Nieco 650G Installation Manual

B UILT-IN R EFRIGERATION

INSTALLATION INSTRUCTIONS

CONTENTS

Installation Recommendations 3

Installation Specifications 4

nstallation Instructions 8

I

Framed Panel Installation 12

Overlay Panel Installation 16

Completing the Installation 20

Service Information 23

Specifications are subject to change without notice.

Check our website, subzero.com, for the most

up-to-date specifications.

As you follow these instructions, you will

notice WARNING and CAUTION symbols.

This blocked information is important for the

safe and efficient installation of Sub-Zero

equipment. Ther

hazards that may occur during installation.

e are two types of potential

SUB-ZERO®is a registered trademark of Sub-Zero Freezer Company, Inc.

signals a situation where minor injury or

oduct damage may occur if you do not

pr

follow instructions.

states a hazard that may cause serious

y or death if pr

injur

followed.

Another footnote we would like to identify is

ANT NOTE: This highlights infor

T

IMPOR

tion that is especially r

ee installation.

fr

ecautions ar

elevant to a pr

e not

ma

oblem-

-

BUILT-IN INSTALLATION RECOMMENDATIONS

INSTALLATION

RECOMMENDATIONS

The importance of the installation of the

Sub-Zero Built-In unit cannot be overempha-

ized. Installation should be done by a

s

qualified installer.

Before you begin the installation process, it

is recommended that you read this entire

nstallation Instructions book. There are key

I

details that you should take special care to

observe during the installation. By reading

these instructions carefully, you will make the

installation process easier, problem-free and,

most importantly, safe.

Any questions or problems about the

installation should be directed to your

Sub-Zero dealer or the Sub-Zero Customer

Service Department at 800-222-7820 or e-mail

customerservice@subzero.com. You can also

visit our website at subzero.com.

TOOLS AND MATERIALS REQUIRED

he following is a list of tools and materials

T

that should be available for proper installation.

Phillips screwdriver set

lotted screwdriver set

S

Torx drive screwdriver set

4' (1.2 m) of

1

/4" copper tubing and saddle

valve for the water line—part #4200880

(do not use self-piercing valves)

Copper tubing cutter

Level—2' (.6 m) and 4' (1.2 m) recom-

mended

Appliance Dolly able to support 700 lbs

(317 kg) and adequate manpower to

handle the weight of the unit

Various sized pliers

Wrench set

Allen wrench set

5

/16" hex bolt nut driver

Crescent wrenches

Cordless drill and assorted drill bits

1

Masonite, plywood,

/8" pressed fiberboard,

cardboard or other suitable material to

otect finished flooring

pr

Appropriate materials to cover and protect

the home and its furnishings during installation

Dimensions in parentheses are in

millimeters unless otherwise specified.

3

BUILT-IN INSTALLATION SPECIFICATIONS

INSTALLATION

SPECIFICATIONS

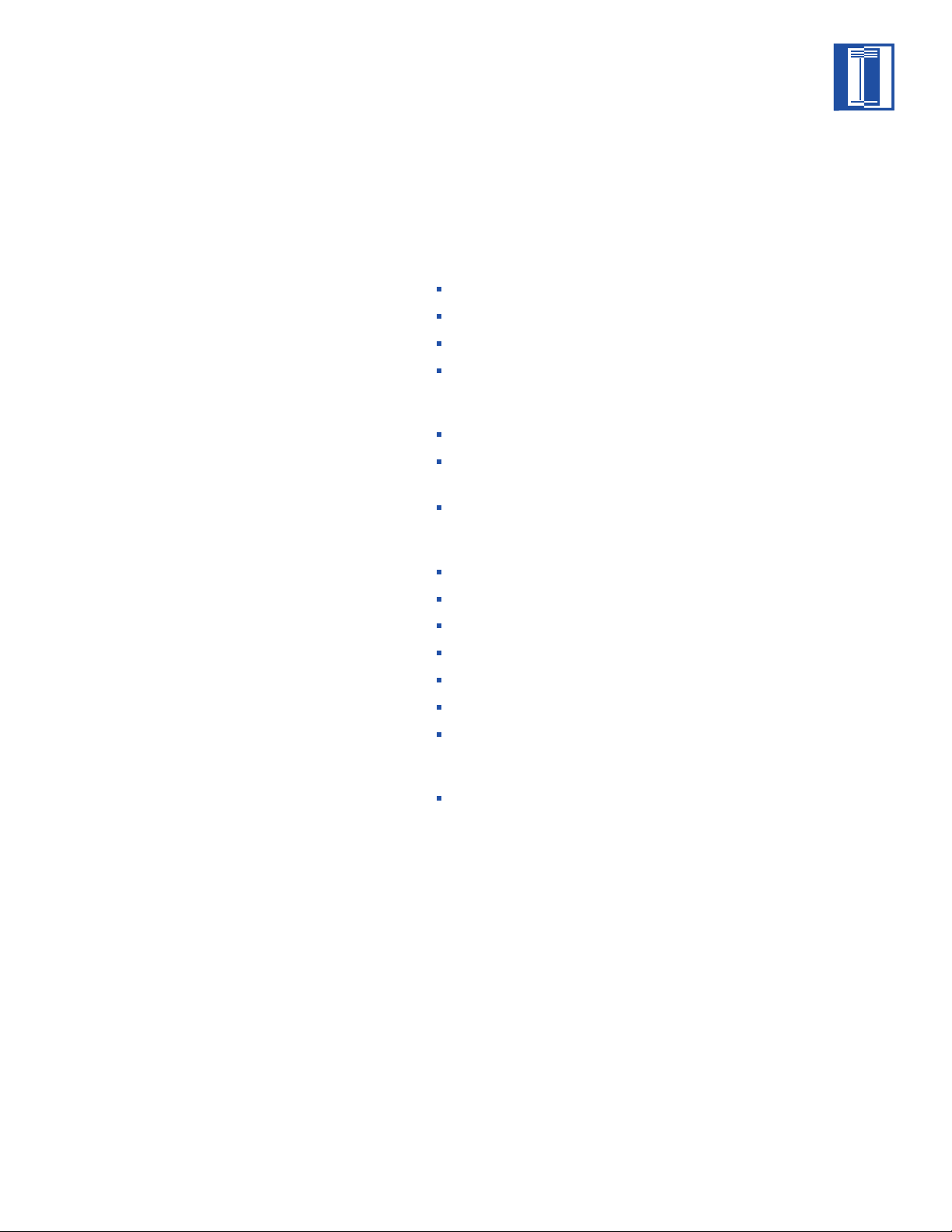

Make sure that the actual equipment that was

shipped to you matches the design you are

xpecting to install. The Sub-Zero Built-In line

e

offers the following design alternatives—

framed, overlay and stainless steel models.

Each of these design options has specific

nstallation requirements, which means it is

i

vital that the unit match your planning and

space needs. Before you begin the installation

process, check the exact model number you

need against the model number on the

shipping carton.

If the unit you receive does not match your

requirements, contact your Sub-Zero dealer.

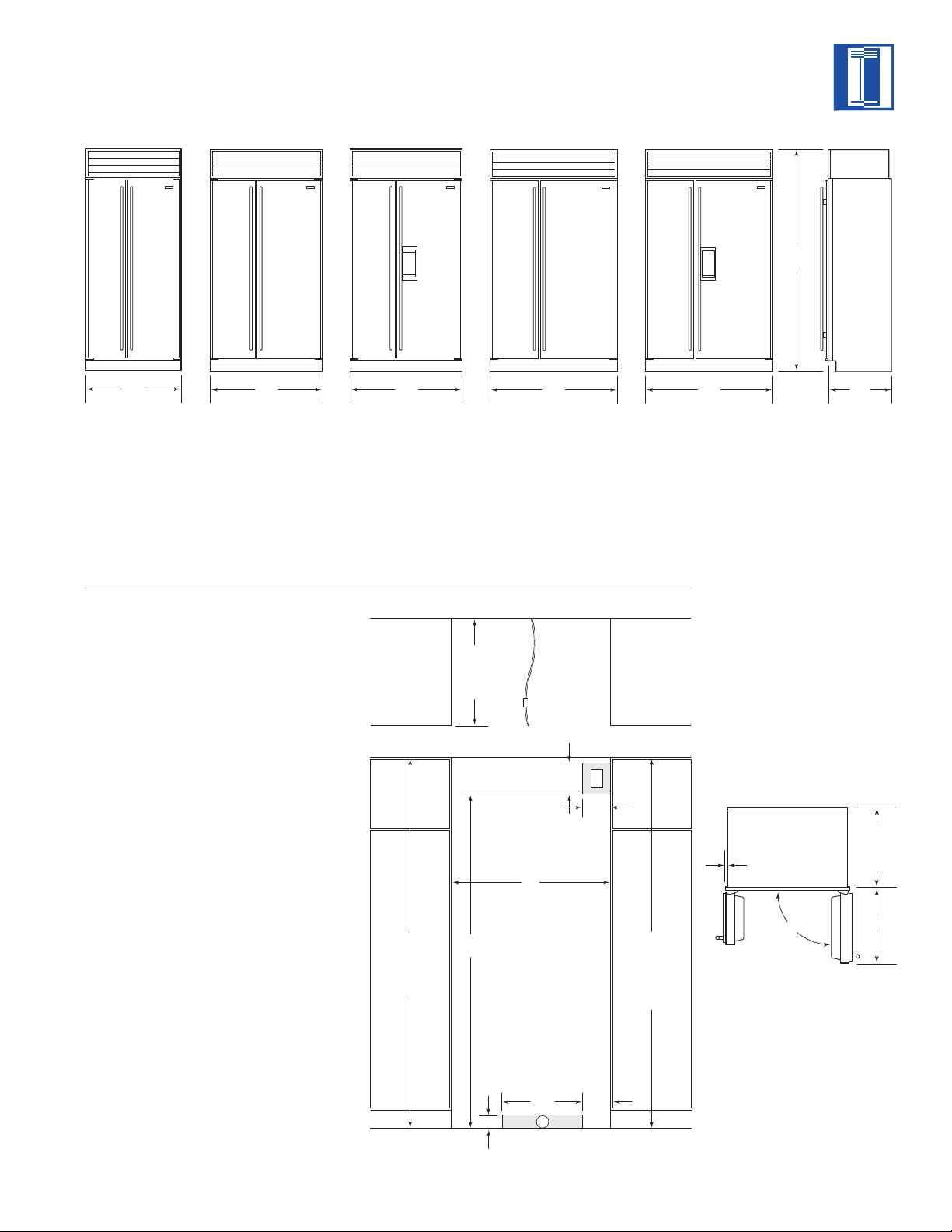

SITE PREPARATION

ake sure that the finished rough opening

M

where the Built-In unit is to be installed is

properly prepared. Refer to the Overall Dimen-

ions and Installation Specifications for your

s

specific model on the following pages. These

specifications are identical for each of the

design alternatives—whether your model is

framed, overlay or stainless steel. Make sure

that the rough opening dimensions, door

swing clearance, electrical service and

plumbing are correct for the model you are

about to install.

If you are installing Built-In units side by side,

a separating filler strip is recommended. Add

the filler strip width to the finished rough

opening dimension. Complete the installation

with the Anchoring Kit (part #4200900), see

page 21.

IMPORTANT NOTE:

To operate properly, the

door must open a minimum of 90˚. Use a

minimum 3" (76) filler in corner installations to

assure a 90˚ door opening. Allow enough clearance in front of the unit for full door swing.

IMPORTANT NOTE:

Make sure the floor under

the unit is level with the surrounding finished

floor.

4

36"

(914)

7

3"

(1854)

3

6"

(914)

7

3"

(

1854)

36"

(914)

24"

(610)

7

3"

(1854)

723/4" (1848)

ROUGH OPENING

HEIGHT TO

FINISHED

FLOORING

723/4" (1848)

MINIMUM HEIGHT

REQUIRED TO

FINISHED

FLOORING

(LEVELERS IN)

24"

(610)

ROUGH

O

PENING

DEPTH

11"

(279)

3"

(76)

24"

(610)

W

LOCATE WATER SUPPLY

WITHIN BOTTOM SHADED

AREA ONLY (601F ONLY )

LOCATE ELECTRICAL

WITHIN ENTIRE SHADED AREA

6"

(152)

E

SHUT-OFF

VALVE

EXTEND

WATER LINE

APPROX 36" (914)

FROM BACK WALL

(

601F ONLY )

351/2" (902)

ROUGH OPENING WIDTH

FRONT VIEW

TOP VIEW

361/16"

(916)

237/8"

(606)

BEHIND

FRAME

3

/8"(10)

FRAME

EXTENSION

90˚

BUILT-IN INSTALLATION SPECIFICATIONS

OVERALL DIMENSIONS

All Refrigerator | All Freezer Models

Model 601R

A

ll Refrigerator

Width 36" (914)

Height 73" (1854)

Depth 24" (610)

Model 601RG

A

ll Refrigerator

with Glass Door

Width 36" (914)

Height 73" (1854)

Depth 24" (610)

Model 601F

A

ll Freezer

Width 36" (914)

Height 73" (1854)

Depth 24" (610)

LL REFRIGERATOR

A

ALL FREEZER

M

odel 601R

A

ll Refrigerator

M

odel 601RG

A

ll Refrigerator

w

ith Glass Door

Model 601F

All Freezer

Illustrations shown in stainless steel design.

INSTALLATION SPECIFICATIONS

All Refrigerator | All Freezer Models

Models 601R and 601RG will not require the

water line connection.

Dimensions are for finished rough openings.

Door swing clearances are based on

stainless steel door and handle dimensions.

Dimensions in parentheses are in

millimeters unless otherwise specified.

5

30"

(762)

84"

(2134)

36"

(914)

84"

(2134)

30"

(762)

84"

(2134)

36"

(

914)

24"

(

610)

84"

(2134)

833/4" (2127)

ROUGH OPENING

HEIGHT TO

FINISHED

FLOORING WITH

STANDARD

11" (279) GRILLE

83" (2108)

MIN HEIGHT

REQUIRED TO

FINISHED

FLOORING

(LEVELERS IN)

751/2"

(1918)

7"

(178)

6"

(152)

A

ROUGH OPENING WIDTH

24"

(610)

R

OUGH

OPENING

DEPTH

E

3"

(76)

18"

(457)

W

LOCATE WATER SUPPLY

WITHIN SHADED AREA

LOCATE ELECTRICAL

WITHIN SHADED AREA

6"

(152)

SHUT-OFF

VALVE

FRONT VIEW

TOP VIEW

EXTEND

WATER LINE

APPROX 36" (914)

FROM BACK WALL

VER-AND-

B

23

7

/8"

(606)

BEHIND

FRAME

3

/8"(10)

FRAME

EXTENSION

90˚

O

UNDER

M

odel 611

Model 611G

w

ith Glass Door

Model 650

Model 650G

w

ith Glass Door

BUILT-IN INSTALLATION SPECIFICATIONS

OVERALL DIMENSIONS

Over-and-Under Models

Model 611

Width 30" (762)

Height 84" (2138)

Depth 24" (610)

Illustra

M

odel 611G

w

ith Glass Door

Width 30" (762)

Height 84" (2138)

Depth 24" (610)

tions shown in stainless steel design.

INSTALLATION SPECIFICATIONS

Over-and-Under Models

Model 611

A) Rough Opening Width 29

Min Door Clearance 301/8" (765)

B)

Model 611G

A)

Rough Opening Width 291/2" (749)

B) Min Door Clearance 30

Model 650

A) Rough Opening Width 35

B) Min Door Clearance 36

Model 650G

A) Rough Opening Width 35

B) Min Door Clearance 36

1

/2" (749)

1

/8" (765)

1

/2" (902)

1

/16" (916)

1

/2" (902)

1

/16" (916)

Model 650

Width 36" (914)

Height 84" (2138)

Depth 24" (610)

M

odel 650G

w

ith Glass Door

Width 36" (914)

Height 84" (2138)

Depth 24" (610)

6

Dimensions are for finished rough openings.

Door swing clearances are based on

stainless steel door and handle dimensions.

36"

(

914)

42"

(

1067)

4

8"

(1219)

42"

(1067)

48"

(

1219)

24"

(

610)

84"

(

2134)

833/4" (2127)

ROUGH OPENING

HEIGHT TO

FINISHED

FLOORING WITH

STANDARD

11" (279) GRILLE

83" (2108)

MIN HEIGHT

REQUIRED TO

FINISHED

FLOORING

(LEVELERS IN)

751/2"

(1918)

7"

(178)

6"

(152)

A

ROUGH OPENING WIDTH

24"

(610)

R

OUGH

OPENING

DEPTH

E

3"

(76)

18"

(457)

W

LOCATE WATER SUPPLY

WITHIN SHADED AREA

LOCATE ELECTRICAL

WITHIN SHADED AREA

6"

(152)

SHUT-OFF

VALVE

FRONT VIEW

TOP VIEW

EXTEND

WATER LINE

APPROX 36" (914)

FROM BACK WALL

B

23

7

/8"

(606)

BEHIND

FRAME

3

/8"(10)

FRAME

EXTENSION

90˚

BUILT-IN INSTALLATION SPECIFICATIONS

OVERALL DIMENSIONS

Side-by-Side Models

Model 661

Width 36" (914)

Height 84" (2138)

Depth 24" (610)

Model 642

Width 42" (1067)

Height 84" (2138)

Depth 24" (610)

INSTALLATION SPECIFICATIONS

Side-by-Side Models

Model 661

A) Rough Opening Width 35

Min Door Clearance 203/4" (527)

B)

Model 642

A)

Rough Opening Width 411/2" (1054)

B) Min Door Clearance 25

Model 685

A) Rough Opening Width 41

B) Min Door Clearance 25

Model 632

A) Rough Opening Width 47

B) Min Door Clearance 29

1

/2" (902)

9

/16" (649)

1

/2" (1054)

9

/16" (649)

1

/2" (1207)

1

/4" (743)

Model 685

I

ce | Water Dispensing

Width 42" (1067)

Height 84" (2138)

Depth 24" (610)

Model 632

Width 48" (1219)

Height 84" (2138)

Depth 24" (610)

Model 695

I

ce | Water Dispensing

Width 48" (1219)

Height 84" (2138)

Depth 24" (610)

Illustra

tions shown in stainless steel design.

SIDE-BY-SIDE

Model 661

Model 642

Model 685

Ice | Water Dispensing

Model 632

Model 695

Ice | Water Dispensing

Model 695

A)

Rough Opening Width 471/2" (1207)

B) Min Door Clearance 29

Dimensions are for finished rough openings.

Door s

stainless steel door and handle dimensions.

Dimensions in parentheses are in

millimeters unless otherwise specified.

1

wing clearances are based on

/4" (743)

7

BUILT-IN INSTALLATION INSTRUCTIONS

ELECTRICAL REQUIREMENTS

A 115 V AC, 60 Hz, 15 amp circuit breaker and

lectrical supply are required. A separate

e

circuit, servicing only this appliance, is

required.

All Sub-Zero Built-In models are equipped with

a power supply cord with a 3-prong grounding

lug, which must be plugged into a mating

p

3-prong grounding-type wall receptacle. Follow

the National Electrical Code and local codes

and ordinances when installing the receptacle.

For location of the electrical supply, refer to the

Installation Specifications illustration for your

specific model on pages 5–7.

IMPORTANT NOTE:

A ground fault circuit

interrupter (GFCI) is not recommended and

may cause interruption of operation.

Do not use an extension cord or twoprong adapter. Electrical ground is

required on this appliance. Do not remove

the power supply cord ground prong.

PLUMBING REQUIREMENTS

For Built-In models with an automatic ice

aker, rough in the water supply line. Connect

m

1

a

/4" OD copper line to the house supply. Use

an easily accessible shut-off valve between the

water supply and the unit. This valve is usually

placed about 6" (152) from the compression

fitting. Do not use self-piercing valves. A

saddle valve kit (part # 4200880) is available

from your Sub-Zero dealer.

The water line should be routed up through

the floor within

1

/2" (13) from the back wall and

no higher than 3" (76) off the floor. If the water

supply is brought in from behind the unit,

route the water line through the back wall, no

more than 3" (76) from the floor. Regardless of

the routing, allow 3' (1 m) of excess copper

tubing to remain outside the wall or floor for

easy connection to the unit. For location of the

water supply, refer to the Installation Specifications illustration for your specific model on

pages 5–7.

A line filter is required when water conditions

have a high sediment content. The ice maker

operates on water pressure of 20 psi (1.4 bar)

to 100 psi (6.9 bar).

The outlet must be checked by a qualified

electrician to be sure that it is wired with

the correct polarity. Verify that the outlet

ovides 115 volts and is properly

pr

grounded.

A reverse osmosis system can be used,

provided there is a consistent water pressure

of 20 psi (1.4 bar) to 100 psi (6.9 bar) supplied

to the water valve at all times.

IMPORTANT NOTE:

In some cases a reverse

osmosis water filter system may not be able to

maintain the minimum water pressure consistently.

Good water is impor

tant for high quality ice.

It is not recommended that the ice maker be

connected to a softened water supply. Water

softener chemicals, such as salt fr

om a

malfunctioning softener, can damage the ice

maker mold and lead to poor ice quality. If a

softened water supply cannot be avoided, it is

important that the water softener be well maintained and operating properly.

Dimensions in parentheses are in

millimeters unless otherwise specified.8

Loading...

Loading...