NX242 Digital TDcontroller

Service Manual

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual r ev10060 6

P.

2

Declaration of conformity

This equipment has been tested and found to comply with the safety objectives and essential requirements of European (73/23/EEC and

89/336/EEC directives) and international Standards, by fulfilling the requirements of the following harmonized standards:

Electrical Safety (EU) : IEC 60065 (12/2001) Audio, video and similar electronic apparatus

Electrical Safety (US) : UL60065 Seventh Edition, dated June 30, 2003 category AZSQ, E241312.

Electrical Safety (CAN) : CSA-C22.2 N°60065:03 Edition, dated April 2003 category AZSQ7, E241312

10CE

A

udio Equipment

10CE

A

udio Equipment

Electrical Safety (Rest of the World) : CB test certificate DK-8371 based on IEC60065-2001 7nd ed. with all national deviation s.

Radiated Emission (EU) : EN55103-1 (1996) Electromagnetic compatibility - Product family standard for audio, video, audiovisual and entertainment lighting control apparatus for professional use.

Radiated Emission (US) : FFC part15 class B

Radiated Emission (CAN) : This Class B digital apparatus complies with Canadian ICES-003.

RF Immunity (EU) : EN55103-2 (1996) Electromagnetic compatibility - Product family standard for audio, video, audio-visual and

entertainment lighting control apparatus for professional use.

Note: EMC conformance testing is based on the use of recommended cable types. The use of other cable types may degrade EMC

performances.

IMPORTANT SAFETY INSTRUCTIONS

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with dry cloth.

7) Do not block any ventilation openings. Install in accordance with the

manufacturer’s instructions.

8) Do not install near any heat sources such as radiators, heat registers, stoves, or

other apparatus (including amplifiers) that produce heat.

9) Do not defeat the safety purpose of the polarized or grounding-type plug. A

polarized plug has two blades with one wider than the other. A grou nding type plug

has two blades and a third grounding prong. The wide blade or the third prong are

provided for your safety. If the provided plug does not fit into your outlet, consult an

electrician for replacement of the obsolete outlet. (US market)

10) Protect the power cord from being walked on or pinched particularly at plugs,

convenience receptacles, and the point where they exit from the apparatus.

11) Only use attachments/accessories specified by the manufacturer.

13) Unplug this apparatus during lightning storms or when unused for long periods of

time.

14) Refer all servicing to qualified service personnel. Servicing is required when the

apparatus has been damaged in any way, such as power-supply cord or plug is

damaged, liquid has been spilled or objects have fallen into the ap paratus, the

apparatus has been exposed to rain or moisture, does not operate normally, or has

been dropped.

Information about products that generate electrical noise :

NOTE: The United States Federal Communications Commission (in 47 CFR 15.105)

has specified that the following notice be brought to the attention of users of this

product:

This equipment has been tested a nd found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are de sign ed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the inte rfe rence by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

The user may find the following booklet, prepared by the Federal Communications

Commission, helpful: How to identify and Resolve Radio/TV Interference Problems.

This booklet is available from the U.S. Government Printing Office, Washington,

D.C. 20402, Stock No. 004-000-00345-4. Use of a shielded cable is required to

comply within Class B limits of Part 15 of FCC Rules. Pursuant to Part 15.2 1 of the

FCC Rules, any changes or modifications to this equipment not expre ssly approved by

NEXO S.A. may cause, harmful interference and void the FCC authorization to

operate this equipment.

To avoid electrical shock, do not remove covers.

Dangerous voltages exist inside.

Refer all servicing to qualified personnel only.

WARNING: To reduce the risk of fire or electric shock,

do not expose this apparatus to rain or moisture.

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

The lightning flash with arrowhead

symbol, within an equilateral triangle

is intended to alert the user to the

presence of uninsulated “dangerous

voltage” within the product's

enclosure that may be of sufficient

magnitude to constitute a risk of

electric shock to persons.

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and

maintenance (servicing) instructions

in the literature accompanying

the appliance.

WARNING ! This appliance is a CLASS 1 apparatus and must be earthed.

The green and yellow wire of the mains cord must always be connected to an installation safety earth or ground. The earth is essential for

personal safety as well as the correct operation of the system, and is internally connected to all exposed metal surfaces. Additional

recommendation for interconnection to other equipment can be found in the FOREWORD at the beginning of this manual

P.

3

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual r ev10060 6

Table of content

IMPORTANT SAFETY INSTRUCTIONS.........................................................................................................................2

FOREWORD..........................................................................................................................................................................4

SAFETY INSTRUCTION.....................................................................................................................................................4

HISTORY................................................................................................................................................................................5

MECHANICAL ISSUES ....................................................................................................................................................... 6

REMOVING THE TOP PANEL.....................................................................................................................................................6

REMOVING THE PCB...............................................................................................................................................................6

HARDWARE PROBLEM ON NX242 S.N. 3880 TO 4049.................................................................................................7

ABSTRACT ................................................................................................................................................................................7

HARDWARE CORRECTION .......................................................................................................................................................7

HARDWARE FIX FOR THE NXTENSION-CAI AND THE NXTENSION-ES4.........................................................11

ABSTRACT ..............................................................................................................................................................................11

HARDWARE CORRECTION .....................................................................................................................................................11

PART LIST...........................................................................................................................................................................14

CRITICAL COMPONENTS........................................................................................................................................................14

SCHEMATICS.....................................................................................................................................................................26

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual r ev10060 6

P.

4

Foreword

CAUTION !

This servicing instruction is for use by qual ified servi ce personnel only. To reduce the risk of electric shock

do not perform any servicing other than that contained in the operating instructions unless you are

qualified to do so.

Safety instruction

Mains Power

WARNING ! THIS APPLIANCE MUST BE EARTHED.

The green and yellow wire of the mains cord must always be connected to an installation safety earth or

ground. The earth is essential for personal safety as well as the correct installation of the system, and is

internally connected to all exposed metal surfaces. Any rack framework into which this unit may be

mounted is assumed to be connected to the same grounding ci rcuit. (see also p.4)

NEXO TDcontrollers don’t provide a mean to switch off the unit from the front pa nel. A s they are inte nde d

to be rack mounted the back panel is not accessible during use. There fore it is left to the us er to pro vide a

disconnection mean readily operable.

Voltage setting

NEXO TDcontrollers use a switch mode power supply (SMPS). This SMPS acc ep ts u n i versal AC power

input voltages in the range 90V to 264V, and requires no manual adjustment for voltages in this range.

Mounting the TDcontroller in a rack (G rounding, shielding & safety issues)

The TDcontroller is intended for rack mounting. The only accessible part during use shall be the front

panel of the TDcontroller. Any space above or under the TDcontroller shall be obstructed with a blank

panel.

The rack is a free grounding and shielding structure and it provides extra shielding. Therefore, it is

desirable that the screws used to fix the TDcontroller in the frame or rack provide an electrical contact

between the chassis of the TDcontroller an d the rack.

The primary reason for grounding is safety. Co nforman ce to t he appli cable req uirem ent s of the authoritie s

having jurisdiction is, of course, mandatory. However, grounding also has an impact on electromagnetic

compatibility. From the EMC point of view, it is desirable to have a low impedance ground network, as a

current flowing in the ground network will then produce low voltage in the network. A low impedance

network can be obtained using a multipoint ground scheme, with as many closed ground loops as is

economically possible.

Fuse

The fuse provided in the unit will not blow during normal operation. If the fuse blows the TDcontroller

has malfunctioned. This fuse must only be ch anged by NEXO ce rtified service personnel. In a ny case do

not replace the fuse with a non-certified NEXO fuse, as this will invalidate the NEXO warranty.

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcont roller S ervic e manual rev100 606

P.

5

History

Partlist PCB ref note S/N Date

V1.0 NX242 V1.8 initial

NX242 V2.0 Minor points fixed for

UL approval

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual rev 10060 6

P.

6

Mechanical issues

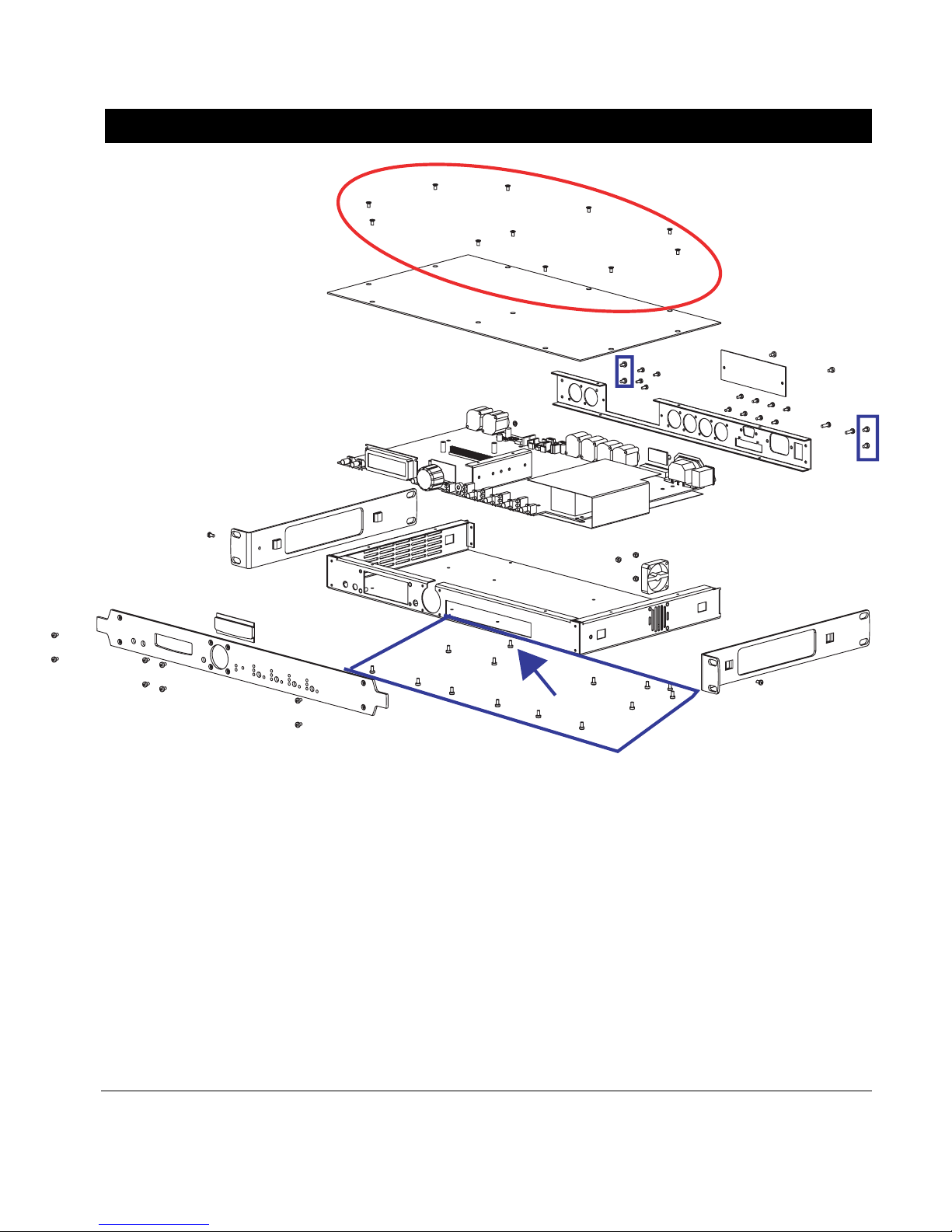

Removing the top panel

First be sure that the NX242 is disconnected from the m ains. Wait 5 minute s to discharge the capa citors

To remove the top panel; unscrew the 11 screws circled in red in the above drawing (POZIDRIVE screwdriver).

When replacing the top panel pay attention to the 2 screws which are above the aluminum heatsink. They

should be screwed with a lesser torque than the other to avoid damagi ng the aluminum th reading.

WARNING: Some of the NX components are sensitive to electros tatic discharges. Be sure to firmly hold the

chassis of the NX242 before touching any component inside. Always keep contact with the chassis to prevent

electrostatic discharge. If possible, use non-magnetic tools.

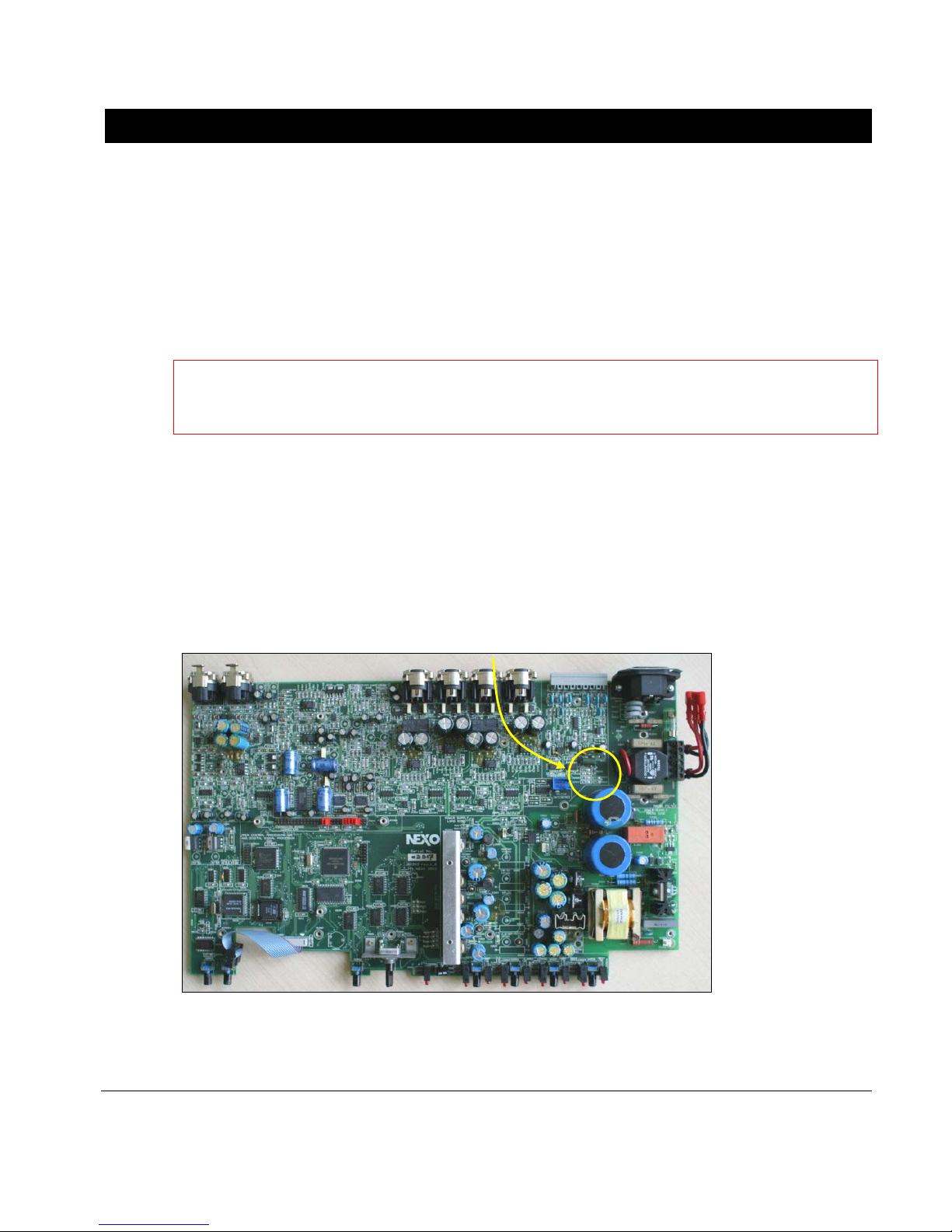

Removing the PCB

The remove the PCB; unscrew the 14 screws in blue square (POZIDRIVE screwdriver). Warning : the screw

pointed by the arrow is smaller than the other. It must be replace at the very same place to avoid so short circuit

problem (affecting slightly the overall dynamic range) on PCB v1.8

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual rev 10060 6

P.

7

Hardware problem on NX242 s.n. 3880 to 4049

Abstract

This document deals with a hardware problem that can be found on any NX242 from serial number 3880 to

4049.

The symptoms of this failure is the following:

- Crackles on the outputs patched on the A Input of the NX242 that ca n be very audibl e.

- Blinking of the Sense green LED even without amplifier connected.

Please note that in case of emergency it is always possible to use the B input of the NX242 that does not

present noise.

Also note that in most of the cases, the noise di sappears after a few mi nutes (after the NX warmed up ).

The solution to solve this problem is to remove faulty capacitors on the NX 242 PCB.

Hardware correction

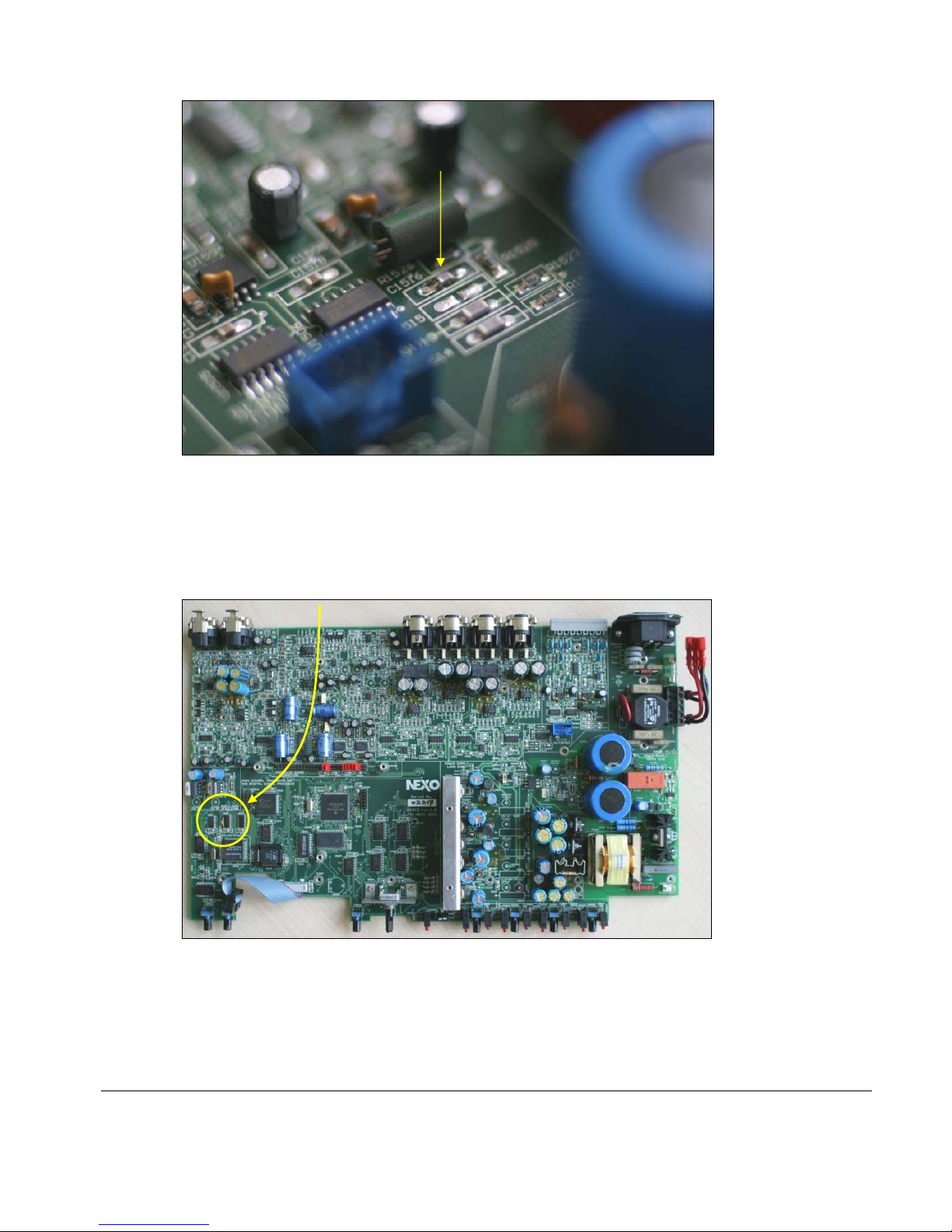

Finding and removing the C1516 co mponent

The C1516 component has been soldered on a few NX242 from serial number 3880 to 4049. In most of the

cases, this component is not present on the motherboard. If not, ple ase go on to the next chapter.

Locate the C1516 component inside the NX242.

The C1516 is a SMD capacitor.

Here is a closer look on the C1516 compo nent, near the connector for t he RS-232 Interfa ce.

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual rev 10060 6

P.

8

Remove this component with a soldering iron. Be sure to let a clear path between the two pad s of the PCB. The

footprint should look like the footprint of the component C1515 just b ellow.

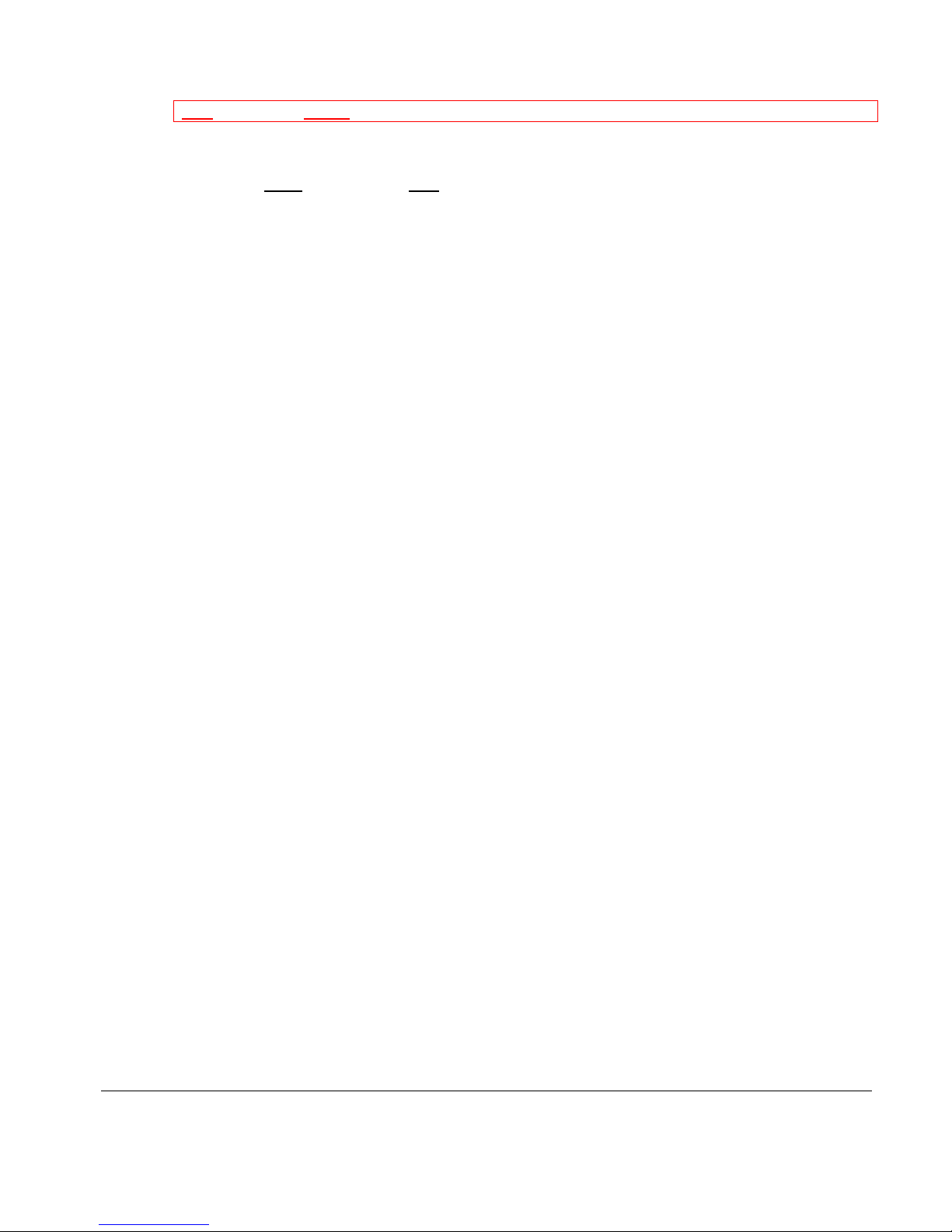

Finding and removing the “Flying” capacitor

First of all locate the Flying capacitor, on the picture bell ow:

Now have a closer look on the component U5401. This component has a traditional capacitor, that can be blue

or orange soldered between the pin 2 and t he pin 8, as you can see on the pict ure bellow.

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual rev 10060 6

P.

9

Please note that the color of the capacitor has no importance.

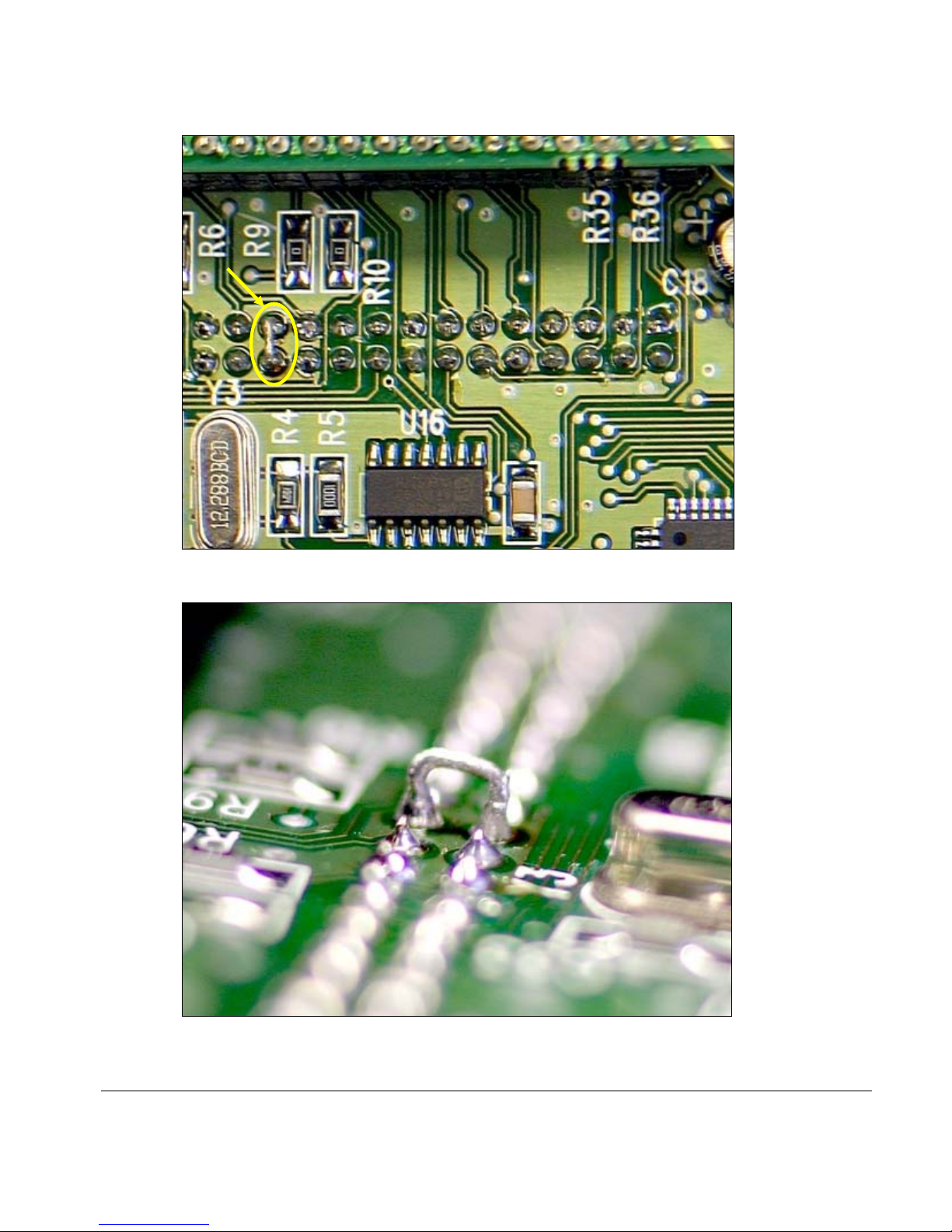

Now, please check the manufacturer of the U5401 component. From NX242 serial number 3200 to 3879, the

component should be a Texas Instrument, and from serial number 3880 to 4049, the component should be a

Philips. Here are two pictures of the possible manufacturer:

The Texas Instrument component:

The Philips component:

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcont roller S ervic e manual rev100 606

P.1

0

Only if you have a Philips component, you have to remov e the added cap acitor

You can unsolder the capacitor, or simply cut the legs as near as possible to t he legs of the Philips component.

If you have a Texas

component, you must have the capacitor betwee n the pin 2 and the pin 8 of U5401.

Once this operation is finished, replace the cover of the NX242, with all of the screws, as they are important for

the shielding of the digital section of the controller. When you power up the unit again, it should boot normally,

and none of your settings should be lost. Check that the noise has disappeared on all the outputs (be sure to

check the input A of the controller).

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual rev 10060 6

P.11

Hardware fix for the Nxtension-CAI and the Nxtension-ES4

Abstract

This document deals with a hardware problem that can be fou nd on Nxtension card with:

- Serial number up to 695 for Nxtension-ES4

- Serial number up to 299 for Nxtension-CAI

The symptoms of this failure are the following:

- Crackles or noise on all the outputs that can be permanent or punctual.

- When using an Nxtension-ES4, the noise disappea rs when switching from Analog to Digital input.

Also note that this problem mostly occurs with Nxtension-CAI cards.

The solution is to connect to a fixed potential a pin on the Nxtension board whi ch was left floating.

Hardware correction

First and foremost, be sure to disconnect the NX242 from the mains before opening the top cover. Once the top

cover of the NX242 is open, you can directly do the hardware correction on t he Nxtension -board itself.

Then locate the large header on the Nxtension card like on the picture above. On this header, you will have to

solder a jumper between two pins (one next to the other). These two pins are located 17 pins from the left or 12

pins from the right (see the picture bellow).

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontr oller S ervice manual rev 10060 6

P.1

2

Bellow is a side view of the soldering: a hard wire is the best solution has it will be less sensible to vibration.

Once it is done, screw the cover back, and check that the NX is booting normally. Check that the audio is

passing through without any problem.

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcont roller S ervic e manual rev100 606

P.1

3

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontroller S ervice manual r ev10060 6

P.1

4

Part list

Critical components

Due to the UL and CB scheme certifications the components marked

shall never be changed with an equivalent part (unless stated in the list below). In case of failure,

the exact same type and reference shall be used. Failing to do so will void th e warranty and the UL re sponsibility and certification.

PCB reference Qty

Reference

Power Supply

L2504

1 Choke, high power, Inductance, radial

10 uH

Panasonic - ELC08D100E

Q2502 1 Hexfet Power MOSF ET

International Rectifier - IRFBE30

Q2501 1 Transistor power TO-220, TIP50

On Semiconductor - TIP50

D2501 D2506 2

Diode, Ultra fast Power rectifier Motorola - MURS160T3

D2504 D2505 2

Diode, schottky power rectifier ST - STPS340U

D2509 1 Diode, Schottky Rectifier, TO220

International Rectifier - 43CTQ100

L2501 1 Choke, EMI suppression, ferrirte core, AXIAL, 800mA, 10%

47 uH Epcos - B82144A2473J000

L2502 L2503 2

Choke, high power, 1.3A, RADIAL 47 uH Panasonic - ELC08D47U

D2507 D2508 2

Diode, Rectifier, Utrafast, rugged, SOT78 case Philips - BYQ28E200

C2604 C2605 C2606 C2607 C2501 C2503 6

Capacitor, Thru Hole, Electrolytic, Radial, 105°C, Low Z, p=3.5mm rating

35V

100 u

BC components - 2222 135 30101

C2521 C2522 C2523 C2524 C2525 C2526 6

Capacitor, electrolytic, Radial, 105°C, Very Low Impedance 470uF 50V (136

RVI) d=12.5mm p=5mm

470 u

BC components - 2222 136 31471

C2514 C2515 C2516 C2517 C2518 C2601 C2602

C2603

8

Capacitor, electrolytic, Radial, 105°C, Very Low Impedance 470UF 16V

(136 RVI) d=10mm p=5mm

470 u

BC components - 2222 136 35471

C2505 C2506 2

Capacitor, Non Solid AI-electrolytic, Power long life, Snap in, 100uF, 400V

(PLL-SI 059 CASE3030)

100 u

BC components - 2222 059 56101

C2508 1 Capacitor, Thru Hole, ceramic class 2 rating=1000V, p=5,08mm tol 20% 2.2 n BC components - 2252 601 ..226

C2502 1

Capacitor, Thru Hole, Polyester MKT Film Capacitor p=22.5mm tol 10%,

rating=630V

100 n Vishay MKT1822-410-63

___________________________________________________________________________________________________

NEXO NX242 DIGITAL TDcontroller S ervice manual r ev10060 6

P.1

5

C0033 C0034 2

Capacitor, EMI suppressor, class X2, metallized paper, 0.1uF, p=20.3mm 0.1 u Evox Rifa PME271M610M

C0029 C0030 C0031 C0032 4

Capacitor, EMI suppressor, class Y2, metallized paper, 2.2nF, p=10.2mm 2.2 n Evox Rifa PME271Y422M

C2511 C2512 2

Capacitor, Thru Hole, ceramic low loss class 1 rating 1000V p=5.08mm 47 p BC component - 2252 561 ..406

R0017 R0026 2

Resistor, Power, 2W, rating 500V, IEC 60115-1 IEC 60115-4 1 M BC components - 2206 198 03015

TR2501 1

Flyback Transformer SIM NX242/01

FUS0001

2 Fuse Holder for diam. 5mm fuse, pitch 5mm

shurter 231683

ME2509 1 Heat sink for TO220 14°C/W of PSTDmk3

ME2506 1

Heat sink for TO220 20°C/W FROM THERMALLOY REF FARNELL 178700

ME2507 ME2508 2

Heat sink for TO220 30°C/W OF PSTDMK3

ME0015 1 Heat sink with 5 places, without solder mask

Nexo Custom

CN0008 1

AC Inlet O.HEIL 1001-X-4460

U2604

1 Negative voltage regulator 79XX TO220

ST - L7918CV

U2605 1 Positive voltage regulator LMXX TO220

ST - LM337SP

BR2501 1 Rectifier Bridge, 1A Singl e P hase D.I.L.

International Rectifier - DF06S

U2602 U2603 2

Regulator, 1A Low Dropout Regulator National semiconductor - LM2940CT-5.0

U2606 1 Positive regulator 78XX TO220

ST - L7818CV

U2601 U2607 2

Positive regulator type LM317 TO220 National semiconductor - LM317T

1

Primary switch, double pole,250Vac 10A, 1E4, V-0,category D (GW 805°C) Arcolectric Switch H8550VB

U2501

1 PWM Controller, Current Mode

Texas instrument - UC3844AD8

D1001 D2601 D2602 D2603 D2604 D2605 6

Rectifier, General purpose Philips - BYD17G/T1

RL2501 1

Relay DPDT Schrack RT Schrack - RT424012

U2503 1

Phototransistor optocoupler Fairchild - CNY17-2.3S

TH0001 TH0002 TH0003 3

Thermistor PTC for overload protection 320mA Vmax=265V BC Component - 2322 662 53213

VDR0001

1 Varistor, Radial, line voltage operation

Harris/Littelfuse - V320LA40B

CN0009 1

Socket connector Plug-in 130 series 6 poles, p=5mm Imo - Plugin 20.130/6

1

Pin Strip for socket connector Imo - Plugin 20.130/PS

2

AWG16 (1.5mm²),600V, 105°C, Orange wire L=70mm, UL AVLV2

[connecting CN0009 to mains switch]

CAEDATA FDC-UL1007.16

Loading...

Loading...