Page 1

Page 2

Page 3

Software Reference for Scanners

Page 4

Page 5

Nikon Software License Agreement

NOTICE TO USER

1.License

A Use the Nikon Device Driver Software only on a single Apple or IBM computer. You must obtain a

B Make one copy of the Nikon Device Driver Software in machine-readable form solely for back-up

C Transfer the Nikon Device Driver Software and all rights under this license to another party together with

D Configure the Nikon Device Driver Software for your own use by adding or removing fonts, desk

You should carefully read the Nikon License Agreement and Disclaimer of Warranty contained

herein before opening this package or breaking any seals.

INDICATE YOUR ACCEPTANCE OF THIS AGREEMENT AND ARE AGREEING TO BECOME

BOUND BY THE TERMS OF THIS AGREEMENT. . If you do not agree to the terms of this

agreement, do not open the package or break any seals. Promptly return within fifteen (15) days

from the date of delivery the unopened package to the authorized Nikon Dealer where you obtained

it for a full fee refund.

In consideration of the payment of the license fee, Nikon grants to you a non-exclusive license

to use the enclosed computer program and documentation ("Nikon Device Driver Software") only

under the terms stated in this agreement. This license is not a sale of the Nikon Device Driver

Software and you do not become owner of it. Nikon retains ownership of Nikon Device Driver

Software and all copies of it, and reserves all rights not expressly granted to you under this

agreement. You only own the disk on which the Nikon Device Driver Software is recorded. This

agreement constitutes the complete and exclusive agreement between you and Nikon and takes the

place of any prior agreement, oral or written, between us relating to the Nikon Device Driver

Software.

This license allows you to:

supplementary license from Nikon before using the Nikon Device Driver Software in connection with

systems, multiple central processing units, computer networks, or emulations on a main frame or

mini computer.

purposes. The Nikon Device Driver Software is protected by United States copyright law. You must

reproduce on each copy the Nikon copyright notice and any other proprietary legends that were on

the original copy.

a copy of this Agreement provided you give Nikon written notice of the transfer and the other party

reads and agrees to accept the terms and conditions of the agreement.

accessories, and/or device drivers.

BY OPENING THIS PACKAGE, YOU

2.Restrictions

3.Term

Except as otherwise stated in this Agreement, you may not distribute copies of the Nikon Device

Driver Software to others or electronically transfer the Nikon Device Driver Software from one

computer to another over a network. The Nikon Device Driver Software contains trade secrets, and

in order to protect them, you may not decompile, reverse engineer, disassemble, or otherwise

reduce the Nikon Device Driver Software to a human perceivable form. YOU MAY NOT MODIFY,

ADAPT, TRANSLATE, RENT, LEASE, LOAN, RESELL FOR PROFIT, DISTRIBUTE, NETWORK,

OR CREATE DERIVATIVE WORKS BASED UPON THE NIKON DEVICE DRIVER SOFTWARE

OR ANY PART THEREOF.

This license is effective until terminated. This license will terminate automatically without notice

from Nikon if you fail to comply with any provisions of this license. Upon termination you must

destroy the Nikon Device Driver Software and all copies thereof. You may terminate this license at

any time by destroying the Nikon Device Driver Software and all copies thereof.

Software Reference for Scanners

Page 6

4.Foreign Export

5.Limited Warranty and Limitations of Warranty and Liability

You agree and certify that neither the Nikon Device Driver Software nor any direct product thereof is

being or will be shipped, transferred, or re-exported, directly or indirectly, into any country prohibited

by the United States Export Administration Act and the regulations thereunder or will be used for

any purpose prohibited by the same.

A Nikon warrants that the disk on which the Nikon Device Driver Software is recorded is free from

B This warranty extends to the original licensee only and is not assignable or transferable. This

C Except for the limited warranty for the disk on which the Nikon Device Driver Software is recorded

defects in material and workmanship under normal use and conditions for a period of ninety (90)

days from date of delivery to the original licensee as evidenced by the original fee receipt. During

this period, if there is any defect in material or workmanship to the disk, return it to the Nikon

authorized dealer from whom you obtained it, together with your original fee receipt and it will be

repaired or replaced free of charge. If you ship the Nikon Device Driver Software to your Nikon

authorized dealer, you must pay all postage, shipping, transportation, insurance and delivery costs.

warranty does not apply to any disk which has been subject to misuse, abuse, negligence or

accident. Any repaired or replaced disk shall be warranted for the remainder of the original limited

warranty or thirty (30) days, whichever is longer. All warranties implied by law on the disk, including

but not limited to merchantability or fitness for a particular purpose, are limited to the duration of the

above warranty. Nikon's entire liability and your exclusive remedy hereunder is limited solely to

repair or replacement of the disk on which the Device Driver Software is recorded, or, at Nikon's

option, a refund of the license fee.

as set forth above, Nikon makes no warranties, either expressed or implied. The Nikon Device

Driver Software is sold "as is" without any warranty of any kind and Nikon, its employees,

distributors, dealers and agents specifically disclaim any warranty of any kind, either expressed or

implied, including but not limited to any implied warranty of merchantability or fitness for a particular

purpose. In no event does Nikon, its employees, distributors, dealers, or agents warrant the

performance of or the results you may obtain from the Nikon Device Driver Software, or that the

Nikon Device Driver Software will meet your requirements, or that the operation of the Nikon Device

Driver Software will be uninterrupted and error-free. If the Nikon Device Driver Software is

defective, you assume all costs of repair or servicing. In no event shall Nikon, its employees,

distributors, dealers or agents be liable to you for any direct, indirect, consequential or incidental

damages, losses or expenses of any kind, including but not limited to the loss of profits, business

information or business interruption, arising out of or resulting from the Nikon Device Driver

Software, however caused, even if Nikon has been advised of the possibility of such damages,

losses or expenses.

6.General.

D EXCEPT AS OTHERWISE PROVIDED IN THIS AGREEMENT, NIKON SHALL HAVE NO

LIABILITY OR RESPONSIBILITY OF ANY KIND (INCLUDING LIABILITY FOR NEGLIGENCE) TO

YOU OR ANY OTHER PERSON OR ENTITY WITH RESPECT TO ANY LIABILITY, LOSS OR

DAMAGE CAUSED OR ALLEGED TO HAVE BEEN CAUSED, DIRECTLY OR INDIRECTLY BY

THE NIKON DEVICE DRIVER SOFTWARE SOLD, LICENSED OR FURNISHED BY NIKON

UNDER THIS AGREEMENT. NOTWITHSTANDING THE ABOVE LIMITATION, NIKON'S

LIABILITY ON ANY CLAIM OF ANY KIND (INCLUDING NEGLIGENCE) FROM THE DELIVERY,

LICENSE, OR USE OF THE NIKON DEVICE DRIVER SOFTWARE FURNISHED UNDER THIS

AGREEMENT SHALL IN NO CASE EXCEED THE FEE YOU PAID FOR THE NIKON DEVICE

DRIVER SOFTWARE.

SOME STATES DO NOT ALLOW (A) LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS OR (B) THE EXCLUSION OR LIMITATIONS OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT

APPLY TO YOU. NIKON'S WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY

ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

This agreement is governed and shall be construed in accordance with the laws of the State of New

York. If any provision of this Agreement shall be determined to be invalid for any reason, the

remaining provisions shall not be invalidated and shall remain in full force and effect.

Software Reference for Scanners

Page 7

Software Reference for Scanners

Page 8

Table of Contents 4-4

Acknowledgments

Nikon Inc. acknowledges with gratitude the contributions of the Planning and Design Sections, and the Electronic Imaging

Department Software Engineering Section. These manuals were written, designed and produced by the Electronic Imaging

Department Development & Marketing Group in collaboration with the Technical Support Section and the 4th Designing Section

of Nikon Corporation. Nikon would also like to thank all those who helped test the LS-3510AF and its software.

This manual may not, in whole or in part, be copied, photocopied, reproduced, translated, or converted to any electronic or

machine readable form without prior written consent of Nikon Inc.

Apple Disclaimer

The following disclaimer is required by Apple Computer, Inc. It applies only to Apple software. All other software is covered by

Nikon's limited warranty

“APPLE COMPUTER, INC. (“APPLE”) MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, REGARDING THE APPLE SOFTWARE. APPLE DOES NOT WARRANT, GUARANTEE OR MAKE ANY

REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE OF THE APPLE SOFTWARE IN TERMS OF ITS CORRECTNESS, ACCURACY, RELIABILITY,

CURRENTNESS OR OTHERWISE. THE ENTIRE RISK AS TO THE RESULTS AND PERFORMANCE OF THE APPLE SOFTWARE IS ASSUMED BY YOU. THE EXCLUSION OF

IMPLIED WARRANTIES IS NOT PERMITTED BY SOME STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.”

“IN NO EVENT WILL APPLE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE TO YOU FOR ANY CONSEQUENTIAL, INCIDENTAL OR INDIRECT

DAMAGES (INCLUDING DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, AND THE LIKE) ARISING OUT OF

THE USE OR INABILITY TO USE THE APPLE SOFTWARE EVEN IF APPLE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

APPLE’S LIABILITY TO YOU FOR ACTUAL DAMAGES FROM ANY CAUSE WHATSOEVER, AND REGARDLESS OF THE FORM OF THE ACTION (WHETHER IN CONTRACT,

TORT (INCLUDING NEGLIGENCE), PRODUCT LIABILITY OR OTHERWISE,) WILL BE LIMITED TO $50.”

Trademark Information

NB Handler CDEV, NB-GPIB, GPIB-AT, MC-GPIB are Copyright National Instruments, Inc.

Windows is a registered trademark of Microsoft Corporation

Nikon Inc.

Electronic Imaging Department

1300 Walt Whitman Road,

Melville, NY 11747

516-547-4355

Nikon, LS-3500, LS3510AF

© 1991, Nikon Inc. All right reserved.

Printed in the United States of America

are trademarks of Nikon Corp.

Software Reference for Scanners

Page 9

4-5 Table of Contents

Table of Contents

Read This First ....................................................................................................... i

About This Manual....................................................... i

The Package Contents .................................................. i

User Registration.......................................................... i

Minimum Macintosh System Requirements ................ i

Minimum PC System Requirements ............................ ii

Before You Begin......................................................... ii

Software Installation............................................................................................... 1-1

Installing the Plugin Modules on the Macintosh.............................................. 1-1

Configuring and Testing the GPIB................................................................... 1-2

Installing the Plugin Modules under Windows 3.1 .......................................... 2-1

Interface Hardware for PC Compatibles .......................................................... 2-3

GPIB (General Purpose Interface Bus) ........................ 2-3

SCSI (Small Computer Systems Interface).................. 2-3

Getting Started on the Macintosh........................................................................... 3-1

Launching the Application ............................................................................... 3-1

Software Reference for Scanners

Page 10

Table of Contents 4-6

Scanning a Preview Image............................................................................... 3-2

Final Scan......................................................................................................... 3-3

Conclusion ....................................................................................................... 3-4

Getting Started on the IBM.................................................................................... 4-1

Launching the Application............................................................................... 4-1

Scanning a Preview Image............................................................................... 4-2

Final Scan......................................................................................................... 4-3

Conclusion ....................................................................................................... 4-4

Using the Macintosh Scanner Plugin..................................................................... 5-1

The Main Dialog .............................................................................................. 5-1

Controls and Indicators .................................................................................... 5-2

Status Line.................................................................... 5-2

Film Type..................................................................... 5-2

Orientation ................................................................... 5-4

Portrait/Landscape ....................................................... 5-4

Vertical/Horizontal Flip ............................................... 5-4

Densitometer ................................................................ 5-4

Sizing and Resolution .................................................. 5-5

Scan Pitch..................................................................... 5-6

Software Reference for Scanners

Page 11

4-7 Table of Contents

Scanning Speed ............................................................ 5-10

Grayscale/Color Preview.............................................. 5-11

Interface Buttons .......................................................... 5-11

Digital and Analog Controls......................................... 5-11

Digital Mode................................................................. 5-12

Analog Mode................................................................ 5-12

Auto Exposure/Auto Mode .......................................... 5-13

The Settings Buttons .................................................... 5-14

Toolkit .......................................................................... 5-14

Calibrating the Lamp.................................................... 5-17

Using the Windows 3.1 Scanner Plugin................................................................. 6-1

The Main Dialog .............................................................................................. 6-1

Controls and Indicators .................................................................................... 6-1

Interface........................................................................ 6-1

Scanner Tools............................................................... 6-3

Calibration.................................................................... 6-4

Scan Size and Resolution ............................................. 6-4

Scan Pitch..................................................................... 6-5

Sizing and Resolution................................................... 6-5

Software Reference for Scanners

Page 12

Table of Contents 4-8

Scanning Speed............................................................ 6-7

Color Adjustment Controls .......................................... 6-7

Film Types ................................................................... 6-10

Autoexposure ............................................................... 6-11

Autofocus..................................................................... 6-11

Manual Focus............................................................... 6-11

Densitometer Readout.................................................. 6-12

Previewing ................................................................... 6-12

Defaults ........................................................................ 6-13

Status Indicator ............................................................ 6-13

Scanning for Reproduction .................................................................................... 7-1

Gamma............................................................................................................. 7-1

Color Balancing ............................................................................................... 7-1

Color Reproduction Background Information ................................................. 7-2

Glossary of Computer Imaging Terms................................................................... 8-1

Software Reference for Scanners

Page 13

Software Reference for Scanners

Page 14

Page 15

Read This First i

Read This First

About This Manual

This reference and disk set contains material for either Apple Macintosh

computers or PC compatibles running MS Windows. Where possible, we have

tried to make both versions of software as similar as possible in feature set and

interface design. There may be occasions, because of operating system

dissimilarities, where the two versions may not match exactly. The explanations

in the respective platform sections may also differ for that reason.

Commands that are taken from the user interface are shown using Helvetica

type. Cautions and Notes are printed in boldfaced type with a triangular marker

in the margin.

The Package Contents

Listed below are the components of the Nikon Software Reference for

Scanners package.

• Nikon Software Reference for Scanners

• Nikon Device Drivers Disks for Macintosh and Windows 3.0

• Nikon User Registration

If any of the above are missing, please contact your Nikon Electronic

Imaging Dealer immediately.

User Registration

If you would like to receive the latest information and updates from Nikon,

please fill in the User Registration and mail it today!

Minimum Macintosh Scanning System Requirements

• Macintosh System 6.0.5 or later

• 32-Bit Quickdraw

• 4MB RAM (8MB recommended)

• 80MB Hard Disk (300MB recommended)

• National Instruments NB-GPIB card with cable when using the

GPIB interface

Software Reference for Scanners

Page 16

ii Read This First

• SCSI II cable adapter when using the LS-3510AF SCSI interface

• 8-bit display (24-bit true-color display highly recommended)

Minimum PC and Compatibles Scanning System Requirements

• Windows 3.0 or later

• 4MB RAM (8MB recommended)

• 80MB Hard Disk (300MB recommended)

• National Instruments GPIB -AT (for ISA bus) or MC-GPIB (for

Microchannel bus) card with cable when using the GPIB interface

• SCSI II cable adapter when using the SCSI interface

• Super VGA display (24-bit true-color display highly recommended)

Before You Begin

Before you begin setting up, make a backup copy of your master diskettes!

Put away the masters in a safe place and work with the backup copies to install the

Nikon Drivers.

Please begin by following the Software Installation procedures for your

particular platform.

The Getting Started section of this manual will get you up and running in the

shortest possible time. This is a condensed instruction manual that will lead you

through the basic steps of scanner setup, configuration, and finally, scanning of the

enclosed sample slide. Don’t worry if you don’t fully understand some of the

terminology and concepts we are introducing here. The idea is to setup quickly and

familiarize yourself with the controls by performing a routine scan.

You will probably require one hour to perform any hardware installation, test

it, and go through a trial run. In this time you will gain a working knowledge of

the scanning system. Before you begin, make sure that you have the minimum

system requirements for a functional scanning system.

In particular, if you are using your scanner with a GPIB interface, you must

have a GPIB interface card installed in your computer, or have one ready to install.

For a thorough explanation of scanner controls, color imaging techniques and

color separation guidelines, we strongly recommend reading the User's Guide

sections of this manual.

For detailed information on the scanning hardware and a full discussion of

programming your own scanner control interface, refer to the Technical and

Programmer's References available from Nikon. Now, let’s begin....

Software Reference for Scanners

Page 17

Software Installation - Macintosh 1-1

Software Installation

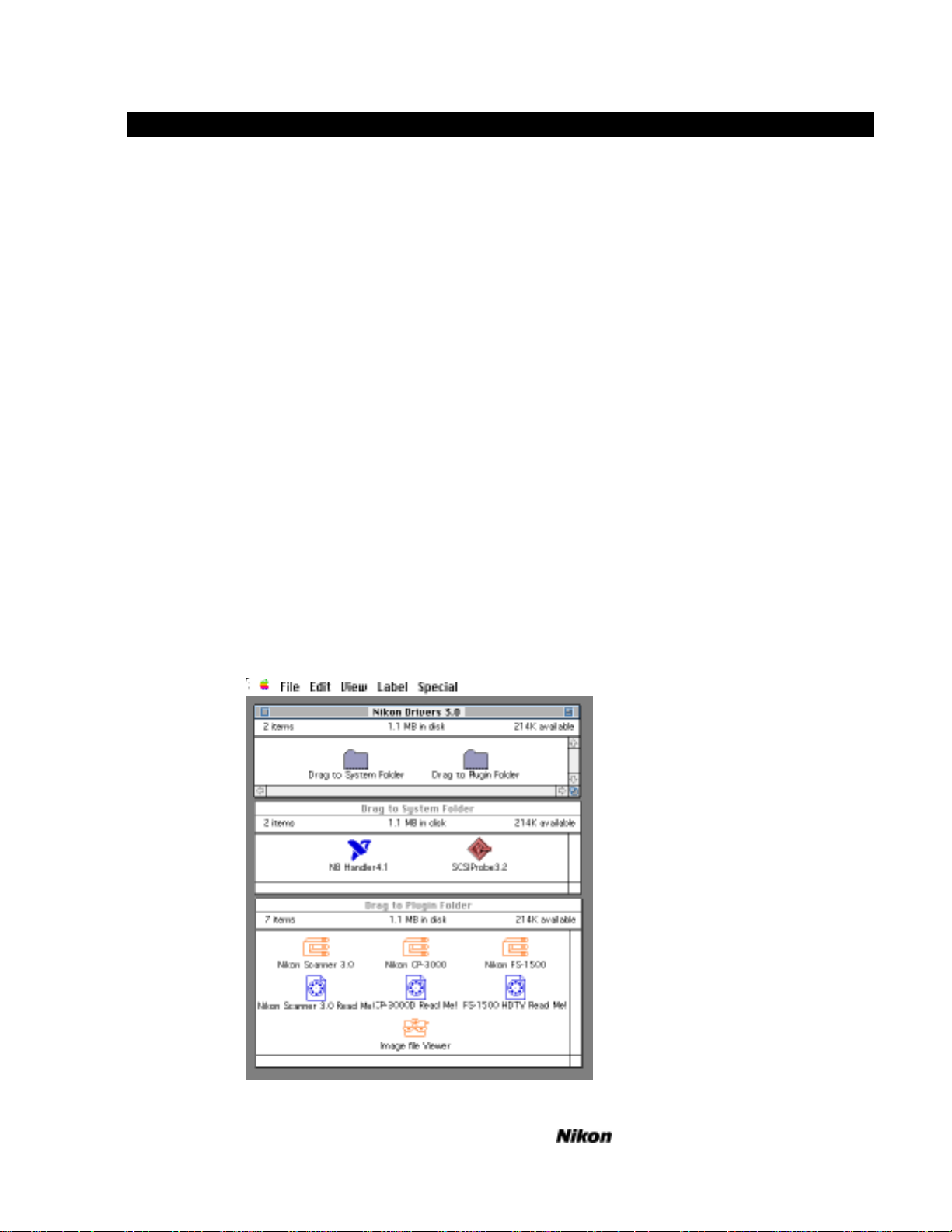

Installing the Plugin Modules on the Macintosh

If you have not already done so, install Photoshop following Adobe's

installation procedure. If you are using ColorStudio, then follow the installation

routine specified by Letraset.

After you have installed and tested your image processing application, you

are ready to install the Nikon Plugin modules. If you are using Photoshop v 2.0,

they should be placed in the Photoshop Plugins folder within the Adobe Photoshop

application folder. If you are using ColorStudio or another image processing

application that uses Photoshop Plugins, install the module in the location

specified for plugins by the manufacturer of the software package.

>Note This plugin works with Photoshop 1.0 or later, or ColorStudio 1.5 or later.

You must update older versions with the new ones before you use this

software

Start your Macintosh and determine if you are running System 6.0.5 or a later

version. If you are unfamiliar with how to do this, please refer to the Macintosh

Owner’s Guide. Insert your backup Nikon Drivers disk into the drive. The disk

icon will appear on your desktop and three windows containing folders will appear

in a vertical column on the left side of your screen, as shown below.

Fig. 1 Desktop

Software Reference for Scanners

Page 18

1-2 Software Installation - Macintosh

If you are using a GPIB interface, select the NB Handler Init in the folder

labeled Drag to System Folder and drag it onto the System Folder on your hard

disk. It will be copied into the Control Panels folder if you are using System 7.

>Caution If you already have a file called NB-Handler INIT installed in your system

folder, move it to another folder before you copy the new file in.

Next, drag the Nikon Drivers disk icon onto your hard disk icon and follow

the prompts. Double click on your hard disk icon to reveal its contents. Now

double click on the Nikon Drivers folder to display the NB Handler Init, the

plugin modules, and the ReadMe documents.

If you are using the built-in SCSI interface on the Macintosh, connect the

DB25 to SCSI II cable adapter to the rear panel connector on the Mac and then to

the Mini 50 pin connector on the Nikon scanner. If this is the only unit on the

SCSI bus, connect a terminator to the second plug on the scanner. Restart your

Macintosh and go on to Using the Plugin Scanning Module.

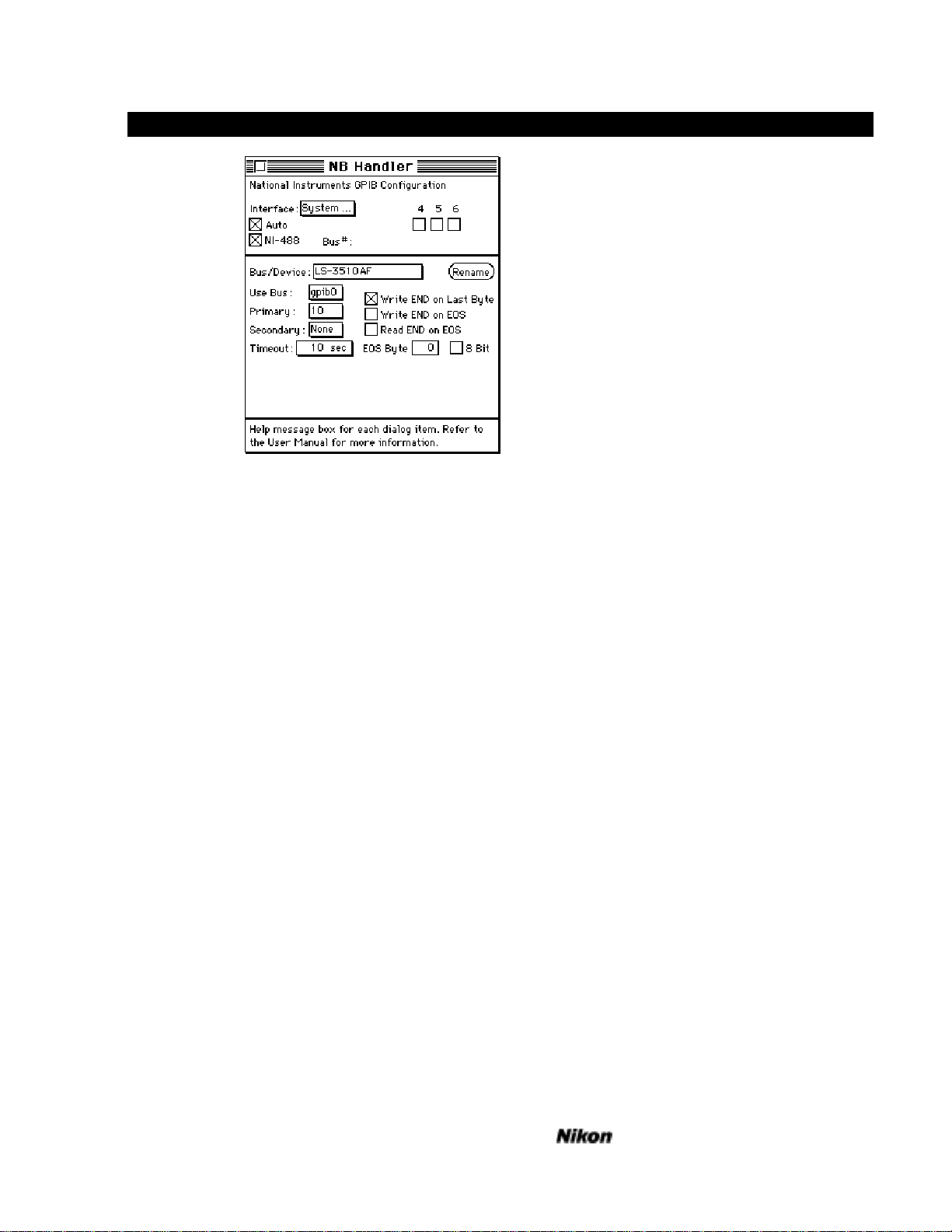

Configuring and Testing the GPIB

If you are using an NB-GPIB interface card, the NB Handler Init must be in

your startup (boot) disk’s System Folder in order for the plugins to work properly.

Using System 7, it should be in the Control Panels folder.

In order for the NB-GPIB interface to communicate properly with the Nikon

Plugins, the NB Handler control panel should be configured to your device address

settings. In particular, it is necessary that the GPIB finds a device called LS-

3510AF, which is the LS-3510AF Film Scanner (or in the case of the LS-3500

scanner, LS3500), when the plugin looks for it. Similarly, if you are using a CP3000 printer, then the name CP-3000 must be used by the NB Handler to indicate

the device. If your NB Handler does not have your scanner or printer address

configured properly, the GPIB may not communicate with the device connected.

If you have an old version of the handler in your system folder, remove it

temporarily and replace it with the new version from the Nikon Drivers disk. This

is a preconfigured file for the Nikon LS-3500, LS-3510AF, CP-3000D and FS1500 devices. Using this Init will get you running in the least amount of time and

you can reconfigure for other devices later on. If you are using the preconfigured

NB Handler, confirm its correct installation by restarting your machine and

opening your NB Handler control panel from your Control Panels under the Apple

Menu.

Software Reference for Scanners

Page 19

Software Installation - Macintosh 1-3

Fig. 2 NB Handler control panel

Check to see that the addresses are correctly entered and conform to the

factory default settings of the device DIP switches. If so, proceed to the next

section, Using The Macintosh Plugin Scanning Module.

If you wish to change the configuration, use the rename button to change any

devx setting to the appropriate name of the device. Set the address in the text-edit

box labeled Primary. It is not necessary to restart your machine for the changes to

take effect. Simply close the Control Panel and go on to Getting Started.

>Note If you have an older NB Handler Init installed it may not be of the control

panel type and will not show up in your Control Panels folder. If so, you can

use the IBCONF utility usually supplied with your National Instruments NBGPIB board to add the Nikon configuration to your old Init, or you can

modify the new one with the control panel shown above to include your other

devices, such as film recorders and other scanners.

Software Reference for Scanners

Page 20

Page 21

Software Installation - IBM 2-1

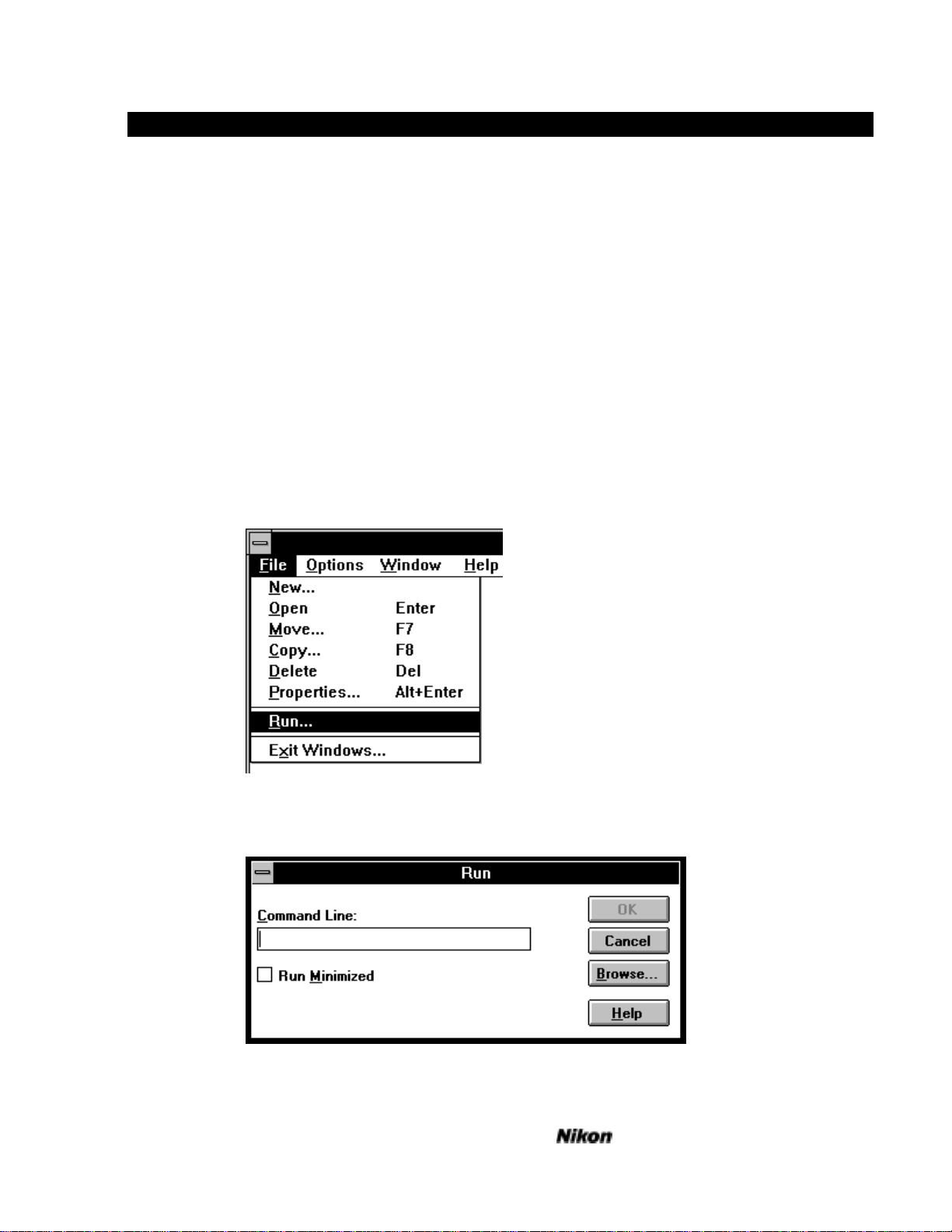

Installing the Plugin Modules under Windows 3.1

If you have not already done so, install PhotoStyler following Aldus’

installation procedure. If you are using another application, then follow the

installation routine specified by the manufacturer.

After you have installed and tested your image processing application, you

are ready to install the Nikon Plugin modules. If you are using PhotoStyler they

should be placed in the PhotoStyler directory.

>Note This plugin works with PhotoStyler 1.0 or later

Launch Windows. If you are unfamiliar with how to do this, please refer to

the Microsoft Windows Owners Guide.

Insert your backup Nikon Installer Disk in your floppy drive - drive A: for

example.

Fig. 3.The Program Manager File Menu

Select Run... from the File menu in the Program Manager.

Fig. 4 The Run... Dialog

Software Reference for Scanners

Page 22

2-2 Software Installation - IBM

Type A:PSSETUP and press enter. Press any key or click the mouse to skip

the startup screen.

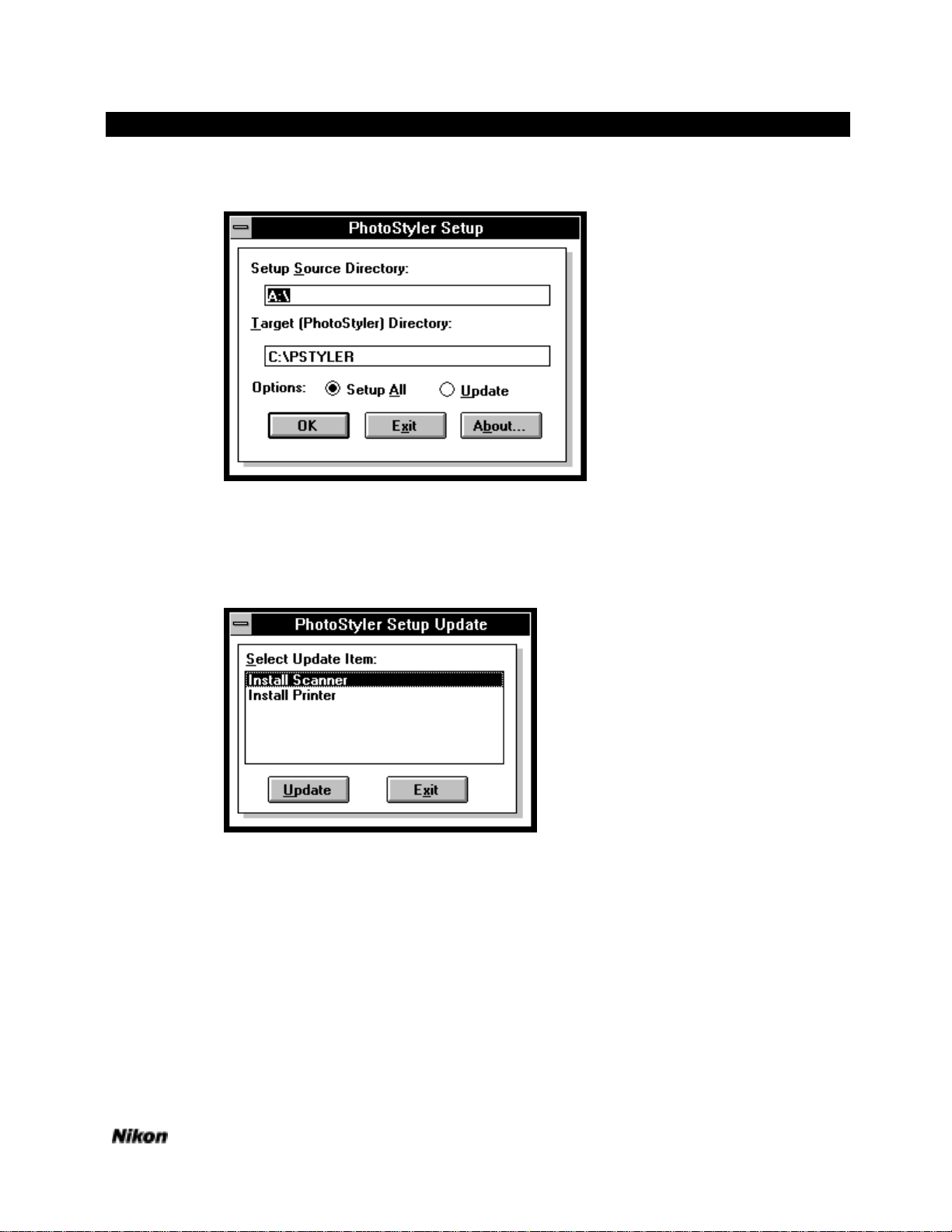

Fig. 5 PhotoStyler Directories

Enter your source and target directories. To install only the Scanner Plugin or

the Nikon CP-3000 printer export, check the Update box before pressing the OK

button. Choosing Setup All will install all the plugins on the disk.

Fig 6 Installing the scanner

If you are updating the scanner, choose the Install Scanner selection.

Software Reference for Scanners

Page 23

Software Installation - IBM 2-3

Fig. 7 Selecting the active scanner for PhotoStyler

You must choose which scanner driver to make active in PhotoStyler. Since

only one driver is available, click OK.

Your drivers are now installed and you can proceed on to the Getting Started

section for the Windows plugins.

Interface Hardware for PC Compatibles

For complete information on installation of GPIB hardware consult your GPIB

installation manual which comes with your GPIB board.

As with any interface board installation, ensure that there are no address,

interrupt or DMA channel conflicts between any boards installed in your

computer.

GPIB (General Purpose Interface Bus)

Currently, only the National Instruments AT-GPIB and MC-GPIB boards are

supported. When installing the software drivers for these boards, be sure to select

the installation for Windows. National Instruments can be reached at

1-800-IEEE-488 (1-800-433-3488).

SCSI (Small Computer Systems Interface)

Any SCSI board with ASPI (Advanced SCSI Programming Interface) drivers

should work, but only the T128 and T228 from Trantor and the AHA-1520, AHA1522, AHA-1540B, AHA-1542B, AHA-1640 and AHA-1642 from Adaptec have

been verified. Trantor can be reached at 1-510-770-1400 and Adaptec can be

reached at 1-800-869-8883. The ASPI drivers may not be included with the

standard software bundle and may have to be specifically requested.

Software Reference for Scanners

Page 24

Page 25

Getting Started On The Macintosh 3-1

Getting Started on the Macintosh

Launching the Application

Launch Photoshop or ColorStudio by double clicking the appropriate icon.

Pull down the File menu to reach the Acquire... menu item and select Nikon

Scanner... from the hierarchical menu. The main scanning dialog will appear as

below and the Device: and Address: lines should indicate that there is a scanner

connected. If the dialog appears as below, you are ready to start scanning and can

proceed to Scanning a Preview Image.

Fig. 8 Main Scanning Dialog

If the message in the upper left-hand corner reads “Nikon LS-3510AF Ver

1.xx” on either a SCSI or GPIB interface, you are ready to make a preview or

scan. If not, the plugin has not found the scanner and you will need to check your

SCSI or GPIB cabling, confirm tight connections and proper termination. For

SCSI installations with other external devices, place the scanner at the end of the

chain with the standard supplied terminator for your machine. If you are unsure

what GPIB or SCSI address to use, consult the Setup Guide included with your

scanner.

Software Reference for Scanners

Page 26

3-2 Getting Started

Scanning a Preview Image

Take out the sample slide included in the disk holder. You will be using the

Standard Slide Holder for this scan. Hold the mount as in the diagram in Fig. 9

below. Insert the slide so that the emulsion side of the film faces the front of the

scanner. When viewing the slide orient the picture so the text is readable. The

emulsion side is the surface furthest away from you. Since the LS-3510AF is an

autofocus scanner, it will not make much difference which way you place the

emulsion (other than image orientation, right-reading or backwards), although

sharpest results will be achieved when the emulsion faces the front of the scanner

because the imaging lens will not be reading the film through the film base, which

may reduce definition, depending on the film type.

Sample

35mm film

in slide mount

Standard Holder

Scanning Stage

Light source

Fig. 9 Loading the Scanner

Insert the Slide Holder into the scanner so that the slide mount is closest to

the lamp. Close the dustproof cover so that the outside light does not affect the

scan.

The sample slide is a portrait (or a vertical image) but we will leave the

default scanning orientation in the horizontal or landscape position.

Fig. 10 Orientation

Software Reference for Scanners

Page 27

Getting Started On The Macintosh 3-3

The quickest way to capture this image is to click the Preview button.

Fig. 11 Previewing an Image

In order to scan the slide under optimal conditions, the LS-3510AF will first

perform an autoexposure and autofocus sequence to determine information about

the nature of the image in the holder.

You should see the green Busy LED light up on the scanner and a message

appear in a small dialog. The message should read Performing an

autoexposure... This status line will keep you informed about the scanner’s

progress.

When the green Busy LED on the LS-3510AF goes out, you have completed

the Autoexposure cycle and the scanner will automatically focus on the slide

displaying the message, Performing autofocus... After this, the Busy LED will

immediately light up again and the scanner will begin the preview cycle as it reads

the picture directly to your monitor display, field by field. We can now see the

image appearing on the video screen in the scan window in the sequence red,

green, then blue screens.

>Note You will not be able to see the high-quality color available from the scanner

unless you have a 24-bit display card installed in your system. Using an 8-bit

card will display a dithered image.

Final Scan

The next step will be to perform the main scan at a higher resolution. Crop

the preview image by placing the cursor at any corner of the preview, and dragging

to enclose the area of interest in a rectangle as in Fig. 12 below.

Fig. 12 Cropping the Preview Image

Software Reference for Scanners

Page 28

3-4 Getting Started

The resolution setting under the preview window can be left at the default

setting of 72DPI. The approximate size of the output image should be 6 x 8

inches.

You are now ready to complete the final scan. Click on the scan button at the

lower right of the Main dialog. The scanner will begin the scanning cycle, making

three successive passes for red, green and blue. Within a moment or two, a

progress indicator dialog will appear, showing the approximate duration of the

scan and the portion remaining to be completed.

Fig. 13 Scanning Progress Indicator

Be sure not to open the dust cover during the scan. If it is opened, extraneous

light could adversely affect your scan and cause density changes to appear in the

image. This scan will take approximately 45 seconds to complete. A new window

containing the image and labeled Untitled-1 will appear after the scan is complete.

You may save the image in the normal manner or close the window and begin

again.

Conclusion

You have completed Getting Started! Feel free to continue exploring on your

own, but if you need quick answers to any questions, don’t hesitate to consult the

User's Guide following this section. It provides complete descriptions of the plugin

controls so you can exploit the full functionality of your Nikon scanning system.

Software Reference for Scanners

Page 29

Getting Started On The IBM 4-1

Getting Started on the IBM

Launching the Application

Launch PhotoStyler by double clicking the appropriate icon.

Pull down the File menu to reach the Scan... menu item and select Nikon

Scanner Control... from the hierarchical menu. The main scanning dialog will

appear as below and the Device: and Address: lines should indicate that there is a

scanner connected. If the dialog appears as below, you are ready to start scanning

and can proceed to Scanning a Preview Image.

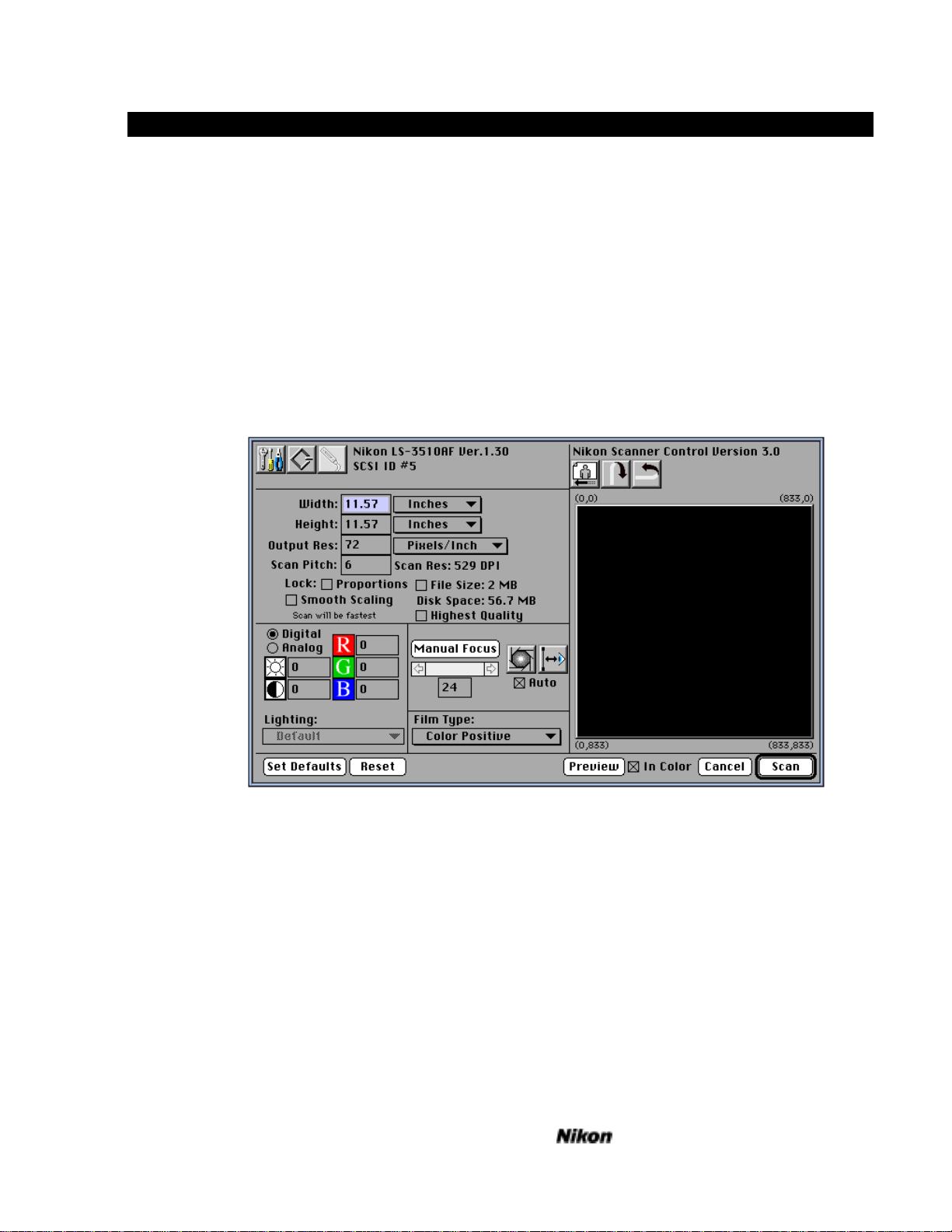

Fig. 14 Main Scanning Dialog

If the message in the upper left-hand corner reads “Nikon LS-3510AF Ver

1.xx” on either a SCSI or GPIB interface, you are ready to make a preview or

scan. If not, the plugin has not found the scanner and you will need to check your

SCSI or GPIB cabling, confirm tight connections and proper termination. For

SCSI installations with other external devices, place the scanner at the end of the

chain with the standard supplied terminator for your machine. If you are unsure

what GPIB or SCSI address to use, consult the Setup Guide included with your

scanner.

Software Reference for Scanners

Page 30

4-2 Getting Started On The IBM

Scanning a Preview Image

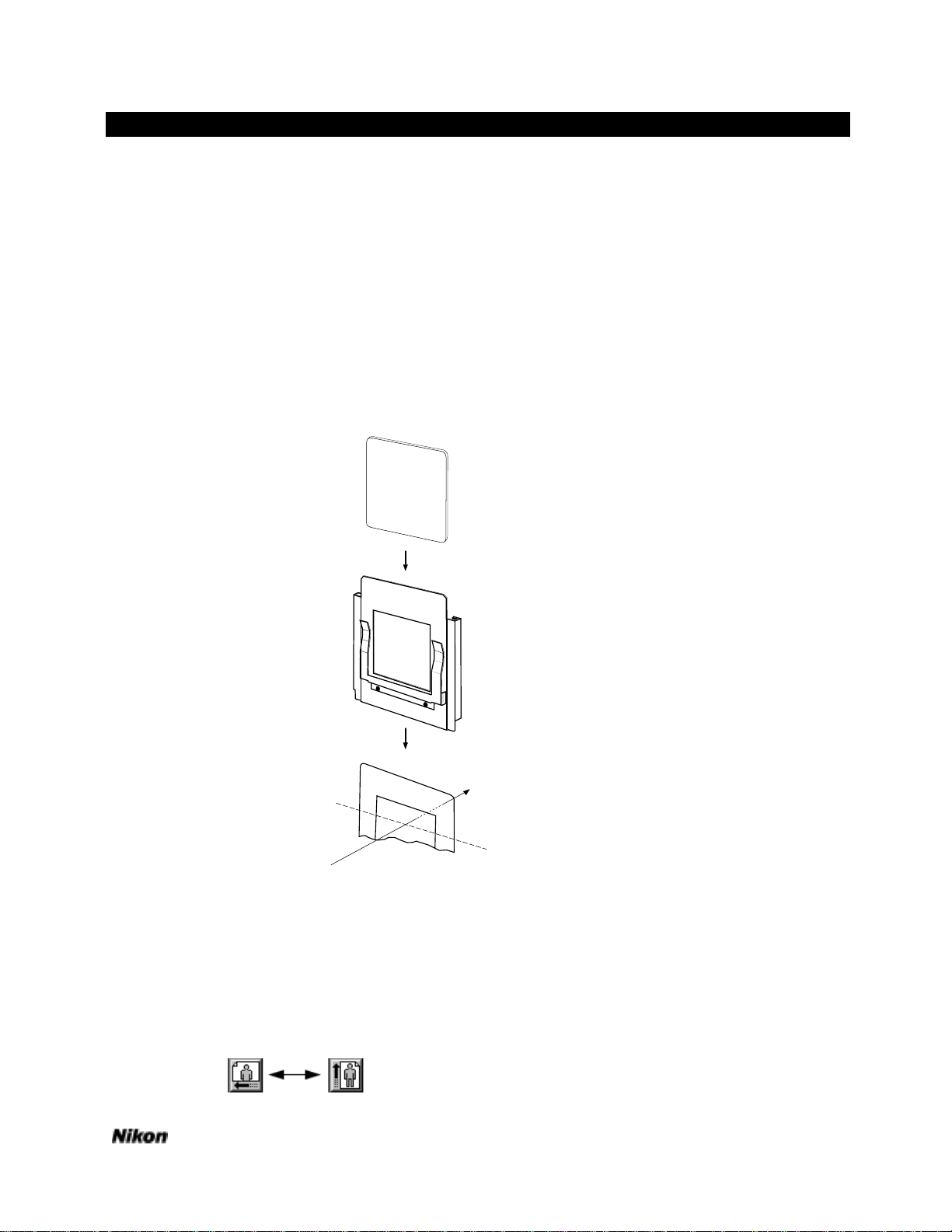

Take out the sample slide included in the disk holder. You will be using the

Standard Slide Holder for this scan. Hold the mount as in the diagram in Fig. 15

below. Insert the slide so that the emulsion side of the film faces the front of the

scanner. When viewing the slide orient the picture so the text is readable. The

emulsion side is the surface furthest away from you. Since the LS-3510AF is an

autofocus scanner, it will not make much difference which way you place the

emulsion (other than image orientation, right-reading or backwards), although

sharpest results will be achieved when the emulsion faces the front of the scanner

because the imaging lens will not be reading the film through the film base, which

may reduce definition, depending on the film type.

Sample

35mm film

in slide mount

Standard Holder

Scanning Stage

Light source

Fig. 15 Loading the Scanner

Insert the Slide Holder into the scanner so that the slide mount is closest to

the lamp. Close the dustproof cover so that the outside light does not affect the

scan.

The sample slide is a portrait (or a vertical image) but we will leave the

default scanning orientation in the horizontal or landscape position.

Fig. 16 Orientation

Software Reference for Scanners

Page 31

Getting Started On The IBM 4-3

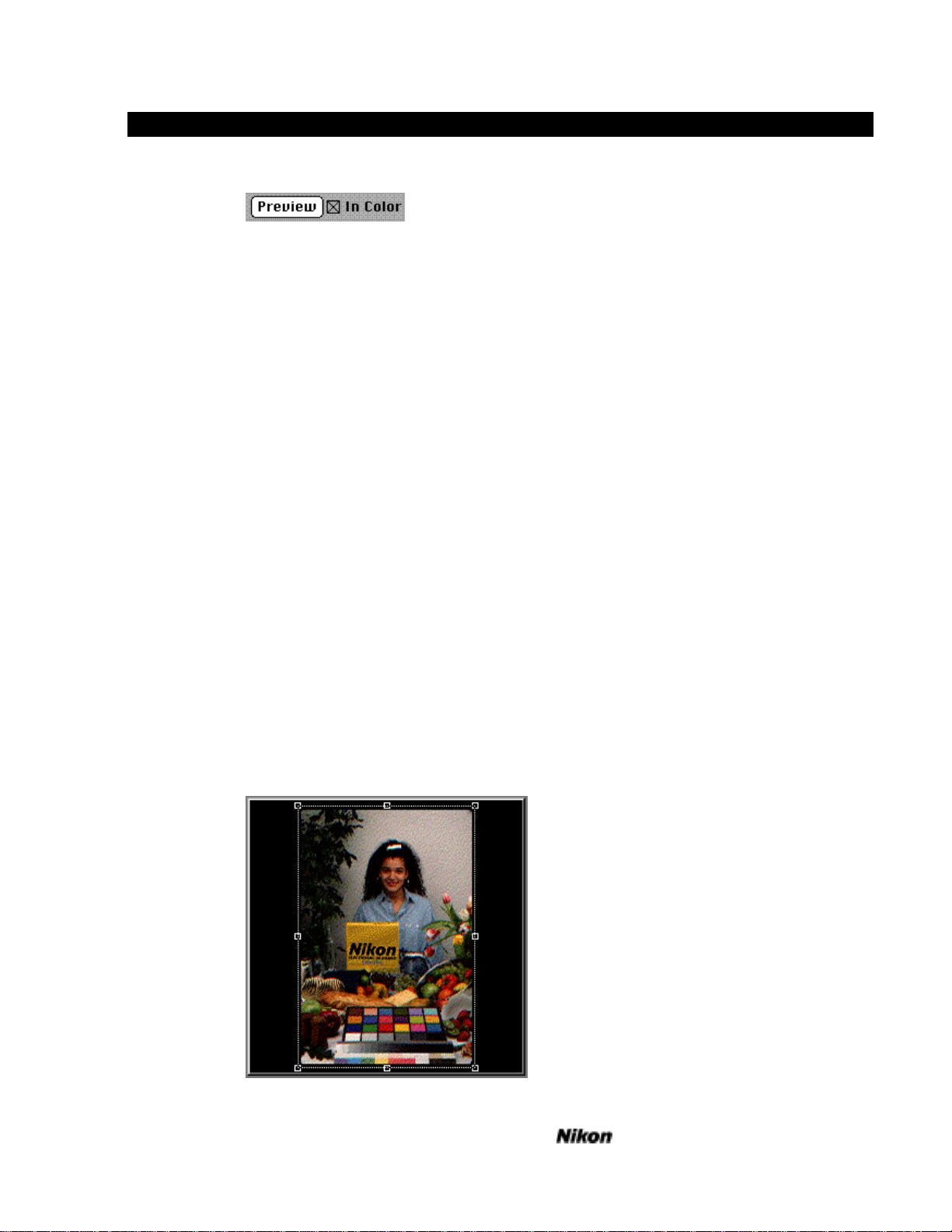

The quickest way to capture this image is to click the Preview button.

Fig. 17 Previewing an Image

In order to scan the slide under optimal conditions the LS-3510AF will first

perform an autoexposure and autofocus sequence to set up information about the

nature of the image in the holder.

You should see the green Busy LED light up on the scanner and a message

appear in a small dialog. The message should read Performing an

autoexposure... This status line will keep you informed about the scanner’s

progress.

When the green Busy LED on the LS-3510AF goes out, you have completed

the Autoexposure cycle and the scanner will automatically focus on the slide

displaying the message, Performing Autofocus. After this, the Busy LED will

immediately light up again and the scanner will begin the preview cycle as it reads

the picture directly to your monitor display, field by field. We can now see the

image appearing on the video screen in the scan window in the sequence red,

green, then blue screens.

>Note You will not be able to see the high-quality color available from the scanner

unless you have a 24-bit display card installed in your system.

Final Scan

The next step will be to perform the main scan at a higher resolution. Crop

the preview image by placing the cursor at any corner of the preview, and drag to

enclose the area of interest in a rectangle as in Fig. 18 below.

Fig. 18 Cropping the Preview Image

Software Reference for Scanners

Page 32

4-4 Getting Started On The IBM

The resolution setting under the preview window can be left at the default

setting of 100DPI. The approximate size of the output image should be 10 x 15

inches.

You are now ready to complete the final scan. Click on the scan button at the

lower right of the Main dialog. The scanner will begin the scanning cycle, making

three successive passes for red, green and blue. Within a moment or two, a

progress indicator dialog will appear, showing the approximate duration of the

scan and the portion remaining to be completed.

Fig. 19 Scanning Progress Indicator

Be sure not to open the dust cover during the scan. If it is opened, extraneous

light could adversely affect your scan and cause density changes to appear in the

image. This scan will take approximately 45 seconds to complete. A new window

containing the image and labeled Untitled-1 will appear after the scan is complete.

You may save the image in the normal manner or close the window and begin

again.

Conclusion

You have completed Getting Started! Feel free to continue exploring on your

own, but if you need quick answers to any questions, don’t hesitate to consult the

User's Guide following this section. It provides complete descriptions of the plugin

controls so you can exploit the full functionality of your Nikon scanning system.

Software Reference for Scanners

Page 33

Using The Macintosh Scanner Plugin 5-1

Using the Macintosh Scanner Plugin

Let’s begin with a full description of the main and auxiliary dialogs. All of

the plugin controls follow the standard Macintosh interface design. If you are

unfamiliar with the operation of the Macintosh interface, please consult your

owner’s manual.

The examples in this reference were used with the LS-3510AF in mind.

Other Nikon scanners will vary slightly in their feature set, although all Nikon

scanners can be controlled with this software.

The Main Dialog

In this section we will discuss each menu and dialog box in detail. The main

dialog looks like this:

Fig. 20 The Main Scanning Dialog

Software Reference for Scanners

Page 34

5-2 Using The Macintosh Scanner Plugin

Controls and Indicators

The purpose of each control and dialog item is discussed below.

Status Line

Fig. 21 Status Line

A status and information line is displayed when an action is begun. Messages

include the current scanner condition and routine being performed. For example,

when the Autoexposure button is pressed, the message will read Performing an

autoexposure...

Film Type

Fig. 22 Film Type

This pop-up menu allows the user to specify film type regardless of what kind

of film is placed in the scanner. If a monochrome scan of a negative color image

is desired, you should choose B & W Negative. The Autoexposure measurements

are compensated according to tone range of the average color values. If a unique

color tone separation is required, a color scan can be made and the appropriate

color channel can then be manipulated in the image processing application to

achieve the desired color/tone balance in black and white.

Software Reference for Scanners

Page 35

Using The Macintosh Scanner Plugin 5-3

This pop-up menu also specifies color and density processing for negative or

positive film types. Since color negative film is not simply the inverse of color

positive film (because of the orange mask used in negative film types), accurate

color and density balance can only be achieved by using analog processing of

gamma and exposure. Accurate, higher quality color is maintained by using this

control to modify the balancing parameters in the analog section of the scanner

rather than in the image processing application where loss of bits and tone range

will result.

To register and calibrate to a new color negative film type, insert a processed

unexposed strip of film into the scanner, and close the cover. Choose Register

from the Film Type pop-up menu and the following dialog will appear.

Fig. 23 Registering Film Type

Type the name you wish to use to indicate this film; no more than 13

characters. The register button will be enabled, and pressing it will start the

calibration cycle in the scanner. This is a custom calibration specific to the film

and processing that you are using. You can store up to 24 custom film types in the

scanner. You can delete any of these film types by using the Delete... menu item

if you need to make space for a new film type.

The calibration provides a neutral black point from the orange clear base of

color negative films. Another way to calibrate is to photograph three aim points.

Place a black card, preferably velvet, an 18% reflectance gray card and a matte

white card in the frame. After processing, place this frame in the scanner in

vertical orientation and go through the same registration procedure.

For more accurate calibration, you can use a five step grayscale for even

closer correction values. Make sure that it is photographed at 5500°K. In

addition, color transparency film can be calibrated the same way. When not using

a grayscale, make sure that an unexposed piece of negative processed film is used.

Insert the processed film so that the gray wedge is vertically oriented in the

scanner.

Software Reference for Scanners

Page 36

5-4 Using The Macintosh Scanner Plugin

Fig. 24 Photo of Gray Step Wedge

Orientation

Portrait/Landscape

Fig. 25 Portrait/Landscape Orientation Switch

This button specifies orientation of the resulting scan from a normally

mounted original. If the original is placed in the scanner in a normal orientation as

viewed from the front, then the landscape button will produce the same orientation

on output to the screen. Depress the button to reveal the portrait icon and the

resulting scan will be rotated 90° from the position it was in the scanner film gate.

Vertical/Horizontal Flip

Fig. 26 Vertical/Horizontal Flip

After previewing the image you may wish to reverse from right-reading to

wrong-reading (i.e. a left/right flip). This is most useful when you wish to flop the

image because you have to scan it with the emulsion facing the front of the

scanner when maximum sharpness is required, avoiding scanning the image

through the base of the film. In the vertical orientation, you can save time if you

inadvertently place the film in upside-down. These buttons stay depressed for the

main scan. If there is slight speed degradation re-orienting a very high resolution

scan, it may be worthwhile to re-orient the film before scanning.

Densitometer

Fig. 27 RGB/CMY Densitometer

You can measure RGB or CMY values anywhere in the preview scan by

placing the cursor over the area of interest. Three numbers will appear at the top

of the preview frame, initially in RGB 8-bit notation (0-255). Holding down the

Command key (1) and clicking the mouse will change the notation to CMY

values from 0-100% where 100% equals maximum density.

Software Reference for Scanners

Page 37

Using The Macintosh Scanner Plugin 5-5

Sizing and Resolution

Fig. 28 Resolution and Size Controls

The scanner's total scan area is a 5000 pixel by 5000 pixel scan covering 40 x

40 millimeters. This makes for a direct-reading scan resolution of 3175 pixels per

inch, or 125 pixels per millimeter. All lower resolution scans are substituted from

this.

A standard 35mm frame has a scannable area of approximately 36mm by

24mm; or 4500 pixels by 3000 pixels at highest resolution. Full frame scans are

typical in most applications.

The actual scan area in Figure 29 is shown as the gray square, while the film

area is shown in white, superimposed over the scan area. The corner coordinates

are the actual pixel coordinates of the scanner's pixel array given in (x, y) form.

Fig. 29 Scan Area of the LS-3510AF

The scanner's "natural" orientation encourages you to place the film into the

scanner with the emulsion facing the light source. You will be the best judge of

whether or not this is how you wish to view the image. The tall/wide and scan

orientation, and the horizontal and vertical "flips" will allow you to view the image

in any way that you like. Figure 30 shows the scan specification area as it appears

in the dialog. The values are the factory defaults for the LS-3510AF scanner

plugin.

Software Reference for Scanners

Page 38

5-6 Using The Macintosh Scanner Plugin

Fig. 30 Resolution and Size Controls

These text edit boxes allow you to enter sizes directly in inches, centimeters

or pixels for either dimension. The numbers can be entered before or after a crop

has been drawn around the subject. One method is to type in the exact numbers

for the final size and resolution, and then lock the File Size and draw the crop box

which will now be constrained. The resolution can also be interpreted based on

CCD Pixels using a 'pitch' number. This is an integer which is used to divide the

total resolution of 5000 pixels. For example, if one enters a value of five, then the

resulting resolution will be 5000 divided by 5, or 1000 pixels over the full 40mm

dimension of the scanning aperture, or 25 pixels/mm, 635 pixels per inch.

Scan Pitch

Scan Pitch is the number of scan area pixels that go into one pixel of the final

output image. If a scan was made at pitch 2, with the crop (shown in Figure 18) of

250, 1000, 4750, 4000; the actual scan would measure 2250 pixels by 1500 pixels

tall; or 1/2 the resolution of the scanner's full scan capability at 1588 pixels per

inch. The image would still cover the area described above, but every other pixel

would be skipped in the scan. Scan pitch is inversely proportional to the native

scanner resolution.

The scanner hardware does not process fractional, or non-integer pitches.

Pitches other than integer pitches are interpolated with an extra scaling step in the

final scan. This can lead to some performance attrition, depending upon the pitch

involved. If the plugin determines that speed may be affected, a small warning

appears in the dialog just below the output scan specification area.

The range of the Scan Pitch does not go below pitch 1, or above pitch 50.

The scan is specified though a combination of selecting a crop in the preview

area, and typing scan parameters into the editable text items displayed above.

There are different approaches that can be taken when defining a scan.

In the first example, to produce an 8 inch by 10 inch image suitable for 150

line screen output, set the height and width unit pop-up menus to inches, and the

resolution units to pixels/inch. Then just type 8 into the width edit field, 10 into

the height edit field, and 300 (for a good half-tone screen of 150) into the

resolution edit field.

Software Reference for Scanners

Page 39

Using The Macintosh Scanner Plugin 5-7

> Note Although the ratio of scanned pixels to output halftone dots is traditionally

2:1, ratios as low as 1:1 can be acceptable in certain applications. We

recommend 1.5:1 for most medium to high resolution four color offset

reproduction.

Fig. 31 Resolution and Size Controls

The crop will automatically resize itself as you do this, and you will end up

with the following display:

Fig. 32 Preview Window Crop

The scan pitch automatically changes to allow for the scan size requested.

You may now move the crop to cover any area of the preview that you wish

to scan by placing the crosshair cursor over the crop box, holding down the mouse

button and dragging the box to the new location.

If you now want to shrink or expand the crop while keeping the same output

resolution and size, you must check the File Size: checkbox. You will now be

able to resize the crop without worrying about changing your output scan

parameters.

In the second example, select a crop in the preview area, and then make the

crop 8 inches wide at 300 dpi. After that, make it 10 inches tall. The important

thing is to get it wide enough to include the elements that you wish to see.

Software Reference for Scanners

Page 40

5-8 Using The Macintosh Scanner Plugin

First, you should select the crop with the mouse:

Fig. 33 Mouse Selected Crop

The resolution specification items may now look like this for the above crop:

Fig. 34 Specifications for Mouse Selected Crop

Now, check the Proportions checkbox. This will allow you to enter a height

or width value without changing the aspect ratio. Type 8 into the width edit field.

The resolution specification items will look like this:

Fig. 35 Lock Proportions

Note the little lock in the previous figure. That means that any changes in

width will cause a change in height to keep the scan rectangle in the same aspect

ratio as before. That is what locked proportions means. The value in the height

edit field changed to 6.4.

Software Reference for Scanners

Page 41

Using The Macintosh Scanner Plugin 5-9

Since you don't want the width to change, unlock the proportions and type 10

into the height field. The crop's length will change, and you will have an 8" x 10"

crop area in the main crop selection area. Type 300 into the resolution field, and

you have the following:

Fig. 36 Changing Resolution

The crop in the main preview area will look like this:

Fig. 35 Specification Crop

If you attempt to type in a number that is too large, the plugin will beep and

the closest acceptable value will be substituted.

Experiment with the crop selection to see how you can best make use of it. It

will allow enough flexibility to enable any scan that you may wish to make.

Software Reference for Scanners

Page 42

5-10 Using The Macintosh Scanner Plugin

The Smooth Scaling checkbox sets a pixel averaging interpolator to produce

smoother pixel transitions in low resolution (Pitch 5 to 50) scans.

Fig. 36 Smooth Scaling Checkbox

The Highest Quality checkbox will cause the scanner to take the scan in a

special slow-speed mode to improve the registration accuracy in low resolution

scans (from pitch 5 to pitch 50). In almost all cases, the difference from the

normally high-quality fast scans will be negligible.

Fig. 37 Highest Quality Checkbox

Scanning Speed

There are several ways to optimize scanner performance.

You should allow Adobe Photoshop to have as much memory as possible. In

order to do this, you should find the application in it's home folder, select it with

the mouse, then select the Get Info menu item in the File menu. A dialog will

appear with two boxes in the bottom right corner: Suggested Size, and Current

Size (in System 7). The Current Size box will be editable. Type in a number

greater than that in Suggested Size, and at least 2 MB less than your maximum

system memory size. When Adobe Photoshop is launched after this, it will use the

maximum possible memory up to the value that you typed in. If you consistently

get a dialog that tells you that the application will be opened in a smaller partition,

you should go back into the "Get Info" dialog, and reduce the memory

requirements.

System 7 users should have 32-bit addressing on and virtual memory off in

the memory control panel for best performance with greater than 8MB of RAM

installed. Minimum requirements for higher performance at high resolution are

32MB installed RAM, addressable under System 7.0.

Scan in Portrait mode and place the slide in the holder in the appropriate

position to get the right preview orientation. This delivers data to Adobe

Photoshop in a more efficient manner than Landscape mode. You might select

the crop in Landscape mode, then switch it to Portrait mode just before the scan

is to be made.

In some cases, Flips may slow the scan by a small amount. Experiment to

see which delivers the best results for you.

Try to use an integer pitch setting. These will always be more efficient than

non-integer pitches. Experiment with selecting crops and specifying integer

pitches for them.

Software Reference for Scanners

Page 43

Using The Macintosh Scanner Plugin 5-11

The Highest Quality checkbox will significantly slow scans. Make sure that

you absolutely need the advantages that it provides for low resolution scans.

Finally, different images will have varying scan times dependent upon their

density. When the scanner makes an autoexposure, it decides upon some baseline

parameters to optimize the image to be scanned. One of these parameters is

exposure time for each color. Higher densities require longer scan times.

Grayscale/Color Preview

Fig. 38 Previewing in Color

Pressing the Preview button will cause a preview scan to be taken. To

preview your image in color, check the In Color checkbox. Previewing in

grayscale allows fast black and white previews of color scans when a quick scan

and crop is required for expediency.

Interface Buttons

Fig. 39 Interface Button

This toggling pair specifies SCSI or GPIB interface. While opening the

plugin, the software will search the GPIB and then the SCSI bus for any scanners.

When found, the device found will have its ID displayed in the upper right-hand

corner. If no device is found, and one is known to be connected, then the toolkit

button provides a means to search the bus again for a particular address.

Digital and Analog Controls

Fig. 40 Digital Control Fig. 41 Analog Control

In order to save dialog space, and to keep the user interface as uncomplicated

as possible, we have assigned dual roles to the five edit items in the lower left

hand corner of the Main Scanning Dialog. These items double as brightness,

contrast, and tint level (digital), and as exposure time, black level, and color

balance (analog). The principal difference between the two types of adjustments is

that analog adjustments work on the actual CCD voltage levels and exposure

times; while the digital adjustments work on the data after it has been collected

from the CCD and digitized within the scanner. The advantages of using the

Software Reference for Scanners

Page 44

5-12 Using The Macintosh Scanner Plugin

analog controls is that they minimize data loss for large changes, such as

compensating for dense images or heavy color casts. In most cases, the digital

controls will afford plenty of control for the kind of minor adjustments that are

usually made. The two figures above show how the two types of control sets will

appear, dependent upon the state of the Digital/Analog radio button pair.

Adjusting these numbers will produce a change in the preview image on screen.

Digital Mode

The digital controls all have a range from -5 to +5 with a nominal value of 0.

All these controls alter the gamma in a LUT (Look Up Table) that follows the A/D

(analog to digital) conversion in the scanner. The gradation changes are minor but

noticeable, and will be simulated in the preview without re-scanning. Best results

will be achieved with the optional 12-bit board installed when using these controls.

Analog Mode

The analog controls have a range of 0 to +255 for the brightness (exposure),

and color balance controls, with a nominal value of 50, and -15 to +15 for the

contrast (black level) control, with a nominal value of 0. There are five Text edit

boxes controlling Exposure, Black level, and RGB color balance.

Adding to any value when scanning positives will shift the color in that

direction. When scanning negatives, adding to the value removes that color. You

can directly control Red, Green, and Blue gain settings from 20 to 120. The

numbers that you input affect the reference value that was determined at Prescan

Photometry. This reference will always be 50, so that the resulting change in

exposure when these controls are manipulated is calculated as follows:

• 25=25/50 = .5 = 50% - meaning an exposure decrease of 1 stop (in

photographic terminology).

• 50=50/50 = 1 = 100% - meaning no increase or decrease in exposure.

• 75=75/50 = 1.5 = 150% - meaning an exposure increase of 1/2 stop

• 100=100/50 = 2 = 200% - meaning an exposure increase of 1 stop.

You cannot shorten the exposure time to be less than the minimum exposure

determined by prescanning. This is very often ~40. You may also find that the

CCD can oversaturate on specular highlights when the exposure time is increased

beyond ~100. The best application of these controls is to greatly alter the densities

and color balance of a scan. For example, if an image is too green, the green

exposure for a color positive can be decreased. Another way to counteract the

overall green cast is to increase the Blue and Red exposures by equal amounts.

Equal amounts of Blue and Red are equivalent to the same amount of Magenta,

which is the complimentaryoor opposite color to Green and will neutralize it.

> Note When increasing the analog exposure for a Positive scan, the resulting image

or color will be lighter than before. When increasing the analog exposure for

a Negative scan, the resulting image or color will become darker.

Software Reference for Scanners

Page 45

Using The Macintosh Scanner Plugin 5-13

The same rules apply to Exposure. Changing the exposure values here will

affect Red, Green and Blue settings by an equal amount. This is a simple way to

increase the brightness of a dark original transparency, without affecting the color

balance of the resulting image. Again, the useful range of values typically falls

between 40 and 120.

The Black Level ranges from -15 to +15. This setting determines the

clamping level of the CCD for the maximum black in the image. Usually, the

(or darkest black) of an Ektachrome transparency measures 3.0 on a

D

max

densitometer. The D

(the lightest portion or specular highlight) often measures

min

.8, making the overall range 2.4. This density range of dark to light is very typical,

but much higher than what we usually print on paper. The Black Level Threshold

control permits the user to lighten or darken the blackest black in the image. This

means that as we lower the setting (when scanning positive film), the blacks will

get lighter and as we raise the setting, they get darker. This happens without

affecting the highlights or midtones of the image.

Auto Exposure/Auto Mode

Fig. 42 Auto Exposure / Auto Mode

The autoexposure icon (the icon on the left) will cause the scanner to do

what's referred to as a Prescan. That is, the scanner adjusts itself to the image by

determining density and contrast. It optimizes it's internal analog levels to make

the best scan possible. In most cases, the autoexposure will do such a good job

that you won't need to adjust the analog or digital controls.

The Auto Mode checkbox means that the plugin will ensure that the scanner

has made at least one autoexposure and autofocus before a preview or scan is

attempted. This will be reset if the film type is changed, or if Photoshop is quit,

then re-launched.

One of the really important features of the LS-3510AF is it's focusing and

auto-focusing features. This eliminates the need for different thickness slide

holders, as used by the LS-3500. In almost all cases, the standard autofocus (the

icon on the right) will assure you the sharpest image possible.

In some cases, however, such as with blurry images, or warped film, you may

wish to manually focus on an area of the slide. This is easily accomplished by

pressing the Manual Focus button. Pressing this button puts the plugin into a

manual focus mode. If you move the mouse over the preview area, you will see

that it becomes a magnifying glass with crosshairs in the center. Place this cursor

over the area you wish to focus on, and click the mouse button.

The scanner will take a small high-resolution grayscale scan and display it in

the preview area. You may then adjust the focus by using the slider (which has

Software Reference for Scanners

Page 46

5-14 Using The Macintosh Scanner Plugin

now become active), or the focus stage position text edit box. The focus stage will

move from 0 to 48. Most focus positions are in the area of 24 for slides mounted

in plastic.

The Settings Buttons

Fig. 43 Settings

To save the complete scanner plugin configuration so that the same initial or

default settings are loaded every time the plugin is opened, use the Set Defaults

button. After you have made changes to the controls during a scan, if you wish to

reset the plugin to the established default, use Reset.

Toolkit

Fig. 44 Toolkit Button

The toolkit button leads to a utilities dialog where you can send low–level

scanner commands, calibrate and test all scanner functions. This is a diagnostic

tool and care should be taken when you use it.

Fig. 45 Utilities Dialog

If you need assistance in understanding some of the scanner commands,

consult the LS-3510AF Technical & Programmer's Reference, available from

Nikon. Call your Nikon Electronic Imaging Dealer or Nikon Technical Support if

you require further assistance.

Software Reference for Scanners

Page 47

Using The Macintosh Scanner Plugin 5-15

The Command: text edit box allows you to enter scanner commands from

the Technical & Programmer's Reference to test various combinations of scanner

operating conditions that are not included in the standard operating software.

Fig. 46 Command Line

If you are developing your own software, this utility is especially helpful to

determine the effect of certain scanner functions that work ‘behind the scenes’ in

the plugin. Although the scanner requires commands in upper case only, this

dialog converts all characters to upper case for you by reversing the operation of

the shift key. The Send button issues the command to the scanner and the Read

button will receive data back. Errors are reported next to the Result: text at the

bottom center of the dialog box.

The SCSI and GPIB search buttons are repeated in this box as in the main

dialog. They lead, however, to auxiliary dialogs as shown below.

Fig. 47 SCSI Search Dialog

The SCSI button brings up the pop-up menu Always Find Device, the

default setting where the SCSI bus is searched each time for an LS-3510AF

scanner.

You may optionally 'hardwire' the device to the plugin by setting a specific

address as shown in Figure 49.

Fig. 48 SCSI Search Dialog

Software Reference for Scanners

Page 48

5-16 Using The Macintosh Scanner Plugin

> Caution Be sure not to choose IDs already in use by disk drives connected to your

CPU! You may cause directory damage if the plugin attempts to write to

your disk

When you are using the GPIB, you can choose the other icon and bring up the

following dialog:

Fig. 49 GPIB Address Selection

Again, you may choose a specific address, as in the SCSI Search dialog box.

Underneath the interface icons there is a Gamma button which will display

the gamma table currently in the scanner. If you press the shift key, you will get

RGB. A neutral line is displayed when all three gamma curves are the same. For

a better understanding of gamma, consult the section Scanning for Reproduction.

Fig. 50 Gamma Button

There is also a preview button next to the gamma icon. This will cause the

scanner to scan and display the results in a preview window at low resolution. If

you press the shift key, you will get an RGB preview.

Fig. 51 Utilities Preview Button

The Record File button will record all transactions sent from the command

line and the data received back from the scanner. To speed up the return of long

data streams from diagnostic commands like the TS5 routine (10Kbytes), leave the

No Display box checked, and the Macintosh will not be required to write all the

incoming data to the screen, a slow procedure. This can be a lengthy procedure if

there are 5-10K worth of characters returned from the scanner in a test routine.

For this reason, there is an Abort button to terminate all testing or other scanner

actions. Use the Record button to write the returned data to a file that can be

inspected later.

If you have long or complex tests to run you can write a macro file of

commands with any ASCII text editor (such as TeachText) which can be opened

using the Script button.

Software Reference for Scanners

Page 49

Using The Macintosh Scanner Plugin 5-17

Just above, is a Reset button for the scanner. This issues the same INT

command that is displayed in the highlighted command line of Fig. 47. The TSO

button sends a short interface test routine which returns several bytes of data.

Clear Display removes all characters from the scrolling data window.

Calibrating the Lamp

Fig. 52 Calibrate Lamp button

> Note The lamp should be calibrated when the scanner is first unpacked from the

shipping carton.

Thereafter, you can recalibrate whenever you change a lamp, or if you install

a 12-bit board. If you move the scanner to a new location you may want to

recalibrate since the bulb may change position in transit and the illumination

pattern must be recompensated. This calibration is not intended for daily use. It

writes color balance and light distribution shading information to the non-volatile

memory in the scanner.

> Note The Calibrate Lamp button should be used with caution!

Before proceeding to calibrate the unit, you must remove any film and film

holders from the unit. Otherwise it will misinterpret the light balance and attempt

to calibrate to a setting that is outside normal limits. This may leave the scanner in

a confused state and possibly require a call to Technical Support to remedy.

To execute calibration, close the dust cover, press the button within the

Utilities dialog and wait a couple of minutes while the unit compensates and saves

the data. When the busy light finally goes out you will be returned to the utilities

dialog again.

> Caution Do not disturb the scanner while this is taking place or the routines will not

complete and the scanner may not calibrate correctly on the next attempt.

You can exit after completion by pressing the Done button.

Software Reference for Scanners

Page 50

Page 51

Using the Windows Scanner Plugin 6-1

Using the Windows 3.1 Scanner Plugin

Let's begin with a full description of the main and auxiliary dialogs. All the

plugin controls follow the standard Windows interface design. If you are

unfamiliar with the operation of the Windows interface, please consult your

owner's manual.

The examples in this reference were used with the LS-3510AF in mind.

Other Nikon scanners will vary slightly in their feature set, although all Nikon

scanners can be controlled with this software.

The Main Dialog

In this section we will discuss each menu and dialog box in detail. The main

dialog looks like this:

Fig. 53 The Main Scanning Dialog

Controls and Indicators

The purpose of each control and dialog item is discussed below.

Software Reference for Scanners

Page 52

6-2 Using the Windows Scanner Plugin

Interface

Fig. 54 The Interface Buttons

Communication with the scanner can be through GPIB or SCSI. Selecting

and setting up an interface is only a matter of clicking on the appropriate button. In

order for the SCSI button to be enabled, there must be a SCSI board installed that

has an ASPI (Advanced SCSI Programming Interface) driver available and loaded.

In order for the GPIB button to be enabled, there must be a National Instruments

GPIB board with drivers for Windows (GPIB.DLL) installed. When either button

is pressed, a dialog will come up.

Fig. 55 The SCSI Interface Dialog

The Address control allows the choice of automatically searching the SCSI

bus for the scanner or selecting a specific address. Every device on a SCSI bus

must have its own address. The SCSI board itself is usually set to address 7. Hard

drives are usually set to address 0. The scanner will be set to address 5 by default.

The default choice is to scan the bus for the scanner.

> Caution If the scanner is connected to a SCSI bus with a hard drive at the same

address as the scanner, the scanner plugin may corrupt the hard drive.

Fig. 56 The GPIB Interface Dialog

The Address control allows the choice of selecting the scanner by device

name or selecting a specific address. If you are not familiar with the procedure for

creating a device name, the simplest method is to choose a specific address. The

Software Reference for Scanners

Page 53

Using the Windows Scanner Plugin 6-3

LS-3500 is set to address 15 by default and the LS-3510AF is set to address 10 by

default.

For either interface, the Test Interface button will try to initiate contact with

the scanner. If this is successful, the plugin will display the scanner's type and

ROM version.

Scanner Tools

Fig. 57 The Scanner Tools Button

The Scanner Tools can be used to communicate directly with the scanner and

to calibrate the lamp. If you need assistance in understanding some of the scanner

commands, consult the Technical Programmer's Reference for your scanner,

available from Nikon. The Scanner Tools button will be disabled if the plugin

cannot establish contact with a scanner.

Fig. 58 The Scanner Tools Dialog

The Command text edit box allows you to enter scanner commands.

Pressing enter will send the command to the scanner and make the Read button

the default button so that pressing enter again will read data from the scanner. All

communication with the scanner will be displayed in the scrolling edit box.

Software Reference for Scanners

Page 54

6-4 Using the Windows Scanner Plugin

Commands sent to the scanner will be preceded by a ">" symbol and data received

from the scanner will be preceded by a "<" symbol.

Calibration

The lamp should be calibrated when the scanner is first unpacked from the

shipping carton. Thereafter, you can calibrate whenever you change the lamp, or if

you move the scanner to a new location. The bulb may change position in transit

and the distribution of light must be adjusted to.

> Note The Calibrate Lamp button should be used sparingly.

Calibrating the lamp will save data in the scanner's EEPROM memory. This

type of memory will retain data when power is not supplied, but can only be

written to about 10,000 times. Therefore, lamp calibration should NOT be a daily

procedure.

Before calibrating the unit, any film or film holders must be removed from

the scanner. If this is not done, the scanner will misinterpret the light balance and

attempt to calibrate to a setting that is outside normal limits. Next, close the dust

cover, press the Calibrate Lamp button and wait until the busy light goes out and

you are returned to the Scanner Tools dialog. This process will take a few minutes

on the LS-3500 and up to 30 seconds on the LS-3510AF. Do not disturb the

scanner or it may not calibrate properly.

The Scanner Tools dialog is closed by pressing the Done button.

Scan Size and Resolution

The LS-3510AF total scanning area is a 5000 pixel by 5000 pixel scan

covering 40 x 40 millimeters. This makes for a scan resolution of 3175 pixels per

inch or 125 pixels per millimeter. All lower resolution scans are derived from this.

Fig. 59 Scan Area of the LS-3510AF