Nikon ED 17-55mm f/2.8G IF Repair Manual

JAA78851-R.3617.A

INC

作成承認印

AF-S DX Zoom-Nikkor

ED 17-55mm f/2.8G IF

配布許可印

JAA78851

REPAIR MANUAL

NIKON CORPORATION

Tokyo, Japan

Recycled paper

Printed in Japan March 2004

Copyright c 2004 by Nikon Corporation.

All Rights Reserved.

SPECIFICATIONS

INC

This lens can be used for Nikon digital SLR camera only.

JAA78851-R.3617.A

Type of lens

Focal length

Maximum aperture

Lens construction

Picture angle

Focal length scale

Distance information

Zoom control

Focusing

Shooting distance scale

Closest focus distance

Diaphragm

Aperture range

Exposure measurement

Attachment size

Dimensions

Weight

G-type AF Zoom- Nikkor lens having built-in CPU and Nikon F bayonet mount

17mm - 55mm (22.5 - 82.5 mm in 35 mm format)

f/2.8

14 elements in 10 groups (3 aspherical lens and 3 ED lens elements)

79° - 28° 50' (with Nikon Digital Camera D1/D1H/D1X/D100)

17,20,24,28,35,45,55mm

Output to camera body

Manually via separate zoom ring

Nikon Internal Focusing (IF) system (utilizing an internal Silent Wave Motor);

manually via separate focus ring

Graduated in meters and feet from 0.36m (1.25ft.) to innity (∞)

0.36m (1.2ft.) at all zoom settings

Fully automatic

f/2.8-f/22 at all zoom settings

Via full-aperture method with cameras having CPU interface system

77mm (P=0.75mm)

Approx. 85.5mm dia. ×110.5mm extension from the camera's lens mount ange

Approx.755g

- M1・AF-S DX17-55/2.8G -

JAA78851-R.3617.A

INC

※ Before Disassembly / (Re)assembly / Adjustment

If the 1st lens group and 4th lens group of this lens are removed, lens alignment

becomes necessary after assmbling.

Therefore, at service agencies where the lens alignment cannot be performed,

remove neither the 1st lens group nor 4th lens group.

- L1・AF-S DX17-55/2.8G -

DISASSEMBLY

INC

FILTER RING

JAA78851-R.3617.A

1ST LENS GROUP

#137

#50×6

Filter ring

#49×3

1st lens group

Note: If the 1st lens group is removed,

lens alignment of the 1st lens

group becomes necessary.

Therefore, at service facilities

where the point tester is not

prepared, do NOT disassemble.

#77

- L2・AF-S DX17-55/2.8G -

JAA78851-R.3617.A

INC

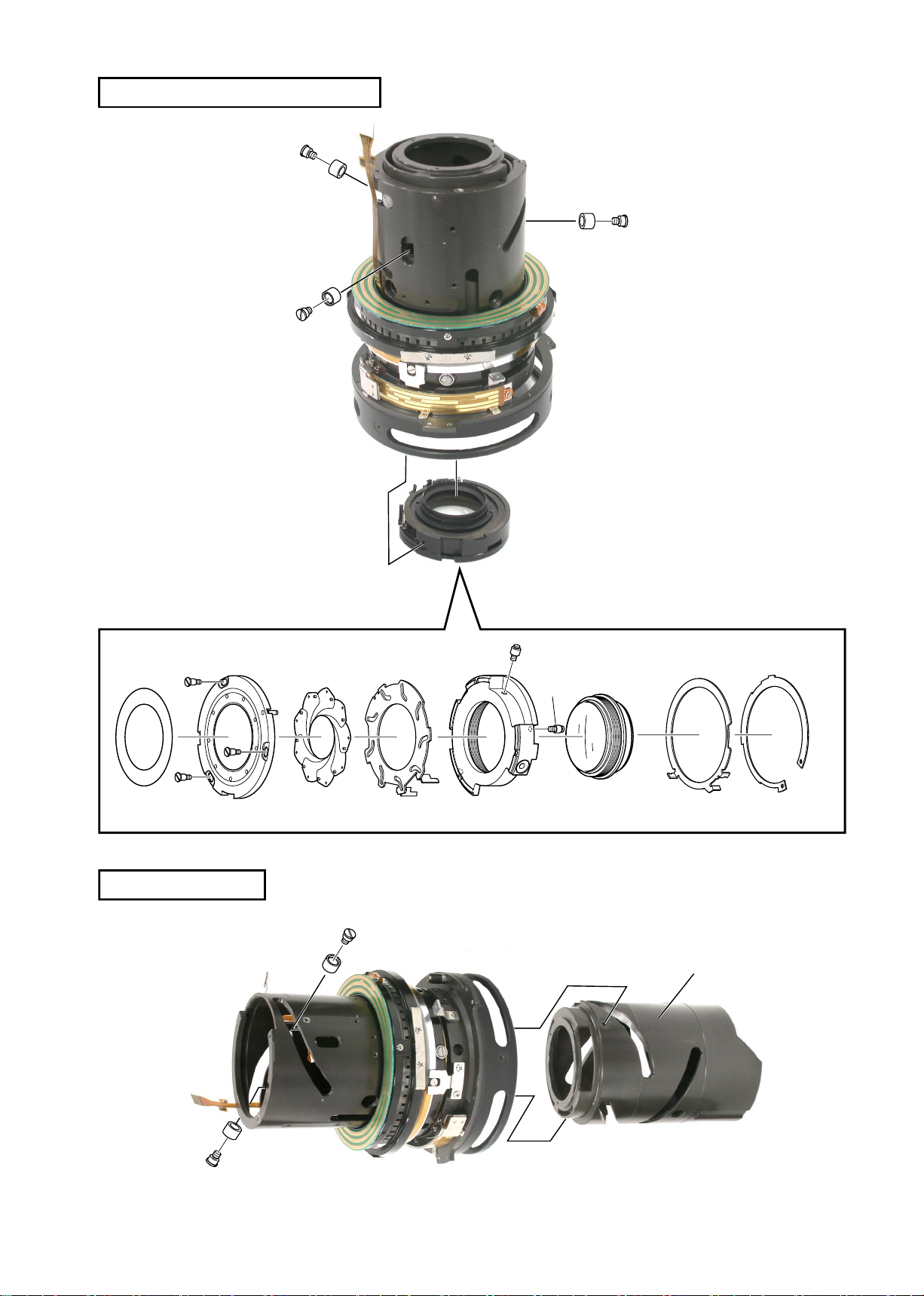

2ND LENS GROUP

#63×3

J11303B

B8 B11

#38

J11303C

J11303A

2nd lens group

Fig.1

Set the focus ring to the close-end, and the zoom ring to slightly 35-mm side from 28 mm.

・

Assemble J11303B into the cam ring to seat in notches of the cam ring, then insert the pin

・

(J11303C) into the hole of J11303B. (ref. Fig.1

Remove the 2nd lens group with the wrench for 2G AF-S 17-35DX (J11303A). (ref. Fig.2)

・

)

Fig.2

- L3・AF-S DX17-55/2.8G -

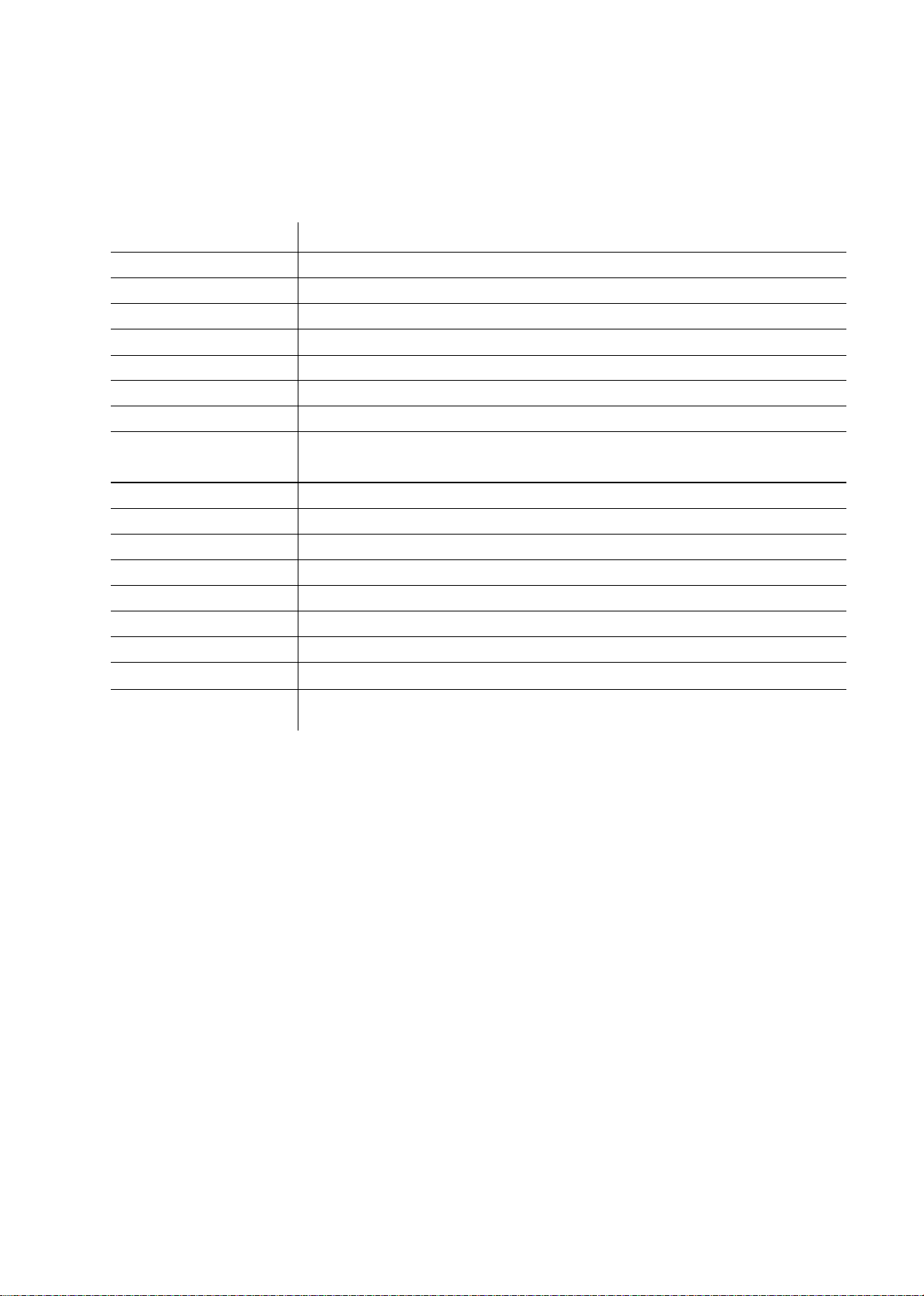

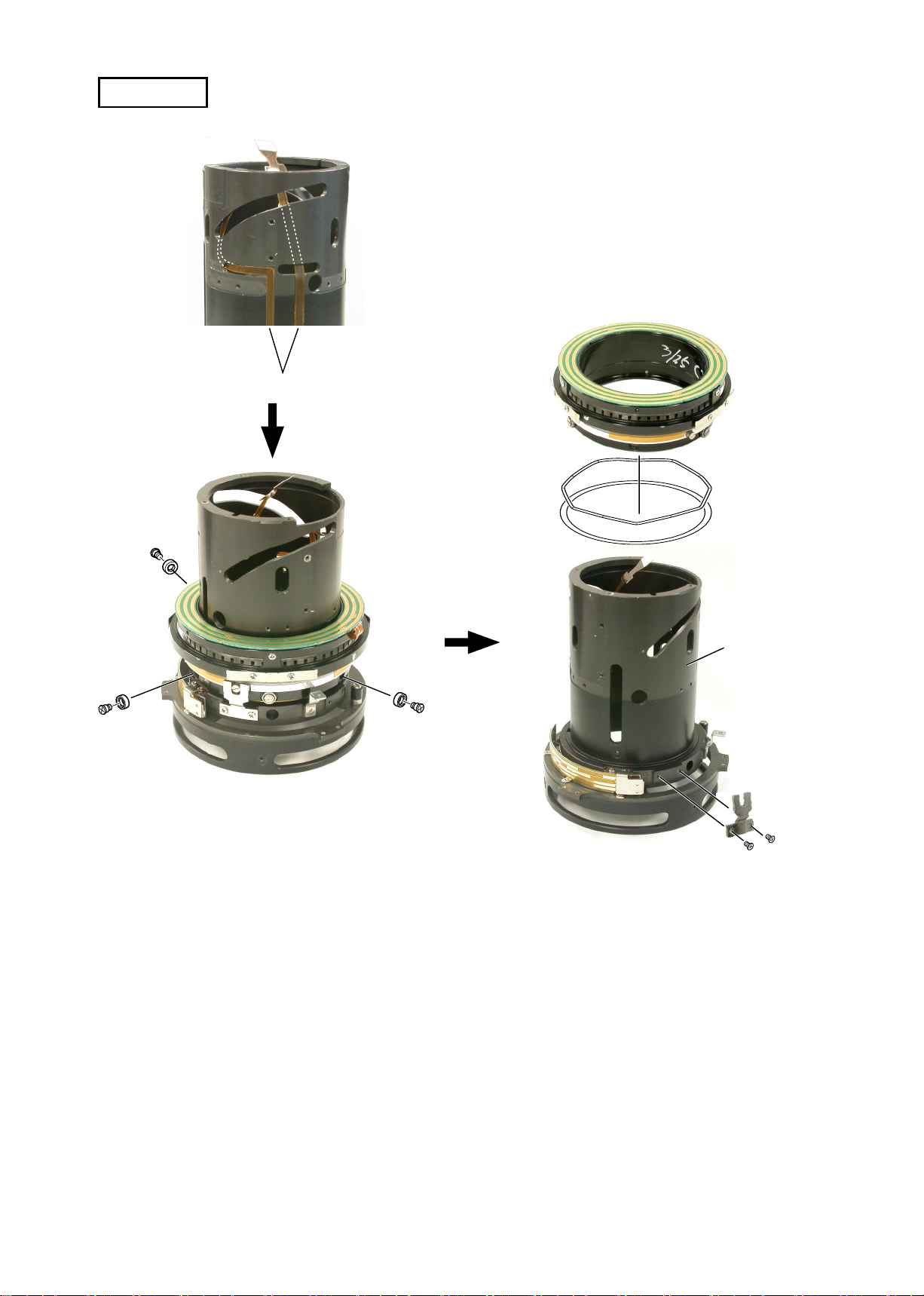

REAR COVER RING

INC

BAYONET MOUNT

JAA78851-R.3617.A

Rear cover ring

#182×3

#172×4

#78

#180×2

- L4・AF-S DX17-55/2.8G -

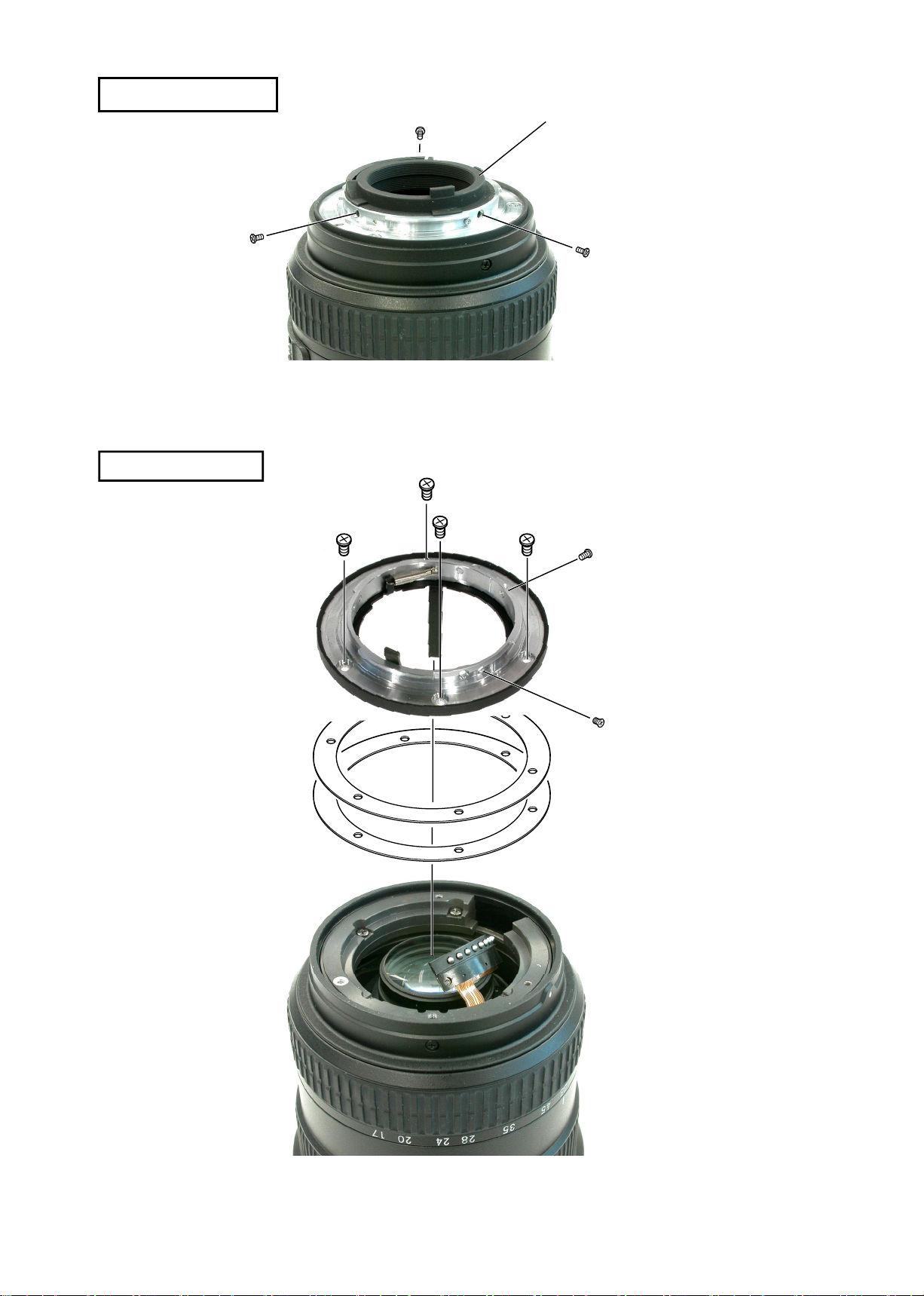

4TH LENS GROUP

INC

#71×3

4th lens group

#47

JAA78851-R.3617.A

Note: If the 4th lens group is removed,

the lens alignment becomes

necessary. Therefore, at service

facilities where the lens alignment

equipment is not prepared, do not

disassemble.

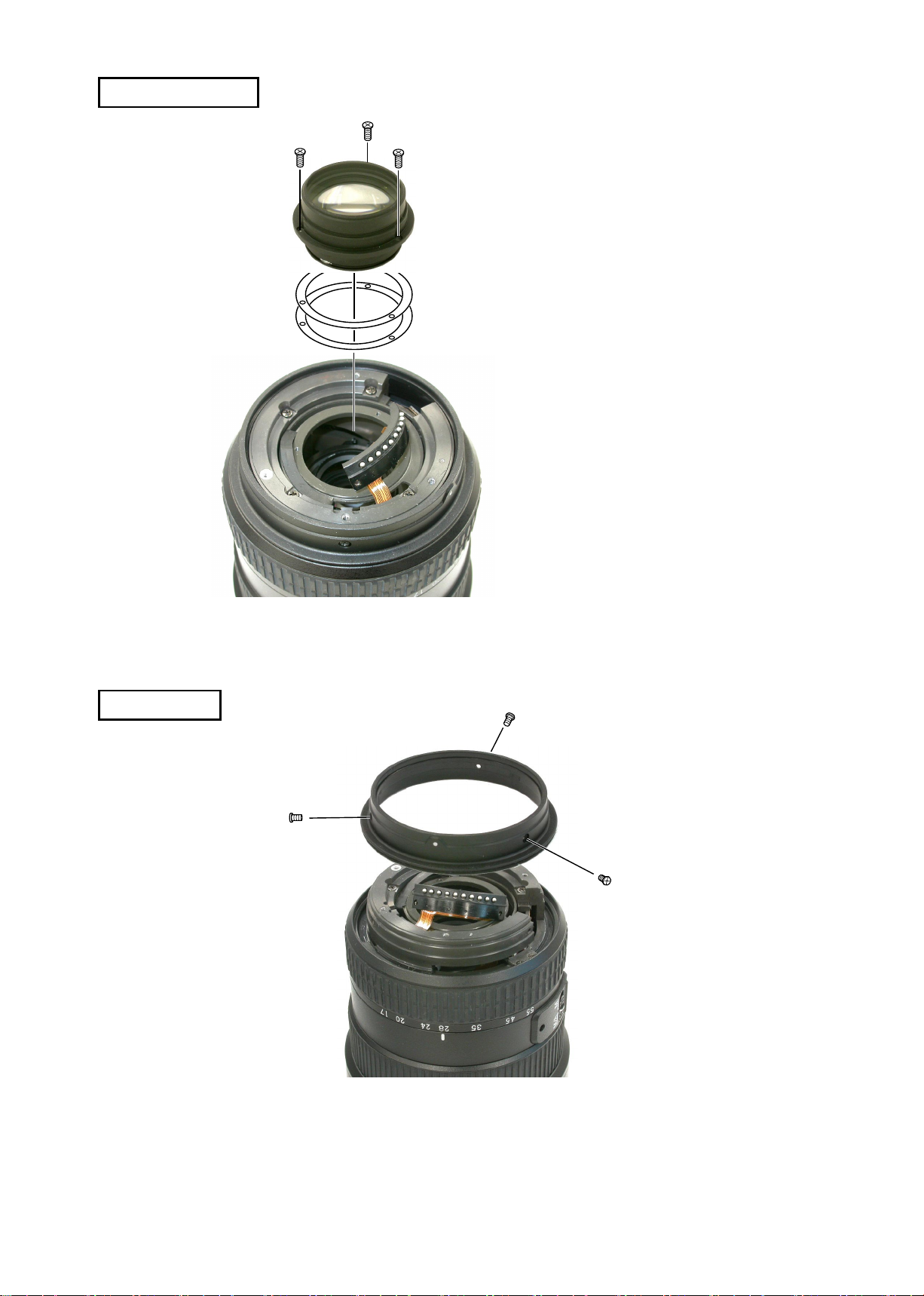

INDEX RING

Index ring

#128×3

- L5・AF-S DX17-55/2.8G -

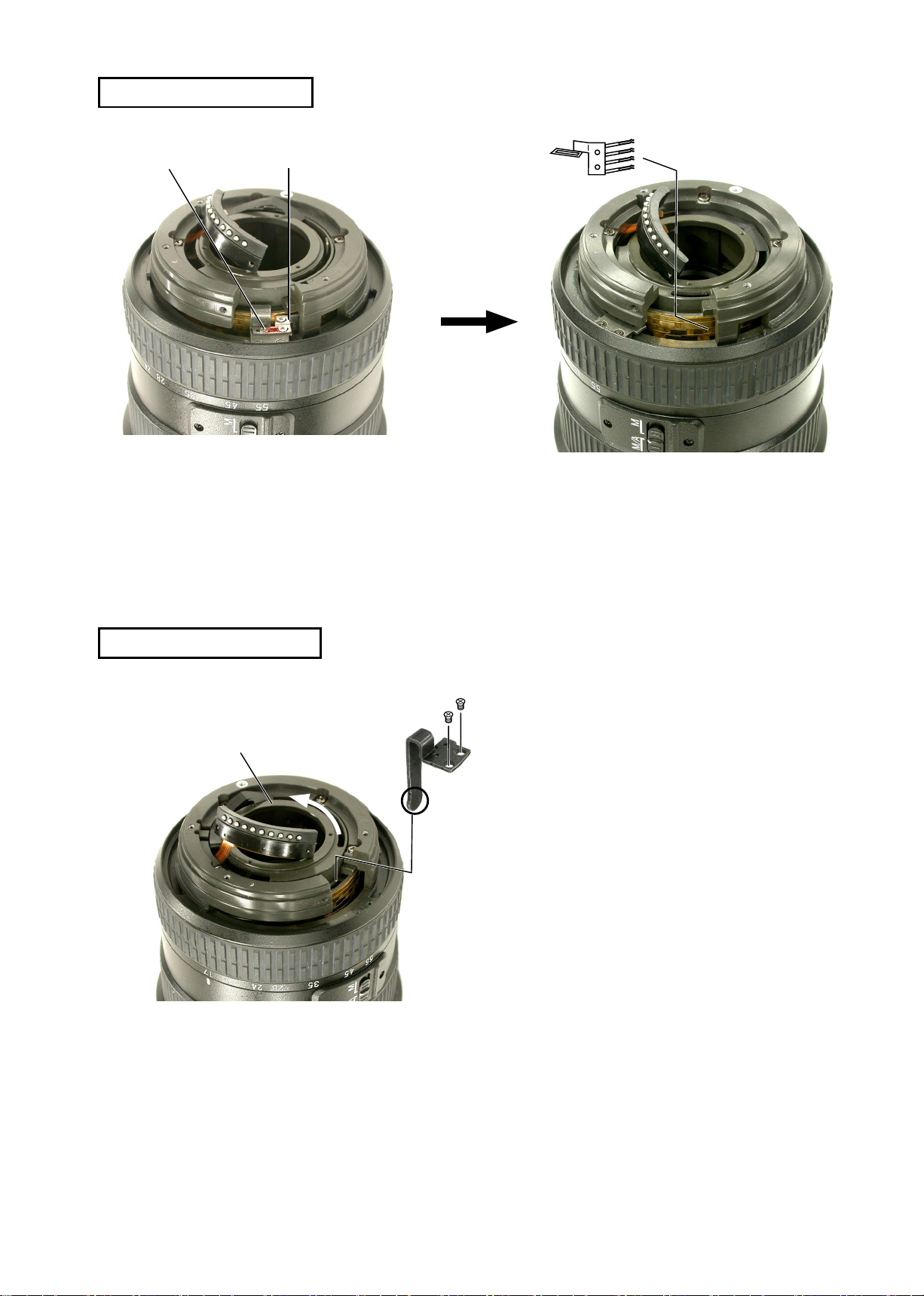

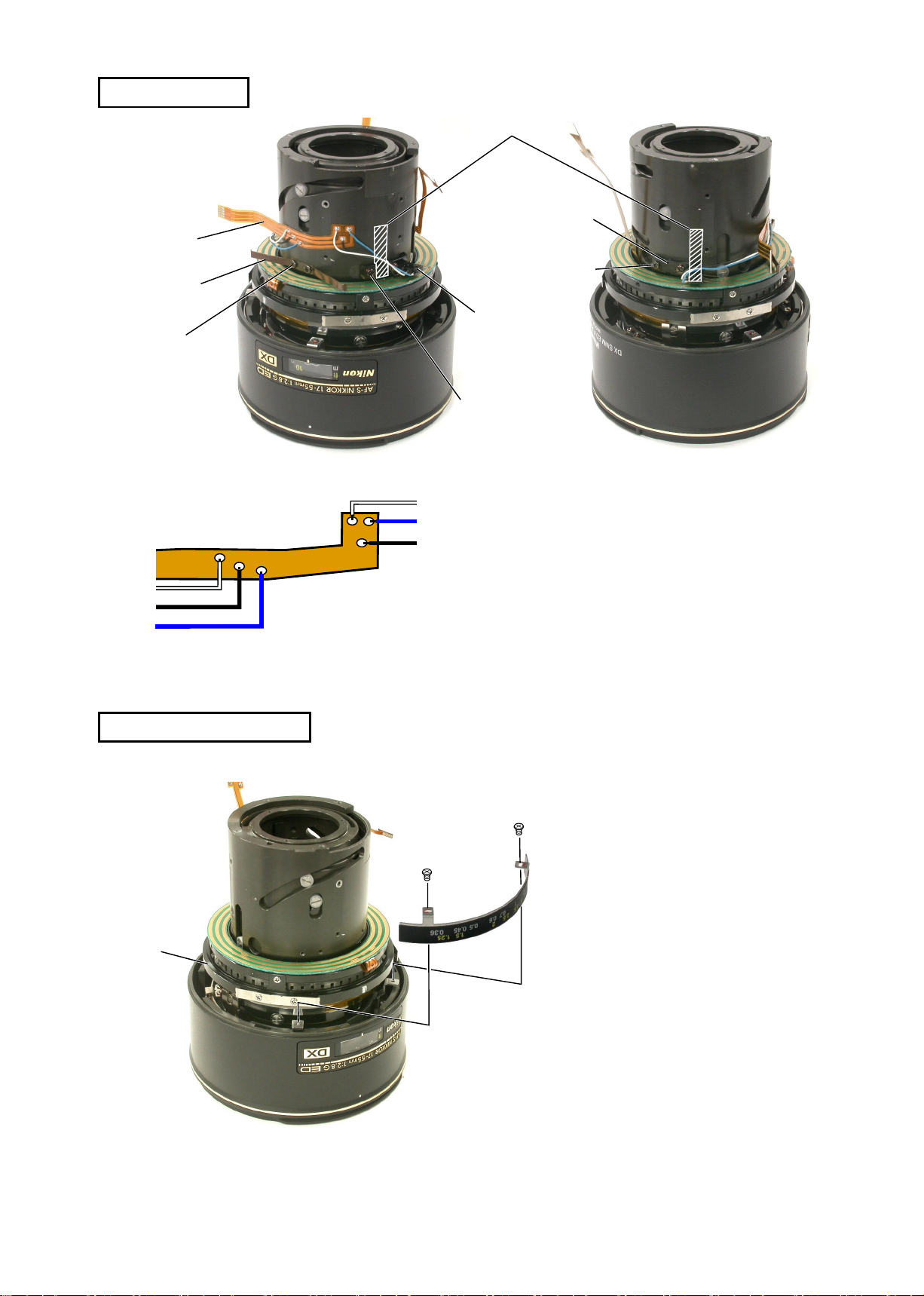

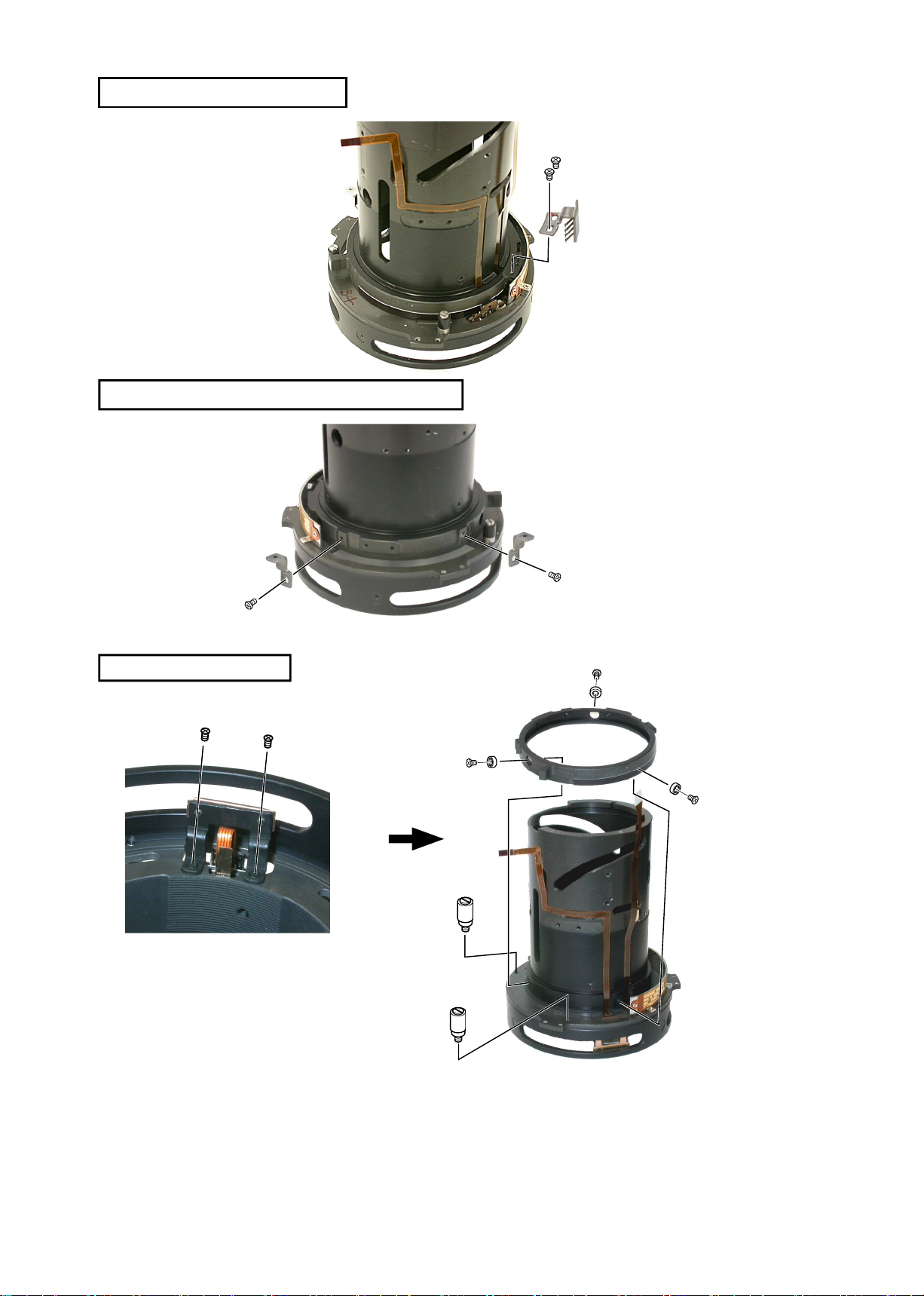

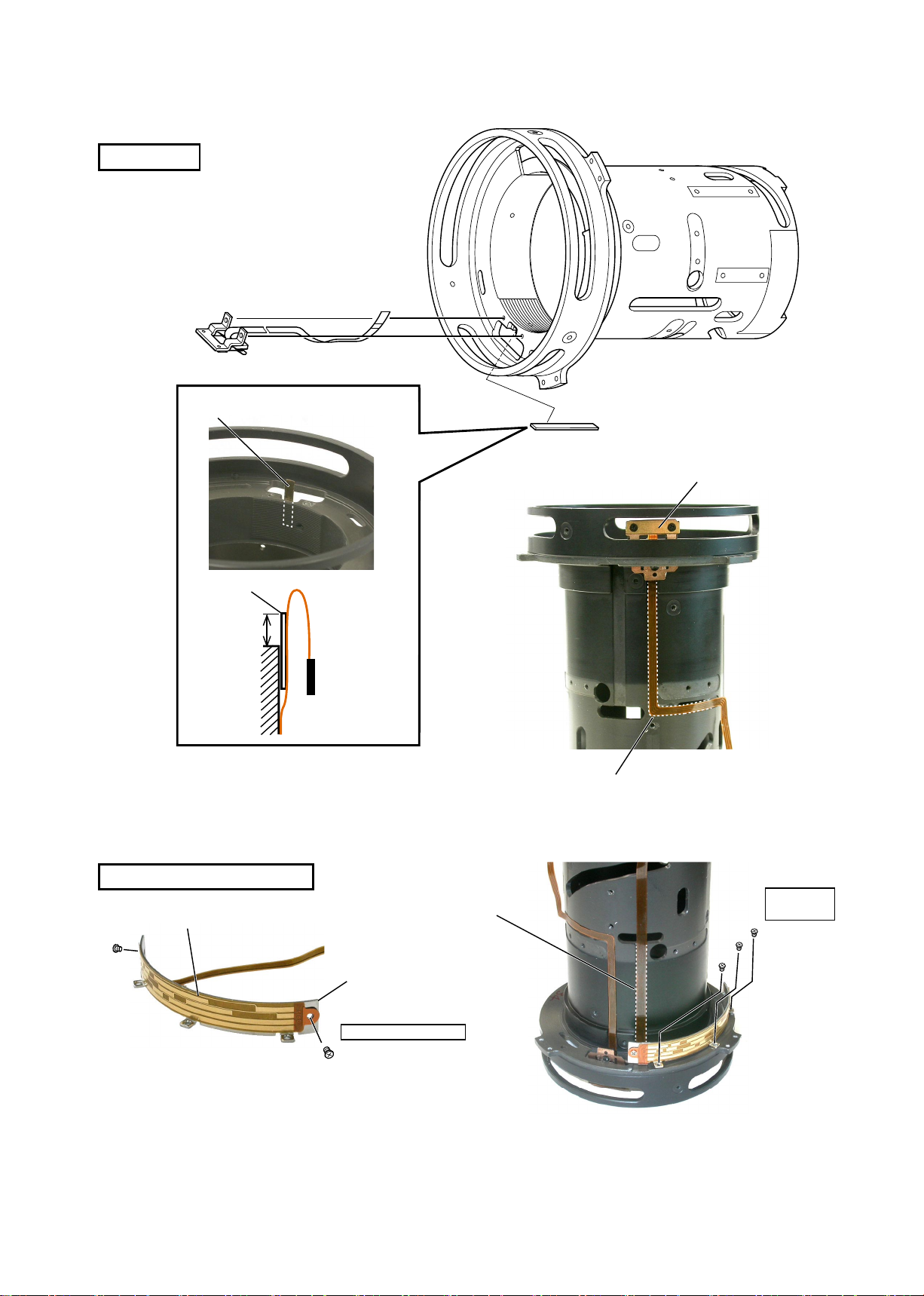

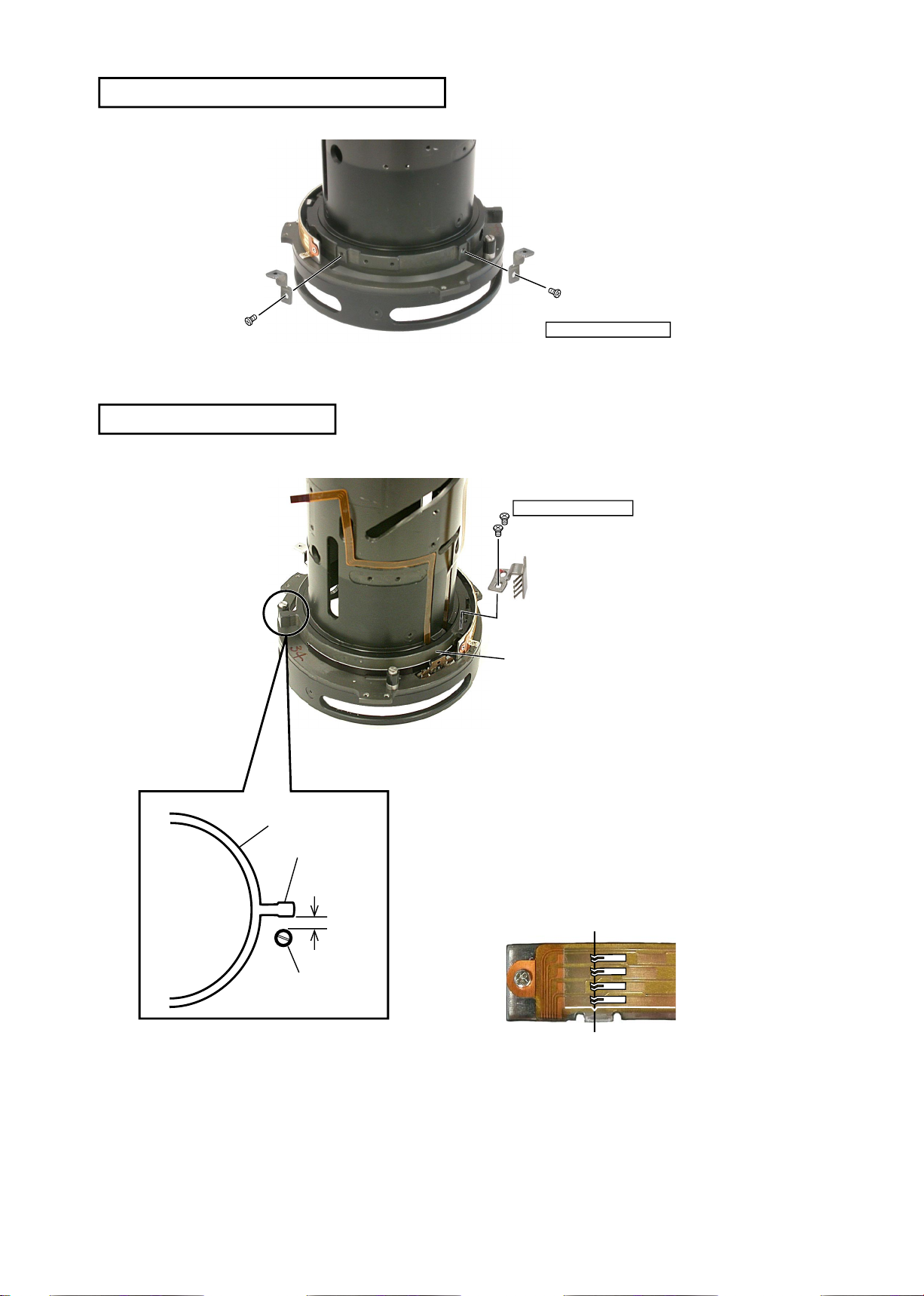

ZOOM ENCODER BRUSH

INC

#96×2

Zoom encoder brush

JAA78851-R.3617.A

Zoom encoder brush

Fig.1

Set the zoom ring to 17 mm, and take out 2 screws (#96). (ref. Fig.1)

・

Set the zoom ring to 28 mm, and remove the zoom encoder brush. (ref. Fig.2)

・

ZOOM CONNECTING PLATE

Cam ring

#59

#184×2

Fig.2

Set the zoom ring to WIDE-end.

・

Take out 2 screws (#184) to remove the

・

zoom connecting plate.

- L6・AF-S DX17-55/2.8G -

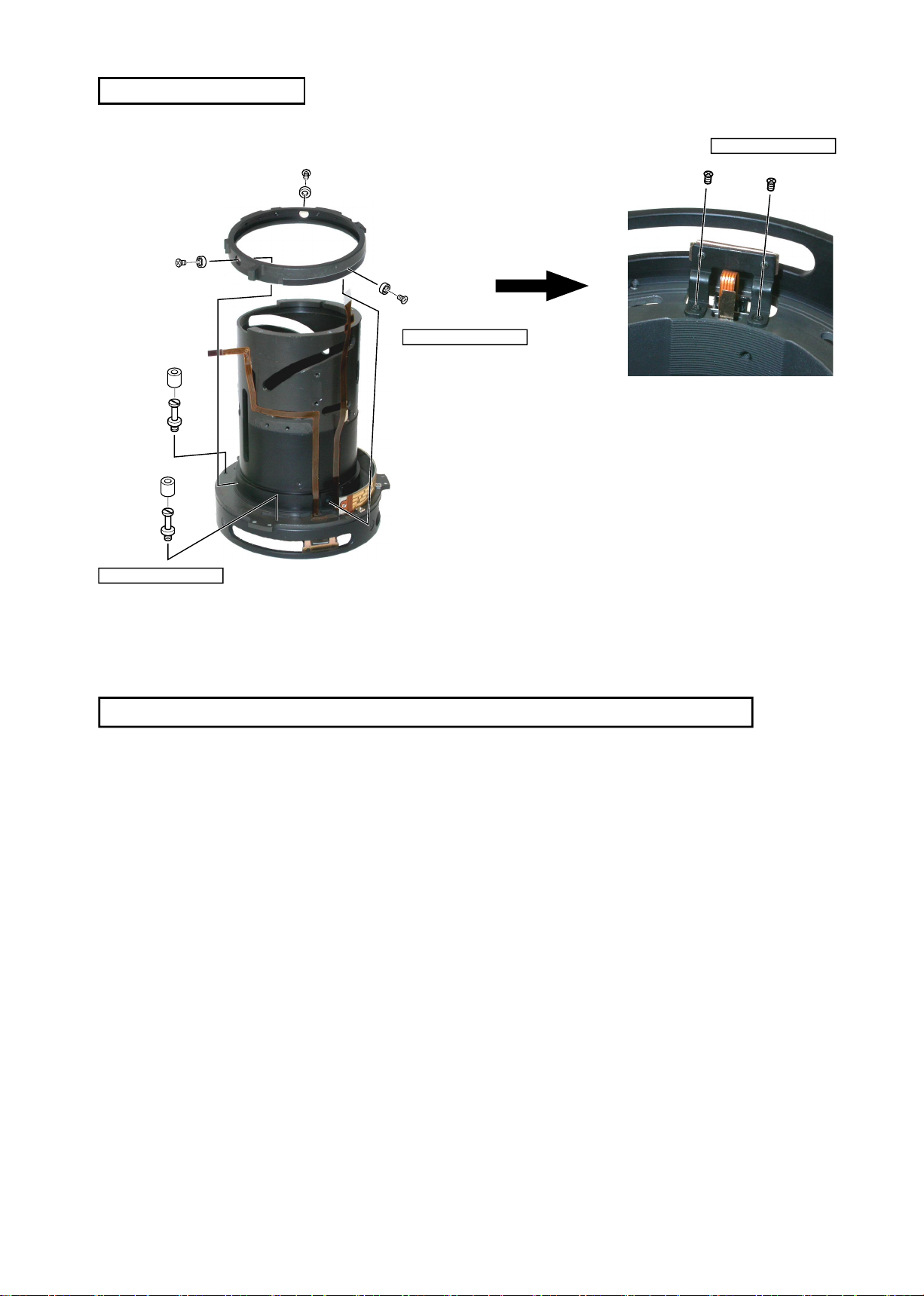

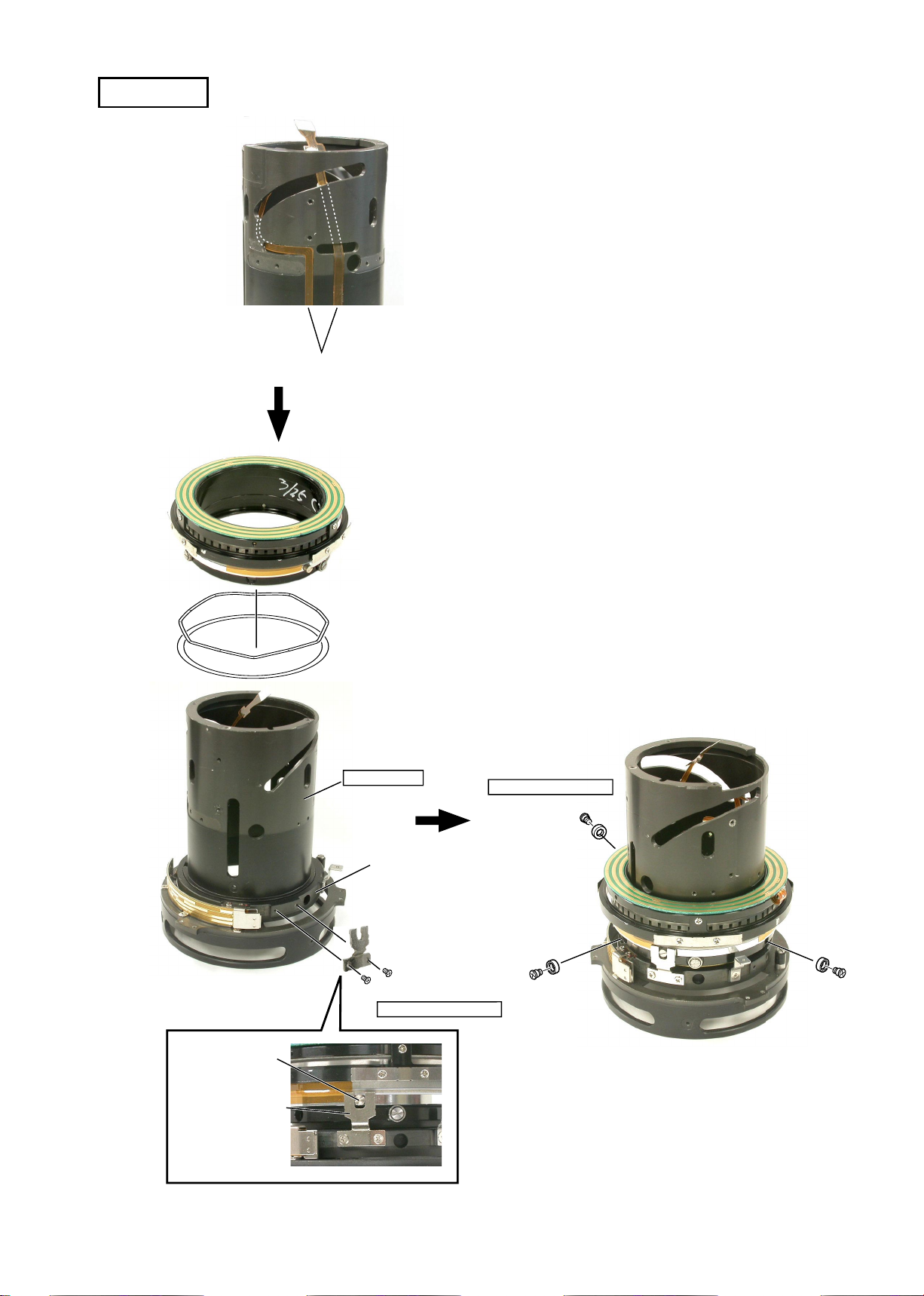

ZOOM RING

INC

#188×2

Take out 4 screws (#115) to remove the

・

zoom ring unit.

Pass the switch part of M/A selector

・

switch through the hole of the zoom

ring unit.

Remove the washer (#169).

・

JAA78851-R.3617.A

#115×4

Zoom ring unit

#169

M/A selector switch

Zoom ring

Zoom ring rubber

・

・

Protrusion

Take out the screw (#131).

Align the notch of the zoom ring with

the protrusion of the rear xed tube, and

remove the zoom ring from the rear xed

tube.

#131

#67×2

Rear xed tube

Notch

- L7・AF-S DX17-55/2.8G -

JAA78851-R.3617.A

INC

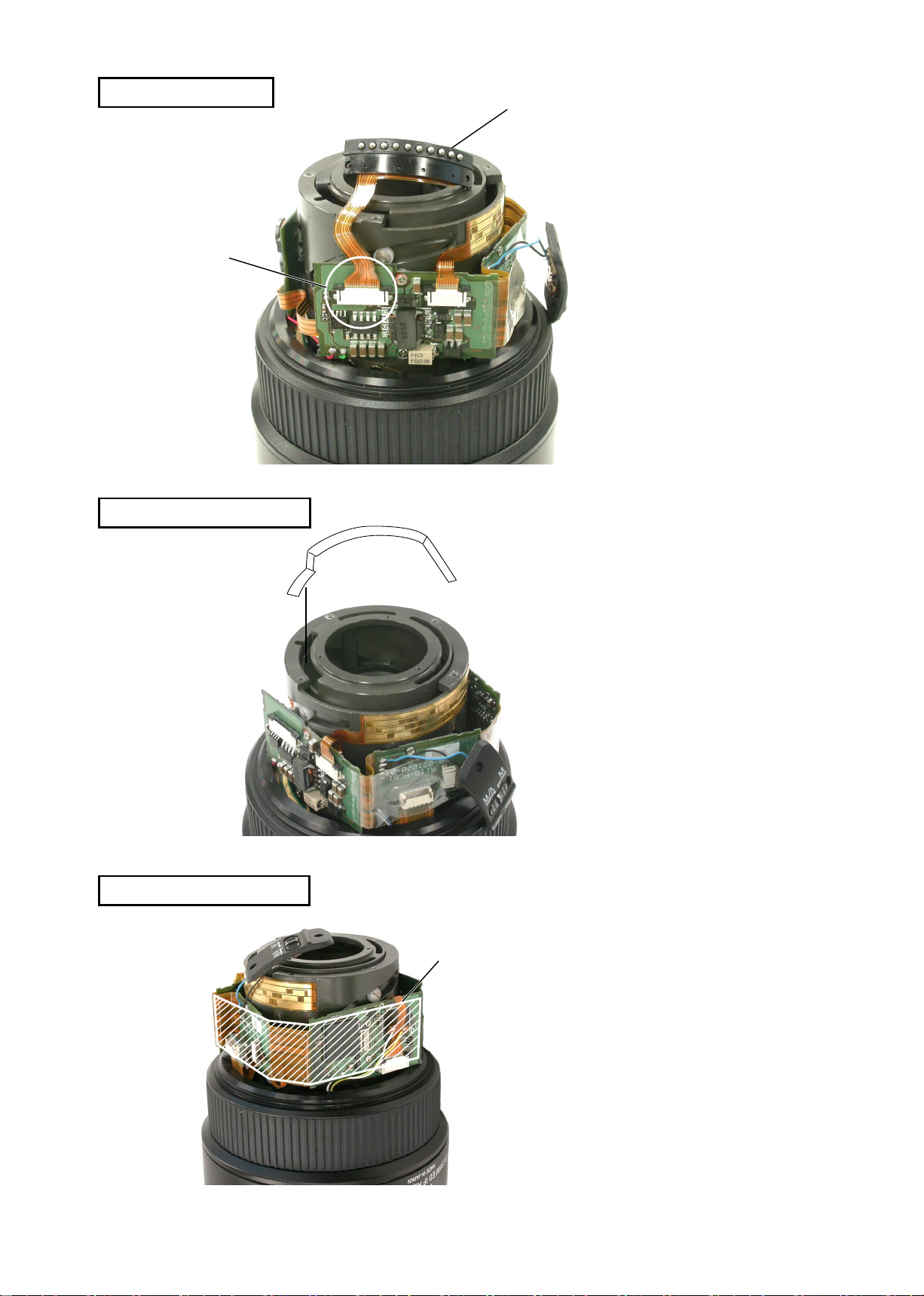

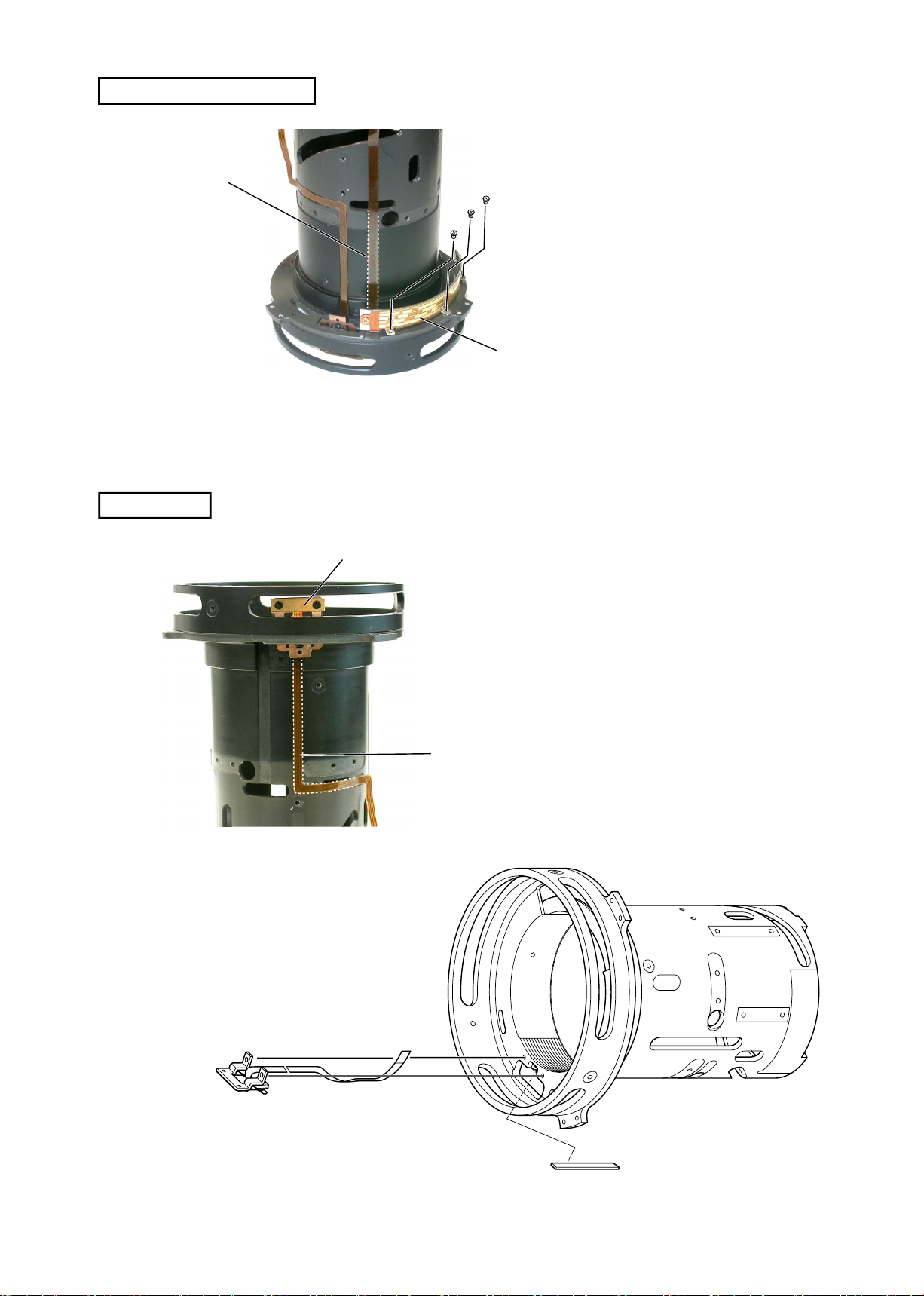

AF CONTACT UNIT

A

LIGHT-SHIELDING SHEET

AF contact unit

・

Remove the AF contact unit from

the connector A of the main PCB.

M/A SELECTOR SWITCH

#200

Tape

Peel off the light-shielding sheet

・

(#200).

Remove the tape of the main PCB.

・

- L8・AF-S DX17-55/2.8G -

JAA78851-R.3617.A

INC

MAIN PCB

Fig.1

Blue

Black

・

(ref. Fig.1)

#134

M/A selector switch

Unsolder 2 parts, and remove the M/A selector switch.

#133

#174×2

A

B

#173×2

#173

Red

Unsolder 2 parts. (ref. Fig.2)

・

Remove 4 connectors (A-D).

・

Take out the screw (#133) and 5 screws (#173) and 2 screws

・

Green

Fig.2

#173×2

C

D

(#174) to remove the main PCB.

- L9・AF-S DX17-55/2.8G -

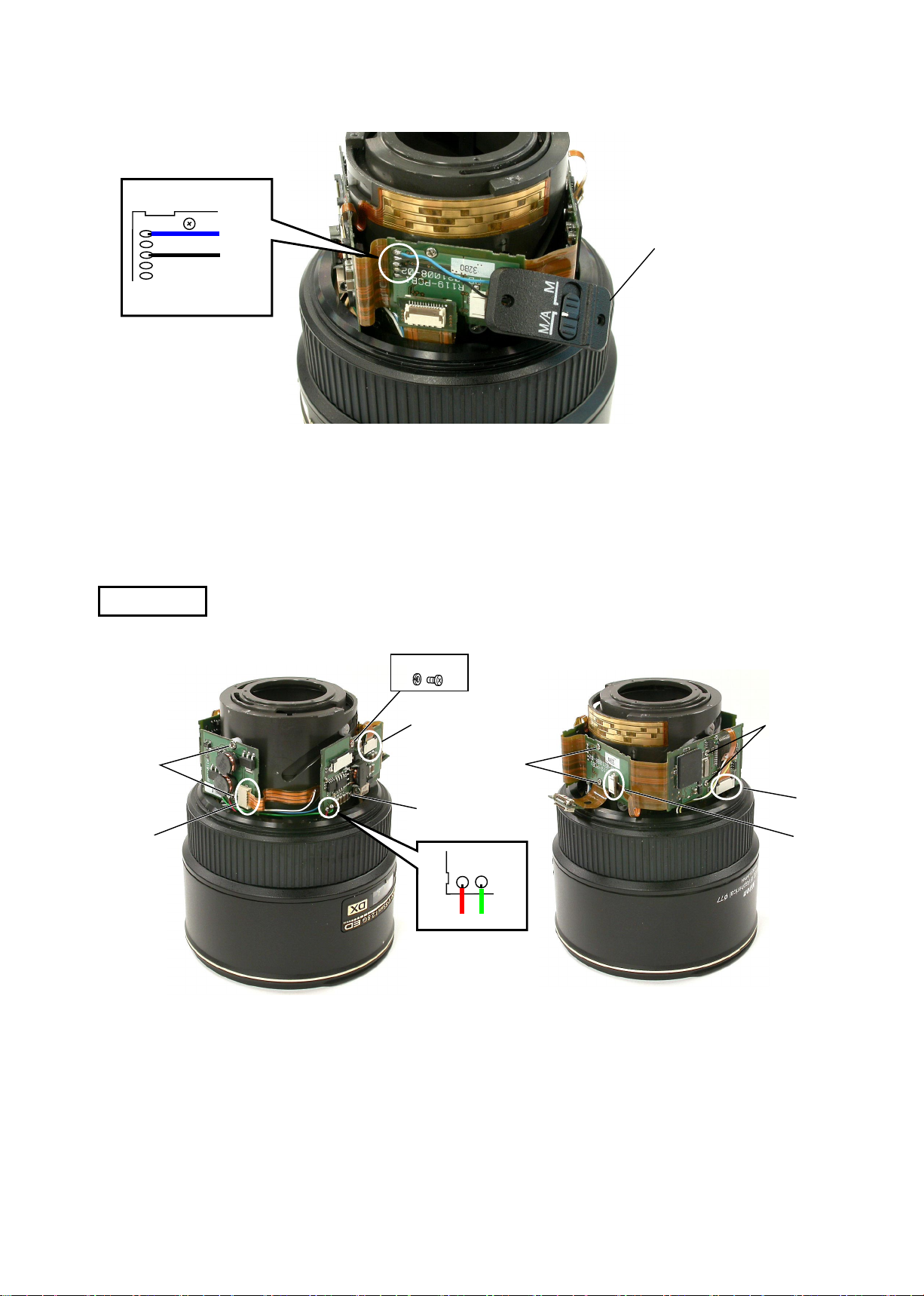

ZOOM ENCODER FPC

INC

FOCUS RING

Zoom encoder FPC

Peel off the zoom encoder FPC.

・

Focus ring

JAA78851-R.3617.A

M/A BRUSH

#49×2

Distance encoder brush

White

M/A Brush

Remove 2 wires of the distance encoder FPC.

・

Yellow

Fig.1

(ref. Fig.1)

Take out 2 screws (#49) to remove M/A brush.

・

- L10・AF-S DX17-55/2.8G -

POWER BRUSH

INC

B3

#85

#79×2

White

Black

Blue

Fig.1

White

Blue

Black

JAA78851-R.3617.A

Tape

B63

#49×2

B63

#49×2

Remove 2 pieces of tapes that x the wire of the

・

power brush.

Unsolder 6 wires of the power brush. (ref. Fig.1)

・

Take out 2 screws (#49) to remove the power brush

・

B63(at 2 parts).

Peel off the FPC B3.

・

Take out 2 screws to remove the spring (#85).

・

DISTANCE SCALE PLATE

SWM

#62×2

Distance scale plate

Take out 2 screws (#62) to remove

・

the distance scale plate.

- L11・AF-S DX17-55/2.8G -

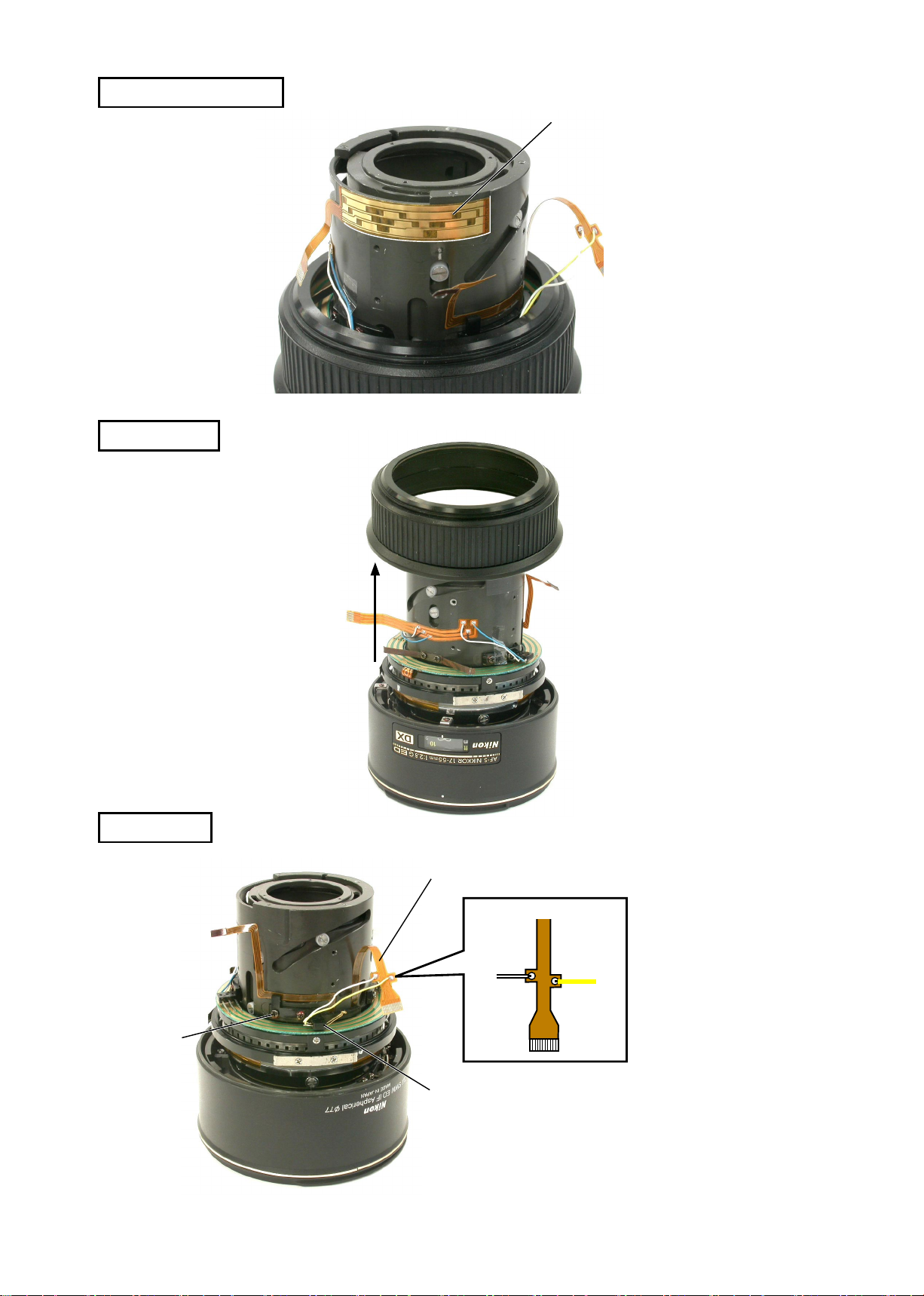

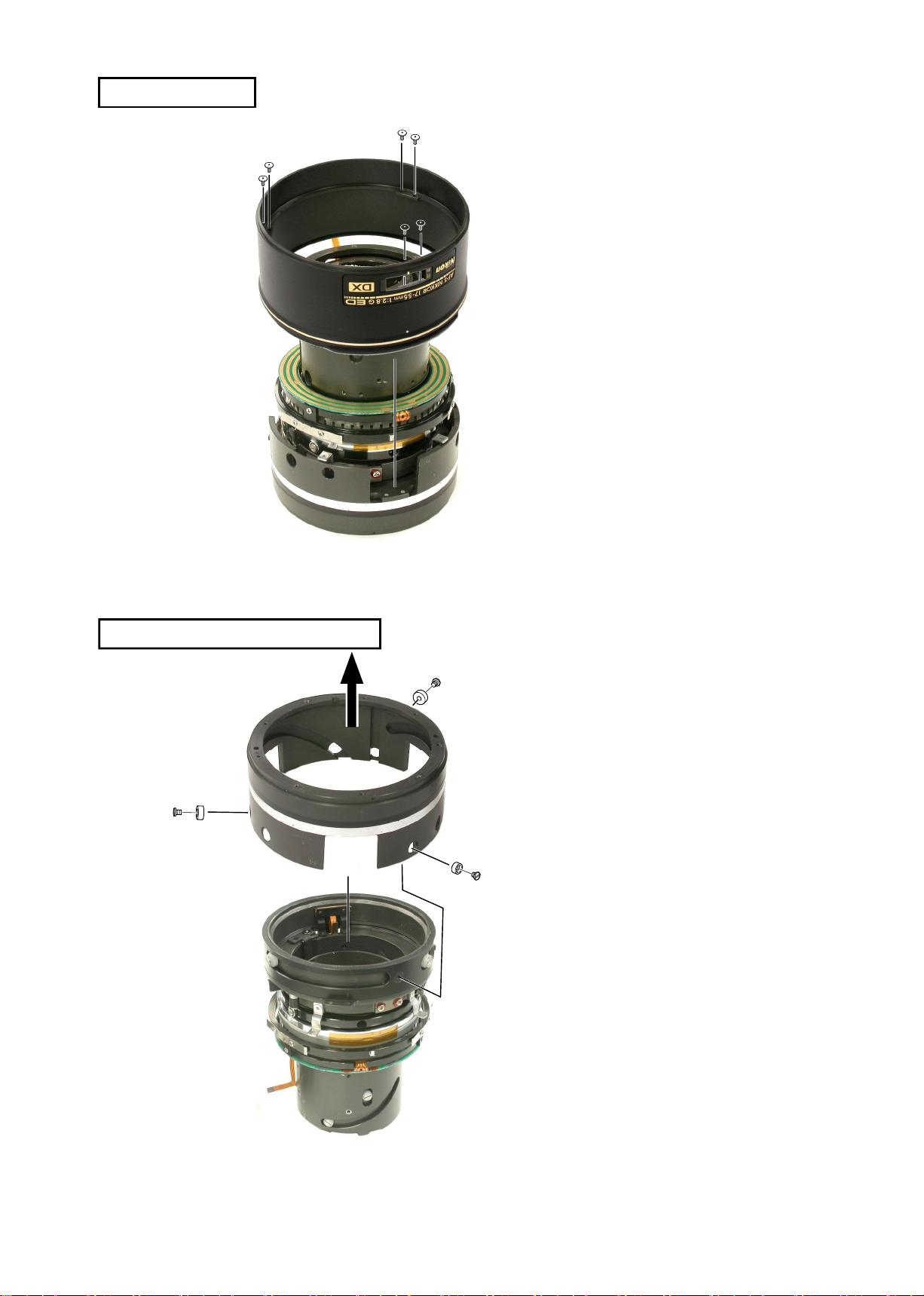

HOOD-FIX TUBE

INC

#166×6

Hood-x tube

JAA78851-R.3617.A

Take out 6 screws (#166) to remove

・

the hood-x tube.

1ST LENS GROUP STRAIGHT RING

1st lens group

straight ring

#192×3

#191×3

Pull up the 1st lens group straight ring

・

in the direction indicated by the arrow,

then take out 3 screws (#191) and 3

rollers (#192) to remove the 1st lens

group straight ring.

- L12・AF-S DX17-55/2.8G -

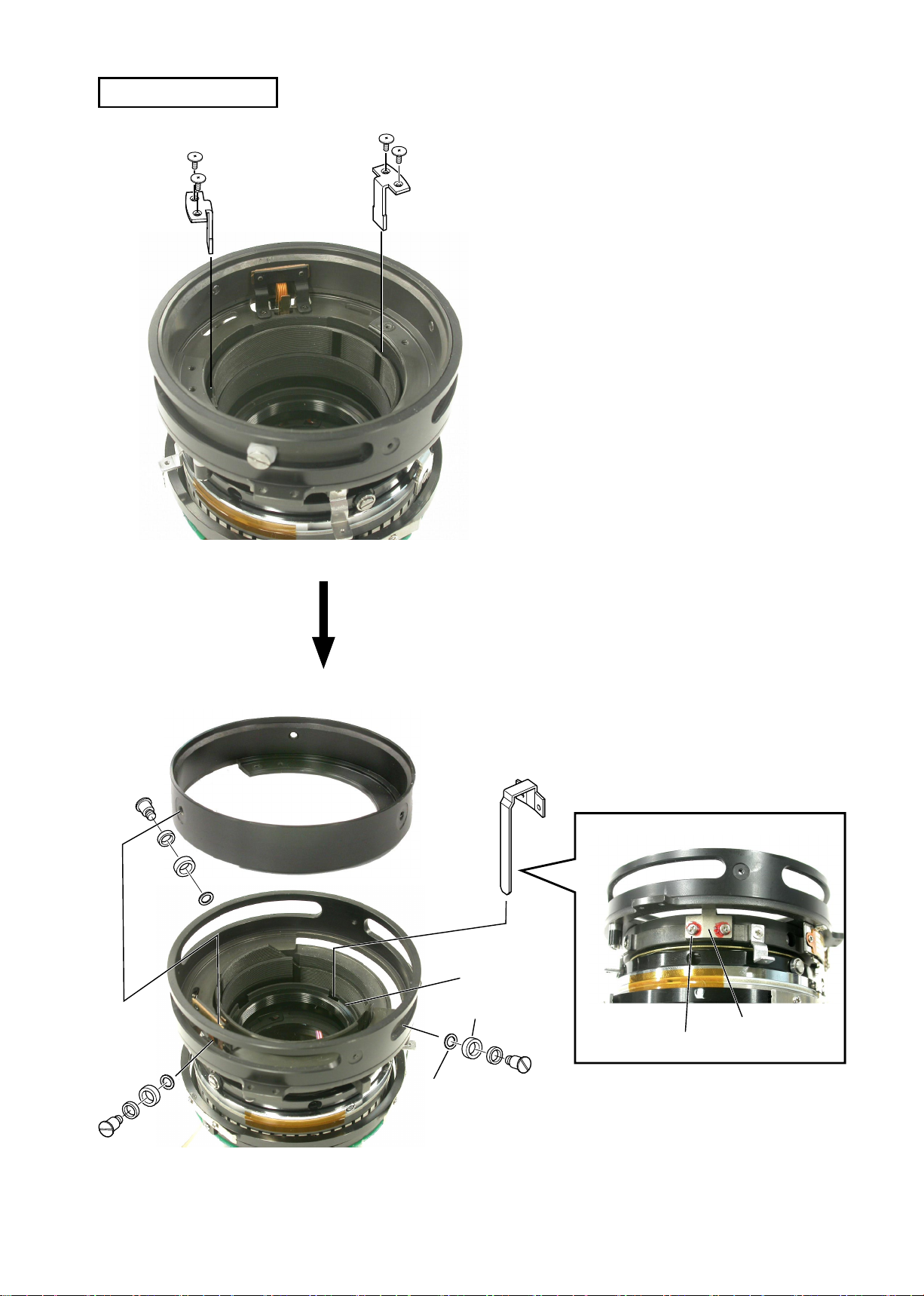

FOCUS SLIDING UNIT

INC

#75×2

#73×2

JAA78851-R.3617.A

Take out 2 screws (#75) to remove 2 levers (#73).

・

#48

Take out 3 screws (#80) to remove #48.

・

Take out 2 screws (#130) to remove #164. (ref. Fig. 1

・

#164

#52

#89×3

#116×3

#87×3

#80×3

#130×2

Fig.1

)

#164

- L13・AF-S DX17-55/2.8G -

#52

INC

Cam ring

#90×3

#82×3

JAA78851-R.3617.A

Turn the cam ring almost all the way to the

・

limit in the direction of the arrow so that

the roller mounting hole of the cam ring

can be seen.

Take out 3 screws (#82) and 3 rollers (#90)

・

to remove #52.

2.5TH LENS GROUP

2.5th lens group

#92×2

#83×2

#81×2

#81×2

#107

#103

Take out 2 screws (#83) and 2 rollers

・

2.5th lens group

(#92) to remove the 2.5th lens group.

- L14・AF-S DX17-55/2.8G -

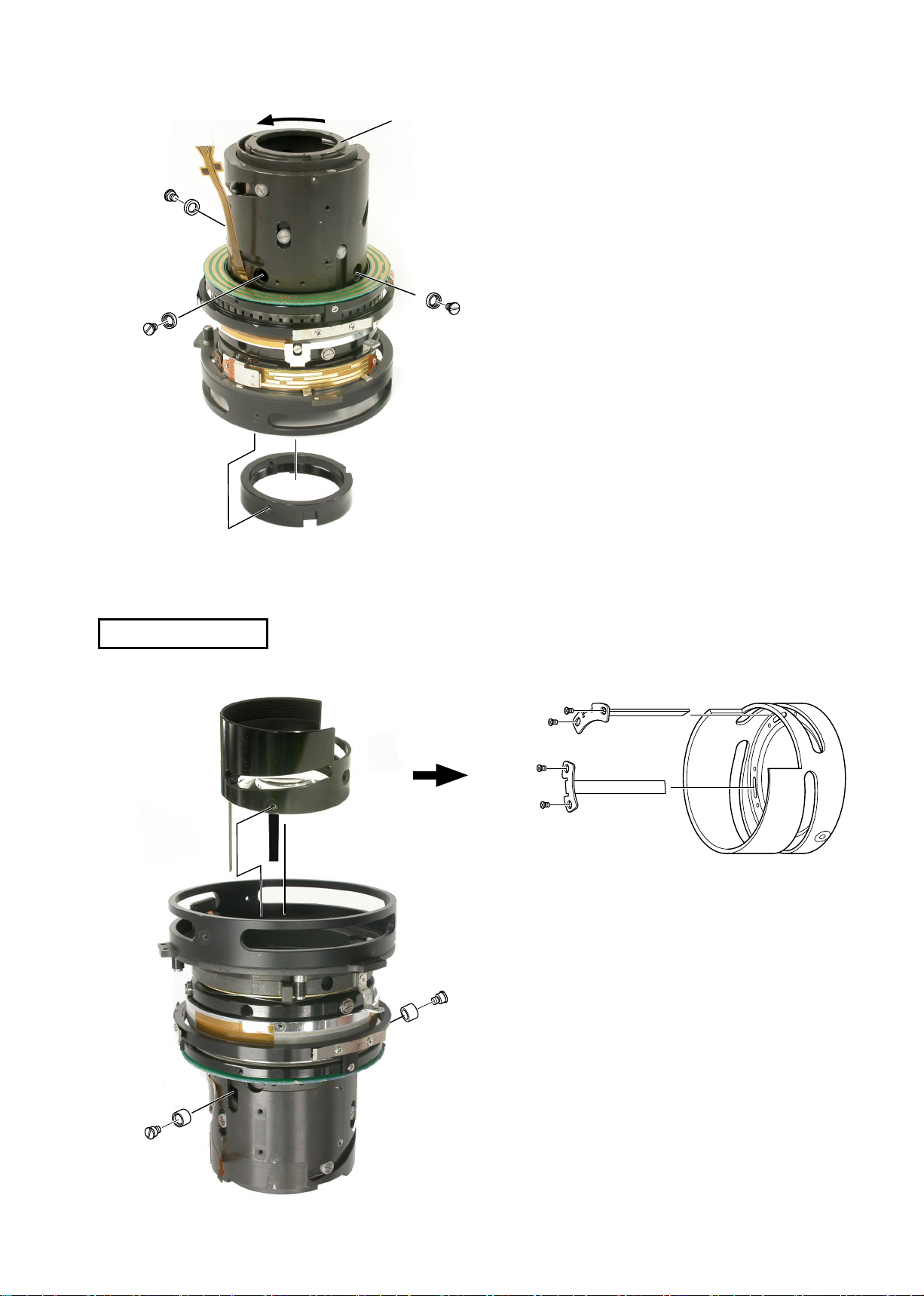

APERTURE BLADE HOUSING UNIT

INC

#91×3

#86×3

JAA78851-R.3617.A

#205

#114×3

B17

CAM RING GROUP

B9×9

#93×2

#33

#84×2

B47

Aperture blade housing unit

#106

#106

3rd lens group

#101

Cam ring

#102

- L15・AF-S DX17-55/2.8G -

SWM UNIT

INC

Fig.1

Body

JAA78851-R.3617.A

Pass the FPC through the hole as shown in Fig.1, and

・

put it into the lens body in position.

Fig.2

FPC

SWM

#161

#160

#159×3

#158×3

#162

Fig.3

Take out 3 screws (#158) and 3 rollers (#159). (ref. Fig.2)

・

Remove the SWM, the washer (#160) and the wave washer (#161).

・

#100×2

(ref. Fig.3)

Take out 2 screws (#100) to remove the SWM connecting key (#162).

・

(ref. Fig.3

Take out the FPC which was put into the lens body.

・

)

- L16・AF-S DX17-55/2.8G -

DISTANCE ENCODER BRUSH

INC

DISTANCE SCALE PLATE MOUNTING-BASE

JAA78851-R.3617.A

#99×2

Distance encoder brush

MAGNETIC TAPE UNIT

#124×2

Fig.1

#61×2

#100×2

Magnetic tape unit

#194×3

#72×3

Stopper screw

Stopper screw

Take out 2 MR head xing screws (#124). (ref. Fig.1)

・

to prevent damage on the magnetic tape unit

(

Take out 3 screws (#72) and 3 rollers (#194) to remove the

・

)

magnetic tape unit.

Take out the 2 stopper screws.

・

- L17・AF-S DX17-55/2.8G -

DISTANCE ENCODER FPC

INC

FPC

JAA78851-R.3617.A

#197×3

Take out 3 screws (#197) to remove the

・

distance encoder FPC.

Peel off part of the FPC shown by broken line.

・

Distance encoder FPC

MR HEAD

Fig.1

MR head

FPC

Peel off part of the FPC shown by

・

broken line. (ref. Fig.1)

Remove the MR head. (ref. Fig.2)

・

MR head

Fixed ring

Fig.2

#127

- L18・AF-S DX17-55/2.8G -

ASSEMBLY

INC

MR HEAD

MR head

#127

JAA78851-R.3617.A

Fixed ring

#127

MR head

#127

6mm

Fixed ring

Attach #127 on the xed tube. (ref. Fig.1)

・

Attach MR head FPC. (ref. Fig.2)

・

Do not screw the MR head at this stage.

FPC

MR head

Fig.1

DISTANCE ENCODER FPC

Distance encoder FPC

Attach the FPC along the

broken lines.

#196

Fig.2

Attach the FPC along the broken lines.

Adhesive:

Lock end B

#197×3

Adhesive: Lock end B

Fig.3

Attach the distance encoder FPC on #196 by aligning it with the screw hole for #193, then tighten 2

・

#193×2

Fig.4

screws (#193). (ref. Fig.3)

Mount #196, on which the distance encoder FPC was attached, on the xed tube, then tighten 3 screws

・

(#197). (ref. Fig.4)

- L19・AF-S DX17-55/2.8G -

MAGNETIC TAPE UINIT

INC

#195×2

#132×2

Adhesive:Lock end B

Fig.1

Magnetic tape unit

#194×3

#72×3

Adhesive:Lock end B

・

・

・

・

JAA78851-R.3617.A

Adhesive:Lock end B

#124×2

Fig.2

Assemble the magnetic tape unit into the xed tube.

(ref. Fig.1)

Note: Do not damage MR head and magnetic tape.

Attach 3 screws (#72) and 3 rollers (#194).

Attach 2 screws (#132) and 2 stopper rubbers (#195).

Fix the MR head with 2 screws (#124). (ref. Fig.2)

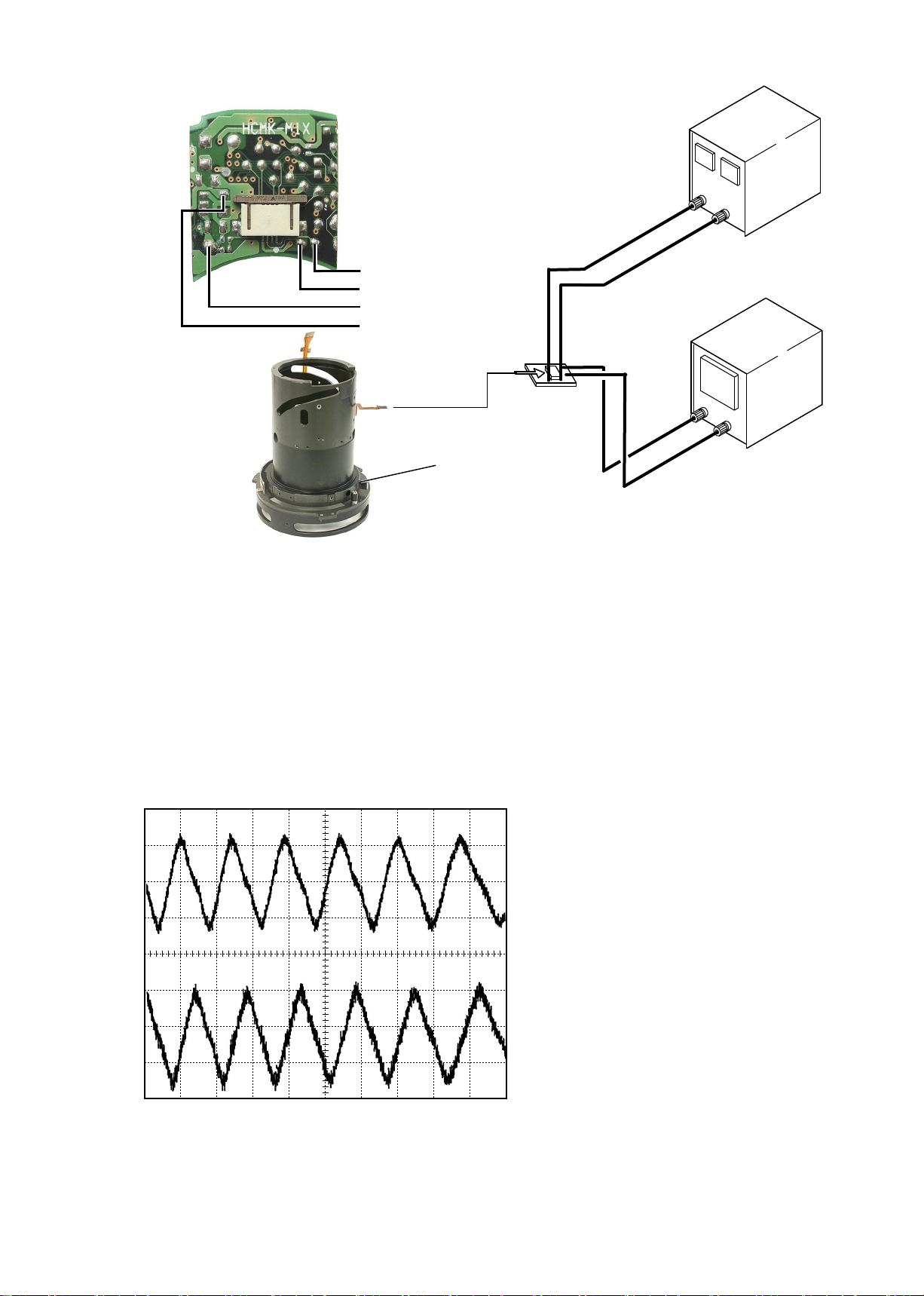

INSPECTION AND ADJUSTMENT FOR THE WAVEFORM OUTPUT FROM MR ENCODER

● In case of disassembling or replacing the MR head, be sure to make an adjustment.

1. Equipment and tools required

・Single output rated voltage power supply: 1 unit With 5.0V and 100mA, applicable to the self-

made tool

・Oscilloscope: 1 unit

・

Note:

Self-made tool: 1 unit

In case of any trouble in continuity between the self-made tool and the contacts of relay

FPC, there may be dust, corrosion or oxidation on the contact surface of relay FPC. Be

sure to polish the contact surface before getting connected to the self-made tool

.

2. Preparation for measuring lens

・Connect the xed tube, on which the MR head and magnetic tape unit were attached, to the

measuring devices. (Refer to the next page.)

- L20・AF-S DX17-55/2.8G -

C H 1= 2 0 m V CH2 = 2 0 mV 5 m s/d i v

AC 1 0: 1 AC 10 :1

NOR M 200 KS/ s

Connection diagram

INC

・

JAA78851-R.3617.A

Power supply

Self made tool

(GND)

(+)

Oscilloscope(2ch)

Oscilloscope(1ch)

Power supply(+)

Power supply(-)

Self made

tool

Magnetic tape unit

Set values

5.0V

100mA

Oscilloscope

(2ch)

・How to make an inspection and adjustment

Make sure that the current and voltage of the connected rated voltage power supply are set values.

①

Then, turn the power on.

② Set the oscilloscope and turn the magnetic tape unit by hand.

Note:Because the shape of waveform varies according to the driving speed of magnetic tape unit, set

Time/Div accordingly.

In case of detecting any wide waveform noise, use the lter function.

③

How to set the ler function by Yokogawa-manufactured DL1540

1.

Press the lter button.

2.

Select "Smooth" in the menu on the PC screen.

CH1

CH2

Standard:The amplitude of every pulse/waveform should be 50mV or more.

●Setting of oscilloscope

V/Div(CH1)

V/Div(CH2)

Coupling

Time/Div

Trigger Mode

Trigger Coupling

Trigger Source

Trigger Position

Trigger Type

Trigger Level

INPUT (ch1)

INPUT (ch2)

20 mV

:

20 mV

:

AC

:

5 m Sec

:

NORMAL

:

AC

:

CH1

:

4div

:+

EDGE

:

0 V

:

AC

:

AC

:

Note:Check the waveform by letting the focus ring to travel from the innity-end to the near

distance-end and vice versa.

- L21・AF-S DX17-55/2.8G -

C H 1= 2 0 m V CH2 = 2 0 mV 5 m s/d i v

AC 1 0: 1 AC 10 :1

NOR M 200 KS/ s

C H 1= 2 0 m V CH2 = 2 0 mV 5 m s/d i v

AC 1 0: 1 AC 10 :1

NOR M 200 KS/ s

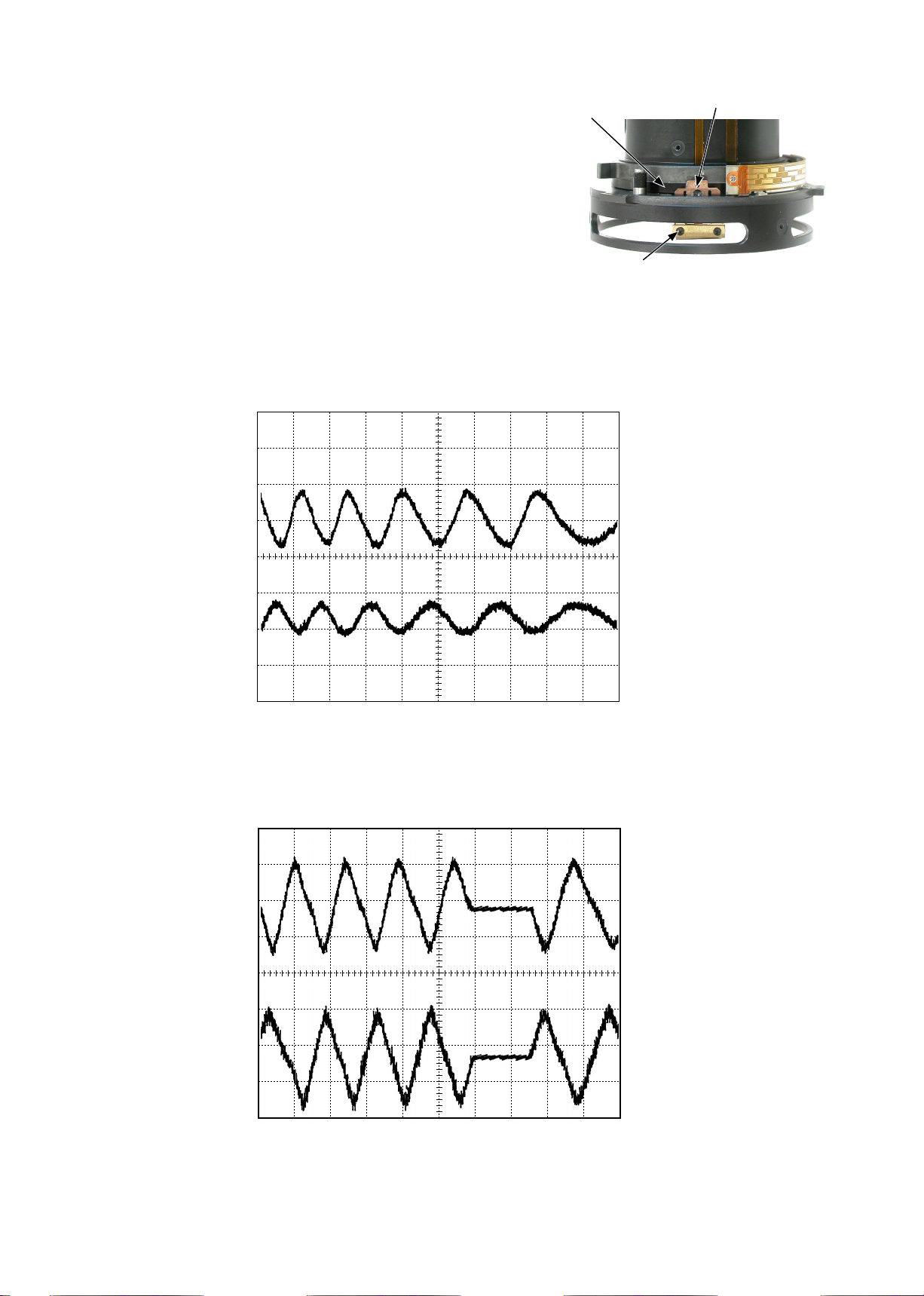

④ In the case of smaller amplitude, loosen 2 screws (#123)

INC

to move the MR head for adjustments as shown in Fig.1.

Note: During adjustment, prevent the magnetic tape and

MRhead from touching the magnetized driver bit.

Otherwise, the magnetic data may be damaged.

Magnetic tape

JAA78851-R.3617.A

MR Head

#123×2

Fig.1

《Reference》

● In case the amplitude of either CH1 or CH2 is smaller, one of 2 screws (#123) may be loosened,

so check for it. But if this is not the case, the MR head is regarded as malfunctioning. Be sure to

replace the MR head unit and adjust it again.

CH1

CH2

●In case there is a partial drop in the amplitude between the innity and the near distance, the magnetic

data of magnetic tape may be damaged. Then, replace the magnetic tape and adjust it again.

CH1

CH2

Fig.2

Fig.3

⑤ Turn off the rated voltage power supply.

- L22・AF-S DX17-55/2.8G -

DISTANCE SCALE PLATE MOUNTING-BASE

INC

DISTANCE ENCODER BRUSH

JAA78851-R.3617.A

#61×2

#100×2

Adhesive:Lock end B

Magnetic tape unit

Protrusion

2mm

Adhesive:Screw Lock

#99×2

Distance encoder brush

Magnetic tape unit

Attach the distance encoder brush on the magnetic tape unit

・

with temporarily 2 screws (#99).

Turn the magnetic tape unit so that the distance between

・

the protrusion and stopper rubber (#132) becomes 2-mm.

(ref. Fig.1)

Adjust so that the contact face of the brush becomes the

・

reference position (ref. Fig.2). After tightening 2 screws

(#99), apply Screw lock.

Fig.1

#132

Fig.2

Reference position

- L23・AF-S DX17-55/2.8G -

SWM UNIT

INC

Fig.1

FPC

#161

SWM

Body

JAA78851-R.3617.A

Pass the FPC through the hole as shown in Fig.1, and

・

put it into the lens body in position.

Attach the SWM connecting key (#162) to the

・

magnetic tape unit with 2 screws (#100).

Put the washer (#160) and wave washer (#161) on.

・

Assemble the SWM and engage the shoulder screw

・

of the SWM in the SWM connecting key. (ref. Fig.2)

Attach 3 screws (#158) and 3 rollers (#159). (ref.

・

Fig.3)

Take out the FPC which was put into the lens body.

・

Shoulder screw

#160

Cam grooves (2 parts)

Large vertical grooves (2 parts)

Small vertical grooves (3 parts)

Grease:GE-8

Magnetic tape unit

#162

#100×2

Adhesive:Lock end B

Adhesive:Lock end B

#158×3

#159×3

Fig.3

SW M co nnecting

key

Fig.2

- L24・AF-S DX17-55/2.8G -

Loading...

Loading...