Page 1

7/10 revised 6/11

FORM NO. 56041978

A-English

B-Türkçe

Instructions for Use

Original Instructions

Kullanim Talimatlari

Models:

56413006(BR1100S), 56413007(BR1100S C / w/sweep system)

56413010(BR1300S), 56413011(BR1300S C / w/sweep system)

BR1100S, BR1300S

INSTRUCTIONS FOR USE

Page 2

A-2 / ENGLISH

TABLE OF CONTENTS

page

Introduction ........................................................................................... A-2

Cautions and Warnings ........................................................................A-3

Know Your Machine .....................................................................A-4 – A-5

Control Panel ........................................................................................ A-6

Prepare the Machine for Use

Install the Batteries ............................................................................... A-7

Install the Brushes .......................................................................A-8 – A-9

Fill the Solution Tank ..........................................................................A-10

Squeegee Installation ......................................................................... A-11

Detergent System ....................................................................A-12 – A-13

Operating the Machine ............................................................A-14 – A-15

Scrubbing ................................................................................A-14 – A-15

Wet Vacuuming .......................................................................A-14 – A-15

After Use .............................................................................................A-16

Maintenance Schedule ....................................................................... A-16

Lubricating the Machine ..........................................................A-16 – A-17

Charging the Batteries ........................................................................ A-18

Check the Battery Water Level ........................................................... A-18

Squeegee Maintenance ......................................................................A-19

Squeegee Adjustment ........................................................................ A-19

Side Skirt Maintenance ............................................................A-20 – A-21

Side Broom Maintenance ...................................................................A-22

Troubleshooting .................................................................................. A-23

Technical Specifi cations .....................................................................A-24

INTRODUCTION

This manual will help you get the most from your Nilfi sk Rider Scrubber. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages A-4 – A-6.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfi sk Service Center, who employs factory trained service personnel, and maintains an inventory

of Nilfi sk original replacement parts and accessories.

Call the NILFISK DEALER named below for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

MODIFICATIONS

Modifi cations and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the customer or user without prior written

approval from Nilfi sk-Advance Inc. Unapproved modifi cations will void the machine warranty and make the customer liable for any resulting accidents.

NAME PLATE

The Model Number and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering repair parts for

the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference.

MODEL NUMBER _______________________________________________________

SERIAL NUMBER ______________________________________________________

UNCRATE THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping carton (if

applicable) so that it can be inspected. Contact the Nilfi sk Customer Service Department immediately to fi le a freight damage claim. Refer to the unpacking

instruction sheet included with the machine to remove the machine from the pallet.

A-2 - FORM NO. 56041978 - BR1100S / BR1300S

revised 6/11

Page 3

ENGLISH / A-3

CAUTIONS AND WARNINGS

SYMBOLS

Nilfi sk uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take the

necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

WARNING!

• This machine shall be used only by properly trained and authorized persons.

• While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only

while ascending (driving up) the ramp.

• Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

• Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away from open

fl ame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable

liquids exist.

• Do not clean this machine with a pressure washer.

• Only use the brushes provided with the appliance or those specifi ed in the instruction manual. The use of other brushes may

impair safety.

CAUTION!

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• Do not use scarifi er discs and grinding stones. Nilfi sk will not be held responsible for any damage to fl oor surfaces caused by

scarifi ers or grinding stones (can also cause damage to the brush drive system).

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that function.

• Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and applying the parking

brake.

• Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery or

detergent tanks or in the hose lines could freeze, causing damage to valves and fi ttings. Flush with windshield washer fl uid.

• The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries should be

safely done in accordance with your local environmental regulations.

• Do not use on surfaces having a gradient exceeding that marked on the machine.

• All doors and covers are to be positioned as indicated in the instruction manual before using the machine.

SAVE THESE INSTRUCTIONS

FORM NO. 56041978 - BR1100S / BR1300S - A-3

Page 4

A-4 / ENGLISH

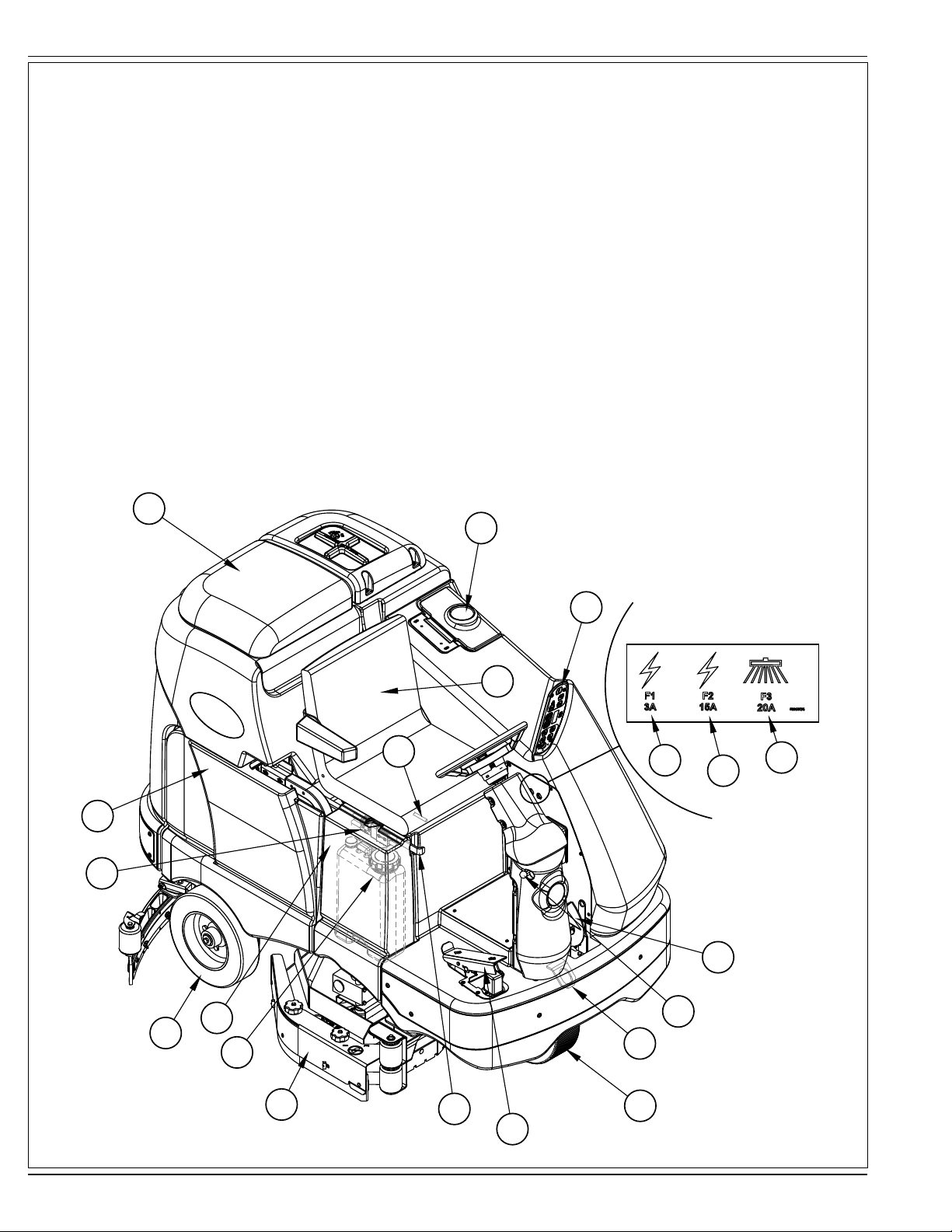

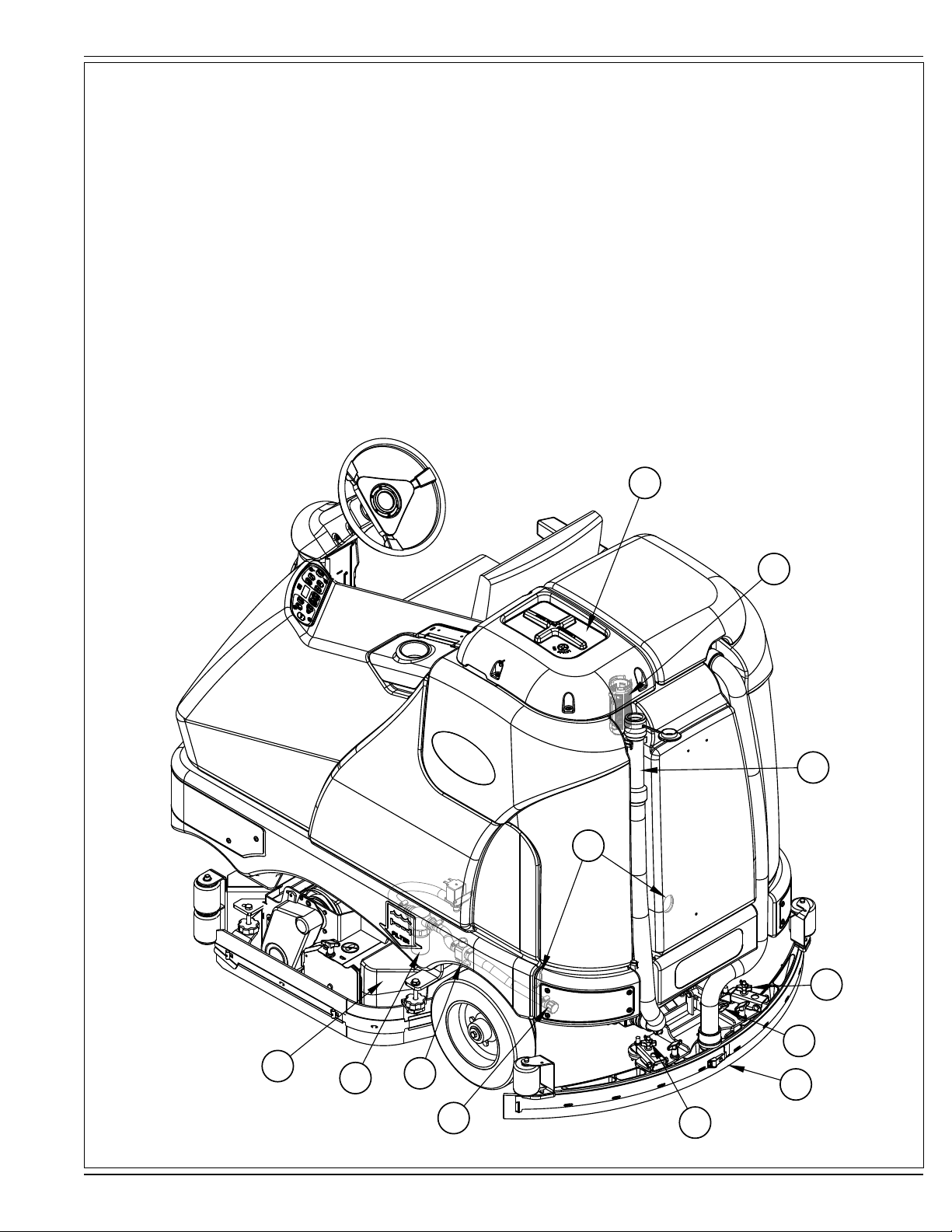

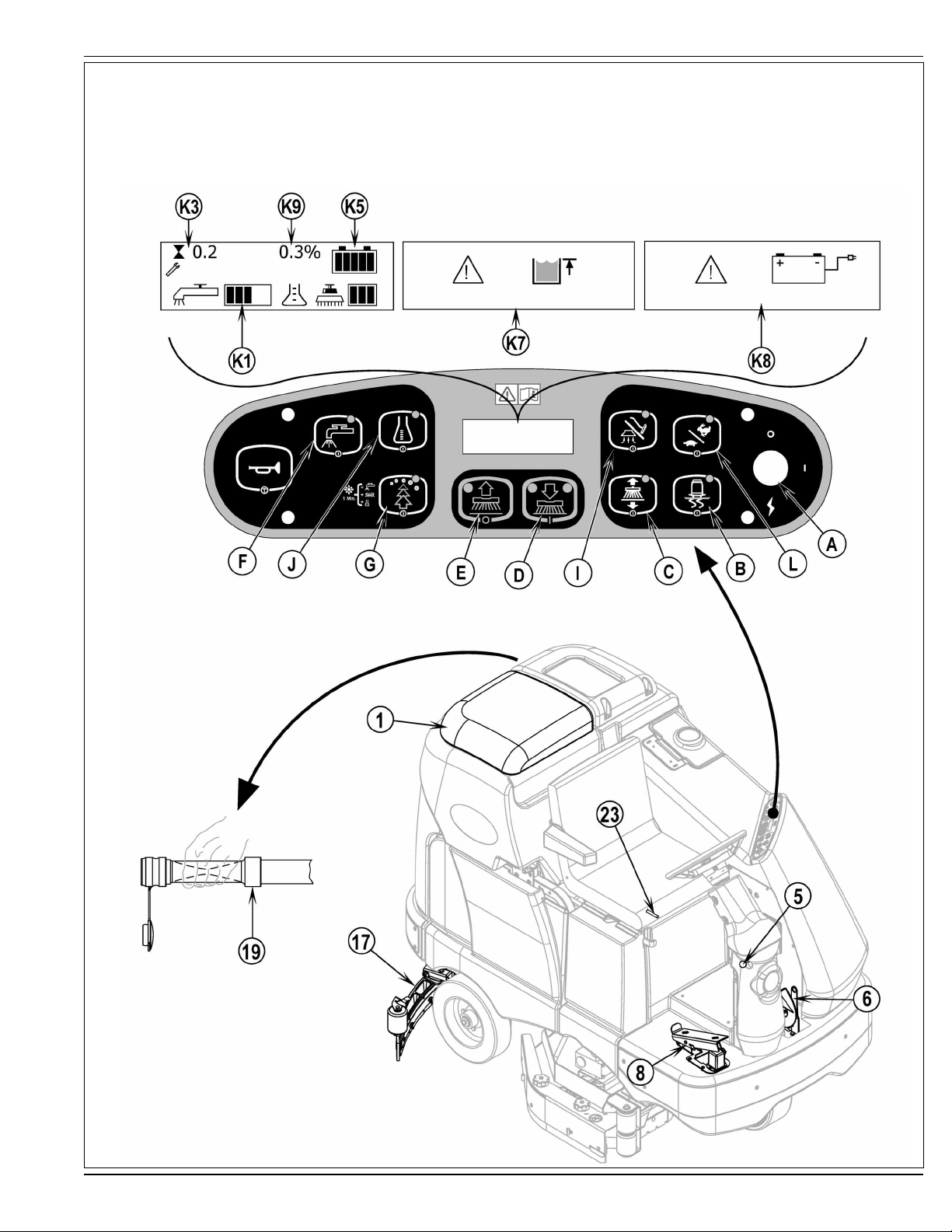

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item shown on these

pages unless otherwise noted. Refer back to these pages whenever necessary to pinpoint the location of an item mentioned in the text. NOTE: Refer to the

service manual for detailed explanations of each item illustrated on the next 3 pages.

1 Recovery Tank Cover

2 Solution Tank Fill Cover

3 Operator’s Seat

4 Solution Tank Drain Hose

5 Steering Wheel Tilt Adjust Knob

6 Brake Pedal / Parking Brake

7 Solution Shut off Valve

8 Drive Pedal, Directional/Speed

9 Hopper (cylindrical models only)

10 Drive and Steer Wheel

11 Emergency Stop Switch / Battery Disconnect

12 Scrub Deck

13 Rear Wheel

14 Battery Compartment (under recovery tank)

14

20

1

2

21

3

23

24

25

26

6

13

27

29

12

A-4 - FORM NO. 56041978 - BR1100S / BR1300S

11

5

30

10

8

revised 6/11

Page 5

KNOW YOUR MACHINE

15 Recovery Tank Shutoff Float

16 Vacuum Motor Filter Housing

17 Squeegee Assembly

18 Solution Filter

19 Recovery Tank Drain Hose

20 Machine Battery Connector

21 Control Panel

22 Squeegee Tilt Adjust Knob

23 Operator Seat Adjustment Lever

24 Control Circuit Breaker

25 Auxiliary Circuit Breaker

26 Side Broom Motor Circuit Breaker

27 Side Access Panel

28 Squeegee Height Adjust Knob

29 Detergent Cartridge (EcoFlex models only)

30 Tie Down Locations

ENGLISH / A-5

16

30

15

19

28

revised 6/11

22

9

18

7

4

28

17

FORM NO. 56041978 - BR1100S / BR1300S - A-5

Page 6

A-6 / ENGLISH

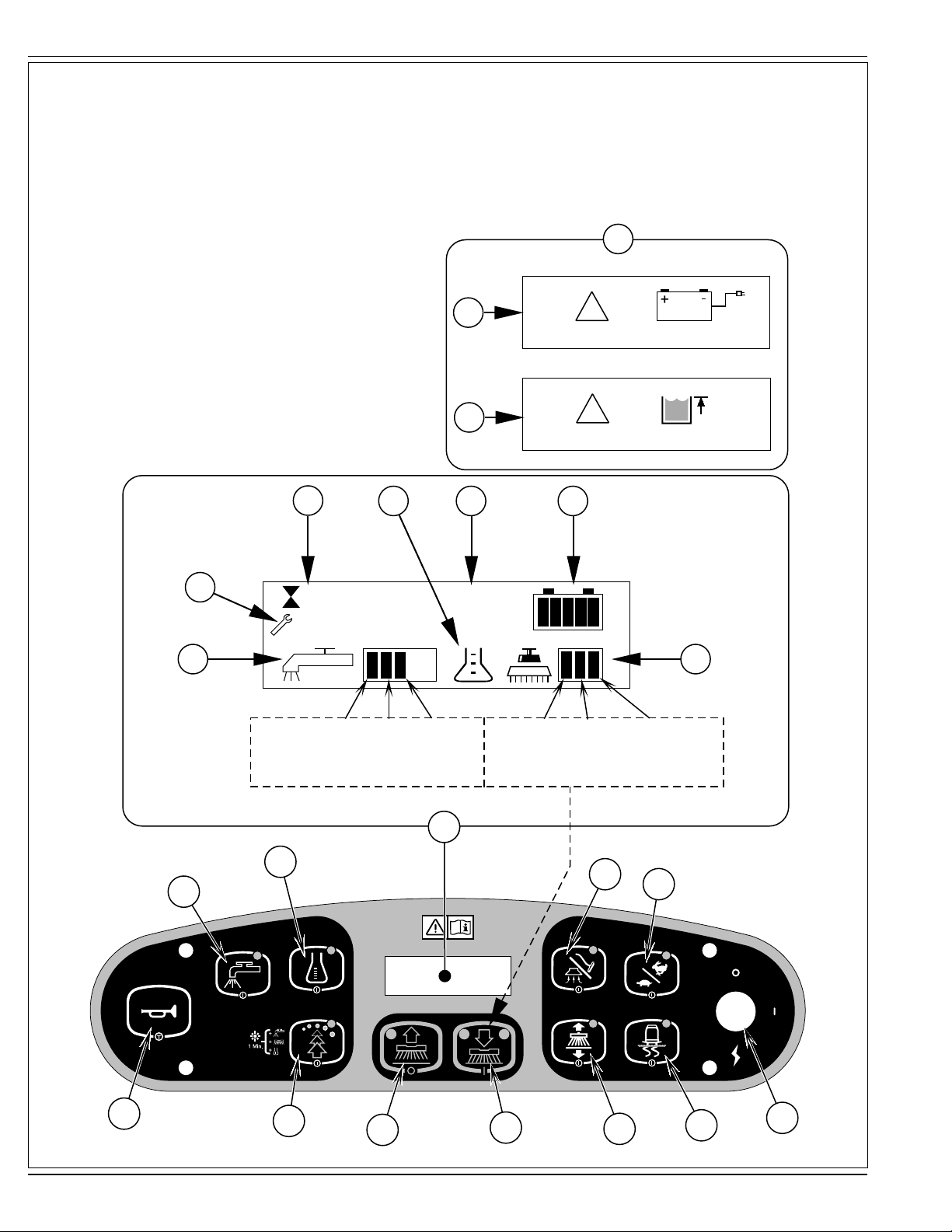

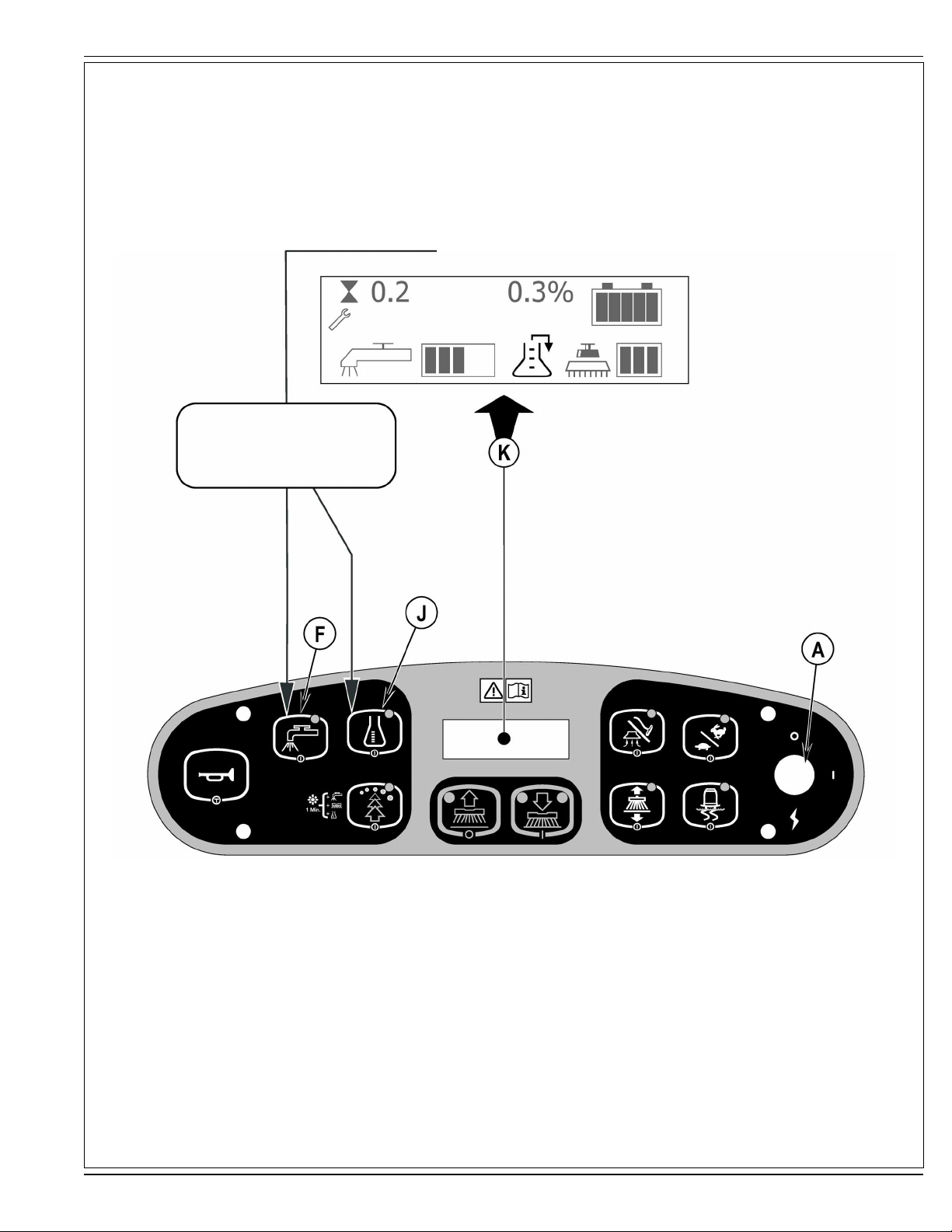

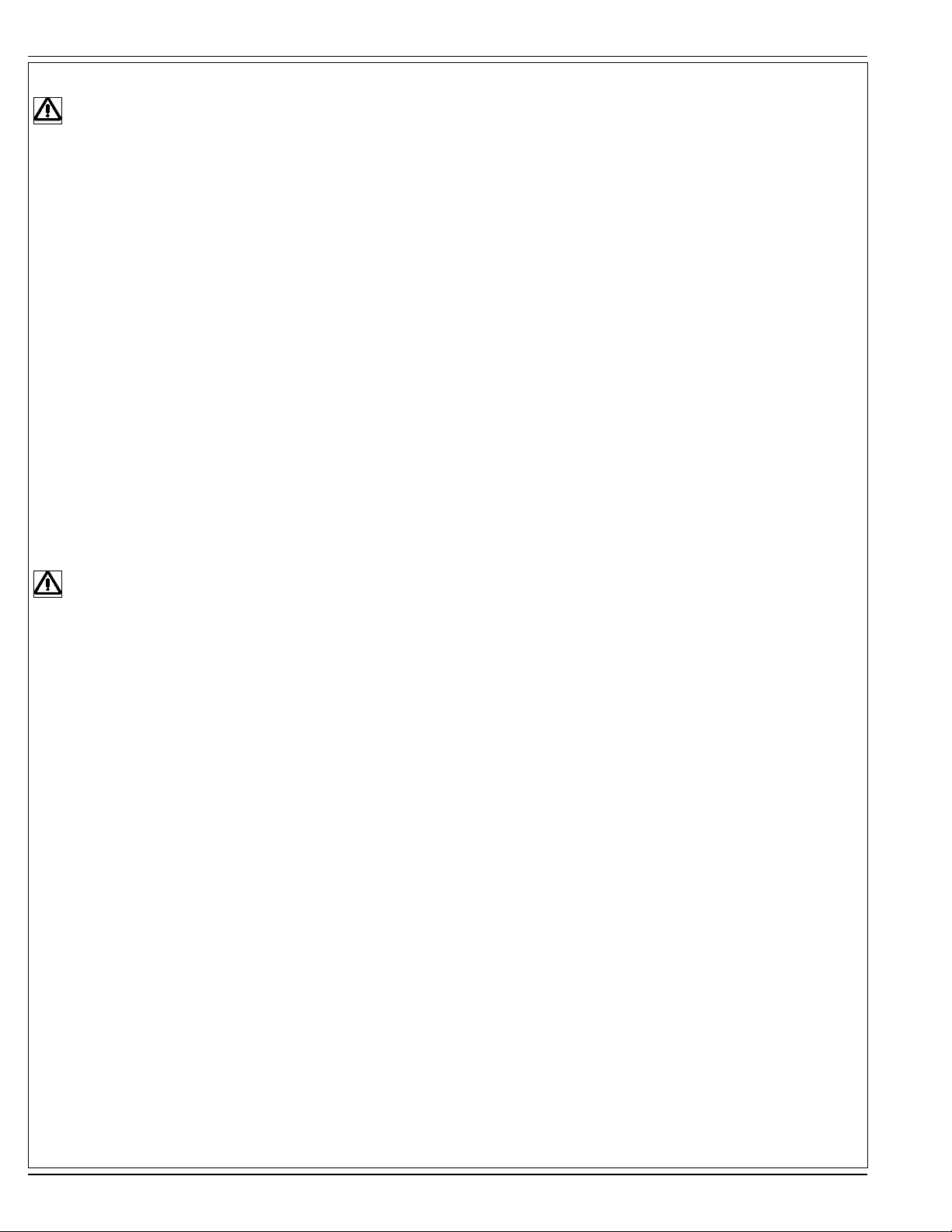

CONTROL PANEL

A Key Switch

B Traction Control Switch

C Side Broom Switch (cylindrical models only)

D Scrub ON / Scrub Mode Select

E Scrub OFF

F Solution Switch

G EcoFlex

H Horn

I Vacuum / Wand Switch

J Detergent System (EcoFlex models only)

K Display

K1 Solution Flow Indicator

K2 Fault Indicator

K3 Hour Meter

K4 Detergent Indicator (if so equipped)

K5 Battery Indicator

K6 Scrub Pressure Indicator

K7 Recovery Tank FULL Indicator

K8 Battery Low Indicator

K9 Detergent Percentage Indicator

L Scrub Speed Switch

™

Switch

K8

K7

K

!

!

K1

F

K2

K3

0.2

K4 K5

K9

0.3%

K6

Flow Flow Flow Regular Heavy Extreme

Rate 1 Rate 2 Rate 3 Scrub Scrub Scrub

(regular scrub) (heavy scrub) (extreme scrub) (press 1 time) (press 2 times) (press 3 times)

K

K

J

I

L

H

G

A-6 - FORM NO. 56041978 - BR1100S / BR1300S

E

D

C

B

A

Page 7

ENGLISH / A-7

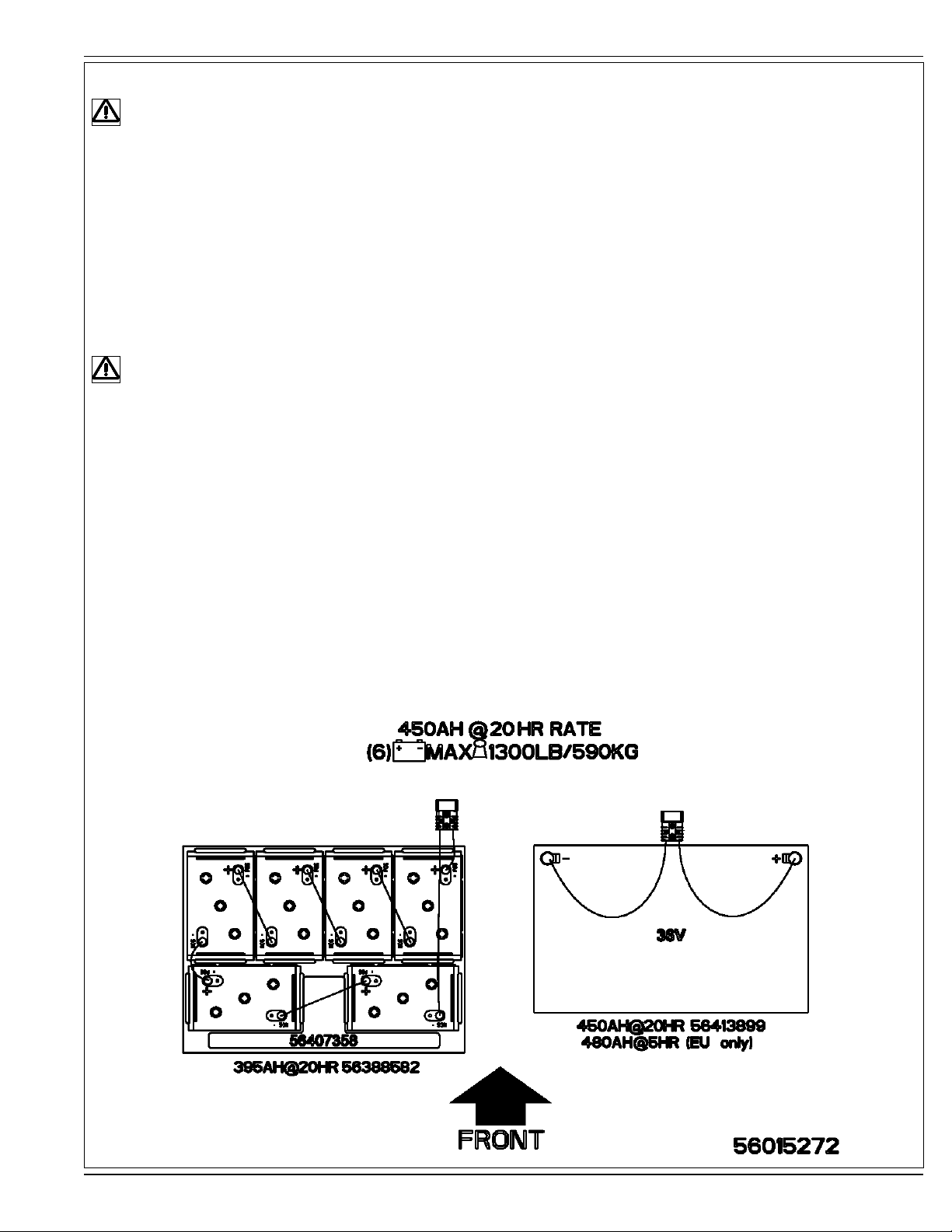

INSTALL THE BATTERIES

WARNING!

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin

or eyes. Explosive hydrogen gas is vented from the batteries through openings in the battery caps. This gas can be ignited by

any electrical arc, spark or fl ame. Do not install any lead-acid battery in a sealed container or enclosure. Hydrogen gas from

overcharging must be allowed to escape.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

Electrical components in this machine can be severely damaged if the batteries are not installed and connected properly. Batteries

should be installed by Nilfi sk or by a qualifi ed electrician.

1 Remove the batteries from their shipping crate and carefully inspect them for cracks or other damage. If damage is evident, contact the carrier that delivered

them or the battery manufacturer to fi le a damage claim.

2 Turn the Master Key Switch (A) OFF and remove the key.

3 Remove the recovery tank from the machine. NOTE: Disconnect the tether and the vacuum motor wiring and lift the tank straight up and off the machine.

4 Your machine comes from the factory with enough battery cables to install six 6 volt batteries. Using at least (2) people and an appropriate lifting strap,

carefully lift the batteries into the battery compartment and arrange them exactly as shown in FIGURE 1. Secure the batteries as close to the front of the

machine as possible. If installing a mono-block battery use an overhead hoist.

5 Install the battery cables as shown. Position the cables so the battery caps can be easily removed for battery service.

6 Carefully tighten the nut in each battery terminal until the terminal will not turn. Do not over-tighten the terminals, or they will be very diffi cult to remove for

future service.

7 Coat the terminals with spray-on battery terminal coating (available at most auto parts stores).

8 Put one of the black rubber boots over each of the terminals and connect the Battery Pack Connector (20).

FIGURE 1

FORM NO. 56041978 - BR1100S / BR1300S - A-7

Page 8

A-8 / ENGLISH

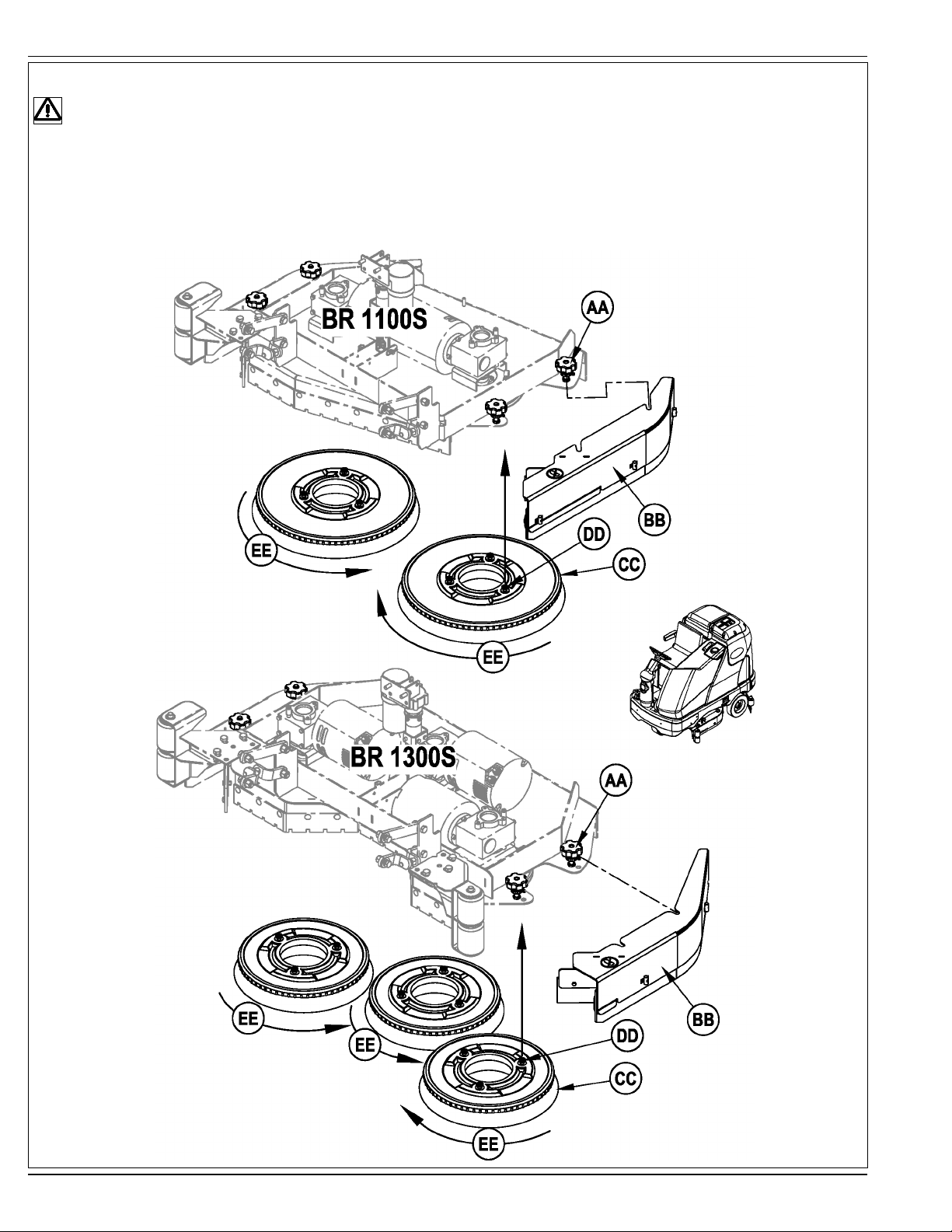

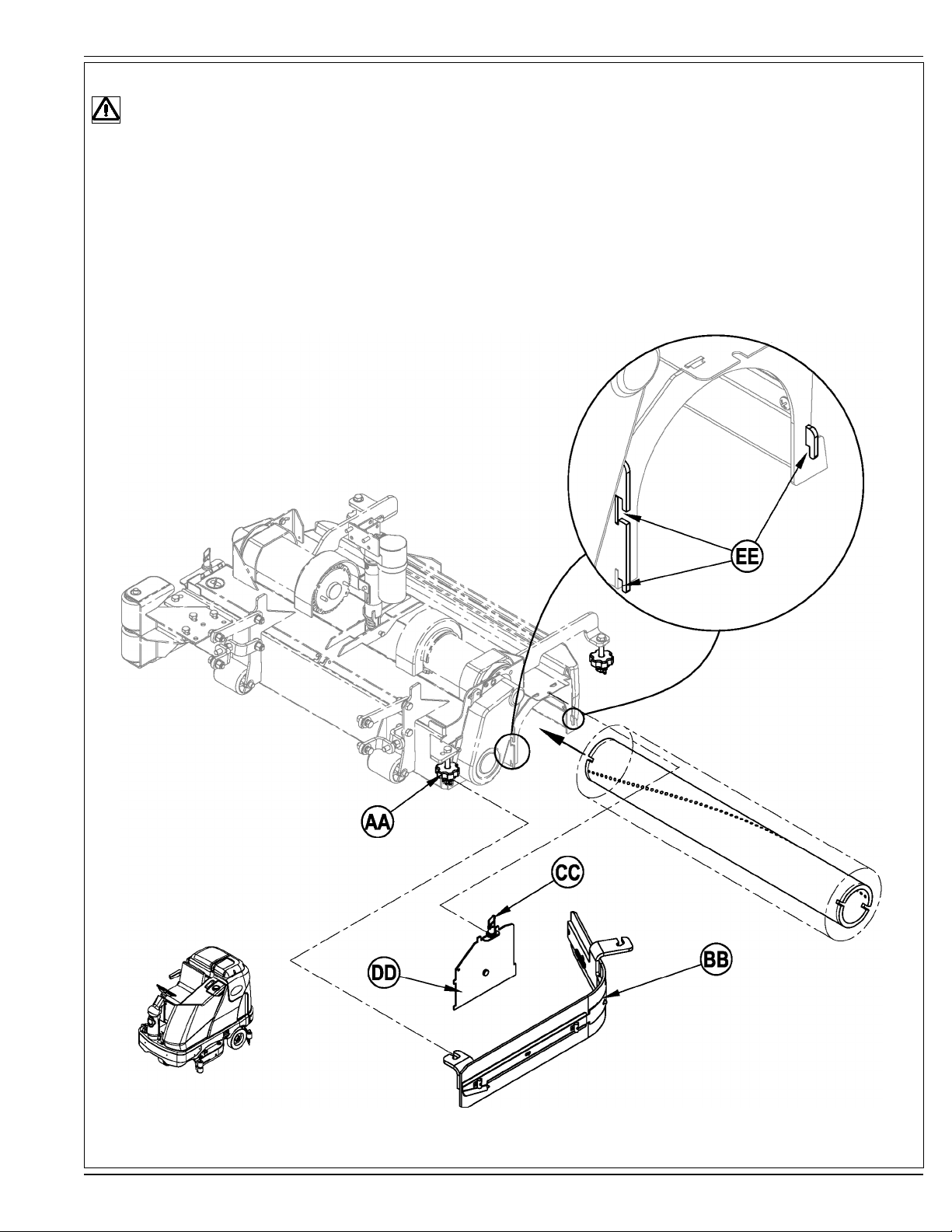

INSTALL THE BRUSHES (DISC SYSTEM)

CAUTION!

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck is in the RAISED position. Make sure the Key Switch (A) is off (O).

2 See Figure 2. Remove both side skirt assemblies. NOTE: The skirts are held in place by two large Knobs (AA). Loosen these knobs and slide the Skirt

Assemblies (BB) off of the Scrub Deck.

3 To mount the Brushes (CC) (or pad holders) align the Lugs (DD) on the brush with the holes on the mounting plate and turn to lock in place (turn the outside

edge of brush towards the front of machine as shown (EE)).

FIGURE 2

A-8 - FORM NO. 56041978 - BR1100S / BR1300S

Page 9

ENGLISH / A-9

INSTALL THE BRUSHES (CYLINDRICAL SYSTEM)

CAUTION!

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck is in the RAISED position. Make sure the Key Switch (A) is off (O).

2 See Figure 3. Remove both side skirt assemblies. NOTE: The skirts are held in place by two large Knobs (AA). Loosen these knobs, slide the Skirt

Assemblies (BB) forward slightly and then off of the Scrub Deck.

3 Loosen the Black Knobs (CC) on top of the Idler Assemblies (DD) until they drop down far enough to disengage from the Notches (EE) and remove.

4 Slide the brush into the housing, lift slightly, push and turn until it seats. Re-install the Idler Assemblies (DD) and Skirt Assemblies (BB).

FIGURE 3

FORM NO. 56041978 - BR1100S / BR1300S - A-9

Page 10

A-10 / ENGLISH

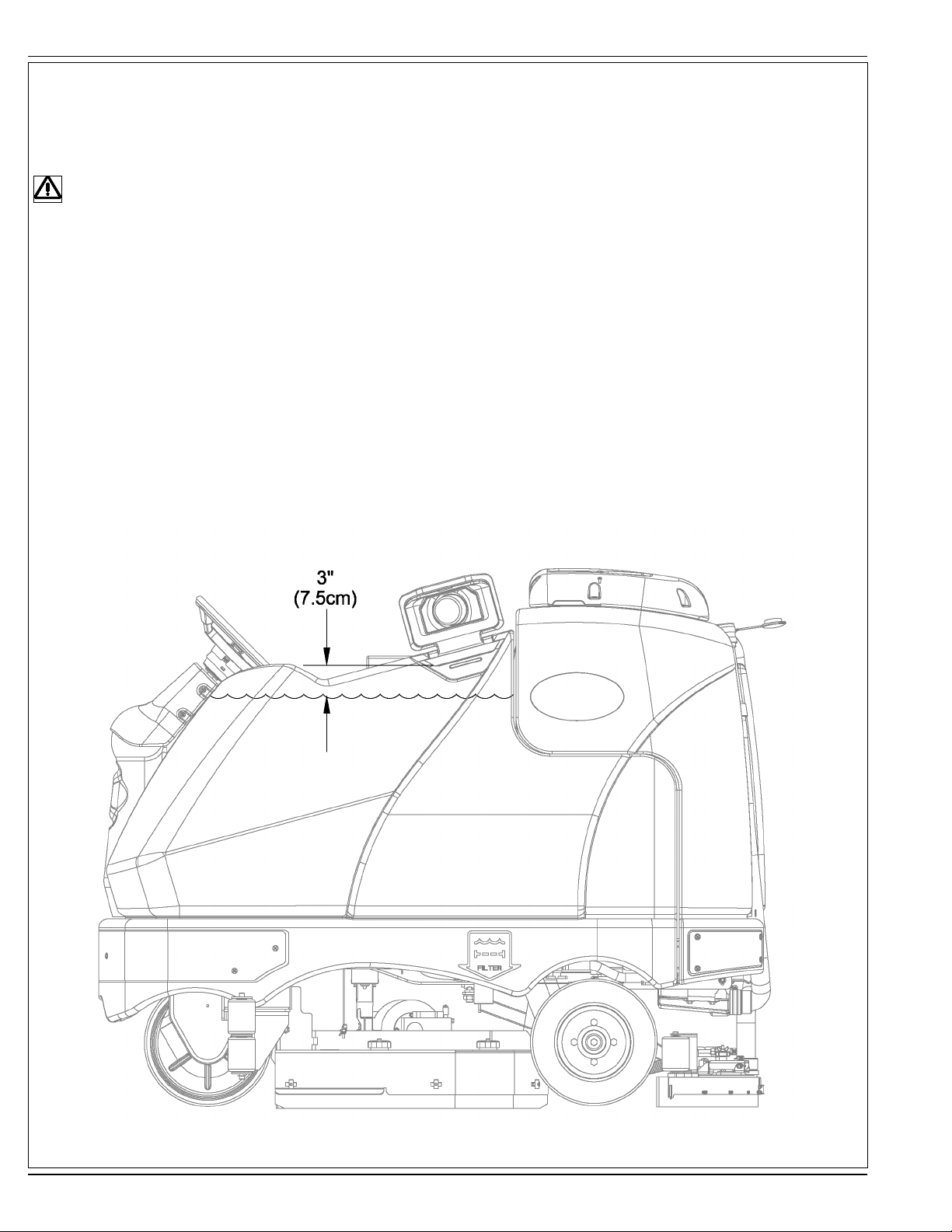

FILLING THE SOLUTION TANK

See Figure 4. Fill the solution tank with a maximum of 70 gallons (264 Liters) of cleaning solution. Do not fi ll the solution tank above 7.5 cm (3 inches) from the

bottom of the Solution Fill (2). The solution should be a mixture of water and the proper cleaning chemical for the job. Always follow the dilution instructions on the

chemical container label. NOTE:

system can be used. When using the detergent dispensing do not mix detergent in the tank, plain water should be used.

EcoFlex machines can either be used conventionally with detergent mixed in the tank or the detergent dispensing

CAUTION!

Use only low-foaming, non-fl ammable liquid detergents intended for machine application. Water temperature should not exceed 130

degrees fahrenheit (54.4 degrees celsius)

FIGURE 4

A-10 - FORM NO. 56041978 - BR1100S / BR1300S

Page 11

ENGLISH / A-11

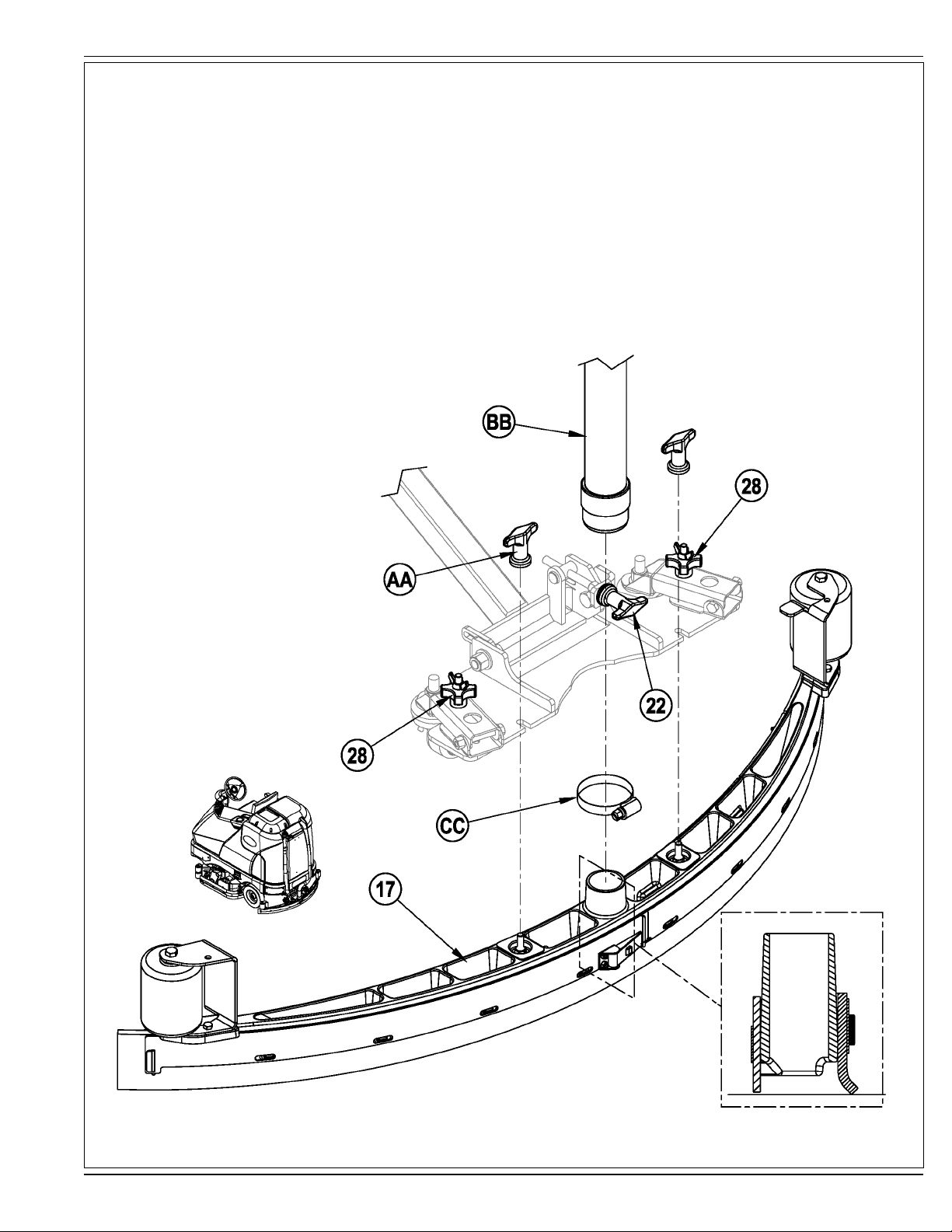

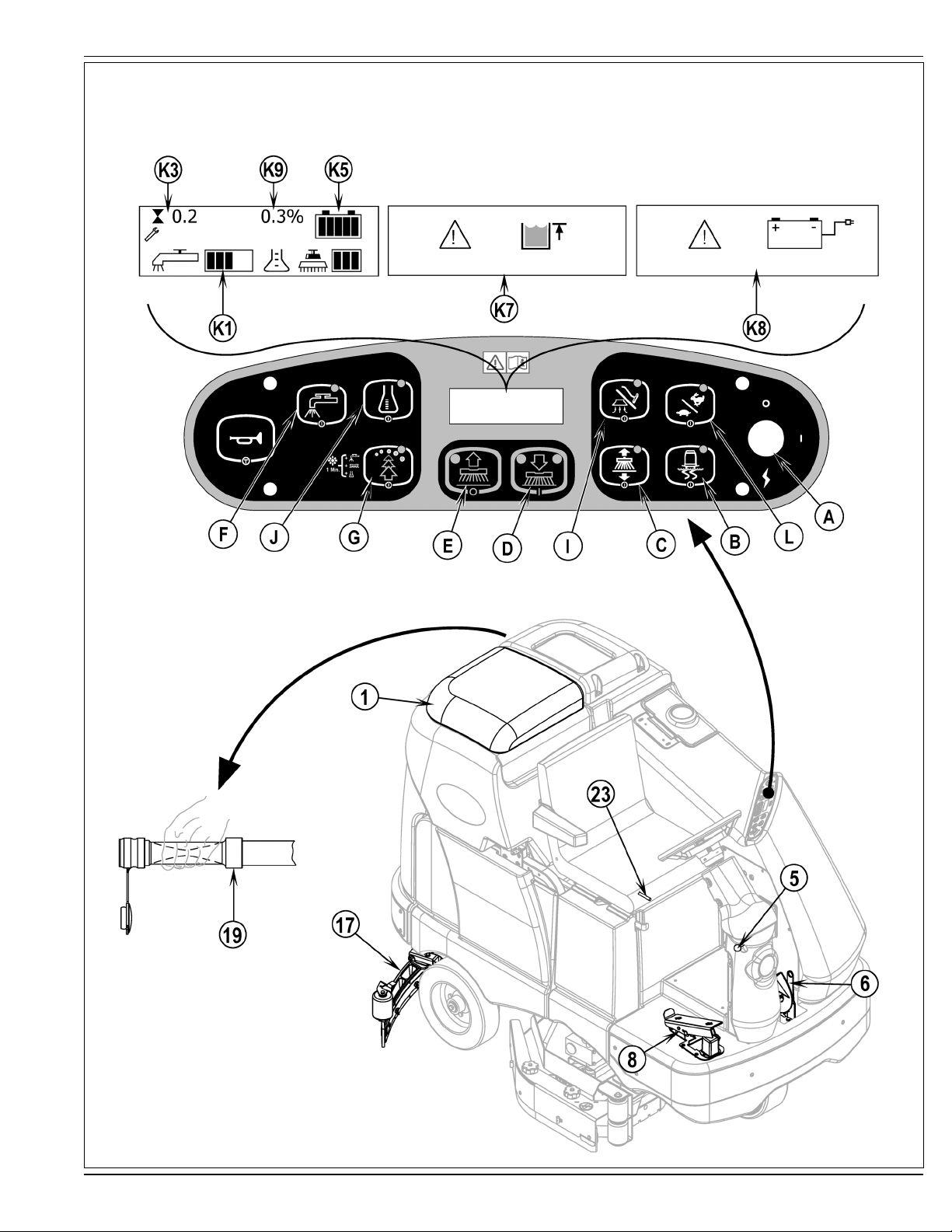

SQUEEGEE INSTALLATION

1 See Figure 5. Slide the Squeegee Assembly (17) onto the squeegee mount bracket and tighten the Squeegee Mount Thumb Nuts (AA).

2 Connect the Recovery Hose (BB) to the squeegee inlet using Hose Clamp (CC).

3 Lower the squeegee, move the machine ahead slightly and adjust the squeegee tilt and height using the Squeegee Tilt Adjust Knob (22) and Squeegee

Height Adjust Knobs (28) so that the rear squeegee blade touches the fl oor evenly across its entire width and is bent over slightly as shown in the squeegee

cross section.

FIGURE 5

FORM NO. 56041978 - BR1100S / BR1300S - A-11

Page 12

A-12 / ENGLISH

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

COMMON INSTRUCTIONS:

Pressing and releasing the Detergent Switch (J) while the solution system is active will cause the detergent system to alternately turn on and off. The system

should be purged of previous detergent when switching to a different detergent. SERVICE NOTE: Move machine over fl oor drain before purging because a small

amount of detergent will be dispensed in the process.

To Purge When Changing Chemicals:

1 Disconnect and remove the detergent cartridge.

2 Turn the Key Switch (A) ON. Press and hold the Solution Switch (F) and the Detergent Switch (J) down for 3 seconds. NOTE: Once activated the purge

process takes 10 seconds. See illustration on next page for Detergent System indicators. Normally one purge cycle is adequate to purge the system.

To Purge Weekly:

1 Disconnect and remove the detergent cartridge. Install and connect a Cartridge fi lled with clean water.

2 Turn the Key Switch (A) ON. Press and hold Solution Switch (F) and the Detergent Switch (J) down for 3 seconds. NOTE: Once activated the purge

process takes 10 seconds. See illustration on next page for Detergent System indicators. Normally one purge cycle is adequate to purge the system.

Detergent Percentage:

1 The detergent percentage default is 0.25%. To change the percentage, the detergent system must be OFF, then press and hold the Detergent ON/OFF

Switch (J) for 2 seconds. The detergent indicator will fl ash and each press of the switch will cycle through the available percentages (3%, 2%, 1.5%, 1%,

0.8%, 0.66%, 0.5%, 0.4%, 0.3%., 0.25%). Once the desired percentage is displayed on the screen (K9), stop and it will lock in after 5 seconds.

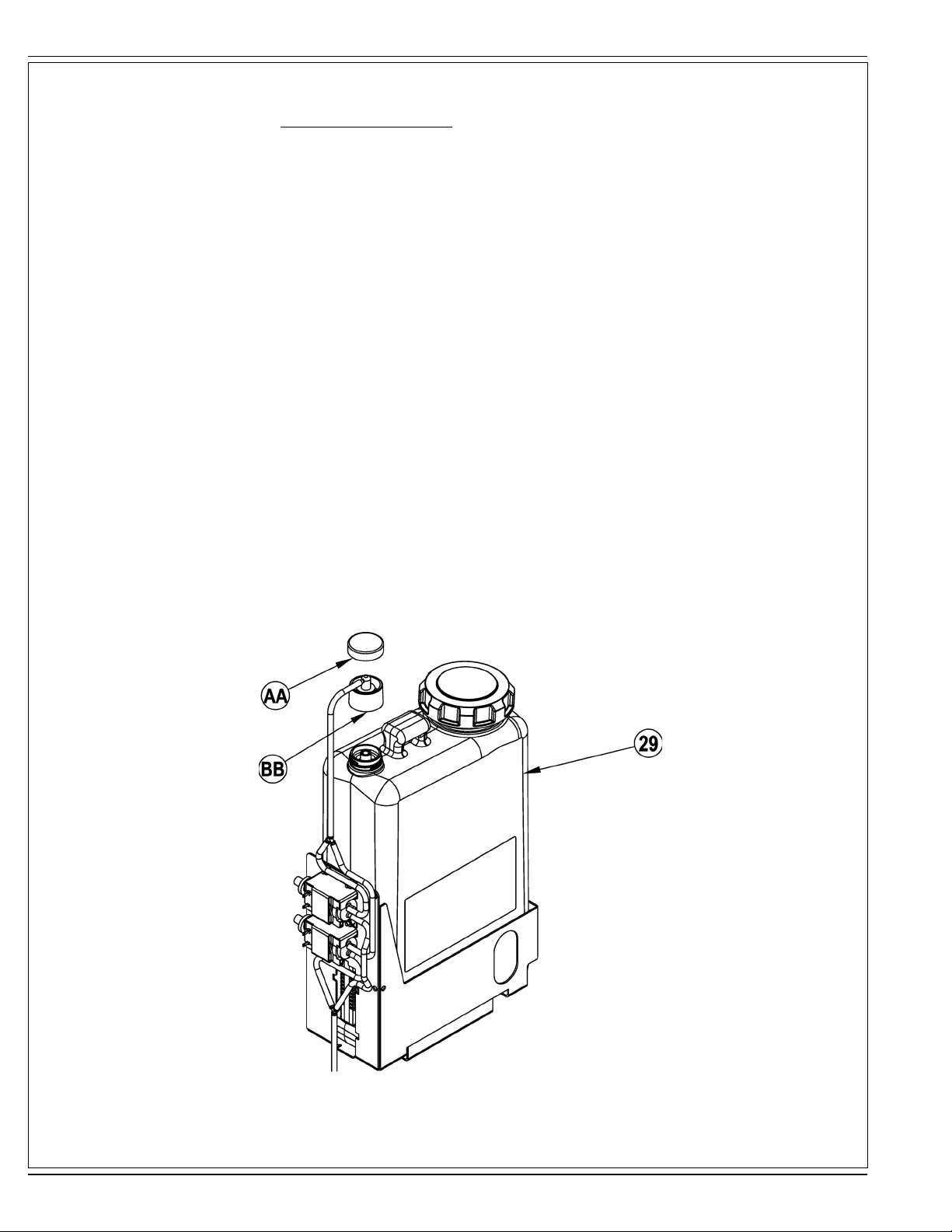

CARTRIDGE INSTRUCTIONS:

The Detergent Cartridge (29) is located behind the Side Access Panel (27). Fill the detergent cartridge with a maximum of 2.2 gallons (8.32 Liters) of detergent.

SERVICE NOTE: Remove the detergent cartridge from the detergent box prior to fi lling to avoid spilling detergent on the machine.

It is recommended that a separate cartridge be used for each detergent you plan to use. The detergent cartridges have a white decal on them so you can write the

detergent name on each cartridge to avoid mixing them up. The system should be purged of previous detergent when switching to a different detergent. When

installing a new cartridge, remove the Cap (AA) and place the cartridge in the detergent box. Install the Dry Break Cap (BB) and detergent hose as shown.

FIGURE 6

A-12 - FORM NO. 56041978 - BR1100S / BR1300S

Page 13

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

FIGURE 7

PURGE

Press (J) & (F) for 3 seconds

to purge.

ENGLISH / A-13

FORM NO. 56041978 - BR1100S / BR1300S - A-13

Page 14

A-14 / ENGLISH

OPERATING THE MACHINE

WARNING!

Be sure you understand the operator controls and their functions.

While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only while

ascending (driving up) the ramp.

To Scrub...

Follow the instructions in preparing the machine for use section of this manual.

1 See Figure 8. While seated on the machine, adjust the seat and steering wheel to a comfortable operating position using the adjustment controls (23) and (5).

2 Turn the Master Key Switch (A) ON (I). This will display the control panel indicator lights. Reference the Battery Condition Indicator (K5) and Hour Meter (K3) before proceeding.

3 Release the Parking Brake (6). To transport the machine to the work area, apply even pressure with your foot on the front of the Drive Pedal (8) to go forward or the rear of the

pedal for reverse. Vary the pressure on the foot pedal to obtain the desired speed.

4 Press the Solution Switch (F) and hold for 5 seconds to pre-wet the fl oor. NOTE: This will help prevent scarring of the fl oor surface when starting to scrub with dry brushes. This

must be done prior to pressing the Scrub ON Switch (D).

5 Press the Scrub ON Switch (D) once for Regular Scrub, twice for Heavy Scrub or three times for Extreme Scrub mode. Both the solution fl ow and detergent (EcoFlex models)

fl ow have 3 presets that coincide with the 3 scrub modes (see Control Panel).

NOTE: There is a solution fl ow rate override function if you wish to increase solution fl ow without increasing scrub pressure. Hold the Solution Switch (F) for 3 seconds (solution

indicator will start fl ashing) and then let go. You then have 3 seconds to set a different fl ow rate by simply pressing the Solution Switch (F) repeatedly until the Solution Flow

Indicator (K1) shows the rate you desire (1-5 / see Control Panel). Any subsequent scrub pressure adjustments will reset the solution fl ow rate to default.

NOTE: The scrub, solution, vacuum, detergent (EcoFlex models) and side broom (cylindrical models) systems are automatically enabled when the Scrub ON Switch (D) is

pressed. Any individual system can be turned OFF or back ON by simply pressing its switch at any time during scrubbing.

6 When the Scrub ON Switch (D) is selected, the brushes, squeegee and side brooms (cylindrical models) are automatically lowered to the fl oor. The scrub, solution, vacuum,

detergent (EcoFlex models) and side broom (cylindrical models) systems all start when the Drive Pedal (8) is activated.

NOTE: When operating the machine in reverse the squeegee automatically raises.

7 Begin scrubbing by driving the machine forward in a straight line at a normal walking speed and overlap each path by 2-3 inches (50-75 mm). Adjust the machine speed and

solution fl ow when necessary according to the condition of the fl oor.

NOTE: The maximum scrub speed can be increased by pressing the Scrub Speed Switch (L). The normal max scrub speed is 80% of transport speed. Pressing this switch

increases it to 100% of transport speed.

If scrubbing on a smooth fl oor surface or double-scrubbing turning on the Traction Control™ button (B) regulates the drive wheel torque providing increased control and

enhanced traction on the fl oor.

The side broom height can be adjusted. See the “Side Broom Maintenance” section of this manual.

CAUTION!

To avoid damaging the fl oor, keep the machine moving while the brushes are turning.

8 When scrubbing, check behind the machine occasionally to see that all of the waste water is being picked up. If there is water trailing the machine, you may be dispensing too

much solution, the recovery tank may be full, or the squeegee tool may require adjustment.

9 The machine defaults to the EcoFlex cleaning mode (EcoFlex Switch Indicator is lit) conserving solution and detergent. Press the EcoFlex Switch (G) to override the EcoFlex

cleaning mode and temporarily increase scrub pressure, solution fl ow and the detergent percentage. This will cause the indicator to fl ash for one minute, solution fl ow rate will

increase to the next level, scrub pressure will increase to the next level and the detergent percentage will increase to the next larger percentage.

10 For extremely dirty fl oors, a one-pass scrubbing operation may not be satisfactory and a “double-scrub” operation may be required. This operation is the same as a one-pass

scrubbing except on the fi rst pass the squeegee is in the up position (press the Vacuum/Wand Switch (I) to raise the squeegee). This allows the cleaning solution to remain on

the fl oor to work longer. The fi nal pass is made over the same area, with the squeegee lowered to pick up the accumulated solution.

11 The recovery tank has a shut-off fl oat (15) that causes ALL systems to turn OFF except the drive system when the recovery tank is full. When this fl oat is activated, the recovery

tank must be emptied. The machine will not pick up water or scrub with the fl oat activated.

NOTE: All other indicators vanish and a “Recovery Tank FULL” Indicator (K7) appears on the Display Panel when the fl oat is activated. If the control repeatedly gives a full

indication when the tank is not full, the automatic shut-off feature can be disabled, have a qualifi ed service technician refer to the service manual to perform this function.

12 When the operator wants to stop scrubbing or the recovery tank is full, press the Scrub OFF Switch (E) once. This will automatically stop the scrub brushes and solution fl ow and

the scrub deck will raise up. The squeegee will raise up after a brief delay and the vacuum will stop after a brief delay (this is to allow any remaining water to be picked up without

turning the vacuum back on).

13 Drive the machine to a designated waste water “DISPOSAL SITE” and empty the recovery tank. To empty, pull the Drain Hose (19) from its rear storage area, then remove the

plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). Refi ll the solution tank and continue scrubbing.

NOTE: Make sure the Recovery Tank Cover (1) and the Recovery Tank Drain Hose (19) cap are properly seated or the machine will not pick-up water correctly.

When the batteries require recharging the Battery LOW Indicator (K8) will come on, the scrub brushes and solution fl ow will stop and the scrub deck will raise up. The squeegee will

raise up after a brief delay and the vacuum will stop after a brief delay. Transport the machine to a service area and recharge the batteries according to the instructions in the Battery

section of this manual.

WET VACUUMING

Steps to follow in fi tting the machine with optional attachments for wet vacuuming.

1 Disconnect the recovery hose from the squeegee (17). Connect the coupler and hose from the wand kit to the recovery hose.

2 Attach suitable wet pick-up tools to the hose. (An optional Wand Kit PN56413687 is available from Nilfi sk).

3 Turn the Master Key Switch (A) ON and press the Vacuum/Wand Switch (I). The vacuum motor and the pump will run continuously until the switch is pressed again to turn it

OFF. NOTE: The “Recovery Tank FULL” indicator is disabled when the wand mode is activated. The fl oat will stop the fl ow into the recovery tank.

SERVICE NOTE: Refer to the service manual for detailed functional descriptions of all controls and optional programmability.

A-14 - FORM NO. 56041978 - BR1100S / BR1300S

Page 15

OPERATING THE MACHINE

FIGURE 8

ENGLISH / A-15

FORM NO. 56041978 - BR1100S / BR1300S - A-15

Page 16

A-16 / ENGLISH

AFTER USE

1 When fi nished scrubbing, press the Scrub Off Switch (E). This will automatically raise, retract and stop all the machine systems (brush, squeegee, vacuum,

solution and detergent (EcoFlex models)). Then drive the machine to a service area for daily maintenance and review of other needed service up keep.

2 To empty the solution tank, remove the Solution Drain Hose (4) from it’s storage clamp. Direct the hose to a designated “DISPOSAL SITE” and remove the

plug. Rinse the tank with clean water.

3 To empty the recovery tank, pull the Recovery Tank Drain Hose (19) from its storage area. Direct the hose to a designated “DISPOSAL SITE” and remove

the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). The Recovery Tank Drain Hose can

be squeezed to regulate the fl ow. Rinse the recovery tank with clean water. Inspect the recovery and vacuum hoses; replace if kinked or damaged.

4 Remove the brushes or pad holders. Rinse the brushes or pads in warm water and hang up to dry.

5 Remove the squeegee, rinse it with warm water and re-install on mount.

6 Remove the hopper on cylindrical systems and clean thoroughly. Remove from either side of the machine by removing the skirt and tilting the hopper up and

away from housing, then pull out.

7 Check the maintenance schedule below and perform any required maintenance before storage

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean Tanks & Hoses X

Check/Clean/Rotate the Brushes/Pads X

Check/Clean the Squeegee X

Check/Clean Vacuum Shut-Off Float X

Check/Clean the vacuum motor foam fi lter(s) X

Clean Hopper on Cylindrical System X

Check Each Battery Cell(s) Water Level X

Inspect Scrub Housing Skirts X

Inspect and clean Solution Filter X

Check Foot/ Parking Brake For Wear & Adjustment X

Clean Solution Trough on Cylindrical System X

Purge Detergent System (EcoFlex only) X

Side Broom Maintenance X

Lubrication - Grease Fittings X

* Check Carbon Brushes X

* Have Nilfi sk check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The brush and drive motor carbon brushes check every

500 hours or once a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

8 Store the machine indoors in a clean dry place. Keep from freezing. Leave the tanks open to air them out.

9 Turn the Master Key Switch (A) OFF (O) and remove the key.

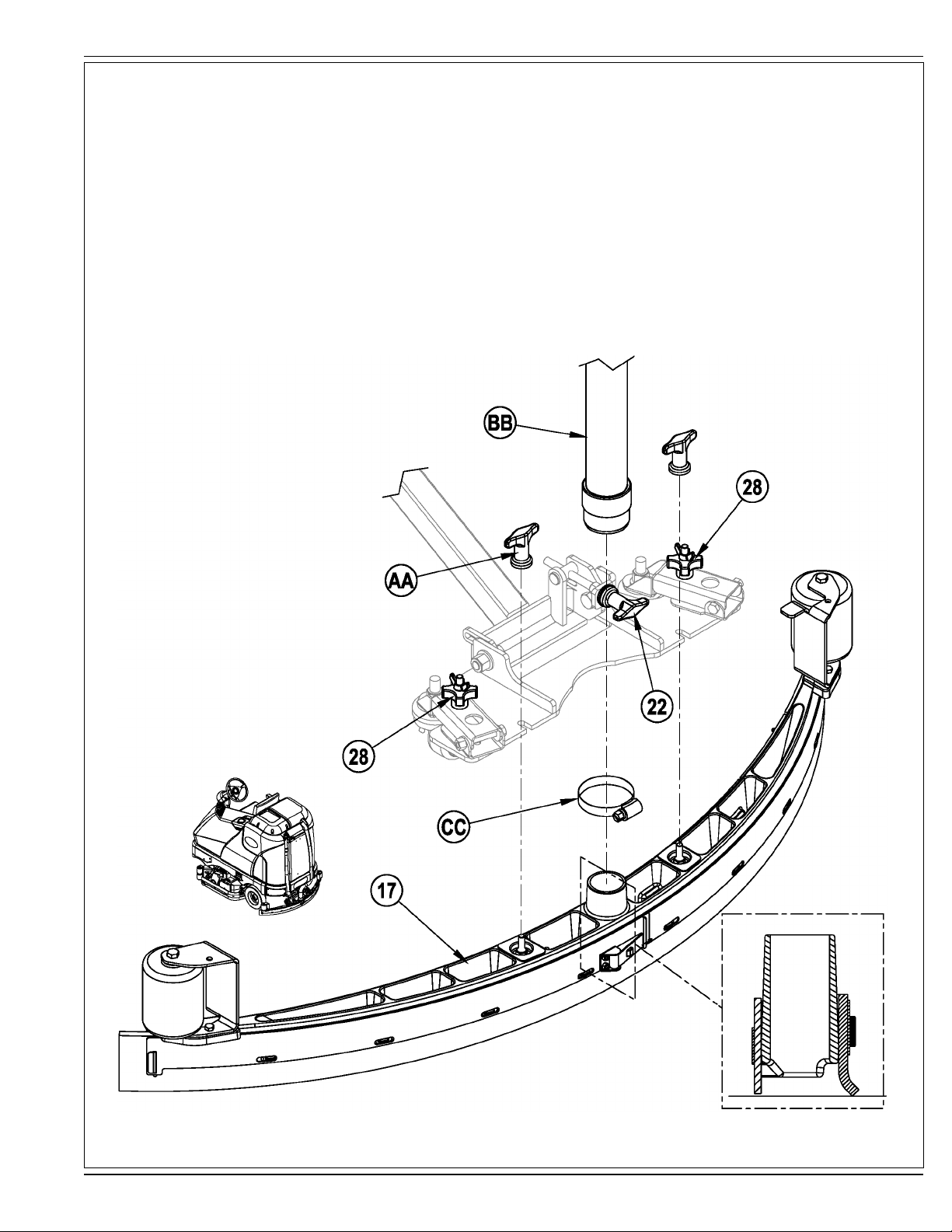

LUBRICATING THE MACHINE – FIGURE 9

Once a month, pump a small amount of grease into each grease fi tting on the machine until grease seeps out around the bearings.

Grease fi tting locations (or apply grease to) (AA):

• Squeegee Caster Wheel Axle and Pivot

• Steering Wheel Shaft Universal joint

• Steering Chain

• Squeegee mount angle adjustment knob threads

Once a month, apply light machine oil to lubricate the (BB):

• Squeegee tool end wheels

• Recovery Tank release latch

• Brake Pedal (parking brake) linkage

A-16 - FORM NO. 56041978 - BR1100S / BR1300S

Page 17

FIGURE 9

ENGLISH / A-17

FORM NO. 56041978 - BR1100S / BR1300S - A-17

Page 18

A-18 / ENGLISH

CHARGING THE BATTERIES

Charge the batteries each time the machine is used or when the Battery Indicator (K5) is reading less than full.

To Charge the Batteries...

1 See Figure 10. Depress the Battery Disconnect (11).

2 Open Side Access Panel (27) and push the connector from the charger into the Battery Connector (20).

3 Follow the instructions on the battery charger.

4 After charging the batteries check the fl uid level in all battery cells. Add distilled water, if necessary, to bring the fl uid level up to the bottom of the fi ller tubes.

WARNING!

Do not fi ll the batteries before charging.

Charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

To avoid damage to fl oor surfaces, wipe water and acid from the top of the batteries after charging.

CHECKING THE BATTERY WATER LEVEL

Check the water level of the batteries at least once a week.

After charging the batteries, remove

the vent caps and check the water

level in each battery cell. Use distilled

or demineralized water in a battery

fi lling dispenser (available at most auto

parts stores) to fi ll each cell to the level

indicator (or to 10 mm over the top of

the separators). DO NOT over-fi ll the

batteries!

CAUTION!

Acid can spill onto the fl oor if the

batteries are overfi lled.

Tighten the vent caps. Wash the tops

of the batteries with a solution of baking

soda and water (2 tablespoons of baking

soda to 1 liter of water).

FIGURE 10

A-18 - FORM NO. 56041978 - BR1100S / BR1300S

Page 19

ENGLISH / A-19

SQUEEGEE MAINTENANCE

If the squeegee leaves narrow streaks or water, the blades may be dirty or damaged. Remove the squeegee, rinse it under warm water and inspect the blades.

Reverse or replace the blades if they are cut, torn, wavy or worn.

To Reverse or Replace the Rear Squeegee Wiping Blade...

1 See Figure 11. Raise the squeegee tool off the fl oor, then unsnap the Center Latch (AA) on the squeegee tool.

2 Remove the Tension Straps (BB).

3 Slip the rear blade off the alignment pins.

4 The squeegee blade has 4 working edges as shown below. Turn the blade so a clean, undamaged edge faces toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

To Reverse or Replace the Front Squeegee Blade...

1 Raise the squeegee tool off the fl oor, then loosen the (2) Thumb Nuts (CC) on top of the squeegee and remove the squeegee tool from the mount.

2 Remove both rear Tension Straps fi rst.

3 Remove all the wing nuts that hold the front blade in place, then remove tension strap and blade.

4 The squeegee blade has 4 working edges as shown below. Turn the blade so a clean, undamaged edge faces toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

SQUEEGEE ADJUSTMENT

There are two squeegee tool adjustments possible, angle and height.

Adjusting the Squeegee Angle

Adjust the squeegee angle whenever a blade is reversed or replaced, or if the squeegee is not wiping the fl oor dry.

1 Park the machine on a fl at, even surface.

2 Lower the squeegee, move the machine ahead slightly and adjust the squeegee tilt and height using the Squeegee Tilt Adjust Knob (22) and Squeegee

Height Adjust Knobs (28) so that the rear squeegee blade touches the fl oor evenly across its entire width and is bent over slightly as shown in the squeegee

cross section.

FIGURE 11

FORM NO. 56041978 - BR1100S / BR1300S - A-19

Page 20

A-20 / ENGLISH

SIDE SKIRT MAINTENANCE

The side skirt’s function is to channel the waste water to the squeegee, helping contain the water within the machines cleaning path. During normal use the blades

will wear in time. The operator will notice a small amount of water leaking out underneath the side skirts. A height adjustment can easily be made to lower the

blades so that all the water can be pick-up by the squeegee.

To reverse or replace the scrub system side skirt(s) ...

1 See Figure 12. Loosen the (2) side skirt Retainer Knobs (AA) (2 per side) and remove the Skirt Assemblies (BB) from the scrub deck. NOTE: Remove the

skirts by fi rst sliding them forward and then pulling them off.

2 Remove all the hardware that holds the blades to the skirt housings. NOTE: The main blade on each skirt housing is held on with Tool-less Retainers. Simply

loosen the large Wing nuts (CC) and then turn the Knobs (DD) on the outside of the skirt housing until they are horizontal and push through the slots. The

small inside Blade (EE) on disk models is held on by (2) screws and nuts and has 2 working edges.

3 The main skirt blade has 4 working edges as shown. Turn the blade so a clean, undamaged edge faces toward the center of the machine. Replace the

blades as a set if all 4 edges are nicked, torn or worn beyond their ability to be adjusted.

4 Reinstall the skirt housing assemblies onto the machine and adjust the blade for proper contact to the fl oor when the brush deck is placed in the scrub

position.

SIDE SKIRT HEIGHT ADJUSTMENT

1 The side skirt housing knob retainer screw studs have leveling Adjuster Collars (FF) that can be raised or lowered to compensate for blade wear.

2 To adjust, remove the Skirt Assemblies (BB) from the scrub deck to access the Adjuster Collars (FF). Adjustment Tip: The skirts Retainer Knobs (AA) can be

loosened with skirts left on and the Adjuster Collars (FF) rotated by reaching under the skirt housing.

3 Turn the Adjuster Collars (FF) (Up or Down) to where the blades just fold over enough when scrubbing that all the waste water is contained inside the skirting.

NOTE: Make small adjustments to obtain good blade wiping. Do not lower the blades too much to where they fold over excessively and cause unneeded

blade wear.

A-20 - FORM NO. 56041978 - BR1100S / BR1300S

Page 21

ENGLISH / A-21

SIDE SKIRT MAINTENANCE

DISK CYLINDRICAL

FIGURE 12

FORM NO. 56041978 - BR1100S / BR1300S - A-21

Page 22

A-22 / ENGLISH

SIDE BROOM MAINTENANCE

The side broom(s) move dirt and debris away from walls or curbs and into the path of the main broom. Adjust the side broom so that the bristles are contacting the

fl oor from the 10 O’clock (AA) to the 3 O’clock (BB) area shown in Figure 13 when the broom is down and running.

The side brooms are adjusted through the adjust mode. To enter the “Adjust Mode” perform the following steps...

1 Turn the Key Switch (A) to the OFF position (O).

2 Press and hold the Side Broom Switch (C) and the Scrub Off Switch (E).

3 While holding the switches (C & E), turn the key switch to the ON position (I).

4 Continue to hold the switches for 2 seconds until side broom, scrub off and scrub on LED’s turn on.

5 Release the switches. The Display (K) will now show “SIDE BROOM ADJUSTMENT”.

Once inside of the “Adjust Mode” perform the following steps to adjust the side broom...

1 Press Scrub On Switch (D) to lower the side brooms and press the Side Broom Switch (C) to raise the side brooms until the desired height is reached.

2 To save the side broom height position, press the Scrub Off Switch (E). The side brooms will raise to the up position and the display will show a key icon

(indicating that the key switch should be cycled off and on).

3 The machine has now been reprogrammed to use the new side broom height position.

NOTE: The machine should be stored with the Side Brooms in the raised position. The Side Brooms should be replaced when the bristles are worn to a length of

3 inches (7.62 cm) or they become ineffective.

To replace the Side Broom...

1 Raise the Side Broom(s).

2 Remove the large Pin (CC) holding the side broom on and remove the broom.

3 Install the new broom by sliding it UP onto the shaft and re-installing the Pin (CC).

FIGURE 13

A-22 - FORM NO. 56041978 - BR1100S / BR1300S

Page 23

GENERAL MACHINE TROUBLESHOOTING

Problem Possible Cause Remedy

Poor water pick-up Worn or torn squeegee blades Reverse or replace

Squeegee out of adjustment Adjust so blades touch fl oor evenly

across entire width

Recovery tank full Empty recovery tank

Recovery tank drain hose leak Secure drain hose cap or replace

Recovery tank cover gasket leak Replace gasket / Seat cover properly

Debris caught in squeegee Clean squeegee tool

Vacuum hose clogged Remove debris

Using too much solution Reduce fl ow via control panel solution button

Foam fi lter cover not seated Seat cover properly

Poor scrubbing performance Worn brush or pad Rotate or replace brushes

Wrong brush or pad type Consult Nilfi sk

Wrong cleaning chemical Consult Nilfi sk

Moving machine too fast Slow down

Not using enough solution Increase fl ow via control panel solution button

Scrub Motors Do Not Run Tripped 20 Amp (F3) circuit breaker Check for electrical short circuit & reset

ENGLISH / A-23

Inadequate solution fl ow

or no solution

Machine does not run Emergency stop switch tripped Reconnect battery connectors

No FWD/REV wheel drive Drive system speed contoller Check error fault codes

Vacuum shuts off and display shows

“FULL” when recovery tank is not full

Poor Sweeping Performance

(Cylindrical System)

No Detergent Flow (EcoFlex models

only)

Solution tank empty Fill solution tank

Solution lines, valves, fi lter or trough clogged Flush lines, trough and clean solution fi lter

Solution turned OFF Activate fl ow via control panel solution button

Solution solenoid valve plugged or defective

Operator seat safety switch Check for open circuit and replace

Main system controller Check error fault codes

Tripped 3 Amp (F1) circuit breaker Check for electrical short circuit & reset

Emergency stop switch tripped Reconnect battery connectors

Plugged squeegee hose Clear debris

Vacuuming large amounts of water

at a high travel speed

Hopper Full Empty and clean hopper

Brushes worn Replace brushes

Bristles have taken a set Rotate brushes

Empty detergent cartridge Fill detergent cartridge

Plugged or kinked detergent fl ow line Purge system, straighten lines to

Dry seal cap on detergent cartridge not sealed Reseat dry seal cap

Detergent pump wiring

disconnected or backwards

Clean or replace valve (see service manual)

(see service manual)

(see service manual)

Slow down or disable auto shut-off feature

(see service manual)

remove any kinks

Connect or reconnect wiring

FORM NO. 56041978 - BR1100S / BR1300S - A-23

Page 24

A-24 / ENGLISH

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model BR1100S C BR1300S C

BR1100S BR1300S

Model No. 56413007 56413011

56413006 56413010

Voltage, Batteries V 36V 36V

Battery Capacity Ah 480 480

Protection Grade IPX3 IPX3

Sound Pressure Level (ISO 11201) 76dB LpA, 3dB KpA 76dB LpA, 3dB KpA

Sound Pressure Level (ISO 11201) 72dB LpA, 3dB KpA 72dB LpA, 3dB KpA

Gross Weight lbs / kg 3325 / 1508 3410 / 1547

Transportation Weight lbs / kg 2897 / 1314 2982 / 1353

Gross Weight lbs / kg 3220 / 1460 3320 / 1506

Transportation Weight lbs / kg 2792 / 1266 2892 / 1312

Maximum Wheel Floor Loading (center front) psi / kg/cm

Maximum Wheel Floor Loading (right rear) psi / kg/cm

Maximum Wheel Floor Loading (left rear) psi / kg/cm

Vibrations at the Hand Controls (ISO 5349-1) m/s

Vibrations at the Hand Controls (ISO 5349-1) Uncertainty m/s

Vibrations at the Seat (EN 1032) m/s

Vibrations at the Seat (EN 1032) Uncertainty m/s

Gradeability

Transport 16% (9°) 16% (9°)

Cleaning 10.5% (6°) 10.5% (6°)

2

2

2

2

2

2

2

116/ 119.9 116/ 119.9

81 / 83.7 81 / 83.7

86 / 88.9 86 / 88.9

2

<1.12m/s

.11 m/s

<0.35m/s

0.035m/s

2

2

2

<1.12m/s

.11 m/s

<0.35m/s

0.035m/s

2

2

2

2

A-24 - FORM NO. 56041978 - BR1100S / BR1300S

revised 6/11

Page 25

Page 26

B-2 / TÜRKÇE

İÇİNDEKİLER

sayfa

Giriş ...................................................................................................... B-2

Önlemler ve Uyarılar ............................................................................. B-3

Makinenizi Tanıyın .......................................................................B-4 – B-5

Kontrol Paneli .......................................................................................B-6

Makinenin Kullanıma Hazırlanması

Bataryaların Takılması .......................................................................... B-7

Fırçaların Takılması .....................................................................B-8 – B-9

Çözelti Deposunun Doldurulması ....................................................... B-10

Lastik Sileceğin Takılması .................................................................. B-11

Deterjan Sistemi ......................................................................B-12 – B-13

Makinenin Çalıştırılması ..........................................................B-14 – B-15

Fırçalama .................................................................................B-14 – B-15

Islak Vakumlama ................................................................................B-15

Kullanım Sonrası ................................................................................ B-16

Bakım Çizelgesi .................................................................................. B-16

Makinenin Yağlanması ............................................................B-16 – B-17

Bataryaların Şarj Edilmesi ..................................................................B-18

Batarya Su Seviyesinin Kontrol Edilmesi ............................................ B-18

Lastik Silecek Bakımı ......................................................................... B-19

Lastik Silecek Ayarı ............................................................................B-19

Yan Etekliğin Bakımı ................................................................B-20 – B-21

Yan Süpürgenin Bakımı ...................................................................... B-22

Sorun Giderme ...................................................................................B-23

Teknik Özellikler .................................................................................. B-24

GIRIŞ

Bu kılavuz, Nilfi sk Temizlik Arabasından en iyi verimi almanızda size yardımcı olacaktır. Makineyi çalıştırmadan önce kılavuzu baştan sona okuyunuz.

Not: Parantez içinde verilen koyu numaralar, B-4- B-6 arası sayfalarda gösterilen bir bileşeni belirtmektedir.

Bu ürün sadece ticari amaçlı kullanıma yöneliktir.

YEDEK PARÇA VE SERVİS

Gerekli hallerde onarım işlemleri, fabrikada eğitilmiş servis personeli istihdam eden ve Nilfi sk orijinal yedek parçaları ve aksesuarlarını kullanan Yetkili Nilfi sk Servis

Merkeziniz tarafından gerçekleştirilmelidir.

Yedek parça veya servis ihtiyaçlarınız için aşağıda adı verilen NILFISK YETKİLİ SATICISINI arayınız. Makinenizle ilgili işlem yaptırmak için Modelini ve Seri

Numarasını belirtiniz.

DEĞİŞİKLİKLER

Temizlik makinesinde, kapasiteyi ve güvenli çalıştırmayı etkileyen değişiklikler ve eklemeler, Nilfi sk-Advance Inc. şirketinden önceden yazılı onay almaksızın

müşteri veya kullanıcı tarafından gerçekleştirilemez. İzinsiz değişiklikler makine garantisini geçersiz kılar ve ortaya çıkan kazalardan müşteri sorumlu olur.

TANITMA LEVHASI

Makinenizin Model Numarası ve Seri Numarası, makine üzerinde bulunan Tanıtma Levhasında gösterilir. Bu bilgiler, makinenin onarım parçalarını sipariş ederken

gereklidir. Gelecekte gerektiğinde kullanmak üzere makinenizin Model Numarası ve Seri Numarasını yazmak için aşağıdaki boş alanları kullanınız.

MODEL NUMARASI _____________________________________________________

SERİ NUMARASI _______________________________________________________

MAKINENIN PAKETTEN ÇIKARILMASI

Makineyi teslim aldığınızda, hasar olup olmadığını kontrol etmek için nakliye kartonunu ve makineyi dikkatlice inceleyiniz. Hasar belirgin ise, denetlenmesi için

nakliye kartonunu saklayınız. Tespit edilen navlun hasarını bildirmek üzere derhal Nilfi sk Müşteri Hizmetleri Departmanı ile irtibata geçiniz.

Kartonu çıkardıktan sonra, plastik şeritleri kesiniz ve tekerleklerin yanındaki tahta blokları çıkarınız. Makineyi paletten zemine indirmek için bir rampa kullanınız.

B-2 - FORM NO. 56041978 - BR1100S / BR1300S

revised 6/11

Page 27

TÜRKÇE / B-3

ÖNLEMLER VE UYARILAR

SIMGELER

Nilfi sk, potansiyel olarak tehlikeli koşulları işaret etmek üzere aşağıdaki simgeleri kullanmaktadır. Her zaman bu bilgileri dikkatlice

okuyunuz ve can ve mal güvenliğini korumak için gerekli önlemleri alınız.

TEHLİKE!

Bu simge, ağır kişisel yaralanma veya ölüme sebep olacak ani tehlikelere karşı uyarı amacıyla kullanılır.

UYARI!

Bu simge, ağır kişisel yaralanmaya sebep olabilecek bir duruma dikkat çekmek üzere kullanılır.

DİKKAT!

Bu simge, hafi f kişisel yaralanma veya makine ya da başka mülkte zarara sebep olabilecek bir duruma dikkat çekmek üzere kullanılır.

Kullanmadan önce bütün talimatları dikkatlice okuyunuz.

GENEL GÜVENLİK TALİMATLARI

Özel Önlemler ve Uyarılar, makine hasarı veya fi ziksel yaralanmadan kaynaklanan potansiyel tehlikelere karşı uyarı amacıyla

verilmektedir.

UYARI!

• Bu makine sadece uygun eğitim almış ve yetkili kişilerce kullanılır.

• Rampa üzerinde ve eğimli yerlerde, yüklü olduğunda ani durma hareketinden kaçının. Ani ve keskin dönüşlerden kaçının.

Düşük hızda gidilebilecek yokuş aşağı yerleri kullanın. Sadece rampadan tırmanırken (yukarıya doğru giderken) temizleyin.

• Kıvılcım, alev ve sigara gibi maddeleri bataryalardan uzak tutun. Patlayıcı gazlar normal kullanım sırasında boşaltılmaktadır.

• Bataryaların şarj edilmesi son derece patlayıcı hidrojen gazı üretmektedir. Bataryaları sadece açık alevlerden uzak iyi

havalandırılmış yerlerde şarj edin. Bataryaları şarj ederken sigara içmeyin.

• Elektrikli parçaların yakınında çalışırken üzerinizdeki her türlü takıları çıkarın.

• Elektrikli parçaları çıkarmadan önce kontak anahtarını kapatın (O) ve bataryaların bağlantısını kesin.

• Makineyi destekleyen emniyet blokları veya sehpaları olmadan makine altında asla çalışmayın.

• Yanıcı temizlik maddelerini etrafa yaymayın, makineyi bu maddeler üzerinde veya yakınında ya da yanıcı sıvıların bulunduğu

alanlarda çalıştırmayın.

• Bu makineyi basınçlı yıkayıcı ile temizlemeyin.

• Sadece aygıtla birlikte verilen ya da kullanma kılavuzunda belirtilen fırçaları kullanın. Başka fırçaların kullanılması emniyet

tehlikesi yaratabilir.

DİKKAT!

• Bu makine kamu yolları veya caddelerinde kullanım için onaylı değildir.

• Bu makine zararlı tozları toplamak için uygun değildir.

• Kazıyıcı diskler ve bileği taşları kullanmayın. Nilfi sk, kazıyıcılar veya bileği taşları (fırça tahrik sistemine de hasar verebilir)

nedeniyle zemin yüzeylerine gelen zarardan sorumlu tutulamaz.

• Bu makineyi kullanırken, özellikle çocuklar olmak üzere üçüncü tarafl arın tehlikeye girmemesine dikkat edin.

• Herhangi bir servis işlevini yerine getirmeden önce, söz konusu işleve ait tüm talimatları dikkatlice okuyun.

• İlk önce kontak anahtarını kapatmadan (O), anahtarı çıkarmadan ve el frenini çekmeden makinenin yanından ayrılmayın.

• Fırçaları değiştirmeden ve herhangi bir erişim panelini açmadan önce kontak anahtarını kapatın (O) ve anahtarı çıkarın.

• Saç, takı veya bol giysilerin hareketleri parçalara takılmasını engellemek için önlem alın.

• Bu makineyi donma sıcaklığının altındaki koşullarda çalıştırırken dikkatli olun. Çözelti, geri alma veya deterjan depolarında ya da tevzi

hortumlarında bulunan su donarak valfl ara ve bağlantı parçalarına zarar verebilir. Otomobil cam yıkama sıvısı ile yıkayın.

• Makine hurdaya çıkarılmadan önce makineden bataryalar çıkarılmalıdır. Bataryaların imha işlemi, yerel çevre düzenlemelerine

uygun olarak güvenli bir şekilde yapılmalıdır.

• Eğim oranı makine üzerinde belirtilenden yüksek olan yüzeylerde kullanmayın.

• Bütün kapılar ve kapaklar makinenin kullanımından önce kılavuzda belirtilen şekilde yerleştirilmelidir.

BU TALİMATLARI SAKLAYIN

FORM NO. 56041978 - BR1100S / BR1300S - B-3

Page 28

B-4 / TÜRKÇE

MAKINENIZI TANIYIN

Bu kılavuzu okurken, parantez içinde koyu harfl e yazılmış bir numara veya harf göreceksiniz- örnek: (2). Bu numaralar, aksi belirtilmedikçe, bu sayfalarda

gösterilen bir bileşene atıf yapmaktadır. Metinde bahsedilen bir bileşenin yerini tam olarak belirlemek için gerekli olduğunda bu sayfalara bakınız. NOT: Takip

eden 4 sayfada gösterilen her bir bileşene ait ayrıntılı açıklamalar için servis el kitabına bakınız.

1 Geri Alma Deposu Kapağı

2 Çözelti Deposu Doldurma Kapağı

3 Sürücü Koltuğu

4 Çözelti Deposu Akıtma Hortumu

5 Direksiyon Eğimi Ayar Düğmesi

6 Fren Pedalı / El Freni

7 Çözelti Kapama Valfı

8 Sürme Pedalı, Yönsel/Hız

9 Huni (sadece silindir modellerde)

10 Sürme ve Yönlendirme Tekerleği

11 Acil Durdurma Anahtarı / Batarya Bağlantısı Kesme

12 Fırçalama Güvertesi

13 Arka Tekerlek

14 Batarya Bölmesi (geri alma deposu altında)

14

20

1

2

21

3

23

24

25

26

6

13

27

29

12

B-4 - FORM NO. 56041978 - BR1100S / BR1300S

11

5

30

10

8

revised 6/11

Page 29

MAKINENIZI TANIYIN

15 Geri Alma Deposu Kesme Şamandırası

16 Vakum Motoru Filtre Karteri

17 Lastik Silecek Tertibatı

18 Çözelti Filtresi

19 Geri Alma Deposu Akıtma Hortumu

20 Makine Batarya Konektörü

21 Kontrol Paneli

22 Lastik Silecek Eğim Ayar Düğmesi

23 Operatör Koltuğu Ayarlama Kolu

24 Kontrol Devresi Kesicisi

25 Yardımcı Devre Kesicisi

26 Yan Süpürge Motoru Devre Kesicisi

27 Yan Erişim Paneli

28 Lastik Silecek Yükseklik Ayar Düğmesi

29 Deterjan Kartuşu (sadece EcoFlex modelleri)

30 Bağlama yerleri

TÜRKÇE / B-5

30

16

15

19

revised 6/11

28

22

9

18

7

4

28

17

FORM NO. 56041978 - BR1100S / BR1300S - B-5

Page 30

B-6 / TÜRKÇE

KONTROL PANELI

A Kontak Anahtarı

B Çekiş Kontrol Anahtarı

C Yan Süpürge Anahtarı (sadece silindir modellerde)

D Fırçalama AÇIK / Fırçalama Modu Seçimi

E Fırçalama KAPALI

F Çözelti Anahtarı

G EcoFlex Anahtarı

H Korna

I Vakum/Çubuk Anahtarı

J Deterjan Sistemi (sadece EcoFlex modellerinde)

K Ekran

K1 Çözelti Akım Göstergesi

K2 Hata Göstergesi

K3 Saat Ölçer

K4 Deterjan Sistemi Göstergesi

K5 Batarya Göstergesi

K6 Ovma Basıncı Göstergesi

K7 Geri Alma Deposu DOLU Göstergesi

K8 Batarya Zayıf Göstergesi

K9 Deterjan Yüzdesi Göstergesi

L Ovma Hızı Anahtarı

K8

K7

K

!

!

K1

F

K2

K3

0.2

Akış Akış Akış Normal Sert Çok Sert

Oranı 1 Oranı 2 Oranı 3 Ovma Ovma Ovma

(normal ovma) (sert ovma) (çok sert ovma) (1 kez basın) (2 kez basın) (3 kez basın)

K4 K5

K9

0.3%

K

K

J

I

L

K6

H

G

B-6 - FORM NO. 56041978 - BR1100S / BR1300S

E

D

C

B

A

Page 31

TÜRKÇE / B-7

BATARYALARIN TAKILMASI

UYARI!

Bataryalarla ilgili işlem yaparken son derece dikkatli olunuz. Bataryalar içindeki sülfürik asit, deri veya gözlerle temas etmesi halinde

ağır yaralanmaya yol açabilir. Patlayıcı hidrojen gazı, batarya kapsüllerinde bulunan açıklıklar yoluyla dışarıya boşaltılmaktadır. Bu

gaz, herhangi bir elektrik arkı, kıvılcım veya alev yoluyla tutuşabilir. Herhangi bir kurşun asitli bataryayı, mühürlü konteyner veya

mahfaza içine takmayınız. Aşırı şarjdan kaynaklanan hidrojen gazının çıkışına izin verilmelidir.

Bataryaların Bakım İşlemleri...

• Bütün takılarınızı çıkarın

• Sigara içmeyin

• Emniyet gözlükleri, lastik eldivenler ve bir lastik önlük takın.

• İyi havalandırılmış alanda çalışın.

• Aletlerin aynı anda birden fazla batarya kutup başına temas etmesine izin vermeyin

• Bataryaları değiştirirken kıvılcım çıkmasını önlemek için HER ZAMAN negatif (toprak) kabloyu önce sökün.

• Bataryaları takarken HER ZAMAN negatif kabloyu en son bağlayın.

DİKKAT!

Bataryaların uygun şekilde takılmaması ve bağlanmaması halinde bu makinedeki elektrikli bileşenler ağır biçimde hasar görebilir.

Bataryalar Nilfi sk veya bir kalifi ye elektrikçi tarafından takılmalıdır.

1 Bataryaları sevkıyat sandığından çıkarın ve herhangi bir çatlak veya başka hasar olup olmadığını dikkatlice kontrol edin. Belirgin bir hasar varsa, hasarı

bildirmek için teslimatı yapan nakliye şirketi veya batarya imalatçısı ile irtibata geçin.

2 Ana Kontak Anahtarını (A) KAPALI konuma getirin ve anahtarı çıkarın.

3 Geri alma deposunu makineden ayırın. NOT: Bağlantı teli ve vakum motoru kablolamasının bağlantısını kesin ve depoyu yukarıya kaldırarak makineden

uzaklaştırın.

4 Makineniz fabrikadan altı adet 6 voltluk batarya monte edilecek şekilde yeterli batarya kablosu ile birlikte gelmektedir. En az (2) kişi ve uygun bir kaldırma

bandı kullanarak, bataryaları dikkatlice batarya bölmesine doğru kaldırın ve ŞEK

makinenin ön tarafına yakın olacak şekilde monte edin. Mono-blok batarya takacaksanız, bir üstten kaldırma aleti kullanın.

5 Batarya kablolarını gösterildiği şekilde takın. Kabloları batarya kapsüllerinin bakım için kolayca çıkarılabileceği şekilde yerleştirin.

6 Her bir batarya kutup başındaki somunu kutup başı dönmez duruma gelene kadar dikkatlice sıkın. Kutup başlarını aşırı sıkmayın, aksi halde gelecekte

bakım amacıyla çıkarılması çok zor olacaktır.

7 Kutup başlarını, üzerine püskürtmeli batarya kutup başı kaplaması ile kaplayın (çoğu oto parça mağazasında mevcuttur).

8 Her bir kutup başının üzerine siyah kauçuk pabuçlardan koyun ve Batarya Takımı Konektörünü (20) bağlayın.

İL 1’de gösterildiği şekilde düzenleyin. Bataryaları mümkün olduğunca

ŞEKIL 1

FORM NO. 56041978 - BR1100S / BR1300S - B-7

Page 32

B-8 / TÜRKÇE

FIRÇALARIN TAKILMASI (DISK SISTEMI)

DİKKAT!

Fırçaları değiştirmeden ve herhangi bir erişim panelini açmadan önce kontak anahtarını kapatın (O) ve anahtarı çıkarın.

1 Fırçalama Güvertesinin KALKIK konumda olmasına dikkat edin. Kontak Anahtarının (A) kapalı (O) konumda olduğundan emin olun.

2 Bkz. Şekil 2. Her iki taraftaki eteklik tertibatını çıkarın. NOT: Eteklikleri yerinde tutan iki büyük Düğme (AA) vardır. Bu düğmeleri gevşetin ve Eteklik

Tertibatlarını (BB) Fırçalama Güvertesinden ayırın.

3 Fırçaları (CC) takmak için (ya da koruyucu yastık tutucular), fırça üzerindeki Dişleri (DD) monte edileceği levha üzerindeki deliklere göre ayarlayın ve yerine

oturtmak için döndürün (fırçanın dış kenarını şekilde gösterildiği gibi makinenin ön tarafına doğru çevirin (EE)).

ŞEKIL 2

B-8 - FORM NO. 56041978 - BR1100S / BR1300S

Page 33

TÜRKÇE / B-9

FIRÇALARIN TAKILMASI (SILINDIR SISTEMI)

DİKKAT!

Fırçaları değiştirmeden ve herhangi bir erişim panelini açmadan önce kontak anahtarını kapatın (O) ve anahtarı çıkarın.

1 Fırçalama Güvertesinin KALKIK konumda olmasına dikkat edin. Kontak Anahtarının (A) kapalı (O) konumda olduğundan emin olun.

2 Bkz. Şekil 3. Her iki taraftaki eteklik tertibatını çıkarın. NOT: Eteklikleri yerinde tutan iki büyük Düğme (AA) vardır. Bu düğmeleri gevşetin, Eteklik

Tertibatlarını (BB) yavaşça öne doğru kaydırın ve Fırçalama Güvertesinden ayırın.

3 Avara Dişlisi Tertibatlarının (DD) üzerinde bulunan Siyah Düğmeleri (CC) Çentiklerden (EE) kurtulacak kadar aşağıya düşecek şekilde gevşetin ve çıkarın.

4 Fırçayı kartere doğru kaydırın, hafi fçe kaldırın, oturana kadar itin ve döndürün. Avara Dişlisi Tertibatlarını (DD) ve Eteklik Tertibatlarını (BB) tekrar takın.

ŞEKIL 3

FORM NO. 56041978 - BR1100S / BR1300S - B-9

Page 34

B-10 / TÜRKÇE

ÇÖZELTI DEPOSUNUN DOLDURULMASI

Bkz. Şekil 4. Çözelti deposunu maksimum 70 galon (264 litre) temizleme çözeltisi ile doldurun. Çözelti deposunu, Çözelti Doldurma (2) yerinin altından itibaren

7.5 cm (3 inç) üzerine çıkmayacak şekilde doldurun. Çözelti, su ve yapılacak iş için uygun bir temizlik maddesinin karışımından oluşmalıdır. Her zaman

kimyasal konteyner etiketi üzerindeki seyreltme talimatlarına uyun. NOT:

yollarla kullanılabilir ya da deterjan yayma sistemi kullanılabilir. Deterjan yayma sistemini kullanırken, depoya deterjan karıştırmayın; sadece su

kullanılmalıdır.

EcoFlex™ makineleri ya deterjanı depo içinde karıştırmak suretiyle geleneksel

DİKKAT!

Sadece makinede kullanıma uygun az köpüren ve yanıcı olmayan sıvı deterjanları kullanınız. Su sıcaklığı, 130 Fahrenheit (54.4 °C)

seviyesini aşmamalıdır.

ŞEKIL 4

B-10 - FORM NO. 56041978 - BR1100S / BR1300S

Page 35

TÜRKÇE / B-11

LASTIK SILECEĞIN TAKILMASI

1 Bkz. Şekil 5. Lastik Silecek Tertibatını (17) lastik silecek montaj dirseğinin üzerine doğru kaydırın ve Lastik Silecek Montaj Kelebek Somunlarını sıkın (AA).

2 Hortum Kelepçesini (CC) kullanarak Geri Alma Hortumunu (BB) lastik silecek girişine bağlayın.

3 Lastik sileceğin arka ağzı bütün uzunluğu boyunca zemine aynı seviyede temas edecek ve lastik silecek kesitinde görüldüğü gibi hafi fçe eğim alacak

şekilde lastik sileceği aşağıya indirin, makineyi hafi fçe öne doğru hareket ettirin ve Lastik Silecek Eğim Ayar Düğmesi (22) ve Lastik Silecek Yükseklik Ayar

Düğmelerini (28) kullanarak lastik silecek eğim ve yükseklik ayarını yapın.

ŞEKIL 5

FORM NO. 56041978 - BR1100S / BR1300S - B-11

Page 36

B-12 / TÜRKÇE

DETERJAN SİSTEMİNİN HAZIRLANMASI VE KULLANILMASI (SADECE ECOFLEX MODELLERİ)

ORTAK TALİMATLAR:

Çözelti sistemi aktifken Deterjan Anahtarına (J) basıp bırakıldığında, deterjan sistemi sırayla açılıp kapanır. Farklı bir deterjana geçerken, sistemin önceki deterjanı

temizlemesi gerekir. SERVİS NOTU: Bu işlem sırasında az miktarda deterjan atılacağından tasfi ye işleminden önce makineyi zemindeki su kanalı üzerine getirin.

Kimyasalların Değiştirilmesi Sırasında Tahliye için:

1 Deterjan kartuşunu sökün ve çıkartın.

2 Kontak Anahtarını (A) AÇIK konuma getirin. Çözelti Anahtarı (F) ve Deterjan Anahtarını (J) 3 saniye basılı tutun. NOT: Tahliye işlemi başlatıldıktan sonra 10

saniye sürer. Deterjan Sistemi göstergeleri için sonraki sayfadaki resme bakı

Haftalık Tahliye için:

1 Deterjan kartuşunu sökün ve çıkartın. Temiz su ile doldurulmuş bir Kartuş takın ve bağlayın.

2 Kontak Anahtarını (A) AÇIK konuma getirin. Çözelti Anahtarı (F) ve Deterjan Anahtarını (J) 3 saniye basılı tutun. NOT: Tahliye işlemi başlatıldıktan sonra 10

saniye sürer. Deterjan Sistemi göstergeleri için sonraki sayfadaki resme bakınız. Normal olarak sistemi tahliye etmek için bir tahliye işlemi yeterlidir.

Deterjan Yüzdesi:

1 Deterjan yüzdesi fabrika ayarı %0,25’tir. Yüzdeyi değiştirmek için, deterjan sistemi KAPALI olmalı, ardından Deterjan Açma/Kapatma Anahtarı (J) 2 saniye

basılı tutulmalıdır. Deterjan göstergesi yanıp sönecek ve anahtara her basıldığında mevcut yüzdeler (%3, %2, %1.5, %1, %0,8, %0,66, %0,5, %0,4, %0,3.,

%0,25) arasında geçiş yapılacaktır. İstenen yüzde ekranda (K9) görüntülendiğinde durum, 5 saniye sonra kilitlenecektir.

KARTUŞ TALİMATLARI

Deterjan Kartuşu (29) operatör bölmesinde Yan Erişim Paneli (27) arkasında bulunmaktadır. Deterjan kartuşunu maksimum 2,2 galon (8,32 litre) deterjanla

doldurun. SERVİS NOTU: Deterjanın makine üzerine dökülmesini önlemek için doldurmadan önce deterjan kartuşunu deterjan kutusundan çıkartın.

Kullanmayı planladığınız her deterjan için ayrı bir kartuş kullanılması tavsiye edilir. Deterjan kartuşları üzerinde beyaz bir çıkartma vardır; her bir kartuş üzerine

deterjanın adını yazarak karışmalarını engelleyebilirsiniz. Yeni bir kartuş takarken, Farklı bir deterjana geçerken, sistemin önceki deterjanı temizlemesi gerekir.

Başlığı (AA) kaldırı

n ve kartuşu deterjan kutusu içine yerleştirin. Kuru Aralık Başlığını (BB) ve deterjan hortumunu görülen şekilde takın.

nız. Normal olarak sistemi tahliye etmek için bir tahliye işlemi yeterlidir.

ŞEKIL 6

B-12 - FORM NO. 56041978 - BR1100S / BR1300S

Page 37

TÜRKÇE / B-13

DETERJAN SİSTEMİNİN HAZIRLANMASI VE KULLANILMASI (SADECE ECOFLEX MODELLERİ)

ŞEKIL 7

TASFİYE

Tas fi ye için (J) ve (F)

anahtarlarına 3 saniye basın.

FORM NO. 56041978 - BR1100S / BR1300S - B-13

Page 38

B-14 / TÜRKÇE

MAKINENIN ÇALIŞTIRILMASI

UYARI!

Operatör kumanda cihazları ve bunların işlevlerini tam olarak anladığınızdan emin olun.

Rampa üzerinde ve eğimli yerlerde, yüklü olduğunda ani durma hareketinden kaçının. Ani ve keskin dönüşlerden kaçının. Düşük

hızda gidilebilecek yokuş aşağı yerleri kullanın. Sadece rampadan tırmanırken (yukarıya doğru giderken) temizleyin.

Ovma işlemi için:

Bu kılavuzun, makinenin kullanıma hazırlanması bölümünde yer alan talimatları uygulayın.

1 Bkz. Şekil 8. Makinenin üzerine çıkarak oturduğunuzda, (23) ve (5) nolu ayarlama mekanizmalarını kullanarak koltuğu ve direksiyonu rahat bir kullanım konumuna getirin.

2 Ana Kontak Anahtarını (A) AÇIK konuma getirin (ı). Bu işlemden sonra kontrol paneli gösterge ışıkları yanacaktır. Devam etmeden önce Batarya Durum Göstergesi (K5) ve Saat

Ölçeri (K3) kontrol edin.

3 El Frenini (6) salın. Makineyi çalışma yapılacak alana götürmek üzere, ileri hareket etmek için Sürme Pedalının (8) ön tarafına ve geriye gitmek için pedalın arka tarafına yatay

basınç uygulayın. İstenilen hızda gitmek için ayak pedalına uygulanan basıncı değiştirin.

4 Zemine ön ıslatma uygulamak için Çözelti Anahtarına (F) basın ve 5 saniye tutun. NOT: Böylece kuru fırçalarla ovmaya başlandığında zemin yüzeyinde iz kalması önlenmiş

olacaktır. Bu işlem Fırçalama AÇIK Anahtarına (D) basmadan önce yapılmalıdır.

5 Normal Ovma için Fırçalama AÇIK Anahtarına (D) bir kez, Sert Ovma için iki kez ve Çok Sert Ovma için ise üç kez basın. Hem çözelti akışı hem de deterjan (EcoFlex

modellerinde) akışı için bu 3 ovma moduna uygun varsayılan 3 ayar mevcuttur (Kontrol Paneline bakınız).

NOT: Ovma basıncını artırmadan çözelti akışını artırmak istemeniz halinde, çözelti akış oranı geçersiz kılma işlevi mevcuttur. Çözelti Anahtarına (F) 3 saniye basılı tutun (çözelti

göstergesi yanıp sönmeye başlayacaktır) ve bırakın. Bundan sonra Çözelti Akış Göstergesinde (K1) istediğiniz oran görünene kadar Çözelti Anahtarına (F) tekrar tekrar basarak

farklı bir akış oranı belirlemek için 3 saniyeniz vardır (1-5 / Kontrol Paneline bakınız). Bundan sonraki bütün ovma basıncı ayarlamaları çözelti akış oranını varsayılan değere

getirecektir.

NOT: Fırçalama AÇIK Anahtarına (D) basıldığında ovma, çözelti, vakum, deterjan (EcoFlex modellerinde) ve yan süpürge (silindir modellerinde) sistemleri otomatik olarak etkin

hale gelir. Ovma işlemi sırasında herhangi bir zamanda ilgili anahtara basmak suretiyle herhangi bir sistem KAPALI veya tekrar AÇIK konuma getirilebilir.

6 Fırçalama AÇIK Anahtarı (D) seçildiğinde, fırçalar, lastik silecek ve yan süpürgeler (silindir modellerde) otomatik olarak zemine indirilir. Sürme Pedalı (8) harekete geçirildiğinde,

ovma, çözelti, vakum, deterjan (EcoFlex modellerinde) ve yan süpürge (silindir modellerinde) sistemleri otomatik olarak çalışmaya başlar.

NOT: Makineyi geriye doğru sürerken, lastik silecek otomatik olarak kalkar.

7 Makineyi düz bir hat üzerinde normal yürüme hızıyla sürerek ovma işlemine başlayın ve dönüşte her yolu 2-3 inç (50-75 mm) kadar çakıştırarak sürün. Gerekli olduğunda

zeminin durumuna göre makine hızını ve çözelti akışını ayarlayın.

NOT: Maksimum ovma hızı, Ovma Hızı Anahtarına (L) basılarak artırılabilir. Normal maksimum ovma hızı, taşıma hızının % 80’i kadardır. Bu anahtara basınca bu hız taşıma

hızının % 100’üne çıkar.

Düz bir zeminde ya da çift ovma işlemi yapıyorsanız, Çekiş Kontrolü (Traction Control™) düğmesine (B) basarak tahrik tekerleğinin torku ayarlanabilir ve daha iyi kontrol ve

zemin çekme gücü sağlanabilir.

Yan süpürge yüksekliği ayarlanabilir. Bu kılavuzun “Yan Süpürge Bakımı” bölümüne bakınız.

DİKKAT!

Zemine zarar vermemek için, fırçalar dönerken makineyi hareketli halde bulundurunuz.

8 Ovma işlemi sırasında, atık suyun tamamen alındığından emin olmak için ara sıra makinenin arkasını kontrol edin. Makinenin arkasında su kalıyorsa, çok fazla çözelti veriyor

olabilirsiniz, geri alma deposu dolu olabilir ya da lastik sileceğin ayarlanması gerekli olabilir.

9 Makine otomatik olarak EcoFlex temizleme moduna geçerek (EcoFlex Anahtarı Göstergesi yanar) çözelti ve deterjandan tasarruf sağlar. EcoFlex Anahtarına (G) basarak,

EcoFlex temizleme modunu devre dışı bırakın ve ovma basıncı, çözelti akışı ve deterjan yüzdesini geçici olarak arttırın. Gösterge bir dakika yanıp sönecek, çözelti debisi bir

sonraki seviyeye yükselecek, ovma basıncı bir sonraki seviyeye yükselecek ve deterjan yüzdesi bir üst yüzdeye yükselecektir.

NOT: EcoFlex Anahtarını (G) 2 saniye basılı tutmak EcoFlex sistemini devre dışı bırakır. Yeniden etkinleştirmenin tek yolu EcoFlex Anahtarına (G) tekrar basmaktır. Anahtar

Sivinin (A) kapatıp aç

10 Çok kirli zeminler için, bir geçişlik ovma işlemi yeterli olmayabilir ve “çift ovma” işlemi gerekli olabilir. Bu işlem tek geçişlik ovma ile aynıdır, ancak birinci geçişte lastik silecek

yukarı konumdadır (sileceği kaldırmak için Vakum/Çubuk Anahtarına (I) basın). Böylece temizlik maddesinin zeminde kalarak üzerinde tekrar çalışma yapılması sağlanır. Son

geçişte, biriken çözeltiyi almak için lastik silecek indirilerek aynı alan üzerinde çalışılır.

11 Geri alma deposunun kesme şamandırası (15), geri alma deposu dolduğunda tahrik sistemi dışında TÜM sistemlerin KAPALI konuma gelmesini sağlar. Bu şamandıra etkin hale

geldiğinde, geri alma deposu boşaltılmalıdı

NOT: Şamandıra etkin olduğunda, tüm diğer göstergeler söner ve Ekran Panelinde “Geri Alma Deposu DOLU” Göstergesi (K7) görünür. Depo dolu olmamasına rağmen

kontrol panelinde sürekli dolu göstergesi yanıyorsa, otomatik kesme özelliği devreden çıkarılabilir; bu işlevi yerine getirmesi için bir kalifi ye servis teknisyeninin servis el kitabını

kullanmasına imkan veriniz.

12 Operatörün ovma işlemini durdurmak istemesi ya da geri alma deposunun dolu olması halinde, Fırçalama KAPALI Anahtarına (E) bir kez basın. Böylece ovma fırçaları ve çözelti

akışı otomatik olarak duracak ve ovma güvertesi yukarı kalkacaktır. Lastik silecek kısa süre sonra yukarı kalkacak ve bir süre sonra da vakum duracaktır (bunun amacı vakumu

tekrar açmadan kalan suların hepsini alabilmektir)

13 Makineyi belirtilen bir atık su “İMHA SAHASINA” götürün ve geri alma deposunu boşaltın. Boşaltmak için, Akıtma Hortumunu (19) arka depolama alanından çekin ve tapasını

çıkarın (atık suyun aniden kontrolsüz şekilde akmasını önlemek için hortumun ucunu depodaki su seviyesinin üzerinde tutun). Çözelti deposunu tekrar doldurun ve ovma

işlemine devam edin.

NOT: Geri Alma Deposu Kapağı (1) ve Geri Alma Deposu Akıtma Hortumu (19) kapsülünün uygun biçimde yerine takılmasına dikkat edin; aksi halde makine kalan suları düzgün

şekilde almayacaktır.

Bataryaların şarj edilmesi gerektiğinde, Batarya ZAYIF Göstergesi (K8) yanacak, ovma fırçaları ve çözelti akışı duracak ve ovma güvertesi yukarı kalkacaktır. Kısa bir süre sonra lastik

silecek yukarı kalkacak ve biraz sonra da vakum duracaktır. Makineyi bir servis alanına götürün ve bu kılavuzun Batarya bölümünde yer alan talimatlara uygun olarak bataryaları şarj

edin.

ılması sistemi yeniden etkinleştirmez. EcoFlex sistemi sadece Ovma Sistemi (D) etkinleştirilmişse çalışır.

r. Şamandıra etkin haldeyken makine suyu almayacak ya da ovma işlemi yapmayacaktır.

B-14 - FORM NO. 56041978 - BR1100S / BR1300S

Page 39

TÜRKÇE / B-15

ISLAK VAKUMLAMA

Makineyi ıslak vakumlama için seçmeli eklentilerle donatmak üzere bu adımları takip ediniz.

1 Geri alma hortumunu lastik silecekten (17) sökün. Kaplini ve hortumu değnek kitinden geri alma hortumuna bağlayın.

2 Uygun ıslak alma aletlerini hortuma takın. (Seçmeli Değnek Kiti olan PN56413687, Nilfi sk’ten temin edilebilir).

3 Ana Kontak Anahtarını (A) AÇIK konuma getirin ve Vakum/Çubuk Anahtarına (I) basın. Vakum motoru ve pompa, KAPALI konuma getirmek için tekrar anahtara basılana kadar

sürekli çalışacaktır. NOT: Değnek modu etkin hale getirildiğinde, “Geri Alma Deposu DOLU” göstergesi devreden çıkar. Şamandıra geri alma deposuna akışı durduracaktır.

SERVİS NOTU: Tüm kumanda donanımı ve seçmeli programlanabilme özelliklerinin ayrıntılı işlev açıklamaları için servis el kitabına bakınız.

ŞEKIL 8

FORM NO. 56041978 - BR1100S / BR1300S - B-15

Page 40

B-16 / TÜRKÇE

KULLANIM SONRASI

1 Ovma işlemi bittiğinde, Fırçalama Kapalı Anahtarına (E) basın. Böylece bütün makine sistemleri otomatik olarak yukarı kalkacak, içeri çekilecek ve duracaktır

(fırça, lastik silecek, vakum, çözelti ve deterjan (EcoFlex modellerinde)). Daha sonra günlük bakım ve diğer gerekli servis işlemlerinin yapılması için makineyi

bir servis alanına götürün.

2 Çözelti deposunu boşaltmak için, Çözelti Akıtma Hortumunu (4) depolama kelepçesinden çıkarın. Hortumu belirtilen bir “İMHA SAHASINA” doğru tutun ve

tapasını çıkarın. Depoyu temiz su ile durulayın.

3 Geri alma deposunu boşaltmak için, Geri Alma DEPOSU Akıtma Hortumunu (19) depolandığı yerden çekin. Hortumu belirtilen “İMHA SAHASINA” doğru

tutun ve tapasını çıkarın (atık suyun aniden kontrolsüz şekilde akmasını önlemek için hortumun ucunu depodaki su seviyesinin üzerinde tutun). Akışı

düzenlemek için Geri Alma Deposu Akıtma Hortumu sı

dolaşmış veya hasar görmüş ise değiştirin.

4 Fırçaları veya yastık tutucuları çıkarın. Fırçaları veya yastıkları ılık su ile yıkayarak kuruması için bir yere asın.

5 Lastik sileceği çıkarın, ılık su içinde durulayın ve tekrar yerine takın.

6 Silindir sistemlerde huniyi çıkarın ve iyice temizleyin. Makinenin herhangi bir kenarından etekliği çıkararak huniyi yukarıya ve karterin dışına doğru kaldırın ve

çekin.

7 Aşağıdaki bakım çizelgesini kontrol edin ve depolamadan önce gerekli bakım i

BAKIM ÇIZELGESI

Bataryaların Şarj Edilmesi X

Depoların & Hortumların Kontrolü/Temizlenmesi X

Fırçaların/Yastıkların Kontrolü/Temizlenmesi/Döndürülmesi X

Lastik Sileceğin Kontrolü/Temizlenmesi X

Vakum Kesme Şamandırasının Kontrolü/Temizlenmesi X

Vakum motoru köpük fi ltresinin (fi ltrelerinin) Kontrolü/Temizlenmesi X

Silindir Sistemde Huninin Temizlenmesi X

Batarya Su Seviyesinin Kontrolü X

Ovma Karteri Etekliklerinin Denetlenmesi X

Çözelti Filtresinin Denetlenmesi ve temizlenmesi X

Aşınma & Ayar için Ayak/El Freninin Kontrolü X

Silindir Sistemde Çözelti Kanalının Temizlenmesi X

Deterjan Sistemi (sadece EcoFlex) tasfi yesi X

* Karbon Fırçaların Kontrolü X

kılabilir. Geri alma deposunu temiz su ile durulayın. Geri alma ve vakum hortumlarını kontrol edin;

şlemlerini gerçekleştirin.

BAKIM KALEMİ Günlük HaftalıkAylıkYıllık

Yan Süpürgenin Bakımı X

Yağlama - Gres Tertibatı X

* Yılda bir kez ya da 300 işletim saatinden sonra vakum motoru karbon motoru fırçalarını Nilfi sk’e kontrol ettirin. Yılda bir kez ya da her 500 saatte bir fırça ve

tahrik motoru karbon fırçalarını

NOT: Bakım ve servis onarımları ile ilgili daha fazla ayrıntı için Servis El Kitabına bakınız.

8 Makineyi kapalı alanda temiz ve kuru bir yerde muhafaza edin. Donmaya karşı koruyun. Depoları havalandırmak için açık bırakın.

9 Ana Kontak Anahtarını (A) KAPALI (O) konuma getirin ve anahtarı çıkarın.

kontrol edin.

MAKİNENİN YAĞLANMASI- ŞEKİL 9

Ayda bir kez, makine üzerindeki gresörlüklere gres, rulmanların dışına sızana kadar bir miktar gres pompalayın.

Gresörlük yerleri (gresin uygulanacağı yerler) (AA):

• Lastik Silecek Ayak Tekerleği Dingil ve Mihveri

• Direksiyon Mili Kardan mafsalı

• Direksiyon Zinciri

• Lastik silecek montaj açısı ayar düğmesi yivleri

Ayda bir kez, aşağıdaki parçaları yağlamak için hafi f makine yağı uygulayın (BB):

• Lastik silecek aleti uç tekerlekleri

• Geri Alma Deposu açma mandalı

• Fren Pedalı (El Freni) bağlantısı

B-16 - FORM NO. 56041978 - BR1100S / BR1300S

Page 41

ŞEKIL 9

TÜRKÇE / B-17

FORM NO. 56041978 - BR1100S / BR1300S - B-17

Page 42

B-18 / TÜRKÇE

BATARYALARIN ŞARJ EDILMESI