Page 1

1 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

LDS1000

Controller for Laser Diode Sensors

1.0 Introduction

This manual describes the operations and conditions necessary for the

proper use and working of the NEWPORT LDS1000 Controller.

It also provides the basic maintenance operations that are useful to keep

the instrument in good working order.

IMPORTANT

NEWPORT LDS series sensors are measuring instruments that provides

results of measurements. The calibration certificate drawn up by NEWPORT for each delivery, or when an instrument is newly calibrated must

ALWAYS be supplied with the sensor. It provides the values of the parameters that must be stored in the memory of the LDS1000 electronic

controller so that the instrument gives accurate measurements. BEFORE

any measuring operation, the operator must make sure that the parameters that are used by the electronic controller are the ones that the instrument is designed to use. Refer to the corresponding chapter to check

and modify the sensor parameters.

RECOMMANDATIONS

You are strongly advised to read the chapter entitled “First use” carefully before connecting your autocollimator.

2.0 Description

The LDS1000 Controller is designed to drive sensors of the NEWPORT LDS

series (for example, LDS-Vector autocollimator or STR500-H rectitude sensor). The latter are compact and self-contained measuring instruments.

The LDS1000 electronic controller provides the means of displaying angular variations by measuring the movement of a spot of light on a position

sensing device. It has the capacity, off-line, to store up to 2048 measurements (14336 measurements with the extended memory option) and to

calculate the averages of these measurements.

When linked to a personal computer it provides the possibility of processing and recording the measurements.

This manual is designed to facilitate the use of the LDS1000 Controller for

all its modes of operation.

A second user’s manual exists which describes and facilitates the use of

the sensor.

Page 2

EDH0170FE1010 – 09/98 2

LDS1000 Controller for Laser Diode Sensors

2.1 Equipment

The LDS1000 electronic controller is delivered with:

•A RS-232-C lead.

•The present user’s manual.

•The LDS-TOOLS Software.

•A connection cable (5 or 10 meters, depending on the order).

•As well as the extra accessories and options that may be ordered.

The sensor is delivered in a protection case which contains:

•The optical head.

•The control certificate.

•The present user’s manual.

2.2 Modes of Operation

2.2.1 Manual Mode

The LDS1000 Controller displays angular rotation values of the mirror on a

frontal display screen. The operator uses the display and the active buttons on the front panel to:

•Read the measurements.

•Modify the integration constant.

•Define the zero point.

•Program the parameters of the connected sensor.

•Modify the communication parameters (RS-232-C or IEEE-488).

•Activate the analog outputs where available.

Refer to the chapter entitled: “Off-line use”.

ATTENTION RAYONNEMENT LASER

EN CAS D'OUVERTURE

EXPOSITION DANGEREUSE

AU FAISCEAU

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL A LASER DE CLASSE 2

Puissance maxi = 0,9 mW à 670 nm

Page 3

3 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

2.2.2 Remote Mode

When linked to a computer by RS-232-C or IEEE-488 connection, the

LDS1000 Controller communicates by ASCII messages. The buttons on the

front panel of the controller are no longer valid.

The following functions are possible:

•Reading the controller’s programmed parameters.

•Modification of the integration constant.

•Transmission of instantaneous values measured.

•Acquisition in the controller’s internal memory, of a number N of points,

at the frequency F.

•Acquisition in the controller’s internal memory, of a number N of points,

at the frequency F, the beginning of the acquisition is started by an

external signal (Trigger).

•Acquisition in the controller’s internal memory of a number N of points,

each acquisition being started by an external signal (Trigger).

Refer to the chapter entitled: “Use with a computer interface”.

2.2.3 Analog Mode

Analog outputs are only available on models that are equipped with this

option. This must be specified at the time of ordering.

There are two voltages at the analog outputs that are respectively proportional to the angular measurements Y and Z of the equipment.

This enables:

•Connection to an analog acquisition chain.

•Visualization of positions on an oscilloscope.

•Use of the LDS-Vector autocollimator for analog controls.

These outputs are obtained by a digital/analog conversion of the values

calculated by the controller.

This conversion is carried out in real time at a frequency of 2000 Hz.

Refer to the chapter entitled: “Off-line use”.

2.3 Available Versions

2.3.1 Controller

The electronic controller is available in eight versions that offer different

measuring possibilities. The references are as follows:

LDS1000 Controller LDS1000-OPT BB CC

with: BB NN No cable.

01 Cable length 5 meters.

02 Cable length 10 meters.

CC NN No controller.

02 Standard controller European standard (220V,

2manuals and EU cable).

12 Analog option controller, EU standard.

22 14K memory option controller, EU standard.

32 2-option controller, EU standard.

Page 4

EDH0170FE1010 – 09/98 4

LDS1000 Controller for Laser Diode Sensors

2.3.2 Sensors

Autocollimator, bilingual user’s manual LDS-Vector

Rectitude sensor, bilingual user’s manual STR500-H

2.3.3 Accessories and Additional Equipment Kits

Calibration blade kit, with certificate LDS-CAL01

2-theta adjustable mount LDS-SL

2-theta + XY adjustable mount LDS-SLXY

4 movement adjustable mount on X26 (complete, for LDS-Vector)

LDS-X26-V

2.4 Dimensions

O

I

329.5 (Depth 352)

IEEE-488

RS-232-C

Y & Z

Outputs

Sensor

Connector

– Front View –

– Rear View –

83.5

21

PWOK

Input

TRIG

Input

!

Page 5

5 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

3.0 Principle of Operation

3.1 Laser Diode Sensors

Laser diode sensors of the NEWPORT LDS series use identical technologies

for the emission and reception of optical signals, but according to a different optical diagram.

The emission is performed by a Laser diode controlled and modulated at

10 kHz.

The reception is performed by a position sensing device that provides analog voltages.

From the electronic controller’s point of view, that becomes:

•Supply the necessary power to the laser diode and to the pre-amplifying

electronic controller.

•Monitor break down and defects.

•Collect the return signals from the analog sensor.

This data is processed by the controller, corrected according to the parameters provided by calibration and usable depending on the different

modes (display, memorization, transmission to the computer interface,

analog output [available as an option]).

3.2 Electronic Controller

The LDS1000 Controller performs:

•Fast acquisition at a set frequency of 2 kHz.

•Analog to digital conversion.

•Correction and integration calculation.

•Memory and display management.

Its technology is based on a 68000, 16 MHz microprocessor.

This controller offers a clear display of the values measured on a luminous

screen and communication via RS-232-C and IEEE-488 interfaces.

One particular model is available with calibrated analog outputs, that are

proportional to the values measured.

Page 6

EDH0170FE1010 – 09/98 6

LDS1000 Controller for Laser Diode Sensors

4.0 Specification

The LDS1000 Controller can be used in conjunction with various optical

heads.. The dependent characteristics of the optical head are given in the

individual manuals.

The measurement results can only take on their full meaning in relation to

a unit that represents the value to be measured (distance, angle…). The

controller enables the result to be displayed on the unit that corresponds

to the sensor used.

4.1 General Characteristics

4.1.1 LDS-Vector Optical Head (example of Sensor)

•Wavelength 670 nm

•Peak power 900 µW

•Modulation 10 kHz

•Beam diameter 31 mm

•Beam direction <0.5 mrad in relation with autocollimator body

•Equivalent focal length 280 mm

•Beam divergence 0.1 mrad

•Ocular field ±15 mrad

•Measurement range ±2000 µrad

•Weight 1.065 kg

4.1.2 LDS1000 Controller

•Microprocessor 68000 (32 bits - 16 MHz)

•Display 2

x20 characters, adjustable brightness

•Interfaces RS-232-C and IEEE-488

•Measurement memory 2048 spots or

14336 spots depending on the option

•Analog output Available as an option

•TTL TRIGG input Measurement synchronization

•TTL PWOK output Beam signal

•Power supply 90/264 VAC, 50/60 Hz

•Consumption 30 VA

4.1.3 Measurements

•Digital resolution 0.1 µrad

•Measurement range ±2000 µrad

•Measurement error ±(1 ±0.02

xmeasurement.) µrad (i.e. ±2%)

•Max. measuring noise 0.02 µrad/√Hz

•Sampling frequency 2000 Hz

•Digital integration from 0.5 msec to 1 sec

Page 7

7 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

4.1.4 Environment

The performances of an optical sensor greatly depend on the conditions in

which it is used.

The contractual characteristics are specified in the manual that goes with

each sensor of the LDS series.

The operating limits of the LDS1000 Controller are the following:

•Operating temperature +15 °C to +25 °C

•Humidity 10% to 80%

•Storage temperature -10 °C to + 50 °C

Refer to the paragraph entitled “Specification Validity” in each user’s

manual for the performances of the sensors according to the conditions of

use.

4.1.5 RS-232-C and IEEE-488 Interfaces

RS-232-C interface

Baud rate 300 to 19200

IEEE-488 interface

Mode SRQ management

4.1.6 Analog Outputs

Analog outputs are only available if the option has been chosen.

•Refresh frequency 2000 Hz

•Digital low-pass filter 1 to 2000 Hz

•Output range ±10 V

•Scale factor 5 mV/incr to 1000 mV/incr

•Resolution 0.5 increment

•Electronic noise 1 mV rms

•Distortion 0.5% (electronic)

•Maximum Offset 50 mV typical

•Output impedance 10 Ω

•Discrepancy equivalent to a pure delay of 1.1 msec (without integration).

•Attenuation equivalent to the one of an order 1 low-pass filter with

600Hz cutoff frequency.

WARNING: SPECTRAL WITHDRAWAL

The analog outputs use an intermediary calculation stage that is based

on a sample at 2000 Hz. This will limit the use of the LDS sensor for studying signals that do not have a significant spectral component over

1000 Hz (this sort of component would find themselves “withdrawn” and

would appear for lower frequencies).

4.2 Validity of Specifications

Refer also to the paragraph entitled “Specification Validity” in each user’s

manual for the performances of the sensors according to the conditions of

use.

Page 8

EDH0170FE1010 – 09/98 8

LDS1000 Controller for Laser Diode Sensors

4.2.1 Calibration

A reading of the linear errors according to the angle measured is provided

with each sensor. This calibration certificate gives, in particular, the value

of the principal parameters to be used to configure the LDS1000 electronic

controller:

•S/N: Series number of the optical head.

•Type: RT (Rotation) for LDS-Vector or TR (Translation) for STR500-H.

X: Beam Axis; Y: Horizontal Axis; Z: Vertical Axis.

–Type RT (Rotation):

Y: Rotation around Y axis.

Z: Rotation around Z axis.

–Type TR (Translation):

Y: Parallel translation with Y axis.

Z: Parallel translation with Z axis.

•Ycoef:Linear correction factor for axis Y.

•Yincr:Count increments for axis Y.

•Yunit:Unit displayed for axis Y.

•Yofs1, Yofs2:Channel Y electronic offsets.

•Zcoef:Linear correction factor for axis Z.

•Zincr:Count increments for axis Z.

•Zunit:Unit displayed for axis Z.

•Zofs1, Zofs2:Channel Z electronic offsets.

These parameters were optimized when the instrument was calibrated in

order to obtain the best results. You are advised not to modify them

without reason.

These parameters have been defined for the following conditions of use:

•Temperature 22 °C ±2 °C

•Mirror diameter >31 mm

•Reflectivity 80% at 670 nm

•Working distance 0.1 m

4.3 Noise Reduction

The LDS1000 Controller constantly carries out acquisitions at a rate of 2000

values per second.

These acquisitions are dealt with on request (transformation of electric

signals into metrological values) for display or emission on a connection.

Depending on the programming of the electronic controller, the returned

value corresponds either to the last acquisition carried out (no average) or

to the average of the last N acquisitions.

ATTENTION RAYONNEMENT LASER

EN CAS D'OUVERTURE

EXPOSITION DANGEREUSE

AU FAISCEAU

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL A LASER DE CLASSE 2

Puissance maxi = 0,9 mW à 670 nm

+Z

+Z

+Y

+X

+Y

Page 9

9 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

In the second case, a low-pass digital selection is carried out which reduces

the noise.

The noise reduction evolves like the square root of the number N of averaged samples, which is itself equal to the averaging time to acquisition period ratio.

The acquisition period is always equal to 0.5 msec (2 kHz).

The duration of the averaging is fixed by the integration constant that can

be parametered INTG.

Refer to the user’s manual of the LDS sensor concerned.

4.4 Offset Coefficient Adjustment

The Yofs1, Yofs2, Zofs1 and Zofs2 coefficients are normaly set to zero

value.

When the reflected light is becoming low, because of poor reflectivity or

small mirror aperture, it is necessary to take into account the value of the

electronic offsets of the detector.

The LDS1000 Controller is designed to make this correction very easily, by

introducing offset coefficients into its memory.

The following procedure must be accomplished:

❶The values of offsets are reached when the instrument does not receive

any light.

In order to get these values, place a black screen in front of the exit

pupil of the instrument.

The requested values are then dispayed by the LDS1000 in the specific

test mode, described in chapter 7.3.

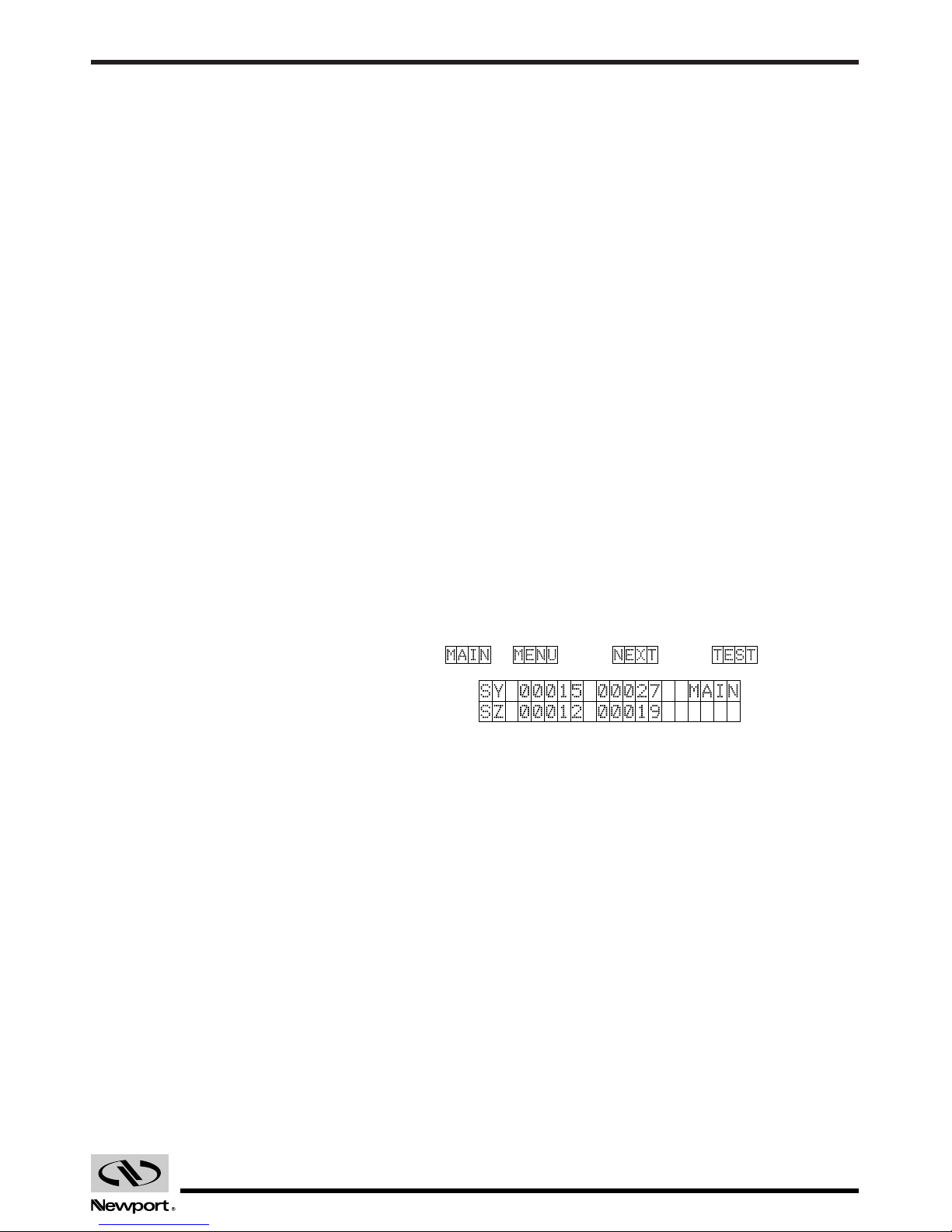

=> (F5) => (F4) => (F2)

The first line gives Yofs1 and Yofs2.

The second line gives Zofs1 and Zofs2.

❷Take notes of these values and go to LDS1000 parameter setting, as

explained in chapter 7.4.

Page 10

EDH0170FE1010 – 09/98 10

LDS1000 Controller for Laser Diode Sensors

5.0 Starting the Equipment

5.1 Setting Up

The setting up of the sensor is explained in each user’s manual of the LDS

instruments.

RECOMMANDATION

You are advised to read the user’s manuals corresponding to each sensor

delivered. They contain important information for optimal use of the instruments. These instructions can vary from one sensor to another.

5.1.1 Mounting

Small movement measurements require specific precautions as far as the

quality of the mounting of the equipment is concerned. It is particularly

important to make sure that the sensor, the reflector and their corresponding supports are solid

5.2 Electric Connections

CAUTION

Before connecting check that all equipment is switched off.

CAUTION

Do not use any cable other than the one supplied by NEWPORT.

The cable provided connects the sensor to the electronic controller. The

male part should be connected to the optical head, the female part to the

controller. Please ensure that all connections are correctly screwed in.

The cable is available in two standard lengths:

Cable for LDS1000, length 5 meters LDS1000-OPT01NN

Cable for LDS1000, length 10 meters LDS1000-OPT02NN

For longer lengths, please consult us.

A lead ensures the connection to the mains supply on a switch and fuse

base.

The controller is equipped with a self-selecting input voltage power supply

(from 90 V to 250 V).

Set the switch to "0" (OFF) position.

Page 11

11 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

5.3 Power Up

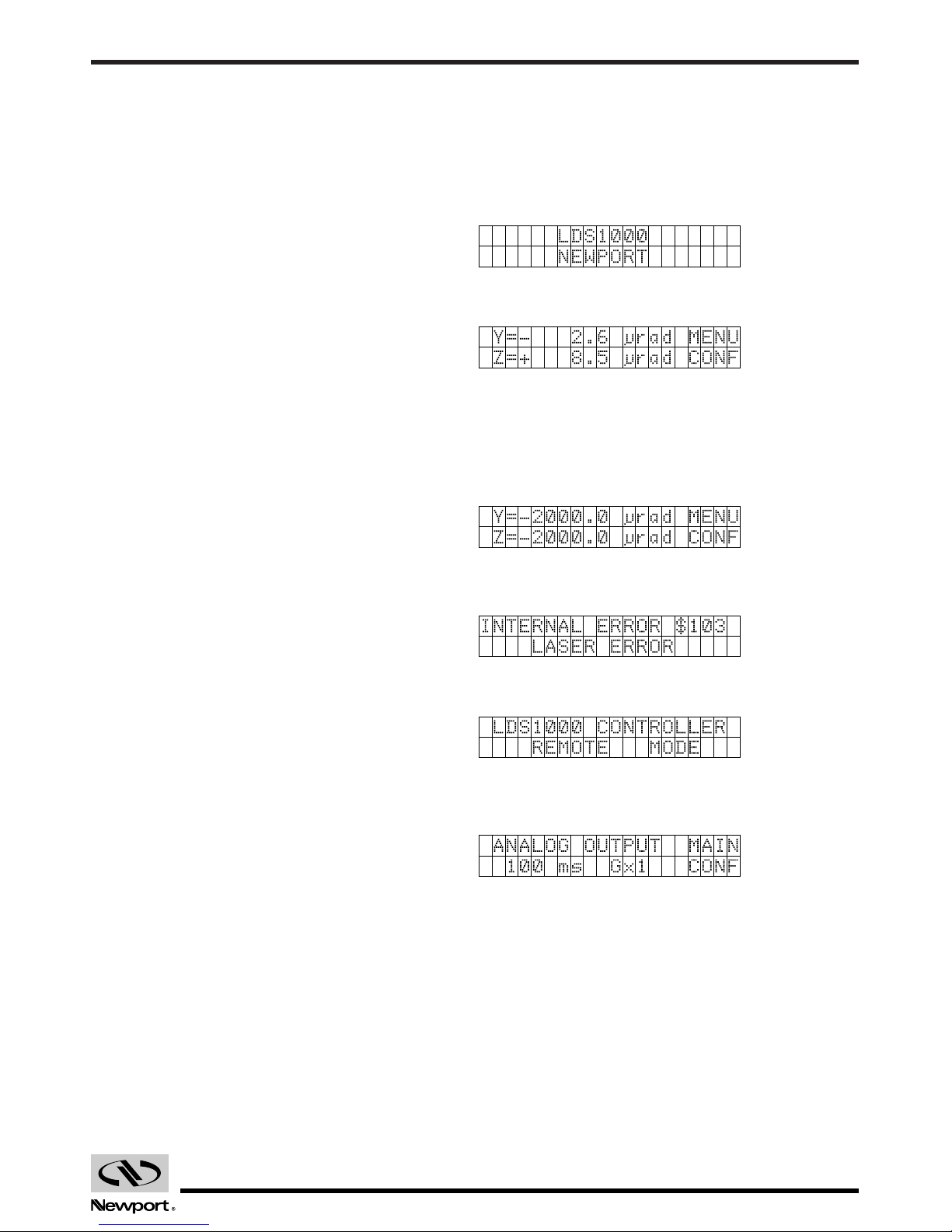

5.3.1 Power Up Messages

Link up the controller to the mains. Set the switch to “I” (IN).

Once turned on, the controller goes into its initialization phase and dis-

plays a welcome message.

Then, the display of values measured according to programming parameters is displayed:

This presumes that the autocollimator is stationary in front of a mirror

which sends the correct beam into the measuring range (see paragraph:

“Alignment”).

In other cases, the controller displays the value of the limits of the measuring range (the most frequent being -2000 µrad) instead of the value measured on the given axis:

See paragraph: “Alignment”.

Other possible messages:

LASER ERROR: This message indicates a connection error in the optical

head or a laser diode emission fault.

This message indicates that the controller is connected to a computer on

which software is running, which has sent the command to freeze the display. Reset the software parameters to regain control.

This type of message indicates, for controllers equipped with analog

options, that the analog output mode is active. Press the MAIN key to

return to the main menu.

5.3.2 Alignment

To visualize an angular measurement, make sure that the return beam

penetrates the LDS-Vector autocollimator and that the return energy is

powerful enough.

The procedure for rapid set up is explained in the user’s manual supplied

with each instrument.

Page 12

EDH0170FE1010 – 09/98 12

LDS1000 Controller for Laser Diode Sensors

6.0 Configuring the Equipment

The controller is configured in manual mode, using the buttons and the display available on the front panel of the LDS1000 Controller. This must be

done before the instruments can be used.

6.1 Sensor Configuration

The LDS1000 electronic controller can receive a variety of sensors: an LDSVector electronic autocollimator or an STR500-H rectitude sensor. In the

same laboratory, it is possible to find several sensors installed for a single

controller which is connected to one or other of the sensors depending on

the needs.

To simplify programming and to minimize the risk of errors, the LDS1000

electronic controller has a memory that can store all the parameters of 10

different sensors. Only Manual mode makes it possible to modify the number of the sensor being used, as this modification requires manual adjustment on the controller (physically connecting the sensor required).

To configure the sensor you will need to consult the control statement delivered with each piece of equipment. Should you lose it, a duplicate of this

document which is of great importance is kept by our metrology department. Just note the number that is marked on the sensor and we will be

able to send you a copy of the document.

The configuration of the sensor is carried out in manual mode and enables:

•The active sensor to be selected.

•The parameters of the active sensor to be visualized.

•The parameters of the active sensor to be modified.

See the chapter entitled: “Off-line use”.

6.2 Interface Configuration

Manual mode enables the parameters and the communication mode of the

controller to be chosen. It is useful to check these values before proceeding with a connection to a computer. This must be done before using the

instrument in Interface Mode.

The LDS1000 Controller communicates with a computer via two standard

protocols available:

•RS-232-C.

•IEEE-488.

6.2.1 RS-232-C Interface

The RS-232-C protocol is available on most commercial computers on ports

COM1 or COM2. The LDS1000 Controller is delivered with a RS-232-C lead

comprising a classical Sub-D9 connector, as well as a Sub-D9/Sub-D25 adapter.

Depending on the standard chosen by the computer manufacturer, it is

always possible to carry out the RS-232-C communication with the LDS1000

Controller. A program written on a given computer will be able to use the

RS-232-C outputs available on another computer without any problems (on

the condition that the right number of the port on which the LDS1000

Controller is connected is given).

Page 13

13 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

The parameters of the RS-232-C interface are the following:

•BAUD RATE Interface speed.

•MSG TERM End of message character.

•WORD LENGTH Length of the transmitted chain.

•STOP BITS Number of stop bits.

•PARITY Parity used by the interface.

6.2.2 IEEE-488 Interface

The IEEE-488 protocol is only possible when the computer is equipped with a

special card that allows IEEE-488 communication. There are several different

models available on the market. Please note that they are not compatible between themselves. As a result, a software program written for a IEEE-488 card

of a model will not work with another IEEE-488 card.

The parameters of the IEEE-488 interface are the following:

•MSG TERM End of message character.

•PRIM ADRESS Instrument’s primary address.

•SECOND ADRESS Instrument’s secondary address.

•TIME OUT Wait time.

The IEEE-488 interface enables several different instruments to be connec-

ted to the same computer input. It is quicker than the RS-232-C interface. For

this connection, the controller operates in SRQ mode.

The parameters of the two communicating instruments must be identical to

obtain the communication (in fact the two instruments must speak the same

language in order to understand each other). The LDS1000 Controller is

considered to be a slave in the communication protocol. Its parameters

must therefore be chosen in accordance with those of the master computer.

Cf. Chapter entitled: “Off-line use”.

6.3 Controller Configuration

The LDS1000 Controller has a program and material configuration that

depends on the options chosen at the time of ordering. In particular, the

internal software version, the size of the memory installed and the installation of the analog output option represent information that is accessible in

manual mode.

Moreover, so that you can comfortably use the controller in different

atmospheres, the brightness of the light can be adjusted.

Accessible functions:

•Reading the version.

•Display brightness.

•Memory size.

•Analog output option.

Refer to the chapter: “Off-line use”.

Page 14

EDH0170FE1010 – 09/98 14

LDS1000 Controller for Laser Diode Sensors

6.4 Analog Output Configuration

The analog outputs are only available by manual mode on the models

equipped with this option.

It is possible to modify the following parameters:

Refer to the chapter: “Off-line use”.

NOTE

The analog outputs deliver two voltages that are respectively proportional to the Y and Z measurements of the equipment.

Among other things this enables:

•Connection to an analog acquisition chain.

•Visualization of positions on an oscilloscope.

•Use of the sensor for analog controls.

These outputs are obtained by a digital/analog conversion of the values

calculated by the controller.

This conversion is carried out in real time at a frequency of 2000 Hz. It

imposes the following limits:

•Resolution limitation 0.5 increment

•Further measurement distortion 0.5%

•Extra noise 1 mV rms (measured with a

load of 1 MΩ).

•Maximum offset 50 mV typical.

•Discrepancy equivalent to a pure delay of 1.1 msec (without integration).

•Attenuation equivalent to the one of an order 1 low-pass filter with

600Hz cutoff frequency.

The output voltages take into account the averaging defined by INTG. The

full scale voltage variation (±10 V) matches the full scale measurement

variation, i.e. a scale factor of 5 mV/increment.

A multiplying factor defined by GAIN (1 to 200) makes it possible to change

this scale factor from 5 to 1000 mV/increment. The gain comes with a limitation of the angular range that can be visualized (outputs limited at ±10 V).

The impedance of the outputs if equal to 10 Ωand the maximum current

they can deliver is 4 mA.

Page 15

15 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

7.0 Off-Line Use (Manual Mode)

The LDS1000 Controller has two modes of operation.

Manual mode which enables:

•The configuration of the controller in accordance with the parameters

of the sensor used.

•To carry out measurements on values displayed.

•To modify the integration time, and the display mode.

•To parameter the communication interface.

•To select the analog outputs (if option available).

Interface mode which enables:

•Flying spot reading of values measured,

•Execution of acquisition sequences that are synchronized or not.

•Reading the sensor status.

Manual mode is valid when the autocollimator is in off-line use, to perform

measurements from the controller display. It is also used to parameter the

computer interface or to access the analog outputs option (if it exists).

7.1 Access to Manual Mode

Manual mode is directly accessible on the controller at the time of Power

up, except in the following cases:

•Sensor non connected or damaged (Laser error).

•Analog output mode valid (Refer to the corresponding chapter).

•Communication in progress via RS-232-C or IEEE-488 (Refer to the

Interface Mode chapter).

The starting point is the main Menu which is the controller’s usual mode of

operation.

Access to the different Menus, parameter scrolling and the choice of values

is obtained by pressing one of the 5 buttons on the front panel of the

controller (F1 to F5).

Position of the buttons on the LDS1000 Controller.

F5

LDS1000

F1 F2 F3 F4

F5

F1 F2 F3 F4

Page 16

EDH0170FE1010 – 09/98 16

LDS1000 Controller for Laser Diode Sensors

The mnemonics corresponding to the function of each button are indicated

by the display shown by the button.

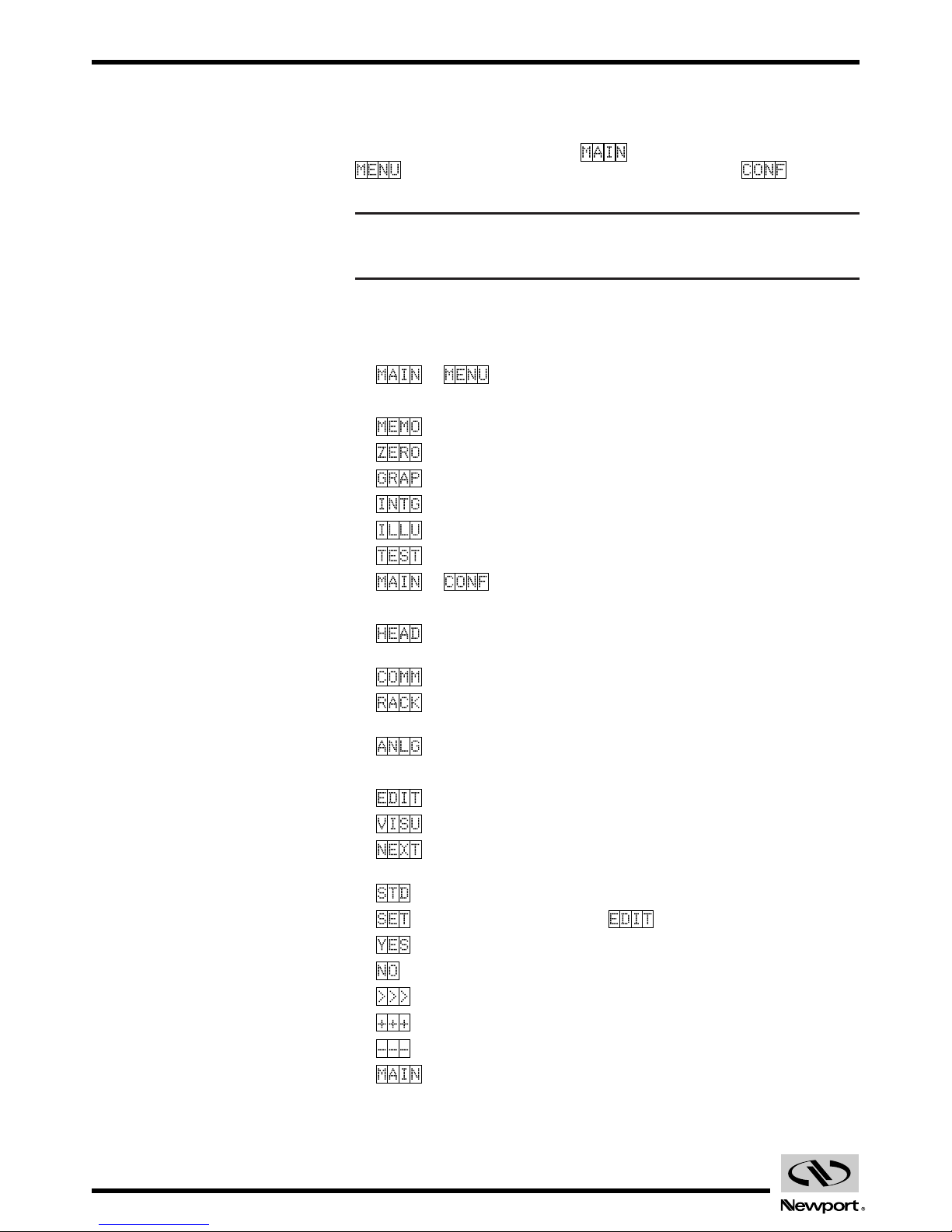

For example, in the main menu , the F5 key enables the function

to be selected, and the F4 key selects the function . The other

keys F1, F2 and F3 have no effect.

WARNING

As a result the keys do not always correspond to the same functions.

7.2 Manual Mode Functions

The main menu gives access to two sub-menus:

• => (F5key)

Ce Mode permet l’accès aux fonctions suivantes:

Display freeze.

Display relative to a current position.

Graphic display.

Modification of the integration constant.

Display the light received.

Test Mode (maintenance).

• => (F4key)

This Mode gives access to the following functions:

Reading/Modification of current sensor parameters.

Memorization / Selection of 10 different sensor configurations.

Choice of communication parameters(RS-232-C, IEEE-488).

Information on the software version, the available memory and

the display brightness.

Commutation to analog outputs (only if the option exists).

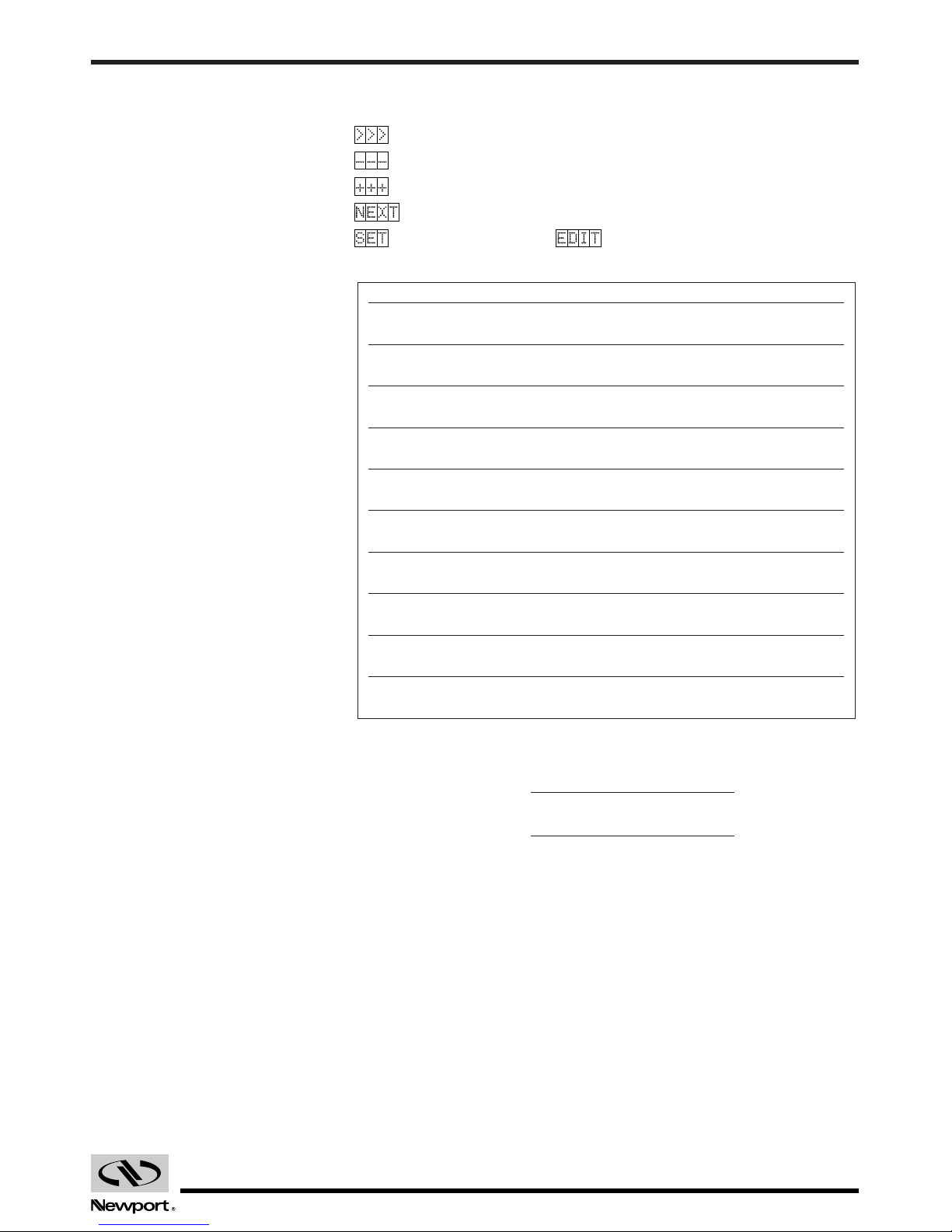

The rolling menus use the following symbols and mnemonics:

Modification of current parameters.

Visualization of current parameters.

Information on the software version, the available memory and

the display brightness.

Reset with default values.

Save modifications (after ).

Message confirmation.

Abandon.

Scrolling of modifiable parameters (or cursor movement).

Next highest value (+1 for digital values).

Lower value (-1 for digital values).

Return directly to main Menu.

After any modification, the configuration will be saved when the equipment

is switched off.

Page 17

17 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

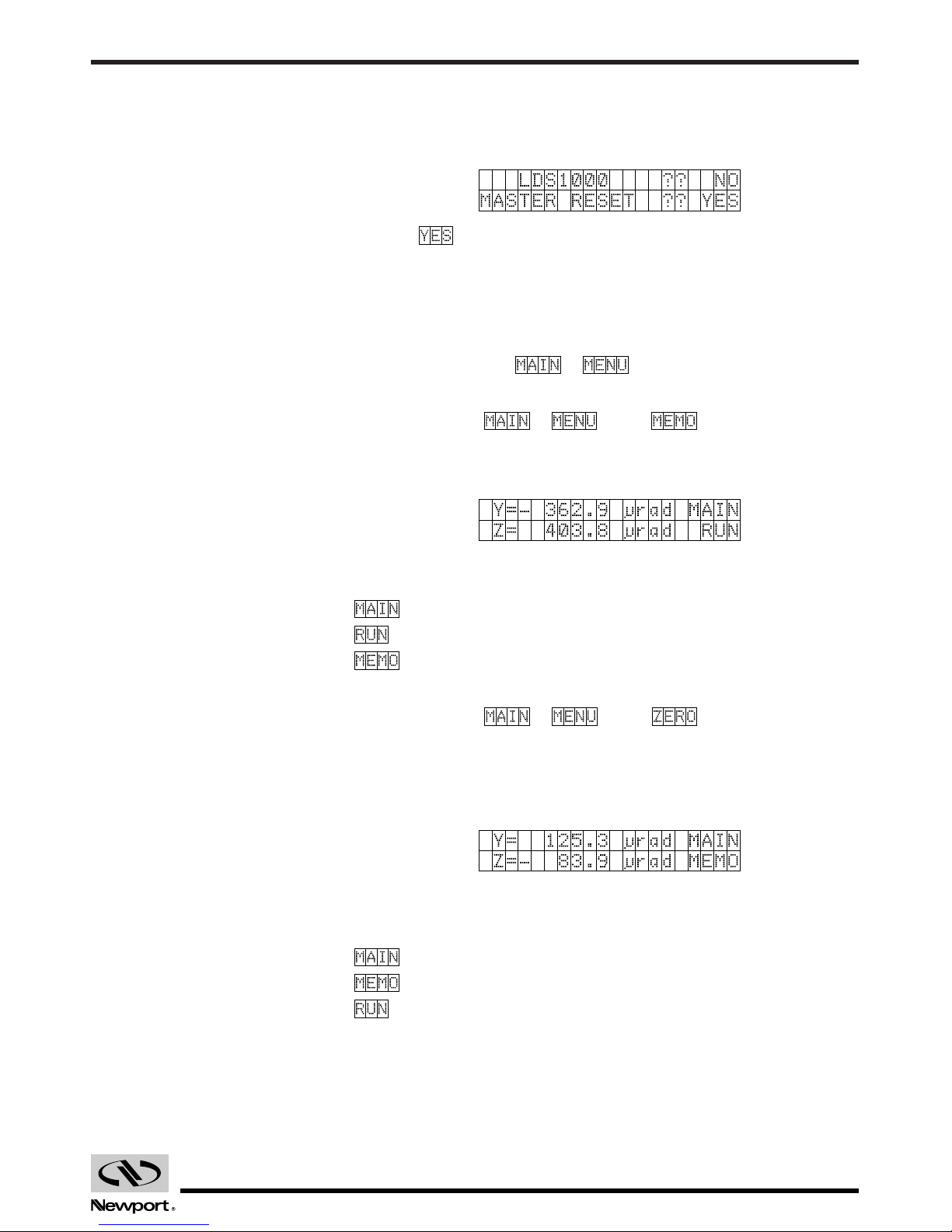

MASTER RESET

On switching on, if you press the F5 key for a few seconds, the controller

suggests changing all the parameters to default values.

Selecting (F4key) will destroy all the data fed into the controller and

will replace all values with default values.

7.3 Measuring Functions

Access to measuring functions, from the main menu, is done with the F5

key:

=> (F5) => …

7.3.1 Display Freeze

=> (F5) => (F1)

The display freeze is useful when carrying out measurements of a vibrating

or moving system spread out over time. The display is frozen and the two

values that correspond to the same instant are available on the screen.

It is therefore possible to read them without haste (this is a flying spot picture of a position).

(F5)Return to main menu.

(F4)Normal display.

(F4)Freeze the display.

7.3.2 Offset Origin

=> (F5) => (F2)

This mode, also called relative display, makes it possible to set the current

point as the origin. The values displayed are therefore given in relation to

this point. This mode is practical to find out the angular distance between

two given positions, without having to adjust the zero point to the center of

the sensor.

However, it is necessary to make sure that you do not go beyond the min.

and max. limits on the cell. You are advised to set the first point near the

center of the sensor.

(F5)Return to main menu.

(F4)Freeze the relative display.

(F4)Relative display.

Page 18

EDH0170FE1010 – 09/98 18

LDS1000 Controller for Laser Diode Sensors

7.3.3 Integration Constant

=> (F5) => (F3)

The accuracy that can be obtained on a measurement depends on the number of readings carried out for that measurement.

In manual mode, the LDS1000 electronic controller carries out measurements at a frequency of 2 kHz. Its own resolution at this frequency is 0.8

µrad when using a standard LDS-Vector autocollimator.

By calculating the average of a large number of measurements, it is possible to obtain a much higher resolution, to the detriment of the system’s

pass band.

The LDS1000 Controller carries out a sliding average of N successive

values, in relation to the INTG parameter that can be selected with this

menu (N = 2 xINTG).

(F2)Lowest INTG value.

(F3)Highest INTG value.

(F5)Return to main menu.

Possible values: INTG = 0,5; 1; 2; 5; 10; 20; 50; 100; 200; 500; 1000

Default value: INTG = 100

Unit: msec

7.3.4 Graphic Display

=> (F5) => (F4) => (F3)

In order to facilitate alignments, a display in the form of a Bar-Graph is

recommended. For each axis, the number 8 digit is considered as the optical center of the autocollimator. The angles measured successively light up

the adjacent digits (7 on each side), logarithmically for accurate alignment

mode. Positive space values light up the digits to the right. The alignment

around the center of the sensor is achieved by switching off as many digits

as possible.

In alignment mode, a function (F4) enables measurements to be performed in relation to the current position which becomes a reference point.

(F5)Return to main menu.

7.3.5 Display Light Received

=> (F5) => (F4) => (F1)

To check if the instrument is working properly, make sure that the rate of

light returned to the sensor is sufficient. This mode is especially useful for

setting up the instrument in complex assemblies, in order to avoid substantial vignetting. The best results are obtained when a maximum amount of

light is received.

Page 19

19 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

The display is in % in relation to the nominal value established at 100%.

(F5)Return to main menu.

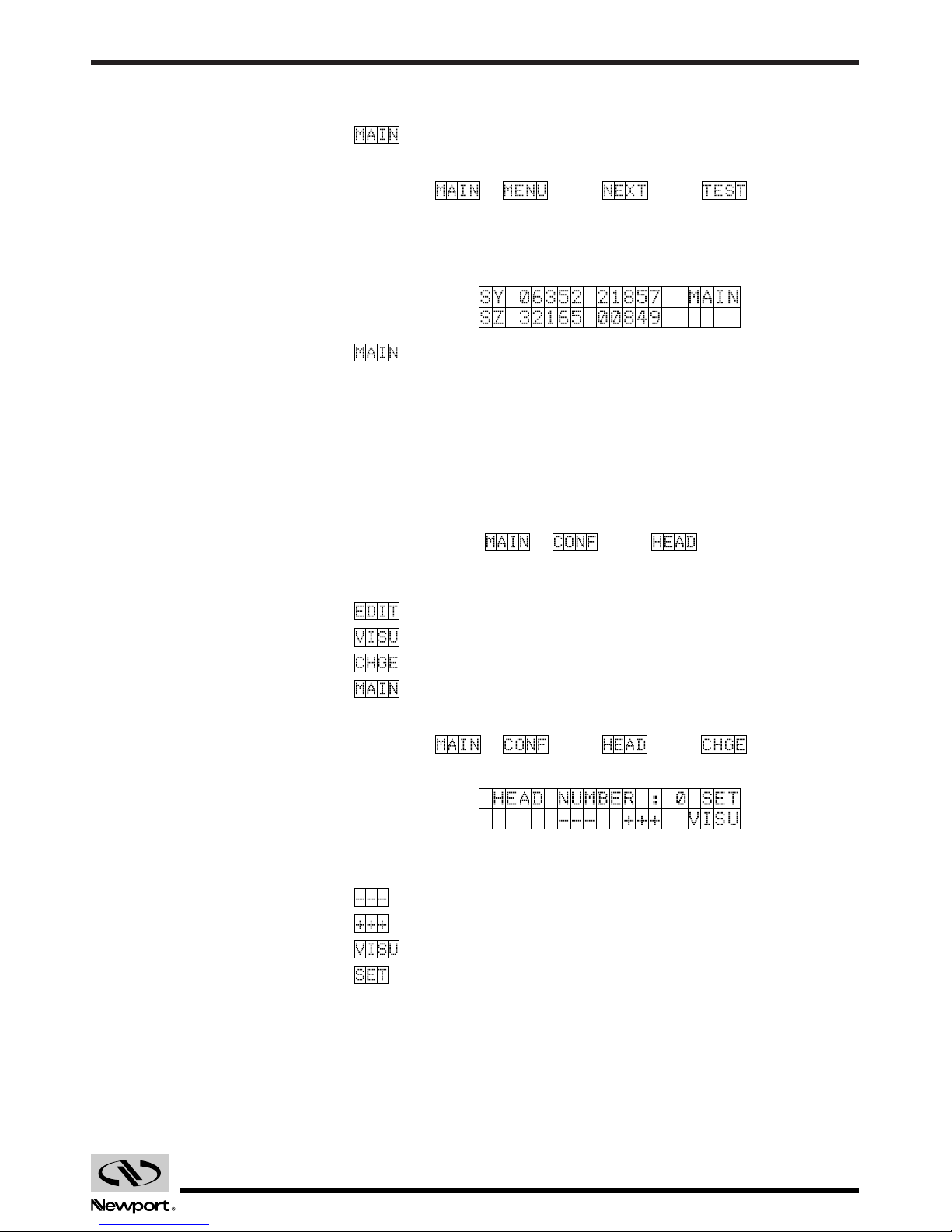

7.3.6 Maintenance Mode

=> (F5) => (F4) => (F2)

Here the brut value of the 4 channels of the analog/digital converter from

the sensor is displayed. Interpreting the values depends on the sensor that

is in place. Their read-out enables the sensor’s electronic offset to be corrected.

(F5)Return to main menu.

7.4 Configuration Functions

Here we find the way to parameter the following elements:

•Parameter input of the sensor used.

•Parameter input of the controller.

•Interface parameter input.

7.4.1 Parameter Input of the Current Sensor or the Memorized Sensors

=> (F4) => (F1)

This mode displays the number of the current sensor (currently valid) and

provides access to the following menus:

(F1)Modification of current sensor parameters.

(F2)Visualization of current sensor parameters.

(F3)Choosing another current sensor.

(F5)Return to main menu.

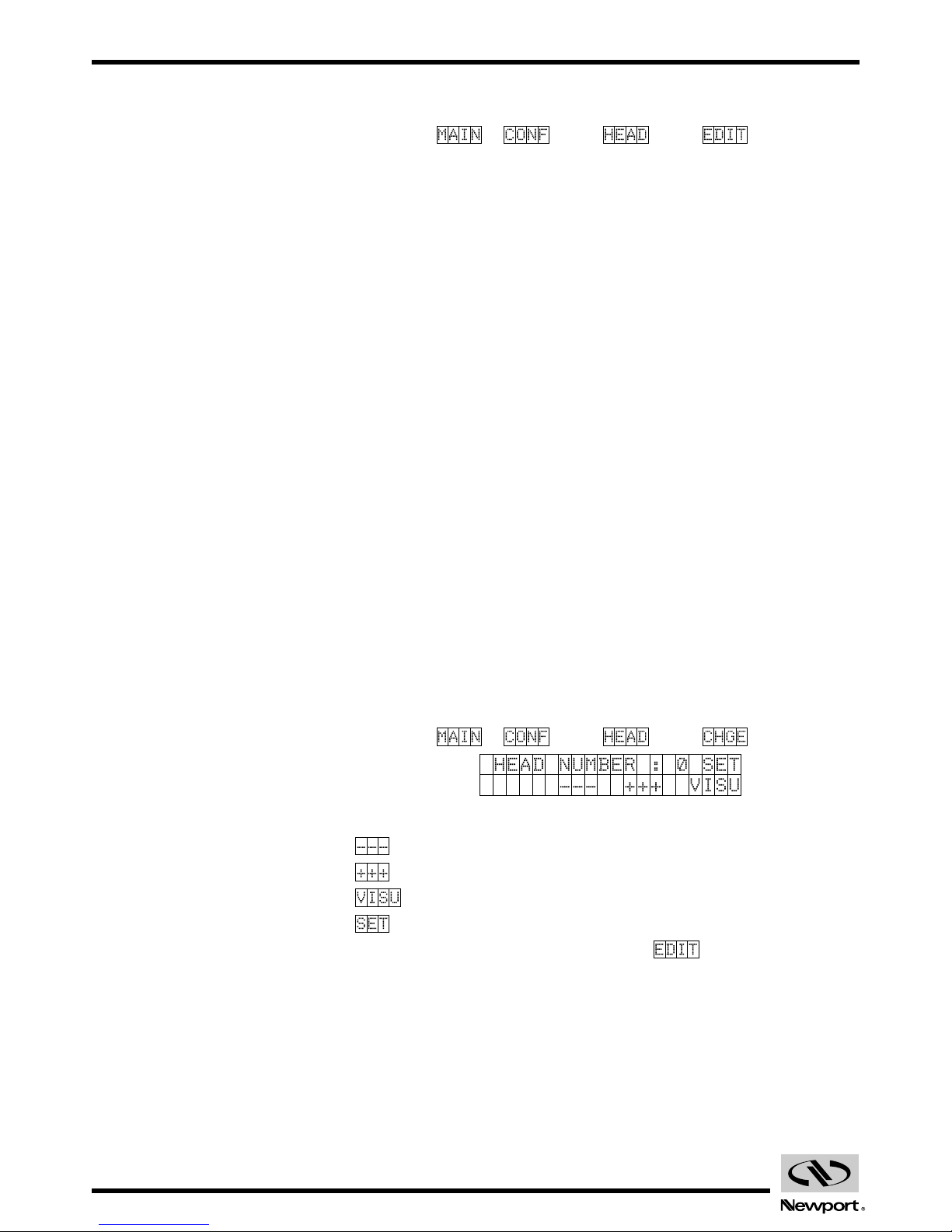

7.4.1.1 Selecting the Number of the Current Sensor

=> (F4) => (F1) => (F3)

From this menu, it is possible to modify the number of the current sensor.

The display then takes into account the parameters associated with the

number of the current sensor.

(F2)Previous number (-1).

(F3)Next number (+1).

(F4)Visualization of parameters of the sensor envisaged.

(F5)Save the new configuration.

Page 20

EDH0170FE1010 – 09/98 20

LDS1000 Controller for Laser Diode Sensors

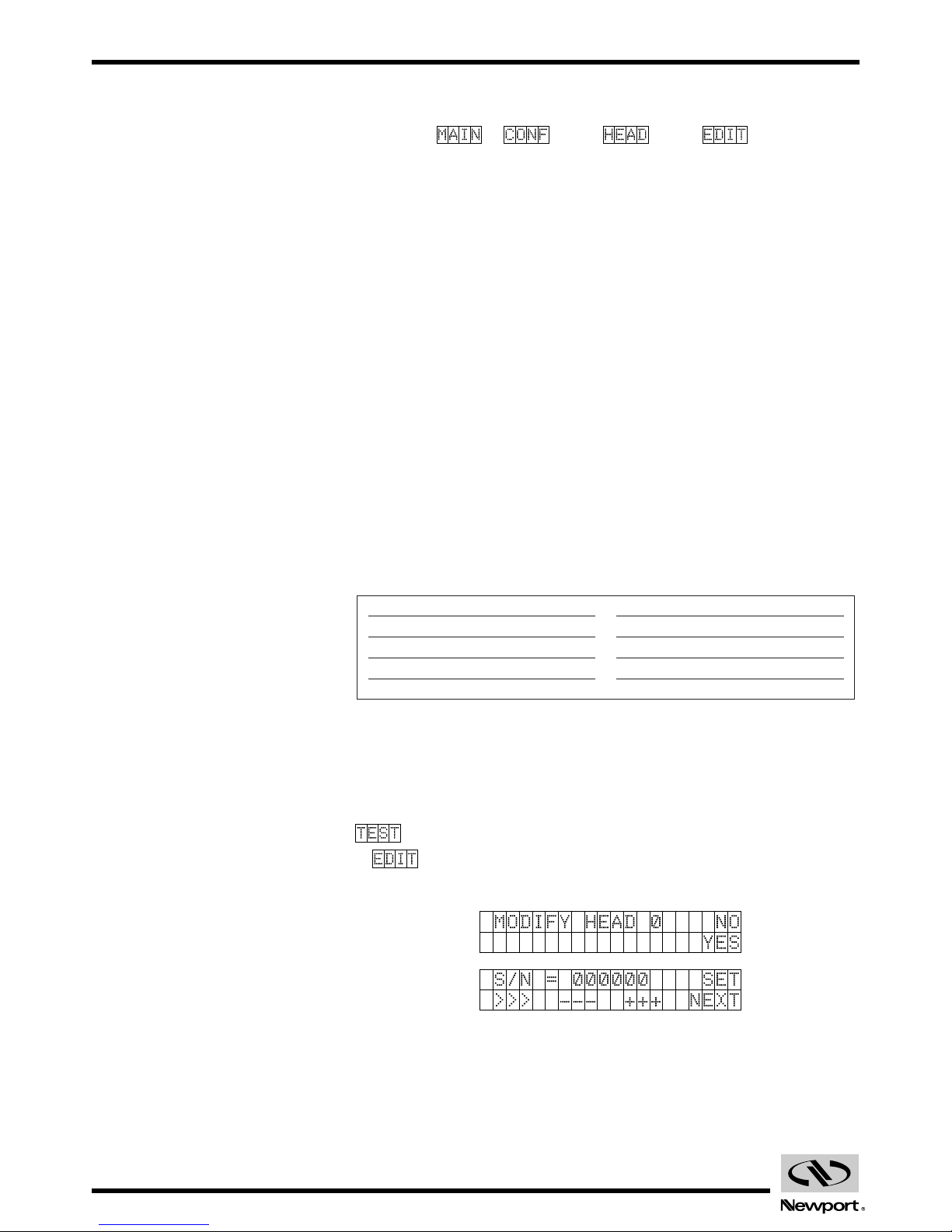

7.4.1.2 Modification of Current Sensor Parameters

=> (F4) => (F1) => (F1)

Each NEWPORT sensor is delivered with a calibration certificate which

enables the correct programming parameters for the LDS1000 Controller to

be established.

This certificate gives the values of the following parameters:

S/N: Series number of the optical head.

A number is allocated to each sensor. It means it can be identified and its

progress can be monitored.

Type: Y axis horizontal (TR) or vertical (RT).

This indication specifies the type of measurements carried out by the sen-

sor. Thus RT, for rotation designates an autocollimator. This value is used

by some programs for a correct display.

Ycoef, Zcoef: Linear correction factor for the axis Y or Z.

The sensor can be calibrated on a measuring bench. The given value of

Ycoef or Zcoef minimizes linear errors in the direction concerned. It is a

multiplying factor of the display.

Yincr, Zincr: Counter increment for the axis Y or Z.

The resolution of each sensor is limited by physical factors (electronic

noise, enlargement, etc.). The value of Yincr or Zincr given is adapted to

the sensor delivered. It is a multiplying factor of the display.

Different measurement limits correspond to each increment value:

Yunit, Zunit: Unit displayed for the axis Y or Z.

It is the unit for which the sensor parameters are established.

Yofs1, Yofs2, Zofs1, Zofs2: Electric offset values.

These values enable the sensor resolution to be refined while taking into

account a possible offset reading. The correct values are achieved in

mode.

In mode the values of the parameters stored for the current sensor

can be modified. As a precaution, a confirmation message asks whether

you really want to modify the current sensor (and specifies the number):

0.1 -199.99 … +199.99

0.2 -399.98 … +399.98

0.5 -999.95 … +999.95

1 -1999.9 … +1999.9

2 -3999.8 … +3999.8

5 -9999.5 … +9999.5

10 -19999 …+19999

20 -39998 …+39998

50 -99995 …+99995

Page 21

21 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

For all the parameters, a modification menu uses the following functions:

(F1)Scrolling of possible parameters (or cursor movement).

(F2)Lower value (-1 for digital values).

(F3)Next highest value (+1 for digital values).

(F4)Next parameter.

(F5)Save and exit mode.

List of parameters:

The values displayed on the screen of the controller are obtained by the

following calculation:

Y

Displayed

=

Y

Calculated

x(Ycoef x10 xYincr)

10

Z

Displayed

=

Z

Calculated

x(Zcoef x10 xZincr)

10

Designation Available Values Default Value

S/N Series number of 6 digits: 000000

the optical head 000000 à 999999

Type Sensor type Y axis horizontal (TR) RT

or vertical (RT)

Ycoef Linear correction 5 digits: 04000

factor for Y axis 00100 to 29999

Yincr Counter increment 0.1; 0.2; 0.5; 1; 2; 5; 1

for Y axis 10; 20; 50

Yunit Unit displayed µrad; sec; mrad; nm; unit

for Y axis µm; mm; unit

Yofs1 Electric offset 5 digits: 00000

Yofs2 values for Y 00000 to 32767

Zcoef Linear correction 5 digits: 04000

factor for Z axis 00100 à 29999

Zincr Counter increment 0.1; 0.2; 0.5; 1; 2; 5; 1

for Z axis 10; 20; 50

Zunit Unit displayed µrad; sec; mrad; nm; unit

for Z axis µm; mm; unit

Zofs1 Electric offset 5 digits: 00000

Zofs2 values for Z 00000 to 32767

Page 22

EDH0170FE1010 – 09/98 22

LDS1000 Controller for Laser Diode Sensors

7.4.1.3 Display of Result in Arc-Seconds (LDS-Vector)

=> (F4) => (F1) => (F1)

The calibration certificate gives the values Ycoef, Zcoef, Yincr and Zincr for

result display in µrad. In general, Yincr and Zincr are equal to 1. The resolution of the display is then 0.1 µrad.

To display the result in arc-sec:

1 arc-sec = 4.85 µrad

1 µrad = 0.2062 arc-sec

Thus: Y µrad = (0.20 x1.0309 xY) arc-sec

Thus we will use the increments Yincr = 0.2 and Zincr = 0.2. That gives display limits of -400 to + 400.

The values Ycoef and Zcoef are corrected by 1.0309:

Ycoef1= Ycoef x1.0309 (rounded to the nearest unit).

Zcoef1= Zcoef x1.0309 (rounded to the nearest unit).

The unit sec will be chosen.

You are advised not to delete the initial parameters, in µrad. You only need

to program a new sensor number.

7.4.1.4 Programming a New Sensor

When an LDS-Vector autocollimator is delivered with its electronic controller, the sensor parameters are fed into the memory of the controller. The

number 0 is used for the current sensor.

The other memories are normally empty, and the values of the parameters

are therefore equal to the default values.

To program a new sensor, a spare place must be found, generally recognizable when S/N = 000000. You can choose to delete an existing sensor.

Access to the mode that enables rapid visualization of the various heads is

obtained by the sequence:

=> (F4) => (F1) => (F3)

It is then possible to modify the number of the current sensor:

(F2)Previous number (-1).

(F3)Next number (+1).

(F4)Visualization of parameters of the sensor envisaged.

(F5)Save the new configuration.

Programming the new sensor is done by the menu (see modification

of sensor parameters).

Page 23

23 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

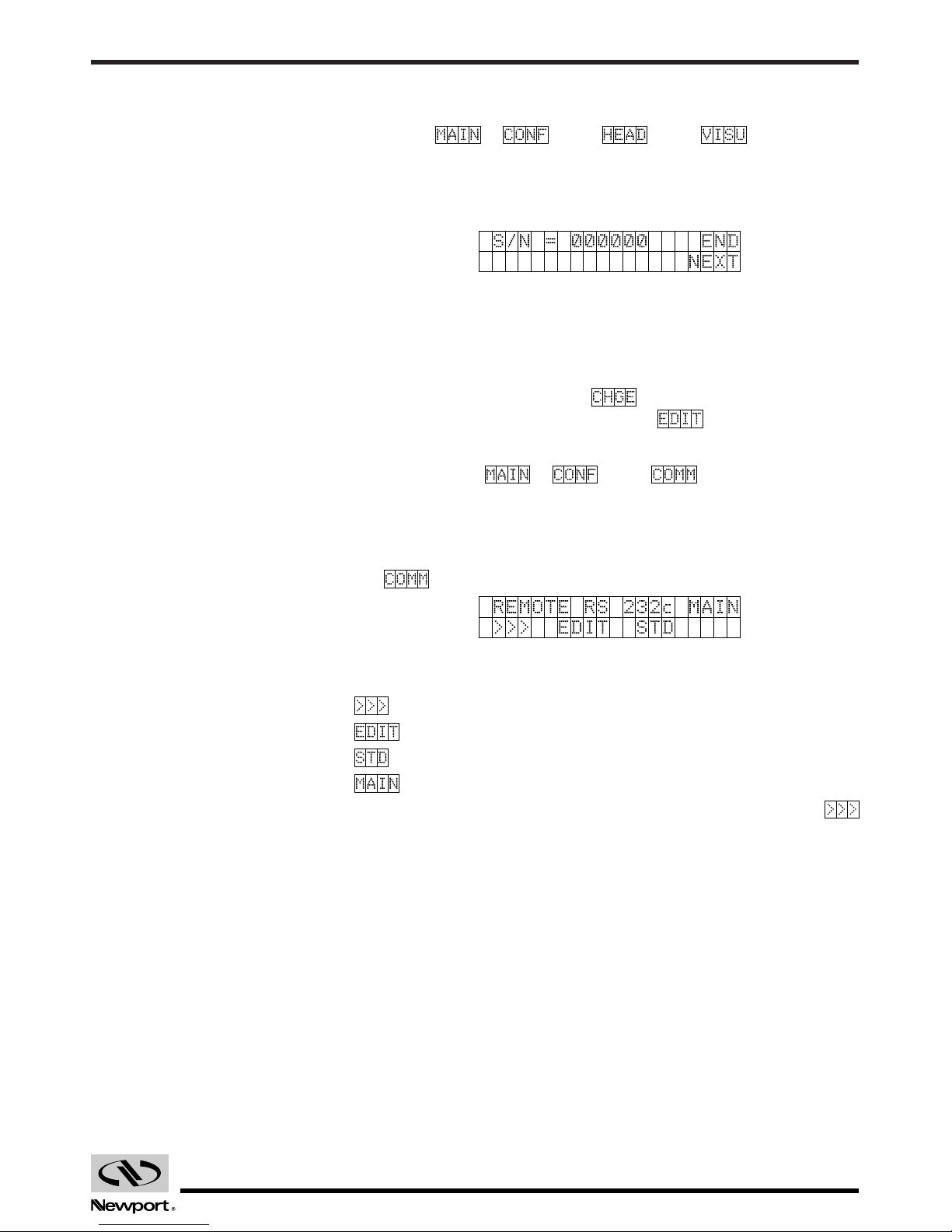

7.4.1.5 Visualization of Current Sensor Parameters

=> (F4) => (F1) => (F2)

You are advised to check that the current sensor really matches the sensor

that is currently connected to the controller. This Visualization mode is

easily accessible and provides the explicit values of the current sensor

parameters.

Check that the series number really matches that of the connected sensor.

For more certainty, compare the values of the parameters to those given in

the calibration certificate supplied with the sensor.

In case of nonconformity, it is necessary to:

•Either find another number of the current sensor (especially if the

series number does not match): Menu.

•Or modify the current sensor parameters: Menu.

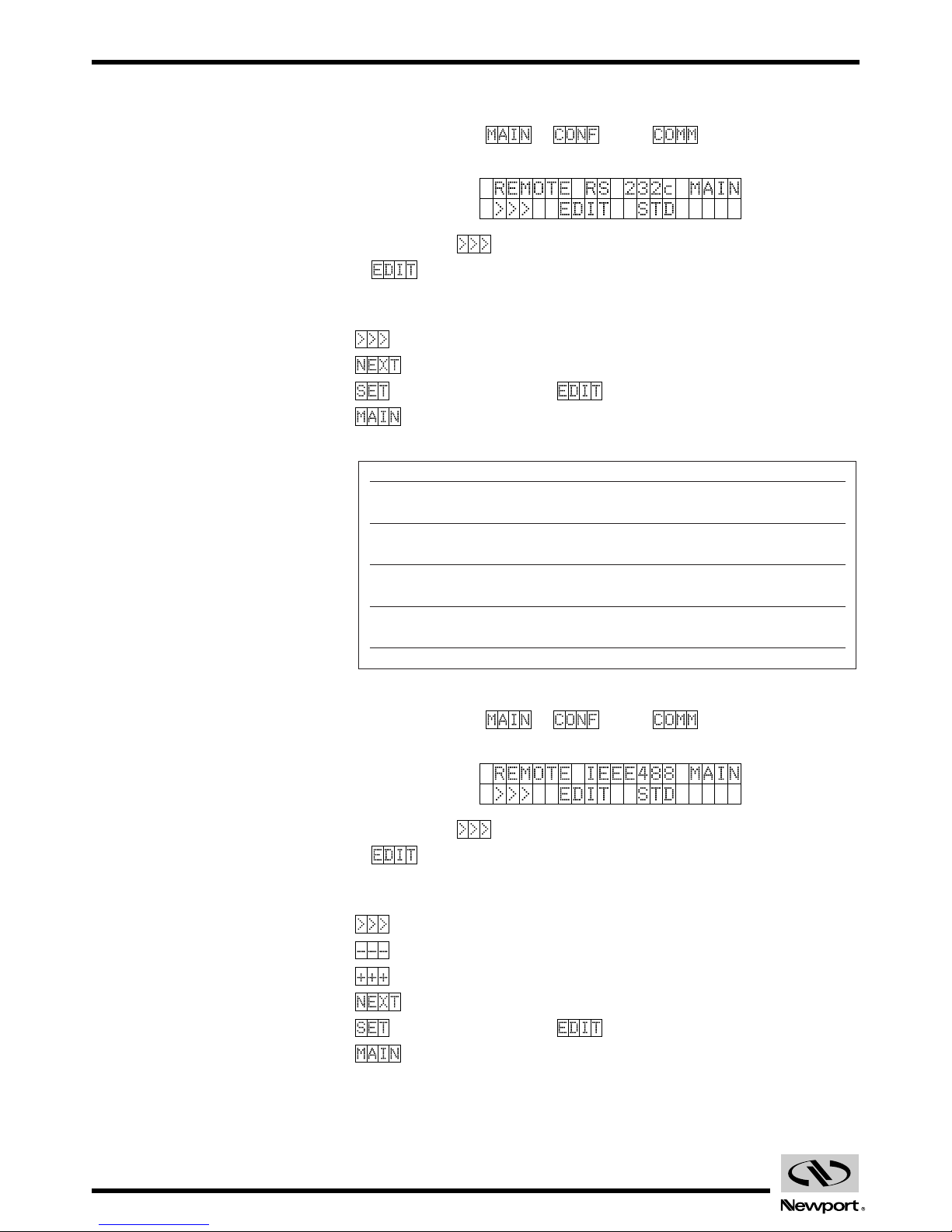

7.4.2 Communication Parameter Input

=> (F4) => (F2)

Access to this menu enables the parameters and the choice of communication mode of the controller to be modified. It is useful to check these values

before connecting to a computer. This must be done before using the instrument in Interface Mode.

The menu makes this selection possible in manual mode

This message indicates that the communication is programmed in RS-232-C.

Access to the following functions is then possible:

(F1)Changing RS-232-C <=> IEEE-488.

(F2)Modification of the parameters of the selected interface.

(F3)Change to default values of the selected interface.

(F5)Return to main menu.

The communication mode can be modified from this menu using the

(F1) key.

Page 24

EDH0170FE1010 – 09/98 24

LDS1000 Controller for Laser Diode Sensors

7.4.2.1 Modification of RS-232-C Parameters

=> (F4) => (F2)

The RS-232-C interface is active if the display is as follows:

Otherwise, the (F1) key provides access to this menu.

In mode the values of the parameters stored for the RS-232-C interfa-

ce can be modified.

For all the parameters, a modification menu uses the following functions:

(F1)Scrolling of possible parameters (and their status).

(F4)Next parameter.

(F5)Save and exit mode.

(F5)Return to main menu.

List of parameters:

7.4.2.2 Modification of IEEE-488 Parameters

=> (F4) => (F2)

The IEEE-488 interface is active if the display is as follows:

Otherwise, the (F1) key provides access to this menu.

In mode the values of the parameters stored for the IEEE-488 interfa-

ce can be modified.

For all the parameters, a modification menu uses the following functions:

(F1)Scrolling of possible parameters (or cursor movement).

(F2)Lower value (-1 for digital values).

(F3)Next highest value (+1 for digital values).

(F4)Next parameter.

(F5)Save and exit mode.

(F5)Return to main menu.

Designation Available Values Default Value

MSG TERM End of sequence CR; LF; CR LF; LF CR CR

terminator

BAUD RATETransmission 300; 600; 1200; 2400; 9600

Speed 4800; 9600; 19200

WORD LENGTH Length of 7; 8 8

the string sended

STOP BITS Stop bit 1; 2 1

number

PARITY Parity NONE; ODD; EVEN NONE

Page 25

25 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

List of parameters:

7.4.2.3 Default Values of Communication Parameters

=> (F4) => (F2)

The communication programs available for the LDS1000 Controller use the

communication parameter default values.

The LDS1000 Controller enables you to quickly return to the correct mode

of operation when the parameter modifications do not allow the Interface

Mode to be used normally.

For each communication mode, RS-232-C or IEEE-488, the (F3) key

makes it possible to return to default values.

As a precaution, a confirmation messages asks if you really want to modify

the current parameters (and specifies the active interface):

7.4.3 LDS1000 Controller Parameter Input

=> (F4) => (F3)

7.4.3.1 Reading the Internal Software Version

=> (F4) => (F3)

This menu displays the version of the LDS1000 software installed in the

controller.

This internal software manages all the controller’s functions, in manual

mode and in Interface Mode. It also operates the controller when analog

outputs are installed. The physical modification of the software is done by

EPROM exchange on the parent card of the 68000 processor.

Should you encounter any operating problems with the controller, this

information will be useful to the maintenance service. It is possible to update the software as long as the material environment remains compatible

with the working of the software.

Access to Menu Rack provides the following display:

The following functions are active:

(F4)Access to next parameter.

(F5)Return to main menu.

Designation Available Values Default Value

MSG TERM End of sequence CR; LF; CR LF; LF CR CR LF

terminator

PRIM ADRESS IEEE-488 2 digits: 15

primary adress 00 to 30

SECOND ADRESS IEEE-488 2 digits: 00

secondary adress 00 to 30

TIME OUT Communication 0.01 to 10 sec 0.5

time-out

Page 26

EDH0170FE1010 – 09/98 26

LDS1000 Controller for Laser Diode Sensors

7.4.3.2 Modification of Display Brightness

=> (F4) => (F3) => (F4)

Four levels of brightness are available.

The following functions are active:

(F3)Highest brightness.

(F2)Lower value.

(F4)Next parameter.

(F5)Return to main menu.

The maximum brightness is the default value.

7.4.3.3 Reading the Size of the Memory Installed

=> (F4) => (F3) => (F4) => (F4)

The memory size depends on the option chosen at the time of ordering. It

is the size of the buffer memory used for automatic acquisitions carried out

by the LDS1000 Controller. This function is only accessible in Interface

Mode. The values read by the sensor can be successively stored in the

memory, at a high frequency.

The RS-232-C or IEEE-488 interface authorizes alternate reading of these

values.

LDS1000 Controllers have a standard memory size of 2048 measurement

points (couples Y, Z). Approximately 1 second of measurement can be stored at the maximum acquisition frequency of 2 kHz. The read-out time of

these values depends on the communication transmission speed and the

size of the host computer. For 2000 points, its value can reach several tens

of seconds.

The extended memory option offers an extended memory of 14336 points.

It enables an event to be stored in the memory the duration of which can

reach 7 seconds at 2 kHz.

The display of this menu directly gives the values of the memory size

expressed in the number of measurements that can be stored (one measurement is a couple of Y, Z values).

7.4.3.4 Reading the Analog Output Option

=> (F4) => (F3) =>

(F4) => (F4) => (F4)

Only possible with controllers that have the analog output option.

The display of this menu shows whether this option is present on the

controller concerned.

For more details on analog outputs, refr to the corresponding paragraph.

Page 27

27 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

8.0 Analog Output Parameter Input

8.1 Selecting Analog Outputs (if option present)

=> (F4) => (F4)

The analog outputs are a material option that must be specified at the time

of ordering. They can be installed later on, but you will need to contact our

after-sales service.

When the analog outputs are activated, the OUTY and OUTZ connectors

located on the rear panel of the controller give two voltages that are proportional to the digital values calculated by the controller. The analog outputs take into account the real calibration performed on the current sensor

and provide the reliable values that can be used directly. The refresh frequency of the analog outputs has been set at 2 kHz which enables events to

be seized rapidly. Thus, when the analog outputs are active, the controller

no longer manages the display, or the communication with the computer.

When the analog outputs have been chosen and the controller is switched

off, the controller memorizes this status. When the controller is switched

on, the analog mode is reactivated. The LDS1000 Controller operates like a

standard analog instrument and can be perfectly integrated into classical

acquisition chains.

The configuration parameters of the analog outputs are the following:

INTG:Integration constant (in msec).

Like the digital version, the value available at the output is obtained by a

sliding average of a given number of values measured at maximum frequency. With this parameter a frequency filter adapted to the signals that you

wish to obtain can be selected.

GAIN:Choice of output gain.

The output voltage is between -10 volts and +10 volts. When the gain is 1,

the voltage of +10 V matches the highest limit of the measurement range.

When the gain is 10, the same voltage only corresponds to a tenth of the

highest limit of the measurement range.

With a gain of 1, the resolution of 1 increment supplies a voltage of 5 mV. It

increases to 50 mV for a gain of 10.

The (F4) menu provides access to the analog outputs that are

immediately available on the rear panel. In addition, it displays the current

parameters:

The first value is the value of the integration constant used, the second

value is the value of the gain.

Page 28

EDH0170FE1010 – 09/98 28

LDS1000 Controller for Laser Diode Sensors

Electric Characteristics of the Analog Outputs:

•Outputs on rear panel of controller2 connectors BNC OUTY and OUTZ

•Refresh frequency 2000 Hz

•Low pass digital filter 1 to 2000 Hz (depending on INTG)

•Output range ±10 V

•Scale factor 5 mV/incr (for Gx1) to

1000 mV/incr (for Gx200)

•Resolution 0.5 increment

•Electronic noise 1 mV rms

•Distortion 0.5% (electronic)

•Maximum offset 50 mV typical

•Discrepancy Pure delay of 1.1 msec

(outside integration)

•Output impedance 10 Ω

WARNING: SPECTRAL WITHDRAWAL

The analog outputs use an intermediary calculation stage that is based

on a sample at 2000 Hz. This will limit the use of the LDS sensor for studying signals that do not have a significant spectral component over

1000 Hz (this sort of component would find themselves “withdrawn” and

would appear for lower frequencies).

The functions accessible by the Menu are the following:

(F4)Modification of analog output parameters.

(F5)Return to main menu.

Return to main menu disables the analog outputs.

8.2 Modification of Analog Output Parameters

=> (F4) => (F4) => (F4)

The integration constant INTG and the gain GAIN can be modified in this

menu.

They will be chosen in relation to the type of measurements to be carried out:

•Rapid measurements: Low integration value.

•Accurate measurements: Long integration value.

•Wide range: Low gain value.

•Reduced range: High gain value (Zoom).

From this menu the active keys are the following:

(F1)Modification of the integration constant.

(F2)Modification of the gain.

(F5)Return to analog output mode.

Page 29

29 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

For each of the parameters, a modification menu uses the following functions:

(F2)Lower value.

(F3)Next highest value.

(F5)Save and Return to analog output mode.

List of parameters:

NOTE

When you exit analog output mode after modifying the integration

constant, the new value is also used to calculate the display of the

controller.

Scale factors that correspond to the combined choice of the gain and the

counter increment.

Example: using the Table.

The controller operates in manual mode with a Yincr value of 0.2 and a unit

given in arc-sec. The following values can therefore be read:

We can therefore expect to obtain the following analog values:

•With a gain of 1: OUTY = - 2.62 x25 = - 65.5 mV

OUTZ = 8.54 x25 = 213.5 mV

•With a gain of 5: OUTY = -2.62 x125 mV = - 327.5 mV

OUTZ = 8.54 x125 mV = 1067.5 mV

OUTY or OUTZ in mV for a Displayed Unit (µrad, sec, …)

Incr. 0.1 0.2 0.5 1 2 5 10 20 50

Gain 1 50 mV 25 mV 10 mV 5 mV 2.5 mV 1 mV 0.5 mV0.25 mV 0.1 mV

2 100 mV 50 mV 20 mV 10 mV 5 mV 2 mV 1 mV 0.5 mV 0.2 mV

5 250 mV125 mV 50 mV 25 mV12.5 mV 5 mV 2.5 mV1.25 mV 0.5 mV

10 500 mV250 mV 100 mV 50 mV 25 mV 10 mV 5 mV 2.5 mV 1 mV

20 1 V 500 mV 200 mV100 mV 50 mV 20 mV 10 mV 5 mV 2 mV

50 2.5 V 1.25 V 500 mV250 mV125 mV 50 mV 25 mV12.5 mV 5 mV

100 5 V 2.5 V 1 V 500 mV250 mV100 mV 50 mV 25 mV 10 mV

200 10 V 5 V 2 V 1 V 500 mV200 mV100 mV 50 mV 20 mV

OUT (mV) = Measure (unit) xGain/Incr. x5

Designation Available Values Default Value

INTG Integration 0.5; 1; 2; 5; 10; 20; 100

constant (msec) 50; 100; 200; 500; 1000

GAIN Output gain 1; 2, 5; 10; 20; 50; 1

Digital/Analog 100; 200

Page 30

EDH0170FE1010 – 09/98 30

LDS1000 Controller for Laser Diode Sensors

9.0 TRIG Input and PWOK Output

9.1 Conventions on Logical Inputs/Outputs

The controller has a logical TRIG input available on a BNC socket on the

rear panel.

It provides a logical PWOK output that indicates if the sensor is receiving

light.

Logical Inputs/Outputs.

•The convention retained for logical inputs/outputs is the following:

–ACTIVE = 1 = High Status = The current flows = Drawn at the ground.

–PASSIVE = 0 = Low Status = The current doesn’t flow = Open wire.

•The output (PWOK) is in High status (value 1) when the sensor receives

light. With the RO command it is possible to read the status of this output.

•The passage of the TRIG input from Low status to High status (upward

front) triggers the start of the synchronized acquisitions. With the RB

command it is possible to read the status of this input.

•The wiring of the logical PWOK output to the logical TRIG input allows

an acquisition cycle to be started when signal inputs into the measurement range of the sensor.

•Max. frequency PWOK: 130 Hz.

•Max. frequency TRIG: 500 Hz.

•The reading is performed with a random delay from 0 to 1 msec.

The logical inputs/outputs can only be used in Interface Mode.

PWOK

Output

TRIG

Input

Page 31

31 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

9.2 TRIG Input

•Compatible TTL input.

•Max. voltage 5 V.

9.3 PWOK Output

•Open collector output.

•Max. voltage 30 V.

•Max. current 20 mA.

PWOK

Output

100 Ω

TRIG

Input

+5 V

10 kΩ

5V1 100 pF

Page 32

EDH0170FE1010 – 09/98 32

LDS1000 Controller for Laser Diode Sensors

10.0 Use with a Computer Interface

The LDS1000 electronic controller offers its full measuring capacity when

connected to a computer via an RS-232-C or IEEE-488 interface. Interface

Mode is activated by sending a computer message. It can only be activated

when:

•The physical connection between the controller and the computer is

correct.

•The controller interface parameters and those of the computer are compatible.

•The correct computer output is commanded.

•The controller is in the main menu when the connection is established.

Interface Mode allows:

•Flying spot reading of the measured values.

•Execution of synchronous acquisition sequences of a clock inside the

controller, or a logical external TRIG signal.

•Reading the sensor status and the I/O available.

The LDS1000 Controller is delivered with an RS-232-C cable. It will work for

example with an IBM PC compatible computer with the following minimum

configuration:

•A IBM PC compatible computer.

•An RS-232-C or IEEE-488 interface (Hewlett Packard or National

Instrument card).

10.1 Checking the Interface

The controller must be connected to a calculator (RS-232-C or IEEE-488) or

a console (RS-232-C) via an adapted cable. Only connect the instruments

when everything is switched off.

WARNING

Before connecting, check that all equipment is switched off.

10.1.1 RS-232-C Interface

The LDS1000 Controller is delivered with an RS-232-C interface cable. This

cable has a male Sub-D25 connector for the controller connection (cf. diagram). When setting it up, make sure you tighten the support screws.

The other connector is a Sub-D9 pin plug compatible with the series output

of the computer. A Sub-D9/Sub-D25 pin adapter enables it to be linked to all

existing standards. It is useful to note the series output of the computer: it

is usually marked by one of the following: SERIAL, COM1, COM2, etc. (refer

to the computer documentation).

The communication must be obtained with a TERMINAL type program.

Read the software documentation to configure the parameters of the RS232-C output. It is recommended, as far as possible, to select the following

parameters, that are the LDS1000 Controller’s default parameters:

Page 33

33 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

•BAUD RATE :9600

•MSG TERM :CR

•WORD LENGTH:8

•STOP BITS :1

•PARITY :NONE

Start up the LDS1000 Controller and check, in Manual mode, the interface

parameters by selecting the RS-232-C protocol.

=> (F4) => (F2)

If the display is:

The RS-232-C interface is active (otherwise press the (F1) key of the

controller to return to the RS-232-C protocol).

Use (F2) mode to visualize and modify the interface parameters if

necessary.

Return to the main display menu of the controller with the (F5) key.

The system is ready to communicate in RS-232-C.

RECOMMANDATION

Refer to the Appendix A: “Example of Program Using RS-232-C Link”.

10.1.2 IEEE-488 Interface

IEEE-488 interface is only possible if the computer is equipped with an IEEE488 communication card. Several models are available on the market.

RECOMMANDATION

NEWPORT recommends the National Instrument AT-GPIB/TNT card for

its software.

An IEEE-488 cable is required for the interface between the LDS1000

Controller and the IEEE-488 card. The cable is symmetrical and allows several instruments to be chained. This is the advantage of a parallel interface.

When setting up, make sure the support screws are properly tightened.

The communication must be obtained with a program. Read the software

documentation to configure the parameters of the IEEE-488 output. It is

recommended, as far as possible, to select the following parameters, that

are the LDS1000 Controller’s default parameters:

•MSG TERM :CR LF

•PRIM ADRESS :15

•SECOND ADRESS:00

•TIME OUT :0.5 sec

The controller operates the IEEE-488 interface in SRQ mode: the controller

status can be read with the SPOL function of the IEEE-488 card. This status

is coded by an 8 bits word, bit 7 of which (value 128) is worth 1 if a message is near: The reading must always be carried out before a new request.

Page 34

EDH0170FE1010 – 09/98 34

LDS1000 Controller for Laser Diode Sensors

Start up the LDS1000 Controller and check, in manual mode, the interface

parameters by selecting the IEEE-488 protocol.

=> (F4) => (F2)

If the display is:

The IEEE-488 interface is active. (Otherwise press the (F1) key of the

controller to return to the IEEE-488 protocol)

Use (F2) mode to visualize and modify the interface parameters if

necessary.

Return to the main display menu of the controller.

The system is ready to communicate in IEEE-488.

RECOMMANDATION

Refer to the Appendix B: “IEEE-488 Link Characteristics”.

10.2 LDS-TOOLS Software

In order to communicate with the controller, the user must have a terminal

or a computer capable of communicating with external devices via a RS-232-C

or IEEE-488 interface.

One approach is to use a communications software that can emulate a terminal. An other solution is to use NEWPORT software, Windows 3.11, Windows

95 and Windows NT compatible, and delivered with the LDS1000

Controller.

You can install this software on a PC compatible computer with the following minimum configuration:

•An IBM‚ Personal Computer or compatible.

•A VGA monitor.

•An 80386 or later processor.

•4 MB of available memory (8 MB recommended).

•A hard disk with enough disk space to install the options you need.

•A Windows™ 3.1x environment.

LDS-TOOLS only accepts the following interfaces:

•COM1 or COM2 standard serial port.

•HP-IB Hewlett-Packard® board, model HPIB 82335.

•HP-IB Hewlett-Packard® board, model HPIB 82340.

•GPIB National Instrument® board, model AT-GPIB/TNT.

ATTENTION

Before to use NEWPORT LDS Tolls software, IEEE-488 boards (listed

above) must be into the initial configuration of the constructor, and installed in accordance with its recommended procedure.

Before to use NEWPORT LDS Tolls software, we advise you to use softwares utilities supplyed with the IEEE-488 board to check that the installation is completed successfully.

Page 35

35 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

This software enables you to quickly master the instrument in Interface

Mode. You are able to promptly check if the communication is working correctly. It is a base for learning the basic functions of the LDS1000

Controller. Finally, it is used as a communication basis with LDS sensors

for a substantial number of applications.

This software will only work with controllers that have a software version

higher than V3.00.

With the software the main functions of LDS instruments can be used:

•Display of the position by a moving spot on a target.

•Diameter of the variable target in relation to the spot position.

•Display of the position in large characters (Remote reading).

•Dialog with the controller, parameter modification.

•Point to point acquisition sequence, analysis and storage.

•Rapid acquisition sequence (max. freq. 2 kHz), analysis and storage.

10.3 Programming

Before we get to this chapter, we presume that the interface parameters

have been checked, and that the connection is established. The LDS-TOOLS

program is useful for checking the material configuration (refer to the previous chapters).

We will also presume that the first lines of the program contain adequate

parameter commands that enable the computer interface to be configured

in the mode chosen. The information on this point is contained:

•In the instructions for the programming software used (Basic instructions for example).

•In the manual of the computer used.

•Possibly in the instructions for the IEEE-488 card chosen.

Whichever protocol is used (RS-232-C or IEEE-488), the communication

logic with the LDS1000 Controller is the same.

Page 36

EDH0170FE1010 – 09/98 36

LDS1000 Controller for Laser Diode Sensors

The computer sends a chain of characters to the controller that may then:

•Respond with a return chain.

•Carry out a modification or a function (without necessarily responding).

•Not respond and not react (message is not recognized).

The communication software must be able to generate ASCII messages

(refer to syntax in the description of recognized commands).

It must also use a send command for this message on the current interface

(refer to syntax in the supplier’s instructions for the programming software).

It must then be able to read the return message or wait for this message

(refer to syntax in the supplier’s instructions for the programming software).

Finally, the message must be interpreted and the information contained in

the chain of characters received must be recognized (values measured,

sensor status, various parameters, …).

A properly structured program will include sub-programs that carry out

these basic functions. Be particularly careful when writing these modules

that are essential for the proper operating of the final program.

In all cases:

•The first order to be sent to the controller is the MR command that activates the controller in Interface Mode.

•If the communication is correct, the controller displays:

In other cases, check that:

•The controller is switched on.

•It is working in Main menu (if not cf. manual mode).

•The physical connection is correct.

•The communication parameters are correct.

•The syntax sent is correct.

•The initialization of the interface is properly carried out.

The reading sub-program should then be tested using, for example, the VE

command which requests the software version of the LDS1000 Controller.

The response must be an ACSII chain of type:

VE LDS1000 CONTROLLER VERSION 3.0

If their is no response, carefully check the structure of the reading sub-program.

10.3.1 Structure of Messages to the Controller

The ASCII chains transmitted by the computer must match the commands

understood by the LDS1000 Controller. Each message transmitted may

include several different commands, separated by commas (,) or semicolons (;) and will end with the appropriate character (CR, LF, CRLF, LFCR).

The <space> characters will be deleted on reception.

Page 37

37 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

The core of each command is made up of two letters. For example:

MR:Set remote mode.

The parameters associated with the command are:

•Either the full digital values, preceding the command core. They usually

indicate the address (or the number) where the information should be

looked for. For example:

42TT:Reading the measurement number 42.

•Or the decimal digital values, using a separating dot (.), according to the

central core. They correspond to a value transmitted to the controller

to modify the parameter concerned. For example:

TM152:Launch the acquisition of 152 measurements.

The commands received by the controller are stored in a communication

buffer of 255 characters. The controller carries them out chronologically by

emptying this buffer memory.

The ASCII chains transmitted from the controller to the computer are the

following:

•Generally they start by copying a part of the message sent.

•They are followed by the value or values of the response parameter.

•Commas are used to separate (,).

For example, when the 1TP command is sent which requests the value

measured on axis 1, the controller returns the chain:

1TP-1596.3 which indicates that the value measured on axis 1 is -1596.3.

Certain commands do not generate return from the LDS1000 Controller. For

example, the SP50 command that sets the sampling period at 50 msec.

Incorrect commands create an error. Only the last error code is stored in

the memory. This code will be reset at @ (no error) when it is read again.

In every case, to find out whether the command has been correctly performed, test the status of the controller using the TB command (Reading the

error).

The list of commands recognized by the LDS1000 Controller are given later

in this manual. You are advised to read the description of a command carefully before using it.

10.3.2 Programming Conventions

•Access to Interface Mode is only driven by the computer (MR command).

•Access to Interface Mode is only possible if the controller is in its main

menu.

•When the controller is in Interface Mode, none of the keys on the front

panel are valid.

•The axes called Y and Z on the display correspond respectively to numbers 1 and 2 of the Interface Mode commands.

•The result matrices are numbered starting at 1. The first value in the

memory is marked value 1.

•The measurements transmitted by the controller have the same format

as the values displayed. They take into account the units used for the

selected sensor.

•The Interface Mode output is activated by computer (ML command).

Page 38

EDH0170FE1010 – 09/98 38

LDS1000 Controller for Laser Diode Sensors

10.4 List of Commands

10.4.1 Commands Listed by Category

10.4.1.1 System Management

Command Description

ML Set Manual mode.

MR Set Interface Mode.

RD Frozen display.

RE Active display.

RS Reset system.

TB Read error.

TE Read error code.

TS Read operational status.

VE Read Soft version.

10.4.1.2 Reading Current Sensor Parameters

Command Description

TA Read current sensor parameters.

TN Reading sensor number and series number.

10.4.1.3 Classical Acquisitions

Command Description

KI Define the integration constant.

TP Read current measurement.

XI Read integration constant.

10.4.1.4 Dynamic Acquisitions

Command Description

MS Read acquisition status.

SP Define sample period

ST Stop current acquisitions.

TK Acquisitions with trigger on TRIG input.

TM Immediate acquisitions.

TQ Acquisitions with synchronization on TRIG input.

TT Re-read acquisitions.

XN Read number of measurements in memory.

XS Read sample period.

10.4.1.5 Reading Logical Inputs/Outputs

Command Description

RB Read TRIGG input status.

RO Read PWOK output status.

Page 39

39 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

10.4.2 Commands Listed in Alphabetic Order

Command Description

KI Define the integration constant.

ML Set Manual mode.

MR Set Interface Mode.

MS Read acquisition status.

RB Read TRIGG input status.

RD Frozen display.

RE Active display.

RO Read PWOK output status.

RS Reset system.

SP Define sample period.

ST Stop current acquisitions.

TA Read current sensor parameters.

TB Read error.

TE Read error code.

TK Acquisitions with trigger on TRIGG input.

TM Immediate acquisitions.

TN Read sensor number and series number.

TP Read current measurement.

TQ Acquisitions with synchronization on TRIGG input.

TS Read operational status.

TT Proof read acquisitions.

VE Read software version.

XI Read integration constant.

XN Number of measurements in memory.

XS Read sample period.

10.5 Description of Commands

The rest of the manual presents the commands recognized in Interface

Mode by the LDS1000 Controller. The format of one page per command is

used to make it easier to look for the correct syntax.

The commands are listed in alphabetic order.

For each command, you will find the following information:

•The modes in which the following can be carried out (if not => error D):

jMNL for manual mode.

jRMT for remote mode (or Interface Mode).

jACT for active (acquisition in progress).

•Its syntax.

•Its parameters and the errors if they are incorrect.

•Its description.

•Its response.

•The related errors.

•An example.

•A comment if necessary.

•The commands related to that command.

Page 40

EDH0170FE1010 – 09/98 40

LDS1000 Controller for Laser Diode Sensors

10.5.01 KI Define the Integration Constant

Use h MNL j RMT h ACT

Syntax KInn

Parameter nn 0; 1; 2; 5; 10; 20; 50; 100; 200; 500; 1000.

Integration constant in msec with 0 = no integration =>

0.5msec).

Possible error

nn other than list below: nn takes nearest value.

Description Set the value of the integration constant INTG to nn msec.

Response None.

Error D Execution not allowed.

Example KI100 |Define integration constant at 100 msec.

NOTE

Do not confuse KI integration constant, and SP sample period.

The integration constant KI sets the duration of the digital averaging car-

ried out on acquisitions to 2 kHz.

The sample period SP sets the time interval separating two successive

measurements (related to commands TK, TM).

Related commands SP Define sample period.

TB Read error.

TE Read error code.

XI Read integration constant.

Page 41

41 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

10.5.02 ML Return to Local Mode

Use h MNL j RMT h ACT

Syntax ML

Parameter None.

Description End of remote mode and return to manual mode.

Response None.

Error D Execution not allowed.

Example ML |Return to manual mode.

NOTES

When returning from Interface Mode to Manual mode, the display

returns to the Main menu, the keys on the front panel are active again,

and the integration constant keeps the value possibly programmed by KI.

The parameters SP,TE,XN are set at the following values:

SP = 0, TE = @ and XN = 0.

Related commands MR Set Interface Mode.

RD Frozen display.

RE Active display.

TB Read error.

TE Read error code.

Page 42

EDH0170FE1010 – 09/98 42

LDS1000 Controller for Laser Diode Sensors

10.5.03 MR Set Interface Mode

Use j MNL h RMT h ACT

Syntax MR

Parameter None.

Description Set Interface Mode from Manual mode (manual mode in main

menu).

Response None.

Error D Execution not allowed.

Example MR |Set Interface Mode.

REMARQUE

The controller then displays LDS1000 REMOTE MODE.

Related commands ML Set manual mode.

RD Frozen display.

RE Active display.

TB Read error.

TE Read error code.

Page 43

43 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

10.5.04 MS Read Acquisition Status

Use h MNL j RMT j ACT

Syntax MS

Parameter None.

Description Read acquisition status. The return value is an ASCII character

the code of which should be translated into binary.

•Bit 0= 0: Correct power received.

= 1: Incorrect power received.

•Bit 1= 0: Correct position.

= 1: Incorrect position.

•Bit 2= 0: Acquisition not started up.

= 1: Acquisition started up - TRIGG wait.

•Bit 3= 0: No acquisition in progress.

= 1: Acquisition in progress.

•Bit 4= 0

•Bit 5= 0

•Bit 6= 1

•Bit 7= 0

Response MSaa aa is an ASCII character.

Errors D Execution not allowed.

S Communication time-out.

Example MS |Read acquisition status.

MS@ |System resting.

Related commands TB Read error.

TE Read error code.

Page 44

EDH0170FE1010 – 09/98 44

LDS1000 Controller for Laser Diode Sensors

10.5.05 RB Read TRIGG Input Status

Use h MNL j RMT j ACT

Syntax RB

Parameter None.

Description Read the status of the TRIGG input. The return value will be

equal to 0 or 1 depending on whether the interface is in high

status or low status.

Response RBnn nn = status of TRIGG input.

Errors D Execution not allowed.

S Communication time-out.

Example RB |Request status of TRIGG input.

RB1 |TRIGG input is in high status.

Related commands RO Read PWOK output status.

TB Read error.

TE Read error code.

10.5.06 RD Set Frozen Display Mode

Use h MNL j RMT j ACT

Syntax RD

Parameter None.

Description Freezes the display on “REMOTE MODE” instruction to remove

response times related to the display refresh.

This is the default display mode for Interface Mode.

Response None.

Error D Execution not allowed.

Example RD |Frozen display. The controller displays:

Related commands RE Active display.

TB Read error.

TE Read error code.

Page 45

45 EDH0170FE1010 – 09/98

LDS1000 Controller for Laser Diode Sensors

10.5.07 RE Set Active Display Mode

Use h MNL j RMT j ACT

Syntax RE

Parameter None.

Description Enable display in remote mode. The response times related to

display refresh may appear.

Response None.

Error D Execution not allowed.

Example RE |Active display.

Related commands RD Frozen display.

TB Read error.

TE Read error code.