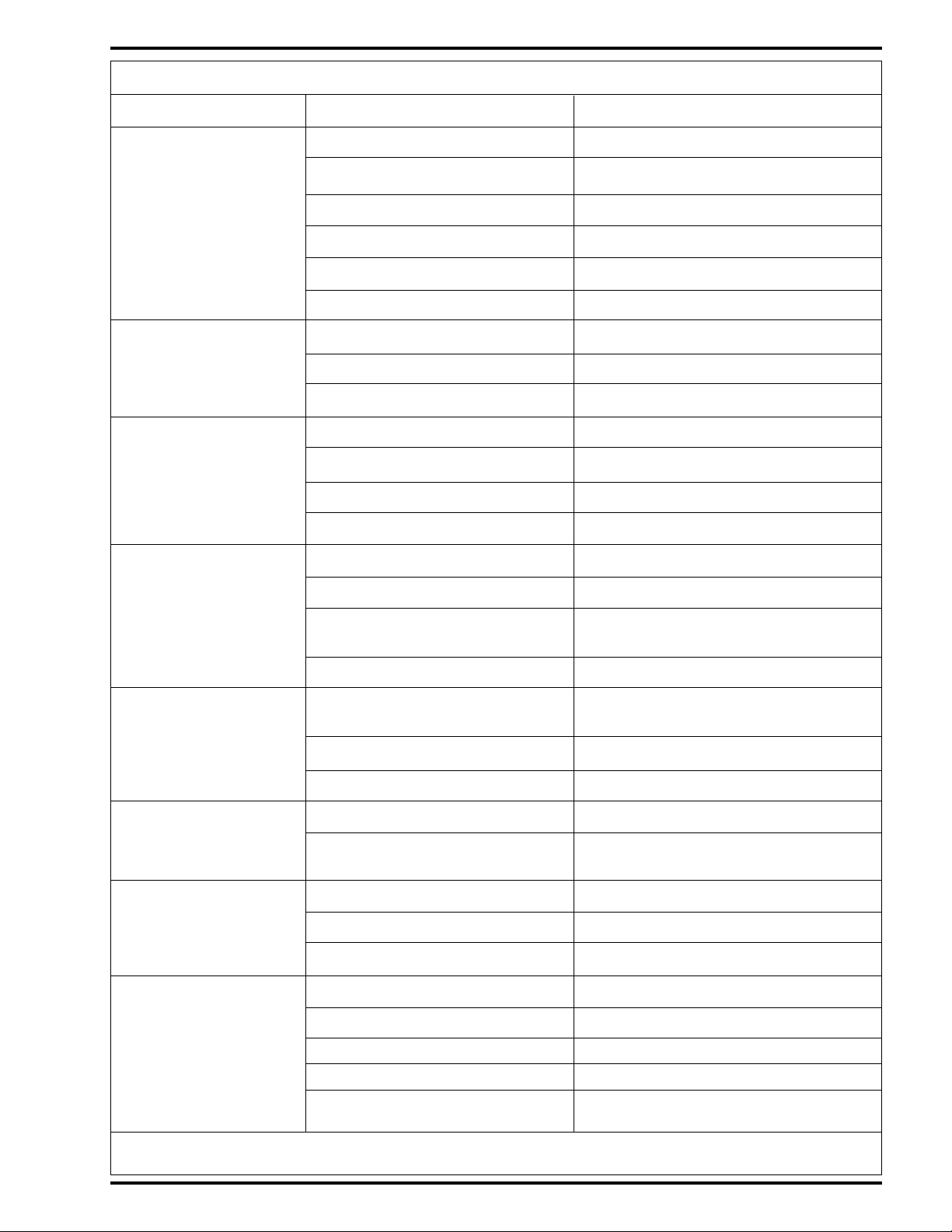

GENERAL MACHINE TROUBLESHOOTING

Problem Possible Cause Remedy

Poor water pick-up Recovery bladder full Empty recovery bladder

Recovery bladder drain hose leak Secure drain hose cap or replace

Recovery tank cover gasket leak Replace gasket / Seat cover properly

Debris caught in vacuum shoes Clean vacuum shoes

Vacuum hose clogged Remove debris

Foam fi lter cover not seated Seat cover properly

Poor extracting performance Worn brushes Rotate or replace brushes

Wrong cleaning chemical Consult Nilfi sk

Moving machine too fast Slow down

Inadequate solution fl ow Solution tank empty Fill solution tank

or no solution

Solution lines, valves, fi lter, or spray jets clogged Flush lines and clean solution fi lter & spray jets

Solution control valve is in closed position Place control valve handle in open position

Solution solenoid valves Clean or replace valves

Machine does not run Emergency stop switch tripped Reconnect battery connectors

Operator seat safety switch Check for open circuit and replace

Main system controller Check for error fault codes

(see service manual)

Tripped 10 Amp circuit breaker Check for electrical short circuit & reset

No FWD/REV wheel drive Drive system speed controller Check for error fault codes

(see service manual)

Tripped 45 Amp circuit breaker Check for drive motor overload

Emergency stop switch tripped Reconnect battery connectors

Vacuum shuts off and display Plugged vacuum hose(s) Clear debris

shows “FULL” when

recovery bladder is not full Vacuuming large amounts of water Slow down or disable auto shut-off feature

at a high travel speed (see service manual)

Poor Sweeping Performance Debris Hopper Full Empty and clean hopper

Brushes worn Replace brushes

Bristles have taken a set Rotate brushes

No Detergent Flow Empty detergent cartridge Fill detergent cartridge

(EDS models only)

Plugged or kinked detergent fl ow line Purge system, straighten lines to remove any kinks

Dry seal cap on detergent cartridge not sealed Reseat dry seal cap

Detergent ratio slider magnet missing Replace slider

Detergent pump wiring disconnected Connect or reconnect wiring

or backwards

revised 3/06

FORM NO. 56041541 - BRX 700, BRX 700 EDS - A-13

A-14 / ENGLISH

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model BRX 700, BRX 700 EDS

Model No. 56314019, 56316516

Current A 65

Voltage, Batteries V 36V

Battery Capacity Ah 238

Protection Grade IPX3

Sound Power Level

(IEC 60335-2-72: 2002 Amend. 1:2005, ISO 3744) dB(A)/20μPa 73

Gross Weight lbs / kg 1570 / 712

Vibrations at the Hand Controls (ISO 5349-1) m/s

Vibrations at the Seat (EN 1032) m/s2 <0.5m/s

Gradeability

Transport 14% (8°)

Cleaning 10% (6°)

2

<2.5m/s

2

2

A-14 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

revised 1/09

B-2 / DEUTSCH

INHALTSÜBERSICHT

Seite

Einleitung .............................................................................................. B-2

Sicherheits- und Warnhinweise ............................................................B-3

Machen Sie sich mit Ihrer Maschine vertraut .......................................B-4

Bedienfeld ............................................................................................. B-5

Vorbereitung der Maschine zum Einsatz

Beschreibung der Batterieanzeigeleuchten .......................................... B-6

Einbau der Batterien ............................................................................. B-6

Füllen des Reinigungslösungstanks .....................................................B-7

Besprühen des Teppichs vor der Reinigung ........................................ B-7

Planung des Reinigungsvorgangs ........................................................ B-7

(EDS) System .................................................................................... B-8-9

Bedienung der Maschine .................................................................... B-10

Benutzung von Zubehörteilen ............................................................ B-10

Nach dem Einsatz .............................................................................. B-11

Wartungsplan ..................................................................................... B-11

Wartung des Saugtrichters ................................................................. B-11

Wartung der Spraydüse ...................................................................... B-11

Schmieren der Maschine .................................................................... B-11

Reinigung der Saugmotorfi lter ............................................................ B-11

Wartung der Power-Bürste ................................................................. B-11

Entfernen der Bürste(n) ......................................................................B-12

Entfernen der Saugtrichter .................................................................B-12

Laden der Batterien ............................................................................B-12

Überprüfen des Batteriefl üssigkeitsstandes .......................................B-12

Fehlerbehebung ................................................................................. B-13

Technische Daten ...............................................................................B-14

EINLEITUNG

Dieses Handbuch wird Ihnen dabei behilfl ich sein, Ihre Maschine Nilfi sk BRX 700 optimal zu nutzen. Lesen Sie es vor Inbetriebnahme der Maschine

sorgfältig durch.

Hinweis: Fettgedruckte Zahlen in Klammern weisen auf ein auf den Seiten B4-B5 dargestelltes Teil hin.

Dieses Produkt ist ausschließlich für den gewerblichen Einsatz bestimmt.

BAUTEILE UND SERVICE

Eventuell erforderliche Reparaturen sollten von Ihrem autorisierten Nilfi sk-Servicezentrum vorgenommen werden. Dort stehen im Werk ausgebildete

Fachkräfte und Nilfi sk-Originalteile zur Verfügung.

Wenden Sie sich wegen Ersatzteilen bzw. Servicearbeiten an den unten angeführten NILFISK-HÄNDLER. Geben Sie dabei das Modell und die

Seriennummer Ihrer Maschine an.

(Händler: Bitte hier Aufkleber anbringen.)

TYPENSCHILD

Die Modellnummer und die Seriennummer Ihrer Maschine sind dem Typenschild an der Maschine zu entnehmen. Diese Angaben sind bei der Bestellung von Ersatzteilen für die

Maschine erforderlich. Tragen Sie nachfolgend die Modellnummer und die Seriennummer Ihrer Maschine ein, um später darauf Bezug nehmen zu können.

MODELLNUMMER _____________________________________________

SERIENNUMMER ______________________________________________

AUSPACKEN DER MASCHINE

Wenn die Maschine geliefert wird, prüfen Sie sorgsam den Versandkarton und die Maschine auf Beschädigungen. Wenn Sie eine Beschädigung sehen,

bewahren Sie den Versandkarton zur Inspektion auf. Kontaktieren Sie die Nilfi sk Kundendienstabteilung sofort, um eine Frachtbeschädigung zu melden.

Nachdem Sie den Karton entfernt haben, schneiden Sie die Plastikriemen durch und nehmen Sie die Holzblöcke neben den Rädern heraus. Rollen Sie die

Maschine mittels einer Rampe von der Palette auf den Boden.

B-2 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

revised 3/06

DEUTSCH / B-3

SICHERHEITS- UND WARNHINWEISE

SYMBOLE

Nilfi sk verwendet die untenstehenden Symbole, um auf eventuelle Gefahrensituationen hinzuweisen. Bitte lesen Sie diese

Informationen jederzeit sorgfältig durch, und treffen Sie die erforderlichen Maßnahmen, um Personen- und Sachschäden zu

vermeiden.

GEFAHR !

Dieses Symbol warnt vor der unmittelbaren Gefahr schwerer Verletzungen mit möglicher Todesfolge.

WARNHINWEIS !

Macht auf eine Situation aufmerksam, in der ein hohes Verletzungsrisiko besteht.

VORSICHT !

Macht auf eine Situation aufmerksam, in der ein Risiko leichter Verletzungen sowie die Gefahr von Sachschäden besteht.

Lesen Sie alle Anweisungen vor Inbetriebnahme der Maschine sorgfältig durch.

ALLGEMEINE SICHERHEITSANWEISUNGEN

Durch diese spezifi schen Vorsichts- und Warnhinweise werden Sie auf Situationen hingewiesen, in denen die Gefahr von

Personen- bzw. Sachschäden besteht.

WARNHINWEIS!

• Diese Maschine darf lediglich von hinreichend ausgebildeten und autorisierten Personen betrieben werden.

• Wenn sich die gefüllte Maschine auf Rampen oder Steigungen befi ndet, sind plötzliche Stopps zu vermeiden. Vermeiden Sie plötzliches,

scharfes Wenden. Abwärtsfahrten sind nur mit niedriger Geschwindigkeit zulässig. Auf Rampen darf lediglich beim Aufwärtsfahren

gereinigt werden.

• Halten Sie Funken, offenes Feuer und Rauch entwickelnde Stoffe von den Batterien fern. Während des Normalbetriebs werden

explosive Gase freigesetzt.

• Beim Laden der Batterien entsteht hochexplosiver gasförmiger Wasserstoff. Laden Sie die Batterien nur in gut belüfteten Bereichen, weit

entfernt von offenem Feuer. Beim Aufl aden der Batterien ist das Rauchen verboten.

• Tragen Sie keinen Schmuck, wenn Sie in der Nähe von elektrischen Komponenten arbeiten.

• Schalten Sie den Schlüsselschalter aus (stellen Sie ihn auf O), und klemmen Sie die Batterien ab, bevor Sie an den elektrischen

Komponenten Wartungsarbeiten ausführen.

• Arbeiten Sie niemals unter einer Maschine, ohne diese mit Sicherheitskeilen oder Stützböcken zu sichern.

• Verwenden Sie keine entfl ammbaren Reinigungslösungen, nehmen Sie die Maschine nicht über oder in der Nähe solcher Stoffe in

Betrieb, und benutzen Sie die Maschine nicht in Bereichen, in denen brennbare Flüssigkeiten gelagert werden.

• Reinigen Sie diese Maschine nicht mit einem Druckreiniger.

VORSICHT!

• Diese Maschine ist nicht zum Einsatz auf öffentlichen Wegen und Straßen zugelassen.

• Diese Maschine ist nicht zur Beseitigung gesundheitsgefährdender Stäube geeignet.

• Sorgen Sie beim Einsatz dieser Maschine dafür, dass andere Personen, insbesondere Kinder, nicht gefährdet werden.

• Lesen Sie vor Wartungsarbeiten alle diesbezüglichen Anweisungen sorgfältig durch.

• Lassen Sie die Maschine nicht unbeaufsichtigt stehen, ohne vorher den Schlüsselschalter auszuschalten (O), den Schlüssel abzuziehen

und die Feststellbremse zu aktivieren.

• Schalten Sie vor dem Wechseln der Bürste und dem Öffnen der Verkleidung den Schlüsselschalter aus (stellen Sie ihn auf O).

• Treffen Sie geeignete Maßnahmen, um zu verhindern, dass sich Ihre Haare, Schmuckgegenstände oder lose Kleidungsstücke in

beweglichen Teilen der Maschine verfangen.

• Beim Betrieb dieser Maschine bei Temperaturen unter dem Gefrierpunkt ist besondere Vorsicht geboten. Jegliches Wasser im

Lösungsmitteltank bzw. im Auffangbehälter oder in den Schlauchleitungen könnte gefrieren, wodurch Ventile und Verschraubungen

beschädigt werden können. Mit Flüssigkeit für Scheibenwaschanlagen durchspülen.

• Vor der Verschrottung der Maschine müssen Sie die Batterien ausbauen. Batterien müssen entsprechend den geltenden

Umweltvorschriften entsorgt werden.

BEWAHREN SIE DIESE ANLEITUNG AUF.

FORM NO. 56041541 - BRX 700, BRX 700 EDS - B-3

B-4 / DEUTSCH

MACHEN SIE SICH MIT IHRER MASCHINE VERTRAUT

1 Deckel des Auffangbehälters

2 Abdeckung des Einfüllstutzens für den Reinigungslösungstank

3 Fahrersitz

4 Ablassschlauch des Reinigungslösungstanks

5 Knopf zur Lenksäulenverstellung

6 Bremspedal / Feststellbremse

7 Spraydüsen für die Reinigungslösung

8 Fahrpedal Richtung/Geschwindigkeit

9 Saugtrichter

10 Antriebs- und Lenkrad

11 Automatsicherung - Radantrieb

12 Automatsicherung - Steuerung

13 Notaus-Taster / Batterie-Trennschalter

14 Bürstengehäuse

15 Hinterrad

16 Batteriefach (unter dem Fahrersitz)

17 Schwimmerschalter des Auffangbehälters

18 Filtergehäuse des Saugmotors

19 Auffangbehälter

20 Filter der Reinigungslösung

21 Ablassschlauch des Auffangbehälters (Rückseite der Maschine)

22 Batterieanschluss

23 Bedienfeld

24 Schmutzbehälter

25 Ventil der Reinigungslösung

15

1

17

4

21

18

3

19

2

23

11

13

12

16

5

22

6

9

24

14

7

B-4 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

25

20

8

10

BEDIENFELD

A Leuchtanzeige Scheuern AUS

B Schalter Scheuern AUS

C Anzeige Schnellreinigungsmodus

D Taster Schnellreinigungsmodus

E Anzeige Tiefenreinigungsmodus

F Taster Tiefenreinigungsmodus

G Anzeige Bestriebsstundenzähler

H Anzeige Saugsystemzubehör

I Schalter Saugsystemzubehör EIN / AUS

J Schlüsselschalter / Hauptstrom

K Batterieanzeige

L Schalter Geschwindigkeitswahl (Absaugen / Transport)

M Anzeige Geschwindigkeitswahl

N Taste für die Hupe

O Saugschalter

P Anzeige Saugsystem

Q Anzeige Reinigungssystem

R Schalter für die Reinigungslösung

DEUTSCH / B-5

L

K

N

M

P

O

R

Q

A

B

C

D

F

E

G

H

I

J

FORM NO. 56041541 - BRX 700, BRX 700 EDS - B-5

B-6 / DEUTSCH

BESCHREIBUNG DER BATTERIEANZEIGELEUCHTEN

Mit Hilfe der Batterie-Anzeigelampen lässt sich der Ladezustand der Batterien feststellen. Eine voll aufgeladene Batterie ohne angelegte Last hat eine

Klemmenspannung von 37,6 Volt (2,09 Volt pro Batteriezelle). Das Modell BRX 700 ist mit einer Unterspannungsabschaltung ausgerüstet, die das

Scheuersystem abschaltet, wenn die Batterien voll entladen sind. Die Abschaltspannung kann je nach dem verwendeten Batterietyp in zwei Stufen eingestellt

werden. Details fi nden Sie im Servicehandbuch. Die Spannungsstufen für die verschiedenen Anzeigen sind (die angegebenen Spannungen entsprechen der

Spannung unter Last):

SPANNUNGSANZEIGESTUFEN FÜR DIE STANDARDABSCHALTUNG (EINSTELLUNG BEI AUSLIEFERUNG)

Grüne Anzeige = vollständig geladen bis 34,00 Volt

Grüne und gelbe Anzeige = 33,99 Volt bis 33,00 Volt

Gelbe Anzeige = 32,99 Volt bis 32,00 Volt

Gelbe und rote Anzeige = 31,99 Volt bis 31,50 Volt

Rote Anzeige = 31,49 Volt bis 31,00 Volt

Blinkende rote Anzeige = weniger als 31,00 Volt – das Scheuersystem wird abgeschaltet.

SPANNUNGSANZEIGESTUFEN FÜR DIE ALTERNATIVE ABSCHALTUNG

Grüne Anzeige = vollständig geladen bis 34,50 Volt

Grüne und gelbe Anzeige = 34,49 Volt bis 34,00 Volt

Gelbe Anzeige = 33,99 Volt bis 33,50 Volt

Gelbe und rote Anzeige = 33,49 Volt bis 33,00 Volt

Rote Anzeige = 32,99 Volt bis 32,5 Volt

Blinkende rote Anzeige = weniger als 32,5 Volt – das Scheuersystem wird abgeschaltet.

HINWEIS: Anweisungen zur Umschaltung auf die Alternativeinteilung fi nden Sie in der Wartungsanleitung.

HINWEIS: Sobald die untere Abschaltspannung erreicht ist (rote Anzeige blinkt), müssen die Batterien VOLL (bis auf 37,6 Volt) aufgeladen werden, sonst

wird die Batterie-Anzeige nicht zurückgesetzt. Das Scheuersystem funktioniert erst, wenn die Anzeige zurückgesetzt wurde.

EINBAU DER BATTERIEN

WARNHINWEIS!

Bei der Arbeit an Batterien ist äußerste Vorsicht geboten. Die Schwefelsäure in den Batterien kann bei Berührung der Haut oder

der Augen erhebliche Verletzungen verursachen. Explosiver, gasförmiger Wasserstoff wird aus dem Inneren der Batterien durch

Öffnungen in den Batteriekappen abgegeben. Dieses Gas kann sich durch einen elektrischen Lichtbogen, einen Funken oder

eine offene Flamme entzünden.

Treffen Sie vor bzw. bei der Arbeit an den Batterien folgende Sicherheitsvorkehrungen:

* Entfernen Sie jeglichen Schmuck.

* Rauchen Sie nicht.

* Tragen Sie Schutzbrillen, eine Gummischürze und Gummihandschuhe.

* Arbeiten Sie in einem gut belüfteten Bereich.

* Lassen Sie nicht zu, dass ein Werkzeug mehr als eine Batterieklemme berührt.

ACHTUNG!

An den elektrischen Komponenten dieser Maschine können erhebliche Schäden entstehen, wenn die Batterien nicht

ordnungsgemäß eingebaut und angeschlossen werden. Die Einbau der Batterien sollte von Nilfi sk oder einem qualifi zierten

Elektriker vorgenommen werden.

1 Drehen Sie den Schlüsselschalter auf (J) OFF (O), und entfernen

Sie den Schlüssel. Daraufhin klappen Sie die Abdeckung des

Batteriefaches (16) auf.

2 Mit Hilfe von (2) Personen und einem passenden Hubriemen heben

Sie die Batterien vorsichtig genau wie abgebildet in das Batteriefach.

Benutzen Sie das Abziehbild 56380512 für den Batteriekabelplan.

3 Siehe Abb. 1.Klemmen Sie die Batteriekabel wie abgebildet an, und

ziehen Sie die Muttern an den Batterieklemmen fest.

4 Installieren Sie die Batteriemanschetten, und befestigen Sie diese mit

den mitgelieferten Bändern sorgfältig an den Batteriekabeln.

5 Schließen Sie den Anschluss des Batteriesatzes am Anschluss

der Maschine (22) an, und schließen Sie die Abdeckung des

Batteriefaches.

ABB. 1

B-6 - FORM NO. 56041541 - BRX 700, BRX 700 EDS

revised 1/09

Loading...

Loading...