Page 1

INSTALLATION & OPERATION GUIDE

MODELS

B LENDING H IGH F IDELITY

AND A RCHITECTURE

®

®

Page 2

Congratulations!

Thank you for choosing a High Definition In-Wall Loudspeaker from Niles. With

proper installation and operation, you'll enjoy years of trouble-free use.

Niles manufactures the industry's most complete line of custom installation components and accessories for audio/video systems.

TABLE OF CONTENTS

INTRODUCTION 2

FEATURES AND BENEFITS 2

INSTALLATION CONSIDERATIONS 4

SPEAKER PLACEMENT 6

INSTALLATION FUNDAMENTALS 9

INSTALLATION OF BRACKETS, FRAMES AND GRILLES IN NEW CONSTRUCTION 13

INSTALLATION OF BRACKETS, FRAMES AND GRILLES IN EXISTING WALLS 15

INSTALLATION OFTHE SPEAKER, SENSOR AND GRILLE IN NEWOR EXISTING CONSTRUCTION 16

REMOVAL OF SPEAKER AND GRILLE 20

OPERATION 20

SPECIFICATIONS 21

NOTES 23

©2008 Niles Audio Corporation. All rights reserved. Niles, the Niles logo, Blending High Fidelity and MicroSensor, System

Integration Amplifiers are registered trademarks of Niles Audio Corporation. BumpBack and TCC are trademarks of Niles Audio

Corporation. Dolby is a registered trademark of Dolby Laboratories Licensing Corporation. Decora is a registered trademark of

Leviton Manufacturing Co. Because Niles strives to continuously improve its products, Niles reserves the right to change product

specifications without notice. The technical and other information contained herein is not intended to set forth all technical and other

specifications of Niles products. Additional information can be obtained on-line at www.nilesaudio.com.DS00282B

Page 3

Introduction

The HD or High Definition group of

In-Wall Loudspeakers offers speakers

expressly designed for superior sonic

quality. They employ advanced technology components designed to extract the

subtle nuances in recorded music or the

Features and Benefits

Injection Molded TCC™ (Talc, Carbon

and Ceramic) Woofer with Butyl Rubber

Surround Vented Pole Piece, Vented

Pole Piece and Custom Debris Screen

The Niles High Definition series loudspeakers employ a newly developed cone

material that combines injection molded

polypropylene with talc, carbon and

ceramic stiffening agents. The result is a

cone that offers extreme stiffness and light

weight for accurate, dynamic response.

Additionally, the woofer employs a vented

pole piece for increased bass linearity and

a Butyl Rubber Surround for improved

midrange damping and clarity as well as

moisture resistance.

1” Teteron Tri-laminate Tweeter

Housed in a Precision Adjustment

Mechanism

The HD series Teteron Tweeter employs a

tri-laminate design consisting of an inner

textile layer which forms the dome, a high

damping layer to kill unwanted resonances

and an outside layer of urethane to add

stiffness and prevent breakup modes. The

result is a transparently clear, sweet, natur

al sounding tweeter which still maintains

extended frequency response.

This advanced tweeter is housed in a precision adjustment mechanism which permits

thunderous action in a movie. They are

perfect anywhere that quality of sound is

most important consideration.

the

An HD5/HD6/HD8/HD8.3 Speaker Kit;

and the corresponding Bracket Kit (5,

6 or 8) is required to install one pair of

HD5/HD6/HD8/HD8.3 In-Wall loudspeakers in either new or existing

construction.

the tweeter to be accurately positioned after

installation for optimum performance and

without the diffraction distortion typical of

traditional pivoting tweeters.

Antiresonant Wave Bracing

The HD speaker’s baffle design employs

specially molded ribs that increase the

rigidity of the baffle and raise the resonant

frequency so that less “out-of-phase” cancellation takes place. Equally important,

the ribs are curved and crossed to further

shift vibration modes away from low-bass

canceling frequencies. This keeps bass

tones rich and dynamic.

Front-Mounted Bass & Treble Controls

Niles High Definition speaker models

feature baffle-mounted tone controls for

Bass and Treble that enable instant fine

tuning after the speakers are installed. This

feature helps to lessen the effects of less

than perfect placement or other room

acoustics anomalies.

Snap-in Baffle Assembly

This proprietary Niles design enables

installers to attach Niles loudspeaker

assemblies to previously installed frames

without additional hardware or tools. Niles'

Snap-in design makes it easy to upgrade

-

Niles' speakers after installation without the

hassles associated with removal and reinstallation of traditional designs. Snap-in

baffles make installation of Niles speaker

baffles easier and faster than other in-wall

brands.

Features and Benefits

2

Page 4

Features and Benefits

BumpBack™ Woofer Magnet

Niles engineers have utilized a unique

motor construction enabling far greater

“throw” or voice coil excursion. This

allows a high level of bass performance to

be achieved.

Moisture Resistant Construction

The HD loudspeakers are suitable for use

in high moisture environments. The drivers are impervious to moisture; the grille

is made of powder-coated aluminum, and

all exposed hardware is made of stainless

steel. However, the speakers are not

waterproof and direct contact with water

should be avoided.

Absolutely Flush to the Wall

Appearance

The unique mounting system of the HD

loudspeakers powerfully clamps the frame

to the bracket, sandwiching the wall material between them. Because the clamping

action is totally uniform around the frame,

there are no shadows or gaps between the

wall and the frame. Additionally, the Niles

mounting system is carefully optimized to

stiffen the surrounding drywall and prevent it from resonating. You hear only the

music, not the drywall.

Easy Retrofit Installation in your

Existing Home

Designed for ease of installation, the Niles

mounting system makes retrofit installations simple and fast. A supplied template

assures fast and accurate hole cutting. The

bracket slips behind the drywall and the

screws secure the bracket to the frame,

sandwiching the drywall between them.

The speaker baffle attaches to the frame,

and the grille mounts over the speaker.

particular stage of construction. When the

framing and wiring are finished, you install

the

bracket. After the drywall is up, but

before the painter begins to paint, you

install the

aluminum

can be painted to match the surroundings.

Only when construction is completely finished do you put the valuable

the wall. You don’t have to mask or prep

the speaker for painting, and worries about

theft during the final phases of construction

are never an issue!

Low Diffraction, MicroPerf™

Aluminum Grilles

HD speakers include aluminum grilles.

The painted aluminum grille has hundreds

of precisely sized perforations, creating an

acoustically transparent grille.

Infrared Sensor Mount

The speaker baffle has a locator designed

for the Niles MS-110 MicroSensor

miniature infrared sensor. The MS110

installs discreetly behind the aluminum

grille and therefore minimizes wall clutter in your home. When you want to

control your equipment, you simply

point your remote control at the speaker

from up to 15 feet awa

frame and provide the rustproof

grilles to the painter so that they

speaker in

®

,a

y.

Three Stage Installation System for

Remodels or New Construction

You install only the parts you need for a

3

Page 5

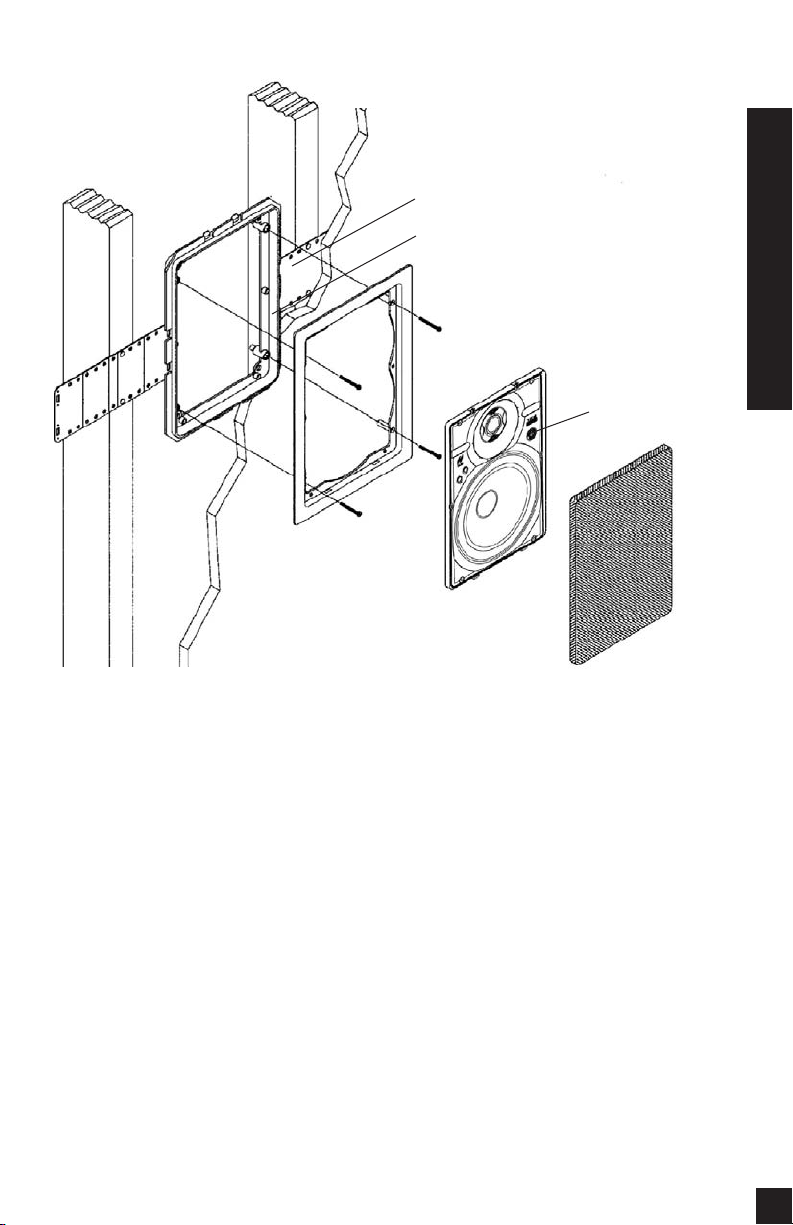

Model HD8 Shown

New Construction Wings

Bracket

Frame

Speaker Baffle

Figure 1

IR Knockout

Installation Considerations

Grille

Installation Considerations

Recommended Amplifier Power

For satisfactory performance, we recommend an amplifier with a power rating of

ten to one hundred watts for the HD5;

and ten to one hundred twenty-five watts

for the HD6, and ten to one hundred fifty

watts for the HD8 and HD8.3. Curiously,

most speakers are not damaged by large

amplifiers but by small amplifiers. If your

system is playing loudly, a small amplifier

will run out of power very quickly. When

an amplifier runs out of power it creates

damaging “clipping” distortion. A large

amplifier will play at the same volume

without distorting. See the section on

operating the speakers for more information about clipping distortion.

Incorporating a Local Volume Control

In a multiroom system there is one indispensible device for true convenience—a

local volume control. It allows you to

adjust the volume of the speakers without

leaving the room.

Plan to wire the system so that each pair

of speakers has its own volume control

built into the wall (think of a volume control as a dimmer switch for sound).

Niles makes a wide range of high performance indoor and outdoor volume controls. They are available in Standard or

Decora

light switches and dimmers).

trols are connected in line with the speak-

®

style cover plates (just like your

olume con

V

-

4

Page 6

Installation Considerations

er, so you must connect the wire from the

amplifier to the volume control and then

from the volume control to the speaker.

Speaker Wire

Use 2-conductor speaker wire when connecting HD speakers to your receiver or

amplifier. For most applications, we recommend you use 16 or 18 gauge stranded

wire. For wiring runs longer than 80 feet

we recommend 14 gauge stranded wire.

The no-strip terminals of the HD speakers

will accommodate 12 to 18 gauge wire.

When you run wire inside walls, special

jacketing (CL-2 or CL-3) is required to

both protect the wire and for fire prevention. In some areas conduit is required.

For a trouble-free installation, low voltage

wire such as speaker wire must be run in

accordance with the National Electrical

Code and any applicable provisions of the

local building code. If you are unsure of

the correct installation techniques, wire

jacket or type of conduit to use, consult a

professional audio/video installer, your

building contractor, or the local building

and inspection department.

Incorporating a Remote Control

If you are planning to use a stereo system

with a hand held IR remote control, consider the advantages of installing a Niles

IR Repeater system. You are able to control all of the functions of your system

from the room with the remote pair of

speakers. Niles makes a number of IR sensors which install in the wall, in the ceiling,

in cabinetry, on tabletops, or even behind

the grille of your Niles HD speakers.

An IR sensor requires that a 2-conductor

shielded wire (West Penn D291 or equivalent) be home run from each sensor location to the main equipment location. This

wire is normally run beside the speaker

wire at the same time. Typically, the sensor is placed in a location that faces your

listening position. Most remote controls

will have an effective line of sight range of

18 to 30 feet with any Niles sensor placed

in a wall, ceiling, on a cabinet or tabletop.

However, when you place a Niles MS110

MicroSensor

minum grille of a speaker the effective

range is reduced to 9 to 15 feet.

Insulating the Wall Cavity

For best performance from your speakers fill

the wall cavity behind the speaker with

fiberglass insulation (e.g. R-19 unbated insulation). Try to keep the same amount of

insulation for each speaker, particularly in

the same room, for consistent bass response.

®

behind the perforated alu-

TECH TIP

Wire size is expressed by its AWG (American Wire

a

G

h

t

umber. The lower the number, the larger

n

)

e

g

u

ire, i.e. twelve AWG is physically larger than

w

e

fourteen AWG.

5

Page 7

Speaker Placement

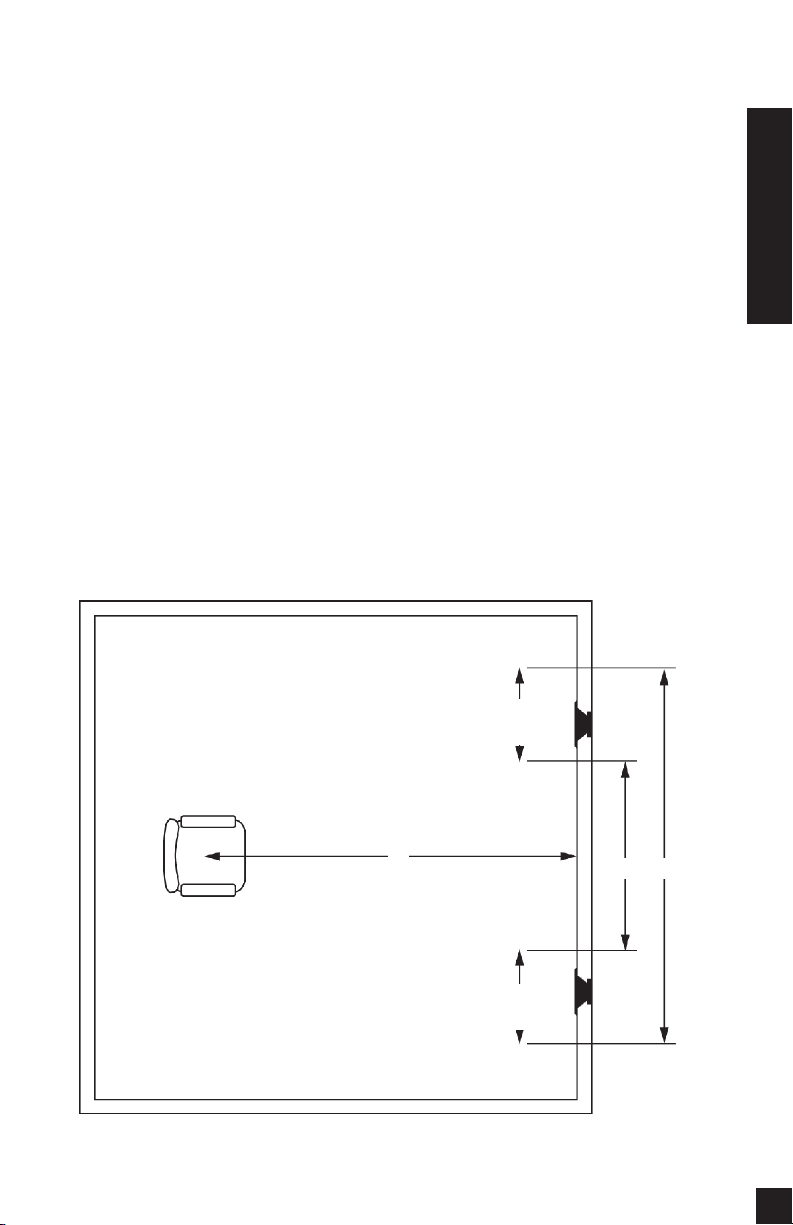

Placement for Critical Listening

If you like to imagine that the band or

orchestra is playing in front of you as you

listen to music, or you are very conscious of

clarity, detail and the textures of the individual instruments, you are a critical listener.

In a home theater, the intelligibility of dialog and action reproduced by the front

speakers is paramount! The position of the

speakers plays a very important role in

how clear the sound is and how a stereo

image is created. Here are some guidelines to make the process of placement

quick and easy.

Make sure the sound will not be blocked

or reflected off of furniture or other objects.

You should have a direct line of sight with

the front of the speaker. To determine the

best position, measure the “listening” distance between the ideal listening position

(your favorite chair or couch) and the wall

in which you plan to install the speakers.

Try to place the speakers so that they are

equally distant from your listening spot and

at least one half of the listening distance

apart (this maintains a large pleasant stereo

“image”). In home theater applications

where there is a center channel you may

choose to space the left and right main

speakers farther apart for a “bigger than

life” sound with Dolby

®

encoded movies

and TV shows. However, for combined

music and movie usage stay within the

good placement zone for music. For example; if you are ten feet back from the wall,

the speakers should be between five and

ten feet apart

(See Figure 2).

Speaker Placement

Figure 2

Speaker

Placement

Zone

10 ’

Speaker

Placement

Zone

5’

10 ’

6

Page 8

Speaker Placement

The Boundary Effect

Corners can affect the bass response of

the speaker powerfully! This is called the

boundary effect. You will emphasize particular bass frequencies and cancel out

other bass frequencies when you place

speakers close to the wall/ceiling boundary or a corner wall boundary. This can

make the speaker sound excessively

boomy and inaccurate to some listeners,

while to others it just seems like more

bass sound. A good rule of thumb is if

you always listen to your current pair of

speakers with the bass turned up, you’ll

enjoy corner placement. If you keep your

tone controls at neutral, try to keep the

speakers at least two or three feet from

the boundaries of the room.

Placement for Varying Listening

Positions

If you want the freedom to sit anywhere

in a room facing any direction, and/or

find that you prefer the “all around you”

sound of some car stereos to a conventional “sound stage” facing you, consider

the speaker placement techniques professional installers use in restaurants and

bars. They place speakers in an array

around the listening area, so that the

music is always surrounding you, regardless of the direction you face.

The rule of thumb is to add one pair of

speakers for every 100 to 200 square feet

of listening area. Curiously, this is not so

that you can play the music louder, but

so that you can play it softer! When you

have only one pair of speakers in a large

room you will notice that when the

sound is perfect in one part of the room,

it is too loud near the speakers. By placing more than one pair in the room you

will avoid these “hot spots” of loud

sound and you will create more sonic

ambiance while maintaining clarity and a

rich sound everywhere.

You can make listener position still less

critical by using mono rather than stereo.

This can be difficult to achieve with normal stereo amplifiers. However, Niles

manufactures Systems Integration

Amplifiers which enable one room to be

wired in stereo while other rooms are

wired in mono! Consult your local Niles

dealer for more information.

In smaller rooms or rooms that are infrequently used, you typically can’t justify

the expense of more than two speakers.

Try to bracket the room with the two

speakers. Diagonal placement is a very

effective way to stretch the coverage pattern of two speakers. You can also compromise between direct sound (for detail

and clarity) and reflected sound (the

ambient or “all around you” effect). By

trying to place the speakers so that they

create as much reflected sound as possible you emphasize the ambient effect.

They can be up high in the wall or even

down low at power outlet height , in the

ceiling, near corners, or directed at

reflective objects and walls. The more

reflected sound there is in the room the

stronger the ambient effect at low volumes. You should use moderation, however, otherwise the compromise becomes

too one sided and at high volumes, the

sound will be blurred and less distinct.

Placement for Home Theater Rear

Applications

In a home theater, the goal is to reproduce the experience of a great movie theater in our homes. The biggest difference

between the two is the rear or surround

speaker array in a commercial theater.

Here, it is not uncommon to see twenty

or thirty speakers around the audience.

This huge array of speakers assures that

you will feel completely surrounded by

the ambient soundtrack of the movie.

Film makers try to use the “surround”

7

Page 9

soundtrack to envelope you in the environment on screen. They will place background music, rain sounds, traffic noise,

etc. on the “surround” soundtrack. In a

home with a single pair of speakers it is

easy for the jungle sounds to sound like

they are “in the middle of your head” just

like headphones!

A single pair of HD Loudspeakers, properly placed, can create a very convincing

simulation of an array of speakers. If you

place them near a hard reflecting surface

you can make one pair of speakers sound

like several. Create as many reflections as

possible by mounting the speaker up high

in the wall so that the ceiling will act as a

powerful reflector. If you place the speakers near a corner, wash the sound down a

wall from a ceiling location, or mount the

speakers as far away as you can from the

listening area, more reflections will occur.

However, all of these placement techniques require that you work your surround sound amplifier channels harder. If

the surround sound system you are using

has a small five or ten watt amplifier for

the rear speakers, stay within five to eight

feet of the listening location. If you are

using a 25 to 50 watt amplifier you can

mount the speakers 10 to 15 feet away

from the listening location and still

achieve reasonably high volume levels.

Of course, the best way to emulate the

sound of multiple speakers is to use multiple speakers. In large or unusually shaped

rooms this might be the only way to

achieve a good effect. If you like to listen

to music surround modes which emulate

concert hall acoustics, more than two surround speakers will prove extraordinarily

effective. With Niles HD loudspeakers it is

easy to add another pair without affecting

the decor of the room. However, you will

need to use a much more powerful amplifier than that which is built into a typical

surround sound receiver or amplifier. Niles

makes a number of Systems Integration

Amplifiers

make them uniquely suited to enhance a

good surround sound system. Consult your

local Niles dealer for more information.

®

with proprietary features that

Speaker Placement

8

Page 10

Installation Fundamentals

Installation

Fundamentals

Running the Speaker Wire in New

Construction

If you have doubts about whether you are

capable of installing a Niles HD loudspeaker in your walls, consult a Niles

dealer or professional installer. They have

special tools, techniques, and experience

to make the impossible possible. The

installer can provide you with an estimate

before any work is done.

Scheduling and Preparation

Plan to schedule the speaker wiring after

the electrical wiring is finished. That way

you can avoid wire routes which could

potentially induce hum over the speaker

wire. The basic rules are:

• Never run speaker wire through the

same hole as an electrical cable.

• Never run speaker wire into the same

J-box as electrical cable.

• Avoid running the speaker wire beside

the electrical cable. Keep your speaker

cable at a distance of at least 18"-22" from

Figure 3

any electrical power cable.

Side-by-side wiring is unavoidable in particular spots in every house, just move the

speaker wire route away as soon as possible. If construction forces a side by side

run for more than ten feet, install metal

conduit or shielded speaker wire. Lowvoltage wires such as doorbells, intercoms, telephone, security, or television

cannot cause interference or hum on your

speaker wires, so you can safely run all of

them at the same time, through the same

holes, side-by-side.

Before you drill any holes, mount the

speaker brackets in the desired speaker

locations and mount p-rings or open

backed J-boxes where the in-wall volume

controls and stereo equipment will be.

Safety First!

Wear gloves, safety goggles and head protection when drilling. Avoid nails, they ruin

bits and they can create injury. Pay particular care when using “hole-hogs” and other

powerful electric drills; the torque of the

drill when suddenly stopped by a nail can

break the wrist of a strong man.

Drilling

Use a bit that is large enough for the wires

you plan to run. An auger bit is the preferred bit for rough-in wiring. It will actually pull itself through the wood, so that

the drill motor, not you, does most of the

work. You may be drilling a lot of holes,

so this is an important consideration.

Always drill the holes in the center of the

stud. If you have to notch the stud or drill

the hole closer than one inch from the

edge of the stud, protect the wire with a

nail plate

When drilling holes in ceiling joists drill

in the center of the joists and try to locate

the hole near the end of the joist.

NOT drill through a “gluelam” or any

load bearing beam without the direction

(See Figure 3).

DO

9

Page 11

of your contractor.

Try to line the holes up perfectly, because

it makes pulling the wire much easier. A

good technique is to snap a chalk line

across the face of the studs or against the

bottom of the ceiling joists. Then work

backward so that you can always see the

holes you have already drilled. Paying

careful attention to this will save you a lot

of time later on!

Pulling the Cable

Pull the cable in sections (from the stereo

to the volume control, from the volume

control to the speaker). Start with the

longest sections and use left over wire to

complete the short sections. If you plan to

pull many rooms at the same time

through a central route, walk off the distance to each destination, add a generous

fudge factor for turns and other obstacles,

then cut off each section so that you have

a bundle of wires you can pull at once.

Whenever you run the wire further than

four and one half feet from a hole in a stud

or joist (open attic space, going up walls,

etc.), fasten the wire to the joists or studs

using cable clamps or appropriately sized

wire staples. The wire should not have

large sags in it, nor should it be too tight.

Try to protect the wire from being stepped

on in attics or other unfinished crawl

spaces. There are guard strips, raceways

and conduits which can be used to protect

the cable. Consult the local building code

for special requirements in your area.

Concealing Speaker Wire

in Existing Walls

This is actually a fairly simple task if you

restrict your choice of speaker locations

and wire routes to the interior walls or

ceilings of your home. Interior walls in

almost all North American residences are

hollow, so that it is easy to flush mount

speakers into them and route new speaker

cable around the house. What you see

when you look at the painted wall

board, plaster, or paneling is only the

skin of the wall. Behind the skin is the

skeleton; two-by-four wood or metal

“studs” running vertically from the floor

to the ceiling in walls and two-by-six or

larger “joists” running horizontally in the

ceilings and floors. In between the studs

and the joists is the space for the wiring

and plumbing of your home.

Exterior walls are different. They must

insulate the house from the heat and cold

outside, so they are stuffed with insulation.

The national building code requires that

the hollow wall space in exterior walls be

broken by a horizontal stud placed

between the vertical studs. This “fire

blocking” makes it very difficult to retrofit

long lengths of wire. In some areas of the

country the exterior walls are constructed

of solid masonry, and have no hollow

space for speakers or wires.

Start by examining all the possible routes

you might take to run the speaker wire

from the speaker to the volume control

and back to the stereo. Use a stud sensor

or other device to locate the internal

structure of the wall. You want to avoid

all studs or joists. A typical route would

be: from the speaker location up the

inside of the wall to a new hole drilled

into the top “plate” (horizontal two-byfour at the top of the inside of the wall),

into the attic crawl space, then down to

the volume control location through

another top plate, back up to the attic,

across the attic, and finally down another plate to the wall behind the stereo system itself

common route is through the bottom

plate of the wall into an unfinished basement or crawl space.

(See Figure 4). The other very

Installation Fundamentals

10

Page 12

Installation Fundamentals

Speaker

Location

Identify where all of your electrical,

phone, and TV wiring is likely to be and

plan to route around it all. You can accidentally induce 60 Hz hum on your

speakers if you run your speaker wire right

beside electrical wire for more than a few

feet. Try to keep speaker wire running parallel to power cables at least 3 feet away.

To find exactly where an electrical cable is

routed, try inspecting the inside of the wall

by turning off the breaker for a particular

power outlet or switch, remov

Volume

Control

Location

Figure 4

Stereo

Location

ing the

If your house is built on a slab or you are

wiring between two finished floors, look

for baseboards which could be removed

and replaced with the wire behind them.

Doorjambs can be removed and often

have enough space for speaker wire all

the way around the door

Sometimes, an under-the-carpet run is

possible (there are special flat speaker

wires made for under-the-rug wire runs).

As a last resort, heating and air conditioning vents can be used as wire raceways for

cover plate and switch or

receptacle, and shining a penlight into the wall. If you have

access to an attic or basement

space you can quickly see

which part of the wall space is

free of obstructions

Figure 5)

When you don’t have access

above or below the wall, try

to estimate the existing wire

and pipe locations from the

positions of electrical outlets

and plumbed fixtures on both

sides of the wall. Take a look

at the outside of your house

too, sometimes conduit, vents

or drain pipe will be visible

that give useful information.

Choose the route with the

fewest potential obstacles.

.

(See Figure 6).

(See

11

Unobstructed space

for speaker wiring

Figure 5

Page 13

plenum rated wire (check your local

building codes, some municipalities

require conduit).

In traditional wood stud/drywall construction you can cut the hole for the speaker

and utilize the large hole to auger holes

across, up or down the wall for as far as

your drill bit will take you. If you have

matching paint and take reasonable care in

patching you can cut a hatch in the drywall at each stud, run your wire, and patch

and touch-up the wall

When you are dealing with the unknown

because of the structure of your home, or

with difficult to patch wall materials like

plaster, lath and plaster, faux finishes,

wallpaper etc., be patient. A careful study

of the potential problems before you start

the job will pay off.

(See Figure7).

Figure 7

Figure 6

Installation Fundamentals

12

Page 14

Installation of Brackets, Frames and Grilles in New Construction

Installation of

Brackets, Frames

and Grilles in New

Construction

Stage One: Before Drywall is Hung.

Insulating the Wall Cavity.

If feasible, fill the wall cavity with insulation at this point.

Attach the wings to the bracket by snapping them into the sides of the bracket.

The wings can be shortened by breaking

them along the scored lines if their length

will interfere with a corner or eaves. You

can mount the bracket horizontally or ver-

(See Figure 8).

tically

Screw one side of the assembled bracket

with wings to the stud using one of the

supplied screws. Level the bracket. Screw

the other side of the bracket to the stud.

Two or three screws (depending upon the

size of the model) on each side makes for

a very secure installation. Attach the wire

to the bracket at the indicated wire tie

points

(See Figure 9).

Stage Two: Before Paint

Screw the frame to the installed bracket

using the supplied screws. Do not overtighten the screws. This will distort the

frame and the grilles will not fit (this is not

permanent, just loosen the screws and the

grille will pop in)

Painting the Aluminum Grilles

The grille is important to the sound of the

(See Figure 10).

13

Figure 8

Page 15

Figure 9

Figure 10

HD loudspeakers. Do not fill the holes of

the grille with paint. The grille is constructed of aluminum with a perfectly even

powder coat overall. This powder coat is

an ideal primer.

Remove the grilles before painting. If you are

using spray paint, use two thin coats without

any primer. If you are using a compressor and

a spray gun, use the finest, most diffuse

setting. Practice first on some paper if you

have no experience painting with spray paint.

If you are using an applicator or brush, and

a can of paint, thin the paint first. You do

not want to have to poke hundreds of

holes in your beautifully painted grilles.

Installation of Brackets, Frames and Grilles in New Construction

14

Page 16

Installation of Brackets, Frames and Grilles in Existing Walls

Figure 11

Installation of

Brackets, Frames

and Grilles in

Existing Walls

IMPORTANT: Before you cut into any

wall, review the sections on running

wire and speaker placement.

1. Drill a 1/8” pilot hole just barely

through the wallboard or dry wall (1/2” to

5/8” deep in most homes) about an inch

below the center of your proposed speaker location (an inch to the side if you are

mounting the speaker horizontally). BE

VERY CAREFUL NOT TO DRILL

THROUGH EXISTING WIRES, PIPES, OR

STRUCTURE. IF YOU FEEL ANY EXTRA

RESISTANCE AS YOU ARE DRILLING,

STOP. Cut a piece of coat hanger equal to

the width of the bracket. Bend the wire in

half creating a right angle. Poke the “Lshaped” wire into the pilot hole and turn it

Figure 12

in a complete circle. If it turns freely,

repeat the procedure from a hole about an

inch above the center of your proposed

speaker location

If the wires movement is obstructed by a

pipe or cable, fill the hole (s) with spackle

or other patching compound and try

another location.

2. When determining the final location of

the cutout keep in mind that the frame

and bracket will extend beyond the

cutout. Make sure that you do not place

the edge of the cutout directly next to a

stud. Locate the studs using a stud sensor

or hand-knocking. Once you have determined the correct position for the cutout,

hold the supplied template up to the wall

surface. Level the template in either the

horizontal or the vertical position and

(See Figure 11).

mark the wall with a pencil.

Drill the four corners with a

1/4” drill bit.

3. If you are cutting a painted

or wall papered drywall use

a sheetrock or keyhole saw.

Cut the hole with the saw at

a 45 degree angle. That way,

the drywall section can be

15

Page 17

replaced cleanly if there is an unseen

obstruction behind the wall. BE VERY

CAREFUL NOT TO SAW THROUGH

EXISTING WIRES, PIPES, OR STRUCTURE.

IF YOU FEEL ANY EXTRA RESISTANCE AS

YOU ARE CUTTING, STOP.

4. If you are cutting into lath and plaster

walls, use masking tape to outline your

penciled marks, drill the four corners with

a 1/4” bit and use a razor to score the

plaster down to the lath beneath. Then use

a chisel to remove all of the plaster within

the taped outline. Finally, insert a metal

cutting blade into a sabre saw and very

slowly and carefully saw the lath. Sawing

the lath can easily vibrate plaster off the

wall. If you have the patience, use a pair

of tin snips to slowly nip away at the lath

instead. There is no risk with this method,

it is just time consuming.

5. Fill the wall cavity with insulation at

this point. Remember to use equal

amounts of insulation for each speaker.

6. Slip the mounting bracket through the

hole and pull it toward you so that its front

edge slides into the hole and stops in place.

7. Attach the frame to the bracket by

screwing the frame to the bracket using

the supplied screws. Do not overtighten

the screws, this will distort the frame and

the grilles will not fit (this is not permanent, just loosen the screws and the grille

will pop in). The screws should pull the

frame and bracket together (sandwiching

the drywall) so that the frame is absolutely

flush with the wall surface. There should

be no gaps between the wall and the

(See Figure 12).

frame

Installation of the Speaker, Sensor and Grille in New or Existing Construction

Installation of the

Speaker, Sensor and

Grille in New or

Existing Construction

Installing a Niles MS110 MicroSensor

There is a 1/2" round molded "IR Sensor

Knockout" on the face of the speaker baffle. To prevent damage to the crossover

network you must remove the knockout

from the rear of the speaker. Do not

attempt to remove the knockout with the

speaker face up. Lay the speaker face

down on a clean carpet or rug. Put the tip

of a screwdriver into the center of the

round "knockout" and sharply tap the

screwdriver handle as necessary. Install

the MS110 using its mounting hex nut and

washer so that it is tightly secured to the

speaker. Connect all wires and continue

your installation.

16

Page 18

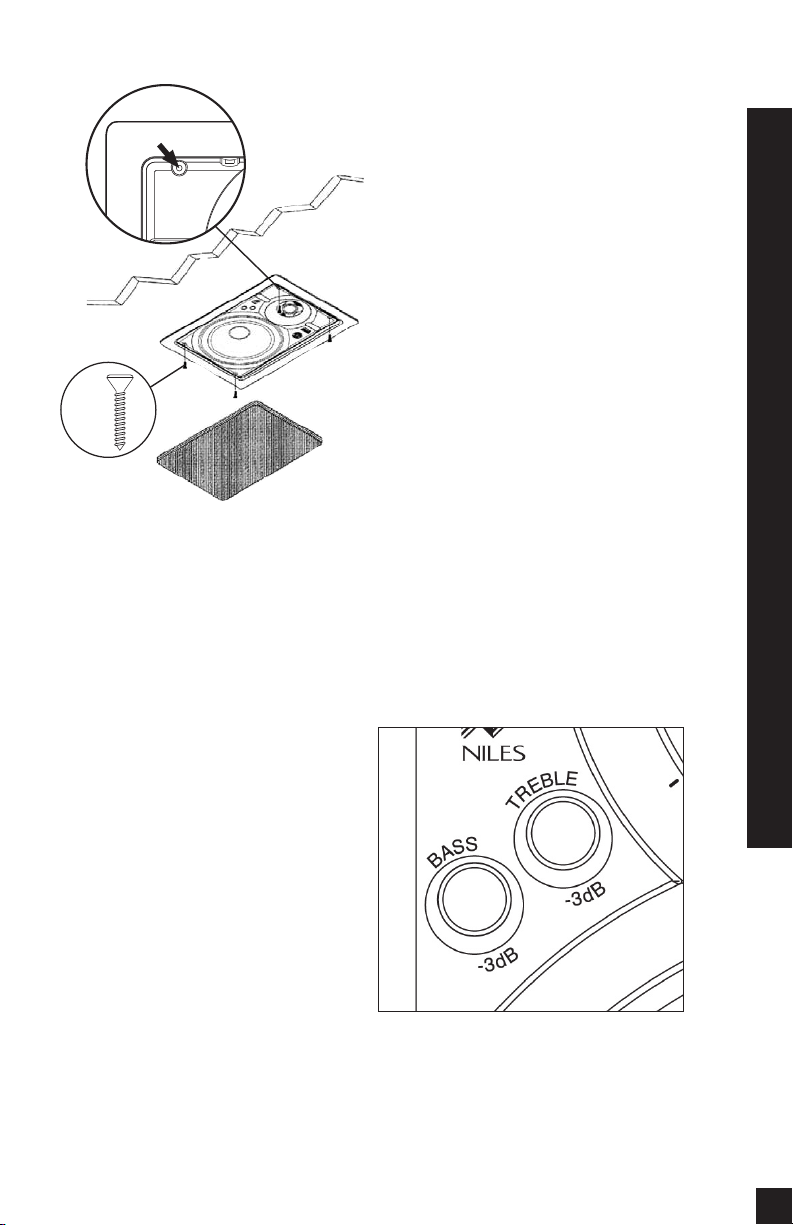

Installation of the Speaker and Grille in New or Existing Construction

Installing the Speaker

If the grille is already

installed, remove it by using

a bent paper clip or the tip

of a corkscrew and pulling

it away from the frame

(See Figure 13).

1. Separate the speaker wire so

that at least two inches of each

conductor are free.

2. Strip 1/2" of insulation from the end of

each conductor. (See Figure 1.)

Figure 13

enclosed sheet metal screws to secure

the baffle to the frame.

a. Locate the dimples on the front baffle.

b. Place the self-tapping sheet metal

screw in the dimple and turn it with a

screw driver until it cuts through the

baffle and anchors securely in the

frame

pushing the speaker for-

ward until the s n a p s

(See Figure 16).

engage

8.

IMPORTANT:

When installing the

speakers in the ceiling, or

if the installation is in an

earthquake zone, it is recom-

mended that you utilize the

(See Figure 17).

Figure 1

3. To connect the stripped end of one conductor to the black terminal, push down

on the black terminal lever. Insert

the stripped end of the conductor into

the opening. Release the pressure on

the lever.

17

4. Repeat #3 with the other conductor and

the red terminal.

5. Connect the opposite ends of these conductors to their respective amplifier terminals. Pay attention to the markings on

the wire. If you are unsure which conductor to insert into which terminal, see

the section titled “Speaker Phase” in the

owner’s manual.

6. Repeat these instructions for each speaker you are connecting to the amplifier.

7. Place the speaker baffle in the frame

by inserting the tabs at the base of

the speaker baffle into the corre

sponding holes in the frame and

Figure 16

Page 19

Figure 17

Speaker Phase

Speaker wire has two conductors. One

conductor is attached to the negative (-)

terminals and one conductor is attached to

the positive (+) terminals of both your

speaker and your amplifier. Usually, the

wire is marked for your convenience.

There are different ways wires are marked:

a stripe on one wire, a ribbed area of one

conductor you can only feel, different colors of metal wire on each conductor, or

there might be a fabric strand or string

wound into one of the conductors. Of

course, there are some wires which appear

completely identical. Be careful, or you

might make a mistake.

If you make a mistake, one speaker will be

playing “out-of-phase” with the other

speaker. An out-of-phase pair of speakers

work against each other and the sound of

the two speakers playing together will be

lacking in bass and be “phasey” sounding.

If you suspect the sound is not right and

you cannot see any markings on the wire,

try this simple test:

1. Stand half way between the two speakers.

2. Play some music with the amplifier or

radio set to Mono.

3. Listen to the richness of the bass and the

loudness of the sound.

4. Turn off the amplifier and reverse the connections on one amplifier channel only.

5. Repeat the listening test with the same

setting of the volume control. When the

sound has a richer bass and is slightly

louder the speakers are working together

or “in-phase”.

Adjusting the Bass and Treble

Controls

The HD High Definition loudspeakers

feature separate baffle-mounted bass and

treble controls for fine tuning after installation. Each control provides for approximately 3dB in steps of 1dB of Bass or

Treble reduction. This is useful if the

speakers are placed near boundaries (Bass

Cut) or in a room with highly reflective

surfaces like glass or tile. (Treble Cut).

(See Figure 18).

Figure 18

Installation of the Speaker and Grille in New or Existing Construction

18

Page 20

Installation of the Speaker and Grille in New or Existing Construction

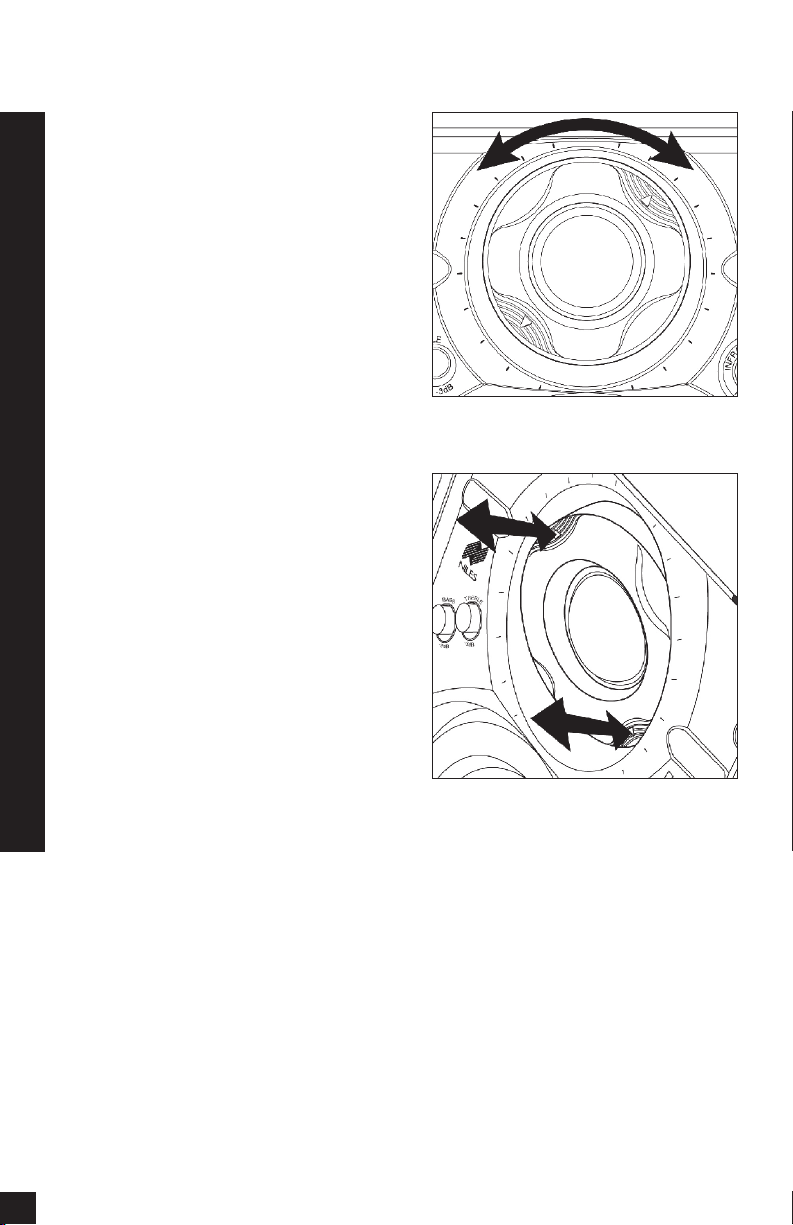

Adjusting the Tweeter

The tweeter is housed in a precision adjustment mechanism which enables precise

aiming of the directional high frequencies to

provide optimum performance. To adjust

the tweeter:

1. Carefully grasp the tweeter housing by

placing your thumb and forefinger in the

indentations provided.

2. Rotate the tweeter housing either clockwise or counter clockwise as required.

The mechanism is indexed at equal

intervals so that both speakers in a pair

can be adjusted equally. Simply count

the number of “clicks” as the first tweeter is adjusted. Repeat the process for the

second speaker, rotating the tweeter the

same number of “clicks” in the opposite

direction

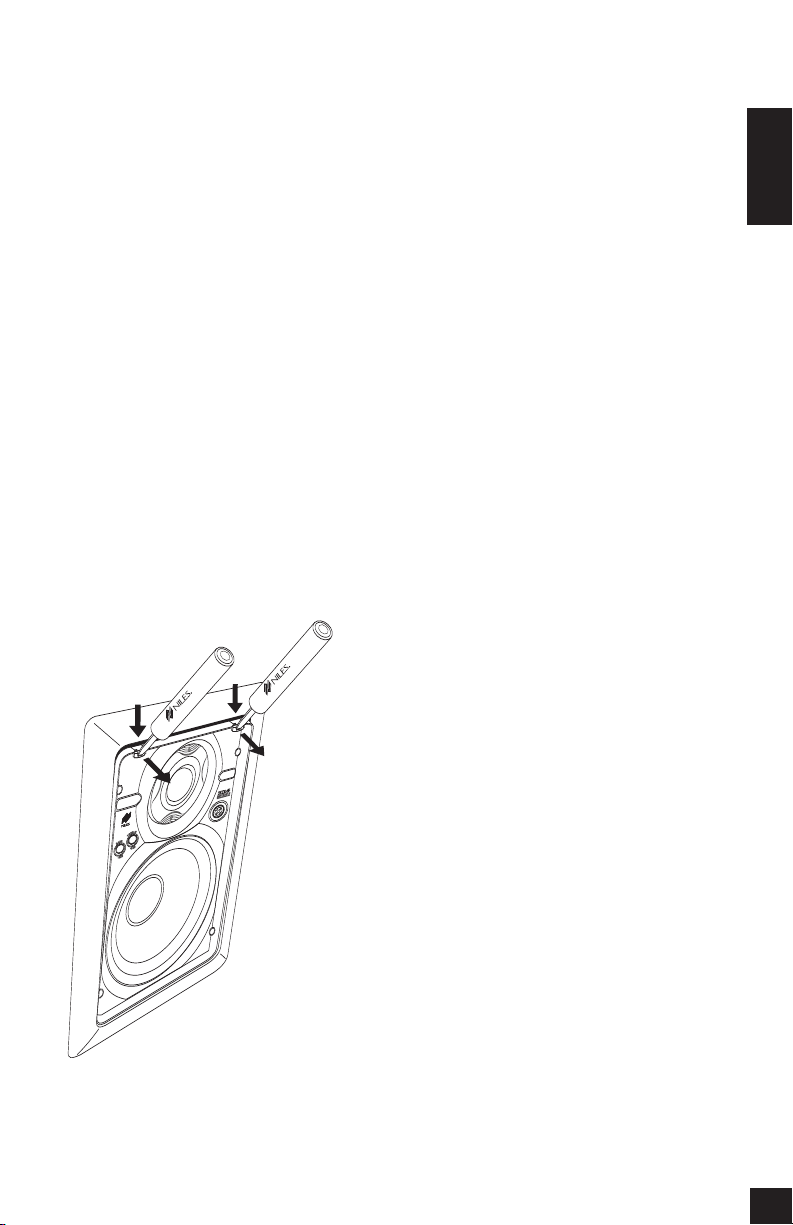

3. Pivot the tweeter on both speakers

equally by depressing the housing at the

arrows until the desired angle is

achieved

Installing the Grille

Carefully fit the grille into its recess so that it

is barely in place. Starting with one corner,

go around the speaker, pushing the grille in

a little bit each time. You should be gentle,

the aluminum grille can be easily bent out

of shape. The speaker will have an absolutely flush appearance when it is properly

installed.

(See Figure 19).

(See Figure 20).

Figure 19

Figure 20

19

Page 21

Operation

I

N

F

R

A

R

E

D

S

E

N

S

O

R

K

N

O

C

K

O

U

T

1

-8

00-BUY-HIFI

1

-

8

0

0

-

2

8

9

-

4

4

3

4

w

w

w

.

n

i

l

e

s

a

u

d

i

o

.

c

o

m

1-800-B

UY-H

IFI

1

-

8

0

0

-

2

8

9

-

443

4

w

w

w

.

n

i

l

e

s

a

u

d

i

o

.

co

m

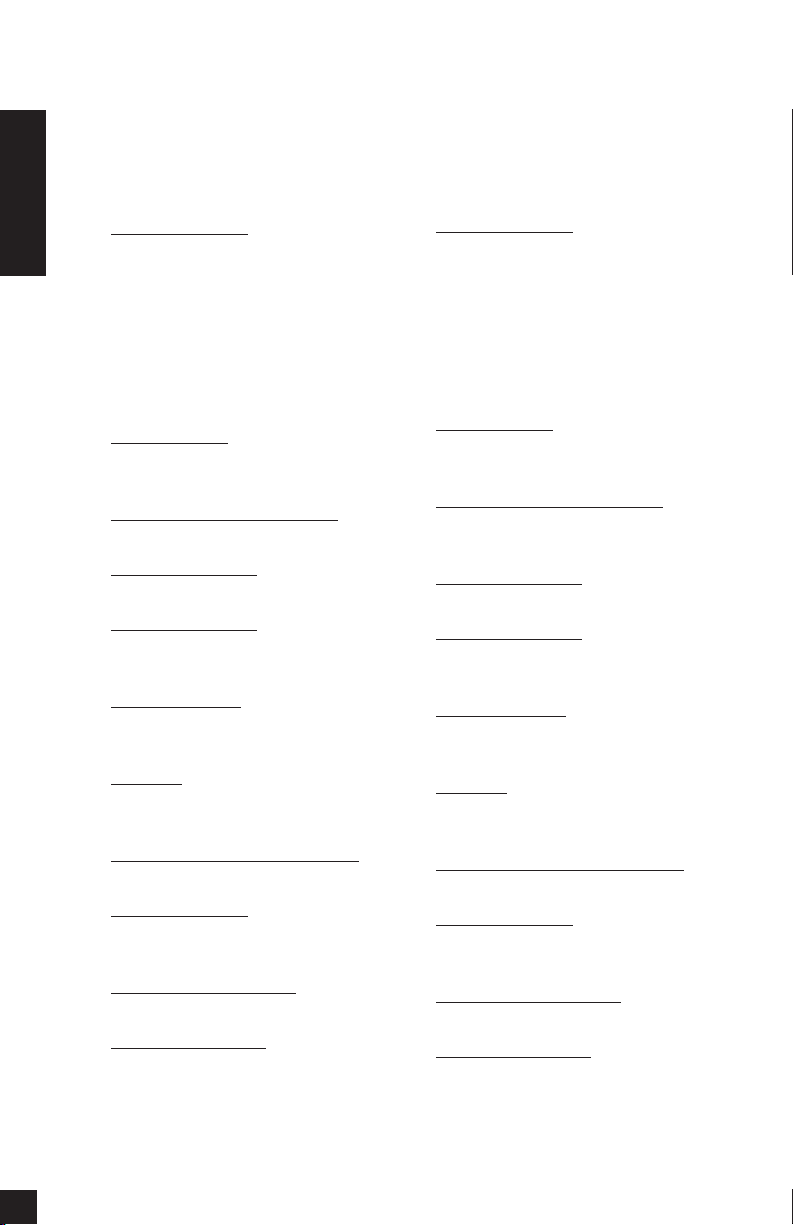

Removal of Speaker

and Grille

Removing The Speaker

If the grille is already installed, remove it by

using a bent paper clip or the tip of a

corkscrew and pulling it away from the frame.

Utilizing two small screwdrivers or two

needle nose pliers, release the snaps that

hold the speaker to the frame. Insert the

screwdrivers into the holes in the snaps

and exert force straight down (towards the

woofer) until the snaps release. Once the

snaps release, the speaker can be tilted

away from the frame to be removed. Do

not attempt to use the frame for leverage,

as this may damage the surface of the

(See Figure 21).

frame

Operation

Listening at Higher Volumes

It requires more power to achieve a reasonable volume of sound in a large room than

it does in a small room. It is possible (even if

you are not a teenager) to turn the volume

so high that the amplifier

This creates “clipping” distortion.

Clipping distortion makes treble sound

very harsh and unmusical. When you hear

harsh sounding treble from any good

speaker, turn the volume down immediately! Those harsh sounds are masking

some much more powerful ultra-high-frequency sound spikes which will quickly

damage any fine loudspeaker. You are

much less likely to damage a speaker with

a large amplifier because it will be very

loud indeed before it produces any clipping distortion.

Cleaning

You can clean the speaker with a dampened soft cloth or paper towel. If the

speaker is mounted high up on a wall or

ceiling, use a broom to gently brush it off.

runs out of power.

Figure 21

20

Page 22

Specifications

Specifications

Model HD5

Model HD6

Driver Compliment

5-1/4” Injection-Molded TCC Woofer with

Custom Debris Screen, Butyl Rubber

Surround, High BL Magnet Structure with

Vented Pole Piece

1” Teteron Tweeter Housed in a Low

Diffraction Precision Adjustment

Mechanism

Design Principle

Infinite baffle for large and varying air

volumes

Recommended Amplifier Power

Ten to One Hundred Watts per Channel

Nominal Impedance

6 Ohms

Frequency Response

60 Hz to 21,000 Hz, plus or minus 3dB

(on axis)

Dispersion Pattern

90 degrees Horizontally or Vertically

(plus or minus 5dB)

Sensitivity

88 decibels for 2.83 volts of Pink Noise,

measured at 1 meter on axis

Overall Exterior Frame Dimensions

7-1/8” x 9-7/8” (18.1 cm x 25.1 cm)

Depth Behind Wall

3-1/8” Deep (assumes 1/2” drywall)

(7.9 cm)

Wall Cut-Out Dimensions

6-1/4” x 9” (15.9 cm x 22.9 cm)

Wiring Requirements

We recommend 16 to 18 gauge stranded

wire for up to 80 feet, 14 gauge stranded

wire for up to two hundred feet.

Connectors accommodate 12 to 18 gauge

stranded wire.

Driver Compliment

6-1/2” Injection-Molded TCC Woofer with

Custom Debris Screen, Butyl Rubber

Surround, High BL Magnet Structure with

Vented Pole Piece

1” Teteron Tweeter Housed in a Low

Diffraction Precision Adjustment

Mechanism

Design Principle

Infinite baffle for large and varying air

volumes

Recommended Amplifier Power

Ten to One Hundred Twenty Five Watts

per Channel

Nominal Impedance

6 Ohms

Frequency Response

50 Hz to 21,000 Hz, plus or minus 3dB

(on axis)

Dispersion Pattern

90 degrees Horizontally or Vertically

(plus or minus 5dB)

Sensitivity

89 decibels for 2.83 volts of Pink Noise,

measured at 1 meter on axis

Overall Exterior Frame Dimensions

8-3/4” x 11-11/16” (22.2 cm x 29.7 cm)

Depth Behind Wall

3-1/8” Deep (assumes 1/2” drywall)

(7.9 cm)

Wall Cut-Out Dimensions

7-5/8” x 10-5/8” (19.4 cm x 27 cm)

Wiring Requirements

We recommend 16 to 18 gauge stranded

wire for up to 80 feet, 14 gauge stranded

wire for up to two hundred feet.

Connectors accommodate 12 to 18 gauge

stranded wire.

21

Page 23

Specifications

Specifications

Model HD8

Driver Compliment

8” Injection-Molded TCC Woofer with

Custom Debris Screen, Butyl Rubber

Surround, High BL Magnet Structure with

Vented Pole Piece

1” Teteron Tweeter Housed in a Low

Diffraction Precision Adjustment

Mechanism

Design Principle

Infinite baffle for large and varying air

volumes

Recommended Amplifier Power

Ten to One Hundred Fifty Watts per

Channel

Nominal Impedance

6 Ohms

Frequency Response

40 Hz to 21,000 Hz, plus or minus 3dB

(on axis)

Dispersion Pattern

90 degrees Horizontally or Vertically

(plus or minus 5dB)

Sensitivity

90 decibels for 2.83 volts of Pink Noise,

measured at 1 meter on axis

Overall Exterior Frame Dimensions

10-3/16” x 14-1/4” (25.9 cm x 36.2 cm)

Depth Behind Wall

3-1/8” Deep (assumes 1/2” drywall)

7.9 cm

Wall Cut-Out Dimensions

9-1/8” x 13-1/8” (23.2 cm x 33.3 cm)

Wiring Requirements

We recommend 16 to 18 gauge stranded

4 gauge stranded

wire for up to 80 feet,

wire for up to two hundred feet.

Connectors accommodate 12 to 18 gauge

stranded wire.

1

Model HD8.3

Driver Compliment

8” Injection-Molded TCC Dual Drive

Woofer with Hyperbolic Dispersion

Stabilizer, Custom Debris Screen, Butyl

Rubber Surround, High BL Magnet

Structure with Vented Pole Piece

1” Teteron Tweeter Housed in a Low

Diffraction Precision Adjustment

Mechanism

Design Principle

Infinite baffle for large and varying air

volumes

Recommended Amplifier Power

Ten to One Hundred Fifty Watts per

Channel

Nominal Impedance

4 Ohms

Frequency Response

40 Hz to 21,000 Hz, plus or minus 3dB

(on axis)

Dispersion Pattern

90 degrees Horizontally or Vertically

(plus or minus 5dB)

Sensitivity

91 decibels for 2.83 volts of Pink Noise,

measured at 1 meter on axis

Overall Exterior Frame Dimensions

10-3/16” x 14-1/4” (25.9 cm x 36.2 cm)

Depth Behind Wall

3-1/8” Deep (assumes 1/2” drywall)

(7.9 cm)

Wall Cut-Out Dimensions

9-1/8” x 13-1/8” (23.2 cm x 33.3 cm)

Wiring Requirements

18 gauge stranded

6 to

We recommend

wire for up to 80 feet, 14 gauge stranded

wire for up to two hundred feet.

Connectors accommodate 12 to 18 gauge

stranded wire.

1

22

Page 24

Notes

Notes

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

23

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

Page 25

Notes

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

Notes

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

24

Page 26

Notes

Notes

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

25

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

Page 27

Notes

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

Notes

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

26

Page 28

Niles Audio Corporation

12331 S.W. 130 Street

Miami, Florida 33186

73

el: (305) 238-4

T

3

Fax: (305) 238-0185

www.nilesaudio.com

©2008 Niles Audio Corporation. Patents applied for and pending. DS00282B

Loading...

Loading...