Newport Brass 1-741, 1-742, 1-743, 1-744 Installation Manual

1-742

1-743

2001 CARNEGIE AVE, SANTA ANA CA 92705

(949) 417-5207

WWW.NEWPORTBRASS.COM

INSTALLATION INSTRUCTIONS

1/2” THERMOSTATIC VALVE AND TRIM

Valve Model No's: 1-741, 1-742, 1-743, 1-744

1-744

1-741

General Characteristics

In case of instantaneous heaters, hot water flow has to at least meet flow required by heater

and maintain burning. (Specified by heater manufacturer)

Operating Specifications

Hot water supply temperature:

Maximum: 185°F (85°C).

Note 1: Maximum temperature through this valve is limited by that of the hot water supply

(up to a maximum of 120°F when accurately calibrated).

Note 2: Minimum difference between hot and mixed temperature is 18°F (10°C).

Cold water supply temperature:

Minimum: 41°F (5°C)

Operating Pressure:

Maximum: 80 PSI

Minimum: 20 PSI

Operating pressure (on hot and cold line) should be kept as balanced as possible in order to

assure maximum efficiency.

When the pressure is greater than 80 PSI, a pressure reducer is required to be fitted

before valve.

Technical Data

The temperature control knob is graduated from 75°F to 120°F with auto stop at 100° to

avoid scalding.

Plumbing Recommendations

• An independent water supply for both hot and cold is required. Do not pipe off ring main.

• Large runs of pipe work will cause frictional loss of pressure.

• The recommended main water supply piping to valve shall be 1/2” minimum

• If more than one valve is installed, the recommended main water supply piping to valve shall

be 3/4” minimum, reducing to 1/2” within 24” of each valve.

(Ensure adequate supply from both hot and cold water can be maintained.)

Water By-Laws

The mixing valve should be installed in compliance with the water by-laws. For further details

refer to the latest copy of by-laws guide or your local water authority.

NWP-1-742

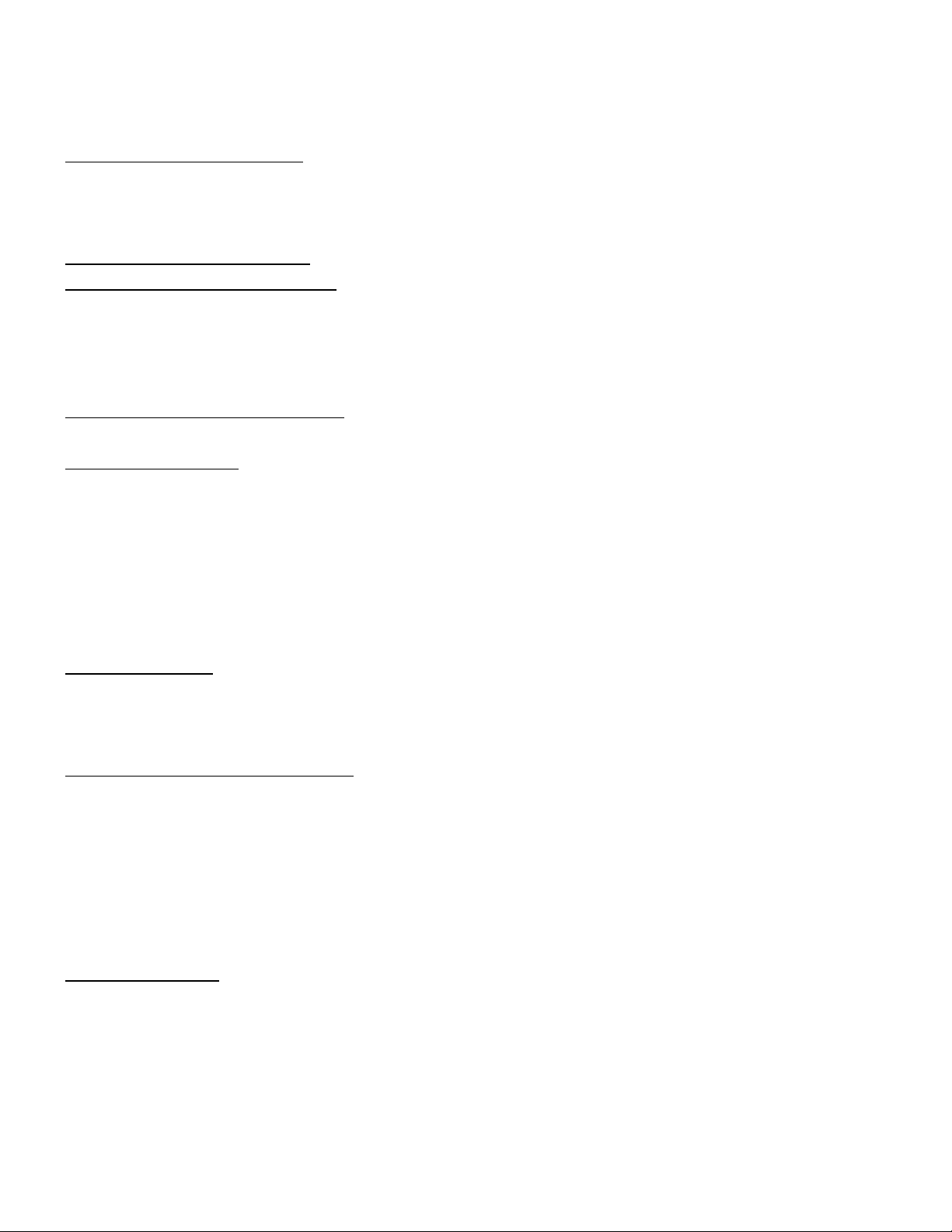

I. Rough in Valve Installation

Note: Use plumbers tape or equivalent to seal all threaded port joints. This valve is design to fit in

a 2" X 4" stud wall (or thicker) installation. Use stem extension kit #1-384 (sold seperately) if valve

installed is too far away from the finished wall.

1. Do not remove mud cover from valve before locating mounting surface depth in the wall.

2. Do not turn the cartridge stem - temperature settings are pre-calibrated at the factory.

3.

Mount valve to cross support using screws (not included). Valve shall be perpendicular and fixed

firmly to cross support to achieve proper trim attachment.(See Fig 1).

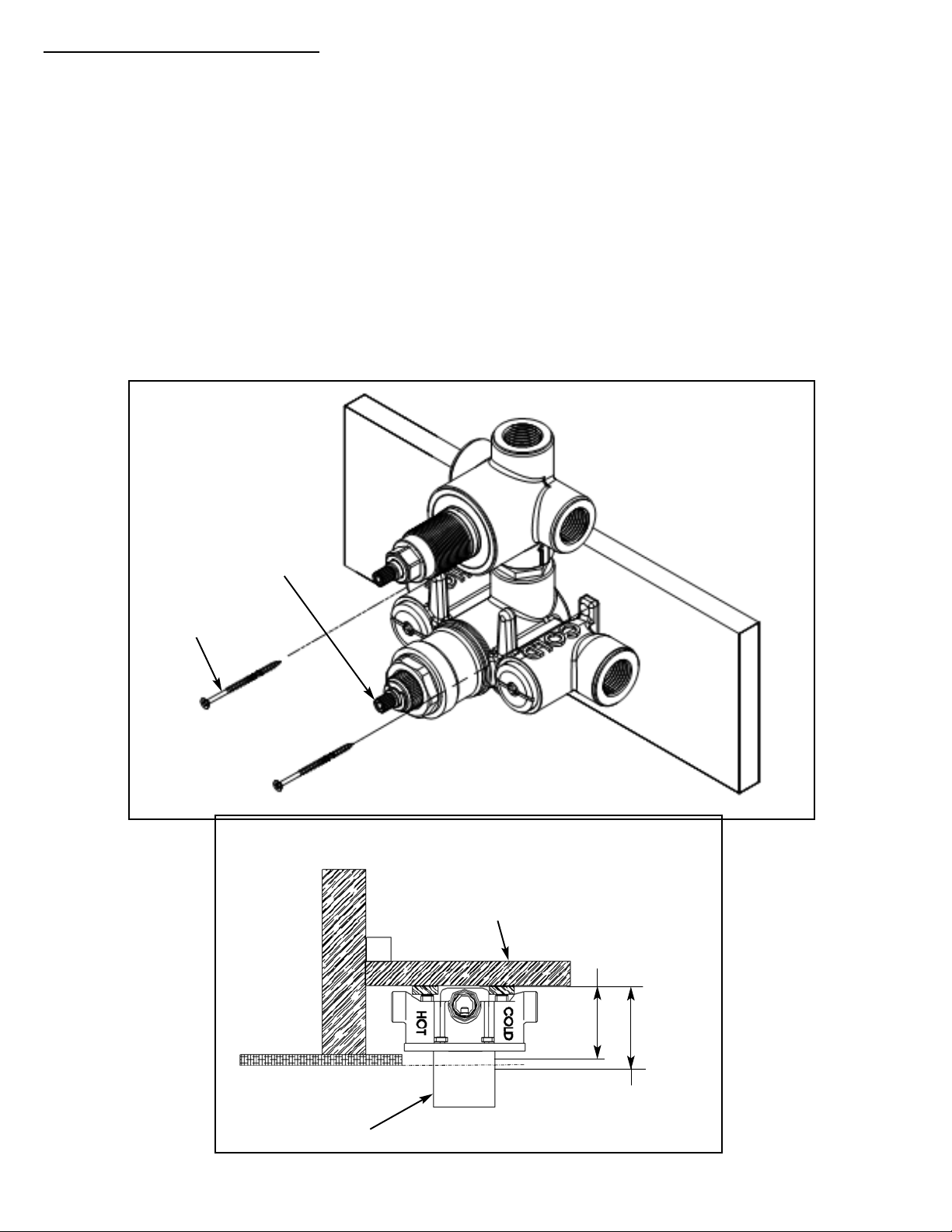

4.

Place the cross support with valve between wall studs. The min./max. valve depth and vertical

height desired within tub/shower enclosure determines the exact cross support placement.

Attach cross support to wall studs.(See Fig 2).

5.

Ensure opening in finished wall comes in contact with the mudcover to ensure seal with

Thermo Wall Plate shown in Fig. 4. (See TEMPLATE FOR FINISHED WALL OPENING in Fig 9).

Fig. 1

Cartridge stem

DO NOT TURN

2-3/8”

Min depth

3-1/8”

Max depth

Finished wall

Mud cover

Wall stud

Cross support

Fig. 2

NWP-1-742

Screws

(Not included)

Loading...

Loading...