Page 1

User’s Guide

Thermoelectric Temperature Controllers

LDT-5910C

LDT-5940C

70045102 March 2019

Page 2

Page 3

Table of Contents

Safety Information and the Manual ............................................................................. v

General Safety Considerations ................................................................................... v

Safety Symbols .......................................................................................................... vi

Safety Marking Symbols ........................................................................................... vii

Warranty ................................................................................................................... vii

Limitations ................................................................................................................ vii

Returning an Instrument .......................................................................................... viii

Claims for Shipping Damage .......................................................................................................... viii

Comments, Suggestions, and Problems ................................................................... ix

Chapter 1: Introduction and Specifications ................................................. 1

Safety Considerations ................................................................................................ 1

Initial Inspection .......................................................................................................... 1

Shipping Kit ................................................................................................................ 1

Product Overview ....................................................................................................... 2

Options and Accessories ............................................................................................ 5

Specifications ............................................................................................................. 6

Chapter 2: General Operation ..................................................................... 9

Grounding Requirements ........................................................................................... 9

AC Line Power Requirements .................................................................................... 9

The Power Up Sequence ........................................................................................... 9

Firmware Upgradeability ........................................................................................... 10

GPIB Communication ............................................................................................... 10

USB Communication ................................................................................................ 10

Tilt Foot Adjustment .................................................................................................. 10

Rack Mounting .......................................................................................................... 10

Connections .............................................................................................................. 11

Front Panel Operation .............................................................................................. 13

Power On / Off ................................................................................................................................ 13

Adjust Knob and Enable Button ..................................................................................................... 13

March 2019 i LDT-5910C and LDT-5940C

Page 4

Setup .............................................................................................................................................. 13

PID Control ..................................................................................................................................... 15

Mode ............................................................................................................................................... 16

Display ............................................................................................................................................ 16

Error Indicators ............................................................................................................................... 17

General Operating Procedures ................................................................................. 17

Warm-Up and Environmental Considerations ................................................................................ 17

General Guidelines for Sensor Selection and Safety Limits .......................................................... 17

Sensor Options ............................................................................................................................... 17

Safety Limits ................................................................................................................................... 22

Constant Temperature Mode Operation ................................................................... 22

Constant Sensor Mode Operation ............................................................................ 22

Constant Current Mode Operation ............................................................................ 24

Resistive Heater Mode Operation ............................................................................. 24

Chapter 3: Remote Operation ................................................................... 25

GPIB Address ........................................................................................................... 25

Basic GPIB Concepts ............................................................................................... 25

Data and Interface Messages ........................................................................................................ 25

Talkers, Listeners, and Controllers ................................................................................................. 26

GPIB Cable Connections ............................................................................................................... 26

The GPIB Connector ...................................................................................................................... 27

Reading the GPIB Address ............................................................................................................ 28

Changing the GPIB Address .......................................................................................................... 28

Basic USB concepts ................................................................................................. 28

Changing Between Local and Remote Operation ..................................................... 29

GPIB vs. USB Communication ................................................................................. 29

Command Syntax ..................................................................................................... 29

Letters ............................................................................................................................................. 29

White Space ................................................................................................................................... 30

Terminators .................................................................................................................................... 30

Command Separators .................................................................................................................... 30

Parameters ..................................................................................................................................... 31

Command Tree Structure ......................................................................................... 32

Syntax Summary ...................................................................................................... 33

IEEE 488.2 Common Commands ............................................................................. 34

Status Reporting ....................................................................................................... 35

Event and Condition Registers ....................................................................................................... 35

March 2019 ii LDT-5910C and LDT-5940C

Page 5

Operation Complete Definition .................................................................................. 36

Output Off Register ................................................................................................... 38

Command Timing ..................................................................................................... 39

Sequential / Overlapped Commands ........................................................................ 39

Query Response Timing ........................................................................................... 39

Chapter 4: Command Reference ............................................................... 41

Remote Command Reference Summary .................................................................. 41

LDT-5910B Compatibility for LDT-5910C ................................................................. 44

Command Reference ............................................................................................... 45

Chapter 5: Calibration and Troubleshooting ............................................. 65

Troubleshooting Guide ............................................................................................. 66

Error Messages ........................................................................................................ 69

Error Code Tables .......................................................................................................................... 69

Calibration Overview ................................................................................................ 71

Recommended Equipment ............................................................................................................. 71

Environmental Conditions .............................................................................................................. 71

Warm-up ......................................................................................................................................... 71

Calibration Adjustments ................................................................................................................. 71

Thermistor Calibration .................................................................................................................... 72

Linearized Thermistor Mode Calibration ........................................................................................ 72

IC-I (AD590 or equivalent) Sensor Calibration ............................................................................... 73

IC-V (LM335 or Equivalent) Sensor Calibration ............................................................................. 73

RTD Sensor Calibration ................................................................................................................. 74

ITE Current Calibration ................................................................................................................... 74

TEC Voltage Measurement Calibration .......................................................................................... 76

Appendix A: AD590 and LM335 Sensor Calibration ................................. 77

AD590 Sensor .......................................................................................................... 77

LM335 Sensor .......................................................................................................... 78

One Point Calibration Method ................................................................................... 79

Two Point Calibration Method ................................................................................... 79

Appendix B: Auto-Tune Method ................................................................ 81

March 2019 iii LDT-5910C and LDT-5940C

Page 6

March 2019 iv LDT-5910C and LDT-5940C

Page 7

Safety and Warranty Information

Details about cautionary symbols

Safety markings used on the instrument

Information about the warranty

Customer service contact information

Safety Information and the Manual

Throughout this manual, you will see the words Caution and Warning indicating potentially

dangerous or hazardous situations which, if not avoided, could result in death, serious or minor injury,

or damage to the product. Specifically:

Caution indicates a potentially hazardous situation which can result in minor or moderate injury or

damage to the product or equipment.

Warning indicates a potentially dangerous situation which can result in serious injury or death.

Visible and/or invisible laser radiation. Avoid direct exposure to the beam.

General Safety Considerations

If any of the following conditions exist, or are even suspected, do not use the instrument until safe

operation can be verified by trained service personnel:

Visible damage

Severe transport stress

Prolonged storage under adverse conditions

Failure to perform intended measurements or functions

If necessary, return the instrument to ILX Lightwave, or authorized local ILX Lightwave distributor, for

service or repair to ensure that safety features are maintained.

All instruments returned to ILX Lightwave are required to have a Return Authorization Number

assigned by an official representative of ILX Lightwave Corporation. See Returning an Instrument for

more information.

March 2019 v LDT-5910C and LDT-5940C

Page 8

Safety Symbols

This section describes the safety symbols and classifications.

Technical specifications including electrical ratings and weight are included within the manual. See

the Table of Contents to locate the specifications and other product information. The following

classifications are standard across all ILX Lightwave products:

Indoor use only

Ordinary Protection: This product is NOT protected against the harmful ingress of

moisture.

IEC Class I Equipment (grounded type)

Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

Pollution Degree II

Installation (overvoltage) Category II for transient over-voltages

Maximum Relative Humidity: <85% RH, non-condensing

Operating temperature range of 10 °C to 40 °C

Storage and transportation temperature of –40 °C to 70 °C

Maximum altitude: 3000 m (9843 ft.)

This equipment is suitable for continuous operation.

March 2019 vi LDT-5910C and LDT-5940C

Page 9

Safety Marking Symbols

This section provides a description of the safety marking symbols that appear on the instrument.

These symbols provide information about potentially dangerous situations which can result in death,

injury, or damage to the instrument and other components.

Caution, refer

to manual

Caution, risk of

electric shock

Earth ground

Terminal

Protective

Conductor

Terminal

Alternating current

Caution,

hot surface

Visible and/or

invisible laser

radiation

Frame or chassis

terminal

Warranty

ILX Lightwave Corporation warrants this instrument to be free from defects in material and

workmanship for a period of one year from date of shipment. During the warranty period, ILX will

repair or replace the unit, at our option, without charge.

Limitations

This warranty does not apply to fuses, lamps, defects caused by abuse, modifications, or to use of

the product for which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty of

merchantability or fitness for any particular purpose. ILX Lightwave Corporation shall not be liable for

any incidental, special, or consequential damages.

If a problem occurs, please contact ILX Lightwave Corporation with the instrument's serial number,

and thoroughly describe the nature of the problem.

March 2019 vii LDT-5910C and LDT-5940C

Page 10

Returning an Instrument

If an instrument is to be shipped to ILX Lightwave for repair or service, be sure to:

Obtain a Return Authorization number (RA) from ILX Customer Service.

Attach a tag to the instrument identifying the owner and indicating the required service or

repair. Include the instrument serial number from the rear panel of the instrument.

Attach the anti-static protective caps that were shipped with the instrument.

Place the instrument in the original packing container with at least 3 inches (7.5 cm) of

compressible packaging material. Shipping damage is not covered by this warranty.

Secure the packing box with fiber reinforced strapping tape or metal bands.

Send the instrument, transportation pre-paid, to ILX Lightwave. Clearly write the return

authorization number on the outside of the box and on the shipping paperwork. ILX

Lightwave recommends you insure the shipment.

If the original shipping container is not available, place your instrument in a container with at

least 3 inches (7.5 cm) of compressible packaging material on all sides.

Repairs are made and the instrument returned transportation pre-paid. Repairs are warranted for the

remainder of the original warranty or for 90 days, whichever is greater.

Claims for Shipping Damage

When you receive the instrument, inspect it immediately for any damage or shortages on the packing

list. If the instrument is damaged, file a claim with the carrier. The factory will supply you with a

quotation for estimated costs of repair. You must negotiate and settle with the carrier for the amount

of damage.

March 2019 viii LDT-5910C and LDT-5940C

Page 11

Comments, Suggestions, and Problems

To ensure that you get the most out of your ILX Lightwave product, we ask that you direct any

product operation or service related questions or comments to ILX Lightwave Customer Support. You

may contact us in whatever way is most convenient:

Phone (800) 459-9459 or (406) 586-1244

Fax (406) 586-9405

On the web at: ilx.custhelp.com

Or mail to:

ILX Lightwave Corporation

31950 East Frontage Road

Bozeman, Montana, U.S.A 59715-8642

www.ilxlightwave.com

When you contact us, please have the following information:

Model Number

Serial Number

End-user Name

Company

Phone

Fax

Description of what is connected to the ILX Lightwave instrument

Description of the problem

If ILX Lightwave determines that a return to the factory is necessary, you are issued a Return

Authorization (RA) number. Please mark this number on the outside of the shipping box.

You or your shipping service are responsible for any shipping damage when returning the instrument

to ILX Lightwave; ILX recommends you insure the shipment. If the original shipping container is not

available, place your instrument in a container with at least 3 inches (7.5 cm) of compressible

packaging material on all sides.

We look forward to serving you even better in the future!

March 2019 ix LDT-5910C and LDT-5940C

Page 12

March 2019 x LDT-5910C and LDT-5940C

Page 13

Chapter 1:

Introduction and Specifications

This chapter is an introduction to the LDT-5910C and LDT-5940C Thermoelectric Temperature

Controllers.

Safety Considerations and unpacking information

Product Overview

Options and accessories

Specifications

Safety Considerations

If any of the following symptoms exist, or are even suspected, remove the LDT-5910C or

LDT-5940C from service. Do not use the LDT-5910C or LDT-5940C until trained service

personnel can verify safe operation.

Visible damage

Severe transport stress

Prolonged storage under adverse conditions

Failure to perform intended measurements or functions

If necessary, return the LDT-5910C or LDT-5940C to ILX Lightwave for service and repair

to ensure that safety features are maintained.

Initial Inspection

When you receive your LDT-5910C or LDT-5940C Thermoelectric Temperature Controller, verity that

the following items were shipped with the instrument

LDT-5900C Series Thermoelectric Temperature Controller Manual

Power Cord

Shipping Kit

Shipping Kit

The shipping kit for the LDT-5910C and LDT-5940C Thermoelectric Temperature Controller includes

a USB A/B cable and a CD containing the ILX Lightwave USB Driver.

March 2019 1 LDT-5910C and LDT-5940C

Page 14

Product Overview

The LDT-5910C and LDT-5940C are high performance thermoelectric temperature controllers

that offers a flexible, extended temperature control range from -100 °C to +200 °C with a choice

of temperature sensors. The LDT-5910C features a linear, bipolar output providing 32 Watts of

power to drive most thermal loads. This output stage offers the low current noise necessary to

achieve the temperature stability required to meet demanding low noise and frequencystabilized laser applications. The LDT-5940C features a switching output providing 60 Watts of

temperature control power for applications requiring increased cooling or heating capacity. The

instruments support thermistor, platinum RTD, and IC temperature sensors. In addition, a

unique linearized thermistor mode allows for the use of a standard 10 k thermistor over an

extended temperature range from -15 °C to 65 °C. A digital PID control loop delivers fast

settling time while maintaining high stability. For quick setup the LDT-5910C and LDT-5940C

incorporate pre-programmed PID values for common applications. In addition, a fast auto-tune

algorithm is available to automatically adjust the PID constants to support a wide range of

thermal loads. The GPIB and USB interfaces ensure trouble-free remote programming and

readout.

Features of the LDT-5910C and LDT-5940C include:

Precision setpoint resolution of ±0.01 °C with long term temperature stability of ±0.002 °C

(LDT-5910C) and ±0.003 °C (LDT-5940C)

Unique, linearized thermistor mode allows a standard 10 k thermistor to be used over the

range from -15 °C to 65 °C

Pseudo 4-Wire Sensor and TEC Measurement (LDT-5940C only)

Fully programmable PID control loop with twelve preset PID values

Auto-tune algorithm automatically adjusts PID constants for a wide range of loads

External analog temperature control input

Independent heating and cooling current limits

TE voltage measurement

Heat only control mode

Remote commands in LDT-5910C and LDT-5940C are compatible with LDT-5910B remote

commands

GPIB/IEEE 488 and USB Interfaces

Normally open and normally closed output interlock

Variable speed external fan control

If cleaning is required, use a clean dry cloth. Do not use solvents.

March 2019 2 LDT-5910C and LDT-5940C

Page 15

Figure 1.1 – LDT-5910C and LDT-5940C Front Panel

Figure 1.2 – LDT-5910C Rear Panel

March 2019 3 LDT-5910C and LDT-5940C

Page 16

Figure 1.4 – LDT-5940C Rear Panel

March 2019 4 LDT-5910C and LDT-5940C

Page 17

Options and Accessories

Options and accessories available for LDT-5910C and LDT-5940C Thermoelectric Temperature

Controllers include the following:

DESCRIPTION MODEL / PART NUMBER

Single Rack Mount Kit RM-144

Dual Rack Mount Kit RM-145

Temperature Controller Interconnect Cable (terminated with 9-pin DSUB) CC-505S [5910C only]

Temperature Controller Interconnect Cable (unterminated) CC-501S [5910C only]

10 Amp TE Interconnect Cable (unterminated without fan connections) CC-591H [5940C only]

10 Amp TE Interconnect Cable (unterminated with fan connections) CC-594H [5940C only]

5 Amp TE/LDM Interconnect Cable (terminated with 9-pin DSUB) CC-595S [5940C only]

10 Amp TE Interconnect Cable (terminated with 7W2 DSUB) CC-596H [5940C only]

Calibrated 10 k Thermistor TS-510

Uncalibrated 10 k Thermistor TS-520

Uncalibrated 5 k Thermistor TS-521

Uncalibrated 20 k Thermistor TS-523

Uncalibrated 100 k Thermistor TS-525

Uncalibrated AD590 IC Temperature Sensor TS-530

Uncalibrated LM335 IC Temperature Sensor TS-540

Unipolar Control Adapter UCA-350

TO-Can Laser Diode Mount LDM-4405

TO-Can Laser Diode Mount LDM-4407

C-Mount Laser Diode Mount LDM-4409

TO-Can Laser Diode Mount (with optional collimating lens) LDM-4412

TELECOM Laser Diode Mount LDM-4980

Production TO-Can Laser Diode Mount LDM-4990

March 2019 5 LDT-5910C and LDT-5940C

Page 18

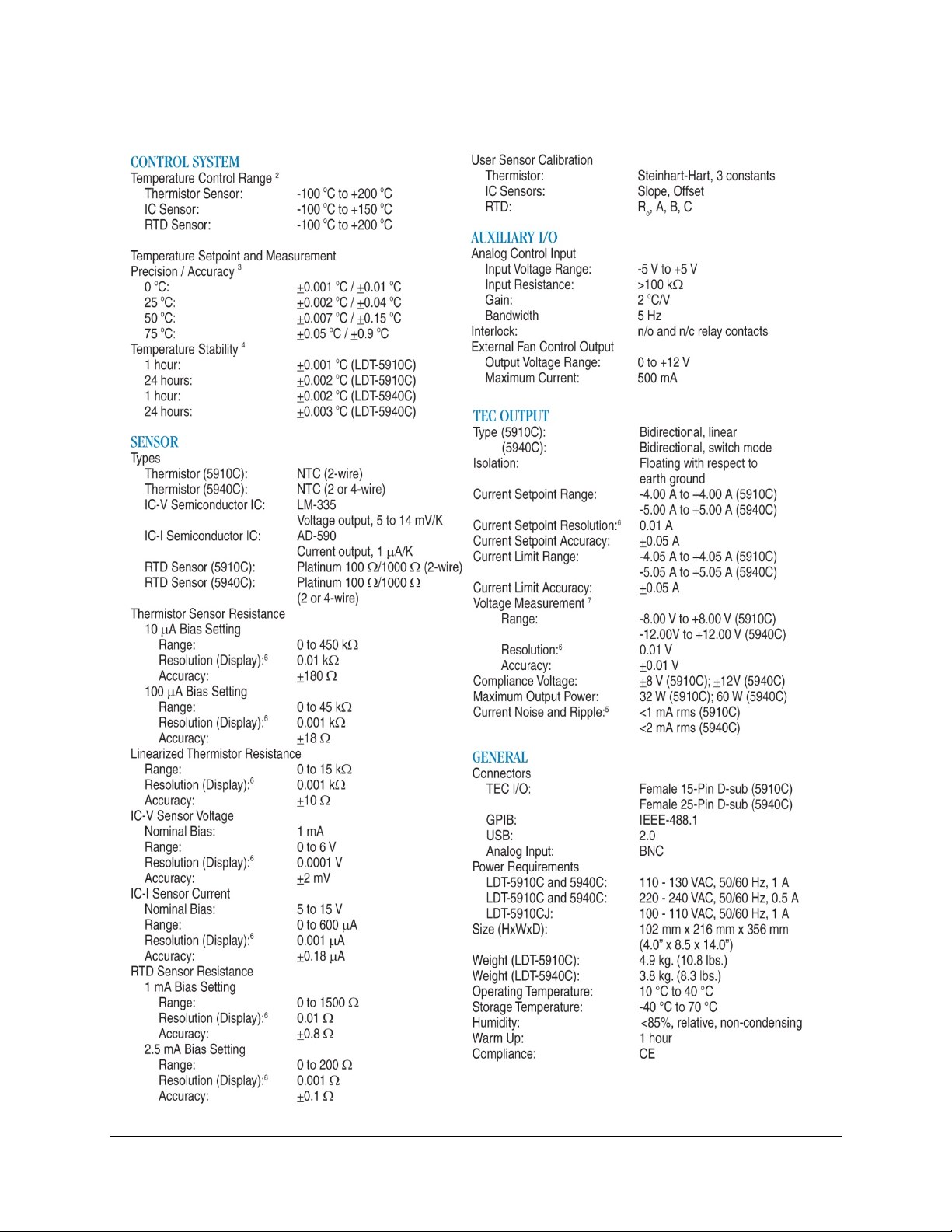

Specifications

March 2019 6 LDT-5910C and LDT-5940C

Page 19

March 2019 7 LDT-5910C and LDT-5940C

Page 20

March 2019 8 LDT-5910C and LDT-5940C

Page 21

Chapter 2:

General Operation

This chapter is an overview of the operation of the LDT-5910C and LDT-5940C Thermoelectric

Temperature Controllers.

Power requirements

Front panel operation

General operating procedures

Grounding Requirements

The LDT-5910C and LDT-5940C Thermoelectric Temperature Controllers come with a three

conductor AC power cable. The power cable must be plugged into an approved three-contact

electrical outlet or used with a three-contact to two-contact adaptor with the grounding wire

connected to an electrical ground (safety ground). ILX Lightwave recommends connecting the

instrument only to properly earth grounded receptacles. The power cord connector and power

cable meet IEC safety standards.

AC Line Power Requirements

The LDT-5910C and LDT-5940C Thermoelectric Temperature Controller can be configured to

operate at nominal line voltages of either 110 - 120 VAC or 220 - 240 VAC and for the LDT-5910CJ

(100V) model 100 – 110 VAC. This is a factory fixed configuration which cannot be changed by the

end user. Check to be sure that the voltage indicated on the back panel of the instrument matches

the power line voltage in your area.

The Power Up Sequence

Prior to power up ensure the fan inlet located on the right hand side of the instrument has

no obstructions that would impede airflow. In addition ensure there is no obstruction in

the rear that may impede airflow.

With the LDT-5910C or LDT-5940C connected to an AC power source, pressing POWER supplies

AC line power to the instrument and starts the following power up sequence where each display last

two to three seconds.

All front panel indicators are ON, all 7-segment displays indicate “8”

All front panel indicators OFF

Display shows the model number, the serial number and the firmware version of the

controller

April 2018 9 LDT-5910C and LDT-5940C

Page 22

During the front panel indicator test, the LDT-5910C and LDT-5940C performs a self-test to ensure

that the internal hardware and software are communicating. If the LDT-5910C and LDT-5940C

cannot successfully complete the test, an error message is displayed. See Chapter 5 for a complete

list of error messages. After the self test, the LDT-5910C and LDT-5940C configuration is set to the

same state as when the power was last turned off.

To quickly set a different configuration you can use the recall function. See Store and Recall for

more information.

Firmware Upgradeability

The firmware on the LDT-5910C and LDT-5940C can be reinstalled or upgraded via USB. Contact

ILX Lightwave technical support for information on upgrading the software of the LDT-5910C and

LDT-5940C.

GPIB Communication

The IEEE 488 GPIB interface connector is located on the rear panel, directly above the power input

module (See Figure 1.2 on page 3 or Figure 1.4 on page 4). Attach the GPIB cable to the 24-pin

connector located on the rear panel. The connector is tapered to ensure proper orientation. Finger

tighten the two screws on the cable connector.

A total of 15 devices can be connected together on the same GPIB interface bus. The cables have

single male/female connectors on each end so that several cables can be stacked. This allows more

than one cable to be attached to any one device. However, the maximum length of the GPIB cables

must not exceed 20 meters (65 feet) total, or 2 meters (6.5 feet) per device. As good practice the

number of GPIB cables connected to one instrument should be limited to less than 6.

USB Communication

The USB connector is located on the back rear panel, next to the GPIB connector. This USB

connector is the square "B"-style connector. A standard USB A/B cable is required to communicate

with the instrument. To communicate with the instrument using USB, please install the Virtual Com

Port Driver found on the accompanying CD or website prior to connecting the unit to the PC. Please

refer to Chapter 3 for more detailed instructions on operating the instrument through USB.

Tilt Foot Adjustment

The LDT-5910C and LDT-5940C have front legs that extend to make it easier to view the display. To

use them, rotate the legs downward until they lock into position.

Rack Mounting

The LDT-5910C and LDT-5940C Thermoelectric Temperature Controllers may be rack mounted in a

single or dual configuration by installing the appropriate rack mount flange on either side of the

enclosure. All rack mount accessory kits contain detailed mounting instructions. Refer to the Options

and Accessories table in Chapter 1 for applicable rack mount accessory part numbers.

March 2019 10 LDT-5910C and LDT-5940C

Page 23

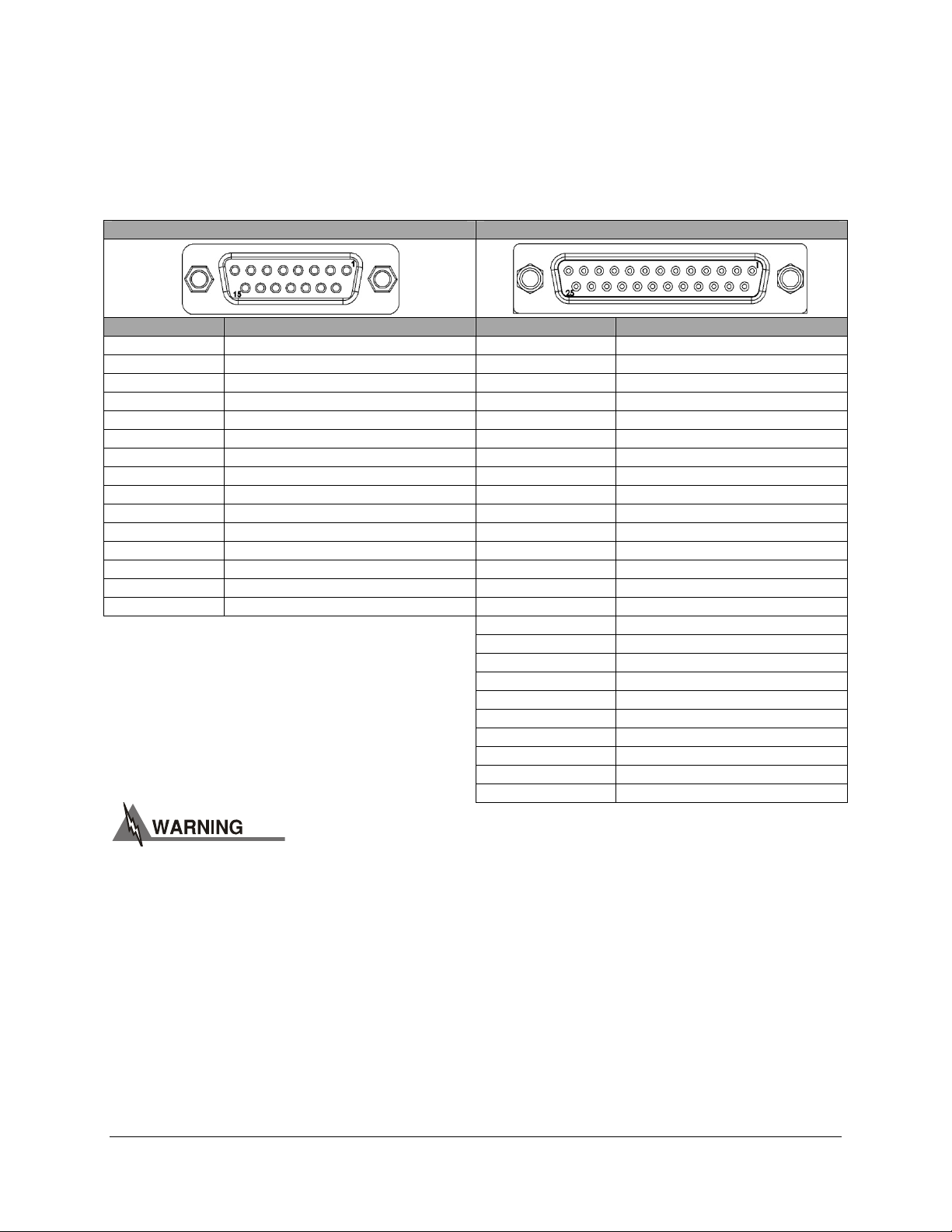

Connections

Temperature Control Output: A 15-pin DSUB connector (5910C) or 25-pin DSUB connector

(5940C) is located on the back panel of the instrument. The connections for each case are shown

below.

LDT-5910C LDT-5940C

PIN NUMBER CONNECTION PIN NUMBER CONNECTION

1 TE Module (+) 1 Sensor (+) Sense Terminal

2 TE Module (+) 2 Sensor (-) Sense Terminal

3 TE Module (-) 3 Fan (+)

4 TE Module (-) 4 N/C

5 TE Module Shield 5 N/C

6 Sensor Shield 6 Sensor / TE Module Shield

7 Sensor (+) 7 TE Module (+) Sense Terminal

8 Sensor (-) 8 TE Module (-) Sense Terminal

9 N/C 9 TE Module (+)

10 N/C 10 TE Module (+)

11 N/C 11 N/C

12 N/C 12 TE Module (-)

13 N/C 13 TE Module (-)

14 Fan (+) 14 Sensor (-)

15 Fan (-) 15 Sensor (+)

16 Fan (-)

17 Cable ID 1

18 Cable ID 2

19 N/C

20 N/C

21 TE Module (+)

22 TE Module (+)

23 N/C

24 TE Module (-)

25 TE Module (-)

The output terminals of the LDT-5910C or LDT-5940C should never be shorted

together or loaded with less than 0.1 Ω. Doing so may result in damage to the

instrument.

Analog Control Input: An isolated BNC connector is located on the rear panel of the LDT-5910C

and LDT-5940C provides the capability to adjust the temperature setpoint by applying a voltage

signal. The LDT-5910C and LDT-5940C can accept a signal from -5 V to +5 V, with a gain of 2 °C/V

and bandwidth of 5 Hz. This feature is useful in applications requiring sweeping of the temperature

without using GPIB or USB remote interface.

March 2019 11 LDT-5910C and LDT-5940C

Page 24

Interlocks: The LDT-5910C and LDT-5940C have normally open and normally closed interlock

contacts. The interlock will change states from the “powered off” condition when the output is

enabled and will change back when the output is disabled; including any error condition that disables

the output.

External Fan Control:

The LDT-5910C and LDT-5940C feature the ability to control an

external fan through either the 15-pin DSUB connector (5910C) or the 25-pin DSUB connector

(5940C). This circuit can provide up to 500 mA and may be controlled from 1 to 12 Vdc. The

circuit will automatically increase the voltage to 12 Vdc start a fan from a stopped condition and

will regulate to the desired voltage once more than 20 mA is drawn.

Pseudo 4-Wire Measurements: The LDT-5940C offers a pseudo 4-wire measurement feature

which helps to minimize errors induced by cable resistance both in thermistor/RTD sensor

modes as well as on the output terminals. This feature is enabled by connecting the appropriate

‘sense’ terminals and is disabled by leaving them disconnected. This feature is not available in

the LDT-5910C.

March 2019 12 LDT-5910C and LDT-5940C

Page 25

Front Panel Operation

This section describes the fundamentals of operation for the LDT-5910C and LDT-5940C

Thermoelectric Temperature Controllers. The order of descriptions will follow the normal progression

of how the user would typically configure the instrument for use for the first time.

Figure 2.1 – Front Panel Display

Power On / Off

The POWER button applies power to the LDT-5910C or LDT-5940C and starts the power up

sequence described above.

Adjust Knob and Enable Button

The ADJUST knob and ENABLE button is located on

the upper right side of the LDT-5910C and LDT-5940C

front panel. It is used to change the setpoints, enter

parameter values, enter the GPIB address, enter Save

or Recall bin numbers or enter instrument calibration

data. The ENABLE button indicates the two modes of

operation of the knob: Disabled (LED off) and Enabled

(LED on).

Setup

SET Button – Allows the user to adjust settings under PARAM, RECALL and STORE. The SET

button will allow the user to select each menu item and a second SET press will allow the user to

adjust the parameter. When a parameter is being adjusted, the units will flash at a constant

frequency. To return to the main menu, the sub menu will contain one option that reads “Return

<SET>.”

March 2019 13 LDT-5910C and LDT-5940C

Page 26

PARAM Button – Uses a menu system for temperature controller setup functions including Limits,

Sensor, Sensor Calibration Constants, External Fan Control, Cable Resistance, Analog Input, GPIB

Address, and Display Brightness. The SET button selects each menu item and a second SET press

allows the user to adjust each parameter. The ADJUST knob can be used to cycle through and

select or modify the following parameters:

Limits:

The Limits menu allows the user to select and modify the temperature, current,

and sensor upper and lower limits

Temperature High / Low Limits

Current Positive / Negative Limits

Sensor High / Low Limits

Depending on the sensor selected, the user can configure high and low limits for resistance,

current or voltage.

Sensor

: The Sensor parameter allows the user to select the type of sensor for the

application: Thermistor, RTD, IC-V, or IC-I. For more information on temperature

sensors see the “Sensor Options” later in this chapter.

Thermistor (100 µA, 10 µA, Auto Ranging, Linearized)

RTD (1 mA, 2.5 mA)

IC – Current

IC - Voltage

Sensor Calibration Constants: The calibration constants menu allows the user to enter

sensor constants for thermistor, current and voltage IC, and RTD. For more information see

the “Sensor Options” later in this chapter.

External Fan Control: Allows the user to enable or disable the external fan. The user can

also set the voltage applied to an external fan.

Cable Resistance: To increase the accuracy of the TEC voltage measurement at higher

currents the user can enter a cable resistance. The value entered for cable resistance should

be equal to the round trip resistance between the temperature controller and the load. If the

wiring is identical on both sides of the connection, as it is with ILX cables, this value is double

the resistance value measured between the temperature controller and the load. The 4-wire

capability of the LDT-5940C may be used instead if using a cable that supports this feature.

Cable resistance should be set to 0.000 when using 4-wire capability.

Analog Control Input: Enables and disables the analog input feature, for optimal stability if a

signal is not applied to the input the analog control input should be disabled.

GPIB Address: Adjust the GPIB address from 1 to 30 using the ADJUST knob.

Display Brightness: Adjust the display brightness from 1 to 10 using the ADJUST knob.

STORE Button – Stores instrument parameters for control mode, setpoint, limits, sensor type,

calibration constants, and PID values for bins numbered 1 – 10.

March 2019 14 LDT-5910C and LDT-5940C

Page 27

RECALL Button – Recalls instrument parameters for control mode, setpoint, limits, sensor type,

calibration constants, and PID values for bins numbered 1 – 10. Recall bin 0 will reset all parameters

to the factory defaults.

Non-volatile memory is used for saving the instrument parameters. When a store operation is

performed, all of the current instrument parameters are stored to a "bin" number (1 - 10). When that

"bin" number is recalled, the instrument configuration is recalled to the stored values.

To enter the STORE/RECALL mode, press either the STORE or RECALL button which will display

the current “bin” number in the bottom of the screen. The current “bin” number will be flashing and

the ADJUST knob can be used to select a new “bin”. The store or recall operation is performed

when the SET button is pressed. If the SET button isn’t pressed after three seconds the LDT-5910C

and LDT-5940C will time out and the new “bin” number will not be stored or recalled.

PID Control

SELECT Button – In PRESET mode, pressing SELECT displays the selected preset gain. In

MANUAL mode, pressing SELECT displays the last PID values used and in AUTO-TUNE mode,

pressing SELECT displays the auto-tuning method implemented. Pressing SELECT repeatedly or

using the ADJUST knob cycles through the presets and PID values.

SET Button – In PRESET mode, pressing SET selects the preset gain range on the display. In

MANUAL mode, pressing SET allows the user to adjust the value on the display. SET in the AUTOTUNE mode starts the auto-tune procedure.

MODE Button –Cycles through PRESET, MANUAL and AUTO-TUNE modes. The selected mode is

indicated by an illuminated LED. The output will not be disabled if the user changes the PID Control

Mode.

Preset: The user can select one of the preprogrammed gain ranges by first selecting the

PRESET LED using the MODE button then pressing the SELECT button or ADJUST knob to

display the correct preset gain for the thermal load and pressing the SET button to select the

gain. The LDT-5910C and LDT-5940C implements the original gain ranges of the LDT5910B (Gain 1, 3, 10, 30, 100, and 300). Presets have also been implemented for specific

ILX Lightwave mounts. When a preset has been selected for a mount, the LDT-5910C and

LDT-5940C will set the PID values, sensor type, and current limits. The following mounts are

compatible with the LDT-5910C and LDT-5940C: LDM-4405, LDM-4407, LDM-4409, LDM4412, LDM-4980, and LDM-4990.

Manual: In MANUAL mode the user can adjust the PID values or select one of the preset

PID values to load into the manual adjust (note: if the user adjusts the preset PID value

loaded into manual PID adjust the change will not permanently affect the preset PID value).

To manually adjust the PID values first select the MANUAL LED by pressing MODE, then

press SELECT to change between P, I, and D. To adjust the PID value, press SET; to move

to the next value press SELECT.

To load a preset PID value use the SELECT button to cycle to the “Adjust Preset” screen,

and then press the SET button, then using the SELECT or ADJUST knob display the preset

PID that you want to load. Once the correct preset is displayed press the SET button to load

the values.

March 2019 15 LDT-5910C and LDT-5940C

Page 28

Auto-tune – The auto-tune mode will calculate a thermal system's PID coefficients

through an iterative PID temperature control process. To enter the auto-tune mode first

press MODE until the AUTO LED is illuminated, and then SET to begin the auto-tune

procedure. When the LDT-5910C and LDT-5940C successfully completes the auto-tune

the instrument will revert back to MANUAL and the calculated PID values will overwrite

the current PID values in MANUAL mode. If the auto-tune process fails an error will be

displayed on the screen. For more information on the auto-tune process see Appendix

B. Additional auto-tune methods may be available in the future via a firmware upgrade,

for more information contact sales at 800-459-9459 / sales@ilxlightwave.com.

There are limitations to the auto-tune feature. Any of the following will cause the

auto-tune algorithm to fail:

Thermal systems requiring the proportional term to be less than 0.5

Noisy temperature measurements

Reaching any output off enable condition (such as temperature or voltage limits) during

the auto-tune operation.

If the auto-tune algorithm fails for a particular thermal system, it may be necessary to

modify the PID coefficients manually.

Mode

SELECT Button – Selects constant temperature, constant sensor and constant current mode. The

selected mode is indicated by an illuminated LED. The output is disabled when the control mode is

changed.

ON Button – Enables and disables the output. An enabled output is indicated by an illumined LED.

A disabled output is indicated by a dark LED.

TEMP – Controls the LDT-5910C or LDT-5940C to a constant temperature

I TE – Sets the LDT-5910C or LDT-5940C to output a constant current

R SNSR – Controls the LDT-5910C or LDT-5940C to a constant sensor value

HEAT – Illuminated when negative current is flowing

COOL– Illuminated when positive current is flowing

I LIMIT – Illuminated if the LDT-5910C or LDT-5940C has reached the user defined

current limit.

Display

The large 7-segment LED displays the measured value in the selected operating mode. When the

setpoint is being adjusted, the 7-segment LED display will show “set” after the dimension and revert

back to reporting the measured value after the three second timeout. The dot matrix display, at the

bottom of the screen, cycles through available measurement and mode setpoint. The available

measurement and setpoint parameters are listed under General Operation Procedures.

The measured values are indicated by an equal sign, as in Figure 2.2 a, and the setpoint values are

indicated by a colon sign, as in Figure 2.2 b.

March 2019 16 LDT-5910C and LDT-5940C

Page 29

Figure 2.2 a – The measured current Figure 2.2 b – The setpoint current

LEFT Button – Cycles through available measurement and setpoint parameters that can be

displayed in the left hand side of the display.

RIGHT Button – Cycles through available measurement and setpoint parameters that can be

displayed in the right hand side of the display.

ADJUST LED – Indicates the status of the ADJUST knob: an illuminated LED means that the knob is

enabled and a dark LED means that the knob is disabled.

Error Indicators

The LDT-5910C and LDT-5940C indicate operational errors on the measurement display with an

error code. A complete list of error codes can be found in Chapter 5.

General Operating Procedures

The discussion below presents guidelines for operation as well as some common operating

procedures. Remote operations are discussed in the next chapter.

The output terminals of the LDT-5910C or LDT-5940C should never be shorted

together or loaded with less than 0.1 Ω. Doing so may result in damage to the

instrument.

Warm-Up and Environmental Considerations

To achieve the rated accuracy, allow the LDT-5910C or LDT-5940C to warm-up for at least one hour

before use. Operate the controller within the environmental limits specified in Chapter 1. The best

accuracy is achieved near the calibration temperatures.

General Guidelines for Sensor Selection and Safety Limits

This section presents some guidelines to assist in selecting the optimal settings for your

application.

Sensor Options

The LDT-5910C and LDT-5940C Thermoelectric Temperature Controllers can measure

temperature through a variety of sensor options; thermistors, IC sensors (IC-I, IC-V) or RTDs.

THERMISTOR – When a thermistor sensor is selected, the LDT-5910C and LDT-5940C

measures temperature based on a negative temperature coefficient (NTC) thermistor. An NTC

thermistor is a device whose resistance decreases as its temperature increases. The controller

provides a sense current (100 µA or 10 µA) through the thermistor which results in a voltage

across the thermistor. This voltage is used as a feedback signal by the LDT-5910C and LDT5940C digital control loops to maintain a constant temperature. The thermistor should be

connected across the Sensor+ and Sensor- pins (pins 7 and 8).

March 2019 17 LDT-5910C and LDT-5940C

Page 30

In constant temperature mode, the quantity that is maintained constant by the controller is the

sensor resistance. In constant temperature mode (T), the LDT-5910C and LDT-5940C convert

the temperature setpoint to a thermistor resistance setpoint using user defined constants.

The Steinhart-Hart equation is used to convert a temperature to a resistance for thermistor

sensors. The equation describes the non-linear resistance versus temperature characteristics of

typical thermistors. Calibrating a thermistor consists of measuring its resistance at various

temperatures and fitting this measured data to the Steinhart-Hart equation. The resulting

coefficients C1, C2, and C3 effectively describe the thermistor for a specific temperature range.

For more information about the Steinhart-Hart equation, see ILX Lightwave Application Note #4

Thermistor Calibration and the Steinhart-Hart Equation.

To measure the precise temperature of a load, you must use a calibrated sensor. For example,

when using a thermistor, enter its Steinhart-Hart coefficients C1, C2, and C3 into the

temperature controller. If the exact temperature is not crucial (within ±1.5 °C) and you are using

a 10 k thermistor, use the default constants provided by the LDT-5910C and LDT-5940C.

Thermistor resistance changes with temperature. The LDT-5910C and LDT-5940C supplies

constant current, either 10 µA or 100 µA, through the thermistor so that a temperature change

results in a voltage change across the thermistor. This voltage change is sensed by the

instrument and fed back to the control loop. The supply current selection depends on the

thermistor operating temperature range and the required temperature resolution. A general rule

of thumb for a 100 k thermistor is to use the 10 µA range for temperatures between -30 °C and

+30 °C and for 10 k thermistor the 100 µA range for temperatures between 10 °C to 70 °C.

Select the thermistor sense current of 10 µA or 100 µA in the front panel PARAM menu. Using

10 µA as the thermistor current allows you to use a maximum thermistor resistance of 450 k.

The 100 µA setting allows a 45 k maximum.

The LDT-5910C and LDT-5940C have the ability to select the sensor current range based on

the resistance of the measurement and will automatically switch between the 10 µA or 100 µA.

Thermistor auto range can be selected under the SENSOR menu in PARAM.

To ensure proper thermistor current and thermistor selection, certain principles must be

considered:

• To ensure measurement accuracy, the voltage across the thermistor must not exceed

6 V.

• To improve control responsiveness and accuracy, the thermistor voltage variations that

result when the load temperature deviates from the setpoint must be as large as

possible. The importance of maximizing voltage variation is shown in Figure 2.3, which

shows resistance as a function of temperature for a thermistor. The values shown were

selected for simplicity in this example, and may not reflect real thermistor values.

In the example shown in Figure 2.3, the thermistor resistance is 25 k at 20°C. Deviations of

one degree at 20 °C cause a resistance variation of about 2 k. If using the 10 µA setting,

there is 20 mV of feedback to the control circuit. Using the 100 µA setting provides 200 mV of

feedback. The larger feedback signal means that the temperature is more precisely controlled.

March 2019 18 LDT-5910C and LDT-5940C

Page 31

Notice also that the lower slope of the curve at the higher temperatures results in a smaller

feedback signal. It may be necessary, if you are controlling to higher temperatures, to use a

thermistor with a different curve.

Figure 2.3 - Example Thermistor Resistance vs. Temperature

LINEARIZED THERMISTOR - The linearized thermistor mode of the LDT-5910C and LDT-

5940C may be used when an expanded range of temperature operation is required but when

ranging discontinuities are unacceptable. The linearized thermistor mode provides +0.2 °C

accuracy over a temperature range of -15 °C to 65 °C and +0.1 °C accuracy over a range of 5

°C to 35 °C without requiring the calibration of two sensors and without the discontinuity that

may arise due to ranging in the auto-ranging thermistor mode.

March 2019 19 LDT-5910C and LDT-5940C

Page 32

1.40

1.20

1.00

0.80

0.60

0.40

0.20

Temperature Measuremeent Uncertainty (C)

0.00

-35-155 25456585

10K Thermistor / 100 uA Bias

10K Thermistor / Linearized

Temperature (C)

IC-I SENSORS – When an IC-I sensor is selected, the LDT-5910C and LDT-5940C measures

temperature based on the current passed through the sensor. An example of an IC-I sensor is

the Analog Devices AD590. This device delivers 1 µA/K or approximately 298 µA at 25 °C. The

(+) terminal of the transducer should be connected to the Sensor+ pin and the (-) terminal

should be connected to Sensor-. The nominal slope for the AD590 is 1 µA/K and the offset is

nominally 0 µA but both can be adjusted to calibrate your particular sensor by entering the

PARAM menu.

The sensor will have approximately 9 V across it at 25 °C but will vary over the temperature

range. In IC-I sensor mode, the LDT-5910C and LDT-5940C have a sensor current limit of 600

µA, which is approximately 325 °C.

For IC-Current sensors used with the LDT-5940C the 4-wire sensor measurements

(pins 1 and 2) should not be connected. The use of the 4-wire sensor will cause

inaccurate sensor measurements.

IC-V SENSORS – When an IC-V sensor is selected the LDT-5910C and LDT-5940C measures

temperature based on the voltage across the sensor. An example of an IC-V sensor is the

National Semiconductor LM335A. This device delivers 10 mV/K or approximately 2.98 V at 25

°C. The (+) terminal of the transducer should be connected to the Sensor+ pin and the (-)

terminal should be connected to Sensor-. The nominal slope for the LM335A is 10 mV/K and

the offset is nominally 0 mV but both can be adjusted to calibrate your particular sensor by

entering the PARAM menu.

March 2019 20 LDT-5910C and LDT-5940C

Page 33

The sensor will have approximately 1 mA of current through it at all times. In IC-V sensor mode,

the LDT-5910C and LDT-5940C have a sensor voltage limit of 6 V, which is approximately 325

°C.

RTD SENSORS – When an RTD sensor is selected, the LDT-5910C and LDT-5940C measures

temperature based on the resistance. An example of an RTD sensor is the Xian Diamond USA

T2001SDL. This device has a positive slope and a nominal resistance at 0 °C of 100 ohms.

Two wire RTDs should be connected across the Sensor+ and Sensor- pins (pins 7 and 8).

The resistance versus temperature function for typical platinum RTDs is accurately modeled by

the Callendar-Van Dusen equation, as shown below.

R

= R0 (1 + AT + BT2 + 100CT3 +CT4)

T

where:

R

= Resistance () at 0 °C

0

R

= Resistance () at temperature T (°C)

T

T = Temperature in °C

The A, B, and C, are derived from resistance measurements at 0 °C (R

260 °C (R

), and are defined as follows:

260

), 100 °C (R

0

100

) and

A = + ( *)/100

B = (- * )/100

2

C

= (- * ß)/1004

T<0

where: = R

- R0 / 100 * R0

100

where: ß = Constant for T < 0 °C

where: = R

* (1 + * 260) - R

0

/ 4.16 * R0 *

260

For temperatures greater than 0 °C, the LDT-5910C and LDT-5940C controller derives the

temperature by solving the following quadratic equation:

A−4(−)

2

T=

−R

A±R

These sensor coefficients (A, B, C and R

accurately report the temperature when utilizing an RTD sensor. Where R

the RTD at 0 °C. Typical RTDs have a nominal resistance (R

) are required for the LDT-5910C and LDT-5940C to

0

is the resistance of

0

) of 100 or 1000 .

0

Common Callendar-Van Dusen constants are listed below and are used as default values in the

LDT-5910C and LDT-5940C.

• A = 3.908 x 10

• B = -5.775 x 10

• C = -4.183 x 10

-3

-7

-12

March 2019 21 LDT-5910C and LDT-5940C

Page 34

For optimal accuracy and stability, the 1 mA current source should be selected for RTD sensors

with resistance of 200 to 1500 and the 2.5 mA range should be used with resistance of 1

to 200 . In general, the change in resistance per change in temperature is much lower for a

typical 100 RTD than that of a typical 10 k thermistor. The proportional and integral terms

for the PID loop must be increased appropriately when using an RTD sensor for optimal setting

time and stability.

Safety Limits

TEC modules may be damaged by excessive current, so module manufacturers typically specify

a maximum safe operating current for their module. The LDT-5910C and LDT-5940C provides a

current limit feature that allows you to set the maximum current that the controller supplies.

It is normal for the controller to operate at the current limit, especially when the load temperature

is far from the setpoint. The current limit LED will display on the front panel when the controller

is in a current limit condition.

If the heatsink is too small for the application, it eventually becomes heat-saturated where in the

heatsink can no longer dissipate the heat being generated. When the heatsink becomes

saturated, the TEC current increases in an attempt to cool the load. The additional current

creates more heat that cannot be dissipated and subsequently, more TEC current is applied.

This situation is referred to as thermal runaway and can cause a load and temperature

controller to become damaged.

To help avoid damage caused by thermal runaway, the LDT-5910C and LDT-5940C

Thermoelectric Temperature Controller provides a high-temperature limit setting. When the load

temperature exceeds the temperature limit, the LDT-5910C and LDT-5940C turns off the TEC

current and generates an error on the dot matrix display.

Constant Temperature Mode Operation

1. Plug the LDT-5910C or LDT-5940C into an AC power source supplying the correct mains

voltage and frequency for your instrument (refer to the rear panel for the correct ratings)

2. Turn on the LDT-5910C or LDT-5940C. The output will be disabled at power up and the unit

will automatically configure its parameters to the state which existed when the power was last

shut off

3. Press MODE until the TEMP LED is selected

4. Press PARAM to adjust the applicable limits, sensor type, calibration constants, GPIB

address, display brightness and external fan voltage

5. Adjust the setpoint by enabling the ADJUST knob and enable the output

6. The user can display measured voltage, current, or sensor value or the temperature setpoint

in either the left or right side of the display by pressing the LEFT and RIGHT display buttons

Constant Sensor Mode Operation

1. Plug the LDT-5910C or LDT-5940C into an AC power source supplying the correct mains

voltage and frequency for your instrument (refer to the rear panel for the correct ratings)

March 2019 22 LDT-5910C and LDT-5940C

Page 35

2. Turn on the LDT-5910C or LDT-5940C. The output will be disabled at power up and the unit

will automatically configure its parameters to the state which existed when the power was last

shut off

3. Press MODE until SNSR is selected

4. Press PARAM to adjust the applicable limits, sensor type, calibration constants, GPIB

address, display brightness and external fan control

5. Adjust the setpoint by enabling the ADJUST knob and enable the output

6. The user can display measured voltage, current, or temperature or the sensor setpoint in

either the left or right side of the display by pressing the LEFT and RIGHT display buttons

March 2019 23 LDT-5910C and LDT-5940C

Page 36

Constant Current Mode Operation

1. Plug the LDT-5910C or LDT-5940C into an AC power source supplying the correct mains

voltage and frequency for your instrument (refer to the rear panel for the correct ratings)

2. Turn on the LDT-5910C or LDT-5940C. The output will be disabled at power up and the unit

will automatically configure its parameters to the state which existed when the power was last

shut off

3. Press MODE until ITE is selected

4. Press PARAM to adjust the applicable limits, sensor type, calibration constants, GPIB

address, display brightness and external fan control

5. Adjust the setpoint by enabling the ADJUST knob and enable the output

6. The user can display measured voltage, sensor value, or temperature or the current setpoint

in either the left or right side of the display by pressing the LEFT and RIGHT display buttons

Resistive Heater Mode Operation

1. Plug the LDT-5910C or LDT-5940C into an AC power source supplying the correct mains

voltage and frequency for your instrument (refer to the rear panel for the correct ratings)

2. Turn on the LDT-5910C or LDT-5940C. The output will be disabled at power up and the unit

will automatically configure its parameters to the state which existed when the power was last

shut off.

3. Press MODE until TEMP LED or SNSR LED is selected

4. Press PARAM then select LIMITS and adjust I- to maximum current limit for your resistive

heater then select I+ and set to 0 amps (by setting the limit to zero when the LDT-5910C or

LDT-5940C attempts to cool the load the output will be limited to 0 amps)

5. Press PARAM to adjust the applicable limits, sensor type, calibration constants, GPIB

address, display brightness and external fan control

6. Adjust the setpoint by enabling the ADJUST knob and enable the output

7. The user can display measured voltage or current and depending upon the mode (constant

TEMP or SNSR) can display either the measured temperature (constant SENSR) or sensor

(constant TEMP) or the setpoint temperature (constant TEMP) or sensor (constant SENSR)

in either the left or right side of the display by pressing the LEFT and RIGHT display buttons

March 2019 24 LDT-5910C and LDT-5940C

Page 37

Chapter 3:

Remote Operation

This chapter is an overview of the remote operation of the LDT-5910C and LDT-5940C

Thermoelectric Temperature Controller.

Fundamentals of Remote Operation

Command Syntax

Command Tree Structure

Status Reporting

Test and measurement equipment with remote operation capability will generally communicate

through either GPIB or USB interfaces. GPIB (General Purpose Interface Bus) is the common name

for ANSI/IEEE Standard 488.2 1987, an industry standard for interconnecting test instruments in a

system. USB (Universal Serial Bus) is the common serial communication protocol used by most

computers for relatively fast communication. Everything that can be done from the front panel can

also be done remotely, and in some cases, with more flexibility. For instance, in remote mode, there

is access to functionality and modes not available from the front panel, such as commands that will

increment (Temperature UP) or decrement (Temperature DOWN) the temperature setpoint by a

predefined step value. The following sections explain the fundamentals of operating the LDT-5910C

and LDT-5940C Thermoelectric Temperature Controller remotely through either the GPIB or USB

computer interface.

GPIB Address

The talk and listen addresses on the LDT-5910C and LDT-5940C Thermoelectric Temperature

Controllers are identical. This GPIB address is read locally by pressing the PARAM button until the

GPIB Address is displayed on the dot matrix display. The driver comes from the factory configured

with the GPIB address set to 1. You can change the LDT-5910C’s and LDT-5940C’s GPIB address

locally (via the front panel). A procedure for changing the address can be found in the section

changing the GPIB Address.

Basic GPIB Concepts

The information in this section is normally not necessary to successfully operate the LDT-5910C and

LDT-5940C through its GPIB interface because the host computer’s GPIB controller usually handles

the details. However, it is a useful introduction to understanding GPIB.

Data and Interface Messages

GPIB devices communicate with each other by sending data and interface messages. Data contains

device-specific information such as programming instructions, measurement results, and instrument

status. Each device has an address number, and ignores all data traffic no addressed to it.

Depending on its content, data is often called a “device dependent message” or a “device dependent

command”. Interface messages manage the bus, with functions such as initializing the bus and

March 2019 25 LDT-5910C and LDT-5940C

Page 38

addressing or un-addressing devices. In addition, some individual bus lines are designated for this

purpose.

Talkers, Listeners, and Controllers

Every GPIB system consists of one or more “talkers” and “listeners”, and often at least one

“controller”. Talkers supply data while listeners accept data. A system can consist of simply a talker

and listener, for example a meter connected to a datalogger or chart recorder. Controllers designate

talkers and listeners. A controller is necessary when the active talkers or listeners must be changed.

When the controller is a computer, it often also designates itself as a listener so it can collect data

from designated talkers.

If there is more than one controller, only one can be the Controller in Charge (CIC). Control can be

passed from one computer to another. In a multiple controller system, there can be one “System

Controller” capable of asserting control (becoming CIC).

GPIB Cable Connections

Standard GPIB connectors can be connected together (stacked) allowing the system to be

configured linearly, or in a star configuration.

Figure 3.1 – GPIB Cable Connection

March 2019 26 LDT-5910C and LDT-5940C

Page 39

The GPIB Connector

The standard GPIB connector consists of 16 signal lines in a 24-pin stackable connector. The extra

pins are used to make twisted pairs with several of the lines. There are eight data input/output lines,

three handshake lines, and five interface management lines.

Eight data I/O (DIO) lines carry both data (including device dependent commands) and interface

messages. The ATN interface management line determines whether these lines contain data or

interface messages.

Figure 3.2 – GPIB Connector

Three handshake lines ensure that all data and messages are reliably transferred:

NRFD (not ready for data) indicates whether a device can receive the next byte of data or

message.

NDAC (not data accepted) indicates whether a receiving device has accepted a byte of

data or message.

DAV (data valid) indicates that the signal levels on the data lines are stable and available

for the receiving device(s) to accept.

Five interface management lines control the flow of information:

ATN (attention) is set by the controller in charge to define the I/O lines for data or

interface messages.

IFC (interface clear) is set by the system controller to initialize the bus and assert itself as

controller in charge.

REN (remote enable) is set by the controller to place addressed devices into remote or

local (front panel) control mode.

SRQ (service request) can be set by any device in the system to request service from the

controller.

EOI (end or identify) is used by talkers to identify the end of a message.

March 2019 27 LDT-5910C and LDT-5940C

Page 40

Reading the GPIB Address

Before operating the LDT-5910C or LDT-5940C remotely, its GPIB address must be known. Simply

press the PARAM button until GPIB Address is displayed in the display. The factory default address

is “GPIB ADDRESS: 1”.

Changing the GPIB Address

Every device on the GPIB bus must have a unique address. If it is necessary to change the address,

press the PARAM button until the GPIB address is displayed. Then press the SET button and adjust

the knob until the desired address value is shown. When the display times out, the new GPIB

address will be stored in nonvolatile RAM. The allowable address range is 1 – 30 for primary GPIB

addressing. It is not recommended that zero be used for an address as that is typically reserved for

the GPIB controller installed in the computer. Extended GPIB addressing is not implemented.

Basic USB concepts

Universal Serial Bus (USB) is a specification to establish communication between devices and a

host controller, which has effectively replaced a variety of earlier interfaces such as serial and

parallel ports. There are three USB standards available, including USB 1.1, USB 2.0, and USB

3.0. Our device is designed to conform to the USB 2.0 standard and USBTMC 488 substandard.

USB cables use 4 lines - Power, Ground and a twisted pair differential +/- data lines. The USB

connectors are designed so that power and ground are applied before the signal lines are

connected. When the host powers up it performs the enumeration process by polling each of the

Slave devices in turn (using the reserved address 0), assigning each one a unique address and

finding out from each device what its speed is and what type of data transfer it wishes to

perform. The enumeration process also takes place whenever a device is plugged into an active

network. The connectors design along with the process of enumeration and a lot of host

software allows devices to be described as "Plug-and-Play".

When the USB device is enumerated and gets an address from the host, it presents the host

with information about itself in the form of a series of descriptors. The device descriptor tells the

host the vendor and the product ID. The configuration descriptors offer a power consumption

value and a number of interface descriptors. Each of these interface descriptors define a

number of endpoints, which are the sources and destinations for data transfers. The endpoint

descriptors provide the following detail transfer type: bulk, interrupt, isochronous, direction,

packet sizes, bandwidth requirement and repeat interval.

In USB communication, a typical transaction consists of a number of packets - a token

indicating the type of data that the host is sending or requiring, the data and in some cases an

acknowledgement. Each packet is preceded by a sync field and followed by an end of packet

marker. These transactions are used to provide four basic data transfer mechanisms, including

control, interrupt, bulk, and isochronous types.

USBTMC stands for USB Test and Measurement Class. USBTMC is a protocol built on top of

USB that allows GPIB-like communication with USB devices. From the user's point of view, the

USB device behaves just like a GPIB device. For example, you can use VISA Write to send the

*IDN? Query and use VISA Read to get the response. The USBTMC protocol supports service

request, triggers and other GPIB specific operations. USBTMC allows instrument manufacturers

to upgrade the physical layer from GPIB to USB while maintaining software compatibility with

existing software, such as instrument drivers and any application that uses VISA.

March 2019 28 LDT-5910C and LDT-5940C

Page 41

Changing Between Local and Remote Operation

Sending a command over the GPIB or USB bus automatically puts the instrument in Remote mode.

The Remote indicator identifies when the controller is in remote operation mode. When the

instrument is in Remote mode, all front panel controls are disabled except for the Local button.

Pressing the Local button returns the instrument to Local control mode.

GPIB vs. USB Communication

When using the USB interface, the remote GPIB command set is fully operable. Command syntax

does not vary between communication protocols. However, the commands which affect GPIB

hardware operation will not be useful. For example, “*SRE” may be sent via USB but service request

(SRQ) via GPIB would not be visible since USB has no hardware to support it. This is because SRQ

is a function of the GPIB interface hardware and is not available via USB.

All commands received by the USB interface are acknowledged by the instrument transmitting

“Ready” when the command operation is complete. Queries are acknowledged by the specific query

response message. Multiple commands/queries separated by semicolons and issued as one

command string are only acknowledged with a “Ready” response if the entire command string

contains no queries. (See the Command Separators section later in this chapter for additional

details.) The LDT-5910C and LDT-5940C terminates all RS-232 transmitted responses with

<CR><LF> (Carriage Return – Line Feed) characters. The LDT-5910C and LDT-5940C expect all

commands or queries to be terminated with any of the following characters: <CR> (Carriage Return),

<LF> (Line Feed), or ASCII 250 character (Hex 0xFA).

Command Syntax

This section describes command syntax and structure. This information must be understood in order

to effectively write GPIB control programs. The syntax of GPIB commands follow the rules defined in

the IEEE 488.2 standard.

Letters

Any GPIB command or query must contain all of the letters or all of the upper case letters which are

shown in the command definition. Upper/lower case does not matter; it is used in this manual to

identify optional letters. Some examples of what works and what does not are shown below.

Table 3.1 – Acceptable and Not Acceptable Spelling

ACCEPTABLE NOT ACCEPTABLE

DISP DS

DISPlay or DISPLAY Displa or DISPL

March 2019 29 LDT-5910C and LDT-5940C

Page 42

White Space

“White space” is normally the space character (space bar). A single white space must separate a

command from its parameters or data. For example:

Table 3.2 – White Space

ACCEPTABLE NOT ACCEPTABLE

ITE 3.0 ITE3.0

To enhance readability, one or more white spaces may be used before a comma, semicolon, or

terminator. Since the computer normally places the terminator at the end of each command string

(line), this simply means that an extra space character at the end of the command line works

acceptably.

A query has no space between the mnemonic and the question mark. For example:

Table 3.3 – Query Formatting

ACCEPTABLE NOT ACCEPTABLE

DISPLAY? DISPLAY ?

Note: Too many consecutive white spaces can overflow the 256-byte data I/O buffer.

Terminators

A program message terminator identifies the end of a command string. These are the valid

terminator sequences:

<NL>

<^END>

<NL><^END>

Many computers terminate with <CR><NL><^END> (Carriage Return – New Line – EOI). A carriage

return (<CR>) is read as white space.

The LDT-5910C and LDT-5940C terminates its responses with <CR><NL><^END>, unless the

TERM command is used to change it.

If problems are encountered with GPIB communications, the terminator string can sometimes be the

cause. Refer to the computer’s GPIB controller manual for information on configuring its terminator

string.

Command Separators

More than one command may be placed in the same command string if each command is separated

by a semicolon. The semicolon can be preceded by one or more spaces. For example:

DISPLAY ON;*IDN?;MODE?

DISPLAY ON ; *IDN?; MODE?

March 2019 30 LDT-5910C and LDT-5940C

Page 43

Parameters

Some commands require a parameter. The parameter must be separated by at least one white

space.

The syntax symbol <nrf value> refers to the flexible numeric representation defined by the GPIB

standard. It means that numbers may be represented in integer or floating point form, or in

engineering/scientific notation. The IEEE 488.2 standard uses the names NR1, NR2, and NR3

respectively to denote “integer”, “floating point”, and “scientific notation”. For example the number

“twenty” may be represented by any of the following ASCII strings:

Table 3.4 – Parameters

NR1 Integer 20 +20

NR2 Floating Point 20.0 +20.0

NR3 Scientific Notation

2.0E+1

2.0e+1

+2.0E+1

+2.0e+1

For more information on these definitions, refer to the IEEE 488.2 standard.

There are no default values for omitted parameters. If a command is expecting a parameter and

nothing is entered, an error is generated.

For further clarity in programming, the Boolean values of one (1) and zero (0) may be used or their

names as indicated in Table 3.5.

Table 3.5 – Substitute Parameter Values

SUBSTITUTE NAME VALUE

ON 1

OFF 0

RUN 1

STOP 0

March 2019 31 LDT-5910C and LDT-5940C

Page 44

Command Tree Structure

The LDT-5910C and LDT-5940C Thermoelectric Temperature Controllers device-dependent

commands are structured in a tree format as shown in Figure 3.3. Each of the legal paths is shown,

followed by its list of path options, followed by the commands themselves. It is recommended that

the first-time user begin learning the commands by using the full path notation. Once familiar with the

commands, command path shortcuts may be used.

Figure 3.3 - Command Path Structure

March 2019 32 LDT-5910C and LDT-5940C

Page 45

Syntax Summary

GPIB commands must contain all of the letters shown in uppercase in the command definition.

Optional letters shown in lowercase for some device dependent commands in the command

reference (Chapter 4) are useful for clarity, but must be in the correct sequence.

A single white space must separate a command from its parameters or data. White space is

normally the space character (space bar). Other control characters are also interpreted as white

space. Do not use white space before the question mark in a query command.

If problems are encountered with communications, the terminator string may be the cause. Refer to

the GPIB interface (controller) manual for additional information. The instrument accepts <NL>, or

<^END>, or <NL><^END> as a command line terminator. Many computers terminate with

<CR><NL><^END> (Carriage Return – New Line – EOI). The instrument ignores <CR> (Carriage

Return) as white space. The LDT-5910C and LDT-5940C terminates its responses with

<CR><NL><^END>.

More than one command may be on the same line (same command string) if the commands are

separated with semicolons.