Nilfisk BR 855, BR 755, BR 755C BROCHURE

BR 755, BR 755C, BR 855

Instructions For Use - Original Instructions

Kullanim Talimatlari

12/08 revised 8/10

FORM NO. 56041743

A-English

B-Türkçe

Nilfi sk Models: 56601014, 56601015, 56601016

A-2 / ENGLISH

TABLE OF CONTENTS

Page

Introduction ........................................................................................... A-2

Cautions and Warnings ........................................................................ A-3

Know Your Machine .....................................................................A-4 – A-5

Control Panel ........................................................................................A-6

Prepare the Machine for Use

Install the Batteries ...............................................................................A-7

Install the Brushes ................................................................................A-8

Install the Squeegee .............................................................................A-9

Fill the Solution Tank ............................................................................ A-9

Detergent System ....................................................................A-10 – A-11

Operating the Machine

Scrubbing ................................................................................A-12 – A-13

Wet Vacuuming .......................................................................A-12 – A-13

After Use ............................................................................................. A-14

Maintenance Schedule .......................................................................A-14

Lubricating the Machine .....................................................................A-14

Charging the Batteries (Wet) .............................................................. A-15

Check the Battery Water Level ........................................................... A-15

Charging the Batteries (Gel) ............................................................... A-15

Squeegee Maintenance ...................................................................... A-16

Squeegee Adjustment ........................................................................ A-16

Side Skirt Maintenance ....................................................................... A-17

Side Skirt Maintenance ....................................................................... A-17

Troubleshooting .................................................................................. A-18

Technical Specifi cations ..................................................................... A-19

INTRODUCTION

This manual will help you get the most from your Nilfi sk Rider Scrubber. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages A-4 – A-6.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfi sk Service Center, who employs factory trained service personnel, and maintains an inventory

of Nilfi sk original replacement parts and accessories.

Call the NILFISK DEALER named below for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

(Dealer, affi x service sticker here.)

NAME PLATE

The Model Number and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering repair parts for

the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference.

MODEL NUMBER ______________________________________________________

SERIAL NUMBER ______________________________________________________

UNCRATE THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping carton (if

applicable) so that it can be inspected. Contact the Nilfi sk Customer Service Department immediately to fi le a freight damage claim. Refer to the unpacking

instruction sheet included with the machine to remove the machine from the pallet.

A-2 - FORM NO. 56041743 - BR 755 series

revised 1/10

ENGLISH / A-3

CAUTIONS AND WARNINGS

SYMBOLS

Nilfi sk uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take the

necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

WARNING!

* This machine shall be used only by properly trained and authorized persons.

* While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only

while ascending (driving up) the ramp.

* Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

* Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away from open

fl ame. Do not smoke while charging the batteries.

* Remove all jewelry when working near electrical components.

* Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

* Never work under a machine without safety blocks or stands to support the machine.

* Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable

liquids exist.

* Do not clean this machine with a pressure washer.

* Only use the brushes provided with the appliance or those specifi ed in the instruction manual. The use of other brushes may

impair safety.

CAUTION!

* This machine is not approved for use on public paths or roads.

* This machine is not suitable for picking up hazardous dust.

* Do not use scarifi er discs and grinding stones. Nilfi sk will not be held responsible for any damage to fl oor surfaces caused by

scarifi ers or grinding stones (can also cause damage to the brush drive system).

* When operating this machine, ensure that third parties, particularly children, are not endangered.

* Before performing any service function, carefully read all instructions pertaining to that function.

* Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and applying the parking

brake.

* Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

* Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

* Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery or

detergent tanks or in the hose lines could freeze, causing damage to valves and fi ttings. Flush with windshield washer fl uid.

* The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries should be

safely done in accordance with your local environmental regulations.

* Do not use on surfaces having a gradient exceeding that marked on the machine.

* All doors and covers are to be positioned as indicated in the instruction manual before using the machine.

SAVE THESE INSTRUCTIONS

FORM NO. 56041743 - BR 755 series - A-3

A-4 / ENGLISH

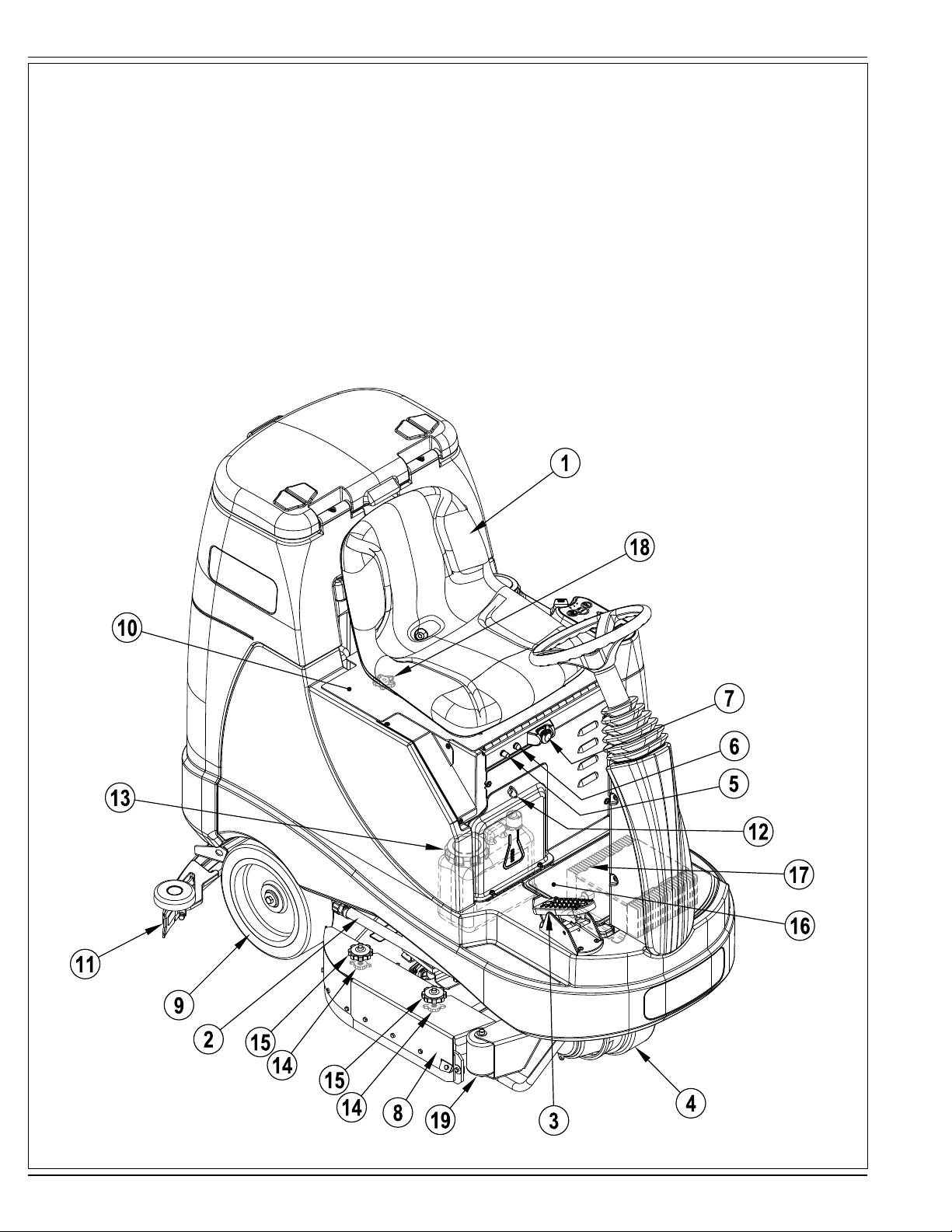

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item shown on these

pages unless otherwise noted. Refer back to these pages whenever necessary to pinpoint the location of an item mentioned in the text. NOTE: Refer to the

service manual for detailed explanations of each item illustrated on the next 3 pages.

1 Operator’s Seat

2 Solution Tank Drain Hose

3 Drive Pedal, Directional/Speed

4 Drive Wheel

5 Drive Wheel Circuit Breaker (70 Amp)

6 Control Circuit Circuit Breaker (10 Amp)

7 Emergency Stop

8 Scrub Deck

9 Rear Wheel

10 Battery Compartment (under seat)

11 Squeegee Assembly

12 Detergent Cartridge Access Cover (EcoFlex models only)

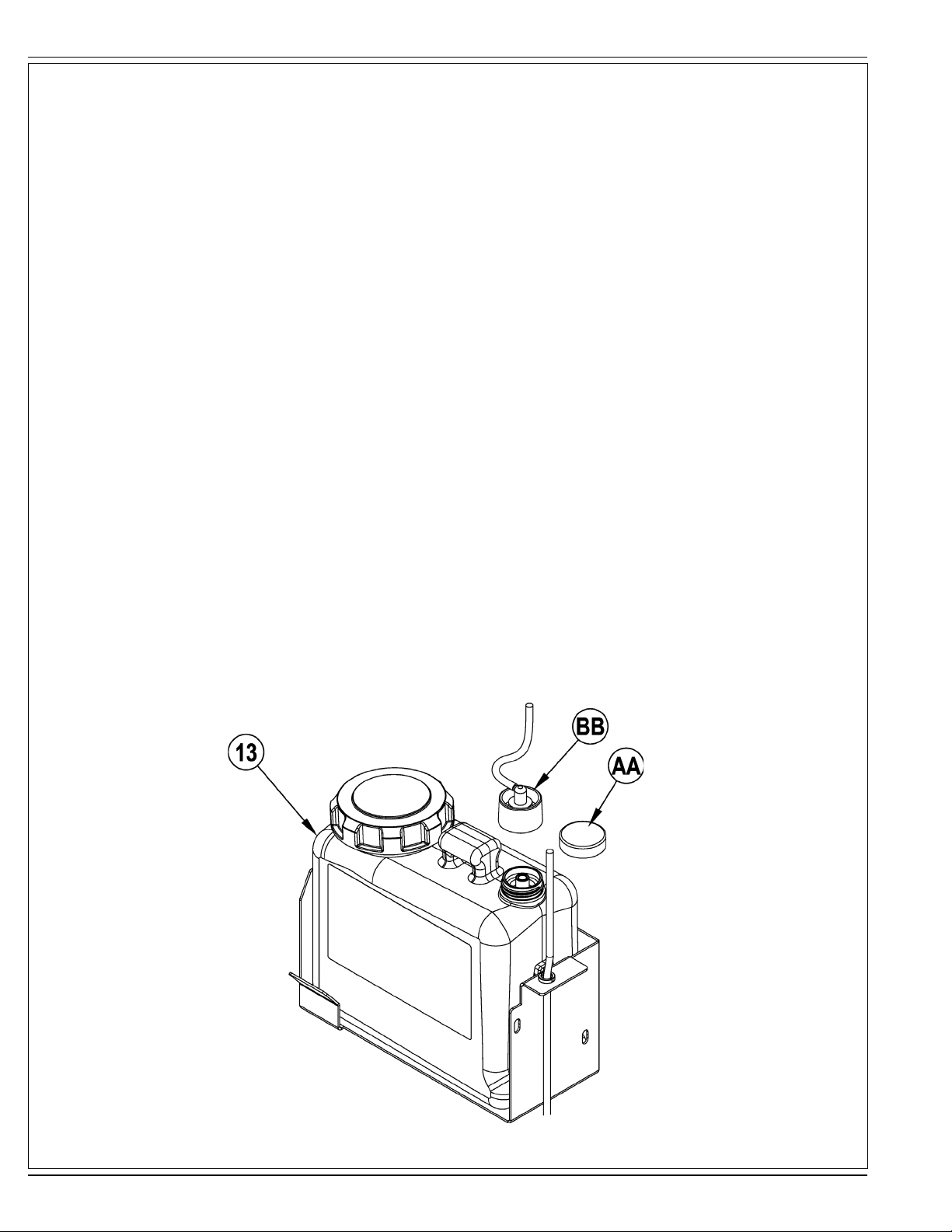

13 Detergent Cartridge (EcoFlex models only)

14 Deck Skirt Height Adjustment Knob

15 Deck Skirt Removal Knobs

16 Battery Charger Access Door

17 Battery Charger (optional)

18 Seat Adjustment Knob

19 Front Roller Bumper

A-4 - FORM NO. 56041743 - BR 755 series

revised 1/10

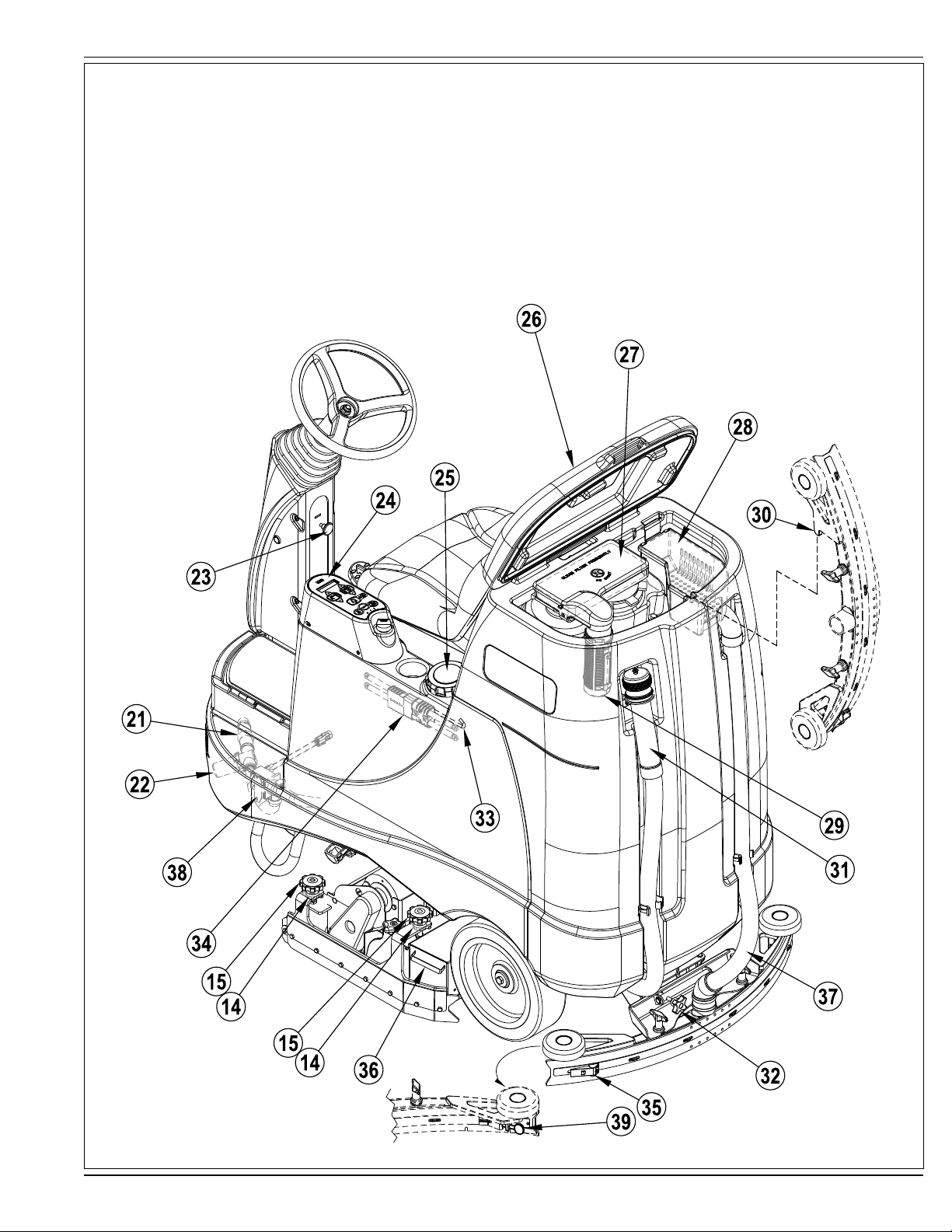

KNOW YOUR MACHINE

21 Solution Shutoff Valve

22 Solution Filter

23 Steering Wheel Tilt Adjust Knob

24 Control Panel

25 Solution Tank Fill Cover

26 Recovery Tank Cover

27 Vacuum Motor Filter Housing

28 Strainer Basket

29 Recovery Tank Shutoff Float

30 Squeegee Storage Hook

ENGLISH / A-5

31 Recovery Tank Drain Hose

32 Squeegee Tilt Adjustment Knob

33 Seat Prop-Rod

34 Machine Battery Connector

35 Rear Squeegee Blade Removal Latch

36 Hopper (Cylindrical models only)

37 Recovery Hose

38 Solution Solenoid Valve

39 Front Squeegee Blade Removal Thumb Nut

FORM NO. 56041743 - BR 755 series - A-5

A-6 / ENGLISH

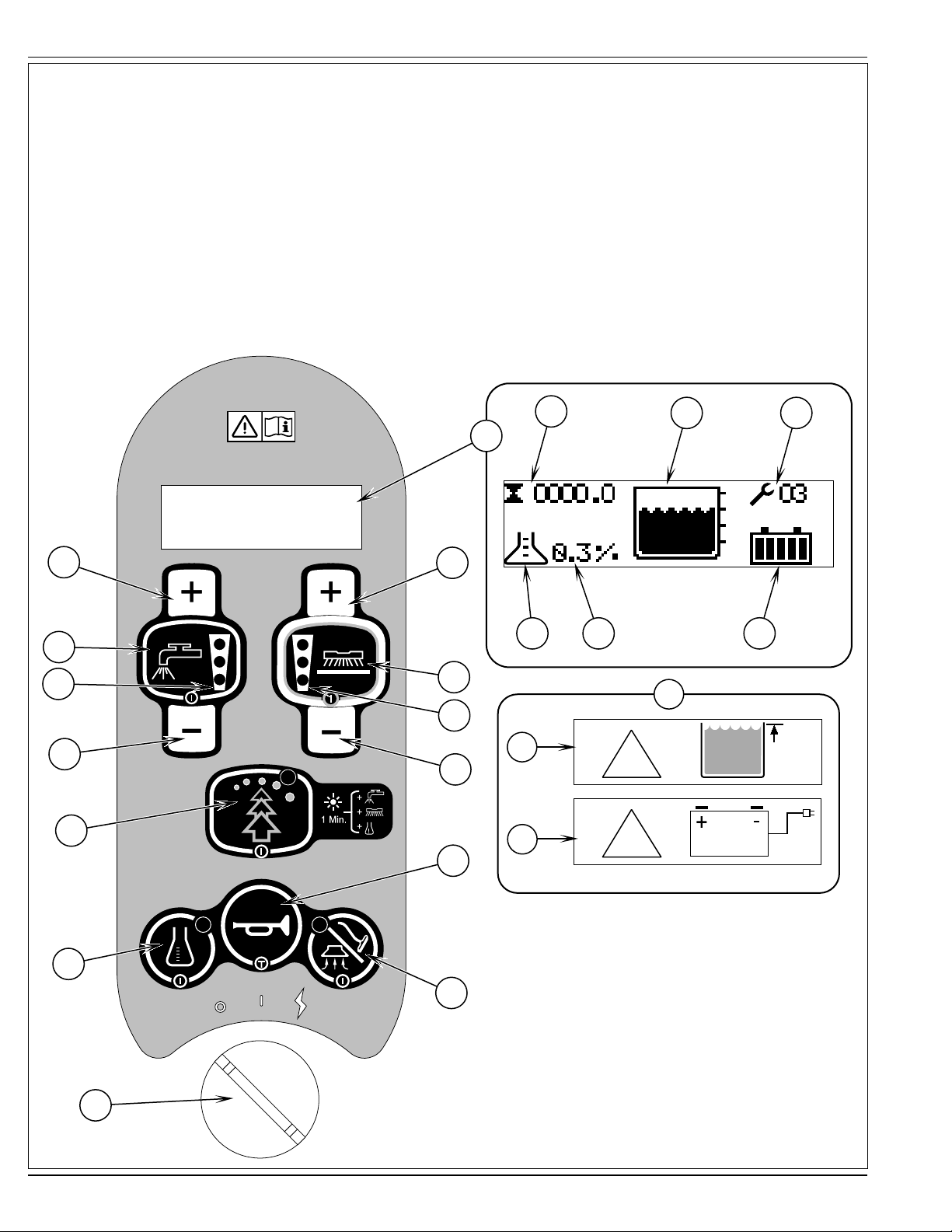

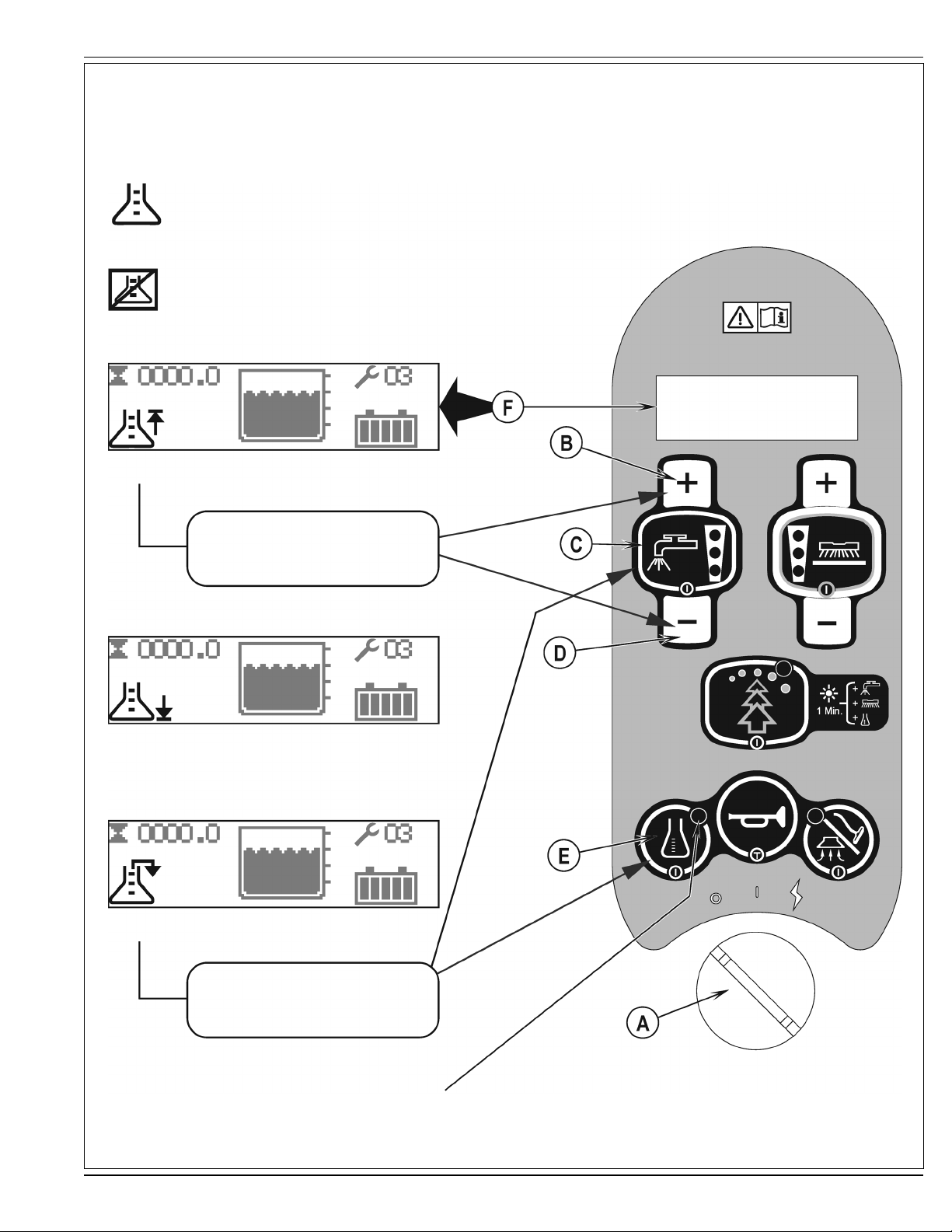

CONTROL PANEL

A Key Switch

B Solution Increase Switch

C Solution ON/OFF Switch

C1 Solution Flow Indicators (Normal, Heavy & Extreme)

D Solution Decrease Switch

E Detergent ON/OFF Switch

F Display

F1 Hour Meter

F2 Solution Tank Level Indicator

F3 Fault Codes

F4 Detergent Indicator (if so equipped)

F5 Detergent Percentage Indicator

F6 Battery Indicator

F7 Recovery Tank FULL Indicator

F8 Battery Low Indicator

G Scrub Pressure Increase Switch

H Scrub ON/OFF Switch

H1 Scrub Pressure Indicators (Normal, Heavy and Extreme)

I Scrub Pressure Decrease Switch

J EcoFlex Switch

K Horn Switch

L Vacuum/Wand Switch

C

C1

B

D

F1

F2 F3

F

G

F4 F5 F6

H

F

H1

F7

I

J

F8

!

!

K

E

A

A-6 - FORM NO. 56041743 - BR 755 series

L

revised 1/10

ENGLISH / A-7

BATTERIES

If your machine shipped with batteries installed do the following:

Check that the batteries are connected to the machine (34).

Turn ON the Key Switch (A) and check the Battery Indicator (F6). If the gauge is completely fi lled, the batteries are ready for use. If the gauge is less than

full, the batteries should be charged before use. See the “Charging The Batteries” section.

IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR INSTRUCTIONS

REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

See TSBUS2008-984 for the latest battery charger algorithms.

If your machine shipped without batteries installed do the following:

Consult your Authorized Nilfi sk dealer for recommended batteries.

Install the batteries by following the instructions below.

DO NOT install two 12 volt batteries in your machine. This affects the stability of the machine.

IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR INSTRUCTIONS

REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

See TSBUS2008-984 for the latest battery charger algorithms.

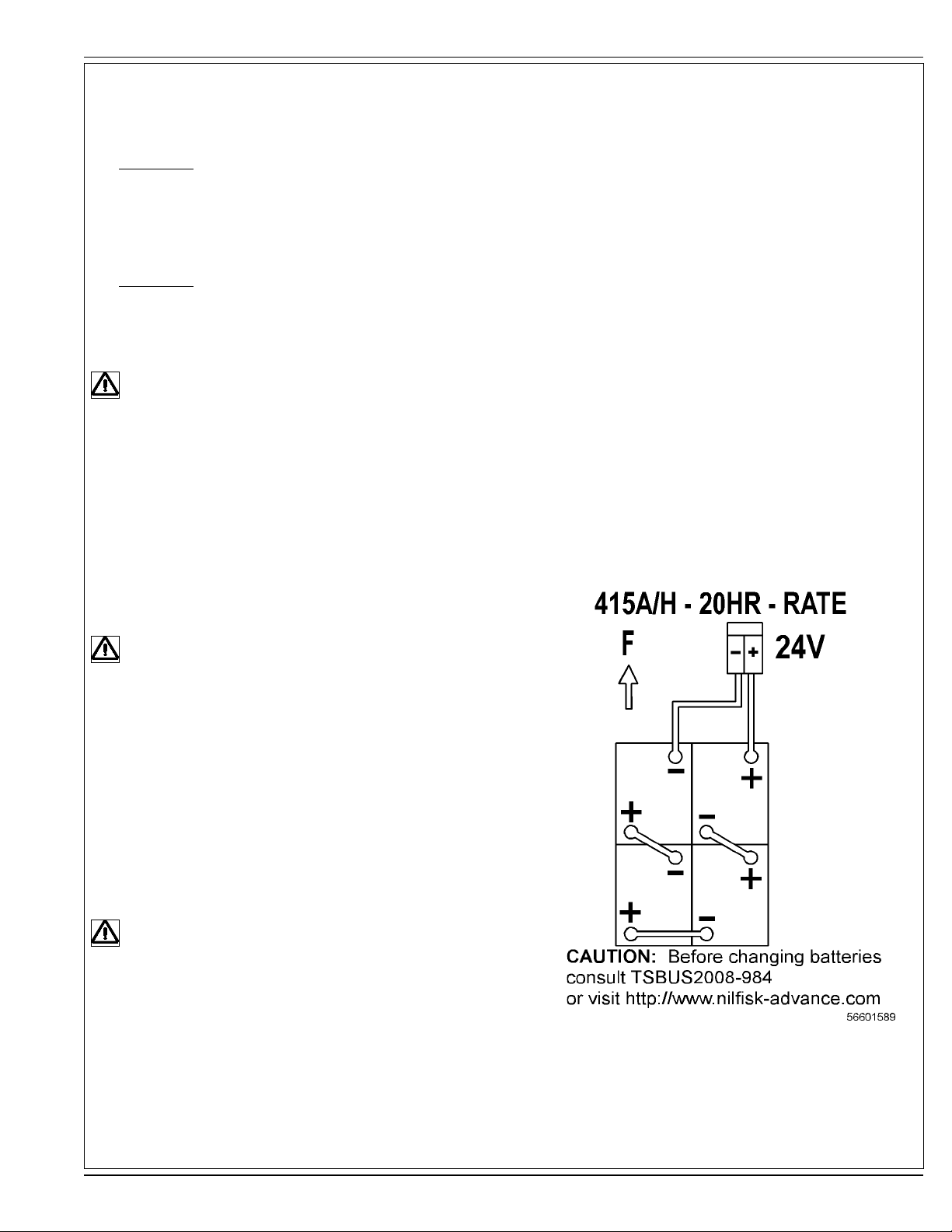

INSTALL THE BATTERIES

WARNING !

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin or

eyes. Explosive hydrogen gas is vented from inside the batteries through openings in the battery caps. This gas can be ignited by

any electrical arc, spark or fl ame.

When Servicing Batteries...

* Remove all jewelry.

* Do not smoke.

* Wear safety glasses, a rubber apron and rubber gloves.

* Work in a well-ventilated area.

* Do not allow tools to touch more than one battery terminal at a time.

* ALWAYS disconnect the negative (ground) cable fi rst when replacing

batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

FIGURE 1

CAUTION !

Electrical components in this machine can be severely damaged

if the batteries are not installed and connected properly. Batteries

should be installed by Nilfi sk or by a qualifi ed electrician.

1 Turn the Key Switch (A) off (O) and remove the key. Then swing open the

Battery Compartment Cover (10) and set the Prop-Rod (33).

2 Using (2) people and an appropriate lifting strap, carefully lift the batteries

into the compartment tray exactly as shown. Refer to decal 56601589

battery cable layout.

3 See Figure 1. Install battery cables as shown and tighten the nuts on the

battery terminals.

4 Install the battery boots and secure tightly to the battery cables with the

supplied tie straps.

5 Connect the battery pack connector to the machine connector (34) and

close the battery compartment cover.

CAUTION !

Before changing batteries consult TSBUS2008-984 or visit http://

www.nilfi sk-advance.com

FORM NO. 56041743 - BR 755 series - A-7

A-8 / ENGLISH

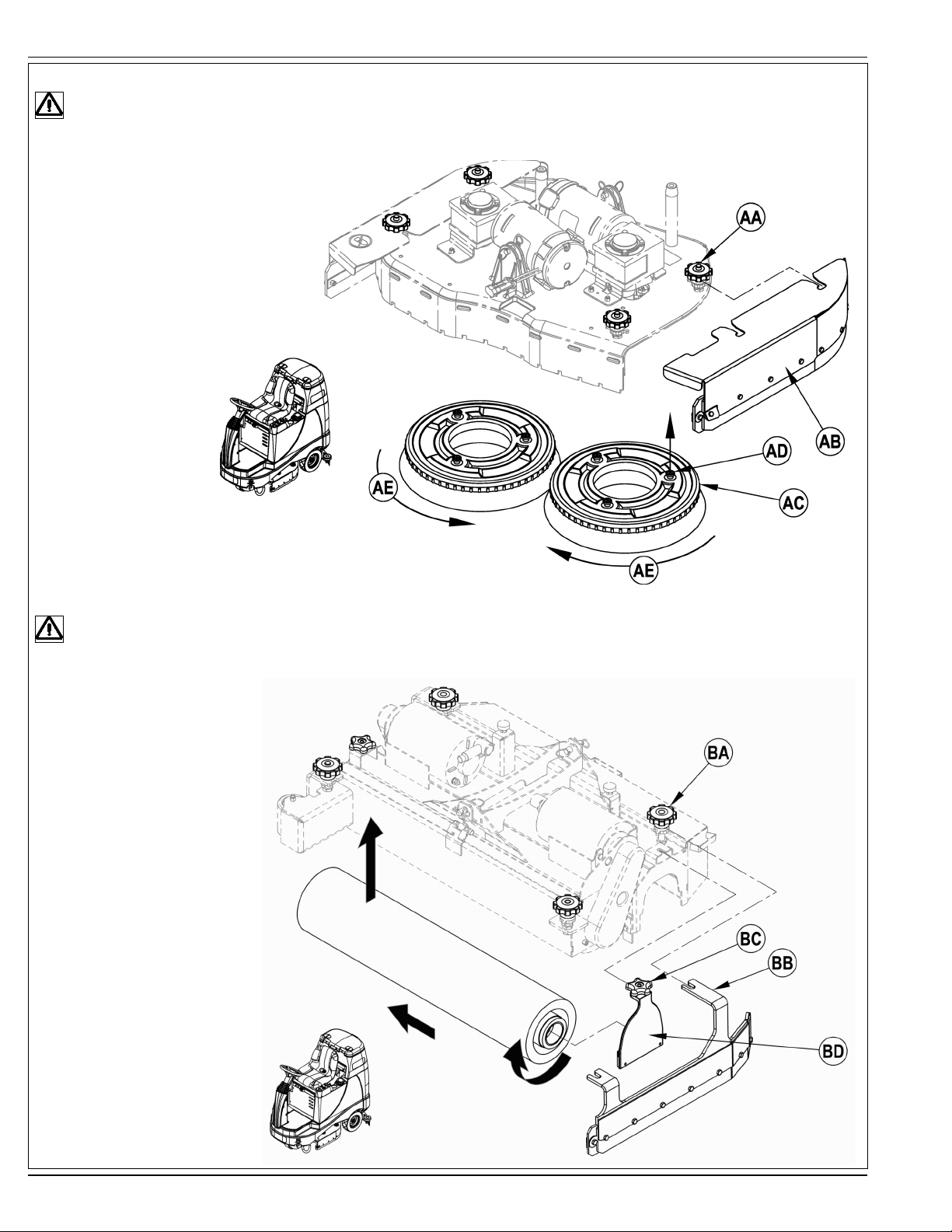

INSTALL THE BRUSHES (DISC SYSTEM)

CAUTION !

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck

is in the RAISED position.

Make sure the Key Switch

(A) is off (O).

2 See Figure 2. Remove

both side skirt assemblies.

NOTE: The skirts are

held in place by two large

Knobs (AA). Loosen these

knobs and slide the Skirt

Assemblies (AB) slightly

forward and then off of the

Scrub Deck.

3 To mount the Brushes (AC)

(or pad holders) align the

Lugs (AD) on the brush with

the holes on the mounting

plate and turn to lock in

place (turn the outside edge

of brush towards the front of

machine as shown (AE)).

FIGURE 2

INSTALL THE BRUSHES (CYLINDRICAL SYSTEM)

CAUTION !

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck is in the

RAISED position. Make sure the Key

Switch (A) is off (O).

2 See Figure 3. Remove both side

skirt assemblies. NOTE: The skirts

are held in place by two large Knobs

(BA). Loosen these knobs and then

slide the Skirt Assemblies (BB) off of

the Scrub Deck.

3 Loosen the Black Knobs (BC) on

top of the Idler Assemblies (BD) and

remove the assembly

4 Slide the brush into the housing, lift

slightly, push and turn until it seats.

Re-install the Idler Assemblies (BD)

and Skirt Assemblies (BB).

FIGURE 3

A-8 - FORM NO. 56041743 - BR 755 series

ENGLISH / A-9

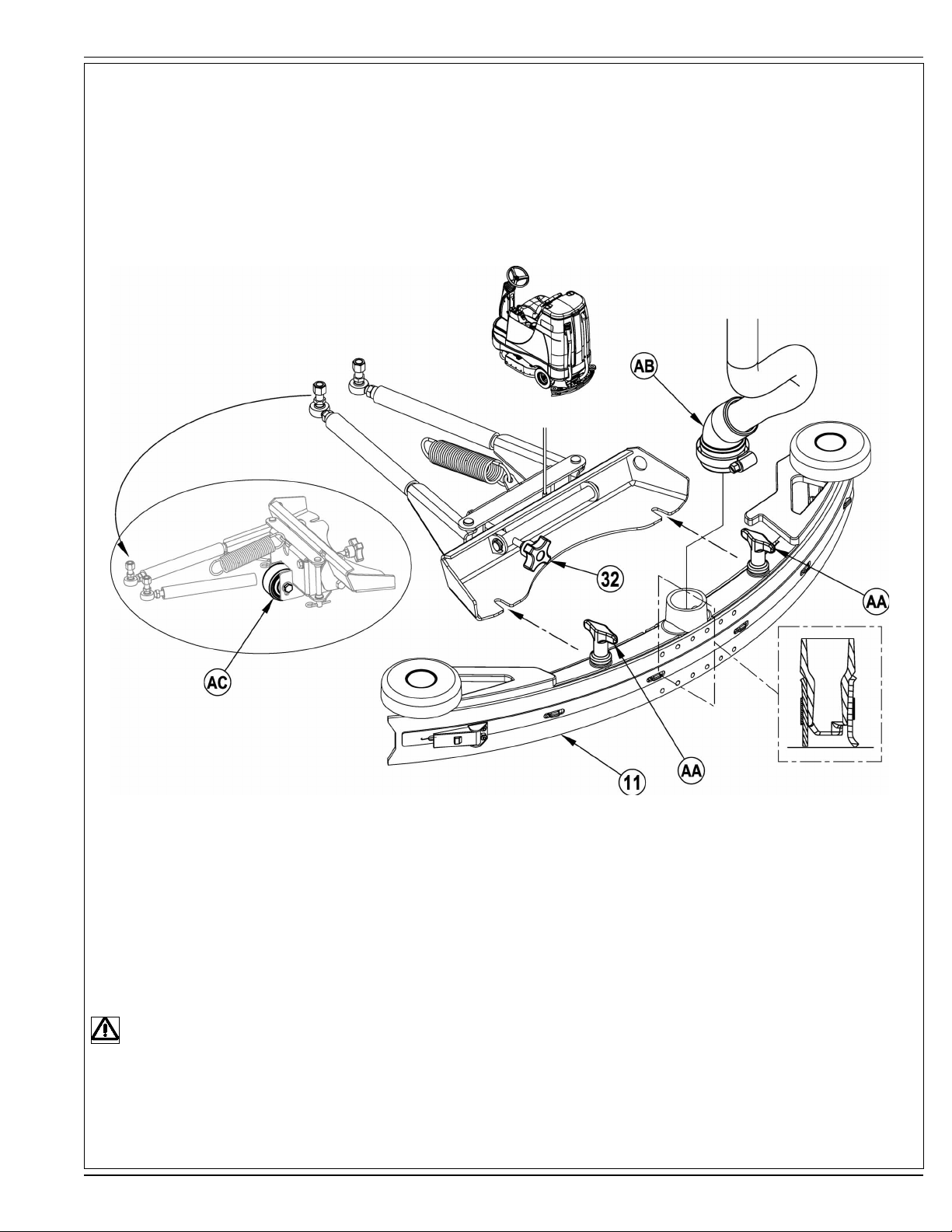

INSTALL THE SQUEEGEE

1 See Figure 4. Slide the Squeegee Assembly (11) onto the squeegee mount bracket and tighten the Squeegee Mount Thumb Nuts (AA).

2 Connect the Recovery Hose (AB) to the squeegee inlet.

3 Lower the squeegee, move the machine ahead slightly and adjust the squeegee tilt and height using the Squeegee Tilt Adjust Knob (32) and Squeegee

Height Wheel (AC) so that the rear squeegee blade touches the fl oor evenly across its entire width and is bent over slightly as shown in the squeegee cross

section.

FIGURE 4

FILL THE SOLUTION TANK

Read the cleaning chemical label and calculate the proper amount of chemical to mix for a tank that holds 28 US gallons (110 liters).

Open the Solution Tank Cover (2), then fi ll the tank 1/3 full of water, add the cleaning chemical, then fi ll up the tank the remainder of the way. NOTE: EcoFlex

machines can either be used conventionally with detergent mixed in the tank or the detergent system can be used. When using the detergent dispensing do not

mix detergent in the tank, plain water should be used.

CAUTION !

Use only low-foaming, non-fl ammable liquid detergents intended for automatic scrubber machine applications. Water temperature

should not exceed 130 degrees Fahrenheit (54.4 degrees Celsius).

revised 1/10

FORM NO. 56041743 - BR 755 series - A-9

A-10 / ENGLISH

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

COMMON INSTRUCTIONS:

Pressing and releasing the Detergent Switch (E) while the solution system is active will cause the detergent system to alternately turn on and off. The system

should be purged of previous detergent when switching to a different detergent. SERVICE NOTE: Move machine over fl oor drain before purging because a small

amount of detergent will be dispensed in the process.

To Purge When Changing Chemicals:

1 Disconnect and remove the detergent cartridge.

2 Turn the Key Switch (A) ON. Press and hold the Solution Switch (C) and the Detergent Switch (E) down for 3 seconds. NOTE: Once activated the purge

process takes 20 seconds. See illustration on next page for Detergent System indicators. Normally one purge cycle is adequate to purge the system.

To Purge Weekly:

1 Disconnect and remove the detergent cartridge. Install and connect a Cartridge fi lled with clean water.

2 Turn the Key Switch (A) ON. Press and hold the Solution Switch (C) and the Detergent Switch (E) down for 3 seconds. NOTE: Once activated the purge

process takes 20 seconds. See illustration on next page for Detergent System indicators. Normally one purge cycle is adequate to purge the system.

When the Detergent Cartridge is almost empty a Display Panel (F4) indicator will come on. The “Low Detergent” indicator will remain on until you reset the

system. Once this indicator comes on you should be able to simply pour an entire gallon bottle of detergent into the Cartridge to refi ll without worrying about

measuring. NOTE: Only reset the system when the cartridge is full. When switching cartridges, the “Low Detergent” indicator is only accurate if the replacement

cartridge is at the same level as the cartridge being replaced.

To Reset:

1 Turn the Key Switch (A) ON. Press and hold the Solution Increase Switch (B) and the Solution Decrease Switch (D) down for 3 seconds. See illustration on

next page for Detergent System indicators.

Detergent Percentage:

1 The detergent percentage default is 0.25%. To change the percentage, the detergent system must be OFF, then press and hold the Detergent ON/OFF

Switch (E) for 2 seconds. The detergent indicator will fl ash and each press of the switch will cycle through the available percentages (3%, 2%, 1.5%, 1%,

0.8%, 0.66%, 0.5%, 0.4%, 0.3%., 0.25%). Once the desired percentage is displayed on the screen (F5), stop and it will lock in after 5 seconds.

CARTRIDGE INSTRUCTIONS:

The Detergent Cartridge (13) is located behind the Detergent Cartridge Access Door (12) in the operator’s compartment. Fill the detergent cartridge with a

maximum of 1.25 gallons (4.73 Liters) of detergent. SERVICE NOTE: Remove the detergent cartridge from the detergent box prior to fi lling to avoid spilling

detergent on the machine.

It is recommended that a separate cartridge be used for each detergent you plan to use. The detergent cartridges have a white decal on them so you can write the

detergent name on each cartridge to avoid mixing them up. When installing a new cartridge, remove the Cap (AA) and place the cartridge in the detergent box.

Install the Dry Break Cap (BB) and detergent hose as shown.

FIGURE 5

A-10 - FORM NO. 56041743 - BR 755 series

revised 1/10

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

DETERGENT ENABLED

DETERGENT DISABLED

FULL (RESET)

ENGLISH / A-11

Press and hold (B) & (D) for 3

seconds to Reset.

LOW DETERGENT

PURGE

Press and hold (C) & (E) for 3

seconds to Purge.

Detergent system is ON when indicator is ON.

revised 1/10

FORM NO. 56041743 - BR 755 series - A-11

A-12 / ENGLISH

OPERATING THE MACHINE

WARNING!

Be sure you understand the operator controls and their functions.

While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only while

ascending (driving up) the ramp.

To Scrub...

Follow the instructions in “preparing the machine for use” section of this manual.

1 See Figure 6. While seated on the machine, adjust the steering wheel to a comfortable position using the Steering Wheel Tilt Adjust Knob (23). The seat can be adjusted if

necessary by tipping up the seat and using the adjustment knob (18).

2 Turn the Master Key Switch (A) ON (I). This will display the control panel indicator lights. Reference the Battery Condition Indicator (F6) and Hour Meter (F1) before proceeding.

3 To transport the machine to the work area, apply even pressure with your foot on the front of the Drive Pedal (3) to go forward or the rear of the pedal for reverse. Vary the

pressure on the foot pedal to obtain the desired speed.

4 Press and hold the Solution Switch (C) to pre-wet the fl oor, solution will be dispensed while the switch is held. NOTE: This will help prevent scarring of the fl oor surface when

starting to scrub with dry brushes. This must be done prior to pressing the Scrub ON Switch (H).

5 Press the Scrub ON/OFF Switch (H), the scrub deck and squeegee will automatically be lowered to the fl oor. The scrub, vacuum, solution and detergent (EcoFlex models)

systems all start when the Drive Pedal (3) is activated.

The scrub pressure will default to Normal (one scrub pressure indicator lit). Use the Scrub Pressure Increase Switch (G) and Scrub Pressure Decrease Switch (I) to change

between Normal, Heavy and Extreme Scrub modes. The solution fl ow rate will automatically adjust to coincide with the scrub pressure.

NOTE: The solution fl ow rate can be changed independently of the scrub pressure by pressing the Solution Increase Switch (B) or Solution Decrease Switch (D). Any

subsequent scrub pressure adjustments will reset the solution fl ow rate to correspond with the scrub pressure.

NOTE: The scrub, solution, vacuum and detergent (EcoFlex models) systems are automatically enabled when the Scrub ON/OFF Switch (H) is pressed. Any individual system

can be turned OFF or back ON by simply pressing its switch at any time during scrubbing.

NOTE: When operating the machine in reverse the squeegee automatically raises.

6 Begin scrubbing by driving the machine forward in a straight line at a normal walking speed and overlap each path by 2-3 inches (50-75 mm). Adjust the machine speed and

solution fl ow when necessary according to the condition of the fl oor.

CAUTION!

To avoid damaging the fl oor, keep the machine moving while the brushes are turning.

7 When scrubbing, check behind the machine occasionally to see that all of the waste water is being picked up. If there is water trailing the machine, you may be dispensing too

much solution, the recovery tank may be full, or the squeegee tool may require adjustment.

8 The machine defaults to the EcoFlex cleaning mode (EcoFlex Switch Indicator is lit GREEN) conserving solution and detergent. Press the EcoFlex Switch (J) to override the

EcoFlex cleaning mode and temporarily increase scrub pressure, solution fl ow and the detergent percentage. This will cause the indicator to fl ash yellow for one minute, solution

fl ow rate will increase to the next level, scrub pressure will increase to the next level and the detergent percentage will increase to the next larger percentage. NOTE: For

machines that do not have detergent installed, pressing the EcoFlex switch will temporarily increase scrub pressure and solution fl ow.

NOTE: Pressing and holding the EcoFlex Switch (J) for 2 seconds disables the EcoFlex system. The only way to re-enable is to push the EcoFlex Switch (J) again. Cycling the

Key Switch (A) does not re-enable the system. The EcoFlex system will only function if the Scrub System (H) has been enabled.

9 For extremely dirty fl oors, a one-pass scrubbing operation may not be satisfactory and a “double-scrub” operation may be required. This operation is the same as a one-pass

scrubbing except on the fi rst pass the squeegee is in the up position (press the Vacuum/Wand Switch (L) to raise the squeegee). This allows the cleaning solution to remain on

the fl oor to work longer. The fi nal pass is made over the same area, with the squeegee lowered to pick up the accumulated solution.

10 The recovery tank has a shut-off fl oat (29) that causes ALL systems to turn OFF except the drive system when the recovery tank is full. When this fl oat is activated, the recovery

tank must be emptied. The machine will not pick up water or scrub with the fl oat activated.

NOTE: All other indicators vanish and a “Recovery Tank FULL” Indicator (F7) appears on the Display Panel when the fl oat is activated.

11 When the operator wants to stop scrubbing or the recovery tank is full, press the Scrub ON/OFF Switch (H) once. This will automatically stop the scrub brushes and solution

fl ow and the scrub deck will raise up. The squeegee will raise up after a brief delay and the vacuum will stop after a brief delay (this is to allow any remaining water to be picked

up without turning the vacuum back on).

12 Drive the machine to a designated waste water “DISPOSAL SITE” and empty the recovery tank. To empty, pull the Drain Hose (31) from its rear storage area, then unscrew the

cap (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). Refi ll the solution tank and continue scrubbing.

NOTE: Make sure the Recovery Tank Cover (26) and the Recovery Tank Drain Hose (31) cap are properly seated or the machine will not pick-up water correctly.

When the batteries require recharging the Battery LOW Indicator (F8) will come on. Then the scrub brushes and solution fl ow will stop and the scrub deck will raise up. The squeegee

will raise up after a brief delay and the vacuum will stop after a brief delay. Transport the machine to a service area and recharge the batteries according to the instructions in the

Battery section of this manual.

WET VACUUMING

Steps to follow in fi tting the machine with optional attachments for wet vacuuming.

1 Disconnect the Recovery Hose (37) from the Squeegee (11). Connect the coupler and hose from the wand kit to the recovery hose.

2 Attach suitable wet pick-up tools to the hose. (An optional Wand Kit PN56601087 is available from Nilfi sk).

3 Turn the Master Key Switch (A) ON and press the Wand Switch (L). NOTE: The operator cannot be in the seat for the vacuum motor to run. The vacuum motor will run

continuously until the switch is pressed again to turn it OFF. NOTE: The “Recovery Tank FULL” indicator is disabled when the wand mode is activated. The fl oat will stop the

fl ow into the recovery tank.

SERVICE NOTE: Refer to the service manual for detailed functional descriptions of all controls and optional programmability.

A-12 - FORM NO. 56041743 - BR 755 series

revised 6/10

Loading...

Loading...