Nex 720-0336c Owner's Manual

JENN-AIR® FREESTANDING OUTDOOR GRILLS

ASADORES A UTÓNOMOS P ARA

EXTERIORES JENN-AIR

®

GRILS D'EXTÉRIEUR AUTOPORTANTS JENN-AIR®

Installation Instructions and Use & Care Guide

For questions about features, operation/performance, parts, accessories or service, call: 1-800-554-5799

or visit our website at www.Nexgrill.net

Instrucciones de instalación y Manual de uso y cuidado

Para consultas respecto a características, funcionamiento, rendimiento, piezas, accesorios o servicio técnico, llame al: 1-800-554-5799

o visite nuestro sitio de internet en www.Nexgrill.net

Instructions d’installation et Guide d’utilisation et d’entretien

Pour des questions à propos des caractéristiques, du fonctionnement/rendement, des pièces, des accessoires ou du service,

composer le : 1-800-554-579 9

ou visitez notre site web www.Nexgrill.net

720/730-0336C

IMPORTANT:

Save for local electrical inspector's use.

Installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

IMPORTANTE:

Guarde para tenerlas a disposición del inspector de electricidad local.

Instalador: Deje las instrucciones de instalación con el propietario.

Propietario: Conserve las instrucciones de instalación para referencia futura.

IMPORTANT :

Conserver pour consultation par l'inspecteur local des installations électriques.

Installateur : Remettre les instructions d'installation au propriétaire.

Propriétaire : Conserver les instructions d'installation pour référence ultérieure.

T abl e of Content s/Índice/Table des matières...........2

T ABLE OF CONTENTS

OUTDOOR GRILL SAFETY ...........................................................3

INSTALLATION REQUIREMENTS................................................5

Tools and Parts............................................................................5

Location Requirements................................................................5

Product Dimensions ....................................................................6

Electrical Requirements...............................................................6

Gas Supply Requirements...........................................................7

Gas Connection Requirements....................................................7

INSTALLATION INSTRUCTIONS..................................................8

Freestanding Outdoor Grill Installation ........................................8

Make Gas Connection................................................................10

GAS CONVERSIONS ...................................................................13

Tools and Parts for Gas Conversion..........................................13

Conversion from LP Gas to Natural Gas...................................13

Check and Adjust the Burners...................................................17

OUTDOOR GRILL USE................................................................18

Using Your Outdoor Grill............................................................18

ÍNDICE

Hood Lights.................................................................................20

Using Your Infrared Sear Burner................................................20

Using Your Rotisserie Burner.....................................................20

Rotisserie Cooking Tips .............................................................21

TIPS FOR OUTDOOR GRILLING ................................................22

Cooking Methods........................................................................22

Grilling Chart...............................................................................23

OUTDOOR GRILL CARE..............................................................25

Replacing the Igniter Battery......................................................25

Changing the Light Bulb.............................................................25

General Cleaning........................................................................26

TROUBLESHOOTING ..................................................................28

ASSISTANCE................................................................................28

Accessories................................................................................28

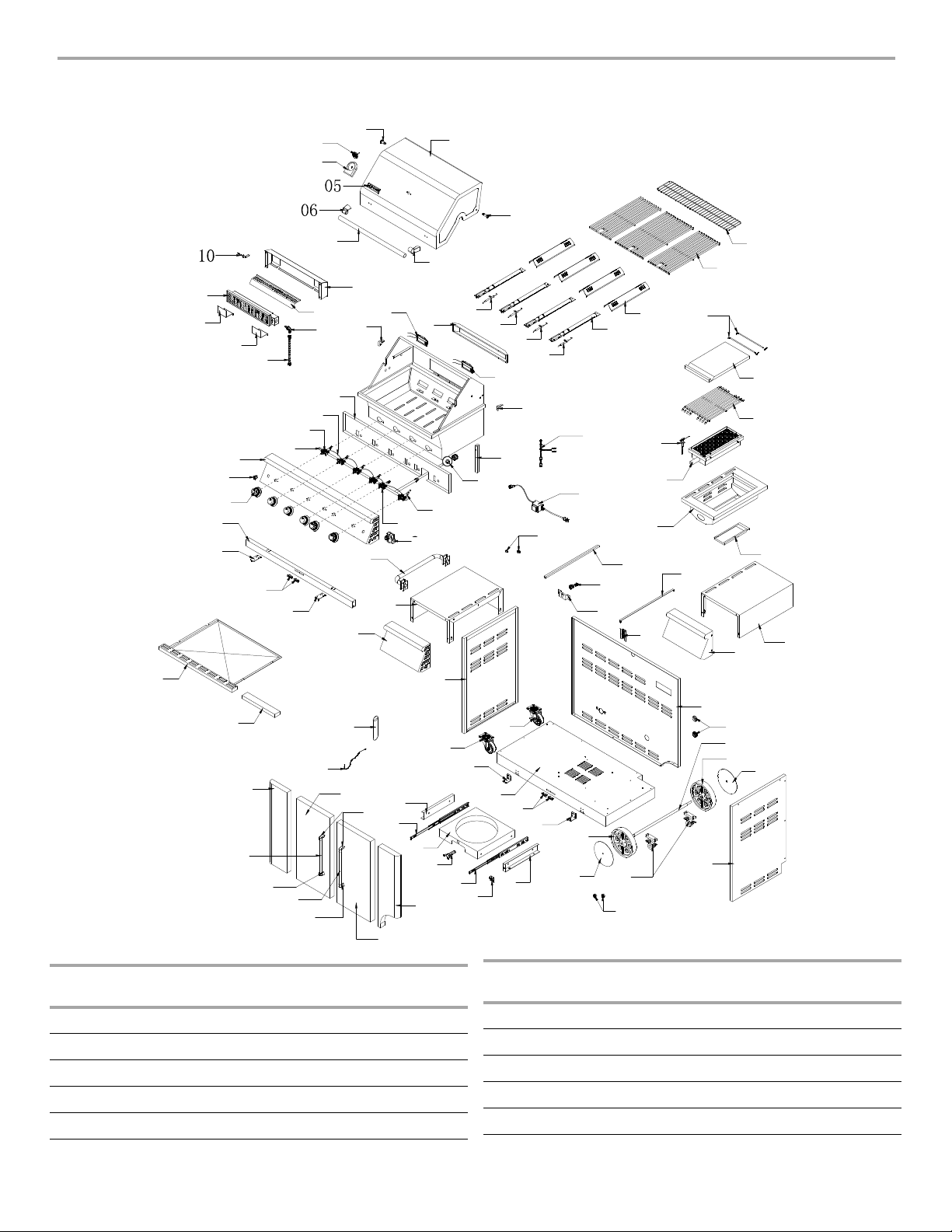

REPLACEMENT PARTS ..............................................................29

WARRANTY ..................................................................................31

SEGURIDAD DEL ASADOR PARA EXTERIORES....................33

REQUISITOS DE INSTALACIÓN.................................................35

Herramientas y piezas................................................................35

Requisitos de ubicación.............................................................35

Medidas del producto.................................................................36

Requisitos eléctricos ..................................................................36

Requisitos del suministro de gas...............................................37

Requisitos para la conexión de gas...........................................38

INSTRUCCIONES DE INSTALACIÓN.........................................39

Instalación del asador autónomo para exteriores......................39

Conexión del suministro de gas.................................................41

CONVERSIONES DE GAS...........................................................43

Herramientas y piezas para la conversión de gas.....................43

Conversión de gas LP a gas natural..........................................43

Revise y regule los quemadores................................................47

USO DEL ASADOR PARA EXTERIORES ..................................49

Cómo usar el asador para exteriores.........................................49

TABLE DES MA TIÈRES

SÉCURITÉ DU GRIL D'EXTÉRIEUR............................................65

EXIGENCES D’INSTALLATION...................................................67

Outils et pièces...........................................................................67

Exigences d'emplacement.........................................................67

Dimensions du produit................................................................68

Spécifications électriques...........................................................68

Spécifications de l'alimentation en gaz......................................69

Exigences concernant le raccordement au gaz.........................70

INSTRUCTIONS D’INSTALLATION ............................................71

Installation du gril d’extérieur autoportant..................................71

Raccordement au gaz................................................................73

CONVERSIONS POUR CHANGEMENT DE GAZ.......................76

Outils et pièces pour conversion de gaz....................................76

Conversion de propane à gaz naturel........................................76

Contrôle et réglage des brûleurs................................................80

UTILISATION DU GRIL D’EXTÉRIEUR.......................................82

Utilisation du gril d’extérieur.......................................................82

Luces de la capota.....................................................................51

Uso del quemador infrarrojo para dorado rápido.......................51

Uso del quemador del rostizador...............................................51

Consejos para la cocción con el rostizador ...............................52

CONSEJOS PARA ASAR AL AIRE LIBRE.................................53

Métodos de cocción....................................................................54

Cuadro para asar........................................................................54

CUIDADO DEL ASADOR PARA EXTERIORES .........................57

Cómo reemplazar la batería del encendedor.............................57

Cómo cambiar el foco ................................................................57

Limpieza general........................................................................58

SOLUCIÓN DE PROBLEMAS......................................................60

ASISTENCIA..................................................................................60

Accesorios..................................................................................60

PIEZAS DE REPUESTO...............................................................61

GARANTÍA ....................................................................................63

Lampes sous le couvercle..........................................................84

Utilisation du brûleur infrarouge à rôtissage...............................84

Utilisation du brûleur de tournebroche.......................................84

Conseils de cuisson à l’aide du tournebroche...........................85

CONSEILS POUR L'UTILISATION DU GRIL

D'EXTÉRIEUR ..............................................................................86

Méthodes de cuisson .................................................................87

Tableau de cuisson au gril .........................................................87

ENTRETIEN DU GRIL D’EXTÉRIEUR .........................................90

Remplacement de la pile de l’allumeur......................................90

Changement de l’ampoule d’éclairage.......................................90

Nettoyage général......................................................................91

DÉPANNAGE ................................................................................92

ASSISTANCE................................................................................93

Accessoires................................................................................93

PIÈCES DE RECHANGE..............................................................94

GARANTIE.....................................................................................96

2

OUTDOOR GRILL SAFETY

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your

gas supplier or your fire department.

DANGER

WARNING

1. Do not store or use gasoline or other

flammable liquids or vapors in the

vicinity of this or any other appliance.

2. An LP cylinder not connected for use

shall not be stored in the vicinity of

this or any other appliance.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

■ If using a ball valve, it shall be a T-handle type.

■ A flexible gas connector, when used, must not exceed 3 feet.

IMPORTANT: This grill is manufactured for outdoor use only. For grills that are to be used at elevations above 2000 ft (609.6 m) orifice

conversion is required. See “Gas Supply Requirements” section. It is the responsibility of the installer to comply with the minimum

installation clearances specified on the model/serial rating plate. The model/serial rating plate for freestanding models can be found on

the right-hand inside cabinet wall.

3

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electrical shock,

injury to persons, or damage when using the outdoor cooking

gas appliance, follow basic precautions, including the

following:

■ Do not install portable or built-in outdoor cooking gas

appliances in or on a recreational vehicle, portable trailer,

boat or in any other moving installation.

■ Always maintain minimum clearances from combustible

construction, see “Location Requirements” section.

■ The outdoor cooking gas appliance shall not be located

under overhead unprotected combustible construction.

■ This outdoor cooking gas appliance shall be used only

outdoors and shall not be used in a building, garage, or any

other enclosed area.

■ Keep any electrical supply cord and fuel supply hose away

from any heated surfaces.

■ Keep outdoor cooking gas appliance area clear and free

from combustible materials, gasoline and other flammable

vapors and liquids.

■ Do not obstruct the flow of combustion and ventilation air.

Keep the ventilation openings of the cylinder enclosure free

and clear from debris.

■ Open the cabinet door and inspect the gas cylinder supply

hose before each use of the outdoor cooking gas

appliance. If the hose shows excessive abrasion or wear,

or is cut, it MUST be replaced before using the outdoor

cooking gas appliance. Contact your dealer and use only

replacement hoses specified for use with the outdoor

cooking gas appliance.

■ Visually check the burner flames.

They should be blue. Slight

yellow tipping is normal for LP

gas. The flames should be

approximately 1" (2.5 cm) high.

■ Check and clean burner/venturi tube for insects and insect

nest. A clogged tube can lead to fire under the outdoor

cooking gas appliance.

■ The LP gas supply cylinder to be used must be:

- constructed and marked in accordance with the

Specification for LP Gas Cylinders of the U.S. Department

of Transportation (DOT) or the National Standard of

Canada, CAN/CSA-B339, Cylinders, Spheres, and Tubes

for Transportation of Dangerous Goods; and Commission.

- provided with a listed overfilling prevention device.

- provided with a cylinder connection device compatible

with the connection for outdoor cooking gas appliances.

■ Always check connections for leaks each time you connect

and disconnect the LP gas supply cylinder. See

“Installation Instructions” section.

■ When the outdoor cooking gas appliance is not in use, the

gas must be turned off at the supply cylinder.

■ Storage of an outdoor cooking gas appliance indoors is

permissible only if the cylinder is disconnected and

removed from the outdoor cooking gas appliance.

■ Cylinders must be stored outdoors and out of the reach of

children and must not be stored in a building, garage, or

any other enclosed area.

■ The pressure regulator and hose assembly supplied with

the outdoor cooking gas appliance must be used. A

replacement pressure regulator and hose assembly

specific to your model is available from your outdoor

cooking gas appliance dealer.

■ Gas cylinder must include a collar to protect the cylinder

valve.

■ For appliances designed to use a CGA791 Connection:

Place a dust cap on cylinder valve outlet whenever the

cylinder is not in use. Only install the type of dust cap on

the cylinder valve outlet that is provided with the cylinder

valve. Other types of caps or plugs may result in leakage

of propane.

If the following information is not followed exactly, a fire

causing death or serious injury may occur.

■ Do not store a spare LP gas cylinder under or near this

outdoor cooking gas appliance.

■ Never fill the cylinder beyond 80 percent full.

1"

(2.5 cm)

4

INSTALLA TION REQUIREMENTS

WARNING

Explosion Hazard

Do not store fuel tank in a garage or indoors.

Do not store grill with fuel tank in a garage or indoors.

Failure to follow these instructions can result in death,

explosion, or fire.

WARNING

Fire Hazard

Do not use grill near combustible materials.

Do not store combustible materials near grill.

Doing so can result in death or fire.

T ools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

T ool s Needed

■ Phillips screwdriver

■ Wrench or pliers

■ Pipe wrench

Parts Supplied

■ Gas pressure regulator/hose assembly set for 11" WCP LP

gas

■ Left side shelf

■ Right side shelf

■ Side shelf push bar

■ Grill cover

■ Battery

■ Warming rack

■ Cooking grid

■ Side burner cooking grid

■ Natural gas orifice for rotisserie/infrared burner

■ Scissors or cutting pliers

(to remove tiedowns)

■ Noncorrosive leak-

detection solution

Location Requirements

Parts Needed

■ 20 lb LP gas fuel tank - approximately 18" (45.7 cm) height

and 12" (30.5 cm) diameter

Parts Needed for C onversio n to Natura l Gas

■ Natural gas conversion kit Part Number 710-0003. See

“Assistance” section to order. The conversion kit includes:

■ Natural gas regulator 4" W.C. (marked “Natural Gas

Regulator”)

■ 10 ft (3.0 m) Natural gas hose with quick connector

■ 5.9" (150 mm) Natural gas regulator hose

■ 6 mm nut driver

■ 6 mm wrench

■ Hex key

■ Gas line shutoff valve

■ ½" male pipe thread nipple for connection to pressure

regulator.

■ LP gas-resistant pipe-joint compound

■ CSA design-certified out door fle xible st ain less ste el app lianc e

connector (4-5 ft [1.2-1.5 m]) or rigid gas supply line as

needed.

Select a location that provides minimum exposure to wind and

traffic paths. The location should be away from strong draft areas.

Do not obstruct flow of combustion and ventilation air.

Clearance to combustible construction for freestanding outdoor

grills:

■ A minimum of 24" (61 cm) must be maintained between the

front of the grill hood, sides and back of the grill and any

combustible construction.

■ A 24" (61 cm) minimum clearance must also be maintained

below the cooking surface, and the grill shall not be used

under overhead combustible construction.

Rotisserie (accessory)*

If you equip your grill with a rotisserie, a 6" (15.2 cm) minimum

clearance is needed for the rotisserie motor.

A grounded, 3-prong outlet located to the left of the grill is

required.

*See “Assistance” section to order.

5

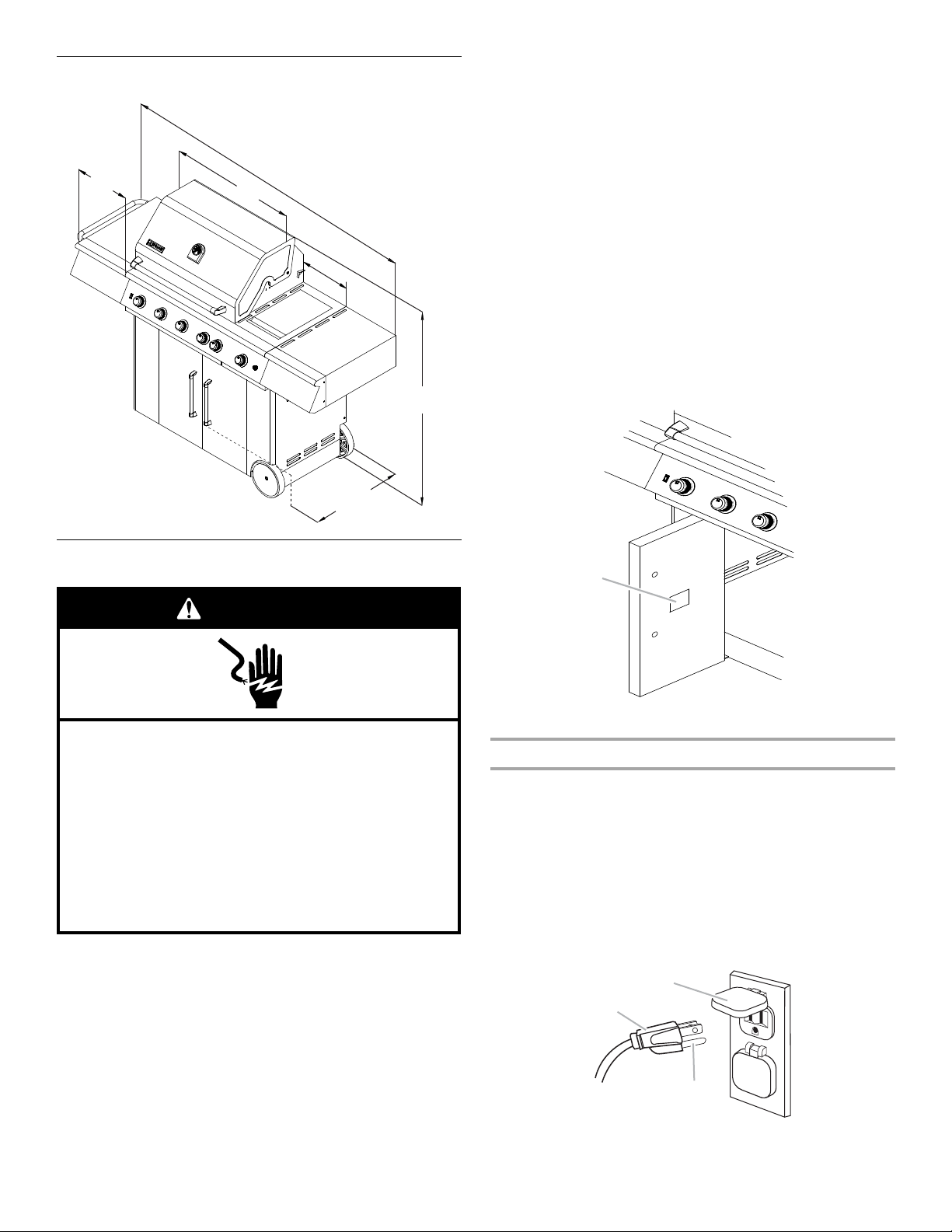

Product Dimensions

12⁵⁄₈"

(32 cm)

69¹⁄₄"

(175.9 cm)

27⁷⁄₈"

(70.8 cm)

48³⁄₄"

(123.8 cm)

23¹⁄₄"

(59.1 cm)

11⁷⁄₈" (30.2 cm)

Electrical Shock Hazard

Use only a UL listed, 14 gauge, 3 wire extension cord

approved for outdoor use, marked W-A, with a

maximum length of 50 ft.

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

A

A

B

C

■ Do not operate any outdoor cooking gas appliance with a

damaged cord, damaged plug, or after the appliance

malfunctions or has been damaged in any manner. Contact

the manufacturer for repair.

■ Do not let the cord hang over the edge of a table or touch hot

surfaces.

■ Do not use an outdoor cooking appliance for purposes other

than intended.

■ When connecting, first connect plug to the outdoor cooking

gas appliance then plug appliance into the outlet.

■ Use only a Ground Fault Interrupter (GFI) protected circuit

with this outdoor cooking gas appliance.

■ Do not remove the ground prong or use with an adapter of

2prongs.

■ Use only extension co rds with a 3 prong grounding plu g rate d

for the power of the equipment and approved for outdoor use

with a W-A marking.

The model/serial number rating plate is located on the inside of

the left cabinet door. See the following illustration.

Electrical Requirements

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Check with a qualified electrician if you are not sure whether the

grill is properly grounded.

A 120-volt, 60-Hz, AC- only, 15-amp, fused e lectrical supply is

required.

It is recommended that a separate circuit servicing only this grill

be provided.

■ To avoid elec trical shock, do not immerse cord or plugs in

■ Unplug from the outlet when not in use and before cleaning.

6

water or ot her liquid.

Allow to cool before putting on or taking off parts.

A. Model/se rial num b er pl ate

Recommended Ground Method

The outdoor grill, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code ANSI/NFPA 70, or Canadian

Electrical Code, CSA C22.1.

Copies of the standards listed above may be obtained from:

CSA International

8501 East Pleasant Valley Rd.

Cleveland, Ohio 44131-5 575

National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

A. 3-prong ground plug

B. 3-prong polarized type out door GFI outlet

C. Ground prong

Gas Supply Requirements

WARNING

Explosion Hazard

Use a new CSA International approved “outdoor”

gas supply line.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 11” (28 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

A

Burner Requirements for High Altitude

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m) above sea level. Orifice

conversion is required. See “Assistance” section to order.

Gas Supply Line Pressure Testing

Testing above ½ psi (3.5 kPa) or 14" (35.5 cm) WCP (gauge):

The grill and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures greater than ½psi (3.5 kPa).

T esting below ½ p si (3.5 kPa) or 14" (35.5 cm) WCP (gauge) or

lower:

The grill must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than ½ psi (3.5 kPa).

Gas Connection Requirements

20 lb LP Gas Fuel Tank

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with either the National Fuel Gas Code, ASNI Z223.1/

NFPA 54, Natural Gas and Propane Installation Code, CSA

B149.1, Propane Storage and Handling Code, B149.2, or the

Stan da rd for R e cre ati ona l Vehicles, ASNI A119.2/ NFPA 1192 and

CSA Z240 RV Series Recreational Vehicle Code as applicable.

IMPORTANT: Grill must be connected to a regulated gas supply.

Refer to the model/serial rating plate for information on the type

of gas that can be used. If this information does not agree with

the type of gas available, check with your local gas supplier.

Gas Conversion:

No attempt shall be made to convert the grill from the gas

specified on the model /serial rating plat e for use with a different

gas type without consulting the serving gas supplier. The

conversion kit supplie d with grill m ust be used. See “Gas

Conversions” section for instructions.

Gas Pressure Regulator

The gas pressure regulator supplied with this grill must be used.

The inlet (supply) pressure to the regulator should be as follows

for proper operation:

LP Gas:

Operating pressure: 11" (27.9 cm) WCP

Inlet (supply) pressure: 11" to 14" (27.9 cm to 35.5 cm) WCP

Natural Gas:

Operating pressure: 4" (10.2 cm) WCP

Inlet (supply) pressure: 7" to 14" (17.8 cm to 35.5 cm) WCP

maximum.

Contact local gas supplier if you are not sure about the inlet

(supply) pressure.

This grill is equipped for use with a 20 lb LP gas fuel tank (fuel

tank not supplied). A gas pressure regulator/hose assembly is

supplied.

Any brand of 20 lb LP gas fuel tank is acceptable for use with the

grill, provided that it is compatible with the grill’s retention means

(tank tray included).

It is also design-certified by CSA International for local LP gas

supply or for Natural gas with appropriate conversion.

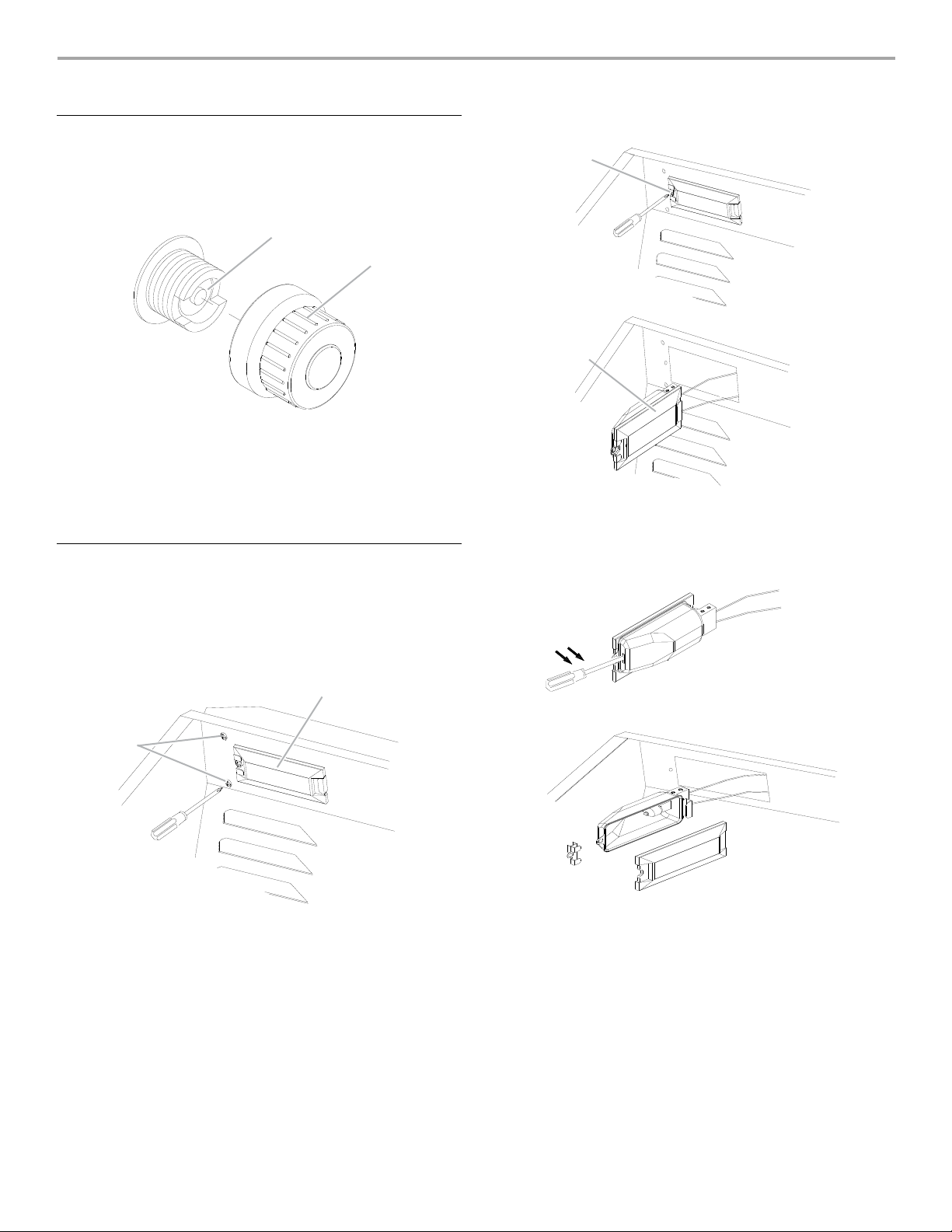

A. Gas pressure regulator/hose assembly

The 20 lb LP gas fuel tank must be mounted and secured.

7

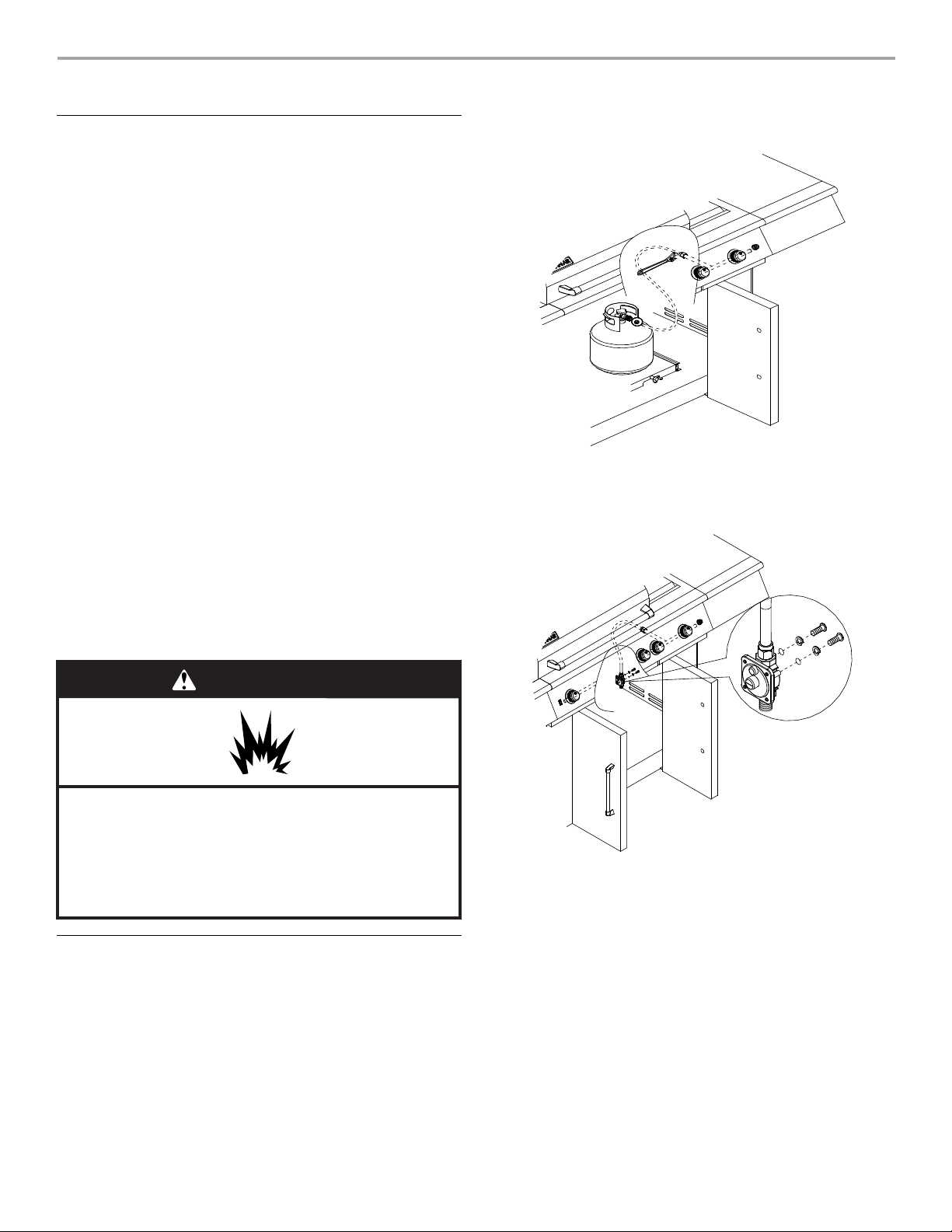

Door Style Tank Tray

A

A

C

B

A

A

B

C

Excessive Weight Hazard

Use two or more people to move and install grill.

WARNING

Failure to do so can result in back or other injury.

A

B

A

1. Open cabinet doors.

2. Slide the tank tray locking bracket counterclockwise 90° and

pull out the tray.

A. Tank tray locking bracker

3. Place the 20 lb LP gas fuel tank bottom collar into the

mounting hole in the tank tray.

4. Tighten the locking screw against the bottom collar of the

20 lb LP gas fuel tank to secure.

A. Locking screw

B. Mounting hole

C. Botto m collar

INSTALLA TION INSTRUCTIONS

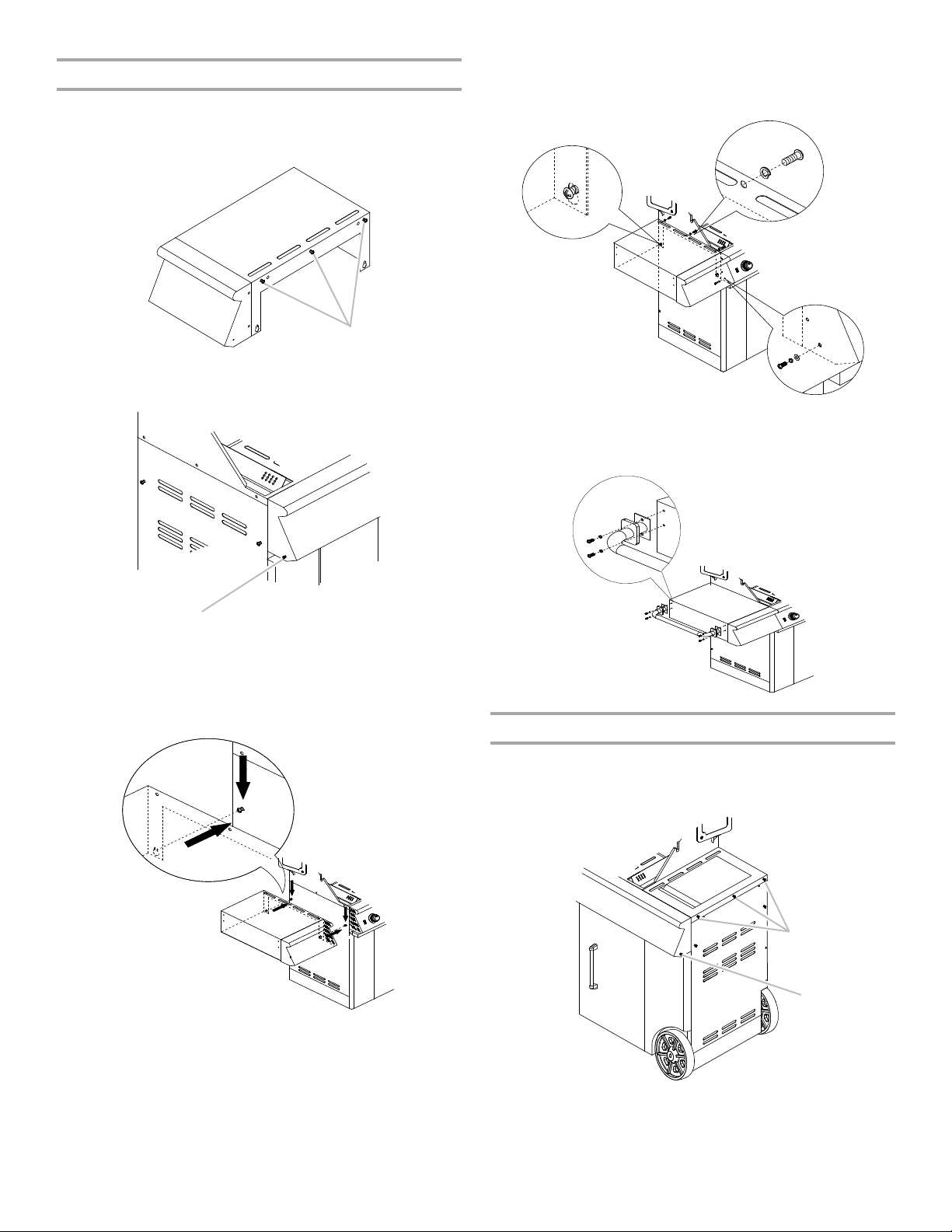

Freestanding Outdoor Grill Installation

Unpack Grill

1. Remove all packaging materials and remove grill from the

shipping base.

2. Move grill close to desired outdoor location.

3. Open the grill hood.

Remove Packaging Materia l Inside the Grill

5. Slide the drawer with the 20 lb LP gas fuel tank back into the

cabinet. Turn the tank tray locking bracket clockwise 90° to

tighten.

A. Tank tray locking bracket

Natural Gas Conversion

Conversion must be made by a qualified gas technician. The

qualified Natural gas technician shall provide the Natural gas

supply to the selected grill location in accordance with the

National Fuel Gas Code ANSI Z223.1/NFPA 54 - latest edition,

and local codes. For conversion to Natural gas, the Natural Gas

Conversion Kit supplied with the grill (on some models) or the

Natural Gas Conve rsion Kit Part Nu mber 710-00 03 must be used.

See “Assistance” section for information on ordering.

IMPORTANT: The gas installation must con form with local codes,

or in the absence of lo cal codes, with the National F uel Gas Code,

ANSI Z223.1/NFPA 54 - latest edition.

Follow instructions for converting to Natural gas in the “Gas

Conversions” section of this manual or the instructions supplied

with Natural Gas Conversion Kit Part Number 710-0003.

The gas supply line shall be equipped with an approved shutoff

valve. This valve should be located in the same area as the grill

and should be in a location that allows ease of opening and

closing. Do not block access to the shutoff valve. The valve is for

turning on or shutting off gas to the grill.

1. Use a utility knife to cut yellow straps and packing tape to

open box from top and remove the boxes.

2. Remove the pac ka ge on the si de burn er.

3. Remove foam block and wrap from inside the grill.

4. Replace the grill grate s.

5. Place warming shelf on brackets as shown.

A. Warming shelf brackets

B. Warming shelf

8

A. Gas supply line

B. Shutoff valve “ope n” posi tion

C. To grill

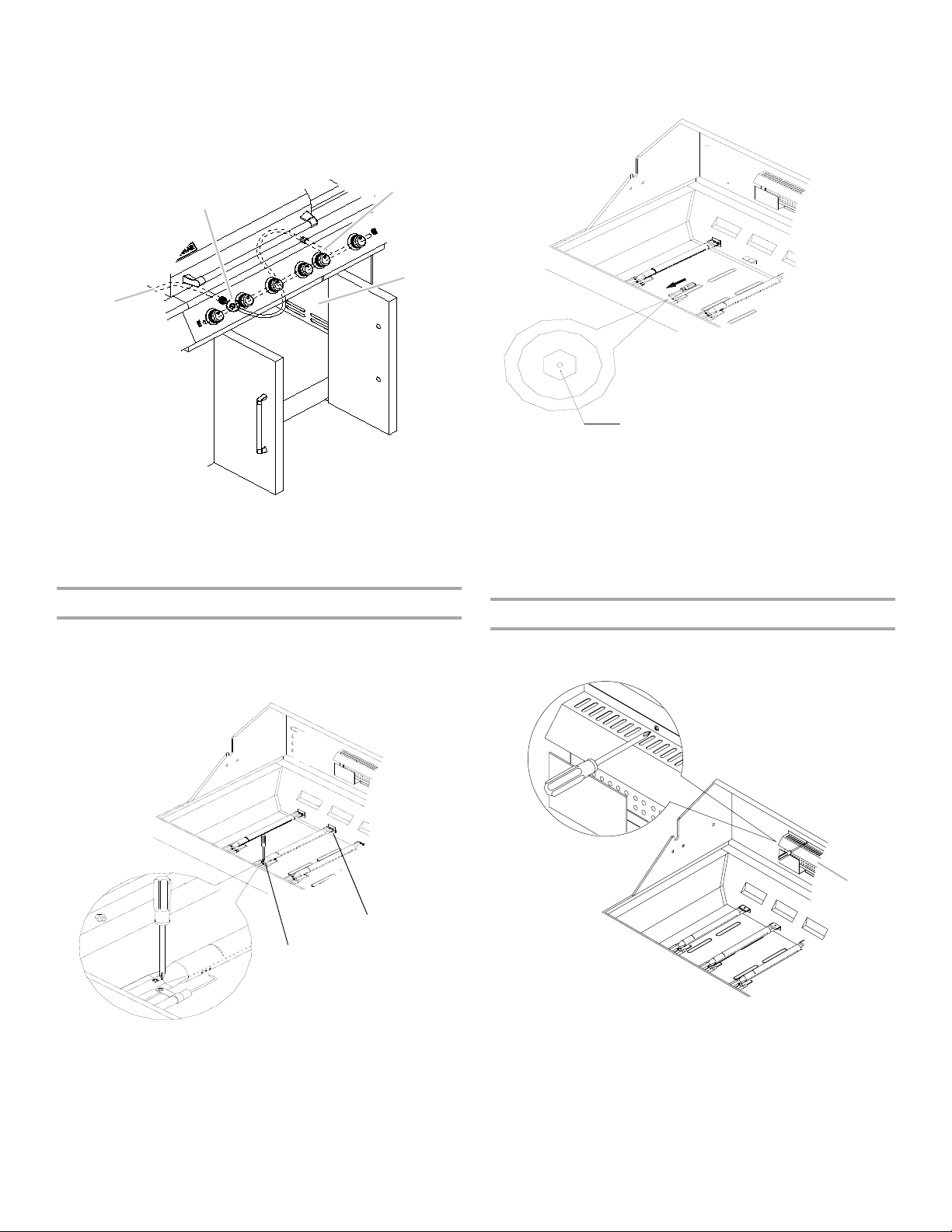

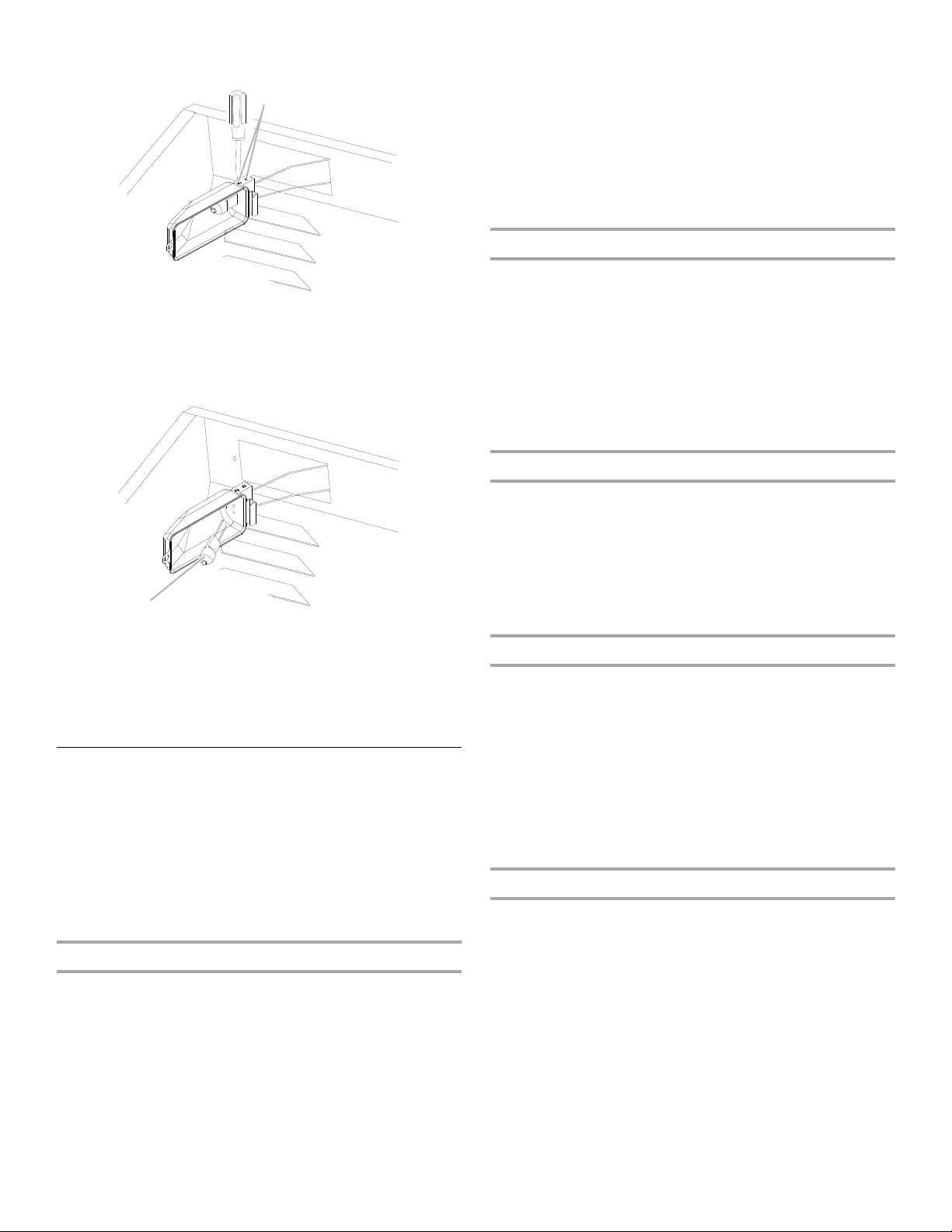

Attach Left Side Shelf

A

A

B

A

C

A

B

1. Unpack left side shelf.

2. Open grill lid.

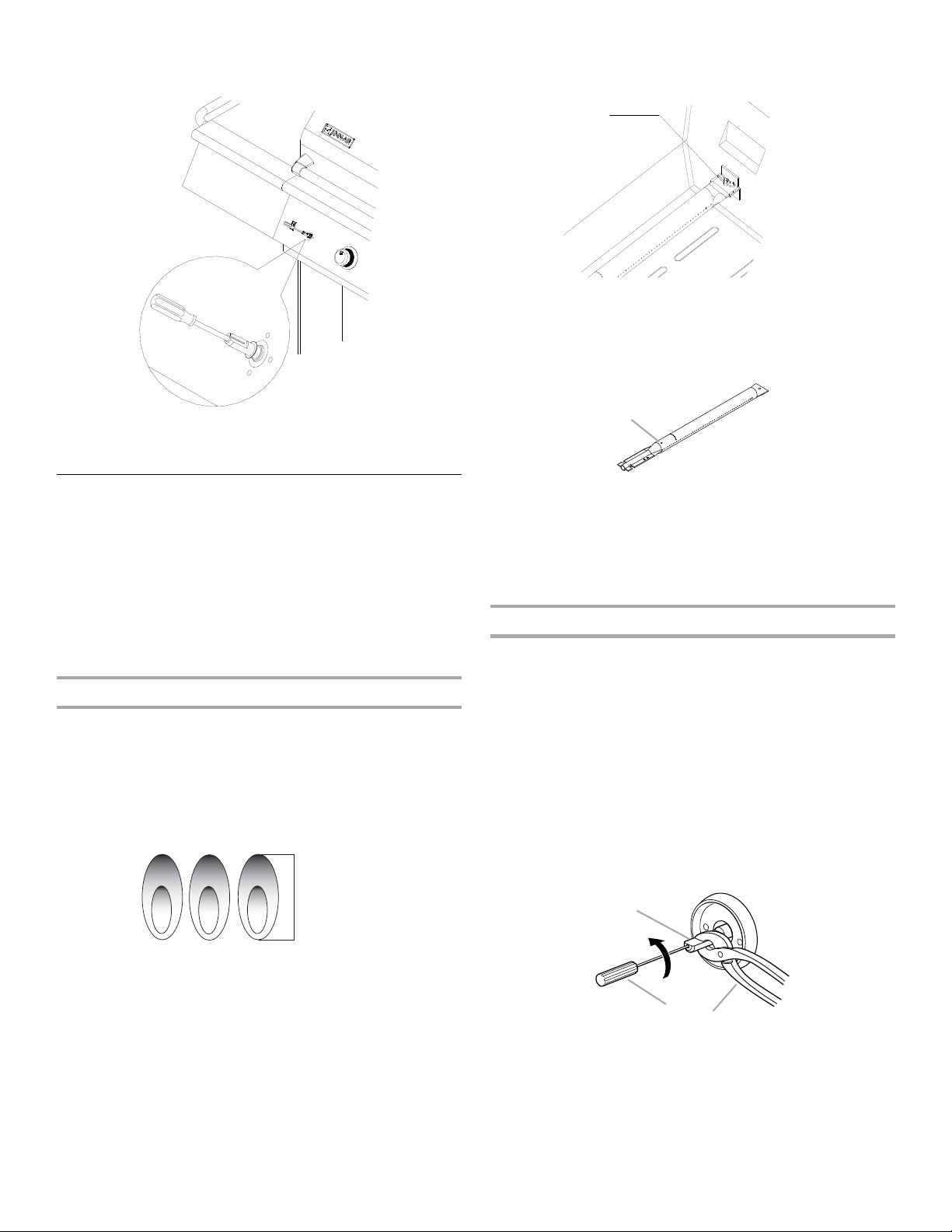

3. Remove 3 screws from the side of the side shelf.

A. Side shelf screws

8. Attach th e s ide s hel f c ont rol p an el to the grill control panel (C)

by inserting the screw removed from the grill control panel in

Step4. Tighten the screw.

4. Remove 1 screw from the side of grill control panel.

A. Grill control panel screw

5. Loosen the 2 screws on the grill side panel and align the

bottom keyhole slot s on the side she lf with the loo se ned

screws. Hook the side shelf onto the tw o loosened screws and

let the side shelf slide down so the screws are in the narrow

neck of the slots.

9. Attach side shelf push bar by aligning the screw holes on the

side shelf with the screw holes in the push bar. Insert the

screws into the push bar screw holes and then into the side

shelf and tighten.

Attach Right Side Shelf

1. Unpack right side shelf.

2. Remove the 3 screws from the grill right side shelf and

1 screw from the grill control panel.

IMPORTANT: This step is meant to help with the installation,

but do not depen d s ol ely o n the tw o sc rew s to hold the weigh t

of the side shelf.

6. Attach the top of the side shelf to the grill (B) by inserting the

3 screws removed in Step 3 into the side shelf from insi de t he

grill hood and tighten.

7. Attach the bottom of the side shelf to the side panel (A) of the

grill by tightening the 2 screws inserted in the keyhole slots in

Step5.

A. Grill cont rol panel screw

B. Grill side shelf screws

9

3. Loosen the 2 screws on the grill side panel and align the

B

A

C

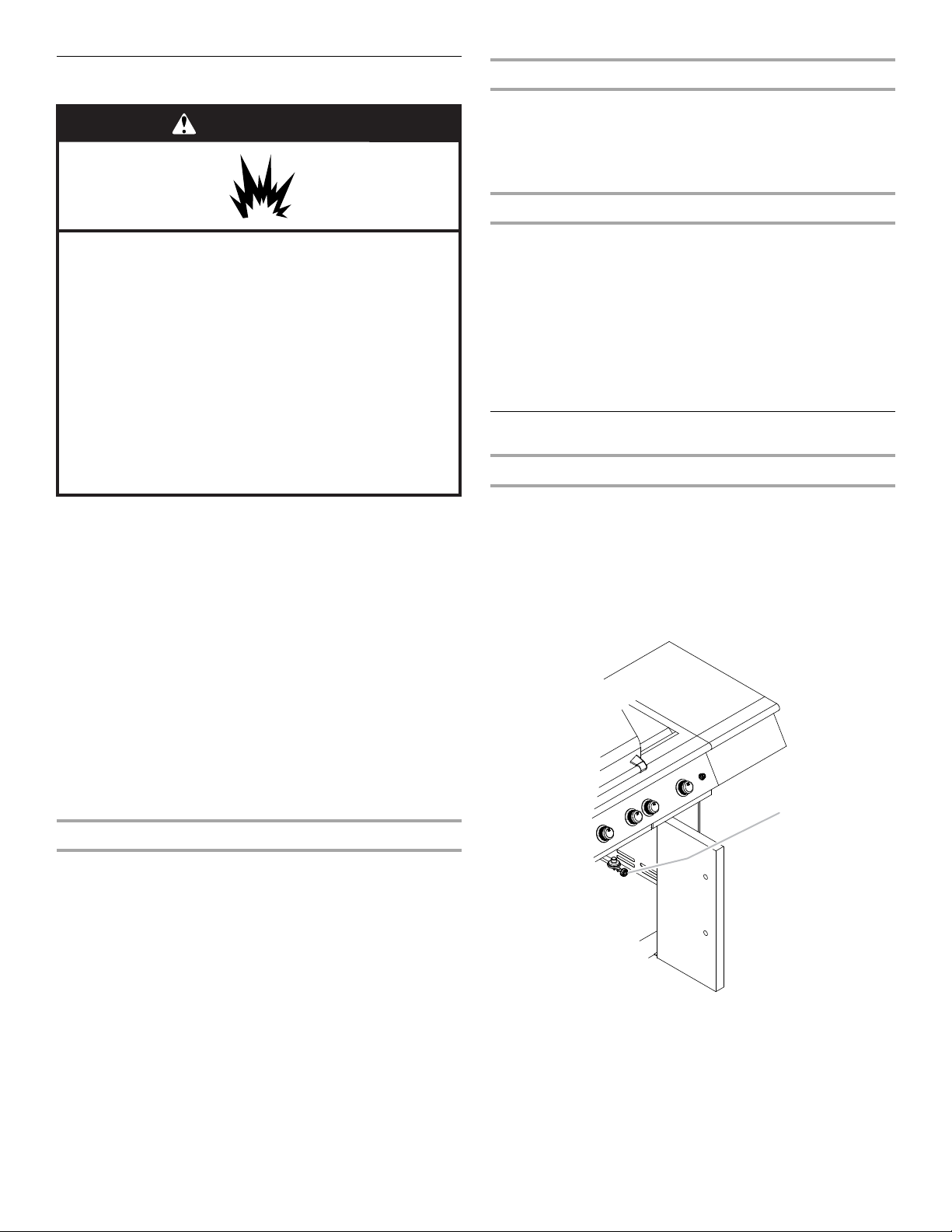

WARNING

Explosion Hazard

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 11” (28 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

A

A

C

B

bottom keyhole slot s on the side she lf with the loo se ned

screws. Hook the side shelf onto the tw o loosened screws and

let the side shelf slide down so the screws are in the narrow

neck of the slots.

IMPORTANT: This step is meant to help with the installation,

but do not depen d s ol ely o n the tw o sc rew s to hold the weigh t

of the side shelf.

4. Attach the top of the side shelf to the grill (B) by inserting the

3 screws removed in Step 2 into the side shelf from insi de t he

side shelf and tighten.

5. Attach the bottom of the side she lf to the side p an el (C) of the

grill by tightening the 2 screws inserted in the keyhole slots in

Step3.

6. Attach the side shelf to the control panel (A) by inserting the

screw removed from the grill control panel in Step 2. Tighten

the screw.

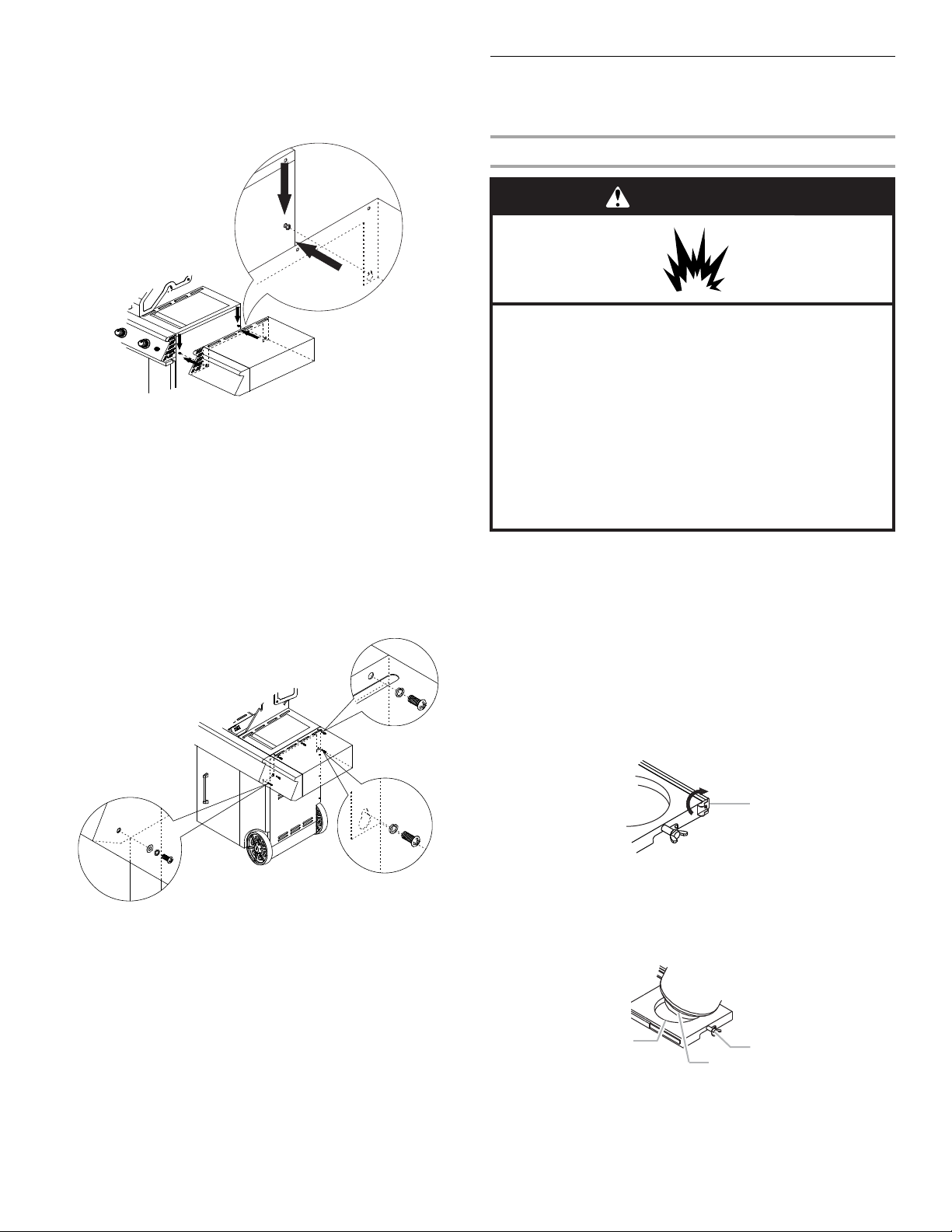

Make Gas Connection

NOTE: If grill is to be conve rted to N at ural gas , fo llo w in stru cti ons

in the “Gas Conversions” section.

20 lb LP Gas Fuel Tank

LP Gas:

IMPORTANT: A 20 lb LP gas fuel tank must be purchased

separately.

IMPORTANT: The gas pressure regulator/hose assembly

supplied with the grill must be used. Replacement gas pressure

regulator/hose assembl y spe ci fic to your mode l, is av ail abl e from

your outdoor grill dealer.

Door Style Tank Tray

1. Open cabinet doors.

2. Slide the tank tray locking bracket counterclock wise 90° and

pull out the tray.

10

A. Tank tray locking bracker

3. Place the 20 lb LP gas fuel tank bottom collar into the

mounting hole in the tank tray.

4. Tighten the locking screw against the bottom collar of the

20 lb LP gas fuel tank to secure.

A. Locking scre w

B. Mounting hol e

C. Botto m collar

5. Slide the tank tr ay wit h the 20 lb L P gas fuel tan k bac k in to the

cabinet and lock the locking bracket.

T o Co nnect the 20 lb LP Gas F uel Tank:

A

B

A

B

1. Check that the 20 lb LP gas fuel t ank is in the “Off” position. If

not, turn the valve clockwise until it stops.

2. Check that the 20 lb LP gas fuel tank valve has the proper

type-1 external male thread connections per ANSI Z21.81.

3. Check that the burner control knobs are in the “Off” position.

4. Remove any debris and inspect the valve connections, port,

and gas pressure regulator/hose assembly for damage.

NOTE: Always keep the LP cylinder at 90° (upright)

orientation to provide vapor withdraw.

5. Using your hand, turn the gas pressure regulato r/hose

assembly clockwis e to connect to the 20 lb LP gas fuel tank as

shown.

Hand tighten only. Use of a wrench could damage the quick

coupling nut.

T o Di sconnect t he 20 lb LP Gas Fuel Tank:

1. Check that the burner control knobs are in the “Off” position

and the grill is cool.

2. Check that the 20 lb LP ga s fuel t ank is in the “Off” position. If

not, turn the valve clockwise until it stops.

3. Using your hand, turn the gas pressure regulator/hose

assembly counterclockwise to disconnect to the 20 lb LP gas

fuel tank as shown.

Hand loosen only. Use of a wrench could damage the quick

coupling nut.

A. 20 lb LP gas fuel tank

B. Gas pressure regulator/hose assembly

Make sure that the cylinder valve connection device properly

mates with the connection device attached to the inlet of the

pressure regulator.

6. Open the tank valve fully by turning the valve

counterclockwise. Wait a few minutes for gas to move through

the gas line.

7. Before lighting the grill, t est all connections by brus hin g on an

approved noncorrosive leak-detection solution. Bubbles will

show a leak.

8. If a leak is found, turn the tank valve off and do not use the

grill. Contact a qualified gas technican to make repairs.

9. Go to “Check and Adjust the Burners” section.

A. Gas pressure regulator/hose assembly

B. 20 lb LP gas fuel tank

4. Place dust cap on cylinder valve outlet whenever the cylinder

is not in use. Only install the type of dust cap on the cylinder

valve outlet that is provided with the cylinder valve. Other

types of caps or plugs may result in leakage of propane.

11

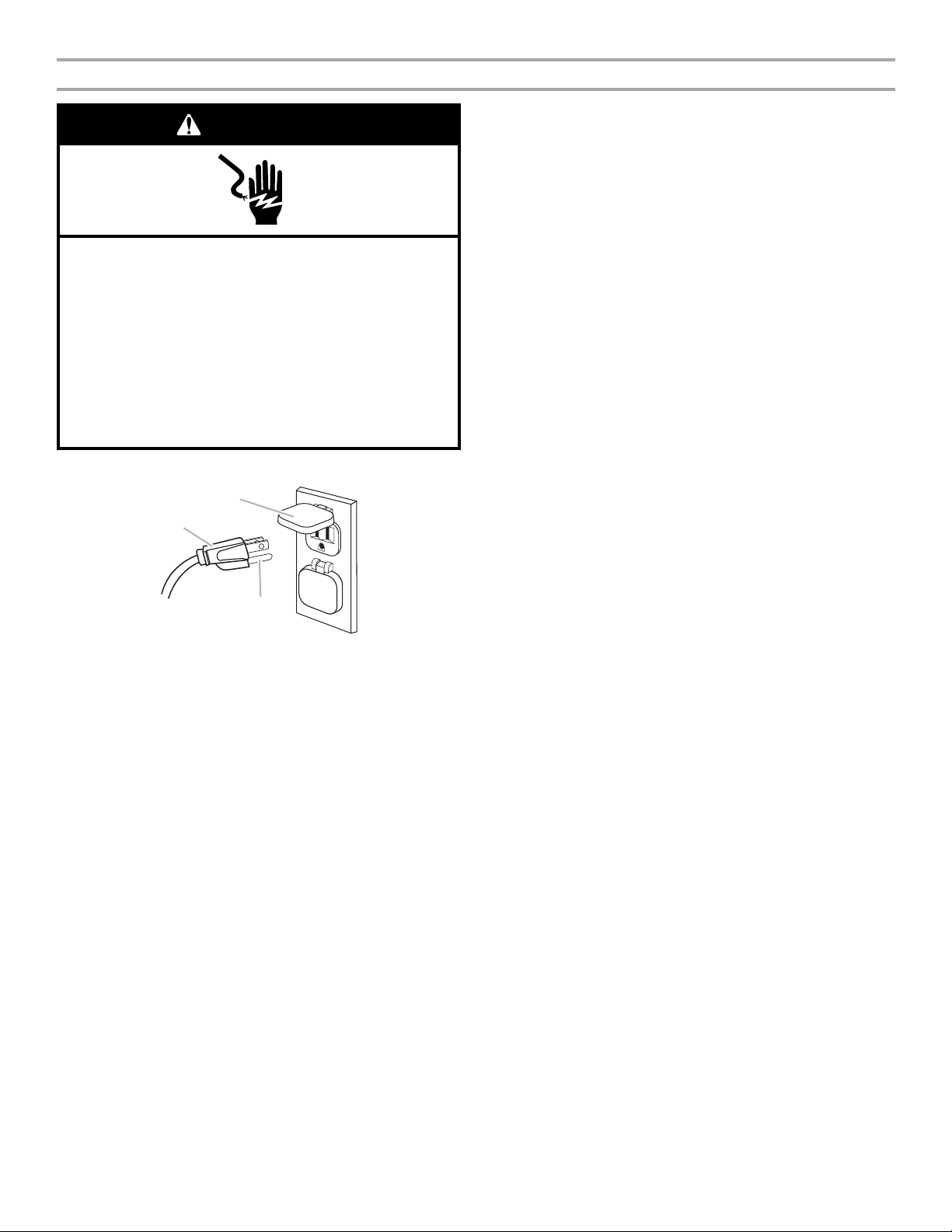

Plug in Grill

Electrical Shock Hazard

Use only a UL listed, 14 gauge, 3 wire extension cord

approved for outdoor use, marked W-A, with a

maximum length of 50 ft.

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

A

B

C

1. Plug extension cord into grounded 3-prong GFI outlet.

■ To avoid electrical shock, do not immerse cord or plugs in

water or other liquid.

■ Unplug from the outlet when not in use and before

cleaning. Allow to cool be fore putt ing on or taking off p art s.

■ Do not operate any outdoor cooking gas appliance with a

damaged cord, damaged plug, or after the appliance

malfunctions or has been damaged in any manner.

Contact the manufacturer for repair.

■ Do not let the cord hang over the edge of a table or touch

hot surfaces.

■ Do not use an outdoor cooking appliance for purposes

other than intended.

■ When connecting, first connect plug to the outdoor

cooking gas appliance then plug appliance into the outlet.

■ Use only a Ground Fault Interru pter (GFI) prot ected c ircuit

with this outdoor cooking gas appliance.

■ Do not remove the ground prong or use with an adapt er of

2prongs.

■ Use only extension cords with a 3 prong grounding plug

rated for the power of the equipment and approved for

outdoor use with a W-A marking.

2. Go to “Check and Adjust the Burners” section

A. 3-prong ground plug

B. 3-prong polarized type outdoor G F I out let

C. Ground prong

12

GAS CONV ERSIONS

WARNING

Explosion Hazard

Use a new CSA International approved “outdoor”

gas supply line.

Securely tighten all gas connections.

Failure to do so can result in death, explosion, or fire.

†®TEFLON is a registered trademar k of E.I . Du Pont De Nemo ur s an d Compa ny.

T ools and Parts for Gas Con version

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

T ools n eeded f or conversio n to Nat ural gas

■ Phillips screwdriver

■ Pipe wrench

■ Adjustable wrench

■ 6 mm socket and wrench

or 6 mm nut driver

Parts supplied for conve rsion to N atural gas

■ Natural gas orifices

Parts neeeded f or conversio n to Natural gas

■ Natural gas conversion kit Part Number 710-0003. See

“Assistance” section to order. The conversion kit includes:

■ Natural gas regulator 4" W.C. (marked “Natural Gas

Regulator”)

■ 10 ft (3.0 m) Natural gas hose with quick connector

■ 5.9" (150 mm) Natural gas regulator hose

■ 6 mm nut driver

■ 6 mm wrench

■ Hex key

IMPORTANT: Gas conversions must be done by a qualified

installer. Before proceeding with conversion, shut off the gas

supply to the appliance prior to disconnecting the electrical power.

■ Thin flat-blade screwdriver

■ Pliers

■ Pipe thread sealant

certified for LP gas

6. Use an adj ustabl e wrenc h to remove the LP regulato r from the

manifold.

7. Use an adjustable wrench to install the Natural gas regulator

hose to the manifold and secure. Attach the Natural gas

regulator to the side panel inside the grill cart with the two

screws that are preassembled on the regulator.

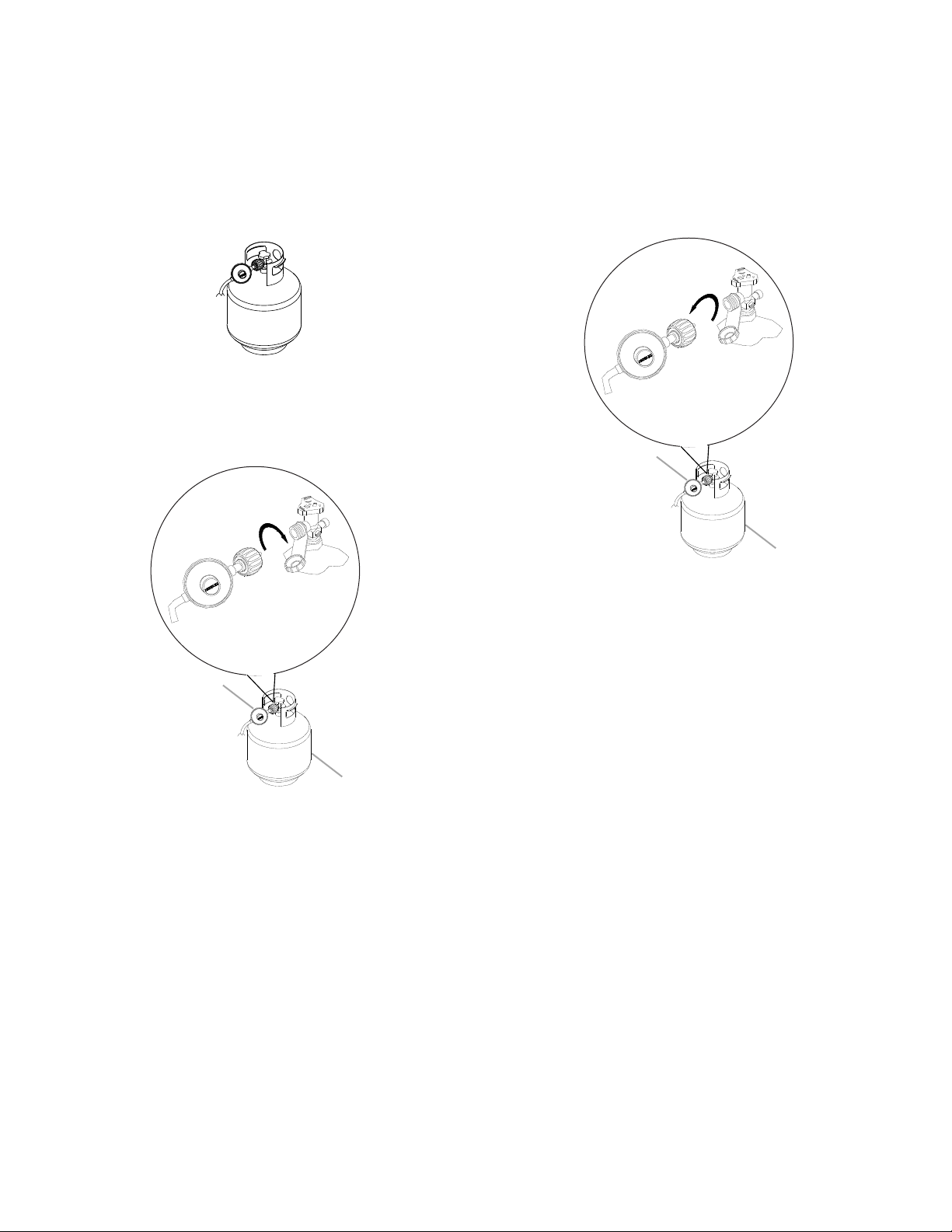

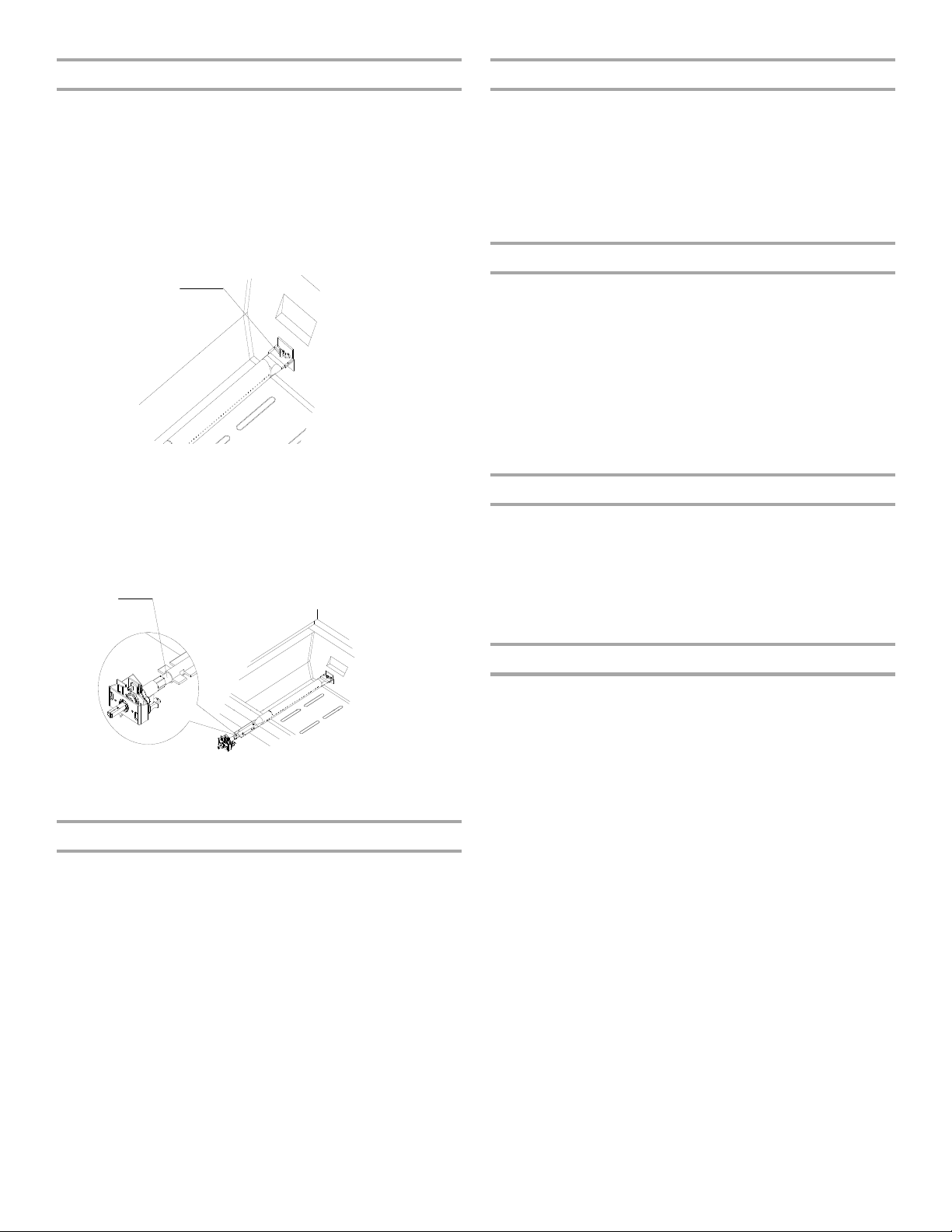

Conv ersion from LP Gas to Natural Gas

Installati on of the reg ulator

1. Turn off the main gas supply valve.

2. Unplug grill or disconnect power.

3. Disconnect 20 lb LP gas fuel tank (if present).

4. Turn off all burner control valv es.

5. Remove the 20 lb LP gas fuel tank (if present) from the grill

cart.

Make Gas Connection

1. A combinatio n of pipe fitting s must be used to connect the gri ll

to the existing gas line.

■ The 10 ft (3.0 m) PVC flexible gas supply hose design-

certified by CSA must be used.

■ Pipe-joint compounds suitable for use with Natural gas

must be used. Do not use Teflon®† tape.

■ There must be a certified manual shutoff valve in the gas

supply line near the grill for easy ac cess.

2. Use a pipe wre nch to connec t the brass con nector on on e end

of the 10 ft (3.0 m) PVC flexible gas supply hose to the

Natural gas pressure regulator.

13

3. Connect the quick connector on the other end of the

A

B

C

D

B

A

A

A

10 ft (3.0 m) PVC flexible gas supply hose to the rigid Natural

gas supply pipe. To use the quick connect fittin g; pull the head

of the quick connec t back, inse rt the end o f the PVC ga s hose

and release the head of the connector. Check the the

connection is secure.

A. 10 ft. (3.0 m) PVC gas hose

B. Natural gas pressure regulator/hose assembly

C. Manifold

D. Right side panel

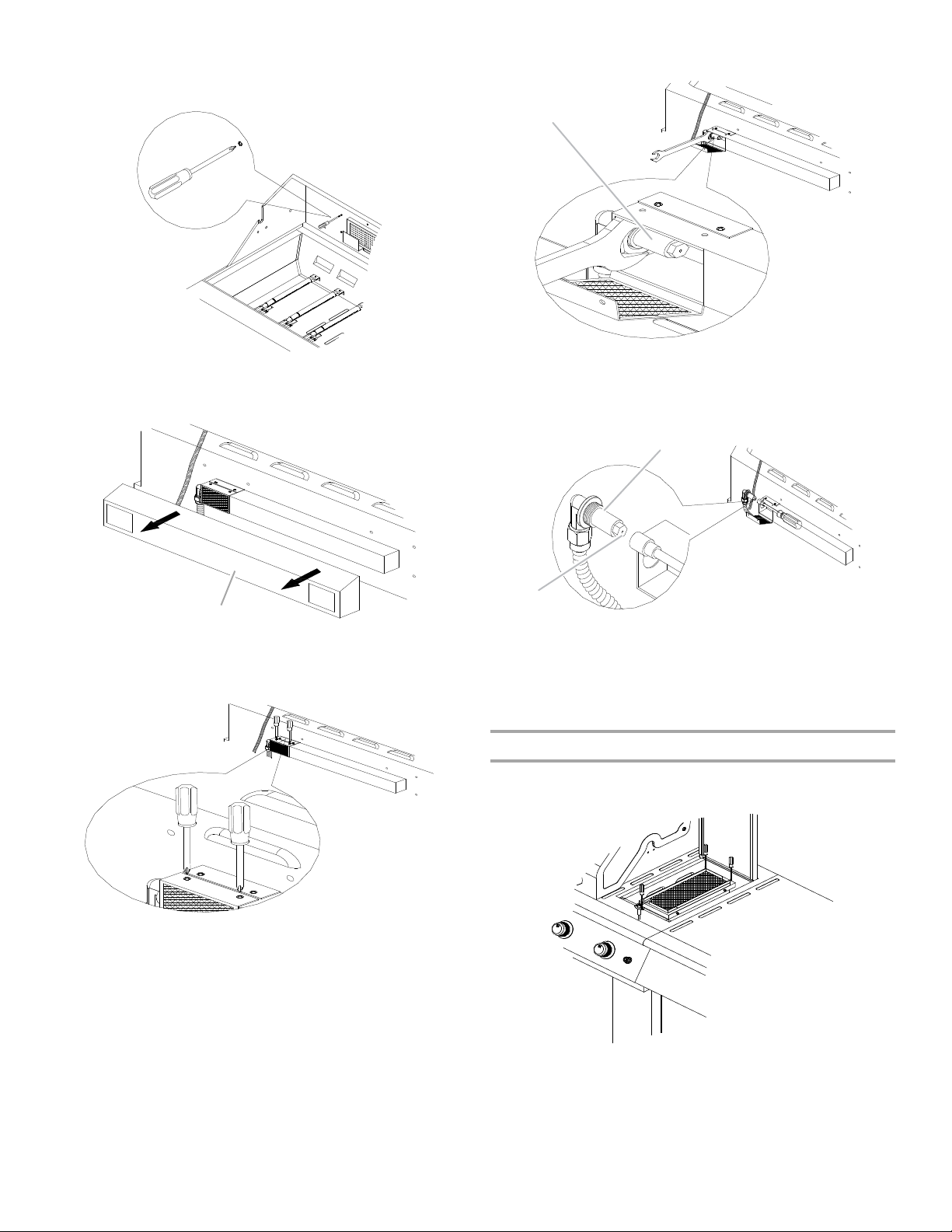

Change Grill Burner Valve Orifices

1. Remove the grates and flame ta mers.

2. Remove the 1 screw and 1 cotter clip that hold the burner in

place. Set the screws aside. Remove the burner from the grill

by lifting the burner out.

3. Use a 6 mm socket and wrench or 6 mm nut driver to remove

the brass orifice from the end of gas valve. The main burner

orifice is located behind the LP orifice, so no additional orifice

needs to be installed.

A. Main burne r orific e

IMPORTANT: Check that the o rifice is properly inst alled i nside

of the burner opening.

4. Reinsert the burner and reattach using the 1 screw and 1

cotter clip previou sly r emove d. Repe at the proce dure fo r each

main burner.

5. Position the igniters so they are ¼" (6.0 mm) away from each

burner.

Change the Rotisserie/ Infrared Burner O rifice

1. Using a Phillips screwdriver, unscrew the 2 screws and

remove the rotisserie/infrared burner wind baffle.

A. Screw

B. Cotter Clip

A. Wind baffle

14

2. Using a Phillips screwdriv er, remove the 4 screws at the back

A

A

A

B

of grill from inside the grill (2 screws on each side of the

rotisserie infrared burner).

3. Remove the access cover at the back of the grill hood by

removing the 4 screws (2 screws on each side of the rotisserie

infrared burner).

5. Use 24 mm wren ch to remove the orifice nut.

A. Orifice nut

6. Take out the orifice support, and then use a 6 mm socket and

wrench or 6 mm nut driver to remove the LP orifice at the end

of the supply pipe. Replace with Natural gas orifice.

A. Access cover

4. Using a Phillips screwdriver, remove the 2 screws holding the

spider guard to the burner.

IMPORTANT: Check that the o rifice is properly inst alled i nside

of the supply pipe.

A. Orifice support

B. Orifice

7. Reinstall the spider guard, access cover, and wind baffle.

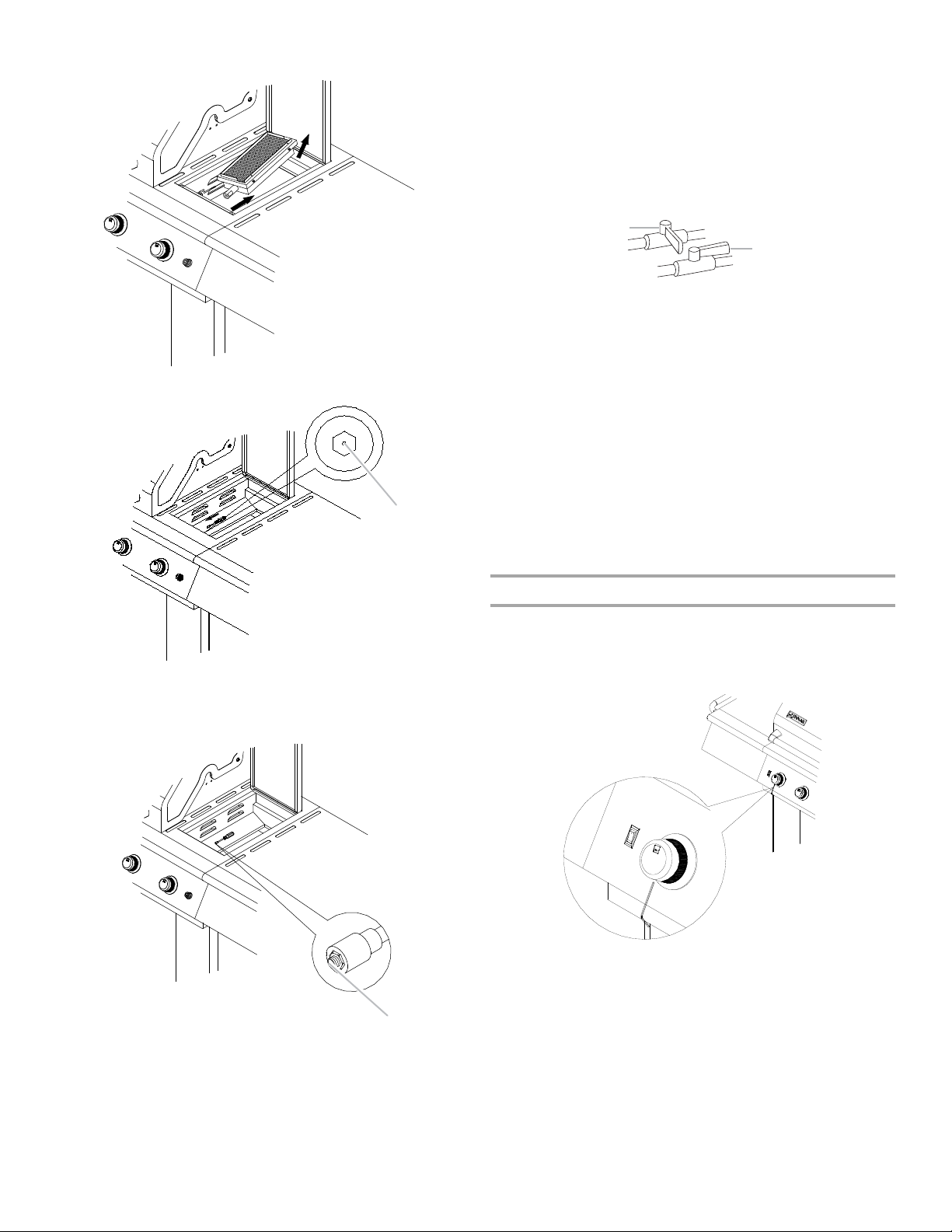

Change the Sear Burne r Orifice s

1. Remove the screw securing the ig nit er and the 2 searing side

burner screws.

15

2. Lift out the searing side burner.

A

A

A

B

3. Locate the Liquid propa ne orifi ce at the end of the valve.

5. Reinstall the searing side burner. Make sure that the igniter is

out of the way to allow proper positioning of burner. Use

Phillips screwdr iver to attach the mounting screws.

6. Use Phillips screwdriver to reattach the igniter and searing

side burner plate.

7. Reinstall searing side burner cover. Use Phillips screwdriver

to attach mounting screws.

8. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed val ve

B. Open valve

9. Test all connections using an approved noncorrosive leakdetection solution. Bubbles will show a leak. Correct any leak

found.

Record Conversion

1. The appliance nameplate is located inside the grill cabinet on

the left-hand cabinet side. With a permanent marker, check

the box next to “Natural gas” and mark through “LP Propane.”

In the last page of the Use and Care Guide, write “Converted to

Natural Gas.” Also record the conversion date and the technician/

company that perform ed the conv ersi on .

NOTE: Place LP gas parts in plastic parts bag for future use and

keep with pack containing literature.

A. Orifice

4. Use 6 mm socket wrench or 6 mm nut driver to remove the

orifice. Replace with the Natural gas orifice.

Adjust High Flame Setting Screw

When converting from LP to Natural gas, you will need to adjust

the high flame setting screw for ideal burner flame height.

1. Remove each control knob for the main burners and side

burner by loosening the set screw with the hex key.

A. Orifice

IMPORTANT: Check tha t the orifice is properl y installed ins ide

of the valve.

16

2. Use a flat-blade screwdriver to turn the high flame setscrew

1" (2.5 cm)

A

A

A

B

C

counterclockwise approximate 90°.

3. Check that burner operates at the new high flame setting. It

may be necessary to adjust the screw setting slightly more to

get the ideal burner flame height.

Check and Adjust the Burners

The burners are tested and factory-set for most efficient

operation. Howeve r, variations in gas supply and ot he r con dit ion s

may make minor adjustments to air shutter or low flame setting

necessary.

It is recommended that a qualified person make burner

adjustments.

NOTE: The rotisserie burner cannot be adjusted.

Checking and adjusting the grill burner flames requires removing

the grates and flame tamers.

Burner Flame Characteristics

The flames of the g rill burne rs and sid e burner s (on some m odels)

should be blue and stable with no excessive noise or lifting (LP

gas flames will h ave a sli ghtly y ellow t ip). A yello w fla me indic ates

not enough air . If flame is noisy or lif ts awa y from the burner, there

is too much air . Some yel low tips on flames when the burn er is set

to HIGH setting are acceptable as long as no carbon or soot

deposits appea r. The flames should be approximately 1" (2.5 cm)

high.

5. Remove the 1 screw and 1 cotter clip that hold the burner in

place. Remove gas burner from the grill.

A. Cotter Clip

6. If flame is yellow (not enough air), turn air shutter adjustment

screw counterclockwise.

If flame is noisy or lifts away from burner (too much air), turn

air shutter adjustment screw clockwise.

A. Air shutter adjustment screw

Adjustment should be made clockwise or counterclockwise

from 1/8" (3.2 mm) to 1/4" (6.4 mm).

7. Replace gas burner, flame tamers and grates.

8. Light grill using information in the “Outdoor Grill Use” section.

See “Burner Flame Characteristics. ”

Low Flame Adjustment

If flame goes out on the “LOW ” setting , the low flam e settin g must

be adjusted.

1. Turn off the valve and wait until grill and burners are cool.

2. Remove grill grates and flame tamers.

3. Light grill using information in the “Outdoor Grill Use” section.

4. Turn burner to its lowest setting.

5. Remove each control knob for the main burn ers and side

burner by loosening the setscrew with the hex key.

6. Hold valve stem with pliers and insert a small flat-blade

screwdriver into the shaft.

7. Watch the flame and slowly turn the screwdriver

counterclockwise.

8. Adjust flame to minimum stable flame.

Check that burners are not blocked by dirt, debris, insect nests,

etc., and clean as necessary. If they are clean, adjust air shutters

as needed.

IMPORTANT: Before adjusting air shutters, let burners cool

completely.

To Adjust:

1. Light grill using information in the “Outdoor Grill Use” section.

2. Observe flame to determine which burners need adjustment

and how the flame is acting.

3. Turn off the valve and wait until grill and burners cool

completely.

4. Remove grill grates and flame t am ers.

9. Replace the control knob and turn off the burner.

10. Repeat steps 3 through 9 for each burner if needed.

11. Replace the flame tamers and grates after the burners have

cooled.

A. Valve stem

B. Small flat -bl ade screwdriver

C. Pliers

17

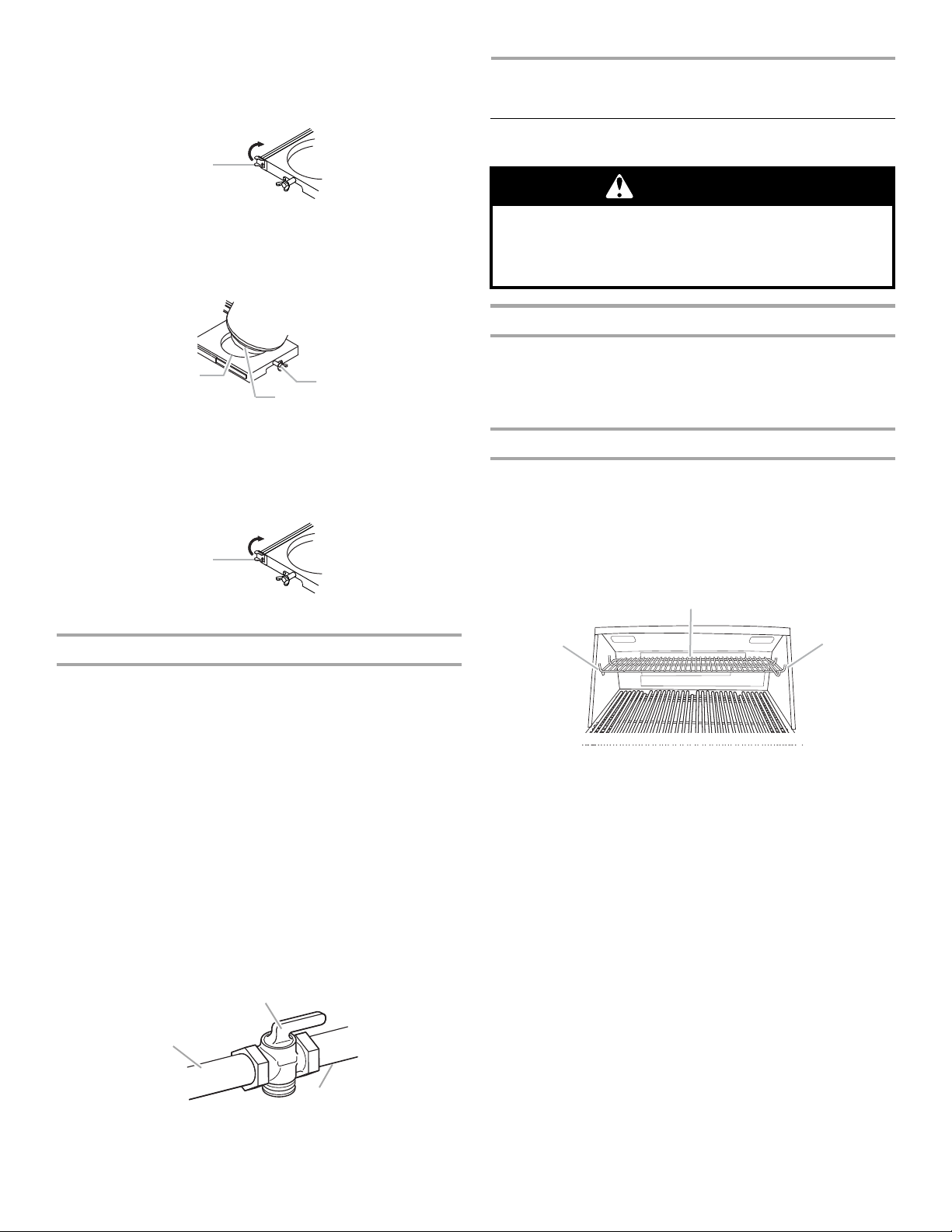

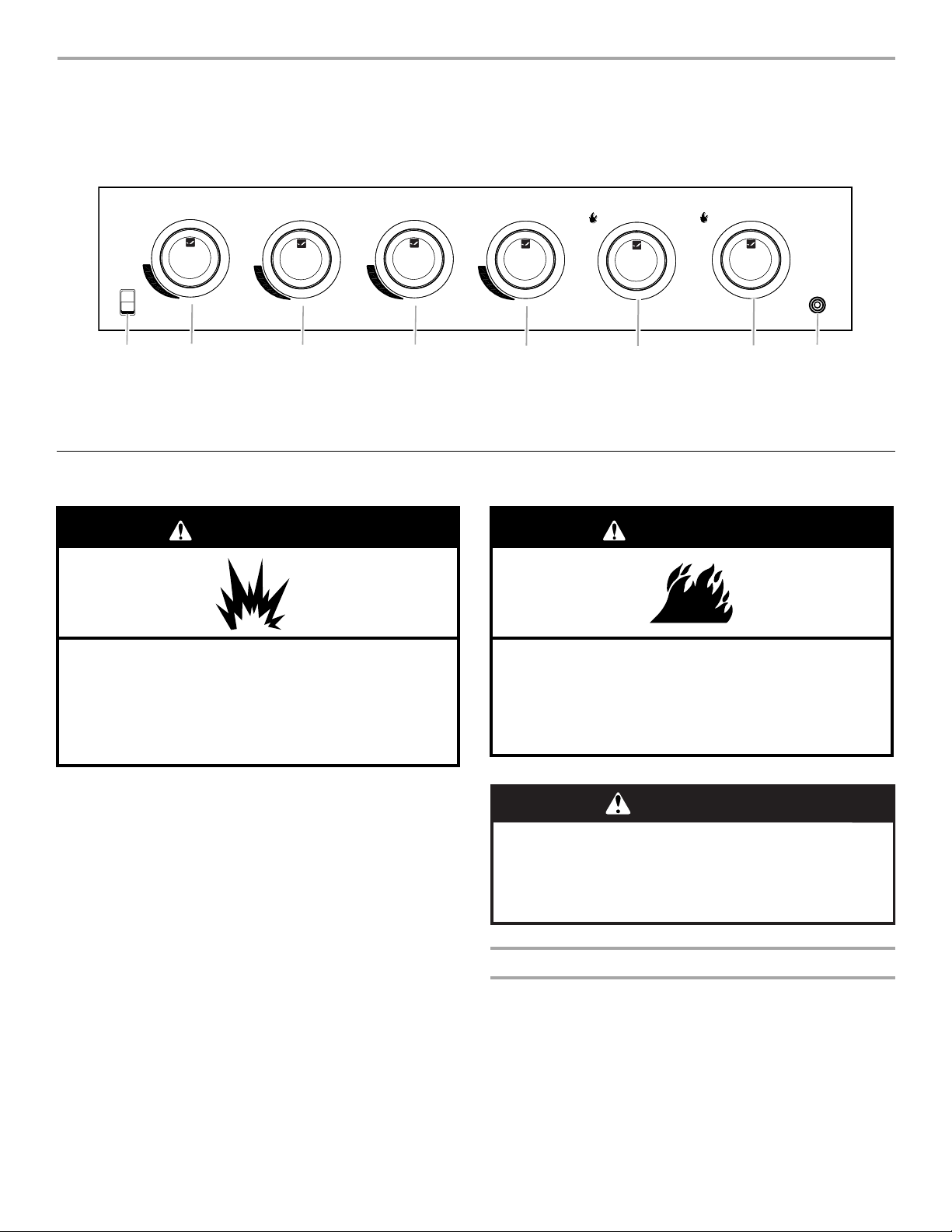

OUTDOOR GRILL USE

A

B

C

D

E

F

G

H

LOW

OFF

IGNITE

/HIGH

OFF

Rear Burner

IGNITE

/ON

OFF

Searing Burner

IGNITE

/ON

ON

OFF

LOW

OFF

IGNITE

/HIGH

LOW

OFF

IGNITE

/HIGH

LOW

OFF

IGNITE

/HIGH

WARNING

Explosion Hazard

Do not store fuel tank in a garage or indoors.

Do not store grill with fuel tank in a garage or indoors.

Failure to follow these instructions can result in death,

explosion, or fire.

WARNING

Fire Hazard

Do not use grill near combustible materials.

Do not store combustible materials near grill.

Doing so can result in death or fire.

WARNING

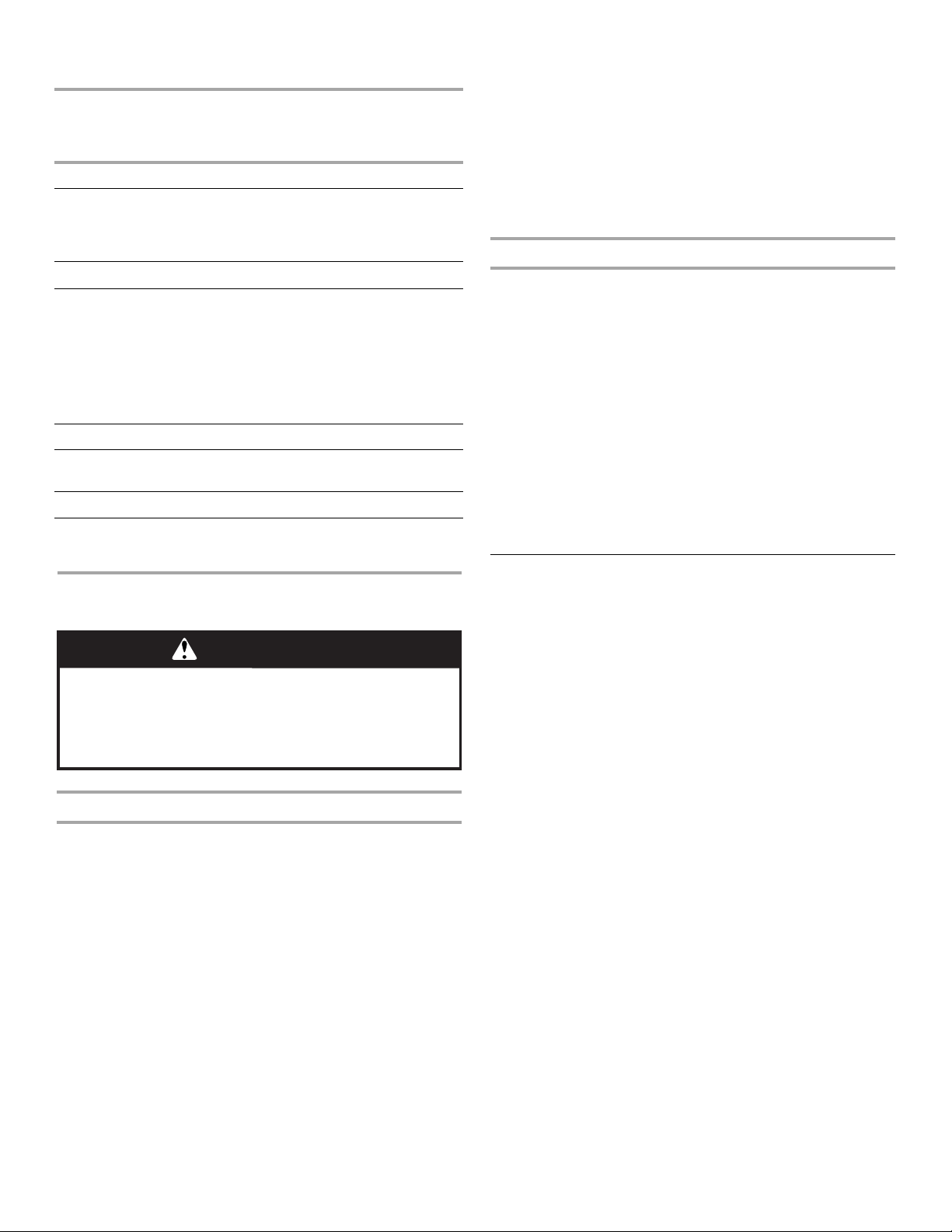

Food Poisoning Hazard

Do not let food sit for more than one hour before or

after cooking.

Doing so can result in food poisoning or sickness.

This manual co vers s everal d if fere nt mod els. T he gril l you have purch ase d may h ave s ome o r al l of th e featu res li st ed. The loca tio ns and

appearances of the features shown here may not match those of your model.

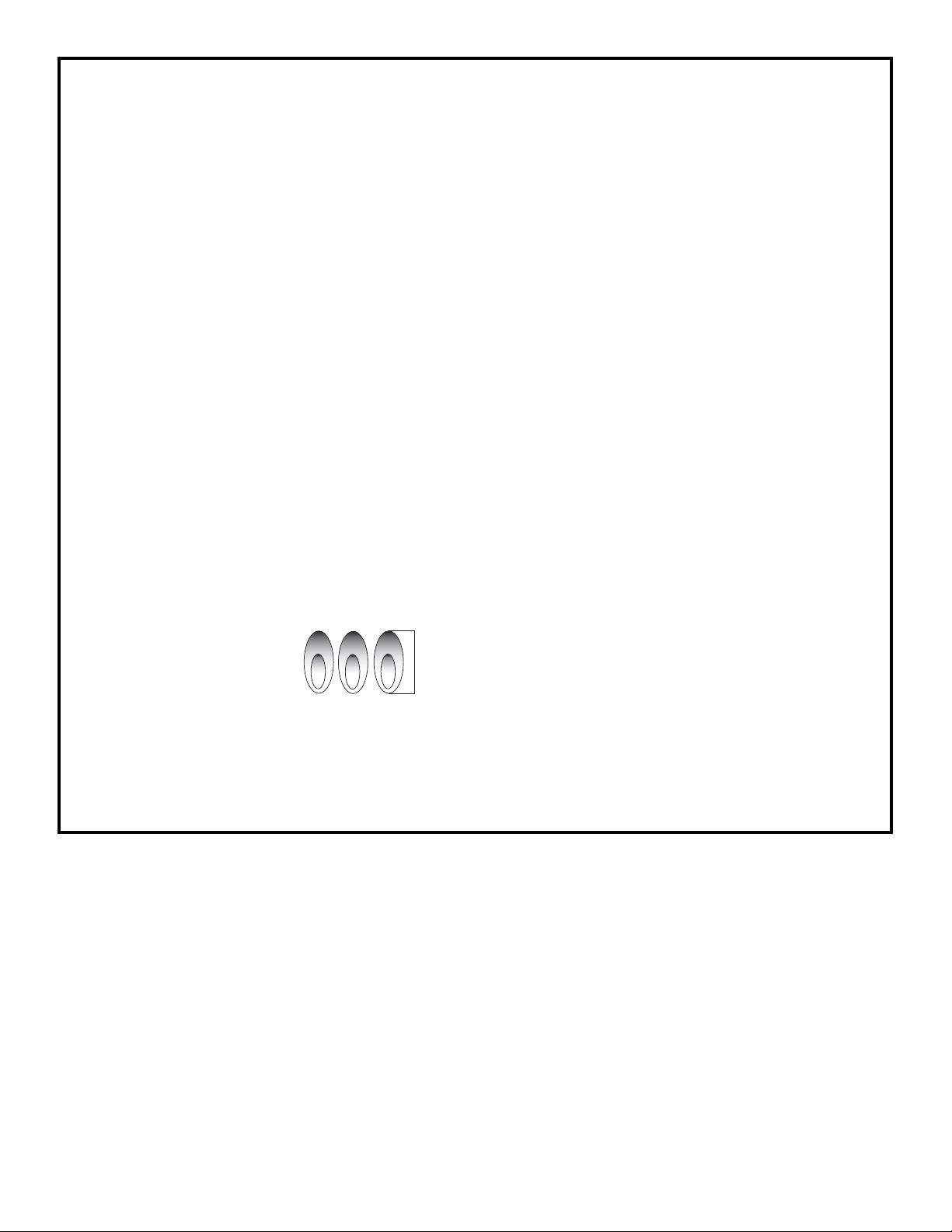

Control Panel

A. Hood lights switch

B. Main burne r control knob

C. Main burner control knob

D. Main burne r control knob

Using Y our Outdoor Grill

E. Main burner control knob

F. Rear burner control knob

G. Infrared sear burner control knob

H. Battery box

18

Inspect the LP Gas Fuel Tank Supply Hose

Inspect the gas pressure regulator/hose assembly before each

use.

1. Open right-hand cabinet door.

2. Inspect the gas pressure regulator/hose assembly for cuts,

abrasions, or excessive wear.

3. If necessary, replace the gas pressure regulator/hose

A

A

A

B

W

O

F

F

/O

N

R

e

a

B

u

r

n

e

r

r

assembly before using the grill.

Contact the dealer and use only replacement hoses specified

for use with the grill.

A. Gas pressure regulator/hose assembly

Prepare the Gril l for Lig hting

1. Open the hood completely. Do not light burners with the hood

closed.

2. Make sure cont rol knobs are turned to OFF. The drip p an must

be in place and pushed all the way to the back.

Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

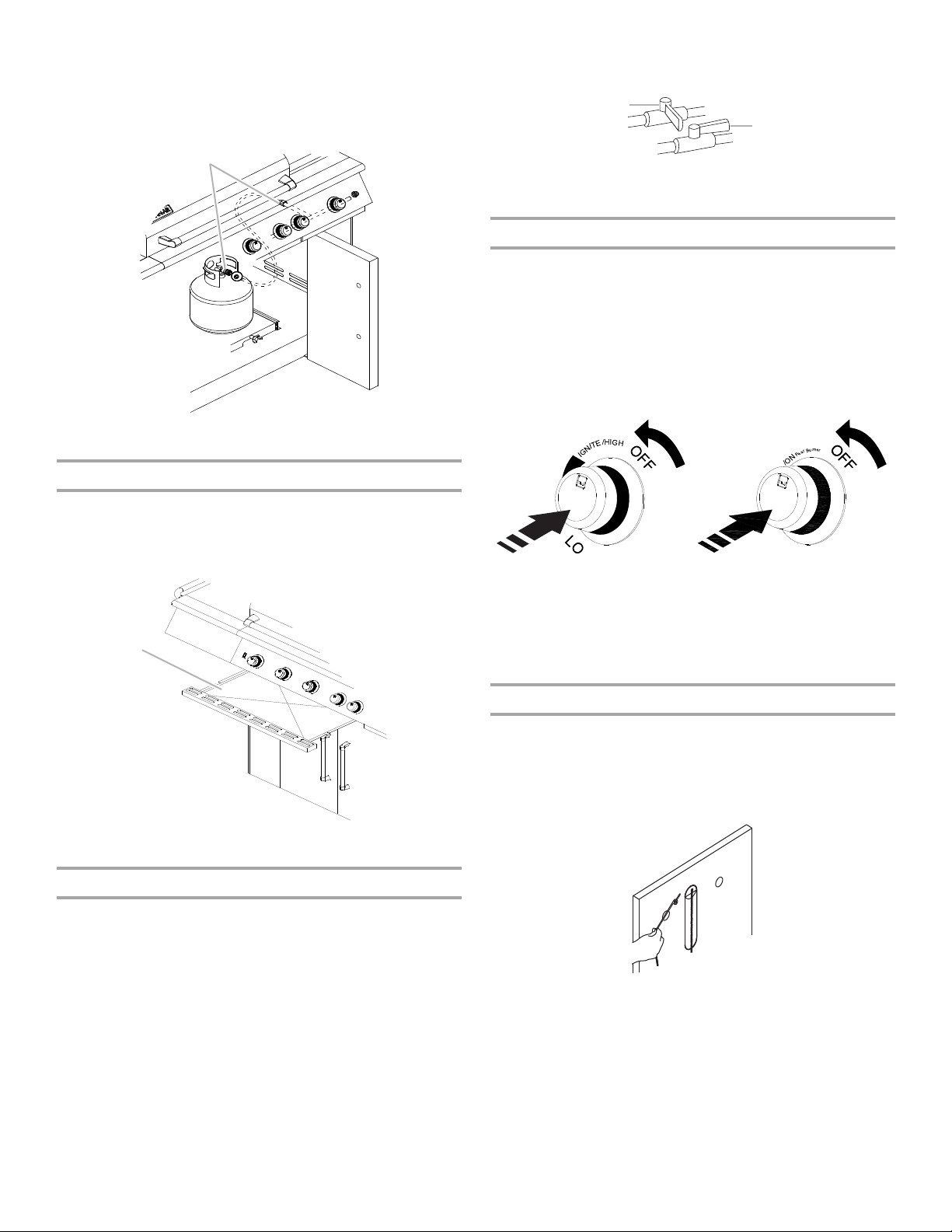

Lighting the Grill and Infrared Sear Burn er

IMPORTANT: If burner does not light immed iately, turn the burner

knob to OFF and wait 5 minutes before relighting.

1. Open the hood completely. Do not light burners with the hood

closed.

2. Do not lean over the grill .

3. Select the burner you want to light. Push in and turn the grill

burner control knob to IGNITE/HIGH or IGNITE/ON, while

continuing to hold it in.

4. You will hear the “snapping” sound of the spark. When burner

is lit, release the knob. Turn knob to desired setting.

5. Repeat for each of the other burners as needed.

IMPORTANT: If burner does not light immediately, turn the

burner knob to OFF and wait 5 minutes before relighting.

Manually Lighting the G rill and Infrared Sear Burne r

1. Open the hood completely. Do not light burners with the hood

closed.

2. Do not lean over the grill .

3. Remove the manual lighting extension (see the following

illustration) and attach a match to the split ring.

A. Drip pan

T ur n the Gas Suppl y On

1. For outdoor grills using a 20 lb LP gas fuel tank:

Slowly open the tank valve.

NOTE: If flow limiti ng devi ce ac tivate s, you r grill m ay not ligh t.

If your grill does light, the flames will be low and will not heat

properly. Turn tank valve and all control knobs off and wait 30

seconds. After shutting off the tank, very slowly open tank

valve and wait 5 seconds before lighting.

2. For outdoor grills u sin g g as sup pl y s our ce o the r tha n 20 lb LP

gas fuel tank:

4. Strike the match to light it.

19

5. Guide the lit match under the grill grate.

W

O

F

F

/O

N

R

e

a

B

u

r

n

e

r

r

2

1

2

6. Push in and turn the burner knob to IGNITE/HIGH or IGNITE/

ON for the burner closest to the lit matc h. Th e burn er w ill li ght

immediately. When burner is lit, turn knob to desired sett ing.

7. Repeat steps 2 through 6 for each main burner.

8. Remove match and replace manual lighting extension on the

right side panel.

IMPORTANT: If burner does not light immediately, turn the burner

knob to OFF and wait 5 minutes before relighting.

If any burners do not light after attempting to light them manually,

contact the Customer Service Center. See the “Assistance”

section.

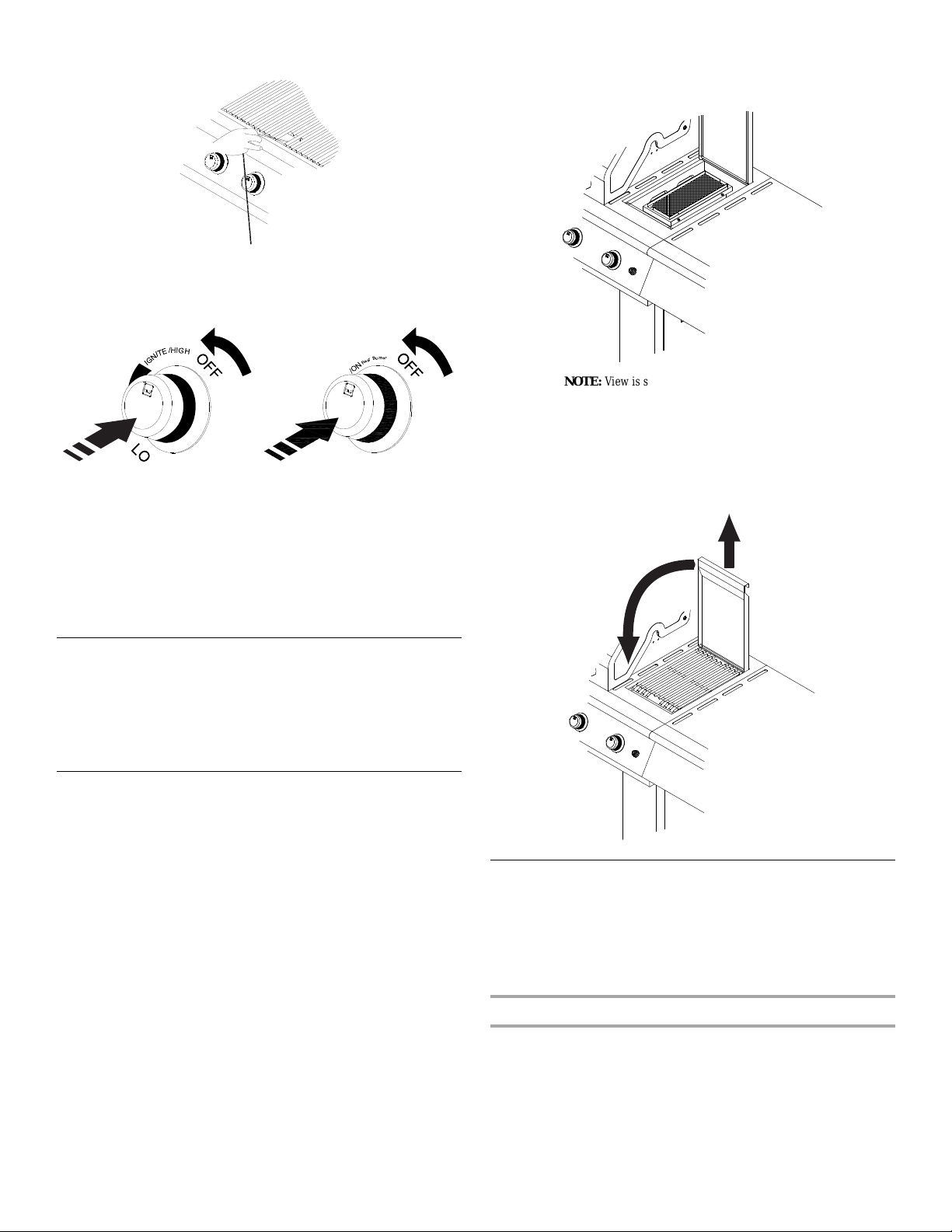

■ Use the infrared sear burner to sear meat 1 to 2 minutes on

each side, then move the meat to the main grill cooking

surface to finish grilling to the desired doneness.

NOTE: View is s ho wn with grates removed. Grates are to be

in place when using the infr ared sear burner.

IMPORTANT: It is recommended that the in frare d sear bur ner

lid be raised when the burner is in use to eliminate the

possibility of increased lid and handle temperatures.

■ To close the infrared sear burner lid, first lift up the lid to

release the lock then lower it to the closed position.

Hood Lights

The grill must be plu gg ed i n fo r the hood lights to w ork . See “Plu g

in Grill” in the “Freestanding Outdoor Grill Installation” section.

To Us e:

Press the LIGHTS button on the control panel to turn the hood

lights on and off.

Using Y our Infrared Sear Burner

Infrared grilling produces intense heat which quickly sears the

meat. Searing locks in flavor and juices while allowing the outer

surface to absorb smoke and food aroma that is produced as

grease and drippings are vaporized by the burner. The result is a

crisp, flavorful outside with a tender, juicy inside.

■ Preheat the infrared sear burner for 5 minutes.

■ Ensure that meats are fully thawed and that all excess fat is

trimmed away prior to grilling.

■ Leave the burner set to On when placing food on the grill to

sear.

Using Y our Rotisserie Burner

A Rotisserie kit can be purchased as an accessory for the grill.

See “Accessories” in the “Assistance” section .

To avoid damage to the warming rack, remove from grill when

using the rotisserie burner.

Do not use the main burners when the rotisserie burner is in use.

Lighting the Rotisserie Burner

1. Open the hood completely. Do not light burners with the hood

closed.

2. Do not lean over the grill .

20

3. Push in and turn the control knob to IGNITE/O N. You will hear

O

F

F

/O

N

R

e

a

B

u

r

n

e

r

r

A

B

O

F

F

/O

N

R

e

a

B

u

r

n

e

r

r

WARNING

Food Poisoning Hazard

Do not let food sit for more than one hour before or

after cooking.

Doing so can result in food poisoning or sickness.

the “snapping” sound of the spark .

4. When the rotisserie burner lights, continue to hold the knob in

for another 10 seconds, th en release the knob and bu rner w i ll

stay lit. You will hear the “snapping” sound of the spark until

the knob is released.

IMPORTANT: If the rotisserie burner does not light immediately,

turn the burner knob to OFF and wait 5 minutes before relighting.

Manually Lighting the Rotisse rie Burner

1. Open the hood completely. Do not light burners with the hood

closed.

2. Do not lean over the grill.

3. Remove the manual lighting extension (see the following

illustration) and attach a match to the split ring.

7. Remove the match and repl ac e the ma nu al li ghting extension

inside the cabinet door.

Rotisserie Cooking Tips

Rotisserie cooking rotates food in front of the rotisserie burner,

creating an intense heat for searing the outside and sealing in

natural juices.

The rotisserie burner reaches cooking temperatures in about

1 minute. It is not necessary to preheat when using the rotisserie.

■ Select tender meat and poultry.

■ Allow at least 1" (2.5 cm) sp ace betwee n rotisseri e burner and

the food.

■ To make cleanup easier, place a pan under the food to catch

drippings.

■ Add barbecue sauce or glaze only during the last 10 minutes

of cooking to keep sauce from burning.

4. Strike the ma tch to light it .

5. Gently hold the lit match close to the rotisserie burner.

A. Lighting extension

B. Rotisserie burner

6. Push in and turn the control knob to IGNITE/ON. Hold this

knob in for 10 seconds after the burner is lit. You will hear the

“snapping” sound of the spark until after the knob is released.

Trussing Poultry for the Rotisserie

1. Load the spit rod by sliding one of the forks on the rod, with

the prongs facing inward. Tighten the screw to keep it from

slipping.

2. Push the rod through the center of the bird.

3. Cut 24" (61.0 cm) of butcher’s string and center it under the

bird, breast side up.

4. Wrap each end of the string arou nd the wings; catch each

wing tip. Bring the string tightly together at the top of the

breast and knot. It is not necessary to cut off the extra string.

5. Cut another 20" (50.8 cm ) of string an d lay it und er the back of

the bird. Wrap it around the tail then around the spit rod,

cinching tightly.

6. Cross the l egs o n top of spit rod; tie s trin g around the crossed

legs.

7. Connect the twine holding the legs, to the string holding the

wings, and knot. Cut off any bits of hanging string.

8. Slide on the s eco nd fork pus hi ng th e ti nes int o the dru ms tic ks .

9. Center the food and forks on the rod and tighten the thumb-

screws. The bird shou ld be firm ly in pla ce on the rotisserie s pit

rod.

ROTISSERIE CHART

Use a portable meat thermometer to check internal doneness of

the food.

Turn off rotisserie burner when meat thermometer reads 5°F/3°C

lower than desired internal temperature. Continue rotating, hood

closed, for 10 minutes before carving.

IMPORTANT: If the rotisserie burner does not light

immediately, turn the rotisserie burner control knob to OFF

and wait 5 minutes before relighting.

21

Timing is af fected by weather c onditions such a s wind an d outs ide

WARNING

Food Poisoning Hazard

Do not let food sit for more than one hour before or

after cooking.

Doing so can result in food poisoning or sickness.

temperature.

Food Weight Internal

Doneness or

Temperature

Approximate

Grilling Time

(min/lb)

(°F/°C)

Beef

Roasts

Rib Eye

Sirloin Tip

Rib, boneless

4-6 lbs

(1.5-2.2 kg)

Medium-rare

(145°F/ 63°C)

Medium

(160°F/71°C)

15-20

20-25

Poultry

Chicken

3-6 lbs

(1.1-2.2 kg)

Breast

(170°F/ 77°C)

Thigh

25-30

25-30

(180°F/82°C)

Turkey, whole

7-10 lbs

(2.6-3.7 kg)

Breast

(170°F/77°C)

Thigh

11-20

11-20

(180°F/82°C)

Lamb

Boneless leg 4-7 lbs

(1.5-2.6 kg)

Medium

(160°F/71°C)

20-25

Pork

Loin roast,

boneless

4-6 lbs

(1.5-2.2 kg)

Medium

(160°F/71°C)

20-23

■ Lightly oil the grill grate s or the food w hen cooking low-fat cut s

of meat, fish or poultry, such as lean hamburger patties,

shrimp or skinless chicken breasts.

■ Using too much oil can cause gray ash to deposit on food.

■ Trim excess fat from meats prior to cooking to reduce

flare-ups.

■ Make vertical cuts at 2" (5 cm ) intervals around the fat edge of

meat to avoid curling.

■ Add seasoning or salt only after the cooking is finished.

During Grilling

■ Turn foods only once. Juices are lost when meat is turned

several times.

■ Turn meat just when juices begin to appear on the surface.

■ Avoid puncturing or cutting the meats to test doneness. This

allows juices to escape.

■ It may be necessary to lower the heat setting for foods that

cook a long time or are marinated or basted in a sugary

sauce.

■ If using a high fla me, add barbecue sauce onl y d uri ng the last

10 minutes of cooking to avoid burning the sauce.

■ The degree of donenes s is influ enced by the ty pe of me at, cut

of meat (size, shape and thickness), heat setting selected,

and length of time on the grill.

■ Cooking time will be longer with an open grill cover.

TIPS FOR OUTDOOR GRILLING

Before Grilling

■ Thaw food items before grilling.

■ Preheat grill on high (use all grill burners) 10 minutes. The

hood must be closed during preheating. There is no need to

use the back rotisserie burner for preheating. Preheating

provides the high heat needed to brown and seal the juices.

■ Shorten the preheat time w hen gri lling h igh-fat cuts of meat or

poultry, such as chicken thighs. This will help reduce

flare-ups.

Cooking Methods

Direct Heat

Cooking by direct heat means the food is placed on grill grates

directly above lighted burners. Hood position can be up or down.

If hood is in the up position, total cooking times may be longer.

Direct heat sears the food. Searing i s a p r oces s that seals nat ural

juices in food by cooking with intense heat for a short period of

time. While juices stay inside, the outside is browned with a

flavorful grilled coating.

Indirect Heat

For best results, do not select the indirect heat cooking method

when it is windy.

Cooking by indirect heat means the food is placed on the grill

grate above an unheated burner, allowing heat from lighted

burner(s) on either side to cook the food.

If possible, turn on 2 burners. Cook with the hood down. This will

shorten the cooking time.

22

■ Knobs have High, Medium and Low settings for flame

adjustment.

■ Heat settings indicated are approximate.

■ Grilling times are aff ec ted by weat her con dit ion s.

Grilling Chart

■ When 2 temperatures are listed, for example: Medium to

Medium-Low, start with the first and adjust based on cooking

progress.

■ Cooking times may vary from chart times depending on the

type of fuel, Natural or LP gas.

FOOD COOKING METHOD/

BURNER SETTING

Beef

Hamburgers ½" (1.3 cm) to

¾" (1.9 cm) thick

Roasts

Rib Eye, Sirloin

Steaks, 1" (2.5 cm)

Porterhouse, Rib, T-bone,

DIRECT

Medium

INDIRECT

Medium/OFF/Medium

DIRECT

Medium

Top Loin, Sirloin

Steaks, 1½" (3.8 cm)

Porterhouse, Rib, T-bone,

DIRECT

Medium

Top Loin, Sirloin

Top Round or Shoulder/

Chuck (London Broil)

DIRECT

Medium

1½" (3.8 cm) thick

Flank, ½" (1.3 cm) thick

DIRECT

Medium

Pork

Chops,

1" (2.5 cm)

1½" (3.8 cm) thick

Ribs

2½-4 lbs (0.9-1.5 kg)

Roast, boneless tenderloin,

1 lb (0.37 kg)

Ham half,

8-10 lbs (3-3.7 kg)

DIRECT

Medium to Med-Low

INDIRECT

Med/OFF/Med

DIRECT

Medium

INDIRECT

Med/OFF/Med

INTERNAL TEMP. TIME

(total minutes)

Medium (160°F/71°C)

Med-Rare (145°F/63°C)

to Medium (160°F/71°C)

Med-Rare (145°F/63°C)

10-15

32-40 per lb

(15-18 per kg)

11-16

to Medium (160°F/71°C)

Med-Rare (145°F/63°C)

18-25

to Medium (160°F/71°C)

Med-Rare (145°F/63°C)

22-29

to Medium (160°F/71°C)

Med-Rare (145°F/63°C)

Medium (160°F/71°C)

11-16

12-22

30-40

Medium (160°F/71°C)

Medium (160°F/71°C)

Reheat (140°F/60°C)

40-60

18-22

2-2½ hours

SPECIAL INSTRUCTIONS

Grill, turning once.

Tent with foil first 45-60 minutes

of cooking time.

Rotate steaks ¼ turn to create

criss-cross grill marks.

Grill, turning occasionally.

During last few minutes brush

with barbecue sauce if desired.

When done, wrap in foil.

Turn during co oking to brown on

all sides.

Wrap entire ham in foil and put

on grill without pan or drip pan.

Ham steak precooked,

½" (1.3 cm) thick

Hot Dogs

Chicken

Breast, boneless

Pieces, 2-3 lbs (0.75-

1.1 kg)

Lamb

Chops and Steaks,

Loin, Rib, Sirloin

1" (2.5 cm) thick

1½" (3.8 cm) thick

DIRECT

Preheat Medium

Grill Medium

DIRECT

Medium

DIRECT

Medium

DIRECT

Med-Low to Medium

DIRECT

Medium

DIRECT

Medium

Reheat (145°F/63°C)

Reheat (145°F/63°C)

170°F/77°C

Breast 170°F/77°C

Thigh 180°F/82°C

Med-rare (145°F/63°C)

to Medium (160°F/71°C)

Med-rare (145°F/63°C)

to Medium (160°F/71°C)

7-10

5-10

Slit skin if desired.

15-22 For even cooking, poun d breas t

to ¾" (2.0 cm) thick.

Start bone side down.

10-20

16-20

23

FOOD COOKING METHOD/

Fish and Seafood

Fillets, Steaks, Chunks

Halibut, Salmon,

Swordfish, 8 oz (0.25 kg)

Whole, Catfish, Rainbow

Trout, 8-11 oz (0.25-

0.34 kg)

Shellfish, Scallops, Shrimp

Turkey

BURNER SETTING

DIRECT

Medium

DIRECT

High

DIRECT

Medium

INTERNAL TEMP. TIME

(total minutes)

4-6 per

½" (1.3 cm)

thickness of fish

5-7 per side

4-8

SPECIAL INSTRUCTIONS

Grill, turning once. Brush grill

with oil to keep fish from

sticking. Remove when inside is

opaque and flaky with skin

easily removed.

Whole breast (bone-in)

Half breast (bone-in)

Whole,

7-12 lbs (2.6-5.4 kg)

Fresh Vegetables

Corn on the cob

Eggplant

Onion,

½" (1.3 cm) thick

Potatoes,

Sweet, whole

Baking, whole

Peppers,

Roasted

Squash,

Summer, Zucchini

Garlic

Roasted

INDIRECT

High/OFF/High

INDIRECT

Medium/OFF/Medium

INDIRECT

High/OFF/High

DIRECT

Medium

DIRECT

Medium

DIRECT

Medium

DIRECT

Medium

DIRECT

High

DIRECT

High

DIRECT

Medium

DIRECT

Medium

170°F/77°C

170°F/77°C

Breast 170°F/77°C

Thigh 180°F/82°C

14-18 per lb

(7-8 per kg)

25-30 per lb

(11-14 per kg)

11-16 per lb

(5-7 per kg)

20-25

7-10

8-20

40-70

45-90

15-22

7-10

20-25

Tent with foil until last

30 minutes of cooking time.

Start skin side down.

Less than 11 lbs (5.0 kg)

Soak in cold water 20 minutes.

Do not husk. Shake off excess

water.

Wash and cut into ½" (1.3 cm)

slices or lengthwise. Brush with

olive oil.

Grill, turning once. Brush with

olive oil. Put a skewer through

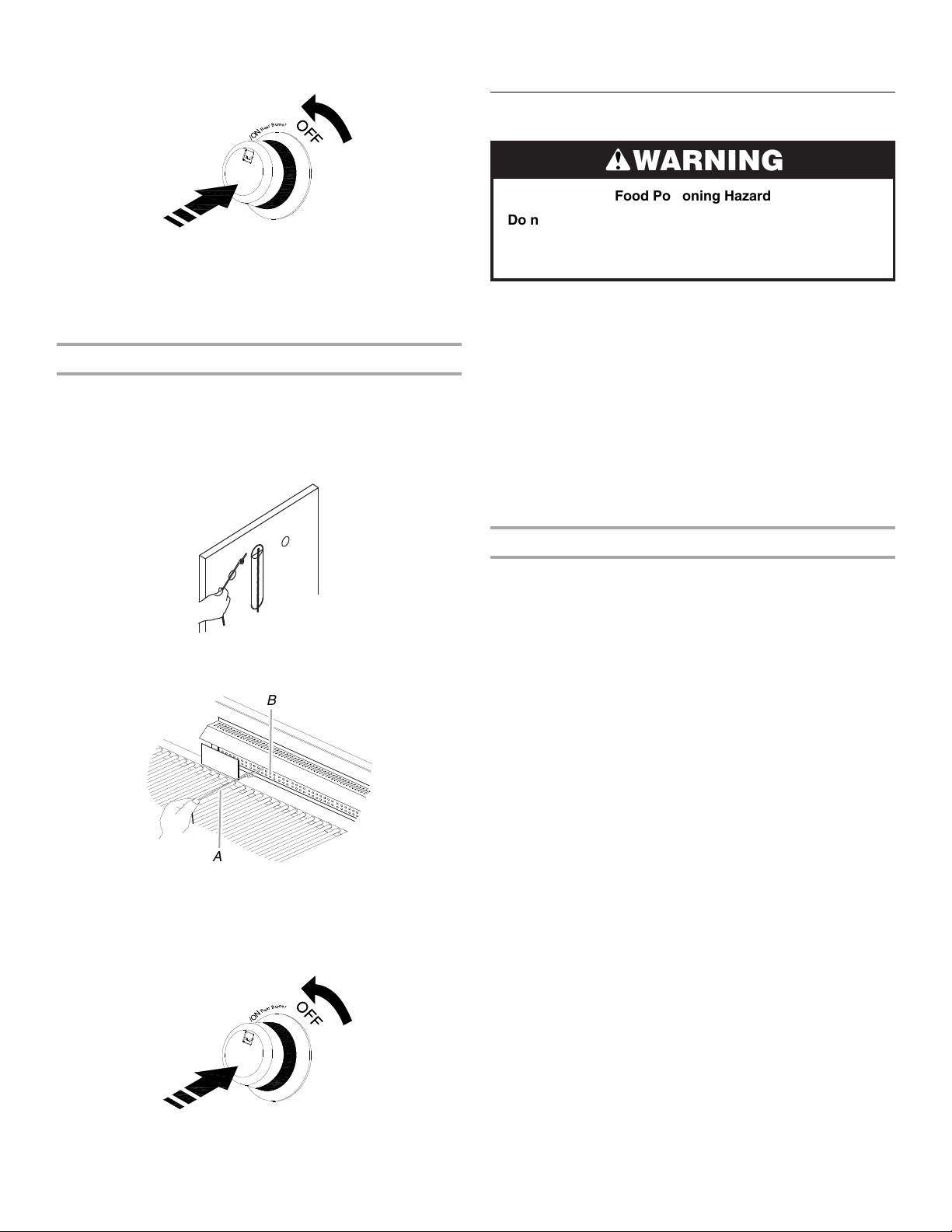

several slices to hold together.

Individually wrap in heavy-duty

foil. Grill, rotating occasionally.

Wash and place on grill whole.

Char skin all around. Cool in a

paper bag or plastic wrap to

loosen blackened skin. Peel

and remove seeds.

Wash and cut into ½" (1.3 cm)

slices or lengthwise. Brush with

olive oil.

Cut off top, drizzle with olive oil

and wrap in double layer of foil.

24

OUTDOOR GRILL C ARE

A

B

A

B

A

B

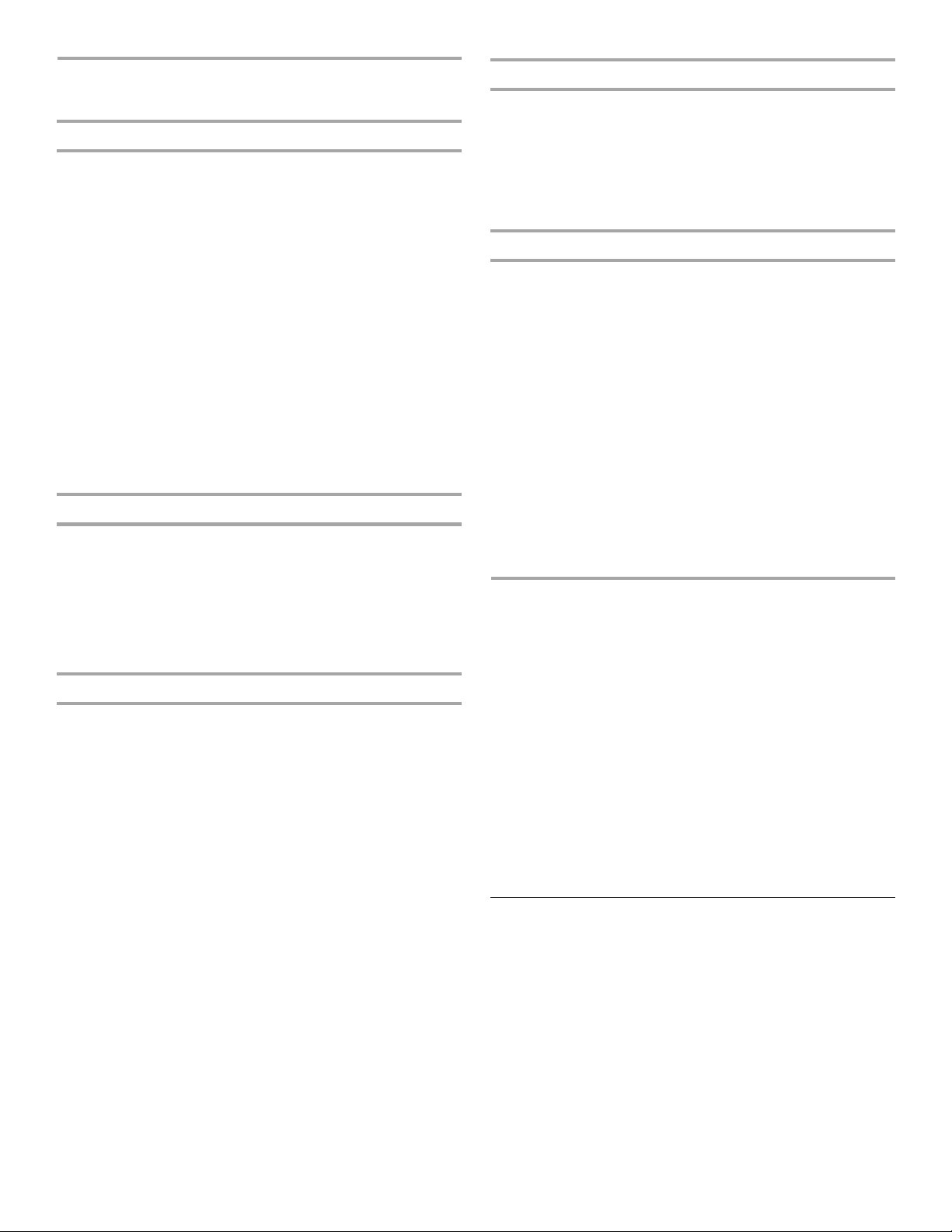

Replacing the Igniter Battery

If igniters stop sparking, the battery should be replaced.

1. Open cabinet door.

2. Unscrew igniter button cap counterclockwise to remove.

A. “AA” size battery

B. Igniter cap

3. Remove battery from the battery compartment.

4. Replace with a new alkaline “AA” size battery. Install battery

with negative end in first.

5. Screw igniter button cap clockwise into place.

Changing the Light Bulb

1. Unplug grill or disconnect power.

2. Make sure the ligh t p ow er switch on the contr ol p an el is in the

OFF position.

3. Use a Phillips screwdriver to loosen the two screws securing

the glass light cover to the grill hood.

4. Loosen the sc rew securi ng the lig ht asse mbly to the grill ho od

and pull out the light with glass light cover.

A. Screw

B. Light assembly

5. To remove glass light cover, remove screw and gently pry

downward with a small flat-blade screwdriver at the left edge

of the cover near the screw and pull away from the retainer.

A. Screws

B. Hood light cover

NOTE: When removing final screw from the glass light cover,

make sure to hold the cover in place, ensuring it doesn’t fall

and shatter.

25

6. Use a flat-blade screwdriver to remov e the two screws locking

A

A

the bulb into place.

A. Screws

7. Remove bulb from socket.

8. Replace bulb with a new 12-volt, 10-watt maximum, halogen

bulb, using a tissue or w earing cotton gloves to handle the

bulb. To avoid damaging the bulb, do not touch the bulb with

bare fingers.

A. Bulb

Cleaning Method:

■ Rub in direction of grain to avoid scratching or damaging the

surface.

■ Stainless steel cleaner

■ Liquid detergent or all-purpose cleaner:

■ Rinse with clean water and dry with soft, lint-free cloth.

■ Vinegar to remove hard water spots.

■ Glass cleaner to remove fingerprints.

GRILL GRATES

IMPORTANT: To avoid damage to grill grates, do not use a steel

or fiber scraper. Immediately after you are finished cooking,

loosen food soil with a brass bristle brush. Turn all burners to

HIGH for 10-15 minutes with the hood clo sed to burn of f foo d soil.

Turn off all burners, raise the hood and let grates cool. Use the

brass bristle brush to remove ash from the grill grates.

When completely cool, grill racks can be removed for thorough

cleaning. Clean them with a mild detergent and warm water.

For baked-on soil, prepare a solution of 1 cup (250 mL) ammonia

to 1 gal. (3.75 L) water. Soak grates for 20 minutes, then rinse

with water and dry completely.

WARMI NG SH ELF

Cleaning Method:

■ Liquid detergent or an all-purpose cleaner.

■ Rinse with clean water and dry with soft, lint-free cloth.

■ For tough spots or baked-on grease, use a commercial

degreaser designed for stainless steel.

IMPORTANT: Make sure gas supply is off and all control knobs

are in the Off position.

9. Tighten the two screws to lock the bulb into place.

10. Replace glass light cover onto light assembly. Secure light

assembly into the grill hood with the removed in Step 4.

Secure glass light cover onto grill hood with two screws

removed in Step 3.

11. Plug in grill or reconnect power.

General Cleaning

IMPORTANT: Before cleaning, make sure all controls are off and

the grill is cool. Always follow label instructions on cleaning

products.

For routine cleaning, wash with soap and water using a soft cloth

or sponge. Rinse with clean water and dry at once with a soft, lintfree cloth to avoid spots and streaks.

Do not use steel wool to clean the grill, as it will scratch the

surface.

To avoid weather damage to finish, use vinyl grill cover.

ST AINLESS STEEL

IMPORTANT: T o a void d amag e to st ain less steel surfac es, do not

use soap-filled scouring pads, abrasive cleaners, cooktop

polishing creme, steel wool, gritty washcloths or paper towels.

Cleaners should not contain chlorine. Damage may occur.

Food spills shou ld be c le ane d as so on as entire grill is co ol. Spills

may cause permanent discoloration.

EXTERIOR

The quality of this material resists most stains and pitting,

providing that the surface is kept clean, polished and covered.

■ Apply stainless steel polish to all non-cooking areas before

first use. Reapply after each cleaning to avoid permanent

damage to surface.

■ Cleaning should always be followed by rinsing with clean

warm water.

■ Wipe the surface completely dry with a soft cloth.

■ For tough spots or baked-on grease, use a commercial

degreaser designed for stainless steel.

INTERIOR

Discoloration of stainless steel on these parts is to be expected,

due to intense heat from the burners. Always rub in the direction

of the grain. Cleaning should always be followed by rinsing with

clean, warm water.

Cleaning Method:

■ Liquid detergent or all-purpose cleaner.

■ Rinse with clean water an d dry co mplete ly with a sof t, li nt-free

cloth.

■ A heavy-duty scrub sponge can be used with mild cleaning

products.

■ For small, difficult-to-clean areas, use a commercial

degreaser designed for stainless steel.

26

BURNERS

A

A

ROTISSIERE BURNER

Cleaning Method:

■ Clean the exterior of the burner with a wire brush.

■ Clear any clogged burner ports with a straightened paper clip.

■ Do not use a toothpick as it may break off and clog the port.

■ Check and clean burner/venturi tubes.

1. Remove grill grates and flame t am ers.

2. Remove the 1 screw and 1 cotter clip that hold the burner

in place. Remove gas burner from the grill.

A. Cotter Clip

3. Use a flashlight to inspect into the burner through the

burner inlet to ensure there is no blockage. I f any

obstruction is se en, use a met al coat hange r that has be en

straightened to clear them.

4. After inspecting the inside of burner for blockage,

reassemble burner by sliding the middle tube of the gas

burner over the gas orifice.

Cleaning Method:

1. Light the rotisserie burner. See the “Using Your Rotisserie

Burner” section.

2. Close the grill hood.

3. Leave the burner on high for approximately 30 minutes.

4. Turn knob to OFF and let cool completely.

5. Brush off ash particles from the rotisserie burner.

DRIP TRAY

IMPORTANT: The drip tray should only be removed when grill is

completely cool.

The full-width drip tray collects grease and food particles that fall

through the grill. Clean often to avoid grease buildup.

Cleaning Method:

■ Remove tray and set on a flat surface.

■ Wipe excess grease with paper towels.

■ Mild detergent and warm water. Rinse and dry thoroughly.

■ Replace tray.

KNOBS AND FLANGE ARE A AROUND KN OBS

IMPORTANT: To avoid damage to knobs or flange area around

knobs, do not use steel wool, abrasive cleaners, or oven cleaner.

Do not soak knobs.

Cleaning Method:

■ Mild detergent, a soft cloth and warm water.

■ Rinse and dry.

A. Burner/orifice connection

5. Reattach gas burner using 1 screw and 1 cotter clip.

INFRARED SEAR B URNER

Cleaning Method:

■ Clean the exterior of the infrared sear burner with a wire

brush.

CONTROL PANEL GRAPHICS

IMPORTANT: To avoid damage to control panel graphics, do not

use steel wool, abrasive cleaners or oven cleaner.

Do not spray cleaner directly onto panel.

Cleaning Method: