NIBCO W-910-B-LF Installation Manual

|

|

|

|

|

|

N I B C O I N C . |

1 5 1 6 M I D D L E B U R Y S T. |

P H O N E : 5 7 4 . 2 9 5 . 3 0 0 0 |

|

|

W O R L D H E A D Q U A R T E R S |

E L K H A R T, I N 4 6 5 1 6 - 4 7 4 0 |

F A X : 5 7 4 . 2 9 5 . 3 3 0 7 |

|

|

|

|

U S A |

W E B : w w w . n i b c o . c o m |

|

|

|

||

|

|

|

|

|

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

Review Date: 01/18/2012

Original Date: 04/07/1996

Operating, Maintenance and Installation Instructions for NIBCO® Flanged End and Wafer Style Check Valves (Series 910 & 960)

WARNING NOTICE:

1.Damage to the valve and/or internal leakage may result if pipe flanges other than those with standard flat faces, conforming to ANSI B16.5 or AWWA C207-86, are used. Flanges having an expanded inside diameter (often found on mortar lined pipe) cannot be used on the inlet side of the valve. A ring flange having a maximum inside diameter as shown in “A” dimension (see next page) must be inserted between the valve and mortar lined pipe flange.

2.Proper centering of ring gasket is important to prevent internal valve leakage.

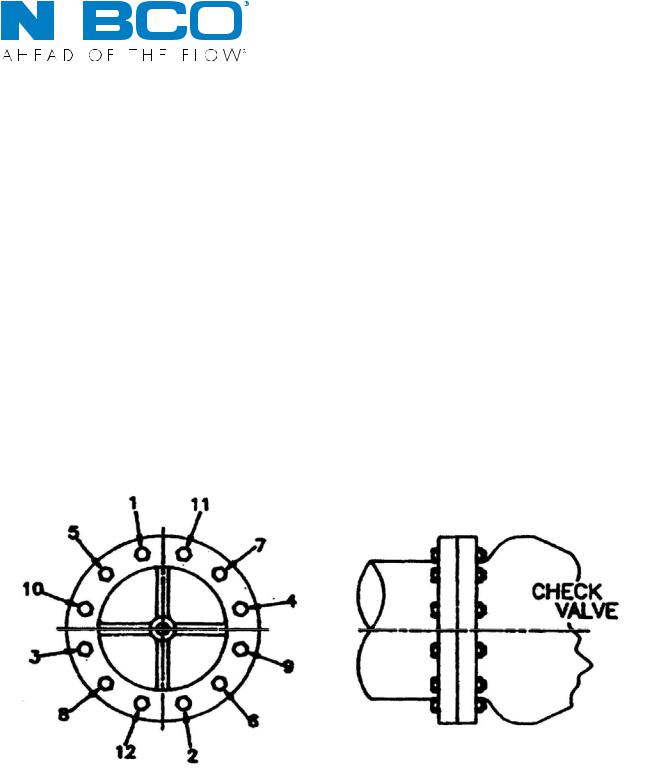

3.The valve and adjacent piping must be supported and aligned to prevent stress from being transferred to the valve’s flanges. The torquing of the flange bolts should then be done in several graduated steps, using the number sequence shown below. This even loading of the flange bolts will eliminate concentrated stresses which could fracture the valve’s flange.

CAUTION: Only qualified personnel should undertake the procedures outlined in this document. NIBCO INC., its agents, representatives and employees assumes no liability for the use of these procedures. These procedures are offered as suggestions only.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

1

Loading...

Loading...