Page 1

90088262 MCS130B, Rev B

s

1/8m Monochromator Family

User's Manual

Cornerstone

™

130B

Page 2

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

2

TABLE OF CONTENTS

1 GENERAL INFORMATION .................................................................................................. 5

1.1 SYMBOLS AND DEFINITIONS ................................................................................ 6

1.2 GENERAL WARNINGS .......................................................................................... 7

1.3 ELECTRICAL HAZARDS ........................................................................................ 7

1.4 MECHANICAL HANDLING ................................ ...................................................... 8

1.5 OPTICS CARE AND HANDLING.............................................................................. 8

2 INTRODUCTION................................................................................................ ................ 9

2.1 OPTICAL CONFIGURATION ................................................................ ................... 9

2.2 STRAY LIGHT REJECTION ...................................................................................10

2.3 AVAILABLE MODELS ...........................................................................................10

2.4 TYPICAL APPLICATIONS......................................................................................11

3 INITIAL SETUP.................................................................................................................12

3.1 WHAT’S INCLUDED..............................................................................................12

3.2 UNPACKING ................................................................ ........................................12

3.3 CHOOSING A LOCATION......................................................................................12

3.4 MOUNTING OPTIONS ..........................................................................................13

3.5 ELECTRICAL AND COMPUTER CONNECTIONS .....................................................14

4 SHUTTER ................................................................................................ ........................16

5 INPUT AND OUTPUT SLITS...............................................................................................17

5.1 FIXED SLITS........................................................................................................17

5.2 MICROMETER ADJUSTABLE SLITS ......................................................................18

6 DIFFRACTION GRATINGS ................................................................................................20

6.1 GRATING TYPES .................................................................................................21

6.2 GRATING EFFICIENCY AND BLAZING ...................................................................22

6.3 POLARIZATION EFFECTS ....................................................................................24

7 MONOCHROMATOR RESOLUTION ................................................................................... 25

7.1 DETERMINING RESOLUTION ...............................................................................26

8 GETTING LIGHT INTO A MONOCHROMATOR ....................................................................28

8.1 ACCEPTANCE PYRAMID ......................................................................................28

8.2 F NUMBER MATCHING.........................................................................................29

9 BLOCKING HIGHER ORDER RADIATION ...........................................................................30

9.1 ORDER SORTING FILTERS ..................................................................................30

10 COMMUNICATION METHODS ...........................................................................................31

10.1 UTILITY SOFTWARE ............................................................................................33

10.2 HAND CONTROLLER ...........................................................................................34

10.3 TRACQ BASIC SOFTWARE...................................................................................35

10.4 LOW-LEVEL COMMANDS .....................................................................................35

11 GRATING INSTALLATION AND CALIBRATION ....................................................................36

11.1 RECALIBRATION SERVICES................................................................ .................36

11.2 SETTING THE WAVELENGTH OFFSET ................................................................ ..36

11.3 DETERMINING THE GRATING CALIBRATION FACTOR ...........................................37

11.4 ALTERNATIVE METHOD (CS130B only) .................................................................37

11.5 GRATING INSTALLATION ................................ .....................................................38

12 TROUBLESHOOTING ................................................................................................ .......40

12.1 CORRUPTED MEMORY........................................................................................40

13 SPECIFICATIONS.............................................................................................................41

14 DIMENSIONS ................................................................ ...................................................42

15 APPENDIX I: LOW LEVEL (REMOTE) COMMANDS AND QUERIES .......................................45

15.1 OPENING RS-232 COMMUNICATION INTERFACE ..................................................65

15.2 COMMAND AND QUERY SYNTAX .........................................................................65

15.3 STANDARD MODE ...............................................................................................65

Page 3

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

3

15.4 HANDSHAKE MODE.............................................................................................65

15.5 CS130B COMMAND REFERENCE SUMMARY ........................................................65

15.6 DETAILED COMMAND REFERENCE......................................................................65

15.7 ERROR CODES ...................................................................................................65

16 APPENDIX II: HAND CONTROLLER COMMANDS ...............................................................65

16.1 ACTIVATING THE HAND CONTROLLER.................................................................65

16.2 USING THE KEYPAD ................................................................ ............................65

16.3 KEY REFERENCE ................................................................................................66

17 APPENDIX IV: GRATING PHYSICS TUTORIAL ...................................................................68

17.1 THE GRATING EQUATION ....................................................................................68

17.2 THE GRATING EQUATION IN PRACTICE ...............................................................69

17.3 GRATING ORDER ................................................................................................70

17.4 GRATING DISPERSION ................................ ........................................................71

17.5 GRATING ILLUMINATION AND RESOLUTION.........................................................71

18 WARRANTY AND SERVICE...............................................................................................72

18.1 CONTACTING NEWPORT CORPORATION.............................................................72

18.2 REQUEST FOR ASSISTANCE / SERVICE ............................................................... 73

18.3 REPAIR SERVICE ................................................................ ................................73

18.4 NON-WARRANTY REPAIR ................................................................ ....................73

18.5 WARRANTY REPAIR ............................................................................................ 74

18.6 LOANER / DEMO MATERIAL ................................................................................. 75

Page 4

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

4

LIST OF FIGURES

Figure 1: Optical Configuration of the Cornerstone 130B ................................ ................................. 9

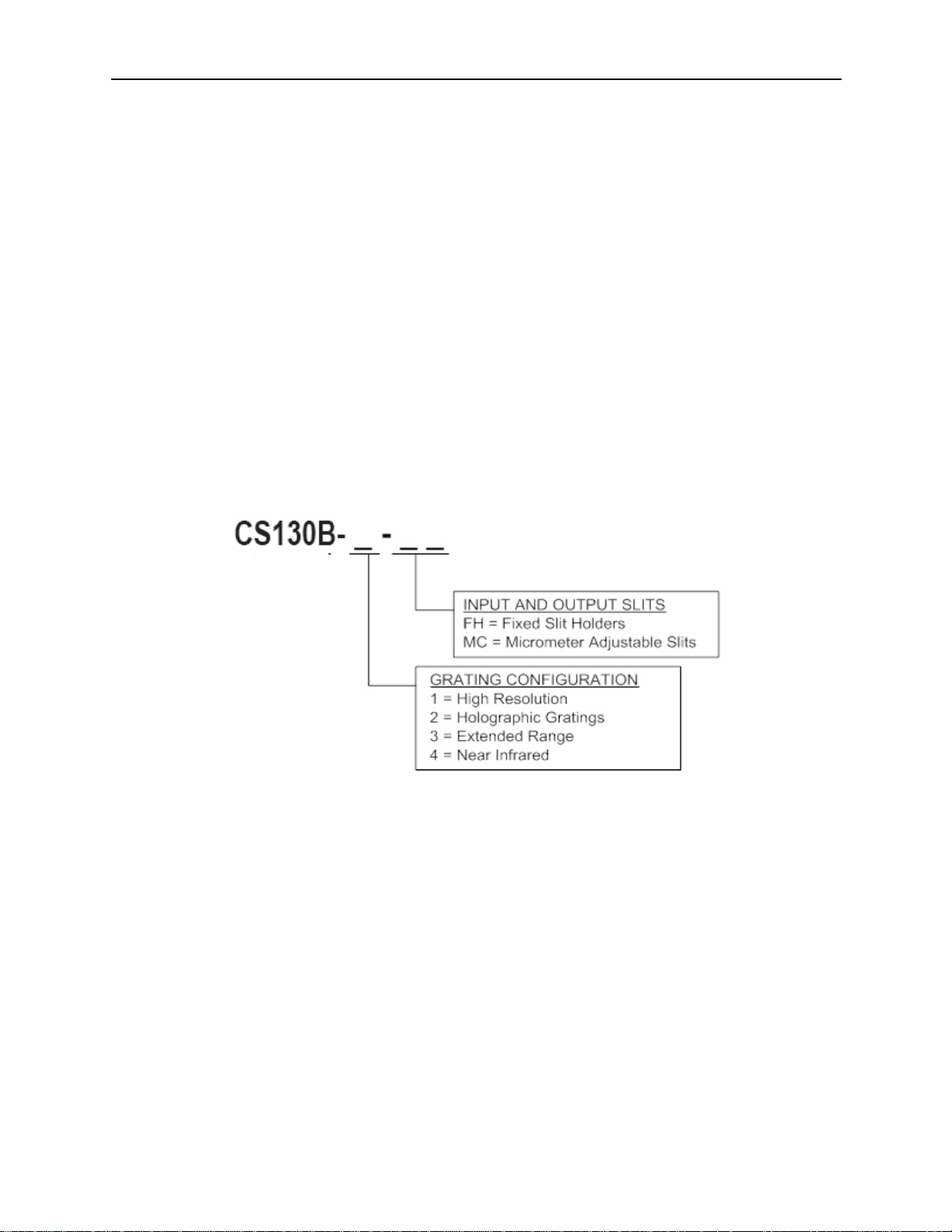

Figure 2: Model Number Codes................................................................................................ ..10

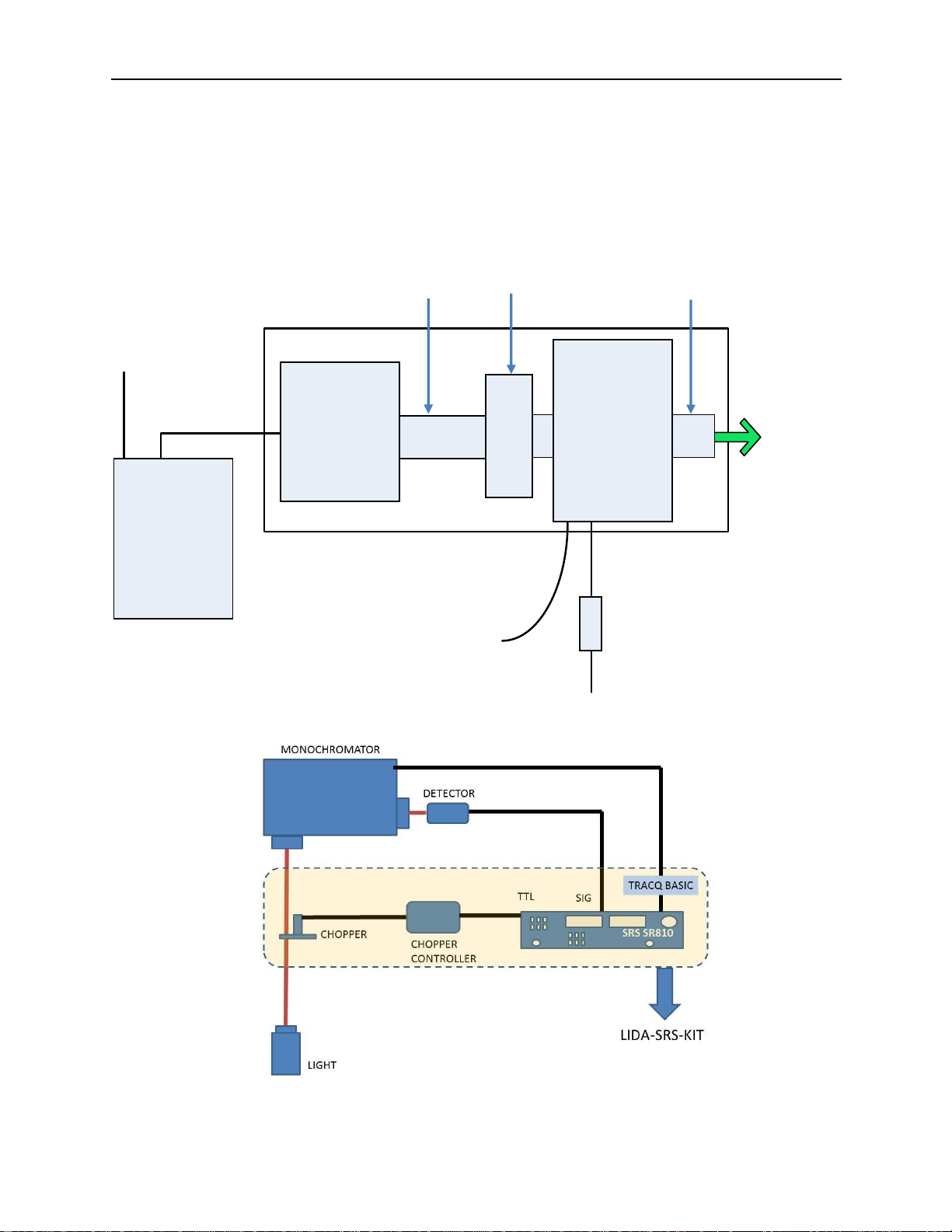

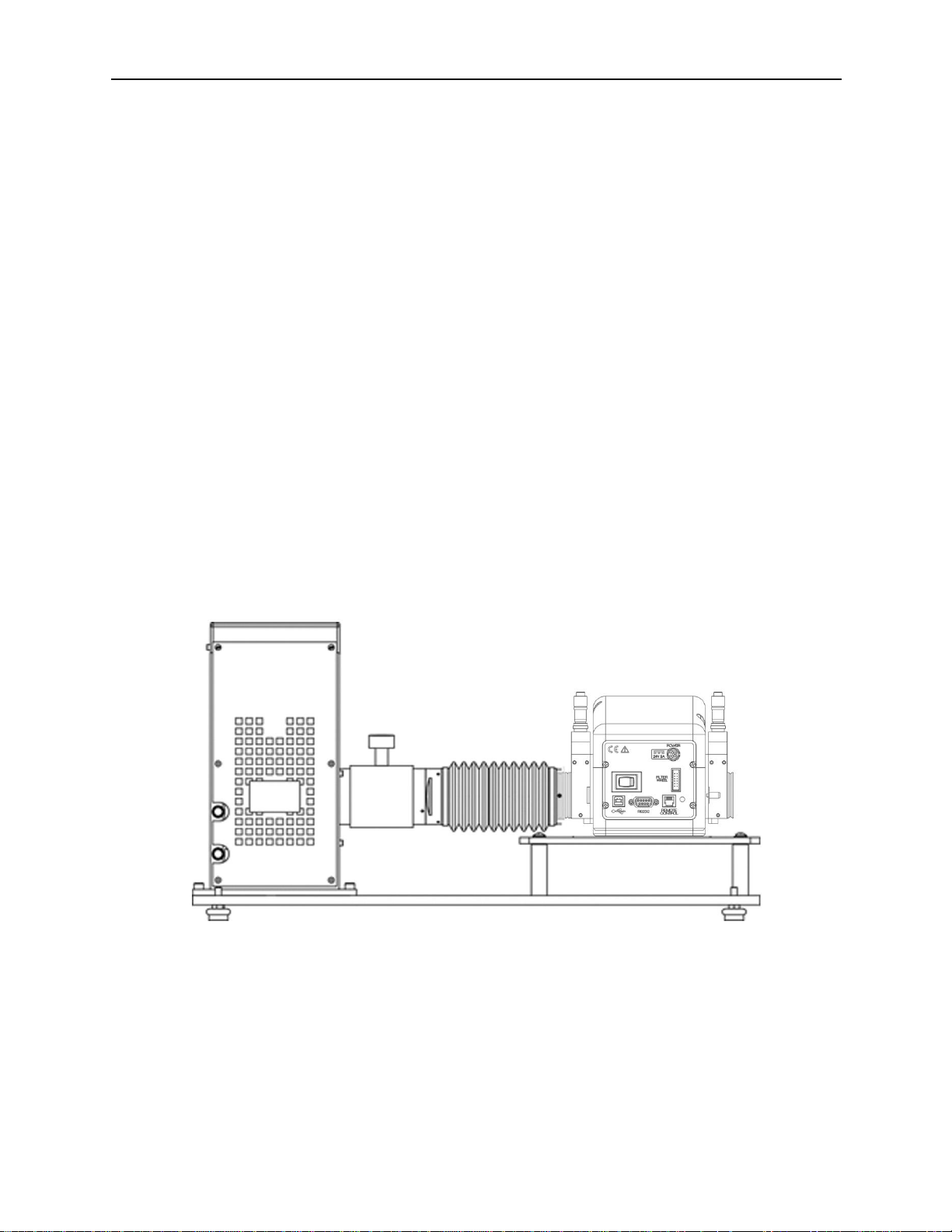

Figure 3: Tunable Monochromatic Light Source ................................ ............................................11

Figure 4: Monochromator with Lock-In Digital Amplifier ..................................................................11

Figure 5: Model 74017 Mounting Kit............................................................................................13

Figure 6: Monochromator Connections ........................................................................................15

Figure 7: A Fixed Slit Installed into the Holder...............................................................................17

Figure 8: Available Fixed Slits Table ...........................................................................................17

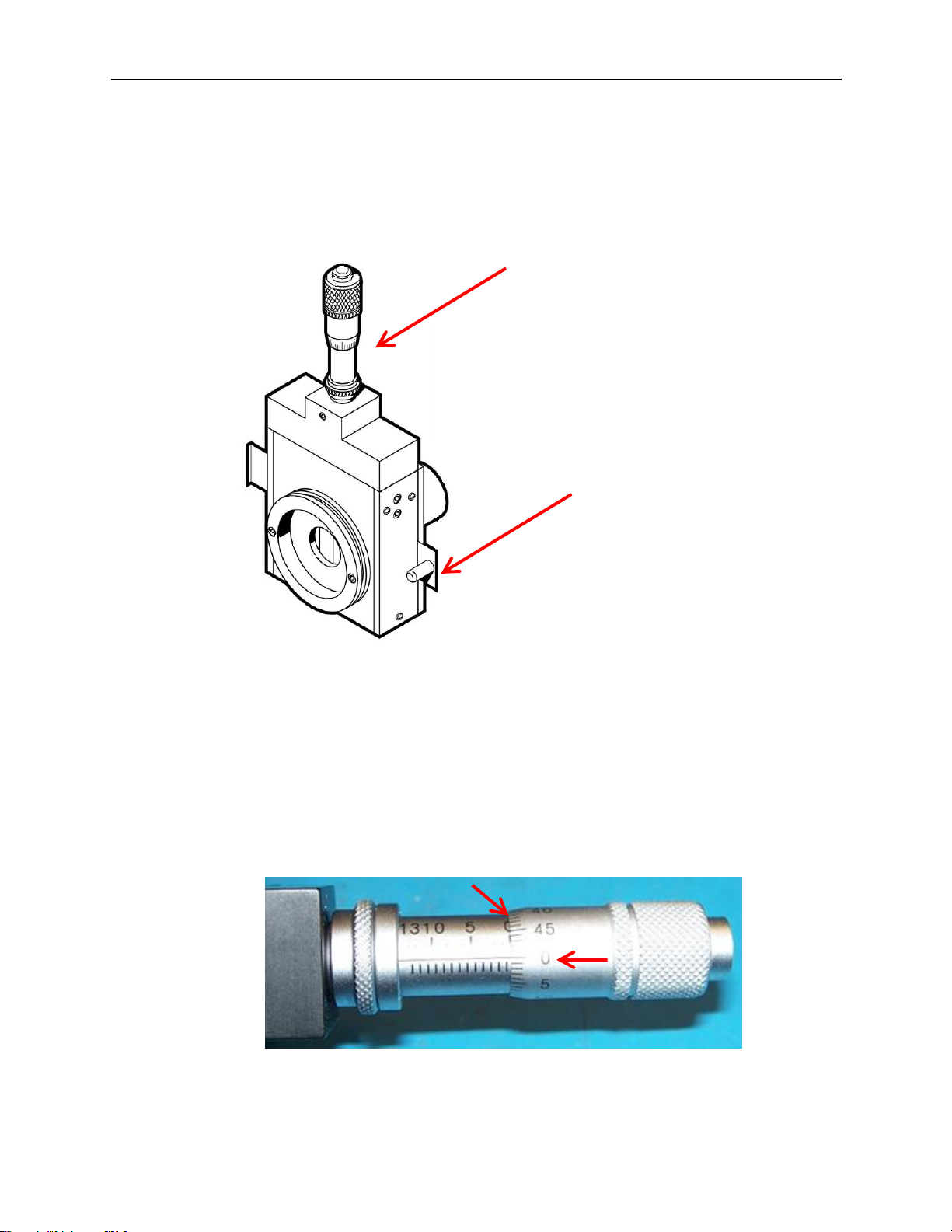

Figure 9: A Micrometer Adjustable Slit ......................................................................................... 18

Figure 10: A Fully Closed Micrometer Adjustable Slit .....................................................................18

Figure 11: Shortest Micrometer Adjustable Slit Height....................................................................19

Figure 12: Tallest Micrometer Adjustable Slit Height ......................................................................19

Figure 13: Grating Installed onto Mount .......................................................................................20

Figure 14: Grating Properties Table ............................................................................................21

Figure 15: Grating Efficiency Curves for CS130B Monochromator Pre-Configured Models ..................23

Figure 16: Resolution vs. Throughput ................................................................ ..........................25

Figure 17: Some of the Fixed Slit Sizes Available..........................................................................27

Figure 18: Acceptance Pyramid of Monochromator .......................................................................28

Figure 19: Grating Correctly “Filled” with Light ..............................................................................28

Figure 20: Mismatched F Numbers Resulting in Stray Light ............................................................ 29

Figure 21: F Number Matcher Used with Fiber Optic Cable ............................................................29

Figure 22: Model USFW-100 Filter Wheel ....................................................................................31

Figure 23: Model 74010 Filter Wheel...........................................................................................32

Figure 24: Mono Utility Software Screens ....................................................................................33

Figure 25: Cornerstone 130B Monochromator with 74009 Hand Controller .......................................34

Figure 26: TracQ Basic Screens .................................................................................................35

Figure 27: Grating Platform without Gratings ................................................................................39

Figure 28: Grating Platform with Gratings Installed ........................................................................39

Figure 29: Entering Calibration Values in Utility Software ...............................................................40

Figure 30: Cornerstone 130B Dimensions ....................................................................................42

Figure 31: 74001 Micrometer Adjustable Slit Dimensions ...............................................................43

Figure 32: 77294 Fixed Slit Dimensions.......................................................................................43

Figure 33: Model 74006 Mounting Plate.......................................................................................44

Figure 34: 74009 Hand Controller Keypad ...................................................................................65

Figure 35: The Sawtooth Pattern of a Grating Section....................................................................68

Figure 36: The Grating Equation Satisfied for a Parallel Beam of Monochromatic Light .......................69

Figure 37: Polychromatic Light Diffracted From a Grating ...............................................................69

Figure 38: Sign Convention for the Angle of Incidence, Angle of Diffraction and Grating Angle .............70

Page 5

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

5

1 0BGENERAL INFORMATION

Thank you for your purchase of this Cornerstone™ 130B Monochromator from Newport-Oriel

Instruments®.

Please carefully read the following important safety precautions prior to unpacking and operating this

equipment. In addition, please refer to the complete User’s Manual and all other documentation provided

for additional important notes and cautionary statements regarding the use and operation of the system.

Do not attempt to operate any system without reading all the information provided with each of the

components.

Please read all instructions that were provided prior to operation of the system. If

there are any questions, please contact Newport Corp. or the representative

through whom the system was purchased.

Page 6

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

6

1.1 18BSYMBOLS AND DEFINITIONS

WARNING

Situation has the potential to cause bodily harm or death.

CAUTION

Situation has the potential to cause damage to property or equipment.

ELECTRICAL SHOCK

Hazard arising from dangerous voltage. Any mishandling could result

in irreparable damage to the equipment, and personal injury or death.

EUROPEAN UNION CE MARK

The presence of the CE Mark on Newport Corporation equipment

means that it has been designed, tested and certified as complying

with all applicable European Union (CE) regulations and

recommendations.

WEEE

This symbol on the product or on its packaging indicates that this

product must not be disposed of with regular waste. Instead, it is the

user’s responsibility to dispose of waste equipment according t o the

local laws. The separate collection and recycling of the waste

equipment at the time of disposal will help to conserve natural

resources and ensure that the materials are recycled in a manner that

protects human health and the environment.

ON

The ON symbol in the above figure indicates the ON position of the

power switch.

OFF

The OFF symbol in the above figure indicates the OFF position of the

power switch.

Page 7

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

7

1.2 19BGENERAL WARNINGS

• Read all warnings and operating instructions for this system prior to setup and use.

• Do not use this equipment in or near water.

• To prevent damage to the equipment, read the instructions in the equipment manual for proper

input voltage and check the requirement on the power supply.

• This equipment is grounded through the grounding conductor of the power cord.

• Route power cords and other cables so they are not likely to be damaged.

• Disconnect power before cleaning the equipment

• Do not use liquid or aerosol cleaners; use only a damp lint-free cloth.

• Lock out all electrical power sources before servicing the equipment.

• To avoid explosion, do not operate this equipment in an explosive atmosphere.

• Qualified service personnel should perform safety checks after any service.

• If this equipment is used in a manner not specified in this manual, the protection provided by this

equipment may be impaired.

• Do not position this product in such a manner that would make it difficult to disconnect the power

cords.

• Use only the specified replacement parts.

• Follow precautions for static sensitive devices when handling this equipment.

• This product should only be powered as described in the manual.

• Do not remove the cover for normal usage.

1.3 20BELECTRICAL HAZARDS

Make all connections to or from the instrument with the power off.

The Cornerstone B requires DC voltage for operation, which is provided by an external power

supply. This power supply has no user serviceable parts. Do not attempt to open the external

power supply. Do not attempt to work in the Cornerstone B compartment without first

disconnecting the power cord, since electrical hazards are present inside the compartment even

with the power switch in the “off” position.

The Cornerstone B monochromator contains a microprocessor and should be installed with

appropriate surge/EMI/RFI protection on the power line. A dedicated power line or line isolation

may be required for some extremely noisy sites. The electronic circuits within the monochromator

are extremely sensitive to static electricity and radiated electromagnetic fields. Operation of this

instrument close to intense pulsed sources (lasers, xenon strobes, arc lamps, etc.) may

compromise performance if shielding is inadequate, and may cause permanent damage to the

microprocessor.

Note: This instrument conforms to CE standards for both safety and EMC. During normal use, this

equipment will not pose any electrical hazards to the user. Read all warnings before installing or

operating this system. If there are any questions or concerns, contact Oriel Instruments or the

regional sales representative for Newport.

Page 8

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

8

1.4 21BMECHANICAL HANDLING

Avoid dropping, sudden shocks, or rough handling of the monochromator since this may cause the

system to go out of calibration and may destroy the high precision drive components or optics.

1.5 22BOPTICS CARE AND HANDLING

Do not touch any optical surfaces since this is likely to cause irreparable damage. Always wear

powder-free gloves to cover the entire hand, not finger cots. Never touch the surface of a

diffraction grating, even when wearing gloves.

Dust or debris on the grating surface may negatively affect performance, so it should be prevented

from entering the instrument by keeping the protective grating covers in place when it is not in use.

If the gratings do require cleaning, do not attempt to clean any optical surface except by blowing

off dust or lint particles with a stream of dry clean air or nitrogen. Wiping the grating surface will

cause permanent damage.

Avoid getting any moisture or condensation onto the grating. Do not breathe on or talk directly in

front of a grating, as the moisture from one’s breath should never be allowed to condens e on t he

grating surface.

This instrument comes with gratings pre-installed, aligned, and the calibration parameters set. An

experienced user may choose to install a different grating in the field, although it is strongly

encouraged to send the instrument back to the factory instead.

If a grating is installed in the field, the grating cover must never touch the grating’s front surfac e.

The specially designed grating cover contacts only the edges of the grating. When removing this

cover, a grating can be scratched easily, so use extreme caution when handling.

Hand tighten the grating mount screws. Do not use tools, since this may cause damage to the

drive assembly. Never touch the surface of the grating, even while wearing gloves. Handle the

grating assembly only by its mount.

Page 9

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

9

2 1BINTRODUCTION

In developing the Cornerstone 130B monochromator, Newport-Oriel Instruments leveraged their

extensive experience to design a compact, inexpensive instrument that has all the versatility required by

researchers. The ease of automated control and small size also make this an ideal monochromator for

many OEM applications.

Each of these instruments includes two diffraction gratings, filter wheel control circuitry, and an integrated

electronic shutter. Communication may be established using USB, RS232, or an optional hand controller

designed specifically for use with the Cornerstone family of monochromators. In addition, this instrument

can be purged with dry nitrogen for work below the oxygen absorption cut-on at 180 nm.

The Cornerstone 130B includes a utility program designed to run on a computer using the Microsoft

Windows operating system. The simple, intuitive interface means that users can get up and running

within minutes of opening the box. Instrument control examples using National Instruments LabVIEW are

provided, along with a command set and API for those wishing to develop their own programs. An

optional hand controller may be used for quick access to all common commands and queries, without

requiring a computer. This is especially beneficial in universities and secure facilities.

A wide selection of grating models is available for the Cornerstone 130B, as well as special order options.

Throughput and resolution can be adjusted by selecting the appropriate slit size. Fixed slits are available

for high accuracy and repeatability, and micrometer adjustable slits may be used for maximum flexibility.

2.1 23BOPTICAL CONFIGURATION

The optical design of the Cornerstone 130B is based on an out-of-plane version of an Ebert-Fastie

monochromator. The input and output ports are in line with each other, simplifying system

alignment. The optical configuration is designed to ensure high resolution and maximum

throughput. This F/3.9 monochromator is optimized to provide excellent stray light rejection while

minimizing aberrations. A high precision motor is used to select the desired wavelength and switch

between diffraction gratings quickly, without sacrificing performance.

Figure 1: Optical Configuration of the Cornerstone 130B

Page 10

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

10

2.2 24BSTRAY LIGHT REJECTION

Stray light may have a variety of origins. Its presence may be caused by a wide variety of design

and manufacturing factors. The level of stray light due to the dispersed radiation inside the

monochromator is affected by the design of the instrument, its baffles, and interior finish. The

Cornerstone 130B incorporates a sophisticated design, proven materials, and a quality

manufacturing system to ensure high stray light rejection.

The amount of stray light measured on top of true signal will depend on many experimental factors

as well as the performance of the instrument. When comparing stray light specifications, it is

important to compare values that were measured under identical circumstances. The spectral

distribution of the source and the response of the detection system are often the dominant factors

when determining a stray light value.

2.3 25BAVAILABLE MODELS

The model number of each Cornerstone monochromator reflects its features. Refer to the part

number code to determine the features present in the instrument. If the model number differs from

the code, it is a Special Order configuration. In that case, refer to the Sales Order for the

instrument for more information.

Figure 2: Model Number Codes

Page 11

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

11

2.4 26BTYPICAL APPLICATIONS

The applications for the Cornerstone 130B monochromator are practically limitless. Here we

present two examples: a tunable monochromatic light source and an optically chopped light

source used with a lock-in digital amplifier to extract small signal levels from background radiation.

All components shown are available from Newport.

Figure 3: Tunable Monochromatic Light Source

Figure 4: Monochromator with Lock-In Digital Amplifier

Interconnect

Power Adapter

with Power Cord

USB Cable to

Computer

Collimating

Lens

Cornerstone

130B

Monochromator

Power Cord

Collimating

and

Focus Optics

Light Source

Motorized

Filter

Wheel

Tunable monochromatic light

source on mounting plate

Monochromatic

Light Output

Arc Lamp

Power Supply

Page 12

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

12

3 2BINITIAL SETUP

3.1 27BWHAT’S INCLUDED

• Two diffraction gratings, installed and aligned

• Electronic shutter at input port

• A choice of micrometer adjustable slits or fixed slit holders at the input and output ports

• Electronics interface for RS232 or USB communication

• An MPT plug to accept a hose barb to purge the instrument compartment for measurements

below 180 nm (actual capability is grating configuration dependent)

• LabVIEW™ based utility software

• Application Programming Interface (API) for LabVIEW™ with examples

• Certificate of Calibration

• Monochromator Power Supply

• Line cords based on geographic location

• User’s manual

3.2 28BUNPACKING

Remove all items from the shipping containers and verify each item is accounted for. The

instrument is carefully packaged to minimize the possibility of damage during shipment. Inspect

the shipping box for external signs of damage or mishandling. Inspect the contents for damage.

If any item is missing or damaged, immediately contact Newport or the representative from whom

the system was purchased.

It is suggested to save the packaging material and shipping container, in case the equipment

needs to be relocated at a future date.

WARNING

Do not attempt to operate this equipment if there is evidence of

shipping damage or there is suspicion that the equipment will not

operate correctly. Damaged equipment may present hazards.

3.3 29BCHOOSING A LOCATION

Choose an installation location where the power requirements can be met for the monochromator,

as well as the rest of the optical system. Be sure power is not applied to the system until the setup

has been completed and all electrical connections made.

Ensure that there is easy access to the monochromator’s power switch and the electrical outlet.

Page 13

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

13

3.4 30BMOUNTING OPTIONS

The ability to mount the monochromator simplifies setup and alignment of the optical system. The

mounting plates or kits also help ensure consistent results over time, as the monochromator

cannot be accidentally moved out of position. The following options are available for securing the

Cornerstone 130B:

• Mounting plate

• Mounting kit to couple with Oriel’s Research Lamp Housings

• Optical rods

The 74006 Mounting Plate is used to secure a Cornerstone 130B Monochromator to an inch or

metric optical table. The plate adds 0.25 inch [6.35 mm] to the optical height. If the Cornerstone

130B will be used with Oriel’s research lamp housing, consider using the 74017 mounting kit.

The 74017 Mounting Kit connects the Cornerstone 130B monochromator to an arc lamp or quartz

tungsten halogen light source. This kit is compatible with Oriel's Research Lamp Housings, which

hold 50 to 250 watt lamps. It includes a base plate, a flexible light shield, a 1.5-inch diameter

focusing lens and lens holder. All the hardware required to mount the lamp housing and

monochromator to the base plate is provided. The mounting kit's base plate comes with four

adjustable leveling feet. The feet may be removed to secure the base plate to an inch or metric

optical table.

The most economical option is to use optical rods and rod holders to mount the Cornerstone 130B

to an optical table or breadboard. On the monochromator’s mounting surface, four #1/4-20

threaded holes may be used to install standard optical rods. Care should be taken to ensure the

instrument is level and secured well enough that its location remains consistent over time, even if

the instrument is bumped or components coupled to the ports.

Figure 5: Model 74017 Mounting Kit

Page 14

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

14

3.5 31BELECTRICAL AND COMPUTER CONNECTIONS

Before powering up the system for the first time, it is suggested to have a qualified electrician

verify the wall socket to be used with the instrument meets the requirements for operation as

noted.

Before making any electrical connections, verify the front panel power switch is in the off position

for the monochromator.

WARNING

To avoid electric shock, connect the instrument to properly earthgrounded, 3-prong receptacles only. Failure to observe this

precaution can result in severe injury or death.

The line voltage requirement is as follows:

Monochromator Power Adapter 100 to 240 VAC, 47-63 Hz

The monochromator conforms to CE standards for both safety and EMC. During normal use, this

equipment will not pose any electrical hazards to the user. Read all warnings before installing or

operating this system. If there are any questions or concerns, contact Oriel Instruments or the

regional sales representative for Newport.

ELECTRICAL SHOCK

Never attempt to open the lamp power supply or monochromator

power adapter. These items do not contain any user serviceable

parts. Failure to follow this warning can result in severe injury or

death.

The monochromator’s power adapter connects to an AC wall socket and supplies DC volt age to

the instrument. Do not open the monochromator cover and attempt to work inside without first

turning the instrument off and disconnecting the power cord from the AC mains.

The ribbon cable connecting the monochromator to the optional filter wheel is installed before

the system ships out. The monochromator provides power to the filter wheel and allows the user

to select which filter is placed in the optical path.

Ensure the monochromator power switch is in the off position (marked as O). Then connect the

power adapter to the monochromator, as shown. Insert the power cord provided into the power

adapter and connect to the AC mains.

Connect the USB or RS232 cable to the monochromator. Plug the other end of the cable into the

computer only after any software controlling the monochromator has been installed.

Page 15

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

15

Figure 6: Monochromator Connections

A USB cable (model 70044) and RS232 cable (model 70040) are included with each Cornerstone

130B.

If using a commercially available USB/GPIB or USB/RS232 converter cable, the driver for this cable

must be installed before communication to the monochromator can be established.

Follow the instructions provided in the Quick Start Guide to install the utility software onto a

computer.

Page 16

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

16

4 3BSHUTTER

An electronic shutter is integrated into the Cornerstone B monochromator’s design. It is mounte d i n s ide

the housing at the input port. This shutter is normally closed.

The shutter is used to close the light path when output light is not required. This allows the light source to

remain on, and therefore remain warmed up, so that it continues to provide stable performance.

Additionally, restarting a lamp results in wear of the filament (with quartz tungsten halogen lamps) or wear

of the anode/cathode (with arc lamps). Therefore, when the light is not needed during short periods,

closing the shutter is suggested.

Diffraction gratings are mounted on a precision rotation stage inside the monochromator. When the

monochromator switches between diffraction gratings, the changing angle of the grating causes light to

be diffracted at various wavelengths. This includes white light, which is output at a higher power than

other individual wavelengths. In order to prevent saturation of a detection system, it is suggested to close

the shutter temporarily while changing gratings. It is especially important to prevent saturation and

possible damage when using a photomultiplier tube.

A scan may be completed while the shutter is closed to perform background subtraction calculations on

subsequent scans completed while the shutter is open.

Please note that the shutter is not designed to block high power direct light. When using a 450W or

greater light source, heat mitigation strategies should be employed. For example, Oriel offers liquid filters

to protect the shutter, filters, and other items to prevent potential heat damage.

Page 17

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

17

5 4BINPUT AND OUTPUT SLITS

To operate any monochromator, slits are required at the input and output port. The slit assemblies

offered with the Cornerstone 130B all have 1.5-inch male flanges, allowing them to be easily connected to

the wide variety of Oriel accessories and instruments.

Note: The slits need to be the same width and height at the input and output ports. A wider input slit

when compared to the output slit results in more stray light inside the instrument. A wider output slit with

respect to the input slit will not increase throughput.

5.1 32BFIXED SLITS

The fixed slits slide into the 77294 holders at the input and output port. The width and height

cannot be adjusted, but may be individually replaced with other slit sizes. Fixed slits are a low cost

alternative to micrometer adjustable slits, and provide excellent repeatability. They are a good

choice when only a few slit sizes are required.

Fixed slits are sold separately to allow customized choices based on the needs of the application.

When ordering, be sure to purchase two fixed slits of the same model – one for the input port, and

the other for the output port. Insert the slit as shown, with the label facing outward. Be sure that it

is fully inserted into the holder’s slot to ensure the best performance and repeatability.

Figure 7: A Fixed Slit Installed into the Holder

Fixed Slit Model

Width

Height

77222

10 µm

2 mm

77221

50 µm

3 mm

77220

25 µm

3 mm

77219

50 µm

6 mm

77218

120 µm

18 mm*

77217

280 µm

18 mm*

77216

600 µm

18 mm*

77215

760 µm

18 mm*

77214

1.24 mm

18 mm*

77213

1.56 mm

18 mm*

77212

3.16 mm

18 mm*

77211

6.32 mm

18 mm*

*Actual slit height is 18 mm, usable height is 12 mm.

Figure 8: Available Fixed Slits Table

Page 18

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

18

5.2 33BMICROMETER ADJUSTABLE SLITS

Micrometer adjustable slit assemblies are continuously variable from fully closed (4 µm) to 3 mm

width. A height adjustment slide allows variation in the height from 3 to 12 mm. Benefits of the

micrometer adjustable slits are flexibility and high throughput. This type of slit is designed primarily

for versatility and convenience in changing resolution and throughput, which are related to the slit

width.

Figure 9: A Micrometer Adjustable Slit

The slit width setting is read on the micrometer. A set of numbers go around the turning dial.

Another set of numbers are located on the shaft. When the zeroes in both these locations line up,

the slit is fully closed. Turning the dial clockwise advances the dial position further down on the

shaft, closer to the body of the micrometer. This opens the slit.

Use a 10x multiplier to convert the micrometer reading to the actual slit opening size. For

example, turning the dial one full revolution starting from the fully closed position will give a

reading of 50 on the micrometer. Using the multiplier, this indicates the micrometer width is set to

500 um. If unsure of the reading, begin at the fully closed position and add up each full revolution

made.

Figure 10: A Fully Closed Micrometer Adjustable Slit

The micrometer is used to make the slit

narrow or wide

The slide is used to

change the slit height

Page 19

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

19

The slit height is continuously adjustable. Pull the lever out for the shortest height. Push the slide

in for the tallest height setting.

Figure 11: Shortest Micrometer Adjustable Slit Height

Figure 12: Tallest Micrometer Adjustable Slit Height

Page 20

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

20

6 5BDIFFRACTION GRATINGS

Diffraction gratings are used to disperse light; that is to spatially separate light of different wavelengths.

They have replaced prisms in most fields of spectral analysis. Two gratings are installed into the

Cornerstone 130B monochromator. In general, the grating with the highest efficiency is chosen at a

particular wavelength. The optional TracQ™ Basic Data Acquisition and Radiometery Software allows

users to set up a specific grating switchover wavelength, so the most appropriate grating will

automatically be chosen while performing a scan over a range of wavelengths.

The Cornerstone 130B monochromators feature diffraction gratings produced by Richardson Gratings.

Both Oriel Instruments and Richardson Gratings are part of Newport, and have a long history of working

together to design monochromators that are appropriate for a wide variety of applications.

A tutorial on grating physics may be found in the Appendix of this user’s manual.

The photo below illustrates a diffraction grating mounted into a holder for installation into the Cornerstone

130B monochromator. An unmounted grating cannot be installed by the user in the field; gratings must

be installed onto the appropriate mount for the Cornerstone 130B monochromator and aligned at the

factory.

Figure 13: Grating Installed onto Mount

Page 21

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

21

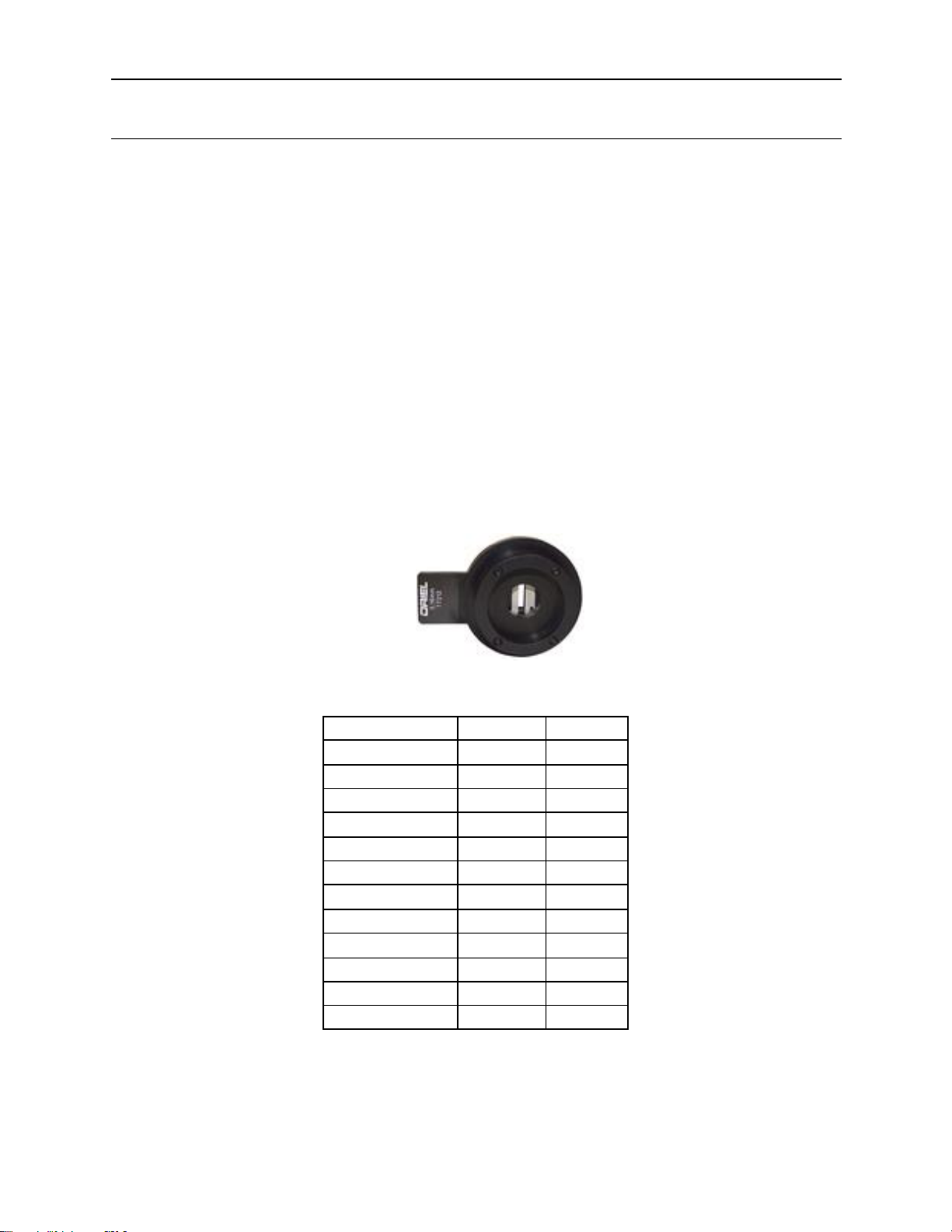

6.1 34BGRATING TYPES

Ruled grating masters are produced using a ruling engine with an extremely fine cutting tool.

Holographic gratings (also called interference gratings) are produced by recording interference

fringes in photoresist. The different techniques cause some differences in performance.

Holographic gratings are most frequently available at high groove densities due to manufacturing

limitations inherent in the technology. They are generally favored for work in the UV and through

the visible to about 600 nm. Holographic gratings produce less scattering, thereby reducing stray

light inside the monochromator.

Ruled gratings typically have higher efficiencies. They may have periodic errors in the grating

grooves caused by minor defects in the ruling machine, resulting in anomalous readings or

“ghosts”. Holographic gratings do not suffer from ghosts, so interpretation of line spectra is

simplified.

The signal-to-noise ratio (SNR) is the ratio of diffracted energy to unwanted light energy. Although it

may be assumed that increasing diffraction efficiency will increase SNR, stray light usually plays the

limiting role in the achievable SNR for a grating system. Note that the actual signal to noise ratio will

depend on the spectral content of the incident light and the detector.

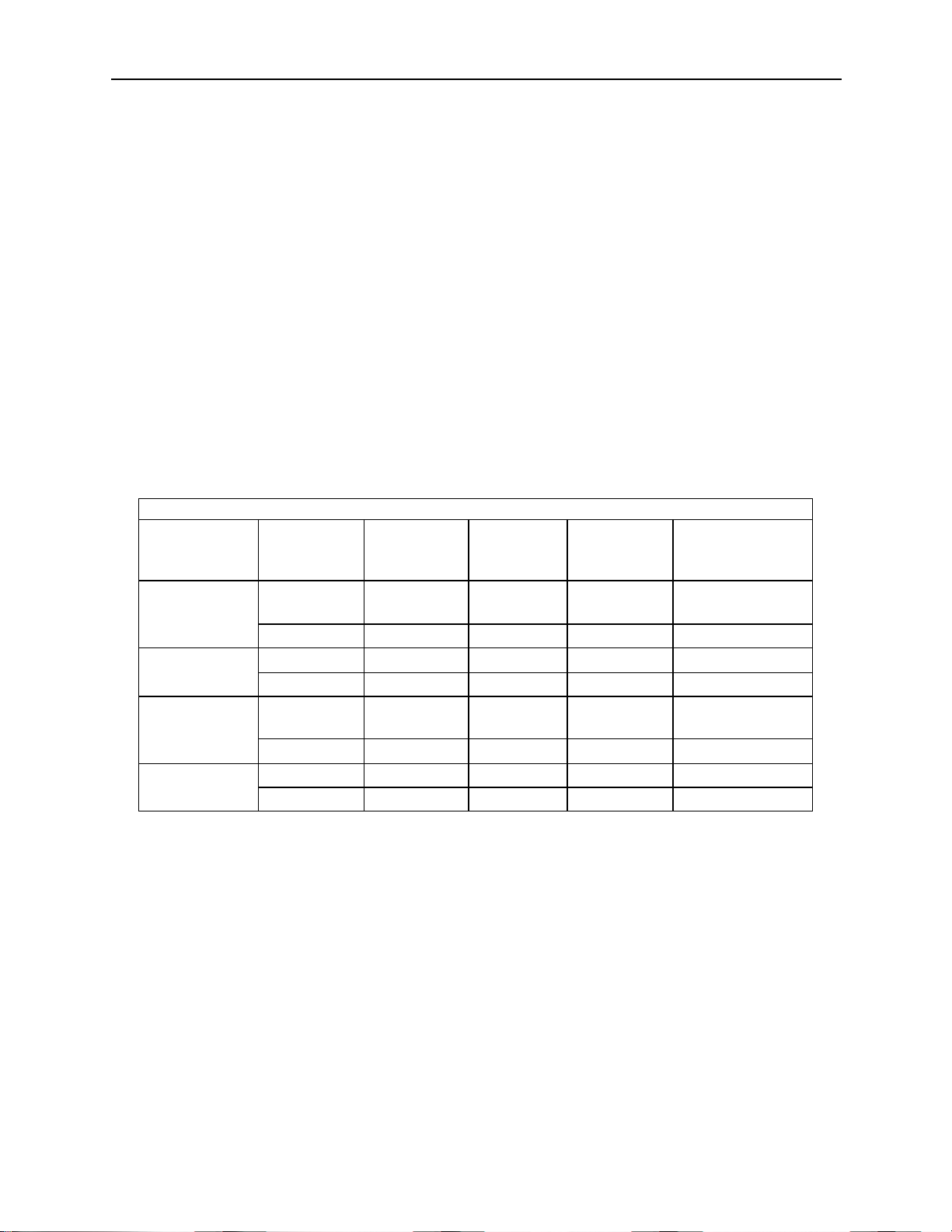

Figure 14: Grating Properties Table

GRATING PROPERTIES

Configuration

Grating

Position

Type

Groove

Density

(lines/mm)

Blaze

Wavelength

(nm)

Reciprocal

Dispersion

(nm/mm)

High

Resolution

#1

Ruled

2400

240

2.7

#2

Ruled

1200

500

5.3

Holographic

#1

Holographic

1200

250

5.5

#2

Holographic

1800

500

3.3

Extended

Range

#1

Ruled

600

400

11

#2

Ruled

600

1000

10.6

Near IR

#1

Ruled

600

1000

10.6

#2

Ruled

300

2000

21.2

Page 22

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

22

6.2 35BGRATING EFFICIENCY AND BLAZING

Efficiency and its variation with wavelength and spectral order are important characteristics of a

diffraction grating. For a reflection grating, efficiency is defined as the energy flow (power) of

monochromatic light diffracted into the order being measured, relative either to the energy flow of

the incident light (absolute efficiency) or to the energy flow of specular reflection from a polished

mirror substrate coated with the same material (relative efficiency). Efficiency is defined similarly for

transmission gratings, except that an uncoated substrate is used in the measurement of relative

efficiency.

High-efficiency gratings are desirable for several reasons. A grating with high efficiency is more

useful than one with lower efficiency in measuring weak transition lines in optical spectra. A grating

with high efficiency may allow the reflectivity and transmissivity specifications for the other

components in the spectrometer to be relaxed. Moreover, higher diffracted energy may imply lower

instrumental stray light due to other diffracted orders, as the total energy flow for a given

wavelength leaving the grating is conserved (being equal to the energy flow incident on it minus any

scattering and absorption).

Control over the magnitude and variation of diffracted energy with wavelength is called blazing, and

it involves the manipulation of the micro-geometry of the grating grooves. The energy flow

distribution (by wavelength) of a diffraction grating can be altered by modifying the shape of the

grating grooves. The blaze wavelength is the wavelength where the grating efficiency is enhanced

by shaping the grating grooves. Although holographic gratings are not shaped like ruled gratings,

the peak grating efficiency wavelength is also referred to as the blaze wavelength.

The choice of an optimal efficiency curve for a grating depends on the specific application. Often

the desired instrumental efficiency is linear; that is, the intensity of light transformed into signal at

the image plane must be constant across the spectrum. To approach this as closely as possible,

the spectral emissivity of the light source and the spectral response of the detector should be

considered, from which the desired grating efficiency curve can be derived. Usually this requires

peak grating efficiency in the region of the spectrum where the detectors are least sensitive.

In many instances, the diffracted power depends on the polarization of the incident light. For

completely unpolarized incident light, the efficiency curve will be exactly halfway between the P and

S efficiency curves. Anomalies are locations on an efficiency curve (efficiency plotted vs.

wavelength) at which the efficiency changes abruptly. These sharp peaks and troughs in an

efficiency curve are sometimes referred to as Wood's anomalies.

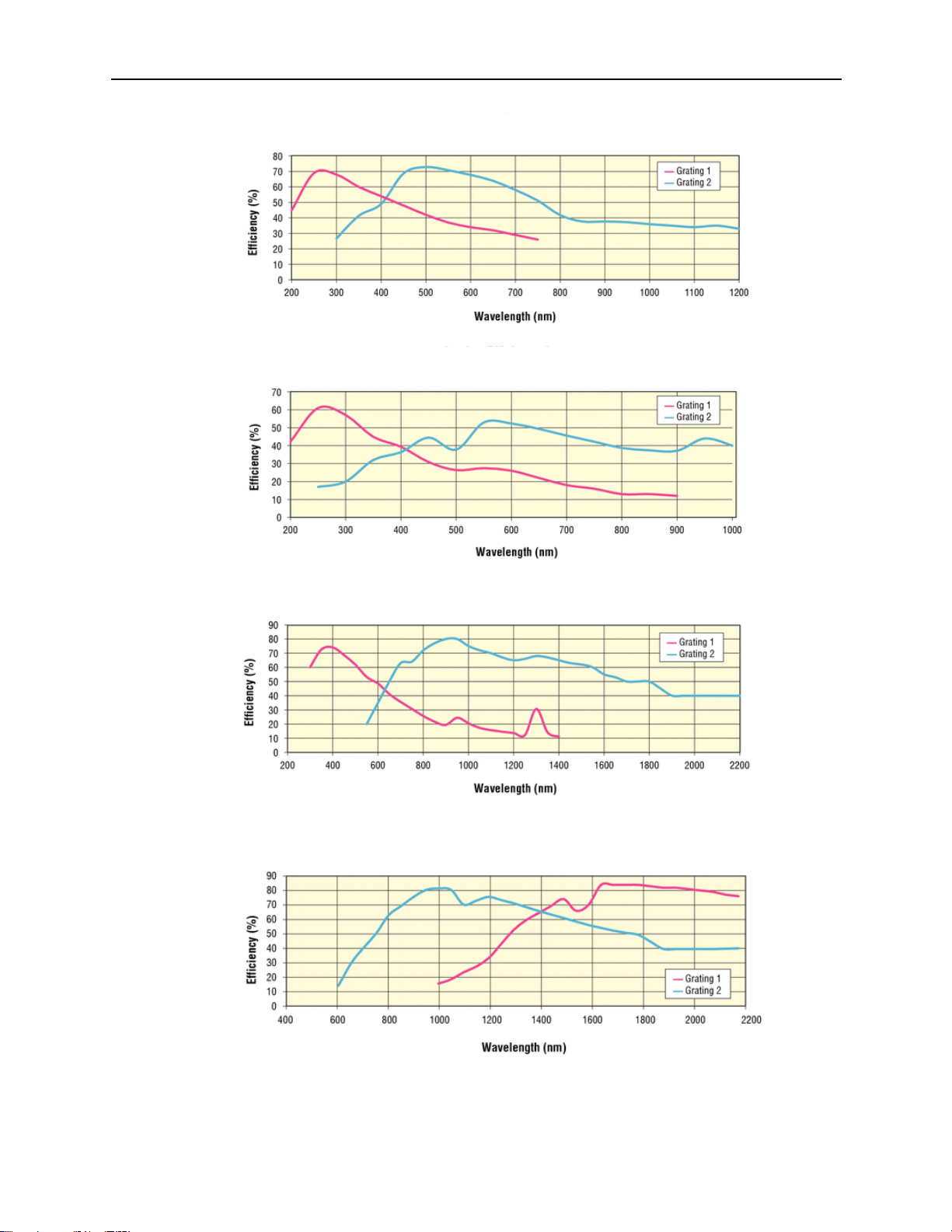

The efficiency curves shown are relative (not absolute) and were measured using an in-plane near

Littrow configuration. Please use the curves as a guide and not as absolute data. Grating

diffraction is dependent on the polarization of the radiation incident on the grating.

Software such as the Mono Utility and TracQ Basic may be configured to switch between gratings

at a specific wavelength. Typically, the most efficient grating is selected, so this switchover

wavelength would be where the two efficiency curves meet. To determine empirically the ideal

switchover wavelength, the output should be measured by an optical detector. Run a scan in the

crossover region using only Grating 1. Repeat the scan using only Grating 2. Where the detector

readings are closest is the optimal switchover wavelength.

If the selected grating’s efficiency has a sudden increase or decrease at a particularly critical

wavelength and the application demands extreme accuracy, it may be more desirable to select the

grating with the more gradual change in efficiency.

Page 23

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

23

Figure 15: Grating Efficiency Curves for CS130B Monochromator Pre-Configured Models

High Resolution Configuration

Holographic Grating Configuration

Extended Range Configuration

Near Infrared Configuration

Page 24

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

24

6.3 36BPOLARIZATION EFFECTS

The diffraction efficiency from a grating usually depends on the polarization of the radiation

incident on the grating. There can be significant differences between the efficiency for radiation

with the electric field vector parallel to the grating grooves and radiation with the electric vector

perpendicular to the grooves.

Radiation with the electric vector restricted to a specific direction is linearly polarized. Linearly

polarized radiation with the electric vector parallel to the grooves is P-polarized. Radiation

polarized perpendicular to the grooves is S-polarized. For Oriel’s monochromators and

spectrographs, P-polarized radiation has the polarization axis parallel to the entrance slit. In most

laboratory applications with the instrument sitting on its mounting surface on a horizontal bench or

optical table, P-polarized radiation is vertically polarized.

Note: this definition of S- and P-polarization for diffraction gratings does not follow the general

rules for S and P-polarization for optics where the plane of incidence, rather than the grooves, are

used to define parallel and perpendicular.

The graphs for the Cornerstone 130B configurations have one efficiency curve per grating. This is

representative of 45-degree polarization, which is the average of the P-polarization and Spolarization efficiency curves.

Typically, the efficiency curve for P-polarized light peaks slightly lower than the nominal blaze

wavelength and smoothly declines to 0% at about three times the blaze wavelength. The curves

for P-polarization are generally smooth, without dramatic changes in direction or sharp features.

The curves for S-polarized light peak slightly above the nominal blaze wavelength and decline.

However, the efficiency can recover dramatically and show good efficiency over a broader

wavelength range. The S-polarization curves can show sharp features (anomalies) which

complicate data deconvolution from spectral scans.

If a source is being measured close to an anomaly, then the real feature may be dramatically

distorted. If possible, a grating should be selected (or polarization) which has no significant

anomaly in the spectral region of interest. Contact a Newport sales engineer for more information

on the effects of polarized light in terms of grating efficiency.

Page 25

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

25

7 6BMONOCHROMATOR RESOLUTION

Gratings are available in various groove densities (i.e. lines/mm). Higher groove densities give higher

reciprocal dispersion and therefore higher resolution. The monochromator bandpass with a 1200

lines/mm grating is half that of the same arrangement with a 600 lines/mm grating. Note that this simple

relationship is not accurate for slit widths below 50 µm, as the optical aberrations begin to play a role in

the bandpass and resolution.

Using a grating with a high groove density may increase resolution, but the spectral range narrows. The

dispersion of a grating changes inversely with the groove density. If the groove density is halved, the

dispersion is doubled. A monochromator mechanism can only tilt the grating through a limited range of

angles. The angle and groove density determine the transmitted wavelength.

The gratings can be tilted to 0 degrees, so the lowest possible wavelength for a UV grating is set by the

transmittance of air at about 180 nm. A MPT plug is available to connect a hose barb and purge the

monochromator compartment with nitrogen, if desired. The ability to output wavelengths below 180 nm is

also dependent on the efficiency characteristics of the grating.

The following graphs are intended to illustrate the effects of slit width selection, in terms of throughput and

resolution. This data was taken using Oriel’s Tunable Light Source (TLS) systems, using various slit

widths to change the resolution. The TLS systems employ a Cornerstone 130 monochromator.

Figure 16: Resolution vs. Throughput

Page 26

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

26

7.1 37BDETERMINING RESOLUTION

All monochromators featuring fixed slit holders require fixed slits to be installed at the input and

output ports. Fixed slits are ordered separately, and should be the same size at the input and

output ports.

Micrometer adjustable slits allow for continuous variation of the width and height. Use the table

below for guidance on resolution vs. slit width. For slit widths not specified in the table, multiply the

micrometer adjustable slit width setting (mm) by the reciprocal dispersion (nm/mm) to calculate the

resolution for each grating.

Resolution is calculated for each grating at the grating's blaze wavelength, i.e. the wavelength with

the greatest efficiency. Actual performance is determined by the monochromator wavelength

accuracy, precision and calibration. Newport suggests having the monochromator recalibrated

annually by a qualified service technician.

Calculation of Resolution Based on Fixed Slit Selection

Fixed Slit

Slit

Width

Grating 1

Grating 2

Grating 1

Grating 2

High Resolution Configuration

Holographic Configuration

77222

10 µm*

0.03 nm

0.05 nm**

0.06 nm

0.03 nm

77221

50 µm*

0.14 nm

0.27 nm

0.28 nm

0.17 nm

77220

25 µm*

0.07 nm

0.13 nm**

0.14 nm

0.08 nm

77219

50 µm*

0.14 nm

0.27 nm**

0.28 nm

0.17 nm

77218

120 µm

0.32 nm

0.64 nm

0.66 nm

0.40 nm

77217

280 µm

0.76 nm

1.5 nm

1.5 nm

0.9 nm

77216

600 µm

1.6 nm

3.2 nm

3.3 nm

2.0 nm

77215

760 µm

2.1 nm

4.0 nm

4.2 nm

2.5 nm

77214

1.24 mm

3.3 nm

6.6 nm

6.8 nm

4.1 nm

77213

1.56 mm

4.2 nm

8.3 nm

8.6 nm

5.1 nm

77212

3.16 mm

8.5 nm

16.7 nm

17.4 nm

10.4 nm

77211

6.32 mm

17.1 nm

33.5 nm

34.8 nm

20.9 nm

* For slits with widths of 50 µm or less, aberrations begin to play a role in the actual achievable

resolution. The values noted above, unless otherwise stated, are calculations based on the slit

widths and grating dispersions.

** Empirically measured resolution values shown which differ from calculations due to aberrations

present when using narrow slit widths.

Page 27

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

27

Calculation of Resolution Based on Fixed Slit Selection

Fixed Slit

Slit

Width

Grating 1

Grating 2

Grating 1

Grating 2

Extended Range Configuration

VIS-NIR Configuration

77222

10 µm*

0.11 nm

0.11 nm

0.11 nm

0.21 nm

77221

50 µm*

0.55 nm

0.53 nm

0.53 nm

1.06 nm

77220

25 µm*

0.28 nm

0.27 nm

0.27 nm

0.53 nm

77219

50 µm*

0.55 nm

0.53 nm

0.53 nm

1.06 nm

77218

120 µm

1.32 nm

1.27 nm

1.27 nm

2.5 nm

77217

280 µm

3.08 nm

2.97 nm

2.97 nm

5.9 nm

77216

600 µm

6.6 nm

6.4 nm

6.4 nm

12.7 nm

77215

760 µm

8.4 nm

8.1 nm

8.1 nm

16.1 nm

77214

1.24 mm

13.6 nm

13.1 nm

13.1 nm

26.3 nm

77213

1.56 mm

17.2 nm

16.5 nm

16.5 nm

33.1 nm

77212

3.16 mm

34.8 nm

33.5 nm

33.5 nm

67.0 nm

77211

6.32 mm

69.5 nm

67.0 nm

67.0 nm

134.0 nm

* For slits with widths of 50 µm or less, aberrations begin to play a role in the actual achievable

resolution. The values noted above, unless otherwise stated, are calculations based on the slit

widths and grating dispersions.

** Empirically measured resolution values shown which differ from calculations due to aberrations

present when using narrow slit widths.

Figure 17: Some of the Fixed Slit Sizes Available

Page 28

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

28

8 7BGETTING LIGHT INTO A MONOCHROMATOR

8.1 38BACCEPTANCE PYRAMID

The figure below shows the optical path of the light input to the instrument. The monochromator

has an acceptance pyramid, often described by an F/#. The position and dimensions of the

internal optics determines the pyramid. The optical equivalent is a grating image located behind

the slit as shown in below. Only light that passes through the slit in the direction of this grating

image is useful.

Always fill the acceptance pyramid of the instrument with light.

Figure 18: Acceptance Pyramid of Monochromator

Figure 19: Grating Correctly “Filled” with Light

Page 29

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

29

8.2 39BF NUMBER MATCHING

The Cornerstone 130B monochromator is an F/3.9 instrument. Without matching the F/# of the

incoming light beam, stray light increases and throughput of desired signal suffers. To illustrate

this, the photos below show a fiber optic cable placed at the entrance of a monochromator. Fibers

are typically F/2. The Oriel model 77529 may be used to match the F/# to the monochromator.

Figure 20: Mismatched F Numbers Resulting in Stray Light

Figure 21: F Number Matcher Used with Fiber Optic Cable

Page 30

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

30

9 8BBLOCKING HIGHER ORDER RADIATION

Detailed information regarding grating physics can be found in the Appendix of this user’s manual. A

summary of grating physics is noted here.

• Only wavelengths that satisfy the grating equation pass through the output port of the

instrument.

• The remainder of the light is scattered and absorbed inside the instrument.

• The grating is rotated to bring different wavelengths of light in line with the output.

• A grating creates interference patterns when light is shown onto it.

• Different wavelengths interfere at different angles off the grating.

• Light occurs when there is constructive interference, called grating orders.

• All wavelengths interfere at one specific angle of the grating. This is called the “zero order”.

• When a parallel beam of monochromatic light is incident on a grating, the light is diffracted from

the grating in directions corresponding to m = -2, -1, 0, 1, 2, 3, etc.

• When a parallel beam on polychromatic light is incident on a grating, the light is dispersed so

that each wavelength satisfies the Grating Equation.

• Usually only the first order is desired. The other wavelengths in higher orders may need to be

blocked.

• The input spectrum and detector sensitivity determine whether order sorting or blocking

filters are needed.

9.1 40BORDER SORTING FILTERS

For meaningful spectral measurements, care should be taken to remove unwanted orders of

radiation, particularly if the input radiation is intense or the detector more sensitive at the higher

order.

Erroneous measurements may be taken because what was thought to be a measurement with a

single wavelength was actually a measurement using radiation at that wavelength – but

contaminated with higher order radiation. Consider using Newport’s Colored-Glass Alternative

Filters for blocking higher order diffraction.

Example 1:

• A monochromator is set to output 600 nm and the signal read by a UV-enhanced Si

detector with a spectral responsivity range of 200 nm to 1100 nm.

• Additional output will be 300 nm (600/2) and 200 nm (600/3). These are the second

and third order wavelengths.

• The second and third order wavelengths are within the responsivity range of this

detector.

• In order to block these extra orders, a filter that blocks wavelengths below 300nm

and transmits light at 600nm needs to be inserted in the optical path.

Example 2:

• A monochromator is set to output 1200 nm and the signal read by a Ge detector

with a spectral responsivity range of 700 nm to 1800 nm.

• Additional output will be 600 nm (1200/2) and 400 nm (1200/3). These are the

second and third order wavelengths.

• No order sorting filter is needed as the second and third order wavelengths are

outside the responsivity range of this detector.

Page 31

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

31

10 9BCOMMUNICATION METHODS

In order to satisfy the needs of as many users as possible, the Cornerstone 130B is designed to be

controlled from a variety of sources.

The Cornerstone 130B is capable of automatically controlling an optional filter wheel, Models USFW-100

or 74010. It is also able to interface with the motorized filter wheel included with Oriel’s APEX2 light

sources. These filter wheels hold up to six 1-inch [25.4 mm] diameter filters. Neutral density filters can be

used for intensity adjustment. Order sorting filters may be installed to block higher order diffraction.

The filter wheel can be mounted to the male flanges of the monochromator slits or slit holders. The filters

are mounted external to the monochromator. Thus, the refractive index and thickness of the filters do not

significantly affect the focal distance to the collimating mirror inside the monochromator. With internal

filters, this distance would be different for every wavelength and every filter, and would therefore

adversely affect resolution. The Cornerstone 130B is designed and manufactured to have errors of only a

fraction of a millimeter in the focal distance. Positioning the filters externally, usually before the input slit,

has only a slight effect on the light throughput. Since the slit acts as a secondary source, the focal

distance is not affected.

Figure 22: Model USFW-100 Filter Wheel

Page 32

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

32

Figure 23: Model 74010 Filter Wheel

Page 33

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

33

10.1 41BUTILITY SOFTWARE

LabVIEW-based utility software is included at no extra cost with all monochromator and

spectrograph models to control both the instrument and filter wheel accessory. The utility software

provided with the monochromator includes USB drivers for Windows 7 or 10 32-bit and 64-bit

operating systems, as well as Mac OS. The software can also control the instrument through an

RS232 connection.

Please refer to the Quick Start Guide provided with the monochromator for instructions on

installation and use.

Figure 24: Mono Utility Software Screens

Page 34

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

34

10.2 42BHAND CONTROLLER

The optional 74009 Hand Controller is designed specifically for use with Oriel’s Cornerstone series

monochromators and MS260i spectrographs. It is very easy to set up – simply plug it into the

instrument and it’s ready to go. There is no need to purchase a computer and set up the software.

The Hand Controller is a convenient option in locations where security is an issue, such as

defense facilities and universities.

There is no need to memorize commands or key sequences. The 24 keys are clearly labeled with

functions like “Shutter”, “Go Wave” and “Filter”. The display provides information about the grating

selection, grating line density, active filter position, current wavelength and shutter status. Using

the Hand Controller is intuitive and provides access to nearly all the functionality of the

monochromators and spectrographs. It comes with a 14-foot [4.3 meter] long cable.

Hand Controller commands are listed in Appendix II of this user’s manual.

Figure 25: Cornerstone 130B Monochromator with 74009 Hand Controller

Page 35

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

35

10.3 43BTRACQ BASIC SOFTWARE

The optional TracQ Basic Data Acquisition and Radiometery Software is an instrument control

package that includes data acquisition and processing. TracQ Basic allows users to acquire

spectroscopic measurement data quickly and easily, without requiring any programming

knowledge. TracQ Basic is true radiometry software, which enables users to acquire basic voltage

measurements or use the built-in algorithms for spectroscopic measurements. Data acquisition

and processing occurs in real time.

TracQ Basic is an application integrating Oriel monochromators with various detection

instruments, such as the Newport Optical Power and Energy Meters, 1918-R, 1936-R and 2936-R,

plus Oriel’s LIDA-SRS-KIT. Software prompts guide users through the measurement process.

Instruments are controlled and scan parameters are set up through simple, intuitive dialog boxes.

The front panel of the software allows one to see instrument status, present wavelength, signal

reading and the selected wavelength units.

Figure 26: TracQ Basic Screens

10.4 44BLOW-LEVEL COMMANDS

A command set is provided for those wishing to create their own programming. A list of these

commands is provided in the user’s manual included with the monochromator. Commands are

simple to use. For example, to query the wavelength, enter “WAVE?” The command to c los e t he

shutter is “SHUTTER C”. A full list of commands is available in the Appendix of this use r’s

manual.

Page 36

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

36

11 10BGRATING INSTALLATION AND CALIBRATION

Grating installation and field calibration are typically performed at one of Newport’s manufacturing

locations, or by qualified field service personnel. The instructions provided in this section are for

advanced users only.

11.1 45BRECALIBRATION SERVICES

Newport suggests that monochromators be returned annually for service. This is to prolong the

life of the instrument so it can continue to provide repeatable, high-performance results. In

addition to verifying the calibration, the instrument would be fully inspected. Any refurbishment

required would be included in the servicing of the instrument.

11.2 46BSETTING THE WAVELENGTH OFFSET

A wavelength offset is used to shift the wavelength position to either a higher or a lower

wavelength. For example, if a HeNe laser operating at 632.8 nm is sent through the

monochromator and the output is visible when the monochromator is set to 640 nm, an offset can

be introduced.

When performing this procedure, it is necessary to use a light source with a known spectral line

appearing within the operating range of the grating. Oriel offers a number of pencil calibration

lamps for this purpose, such as the model 6035 Hg lamp. Another line source such as a laser may

also be used. Always be sure to follow the appropriate safety precautions when dealing with any

light source.

Procedure:

1. Select a radiation source that has at least one narrow spectral line in the

wavelength region of interest.

2. Select a detector with an operating range appropriate for the spectral line.

3. Focus the radiation onto the entrance slit (the monochromator is F/3.9). Note that

a narrower slit provides greater resolution.

4. Ensure the focused beam is parallel to the monochromator’s optical axis.

5. Command the monochromator to select the grating for which the offset is to be

applied.

6. Use the STEP command to move the grating position until the spectral line is

visible at the output.

7. Use the CALIBRATE command to enter the exact wavelength of the spectral line.

The Cornerstone wavelength offset has now been entered into memory. This

offset applies to all other wavelength positions when using this grating.

8. Repeat the process for the second grating, if required.

Page 37

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

37

11.3 47BDETERMINING THE GRATING CALIBRATION FACTOR

The following procedure allows advanced users to perform a two-point grating calibration.

Procedure:

1. Select a radiation source that has at least two narrow spectral lines in the

wavelength region of interest.

2. Select a detector with an operating range appropriate for the spectral lines.

3. Focus the radiation onto the entrance slit (the monochromator is F/3.9). Note that

a narrower slit provides greater resolution.

4. Ensure the focused beam is parallel to the monochromator’s optical axis.

5. Command the monochromator to select the grating to be recalibrated.

6. Use the STEP command to move the grating position until the first spectral line is

visible at the output.

7. Note the wavelength at which this first spectral line peak appears.

8. Use the STEP command to move the grating position until the second spectral line

is visible at the output.

9. Note the wavelength at which this second spectral line peak appears.

10. Use the formula to calculate the new Grating Factor.

11. Use the utility software to enter the new Grating Factor. The GRATINGnFACTOR

command may also be used.

12. Repeat the process for the second grating, if required.

Spectral Line

Observed Peak

Wavelength 1

Wavelength 2

FACTOR = | L1 – L2 | / | P1 – P2 |

Example:

Spectral Line

Observed Peak

Wavelength 1

546

577

Wavelength 2

365

372

FACTOR = |546 – 365| / |577 – 372| = 181 / 205 = 0.8829268

11.4 48BALTERNATIVE METHOD (CS130B ONLY)

Instead of noting the wavelength in step 7, send the command “user:cal:lambda1 XXX.XXX”,

where the X’s represent the wavelength (in the currently selected units) observed at the output. In

step 9, send the second wavelength using the command “user:cal:lambda2 XXX.XXX”. The

CS130B will compute and store the new grating factor and offset.

Page 38

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

38

11.5 49BGRATING INSTALLATION

Each grating comes mounted and aligned on a grating mount. For most applications, there is no

need to adjust this grating holder. Refer to the general warnings and precautions section of this

manual regarding the care and handling of diffraction gratings. Note that only one grating should

be replaced at a time.

Procedure:

1. Using the Cornerstone Hand Controller or utility software, close the shutter.

2. Command the Cornerstone to go to the grating that is to be replaced.

3. Go to wavelength 0. The grating facing the collimating mirror is the grating that was selected.

4. Turn off the power switch on the monochromator and unplug the instrument from the

electrical mains.

5. Remove all screws holding the monochromator cover in place, then remove the cover.

6. Two long screws, one on each side of the grating, must be removed. Used a screwdriver to

loosen these screws.

7. Grasp the sides of the grating mount with one hand and firmly pull the grating up and out of

the instrument. Pull in a direction parallel to the grating face – not directly upwards. During

this process, ensure the other grating does not move. It should be held in place using a free

hand by grasping or pressing down on the grating holder.

8. Carefully uncover the new grating to be installed and set aside.

9. Use the cover from the new grating to protect the grating that was just removed.

10. Install the new grating onto the grating platform and ensure the new grating is parallel to the

other grating. The grating should fit into a pin located on the platform.

11. Push the new grating up against the large central pin in the middle of the platform.

12. Re-install the long screws that held the previous grating in place. Use only firm finger

pressure to tighten them. Do not tighten one completely while the other screw is loose. It is

best to alternate tightening between the two screws. Ensure the screws line up parallel with

the grating face.

13. Replace the cover on the monochromator and secure using all screws provided. Failure to

use all hardware will result in increased stray light.

14. Connect the monochromator to the electrical mains and switch on the power.

15. Follow the procedures outlined in this manual to determine the grating factor and any offset.

16. Use the Mono utility software to update the calibration parameters as needed.

17. It is suggested to verify the calibration factors and offsets of the other gratings that were not

replaced, as they may have accidentally been moved during this process.

Page 39

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

39

Figure 27: Grating Platform without Gratings

Figure 28: Grating Platform with Gratings Installed

Page 40

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

40

12 11BTROUBLESHOOTING

This section suggests solutions to potential issues that may be encountered when operating the

Cornerstone monochromator. If the tips in this section do not restore the instrument to working condition,

contact Newport to arrange for technical support or repair. Contact information can be found in the

Warranty and Service section of this user’s manual.

12.1 50BCORRUPTED MEMORY

The monochromator comes with calibration parameters, which are stored in a file on the memory

stick shipped with the instrument. If these parameters were corrupted from, possibly, performing

an incorrect field calibration, they will need to be reset. Other possible causes include electrostatic

discharge or other high field radiation near or in contact with the instrument.

The instrument parameters need to be reloaded from the calibration parameter sheet. Use the

utility program and select the first grating. Update the parameters for this grating. Then go to the

second grating and also update these parameters.

Figure 29: Entering Calibration Values in Utility Software

Page 41

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

41

13 12BSPECIFICATIONS

General Specifications

Focal Length

130 mm

F/#

F/3.9

Wavelength Selection Method

Motorized

Usable Wavelength Range

280 to 2500 nm, grating dependent

Spectral Resolution

Grating dispersion and slit width dependent

Wavelength Accuracy

+/- 0.25 nm

Wavelength Precision

+/- 0.075 nm

Stray Light

0.03%

Ports

1 input port, 1 output port

Shutter Control

Software, Hand Controller, low-level commands

Shutter minimum exposure

0.3 s

Shutter maximum repetition

2.0 Hz

Wavelength Scan Speed

3 nm/s at 1 nm step rate; 24 nm/s at 10 nm step rate

Motorized Filter Wheel

Models USFW-100, 74010, Apex2 filter wheel

Utility Software Requirements

Windows 10 and MAC OS-X (Windows XP compatible

software also available)

TracQ Basic Software

Compatible

Yes

74009 Hand Controller

Compatible

Yes

Voltage

100-240 VAC, 47-63 Hz

Weight

12 lb [5.4 kg]

Micrometer Adjustable Slit Specifications

Width Range

4 μm to 3 mm

Height Range

3 mm to 12 mm

Repeatability

± 10 μm

Accuracy

± 10 μm (width from 4 μm to 250 um)

± 5% (width from 250 μm to 3 mm)

Wavelength Accuracy:

The capability of the monochromator to output the desired wavelength.

Wavelength Precision:

The ability of a wavelength to be consistently reproduced and the number of

significant digits to which it has been reliably measured.

Page 42

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

42

14 13BDIMENSIONS

Figure 30: Cornerstone 130B Dimensions

Page 43

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

43

Figure 31: 74001 Micrometer Adjustable Slit Dimensions

Figure 32: 77294 Fixed Slit Dimensions

Page 44

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

44

Figure 33: Model 74006 Mounting Plate

Page 45

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

45

15 1APPENDIX I: REMOTE COMMANDS AND QUERIES

15.1 OPENING RS-232 COMMUNICATION INTERFACE

The CS130B’s USB port implements the USB Test and Measurement class (USBTMC), making i t

directly compatible with National Instruments’ LabVIEW programming system. It provides a robust

way to send messages to the CS130B. However, RS232 continues to be an extremely simple

communications bus, once it is configured correctly.

Commands and Queries may be sent to the CS130B’s RS-232 port using HyperTerminal, PuTTY,

YAT, Newport’s MonoTerm, or other similar terminal-emulation programs. Connect a standard 9-

pin PC serial port to the CS130B using a straight-through (not null modem) cable. Once the

terminal program is open and running, select the connected COM port and configure it according

to the following settings:

Baud Rate:

9600

Data Bits:

8

Parity:

None

Stop Bits:

1

Flow Control:

None

The CS130B requires all Statements to be terminated by a carriage return followed by a linefeed.

Configure the terminal emulator to send a carriage return and line feed (CR-LF) as its terminator1.

All responses from the CS130B end with a carriage return followed by a linefeed.

When shipped from the factory, the CS130B echoes each RS-232 character as it receives it. This

feature can be turned off or on using the “Echo” command (see the Command Reference). The

echo can be handy when troubleshooting a serial connection, but it may be troublesome when

developing a test program.

Note: the RS-232, USB, and Hand Controller ports are all active at all times. There are times when

this can be useful but it’s important to recognize the possibility that commands rec ei ved on o ne

port could override those from another.

1

Some terminal emulators call the terminator the “EOL (end of line) sequence”.

Page 46

90088262 MCS130B

CORNERSTONE 130B MONOCHROMATORS

46

15.2 TROUBLESHOOTING RS-232

One of the most common problems when first connecting a PC to an RS-232 device is that the

cable may swap the signals. The cable should be the straight-through type, and if you aren’t sure