Page 1

Page 2

-

Newport

Medical

Instruments

Newport

Breeze

E

150

Ventilator

Service

Instructions

SERI 50

Rev.

B

[serial #901

0081

60

and later]

EU REPRESENTATIVE:

Newport Medical Instruments

Att: Robert Brink

Barton-on-Humber

18 Pasture Rd.

South Humberside Tel: 44.4682.31311

DN18

5HN,

England Fax: 44.1652.633399

NEWPORT MEDICAL INSTRUMENTS

Post Office Box 2600

Newport Beach, California 92658 USA

800.451.3111

949.642.3910

949.548.3091

FAX

Customer Service Ext.

282

Page 3

Table

of

Contents

Section One

1.1

INTRODUCTION

1.2

NEWPORT BREEZE VENTILATOR

PRESSURE RELIEF VALVE

EXHALATION VALVE

WATER TRAP ASSEMBLY

STAND AND POLE ASSEMBLY

1.3

OPTIONAL ACCESSORIES

1.4

NEWPORT BREEZE SPECIFICATIONS

Section

Two

2.1

GENERAL

2.2

POWER SOURCE

2.3

SOLENOIDS AND VALVES

2.4

AIR I OXYGEN MIXER

2.5

PRINTED CIRCUIT BOARDS

2.6

MANOMETER ASSEMBLY

2.7

THEORY

OF

OPERATION

2.7.1

GENERAL

Page 4

Table

of

Contents

2.7.2

VOLUME LIMITED MODE

2.7.3

PRESSURE LIMITED MODE

2.7.4

SPONTANEOUS MODE

2.7.5

NEBULIZER

Section

Three

3.1

GENERAL CALIBRATION PROCEDURE

3.2

PREVENTATIVE MAINTENANCE

3.3

OPERATIONAL VERIFICATION AND

CALIBRATION PROCEDURE

Drawinas

FIGURE 1-1

VENTILATOR FRONT

VIEW

FIGURE 1-2

PRESSURE

REILEF VALVE

FIGURE 1-3A

EXHALATION VALVE ASSEMBLY

FIGURE 1-3B

PB EXHALATION VALVE BLOCK ASSEMBLY

FIGURE 1-4

WATER TRAP ASSEMBLY

FIGURE 1-5

STANDING POLE ASSEMBLY

Page 5

Table

of

Contents

Drawinqs

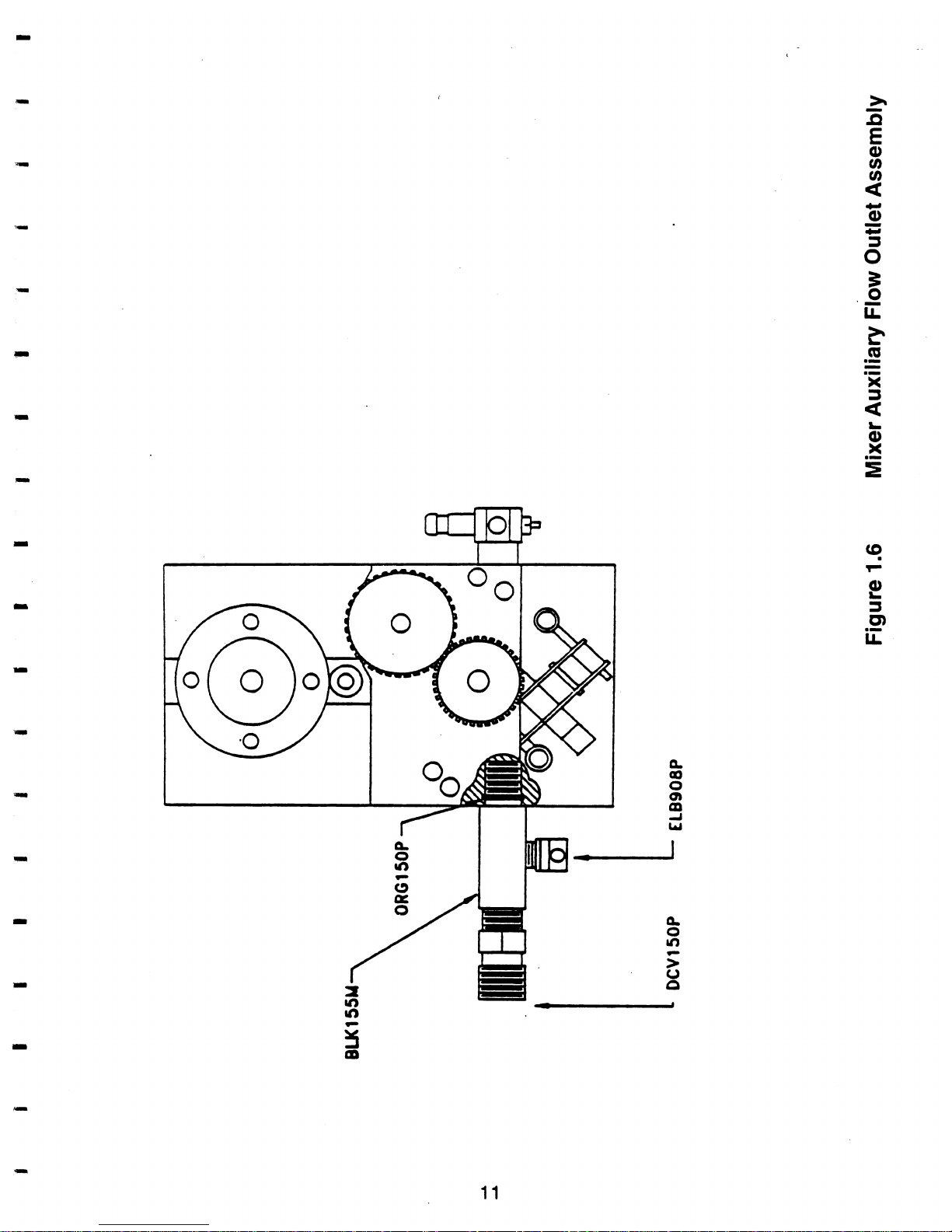

FIGURE 1-6

MIXER AUXILIARY FLOW OUTLET ASSEMBLY

FIGURE 2-1

AIR

/

OXYGEN MIXER

FIGURE 2-2

MANOMETER ASSEMBLY

FIGURE 2-7

PNEUMATIC TUBING DIAGRAM

FIGURE 4-1

BASE PLATE (TOP VIEW)

FIGURE 4-2

BEZEL (FRONT VIEW)

FIGURE 4-3

FRONT PANEL ASSEMBLY

FIGURE 4-4BACK PANEL (INSIDE VIEW)

FIGURE 4-5

BACK PANEL (OUTSIDE VIEW)

FIGURE 4-6

FLOW CONTROLLER AND

LO/HI POTENTIOMETER ASSEMBLY

FIGURE 4-7

SPONTANEOUS FLOW ASSEMBLY

FIGURE 4-8

I.T.

/

R&R POTENTIOMETER ASSEMBLY

FIGURE 4-9

PEEP

/

PIP ASSEMBLY

FIGURE 4-1

0

PNEUMATIC BRACKET ASSEMBLY

Page 6

1

.I

INTRODUCTION

The Newport Breeze Ventilator can be used to ventilate infant,

pediatric or adult patients. It's versatility provides for a safe and

effective use throughout the entire patient range.

This service manual

(Part No. SER150)

contains the necessary

information to enable a

qualified service person

to maintain and

service the

Newport Breeze ventilator. This manual is a companion to

the operating manual

(Part No. OPR150).

Both the operating and

service manuals should be read before any service or repair is

attempted on the Breeze.

Together the manuals will provide the service person with enough

information to operate, maintain and service the Breeze to an

assembly or subassembly level.

We recommend that you do not attempt to make repairs of a complex

nature such as electronic circuit board repairs unless you are a

.fully

qualified service person and possess the appropriate test equipment.

We also recommend that you contact your authorized service

representative or the service department at

NEWPORT MEDICAL

INSTRUMENTS INC.

for circuit board and other complex repairs, as

the

Newport Medical personnel are properly trained and equipped to

provide this service.

If at any time the Breeze cannot be restored to properly operating

condition the unit should be returned to the NMI factory for the service

or repairs as needed.

The material in this manual is organized as follows:

Section One provides a brief description of the

Newport Breeze

Ventilator, options and accessories.

Section Two covers mechanical drawings and parts.

Section Three covers acceptance tests and calibration procedures.

Page 7

Parts, Accessories and Optional equipment may be ordered by part

number through your local NMI dealer or by contacting NMI customer

service.

Customer Service

800 451 .3111

or

949 642 .3910 ext. 282

Fax 949

548 3091

Technical Support

800.451 3111

or

949.642 391 0 ext. 500

Fax 949

548 3091

Newport Medical Instruments Inc.

Corres~ondence:

Post Office Box 2600

Newport Beach, CA 92658

Ship ~roduct to:

760

W,

16th Street, Bldg

B

Costa Mesa, CA 92627

Page 8

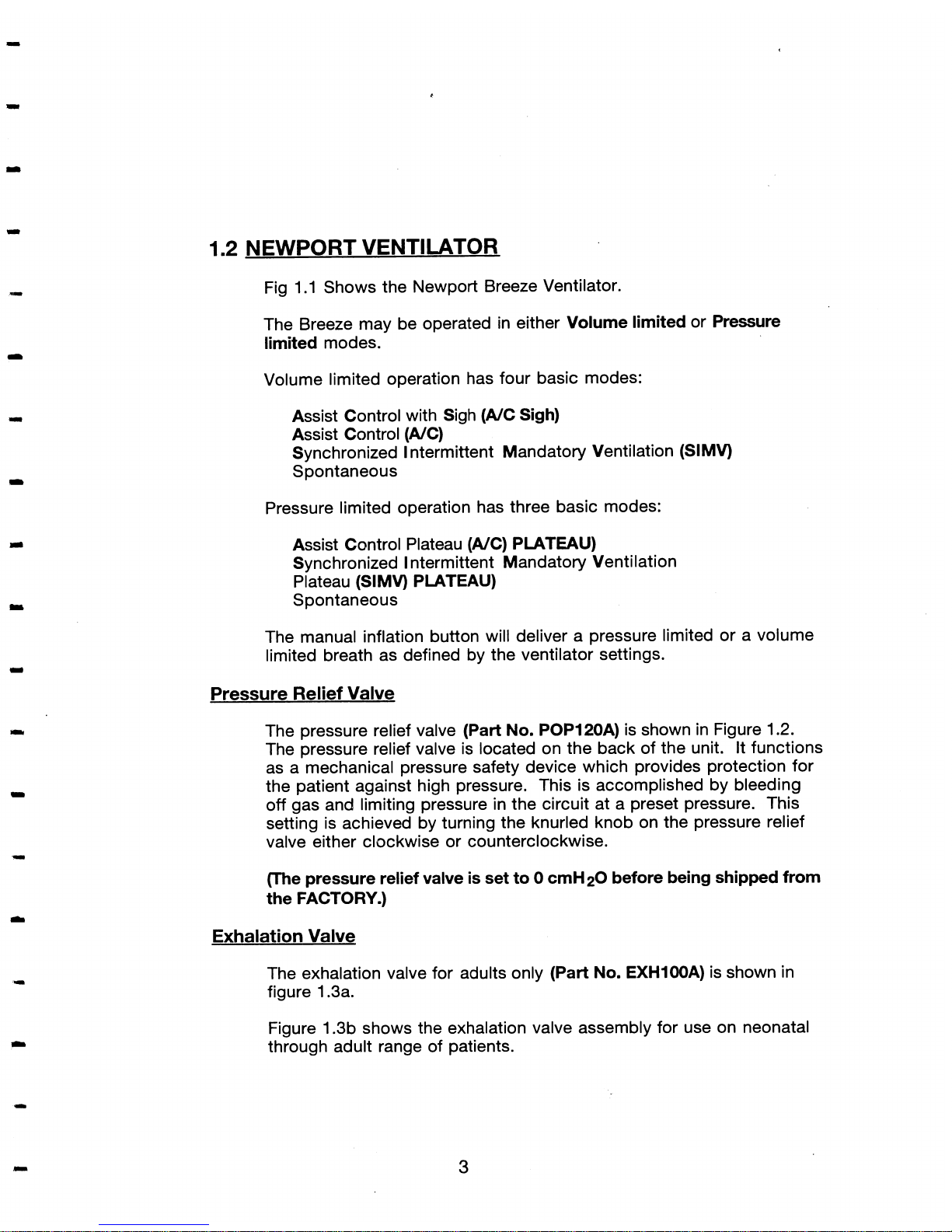

1.2

NEWPORT VENTILATOR

Fig

1.1

Shows the Newport Breeze Ventilator.

The Breeze may be operated in either Volume limited or Pressure

limited modes.

Volume limited operation has four basic modes:

Assist Control with Sigh (AIC Sigh)

Assist Control

(NC)

Synchronized l ntermittent Mandatory Ventilation (SIMV)

Spontaneous

Pressure limited operation has three basic modes:

Assist Control Plateau

(NC) PLATEAU)

Synchronized

l

ntermittent Mandatory Ventilation

Plateau (SIMV) PLATEAU)

Spontaneous

The manual inflation button will deliver a pressure limited or a volume

limited breath as defined by the ventilator settings.

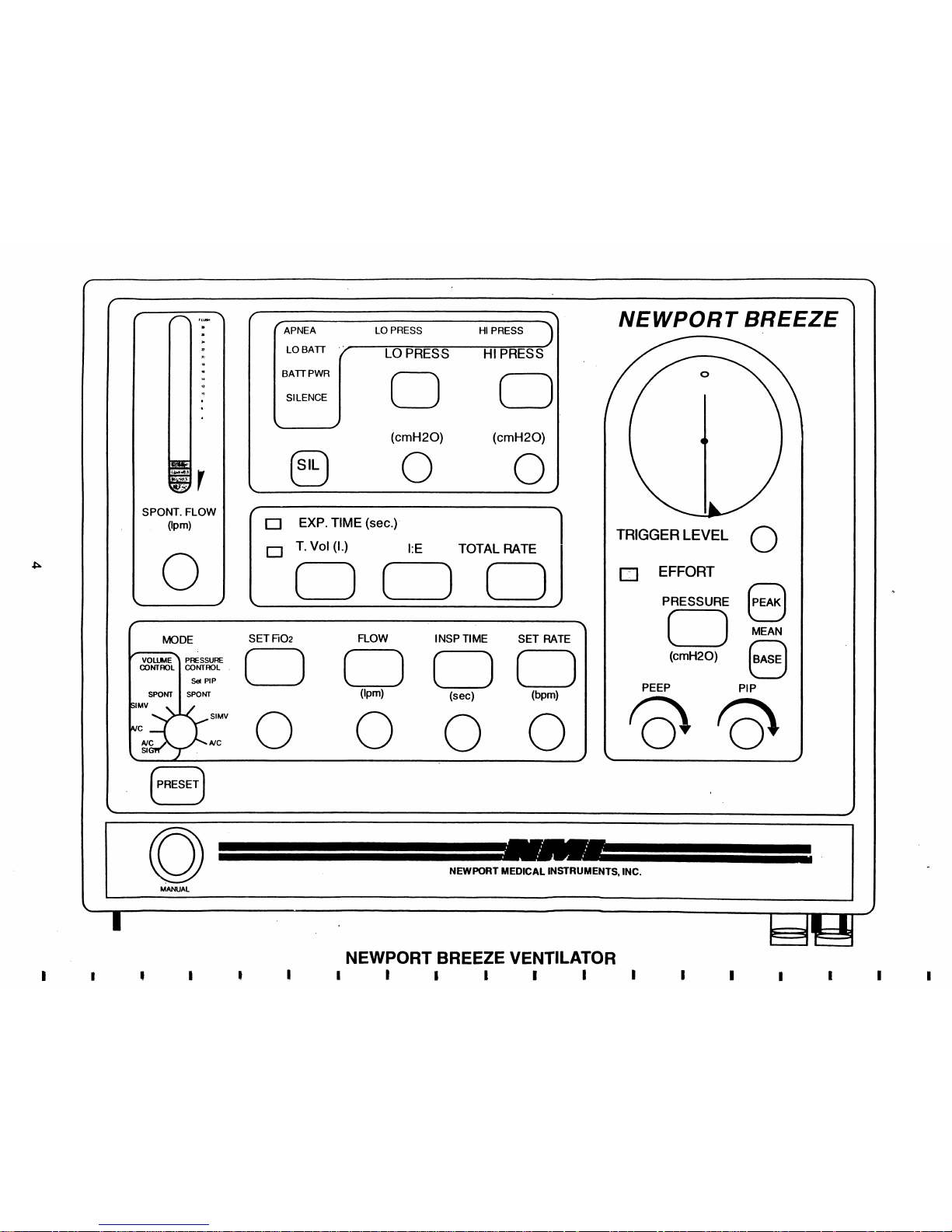

Pressure Relief Valve

The pressure relief valve (Part No.

POP120A) is shown in Figure 1.2.

The pressure relief valve is located on the back of the unit. It functions

as a mechanical pressure safety device which provides protection for

the patient against high pressure. This is accomplished by bleeding

off gas and limiting pressure in the circuit at a preset pressure. This

setting is achieved by turning the knurled knob on the pressure relief

valve either clockwise or counterclockwise.

(The pressure relief valve is set to

0 cmH2O before being shipped from

the FACTORY.)

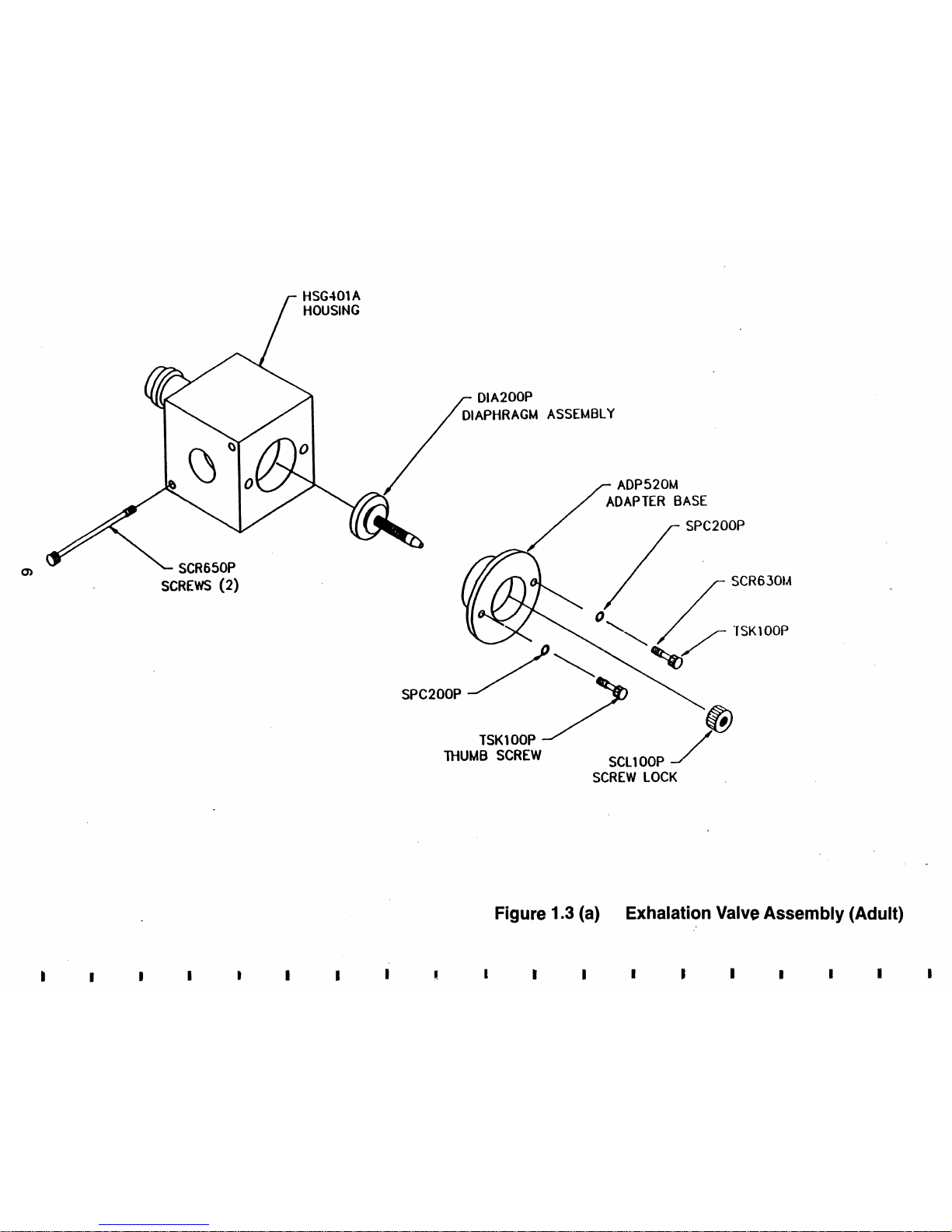

Exhalation Valve

The exhalation valve for adults only (Part No.

EXH100A) is shown in

figure

1.3a.

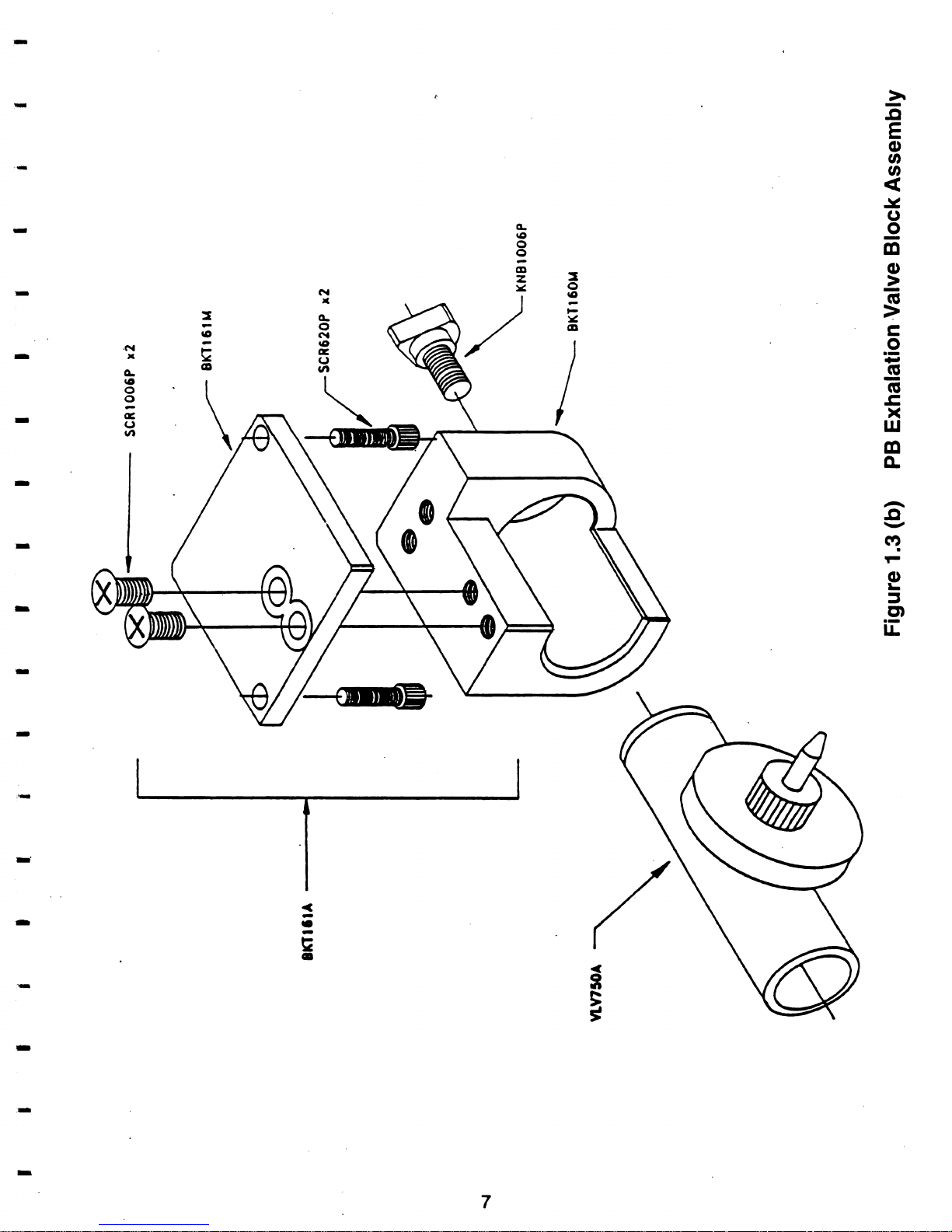

Figure 1.3b shows the exhalation valve assembly for use on neonatal

through adult range of patients.

Page 9

f

3

T

\

<

[APNE

A

LO

PRESS

HI

PRESS

NEWPORT BREEZE

NEWPORT BREEZE VENTILATOR

I

I

I

I

I

I

I

f

\

MODE SET F10z FLOW

l

NSP TI ME SET RATE

vPSU a3NTrnL CONTROL

(1

(-1

(-1

(-1

0

LO

BAlT

LO

PRESS

HI

PRESS

SPONT

SlMV

\

0

SPONT. FLOW

0,

f

3

0

EXP. TIME (sec.)

1.

Vol (I.) I:E TOTAL RATE

cb

TRIGGER 0 EFFORT LEVEL

0

0(3c_>,

PRESSURE

@

(-1

MEAN

(cmH20)

@

\B

6,

L

1

0

MANUAL

NEWPORT MEDICAL INSTRUMENTS, INC.

\

I

1

BAT

PWR

SILENCE

Sel

PIP

SPONT

upm)

(set)

(bpm)

0

0

AJC

AJC

NC

SI

lMV

0

0

0

0,

PRESET

0

\

1

(cmH20) (cmH20)

Page 10

Page 11

HSG4Ol A

HOUSING

DIA200P

DIAPHRAGM ASSEMBLY

1

/

/

ADP520M

4

/"-

ADAPTER

BASE

SCREWS

(2)

TSKl

OOP

/

THUMB

SCREW

SCLl OOP

SCREW LOCK

Figure

1.3

(a)

Exhalation Valve Assembly (Adult)

Page 12

Page 13

The exhalation valve is mounted beneath the Breeze in the square

area marked EXH VALVE. The exhalation valve controls the release of

the exhaled gas to the atmosphere. The opening and closing of the

valve is controlled by the pressure in the pneumatic drive line, marked

EXP. OUTLET, located beneath the unit and to the left of the

exhalation valve. The drive

line(EXP. OUTLET) is connected to the

exhalation valve .by means of a tubing.

Water Tra~ Assembly

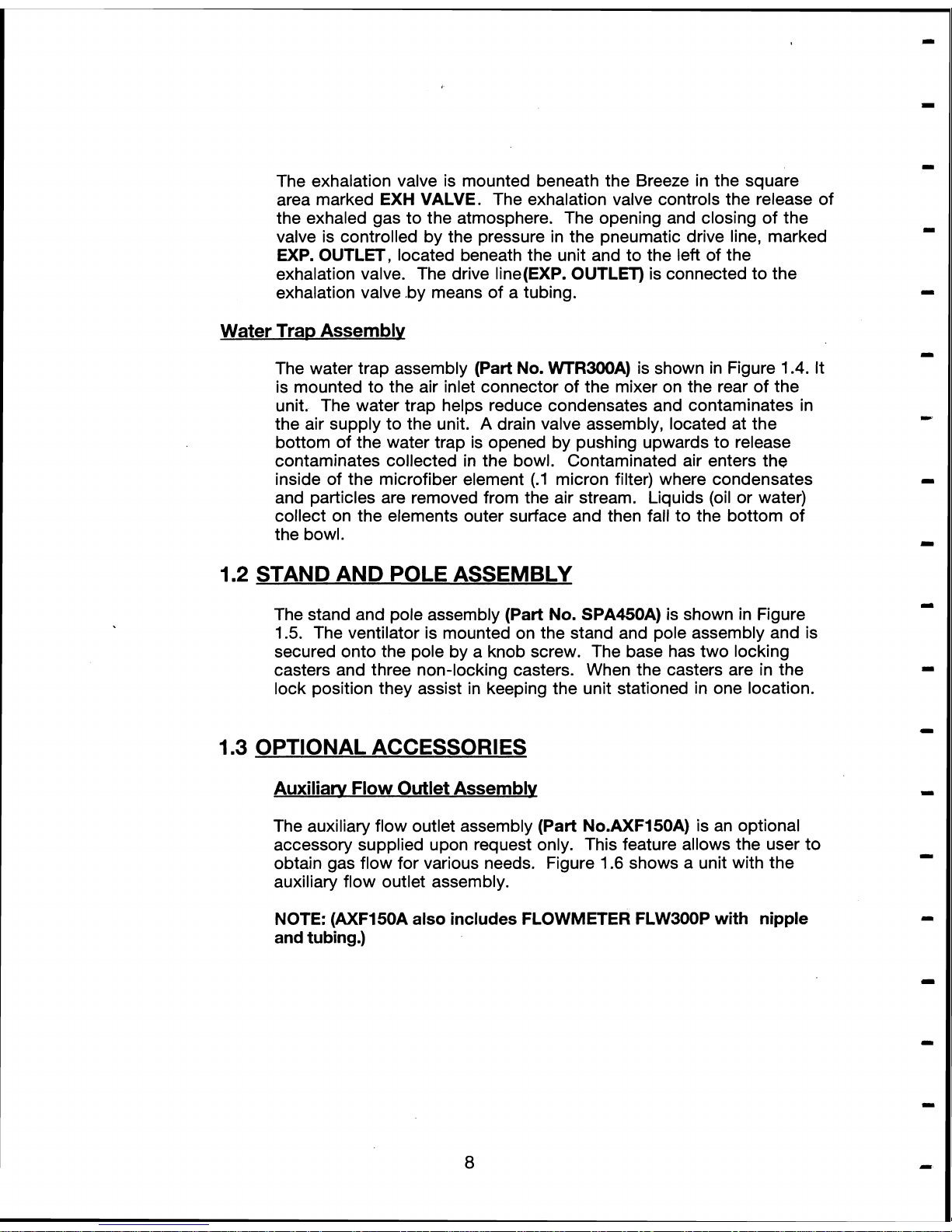

The water trap assembly (Part No. WR300A) is shown in Figure 1.4. It

is mounted to the air inlet connector of the mixer on the rear of the

unit. The water trap helps reduce condensates and contaminates in

the air supply to the unit.

A

drain valve assembly, located at the

bottom of the water trap is opened by pushing upwards to release

contaminates collected in the bowl. Contaminated air enters the

inside of the microfiber element

(.I micron filter) where condensates

and particles are removed from the air stream. Liquids (oil or water)

collect on the elements outer surface and then fall to the bottom of

the bowl.

1.2

STAND AND POLE ASSEMBLY

The stand and pole assembly (Part No. SPA450A) is shown in Figure

1.5. The ventilator is mounted on the stand and pole assembly and is

secured onto the pole by a knob screw. The base has two locking

casters and three non-locking casters. When the casters are in the

lock position they assist in keeping the unit stationed in one location.

I

.3

OPTIONAL ACCESSORIES

Auxiliatv Flow Outlet Assemblv

The auxiliary flow outlet assembly (Part No.AXF150A) is an optional

accessory supplied upon request only. This feature allows the user to

obtain gas flow for various needs. Figure 1.6 shows a unit with the

auxiliary flow outlet assembly.

NOTE:

(AXF150A also includes FLOWMETER FLW300P with

nipple

and tubing.)

Page 14

Page 15

Page 16

Page 17

1.4

NEWPORT BREEZE SPECIFICATIONS

CONTROLS

Power Switch:

F102:

FLOW:

lnspiratory Time

:

Rate

:

PEEP 1 CPAP

Peak Insp. Pressure

Spontaneous Flow

Trigger Level

Pneumatic Pressure Relief

Nebulizer

MODES:

VOLUME LIMITED

Assist CMV + Sigh

Assist CMV

Sl MV

Spontaneous

Manual Breath

Alarm Loudness

Alarm Silence

ON-OFF / charge

21

% - 100%

3

-

120 LPM

0.1

-

3.0

sec.

1 - 150 BPM

0 - 60 cmH20

0

-

60 cmH20

0 - 40+ LPM

-10

-

+60 cmH20

0 - 120 cmH20

ON / OFF

PRESSURE LIMITED

SlMV Plateau

A,C Plateau

Spontaneous

2

sec. Max.

72

-

97 dBa

(at a distance of 1 meter.)

60

sec.

Page 18

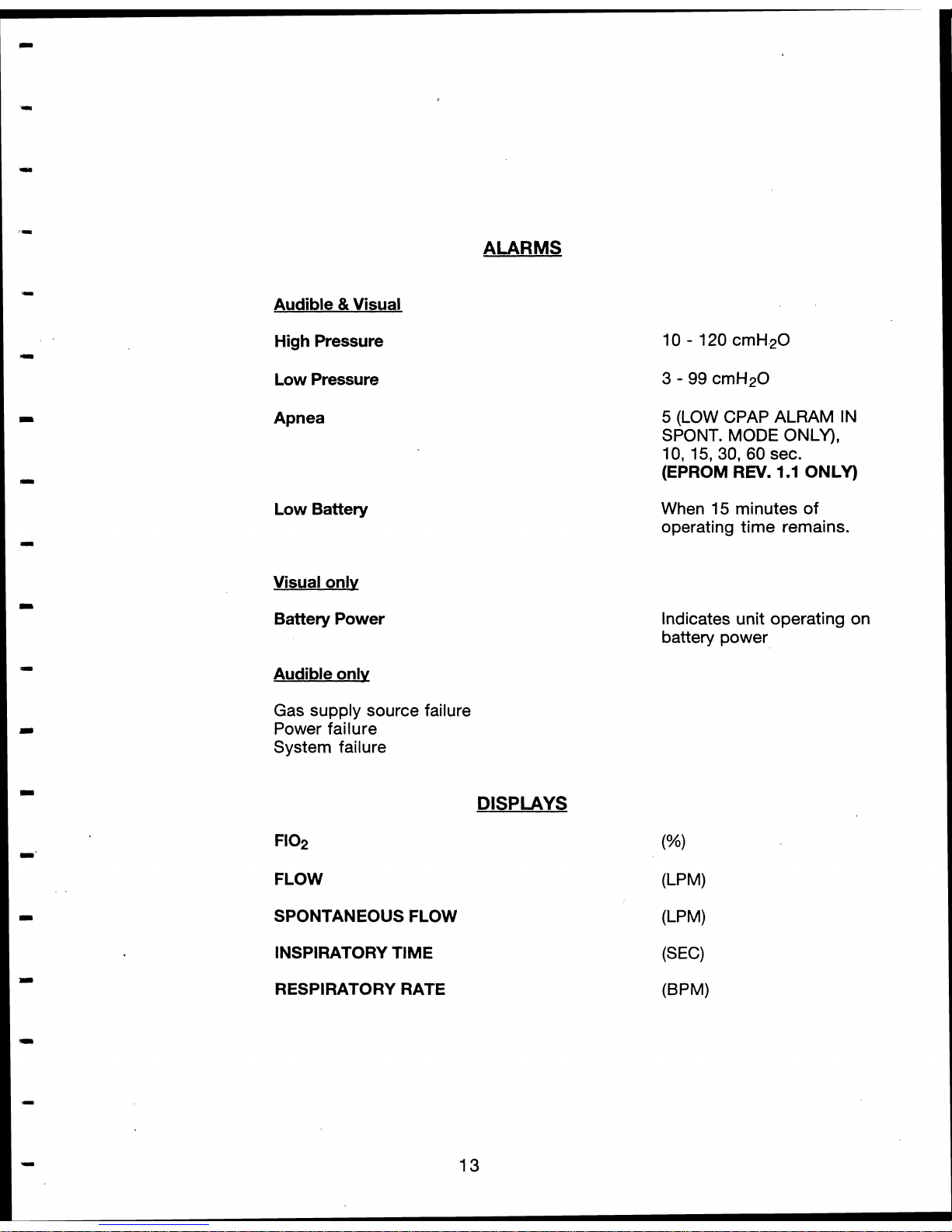

Audible & Visual

High Pressure

Low Pressure

Apnea

Low Battery

Visual onlv

Battery Power

ALARMS

Audible only

Gas supply source failure

Power failure

System failure

DISPLAYS

F102

FLOW

SPONTANEOUS FLOW

INSPIRATORY TIME

RESPIRATORY RATE

5

(LOW CPAP ALRAM IN

SPONT.

MODE

ONLY),

10, 15, 30, 60

sec.

(EPROM

REV.

1.1

ONLY)

When

15

minutes of

operating time remains.

Indicates unit operating on

battery power

Page 19

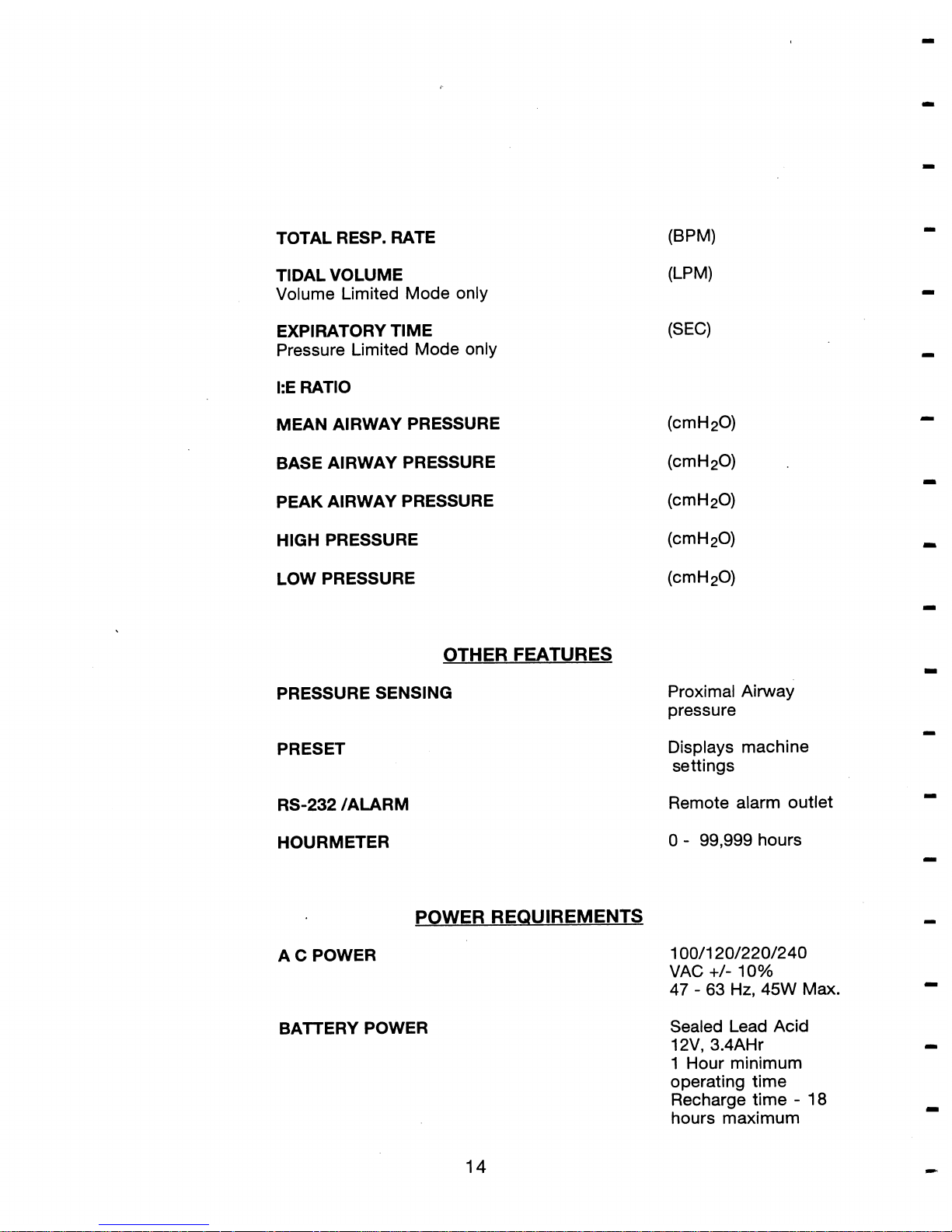

TOTAL RESP. RATE

TIDAL VOLUME

Volume Limited Mode only

EXPIRATORY TIME

Pressure Limited Mode only

I:E RATIO

MEAN AIRWAY PRESSURE

BASE AIRWAY PRESSURE

PEAK AIRWAY PRESSURE

HIGH PRESSURE

LOW PRESSURE

OTHER FEATURES

PRESSURE SENSING

PRESET

Proximal Airway

pressure

Displays machine

settings

RS-232 /ALARM

Remote alarm outlet

HOURMETER

0

-

99,999

hours

POWER REQUIREMENTS

A C POWER

BAlTERY POWER

1

00/120/220/240

VAC

+/-

1

0%

47

-

63 Hz, 45W

Max.

Sealed Lead Acid

12V,

3.4AHr

1

Hour minimum

operating time

Recharge time

-

18

hours maximum

Page 20

GAS REQUIREMENTS

AIR

OXYGEN

40 - 60 PSI

(2.81

-

4.22 kg/cm2)

40 - 60 psi

(2.81

-

4.22 kg/cm2)

DIMENSIONS & WEIGHT

HEIGHT

11 " (27.94 cm)

WIDTH

13" (33 cm)

DEPTH

12" (30.5 cm)

WEIGHT

32 Lbs. (14.6 kg)

SHIP WEIGHT

64 Lbs. (29 kg)

AGENCY REQUIREMENTS

Meets requirements

of

UL 544, CSA 22.2, IEC

601

-

1 and City

of

Los Angeles - Electrical

Testing Lab.

Page 21

SECTION TWO

INSTRUMENT DESCRIPTION

2.1

GENERAL

A

simple functional description and principle of operation of the

Newport Breeze is presented in this section.

The function of various

components, different modes and various settings are also explained.

2.2

POWER SOURCE

The ventilator may be powered by an electrical supply of IOOvac,

120vac, 220vac or 240vac

+/-

10% at 47

-

63

Hz, 45W maximum. The

voltage adjustment on the power entry module located at the rear of

the unit must be set for the supply voltage.

2.3

SOLENOIDS AND VALVES

The Newport Breeze has four solenoids and four valves. The solenoids

are electronically controlled and the valves are pneumatically

controlled by the solenoids. The function, switching cycles and control

methods of these components are explained in Table 1 and Table 2.

The reader is advised to refer to pneumatic diagram Figure 2.7.

Page 22

2.3

TABLE

1

Valvel

Solenoid

Flow Pilot Solenoid

PEEP Solenoid

Plateau Solenoid

Nebulizer Solenoid

Main Flow Valve

Spontaneous Flow Valve

Plateau Valve

PEEP/Exhalation

Part

Number

PLV150P

PLV300P

PLV350P

PLV250P

SOL200P

VLV150P

VLV150P

VLV150P

Function

Control of main flow valve

and spontaneous flow valve.

Control of PEEP and

exhalation valve.

Control of Plateau valve.

Control of Nebulizer output

Control Valve Main flow

output.

Control Spontaneous

flow output.

Control of Plateau pressure.

Controls PEEP and

Expiratory drive line

pressure.

Page 23

2.3

TABLE

2

NOTE:

During SPONTANEOUS

-

PEEP solenoid is always closed except

during manual breath and the peeplexhalation solenoid is NC

(normal closed) to load.

Normal:

OPEN ONLY WHEN NEBULIZER SWITCH IS TURNED ON.

Controlled by

electronics

electronics

electronics

electronics

flow pilot

solenoid

flow pilot

solenoid

plateau solenoid

PEEP solenoid

S

=

SOURCE,

L

=

LOAD,

EXH

=

EXHAUST

Condition

Expiratory Phase

closed

closed

open

closed

open

closed

open

L- S

S- L

EXH- L

L-

EXH

EXH

-

L

L- EXH

Valve1

Solenoid

Pilot Solenoid

PEEP Solenoid

Plateau Solenoid

Nebulizer Solenoid

Main flow Valve

Spontaneous Flow

Valve

Plateau Solenoid

PEEP/Exhalation

Valve

Part

Number

PLV150P

PLV300P

PLV350P

PLV250P

SOL200P

VLV150P

VLV150P

VLV15OP

Condition

lnspiratory Phase

open

open

In pressure limited

open

In volume limited

closed

normal

open

closed

pressure limited:

open between

L-

S

S- L

volume limited:

EXH- L

L- EXH

S- L

L- S

Page 24

2.4

AIR

1

OXYGEN

MIXER

The air/oxygen mixer has the dual function of mixing air and oxygen to

a desired

F102 and regulating the output mixture to a preset pressure.

The pressure of the air and oxygen supply gases are lowered to 2.0

kg/cm2 (28.5 psi) by means of a diaphragm and regulator assembly.

The regulated gases are then mixed and supplied at the desired

F102.

The input pressure of the gases must be between 40 - 60 psi for the

mixer to maintain accurate

F102 and regulate the output pressure.

Figure

2.1

displays the four output ports of the mixer.

(1)

Main Flow port:

Supplies the main flow of the unit.

(2) Continuous Flow port:

Supplies bleed flow to the atmosphere. This flow is the

minimum flow required out of the mixer to maintain the

F102

within specifications.

(3)

Auxiliary Flow port:

Supplies the Spontaneous flow and Auxiliary flow to the

unit.

(4) Air Port:

Supplies gas to the pneumatic control circuit and is equal to

the input pressure of the air side.

Page 25

MIXER

ASSEMBLY

(AUXILIARY FLOW PORT)

Y

-PASS

OUTLET

FIG.

2-1

Page 26

2.5

PRINTED CIRCUIT BOARDS

The

NEWPORT

BREEZE

has three printed circuit boards which

control and display its functions:

These are:

(1) The power board (PCB

420A).

(2) The main (CPU) board (PCB 410A).

(3)

The display board (PCB 400A).

The power board is located on the back panel. It receives AC input

power from the transformer and it rectifies the AC to DC and then

regulates the DC output voltage to the battery, hourmeter and the

main (CPU) board.

The CPU board is located in the top portion of the unit and contains

the electronic circuitry that controls and monitors the operation of the

unit.

The display board is located behind the front panel and consists of

LEDs which display the various settings and alarms as determined by

the CPU board.

2.6

MANOMETER ASSEMBLY

The manometer assembly (Part No. MAN120A, Figure 2.2) consists of

the manometer and the trigger level mechanism. The manometer has

a pressure range of -1 0 to 120

cmH20. The trigger level mechanism

consists of a photocell (for sensing patient inspiratory effort) and a

gear and shaft assembly for trigger level setting. The photocell is

attached onto the trigger level indicator such that the needle passes

through the photocell and cuts it's photo beam each time the

instantaneous inspiratory pressure equals the trigger level setting.

This cutting of the photo beam is sensed by the electronic circuitry

2nd is used as a means of sensing patient effort.

Page 27

SHF001

A

FIG.

2-2

Page 28

2.7

THEORY

of

OPERATION

2.7.1 GENERAL

The theory of operation of the ventilator in the volume limited and

pressure limited modes will be discussed in this section. We shall

study the path of gas flow from the mixer to the main flow outputs. We

shall consider various conditions that affect or change the flow path.

The inspiratory time, respiratory rate,

F102 and the amount of flow will

not be considered since these do not affect the flow path. They will

only determine the quantity, quality and duration of the flow. An

understanding of the switching of the solenoids and valves is

important in tracing the flow of gas and the outputs in the

Newport

Breeze.

2.7.2 VOLUME LIMITED MODES

The flow path in the three modes

(A)

Assist Control + sigh (NC + sigh)

(B) Assist Control

(NC)

(C) Synchronized l ntermittent Mandatory Ventilation (SIMV)

is different only in the pattern in which it is delivered. The difference

between

A/C and

A/C

+

Sigh is that in A/C + Sigh the first breath has

an inspiratory time 1.5 times that of the setting and thereafter every

100th breath is equal to 1.5 times the inspiratory time setting. The

difference between

A/C and SlMV is in the timing of the delivered

breath. In SlMV the timing of the synchronized breaths is set by the

respiratory rate.

EXAMPLE:

If the respiratory rate is set at 6 BPM then the

Synchronized Timing Period

=

60 / 6 = 10 seconds. The

10

sec. is divided into a 75% and 25% window. A breath

can not be initiated during the 75% window. The

machine watches for the patient effort during the

25%

window and will deliver a breath when a patient effort is

sensed. If no patient effort is sensed the machine will

deliver a breath at the end of the

25%

window.

In the

A/C mode a breath is delivered each time an inspiratory patient

effort is sensed regardless of the respiratory rate setting, while the

SlMV breaths are delivered only at the respiratory rate setting.

Page 29

FLOW

PATHS

Figure

2.3

and Figure

2.4

show the path of flow during the inspiratory

and expiratory phase in the volume limited

A/C

mode.

INSPIRATORY PHASE

In the inspiratory phase the flow pilot solenoid receives an electrical

signal which opens the solenoid. This sends a pneumatic signal to the

master valve. The master flow valve opens allowing gas to flow

through the main flow valve tubing into the main flow adapter

assembly from where it is delivered to the breathing circuit. At the

same instant the spontaneous valve (which is normally open) receives

a pneumatic signal which shuts off the spontaneous flow.

The Plateau solenoid is off and the plateau valve is closed during

volume limited modes which allows flow between the exhaust

(EXH)

and load

(L)

ports.

The PEEP solenoid receives an electrical signal during each

inspiratory cycle. This signal opens the solenoid, supplying a

pneumatic signal to the

PEEP/Exhalation valve which opens allowing

gas flow between supply

(S)

and load

(L)

ports. The gas from the

auxiliary

flow block passes through the plateau valve into the

PEEP/Exhalation valve and then into the Expiratory drive line. This

causes a pressure build up in the Expiratory drive line. The Exhalation

valve closes resulting in gas flow to the patient.

Page 30

-

Emergency Intake

Valve

-

I

Microprocessor

I

NEWPORT

BREEZE

VENTILATOR

Pneumatic

Diagram

Volume limited mode, inspiratory phase

Fig.

2-3

Exh.: Exh.

Port

S: Supply

Port

L: Load Port

Page 31

b-

--------.-.-

-.--..-..----.--.----.--------

1

ri

=

I

w

Microprocessor

a

Y

-

L

m

1

m

1

NEWPORT

BREEZE

VENTILATOR

rn

Pneumatic Diagram

Volume limited mode, expiratory phase

(PEEP

ON)

-

Exh.: Exh.

Port

S: supply

port

Fig.

2-4

L:

Load Port

Page 32

EXPIRATORY PHASE

At the beginning of the Expiratory phase the electrical signal to the

PEEP solenoid is turned off, which closes it. The pneumatic signal to

the

PEEP/Exhalation valve is removed and the valve closes. The gas

in the peep valve now flows only between the

load(L) and

exhaust(EXH). If PEEP is set at 0 cmH20 there is no gas flow from the

PEEP regulator into the PEEP venturi assembly. The gas from the

expiratory drive line flows back into the

PEEP/exh. valve and bleeds

out of the PEEP venturi assembly.

The expiratory drive line pressure

falls to

0

cmH2O and the exhalation valve opens allowing the patient

to exhale.

If the PEEP were set above zero, then at the end of inspiration, the gas

from the PEEP regulator would flow into the PEEP venturi assembly,

and through the

PEEP/Exhalation valve to maintain the expiratory

drive line pressure. The expiratory drive line pressure depends on the

PEEP setting. The expiratory drive line pressure will close the

exhalation valve enough to maintain the PEEP pressure in the

breathing circuit. The PEEP pressure in the circuit is read on the

manometer or baseline pressure display during expiration. In normal

operation the PEEP pressure is always set below peak inspiratory

pressure. In the expiratory phase the spontaneous valve is open and a

spontaneous flow (depending on the settings), flows through the

circuit.

Page 33

2.7.3

PRESSURE LIMITED MODES

The pressure limited modes

(a) Assist Control Mechanical Ventilation with Plateau

(AK

Plateau)

(b)

Spontaneous Intermittent Mechanical Ventilation/ Plateau

(SIMV/ Plateau)

differ from one another in the same way as in the volume limited

mode. In the pressure limited modes each breath is limited in

inspiratory pressure by the peak inspiratory pressure (PIP) setting. The

PEEP/exhalation valve controls the expiratory drive line pressure

which limits the maximuminspiratory pressure. In the pressure limited

modes the path of main flow and spontaneous flow is similar to that of

the volume limited mode. Figure

2.5

and Figure

2.6

show the path of

gas flow in the inspiratory phase and expiratory phase respectively.

The operation of PEEP and PIP (Peak lnspiratory Pressure) in the

pressure limited modes is as follows:

With

PEEP

In the inspiratory phase the PEEP solenoid receives an electrical

signal thereby supplying a pneumatic signal to the

PEEP/exhalation

valve which opens allowing gas to flow between the load

(L)

and supply

(S) ports. Air flows into the plateau regulator and the regulated output

flows through the plateau venturi assembly, and this generates the

control pressure which flows into the PEEP plateau assembly. This

gas flows out of the

PEEP/Exhalation valve into the expiratory drive

line building up a pressure which depends on the plateau (PIP)

regulator setting. The main flow at this time flows into the breathing

circuit where it is confined by the exhalation valve. When the pressure

of the gas in the breathing circuit exceeds that of the expiratory drive

line pressure the exhalation valve opens up partially to bleed off the

excess gas and thereby maintains the Peak lnspiratory Pressure (PIP).

Page 34

In the expiratory phase the PEEP solenoid is closed and therefore the

PEEP/Exhalation valve is in the normally closed condition. It allows

flow through the Exhaust and Load ports. The gas from the PEEP

regulator flows into the

PEEP/Exhalation valve through its venturi

assembly. The excess gas is bled off from the venturi assembly. An

increase or decrease in the expiratory drive line pressure is obtained

by adjusting the PEEP pressure regulator. This results in a similar

change in the exhalation valve, and thus the PEEP pressure.

WITH

NO

PEEP

With PEEP off (i.e. set at zero) the opening and closing of the valves

and solenoid is similar to the case with PEEP on. Since there is no

flow out of the PEEP regulator, there is no flow into the PEEP venturi

assembly or into the

PEEP/Exhalation valve, so at end of the

inspiration cycle the gas in the expiratory drive line bleeds out of the

PEEP venturi base assembly dropping the pressure in the expiratory

drive line to

0

cmH20 and subsequently the exhalation valve opens

allowing the patient to exhale. This in turn results in a drop in pressure

in the breathing circuit and lung to zero.

Page 35

Emergency

Intake

Valve

-

'1.

m

-

m

G

Microprocessor

m

-

a

L

I

-,

.

-

NEWPORT

BREEZE

VENTILATOR

1

Pneumatic Diagram

Pressure limited mode, inspiratory phase

-

Exh.: Exh.

Port

S:

Supply

Port

L:

Load

Port

Fig.

2-5

Page 36

Emergency Intake

Valve

I

=*

I

w

-

d

m

Exh.: Exh.

Port

S:

Supply

Port

L:

Load Port

NEWPORT

BREEZE

VENTILATOR

Pneumatic

Diagram

Pressure limited mode, expiratory phase.

(PEEP

ON)

Fig.

2-6

3

1

Page 37

Figure

2.7

El50

Breeze Pneumatic Diagram

Page 38

2.7.4

SPONTANEOUS MODES

In the spontaneous modes

(A)

Volume Limited

(B)

Pressure Limited

there is continuous flow into the breathing circuit from the

spontaneous flow valve depending on setting. If PEEP is set to some

value the gas flow from the PEEP regulator flows into the venturi base

assembly, and into the PEEP valve and then into the expiratory drive

line. This flow results in a pressure build up in the expiratory drive line

resulting in PEEP.

If the

manual breath button is depressed in the spontaneous mode the

ventilator will deliver a breath whose characteristics depend on the

ventilator settings, which are displayed when the preset switch is

depressed. In the volume limited spontaneous mode the ventilator will

deliver a volume limited breath as per the machine settings. While in

the pressure limited spontaneous mode the ventilator will deliver

a

pressure limited breath as per the machine settings.

2.7.5

NEBULIZER

The nebulizer is operational when the

NEB.

switch located on the front

of the unit behind the door is turned "ON". When the switch is turned

"ON" an electrical signal is supplied to the Nebulizer solenoid, which

opens. The opening of the solenoid allows gas to flow from the main

flow and out to the nebulizer through the outlet located on the right

hand side the unit. The gas flows in the nebulizer circuit only during the

inspiratory cycle. The nebulizer flow is about

6

LPM (100 cclsec).

When the nebulizer switch is turned on the tidal volume displayed

takes into account the flow through the nebulizer and adds the

apprcpriate volume to the display tidal volume.

Page 39

SECTION

3

CALIBRATION AND OPERATIONAL VERIFICATION PROCEDURE

3.1

GENERAL

This section. describes the various test and calibration procedures.

The unit should be tested periodically to verify that operation is within

the specifications. The Operational verification should be performed at

least every month. If the BREEZE is subjected to heavy usage the

frequency of the operational verification should be increased

accordingly. All alarms (audible and visual) and the

F102 should be

checked regularly (every

24

hours) if the unit is used continuously.

NOTE: The unit should be inspected each time new usage is begun.

3.2

PREVENTATIVE MAINTENANCE

Preventive Maintenance on the ventilator should be completed after

every 3000 hours of operation (or earlier if required), or a minimum of

once each year. The Preventive Maintenance is intended to be done

in the hospital.

The preventive maintenance includes:

*

Visual inspection of external surfaces, controls,

attachments and accessories.

*

Replacing the Air and O2 mixer inlet filters (part no.

MFK11 OA).

Cleaning the air inlet Water Trap (WTR300P) and replacing

the jar filter

(JFK100P).

*

Removing top cover and visually inspecting the interior, all

tubing, wires and wiring connectors,

screws,nuts and

hardware, checking the general condition of the

components.

*

Performing operational verification on the unit and

recalibration of the unit if required.

CAUTION

:

Do not use strong solutions for cleaning the unit. Use

only alcohol or a mild soap solution.

Page 40

Overhaul

The ventilator should be overhauled every 3 years or after 15000 hours

of operation or more often if required. The overhaul

s.hould be

performed by a

Newport Medical service technician at the factory

service center.

Iri addition to the items performed during Preventive

Maintenance, an overhaul will include the overhaul of the

Air/02 mixer

and replacement of moving parts if required. Contact NMI customer

service for further information on the above service.

3.3

OPERATIONAL VERFCATlON

AND

CALIBRATION PROCEDURES

This procedure is included to assist the Qualified Operator or Hospital

Service Technician in establishing a routine verification procedure to

verify that the

BREEZE

ventilator is in operating condition. The

procedure is explained and is intended to help test the unit after

repair/replacement of parts on the unit.

CAUTION: Before using any test equipment for calibration, verify

that the accuracy of the instrument is certified by a

testing laboratory whose master test instruments are

traceable to The National

Institute of Standards and

Technology or equivalent.

Preliminary Adjustments:

The Preliminary adjustments are done at the factory and need not

be

adjusted unless the parts that directly affect them are replaced.

Connect Air and

O2

sources to their respective inlets at the rear of the unit.

1.

Input Voltage:

Adjust the power input on the power entry module

on the back of the unit to desired input voltage.

For

U.S.A.:

120 vac., 1A

Page 41

2. a). Pull out the tubing at the output of the pressure regulator for

PEEPIPlateau supply.

b). Hook a standard pressure gauge to it.

c). Adjust the regulator output to read 25 psi.

d).

Reattach tubing.

3.

Transducer adjustments:

a. R14 (Reference voltage)

1. Measure the voltage across VREF TP3 and Pin

7

of I.C. U20

on the CPU PC board (PCB41

OA).

2. Adjust trim pot R14 to adjust the voltage read to 5 volts.

b. R22 (Transducer offset)

1.

Fix a jumper on

JP1 on CPU PC board.

2.

Turn the mode selector switch to spontaneous mode.

3.

Adjust the pot R22 (offset) to get a pressure display

readout of

0

cmH20. (The left digit display of the

pressure display helps adjust the precise zero value.

When the adjusted value is towards the positive side the

top segment of the left display shall light up and the

bottom segment shall light up when the adjusted zero

value is towards the negative end. The pot R22 should

be adjusted so that the display toggles between the two

segments indicating the most precise zero value.)

c. R27 (Transducer gain)

1.

Pull out the tubing that feeds the manometer and the

pressure transducer at the tee.

1-

Pull Out

I/

-

-1

1-

to manometer <--------I tee1

OOD

I-------- > to Transducer

Page 42

2.

Fix a syringe (150cc) at the tee.

3.

With the

help of the Syringe build a pressure of 60

cmH20 in the assembly so that the manometer reads 60

cmH20.

4.

Adjust pot RZ7 so that display reads 60 cmH20.

NOTE: REPEAT

steps (b) and (c) after each time the pots

are adjusted.

5.

REMOVE JUMPER

on JP1 on CPU board.

6.

RECONNECT TUBING.

d. R4 (Battery charging voltage)

CAUTION: Caution must be taken to avoid a short between the

battery terminals.

1.

Remove the positive

terminal to input of the battery.

2.

Hold a voltmeter across the terminal and fuse mounting

contact of fuse fl of the power supply board

(PCB420A).

3.

Connect a load resistor(

e.g. 1.5K ohm, 112 watt)

between the positive input

terminal of the battery and

the voltmeter probe.

4.

Adjust R4 (BATT CHARGE) on the power PC board on

the back

panel so that the charging voltage read by

voltmeter is 13.8 volts.

5.

Reconnect the wire onto the battery.

OPERATIONAL VERIFICATION AND CALIBRATION PROCEDURE

Set up the unit with the standard breathing circuit as shown in

fig

3-1.

Connect the input Air and

O2

supply lines at the input to the ventilator

located at the rear of

thb unit. Adjust the input pressures of the input

gases to 50 psi.

Page 43

CONNECT TO MAIN FLOW OUTLET

FOR CALIBRATION OF:

1.

SPONTANEOUS FLOW

2.

MAIN FLOW

3.

RESPIRATORY RATE

4.

INSPIRATOR TIME

5.

A/C SIGH

EXP. OUTLET

Y

EXHALATION VALVE

-

RESERVOIR

1

LITER TEST LUNG

SPASSOA

BAG

Figure

3.1:

BREEZE

TEST

SET-UP

Page 44

NOTE:

For several of the operational verification tests we have used the

calibration analyzer series RT-200 manufactured by Timemeter

Instrument Corporation. However any flow measuring instrument

capable of reading flows up to 120 LPM may be used.

Gas

Input Pressure Alarm Test:

1.

Adjust the pressure of input air source to 50 psi.

2.

Reduce the pressure of the input

02

source slowly and note

the pressure at which the low input pressure alarm sounds.

Verify that the alarm sounds when the pressure of the

source is 31

+

3 psi.

3.

Adjust the pressure on the

O2 side to 50 psi.

4.

Reduce the pressure on the Air source side slowly and verify

that the alarm sounds when the pressure drops to around 31

+

3 psi. If the low gas input pressure alarm fails to sound,

-

check that the alarm hole located and marked mixer

audible alarm on the rear of the panel is not occluded. The

alarm may not sound if contaminated with moisture from

the input sources. Unscrew the alarm by turning counterclockwise and dry by blowing out the air gently or leaving it

open until dry. Do not handle the reed in the alarm. It is

easily damaged by handling.

TEST

1

CALIBRATION PROCEDURE

Adjust the front panel controls to the following standard settings.

Return to the standard settings after each test unless otherwise

stated.

Power

IMcrde

Fi02

Flow

I .T.

Resp. Rate

Peak Insp. Press (PIP)

:

Apnea time

Nebulizer

Trigger Level

ON

AIC

.60

20

LPM

1.0 Sec

20

BPMPEEP:O cmH20

OFF (Fully counter-clockwise)

LOW

CPAP ALARM

OFF

-10

cmH20

Page 45

Turn OFF unit and turn ON again. Verify that the LED'S light up and

the alarm sounds momentarily before the unit resumes cycling as

per the settings.

2. ALARM LOUDNESS

A. Disconnect breathing circuit at the main flow outlet. Verify that

the

low pressure alarm sounds.

B.

Rotate the alarm loudness knob and verify that the alarm

volume increases or decreases as the knob is turned.

3.

FLOW

A.

S~ontaneous Flow

1.

Connect main flow outlet of the unit to RT-200 with a 24" large

bore tube.

2. Set the RT-200 to read flows.

3.

Set ventilator to spontaneous mode.

4.

Attach a reservoir bag (or plug) at the reservoir outlet.

5.

Adjust spontaneous flow to various settings and verify that flow

is within

+

2 LPM of the displayed value.

Calibration method for spontaneous flow

1.

Disengage potentiometer on spontaneous flow assembly on

the back of the front panel. This is done by loosening the screw

on the gear on the

potentiometer.(use

1.5

mm allen wrench)

2. Adjust display to read the same as the actual flow read by the

RT-200, by turning the shaft of the pot.

3.

Tighten the screw on the gear of the pot to re-engage it

electrically to the spontaneuous flow assembly.

4.

Verify calibration. (Tolerance range

+

3

LPM).

Page 46

B. Main Flow

1.

Adjust the front panel controls as follows:

Mode

A/C

R.R.

,

10 BPM

I .T. 3.0

Sec.

Spontaneous flow OFF

2. Remove the reservoir bag (or plug) so that the reservoir outlet is

open to atmosphere.

3. Attach RT-200 to the main flow outlet of the unit using a 24"

adult breathing circuit tube.

4. Adjust RT-200 to read flows.

5. Set the flow on unit and verify that the flow read by the RT-200

is within the tolerance range.

6.

Repeat step (5) for several settings.

NOTE:

Refer to Test Record sheet for settings and their tolerance ranges.

Calibration Method for Main flow

Use the potentiometer R54 on the CPU PC board

(PCB410A) to

make adjustments in the flow. If the flow cannot be calibrated with

R54, then use the flow potentiometer on the flow control assembly

and adjust as explained in the following steps.

1.

Set R54 in mid-range so that it could be used for fine flow

adjustments during calibration.

2. Loosen the set screw on the potentiometer mounted on the

assembly so as to disengage it electrically from the main flow

assembly.

3.

Adjust the display to read the same as the actual flow read by

the RT-200, by turning the shaft of the potentiometer manually.

Page 47

4.

Tighten the set screw on the gear of the potentiometer to re-

engage the potentiometer electrically to the flow assembly.

5. Verify calibration. Repeat if necessary.

TOLERANCE RANGE

TOLERANCE

+

3

LPM

-

+

4

LPM

-

+

5

LPM

-

4.

RESPIRATORY RATE

1. Adjust lnspiratory Time to 0.2

sec.

2. Set Respiratory Rate to 1 BPM.

3.

With a stop-watch verify that the unit cycles at the

rate of 1 BPM.

4.

Connect RT-200 to the main flow of unit with 24" adult

breathing tube.

5. Adjust

FIT-200 to read Respiratory Rate.

6.

Set the Respiratory Rate on the unit to 50 BPM.

7.

Verify that the RT-200 readout indicates 50

+I.

8.

Repeat steps

(6)

and

(7)

for Respiratory Rate settings of 100 and

150 BPM.

5.

INSPIRATORY TIME

1. Connect RT-200 to the main flow of unit.

2. Adjust RT-200 to read lnspiratory Time.

3.

Set Respiratory Rate to 10 BPM.

4.

Set lnspiratory Time control to 0.1 sec.

5. Verify that lnspiratory Time read by RT-200 indicates 0.1 to 0.2 sec.

Page 48

6.

Verify lnspiratory Time for setting of 1.0 sec, 2.0 sec, and 3.0

sec. (tolerance range +.I).

NOTE: For tolerance range refer to Test Record sheet.

6.

A/C SIGH

1.

Connect RT-200 to main flow of unit.

2. Adjust RT-200 to read lnspiratory Time.

3. Set lnspiratory Time to 2.0

sec

.

4.

Note the lnspiratory Time readout on the RT-200.

NOTE: The unit gives an

AIC

Sigh in its first breath after switching

into this mode and thereafter every

100th breath is an

A/C

Sigh. Othe~lise in this mode the unit functions the same as

in

AIC

mode.

5.

Switch the mode control to A/C Sigh.

6.

Note the lnspiratory Time readout of the RT-200 in the first

breath.

7.

Note the lnspiratory Time in its regular breaths.

8.

Verify that the lnspiratory Time is 1.5 times longer in the A/C

Sigh breath than the set value of I.T.

9.

Note also that the Tidal Volume display flashes and displays a

larger (1.5 times) Tidal Volume in the breath that delivers an

A/C Sigh breath.

10. Allow the unit to cycle and verify that every 100th breaths is an

'

A/C Sigh breath.

7.

NEBULIZER

1.

Depress nebulizer switch.

2.

Connect a standard pressure gauge at the nebulizer outlet.

Range:

0 - 50 psi

Page 49

3.

Verify that during each inspiration phase the pressure gauge

indicates pressure between 16 psi to 30 psi during the full

inspiration.

4.

Check nebulizer pressure over the entire flow range and verify

that it is between 16 PSI and 30 PSI.

NOTE: With the nebulizer switch ON the tidal volume displayed is

equal to the actual tidal volume (tidal volume

=

flow x I.T.)

plus

6

LPM. The additional 6 LPM accounts for the gas flow

through the nebulizer circuit.

8.

PEEP

1. Turn mode switch to spontaneuous.

2.

Attach a reservoir bag to (or plug) the reservoir outlet.

3.

Turn spontaneous flow to 10 LPM.

4.

Turn PEEP control clockwise until PEEP holds at around 60

cmH20.

5.

If unable to obtain 60 cmH20 then use the following steps.

Setting of PEEP:

1.

To limit the PEEP to 60 cmH20 first adjust the PEEP to read 60

cmH20.

2.

Using a

COLLET

wrench loosen the knob on PEEP control. (A

collet wrench may be acquired from Newport Medical

Instruments.).

3.

Push knob on face of panel and retighten knob.

Page 50

9.

PEAK INSPIRATORY PRESSURE [PIP)

1. Turn mode control to SlMV or

A/C

plateau mode.

2. Attach a standard 750

C.C.

test lung to breathing circuit.

3.

Set Respiratory Rate control to 10 BPM and lnspiratory Time to

3.0

sec.

4.

Turn the PIP to control knob clockwise till the pressure plateau

of 60

cmH20 is reached.

5. If unable to obtain 60 cmH20 then use the following steps.

Setting the

PIP:

1. Set the flow on the unit to 20 LPM.

2.

Loosen the knob on the control and set the PIP on

the unit to

60

cmH20.

3.

Allow the unit to cycle and verify that the PIP is 60cm.H20.

4.

Push knob on face of panel and retighten knob.

10. LEAKAGE TEST

1.

Attach a 50

C.C.

infant test lung on breathing

circuit.

2. Turn PEEP control to maximum.

3.

Set mode control to spontaneous mode.

4.

Depress manual switch and observe peak pressure

on manometer. Obtain a pressure of 50

-

70 cmH20.

CAUTION :Do not depress manual switch for more than

0.2

sec. to

avoid damage to the manometer. Repeat if required.

Page 51

5. If the peak pressure drops more than 5 cmH20 in 1 minute,

check the entire circuit for leakage.

NOTE:

There will be an initial pressure drop due to compliance of

the circuit and expiratory pressure conditions at the

exhalation valve. This drop will be fairly rapid after which

the pressure should hold steady. The actual leakage

would

be

slower and the pressure would drop down finally

to

0

cmH

20.

11. TIDAL VOLUME

Verify that the Tidal Volume displayed by the unit for the

following settings of flow and

lnspiratory Time.

Flow(LPM)

I .T.(sec) calculated value

30

1

.O

0.5

20

2.0 0.67

40

3.0 2.0

12. TOTAL RATE

1. Set the Resp. Rate to 10 BPM.

2. Verify that unit displays Total Rate of 10 BPM. after 1 minute.

3. Initiate spontaneous breaths which are detected by the trigger

level (Effort LED glows when breath is sensed

i.e. when

manometer needle passes through trigger level setting).

4.

Verify that the total rate displayed is the total of the machine

breaths delivered by the machine and the mechanical

(spontaneous) breaths detected by the trigger level.

5. Set Resp. Rate to 150 BPM.

6. Verify that the unit displays Total Rate of 150 BPM after 1

minute.

Page 52

13. 1:E RATIO

Verify the

1:E ratio displayed for the following settings of BPM

and lnspiratory Time.

BPM

'

I .T.(Sec.) Calculated Value

of

1:E Ratio

NOTE: The El50 has an I:E ratio ranging from 4:1 to 1:99. The

display will flash when the

I:E ratio exceeds 199.

14. MANUAL BREATH

1.

Turn Resp. Rate to 10 BPM.

2.

Depress the manual breath switch and verify that a breath is

delivered each time the manual switch is depressed.

NOTE: The duration of the manual breath is limited to period for

which the switch is depressed. The maximum duration of

the breath is limited to 2.0

secs.

15. ALARM SILENCE

1. Pull out the breathing tube at the main flow outlet. The low

pressure alarm will sound.

2.

Depress the alarm silence switch.

3.

Verify that the alarm is silenced for one minute.

4. Depress the Silence switch. The Silence display should turn on.

16. EXPIRATION

TIMWLED

1.

Turn the mode selector to SlMV plateau.

2.

Verify that the Expiratory Time LED lights up and the display

now displays Expiratory Time instead of tidal volume.

Page 53

EXAMPLE: SElTING READING

I .T.

R.R. Expiratory Time

3.00 SEC

10 BPM 3.00

NOTE: The expiratory time displayed depends on the inspiratory

time and BPM settings.

17. APNEA TIM€

1. Turn mode switch to Spontaneous mode.

2.

Turn apnea time selector switch to 10 sec.

3.

Move the trigger level through the manometer needle.

4.

Verify that the Apnea Alarm sounds and its indicator light

comes

ON

after 10 seconds.

5.

Repeat the above steps to verify that the alarm operates for all

apnea time settings.

18. PRESET

1. Turn the mode selector switch to Spontaneous mode.

2.

Notice that all the displays do not light up.

3. Press PRESET button and verify that all the displays light up

and indicate their respective control settings.

19. PRESSURE (Peak. Mean

&

Basel

NOTE: Normally the pressure displayed is Mean Pressure. The

Base or Peak value of the pressure will be displayed for a

period of

30

seconds when the Base or Peak switch is

depressed. The

30

second time will start from the time the

switch is depressed. If the Base value is being displayed

and the Peak switch is depressed before the

30

second

time has elapsed then the machine shall reset and will now

display the Peak value. The time shall be calculated from

the last time the switch is depressed and will display the

value for which the switch was depressed.

Page 54

The preset switch should be pressed to return to the Mean value

anytime the Mean value of presssure is to displayed. Otherwise the

machine will return to the Mean value after the 30 second time has

elapsed.

1.

Press Peak Pressure button located near the pressure display.

Verify that the displayed value is the peak pressure (by

comparing to manometer) and that it is displayed for 30

seconds before the display returns to the Mean value.

2.

Press switch for Base Pressure and verify that the pressure

displayed is the Base Pressure (by comparing to the

manometer) and that it is displayed for a period of 30 seconds

before it returns to the Mean value.

3. Depress the Base and Peak switches one after the other in

sequence and verify that the display changes to the value of

the last switch depressed even before the 30 second time has

elapsed.

20. MODE SELECTOR

Rotate the switch through all the modes and verify the unit's

operation in the various modes.

21. TRIGGER LEVEL

1.

Turn the mode selector switch to Spontaneous mode or SIMV.

2.

Shift the trigger level manually so as to pass through the

manometer needle.

3.

Verify that the effort LED is lit up momentarily each time the

needle passes through the trigger indicator.

4.

Turn the mode selector switch to A/C mode.

5.

Adjust Respiratory Rate to 1 BPM.

6.

Repeat Step 2 and verify that the machine gives a breath each

time the needle passes through the trigger sensor.

Page 55

NOTE:

After the end of each breath there is a trigger lockout time

for which the machine will not sense any trigger effort. This

lockout time is equal to

1/4th of the inspiratory time setting

or a maximum of

400

msec.

22.

LOW PRESSURE ALARM

1.

Pull out the breathing tube at the main flow outlet.

2.

Verify that the low pressure alarm sounds and the visual

indicator lights up.

3.

Press the Silence switch and verify that the alarm is silenced

for

a

period of 1 minute.

23.

HIGH PRESSURE ALARM

1.

Adjust the high pressure alarm to

60

cm.H20.

2.

Increase the flow and allow the unit to cycle.

3.

Verify that the high pressure alarm comes on when the high

pressure setting is reached and the breath is cut off.

4.

Verify also that the visual indicator lights up.

24.

EXTERNAL POWER OFF/POWER DISCONNECT ALARM

1.

Pull out the input power cord on the rear of the unit.

2.

Verify that the unit switches over to battery power and BAlT

PWR indicator lights up. Also verify that the Battery power

alarm sounds momentarily and repeats every five minutes.

3.

Connect power cord and verify that the alarms disappear.

Page 56

BAlTERY POWER

1.

Run the unit on battery power until the low battery alarm

sounds and its indicator lights up. Verify that the battery

powers the unit for a minimum of

1

hour before the alarm

comes on.

2.

Recharge the battery. The battery should charge fully in a

minimum of

18

Hours.

26.

LOW BAlTERY ALARM

1.

Disconnect electric power to the unit.

2.

Connect the battery terminals to an already discharged battery

(or a low voltage battery).

3.

Verify that the low battery alarm display lights up and that the

audible alarm sounds.

NOTE: The above test can be done along with the battery power

test

VEST no.

25).

27.

SYSTEM FAILURE ALARM

The system failure alarm will sound when there is a malfunction in

the electronics. The system failure alarm may be tested by

shorting capacitor C4. When capacitor C4 is shorted a continuous

alarm will sound, after approximately

3

seconds the unit should

reset to the cycle mode in which it is in.

28.

NURSE'S CALUREMOTE

NOTE: To use this feature the output from unit is connected to the

hospitals Nurse's call circuit. Pin Nos.

4

& 9 on the terminal

marked

RS232,ALARM

located on the back of the unit

functions like a contact which is normally open, and is

closed during an alarm condition. This feature can be used

for remote monitoring of the alarms.

Page 57

1. Connect a multimeter across the Pins

4

&

9 of the terminal

marked RS 232 to check continuity.

2. Verify that with normal operation of unit and (no alarm

conditions exist) the pins show discontinuity (open contact).

3.

Create an alarm condition.Verify that in an alarm condition the

pins show continuity (close contact).

29. PROXIMAL

1.

Pinch the proximal tubing connected to the proximal inlet.

2. Verify that the pressure in the proximal circuit rises and the

manometer reads

a

pressure of 30 - 60 cm.H20.

3.

If the pressure is not within the specified range, clean out or

replace restrictors

RES206 and RES122 in the proximal circuit.

(Refer to figure 2.7, pneumatic diagram)

1. Connect

a

standard Oxygen Analyzer at the main flow side of

the unit.

2. Remove reservoir bag and plug the outlet for the reservoir bag.

3. Set the unit to spontaneous mode.

4.

Adjust the spontaneous flow to

10

LPM.

5.

Set the F102 at .21 and note F102 read by the analyzer.

6. Repeat step

5

for F102 settings of

.3,

.6, .9,and 1

.O.

7.

Verify that the F102 read is within tolerance range.

Page 58

TOLERANCE RANGE

.2 1 20.9 - 24.0

.30 26.5

-

33.4

.60

56.5 - 63.4

.90 86.5

-

93.4

1

.O

96.5 - ABOVE

CALIBRATION

of FIO:,

-

NOTE:

Use a certified

02

analyzer for F102.

1. To calibrate F102, Set the spontaneous flow to maximum.

(approximately 45 Ipm)

2.

Adjust pot R55 on CPU

PC

board so that the displayed value is

equal to the actual

F102 read.

3.

Turn the F102 knob through its full range to verify that the

display indicates full range.

4. If the display does not go through its full range adjust pot R55

to its mid position.

5. Loosen the set screw and disengage the gear on the

F102 pot

mounted on the mixer.

6. Adjust the pot until the display reads the same as the actual

F102 reading.

7.

Re-engage the gear with the mixer gear and tighten the set

screw.

8.

Verify that the display and actual F102 are the same. (If not

adjust pot R55 on the CPU board or repeat steps 5 to

7

until

there is no difference.)

9.

Turn the spontaneous flow to 10 Ipm and verify the actual F102

and the display read the same at several settings through the

entire range.

31. HOURMETER

Record the hours indicated by the hourmeter at the end of the test.

Page 59

BASE PLATE ASSEMBLY

(TOP

VIEW)

MlX155A BKT190M BAT150P HSGISOA

A

SCR2OOP x2

(0'

(FRW

BOTTOM)

J

BPRISOP X

4

SCRZOOP x2

(FROM BOTTOM)

SCR4WP x2

TOP COMR MOUNTING

SCREW SCR250P X

4

RESERVOIR ADAPTER

ADP402M (TO HSGI5OA)

SCR232P

X

3

cm

mrmo

(FROM BOTTOM)

ADP050M LOCATION

SCR032P X

2

CFROM BOTTOW

-

BKT175M

TOP COVER SCREWS

SCR250P 2 PLCS

ul

P

EXP ClllT335M

MAIN FLOW ADAPTER

ADP402M (TO ADP700A)

SCREEEP x2

CON200P

-

CFROW

TOP>

BEZEL

MOUNTING SCREWS

SCREOOP

x4

cm

mrrm

FIG.

4-1

Page 60

El

50

FRONT

VIEW

WWrA

In

PRESS

HI

P(M

U)

BIn

Ull

M

(cmHZO) (cmH2O)

SPONT. FLOW

0

EXP.TIME(sec.)

TRIGGER LEVEL

TOTAL RATE

u1

0

EFFORT

U1

MODE SET F102 FLOW INSP TIME SET RATE

3

VOWYE

PRmUlE

CMlTROC

mwml

PIP)

(IP~)

b-4

(bpm)

PRESET

1

J

A

0

PUSH

MANUAL

SCR2OOP x 2

-/

lSCR2OOP r 2

FIG.

4-2

Page 61

FRONT PANEL PNL150A ASSEMBLY DIAGRAM

HI/LO PRESSURE CONTROLS

(REFER TO FIG 22)

(REFER TO FIG. 4-6)

PCB400A (DISPLAY BRD.)

SPONT. FLOW CONTROL FCL300A

(REFER TO FIG 4-7)

NUTB32P X 2

UI

0,

r

MODE SWITCH SWR410P

(REFER TO FIG 4-71

PIP CONTROLLER

(REFER TO FIG. 4-9) (REFER TO FIG

4-8)

PEEP CONTROLLER NDLISOA

FLOW CONTROL FCL250A

(REFER TO FIG. 4-9)

(REFER TO FIG

4-6)

INSP. TIME CONTROL

(REFER TO FIG

4-8)

RESP. RATE CONTROL

(REFER TO FIG.

4-8)

FIG.

4-3

Page 62

INSIDE

VIEW

OF

BACK-

PANEL

HOUR METER

ALARM BUZZER

TRANSFORMER

POWER SUPPLY

BOARD

RELIEF VALVE

MlT440P

x

2

SCR666P

X

2

POWER ENTRY MODULE

GROUND WIRE

TO BASEPLATE

NUT440P

x

2

GROUND SYMBOL STICKER

.

NUT832P SCRBOOP

HOK150M

AC

MODULE

HOOK

ASSEMBLY

FIG.

4-4

1

I

I

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Page 63

BACK PANEL ASSEMBLY-PNL175A (BACK

VIEW)

CVRILOP 3 PLCS

SCREW COVERS

6

PLCS

MONITOR RS-232/ALARM

SCRB3EP

X

4

TRNISOP REGISOP

m

--

a3

SCR666P

x

2

CAUTION1

RISK

ff

ELECTRICK

SHOCK.

DO

MT

REMOVE PANEL.

REFER SERYlClffi TO

DWlFlED SERVICE PERSOWEL.

CAUTIW

USA FEKIUL

LAY

KSTPICTS THIS DEVICE TO

SALE

N

OR ON THE

CUER

A

PHYSICIAN.

FIG.

4-5

Page 64

FLOW CONTROLLER FCL250A AND HI/LO PRESSURE CONTROL ASSEMBLIES

RVP410M

rn

-

-

-

FTG300M

(WITH

ORGlSOP)

REFER TO

#I

PRIMARY

GEAR

OPACKET

ClOUNTlNG

HI/LO

PRESS.

CONTROL

(2

PLCS)

CVRISDP

NUTISOM

FRONT PANEL

U1

(D

/-

FLOW CONTROLLER

SCR444P X 3

FIG.

4-6

-

-

Page 65

SPONT. FLOW FCL300A AND MODE SWITCH SWR410P ASSEMBLY DIAGRAM

-

PLG1ooP

-,

FRONT PANEL ELB400P

-

SPONT. FLOW CONTROL

cn

0

SCR444P

X

3

MODE SWITCH

POT

BRACKET

LOCATING

PIN

PRIMARY GEAR

BRACKET MOUNTING

SCREWS

(2)

POTENTIOMETER ASSEMBLY

TO

FLOW CONTROLLER FCLEOOP.

FIG.

4-7

Page 66

I.T,/R,R. POTENTIOMETER (RVP410P) ASSEMBLY AND MIXER SHAFT ASSEMBLY.

MIXER SHAFT ASSEMBLY

MIXER SHAFT

NUT440P

x

2

SCROOlP

x

2

2

FRONT PANEL PANEL STUD

SPC250P X

2

I.T.

AND

R.R.

POT.

ASSY

SCROOlP

X

2

-

WSH700P

X

2

SET1003P

x

2

FIG.

4-8

Page 67

PEEP/PIP

ASSEMBLY

REG310A

ELB400P

X

2

PLGlOOP

X

2

FRONT PANEL

FIG.

4-9

Page 68

PNEUMATIC BRACKET ASSEMBLY BKT180A

ELB400P

2

PLCS

REGULATOR REG300P

(V/NUTlSOP)

PEEP/PIP VALVES

BRACKET

WITH

2

PLUG PLGlOOP 2 PLCS

INPUT PORTS

(W/2 X SCR666P)

ACTUATOR PLVBOOA

X

SCR666P)

CW/2 X SCR666P)

1

ARE SUPPORTED TO

SCREWS

SCR888P.

PNEUMATIC BRACKET BKTl8OM

1

I

FIG.

4-1

0

Page 69

WARRANTY

Newport Medical Instruments, Inc. (NMI) warrants this product to meet the published

specifications and to be free from defects in material and workmanship under normal use

for a period of one

(1)

year from date of purchase. The foregoing is in lieu of any other

warranty, expressed, implied or statutory, including without limitation any warranty or

machinability, warranty of fitness for any particular purpose,

or

warranty of any kind as to

design. The sole liability of NMI under this warranty is limited to replacing, repairing or

issuing credit at the discretion of NMI for the products, equipment or parts which fail to

meet the published specifications or which become defective during warranty period and

which are, upon examination

by NMI, found not to meet the published specifications or to

be defective in materials or workmanship. NMI will not

be

liable under this warranty unless

the following provisions are strictly complied with. (a) NMI is promptly notified, in writing,

upon. discovery of the failure of the said product or equipment to meet the published

specifications or of the defects in materials

or

workmanship.

@)

The defective product,

equipment or part thereof is returned to NMI, transportation charges prepaid by the buyer..

(c) The defective part is received by NMI for examination no later than one

(1)

month

following the expiration of the warranty period and provided

(d)

that examination by NMI of

said product, equipment or part shall disclose to

NMl's satisfaction that such defect has not

been caused by improper usage, accident, neglect, alteration, abuse, improper installation

or unauthorized repair. Products, equipment or parts replaced under this warranty are

warranted only through the terms of the original warranty. NMI neither assumes nor

authorizes any other person or entity to assume for it any other warranty, obligation or

liability in connection with its products or equipment whatsoever, and as to the fitness or

usefulness of the equipment manufactured by it for any medical treatment, physical

condition or other purpose whatsoever. In no event shall NMI be liable for personal injury,

property damage or any special or consequential damage to the buyer, user or any other

person whomsoever, including, but not limited to, loss of profits, loss of use of the product or

equipment, or for damages of any kind whatsoever based on a claim for breach of warranty

other than a refund of the purchase price of any defective product or equipment.

Any

authorization for repair or alteration by buyer must be in writing from NMI to prevent the

voiding of this warranty. In the event NMI or its representatives render any technical advice

or service of any kind to buyer or anyone else in connection with the equipment or products

covered by this warranty, the buyer hereby releases NMI from all liability of any kind

whatsoever as a result thereof; and the warranty as here in before set fourth shall not

be

enlarged

or

affected by said action by NMI.

Loading...

Loading...