Page 1

E

Operating

Instructions

530 / 530cc

Upright

Vacuum

Instrucciones

De Operacion

Instructions

D'Operation

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read

this book prior to operating or attempting any service or maintenance procedure to your ALTO

machine could result in injury to you or to other personnel; damage to the machine or to other property

could occur as well. You must have training in the operation of this machine before using it. If

operator(s) cannot read English, have this manual explained fully before attempting to operate this

machine.

Barredoras

Verticales

Balayeuse

All directions given in this book are as seen from the operator’s position at the rear of the machine.

For new books write to: ALTO U.S. Inc., 2100 Highway 265, Springdale, Arkansas 72764.

Form No. 70069A 7/99 Clarke Technology Printed in the U.S.A.

Page 2

Table of Contents

Important Safety Instructions ..................................................................................5

Grounding Instructions ............................................................................................ 8

General Diagram and Parts List ............................................................................. 10

How To Assemble ................................................................................................... 11

How To Use ............................................................................................................ 14

Height Adjustment ................................................................................................... 14

How To Change Disposable Paper Bag .................................................................. 16

How To Clean Permanent Bag ................................................................................ 16

How To Replace Brush Roll Belt ............................................................................. 18

How To Replace Motor ........................................................................................... 20

Page -2- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 3

Table of Contents

Advertencias ...........................................................................................................6

Instrucciones Para La Conexion Electrica De Maquina ........................................... 8

Diagrama General/Lista de Partes ......................................................................... 10

Commo Ensambler ................................................................................................. 12

Commo Utilizarse .................................................................................................... 15

Ajuste De Altura ...................................................................................................... 15

Como Cambiar La Bolsa De Papel ......................................................................... 17

Como Limpiar Bolsa Permanente ........................................................................... 17

Como Reponer La Baner De Cepillo Girantorio ...................................................... 19

Como Reemplazar El Motor ................................................................................... 21

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page -3-

Page 4

Table of Contents

Importantes Mesures De Sécurité .......................................................................... 7

Instructions Visant La Mise A La Terre.................................................................... 9

Diagramme Generale/Liste Des Pieces .................................................................. 10

Comment L'Assembler ............................................................................................13

Comment L'Utiliser .................................................................................................. 15

Reglage De La Hauteur .......................................................................................... 15

Comment Changer Le Sac De Papier .....................................................................17

Comment Essuyer Le Sac Permanent .................................................................... 17

Comment Remplacer La Courroie De La Brosse .................................................... 19

Comment Remplacer Le Moteur ............................................................................. 21

Page -4- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 5

This machine is intended for commercial use.

IMPORTANT SAFETY INSTRUCTIONS

WHEN USING AN ELECTRICAL UPRIGHT VACUUM CLEANER, BASIC PRECAUTIONS SHOULD BE

FOLLOWED, INCLUDING THE FOLLOWING:

READ ALL INSTRUCTIONS BEFORE USING VACUUM CLEANER.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING: To reduce the risk of fire, electric shock, or injury:

1. Do not use outdoors or on wet surfaces.

2. Do not leave vacuum cleaner unattended when plugged in. Turn off the switch and unplug the

electrical cord when not in use and before servicing.

3. Do not allow to be used as a toy. Close attention is necessary when used by or near

children.

4. Use only as described in this manual. Use only manufacturer's recommended attachments.

5. Do not use with damaged cord or plug. If vacuum cleaner is not working as it should, has

been dropped, damaged, left outdoors, or dropped into water, return it to a service center

before using.

6. Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull a cord around

sharp edges or corners. Do not run vacuum cleaner over cord. Keep cord away from heated

surfaces.

7. Do not use extension cords or outlets with inadequate current carrying capacity.

8. Turn off all controls before unplugging.

9. Do not handle plug or vacuum cleaner with wet hands.

10. Do not put any objects into openings. Do not use with any opening blocked, keep free of

dust, lint, hair, and anything that may reduce airflow.

11. This vacuum cleaner creates suction and contains a revolving brush roll. Keep hair, loose

clothing, fingers and all parts of body away from openings and moving parts.

12. Do not pick up anything that is burning or smoking, such as cigarettes, matches or hot

ashes.

13. Do not use without dust bag in place.

14. Use extra care when cleaning on stairs.

15. Do not use to pick up flammable or combustible liquids such as gasoline, or use in areas

where they may be present.

16. Store your cleaner indoors in a cool, dry area.

17. Do not unplug by pulling on cord. To unplug, grasp the plug, NOT THE CORD.

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page -5-

Page 6

Los modelos estan diseñados para usos comercial

ADVERTENCIAS

AL UTILIZAR SU BARREDORA, SE DEBEN SEGUIR LAS SIGUIENTES PRECAUCIONES.

LEA TODAS LAS INSTRUCCIONES ANTES DE UTILIZAR SU BARREDORA.

GUARDE ESTE MANUAL PARA FUTURAS REFERENCIAS

PRECAUCIONES: Para reducir el riesgo de fuego, choque eléctrico o heridas:

1. No se use en áreas exteriores o en superficies mojadas.

2. No deje la barredora sola cuando está conectada. Cuando no esté en uso y antes de darle

servicio apague y desconecte su barredora.

3. No permita que sea utilizada como un juguete. Cuando utilice su barredora cerca de los

niños, o sea usada por ellos favor de tener extremo cuidado.

4. Usese sólo como se describe en este manual. Utilice únicamente accesorios recomendados

por el fabricante.

5. No se use con el cordón o la clavija dañados. Si la barredora no está trabajando como

debiera, si se ha caído, dañado, dejado fuera o le ha caido agua, enviela a un centro de

servicio antes de usarse.

6. No cargue o jale la barredora con el cordón, ni lo use como manija, no jale el cordón sobre

orillas o esquinas filosas y manténgalo alejado de superficies calientes.

7. No pase la barredora sobre el cordón.

8. No utilice extensiones o enchufes sin capacidad de corriente adecuados.

9. Apague todos los controles antes de desconectar.

10.No maneje la barredora o la clavija con las manos mojadas.

11.No ponga ningún objeto en ninguna de las aberturas, ni se utilice con alguna abertura

bloqueada. Mantenga su barredora libre de polvo, cabello, pelusa o cualquier cosa que

pueda reducir el paso del aire.

12.Esta barredora crea succión y contiene un cepillo giratorio. Mantenga la ropa suelta, dedos,

cabellos y cualquier parte del cuerpo lejos de las aberturas de las partes movibles.

13.No recoja nada que se esté quemando o humeando como cigarros, cerillos o cenizas

calientes.

14.No se utilice sin la bolsa para polvo en su lugar.

15.Tenga cuidado especial cuando aspire las escaleras.

16.No utilice su barredora cerca de, o para recoger liquidos inflamables o combustibles como la

gasolina.

17.Guarde su barredora en un lugar seco, fresco e interior.

18.No desconecte su barredora jalándola por el cable. Para desconectaria jálela de la clavija.

Page -6- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 7

Les modéles destinés á des usages commercial.

IMPROTANTES MESURES DE SÉCURITÉ

L'UTILISATION D'UN ASPIRATEUR ELECTRIQUE DEMANDE CERTAINES PRECAUTIONS.

LIRE TOUTES LES INSTRUCTIONS AVANT DE FAIRE FONCTIONNER CET ASPIRATEUR.

CONSERVER CES INSTRUCTIONS

AVERTISSEMENT: Pour reduire las risques d'incendie, de choc électrique ou de

blessure:

1. Ne pas laisser l'appareil sans surveillance lorsqu'il est branché débrancher lorsque l'appareil

n'est pas utilisé et avant l'entretien.

2. Ne pas permettre aux enfants de jouer avec l'appareil. Une attention particuliére est nécessaire

lorsque l'appareil est utilisé par des enfants ou a proximité de ces derniers.

3. Ne pas utiliser a l'extérieur et ne pas aspirer de matiéres humides.

4. N'utiliser que conformément à cette notice avec les accessories recommandés par le fabricant.

5. Ne pas utiliser si le cordon ou la fiche est endommegé retourner l'appareil á un atelier de

réparation s'il ne fonctionne pas bien, s'il est tombé ou s'il a été endommagé, oublié á extérieur

ou immergé. Ne pas tirer soulever ou trainer l'appareil par le cordon. Ne pas utiliser le cordon

comme une poignée, le coincer dans i'embrasure d'une porte ou l'appuyer contre des arétes

vives ou des coins. Ne pas faire rouler l'appareil sur le cordon.

6. Garder le cordon á l'écart des surfaces chaudes.

7. Ne pas débrancher en tirant sur le cordon. Tirer plutót la fiche.

8. Ne pas toucher la fiche ou l'appareil lorsque vos mains sont humides.

9. Ne pas aspirer de matiéres en combustion ou qui dégagent de la fumée, comme des cigarettes, des allumettes ou des cendres chaudes.

10.Mettre toutes les commandes á la position arrét avant de débrancher l'appareil.

11.User de prudence lors du netoyage des escaliers.

Ne pas aspirer des liquides inflammables ou combustibles comme de l'essence, et ne pas faire

fonctionner dans des endroits oú peuvent se trouver de tels liquides.

12.N'insérer aucun object dans les ouvertures, ne pas utiliser l'appareil lorsqu'une ouverture est

bloqée. S'assurer que de la poussiere, de la peluche, des cheveux ou dáutres matiéres ne

réduisent pas le débit d'air.

13.Maintenir les cheveux, les vétements amples, les doigts et toutes les parties du corps a l'écart

des ouvertures et des piéces mobiles.

14.Ne pas utiliser l'appareil si le sac á poussiére n'est pas placé.

15.Ne pas utiliser des prolongateurs ou des prises de courant avec une capacité porteuse de

courant inadéquate.

16.Cet aspirateur crée de la succion et contient une brosse giratoire, maintenir les cheveux, les

vetements amples, les doigts et toutes es parties du corps á l'ecart des ouvertures et des

piéces mobiles.

17.Garder láspirateur á l'intérieur dans une aire froide et séche.

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page -7-

Page 8

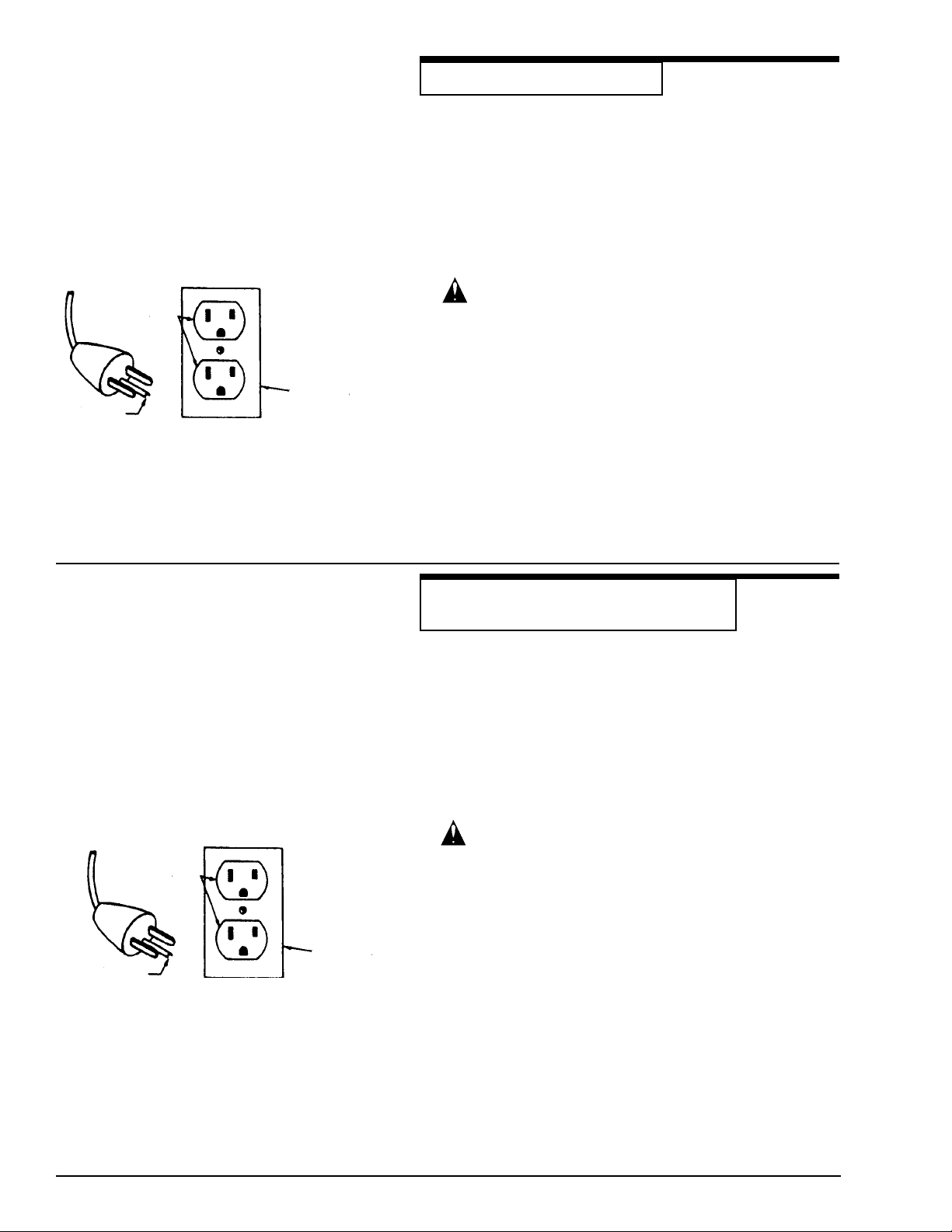

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should malfunction or

breakdown, grounding provides a path of least resisitance for

electric current to reduce the risk of electric shock. This

appliance is equipped with a cord having an equipmentgrounding conductor and grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

Grounding

Pin

Grounded

Outlet

Fig. 1

Grounded

Outlet

Box

WARNING: Improper connection of the

equipment-grounding conductor can result in risk of

electric shock. Check with a qualified electrician or

service person if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug

provided with the appliance - if it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

This appliance is for use on a nominal 120-volt circuit and

has a ground plug that looks like the plug illustrated in figure

1. Make sure that the appliance is connected to an outlet

having the same configuration as the plug. No adapter

should be used with this appliance.

INSTRUCCIONES PARA LA CONEXION ELECTRICA DE LA MAQUINA

La máquina debe ser puesta a tierra. En caso de mal

funcionamiento o de avería, el hilo de tierra es un camino de

menor resistencia que permite el paso de corriente ; por lo

cual se reduce el riesgo de choque eléctrico. La máquina

tiene un cable de alimentación con tres cordones y un

enchufe con tres clavijas de las cuales una está puesta a

tierra. El enchufe sólo puede ser conectado con una caja de

enchufe reglamentaria, puesta a tierra con todas las reglas

del arte y conforme a los reglamentos locales.

Toma

corriente

con polo

de tierra.

AVISO: Una conexión incorrecta del

conductor de puesta a tierra puede causar un

choque eléctrico. Acuda a un técnico

autorizado o a un electricista si tiene alguna

duda acerca de la puesta a tierra correcta de su

caja de enchufe. Nunca modifique el enchufe

suministrado con la máquina. Si no encaja el

enchufe en la caja de enchufe, haga cambiar su

caja de enchufe por un electricista autorizado.

Terminal de

tierra.

Fig. 2

Tapa del toma

corriente con

polo de tierra

La máquina se concibió para funcionar en un circuito de

potencia nominal de 220 V. Tiene un enchufe con puesta a

tierra semejante al enchufe reproducido en el esquema A de

la figura 2. Compruebe que la máquina esté conectada con

una caja de enchufe que tiene la configuración adecuada.

No utilice ningún adaptador para conectar esta máquina.

Page -8- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 9

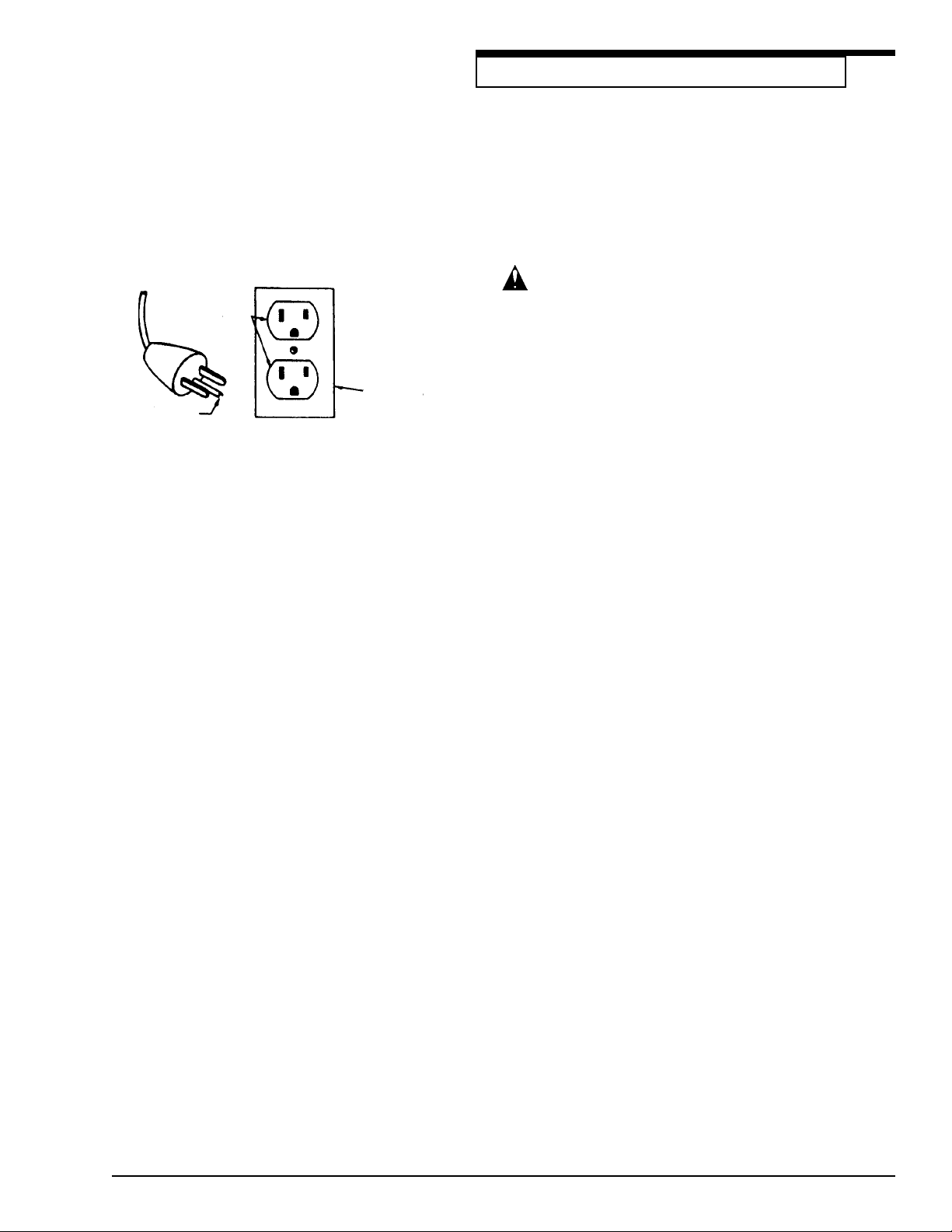

INSTRUCTIONS VISANT LA MISE A LA TERRE

Cet appareil doit être mis à la terre. En cas de défaillance

ou de panne éventuelles, la mise à la terre fournit au courant

un chemin de moindre résistance quI réduit le risque de choc

électrique. Cet appareil est pourvu d'un cordon muni d'un

conducteur de terre et d'une fiche avec broche de terre. La

fiche doit être branchée dans une prise appropriée

correctement installée et mise a la terre conformément aux

règlements et ordonnances municipaux.

Prise de courant

avec mise à la

Broche de mise

à la terre

terre

(A)

Fig. 3

Boîte de sortie

mise à la terre

AVERTISSEMENT: Un coducteur

de terre mal raccordé peut entraîner un risque de

choc électrique. Consulter un électricien ou un

technicien d'entretien qualifié si vous n'êtes pas

certain que la prise est correctement mise à la

terre. Ne pas modifier la fiche fournie avec

l'appareil - si elle ne peut être inséreé dans la prise,

faire installer une prise adéquate par un électricien

qualifié.

Cet appareil est destiné à un circuit de 120V et est muni

d'une fiche de mise à la terre semblable à celle illustrée par

le croquis A de la figure 3. S'assurer que l'appareil est

branché à une prise de courant ayant la même configuration

que la fiche. Aucun adaptateur ne devrait être utilisé avec

cet appareil.

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page -9-

Page 10

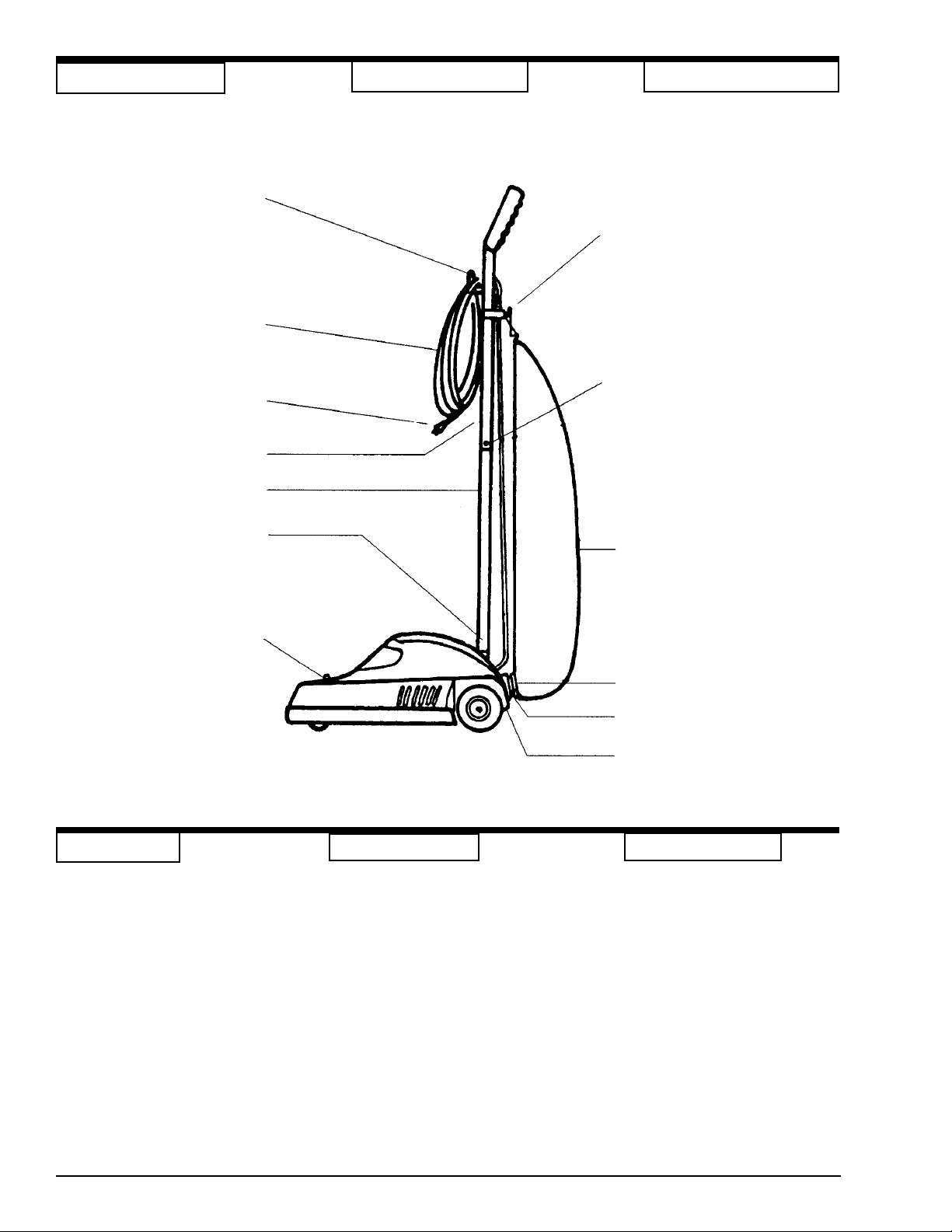

GENERAL DIAGRAM DIAGRAMA GENERAL DIAGRAMME GENERALE

1

11

12

3

13

2

4

5

10

6

8

7

9

PARTS LIST LISTA DE PARTES LISTE DES PIECES

1. Cord Hook

2. Upper Handle Tube

3. Nut & Bolt

4. Lower Handle Tube

5. Nut & Bolt

6. Height Adjustment

7. Bag Inlet

8. Bag Support

9. Handle Release Pedal

10. Bag

11. Spring Bag Hook

12. 35 Foot Line Cord

13. 3 Wire Grounded Plug

1. Gancho del cordón

2. Tubo superior de la manija

3. Tornillo y tuerca

4. Tubo inferior de la manija

5. Tornillo y tuerca

6. Ajuste de altura

7. Entrada de la bolsa

8. Soporte de la bolsa

9. Pedal retén manija

10. Bolsa

11. Sostén de la bolsa

12. Cable de 11 metros

13. Clavija aterrizada

1. Crochet pour le cordon

2. Tube supérieur de la poignée

3. Vis et écrou

4. Tube inférieur de la poignée

5. Vis et écrou

6. Réglage de la hauteur

7. Entrée du sac

8. Support du sac

9. Pédale suport poignée

10. Sac

11. Support du sac

12. Cable de 11 meters

13. Broche de mise a la terre

Page -10- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 11

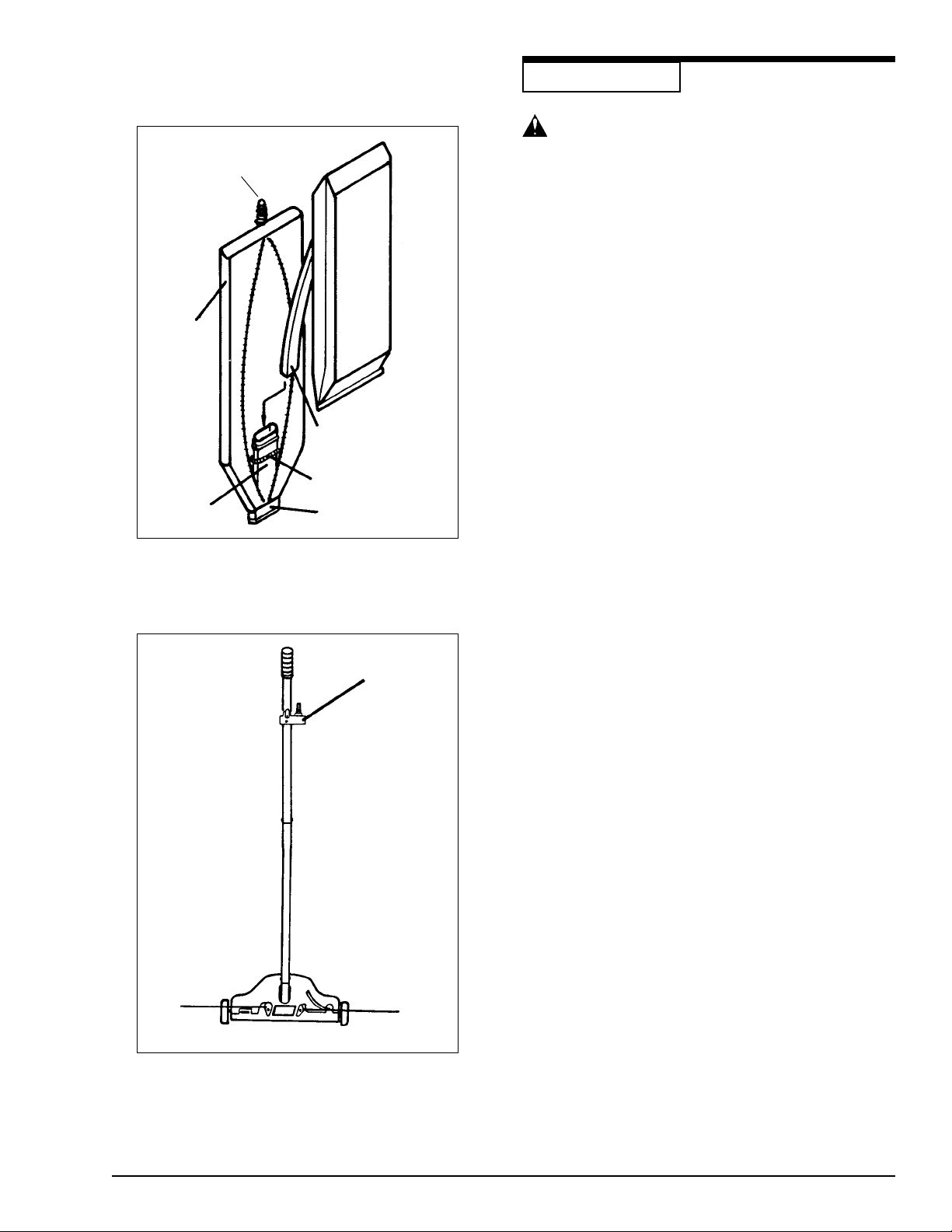

Paper Bag

Cover

Dust Bag

Connector

Top Spring

Figure 4

Paper Bag

Tube

Spring

Lower Bag Support

Line Cord

Support

and Bag

Hook

HOW TO ASSEMBLE

CAUTION: Fully assemble the unit before

using.

Hardware Package: The package contains two nuts

and bolts, one screw and one spring.

1. Assemble Lower Handle

Attach lower handle over socket, align holes and

fasten with bolt and internally threaded nut provided

in hardware package.

2. Attach Upper Handle

Place upper handle over lower handle align holes

and fasten with bolt and internally threaded nut

included in hardware package.

3. Install Line Cord Support and Bag Hook

Attach spring bag hook to rear upper handle tube.

Insert fitting end into rectangular hole. Align holes

and fasten with screw provided in hardware package.

4. Bag Assembly (OPTIONAL ACCESSORY)

Open zipper of paper bag cover. Attach spring

around dust bag connector located inside paper bag

cover (see figure 4). Slide paper bag tube over

connector and roll spring up to hold bag. Be sure

zipper printing on paper aligns up with zipper on

paper bag cover. Hold paper bag cover on back of

the unit with printing facing handle tube.

Knob

Bag

Support

Guide

Figure 5

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

5. Install Bag to Upright Vacuum

Slide lower bag support into slots of bag support

guide, pressing right. Push bag support towards

inlet and turn knob clockwise. Insert top spring into

hook (see figure 5).

Page -11-

Page 12

COMO ENSAMBLAR

Resorte

superior

Cubierta

de la

bolsa

de papel

Cople para

bolsa de papel

Tubo de la

bolsa de papel

Resorte soporte

Soporte inferior

para bolsa

Fig. 6

Gancho para

resorte

superior de

la bolsay

sosten del

cable

PRECAUCION: Antes de utilizar su unidad,

ensámblela completamente.

Paquette: El paquette contiene dos tornillos y tuercas,

una pija y un resorte.

1. Ensamble el tubo interior

Asegure el tubo inferior al socket, alinie los aqujeros

y asegure con el tornillo y la tuerca incluidos en el

paquete.

2. Coloque el tubo superior sobre el tubo inferior, alinie

los agujeros y apriete con el tornillo y la tuerca

incluidos en el paquete.

3.

Instale el soporte del cordón y el sostén de la bolsa

Coloque el sostén de la bolsa en la parte trasera del

tubo superior, inserte el extremo al hoyo rectangular. Alinie los agujeros y asegure con la pija

incluida en el paquete.

4. Ensamble de la bolsa (Accesorio Opcional)

Abra el cierre de la cubietra de la bolsa de papel.

Coloque el resorte alrededor de la bolsa de papel

localizado en el interior de la cubierta de la bolas de

papel (ver fig. 6). Deslice el tubo de la bolsa de

papel sobre el conector y acomode el resorte para

que sujete la bolsa. Asegúrese que el cierre

impreso en la bolsa de papel esté alineado o con el

cierre de la cubierta de la bolsa de papel. Acomode

la bolsa de papel dentro de la cubierta de la bolsa

de papel. Asegúrese que la bolsa de papel esté

extendida completamente dentro de la cubierta.

Mantenga la cubierta de la bolsa de papel en la

parte trasera de la unidad con la impresión mirando

hacia el tubo superior.

5. Instale la bolsa a la barredora vertical.

Deslice el soporte inferior de la bolsa dentro de las

ranuras del retén de la bolsa moviéndola hacia la

derecha. Empuje el soporte de la bolsa hacia la

entrada de aire de la barredora y de vuelta a la

perilla para asegurarla. Inserte el resorte superior al

gancho (Ver fig. 7)

Perilla

Reten

para

cople

de la

bolsa

Fig. 7

Page -12- CLARKE TECHNOLOGY 530 Upright Operator's Manual

Page 13

COMMENT L'ASSEMBLER

Ressort

supérieur

Enveloppe

du sac de

papier

Piéce pour

recevoir le sac

Tube du sac

de papier

Support en ressort

Support inférieur du

sac

Fig. 8

Crochet pour

ressort

supérieur

du sac et

support du

cable

PRECAUTION: Avan d'utiliser son appareil,

l'assambler complétement.

Emballage: L'emballage contient deux vis et écrous,

une pige et une ressort.

1. Assembler le tube inférieur.

Fixen le tube inférieur sur le manchon, aligner les

trous et fixet avec la vis et l'écrou inclus dans

l'emballage.

2. Placer le tube supérieur sur le tube inférieur, aligner

les trous et serrer avec la vis et l'écrou inclus dans

l'emballage.

3.

Instaler le support du cordon et le support du sac.

Placer le support du sac dans la partie arrière du

tube supérieur, insérer l'extrémité au trou

rectangulaire, aligner les trous et fixer avec la pige

inclus dan l'emballage.

4. Assemblage du sac. (Accessorie Optionel)

Ouvrir la fermeture de l'enveloppe du sac de papier.

Placer le ressort autour du sac de papier situé dans

l'iterieru du sac de papier. (voir fig 8). Faire glisser

le tube du sac de papier sur le connecteur et

positionner le ressort qui fixe le sac. S'assurer que

la fermeture imprimé du sac en papier est alignée

avec la fermeture de l'enveloppe du sac de papier.

Positionner le sac de papier á l'intérieur de

l'enveloppe du sac de papier. S'assurer que le sac

de papier est deplié completemment a l'interieur de

l'enveloppe. Maintenir l'enveloppe du sac de papier

dans la partie arrière de l'appareil avec l'imprimé

regardant vers le tube supérieur.

Piéce pour

Bouton

recevoir le sac

Fig. 9

CLARKE TECHNOLOGY 530 Upright Operator's Manual

5. Installer le sac a la balayeuse verticale.

Faire glisser le support inférieur du sac dans les

rainures du renfort du sac en le déplacant vers la

droite. Pousser le support du sac vers l'entrée de

l'air de la balayeuse et tourner le bouton pour

l'assurer. Placer le ressort supérieur au crochet

(vour fig. 9).

Page -13-

Page 14

HOW TO USE

(See Fig. 10)

Store

Apagado

Éteint

Fig. 10

Operate

En operacion

En marche

Clean under

Aspirado por debajo

Aspiration en dessous

1. Remove electrical cord from hook and plug into

electrical outlet.

2. Slide height adjustment to the desired setting.

3. Press the handle release pedal and pull the handle

to the desired position, the unit will turn on automatically when handle is pulled down. To clean

under, press the pedal again and lower the handle.

4. Vacuum slowly with forward and backward strokes,

covering small areas at a time. The time required to

clean the carpet will depend on type of carpet and

amount of dirt.

5. The unit will turn off automatically when the handle

is returned to the vertical position.

HEIGHT ADJUSTMENT

The front of the cleaner has a continuous height

adjustment which raises or lowers the cleaner base to

match the type of carpet. With the cleaner cord

unplugged, set the adjustment according to your

specific needs (Fig. 11).

Height Adjustment

Adjuste de altura

Réglage de la hauteur

While the cleaner is off and disconnected from the

outlet, tilt the cleaner back to remove weight from the

front wheels, and adjust the setting.

Plug the cleaner into electrical outlet, press the handle

release, lower handle and pass the cleaner over the

carpet. If the cleaner is difficult to push, follow the

procedure and test the cleaner at the next height

setting until the unit is comfortable to move. the brush

roll must make contact with the carpet for effective

cleaning.

Fig. 11

Page -14- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 15

COMO UTILIZARSE

COMMENT L'UTILISER

(Fig. 10)

1. Desenrolle el cordón eléctrico y conéctelo a un

tomacorriente de 120V, 60Hz.

2. Deslice la perilla de ajuste de altura a la altura

deseada.

3. Presione el pedal de retén manija y mueva la manija

a la posición deseada. La unidad encenderá

automáticamente. Para aspirar por debajo,

presione el pedal otra vez y baje la manija.

4. Aspire despacio con movimientos hacia adelante y

hacia atrás cubriendo áreas pequeñas. El tiempo

que se requiera para aspirar la alfombra dependerá

del tipo de alfombra y la cantidad de polvo que ésta

contenga.

5. La barredora se apagara automáticamente en el

momento en el que la manija esté en la posición

vertical.

AJUSTE DE ALTURA

(Fig. 10)

1. Dérouler le fil électrique et brancher á une prise de

courant 120V, 60 Hz.

2. Faire glisser la manche á la hauteur désirée.

3. Pressioner la pédale support poignée et tourrer la

poignée à la position désirée. L'appareil sállumera

automatiquement. Pour aspirer en dessous,

acttioner la pédale une autre fois et baisser la

poignée.

4. Aspirer lentement avec mouvements vers l'avant et

vers l'arrière couvrant de petites surfaces. Le temps

nécéssaire pour nettoyer une moquette dépendera

du type de la moquette et la quantité de poussière

qui y est contenu.

5. La balayeuse s'éteindra automatiquement au

moment que la poignée sera en position verticale.

REGLAGE DE LA HAUTEUR

El frente de la barredora tiene un ajuste de altura que

baja o sube para que coincida con el tipo de alfombra

que usted tiene. Con el cable eléctrico desconectado

escoja el ajuste de acuerdo con sus necesidades

especificas (fig. 11).

Con la barredora apagada y desconectada, levante la

barredora hacia atrás para disminuir el peso en las

llantas y ajuste la altura.

Conecte la barredora, presione el pedal de posiciones

para liberar la manija y deslice la barredora sobre la

alfombra. Si le es dificil empujar la barredora, repita el

procedimiento anterior y pruebe con la altura diferente.

Repitalo hasta que le sea cómodo mover la barredora.

El cepillo debe estar siempre en contacto con la

alfombra para tener una limpieza efectiva.

Sur la partie frontale de la balayeuse il y a un réglage

qui perment de baisser ou moteur selon le type de

moquette que vous avez. Avec le cable électrique

debranché choissez le réglage approprié. (Fig. 11)

Avec la balayeuse déconnectée, incliner la balayeuse

vers l'arriére pour dimunuer le poids sur les roues et

régler la hauteur.

Brancher la balayeuse, actionner la pédale de positions

pour libérer la poignée et faire glisser la balayeuse sur

la moquette. Si cela est difficile de pousser la

balayeuse, recommencer le pocédé antérieur et

essayer á différentes hauteurs. Recommancer jusqu'

áu moment ou cela est commode de déplacer la

balayeuse. La brosse doit être toujours en contact

avec la moquette pour obtenir un bon nettoyage.

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page -15-

Page 16

HOW TO CHANGE DISPOSABLE PAPER BAG

How to Change Disposable Paper Bag (Optional

Accessory - See page 7, #4)

Disconnect unit from electrical outlet before changing

bag.

Change the dust bag frequently. Some fine particles

can restrict airflow very quickly and will decrease

performance even before the bag appears to be full.

For that reason, when vacuuming carpet freshners or

cleaners, powder, plastic dust, or similar fine substances, the bag may need to be changed more often.

1. Unzip the paper bag cover. Roll spring down to

release paper bag tube from dust bag connector.

2. Put a new paper bag in the vacuum cleaner. Slide

paper bag tube over connector and roll spring up to

hold bag. Be sure zipper printing on paper aligns-up

with zipper on paper bag cover. Tuck dust bag into

permanent bag. Make sure dust bag is fully

extended in the bag cover, zip the bag cover.

CAUTION: Be sure to clean impeller chamber every

time you change the disposable paper

bag. Do not attempt to empty and

reuse your paper bag when full, always

replace it with a new one.

HOW TO CLEAN PERMANENT BAG

Disconnect unit from electrical outlet before cleaning

bag.

1. Un hook spring from hook.

2. Turn knob and release bag support from bag support

guide.

3. Release bag closing clip from Permanent Bag. Still

holding the bag, put the opening in a plastic bag and

shake well to empty it.

4. Insert bag closing clip to Permanent Bag.

5. Hold Permanent Bag on back of unit with printing

facing handle tube. Slide lower bag support into

slots of bag support guide. Push bag support

towards inlet and turn knob to fasten. Insert Spring

onto hook.

CAUTION: Be sure to clean fan chamber every time

you empty permanent bag.

Page -16- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 17

COMO CAMBIAR LA BOLSA DE PAPEL

COMMENT CHANGER LE SAC DE PAPIER

Como cambiar la bolsa de papel (Accesorio

Opcional- pagina 7, #4)

Desconecte la unidad antes de cambiar la bolsa.

Cambie la bolsa de papel frecuentemente, algunas

particulas muy finas pueden restringir el paso del aire y

disminuir el poder de succión aún antes de que la

bolsa parezca estar llena. Por esta razón, la bolsa

necesitará ser cambiada más seguido al aspirar polvos

para limpiar alfombras, polvo de pastas o substancias

finas similares.

1. Abras el cierre de la cubierta de la bolsa de papel,

baje el resorte para soltar el tubo de la bolsa de

papel del conector de la bolsa.

2. Coloque una nueva bolsa de papel en la barredora,

deslice el tubo de la bolsa de papel sobre la

conección y ajuste el resorte para que sostenga la

bolsa, asegúrese de que la impresión del cierre en

el papel coincida con el cierre en la cubierta de la

bolsa, acomode la bolsa de papel dentro de la

cubierta de la bolsa asegurándose que esté

completamente extendida dentro de ésta, cierre la

cubierta de la bolsa.

PRECAUCION: Asegúrese de limpiar la entrada de

la barredora cada vez que cambie

la bolsa de papel, no trate de

vaciar la bolsa de papel para volver

a usarla, siempre sustitúyala por

una nueva.

Comment changer le dac de papier (Accessoire

Optionel - page 7, #4)

Debranchér l'appareil avant de changer le sac.

Changer le sac de papier fréquemment, quelques

particules trés fines pouvent boucher le passage de l'air

et diminuer le pouvoir de succion avant que le sac soit

plein. Pour cette raison, le sac nécessitera être

changé plus souventt lorsque qu'il s'agira de poussiére

en p

âte ou substances similaires très fines.

1. Ouvrir la fermeture de l'enveloppe du sac de papier,

baisser le ressort pour libérer le tube du sac de

papier du connecteur.

2. Possitioner un nouveau sac de papier dans la

balayeuse, faire glisser le tube du sac de papier sur

la connexion et ajuster le ressort pour qu'il puisse

soutenir le sac, s'assurer qu'il imprimé de la

fermeture du sac coincide avec la fermeture de

l'enveloppe du sac accommoder le sac de papier à

l'intérieur de l'enveloppe du sac, s'assurant qu'il est

complètement déplié á l'interieur de celui-ci ferner le

couvert du sac.

PRECAUTION: Nettoyer l'entrée de la balayeuse

chaque fois que vouz changez le

sac, n'essayez pas de vider le sac

de papier pour le réutilicer, toújours

remplacez-le.

COMO LIMPIAR LA BOLSA PERMANENTE

Desconecte la unidad antes de limpiar la bolsa.

1. Quite el resorte del sostén de la bolsa.

2. Dele vuelta a la perilla y deslice el soporte de la

bolsa para sacario.

3. Libere el clip para cerra la bolsa deslizandolo hacia

afuera, sosteniendo la bolsa, introduzca la abertura

en una bolsa de plástico y sacúdala para vaciarlà.

4. Inserte el clip para cerrar la bolsa permanente.

5. Sostenga la bolsa permanente en la parte trasera

de la unidad con la impresión mirando hacia el tubo

de la manija, deslice el soporte de la bolsa dentro

de las ranuras del retén de la bolsa, empuje el

soporte de la bolsa hacia la entrada de la vuelta de

la perilla para asegurarlo, inserte el resorte al

sostén de la bolsa.

PRECAUCION: Asegúrese de limpiar la entrada de

la barredora cada vez que vacie la

bolsa permanente.

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

COMMENT ESSUYER LE SAC PERMANENT

Debranchér l'appareil avant d'essuyer le sac.

1. Enlevez le ressort d'appui du sac.

2. Turnez la poire et glissez le support du sac pour

l'enlever.

3. Liberez le clip pour fermer le sac en le glissant audehors, en soutenant le sac mettez l'overture dans

un sac en plastique et secouez-le por le vider.

4. Mettez le clip pour fermer le sac permanent.

5. Soutenez le sac permanent a l'arriére de l'appareil

avec l'impression vers le tube de la poignée, glissez

le support du sac vers l'entrée de la poire pour

l'assurer, mettez le ressort d'appui du filtre.

PRECAUTION: Assurez-vous d'essuyer l'entrée de

la balayeuse chaque fois que vous

videz le sac permanent.

Page -17-

Page 18

HOW TO REPLACE BRUSH ROLL BELT

Retainer Bar

Varilla reten

Corde á piano

Brush Roll

Cepillo Giratorio

Brosse tournante

Motor Cover

Cubierta del

motor

Couvercle du

moteur

Fig. 12

Bottom Plate

Tapa Rodillo

Cache rouleau

Fan Cover

Cubierta del

ventilador

Couvercle du

ventilateur

Motor Nut

Tuerca del

ventilador

É crou du

moteur

NOTE: Turn off the switch and unplug the electrical

cord before replacing belt. Belt can become hot during

normal use. To prevent injury, avoid touching the belt

and motor nut when it is hot.

CAUTION: Improper installation of the brush roll or

brush roll belt could cause carpet

cleaner damage.

1. Push handle release and lower handle; push the

height setting to th lowest position. Turn the

vacuum cleaner so the underneath side and brush

roll face toward you. (Fig. 12)

2. Remover retainer bar by pushing downward on the

right end, until it unhooks. Release other end.

CAUTION: While pushing one end of retainer bar,

hold the machine down to avoid tilting.

3. Remove bottom plate and fan cover by lifting off from

motor. (Fig. 13)

4. Remove belt from motor nut. Pull brush roll up,

remove belt from brush roll and change with a new

belt.

5. Insert brush roll making sure the tabs on the edge of

bearing support are facing upward. Bristles on

brush roll must form a "V" facing toward you.

Low side of belt

Posicion baja de la

banda

Position basse de la

courroie

Belt

Banda

Courroie

Fig. 13

6. Twist the belt towards the right and place around

motor nut. The higher end of the belt must be on

the right side, and the lower end on the left side, as

shown in the drawing below (Fig. 14). Rotate brush

to ensure belt is positioned correctly.

High side of belt

Posicion alta de la

banda

Position haute de la

courroie

Fig. 14

Page -18- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 19

COMO REPONER LA BANDA DE CEPILLO GIRATORIO

COMMENT REMPLACER LA COURROIE DE LA BROSSE

NOTA: Apague la unidad y desconéctela antes de

sustituir la banda. La banda puede calentarse durante

el uso normal. Para evitar lesiones, evite tocar la

banda y la tuerca del motor cuando esté caliente.

PRECAUCION: La instalación inapropiada del

cepillo o de la banda puede danar

la barredora.

1. Empuje el pedal de posiciones para liberar la

manija, bájela, empuje el ajuste de altura a la más

baja, voltee la barredora boca abajo. (Fig. 12)

2. Quite la barra retén empujándola hacia abajo por el

extremo derecho hasta que se desenganche, libere

el otro extremo.

PRECAUCION: Mientras empuja un extremo de la

barra retén, sostenga y presione el

otro lado del aparato para evitar

que salte la barra.

3. Quite la tapa inferior del ventilador levantándola del

motor. (Fig. 13)

4. Quite la banda de là tuerca del motor. Empuje el

cepillo hacia arriba, quite la banda de cepillo y

sustitúyala por una nueva.

5. Inserte el cepillo asegurándose que ambas orillas

del soporte balero se encuentren hacia arriba. Las

cerdas del cepillo deben formar una "V" frente a

usted.

NOTE: Eteindre l'appareil et la débroncher avant de

changer la counroie, peut s'echauffer pendant l'unage

normal. Pour éviter de blessures, éviter de toucher la

counroie et l'écrou du moteur quand il est chaud.

PRECAUTION: La mauvaise installation de la

brosse peut endomager la

balayeuse.

1. Poueser la pédale de réglages pour libérer la

poignée, baisez-la, mettre le réglage á la position la

plus basse, tournez la balayouse á l'envers.(Fig. 12)

2. Enlever la barre support en la poussant vers le bas

par l'extrême droite jusqu'a qu'elle se degage, libérer

l'autre extrémité.

PRECAUTION: Pendant que vouz pousserez

l'extrémité de la barre support

soutenir et pressionner de l'autre

côté de l'appareil pour éviter que

saute la barre.

3. Oter l'couvercle inférieur du ventilateur, enlever le

moteur. (Fig. 13)

4. Enlever la courroie de l'ecroue du moteur. Posser la

brosse vers le haut, enlever la courroie de la brosse

et changez-la.

5. Insérer la brosse s'assurant que les deux bords du

support soulement se trouvent vers le haut, la soir

de la brosse doivent former un "V" fase á vous.

6. Tuerza la banda hacia la derecha y acomódela

alrededor de la tuerca del motor. La parte alta de la

banda debe localizarse del lado derecho mientras

que la parte baja del lado izquierdo, como se

demuestra en el dibujo (Fig. 14). Gire el cepillo para

asegurarse que la banda esté colocada

correctamente.

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

6. Tournez la courroie vers la droite et positionnez-la

hauteur de l'écrou du moteur. La partie haute de la

corroie doit se placcer du côté droit tandis que la

partie basse de côté gauche, comme le montre la

figure 14. Tournez la brosse pour s'assurer que la

courroie est placée correctement.

Page -19-

Page 20

HOW TO REPLACE MOTOR

IMPORTANT: Disconnect machine before replacing

motor.

4

1

5

1. Detach bag (1).

2. Remove screw (2) and nut (3) at bottom of handle

tube.

3. Press the handle release pedal (9) and pull handle

down to horizontal position.

4. Remove handle tube from socket.

6

7

3

5. Remove screw (6).

6. Remove height adjustment knob (7).

2

7. Turn machine upside down.

8

9

8. Remove cover springs (8).

9. Remove retainer bar (19).

10. Remove bottom plate (10).

Fig. 15

11. Remove fan cover (11).

15

12. Remove band (12).

13

16

14

13. Hold vacuum cleaner from the motor cover and turn

to the upright position. Remove motor cover.

18

17

19

10

12

11

14. Remove tunnels from motor (13, 14).

15. Remove screws (15, 16, 17, 18).

16. Disconnect cord from switch.

17. Disconnect connector.

18. Remove motor (fig. 11).

19. Replace new motor.

To assemble machine, follow above steps in a reverse

order.

Fig. 16

Page -20- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 21

COMO REEMPLAZAR EL MOTOR

COMMENT REMPLACER LE MOTEUR

IMPORTANTE: Desconecte la máquina antes de

reemplazar el motor.

1. Desmonte la bolsa (1).

2. Quitar el tornillo y la tuerca de la base del tubo (2,

3).

3. Presione el pedal de retén manija (9) y baje la

manija a la posicion horizontal.

4. Quite el tubo manija (5).

5. Quite la pija fijadora de la perilla de ajuste de altura

(6).

6. Remueva la perilla de ajuste de altura (7).

7. Voltee la barredora hacia abajo.

8. Quite los resortes de sostén de la cubierta (8).

9. Remueva la varilla retén tapa (19).

10. Quite la tapa del rodillo (10).

IMPORTANT: débranchez l'appareil avant de

remplacer le moteur.

1. Retirer le sac.

2. Enlever la vis et l'écrou du table (2, 3).

3. Appuyer sur la pédale support poignée (9) et

baisser la poignée á la position horizontale.

4. Enlever le tube support poignée (5).

5. Retirer la pige qui supporte le bouton de réglage de

la hauteur.

6. Remuer le bouton de réglage de la hauteur (7) (fig.

10).

7. Tourner la balayeuse á l'envers.

8. Retirer les ressorts du support du couvercie (8).

9. Remuer la conde á piano (19).

10. Eniever le convercle du rouleau (10).

11. Quite la tapa ventilador (11).

12. Quite la banda (12).

13. Sostenga la barredora por la cubierta del motor y

voltéela a que quede en la posicion correcta.

Desmonte lá cubierta del motor.

14. Quite los tuneless del motor (13, 14).

15. Remueva los tornillos del motor (15, 16, 17, 18).

16. Desconecte el cable del interruptor o switch.

17. Desconecte el conector manual.

18. Quite el motor (fig. 11).

19. Instale el nuevo motor y arme su barredora

siguiendo los pasos anteriores en sentido inverso.

11. Retirer le couvercle du ventilateur (11).

12. Retirer la courroie (12).

13. Soutenir la balayeuse par le couvercle du moteur et

retourner-la pour trouver une position correcte.

Démonter le couvercle du moteur.

14. Retirer les pieces en formes de tunnel (13, 14).

15. Dévisser les vis du moteur (15, 16, 17, 18).

16. Débrancher le cable de l'interrupteur.

17. Renlever le connecteur manuel.

18. Enlever le moteur (Fig. 11).

19. Installer le nouveau moteur et assambler la

balayeuse en suivant les instructions en sens

inverse.

CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page -21-

Page 22

NOTES

Page 23

ALTO® PRODUCT SUPPORT BRANCHES

U. S. A. Locations European Locations

HEAD OFFICE

AL T O U.S . Inc., St. Louis, Missouri

16253 Swingley Ridge Road, Suite 200

Chesterfield, Missouri 63017-1725

PRODUCTION FACILITIES

AL T O U.S. Inc., Springdale, Arkansas

2100 Highway 265

Springdale, Arkansas 72764

(501) 750-1000

Customer Service - 1-800-253-0367

Tec hnical Service - 1-800-356-7274

AL T O U.S . Inc., Bo wling Green, Ohio 43402

1100 Haskins

SERVICE FACILITIES

AL T O U .S. Inc., Carlstadt, New Jersey 07072

150 Commerce Road

(201) 460-4774

AL T O U .S. Inc., Elk Grov e, Illinois 60007

2280 Elmhurst Road

(847) 956-7900

AL T O U.S. Inc., Den ver , Colorado 80204

1955 West 13th A ve .

(303) 623-4367

AL T O U.S . Inc., Houston, Texas 77040

7215 North Gessner Road

PRODUCTION FACILITIES

AL T O Danmark A/S, Aalborg

Blytaekkervej 2

DK-9000 Aalborg

+45 72 18 21 00

AL T O Danmark A/S, Hadsund

Industrikvarteret

DK-9560 Hadsund

+45 72 18 21 00

SALES SUBSIDIARIES

AL TO Canada Ltd., Re xdale Ontario

24 Constellation Ct.

(416) 675-5830

ALTO Overseas Inc., Sydney (Australia)

1B/8 Resolution Drive

Caringbah NSW 2229

+61 2 9524 6122

AL T O Cleaning Systems Asia Pte Ltd., Singapore

No. 17 Link Road

Singapore 619034

+65 268 1006

AL TO Deutschland GmbH, Bellenberg (Germany)

Guido-Oberdorfer-Straße 2-8

89287 Bellenberg

+49 0180 5 37 37 37

AL T O Cleaning Systems (UK) Ltd., Penrith

Gilwilly Industrial Estate

Penrith

Cumbria CA11 9BN

+44 1768 868 995

SALES AND SERVICE FACILITIES

AL TO U.S. Inc., Madison Heights, Michigan 48071-0158

29815 John R.

(810) 544-6300

AL TO U .S. Inc., Marietta, Georgia 30062

1355 West Oak Common Lane

(770) 973-5225

CLARKE TECHNOLOGY

AMERICAN SANDERS TECHNOLOGY

A.L. COOK TECHNOLOGY

Customer Service Headquarters and Factory

2100 Highway 265

Springdale, Arkansas 72764

(501) 750-1000

Technical Service

1-800-356-7274

AL T O France S .A. Strasbourg

B.P. 44, 4 Place d’Ostwald

F-67036 Strasbourg

Cedex 2

+33 3 8828 8400

AL TO Nederland B .V . Vianen

Stuartweg 4C

NL-4131 NJ Vianen

+31 347 324000

AL TO Sv erige AB, Molndal (Sweden)

Aminogatan 18

Box 4029

S-431 04 Molndal

+46 31 706 73 00

ALTO Norge A/S, Oslo (Norway)

Bjornerudveien 24

N-1266

+47 2275 1770

Page 24

CLARKE TECHNOLOGY WARRANTY

This Clarke Technology Industrial/Commercial Product is warranted to be free from defects in materials and

workmanship under normal use and service for a period of one year from the date of purchase, when operated and

maintained in accordance with Clarke Technology's Maintenance and Operations instructions.

This warranty is extended only to the original purchaser for use of the product. It does not cover normal

wear parts such as electrical cable, rubber parts, hoses and motor brushes.

If difficulty develops with the product, you should:

(a). Contact the nearest authorized Clarke Technology repair location or contact the Clarke Technology Service

Operations Department, 2100 Highway 265, Springdale, Arkansas 72764, for the nearest authorized Clarke Technology repair location. Only these locations are authorized to make repairs to the product under this warranty.

(b). Return the product to the nearest Clarke Technology repair location. Transportation charges to and from the

repair location must be prepaid by the purchaser.

(c). Clarke Technology will repair the product and or replace any defective parts without charge within a reasonable time after receipt of the product.

Clarke Technology's liability under this warranty is limited to repair of the product and/or replacement of parts

and is given to purchaser in lieu of all other remedies, including INCIDENTAL AND CONSEQUENTIAL DAMAGES.

THERE ARE NO EXPRESS WARRANTIES OTHER THAN THOSE SPECIFIED HEREIN. THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE FACE HEREOF. NO WARRANTIES,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MECHANTABILITY, SHALL BE IMPLIED. A warranty

registration card is provided with your Clarke Technology product. Return the card to assist Clarke Technology in

providing the performance you expect from your new floor machine.

ALTO U.S. Inc., 2100 Highway 265, Springdale, Arkansas 72764.

CLARKE TECHNOLOGY reserves the right to make

changes or improvements to its machine without notice.

Always use genuine Clarke Technology Parts for repair.

CLARKE TECHNOLOGY

2100 Highway 265

Springdale, Arkansas, 72764

Page 25

Repair Parts

530 / 530cc

List

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read

this book prior to operating or attempting any service or maintenance procedure to your ALTO machine

could result in injury to you or to other personnel; damage to the machine or to other property could

occur as well. You must have training in the operation of this machine before using it. If operator(s)

cannot read English, have this manual explained fully before attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

For new books write to: ALTO U.S. Inc., 2100 Highway 265, Springdale, Arkansas 72764.

Upright Vacuum

Form No. 70070A 7/99 Clarke Technology Printed in the U.S.A.

Page 26

Table of Contents

Final Test for Product Safety .................................................................................. 3

Replacement Procedures ....................................................................................... 3

To Disassemble the Motor ...................................................................................... 4

530 Upright Vacuum External Parts ........................................................................ 5

530 Upright Vacuum Internal Parts ......................................................................... 6

530 Upright Motor Assembly................................................................................... 8

Trouble Shooting Guide .......................................................................................... 9

Wiring Diagram ....................................................................................................... 9

530cc Drawing Assembly and Parts List ................................................................. 10

Page -2- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 27

FINAL TEST FOR PRODUCT SAFETY

At the completion of any repairs the product should be

electrically tested for running and electric strength as

follows:

Electric Strength

1. Set hi-pot test meter to 1500 volts.

2. Product switch to ON-position.

3. Touch one probe of tester to one blade of power

cord plug and touch other probe to handle tube.

There should be no breakdown.

Running

Run the machine with the height adjustment knob on

high and check:

1. There should be no abnormal noise or vibration.

2. The carbon brushes spark should be small and

uniform.

3. The current should not exceed 9.0 amps.

NOTE: The letters with the item no., references,

identify item number on internal (I), external (E) or

motor (M) illustrations.

REPLACEMENT PROCEDURES

1. To Remove Bag (30-E).

Release Spring (36-E) from handle, turn knob on

bag coupling ccw (25-E), slide coupling off unit.

2. To Remove Handle Tube (7-E, 10-E).

a. Disengage line cord from line cord retainer (3E)

pulling cord outward from retainer bottom.

b. Remove bolt and nut (8E and 9E) on handle

socket (24-I) and pull tube out.

4. To Replace the Brush Roll (52-I) or Bearing

Supports (54-I).

a. Follow steps indicated on point 3a and 3b.

b. Remove bearing support (54-I) pulling them

away from brush roll (old or new).

c. Place bearing supports on new brush roll, place

belt over roll and replace it on chassis following

steps 3e.

5. To Replace Rear Wheels (16-I).

a. Remove hood as in step 7.

b. Pull out retainer pin (19-I) from axle, and slide

wheels outward.

c. Replace the new wheel and axle, and insert the

pin.

d. Replace hood.

6. To Replace Front Wheels (42-E).

a. Remove hood as in step 7.

b. Remove screws (44-I) from front axle supports

(45-I) and take out axle assembly.

c. Remove cotter pin (43-E) and flat washer (59-I)

and pull out wheel.

d. Replace the new front wheel, washer and cotter

pin.

e. Replace axle assembly on chassis making

sure springs (51 and 47-I) are in place.

f. Replace hood.

7. To Remove the Hood (17-E).

a. Remove bag and handle tube as in steps 1 and

2.

b. Depress handle release pedal (31-I) and rotate

socket (24-I) to horizontal position.

c. Remove screw from height adjustment knob

(11-E) and pull out knob (12-E).

d. Place upright on hood so wheels face upward,

make sure to place on protected surface not to

damage hood.

e. Remove springs (18-E) from "V" tabs on

chassis, turn upright holding hood and separate

hood from chassis.

3. To Replace The Belt (39-I)

a. Place upright on hood so wheels face upward.

Make sure to place on protected surface not to

damage hood.

b. Remove retaining bar (58-I) by pressing down

on right side (longest), remove brush roll cover

(57-I) and fan cover (38-I).

c. Stretch and twist belt over motor pulley (15-M)

to pull it out. (If not broken).

d. Remove complete brush roll (52-I) with bearing

supports (54-I) pulling it out near the bearings.

e. Place new belt on roll, replace roll on chassis

making sure the mark "top" on bearings

support faces towards the brush roll cover and

reassemble.

CLARKE TECHNOLOGY 539 Upright Vacuum Operator's Manual

8. To Replace Motor (3-I).

a. Remove belt as in steps 3a to 3c.

b. Remove hood as in step 7.

c. Release air ducts (1-I and 15-I) applying

pressure on both sides and slide out.

d. Remove the four motor base screws (4-I)

disconnect switch leads and pull out motor.

9. To Replace Height Adjustment Cam (13-I).

a. Remove hood as in step 7.

b. Slide cam assembly out.

c. Replace new cam and reassemble.

10. To Replace Handle Release Pedal (31-I).

a. Remove hood as in step 7.

b. Remove spring (32-I) from chassis.

c. Pull pedal towards spring slide and remove.

Page -3-

Page 28

REPLACEMENT PROCEDURES (cont.)

11.

To Replace Handle Socket (24-I).

a. Remove hood as in step 7.

b. Remove handle release pedal as in step 10.

c. Remove "C" washers (17-I) from socket bolt

(18-I) pull out bolt and remove socket.

12. To Replace Handle Position Cam (27-I).

a. Remove handle socket as in step 11.

b. Pull out "c" washer (30-I) and bolt (29-I) remove

cam and cam spring (28-I).

c. When reassembling be sure spring (28-I) is

located as before.

16. To Replace the Fan.

a. Remove the belt as in point 3 a , b and c.

b. Hold the fan (14-M) while turning loose the nut

(15-M).

c. Remove nut and fan.

d. Remove the new fan and reassemble.

17. Motor Servicing.

The only possible motor repairs are :

a. Replace carbon brushes.

b. Replace armature.

c. Replace field.

NOTE: Never try to repair the field or armature, if

defective replace with a new one.

13. To Replace the Line Cord (2A-I).

a. Disengage line cord from retainer in handle as

in step 2a.

b. Remove handle tube as in step 2.

c. Remove hood as in step 7.

d. Disconnect switch and ground leads.

e. Remove the insulating cover from switch lead

forcing a sharp 1/16 needle to rise the rib inside

the insulator and pull it out. (Or cut wire to

insulated terminal leaving enough wire to

reconnect.)

f. Remove Heyco strain relief (20-I) from chassis

with Heyco pliers and slide it out of the line

cord.

g. Slide strain reliefs and hook on the new line

cord, and reassemble with the Heyco pliers

making sure to locate the strain relief as it was

before.

14. To Replace the On-Off Switch (12-M).

a. Remove hood as in step 7.

b. Disconnect the electrical terminal from switch.

c. Press the side tabs on the switch and pull it

out.

d. Press the new switch on the opening until the

tabs snap, and reconnect the terminal.

TO DISASSEMBLE THE MOTOR

1. Remove motor as in point 8.

2. Hold the fan (14-M) while turning loose nut (15-M)

and remove nut and fan.

3. Remove the electrical connection to carbon

brushes pulling them out of the terminals.

4. Remove the brush holders support screws (5-M)

and take out the brush holder assembly (3-M). If

the carbon brush is worn out replace the complete

assembly (3-M).

5. Remove the four motor cover screws (2-M) and lift

the motor cover (1).

6. Remove field and armature and replace as

required.

7. Reassemble in reverse order making sure the field

springs (10-M), the ground washer (16-M) and the

ground lead are in correct position.

15. To Replace the Switch Actuator (22-I).

a. Remove hood as in step 7.

b. Remove "C" washer (25-I) from bolt (23) and

slide out the bolt and the actuator assembly.

c. Replace the new actuator and assemble.

Page -4- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 29

CLARKE TECHNOLOGY

530 Upright Vacuum

External Parts 7/99

1

2A

11

12

14

17

18

5

6

7

10

3

31

32

4

8

9

65

8

33

29

34

30B

20

35

30C

29D

21

20

22

30D

29D

19

28

23

19

27

24

25

26

36

36A

36B

NOTE: uindicates a change has taken place

since last publication of this manual.

Ref. Part No. Description Qty

1 50037A Handle Grip 1

2A 50038A Line Cord Assembly, 3W/120v 1

2A 52092Au Line cord Assembly, 3W/230v 1

3 50039A Cord Retainer 1

4 962731 Screw Type "A" #8 x ½ 1

5 50040A Pop Rivet 5/32 x ¼ 2

6 50041A Cord Hook 2

7 50042A Upper Handle 1

8 50043A Handle Nut 2

9 85361Au Screw, #10-32 X 1 2

10 50044A Lower Handle 1

11 962606u Screw, 6 x

3

/8 1

12 50045A Wheel Height Knob 1

14 50047A Felt 1

17 50054A Hood, without Lens 1

18 50055A Hood Spring 2

19 920224u Nut #10-32 2

20 50056A Star Washer, #10 x .204 2

21 50057A Bag Support 1

22 85307A Screw, #10-32 x 5/8 1

36

36A

36B

Ref. Part No. Description Qty

23 50058A Ball 1

24 50059A Bag Knob Spacer 1

25 50060A Bag Knob 1

26 85383A Screw, #10-32 x 3/4 1

27 50061A Screw, 6 x 55/16 1

28 50062A Knob Spring 1

29 50064A Permanent Cloth Bag Asm. 1

29D 50067A Plastic Strap 2

30 50069A Zipper Bag Assembly 1

30B 50072A Paper Bag Connector 1

30C 50073A Spring Paper Bag 1

30D 50074A Zipper Bag Hose 1

31 660683u Paper Bag 1

32 50076A Clip Bag 1

33 920108 Hexagonal Nut 8-32 2

34 50077A Star Washer 2

35 85303A Screw, 8-32 x 3/8 1

36 50078A Bag Coupling Gasket Asm. 1

36A 50079A Bag Coupling Gasket 1

36B 50080A Bag Coupling 1

CLARKE TECHNOLOGY 539 Upright Vacuum Operator's Manual

Page -5-

Page 30

CLARKE TECHNOLOGY

530 Upright Vacuum

Internal Parts 7/99

65

1

61

62

63

43

42

22A

22

22B

20

24

2

3

61

62

4

5

4

5

26

25

27

28

29

30

10

15

16

17

8

18

19

1

64

65

63

11

12

13

17

31

32

19

60

16

59

53

53A

53B

53C

51

52

57

58

48

49

50

47

46

44

45

59

40

42

43

41

53C

39

53B

53A

36

35

33

34

37

8

37A

37B

53

Page -6- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 31

CLARKE TECHNOLOGY

530 Upright Vacuum

Internal Parts 7/99

Ref. Part No. Description Qty.

1 50081A Air Duct Gasket 1

2 50082A Right Air Duct 1

3 50084A Motor Assembly, 120v 1

3 50085A Motor Assembly, 230v 1

4 962027 Screw, #8-32 x ½ 4

5 50087A Flat Washer .208 x ½ 4

8 50090A Rear Wheel Hub Asm. 2

10 85313C Screw, #6-32 x 3/8 3

11 50091A Flat Washer .208 x ½ 3

12 50092A Plate Cam Guide 1

13 50093A Can Spring Asm. 1

15 50094A Left Air Duct 1

16 50095A Rear Wheel 2

17 50096A Washer 15/16 2

18 50097A Socket Bolt 1

19 50098A Retainer Clip 2

22 50099A Switch Actuator Asm. 1

22A 50171A Switch Actuator 1

22B 50172A Switch Bolt 1

24 50173A Tube Socket 1

25 50174A Washer, .207 x .507 1

26 50175A Spring 1

27 50176A Handle Cam 1

28 50177A Cam Spring 1

29 50178A Cam Bolt 1

30 50179A Washer 3-16 2

31 50180A Handle Release Pedal 1

32 50181A Spring 1

33 962350 Screw, #10-32 x ½ 2

34 50182A Flat Washer .200x .624 2

35 50183A Star Washer #10 x .204 2

36 920224 Nut 10-32 2

37 50184A Fan Cover With Gasket 2

37A 50185A Fan Cover Gasket

37B 50186A Fan Cover 1

39 903340u Brush Roll Belt 1

40 50188A Chassis 1

41 50189A Bumper 1

42 50190A Front Wheel 2

43 50191A Cotter Pin 2

44 962027 Screw, #8-32 x ½ 3

45 50192A Front Axle Retainer 2

46 50193A Front Axle Assembly 1

NOTE: uindicates a

change has taken place

since last publication of

this manual.

CLARKE TECHNOLOGY 539 Upright Vacuum Operator's Manual

47 50194A Front Axle Spring 1

48 50195A Type B Rivet 1

49 50196A Flat Washer, .171 x .500 1

50 50197A Axle Bushing 1

51 50198A Front Axle Spring 1

52 50199A Brush Roll Assembly 1

53 50210A Bearing Support Assembly 1

53A 50211A Bearing Support Gasket 2

53B 50212A Bearing Support 2

53C 50213A Bearing Support Felt 2

57 50214A Bottom Plate With Gasket 1

58 50215A Bottom Plate Retainer 1

59 50216A Flat Washer, .315 x .627 2

60 962992 Screw, #8.32 x 5/8 1

61 920108 Hexagonal Nut 8-32 2

62 50217A Star Washer, 10 x .204 3

63 50218A Ground Lead 1

64 962606

65 52091Au Radio Supressor (230V) 1

u Screw, #6 x 5/16 1

Page -7-

Page 32

CLARKE TECHNOLOGY

530 Upright Vacuum

Motor Assembly 7/99

7

1

1A

9

10

5

4

3

2

15

16

14

10

1B

2

3

4

5

12

11B

11

NOTE: uindicates a change has taken

place since last publication of this

manual.

Ref. Part No. Description Qty

1 50219A Motor Cover Assembly 1

1A 50220A Motor Cover 1

1B 50221A Nut #8-32 2

2 962731 Screw, 8 x ½ 4

3 50222A Brush Holder Assembly 2

4 50223A Brush Holder Support 2

5 85303A Screw #8-32 x 3/8 2

7 50224A Washer .850 x .017 1

8 52088Au Armature Assembly 120v 1

Ref. Part No. Description Qty

9 50226A Field Assembly 120v 1

9 52090Au Field Assembly 230v 1

10 50228A Spring 2

11 50229A Motor Base with Gasket 1

11B 50231A Motor Base Gasket

12 50232A Rocker Switch 1

14 50233A Fan 1

15 50234A Belt Pulley Nut 1

16 50235A Ground Washer 1

8 52089Au Armature Assembly 230v 1

Page -8- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 33

TROUBLE SHOOTING GUIDE

PROBLEM POSSIBLE CAUSE SOLUTION

Motor does not run. 1) Not firmly plugged in. 1) Check attachement plug.

2) Bad On-Off switch. 2) Replace switch.

3) Line open. 3) Replace cord.

4) Motor open. 4) Check motor and wiring.

5) Fan locked by material. 5) Remove obstruction.

Motor runs but cleaner 1) Belt broken. 1) Replace belt.

does not pick up. 2) Blocked air system. 2) Clean obstruction.

3) Fan broken. 3) Replace fan.

4) Worn brush roll. 4) Replace brush roll.

5) Motor slow. 5) Check carbon brushes.

6) Bag full. 6) Empty bag (or change paper bag).

Motor runs erratically. 1) Worn carbon brushes. 1) Replace brushes.

2) Defective armature. 2) Check spark, replace armature.

3) Bad electrical connection. 3) Check wiring.

4) Defective On-Off switch. 4) Replace switch.

Brush roll vibrates. 1) Ball bearing worn out. 1) Replace brush roll.

2) Ball bearing holder damaged. 2) Replace ball bearing holder.

CLARKE TECHNOLOGY

530 Upright Vacuum

Wiring Diagram 8/98

CLARKE TECHNOLOGY 539 Upright Vacuum Operator's Manual

Page -9-

Page 34

CLARKE TECHNOLOGY

530cc Upright Vacuum

Assembly Drawing and Parts List 7/99

Ref. Part No. Description Qty

1 50807A Bag Spring 1

2 50808A Bag Clip 1

3 50809A Bag Assembly 1

4 50810A Cup Frame 1

5 85303A Screw, 8-32 x 3/8 2

6 50087A Flat Washer 2

7 50221A Hex Nut, 8-32 2

8 50811A Clamp 1

9 50812A Cup Gasket 1

10 50813A Cup Assembly 1

11 50814A Upper Hose Seal 1

12 50815A Exhaust Hose 1

13 619221 Cable Tie 2

14 50816A Dust Cup Hose 1

15 50078A Bag Coupling Gasket Asm. 1

15a 50080A Bag Coupling 1

15b 50079A Bag Coupling Gasket 1

Page -10- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Page 35

ALTO® PRODUCT SUPPORT BRANCHES

U. S. A. Locations European Locations

HEAD OFFICE

AL T O U.S . Inc., St. Louis, Missouri

16253 Swingley Ridge Road, Suite 200

Chesterfield, Missouri 63017-1725

PRODUCTION FACILITIES

AL T O U.S. Inc., Springdale, Arkansas

2100 Highway 265

Springdale, Arkansas 72764

(501) 750-1000

Customer Service - 1-800-253-0367

Technical Service - 1-800-356-7274

AL T O U.S . Inc., Bo wling Green, Ohio 43402

1100 Haskins

SERVICE FACILITIES

AL T O U .S. Inc., Carlstadt, New Jersey 07072

150 Commerce Road

(201) 460-4774

AL T O U .S. Inc., Elk Grov e, Illinois 60007

2280 Elmhurst Road

(847) 956-7900

AL T O U.S. Inc., Den ver , Colorado 80204

1955 West 13th A ve .

(303) 623-4367

AL T O U.S . Inc., Houston, Texas 77040

7215 North Gessner Road

PRODUCTION FACILITIES

AL T O Danmark A/S, Aalborg

Blytaekkervej 2

DK-9000 Aalborg

+45 72 18 21 00

AL T O Danmark A/S, Hadsund

Industrikvarteret

DK-9560 Hadsund

+45 72 18 21 00

SALES SUBSIDIARIES

AL T O Canada Ltd., Rexdale Ontario

24 Constellation Ct.

(416) 675-5830

ALTO Overseas Inc., Sydney (Austr alia)

1B/8 Resolution Drive

Caringbah NSW 2229

+61 2 9524 6122

AL T O Cleaning Systems Asia Pte Ltd., Singapore

No. 17 Link Road

Singapore 619034

+65 268 1006

AL TO Deutschland GmbH, Bellenberg (Germany)

Guido-Oberdorfer-Straße 2-8

89287 Bellenberg

+49 0180 5 37 37 37

AL T O Cleaning Systems (UK) Ltd., Penrith

Gilwilly Industrial Estate

Penrith

Cumbria CA11 9BN

+44 1768 868 995

SALES AND SERVICE FACILITIES

AL TO U.S. Inc., Madison Heights, Michigan 48071-0158

29815 John R.

(810) 544-6300

AL TO U .S. Inc., Marietta, Georgia 30062

1355 West Oak Common Lane

(770) 973-5225

CLARKE TECHNOLOGY

AMERICAN SANDERS TECHNOLOGY

A.L. COOK TECHNOLOGY

Customer Service Headquarters and Factory

2100 Highway 265

Springdale, Arkansas 72764

(501) 750-1000

Technical Service

1-800-356-7274

AL T O France S .A. Str asbourg

B.P. 44, 4 Place d’Ostwald

F-67036 Strasbourg

Cedex 2

+33 3 8828 8400

AL T O Nederland B.V . Vianen

Stuartweg 4C

NL-4131 NJ Vianen

+31 347 324000

AL T O Sverige AB, Molndal (Sweden)

Aminogatan 18

Box 4029

S-431 04 Molndal

+46 31 706 73 00

ALTO Norge A/S, Oslo (Norway)

Bjornerudveien 24

N-1266

+47 2275 1770

Page 36

CLARKE TECHNOLOGY WARRANTY

This Clarke Technology Industrial/Commercial Product is warranted to be free from defects in materials and

workmanship under normal use and service for a period of one year from the date of purchase, when operated and

maintained in accordance with Clarke Technology's Maintenance and Operations instructions.

This warranty is extended only to the original purchaser for use of the product. It does not cover normal

wear parts such as electrical cable, rubber parts, hoses and motor brushes.

If difficulty develops with the product, you should:

(a). Contact the nearest authorized Clarke Technology repair location or contact the Clarke Technology Service

Operations Department, 2100 Highway 265, Springdale, Arkansas 72764, for the nearest authorized Clarke Technology repair location. Only these locations are authorized to make repairs to the product under this warranty.

(b). Return the product to the nearest Clarke Technology repair location. Transportation charges to and from the

repair location must be prepaid by the purchaser.

(c). Clarke Technology will repair the product and or replace any defective parts without charge within a reasonable time after receipt of the product.

Clarke Technology's liability under this warranty is limited to repair of the product and/or replacement of parts

and is given to purchaser in lieu of all other remedies, including INCIDENTAL AND CONSEQUENTIAL DAMAGES.

THERE ARE NO EXPRESS WARRANTIES OTHER THAN THOSE SPECIFIED HEREIN. THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE FACE HEREOF. NO WARRANTIES,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MECHANTABILITY, SHALL BE IMPLIED. A warranty

registration card is provided with your Clarke Technology product. Return the card to assist Clarke Technology in

providing the performance you expect from your new floor machine.

ALTO U.S. Inc., 2100 Highway 265, Springdale, Arkansas 72764.

CLARKE TECHNOLOGY reserves the right to make

changes or improvements to its machine without notice.

Always use genuine Clarke Technology Parts for repair.

CLARKE TECHNOLOGY

2100 Highway 265

Springdale, Arkansas, 72764

Page -12- CLARKE TECHNOLOGY 530 Upright Vacuum Operator's Manual

Loading...

Loading...