Nieco 624 Installation Manual

INSTALLATION & OPERATING

INSTRUCTIONS

Raytherm™

Heating

Boilers

Models 133–4001

Type H

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury or loss of life. Refer to this manual.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future

reference.

CATALOG NO. 2000.50AG Effective: 09-16-10 Replaces: 01-06-10 P/N 240035 Rev. 34

Rev. 34 reflects the following:

Changes to: Clarification of Note 1 and Note 2 on page 7, Fig. 26 on page 21, Warranty info on page 42

Additions: None

Deletions: None

2

CONTENTS

WARNINGS 4

Pay Attention to These Terms 4

MODEL IDENTIFICATION 5

RECEIVING EQUIPMENT 6

CERTIFICATIONS 6

BOILER TYPES 6

Type H1 - Mechanical Modulating 6

Type H2 - Motorized Modulating 6

Type H3 - 2-Stage Controls 6

Type H4 - On-Off Controls 6

Type H5 - Mechanical Modulating 6

Type H9 - 4-Stage 6

INSTALLATION 6

Installation Codes 7

Installation Base 7

Clearances 7

Outdoor Boilers 8

High-Wind Conditions (Outdoor Units Only)8

Combustion and Ventilation Air 8

(Indoor Units Only) 8

Venting 9

Indoor Installations 10

Vent Piping 13

Vent Damper Installation 15

Plumbing 16

Gas Supply Connections 16

CONTROLS 21

Economaster Controls 21

Electronic Ignition 21

Operating Controls 21

Limit Controls 23

ELECTRICAL CONNECTIONS 24

START-UP 25

Before Start-Up 25

General 25

Filling System - Heating Boilers 25

Ethylene Glycol Systems Heating Boilers 25

Initial Start-Up - Pump And Motor 25

For Models with Automatic Gas Valves 28

After Start-Up 28

Standing Pilot Checkout

Procedure 28

Intermittent Pilot System

Checkout (S8600) 28

Inspections 29

Burners 29

Controls 29

Suggested Inspection Schedule 29

LOW NOx BOILERS 30

Models 181 to 401 30

Operation 30

Start-Up (S8600M) 30

Blower Adjustment 30

Visual Inspection 30

Electrical 30

Flame Roll-Out Safety Switch 31

Service 31

Burner Tray Removal 31

Gas Valve Removal 31

Main Burner and Orifice Removal 31

Pilot Removal 32

Combustion Fan Removal 32

TROUBLESHOOTING 33

Service 38

Repair Section 38

REPLACEMENT PARTS 41

WARRANTY 42

3

WARNINGS—Pay Attention to These Terms

ANGER:

D

WARNING:

CAUTION:

NOTE:

DANGER: Make sure the gas on which the heater

will operate is the same type as that specified on the

heater rating plate.

WARNING: Should overheating occur or the gas

supply valve fail to shut, do not turn off or disconnect

the electrical supply to the heater. Instead, shut off

the gas supply at a location external to the heater.

WARNING: Do not use this heater if any part has

been under water. Immediately call a qualified

service technician to inspect the heater and to

replace any part of the control system and any gas

control which has been under water.

Indicates the presence of immediate hazards which will cause severe

personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

severe personal injury, death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause

minor personal injury or product or property damage if ignored.

Indicates special instructions on installation, operation, or maintenance which

are important but not related to personal injury hazards.

WARNING - CALIFORNIA PROPOSITION

65: This product contains chemicals known to the

State of California to cause cancer, birth defects or

other reproductive harm.

WARNING: To minimize the possibility of improper

operation, serious personal injury, fire, or damage to

the heater:

• Always keep the area around the heater free of

combustible materials, gasoline, and other

flammable liquids and vapors.

• Heater should never be covered or have any

blockage to the flow of fresh air to the heater.

WARNING: This unit contains refractory ceramic

fiber (RCF) insulation in the combustion chamber.

RCF, as manufactured, does not contain respirable

crystalline silica. However, following sustained

exposure to very high temperatures (>2192F), the

RCF can transform into crystalline silica

(cristabolite). The International Agency for Research

on Cancer (IARC) has classified the inhalation of

crystalline silica (cristabolite) as carcinogenic to

humans.

When removing the burners or heat exchangers,

take precautions to avoid creating airborne dust and

avoid inhaling airborne fibers. When cleaning spills,

use wet sweeping or High Efficiency Particulate Air

(HEPA) filtered vacuum to minimize airborne dust.

Use feasible engineering controls such as local

exhaust ventilation or dust collecting systems to

minimize airborne dust. Wear appropriate personal

protective equipment including gloves, safety

glasses with side shields, and appropriate NIOSH

certified respiratory protection, to avoid inhalation of

airborne dust and airborne fiber particles.

WARNING: Risk of electrical shock. More than one

disconnect switch may be required to de-energize

the equipment before servicing.

CAUTION: Operation of this heater in low

temperature systems requires special piping.

Harmful internal condensation will occur if the inlet

water temperature does not exceed 105°F. Warranty

claims will be denied when condensation occurs.

CAUTION: If this heater is to be installed above

radiation level, it must be provided with a low water

cut-off device at the time of heater installation.

CAUTION: This heater requires forced water

circulation when the burner is operating. See

minimum and maximum flow rates. Severe damage

will occur if the heater is operated without proper

water flow circulation.

CAUTION: If this heater is to be installed in a

negative or positive pressure equipment room, there

are special installation requirements. Consult factory

for details.

4

MODEL

MODEL NUMBER EXAMPLE:

H 3 - 0 5 1 4 A

Series

Model Size

Representative of approximate MBTUH input

(Model 0514 has input of 511,500 BTUH)

Firing Mode

1 Mechanical Modulation

2 Motorized Modulation

3 2-Stage Firing

4 On-Off Firing

5 Low Temperature Mechanical Modulation

9 4-Stage Firing

Application

H = Heating Boiler

Boiler rating plate showing model number

IDENTIFICATION

he model number of a boiler can be found on the

T

Sales Order and the boiler's rating plate. The example

below identifies what the characters of the model number represent.

5

RECEIVING EQUIPMENT

BOILER TYPES

On receipt of the equipment, visually check for exter-

al damage to the carton or the shipping crate. If either

n

is damaged, make a note on the Bill of Lading and

eport the damage to the Carrier immediately. Remove

r

the boiler from the carton or the shipping crate.

On occasion, items are shipped loose. Be sure that

you receive the number of packages indicated on the

Bill of Lading.

When ordering parts, you must specify the Model and

Serial Number of the boiler. When ordering under warranty conditions, you must also specify the date of

installation.

Raypak recommends that this manual be reviewed

thoroughly before installing your Raypak boiler. If there

are any questions which this manual does not answer,

please contact the factory or your local Raypak representative.

Claims for shortages and damages must be filed with

carrier by consignee. Permission to return goods must

be factory authorized and are subject to a stocking

charge.

Purchased parts are subject to replacement only

under the manufacturer's warranty. Debits for defective replacement parts will not be accepted and will be

replaced in kind only per our standard warranties.

Type H1 - Mechanical

Modulating, Models 133-1826

Central heating boiler with 150°-210°F mechanical

modulating gas valve(s). The number of valves varies

with the model size.

Type H2 - Motorized

Modulating, Models 514-4001

Central heating boiler with a motorized modulating gas

valve. Modulating controller optional.

Type H3 - 2-Stage Controls,

Models 181-4001

Central heating boiler with single 2-stage gas valve

and optional 2-stage controller.

Type H4 - On-Off Controls,

Models 181-4001

Central heating boiler with on-off firing.

Type H5 - Mechanical

Modulating, Models 181-1826

CERTIFICATIONS

The Raypak hydronic boilers are design certified and

tested under the latest requirements of the American

National Standard, ANSI Z21.13. Each boiler has been

constructed and pressure tested in accordance with

the requirements of Section IV of the American Society

of Mechanical Engineers Code, and factory fire tested.

All models are National Board approved. Temperature

and pressure gauge is standard. Model 0133 has a 4pass heat exchanger, 1 tube per pass. Models

0181-1826 have 2-pass heat exchangers, 5 tubes first

pass, 4 tubes second pass. Models 2100-4001 have

2-pass heat exchangers, 9 tubes per pass. Models

926-4001 have optional single-pass heat exchangers

with cast iron headers only.

Central heating boiler with 110°-170°F mechanical

modulating gas valve(s).

Type H9 - 4-Stage, Models 5144001

Central heating boiler with 4-stage firing. Controller

optional.

INSTALLATION

Installation Codes

The installation must conform with these instructions

and the latest editions of the National Fuel Gas Code

ANSI Z223.1, the National Electric Code ANSI/NFPA

70 and local codes. All boiler installations must conform to ASME boiler code. Hot water pipes must be

installed with minimum clearances to combustible

material as required by code.

6

Installation Base

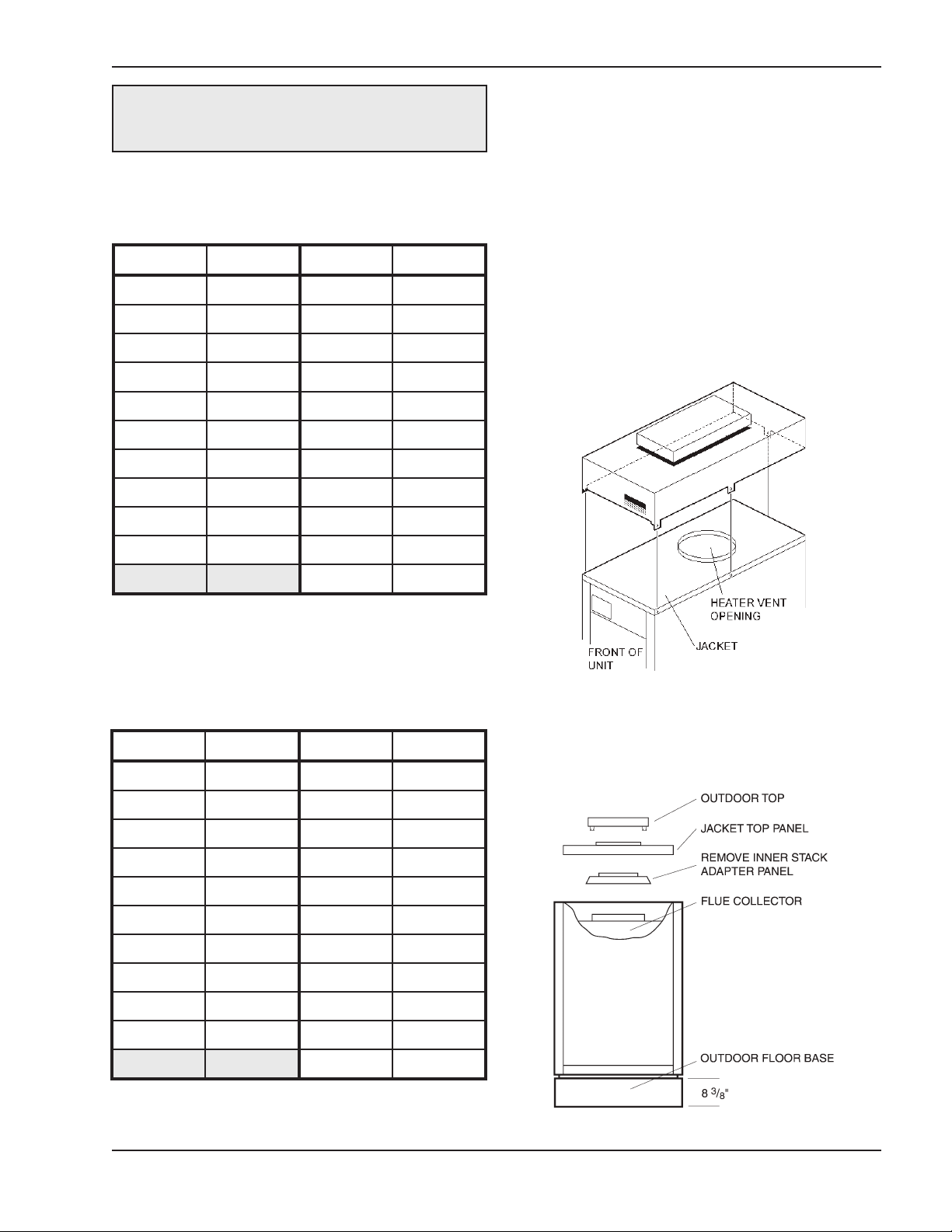

Boiler Model No. Base Part No. Boiler Model No. Base Part No.

926*

1083*

1178*

1287*

1414*

1571*

1758*

962

1125

1223

1336

1468

1631

1826

001749

058313

058314

058315

058316

056199

056200

056201

056202

133

182/181

260/261

330/331

400/401

514

624

724

824

054597

054598

054599

054600

054601

058378

058379

059233

059234

059235

059236

059237

059238

059239

MODEL

133

181 to

401

514 to

824

926 to

1826

2100 to

4001

The boiler should be mounted on a level, non-combustible surface. Boiler must not be installed on

carpeting. The boiler can be installed on a combustible

surface only when a suitable floor shield base is pro-

ided. Raypak offers an optional floor shield base

v

which can be factory installed on all indoor models

except Model 133; the Model 133 floor shield base is

shipped loose and must be installed by the contractor.

Do NOT use the shipping crate base as an installation

base.

NOTE: For Models 2100-4001, a factory-installed

floor shield is standard. Table B provides the floor

shield ordering information for other models.

NOTE: The boiler should be located in an area

where water leakage will not result in damage to the

area adjacent to the appliance or to the structure.

When such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance. The pan

must not restrict air flow.

In addition, the boiler shall be installed such that the

gas ignition system components are protected from

water (dripping, spraying, rain, etc.) during appliance

operation and service (circulator replacement, control

replacement, etc.).

Fig. 2: Alternate Method for Providing a Non-

Combustible Base

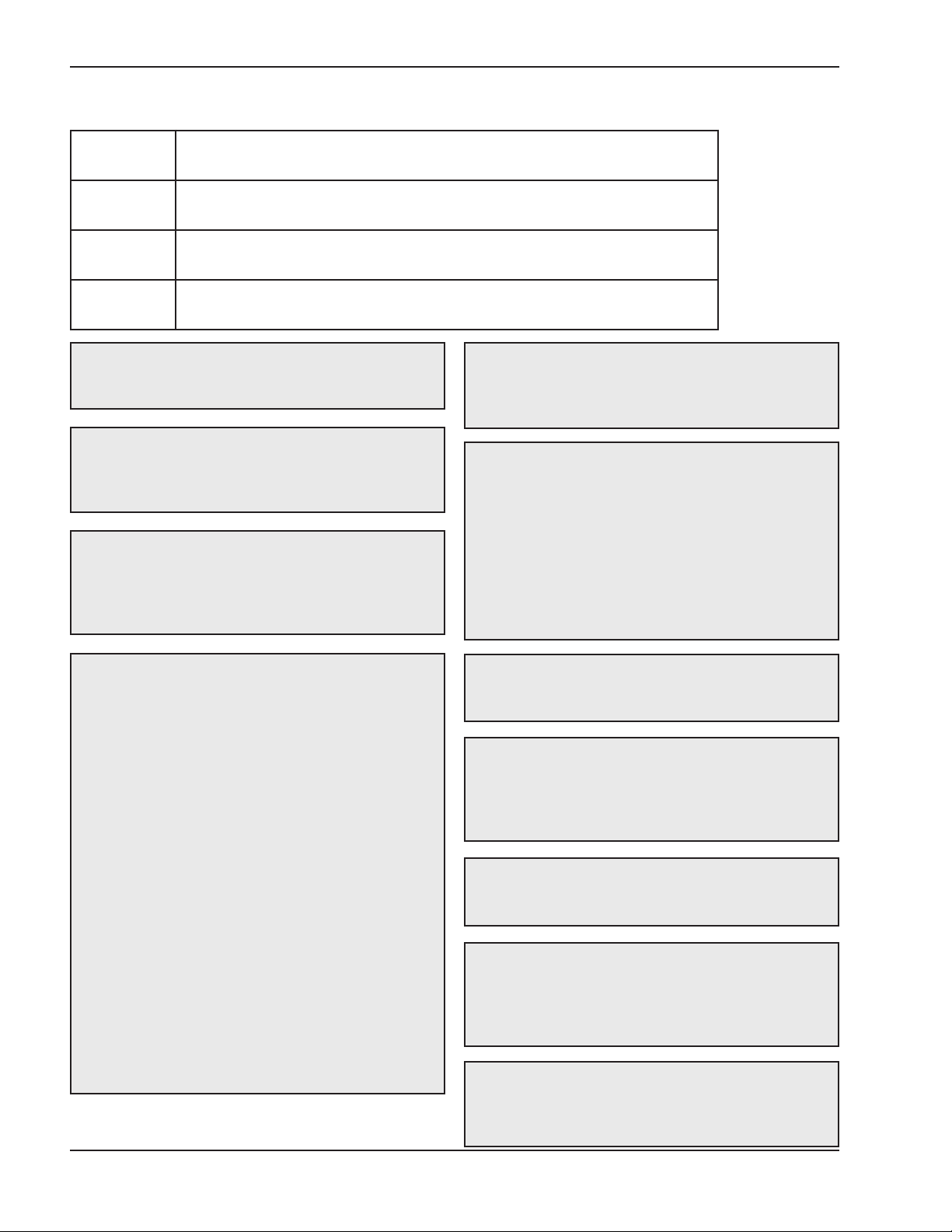

Clearances

All dimensions are in inches.

Derived from National Fuel Gas Code, Table 6.2.3(a)

*Vent includes factory-supplied drafthood and does not include fieldsupplied vent systems above the drafthood. On Models 2100-4001

drafthood is built into boiler.

Table C: Clearances from Combustible Surfaces

* Models with factory-installed floor shield as standard.

BOLD type indicates Low NOx models.

Table B: Combustible Floor Shield Ordering

Information

NOTE 1: Combustible floor shield is required when

boiler is to be installed on a combustible surface. (See

ordering information in Table B.)

NOTE 2: Servicing Clearances: Provide at least 24"

(Models 133-1826), 48" (Models 2100-4001) in front of

unit for removal and servicing of the Controls & Burner

Tray. Provide at least 18" on side opposite water

connections for deliming of Heat Exchanger Tubes.

7

NOTE: The boiler shall be installed in a space large

n comparison to the size of the boiler. Large space

i

is defined as having a volume at least sixteen (16)

times the total volume of the boiler.

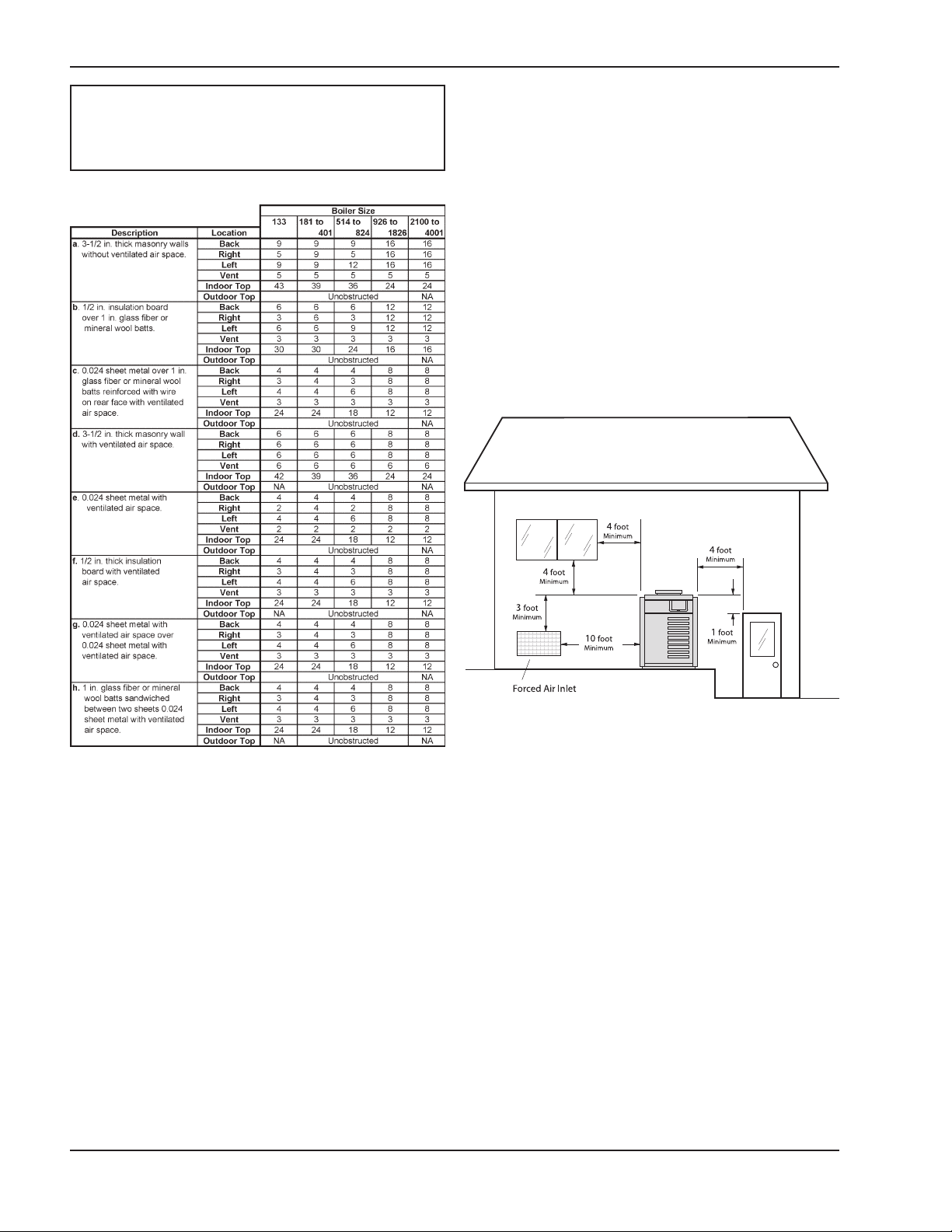

Outdoor Boilers

These boilers are design certified for outdoor installation. Boilers must not be installed under an overhang

within three (3) feet from the top on the boiler. Three

(3) sides must be open in the area under the over-

ang. Roof water drainage must be diverted away

h

from the boilers with the use of gutters.

The point from where the flue products exit the boiler

must be a minimum of four (4) feet below, four (4) feet

horizontally from or one (1) foot above any door, window or gravity inlet to a building. The top surface of the

boiler shall be at least three (3) feet above any forced

air inlet, or intake ducts located within ten (10) feet horizontally.

Derived from National Fuel Gas Code, Table 6.2.3(b)

Table D: Reduction of Clearances to Protected

Surfaces

Fig. 3: Minimum Distances to Building Openings from

Where Flue Products Exit the Boiler

High-Wind Conditions (Outdoor Units Only)

In areas where high winds are frequent, it may be necessary to locate the boiler a minimum of 3' from high

vertical walls, or install a wind break so the boiler is not

in direct wind current.

Combustion and Ventilation Air

(Indoor Units Only)

The boiler must have both combustion and ventilation

air. Minimum requirements for net free air supply

openings are 12 inches from ceiling for ventilation and

12 inches from the floor for combustion air as outlined

in Z223.1 - latest edition and any local codes that may

have jurisdiction.

8

CAUTION: Combustion air must not be

(Part of heater)

ontaminated by corrosive chemical fumes which

c

can damage the boiler and void the warranty.

Venting

Outdoor Installations

a. All Air From Inside The Building:

Each opening shall have a minimum net free

square inches as noted in Table E.

Model Sq. Inches Model Sq. Inches

133 136 1125 1125

182/181 181 1223 1223

260/261 264 1336 1337

330/331 334 1468 1467

400/401 399 1631 1630

514 512 1826 1826

624 627 2100 2100

724 726 2500 2499

824 825 3001 3000

962 962 3500 3500

4001 4000

Table E: Minimum Net Free Air from Inside Building

Model 133

1. Remove the front (4) screws.

2. Line up outdoor top vent opening over heater vent

opening.

3. Lower outdoor top onto unit lining up slots in the

outdoor top with screw holes in jacket top.

4. Reinstall (5) screws to secure jacket top and outdoor top to unit.

b. All Air From Outdoors:

When air is supplied directly from outside of building, each opening shall have a minimum net free

square inches as noted in Table F.

Model Sq. Inches Model Sq. Inches

133 34 1125 282

182/181 46 1223 306

260/261 66 1336 335

330/331 84 1468 367

400/401 100 1631 408

514 128 1826 457

624 157 2100 525

724 182 2500 625

824 207 3001 750

962 241 3500 875

4001 1000

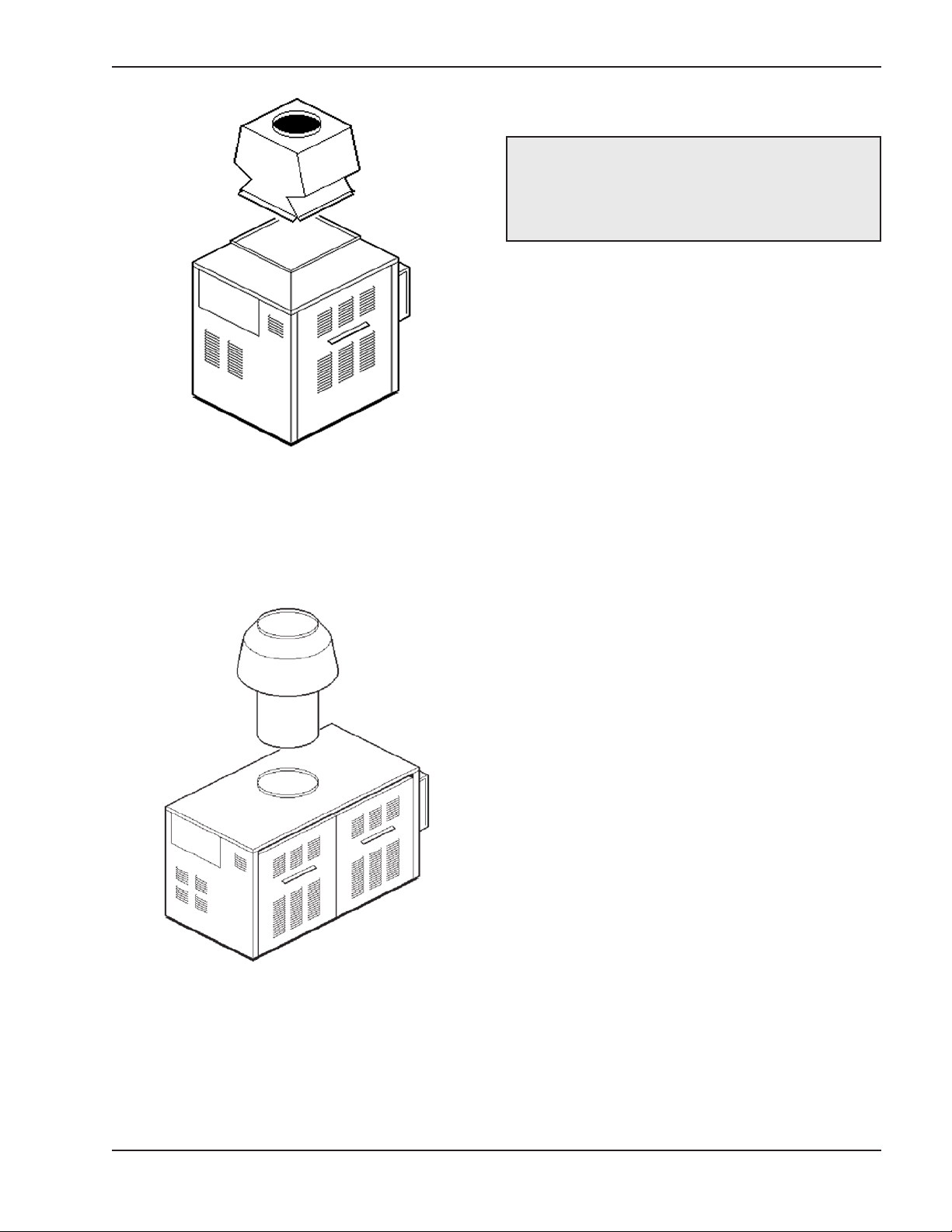

Fig. 4: Installing Outdoor Top—Model 133

Models 181-401 & 182-400

Outdoor Top Installation

Table F: Minimum Net Free Air from Outside Building

Fig. 5: Installing Outdoor Top—Models 181-401 & 182-

400

9

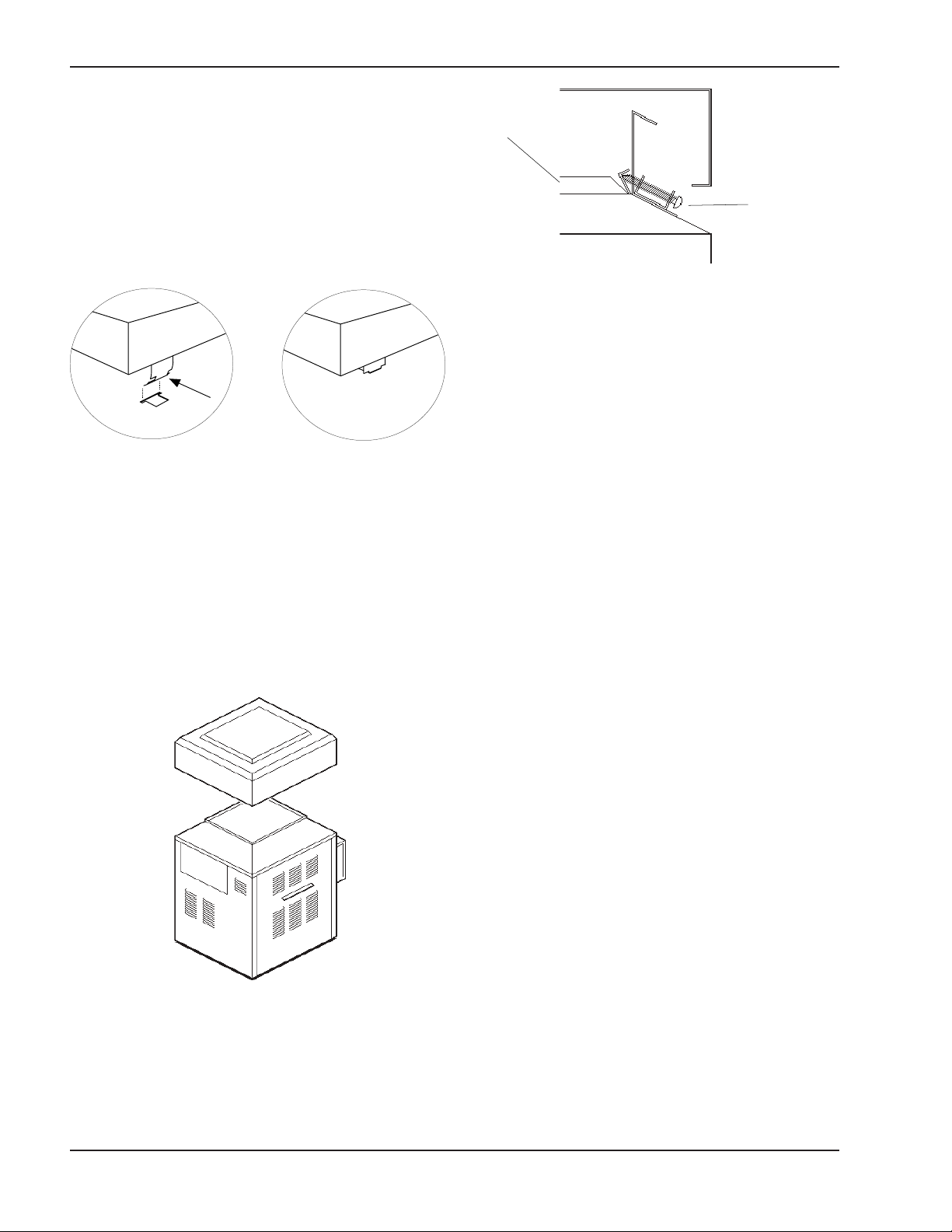

1. Remove jacket top panel.

Outdoor Top

(Shipped Loose with Heater)

Detail A Detail B

JACKET TOP

F

ASTENING

SCREW

2. Remove and discard inner stack adapter panel.

3. Install jacket top panel.

4. Insert tabs of outdoor top into keyholes located on

jacket top panel (4 places). See Detail A.

5. Snap tabs on outdoor top into the locked position

of the keyhole so the top will not pull out. See

Detail B.

Fig. 8: Installing Outdoor Top Detail—Models 514–824

Models 926-1758

Boilers are shipped with outdoor vent terminal factory

installed.

Indoor Installations

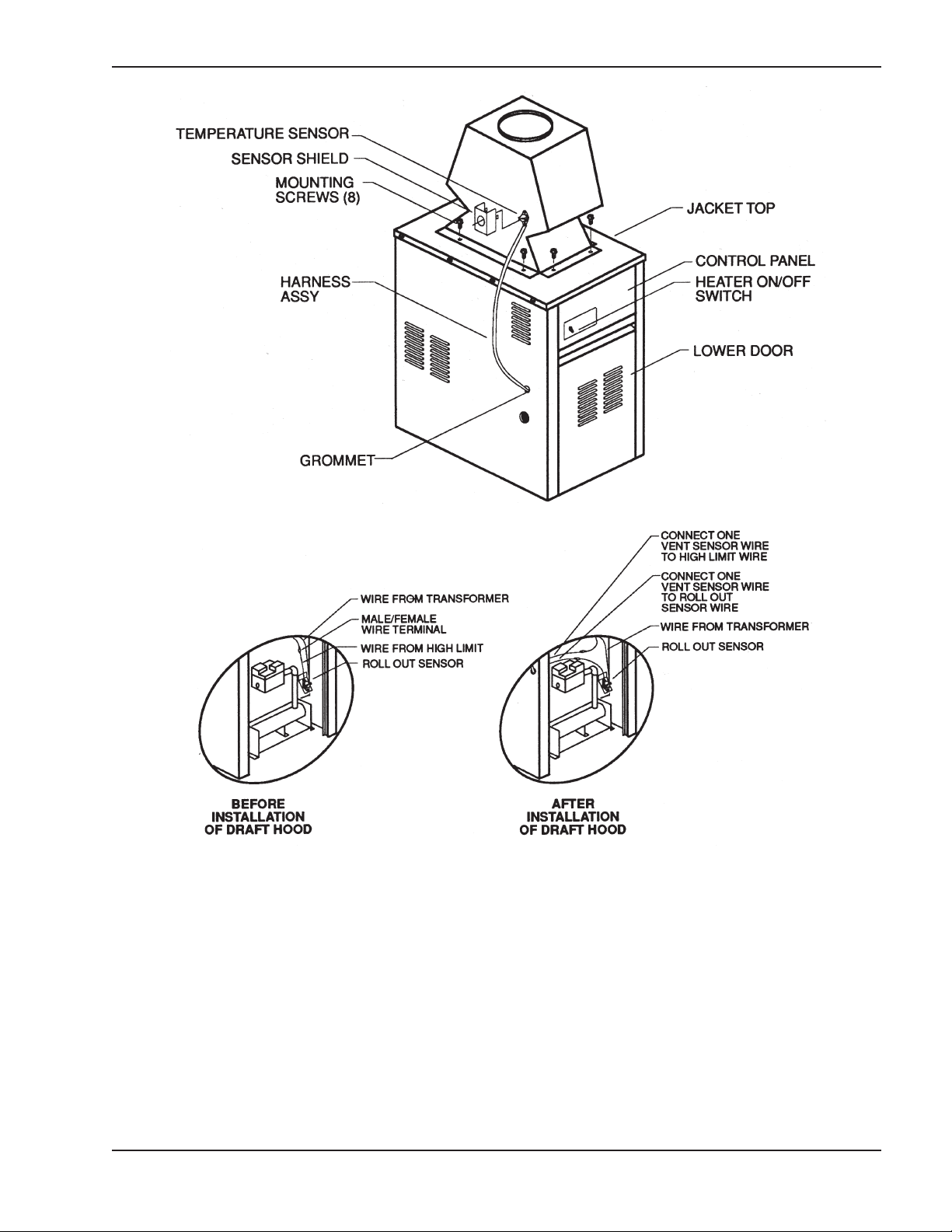

Model 133

1. Shut-off main electrical power switch to boiler.

Fig. 6: Installing Outdoor Top—Models 181-401 & 182-

400

Models 514-824

1. Lower outdoor top onto unit. Position top so it is

centered on unit from side to side and front to rear.

2. Turn heater manual switch located in upper control

panel to the "OFF" position.

3. Shut-off gas supply and water supply to the boiler.

4. Mount drafthood on boiler and attach with the

sheet metal screws provided. Drafthood should be

positioned with the vent sensor located on the

front left side (see next page).

5. Remove plastic plug from left side of boiler jacket

and install the plastic grommet provided.

6. Route flue sensor wire harness through the grommet installed in Step 5.

7. Remove door and locate wire from roll-out sensor

to high limit with the male/female connector.

8. Disconnect male/female connector and attach to

the 2 wires from drafthood vent sensor harness.

2. Tighten the (4) screws (as indicated in Fig. 8) until

Fig. 7: Installing Outdoor Top—Models 514–824

they come in contact with the unit jacket top, then

evenly tighten all (4) screws to secure to unit.

10

Fig. 9: Indoor Installation—Model 133

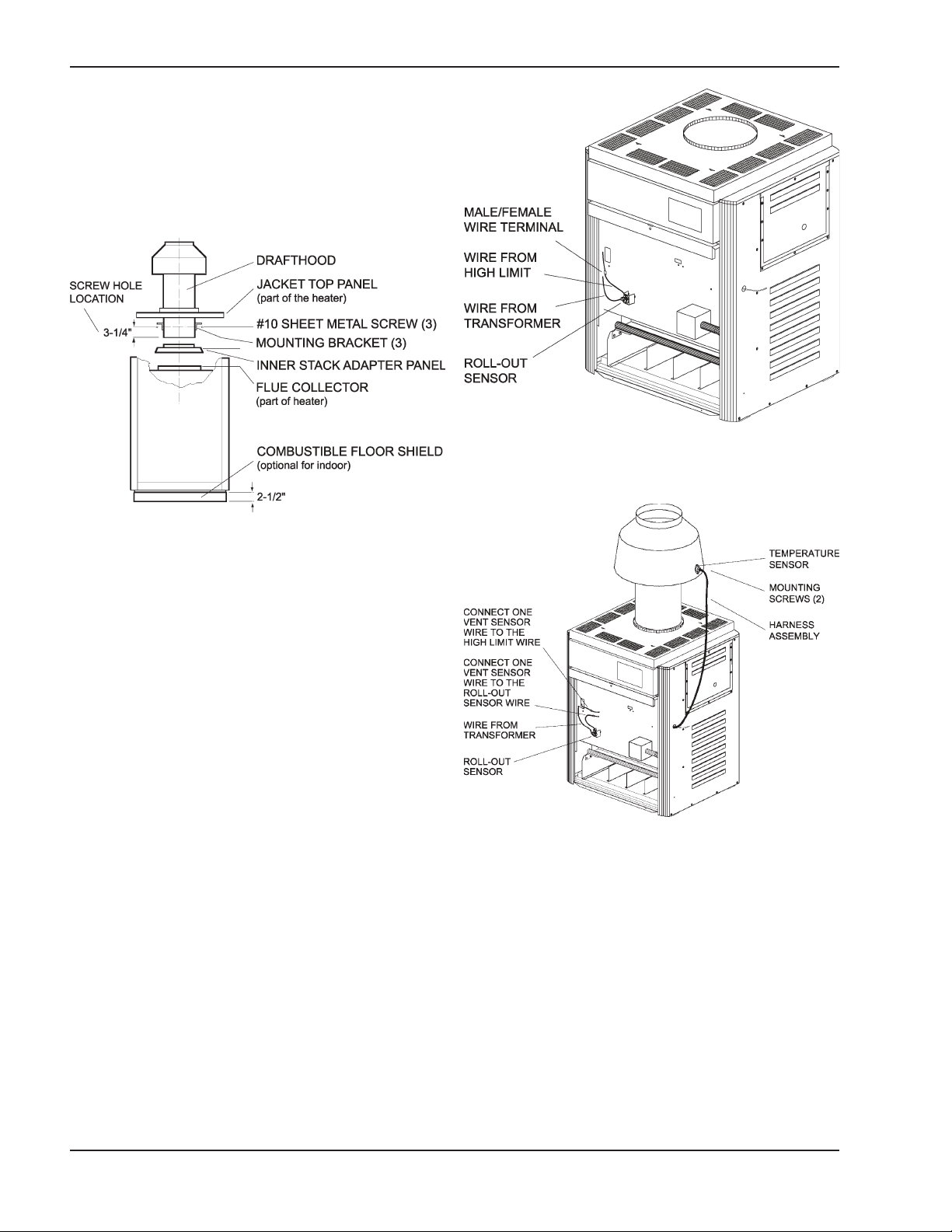

Models 181-401 & 182-400

Indoor Stack Installation

1. Remove the louvered jacket top by removing four

(4) #10 flathead screws.

2. If originally installed, remove outdoor top from the

louvered jacket top.

3. Place the inner stack adapter panel over the flue

collector inside the heater. Make sure the flanged

side of the flue opening is up.

4. Turn the stack (drafthood) upside down and set it

down bottom side up.

5. Turn the jacket top panel (removed in step 1)

upside down and place it over the stack.

6. Attach the three (3) mounting brackets to the stack

using the screws provided and the holes that are

pre-drilled in the stack. Make sure the brackets

are positioned with the flange near the top side

of the stack (see Fig. 10). Caution must be

taken not to over tighten and strip the screw

threads.

11

7. Turn the assembled stack and jacket top, rightside

up. The jacket top will be trapped between the

brackets and the top of the stack. Place the stack

over the inner stack adapter panel flanged hole

and lower the louvered jacket top panel back into

its original position. Reinstall the four (4) #10 flathead screws removed in step 1 above.

Fig. 10: Indoor Installation—Models 181-401 & 182-400

Fig. 11: Boiler Before Drafthood Installation—Models

181-401 & 182-400

Models 181-401 & 182-400

1. Shut-off main electrical power switch to boiler.

2. Turn heater manual switch located in upper control

panel to the "OFF" position.

3. Shut-off gas supply and water supply to the boiler.

4. Mount drafthood on top of boiler as shown in Fig.

12. Drafthood should be positioned with the vent

sensor located on the front right side as shown.

5. Remove plastic plug from left side of boiler jacket

and install plastic grommet provided.

6. Route flue sensor wire harness through the grommet installed in Step 5.

7. Remove door and locate wire from roll-out sensor

to high limit with the male/female connector.

8. Disconnect male/female connector and attach to

the 2 wires from drafthood vent sensor harness.

Fig. 12: Boiler After Drafthood Installation—Models

181-401 & 182-400

Models 514-824

Locate and assemble as shown in Fig. 13. Secure with

screws supplied in envelope in carton.

12

Fig. 13: Drafthood Installation—Models 514–824

Models 962-1826

Locate and assemble as shown in Fig. 14. Secure with

screws supplied in envelope in carton.

Vent Piping

WARNING: Indoor boilers require a drafthood

that must be connected to a vent pipe and properly

vented to the outside. Failure to follow this

rocedure can cause fire or fatal carbon monoxide

p

poisoning.

Vent piping the same size or larger than the drafthood

outlet is recommended, however, when the total vent

height is at least 10 ft. (drafthood relief opening to vent

terminal), the vent pipe size may be reduced as specified in Chapter 10 of the latest edition of the National

Fuel Gas Code, ANSI Z223.1.

As much as possible, avoid long horizontal runs of

vent pipe and too many elbows. If installation requires

horizontal non-vertical runs, the vent pipe must have a

minimum of 1/4 inch per foot rise and should be supported at not more than 5 ft. intervals. Plumbers tape,

criss-crossed, will serve to space both horizontal and

vertical piping.

Gas vents supported only by the flashing and extending above the roof more than 5 ft. should be securely

guyed or braced to withstand snow and wind loads.

Fig. 14: Drafthood Installation—Models 962–1826

Models 2100-4001

These models have built-in drafthoods. For proper

operation, the drafthood outlet must be connected to

the venting system.

We recommend the use of insulated vent pipe spacers

through the roof and walls.

For protection against rain or blockage by snow, the

vent pipe must terminate with a vent cap which complies with the local codes or, in the absence of such

codes, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1.

The discharge opening must be a minimum of 2 ft. vertically from the roof surface and at least 2 ft. higher

than any part of the building within 10 ft.

Vent stack shall be at least 5 ft. in vertical height above

the drafthood outlet. The vent cap location shall have

a minimum clearance of 4 feet horizontally from, and

in no case above or below, unless a 4-foot horizontal

distance is maintained, from electric meters, gas

meters regulators and relief equipment.

The weight of the vent stack or chimney must not rest

on boiler drafthood. Support must be provided in compliance with applicable codes. The boiler top and

drafthood must be readily removable for maintenance

and inspection. Vent pipe should be adequately supported to maintain proper clearances from combustible

construction.

13

Type "B" double-wall or equivalent vent pipe is recom-

5' MIN

2' MIN

10' OR LESS

2' MIN

VENT CAP

VENT PIPE

DRAFT HOOD

H

EATER

mended. However, single-wall metal vent pipe may be

used as specified in the latest edition of the National

Fuel Gas Code ANSI Z223.1.

Manifolds that connect more than one boiler to a common chimney must be sized to handle the combined

load. Consult available guides for proper sizing of the

manifold and the chimney. At no time should the area

be less than the area of the largest outlet.

Fig. 16: Venting Clearances

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

Fig. 15: Common Venting

At the time of removal of an existing boiler, the following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remaining connected to the common venting system are not

in operation.

(a) Seal any unused openings in the common venting

system.

(b) Visually inspect the venting system for proper size

and horizontal pitch and make sure there is no

blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

(c) As much as possible, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common venting system are located and other spaces

of the building. Turn on clothes dryers and any

appliance not connected to the common venting

system. Turn on any exhaust fans, such as range

(d) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

(e) Test for spillage at the drafthood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a cigarette, cigar or pipe.

(f) After it has been determined that each appliance

remaining connected to the common venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and any other gas burning appliance to

their previous conditions of use.

(g) Any improper operation of the common venting

system should be corrected so that the installation

conforms with the latest edition of the National

Fuel Gas Code, ANSI Z223.1. When re-sizing any

portion of the common venting system, the common venting system should be re-sized to

approach the minimum size as determined using

the appropriate tables in Part 11 of the National

Fuel Gas Code, ANSI Z223.1.

For special venting applications that require reduced

vent sizes and through-the-wall venting, the Type D

Induced Draft Assembly can be used. Consult the factory or your local Raypak representative.

14

Loading...

Loading...