Page 1

R

RCA3

Remote Control

Anywhere! Kit

EMOTE

C

ONTROL

A

NYWHERE

! K

IT

TABLE OF CONTENTS

Introduction 2

Getting

Started 4

Installation 4

System

Operation 13

Optional

Accessories 14

Running Sensor

Cable in New

Construction 16

Concealing

Sensor Cable

in Existing

Walls 18

Specifications 22

WARNING – To prevent possible injury, the

following basic safety precautions should be

observed in the installation and use of your

Remote Control Anywhere Kit.

1. Read through the entire manual – Before attempting

any installation, read this manual thoroughly and keep it for

future reference.

2.

Avoid contact with all high voltage electrical wiring

and equipment!

3. Keep away from water and moisture – Never use or

install electronic products near water, ie., near a bathtub,

sink, washing machine, in a wet basement, near a swimming pool, or anywhere else the product may be exposed

to water or moisture.

4. Power supply cord protection – Do not run the power

cord where it may be subject to wear or abuse. Do not

allow anything to rest on or roll over the power cord which

may damage it.

6.

Lightning – It is suggested that you remove the power

supply from the wall if your system will not be used for long

periods of time. Power surges due to lightning strikes may

damage your equipment.

7.

Check your local building and electrical codes –

There may be specific requirements regarding running low

voltage in your area.

Page 2

R

3-30V

AC/DC

ST

ATUS

IN

EMOTECONTROL

Introduction

The Remote Control Anywhere! Kit

enables you to operate your remote controlled audio/video equipment from virtually any location. Now you can place

your audio/video (A/V) components out

of sight (behind cabinet doors, in the rear

of a room, or in a different room) and still

conveniently control your system.

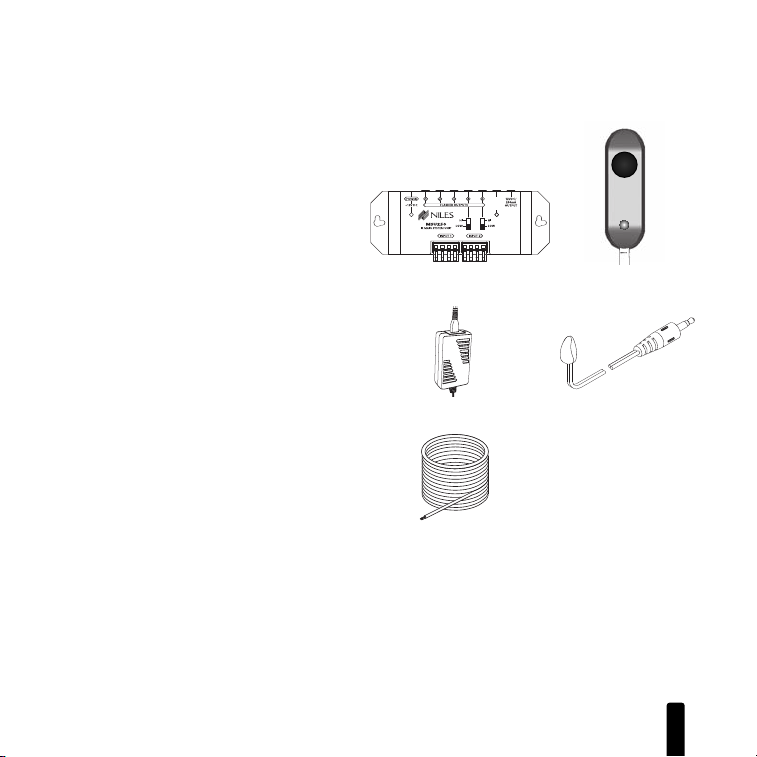

Kit Contents

Check that your Remote Control

Anywhere! Kit contains the following:

• Connection hub

• Surface mount sensor

• 12VDC power supply

• MicroFlashers (5)

• Category 5 sensor cable (50')

A

NYWHERE

! K

IT

Connection Hub Table-Top Sensor

12VDC Power Supply

MicroFlashers (5)

Category 5 sensor

Cable (50ft)

2

Page 3

R

EMOTECONTROL

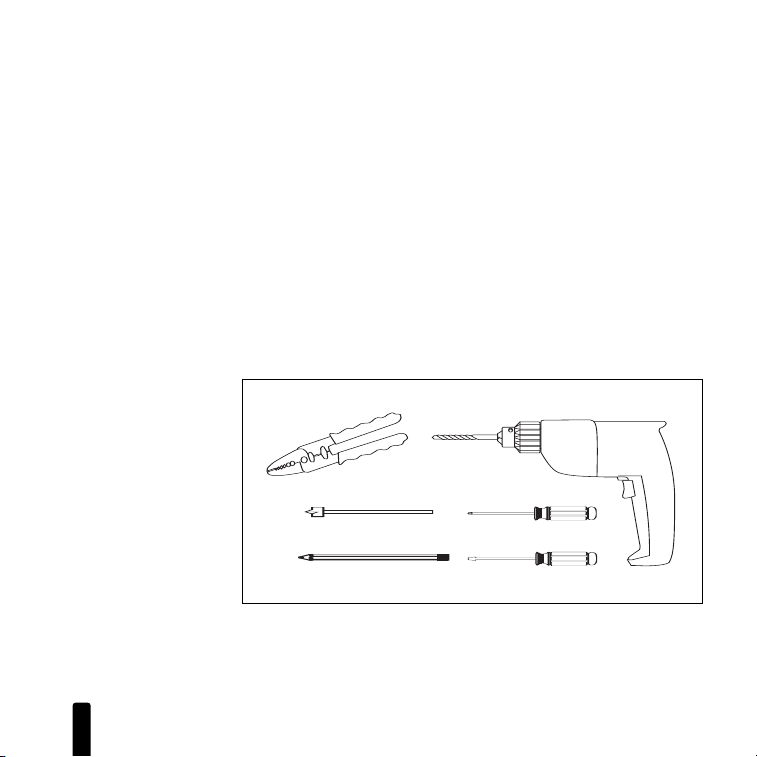

Tools Needed

• Pencil

• Standard screwdriver

• Phillips screwdriver

• Wire strippers

• Drill (and assorted bits)

A

NYWHERE

! K

IT

3

Page 4

R

3-30V

AC/DC

ST

ATUS

IN

EMOTECONTROL

A

NYWHERE

Getting Started

While the Remote Control Anywhere! Kit is compatible

with most brands of audio/video components, there are

a few exceptions. You should perform a temporary hookup to test for compatibility before you conceal wire or

permanently mount any parts.

Steps One through Five describe how to perform a

quick and easy check for compatibility.

Once you have determined that all of your remote

controlled A/V components are compatible,

proceed with the rest of the installation.

Installation

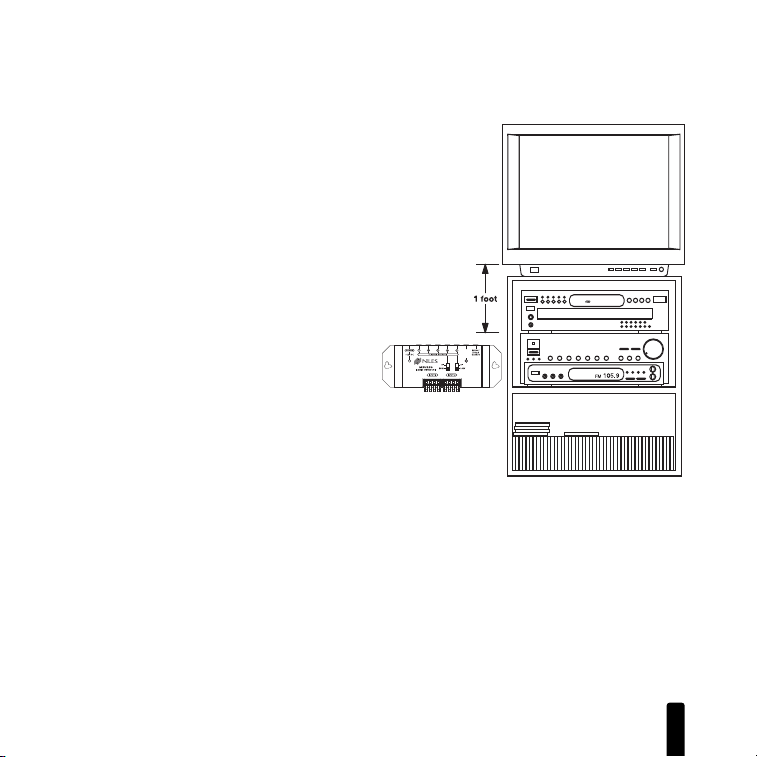

Step 1 – Placing the Connection Hub

Place the Connection Hub so that the MicroFlasher wires

will reach the components.

Never place the connection hub closer than

1' away from a television set (Figure 1).

! K

IT

Figure 1: Connection

Hub Placement

4

Page 5

R

3-30V

AC/DC

STATUS

IN

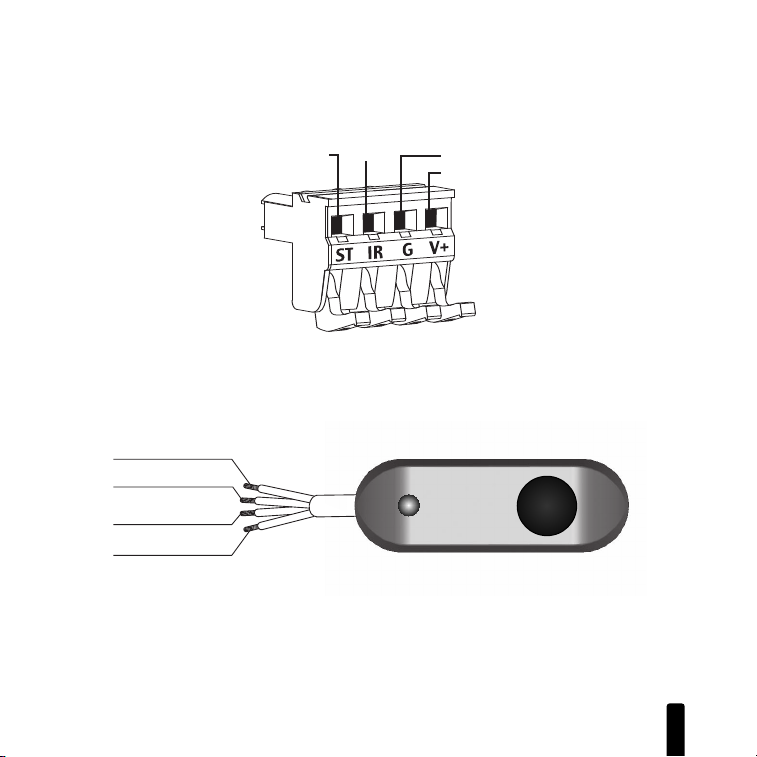

Red = 12V+

Black = Ground

Yellow = Data

White = Status

EMOTECONTROL

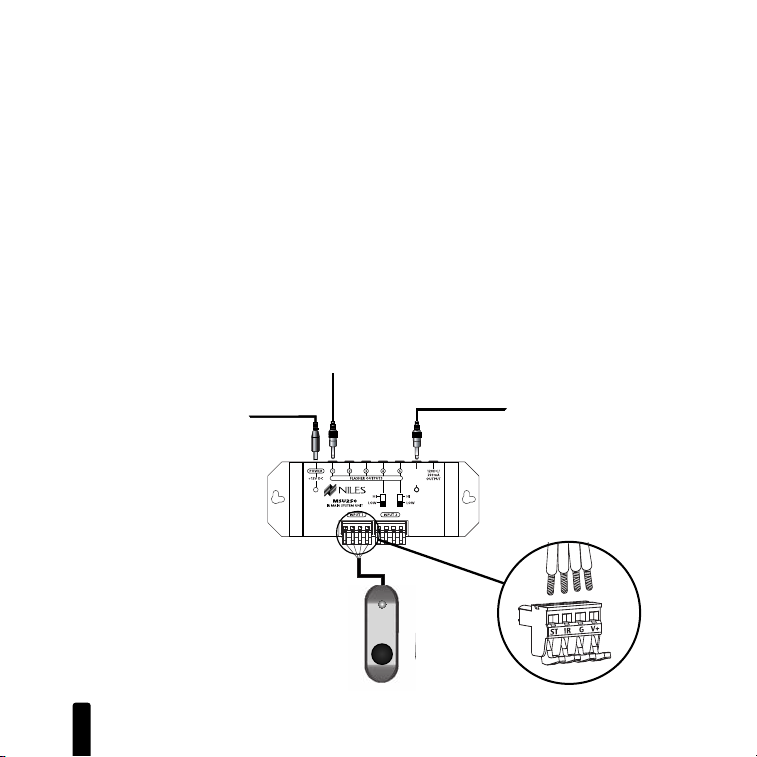

Step 2 – Connecting the Sensor Cable to the

Connection Hub

For your convenience, the sensor cable ends have

been stripped.

Insert each wire into the appropriate hole on the removable

connector plug (

To help you, the connector plug is keyed. Insert the smooth

side of the connector plug into the smooth side of the socket.

Don’t force the scalloped side of the connector plug into the

smooth side of the socket.

Make sure that the orientation of the connector matches the

sensor (Figure 3).

A

NYWHERE

! K

IT

Figure 2), and snap the locking tab down.

o uns

T

AC Outlet

witched

To Niles

IR Flasher

To 12VDC Power Supply

Plugged into a switched AC Outlet.

Typically found in back of a receiver.

Figure 2:

MSU250 Installation

5

MSU250

MS200 Sensor

MSU250 Sensor

onnection

C

Page 6

R

1 = STATUS

4 = 12V DC

2 = DATA 3 = GROUND

Red = 12V+

Black = Ground

Yellow = Data

White = Status

EMOTECONTROL

Figure 3: Removable

A

Connector Plug

NYWHERE

! K

IT

Figure 4: Wiring legend

6

Page 7

R

Additional

Flashers

REMOTE CONTROL ANYWHERE!

CONNECTION HUB

3-30V

AC/DC

STATUS

IN

EMOTECONTROL

A

NYWHERE

! K

IT

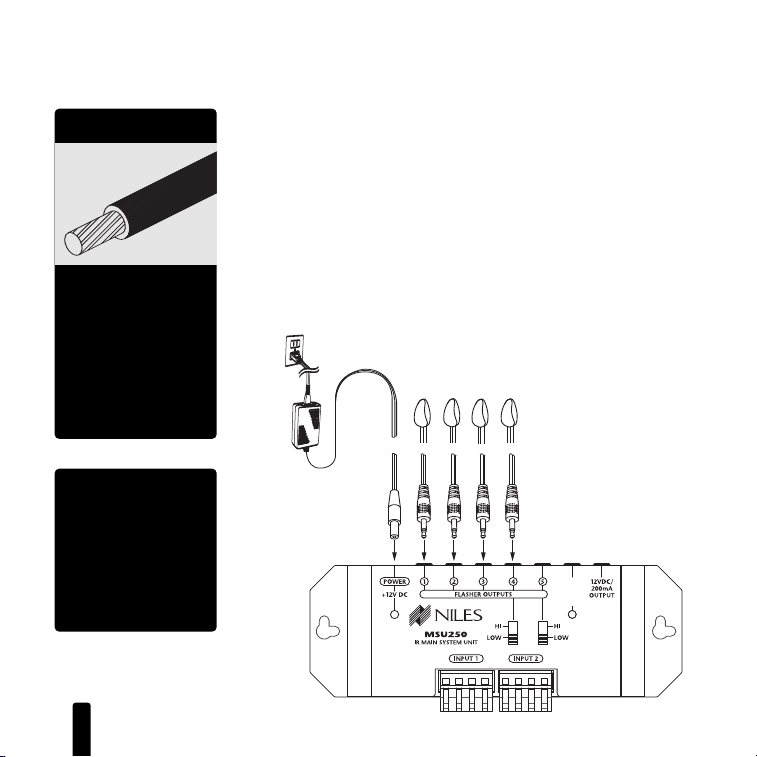

“TECH TIP”

Wire size is expressed

by it’s AWG (American

Wire Gauge) number.

The lower the AWG

number, the larger

the wire, i.e., 20 AWG

wire is physically larger

than 22 AWG.

“TECH TIP”

Make all final connec-

tions to the MSU

before connecting the

power supply. This will

avoid potential dam-

age to components.

Step 3 – Connecting the 12VDC In-Line Power Supply

and MicroFlashers

Plug the MicroFlashers into any of the sockets labeled FLASHER

OUTPUTS on the connection hub (

Figure 5).

Plug the connector on the supplied 12VDC power supply into

the socket labeled POWER on the connection hub and then

plug the wall adapter into a live electrical outlet. The power

LED should light.

If the LED does not light, confirm that the outlet you used is

live by plugging in a lamp.

Figure 5:

Connection Ports

7

Page 8

R

EMOTECONTROL

A

NYWHERE

Step 4 – Mounting a MicroFlasher to A/V Components

Make sure all of your remote controls have batteries and that

they are able to operate the A/V components.

Locate a place for the remote control that is within arm’s

length of the A/V components, yet cannot directly control

them. Place the table-top sensor no closer than two feet in

front of the remote control (

Figure 6).

Hold the MicroFlasher four inches

in front of the remote sensor

window on the A/V component’s front panel. Press buttons on the remote control

while watching the front

panel of the A/V component. When the component responds repeatedly

to the commands, peel off

the protective backing on

the MicroFlasher and place

the MicroFlasher in that

location.

If the A/V component’s

remote sensor is not clearly

marked, slowly move the

MicroFlasher over the window of the A/V component

while pushing buttons on

the remote control until you

get a response (

Figure 7).

! K

IT

Figure 6:

Locating IR Sensor

8

Page 9

R

EMOTECONTROL

Figure 7: Locating IR Sensor

supply from the electrical outlet and disconnect the sensor and

the MicroFlasher cables from the connection hub (

The connection hub can be either mounted on a wall using

screws or placed on a shelf using the included adhesive feet

(Figure 9).

A

NYWHERE

! K

IT

Repeat this procedure for each A/V component

you wish to control.

When the A/V component responds repeatedly,

peel off the protective backing on the

MicroFlasher and place the MicroFlasher in that

location.

If you get no response at all, call Niles Technical

Support at 1-800-289-4434 (M-F 8:00 AM –

7:00 PM ET).

Step 5 – Mounting the Connection Hub

Make sure that your system tested OK before

proceeding

Once you have decided on the ideal location for

the connection hub, unplug the 12VDC power

Figure 8).

9

Page 10

R

3-30V

AC/DC

STATUS

IN

1

2

3

4

POWER

+

12V D

C

3-30V

AC/DC

STA

TUS

IN

FLASHER OUTPUTS

MS

U14

0

IR MAIN SYSTEM UNIT

INPUT 1

EMOTECONTROL

A

NYWHERE

! K

IT

Figure 8: Removing Cables

Figure 9A & B

Wall mounting

A:

B: If you desire to shelf mount the connection hub, stick the included adhesive backed feet on the bottom

of the unit and place it on the shelf

MSU250 Base

Figure 9A: Wall-mount placement

Use sheetrock screws

Figure 9B: Table-top placement

Self-Adhesive

Rubber Feet

Affix the enclosed self-adhesive

rubber feet to the base of the MSU250

10

Page 11

R

EMOTECONTROL

Step 6 – Running the Sensor Cable

Conceal the sensor cable between the sensor and the

connection hub.

For specific information refer to “Running Sensor Cable in New

Construction”, located on

Cable in Existing Walls”, located on page 18.

If you need to cut and restrip the wire, make sure that only

1/4" of wire is exposed. Exposing too much wire could create

“shorts” within the system.

If you have doubts about whether you are capable of installing

a Niles Remote Control Anywhere! Kit in your walls, consult a Niles

dealer or professional installer. They have special tools, techniques,

and experience to make the impossible possible. The installer can

provide you with an estimate before any work is done.

A

NYWHERE

! K

page 16, or “Concealing Sensor

IMPORTANT

IT

11

Page 12

R

Additional

Flashers

REMOTE CONTROL ANYWHERE!

CONNECTION HUB

3-30V

AC/DC

STATUS

IN

EMOTECONTROL

A

NYWHERE

! K

IT

Step 7 – Reconnecting the Connection Hub

Reconnect the sensor plug, flashers and power supply as

outlined in steps 2, 3 and 4 (

Figure 10).

That’s it! Now you are ready to control your audio/video

equipment from the room you chose.

Figure 10: Connecting

Power Supply and

Flashers

NOTE

Make sure that the

stripped ends of the

wire do not come

in contact with

one another or any

surface other than

the connector.

12

Page 13

R

EMOTECONTROL

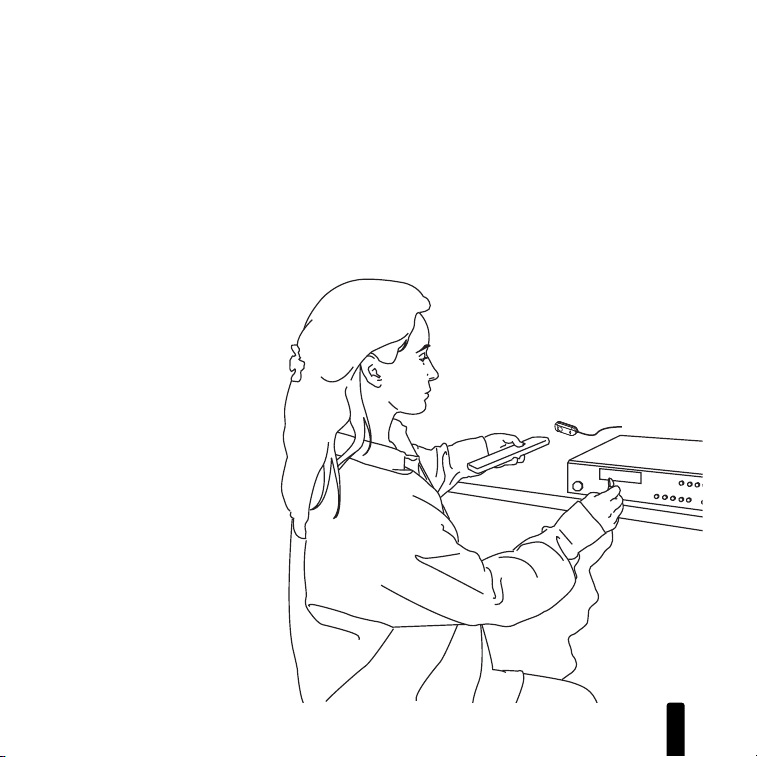

Normal Operation

To control your audio/video components, simply aim your

remote control at the table-top sensor.

If you are within range (and your remote control’s

batteries are fresh), the LED on the sensor will flash a bright blue

color each time you press a button on the remote (

If you are using a remote control with macro capabilities (a single

press of a button issues a string of commands), allow sufficient

time for all of the commands to execute.

A

Figure 11:

System Operation

NYWHERE

! K

IT

Figure 11).

13

Page 14

REMOTE CONTROL ANYWHERE! KIT

CONNECTION HUB

3-30V

AC/DC

STATUS

IN

R

EMOTECONTROL

A

NYWHERE

Optional Accessories

Status Feedback Wall Adapter

The sensor features a status feedback LED that glows green

whenever your system is on. This is a very useful feature when

operating your equipment from a remote location. For this

feature to work, your system receiver (or preamp) must have a

switched AC outlet and you must purchase the optional Status

Feedback 12VDC Wall Adapter (FG00665). The Status

Feedback wall adapter is plugged into the switched AC outlet

of your receiver. The 12VDC output plug is inserted into the

connection hub’s Status Input (

Figure 12: Connecting the

Status Adaptor

Figure 12).

Switched outlet on

the back of receiver

or preamp.

! K

IT

14

Page 15

R

EMOTECONTROL

Additional Sensors

The Remote Control Anywhere! Kit includes one surface

mount sensor. The included MSU250 main system unit

will accommodate a second IR sensor. Niles makes a variety of

sensors for virtually any application. See your Niles dealer for

more information.

A

NYWHERE

! K

IT

15

Page 16

R

EMOTECONTROL

A

NYWHERE

Running Sensor Cable in New Construction

Scheduling and Preparation

Plan to schedule the sensor wiring after the electrical wiring is

finished. That way you can avoid cable routes which could

potentially induce interference over the sensor cable. The basic

rules are:

Never run the sensor cable through the same hole as

an electrical cable.

Never run the sensor cable into the same J-box as

electrical cable.

Avoid running the sensor cable beside the electrical

cable. Keep it at least 3 or 4 feet distant from any

electrical power cable.

As side-by-side wiring is unavoidable in particular spots in

every house, just move the sensor cable route away as soon as

possible. If construction forces a side by side run for more than

ten feet, install metal conduit or shielded sensor cable. Lowvoltage cables such as doorbells, intercoms, telephone, speaker, security, or television cannot cause interference on your

sensor cables, so you can safely run all of them at the same

time, through the same holes, side-by-side.

! K

IT

16

Page 17

R

EMOTECONTROL

Safety First!

Wear gloves, safety goggles and head protection when drilling.

Avoid nails, they ruin bits and they can cause injury. Pay particular attention when using “hole-hogs” and other powerful

electric drills; the torque of the drill when suddenly stopped by

a nail can break a strong person’s wrist.

Drilling

Use a bit that is large enough for the cables you plan to run.

An auger bit is the preferred bit for rough-in wiring. It will

actually pull itself through the wood, so that the drill motor,

not you, does most of the work.

Always drill the holes in the center of the stud. If you have to

notch the stud or drill the hole closer than one inch from the

edge of the stud, protect the cable with a nail plate.

When drilling holes in ceiling joists, drill in the center of the

joists and try to locate the hole near the end of the joist.

DO NOT drill through a “gluelam” or any load bearing

beam without the direction of your contractor.

Try to line the holes up perfectly, because it makes pulling the

cable much easier. A good technique is to snap a chalk line

across the face of the studs or against the bottom of the ceiling

joists. Then work backward so that you can always see the

holes you have already drilled. Paying careful attention to this

will save you a lot of time later!

A

NYWHERE

! K

IT

17

Page 18

R

EMOTECONTROL

A

NYWHERE

Pulling the Cable

Whenever you run the cable farther than 4-1/2 feet from a

hole in a stud or joist (open attic space, going up walls, etc.),

fasten the cable to the joists or studs using cable clamps or

appropriately sized cable staples. The cable should not have

large sags in it, nor should it be too tight. Try to protect the

cable from being stepped on in attics or other unfinished

crawl spaces. There are guard strips, raceways and conduits

which can be used to protect the cable. Consult the local

building code for special requirements in your area.

Concealing Sensor Cable in Existing Walls

This is actually a fairly simple task if you restrict your choice of

the table-top sensor location and cable routes to the interior

walls or ceilings of your home. Interior walls in almost all

North American residences are hollow, so that it is easy to

route new sensor cable around the house. What you see

when you look at the painted wall board, plaster, or paneling

is only the skin of the wall. Behind the skin is the skeleton;

two-by-four wood or metal “studs” running vertically from

the floor to the ceiling in walls and 2 x 6 or larger “joists” running horizontally in the ceilings and floors. In between the

studs and the joists is the space for the wiring and plumbing

of your home.

! K

IT

18

Page 19

R

EMOTECONTROL

A

NYWHERE

! K

IT

Exterior walls are different. They must insulate the house from

the heat and cold outside, so they are stuffed with insulation.

The national building code requires that the hollow wall space

in exterior walls be broken by a horizontal stud placed

between the vertical studs. This “fire blocking” makes it very

difficult to retrofit long lengths of cable. In some areas of the

country the exterior walls are constructed of solid masonry,

and have no hollow space for cables.

Start by examining all the possible routes you might take to run

the sensor cable from the sensor location to the A/V components to be controlled. Use a stud sensor or other device to

locate the internal structure of the wall. You want to avoid all

studs or joists. A typical route would be from the sensor location up the inside of the wall to a new hole drilled into the top

“plate” (horizontal 2 x 4 at the top of the inside of the wall),

into the attic crawl space, then down another plate to the wall

behind the stereo system itself. The other very common route is

through the bottom plate of the wall into an unfinished basement or crawl space.

Identify where all of your electrical, phone, and TV wiring is

likely to be and plan to route around it all. You can accidentally induce interference on your sensor cable right beside electrical cable for more than a few feet. Try to keep sensor cable

running parallel to power cables at least 3 feet away. To find

exactly where an electrical cable is routed, try inspecting the

inside of the wall by turning off the breaker for a particular

power outlet or switch, removing the cover plate and switch

or receptacle, and shining a penlight into the wall. If you have

access to an attic or basement space, you can see which part

of the wall space is free of obstructions (

19

Figure 13).

Page 20

R

EMOTECONTROL

A

NYWHERE

When you don’t have access

above or below the wall, try

to estimate the existing cable

and pipe locations from the

positions of electrical outlets

and plumbing fixtures on

both sides of the wall. Also,

take a look at the outside of

your house, sometimes a

conduit, vent or drain pipe

will be visible and will offer

useful information. Choose

the route with the fewest

Figure 13:

Unobstructed space

for sensor cable

potential obstacles. If your

house is built on a slab or

you are wiring between two finished floors, look for baseboards which could be removed and replaced with the cable

behind them. Doorjambs can be removed and often have

enough space for sensor cable all the way around the door

Figure 14).

(

Sometimes, an under-the-carpet run is possible. As a last

resort, heating and air conditioning vents can be used as cable

raceways for plenum rated cable (check your local building

codes, some municipalities require a conduit).

! K

IT

20

Page 21

R

EMOTECONTROLANYWHERE

! K

IT

When you are dealing with the

unknown because of the structure of your home, or with difficult materials to patch the wall,

such as plaster, lath and plaster,

faux finishes, wallpaper etc., be

patient. A careful study of the

potential problems before you

start the job will pay off later.

Figure 14: Routing Wire

Around a Door

21

Page 22

R

EMOTECONTROL

A

NYWHERE

! K

IT

Specifications

MSU250

IR System

Compatible with virtually all brands of remotes

using carrier frequencies between 26 and

105kHz.

iring Requirements

W

Individual home-runs of category 5 cable from

each sensor/keypad.

Unit Dimensions

5-5/8" wide x 1-1/4" high x 2" deep

Power Requirements

12 vDC power supply (included).

MS200

IR System

Compatible with virtually all brands of remotes

using carrier frequencies between 26 and

105 kHz

IR Receiving Range

18' to 30' depending upon the strength of the

remote control

IR Receiving Angle

30° off-axis (horizontal and vertical) at 20'

Mounting

Surface mount

Wiring Requirements

Individual “home-runs” of category 5 cable

Unit Dimensions

11/16" wide x 1/2" high x 2-1/16" deep

MF1VF

IR System

Compatible with virtually all brands of remotes

using carrier frequencies between 20 and 455

IR Transmitting Range

Up to 4' (Typically mounts to the IR remote

sensor window of an audio/video component).

IR T

ransmitting Angle

Transmits in a “pinpoint” transmission pattern

(the off-axis power drops off very rapidly).

Unit Dimensions

5/16" Wide x 3/16" High x 1/2" Long.

kHz

.

22

Page 23

Niles Audio

Corporation

www.nilesaudio.com

12331 S.W. 130 Street

Miami, Florida, 33186

Tel: (305) 238-4373

Fax: (305) 238-0185

2004 Niles Audio Corporation. All rights reserved. Niles, the Niles logo, IntelliPad and Blending High Fidelity

©

and Architecture are registered trademarks of Niles Audio Corporation. MicroFlasher is a trademark of Niles

Audio Corporation. Because we strive to improve our products. All other trademarks are the property of their

respective owners. Niles reserves the right to change product specifications without notice. The technical and

other information contained herein is not intended to set forth all technical and other specifications of

Niles products. Additional information can be obtained on-line at www.nilesaudio.com or by calling Niles at

1-800-289-4434. 09/04 Printed in China. DS00408ACN

Page 24

INSTALLATION & OPERATION GUIDE

Remote Control

Remote Control

Anywhere!™Kit

Anywhere!™Kit

B LENDING H IGH F IDELITY AND A RCHITECTURE

®

Loading...

Loading...