Page 1

MODEL

IRP2+

IRP2+

IRP2+

INFRARED EXTENDER MAIN SYSTEM UNIT

INSTALLATION & OPERATION GUIDE

Page 2

II

NN FF RR AA RR EE DD

IIRRPP22++

Infrared Extender

Main System Unit

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

TABLE OF CONTENTS

Introduction 1

Features and

Benefits 3

IRP2+ Parts

Guide 4

Installation

Considerations 5

Installation 8

Testing the

IR Extender

System 11

TroubleShooting 12

Power Status 22

Specifications 26

Introduction

An infrared (IR) extender system enables you to control your IR

remote controlled A/V equipment from a remote location. This

enables you to place your A/V components out of sight (behind cabinet doors, in the rear of a room, or in a different room) and still conveniently control your equipment.

The model IRP2+ is an IR Main System Unit. It is one of three elements

that make up an infrared extender system:

1. IR Sensors receive IR commands from hand-held remote controls

and relay the commands to the Main System Unit via a 2-conductor

shielded cable. Generally, sensors are placed so that you can easily

and naturally point your remote control directly at them. Niles offers

an array of easily concealable sensors: wall-mount, ceiling-mount, surface-mount and table-top. IR sensors are the “eyes” of the system.

2. The IR Main System Unit provides a connection hub for the IR

sensors and the IR flashers and is generally located near the A/V components. The Main System Unit’s level controls and LED indicators

enable you to calibrate and troubleshoot an IR extender system. The

Main System Unit is the “heart” of an IR extender system.

3. Infrared Flashers transmit the infrared signals from the IR Main

System Unit to your A/V components. Niles manufactures both flooding flashers (model IRC-1) and miniature “pin-point” flashers (model

IRC-2). Flashers are the “voice” of an IR extender system.

Page 3

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

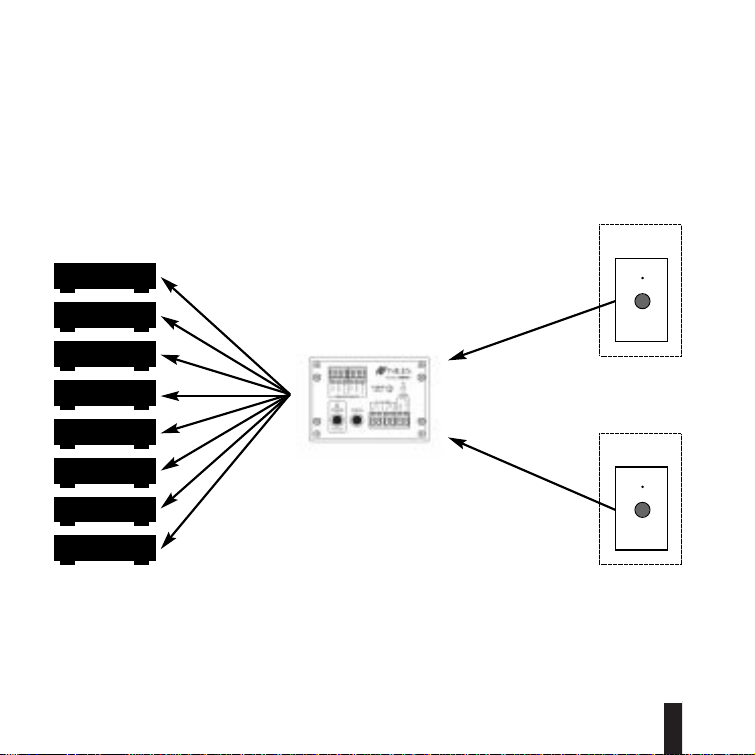

IR Controllable

A/V Components

Room 1

IR Main System Unit

Remotely

Located

IR Sensors

Room 2

Figure 1 In a typical system, the IRP2+ provides for the connection of up to two remote room sensors

(or keypads) and will control a maximum of eight audio/video components via its flasher connections

(four IRC-1 flashers or eight IRC-2 flashers).

2

Page 4

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

Features and Benefits

The IRP2+ offers a number of improvements over other IR Extender

Main System Units:

● Universal system — compatible with virtually all brands of A/V

equipment and remote controls (the only exceptions are those

brands using carrier frequencies higher than 64kHz).

● ExclusiveNiles short-circuit protectionprovides foreasy installation.

● Accommodates two IR sensors or keypads.

● Provides two low-distortion, high-current Mosfet IR Flasher outputs;

one at full power, one with variable power.

● Red "Power" L.E.D. enables you to test for proper power supply

operation and shorts between + (positive) and GND (ground) on

your sensor connections.

● Green "IR" Test L.E.D. enables you to test for proper operation,

interference, and for shorts between + and DATA on your sensor

connections.

● Built in “Status” generator broadcasts the amplifier “on/off” power

status over existing IR wiring to provide power status display when

used with other Niles products like the IntelliPad that feature status

display LED’s.

● Screw connectors simplify installation.

● Printed circuit board design assures high reliability.

● Two year parts and labor warranty.

● Proudly made in the USA.

3

Page 5

II

NN FF RR AA RR EE DD

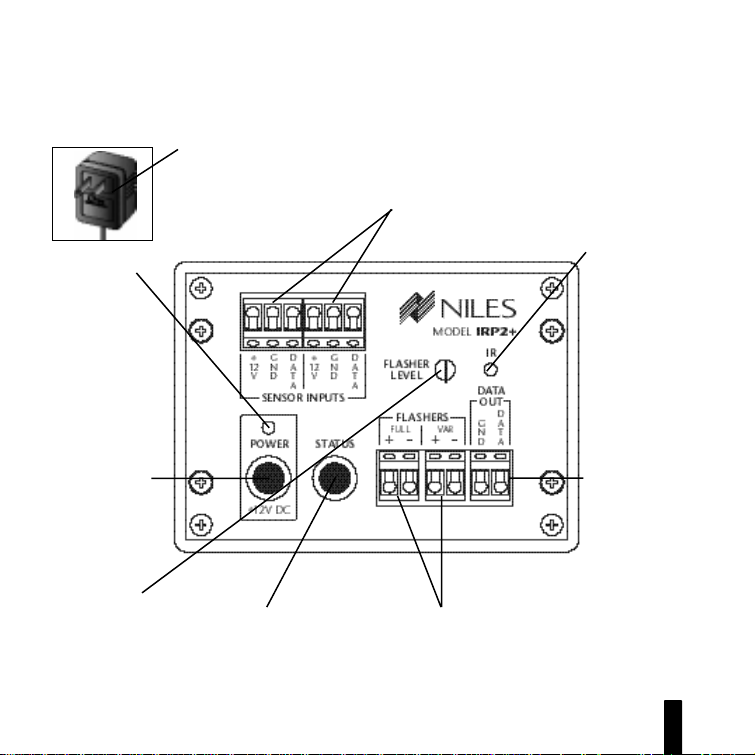

IRP2+ P arts Guide

Power Supply

is a UL listed and

approved 12vDC

wall adapter.

Red Power

Test LED

enables you to

test for proper

power supply

operation and

shorts between

+ and GND on

your sensor connections.

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

Remote Sensor Connections

enable you to connect up to

two remotely located IR sensors or keypads to the IRP2+.

SS

YY SS TT EE MM

Green IR Test LED

enables you to test

for proper operation,

interference, and for

shorts between + and

DATA on your sensor

connections.

UU

NN II TT

Power Socket

provides fast and

convenient connection of the

power supply.

Flasher Level

Control

enables you to reduce flasher level to

match your A/V component’s sensitivity.

Status Socket

allows 12vDC wall adapter to

provide amplifier on/off signal

to “status” generator circuitry.

See Power status page 22.

IR Data

Output

allows the linking of multiple

IRP units for

systems requiring large numbers of flashers.

Flasher Connections

provide for a maximum of eight flashers

(four IRC-1 flashers or eight IRC-2 flashers).

When more than one flasher is connected

to a single output, it is connected in series.

4

Page 6

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

Installation Considerations

UU

NN II TT

IMPORTANT

Do not place the

IRP2+ on top of or

directly behind a

television set.

Some television

sets produce

intense electro-

magnetic interfer-

ence which may

disable your IR

extender system.

5

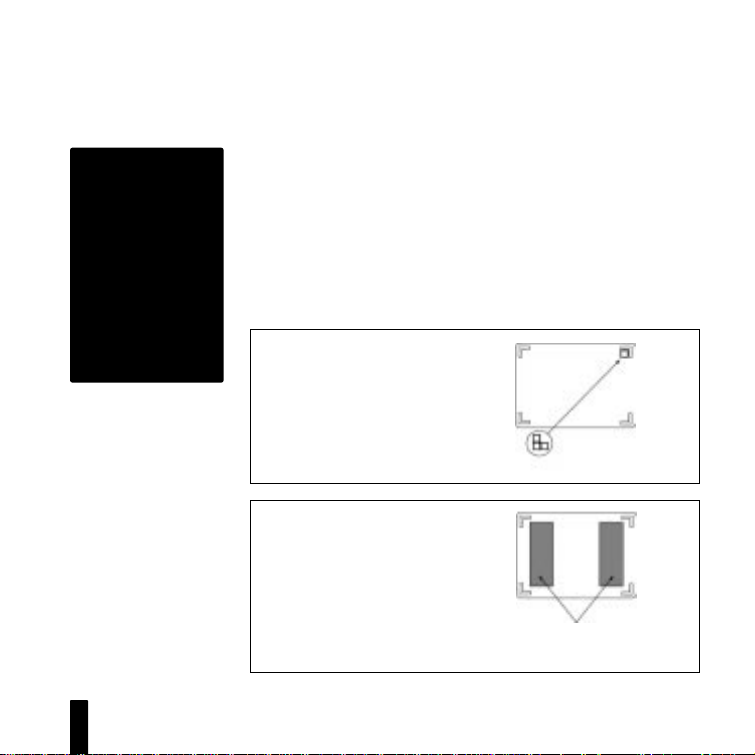

Placement of the IRP2+

Place the IRP2+ conveniently close to the equipment it will be controlling. Generally, the unit is placed in a concealed location because

its controls and indicators are only used during installation. Placement

possibilities include:

1) Table-top (on the floor or shelf behind the equipment) See Figure 2.

2) Wall-mount (affixed to the back of the equipment cabinet or a

nearby wall) See Figure 3 .

Figure 2: Table-Top Placement

1) Clean the bottom of the IRP2+

and the mounting surface with the

enclosed alcohol pad.

2) Affix the enclosed self-adhesive

rubber feet to the base of the

IRP2+.

Figure 3: Wall-Mount Placement

1) Clean both mounting surfaces with the

enclosed alcohol pad.

2) Affix the two enclosed strips of self

adhesive Velcro® to the back of the

IRP2+.

3) Mount the IRP2+ to the wall or cabinet

back. Allow the adhesive to set as long

as possible before connecting cables.

Self-Adhesive

Rubber Feet

Self-Adhesive

®

Velcro

IRP2+

Base

IRP2+

Base

strips

Page 7

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

Wiring

From every IR Sensor location you must “home-run” a cable back to

the IRP2+. Home run means that an individual cable is connected

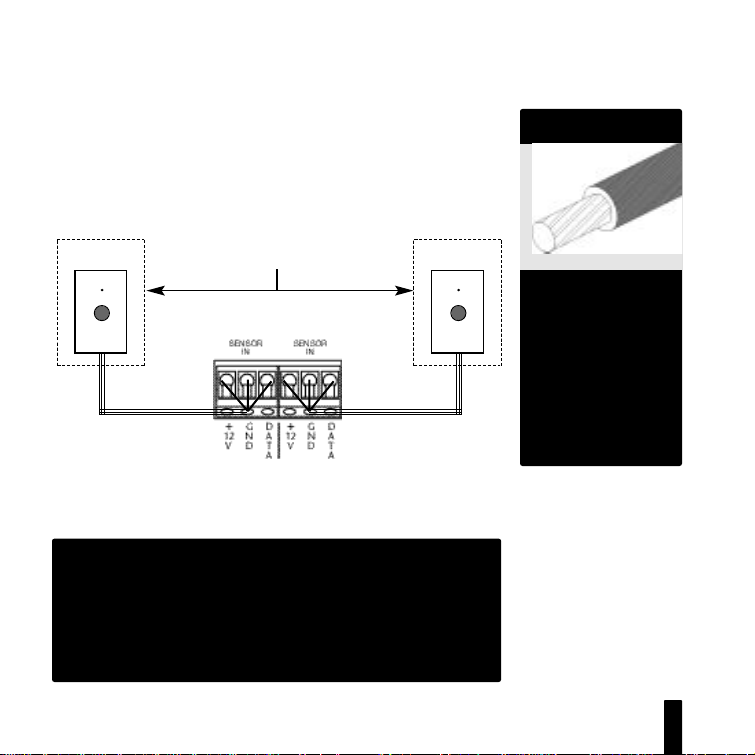

between each IR Sensor and the IRP2+. See Figure 4.

Room 1

Remotely Located

IR Sensors

Room 2

IRP2+

Figure 4: Home run the sensor cable from each sensor to the IRP2+.

IMPORTANT – AVOIDING INTERFERENCE

Avoid locating any of the cables, Sensors, Keypads or the

Main System Unit near any potential sources of ElectroMagnetic Interference (EMI), such as light dimmers, speed

controls for ceiling fans, electrical ballasts, television sets,

large motors, heaters or air conditioners.

TECH TIP

Wire size is

expressed by it's

AWG (American

Wire Gauge)

number . The lower

the AWG number,

the larger the wire,

i.e., 20 AWG wire is

physically larger than

22 AWG.

6

Page 8

II

NN FF RR AA RR EE DD

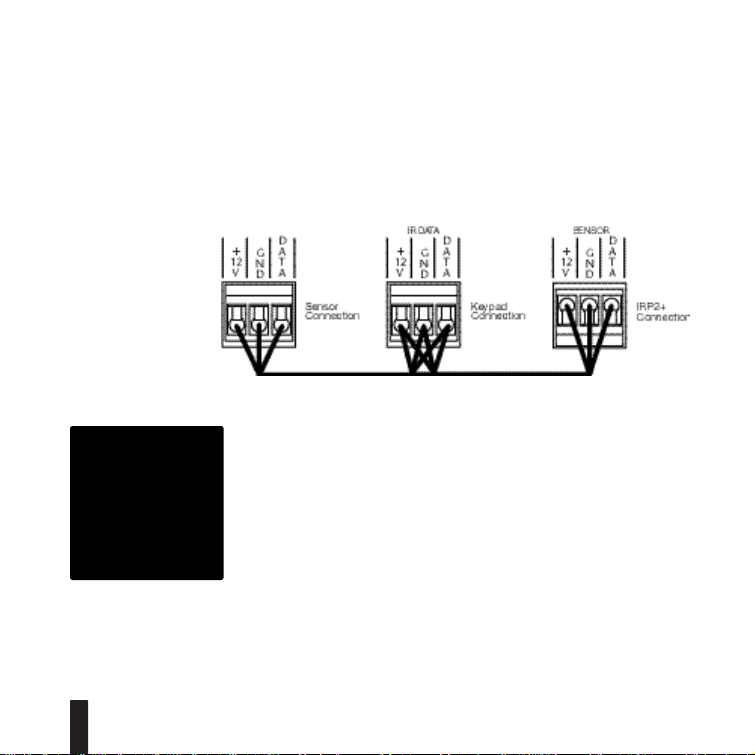

Figure 5: An IR

sensor cable is

“daisy-chained”

from a sensor to a

keypad and then

back to the IRP2+.

CAUTION!

Do not use unshielded cable

between any

remote IR sensor

or keypad and the

IRP2+.

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

Keypad Wiring

When you are placing both a keypad and a sensor (or two keypads)

in one room you may “daisy-chain” using a single cable. A cable is

run between the keypad and the sensor and a single cable is run from

either the sensor or the keypad back to the IRP2+. See Figure 5.

Sensor/Keypad Cable

The IRP2+ connects to IR sensors and keypads with 2-conductor shielded cable. Recommended cables are “data grade” cables made of two

22 gauge (or larger) conductors surrounded by a foil shield and a bare

drain (ground) wire. Data grade cable provides the capability for runs

of up to 500 feet to each sensor. Examples are West Penn D291,

Belden 8761 or Carol C2516. Any 22 to 16 gauge 2-conductor shielded cable available at a hardware store will accommodate 150 foot runs

to each sensor.

Flasher Cable

Niles infrared flashers come supplied with a 10 foot 2-conductor 22

gauge cable. Should you need to extend it, use a 16 gauge 2-conductor cable (“zip-cord”). Shielding is not necessary for a flasher. Flasher

wires can be extended up to 200 feet.

7

Page 9

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

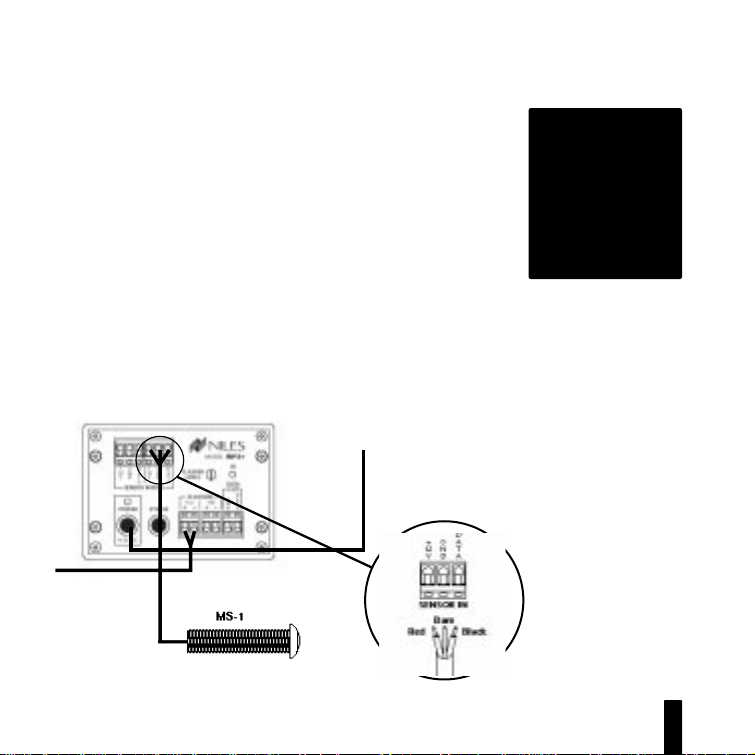

Installation

Before you begin, make sure that the sensor/keypad cables, the flasher cables and the 12vDC power supply cable will all reach the proposed location of the IRP2+. Mark the cables with labels describing

where the cable originates (rather than which terminal on the IRP2+

it should connect).

For proper installation, follow the steps outlined below in the correct

order. If you discover a fault in the course of installation, go on to the

Troubleshooting Guide before continuing with the next installation step.

To

unswitched

AC outlet

Receiver

IRP2+

MS-1 Sensor

TOOLS

REQUIRED

• 1/8" Standard

Slotted

Screwdriver

• Wire Stripper

Figure 6:

IRP2+ Installation

IRP2+ Sensor

Connection

8

Page 10

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

STEP

1. Connect and test the

power supply. If it tests OK,

unplug the connector from

the power socket and proceed.

2. Connect the first Sensor/

Keypad cable to either one of

the Sensor inputs.

3. Test for shorts and interference.

DESCRIPTION

A) Plug the supplied 12vDC power supply into an unswitched

120V AC outlet .

B) Plug the connector into the socket marked “Power” on the

IRP2+.

C) If the Power LED does not light, test the unswitched 120

VAC outlet with another appliance. If the outlet tests OK, you

have a defective power supply which must be replaced for you

to continue.

A) Strip 1/4” of insulation from the wire ends of the cable.

B) Attach the exposed wire ends to the appropriate connector.

Be careful to prevent a filament of wire from shorting out two

connectors. Red = +12v Bare = GND Black = DATA

A) Reconnect the power supply. If the Power LED lights and

the IR Test LED stays off, unplug the connector from the

power socket and proceed to Step 4. The following LED conditions show a fault:

• If Power LED is Off there is a short between +12v and GND

• If IR Test LED is On or Flickers there is a short between DATA

and GND Or Interference is present.

Before you proceed to Step 4 consult the Troubleshooting

Section beginning on page 12

9

Page 11

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

STEP

4. Connect the flashers to the

flasher outputs. If you need to

extend the wire, use a 2-conductor 16 gauge or larger (See

DESCRIPTION

Route the connecting 2-conductor wire to the IR Main

System Unit. Connect the ends of the wire to the corresponding positive and negative terminals labeled “Flasher”

on the IRP2+.

Tech T ip on page 6).

BE SURE TO OBSERVE PROPER POLARITY WHEN

CONNECTING OR EXTENDING THE FLASHER WIRE.

IRC-1 the wire lead marked with a gray stripe is

negative (-); the unmarked lead is positive (+).

IRC-2 the silver colored wire lead is negative (-); the

copper colored wire lead is positive (+).

5. Connect multiple flashers to

a single output by connecting

in series.

Use crimp caps, wire nuts or solder to connect the negative

of one flasher to the positive of the next flasher as shown to

create a series circuit.

IRC-1 Flooding Flasher allows a maximum of TWO in series

–+

IRC-2 MicroFlasher allows a maximum of FOUR in series

+–

6. Test for proper operation

with all sensors and remote

controls.

10

Page 12

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

T esting the IR Extender System

Test your IR Extender system by following the three principal guidelines:

1. All components can be operated. Test all of your remote controls

for all of your equipment.

2. Operation is consistent. A good test is to repeatedly step from

Pause to Play with your VCR, CD, Laser, or Tape player remote control. Operation should be identical to standing in front of the component with the remote control pointed directly at the sensor window.

3. Maximum Range between the Remote Control and the Niles IR

Sensor is similar to the maximum range between the Remote Control

and the A/V component’s IR sensor. Typically a remote control with

two batteries will have a 15 to 20 foot range and a remote with four

batteries will have a 20 to 30 foot range.

11

Page 13

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

T roubleshooting Guidelines

There are four basic problems which prevent proper operation. In the

order of probability the problems are:

Bad Connections or Wiring

If the connections or wiring are wrong, loose, shorted or open the system

will not operate properly. The symptoms could include: Power LED flickers

or is off, IR Test LED is continuously flickering or on without any remote

control use, intermittent operation or no operation.

3

4

and

Steps

•

13

Steps

•

15

Steps

•

26

Steps

•

Flasher Level is Too High

Many audio/video co mp on e nt ’s sen so rs ar e o ve rl oaded by receiving

to o st r o ng of an IR com ma n d f r o m t h e flasher. Symptoms can include:

popping and clicking sounds from the speakers when a button is pressed on

the remote control, poor IR receiving range, intermittent operation or no

operation.

15

Step

•

Optical or Electromagnetic Interference

Sunlight, reflections, neon signs and other sources of infrared light or television sets, light dimming controls and other sources of electromagnetic fields

can induce noise and interference into your IR extender system. Symptoms

can include: flashback LED’s continuously flickering or on without any

remote control use, poor range, intermittent operation or no operation.

32

Steps

•

test your power supply connections.

•

14

23

thru

,

•

•

18

thru

•

27

and

tests your cable for shorts and opens.

•

provides detailed instructions on setting the proper flasher level.

through

25

thru

test your Sensor connections.

•

test your Flasher connections.

38

troubleshoot interference problems.

•

UU

NN II TT

12

Page 14

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

Optical Feedback Loop

If you have an IR sensor in the same room as a flasher, and you have

some low-level noise or interference, an optical feedback loop can

occur which will interfere with proper operation. Symptoms can

include: poor range, intermittent operation or no operation.

19

Steps

•

feedback loops.

Start from Step One

In your installation you may be faced with a combination of the four

problems or symptoms that are universal to all of the problems.

Rather than trying to guess which problem you have, use a process of

elimination. The Troubleshooting section is designed to eliminate the

most common problems first. If you start from Step 1 and methodically check everything you will find the problem in much less time than

the troubleshooter who makes assumptions.

through

-- MM

AA II NN

22

provide instructions for eliminating optical

•

SS

YY SS TT EE MM

UU

NN II TT

13

Page 15

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

T roubleshooting Guide

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

1

•

Test Remote Control

Verify that the remote control works by operating the equipment directly. If the remote does

not operate your system directly, replace the

batteries of the remote control. Replace the

remote control if necessary

2

•

Flasher Positioning

Flashers operate line-of-sight; be sure they are

unobstructed and aimed at the front panel

sensor windows of your components.

3

•

12v DC Power Supply

Test that the red IRP2+ power LED is on when

the wall adapter is plugged into an

unswitched AC outlet.

• Power LED On: Go to Step 13

• Power LED Off: Go to Step 4

4

•

Disconnect Sensors

If the power LED does not light, disconnect all

sensors and retest the power supply.

• Power LED On: Go to Step 6

• Power LED Off: Go to Step 5

.

5

•

Replace Power Supply

Either your power supply or your IRP2+ is defective. If you have another 12v DC power supply,

first check that it has the same polarity (+ on

the tip, GND on the sleeve). Plug the new

power supply in and observe the Power LED.

• Power LED On: Retest System per page 11

• Power LED Off: Return IRP2+ to your local

Niles dealer for testing

6

•

Test Sensor Input 1

Reconnect one of the sensor cables. Re-test;

plug the power supply back in and observe

the Power LED.

• Power LED On: Go to Step 7

• Power LED Off: Go to Step 8

7

•

Test Sensor Input 2

A) If you DO NOT have a second sensor/keypad,

Go to Step 12.

B) If you DO have another sensor/keypad, connect it to the second sensor input and re-test.

• Power LED On: Go to Step 12

• Power LED Off: Go to Step 8

14

Page 16

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

8

•

Short between +12v (positive) and GND

(ground).

Examine the connectors for a hair-like filament

of wire between any of the contacts at the

IRP2+ and at the sensor or keypad.Then retest.

• Power LED On: Go to Step 12

• Power LED Off: Go to Step 9

9

•

Test the Cable for Shorts

Disconnect the cable at both ends (at the sensor and at the IRP2+) and test it for shorts. Use

an ohm meter or electrical continuity checker.

You should read an open (Infinite Ohms)

between Red and Bare, Red and Black or Bare

and Black.

• Short in Cable: Replace cable

• Cable tests OK: Go to Step 10

10

•

Replace the IRP2+

If you have another IRP2+, replace the one in

the system and retest, if not go to Step 11.

11

•

Replace the Sensor or Keypad

If you have another Sensor or Keypad,

exchange it and retest the system, otherwise

return the IRP2+ and the sensor/keypad(s) to

your local Niles dealer for testing.

15

12

•

System suddenly seems to beOK again.

The connections were poor and by touching

and inspecting them you have changed their

condition. Jiggle and tug on the wires and

recheck the connections. If they all seem secure,

retest the entire system per the guidelines on

page 1 1.

13

•

IR LED without any IR input.

Observe the green IR Test LED on the IRP2+

with the power supply plugged in and all sensors and flashers connected.

• IR Test LED is Onor is Flickering: Go to

Step 32

• IR Test LED is Off: Go to Step 14

14

•

IR LED with IR input.

Have someone watch the green IR LED on the

IRP2+ while you aim a remote control at a

remote sensor and press a button.

• IR Test LED Flashes: Go to Step 15

• IR Test LED Off: Go to Step 23

15

•

Flasher Connections

Verify the polarity of the flasher connections.

Flashers must be connected according to

Steps 4 and 5 on page 10. Examine the con-

Page 17

II

NN FF RR AA RR EE DDEEXX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

nectors for a hair-like filament of wire between

any of the contacts. Retest the system according to the guidelines on page 11.

• Good Operation: Congratulations!

• Poor Operation: Go to Step 16

16

•

Flasher Output Too High

Som e audio/video c o m ponent’s sensors are

overloaded by too strong a command

fr om the flasher. Connect the flasher(s) to the

variable output of the IRP2+ and use a 1/8”

slotted screwdriver to reduce the output level

to minimum (counter-clockwise). Retest the

system according to the guidelines on page 11.

• Poor Operation: Move the flasher so that it

is farther away from the sensor window

or off to the side of the sensor window.

Retest the system.

• Poor Operation: Start raising the level (a

quarter turn clockwise each time) and retesting until level is back to full.

• Poor Operation Continues: Go to Step 17

17

•

Test Flashers.

A) If you have only ONE FLASHER, reconnect it

to the other flasher output. Retest the system

according to the guidelines on page 11.

• Good Operation: Congratulations!

• Poor Operation: Go to Step 19

B) If you have MORE THAN ONE FLASHER, disconnect all of them and reconnect one flasher

at a time. Test for improved operation.

Continue testing until you have identified the

defective flasher. Test all of your flashers.

•All flashers appear defective:Go toStep18

• One flasher doesn’t work: Return the defec-

tive flasher to your dealer

• All flashers now work: Congratulations!

18

•

Test Flasher Outputs

Reconnect one flasher to the second flasher output of the IRP2+. Test for improved operation.

Repeat Step 16 (adjust flasher level and position). Test for improved operation.

• Good Operation: Congratulations!

• Poor Operation: Repeat this step with anoth-

er flasher. Retest.

• Poor Operation Continues: Go to Step 19

19

•

Sensors in the Same Room as a Flasher?

• If you have sensors in the same room as a

flasher: Go to Step 20

• If all sensors are in remote locations with-

out flashers : Go to Step 21

• If you have keypads only: Go to Step 21

16

Page 18

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

20

•

Optical Feedback Loop

If there is an IR sensor and an IR flasher located

within the same room an "optical IR feedback

loop" can occur. Replace the IRC-1 Flooding

Flasher with an IRC-2 MicroFlasher on the front

panel sensor window of each component.

Place the enclosed IR blocking cover over each

of the IRC-2 flashers. Retest the system.

• Good Operation: Congratulations!

• Poor Operation: Go to Step 16 (adjust Flasher

Level and Position) Retest system.

• Still Poor Operation: Go to Step 21

21

•

Replace IRP2+ and Flasher(s)

Reconnect the system with a new IRP2+ and

new flasher(s).

• Poor Operation Continues: Go to Step 22

22

•

Interference that Does Not Light the IR

Test LED

Some very rare examples of interference (both

optical and electro-magnetic) do not light up

the IR test LED but do prevent proper operation. Go to steps 36 and 37. Examine your

installation carefully for a source of low-level

optical or electromagnetic interference.

23

•

Disconnect All Sensors and Keypads and

Test One Sensor Input

Disconnect all Sensors and Keypads.

Reconnect one of the sensor cables and retest

the system (Have someone watch the green IR

LED on the IRP2+ while you aim a remote control at a remote sensor and press a button).

• IR Test LED Flashes: Go to Step 24

• IR Test LED Off: Go to Step 25

24

•

Test Second Sensor Input

A) If you DO NOT have a second sensor/

Keypad, Go to Step 25.

B) If you DO have another sensor/keypad,

connect it to the second sensor input. Retest

the system (Have someone watch the green IR

LED on the IRP2+ while you aim a remote control at a remote sensor and press a button).

• IR Test LEDFlashes: Go to Step 12

• IR Test LED Off: Go to Step 25

25

•

Bad Connections at the IRP2+ and/or at

the Sensor/Keypad.

Verify that all connections are good both at

the IRP2+ Sensor Inputs and at the remote

sensor/keypad. Check that the jacket of each

conductor has been properly stripped and

17

Page 19

II

NN FF RR AA RR EE DDEEXX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

inserted into the connector. Examine the connectors for a hair-like filament of wire between

any of the contacts. Repair as necessary. Retest

the system (have someone watch the green IR

LED on the IRP2+ while you aim a remote control at a remote sensor and press a button).

• IR Test LED Flashes: Congratulations!

• IR Test LED Off: Go to Step 26

26

•

Test Cable for Shorts

Disconnect the cable at both ends (at the sensor

and at the IRP2+) and test it for shorts. Use an

ohm meter or electrical continuity checker. You

should read an open (Infinite Ohms) between

Red and Bare, Red and Black or Bare and Black.

If you find a short, replace or repair the cable as

necessary. Retest the system (Have someone

watch the green IR LED on the IRP2+ while you

aim a remote control at a remote sensor and

press a button).

• IR Test LED Flashes: Congratulations!

• IR Test LED Off: Go to Step 27

27

•

Test Cable for Opens

At one end of the cable, twist the exposed

copper ends of the Red (+) and the bare

(GND) conductors together. At the other end

of the cable, use an Ohm meter or continuity

checker to check for a break in the cable. You

should read a short (zero ohms) between the

exposed copper ends of the Red (+) and the

bare (GND) conductors. Repeat this test with

the Red (+) and the Black (DATA) conductors.

If you find an open, replace or repair the cable

as necessary. Retest the system (have someone

watch the green IR LED on the IRP2+ while

you aim a remote control at a remote sensor

and press a button).

• IR Test LED Flashes: Congratulations!

• IR Test LED Off: Go to Step 28

28

•

Connect Sensor to Other Input of the IRP2+

Disconnect the sensor and reconnect it to the

other sensor port on the IRP2+. Retest the system (Have someone watch the green IR LED

on the IRP2+ while you aim a remote control

at a remote sensor and press a button).

• IR Test LED Flashes: Congratulations!

• IR Test LED Off: Go to Step 29

29

•

Replace the IRP2+ and/or the Sensor/Keypad

If you have another IRP2+, sensor or keypad,

change it and retest the system, otherwise

return the IRP2+ and the sensor/keypads to

your local Niles dealer for testing.

18

Page 20

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

30

•

Disconnect All Sensors and Keypads

Observe the IR Test LED.

• IR Test LED is ONor Flickering: Go to Step 33

• IR Test LED is OFF: Go to Step 35

31

•

Move the IRP2+ to avoid Electromagnetic

Interference

It is possible that the IRP2+ is receiving electromagnetic interference from a nearby television

or other appliance. Move the IRP2+ to another

location and reconnect the power supply.

Observe the IR Test LED.

• IR Test LED is ONor Flickering: Go to Step 34

• IR Test LED is OFF: Y ou have EMI in your origi-

nal location. Relocate the IRP2+ according to

the guidelines on Page 5.

32

•

Replace the IRP2+

If you have another IRP2+, exchange it and

retest the system, otherwise, return the IRP2+

to your local Niles dealer for testing.

33

•

Test First Sensor Input

Connect one sensor/keypad to the first Sensor

Input. Observe the IR Test LED.

• IR Test LED Off: Go to Step 36

• IR Test LEDis On or Flickering: Go to Step 37

34

•

Test Second Sensor Input

A) If you DO NOT have a second sensor/keypad, Go to Step 12.

B) If you DO have another sensor/keypad, connect it to the second sensor input. Observe the

IR Test LED.

• IR Test LEDis On or Flickering: Go to Step 37

• IR Test LED Off: Go to Step 12

35

•

Test for Shorts

A) Verify that all connections at the IRP2+ are

correct. Look for a hair-like filament of wire

between the two contacts.

B) Verify that the sensor/keypad connections

are correct. Look for a hair-like filament of wire

between the two contacts.

C) Disconnect the sensor/keypad cable at both

ends and test the cable itself for shorts. Use an

ohm meter or electrical continuity checker. You

should read an open (Infinite Ohms) between

Red and Bare, Red and Black or Bare and Black.

After testing all connections and cable, observe

the IR test LED.

• IR Test LED is Onor Flickering: Go to Step 38

• IR Test LED is Off: Congratulations

19

Page 21

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

36

•

Test for Optical Interference

Reconnect the problematic sensor/keypad to

the IRP2+. Cover up the Sensor with a piece of

cardboard (your hand will actually create electromagnetic interference under some conditions). Observe the IR test LED.

• IR Test LED On or Flickering: Go to 3 7

• IR Test LED Off: Go to 3 6

37

•

Optical Interference

Identify the source of the interference. The

most common sources of optical interference

are listed in the order of their probability:

A) Sunlight. Reflections from windows, mirrors,

swimming pools, shiny floors or objects.

B) Fluorescent light fixtures.

C) Neon signs.

D) A malfunctioning IR Remote Control.

E) A malfunctioning Infrared Motion Detector

on your Security system.

Either re-orient the sensor or move the source

of interference. Niles infrared sensors have

built-in filters to attenuate the effect of visible

light. If you add additional filtration you will

reduce the effectiveness of the system with

remote controls as well as the interference.

If you are using the MS-1 or the MS-2 miniature sensors consider exchanging them for

IRR-4D, TIR-1 or the CMS-3 ceiling sensor.

These three sensors have AGC circuits which

serve as automatic filters.

If you choose to attempt to filter an MS-1 or

MS-2, try a temporary material (e.g. a single

thickness of facial tissue) and test whether filtration will solve the interference and still give

acceptable range.

38

•

Electromagnetic Interference (EMI)

Identify the source of the interference. The

most common sources of electromagnetic

interference are listed in the order of their

probability:

A) Televisions (particularly large direct view

sets).

B) Wall-mounted light dimmers or variable

speed controls for ceiling fans. These controls

emit more interference when turned down

halfway. They emit little or no interference

when turned up all the way (brightest position).

C) Fluorescent lights (the electronic ballast

sometimes emits EMI)

D) Large appliances (air-conditioners, pumps,

motors, compressors etc.)

E) AC line noise (noise brought into the system

20

Page 22

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

via the wall outlet connected to the IRP2+)

Identify the EMI source by turning potential

sources on and off (or fully up and fully down)

and watching for any change in the IR Test LED

on your IRP2+. Once you have identified the

source of interference:

1) Move the sensor or the sensor cable away

from the EMI source or move the source of the

EMI away from the sensor or the cable.

2) Shield the sensor with a metal J-Box.

3) Connect the Sensor’s GND terminal to true

earth ground (if this isn’t feasible use the IRP2+

GND terminal).

4) Place a ferrite ring around the cable creating

the interference. Ferrite rings can be purchased

from an electronic supply store.

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

21

Page 23

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

IMPORTANT

For the

IntelliPad’s status

feedback feature

to work, the pre-

amp/receiver con-

trolling your sys-

tem should have a

switched AC out-

let, a switched

outlet is a 120v

AC outlet that

switches off,

when the preamp/

rec-eiver is off

and switches on

when it is on via

remote control.

Power Status — Introduction

By adding an IntelliPad™ to your IRP2+ Infrared Extender System you

will add a remarkable level of convenience to your system. The IntelliPad

is the world’s first programmable, wall-mounted keypad system that

provides a unique L.E.D. power status display and the convenience of

true one-touch remote control of complex audio/video systems.

The IntelliPad’s status feedback feature eliminates the guesswork common with standard IR control systems. The power L.E.D. on the

IntelliPad indicates the On/Off condition of the system’s

preamp/receiver.

Built-in intelligence tracks the On/Off condition of the preamp/receiver so the IntelliPad knows when it’s appropriate to issue the power

command, even when the user doesn’t. The system maintains perfect

synchronization between the amplifier and the user.

By combining an optional Niles 12vDC power supply with your IRP2+

you can send a status signal to an IntelliPad without running any additional wiring. Built into the IRP2+ is a Niles Status Signal Generator.

When the IRP2+ sees 12vDC at the status jack it broadcasts a Status

signal over your existing IR sensor wires. Any IntelliPad connected to

one of your sensor wires will display power status.

22

Page 24

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

The IntelliPad

®

Source Select Keys

A single press of one of these

keys will:

1. T urn on the Preamp/Receiver

if it was off.

2. Change the input of your preamp/receiver to the selected

source.

3. Changes the function of the

Source Control Keys so that

they operate the selected

source.

4. Display which source is

selected by backlighting the

corresponding Sour

ce Label.

5. T urn on the local speakers

(un-mute the speaker relay)

Status LED

When the preamp/receiver is

on, the status LED is lit. The

color of the LED displays

whether the local speakers are

on or muted.

GREEN - Local Speakers and

the Preamp/Receiver are on

RED - Local speakers are off,

but the system is on.

OFF - System is off.

23

Source Control Keys

A touch to any of the source

control keys will operate the

selected source only.

Mute Key

A touch to this key controls the IntelliPad’s

built in speaker mute feature. You can mute

the local speakers anytime, by pressing the

Mute Key. To turn the local speakers back

on (or unmute) you may press either the

Mute key or one of the six Source Select

keys.

olume Key

V

This key raises

and lowers the

volume of your

main system

amplifier.

Page 25

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

CONVERTING

A LOW

VOL TAGE

CONTROL

OUTPUT TO

V

DC

12

Many compo-

nents, particularly

surround proces-

sors and digital

preamplifiers,

provide a low

voltage whenever

the component is

“on” rather than

in “standby”. For

the IRP2+ to cor-

rectly broadcast

power status you

must install an

optional Niles

OTI-512 Opto-

Isolated trigger

interface. The

OTI-512 will con-

vert 3-30 volts AC

or DC to 12vDC.

Power Status — Installation Considerations

Proper Power Supply

You must connect a Niles 12vDC wall adapter (Niles FG00665) into

the switched AC power outlet of the preamp/receiver in your system.

Any 12vDC power supply with a minimum of 100mA current capacity can be substituted.

Extending the Cable

If you must extend the cable from the wall adapter to the IRP2+’s status input jack be sure to maintain correct polarity. The tip of the plug

should be positive (+) and the sleeve negative (-). Any 16 gauge 2conductor cable can be used to extend the power status cable up to

200 feet.

Checking the Power Supply

It is possible to check the status power supply itself and any connections that were made to extend the cable by inserting the status plug

into the Power jack on the IRP2+. If the Power LED lights the status

power supply and connections are OK. If the Power LED does not

light check all connections and replace the power supply if necessary.

For more details on incorporating the IntelliPad please refer to the

IntelliPad’s users manual.

24

Page 26

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

YY SS TT EE MM

UU

NN II TT

Stereo Receiver

IR Flasher

DC Power

Supply

Rear Panel of

Intellipad™

plugged

into

Switched

Outlet

Figure 7:

IntelliPad Basic Configuration

utilizing Status Feedback and

Speaker Relay Features.

Loudspeaker Loudspeaker

IRP2+

DC Power

Supply

25

Page 27

II

NN FF RR AA RR EE DD

EE

XX TT EE NN DD EE RR

-- MM

AA II NN

SS

Specificat ions

IR System

Compatible with virtually all brands of remotes using carrier frequencies between 18 and 100kHz. As of this publication date, the only

known components using carrier frequencies outside this range are

Bang & Olufsen components and 1996 model year Pioneer receivers

using the ISC remote control (e.g. VSX-D704S).

iring Requirements

W

Individual home-runs of 2 conductor shielded cable from each

sensor/keypad, West Penn D291 or equivalent

Unit Dimensions

4” wide x 1 3/4” high x 2 7/8” deep

YY SS TT EE MM

UU

NN II TT

Power Requir

ements

12vDC500 mA power supply (included).

26

Page 28

Niles Audio

Corporation

www.nilesaudio.com

12331 S.W. 130 Street

Miami, Florida, 33186

Tel: (305) 238-4373

Fax: (305) 238-0185

© 1999 Niles Audio Corporation. All rights reserved. Because Niles constantly strives to improve the

quality of its products, Niles reserves the right to change product specifications without notice. Niles,

the Niles logo and IntelliPad are registered trademarks of Niles Audio Corporation. Velcro is a

registered trademark of Velcro (USA), Inc. Decora Home Controls is a registered trademark of Leviton

Manufacturing Company. Printed in USA 1/99 DS00156A

Loading...

Loading...