Page 1

INSTALLATION & OPERATION GUIDE

IRB1

IRB1

High Ouput

Infrared Flasher

B LENDING H IGH F IDELITY

AND

A RCHITECTURE

®

Page 2

INTRODUCTION

The IRB1 is a small, cabinet-mount high output

infrared flasher. The IRB1 is just one part of the

three building blocks necessary to complete a

Niles IR extender system:

• IR Main System Unit—Models MSU140,

MSU250, MSU480 and MSU440Z.

• IR Sensors/Keypads—Models WS100, TS100,

MS100, MS200, CS100, MVC100IR and the

®

IntelliPad

• IR Flashers—Models MF1, MF1VF, MF2,

MF2VF and the IRB1.

An IR sensor expansion hub, Model IRH610,

is available to provide additional sensor inputs

to your system.

When an IR remote sensor receives a command

from a hand-held remote control, it sends a corresponding electronic signal through a wire to

the main system unit. Here, the main system

unit cleans and amplifies the electronic signal.

Finally, the main system unit outputs the signal

to the IR flasher which relays the infrared command to the audio/video component you wish

to control.

The IRB1 relays the infrared command using

“flashes” of infrared light in a powerful flooding pattern from its two infrared LEDs. The output is extraordinarily accurate over a wide

bandwidth. This allows the IRB1 to control

most makes and models of IR controlled

audio/video components.

.

1233 5

The IRB1 is compatible with all Niles infrared

extenders systems, IntelliControl

®

and

MultiZone recivers and preamplifiers.

FEATURES & BENEFITS

• Two infrared LEDs give the IRB1 exceptional

range and power. With proper placement, a

single IRB1 flasher can control an entire stack

of audio/video components.

• The IRB1 is equipped with a 3.5mm plug.

This provides you with easy hookup.

• An adhesive-backed strip is included with the

IRB1, providing quick, secure, mounting.

• The IRB1 is supplied with an ample 10' of

connecting wire.

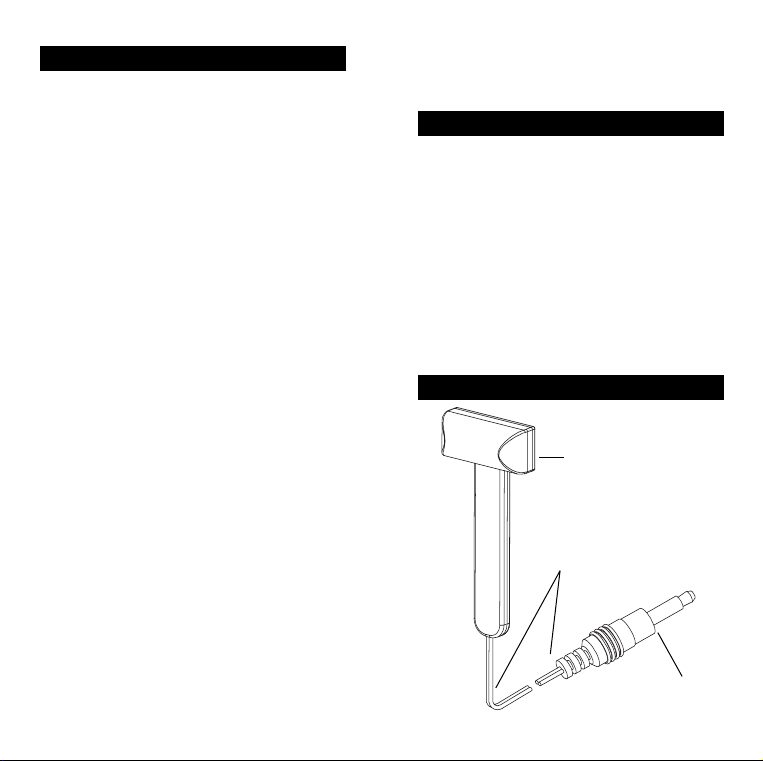

IRB1 PARTS GUIDE

Double

sided tape

10 f eet of

2-conductor

22 gauge

connecting

wire

3.5mm Plug

Page 3

INSTALLATION CONSIDERATIONS

The IRB1 is typically used as a “flooding” flasher

to control a stack of audio/video components.

For this type of application, place the IRB1 with

its LEDs pointed straight up and at least an inch

in front of the equipment you wish to control

(See Figure 2). The effective range varies

between 8' to 30' depending on the brand

and/or the model of the audio/video component. Note: If cabinet dimensions permit, experimenting with the placement of the IRB1 may

yield better operating results.

For tall stacks of components use multiple IRB1

flashers. For example, place one IRB1 at the top

of a stack with the LEDs pointing down and one

IRB1 at the base of the stack with the LEDs

pointing up (See Figure 3).

In some installations there are shelves blocking

a direct path between the IRB1 and the components’ IR sensor window. It is possible to

bounce infrared light off of smooth reflective

surfaces (particularly white surfaces). If a suitable surface exists (like the back of a cabinet

door, or a white wall within a few feet) try to

place the IRB1 so that its reflected output reaches the sensor windows of the components (See

Figure 4). If some of the components are still not

getting adequate signal, mount a Niles MF series

MicroFlasher

the problematic components.

Sometimes, it is desirable to mount the IRB1 so

that it directly faces the equipment from across

®

on the sensor window of each of

a room. In this type of situation the IRB1 has an

effective operational range of 18' to 30'

(depending on brand and model of audio/video

equipment).

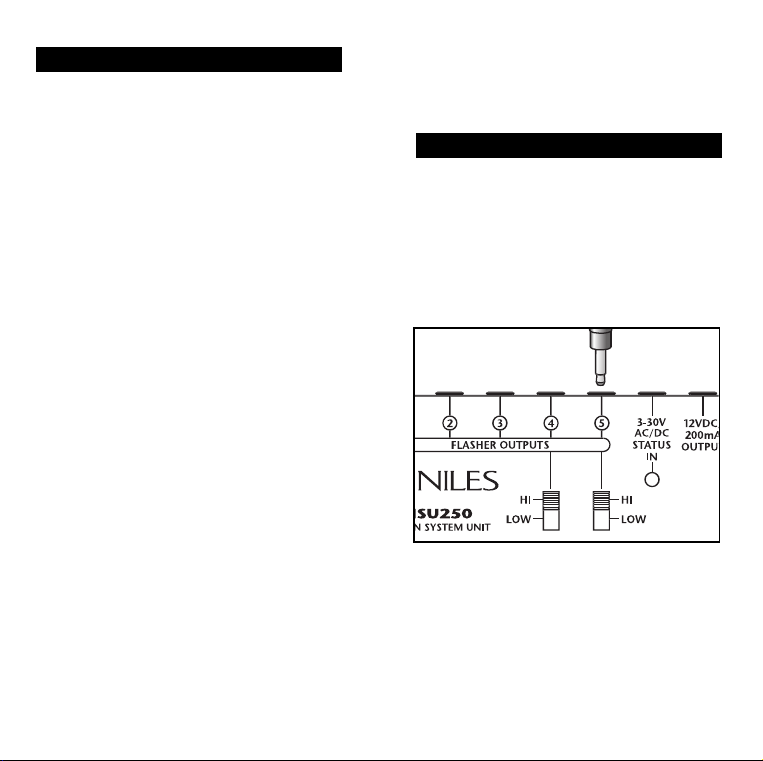

INSTALLATION & OPERATION

Route the connecting wire to the main system

unit. Most Niles IR main system units feature

specific flasher outputs that are selectable

between low and high output. Insert the 3.5mm

plug of the IRB1into one of these selectable

“FLASHER OUTPUTS” jacks on the MSU. Slide

the corresponding switch on the MSU to the

”high” position (See Figure 1).

FIGURE 1 Connecting the IRB1 to the main system

unit’s flasher outputs.

Increasing the Wire Length

If the connecting wire is too short to reach the

main system unit, a new length of heavier gauge

wire should be spliced onto a six inch length of

the original wire. For distances between ten and

twenty feet upgrade the original wire to an

4

Page 4

FIGURE 2 IRB1 placed at the bot-

tom of the cabinet controlling a

stack of components .

FIGURE 3 IRB1 placed at the bot-

tom and the top of the cabinet controlling a tall stack of components.

FIGURE 4 IRB1 placed facing the

cabinet door controlling a stack of

components by reflecting infrared

commands.

6

Over Please

Page 5

eighteen gauge two-conductor wire. For distances of up to two hundred feet use a sixteen

gauge two-conductor wire.

BE SURE TO OBSERVE PROPER POLARITY

WHEN EXTENDING THE FLASHER WIRE.

The wire lead marked with a gray stripe

is positive (+); the unmarked lead is negative (-).

Mounting the IRB1

Test the operation of the IRB1 in the planned

mounting location. If all of the components

operate correctly via the IR repeater system,

mount the IRB1 using it’s self-adhesive strip.

Make sure the mounting surface is clean and

dry. Remove the protective coating from the

back of the strip attached to the IRB1 and stick it

in place. Coil any excess connecting wire and

tie it in place.

TROUBLESHOOTING

This troubleshooting guide discusses the most

common problems that prevent an IR flasher

from operating correctly.

Testing the Remote Control

Test that the hand-held remote control operates

the component when you point it at the front

panel (check the batteries if it does not).

Main System Unit Power Supply

Check that the red power light on the main sys-

tem unit is lit (the in-line power supply should

be plugged into an active AC wall outlet and

supplying 12V DC).

78 109

“TECH TIP”

Wire size is expressed by its

AWG (American Wire Gauge)

number. The lower the number,

the larger the wire, i.e. twelve

AWG is physically larger

than fourteen AWG.

Optical IR Feedback Loop

If there is an IR sensor and an IR flasher located

within the same room—an “optical IR feedback

loop” can occur. This occurs when the IR output

from a flasher unintentionally reaches an IR sensor located within the same room. The IR commands are eventually forwarded back to the IR

flasher and the whole process endlessly repeats

itself. This effect is similar to acoustical feedback

(the howling or whistling sound heard in a P.A.

system when the microphone is placed too

close to the speaker).

The optical IR feedback loop can be eliminated

by one of the two following methods.

1. Relocating the sensor in order to break the

IR feedback loop.

2. Replace the IRB1 with a MF Series

MicroFlasher (MF1, MF1VF, MF2, MF2VF) for

each component controlled by the problemcausing flasher.

If problems persist, refer to the user’s manual

for the main system unit or contact your

local Niles dealer. If further assistance

is required contact Niles Technical Support at

1-800-289-4434.

Page 6

SPECIFICATIONS

IR System

Compatible with virtually all brands of remotes

using carrier frequencies between 20 and

455 kHz.

IR Transmitting Range

18' to 30' if mounted so that the transmitting

LEDs face the sensors in a direct line of sight.

IR Transmitting Angle

Variable with the brand and/or model of the

audio/video component. Because of the high

power and “flooding” pattern of the IRB1, extreme

transmitting angles can be successfully used if the

sensor window of the component is close.

Unit Dimensions

1" Wide x 2" High x 3/4" Deep (Includes double

sided tape).

Mounting

Supplied with self-adhesive tape.

Wiring Requirements

Supplied with 10' of 2-conductor 22 gauge con-

necting wire and 3.5mm plug. Substitute an

18 gauge 2-conductor wire for distances ranging

from 10 to 20' and a 16 gauge 2-conductor wire

for up to 200'.

Page 7

Niles Audio Corporation

12331 S.W. 130 Street Miami, Florida 33186

Tel: (305) 238-4373 Fax: (305) 238-0185

©2004 Niles Audio Corporation. All rights reserved. Niles, the Niles logo

and Blending High Fidelity and Architecture are registered trademarks of

Niles Audio Corporation. Because we strive to improve our products,

Niles reserves the right to change product specifications without notice.

The technical and other information contained herein is not intended to

set forth all technical and other specifications of Niles products. Additional

information can be obtained on-line at www.nilesaudio.com or by calling

Niles at 1-800-289-4434. 01/04 Printed in China DS00348ACN

www.nilesaudio.com

Loading...

Loading...