FLOR

EN - Instructions and warnings for

installation and use

IT - Istruzioni ed avvertenze per

l’installazione e l’uso

FR - Instructions et avertissements

pour l’installation et l’utilisation

ES - Instrucciones y advertencias

para la instalación y el uso

DE - Installierungs-und Gebrauchs-

anleitungen und Hinweise

PL - Instrukcje i ostrzeżenia do

instalacji i użytkowania

NL - Aanwijzingen en aanbevelingen

voor installatie en gebruik

Receiver

FLOXR family

EN

English - 1

Original instructions

ENGLISH

1 – PRODUCT DESCRIPTION AND

INTENDED USE

This receiver is part of the “Flor” series by Nice spa. This

series of receivers is intended for use on the Control units

featured in automated systems for gates, garage doors and

road barriers. Any other use is to be considered incorrect

and forbidden! The manufacturer shall not be held liable

for damage due to improper use of the product other

than that specified in this manual.

2 – PRODUCT TECHNICAL

SPECIFICATIONS

• For all models

– The receiver handles “Flor” type radio encoding with a

variable code (rolling-code) and also recognises the C-

Code encoding of the Opera series for the basic functions.

– These models have 1 or 2 relays with clean contact output;

they can therefore be used with any type of Control unit.

3 – PRODUCT INSTALLATION

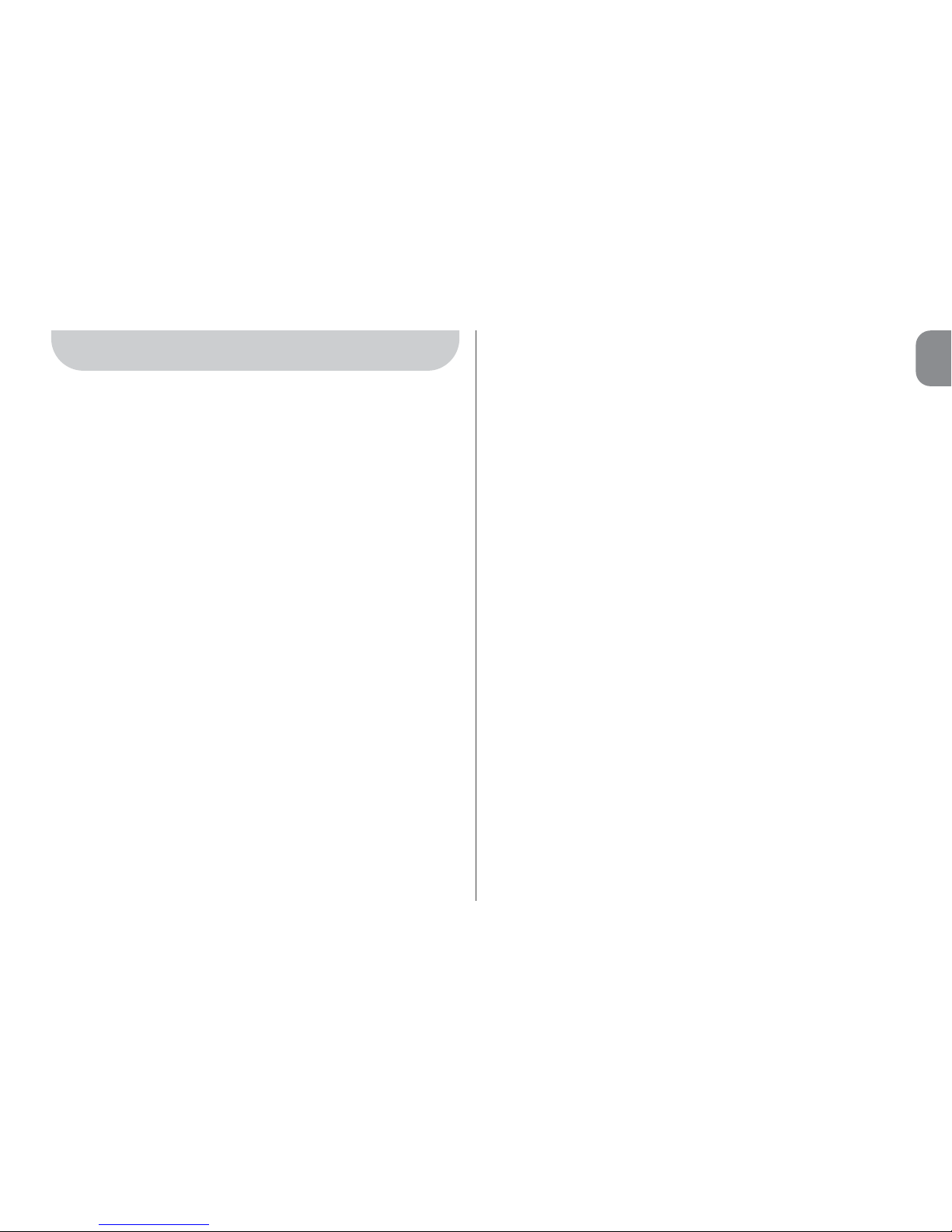

• For models with “NICE” connector

These models are connected to the Control system by

inserting their connector into the specific one featured on the

Control unit. Important! – Before connecting or removing

the receiver, cut off the electricity supply to the Control

unit.

In addition, you should install the aerial provided, connecting

it to the purpose-provided terminals on the Control unit.

WARNINGS

WORKING IN SAFETY!

CAUTION! – For personal safety it is important to

observe these instructions.

CAUTION! – Warning - Important safety instructions:

keep these instructions in a safe place.

CAUTION! – All product installation, connection,

programming and maintenance operations must be

performed exclusively by a qualified and skilled te chnician.

Observe the following warnings:

– Never make any modifications to part of the product

other than those specified in this manual. Unauthorised operations can be the source of hazards and

malfunctions. The manufacturer declines all liability for

damage caused by makeshift modifications to the

product.

– Keep this manual in a safe place to enable future product

maintenance and programming operations.

– The product packaging material must be disposed of in full

ob servance of current local legislation governing waste

disposal.

2 - English

EN

Fig. 1 illustrates the electrical connections on the connector:

A = not used

B = electricity supply

C = relay 1 output

D = relay 2 output

E = aerial

• For models with universal connection

These models with a terminal board make universal use possible; they can be wall-mounted using screws (not provided)

or using the adhesive on the bottom of the box.

––– Electrical connections

–––

Make the connections as follows (fig. 2):

2

12345612

L1 P1 BM

1

1

2

AERIAL

Opening of the box for receivers with universal connection:

L1 P1 BM

ABCDE

1

relay 1 relay 2

relay 1 relay 2

EN

English - 3

1-2 POWER SUPPLY 12/24 V direct or alternating.

3-4 1

st

RELAY OUTPUT: clean contact of a normally open

relay.

5-6 2

nd

RELAY OUTPUT: clean contact of a normally open

relay (only on receivers with 2 channels).

1-2 AERIAL: aerial signal input.

––– Installing an external aerial

–––

If the aerial provided is in an unfavourable position and the

radio signal is weak, we recommend you improve reception

by replacing the aerial through the installation of an external

one (mod. ABF or ABFKIT). The new aerial should be positioned as high as possible and above any metallic or reinforced concrete structures in the area.

If necessary, use a coaxial cable with an impedance of 50

ohm (for example, the RG58 low-loss cable). Important! –

To reduce signal dispersion, use the shortest possible cable

(it should not exceed 10 m in length).

– Aerial connection

(only for models with universal con-

nection): connect the aerial cable to terminal 1 and 2 (fig.

2): terminal 1 = sheath; terminal 2 = core.

– Aerial connection for models with Nice connector

:

connect the aerial cable to the purpose-provided terminals

on the control unit.

• For all models:

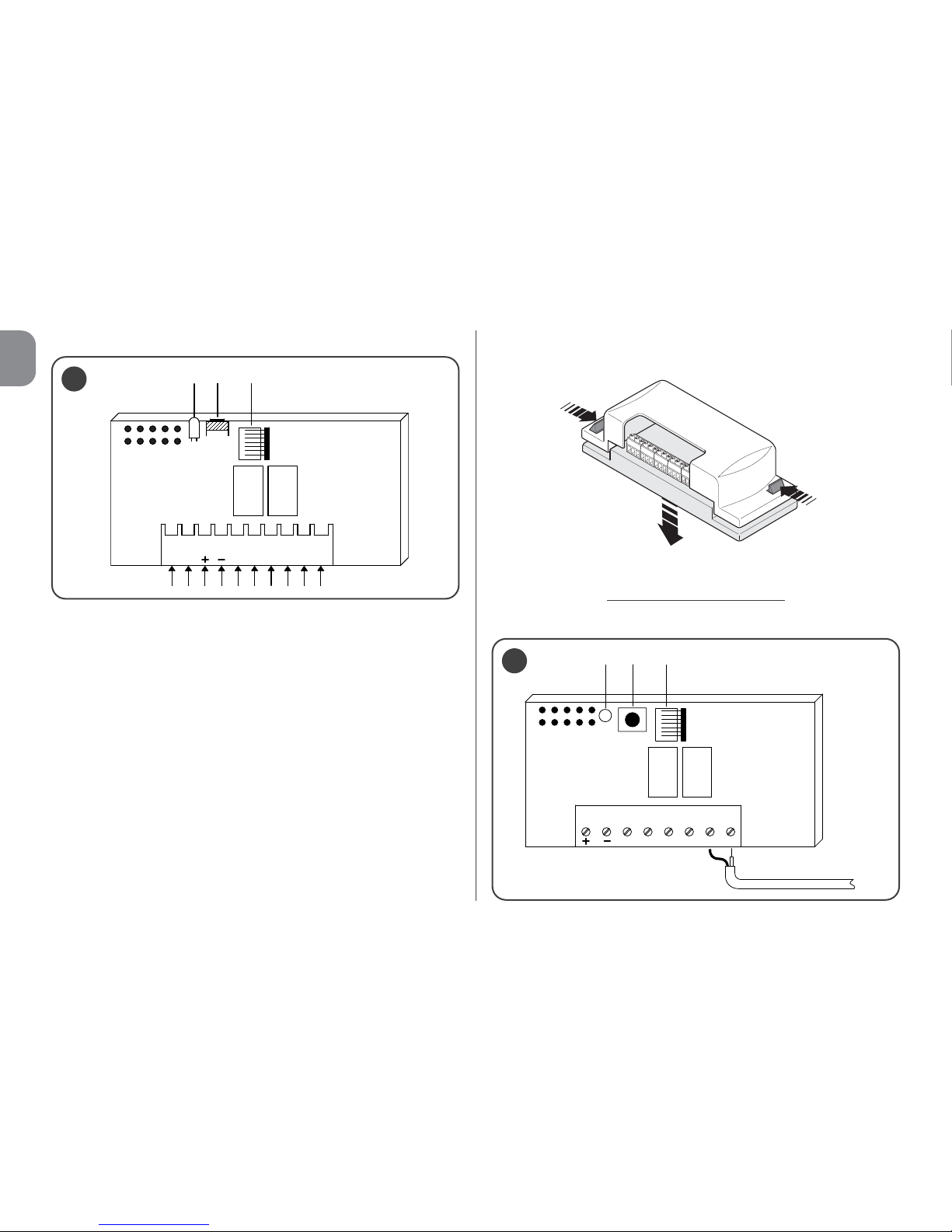

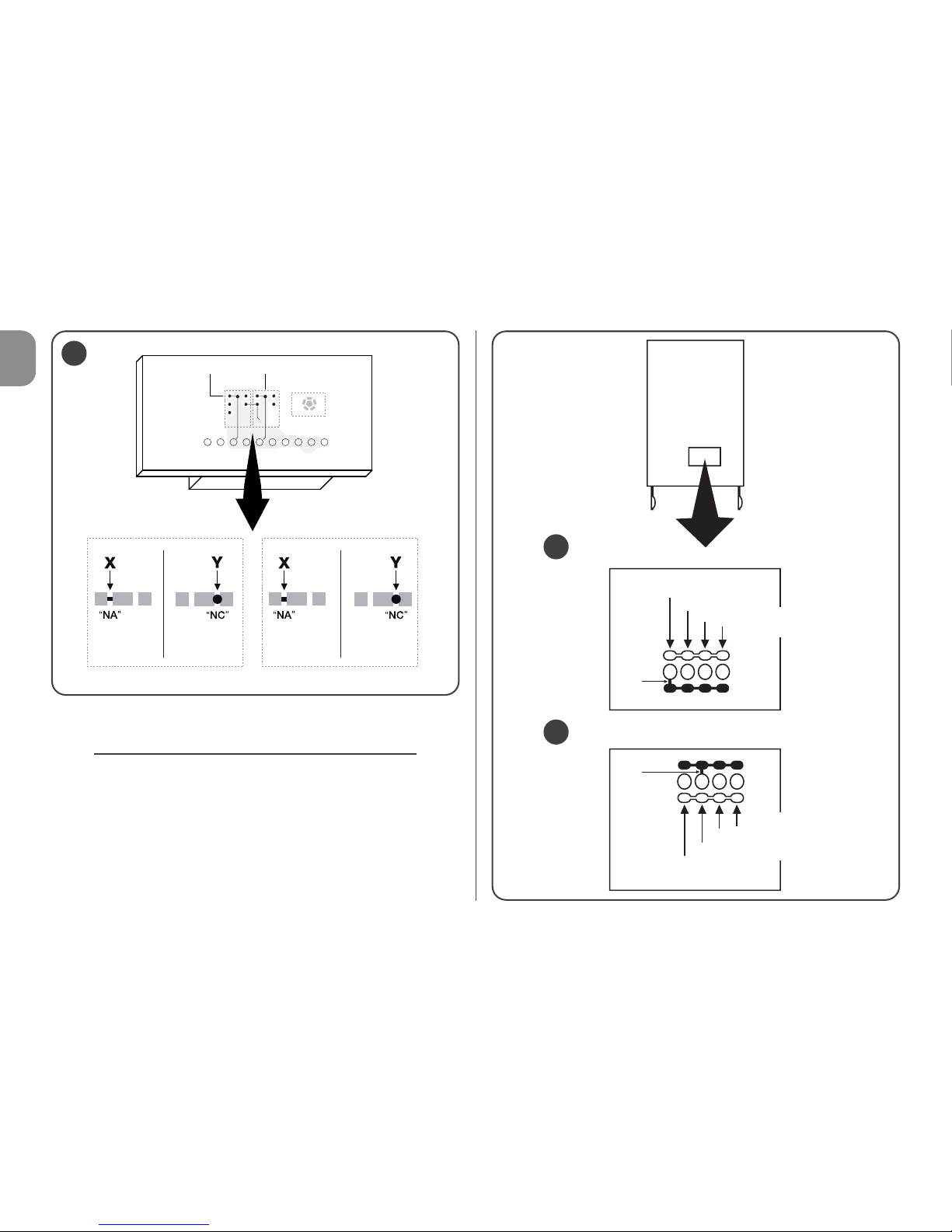

––– Relay selection on channels –––

Each receiver is designed to recognise all 4 keys on the

transmitter. This is possible thanks to the association of the

output relays with the desired key, through an electric jumper

which should be inserted in the purpose-provided connectors: see Table 1.

––– How to obtain “NC” type contacts

–––

The outputs are operated by 2 relays with a “NO” (normally

open) type contact. If you want to achieve a “NC” (normally

closed) contact, proceed as follows:

01. Disconnect the electrical power supply to the receiver.

02. Remove the board carefully and turn it over: the side

with the welding should be facing you.

03. On the side with the welding, carry out the following

steps (fig. 3):

– Cut the section of line at point “X”.

– Using a drop of tin, join the spots at points “Y”.

Note – these changes can be made on one relay or on both,

depending on your requirements.

Key: 1

TABLE 1

Relay 1 Output Relay 2 Output (where present)

Key: 2

Key: 3

Key: 4

4 - English

EN

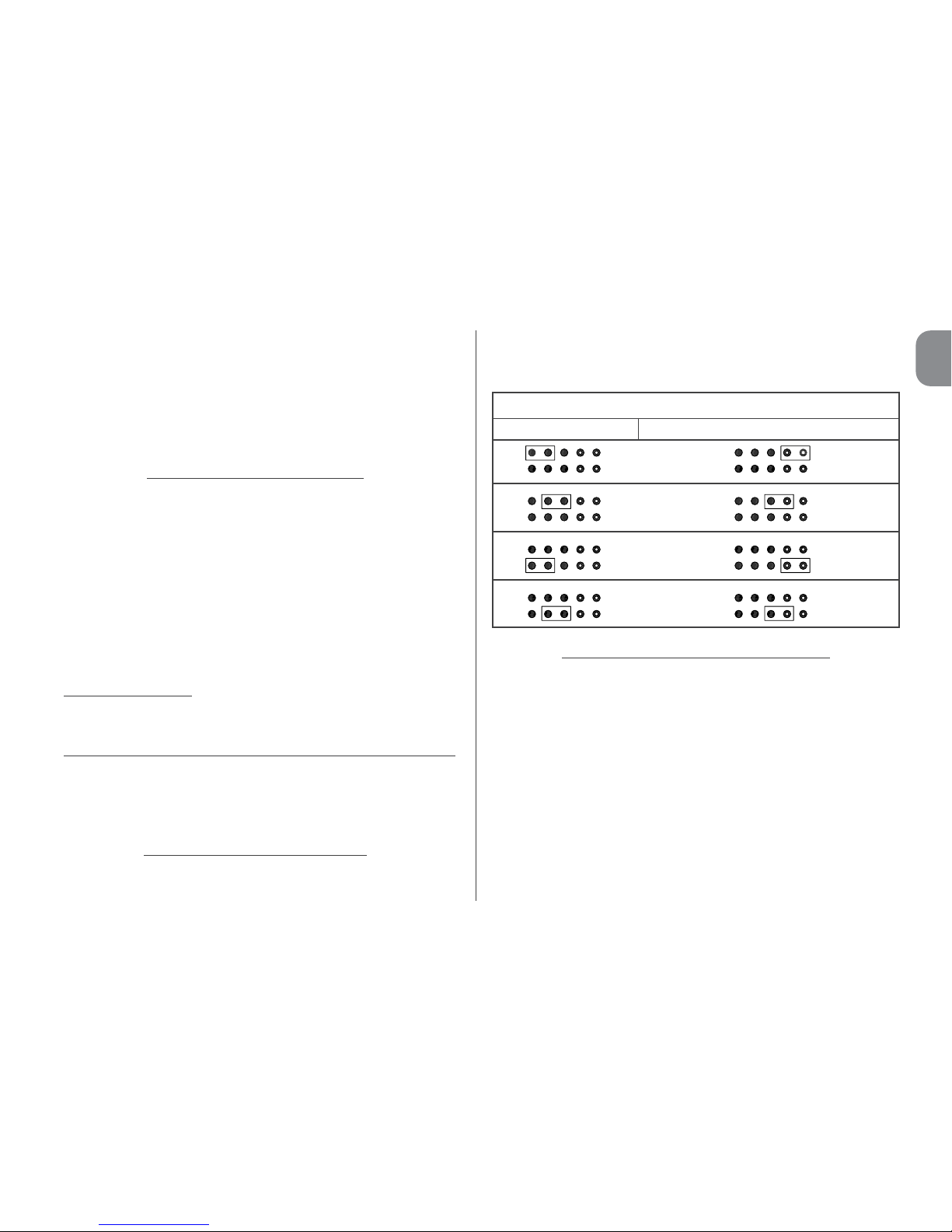

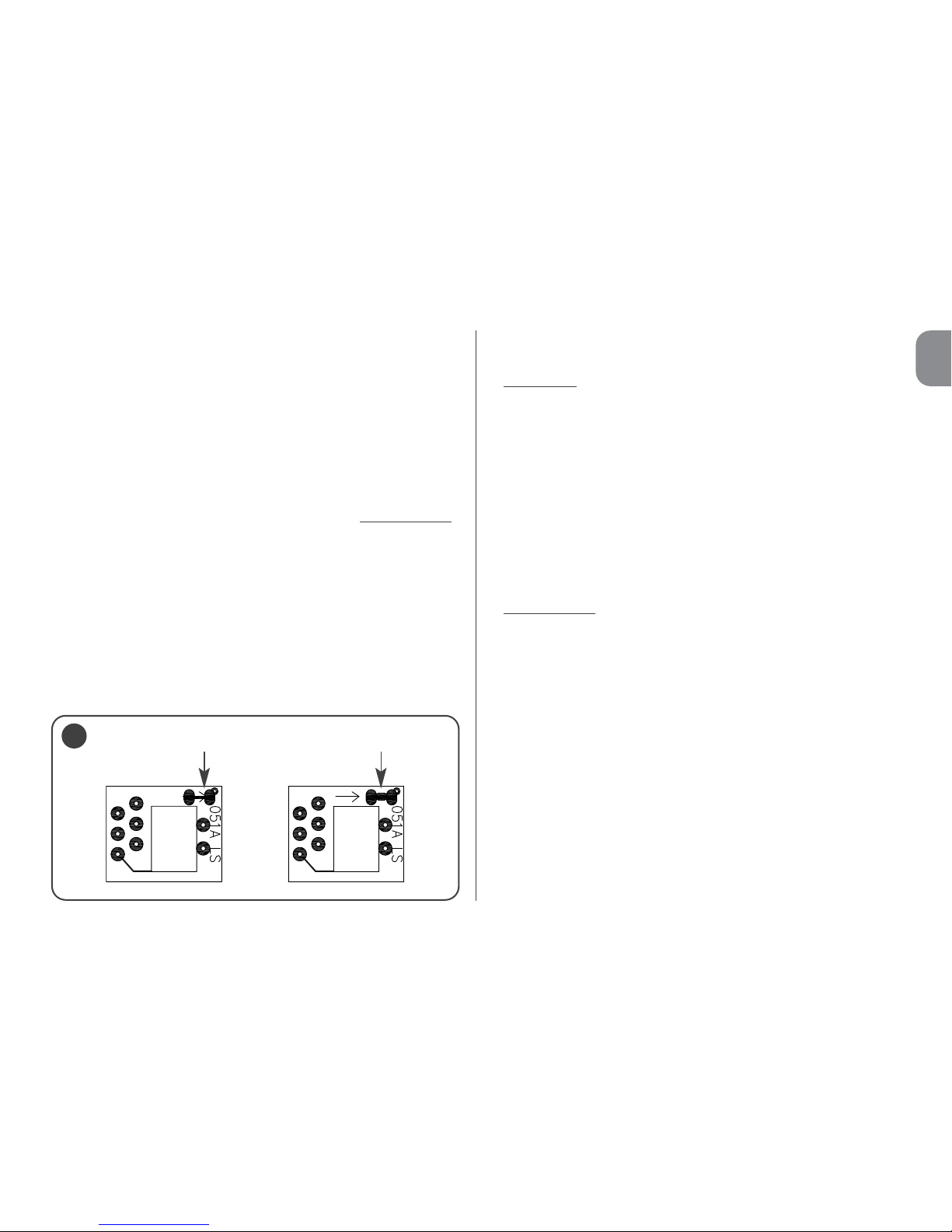

––– Selecting the channel on the transmitter –––

On the FLOR series of transmitters, the association of the

transmitter key with the receiver channel can be modified:

• For key 1 of the transmitter, proceed as shown in fig. 4a:

cut the track that associates key 1 with channel 1 and connect one of the other spots on the right with a drop of tin, to

obtain the association with channel 2, 3 or 4.

• For key 2 of the transmitter, proceed as shown in fig. 4b.

4a

4b

1stCHANNEL

2

nd

CHANNEL

1stCHANNEL

2ndCHANNEL

3rdCHANNEL

4thCHANNEL

2ndKEY

1

st

KEY

CUT

CUT

4thCHANNEL

3

NA NC

3rdCHANNEL

relay 2 relay 1

relay 2 relay 1

EN

English - 5

4 – PROGRAMMING

Warnings

The programming featured in this chapter requires the

use of key P1 and of LED L1 on the receiver (fig. 1). To

indicate the status of the activity under way, the LED

emits a specific number of flashes for a specific amount

of time. To find out the meaning of these indications,

please consult Table 2.

To facilitate programming, you ca use the BUPC and OBox

programmers.

TABLE 2

SIGNALS EMITTED BY LED L1 ON THE RECEIVER

–– SLOW 1/2 second FLASH ––

1 ✺ =

The code received is not among those authorised.

2 ✺ = Recognition time over without success.*

3 ✺ = Recognition successfully completed (code authorised).

4 ✺ = The code is already in the list of those authorised.

5 ✺ = The list is empty (no code).

6 ✺ = The list is full (there is no room for any more codes).

7 ✺ = The deletion of a non-existent code has been requested.

8 ✺ = Different codes were received during the recognition phase.

9 ✺ = Password entered.

* Note

- If the software memor

y lock is activated

, the 2nd flash is longer

than the 1st one

- If the software memor

y lock is deactivated

the two flashes are

the same.

–– FAST 1/4 second FLASH ––

• During initialisation

:

1 ✺ = A BM60 memory is present

2 ✺ = A BM250 memory is present

3 ✺ = A BM1000 memory is present

4 ✺ = The memory has codes entered which are not from the

Flor version

5 ✺ = An error was detected during memory reading

• During operation

:

1 ✺ = The code received is a “copy”; only “original” codes are

valid.

3 ✺ = The code is not inside the codes window, but it has been

resynchronised.

4 ✺ = The code is not inside the codes window and resynchroni-

sation is locked.

5 ✺ = The code is not inside the codes window and resynchroni-

sation is not possible.

The receiver is fitted standard with the BM250 memory

which can store up to 63 codes; when the receiver is powered, it displays the type of memory used with various flashes of LED L1 (fig. 1), see Table 2.

The usable memories are as follows:

– memory BM60 = 16 storable codes

– memory BM250 = 63 storable codes

– memory BM1000 = 255 storable codes

The memory contains all the transmitter codes stor

ed; to

obtain maximum safety and avoid the accidental storage of

foreign codes, you can lock the code recognition function

(see paragraph 6.1 - Locking the memory).

6 - English

EN

4.1 – Storage of a transmitter

A transmitter (its code) can be stored in the memory of a

receiver in two ways:

- rapid mode

- standard mode

4.1.1 – Rapid mode

This is the quickest mode to use, but it is not extremely safe

because during the code storage operation, the receiver

may acquire a different signal from another transmitter within

its operating range and store it by mistake. We recommend

you assess this risk before selecting your storage mode.

01. Press and keep key P1 (fig. 1) on the receiver pressed:

LED L1 is turned on;

02. Press any key on the transmitter and transmit the code

until LED L1 on the receiver is turned off;

03. Then release the key on the transmitter: LED L1 is

turned back on and the receiver is ready for another

task;

04. To store the other transmitters, repeat the process from

step 02. When storage is complete, release key P1 on

the receiver.

4.1.2 – Standard mode

01. Press and release key P1 (fig. 1) on the receiver; LED L1

is turned on for 5 sec.;

02. During these 5 sec. transmit the code until LED L1 on

the receiver is turned off;

03. Then release the key on the transmitter and wait for 1

sec.;

04. Press and keep any key on the transmitter pressed, to

send the code, until LED L1 on the receiver is turned off;

the LED will emit three flashes to indicate that the

process was successful;

If this does not happen, then repeat the process.

05. To store the other transmitters, repeat the process from

step 01.

N.B. – To avoid the storage in the receiver of a signal casually transmitted by a transmitter which has nothing to do with

the automated system in question, the BM memory can be

locked; please see paragraph 5.4.

4.1.3 – Storage of a transmitter using the procedure ‘in

the vicinity of the receiver’ (with a transmitter

already stored)

A NEW transmitter can be stored in the memory of the

receiver without intervening directly on the key of this receiver, but simply by operating in its range of reception. To implement this procedure, you need to have an OLD transmitter at

hand, which has already been stored and is operational.

Warnings:

• The procedure must be performed while operating in

the range of reception of the receiver (10-20 m from

the receiver).

• Repeat the entire process for each transmitter you

wish to store.

01. On the NEW transmitter, keep key... pressed for at least

5 seconds. and then release it.

02. On the OLD transmitter, press key ....three times and

then release it.

EN

English - 7

03. On the NEW transmitter, press the same key as in step

01 once and then release it.

4.2 – Total deletion of the receiver memory

WARNING! – When you do this, the software lock function is

also deleted and the "Timer" is automatically set to 3 sec.

01. Press and keep key P1 (fig. 1) on the receiver pressed:

after 3 sec. LED L1 is turned off;

02. When LED L1 starts flashing again, on the 3rd flash,

release key P1 and wait approximately 3 sec.;

03. As soon as LED L1 is turned back on, press key P1 and

release it as soon as the LED is turned off.

Depending on the type of memory fitted on the receiver, the

process may take a few seconds. During this phase, LED L1

flashes quickly, followed by 5 slow flashes to indicate that

total deletion was successful and that the memory is empty.

If this does not happen, then repeat the process.

4.3 – Deletion of a single transmitter from the

receiver memory

01. Press and keep key P1 (fig. 1) on the receiver pressed

for approximately 3 sec.: LED L1 is turned off, then

release the key;

02. Press and keep any key on the transmitter pressed, to

send the code, until LED L1 on the receiver is turned off;

03. Release the key on the transmitter and wait 1 sec.;

04. Press and keep any key on the transmitter pressed, to

confirm: LED L1 emits 1 flash to indicate that the code

has been deleted.

If this does not happen, then repeat the process from

step 01.

5 – OTHER FUNCTIONS

Usually the output relay function is momentary: i.e. the relays

are activated a few seconds after a key is pressed on the

transmitter (delay due to the code recognition time) and the

activation ends 300 mS after the receipt of the last valid

code.

Below is a description of other special functions, available for

the output relays.

IMPORTANT! – To activate the special functions, you

will need to use a small drop of tin, see fig. 5.

5.1 – STEP-STEP Function

The relay is activated by pressing a key on the transmitter

and it remains activated even after the key has been

released; the key needs to be pressed again to deactivate

the relay.

5.2 – TIMER Function

The relay is activated by pressing a key on the transmitter

and it remains activated until the programmed amount of

time lapses. The countdown of the programmed time

restarts every time the key on the transmitter is pressed

again and it can be stopped early by keeping the same key

pressed for at least 3 sec.

5.2.1 – Programming the timer

To program the timer, you need to activate the TIMER func-

8 - English

EN

tion (electric jumper 3, fig. 5). If - during programming - you

prefer the relays not to be activated, you will need to remove

the electric jumper for the channel selection temporarily.

Programming

01. Press and keep key 1 of an operational transmitter

pressed;

02. Within 3 sec., also press and keep key P1 (fig. 1) on the

receiver pressed and then release the key on the transmitter;

03. Keep key P1 pressed for the time you wish to program

(max 2 h 30’) and then release key P1.

At this stage, the desired time has been stored and

remains valid until a new programming is performed.

Note – During the timer programming phase, the normal

operation of the receiver is inhibited.

5.3 – BURGLAR ALARM Function

Activate this function to obtain the combined function of

relays 1 and 2. Press key 1 on the transmitter to obtain the

"Step-step" function on relay 1 of the receiver (this function is

suitable for enabling/disabling a burglar alarm).

Concurrently, relay 2 (where present) performs 1 brief activation when relay 1 switches from OFF to ON and 2 brief activations when relay 1 switches from ON to OFF.

This way, relay 2 can be connected to an optical or acoustic

signal which can be used to notify that a burglar alarm has

been enabled/disabled.

Note – If this function is activated, relay 2 maintains its normal operation associated with key 2 of the transmitter.

NA NC

5

NO JUMPER all channels momentary

JUMPER 1 1 step-step....2, 3, 4 momentary

JUMPER 2 1, 2 step-step....3, 4 momentary

JUMPER 3 1 timer....2, 3, 4 momentary

JUMPER 4 1 + 2 burglar alarm....3, 4 momentary

JUMPER 5 all channels step-step

relay 2 relay 1

EN

English - 9

5.4 – Locking the memory

There are two ways to do this:

– Locking the memory via the hardwar

e (paragraph 5.4.1)

– Locking the memory via the softwar

e (paragraph 5.4.2)

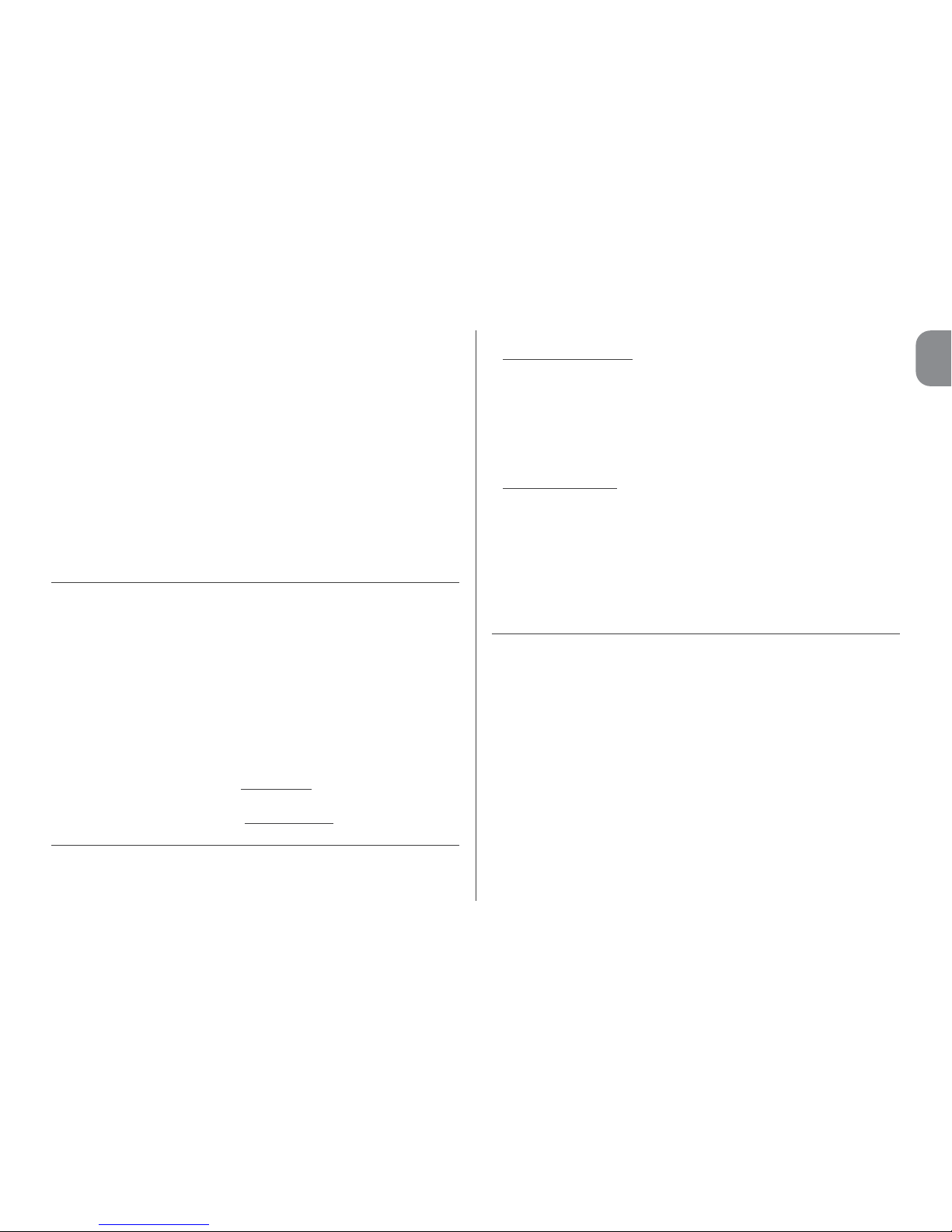

5.4.1 – Activating the memory lock: hardware

This locking mode is very simple to perform but it is not very

safe. Indeed, it can easily be cancelled by outsiders.

IMPORTANT! – The memory enabling/disabling operations must be performed with the receiver not powered

.

After inserting the desired transmitter codes, proceed as

shown in fig. 6: cut (X) the track indicated by the arrow.

If you later wish to insert other codes, proceed as shown in

fig. 6: join (Y) the two spots with a drop of tin.

5.4.2 – Activating and deactivating the memory lock:

software

This is a safer way to activate the memory lock. In fact, you

need to have a transmitter that has already been stored in

the receiver to deactivate it.

• Activating

the memory lock

01. Press and immediately release key P1 (fig. 1) on the

receiver;

02. Wait for LED L1 to flash twice, indicating the time is up

(approx. 5 sec.) and at the 2nd flash, press key P1 and

then release it when LED L1 is turned off.

Next, LED L1 emits two flashes: if the second flash lasts

longer than the first, this means that the memory lock has

been activated. If the flashes last the same, this means that

the memory lock has not been activated. In this case, repeat

the process from step 01.

• Deactivating

the memory lock

To deactivate the memory lock, you need to have a transmitter that has already been stored. Proceed as follows:

01. Press and immediately release key P1 (fig. 1) on the

receiver: LED L1 is turned on for 5 sec.;

02. During these 5 sec. press any key on the transmitter, to

transmit the code, until LED L1 is turned off;

03. Then release the key on the transmitter and wait for 1

sec.;

04. Press and keep any key on the transmitter pressed, to

send the code: LED L1 will emit 4 flashes to indicate that

that code is already on the list;

05. During the 4th flash, press key P1 and release it when

LED L1 is turned off.

Next, LED L1 will emit 2 flashes for the same amount of time,

which means that the memory lock is no longer activated.

X Y

6

10 - English

EN

If this does not happen, then repeat the process from step 01.

The memory lock can also be activated in a safer and more

controlled way: using a “PASSWORD”: this method can only

be implemented with the use of the BUPC and OBox programmers.

EN

English - 11

DISPOSING OF THE PRODUCT

This product is an integral part of the automation system,

and should therefore be disposed of together with it.

As for the installation operations, even at the end of this

product's life span, the dismantling operations must be carried out by qualified experts.

This product is made up of various types of materials: some

can be recycled while others need to be disposed of. Find

out about the recycling or disposal systems envisaged by

your local regulations for this product category.

Important! – parts of the product could contain pollutants or

hazardous substances which, if released into the environment,

could cause harmful effects to the environment itself as well as

to human health.

As indicated by the symbol opposite,

throwing away this product as domestic

waste is strictly forbidden. So dispose of it

as differentiated waste, in accordance with

your local regulations, or return the product to the retailer when you purchase a

new equivalent product.

Important! – the local applicable regulations may envisage

heavy sanctions in the event of illegal disposal of this product.

PRODUCT TECHNICAL SPECIFICATIONS

WARNINGS: • All technical specifications are referred to a

room temperature of 20°C (± 5°C). • Nice S.p.a. reserves the

right to make any changes deemed necessary to the product at any time while maintaining the same functions and

intended use. • The operating distance between transmitters

and receivers (range) is heavily influenced by other devices

operating in the vicinity at the same frequency (for example

headphones, alarm systems, etc.). In such cases, Nice cannot provide any guarantee as regards the effective range of

its devices.

• Decoding: “FloR”

• Power supply: 12-24 V direct or alternating. Limits from

10 to 28 V

• Power consumption when idle: 16 mA at 24 VDC

• Power consumption with 2 relays active: 80 mA at 24

VDC

• Reception frequency: 433.92 MHz

• Sensitivity: better than 0.5 μV

• No. of relays: 1 or 2 depending on the model

• Normally open relay contact: max 0.5 A and 50 V SELV

• Operating temp.: from –20° C to +55° C

• Protection rating: IP 30

• Dimensions and weight: 58 mm x 86 mm x H 22 mm; 55 g

12 - English

EN

EC DECLARATION OF CONFORMITY

Note – This Declaration of Conformity gathers the contents of all the individual declarations of conformity of each product mentioned herein; it is updated to the date of publication of this manual and was re-adapted for publishing purposes.

A copy of the original declaration for each product can be requested from Nice S.p.a. (TV) I.

Number: 201/FLOX Revision: 2

The undersigned Luigi Paro, as Managing Director, declares on his own responsibility that the product:

Name of manufacturer: NICE s.p.a.

Address: Via Pezza Alta 13, Z.I. Rustignè, 31046 Oderzo (TV) Italy

Type: 433.92MHz receiver for the remote control of automated gates, doors, blinds, awnings,

shutters and similar applications

Models: FLOX1, FLOX2, FLOXI, FLOXB2, FLOXI2, FLOXM, FLOXM220

Accessories:

Compliant with the essential requirements provided for in Art. 3 of the following EC directive, for the use for which the

products are intended:

• 1999/5/EC DIRECTIVE 1999/5/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 9 March 1999 concerning radio equipment and terminal telecommunications units and the reciprocal acknowledgment of their compliance

In accordance with the following harmonized standards health protection: EN 50371:2002; electrical safety:

EN 60950-1:2006;

electromagnetic compatibility: EN 301 489-1V1.8.1:2008; EN 301 489-3V1.4.1:2002; radio spectrum:

EN 300 220-2 V2.1.2:2007

Oderzo, 20

th

March 2009 Luigi Paro (Managing Director)

D0865 Rev2

Loading...

Loading...