Page 1

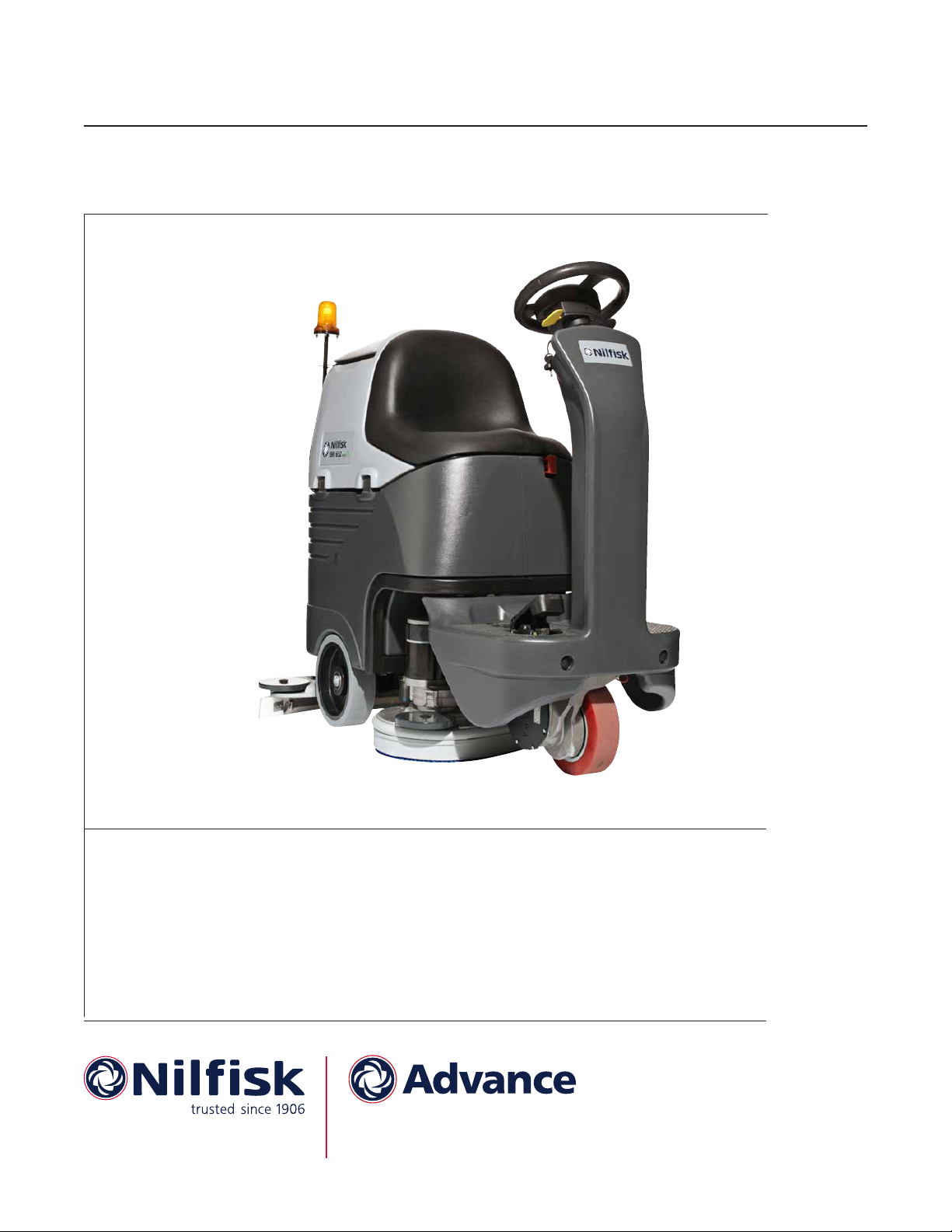

SC3000

Service Manual

Nilsk BR 652, 9087260020 - 9087261020

Nilsk BR 752, 9087262020 - 9087263020

Nilsk BR 752C, 9087264020 - 9087265020

Advance SC3000, 9087267020

English

2010-06 - Revised 2014-09

(6) Form No. 9098686000

Page 2

Table of contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Machine General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Service Manual Purpose and Field of Application . . . . . . . . . . . . . . . . . . . . . . 4

Other Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Number Decal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Machine Lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Machine Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Machine Nomenclature (know your machine) . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Service and Diagnostic Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Scheduled Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Table of contents 2Service Manual – SC3000

Chassis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Frame (main parts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Function Electronic Board Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Display of Current Values of Signicant Variables, Hour Counters and Stored Alarms . .28

Display and Change of Parameters Which can be Set by the Technician . . . . . . . . . . 30

Function Electronic Board Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Battery charger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Wiring Diagram (SPE charger) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wiring Diagram (Delta-Q charger) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

General Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Recovery System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Page 3

Table of contents 3Service Manual – SC3000

Scrub System, Cylindrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Scrub System, Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Solution System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Squeegee System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Steering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Driving Wheel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Page 4

Table of contents 4Service Manual – SC3000

Page 5

Service Manual – SC3000

General Information

General Information

Machine General Description

The SC3000 is a “Ride-on” industrial machine designed to wash and dry oors in one pass. The machine is

powered by on-board batteries, models can be equipped with EcoFlex™ system (optional). The machine features variable oor pressure disc or cylindrical brushes, controlled detergent solution dosing and a rear squeegee with rubber blades that vacuums and dries the oor.

Service Manual Purpose and Field of Application

The Service Manual is a technical resource intended to help service technicians when carrying out maintenance and repairs on the SC3000, to guarantee the best cleaning performance and a long working life for the

machine.

Please read this manual carefully before performing any maintenance and repair procedure on the machine.

Other Reference Manuals

5

Model Product Code User Manual Spare Parts List

Nilsk BR 652 9087260020

Nilsk BR 652 - Car 9087261020

Nilsk BR 752 9087262020

Nilsk BR 752 - Car 9087263020

Nilsk BR 752C 9087264020

Nilsk BR 752C - Car 9087265020

Advance SC3000 9087267020 9098827000 9098828000

Assembly Instructions Instruction Code Machines concerned

24V 670W vacuum system motor kit 9098456000 Nilsk BR 652 - BR 752 - BR 752C

EcoFlex™ Kit 9098219000 Advance SC3000

Battery charger kit 9098215000 Nilsk BR 652 - BR 752 - BR 752C

Reverse gear buzzer kit 9098773000 Nilsk BR 652 - BR 752 - BR 752C

9098684000 9098685000

These manuals are available at:

• Local Advance or Nilsk Retailer

• Advance website: www.advance-us.com

• Nilsk website: www.nilsk.com

Page 6

Service Manual – SC3000

General Information

Conventions

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to

say in driving position.

Service and Spare Parts

Service and repairs must be performed only by authorised personnel or Nilsk Service Centers. The authorised

personnel is trained directly at the manufacturer's premises and has original spare parts and accessories.

Contact Nilsk Retailer indicated below for service or to order spare parts and accessories, specifying the machine model and serial number.

(Apply Retailer label here)

6

Serial Number Decal

The machine model and serial number are marked

on the plate (see the example to the side).

Product code and year of production are marked on

the same plate.

This information is useful when requiring machine

spare parts. Use the following table to write down

the machine identication data.

Model: Scrubber-Dryer SC3000 26D EcoFlex

Prod. Nr: 9087267020

GVW: 453 kg/999 lb

63 A

Type E Floor cleaning machine

UL STD 583

CSA STD C22.2 N.68-92

A Nilfisk-Advance Brand

IPX4

Charg.100-240Vac 50-60Hz

Control Nr:

3084826

Serial No: ..................

Date code: .......

LpA = 65 dB(A)

Battery 24 Vdc

2%

“Made in Hungary”

Nilfisk-Advance, Inc.

Plymouth, MN, USA

www.advance-us.com

P100544

MACHINE model .............................................................................................

PRODUCT code ..............................................................................................

MACHINE serial number .................................................................................

Page 7

Service Manual – SC3000

General Information

Safety

The following symbols indicate potentially dangerous situations. Always read this information carefully and

take all necessary precautions to safeguard people and property.

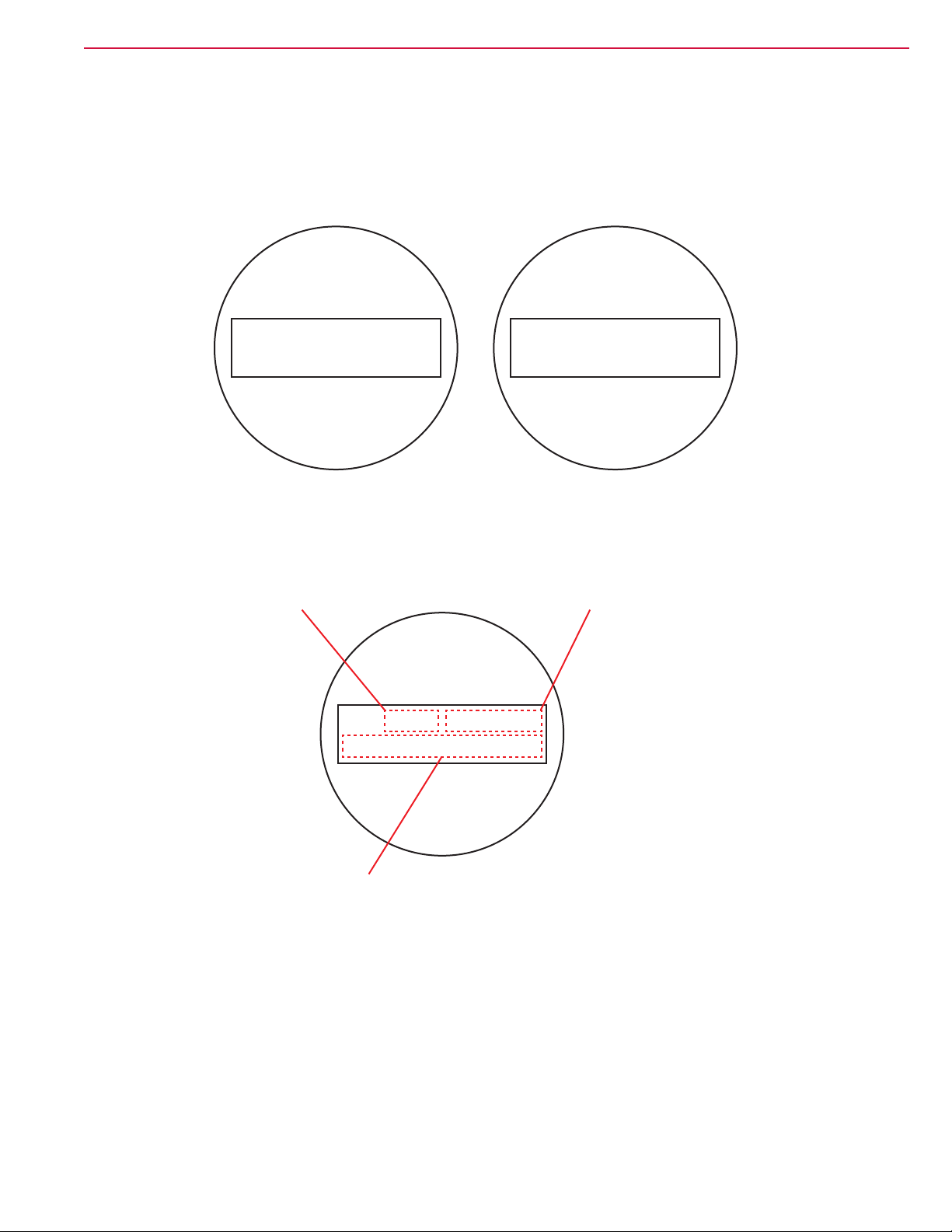

Symbols

Danger! It indicates a dangerous situation with risk of death for the operator.

Warning! It indicates a potential risk of injury for people or damage to objects.

Caution! It indicates a caution related to important or useful functions.

Note: It indicates a remark related to important or useful functions.

7

General Instructions

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

Warning! Make sure to follow the safety precautions to avoid situations that may lead to

serious injuries.

− Before performing any maintenance, repair, cleaning or replacement procedure disconnect the

battery connector and remove the ignition key.

− This machine must be used by properly trained operators only.

− Keep the batteries away from sparks, ames and incandescent material. During the normal op-

eration explosive gases are released.

− Do not wear jewelry when working near electrical components.

− Do not work under the lifted machine without supporting it with safety stands.

− Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids

or vapors: This machine is not suitable for collecting dangerous powders.

− Battery charging produces highly explosive hydrogen gas. Keep the tank assembly open during battery charging and perform this procedure in well-ventilated areas and away from naked

ames.

Page 8

Service Manual – SC3000

Caution! Make sure to follow the safety precautions to avoid situations that may lead to

serious injuries, damages to materials or equipments.

− Carefully read all the instructions before performing any maintenance/repair procedure.

− Before using the battery charger, ensure that frequency and voltage values, indicated on the

machine serial number plate, match the electrical mains voltage.

− Do not pull or carry the machine by the battery charger cable and never use the battery charger

cable as a handle. Do not close a door on the battery charger cable, or pull the battery charger

cable around sharp edges or corners. Do not run the machine on the battery charger cable.

− Keep the battery charger cable away from heated surfaces.

− Do not use the machine if the battery charger cable or plug is damaged. If the machine is not

working as it should, has been damaged, left outdoors or dropped into water, return it to the

Service Center.

− To reduce the risk of re, electric shock, or injury, do not leave the machine unattended when

it is plugged in. Before performing any maintenance procedure, disconnect the battery charger

cable from the electrical mains.

− Do not smoke while charging the batteries.

− To avoid any unauthorized use of the machine, remove the ignition key.

− Do not leave the machine unattended without being sure that it cannot move independently.

− Always protect the machine against the sun, rain and bad weather, both under operation and

inactivity condition. Store the machine indoors, in a dry place: This machine must be used in dry

conditions, it must not be used or kept outdoors in wet conditions.

− Before using the machine, close all doors and/or covers as shown in the User Manual.

− This machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the machine by a person responsible for they safety.

Children should be supervised to ensure that they do not play with the machine.

− Close attention is necessary when the machine is used near children.

− Use only as shown in this Manual. Use only Nilsk’s recommended accessories.

− Take all necessary precautions to prevent hair, jewelry and loose clothes from being caught by

the machine moving parts.

− Do not use the machine on slopes with a gradient exceeding the specications.

− Do not use the machine in particularly dusty areas.

− Use the machine only where a proper lighting is provided.

− If the machine is to be used where there are other people besides the operator, it is necessary to

install the pivoting light and the reverse gear buzzer (optional).

− While using this machine, take care not to cause damage to people or objects.

− Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects.

− Do not put any can containing uids on the machine.

General Information

8

Page 9

Service Manual – SC3000

− The machine working temperature must be between 0 °C and +40 °C.

− The machine storage temperature must be between 0 °C and +40 °C.

− The humidity must be between 30% and 95%.

− When using oor cleaning detergents, follow the instructions on the labels of the detergent

bottles.

− To handle oor cleaning detergents, wear suitable gloves and protections.

− Do not use the machine as a means of transport.

− Do not allow the brushes to operate while the machine is stationary to avoid damaging the oor.

− In case of re, use a powder re extinguisher, not a water one.

− Do not tamper with the machine safety guards and follow the ordinary maintenance instructions

scrupulously.

− Do not allow any object to enter into the openings. Do not use the machine if the openings are

clogged. Always keep the openings free from dust, hairs and any other foreign material which

could reduce the air ow.

− Do not remove or modify the plates afxed to the machine.

− To manually move the machine, the electromagnetic brake must be disengaged. After moving the

machine manually, engage the electromagnetic brake again. Do not use the machine when the

electromagnetic brake handwheel is screwed down.

− When the machine is to be pushed for service reasons (missing or discharged batteries, etc.), the

speed must not exceed 4 km/h.

− This machine cannot be used on roads or public streets.

− Pay attention during machine transportation when temperature is below freezing point. The

water in the recovery tank or in the hoses could freeze and seriously damage the machine.

− Use brushes and pads supplied with the machine and those specied in the User Manual. Using

other brushes or pads could reduce safety.

− In case of machine malfunctions, ensure that these are not due to lack of maintenance. Otherwise, request assistance from the authorised personnel or from an authorised Service Center.

− If parts must be replaced, require ORIGINAL spare parts from an Authorised Dealer or Retailer.

− To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant

chapter of this Manual, must be performed by the authorised personnel or by an authorised Service Center.

− Do not wash the machine with direct or pressurised water jets, or with corrosive substances.

− When WET batteries are installed on the machine, do not tilt the machine for more than 30°

from the horizontal plane to prevent the highly corrosive acid from leaking out of the batteries. If

the machine must be tilted to perform any maintenance procedure, remove the batteries.

− The machine must be disposed of properly, because of the presence of toxic-harmful materials (batteries, etc.), which are subject to standards that require disposal in special centres (see

Scrapping chapter).

General Information

9

Page 10

Service Manual – SC3000

Machine Lifting

Warning! Do not work under the lifted machine without supporting it with safety stands.

Machine Transportation

Warning! Before transporting the machine, make sure that:

All covers are closed.

The ignition key is removed.

The machine is securely fastened to the means of transport.

General Information

10

Page 11

Service Manual – SC3000

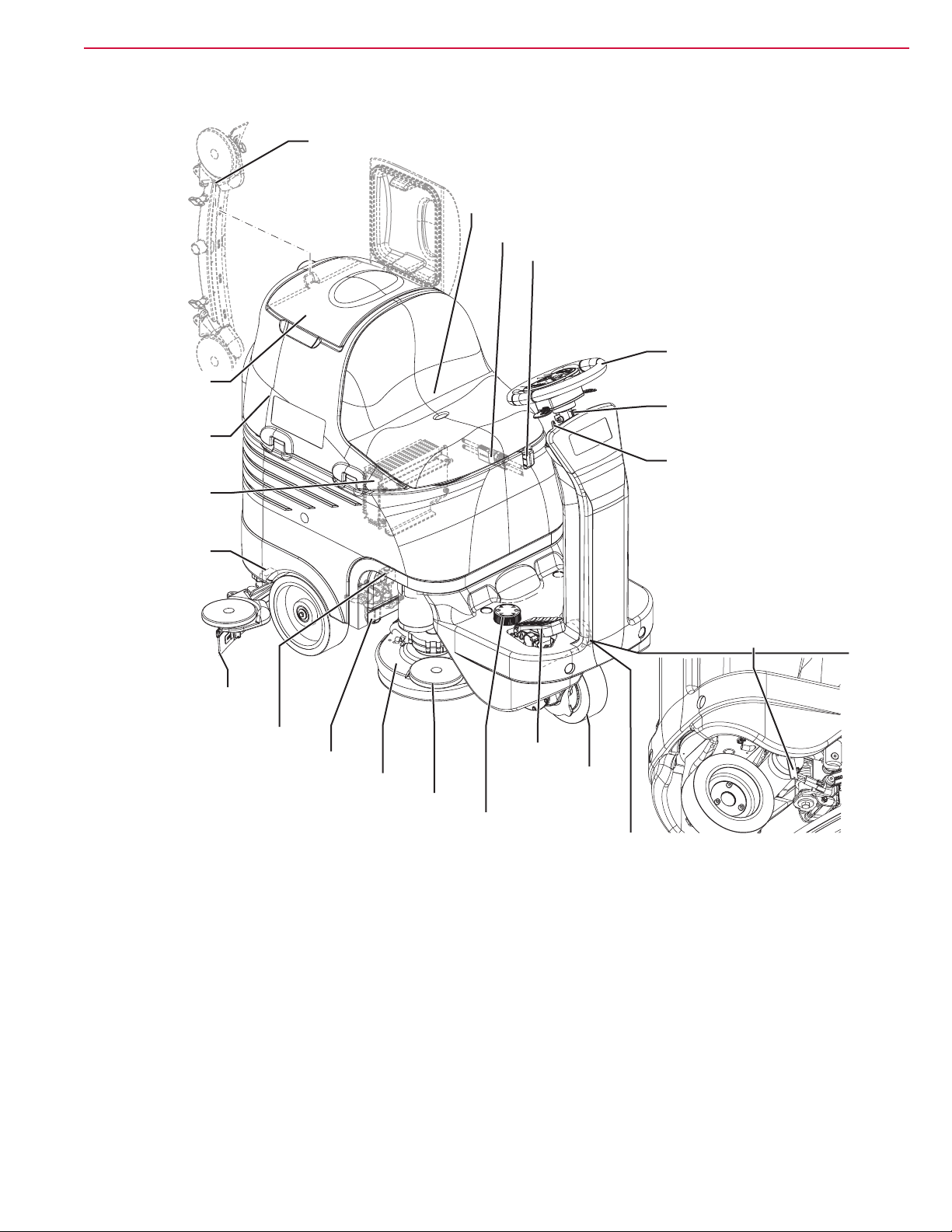

Machine Nomenclature (know your machine)

Squeegee hook

Seat

Battery connector

Emergency push-button

Recovery

tank cover

Dumping recovery

tank assembly

General Information

Steering wheel with

control panel

Steering wheel

height control lever

Ignition key

11

Battery

charger

Solution/clean

water tank

opening/closing

valve

Squeegee

blades assembly

Solenoid valve

Solution filter

Brush/pad-holder deck

Bumper wheel

height adjustment

Heel support

Electromagnetic

brake unlocking lever

Drive pedal

Front steering,

driving and

braking wheel

P100370

Page 12

Service Manual – SC3000

Detergent tank

Machine Nomenclature (continued)

Vacuum grid with

automatic shut-off float

Container with

Rating plate

debris collection grid

Battery charger cable

Electronic component

compartment cover

Lifted tank assembly

and driver's seat

Tank assembly stand

Vacuum system motor filter

Vacuum system motor

General Information

Battery connection

diagram

12

Cylindrical brush

deck side skirt

Cylindrical

brush deck

Solution/clean

water draining valve

Squeegee balance

adjusting handwheel

Recovery water drain hose

Solution/clean

water draining adapter

Solution/clean water

tank filler plug with removable filler hose

Solution/clean water tank

Squeegee vacuum hose

Squeegee bumper wheels

Squeegee mounting handwheels

Squeegee support wheels

Squeegee

24V

Front

Batteries

Battery caps

P100359

Page 13

Service Manual – SC3000

Battery lights

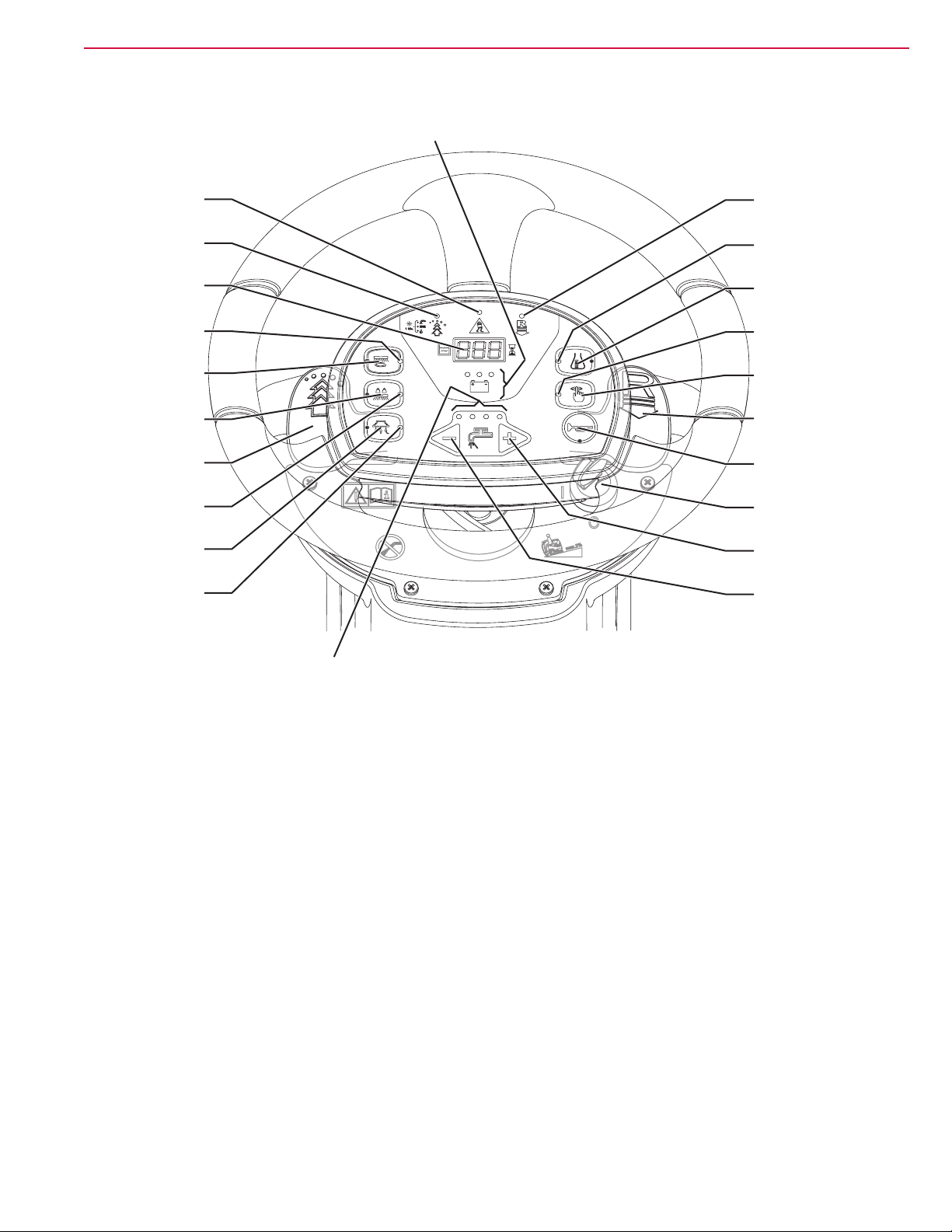

Control Panel

General Information

13

Anti-skid control

activation

led indicator

EcoFlex™ system

led indicator

Hour counter and

solution level display

Scrub On/Off

led indicator

Scrub On/Off

push button

Extra pressure

push button

EcoFlex™

lever

Extra pressure

led indicator

Vacuum system

push button

Vacuum system

led indicator

Reverse gear

led indicator

Washing detergent

flow control

led indicator

Detergent flow

control push button

Mute function

led indicator

Mute function

push button

Reverse gear

lever

Horn push button

Ignition key

Solution flow

increase

push button

Solution flow

decrease

push button

Solution flow indicator

P100372

Page 14

Service Manual – SC3000

General Information

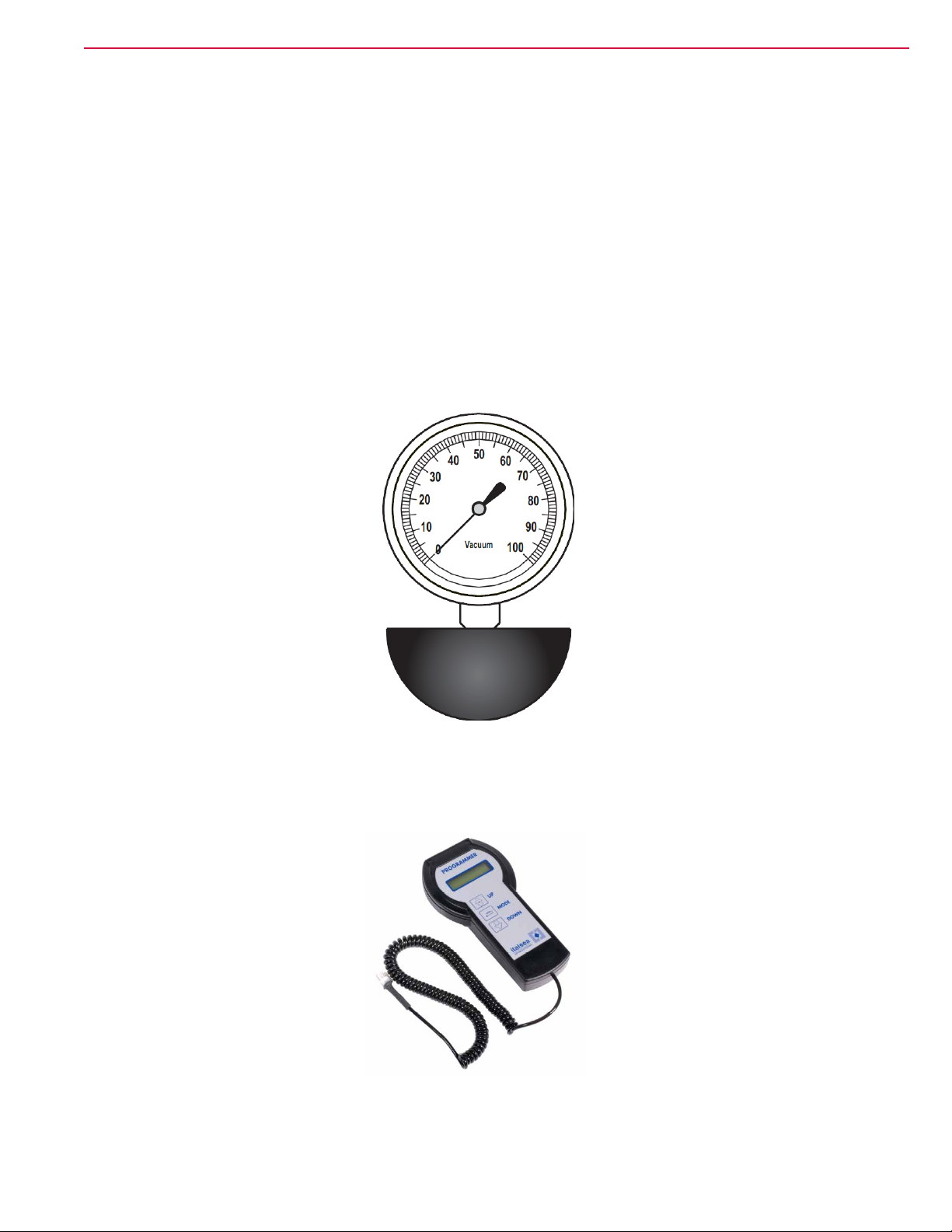

Service and Diagnostic Equipment

Besides a complete set of standard meters, the following instruments are necessary to perform fast checks and

repairs on Nilsk-Advance machines:

• Laptop computer charged with the current version of EzParts, Adobe Reader and (if possible) Internet

connection

• Digital Volt Meter (DVM)

• Amperometric pliers with possibility of making DC measurements

• Hydrometer

• Battery charge tester to check 12V batteries

• Static control wrist strap

• Dynamometric wrench set

• A copy of the User Manual and Spare Parts List of the machine to be serviced (provided with the machine

or available at www.advance-us.com or other Nilsk-Advance websites).

The following equipment is also available at Nilsk-Advance Centers:

• Vacuum water lift gauge, P/N 56205281

14

• Italsea universal programmer, P/N 9097297000

Page 15

Service Manual – SC3000

General Information

Technical Data

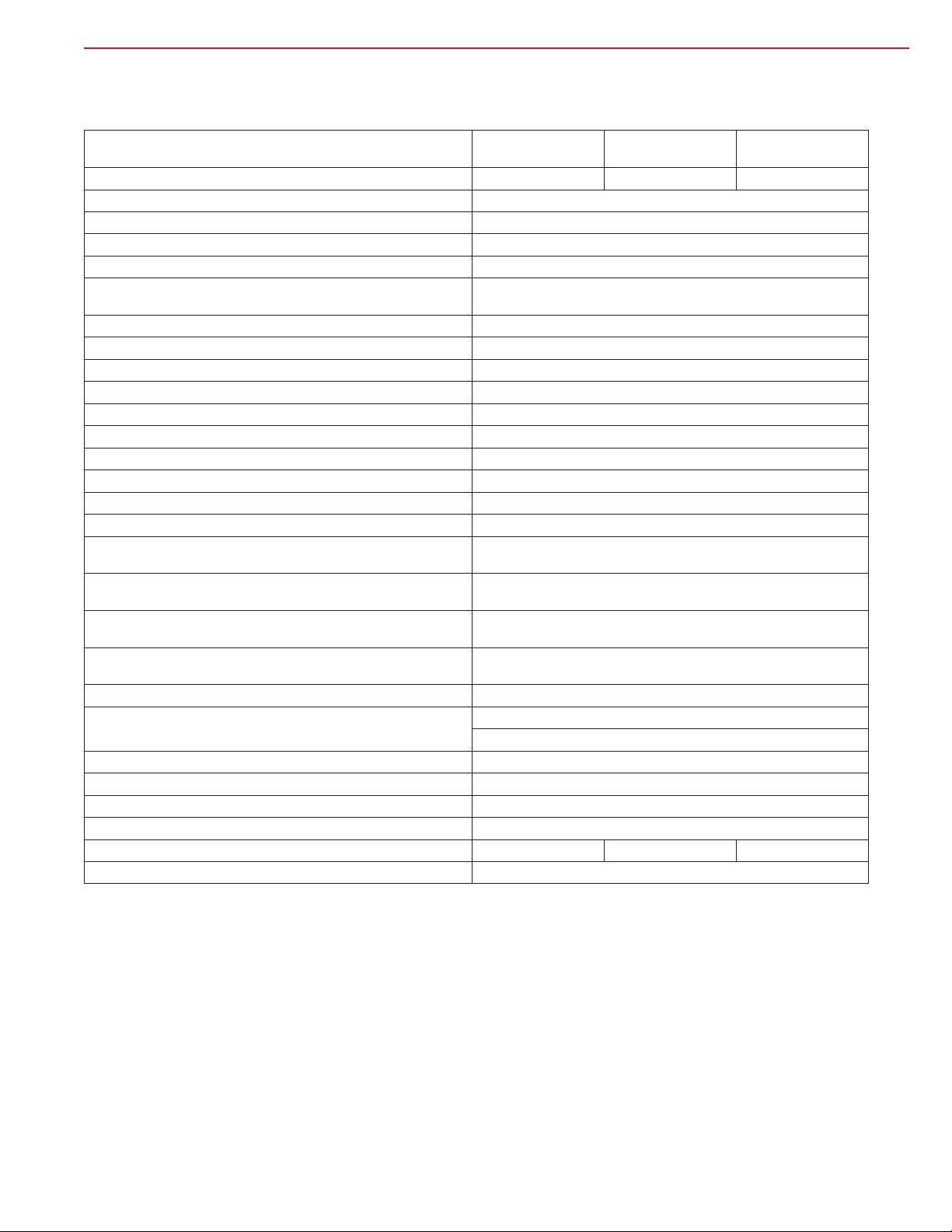

General technical data

Description

Cleaning width 26 in (660 mm) 30 in (710 mm) 30 in (710 mm)

Squeegee width 35 in (890 mm)

Solution/clean water tank capacity 21 US gal (80 L)

Solution ow 0.26 ÷ 0.8 US gal/min. (1 ÷ 3 L/min.)

Recovery tank capacity 21 US gal (80 L)

Minimum/maximum solution ow (with and without EcoFlex™

system)

EcoFlex™ kit tank capacity 1.3 US gal (5 L)

EcoFlex™ kit detergent ow setting Ratio 1:400 ÷ 1:33 (0.25% ÷ 3%)

Rear wheel diameter 9.8 in (250 mm)

Front wheel specic pressure on the oor (*) 72 psi (0.5 N/mm2)

Rear wheel specic pressure on the oor (*) 130 psi (0.9 N/mm2)

Front steering, driving and braking wheel diameter 8.8 in (225 mm)

Vacuum system motor power 0.56 hp (420 W)

Drive system motor power 0.4 hp (300 W)

Maximum speed 3.7 mi/h (6 km/h)

Maximum gradient when working 2% (1.14°)

Sound pressure level at workstation

(ISO 11201, ISO 4871, EN 60335-2-72) (LpA)

Machine sound pressure level

(ISO 3744, ISO 4871, EN 60335-2-72) (LwA)

Vibration level at the operator's arms

(ISO 5349-1, EN 60335-2-72)

Vibration level at the operator's body

(ISO 2631-1, EN 60335-2-72)

Battery compartment size (length x width x height) 14.9 x 21.2 x 11.8 in (380 x 540 x 300 mm)

Battery type

Standard batteries autonomy 2.5 - 3.5 hours

Total electrical input 60 A

Machine height 46.8 in (1,190 mm)

Machine maximum length 53.5 in (1,360 mm)

Machine width without squeegee 26.4 in (670 mm) 29.4 in (748 mm) 31.9 in (810 mm)

Vacuum performance 0.0098 MPa (1,000 mmH2O)

Nilsk BR 652

Advance SC3000

4 6V batteries, 180 Ah C5 (GEL/AGM)

Nilsk BR 752 Nilsk BR 752C

0 ÷ 0.8 US gal/min. (0 ÷ 3 L/min.)

65 dB(A) ± 3 dB(A)

82 dB(A)

< 98.4 in/s2 (< 2.5 m/s2)

3.1 in/s2 (0.8 m/s2)

4 6V batteries, 180 Ah C5 (WET)

15

(*) Machines have been tested under the following conditions:

◦ With operator on board (165.3 lb - 75 kg)

◦ Maximum battery size

◦ Maximum brush and squeegee size

◦ Full clean water tank

◦ Optional components installed

◦ Weight on wheels checked

◦ Print on the oor checked on cement for each single wheel

◦ Result expressed as maximum value for front and rear wheels

Page 16

Service Manual – SC3000

General Information

Technical Data (continued)

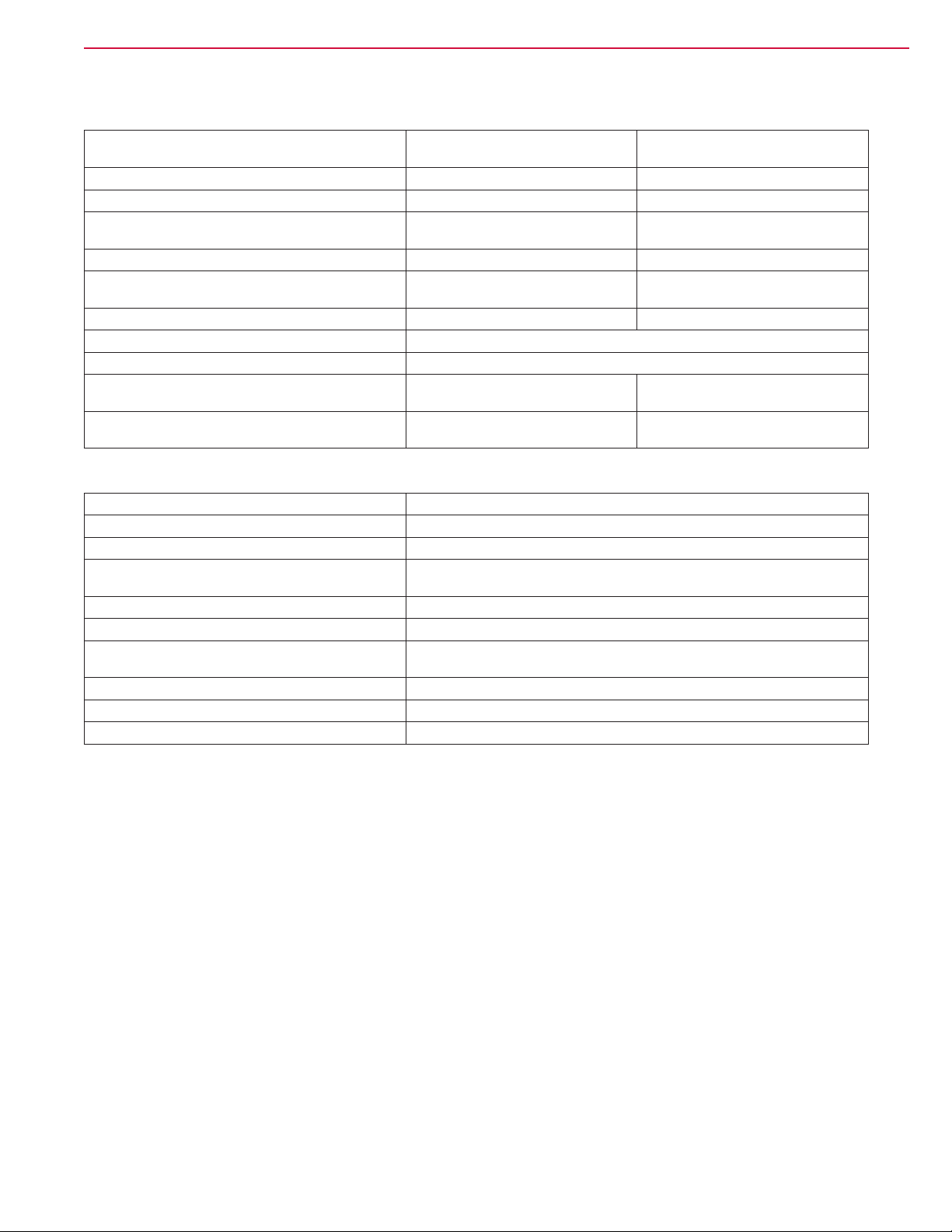

Technical data for machines with disc deck

Description

Brush/pad diameter 13 in (330 mm) 355 mm

Weight without batteries and with empty tanks 385.8 lb (175 kg) 177 kg

Maximum weight with batteries, full tanks and operator

(GVW)

Hourly efciency (4 km/h) ~ 24,488 ft2 (~ 2,275 m2) ~ 2,500 m

Deck right/left offset (variable)

Brush distance from the oor (when lifted) 1.9 in (48 mm) 48 mm

Brush/pad-holder motor power 2 x 0.53 hp (2 x 400 W)

Brush/pad-holder speed 230 rpm

Brush/pad-holder pressure with extra-pressure function

turned off

Brush/pad-holder pressure with extra-pressure function

turned on

Technical data for machines with cylindrical brush deck

Description Nilsk BR 752C

Cylindrical brush size (diameter x length) 5.7 x 27.2 in (145 x 690 mm)

Weight without batteries and with empty tanks 396.8 lb (180 kg)

Maximum weight with batteries, full tanks and operator

(GVW)

Hourly efciency (4 km/h) ~ 26910 ft2 (~ 2,500 m2)

Deck right/left offset 3.5 / 3.5 in (90 / 90 mm)

Cylindrical brush deck distance from the oor (when

lifted)

Cylindrical brush motor power 2 x 0.8 hp (2 x 600 W)

Cylindrical brush speed 720 rpm

Cylindrical brush pressure 77.1 lb (35 kg)

Nilsk BR 652

Advance SC3000

983.2 lb (446 kg) 448 kg

0 ÷ 3.9 in / 1 ÷ 0 in

(0 ÷ 100 mm / 25 ÷ 0 mm)

66.1 lb (30 kg) 32 kg

105.8 lb (48 kg) 50 kg

994.3 lb (451 kg)

0.8 in (22 mm)

15 / 150 mm - 105 / 0 mm

Nilsk BR 752

16

2

Page 17

Service Manual – SC3000

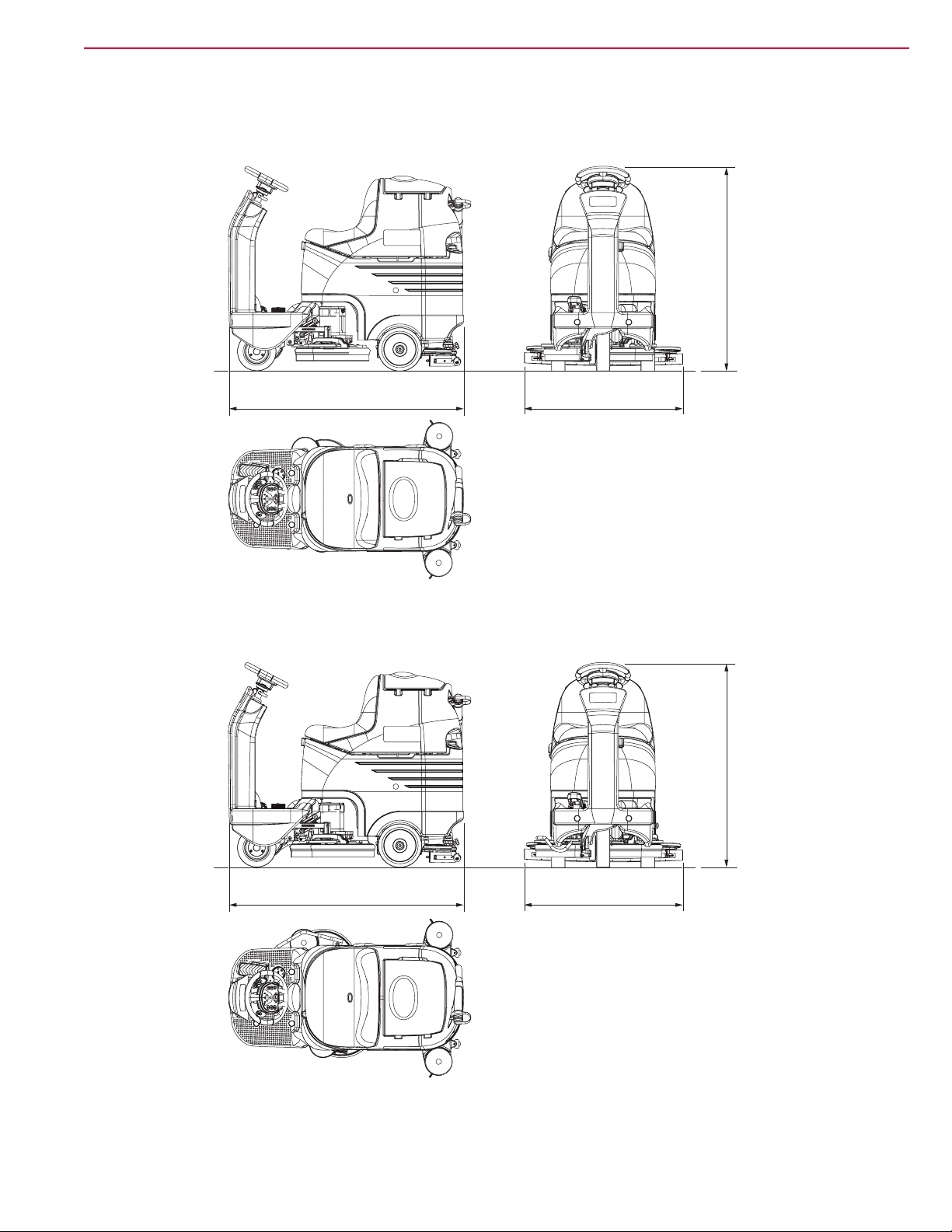

Dimensions

Nilsk BR 652 - Advance SC3000

General Information

1190 mm (46.85 in)

890 mm (35 in)1360 mm (53.5 in)

17

Nilsk BR 752

P100367

1190 mm (46.85 in)

890 mm (35 in)1360 mm (53.5 in)

P100368

Page 18

Service Manual – SC3000

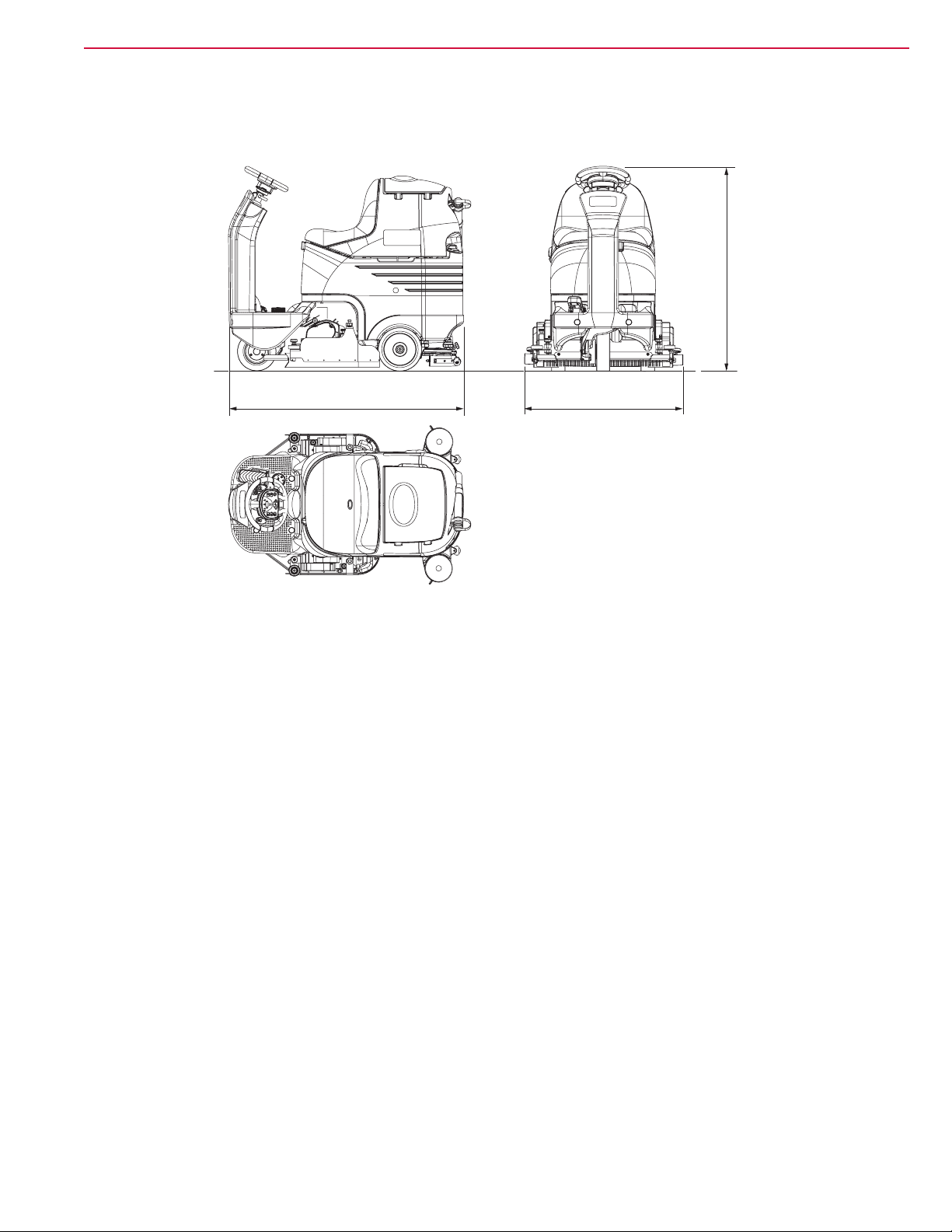

Dimensions (continued)

Nilsk BR 752C

General Information

1190 mm (46.85 in)

890 mm (35 in)1360 mm (53.5 in)

18

P100369

Page 19

Service Manual – SC3000

General Information

Maintenance

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

Warning! Read carefully the instructions in the Safety chapter before performing any

maintenance procedure.

The following tables provides the scheduled maintenance. The intervals shown may vary according to particular working conditions, which are to be dened by the person in charge of the maintenance.

For instructions on maintenance procedures, see the following paragraphs.

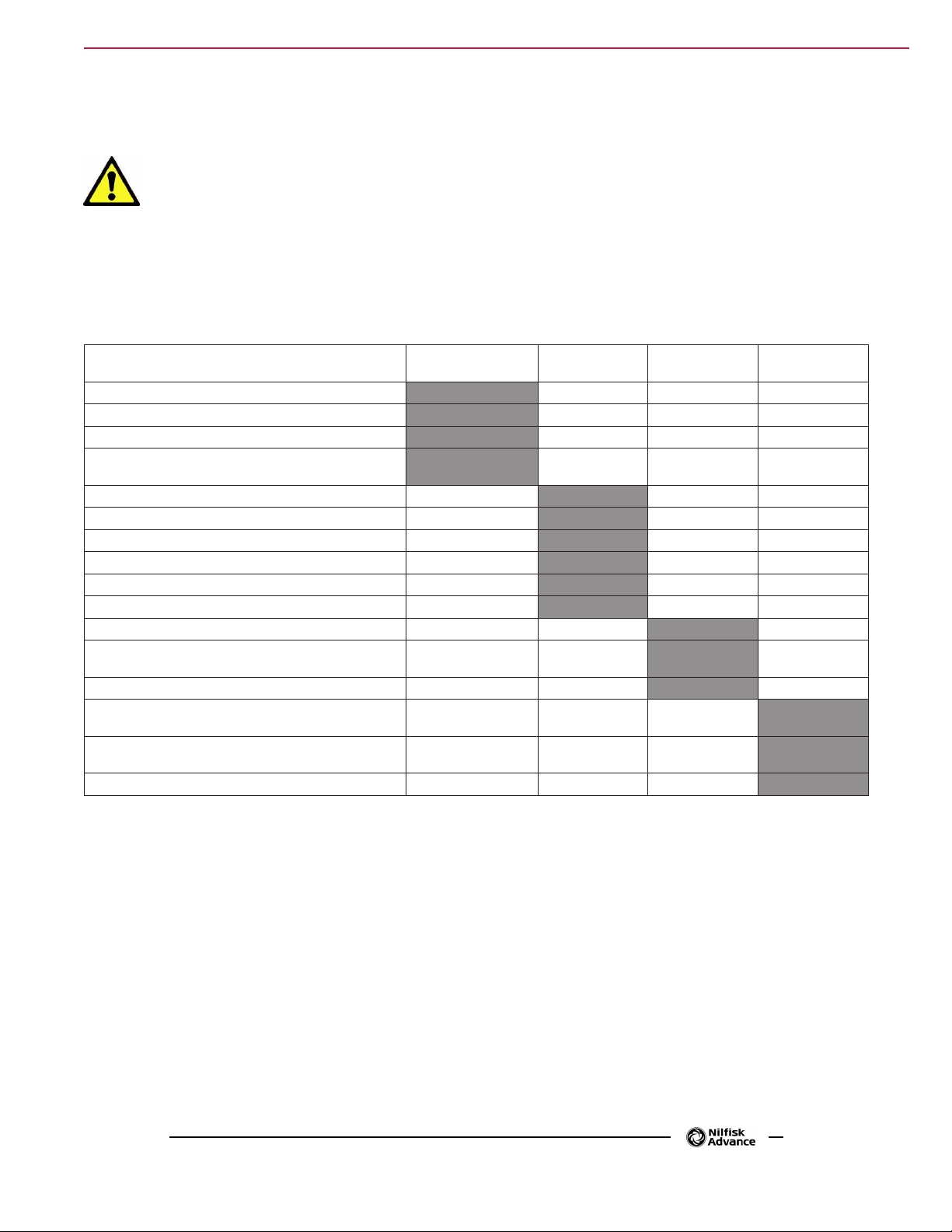

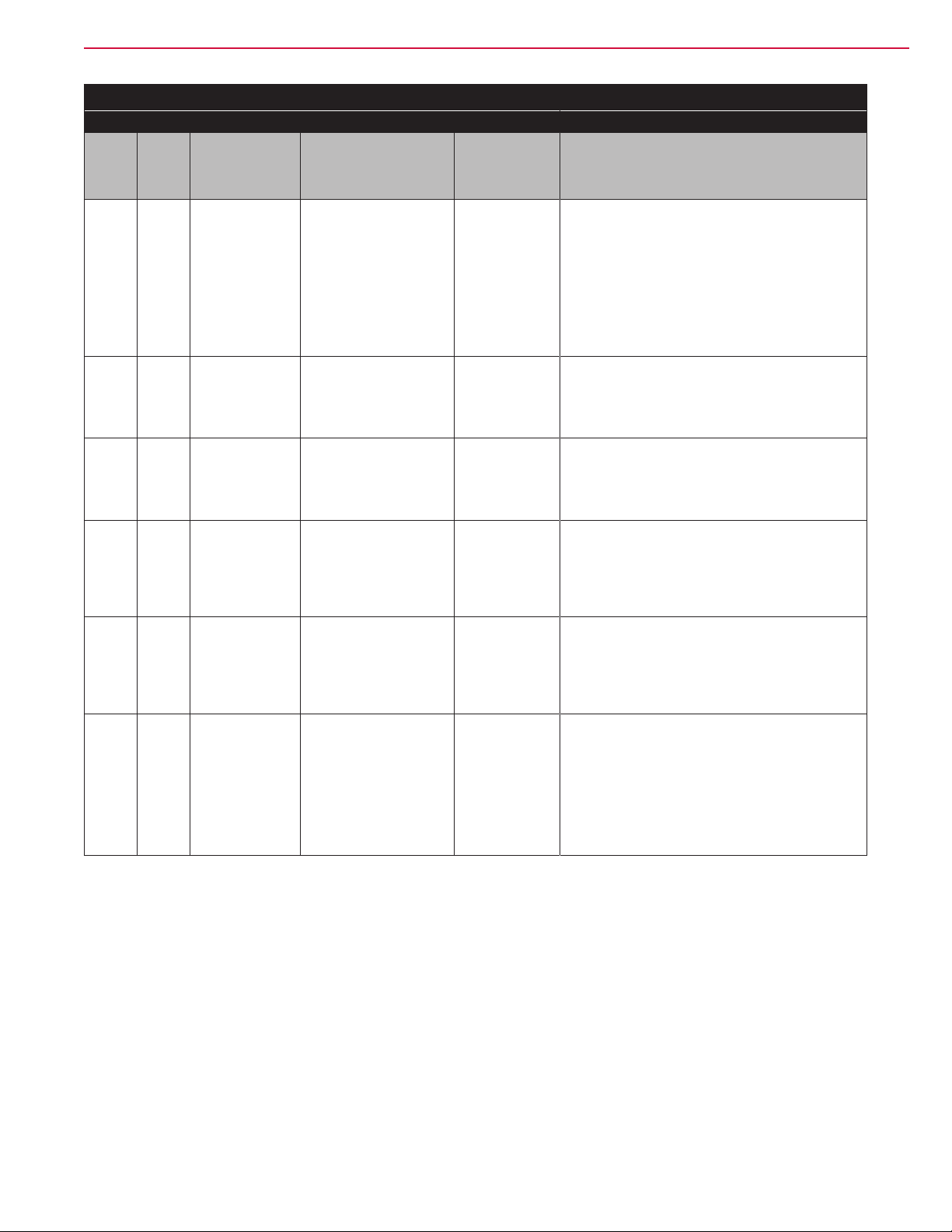

Scheduled Maintenance Table

Procedure

Battery charging

Squeegee cleaning

Brush/cylindrical brush cleaning

Tank, debris collection grid and vacuum grid with oat

cleaning, and cover gasket check

EcoFlex™ system cleaning and draining (optional)

Squeegee blade check and replacement

Side skirt check (only for BR 752C)

Solution lter cleaning

Vacuum system motor lter cleaning

Battery (WET) uid level check

Screw and nut tightening check (1)

Check and adjustment of driving belts between motors

and cylindrical brushes (only for BR 752C)

Electromagnetic brake efciency check

Brush/pad-holder motor carbon brush check or

replacement

Vacuum system motor carbon brush check or

replacement

Drive system motor carbon brush check or replacement

Daily, after using

the machine

Weekly

Every six

months

Yearly

19

(1) And after the rst 8 working hours.

Page 20

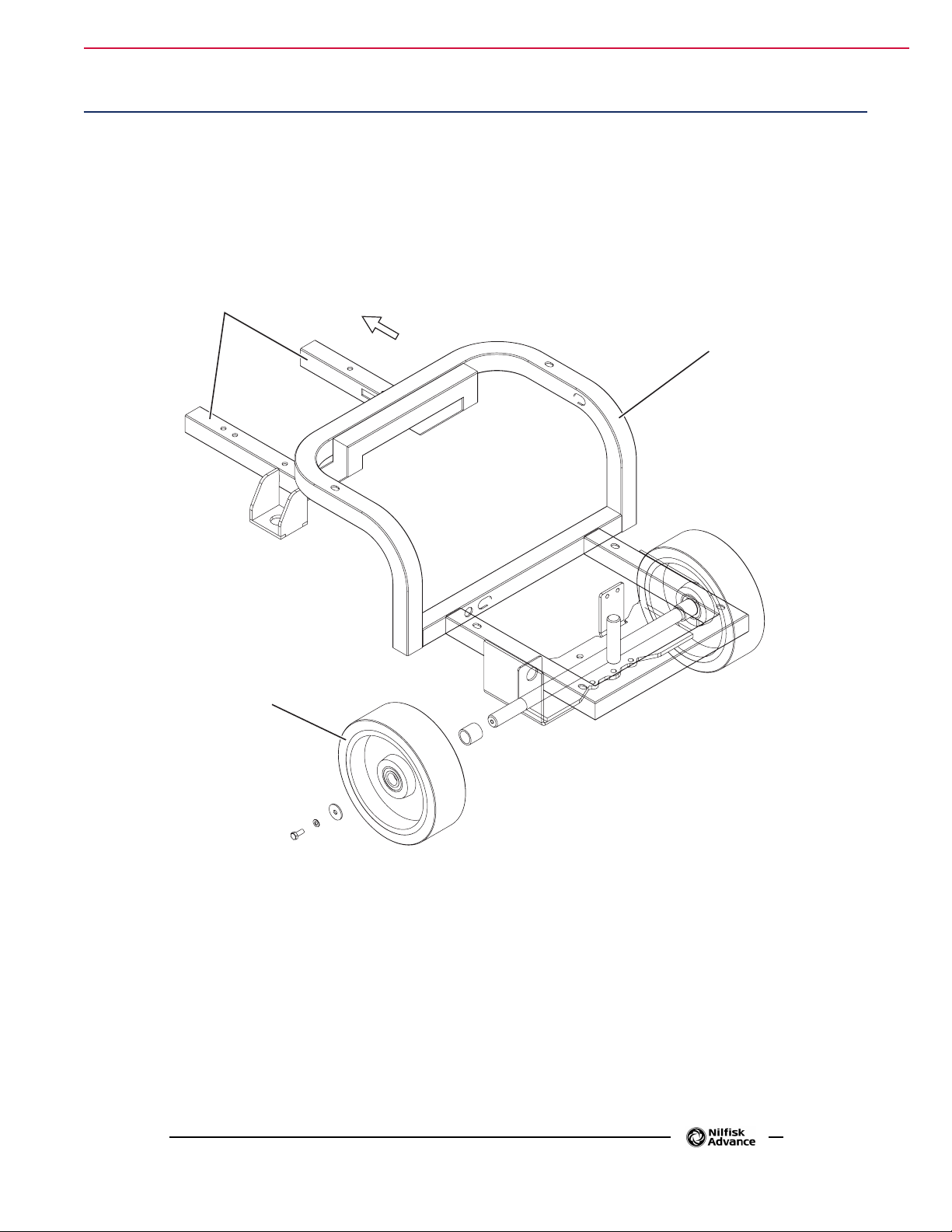

Chassis System

Front

1

Frame (main parts)

1. Steering assembly plate holder

2. Tanks and driver's seat holder

3. Rear wheels on xed axle

Chassis System 20Service Manual – SC3000

2

3

P100545

Page 21

Control System 21Service Manual – SC3000

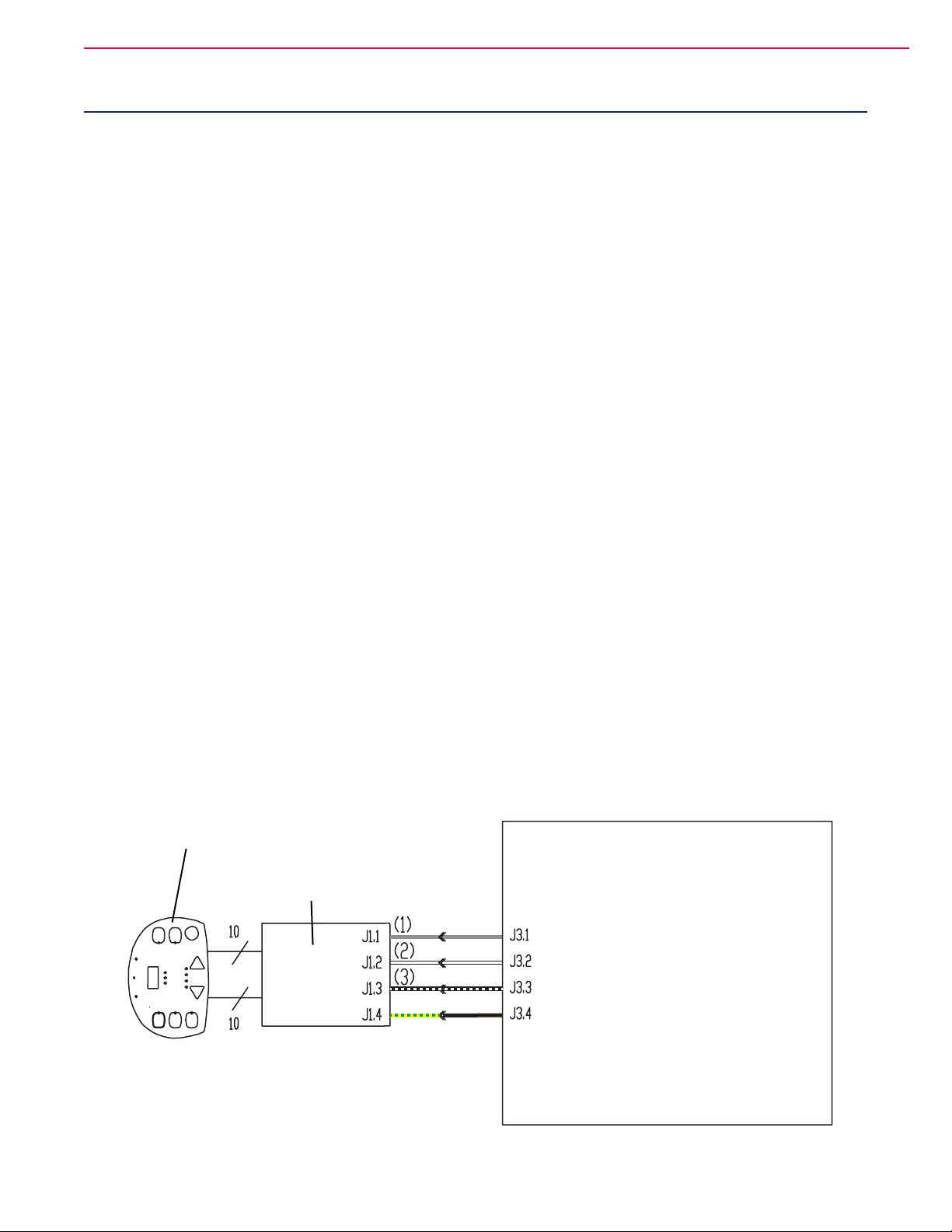

Control System

Functional Description

The architecture of the electronic system controlling the electrical machine utilities consists of a main electronic board (EB1), and a display electronic board (EB2) which is connected to the dashboard (EB3) - the main

user interface.

The main electronic board (EB1) manages all the utilities.

It drives directly the following accessories:

− Drive system motor with electromagnetic parking brake

− Vacuum system motor

− Deck actuator

− Squeegee actuator

− Solution ow solenoid valve

− Detergent pump

− Buzzer

It drives the brush deck motors by means of the electromagnetic switch.

The display electronic board (EB2) manages all the input signals (push-buttons) and the output signals (LED)

from keyboard (EB3) to which it is connected by 2 at cables.

There is also a 3-gure display on the display electronic board (EB2), which is mainly used to display the hour

counter, the solution tank level, and for any alarms (see below). There are also 2 microswitches activated by

the levers under the steering wheel.

The display electronic board (EB2) sends all the input and output signals of these components to the main

electronic board (EB1) using 2-wire 2-way serial communications protocol.

The system also has an on-board battery charger which also communicates with the main electronic board

(EB1) using propriety serial protocol, so the operator can see the operating state (charging phase) on the same

user interface of the dashboard (EB3).

Wiring Diagram

Dashboard instrument electronic board (EB3)

Function electronic board (EB1)

Display electronic board (EB2)

Dashboard power supply +

Dashboard serial +

Dashboard serial -

Dashboard power supply -

P100546

Page 22

Component Location

• Function electronic board (EB1)

• Control panel electronic board (EB2)

• Dashboard (EB3)

Control System 22Service Manual – SC3000

Function electronic

1

board (EB1)

Control panel elec-

2

tronic board (EB2)

Dashboard (EB3)

3

P100547

P100548

Page 23

Control System 23Service Manual – SC3000

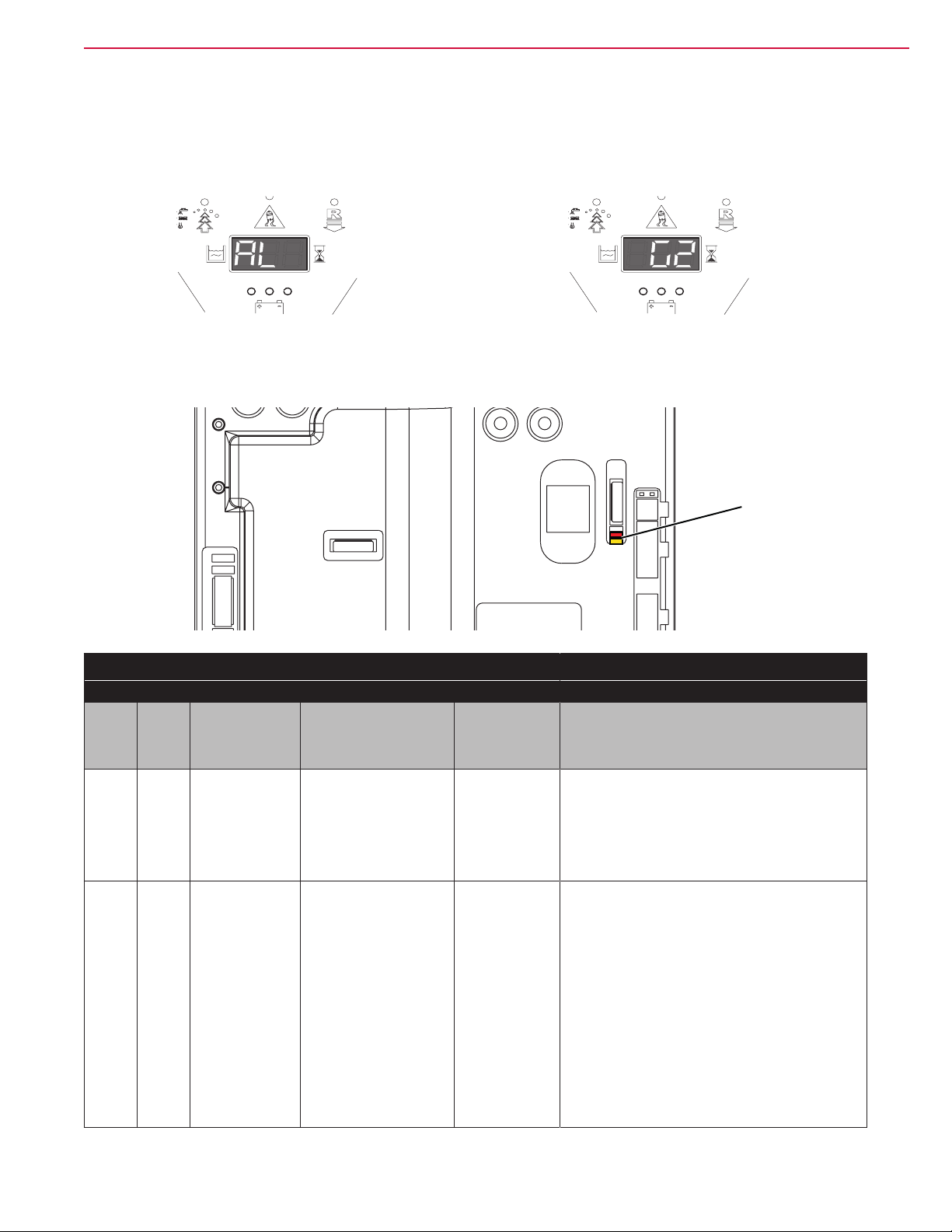

Function Electronic Board Alarm Codes

The function electronic board indicates a series of alarms in case of malfunction of one or more systems, and

in case of abnormal conditions detected in the input signals.

The alarms are shown on the display (except “F6”) by 2 signs following each other:

“AL” and “G2”, where G2 is one of the alarm codes (see the descriptions in the following tables).

P100549 P100550

Also, the alarms are repeated (in case of display malfunction) by the diagnostic LEDs (yellow and red) on the

electronic board, as described in the following tables.

General alarms

Alarm on the function electronic board - YELLOW LED + RED LED FLASHING

Alarm

Code

on the

display

No. of

ashes

on the

board

G2 2 EEPROM error. EEPROM error. Function block

G3 3 General thermal

Meaning Condition Effect

+ Default setting

reset.

protection.

The heatsink of the board

reached a temperature

up to 194 °F (90 °C).

Function block.

A

P100401A

Troubleshooting action

If the machine is normally working after the G2 message appearing, it could be caused by an electromagnetic spike from the environment that didn’t damage

the system.

1. Check all the parameter (see page 32 - 33)

settings (battery type, parameters etc.) because

of they could be restored to default.

1. Check the current ow in the drive motor (it has

to be 6-8amps without load and it has to remain

below 20 amps during operations).

2. Check the current ow in the vacuum motor (it

has to be less than 20 amps).

3. Verify the correct thermal dissipation of the board:

the correct installation on the metal bracket,

obstacles to the air ow from the bottom (deck

area) to the extraction hole on the top cover of the

electric box.

4. If all is ok, it could be generated by extreme

working conditions like room temperature >30°C,

slopes in the working path. The machine has

to be maintained off in order to restore the right

temperature into the board and then it could be

used.

Page 24

General alarms

Alarm on the function electronic board - YELLOW LED + RED LED FLASHING

Alarm

Code

on the

display

No. of

ashes

on the

board

G4 4 Blown F2 fuse. Blown F2 fuse. Function block.

G5 5 Wrong KEY

G6 6 No signal from

G7 7 Undervoltage. The battery voltage

G8 8 Serial

G9 9 Battery voltage

Meaning Condition Effect

sequence.

BATTERY

CHARGER

communication

error with

dashboard

electronic board.

drop.

Voltage dip (of the order

of 100ms or less) of the

key input.

No signal from battery

charger on the

communication yellow

wire to pin 11 of J1

connector

stay for more than 10

senconds lower than

18,4 Volt (for WET

batteries, 19,6 Volt for

GEL-AGM batteries).

No signal or

decoding error in the

communication between

the function Electronic

board (EB1) and the

display board (EB2).

Battery voltage drop

bigger than 3 Volt in less

than 1 sencond.

Function block.

The charging

battery phase is

not shown

Function block.

No block.

Drive system +

electromagnetic

brake block.

Control System 24Service Manual – SC3000

Troubleshooting action

F2 fuse is a power safety fuse (100 amps rated)

and its primary function is to avoid that a short drive

so much current to generate smoke or re into the

board. The F2 opening is normally due to a severe

damage of the board.

1. Open the board plastic cover to verify the

condition of the board.

2. If everythink seems ok try to substitute F2 fuse

otherwise substitute the board.

3. Take care to properly tight the fuse .

1. Check any bad contact in the key switch.

2. Check for any bad contact in the wires from the

key switch to the pin 5 and 6 of J3 connector on

the board.

3. If necessary substitute the key switch.

1. Check the continuity of the yellow wire from the 3

way charger connector to pin 11 of J1 connector.

2. If ok, it is necessary to substitute the charger or

the board.

1. Check the battery voltage without and with load. If

necessary substitute the bad batteries.

2. Charge the batteries with a complete charging

cycle.

1. Check the 4 wires from the 4 ways connector on

the dashboard to the pin 1,2,3,4 of J3.

2. If ok substitute the dashboard.

G9 tipically shows that the red safety button under

the seat (that mechanically open the ANDERSON

CONNECTOR) was pressed during the machine

operation.

If this is not the case, check the power wirings from

the batteries to the ANDERSON connector: it could

be a bad contact in one of these power connections.

Otherwise it could be caused by one or more batteries damaged or to be replaced.

Page 25

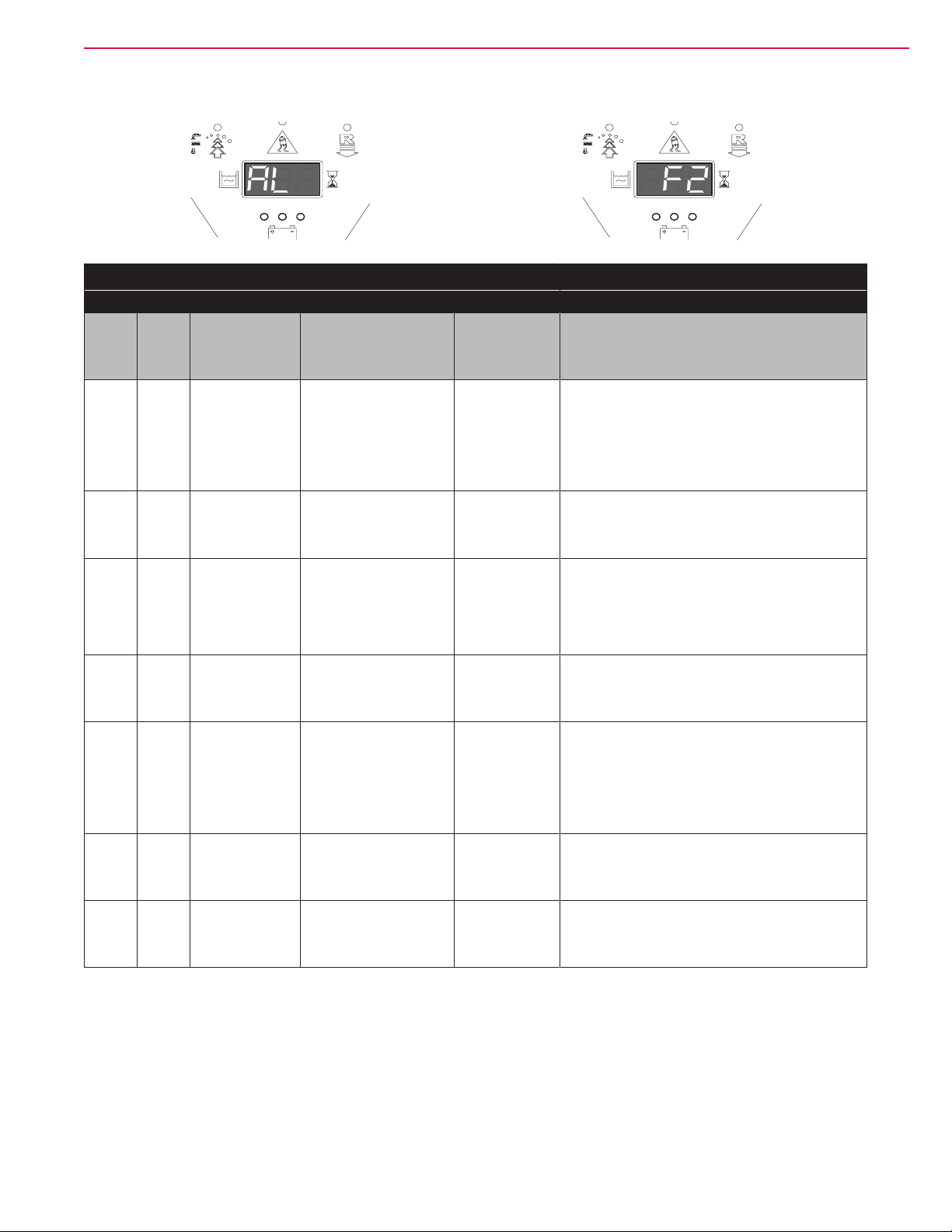

Function Electronic Board Alarm Codes (continued)

P100549 P100551

Function electronic board alarms

Alarm on the function electronic board - RED LED FLASHING

Alarm

Code

on the

display

No. of

ashes

on the

board

F2 2 BRUSH motor

F3 3 VACUUM

F4 4 DECK

F5 5 VACUUM

F6 6 PRESSURE

F7 7 VACUUM

F8 8 Function general

Meaning Condition Effect

amperometric

protection.

SYSTEM

amperometric

protection

ACTUATOR

position

irregularity.

SYSTEM power

section damage.

SWITCH signal

fault.

SYSTEM output

short circuit.

relay fault.

The voltage drop

measured on the F1

fuse is higher than the

value of the parameter

(see page 32 - 33) VS1

(for disc deck, VS2 for

cylindrical deck).

The current draw in the

vacuum motor is higher

than 30 Amp for more

than 10 senconds.

End-of-stroke

microswitch conguration

not plausible or endof-stroke microswitch

not reached within 10

senconds.

Internal board mosfet

short circuit.

Pressure switch input

higher than 4.0 Volt.

The inrush current draw

in the vacuum motor is

higher than 100 amps.

The main relays inside

the board is stuck

(always closed or always

open).

Brush

electromagnetic

switch output

block.

Vacuum system

block

Deck actuator

block.

Vacuum system

block.

Water level

visualization

missing +

water ow and

% detergent

management

fault.

Vacuum system

block.

Function block.

Troubleshooting action

1. Check the current ow in the brush motors (the

sum of the 2 motors has to be under 50 amps on

disc decks, under 70 amps on cylindric decks).

2. If the current is ok check the correct tight of the

F1 fuse nuts (F1 fuse is on the bracket under the

function board).

1. Check for any debris into the vacuum motor

2. Check that the vacuum motor fan is free to rotate

(bearing stuck ?).

3. If necessary substitute the vacuum motor.

1. Check the deck actuator wire and its connection

to the 6 way J4 connector on the board.

2. Check for any obstacle or excessive friction that

don’t allow the actuator to move.

3. If necessary substitute the actuator.

1. Check any short in the vacuum motor wiring.

2. Check the vacuum motor operation (try to power

it directly).

3. Substitute the board.

1. Check for the correct positioning of the pressure

gauge module into the board: take care of the 2

side connectors that have to be tted in properly.

2. If the connection is ok, substitute ALL THE

pressure gauge KIT.

1. Check any short in the vacuum motor wiring.

2. Check the vacuum motor operation (try to power

it directly).

3. Substitute the vacuum motor.

Substitute the board.

Control System 25Service Manual – SC3000

All “general” and “function” alarms, and their relevant effects remain until reset from KEY input. In case of

simultaneous errors, the one with greater priority is shown rst (priority order is opposite to the number of

ashes).

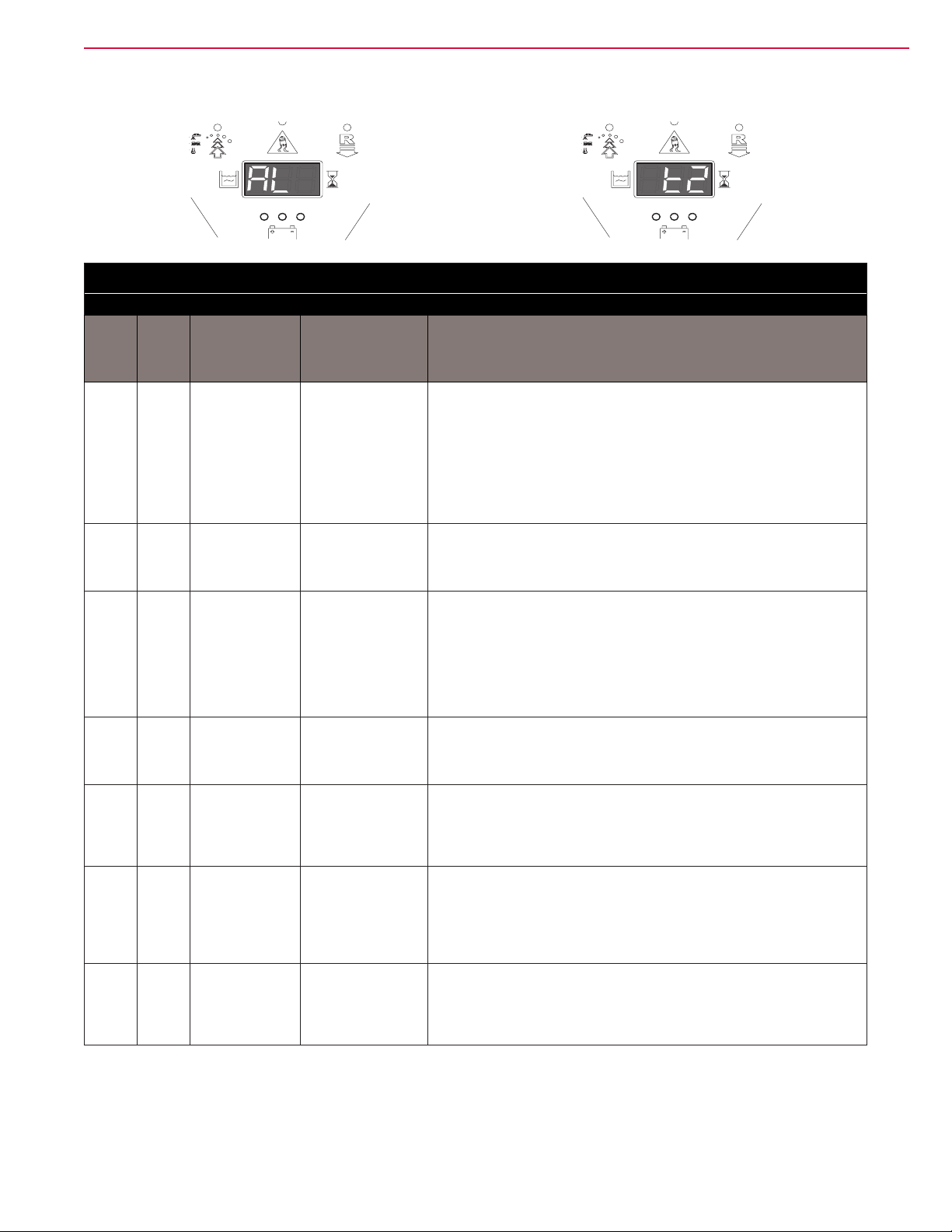

Page 26

Function Electronic Board Alarm Codes (continued)

P100549 P100552

Drive system alarms

Alarm on the function electronic board - YELLOW LED FLASHING

Alarm

Code

on the

display

No. of

ashes

on the

board

t2 2 Amperometric

t3 3 Electromagnetic

t4 4 Pedal input

t5 5 Drive system

t6 6 Pedal input not

t7 7 Overcurrent

t8 8 Drive system

Meaning Condition

protection

intervention.

brake not present

activated by

ignition.

power section

damage.

admitted.

(motor D.C.).

relay fault.

Current draw in

to the drive motor

higher than the

parameter (see

page 32 - 33)

“INOM“ for more

than parameter

(see page 32 - 33)

“TMAX“ time.

Open circuit

between J5.1 and

J5.2

Pedal output on

J3.8 higher than

the parameter

(see page 32 - 33)

“DEADL” when

the machine was

switched on by the

key.

Internal board

mosfet short circuit.

Open circuit

between J3.7 and

J3.9 or pedal output

on J3.8 higher than

5 Volt.

Drive motor current

higher than 1.5

times the value

of the parameter

(see page 32 - 33)

“IMAX”.

The Drive system

relays inside the

board is stuck

(always closed or

always open).

Troubleshooting action

Check the drive motor current draw: it has to be 6-8 amps without load and it

has to remain under 20 amps during operation.

1. Check the continuity of the 2 wires of the electrobrake of the motorwheel

up to the 2 way connector J5 on the board.

2. Check for the electrobrake impedance: has to be about 40 Ohms.

3. If necessary substitute the electrobrake.

1. Check that the pedal returns into its released position when not pressed.

2. If necessary substitute the pedal.

1. Check any short in the main motorwheel wires.

2. Try to disconnect the 2 Ø6 mm fast connectors M1 and M2 from the

board, switch on the machine and press the pedal.

3. If the alarm still appears, substitute the board.

Check the wiring from the pedal and the J3 connector pins 7, 8, 9.

From the battery – you have to measure:

- About 5 Volt on pin 7.

- From 0.7 to 4.5 Volt on pin 8 (it has to change moving the pedal).

- About 0 – 0.7 Volt on pin 9.

1. Check any short in the main motorwheel wires.

2. Check the impedance of the motorwheel motor: it has to be about 0.6 –

0.8 Ohms.

3. If necessary substitute the motorwheel motor.

Substitute the board.

Control System 26Service Manual – SC3000

All the drive system alarms activates to cut off the power supply to the driving wheel motor (not to the ELECTROMAGNETIC BRAKE), until reset from KEY input [except alarm t4 which is reset as soon as J3.8 voltage

(drive pedal output) became less then the value of the parameter “DEADL” (see table “Function electronic

board parameters” page 32 - 33). In case of simultaneous errors, the one with greater priority is shown rst

(priority order is opposite to the number of ashes).

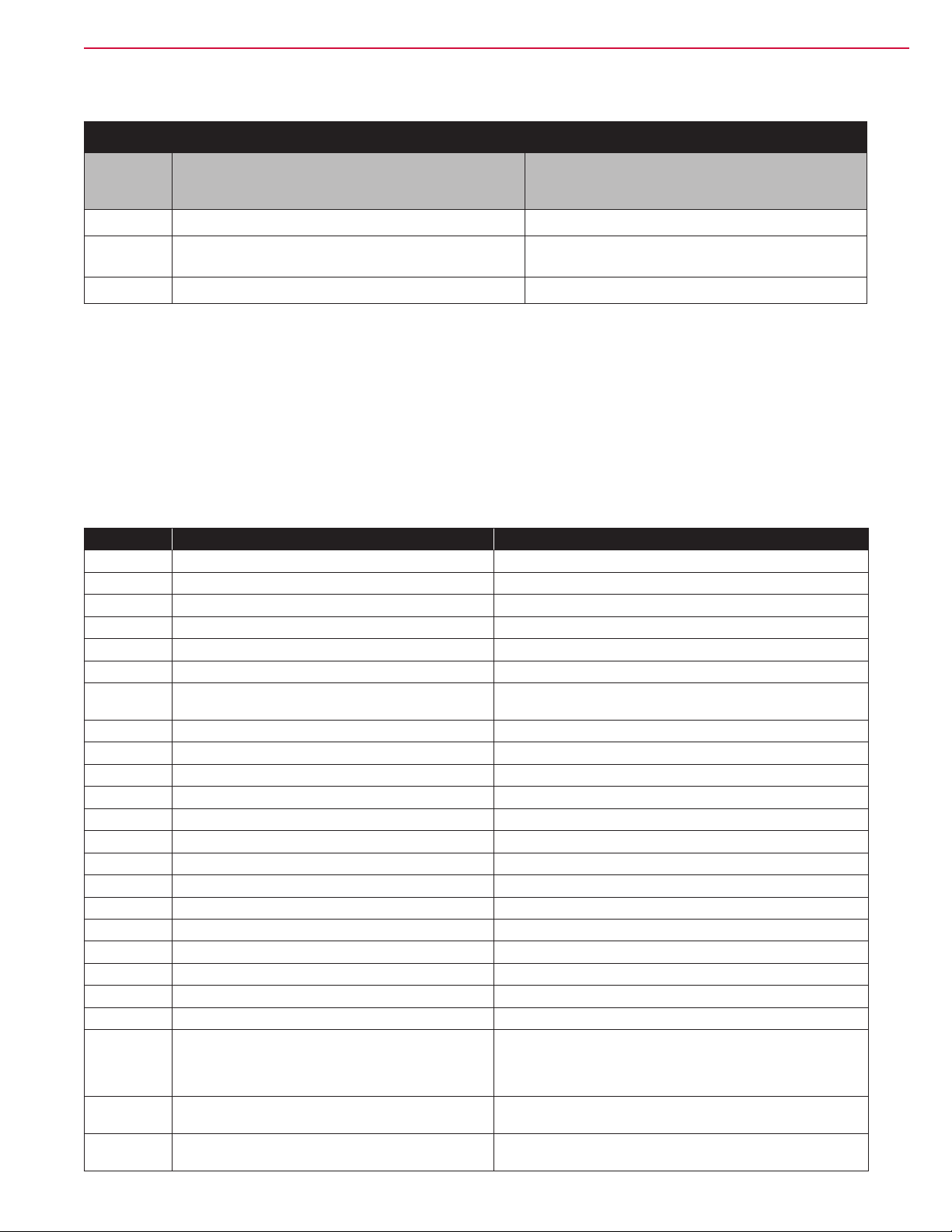

Page 27

Function Electronic Board Alarm Codes (continued)

Other alarm indications on the display

Alarm Code

on the

display

“---” Water level signal missing or not as specied. Pressure switch module output higher than 4.0 Volt.

Meaning Condition

Control System 27Service Manual – SC3000

“888”

Off Dashboard electronic board power supply missing. Voltage between J1.1 and J1.4 less than 12 Volt.

Serial communication problem between dashboard electronic

board and function electronic board.

Signal missing or errors.

Black-box: Record of Alarms, Battery Management Parameters (see page 32

- 33), Partial Hour Counter

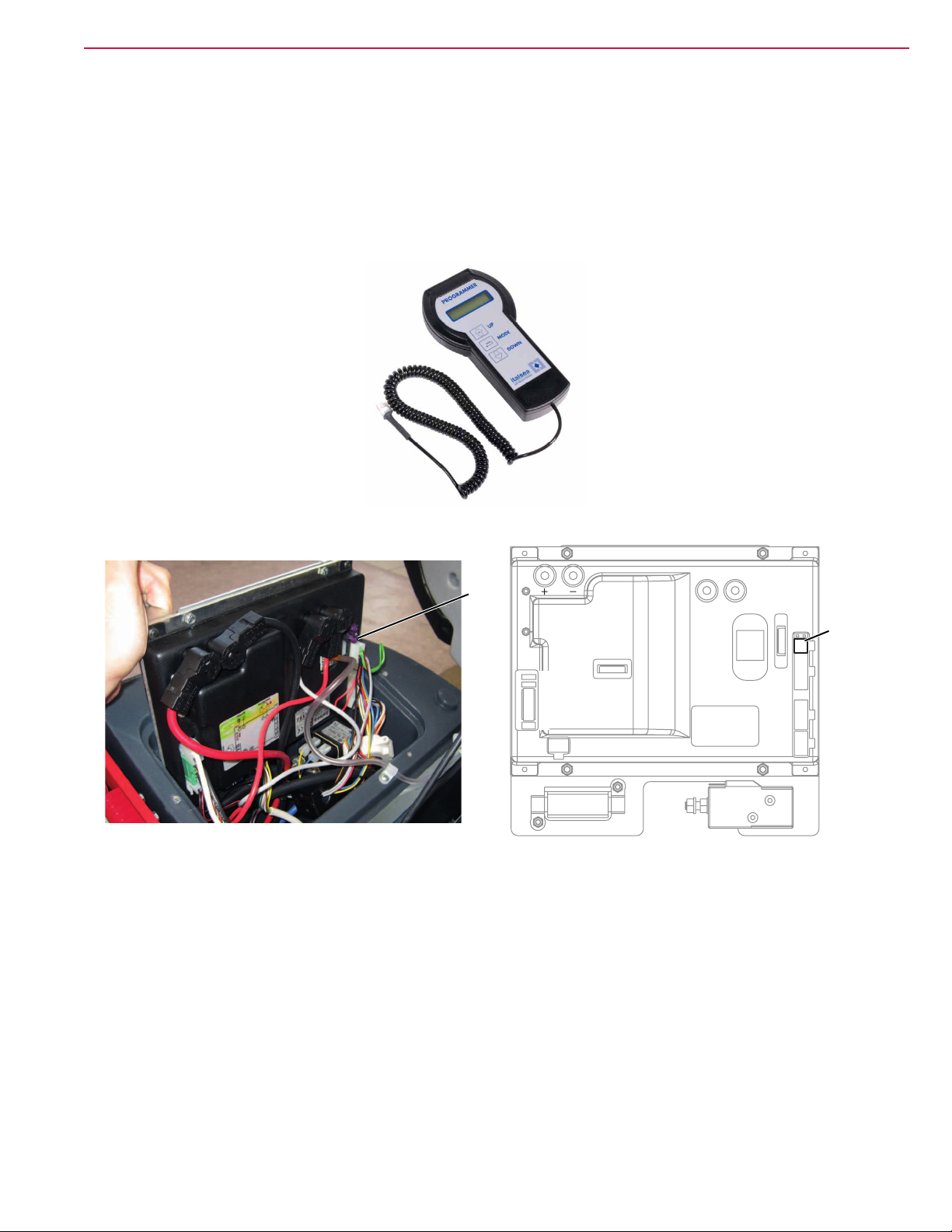

The data indicated in the following table (ALARMS, BATTERY MANAGEMENT DATA) are stored in the nonvolatile memory of the electronic board and can be recalled and displayed by the external programmer (ITALSEA UNIVERSAL PROGRAMMER, NILFISK P/N 9097297000) connect to port J9. For each stored datum

(event) the value HOURS.MINUTES of the TOTAL hour counter is associated when the alarm occurred. The

last 20 events are stored. When the total number of events is used up, the next events overwrite the older ones.

The data are shown on the programmer display, listed by decreasing order (starting from the latest) as: DATUM - HOUR (1 per page). The UP and DOWN buttons are used to select 1 page at a time. All the stored paged

can be scrolled. The “info” button shows the DATUM - EVENT DESCRIPTION for the selected line.

DATUM EVENT DESCRIPTION Condition

G2 EEPROM error See alarm code description

G3 General thermal protection See alarm code description

G4 Blown F2 fuse See alarm code description

G5 Wrong KEY sequence See alarm code description

G6 No signal from BATTERY CHARGER See alarm code description

G7 Battery undervoltage See alarm code description

G8

G9 Battery voltage drop See alarm code description

F2 Brush motor protection intervention See alarm code description

F3 VACUUM SYSTEM overcurrent See alarm code description

F4 DECK ACTUATOR position irregularity See alarm code description

F5 VACUUM SYSTEM power section damage See alarm code description

F6 PRESSURE SWITCH signal fault See alarm code description

F7 VACUUM SYSTEM output short circuit See alarm code description

F8 Function general relay fault See alarm code description

t2 Drive system amperometric protection intervention See alarm code description

t3 Electromagnetic brake not present See alarm code description

t5 Drive system power section damage See alarm code description

t6 Pedal input not admitted See alarm code description

t7 Drive system overcurrent See alarm code description

t8 Drive system relay fault See alarm code description

GB-N Time of continuous use with discharged batteries

GC Charging cycle interrupted before completion

GD-N Charging phase duration

Serial communication error with dashboard electronic

board

See alarm code description

“N” is the number of hours from the key switching ON and OFF

during the battery level is under 18,4 Volt for WET, 19,6 for

AGM. This event is not recorded if the above time is less than 10

minutes.

Battery charger disconnection before PHASE IV (= with red or

yellow LED on)

N = Number of hours from battery charger connection to

completion of PHASE II (red LED on) if < 4

Page 28

Control System 28Service Manual – SC3000

Last stored event

Machine working hours

Black-box: Record of Alarms, Battery Management Parameters (see page 32

- 33), Partial Hour Counter (continued)

Example 1:

Last stored alarm: alarm G8 occurred when the machine working hours were 24h and 19m, next to last stored

alarm: alarm F4 occurred when the machine working hours were 22h and 5m.

PROGRAMMER

Logged alarm-1:

ALL_G8: 24h,19m

Example 2:

Charging cycle interrupted before completion when the machine working hours were 15h and 45m (last stored

event).

PROGRAMMERPROGRAMMER

Logged alarm-2:

ALL_F4: 22h,55m

P100399

PROGRAMMER

GC (-1) 15h,45m

21hours, 31 min

Charging cycle time when interrupted

P100400

Page 29

Control System 29Service Manual – SC3000

Display of Current Values of Signicant Variables, Hour Counters and

Stored Alarms

1. Turn the ignition switch to “0”.

2. Open the electrical component compartment.

3. Connect the ITALSEA programmer, NILFISK P/N 9097297000 to the function electronic board

connector J9 (A).

A

M2

M1

VAVA+

J6

J5

J4

4. Turn the ignition switch to “I”.

5. Scroll with the UP and DOWN buttons the pages in the order shown in the table below.

J7A

J7B

J8

J9

J1

J3

J2

A

P100401

Page 30

Control System 30Service Manual – SC3000

Display of Current Values of Signicant Variables, Hour Counters and

Stored Alarms (continued)

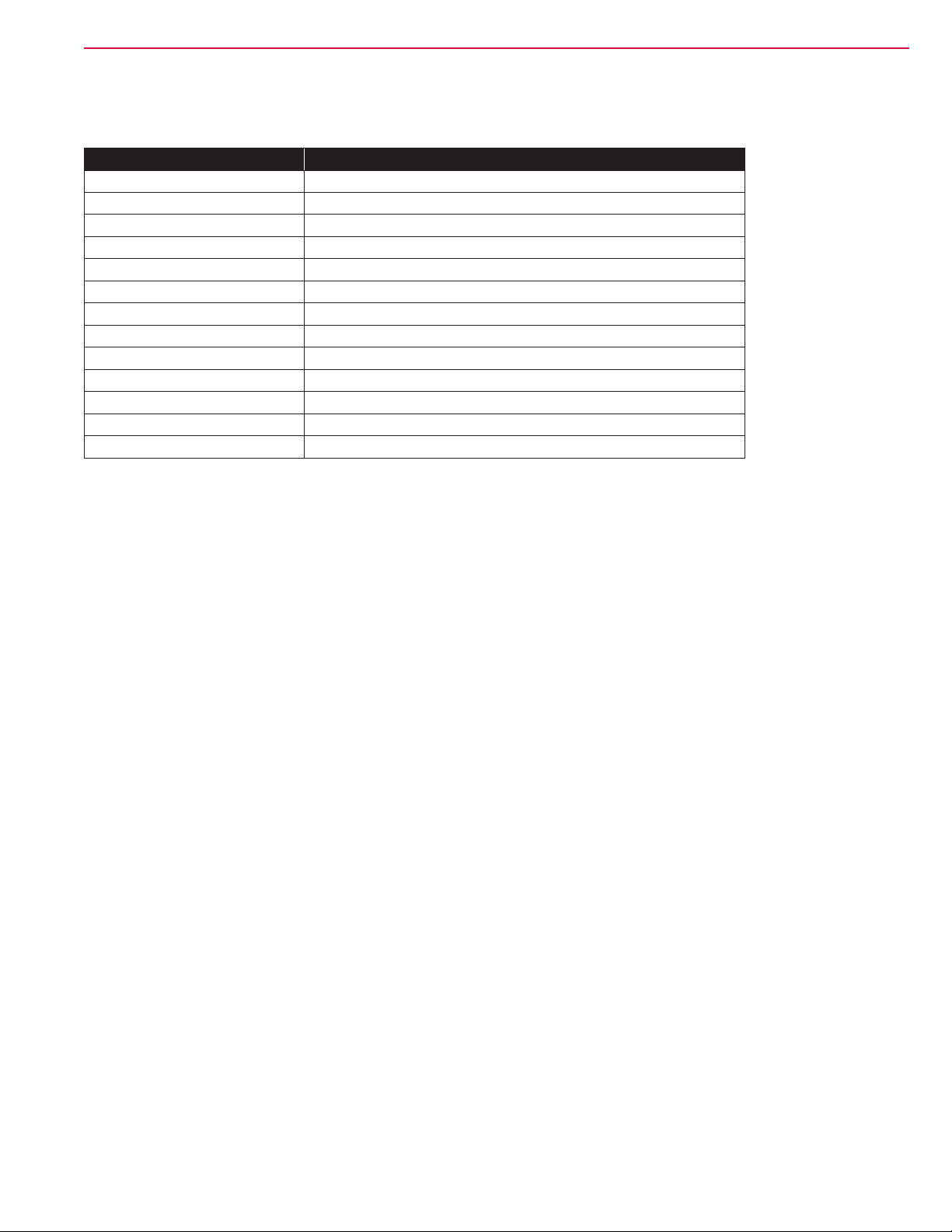

Variable description Value meaning

Software Release Software version loaded on the electronic board

Supply Voltage Battery voltage (V)

Ref. Voltage Drive pedal input voltage (V)

Drive Motor Voltage Drive system motor output voltage (V)

Drive Motor Current Drive system motor current (A)

Brushes Current Brush deck motor current (mV) (*)

Vacuum Current Vacuum system motor current (A)

Heatsink Temp. Temperature detected on the electronic board heatsink (°C)

Hour counter: total TOTAL HOUR COUNTER (h.min)

Hour counter: drive system DRIVE SYSTEM HOUR COUNTER (h.min)

Hour counter: brushes BRUSH HOUR COUNTER (h.min)

Hour counter: vacuum VACUUM SYSTEM HOUR COUNTER (h.min)

Logged Alarm-N ALARM STORAGE (possible) (**)

(*) The value is the same as the voltage drop on the F1 fuse, which is proportional to the current but does not

have the same value in Amp.

(**) See BLACK-BOX paragraph

Page 31

Control System 31Service Manual – SC3000

Display and Change of Parameters Which can be Set by the Technician

The stored value of each parameter shown in the following table could be modied by the Service Operator

from its Default value to another in the range dened from “Min. value” to “Max. value”.

The default value should be ok for most of the applications, however it could be useful to change a parameter

value in order to:

– Customize the machine behavior to particular customer needing (like Maximum speed in forward

(FVM), max speed in reverse (RVM), maximum and minimum pre-set working speeds (WSMIN and

SWMAX if present), reaction time to the pedal pressure variation (AR and DR), time of the ECOFLEX

temporary function (SPT), etc..

– Adapt the board tolerance to partcular devices that are a little bit out of their normal tolerances (ex.

voltage of the pedal output when released (DEADL), voltage when the pedal is fully pressed (DEADH).

– Adapt the board output power limits to protect the motors in particular heavy duty applications (like

Max. current in the deck motors (VS1 for disc, VS2 for cylindrical), max continous current in the drive

motorwheel (INOM) etc.)

1. Turn the ignition switch to “0”.

2. Open the electrical component compartment.

3. Connect the programmer to the function electronic board connector J9 (see gure).

4. Turn the ignition switch to “I”.

5. Press the MODE button.

6. Scroll the parameters with the UP and DOWN buttons to nd the one to be changed.

7. Press the MODE button to enter the “change” mode (the parameter starts to ash).

8. Change the value with the UP and DOWN buttons.

9. Store the new set value by pressing the MODE button.

Page 32

Function Electronic Board Parameters

Parameters which can be set through programming port J9

Code Description

VRID

VS1

VS2

DT

SPT SPOT function timer (s) 5 60 300

DEADL Drive pedal bottom dead area (V) 0.0 0.9 1.5

DEADH Drive pedal top dead area (V) 0.0 2.2 2.5

FVM0 Maximum forward speed (%) 10 100 100

Vacuum system partial supply

voltage (V)

Brush motor protection threshold 1

(mV)

Brush motor protection threshold 2

(mV)

Deck actuator m1 microswitch delay

(ms)

Min.

values

10 16 20

30 50 90

30 60 90

0 0 10

Default

values *

Max.

values

Control System 32Service Manual – SC3000

Meaning

It is the voltage supplied to the vacuum motor when

the SILENCE MODE is active: it could be reduced

to reduce further the noise or increased to increase

the vacuum performances.

It is the max current that is possible to supply to the

disc brush deck.

PAY ATTENTION: increasing this value you will

take more overheating risk on the motors.

It is the max current that is possible to supply to the

cylindrical brush deck.

PAY ATTENTION: increasing this value you will

take more overheating risk on the motors.

Engineering parameter to bias the deck actuator

normal working position.

– Do not modify.

Time of the ECOFLEX temporary function

(ECOFLEX lever / button) after that the normal

settings will be restored.

Pedal output voltage when the pedal is in its

released position.

Pedal output voltage when the pedal is fully

pressed.

Max forward speed.

RVM0 Maximum reverse speed (%) 10 70 100

AR Maximum acceleration ramp (s) 0.5 3.0 5.0

DR Maximum deceleration ramp (s) 0.5 1.0 5.0

Maximum deceleration ramp on

IR

BRK

INOM

reversal (s)

Electromagnetic brake activation

delay (s)

Drive system rated current (A)

Up to machine SN: 3510133204430

Drive system rated current (A)

Starting m. SN: 3510133204431

0.5 0.5 5.0

0.5 1.0 5.0

10 20 30

10 25 30

Max reverse speed.

Time to reach the max forward speed from the

stopped position. Increase to have a slower

reactive drive behavior, decrease to have a more

reactive drive behavior.

Time to reach the machine stopped from the max

speed. Increase to have a slower reactive drive

behavior, decrease to have a more reactive drive

behavior.

PAY ATTENTION: increasing this value would

make the braking spaces longer.

Time to reach the machine stopped from the max

speed, when the gear is reversed. Increase to have

a slower reactive drive behavior, decrease to have

a more reactive drive behavior.

PAY ATTENTION: increasing this value would

make the braking spaces longer.

Delay to the parking brake activation after the

machine is stopped. Decrease to allow the machine

parking in a slope

NOTE: that this machine is not designed to

operate on slopes, so in any case advise the

customer about that.

It is the max continous current that is possible to

supply to the drive motorwheel.

PAY ATTENTION: increasing this value you will

take more overheating risk on the motor.

Page 33

Parameters which can be set through programming port J9

Code Description

IMAX Drive system maximum current (A) 10 80 100

Protection intervention time for IMAX

(s)

TMAX

AMAX Maximum lateral acceleration (g/100) 1 15 100

KG Lateral acceleration control constant 1.0 1.6 2.0

WSMIN (Not used) - -

Up to machine SN: 3510133204430

Protection intervention time for IMAX

(s)

Starting m. SN: 3510133204431

Min.

values

0 15 60

0 20 60

Default

values *

Max.

values

Control System 33Service Manual – SC3000

Meaning

It is the max istantaneous current that is possible to

supply to the drive motorwheel.

PAY ATTENTION: increasing this value you will

take more overheating risk on the motor

It is the time reaction of the drive motorwheel

overloading protection: this parameter is used in

combination with IMAX to have the right response

time curve of the drive motor overloading protection

system.

PAY ATTENTION: increasing this value you will

take more overheating risk on the motor

It is the max side acceleration allowed to the

machine. Over this value the drive system will cut

the power to the motorwheel in order to mantain the

machine stability.

PAY ATTENTION: increasing this value you will

take more tipping risks

Engineering parameter related to AMAX.

- Do not modify.

(available only on other models).

WSMAX (Not used) - -

(available only on other models).

(*) The default value is stored in the electronic board by the manufacturer.

Page 34

Control System 34Service Manual – SC3000

Removal and Installation

Display Electronic Board and Dashboard Electronic Board Replacement

Display Electronic Board Disassembly

1. Drive the machine on a level oor.

2. Turn the ignition key to “0” and disconnect the batteries.

3. Remove the steering wheel height control lever and disconnect the wiring harness connection (A).

4. At the workbench, remove the screws (B), the cover (C) and recover the gasket (D).

5. Disconnect the at connections (E) and (F) from the display electronic board.

6. Remove the screws (I), remove the display electronic board (G) and recover the springs (J) of the

microswitches (K).

C

J

K

I

K

J

A

B

D

E

F

I

G

B

P100398

Page 35

Control System 35Service Manual – SC3000

Display Electronic Board and Dashboard Electronic Board Replacement (continued)

Dashboard Electronic Board Disassembly

7. Perform steps 1 to 5 of the Display Electronic Board Disassembly.

8. Carefully lift and remove the dashboard electronic board (H) from the cover (C).

Assembly

9. Assemble the components in the reverse order of disassembly and note the following:

◦ Install the display electronic board (G) and check the proper operation of springs (J), microswitches

(K) and levers (L and M).

◦ Install the dashboard electronic board (H) by carefully attaching it to the cover and paying attention

to the routing of the at connections (E) and (F) in the cover slots (C).

C

J

K

I

K

J

A

B

D

E

F

I

G

B

P100398

Page 36

Control System 36Service Manual – SC3000

C

DCBA

Function Electronic Board Lay-Out and Disassembly/Assembly

Disassembly

1. Drive the machine on a level oor.

2. Turn the ignition key to “0” and disconnect the batteries.

3. Lift the recovery tank assembly.

4. Remove the 6 screws and remove the electronic component compartment cover.

5. Remove the 2 mounting screws of the function electronic board assembly and carefully remove it from

the housing.

6. Disconnect the following connections sequentially:

◦ (A) and (B) Power supply connection (+) and (-) .

◦ (C and D) Driving wheel connection (M1) and (M2).

◦ (E) Pressure switch module connection (J7A and J7B).

D

B

A

E

VAVA+

J6

J5

J4

M2

M1

J7B

J8

J9

J1

J3

J2

J7A

E

P100553A

Warning! Do not try to remove the pressure switch module by pulling the transparent hose:

the connection between the hose and sensor can be irretrievably damaged. Remove

the module by forcing on the PCB as shown in the gure.

OK NO

P100553B

Page 37

Function Electronic Board Lay-Out and Disassembly/Assembly (continued)

F

F

M M

◦ (F) Electrical component wiring harness connection (J1).

◦ (G) Foot board wiring harness connection (J3).

◦ (H) Frame wiring harness connection (J2).

◦ (I) Vacuum system wiring harness connection (VA+ and VA-).

Control System 37Service Manual – SC3000

G

I

H

VAVA+

J6

J5

J4

I

◦ (J) Recovery tank wiring harness connection (J6).

◦ (K) Electromagnetic brake wiring harness connection (J5).

◦ (L) Brush deck actuator wiring harness connection (J4).

7. Remove the function electronic board mounting screws (M) from the plate.

M

M2

M1

J7B

J8

J9

J1

J7A

F

J3

J2

G

H

P100553C

J

J

K

K

L

M

Assembly

8. Assemble the components in the reverse order of disassembly.

L

VAVA+

J6

J5

J4

M M

M2

M1

J7B

J8

J9

J1

J3

J2

P100553D

J7A

Page 38

Specications

Connectors on the function electronic board

M2 M1

J7A

VAVA+

J6

J5

J4

Power connections (male RADSOK terminals Ø6mm (AMPHENOL P/N N01 060 0001 1 or equivalent))

Ref. Description

Electronic board

in/out

B+ Electronic board power supply + in 24V 120A BAT+

B- Electronic board power supply - in 24V 120A B AT-

M1 Drive system motor + out 24V 100A M3+

M2 Drive system motor - out 24V 100A M3-

J8

J9

J7B

J1

J3

J2

V ref. I max. Connected to

Control System 38Service Manual – SC3000

M2 M1

J7B

J8

J9

J1

J3

J2

VAVA+

J7A

J6

J5

J4

Vacuum system connections (2-ways male faston 6.3x0.8 – pitch 6.5mm)

Ref. Description

Electronic board

in/out

V ref. I max. Connected to

VA+ Vacuum system power supply + out 0V 30A M2+

VA- Vacuum system power supply - out 10-24V 30A M2-

Page 39

Connectors (continued)

M2 M1

J7A

VAVA+

J6

J5

J4

J1: MOLEX MINIFIT type, 12-ways vertical

PIN Description

1

2

Brush electromagnetic switch power

supply +

Brush electromagnetic switch power

supply -

Electronic board

in/out

out 24V <1A ES1

out 0V <1A ES1

3 Brush fuse voltage drop reading + in 0V <1A F1

4 Brush fuse voltage drop reading - in 0V <1A F1

5 Power supply for N/A version congurator out 0V <1A J1.6

6 N/A version congurator return in 0V <1A J1.5

7 Power supply for deck congurator out 0V <1A J1.8

8 Deck congurator return in 0V <1A J1.7

9 Consent for battery charger out 24V <1A CH.1

10 Enabling from battery charger in 24V <1A CH.2

11 Battery charger data communication slot in/out 5V <1A CH.3

12 Auxiliary power supply + (under key) out 24V <1A -

J8

J9

J7B

J1

J3

J2

V ref. I max. Connected to

Control System 39Service Manual – SC3000

M2 M1

J7B

J8

J9

J1

J3

J2

VAVA+

J7A

J6

J5

J4

J2: MOLEX MINIFIT type, 8-ways vertical

PIN Description

Electronic board

in/out

V ref. I max. Connected to

1 Solenoid valve power supply + out 24V 1A EV1

2 Solenoid valve power supply - out 0V 1A EV1

3 Detergent pump power supply + out 24V <1A M4

4 Detergent pump power supply - out 0V <1A M4

5 Buzzer power supply + out 24V <1A BZ1.+ / PR1+

6 Buzzer power supply - out 0V <1A BZ1.cont

7 Auxiliary power supply + (under key) out 24V <1A -

Page 40

8 Auxiliary power supply - out 0V <1A -

Connectors (continued)

M2 M1

J7A

VAVA+

J6

J5

J4

J3: MOLEX MINIFIT type, 10-ways vertical

PIN Description

Electronic board

in/out

1 Dashboard power supply + out 24V <1A EB2.1

2 Dashboard serial + in/out 5V <1A EB2.2

3 Dashboard serial - in/out 0V <1A EB2.3

4 Dashboard power supply - out 0V <1A EB2.4

5 Power supply for key circuit out 24V <1A K1

6 Return from key in 24V <1A K1

7 Pedal potentiometer power supply + out 5V <1A RV1.F

8 Pedal potentiometer return - In 0-5V <1A RV1.E

9 Pedal potentiometer power supply - out 0V <1A RV1.D

10 -

J8

J9

J7B

J1

J3

J2

V ref. I max. Connected to

Control System 40Service Manual – SC3000

M2 M1

J7B

J8

J9

J1

J3

J2

VAVA+

J7A

J6

J5

J4

J4: MOLEX MINIFIT type, 6-ways vertical

PIN Description

Electronic board

in/out

V ref. I max. Connected to

1 Actuator power supply - microswitch out 0V <1A M5.m0,1,2

2 Return from microswitch actuator m0 in 0V <1A M5.m0

3 Return from microswitch actuator m1 in 0V <1A M5.m1

4 Return from microswitch actuator m2 in 0V <1A M5.m2

5 Deck actuator power supply +/- out 0/24V 8A M5

6 Deck actuator power supply -/+ out 0/24V 8A M5

Page 41

Connectors (continued)

M2 M1

J7A

VAVA+

J6

J5

J4

J5: MOLEX MINIFIT type, 2-ways vertical

PIN Description

Electronic board

in/out

1 Driving wheel brake power supply + out 24V 1A BRK

2 Driving wheel brake power supply - out 0V 1A BRK

J8

J9

J7B

J1

J3

J2

V ref. I max. Connected to

Control System 41Service Manual – SC3000

M2 M1

J7B

J8

J9

J1

J3

J2

VAVA+

J7A

J6

J5

J4

J6: TYCO MODU1 type, 6-ways vertical

PIN Description

Electronic board

in/out

V ref. I max. Connected to

1 Squeegee actuator power supply +/- out 0/24V 8A M6

2 Squeegee actuator power supply -/+ out 0/24V 8A M6

3 Flashing light power supply + out 24V <1A BE

4

Lamp / seat microswitch / oat power

supply -

out 0V <1A BE / SW1,2

5 Return from driver's seat microswitch in 0V <1A SW1

6 Return from oat in 0V <1A SW2

Page 42

Connectors (continued)

M2 M1

J7B

J8

J9

J1

J3

J2

J7A

VAVA+

J6

J5

J4

J7: PRESSURE SWITCH connector, Berger type, 3+3-ways vertical ( )

A1 Pressure switch power supply + out 5V <1A Press.A1

A2 Pressure switch power supply - out 0V <1A Press.A2

A3 - - - - Press.A3

B1 - - - - Press.B1

B2 Pressure switch signal + in 0-5V <1A Press.B2

B3 Pressure switch signal - in 0V <1A Press.B3

Control System 42Service Manual – SC3000

M2 M1

J7A

VAVA+

J6

J5

J4

J8: JUMPER, 2-ways vertical

M2 M1

J7A

VAVA+

J6

J5

J4

J9: MOLEX MINIFIT type, 4-ways vertical

Connector for parameter programming

J7B

J7B

J8

J9

J1

J3

J2

J8

J9

J1

J3

J2

Page 43

Electrical System 43Service Manual – SC3000

Electrical System

Functional Description

The batteries (two 12V or four 6V) are connected in series by bridge cables.

(For Nilsk scrubbers version only) One of the bridge cables has a safety fuse (F0).

If the voltage at battery connector (C1) = 0V, check the continuity of the cable with the fuse (F0) (for Nilsk

scrubbers version only). In case of a break in continuity, replace the cable.

The battery charger (CH) is connected to the machine by two connectors (C) (power connection to the batteries)

and C3 (3-way signal connection).

(Only for SPE Charger) The grey cables (terminals

1 and 2 of connector C3) are short-circuited in battery

charger (CH) when it is not connected to the electrical mains. If this connection is not made, all machine

functions are disabled.

The yellow cable (terminal 3 of connector C3) is the

data cable between board (EB1) and battery charger

(CH). This connection is used to set battery charger

charging curves directly on the machine dashboard

and displays the state of the battery charger when

charging, on the 3 battery dashboard LEDS:

Red LED lit = main charging phase

Yellow LED lit = equalization phase (charge comple-

tion)

Green LED lit = charging phase successfully complet-

ed

If the optional battery charger has not been installed, the relevant bridge must be used on connector C3.

(Only for Delta-Q Charger) The terminal 2 of connector C3 is shorted to the battery + (B+) internally

to the charger when it is not connected to the electrical mains. If this connection is not made, all machine

functions are disabled.

Battery charger

The SC3000 may be equipped with an optional onboard battery charger. Depending on the market area and

when the machine was manufactured, the charger may be an SPE charger or a Delta-Q charger.

SPE DQ

SPE charger Delta-Q charger

Page 44

Wiring Diagram (SPE charger)

24 V battery

box (BAT)

Battery fuse

(F0) (**)

B+

Battery

charger (CH)

B-

MP

(*)

Function

electronic

board (EB1)

Consent for battery charger

Enabling from battery charger

Battery charger data communication

Signal circuit

fuse (F3)

Power supply for key circuit

Main electronic

board fuse (F2)

Return from key

Electrical System 44Service Manual – SC3000

Ignition

switch (K1)

(*) Versions without on-board battery charger

(**) For Nilsk scrubbers version only

Wiring Diagram (Delta-Q charger)

24 V battery

box (BAT)

Signal circuit

fuse (F3)

B+

Battery

charger (CH)

B-

(*)

Enabling from battery charger

Main electronic

(***)

Power supply for key circuit

board fuse (F2)

Return from key

Function

electronic

board (EB1)

P100554SPE

Ignition

switch (K1)

P100554DQ

(*) Versions without on-board battery charger

(***) F3 on the Function electronic board is not used. Its function is performed by the F3 fuse on the wire

Page 45

Component Location

1

• Batteries (BAT)

• Battery connections

• SPE charger (CH)

• (for Nilsk scrubbers version only) Battery fuse (F0)

• Battery connector (C1)

• Delta-Q charger (CH)

Electrical System 45Service Manual – SC3000

SPE charger (CH)

Battery connector

(C1)

3

6

Batteries (BAT)

1

Battery fuse (F0)

5

(for Nilsk scrubbers

version only)

Battery connections

2

P100555

Delta-Q charger (CH)

P100555B

Page 46

Component Location (continues)

• Electrical panel

• Function electronic board (EB1)

Electrical System 46Service Manual – SC3000

Electrical panel

4 4

Function electronic

board (EB1)

P100556

Page 47

Electrical System 47Service Manual – SC3000

Maintenance and Adjustments

Charge condition display (SPE charger only)

Set the electronic board of the machine and the on board battery charger according to the type of batteries

installed (WET or GEL/AGM) as shown below:

1. Turn the ignition key to “I” and, in the very rst seconds of machine operation, detect the current setting

by counting the number of ashes of the battery warning lights, as shown in the following table:

SETTING DISPLAY BATTERY WARNING LIGHT INDICATION BATTERY TYPE CHARGING CURRENT

1 4 ashes of the red warning light WET

STANDARD2 4 ashes of the green warning light GEL-AGM

3 4 ashes of the yellow warning light GEL EXIDE® type

4 2 ashes of the red warning light WET

5 2 ashes of the green warning light GEL-AGM

6 2 ashes of the yellow warning light GEL EXIDE® type

REDUCED (see note)

2. If the setting is to be changed, perform the following procedure.

3. Turn off the machine by turning the ignition key to “0”.

4. Press and hold the scrub On/Off push button and the vacuum system push button at the

same time, then turn the ignition key to “I”.

5. Release the scrub On/Off push button and the vacuum system push button at least 5

seconds after starting the machine.

6. Within 3 seconds, shortly press the scrub On/Off push button to go to the next setting (1 to 6 in

cyclic sequence).

Note: When performing steps 5 and 6, the settings are shown on the display too, by the code in

the table.

Note: When using batteries with a capacity lower than 160Ah@5h (in case of doubt, refer to

the battery documents), to avoid battery overheating during charging procedure, use the

REDUCED charging current with setting 4, 5 or 6 shown in the table, according to the

type of batteries installed.

Note: The on board battery charger must be set according to the type of batteries.

Page 48

Electrical System 48Service Manual – SC3000

Delta-Q IC 650 Charge Prole Selection

Set the DELTA-Q on-board charger according to the type of batteries installed as shown below:

7. Disconnect AC input (A) from the charger, or from the wall outlet. Wait 30 seconds for the input relay to

open.

8. While reconnecting AC input (B), press and hold the

Select Charge Prole Button (C). Hold the button until

Error Indicator (D) is on and Amber in color and Battery

Charging Indicator (E) starts ashing Green.

Note: You will have to hold the button for 15-

20 seconds for this to occur.

9. Press and release the Select Charge Prole Button (C) to

advance through charging proles loaded on the charger.

The selected charging prole will be displayed (F) up to

three times (e.g. “P-0-1-1” for Prole 11).

Note: See the BATTERY CHARGER PROFILE

SELECTION CHART in the next page

for the relevant prole. Process will time

out and prole will remain unchanged if

there is 15 seconds of inactivity, a prole

number is allowed to display three times,

or if AC power is cycled.

10. Once desired charging prole is displayed, press and hold

button (C) for 10 seconds to conrm selection and exit

Prole Selection Mode.

Note: Make sure both the Error Indicator and

the Battery Charging Indicator are no

longer illuminated before releasing the

button.

11. Press the Select Charge Prole Button (C) to check that

the desired prole is selected.

A

B

D

E

FC

P100396

Page 49

Electrical System 49Service Manual – SC3000

Delta-Q IC 650 Charge Prole Selection (continues)

Available charging proles are as follows:

BATTERY CHARGER PROFILE SELECTION CHART FOR USE WITH DELTA-Q ON-BOARD CHARGER (N-A P/N 56383856)

Battery

Manufacturer

DISCOVER EV12A-A 1 56380239 2 140 P-0-4-2

DISCOVER EV185A- A 56393912 12 234 P-0-4-3