Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Model 2835-C

Multi-Function Optical Meter

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Model 2835-C

Multi-Function Optical Meter

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Warranty

Newport Corporation warrants this product to be free from defects in material and

workmanship for a period of 1 year from the date of shipment. If found to be

defective during the warranty period, the product will either be repaired or

replaced at Newport’s option.

To exercise this warranty, write or call your local Newport representative, or

contact Newport headquarters in Irvine, California. You will be given prompt

assistance and return instructions. Send the instrument, transportation prepaid,

to the indicated service facility. Repairs will be made and the instrument returned, transportation prepaid. Repaired products are warranted for the balance

of the original warranty period, or at least 90 days.

Limitation of Warranty

This warranty does not apply to defects resulting from modification or misuse

of any product or part. This warranty also does not apply to fuses, batteries,

or damage from battery leakage.

This warranty is in lieu of all other warranties, expressed or implied, including

any implied warranty of merchantability or fitness for a particular use.

Newport Corporation shall not be liable for any indirect, special, or consequential damages.

Statement of Calibration

This instrument has been inspected and tested in accordance with specifications published by Newport Corporation.

The accuracy and calibration of this instrument and photodetector (where

applicable) is traceable to the National Institute for Standards and Technology through equipment which is calibrated at planned intervals by comparison to the certified standards maintained at Newport Corporation.

Copyright 1994, Newport Corporation

Part No. 20303-01, Rev. D

IN-11932 (06-00)

ii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii

Page 5

EC DECLARATION OF CONFORMITY

Model 2835-C

We declare that the accompanying product, identified with the

" " mark, meets the intent of the Electromagnetic Compatibility

Directive, 89/336/EEC and Low Voltage Directive 73/23/EEC.

Compliance was demonstrated to the following specifications:

EN50081-1 EMISSIONS:

Radiated and conducted emissions per EN55011, Group 1,

Class A

EN50082-1 IMMUNITY:

Electrostatic Discharge per IEC 1000-4-2, severity level 3

Radiated Emission Immunity per IEC 1000-4-3, severity level 2

Fast Burst Transients per IEC 1000-4-4, severity level 3

Surge Immunity per IEC 1000 4-5, severity level 3

IEC SAFETY:

Safety requirements for electrical equipment specified in

IEC 1010-1.

Alain Danielo Jeff Cannon

VP European Operations General Manager-Precision Systems

Zone Industrielle 1791 Deere Avenue

45340 Beaune-la-Rolande, France Irvine, CA USA

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iii

Page 6

Table of Contents

Warranty ................................................................................................................. ii

EC Declaration of Conformity ............................................................................... iii

List of Figures ........................................................................................................ vii

List of Tables ........................................................................................................ viii

Safety Symbols and Terms .................................................................................... ix

Definitions ............................................................................................................... x

Specifications ......................................................................................................... xi

Detector Signals and Calculations ...................................................................... xiv

Section 1 - General Information

1.1 System Overview ...................................................................................... 1

1.2 Scope of this manual ................................................................................ 2

1.3 Unpacking and Inspection ........................................................................ 2

1.4 Preparation for Use .................................................................................. 3

1.5 Optional Accessories and Services ......................................................... 3

Section 2 - System Operation

2.1 Introduction .............................................................................................. 4

2.2 Display ....................................................................................................... 4

2.3 Top Level Key Functions .......................................................................... 5

2.3.1

2.3.2 SHIFT .............................................................................................. 7

2.3.3 DISP , Display Brightness ........................................................... 7

2.3.4 FILTER, Signal Filtering ................................................................. 7

2.3.5 ZERO, Offset Subtraction ............................................................. 8

2.3.6 AUTO, Automatic Gain Ranging ................................................... 8

2.3.7 STO REF, Store Reference Value .................................................. 8

2.3.8 CH A (B), Display Channel A (or B) ............................................. 8

2.3.9 REF SEL, Reference Select ............................................................ 9

2.3.10 λ, Wavelength................................................................................ 9

2.3.11 RANGE, Signal Range .................................................................... 9

2.3.12 R/S, Run-Stop ............................................................................... 10

2.3.13 MODE, Measurement Mode ....................................................... 10

2.3.14 UNITS, Display Units ................................................................... 11

2.3.15 STATS, Moving Statistics ........................................................... 12

2.3.16 R/S A (B), Run-Stop Channel A (or B) ........................................ 12

2.3.17 EXT, External Trigger ................................................................. 13

2.3.18 MENU ........................................................................................... 13

2.3.19 ENTER .......................................................................................... 13

2.3.20 ESC, Escape ................................................................................. 13

2.3.21 , , , Adjust.................................................................... 14

OI

, Power .................................................................................... 7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

Page 7

2.4 Menu Level Functions ............................................................................ 14

2.4.1 Menu Access and Movement ..................................................... 14

2.4.2 Data Store .................................................................................... 16

2.4.3 Meter Configuration ................................................................... 17

2.4.4 Auto Cal ....................................................................................... 18

2.4.5 Attenuator ................................................................................... 19

2.4.6 User Calibration .......................................................................... 19

2.4.7 DC Sampling ................................................................................ 20

2.4.8 Trigger Output ............................................................................ 20

2.4.9 Trigger Input ............................................................................... 21

2.4.10 Bar Graph .................................................................................... 22

2.4.11 Tone ............................................................................................. 22

2.4.12 Detector Switch Position ............................................................ 22

2.4.13 Remote Setup .............................................................................. 22

2.4.14 General Information Functions .................................................. 23

2.5 Connecting AC Power .................................................................................... 23

2.6 Detector Connection and Setup .................................................................... 24

2.7 Power Up ........................................................................................................ 25

2.8 Performing Basic Measurements .................................................................. 25

2.8.1 Making DC Power Measurements .............................................. 25

2.8.2 Making Peak-to-Peak Power Measurements ............................. 25

2.8.3 Making Pulse Energy Measurements ........................................ 26

2.8.4 Making a Signal Integration Measurement ................................ 26

2.8.5 Measuring a Laser Pulse Energy with a Thermopile Detector .. 26

2.8.6 Using the Model 2835-C as an Exposure Controller ................. 27

Section 3 - Principles of Operation

3.1 Introduction ............................................................................................ 29

3.2 Analog Signal Flow .................................................................................. 29

3.3 Digitized Signal Flow ............................................................................... 30

3.4 Typical Detector Signals......................................................................... 31

3.5 Thermopile Detector Signals ................................................................. 32

3.6 Pulse Energy Detector Signals ............................................................... 32

3.7 Peak-to-Peak (Photodiode) Detector Signals ........................................ 33

3.8 Integration of Detector Signals .............................................................. 34

3.9 Analog Output ......................................................................................... 35

3.10 Measurement Considerations ................................................................ 36

3.10.1 Detector Calibration and Accuracy ........................................... 36

3.10.2 Quantum Detector Temperature Effects .................................. 36

3.10.3 Thermopile Detector Temperature Effects .............................. 37

3.10.4 Energy Detector Temperature Effects ...................................... 37

3.10.5 Ambient and Stray Light ............................................................ 37

3.10.6 Common Measurement Errors .................................................. 38

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

v

Page 8

Section 4 - Computer Interfacing

4.1 General Guidelines .................................................................................. 39

4.2 Computer Interface Terminology .......................................................... 39

4.3 Entering Remote Computer Interface Mode ......................................... 41

4.4 RS-232C Communication ........................................................................ 41

4.4.1 Setting Baud Rate and Echo Mode from the Keypad. .............. 42

4.4.2 Setting Baud Rate and Echo Mode from a Remote Interface .. 42

4.5 RS-232C XON/XOFF Handshaking Protocol .......................................... 43

4.6 GPIB Communication ............................................................................. 43

4.6.1 Setting the GPIB Address ........................................................... 43

Section 5 - Remote Command Reference

5.1 Model 2835-C Remote Interface Commands ......................................... 44

5.2 Device Independent Commands ............................................................ 46

5.3 Device Dependent Commands............................................................... 57

Section 6 - Maintenance, Test and Troubleshooting

6.1 Maintenance Procedures ....................................................................... 91

6.2 Power Up Self Test .................................................................................. 91

6.3 Troubleshooting Guide .......................................................................... 92

Section 7 - Factory Service

7.1 Introduction ............................................................................................ 94

7.2 Obtaining Service .................................................................................... 94

Service Form ..................................................................................................... 95

Appendices

A Syntax and Definitions ............................................................................ 97

B Error Messages ..................................................................................... 101

C Status Reporting System ...................................................................... 104

D Sample Programs .................................................................................. 109

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vi

Page 9

List of Figures

1. Model 2835-C Controller and Accessories .............................................. 1

2a. Model 2835-C VFD Display ....................................................................... 4

2b. Description of Model 2835-C Display Regions ........................................ 4

3. Front Panel Key Pad ................................................................................. 6

4. Decimal Point Indication of Menu Hierarchy Position ......................... 14

5. Rear Panel Power Supply Voltage Switches in Positions L, R ............. 23

6. Connecting a Detector with its Calibration Module ............................. 24

7. Model 2835-C Detector Calibration Module Input Port........................ 24

8. Measuring Laser Pulse Energy via a Thermopile in INTG Mode ......... 27

9. Model 2835-C Analog Signal Flow Diagram ........................................... 29

10. Model 2835-C Digitized Signal Flow Block Diagram .............................. 30

11. Thermopile Signals ................................................................................. 32

12. Energy Detector Signal from a Single Optical Pulse ............................. 33

13. Negative Baseline Drift Voltage to a Pulse Train .................................. 33

14. Time Varying Signal Measurements ...................................................... 34

15. Integrated Energy Via a Trapezoid Approximation ............................. 35

16. Measuring Laser Pulse Energy with a Thermopile ............................... 35

17. RS-232 Cable Connections ...................................................................... 42

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vii

Page 10

List of Tables

Table 1. Model 2835-C Display Annunciators............................................. 5

Table 2. Model 2835-C Top Level Key Functions and Associated

Remote Commands ....................................................................... 6

Table 3. Newport Detector Families and Available Measurement Modes . 10

Table 4. Model 2835-C Measurement Modes ........................................... 11

Table 5. Valid Display Units Available to Detector Families by MODE .... 12

Table 6. Displayed Unit Abbreviations vs. Actual Measurement Units ...... 12

Table 7. Menu Level Key Functions and Parameters .............................. 15

Table 8. Data Store Operations ................................................................. 16

Table 9. Configuration Parameters and Default Conditions ................... 17

Table 10. Meter Configuration Operations ................................................. 18

Table 11. User Calibration Operations ....................................................... 19

Table 12. SAMPLE PREC States and Limits ................................................ 20

Table 13. DC SAMPLING Operations ........................................................... 20

Table 14. TRIGGER OUT Operations ........................................................... 21

Table 15. EXT TRIGGER IN Operations ....................................................... 21

Table 16. BAR GRAPH Operations .............................................................. 22

Table 17. TONE Operations ......................................................................... 22

Table 18. DET SWITCH POS Operations ..................................................... 22

Table 19. REMOTE SETUP Operations ....................................................... 22

Table 20. GENERAL INFO Operations ......................................................... 23

Table 21. Power Supply Voltage Switch Positions..................................... 23

Table 22. Analog Signal Flow Paths ............................................................ 30

Table 23 Common Measurement Errors ................................................... 38

Table 24 Model 2835-C IEEE-488.1 Capabilities Summary ........................ 43

Table 25 Device Independent Status Commands ..................................... 44

Table 26 Device Dependent Commands .................................................... 45

Table 27. Symptom/Fault Troubleshooting Guide .................................... 92

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

viii

Page 11

Safety Symbols and Terms

The following safety terms are used in this manual:

The WARNING heading in this manual explains dangers that could result in

personal injury or death.

The CAUTION heading in this manual explains hazards that could damage

the instrument.

In addition, a NOTES heading gives information to the user that may be

beneficial in the use of this instrument.

The following general warnings and cautions are applicable to this

GENERAL WARNINGS AND CAUTIONS

instrument:

WARNING

This instrument is intended for use by qualified personnel who recog-

nize shock hazards or laser hazards and are familiar with safety precau-

tions required to avoid possible injury. Read the instruction manual

thoroughly before using, to become familiar with the instrument’s

operations and capabilities.

WARNING

The American National Safety Institute (ANSI) states that a shock hazard

exists when probes or sensors are exposed to voltage levels greater then

42VDC or 42V peak AC. Do not exceed 42V between any portion of the

Model 2835-C (or any attached detector or probe) and earth ground or a

shock hazard will result.

CAUTION

There are no user serviceable parts inside the Model 2835-C. Work

performed by persons not authorized by Newport may void the war-

ranty. For instructions on obtaining warranty repair or service please

refer to Section 5 of this manual.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ix

Page 12

Definitions

A amps

AC alternating current

ADC analog-to-digital converter

BAT battery option

BIC biconic fiber connector

BNC standard coaxial connector type

C degrees Centigrade

DC direct current

F degrees Fahrenheit

fA femtoamps

Hz hertz (cycles per second)

I-V current-to-voltage converter

kHz kilohertz

LSD least significant digit

k kiloOhms

mA milliamps

mV millivolts

nA nanoamps

nF nanofarads

nm nanometers

pA picoamps

P-P peak-to-peak

RH relative humidity

S/N serial number

µA microamps

µs microsecond

V volts

W watts

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

x

Page 13

Specifications

Physical Specifications:

Dimensions: 4.2 x 8.8 x 13.9 in (107 x 224 x 353 mm)

Weight: 8 lb, 3 oz (3.7 kg)

Enclosure: Metal case, painted

Connectors: (2) 8-Pin Sub Mini DIN CAL MODULE Inputs;

(2) BNC Analog Outputs, Trigger Output and

Trigger Input;

9 Pin D-Sub RS-232, 24 Conductor GPIB

Power: 100/120/220/240 VAC ±10%, 50/60 Hz

Display: 5.5 digit annunciated VFD

Display Update Rate: 10 Hz

Gain Ranges: Up to 7 decades (Detector and MODE dependent)

Operating Environment: 0°C - 40°C; < 70% RH noncondensing

Storage Environment: -20°C - 60°C; < 90% RH noncondensing

Compatible Detectors: Low-Power (Semiconductor) Family

High-Power (Thermopile) Family

Energy (Pyroelectric) Family

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

xi

Page 14

Electrical Specifications:

DC Current Measurement (Low-Power, Semiconductor Photodiode CAL MODULE)

Signal Range:

1,2

01 23 456

Full-Scale Current:

4

2.51 nA 25.1 nA 251 nA 2.51 µA 25.1 µA 251 µA 2.50 mA

A/D Resolution: 126 fA 1.26 pA 12.6 pA 126 pA 1.26 nA 12.6 nA 126 nA

(20,000 Count Precision)

Display Noise Floor: ≤ 8 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD

(Input Open, Filter Off)

Full-Scale Accuracy:

3

± 0.1% 0.05% 0.05% 0.05% 0.05% 0.05% 0.05%

(Typical)

Full-Scale Accuracy:

3

±0.48% .30% .30% .30% .30% .30% .30%

(Worst-Case)

Peak-Peak Current Measurement (Low-Power, Semiconductor Photodiode CAL MODULE)

Signal Range:

1, 2

012345678

Full Scale (P-P) Current:4253 nA 797 nA 2.52 µA 7.97 µA 25.1 µA 79.3 µA 251 µA 793 µA 2.51 mA

A/D Resolution: 61.7 pA 195 pA 616 pA 1.95 nA 6.13 nA 19.4 nA 61.3 nA 194 nA 613 nA

Full-Scale Accuracy:

3

±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1%

(Typical)

Full-Scale Accuracy:

3

±2% ±2% ±2% ±2% ±2% ±2% ±2% ±2% ±2%

(Worst Case)

Bandwidth (3db): (5 Hz - 1 kHz) (5 Hz - 10 kHz) (5 Hz - 47 kHz)

Frequency Range for

±2% (Typ) Accuracy: (50 Hz - 100 Hz) (50 Hz - 1.4 kHz) (50 Hz - 7 kHz)

Trigger Level: 4% of full scale (fixed) above ground.

1

Listed signal ranges specify meter capability. Available signal ranges are detector dependent.

2

Maximum measurable signal is detector dependent. See description of detector saturation message “SA”, page 83.

3

After 60 min warm-up, followed by execution of AUTOCAL command. See Section 2.4.4.

4

Full scale current may vary due to AUTOCAL compensation of DC offsets.

Analog Output

Full Scale Voltage: 0 - 2.5V into 50Ω

Accuracy: ± 2.5%

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

xii

Page 15

D.C. Voltage Measurement (Thermopile CAL MODULE)

Signal Range:

1, 2

01 2 3

Full Scale Voltage:

4

2.49 mV 24.9 mV 249 mV 2.49 V

(20,000 Count Precision)

Resolution: 125 nV 1.25 µV 12.5 µV 125 µV

(20,000 Count Precision)

Display Noise Floor: ≤ 8 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD

(Input Shorted)

Full Scale Accuracy (Typ.):

3

± .3% ± .2% ± .1% ± .05%

Full Scale Accuracy: ± .56% ± .36% ± .18% ± .1%

(Worst Case)

Bandwidth (3db): 5 Hz 5 Hz 5 Hz 5 Hz

Pulse Voltage Measurement (Energy, Pyroelectric CAL MODULE)

Signal Range:

Full Scale Voltage:

1

2,4

0123456789

789 µV 2.50 mV 7.89 mV 25.0 mV 78.9 mV 250 mV 789 mV 2.50 V 7.91 V 25.0 V

A/D Resolution: 193 nV 610 nV 1.93 µV 6.10 µV 19.3 µV 61.0 µV 193 µV 610 µV 1.93 mV 6.10 mV

Full-Scale Accuracy:3±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1%

(Typical)

Full-Scale Accuracy:3± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2%

(Worst Case)

Maximum Pulse Repetition Rate: 2 kHz

Trigger Level: 8% of Full Scale1 (fixed)

1

Listed signal ranges specify meter capability. Available signal ranges are detector dependent.

2

Full scale voltage is measured relative to baseline voltage.

3

After 60 min warm-up, followed by AUTOCAL command. See Section 2.4.4.

4

Full scale voltage may vary due to AUTOCAL compensation of DC offsets.

Analog Output

Full Scale Voltage: 0 - 2.5V into 50Ω

Accuracy: ± 5.0%

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

xiii

Page 16

Detector Signals and Calculations:

S Represents the most recent signal value ob-

tained from the A/D converter. It may represent

amps or volts and may be analog and or digitally

filtered.

S

d

S – S

d

SS

−

()

d

R

λ

101log

()

()

SS R

−

/

d

−

λ

d

mW

/SS R

STO-REF

−

10 log

()

/SS R

d

STO-REF

Represents the value stored as a reference signal

for subsequent use in signal offset, i.e. ZERO

calculations. Sd=0 when ZERO is off.

Represents the most recent net signal value.

This is the value that is displayed when units are

set to Amps or Volts. Note that Sd = 0 when

ZERO is off.

Measurement calculation when the display units

are Watts or Joules. Rλ is the detector

responsivity associated with the current wavelength setting.

λ

Measurement calculation when the display

units are ten times the (base ten) logarithm of the

ratio of the measured power to 1 mW, i.e. dBm.

Measurement calculation when the display units

are the ratio of measured power to the value

stored by the STO-REF function.

λ

Measurement calculation when the display units

are ten times the (base ten) logarithm of the

ratio of measured power to the value stored by

the STO-REF function.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

xiv

Page 17

Section 1

General Information

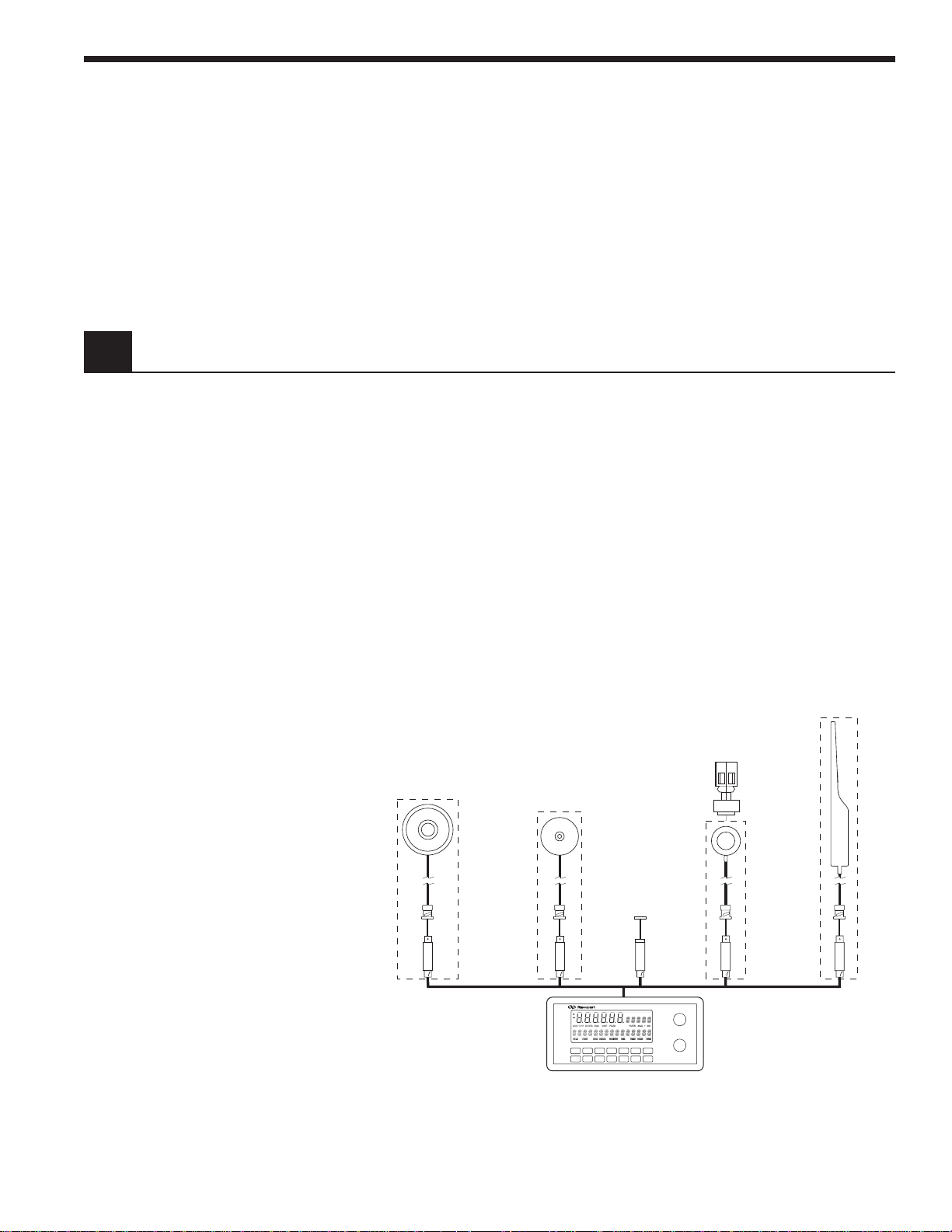

1.1 System Review

The Model 2835-C Multi-Function Optical Meter is a high performance

instrument with a wealth of measurement and triggering features designed

to provide measurement sensitivity, flexibility and speed. In spite of its

power, Model 2835-C is also designed to provide simple operation with

direct panel access to basic features and a shallow menu for access to

advanced features.

Great flexibility exists within the command structure of the Model 2835-C

so that even complex measurements can be set up quickly and easily. The

2835-C can react to or provide triggering, act as an exposure or noise meter,

or data log up to 1,000 measurements per channel!

The Model 2835-C is compatible with all of Newport’s Low-Power, High-Power

and Energy detector families. A family tree of the 2835-C compatible detectors

and accessories is shown in Figure 1 below.

818T-10/CM

818T-30/CM

818T-150/CM

818T-150X/CM

818J-09/CM

818J-09B/CM

818J-25/CM

818J-25B/CM

818J-50/CM

818J-50B/CM

818-FA3-SMA

818-FA3-ST

818-FA3-FC

818-F-SL

818-F-IR

■

Multi-Function Optical Meter ■

818-UV/CM

818-SL/CM

818-IR/CM

Model 2835-C

DISP: CHA CHB

FP3-FH1

818-FA2

818-ST/CM

Figure 1 – Model 2835-C Controller and Accessories

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

1.2 Scope of This Manual

The Model 2835-C connects to detectors through a calibration module containing information unique to the detector being used. Calibration modules

are ordered with a detector at the time of purchase and are labeled with the

detector’s model number and serial number. Detectors with calibration

modules have a “/CM” appended to their model number.

EXAMPLE: 818-SL (no calib. module) 818-SL/CM (with calibration module)

Please carefully read this instruction manual before using the Model 2835-C

Multi-Function Optical Meter. Be especially careful to observe the warnings and

cautions throughout this manual. If any operating instructions are not clear,

contact Newport Corporation. This instruction manual contains the necessary

information for operation and maintenance of the Newport Model 2835-C MultiFunction Optical Meter as well as information for troubleshooting and obtaining

service if necessary. This information is divided into the following sections:

Section 1 General Information and Functional Description

Section 2 System Operation

Section 3 Principles of Operation

Section 4 Computer Interfacing

1.3 Unpacking and Inspection

Section 5 Remote Command Reference

Section 6 Maintenance, Test, and Troubleshooting

Section 7 Factory Service

Appendix A Syntax and Definitions

Appendix B Error Messages

Appendix C Status Reporting System

Appendix D Sample Programs

All Model 2835-C Multi-Function Optical Meters are carefully assembled,

tested and inspected before shipment. Upon receiving this instrument, check

for any obvious signs of physical damage that might have occurred during

shipment. Report any such damage to the shipping agent immediately. Retain

the original packing materials in case reshipment becomes necessary.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

Page 19

1.4 Preparation for Use

The Model 2835-C Multi-Function Optical Meter should have some operations

performed before measurements are made. These include:

Connecting AC Power (Section 2.5)

Detector Connection and Setup (Section 2.6)

1.5 Optional Accessories and Services

The Newport Catalog presents up-to-date information on detectors, detector

accessories and detector calibration services available for use with the Model

2835-C. Refer to Figure 1 for the Model 2835-C family tree of accessories.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Page 20

Section 2

System Operation

2.1 Introduction

2.2 Display

The Model 2835-C is designed to provide quick operation and to avoid a steep

learning curve. This section starts by giving a brief listing of display, key pad

and menu command features. Much of the Model 2835-C’s operation will be

obvious after these descriptions. The manual then explains each key operation and menu command in detail. Reference each of these detailed explanations as required when getting started.

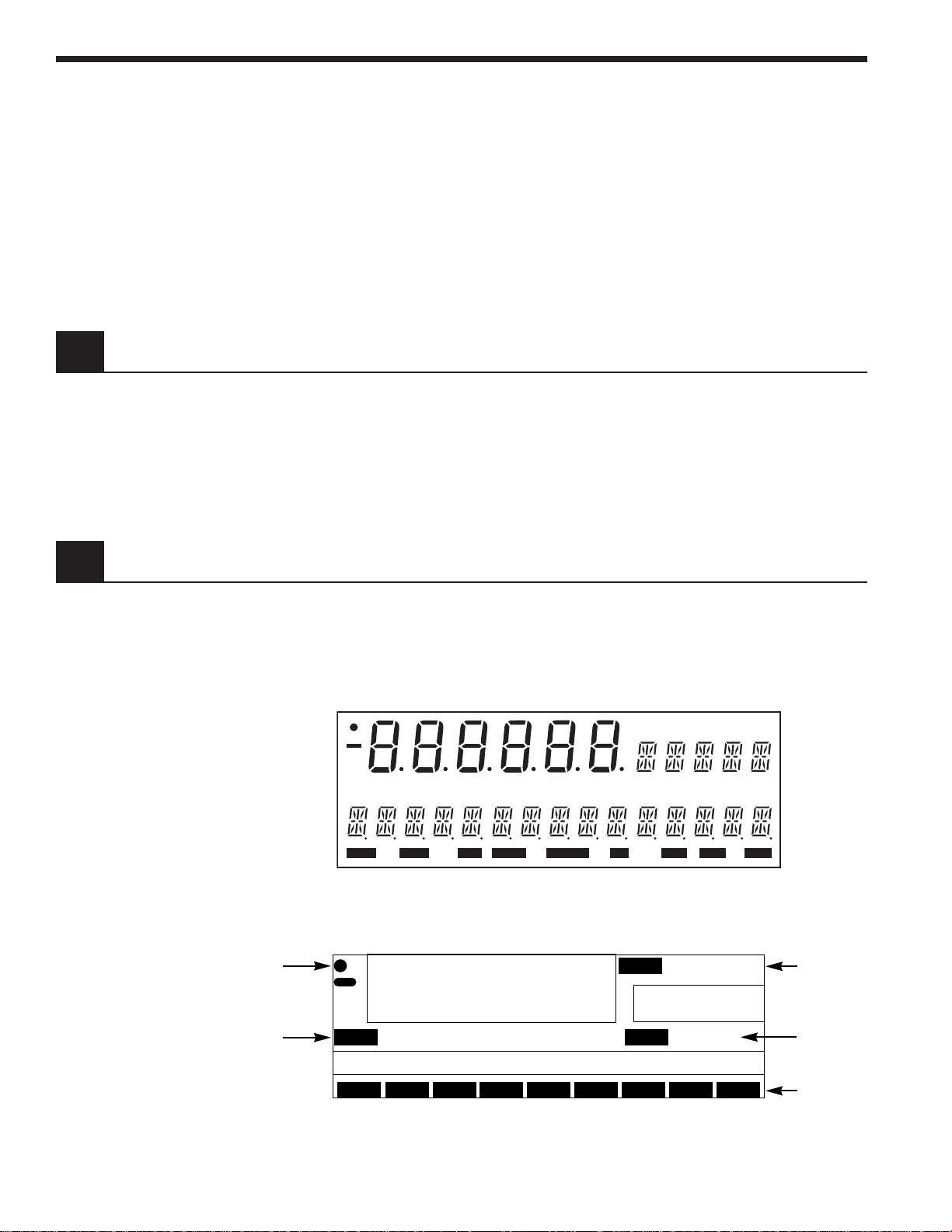

Measurement

Activity

Annunciator

Measurement

Mode

Annunciators

The Model 2835-C incorporates a vacuum fluorescent display, VFD, which can

be clearly observed with most laser goggles and at high angles of incidence.

Figure 2 illustrates and identifies the primary regions and annunciators within

the Model 2835-C’s display.

DISP: CHA CHB

PULSECONTSNGLDC INTGMODE: % P-P

MENU EDITSHIFT STORE USR CAL EXT ATTN ZERO

FILTER: ANLG + DIG

AUTO

Figure 2a – Model 2835-C VFD Display

DISP:

= CHA + CHB

Measurement Display Area

Units Display

MODE: FLTR:

= P-P DC INTG SNGL CONT PULSE

Bar Graph, Menu and Message Display Area

SHIFT MENU EDIT STORE USRCAL EXT ATTN ZERO AUTO

= ANLG + DIG

Display Channel

Annunciators

Signal Filtering

Annunciators

Status

Annunciators

Figure 2b – Description of Model 2835-C Display Regions

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Table 1 – Model 2835-C Display Annunciators

Annunciator Comment

CH A The display is showing Channel A information.

CH B The display is showing Channel B information.

Blinking indicates that the meter is making

measurements.

DC Meter is set to make DC signal measurements.

INTG Meter is set to make INTEGRATED signal

measurements.

P-P Meter is set to make Peak-to-Peak signal

measurements.

SNGL Meter will make only one measurement per front

panel or external trigger.

CONT Meter will continuously make measurements until

stopped.

PULSE Meter is set to make pulse energy measurements.

ANLG Analog signal filtering is on.

2.3 Top Level Key Functions

DIG Digital signal filtering is on.

SHIFT Indicates that the next key press will execute a blue

key function.

MENU Meter and display are in menu mode. Measurement

is stopped.

STORE Meter is logging measurements into memory, i.e.

data logging.

USRCAL User (versus calibration module) has supplied the

detector responsivity in use.

EXT External trigger input is enabled.

AUTO Automatic signal gain ranging is on.

ZERO Background signal subtraction (zeroing) is on.

ATTN The responsivity in use includes the affect of the

detector’s attenuator.

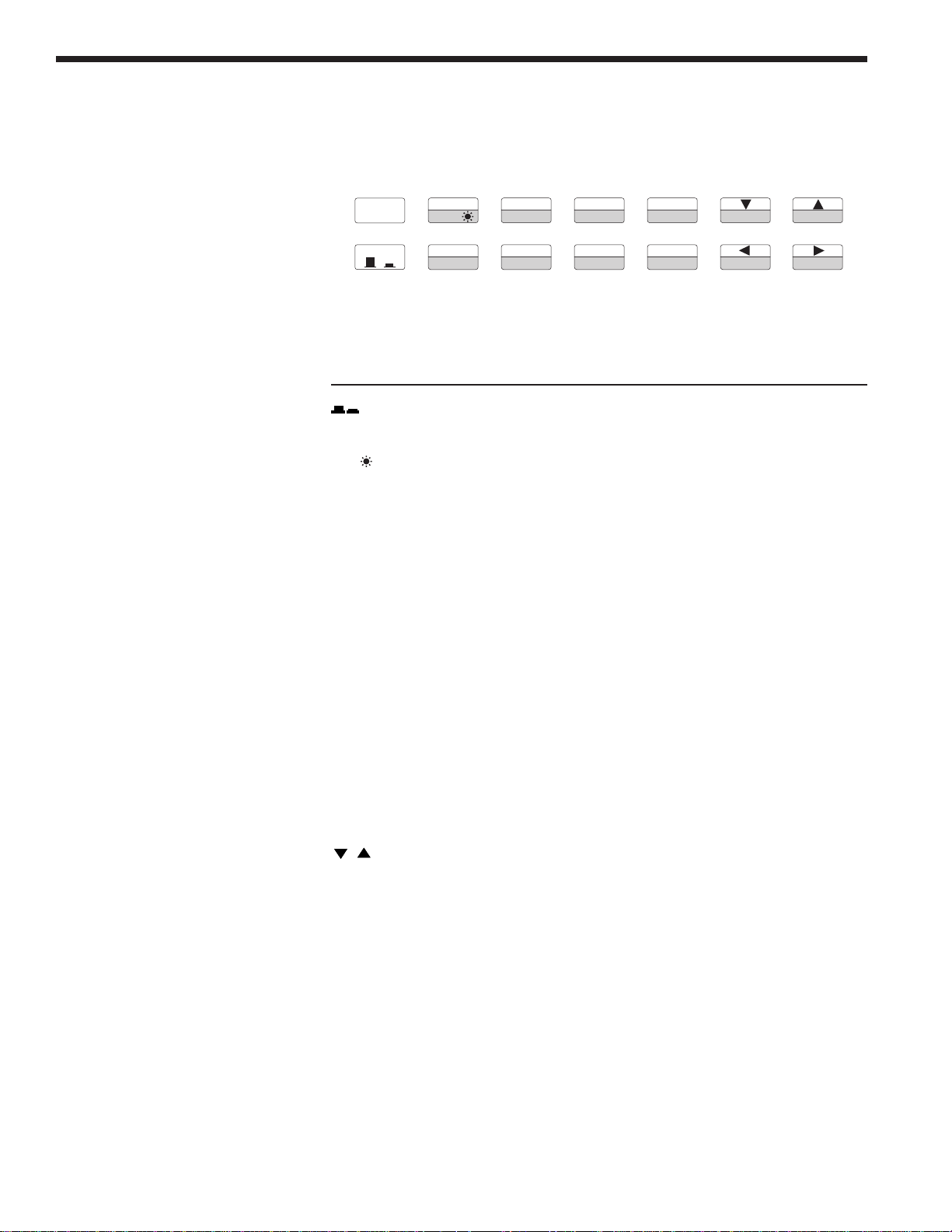

Operating controls for the Model 2835-C are found on both the front and rear

panels of the Model 2835-C. For measurement operation, only the front panel

controls are used. Rear panel controls are used for AC line power setup,

Section 2.5. The front panel key pad of the Model 2835-C, Figure 3, provides

quick access to measurement functions and menu access to advanced features and setup parameters. Most of the keys on the front panel only affect

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

Page 22

the channel indicated by the display channel annunciators. Table 2 and

Sections 2.3.1 through 2.3.21 list and describe each top level key function.

Menu level key functions are discussed in Section 2.4.

(LOCAL)

SHIFT

O I

STO REF

DISP

EXT

R/S

REF SEL

FILTER

MENU

MODE

λ

ZERO

ENTER

UNITS

RANGE

AUTO

ESC

STAT S

CH A

R/S A

CH B

R/S B

Figure 3 – Front Panel Key Pad

Table 2 – Top Level Key Functions and Associated Remote Commands

Keypad Remote Commands Description

OI

SHIFT None Enables the blue key functions.

DISP

FILTER FILTER_n, FILTER_n? Cycles signal filtering:

ZERO ZERO_n, ZERO_n?, Zeroes the display via offset subtraction.

AUTO AUTO_n, AUTO_n? Turns automatic gain ranging on and off.

CH A DISPCH, DISPCH? Selects channel A as the display channel.

None Turns the Model 2835-C on and off.

DISP, DISP? Cycles display brightness:

OFF,LOW,NORM and HIGH.

OFF, ANLG, DIG and ANLG+DIG.

STOZERO_n, ZEROVAL_n?

CH B DISPCH, DISPCH? Selects channel B as the display channel.

STO REF STOREF_n, STOREF_n? Stores last reading for future dB and

REL measurements.

REF SEL REFSEL_n, REFSEL_n? Selects the reference source to be used

for dB and REL measurements.

λ LAMBDA_n, LAMBDA_n? Displays and edits the calibration

wavelength in use.

RANGE RANGE_n, RANGE_n? Displays signal gain range in use.

, None Adjusts gain range or parameter

values or moves through a list.

R/S RUN, STOP Toggles the signal acquisition of

both channels.

MODE MODE_n, MODE_n? Cycles meter bet ween allowed

measurement modes.

UNITS UNITS_n, UNITS_n? Cycles display measurement units

between those allowed.

STATS STSIZE_n, STSIZE_n?, STMAX_n? Displays statistics.: Max, Min,

STMIN_n?, STMXMN_n? Max-Min, Mean and Std. Dev.

STMEAN_n, STSDEV_n?

R/S A RUN_A, RUN_A? Starts and stops channel A signal

acquisition.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6

Page 23

R/S B RUN_B, RUN_B? Starts and stops channel B signal

acquisition.

EXT EXT Enable or disable external triggering.

MENU None Enter or exit MENU command mode.

ENTER None Select next lower menu level or enter

edit mode.

ESC None Escape to next higher menu level or

escape edit mode.

, None Zooms bargraph in or out. When in

Edit mode, selects the digit to be

edited by the

, keys.

Note: n in a remote command stands for A (channel A) or B (channel B).

2.3.1

OI

, Power

The OI key toggles the Model 2835-C on and off. To turn the meter on, depress

the OI key in until it clicks and stays in its depressed position. To turn the

meter off, press the key again until it clicks and rebounds to its original length.

2.3.2 SHIFT

When SHIFT is pressed, the SHIFT display annunciator lights and the blue key

functions (such as STOREF) are enabled. The next key press will cause that

blue function to be executed and the “shift status” to disable.

2.3.3 DISP , Display Brightness

This key cycles the display and the backlit key pad through: OFF, LOW, NORM

and HIGH brightness levels. This allows a user to operate in a dark environment without light pollution from the display, (except for one dim scanning

decimal point and the measurement activity annunciator).When the display is

OFF, the R/S, R/S A, or R/S B keys may be used to manually trigger measurements. Any other key press returns the display to the LOW brightness state

while ignoring the key function.

2.3.4 FILTER, Signal Filtering

Press this key to cycle input signal filtering between: OFF, ANLG, DIG,

ANLG+DIG. This function provides methods of lowering the noise observed in

the measurement data and the analog output. When the ANLG annunciator is

lit, a 5Hz low pass filter lowers the noise floor by attenuating high frequency

signal components. ANLG filtering is not available to High Power detectors,

Energy detectors or any P-P modes.

When the DIG display annunciator is lit, measurements pass through a moving

10-sample averaging buffer before being further processed, stored or communicated to the display or computer interfaces. With DIG on, all observable values

represent digitally averaged results relative to the original A/D conversions.

This averaging is independent of the subsequent processing available through

the STATS buffer, Section 2.3.15.

7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

2.3.5 ZERO, Offset Subtraction

This key turns offset subtraction on and off. When turned on, the ZERO

annunciator lights and the last signal reading is saved as Sd and subtracted

from all subsequent signal readings S. This causes subsequent signal calculations (and the display) to use the value S-Sd instead of S.

Offset subtraction allows one to remove the effects of ambient DC signals, by

zeroing the display before making a measurement. Pressing the ZERO key a

second time turns off the ZERO annunciator and stops offset subtraction.

2.3.6 AUTO, Automatic Gain Ranging

The AUTO key toggles automatic signal ranging on and off. When on, the

AUTO annunciator lights and the signal range (amplifier gain) is adjusted to

utilize maximum analog-to-digital converter resolution. When AUTO is turned

off, the AUTO annunciator is turned off and the signal range is left in its

current state.

Signal range can be manually controlled by the , arrow keys. Pressing an

, arrow key when AUTO is on (and STATS, MENU and λ are off), turns

AUTO off and executes the manual range change. See RANGE, Section 2.3.11.

Signal range changes will often not coincide with observable changes to the

display value as the display is scaled by the detector responsivity and so must

adjust independently. Signal range gains will occur in 1 decade steps when auto

ranging and 1 or 1/2 decade steps (depending on MODE) when manual ranging.

When auto ranging in CONT PULSE mode, the arrival rate of pulses must be

above 1 Hz. In P-P CONT mode, the arrival rate of peaks must be above 50 Hz.

AUTO gain ranging is not allowed in SNGL measurement modes. When exiting

a SNGL measurement MODE, AUTO will turn back on if it was on when the

SNGL measurement mode was entered. (See MODE, Section 2.3.13)

2.3.7 CH A (B), Display Channel A (or B)

CH A causes channel A to be the display channel. CH B causes channel B to be

the display channel. The display channel annunciators will indicate which

channel is currently the display channel. When a display channel is selected,

the front panel will change to reflect its settings and measurement data.

Operations from the keypad or menu that affect a specific channel will only

affect the currently displayed channel and not the other.

2.3.8 STO REF, Store Reference Value

STO REF causes the last measurement, D, to be stored as D

use in relative measurement calculations. When units are relative, REL, and

the stored reference is selected, the displayed value is the ratio D/D

units are logarithmic relative, dB, and the stored reference is selected the

displayed value is the function 10 log (D/D

ref

). D

is always a power reading

ref

stored in the units of Watts. Press STO REF to cause a new D

existing D

value.

ref

for subsequent

ref

. When

ref

to overwrite the

ref

NOTE

When not using remote interface operation and when displaying relative dB

or REL measurements with the stored reference selected, the message

display area will show the STO REF value used in the calculation.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8

Page 25

2.3.9 REF SEL, Select Reference

The REF SEL key is used to select the reference value, Dref, to be used for

relative, REL, and logarithmic relative, dB, unit readings. Press the REF SEL

key to display the reference source in the message display area. The EDIT

annunciator will be lit and the current selection will blink. Press , to

select a new reference source. The choices will be:

STO REF - The last stored measurement

USR REF - User defined reference (see the USRREF command in Section 5.3

Device Dependent Commands)

CH A(B) - The other channel

Press ENTER to accept the new reference source and exit the select reference

mode. Press REF SEL or ESC to exit without changing the reference source.

NOTE

The CH A(B) source is only applicable if the other channel is available. If the

other channel is not availble then N/A will appear next to CH A(B) and you

will not be able to select it.

2.3.10 λ, Wavelength

A detector calibration module contains responsivity data for its assigned

detector at discrete wavelengths. By telling the meter which wavelength is

being measured, the correct responsivity value is used in calculating the

measured power or energy. When a wavelength falls between two calibration

points, linear interpolation is used to approximate the true responsivity value.

Press the λ key to display the measurement wavelength in the message

display area. Press ENTER to light the EDIT annunciator and cause the last

digit of the wavelength to blink. Press , to adjust the blinking digit up or

down and , to change which digit blinks. Press the ENTER a second time

to accept the new wavelength and exit the wavelength edit/display mode.

Press λ or ESC to exit without changing the wavelength.

2.3.11 RANGE, Signal Range

RANGE key allows the user to view the amplifier signal range. Signal ranges

step in 1 or 1/2 decade gain increments (MODE dependent) as the RANGE is

changed in order to utilize maximum resolution from the meter’s analog-todigital converters. The available signal ranges are detector and mode dependent. Press RANGE to display the signal range number in the message display

area. If AUTO is on, then the signal range number will change if the detector signal

varies more than a decade in magnitude. Signal range changes can occur without

an effect on the displayed measurement value. Press RANGE a second time to exit

the signal range display mode.

Press the , arrow keys to increase or decrease the signal range. If AUTO

is on, pressing the , arrow keys will disable AUTO and cause the signal

range to change. Manual ranging is useful when working with external analog

recording equipment.

NOTE

Pressing the , arrow keys will disable AUTO ranging and change the signal

range even when the signal range is not being displayed via the RANGE key.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

Page 26

2.3.12 R/S, Run-Stop

The R/S run-stop key provides front panel control over data acquisition for both

channels simultaneously. If the channel is in SNGL measurement mode, each

R/S key press causes one reading to be taken. In CONT measurement mode, each

R/S key press toggles continuous data acquisition on and off.

The activity annunciator (Figure 2b) flashes to indicate that readings are being

taken on the displayed channel as indicated in the upper right hand corner of

the display. A steady glow indicates that the meter is armed and waiting for a

pulse or P-P waveform to arrive. The indicator is off when data acquisition on

the displayed channel has been stopped. In the special case that both channels are started together in DC CONT mode the readings will be synchronized

together with channel A readings leading channel B readings by about 70 µsec.

Otherwise the channels run independent of each other.

2.3.13 MODE, Measurement Mode

The Model 2835-C provides a number of measurement modes for acquiring

data. At power on, the meter checks the detector’s calibration module to

determine which measurement modes the detector supports. Table 3

describes the measurement modes available for each detector family.

Table 3 – Newport Detector Families and Available Measurement Modes

Low-Power High-Power Energy

DC CONT 䊉䊉

DC SNGL 䊊䊊

INTG 䊊䊊

P-P CONT 䊊

P-P SNGL 䊊

CONT PULSE 䊉

SNGL PULSE 䊊

䊉 marks the default mode for the detector family.

Press the MODE key repeatedly until the desired mode is indicated in the mode

annunciator area of the display, see Table 4. When selecting a new mode, the

display units will change to appropriate default units. See Section 2.3.14 for

more details about units.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10

Page 27

Table 4 – Model 2835-C Measurement Modes

Mode Description

DC CONT Measurement occurs at a programmable sample rate,

Section 2.4.7.

DC SNGL A measurement is taken every time the meter receives a

trigger up to a 500Hz rate when two detector calibration

modules are plugged into the meter and 1000Hz for one.

(AUTO is disabled in SNGL mode.)

INTG Measurements occur at 400Hz and are trapezoidally

integrated to get an energy result. An R/S key press or

external trigger sets the display to 0.0000 and sampling

starts. A second R/S keypress or external trigger terminates integration.

P-P CONT Acquisition is driven by the arrival of high-low peak

pairs. A measurement is processed for every high-low

peak pair up to a frequency of 500Hz when two detector

calibration modules are plugged into the meter and

1000Hz for one. NOTE: pair captures experience a

minimum 2 or 1 ms separation respectively.

P-P SNGL A trigger1 arms the meter to capture the next high-low

peak pair. Triggers can occur at a rate of up to 500Hz

when two detector calibration modules are plugged into

the meter and 1000Hz for one. (AUTO is disabled in

SNGL mode.)

CONT PULSE The meter captures every energy pulse up to a frequency

of 500Hz when two detector calibration modules are

plugged into the meter and 1000Hz for one. Above this

rate, pulse acquisitions experience a minimum 2 or 1 ms

separation respectively.

SNGL PULSE A trigger1 arms the meter to capture the next energy

pulse. Triggers can occur at a rate of up to 500Hz when

two detector calibration modules are plugged into the

meter and 1000Hz for one. (AUTO is disabled in SNGL

mode.)

1

“Trigger” refers to a command to start or stop signal acquisition. Trigger

sources are the R/S key, the external trigger input and remote interface

commands.

2.3.14 UNITS, Display Units

Measurements can be displayed in various units. The set of units available at

any given time is determined by the detector type and the measurement

mode. Press the UNITS key repeatedly to cycle the display through the set of

available units. Table 5 describes the sets of available units for each detector

family as a function of the measurement mode.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

Page 28

Table 5 – Valid Display Units Available to Detector Families by MODE.

FAMILY MODE V A W W/cm

2

J J/cm2Erg Erg/cm2dBm dB REL

Low-Power DC CONT 䊊䊉䊊 䊊䊊䊊

Low-Power DC SNGL 䊊䊉䊊 䊊䊊䊊

Low-Power INTG 䊉䊊䊊䊊

Low-Power P-P CONT 䊊䊉䊊 䊊䊊䊊

Low-Power P-P SNGL 䊊䊉䊊 䊊䊊䊊

High-Power DC CONT 䊊 䊉䊊 䊊䊊䊊

High-Power DC SNGL 䊊 䊉䊊 䊊䊊䊊

High-Power INTG 䊉䊊䊊䊊

Energy CONT PULSE 䊊 䊉䊊䊊䊊 䊊

Energy SNGL PULSE 䊊 䊉䊊䊊䊊 䊊

䊉 denotes the default units for the detector family in the given measurement

mode. Some display units are abbreviated. Table 6 lists displayed units

versus actual measurement units. Display units are limited to four characters

in order to provide for display engineering prefixes such as: p, n, µ, m and k

(pico, nano, micro, milli and kilo respectively).

Table 6 – Displayed Unit Abbreviations Versus Actual Measurement Units.

Actual Units V A W J Erg W/cm2J/cm2Erg/cm2dBm dB REL

Displayed Units V A W J ERG W/cm J/cm E/cm dBm dB E±dd

2.3.15 STATS, Moving Statistics

The STATS key causes a list of statistical results from the stats buffer of the

display channel to be displayed in the message display area. The stats buffer

is a moving data window containing the most recent measurements to a depth

1 ≤ N ≤ 100. The default value is N = 10. Display occurs without disrupting

data acquisition or storage and results are continuously updated.

Press the STATS key to enter the stats display list. The first statistic displayed

will be the stats buffer depth N. Press the , adjust keys to move through

the list. The following statistics are available: N, MAX, MIN, MAX-MIN, MEAN

and STD DEV.

When the STATS buffer depth, N, is displayed, it can be adjusted by pressing

ENTER and using the , keys to set a new value for N. Press the ENTER

key to adopt the new value for N and escape the edit mode. The STATS buffer

is cleared whenever a new stats buffer depth N, or MODE or UNITS is established. Press the STATS key a second time to exit the stats display mode.

2.3.16 R/S A(B), Run-Stop Channel A (or B)

The R/S A and R/S B run-stop keys provides front panel control over data

acquisition for each individual channel. When in SNGL measurement mode,

each R/S A(B) key press causes one reading to be taken on the respective

channel. In CONT measurement mode, each R/S A(B) key press toggles

continuous data acquisition on and off on the respective channel.

12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

The activity annunciator (Figure 2b) flashes to indicate that readings are being

taken on the display channel as indicated in the upper righthand corner of the

display. A steady glow indicates that the meter is armed and waiting for a

pulse or P-P waveform to arrive. The indicator is off when data acquisition on

the displayed channel has been stopped.

2.3.17 EXT, External Trigger

EXT enables and disables the triggering of data acquisition through the rear

panel trigger input BNC connector. The meter can be configured to be

triggered by either a rising or falling edge TTL signal. See Section 2.4.9.

Press EXT to light the EXT annunciator and enable the external trigger input to

both channels. The Model 2835-C will still respond to triggers from the R/S, R/S

A, or R/S B keys even when the EXT trigger is enabled. Press the EXT key a

second time to turn off the annunciator and disable the external trigger input.

2.3.18 MENU

The MENU key provides access to advanced features and parameters. Press

the MENU key to stop all data acquisition, light the MENU annunciator, and

display the first item of the top level menu list. Press the MENU key a second

time to immediately exit the menu. Menu structure and functions are presented in Section 2.4. The menu consists of a series of lists and parameter

values. Most parameter values can be edited to configure the meter. Lists are

moved through via the , keys. To move to a lower level list, press the

ENTER key. To escape a lower level list, press the ESC key.

In the menu, all key functions are ignored except for the MENU, ENTER, ESC

and the , keys. Each key will act without having to initially press SHIFT.

Pressing SHIFT will toggle the SHIFT annunciator, but it will not effect anything

else when in MENU mode.

To edit a displayed parameter press ENTER. This enables the edit mode and

causes the parameter (or a digit) to blink. Press the , keys to adjust the

parameter through its allowed list or to count the blinking digit up and down.

When adjusting a numerical value, the , keys can be used to change

which decimal digit blinks. Press ENTER to adopt the new value and escape

the editing mode. Press ESC to leave the editing mode without adopting the

new value.

2.3.19 ENTER

ENTER allows one to move lower into the menu when in menu mode, to enter

editing mode when an editable parameter is being displayed and to adopt a

new parameter value after it has been edited. Editable parameters can be

found both in and out of the menu mode. If ENTER is pressed when a noneditable parameter is being displayed, the key press is ignored.

2.3.20 ESC, Escape

ESC allows one to escape to the next higher level when in menu mode and to

escape editing mode when editing a parameter value without adopting any

changes to the parameter. At the top level of the menu, pressing the ESC key

exits the menu mode. The ESC key also allows one to escape various other

display modes such as STATS or wavelength display or amplifier signal gain

range display modes. When there is nothing to escape from, the ESC key is

ignored.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

Page 30

2.4 Menu Level Functions

2.3.21 , , , Adjust

The , , , keys allow one to adjust various parameter states and values.

In normal operation, the , keys turn AUTO off and adjust the amplifier

signal gain. In any other mode, the , keys cause one to move through a list

or to adjust a blinking digit. The , keys zoom the bargraph ( in, out)

and in edit mode, select which digit of a numerical value will blink.

Menu functions provide control over parameter values and methods of

making measurements. The menu consists of a number of lists and parameter values. Table 7 presents a quick summary of the hierarchy of the

menu functions and parameters. Most settings displayed in the menu and

changes to those settings affect the channel indicated by the display

channel annunciator.

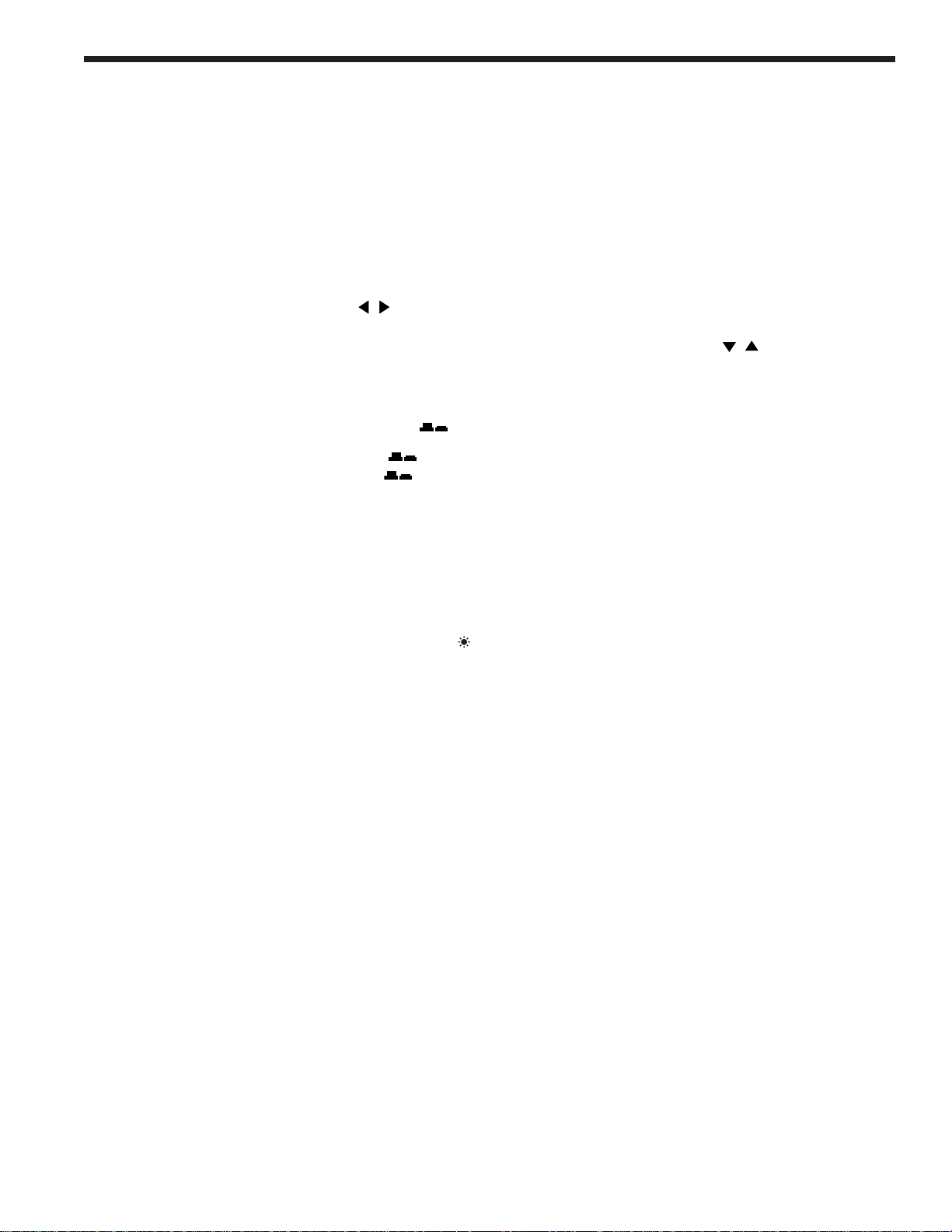

2.4.1 Menu Access and Movement

To access the menu press MENU. The MENU annunciator will light and data

acquisition will stop. Menu labels and parameter values are displayed in the

message display area. The first, second and third leftmost decimal points

within this area indicate a current position at the top, second, third or fourth

level of the menu hierarchy, Figure 4. Table 7 presents the menu functions

and their hierarchy.

Top Level

Second Level

Third Level

Fourth Level

Figure 4 – Decimal Point Indication of Menu Hierarchy Position

In the menu, valid keys are limited to those needed to perform operations to

move through the menu or edit a parameter value. In the menu, it is not

necessary to hit the SHIFT key to invoke the action of the menu keys: MENU,

ENTER, ESC or , , , . The SHIFT key will toggle the SHIFT annunciator,

but with no effect on subsequent pressings of other keys. Once in the menu,

the rules for moving through the menu are as follows:

i. Press ENTER to move to the next level down or to enter the edit mode if a

editable parameter is being displayed and to accept a parameter value in

its currently displayed state and exit edit mode.

ii. Press ESC to move to the next level up or to escape the menu when at the

top level or to exit edit mode without changing the parameter value being

edited.

iii. Press MENU to immediately escape the menu regardless of current level

within the menu.

14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

iv. Use the , keys to move up or down through a menu list on a given

level. Also use these keys to adjust a parameter or decimal value when in

edit mode.

v. Use the , keys to select the digit being adjusted when in edit mode.

Table 7 – Menu Level Key Functions and Parameters

Top Level Second Level Third Level

DATA STORE <- -> DATA STORE OFF <- -> DATA STORE ON, OFF

CLR DATA BUFFER

(or DATA BUFFER CLR)

SLIDE BUFFER <- -> SLIDE, FIX BUFFER

D_BUF SIZE dddd <- -> D_BUF_SIZE dddd

VIEW DATA <- -> dddd OF dddd

SAVE CONFIG <- -> SAVE TO d

RECALL CONFIG <- -> RCL DEFAULT, d

ATTENUATOR <- -> ATTN ON, OFF

AUTO CAL

DET SWITCH POS <- -> SWITCH POS S, I, L

USER CALIB <- -> USR CAL OFF <- -> USR CAL ON, OFF

USR RESP <- -> d.dddE±d A/W

PRESENT RESP <- -> d.dddE±d A/W

†

†

DC SAMPLING <- -> SAMPLE PREC <- -> PREC= 20000, 4096

CNT

SAMPLE FREQ <- -> FREQ = ddd.ddd HZ

TRIGGER OUT <- -> TRIG ON CMPLT <- -> TRIG ON CMPLT,

TRIG AT FREQ ,

TRIG ON LEVEL,

TRIG ON INTG,

TRIG OUT OFF

TRIG POLARITY <- -> TRIG ACTIVE LO, HI

TRIGGER FREQ <- -> FREQ= dddd.ddd H Z

TRIGGER LEVEL <- -> LVL= ±d.ddd E±dd W

TRIGGER INTG <- -> INTG= ±d.ddd E±dd J

EXT TRIGGER IN <- -> FALLING , RISING EDGE

BAR GRAPH ON <- -> BAR GRAPH ON, OFF

TONE OFF <- -> TONE ON, OFF

REMOTE SETUP <- -> GPIB ADDR dd <- -> GPIB ADDR dd

BAUD RATE 9600 <- -> BAUD RATE 1200,

2400, 4800, 9600, 19.2K

RS-232 ECHO OFF <- -> RS-232 ECHO ON, OFF

GENERAL INFO <- -> MODEL 2835-C

SW VERSION d.d

DETECTOR INFO <- -> MODEL xxxxxx

DET SN ddddd

ATTN SN ddddd

CAL ddMONyyyy

†

Units may be in A/W, V/W or V/J.

15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Items in bold italics type are editable states or decimal values. Decimals are

denoted by d. Move vertically via the , keys. Move horizontally via

ENTER and ESC.

2.4.2 Data Store

The Model 2835-C allows a user to save up to 1000 measurements for each

channel for a total of 2000 measurements. These measurements are stored in

an internal buffer for subsequent viewing or transmission over a computer

interface. A separate buffer is maintained and configured for each channel.

Data is maintained on power down, but lost when a new configuration is

loaded, Section 2.4.3, or when the buffer is cleared via the CLR DATA BUFFER

command or when data with new units is being stored.

The data store buffer operates in two ways: SLIDE or FIX. In SLIDE configuration, the buffer slides along storing the most recent measurements up to the

size of the buffer. Beyond this, as data enters the buffer, the oldest data is

pushed out and lost. In FIX configuration, data storing continues until the data

buffer is full. After this, data acquisition stops and no additional data can be

stored without first clearing the buffer via the CLR DATA BUFFER command.

DATA BUFFER CLR is displayed when the buffer is empty.

The size of the buffer is set by the D_BUF_SIZE dddd menu function. Edit the

value dddd to establish the number of data points that the buffer will hold

before dropping old data or stopping data storage.

Data storing is enabled by the user via the DATA STORE menu function. Edit

the ON, OFF condition to enable or disable data storing and the associated

STORE annunciator.

When in CONT mode, data acquisition and storage is resumed immediately

upon exiting the menus if acquisition is active as the menu is entered. When

acquisition is not active when the menu is entered, or when in SNGL or INTG

mode, data acquisition and storage requires an initiating R/S key press,

external trigger or a remote RUN command upon exiting the menu.

Buffer data can be viewed via the VIEW DATA menu command. Data are dis-played

in the measurement area while the message area displays the position within the

buffer: dddd of dddd. Use the , keys to move through the buffer data. The

value dddd = 0001 is the first, i.e. the oldest datum.

NOTE

When DATA STORE is off, CONT acquisition mode behavior defaults to the

condition where data acquisition is begun without the requirement of a

starting trigger. SNGL acquisition modes always require a trigger for each

acquisition.

Table 8 – Data Store Operations

Menu Operation Keypad Commands Associated Remote Commands

DATA STORE ON, OFF Edit ON, OFF status. DSE_n, DSE_n?

DATA BUFFER CLR or

CLR DATA BUFFER If CLR DATA BUFFER, DSCLR_n

press ENTER to clear buffer

SLIDE, FIX BUFFER Edit SLIDE, FIX BUFFER DSBUF_n, DSBUF_n?

D_BUF_SIZE dddd Edit D_BUF_SIZE dddd DSSZ_n, DSSZ_n?

VIEW DATA Press ENTER and use DS_n?, DSCNT_n?, DSUNITS_n?

, keys.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

16

Page 33

NOTE

n in a remote command stands for A (channel A) or B (channel B).

2.4.3 Meter Configuration

The Model 2835-C provides a method to save the configuration of the entire

meter and to recall that configuration for later use even if the meter has been

turned off. This is accomplished through configuration buffers maintained in

nonvolatile memory. Configuration buffers are numbered 0 to 9 with buffer 0

being a DEFAULT buffer which can only be recalled but not saved to. The

reset state of all the buffers except the default buffer is empty. Empty buffers

cannot be recalled.

A recalled configuration becomes the current configuration of the meter. Any

changes to the current configuration must be saved via SAVE CONFIG or they

will be lost when a new configuration is recalled.

The meter will not recall a configuration that is not compatible with either

detector calibration module currently plugged into the meter. Configurations

using the same model of detector are compatible while configurations using

different models of detectors are incompatible.The default configuration of

the meter depends upon the detector family. The list of configuration parameters stored in a configuration buffer as well as their default values versus

detector family are listed in Table 9 below:

Table 9 – Configuration Parameters and Default Conditions

Parameter Detector Family Default Condition

MODE Low-Power, High-Power DC CONT

Energy CONT PULSE

UNITS Low-Power, High-Power W

Energy J

λ, Lambda Lowest available

PRESENT RESP PRESENT RESP

USR CAL OFF

ATTN OFF

FILTER OFF

DC SAMPLE PREC Low-Power, High-Power 20,000 CNT

DC SAMPLE FREQ 25 Hz

AUTO ON

RANGE Lowest available

ZERO OFF

Zero Value 0.000

REF SEL STO REF

Reference Value 0.001

STATS Buffer Size 10

DET SWITCH POS Energy I,(Intermediate)

DATA STORE OFF

DATA STORE BUFFER SLIDE

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17

Page 34

Parameter Detector Family Default Condition

D_BUF_SIZE 100

Data Store Units Same as UNITS

EXT OFF

EXT TRIG IN FALLING

TRIGGER OUT TRIG ON CMPLT

TRIG OUT POL TRIG ACTIVE LO

TRIG OUT FREQ FREQ = 30 Hz

TRIG LEVEL Low-Power, High-Power LVL = 0.001 W

Energy LVL = 0.001 J

TRIG INTG LVL Low-Power, High-Power INTG = 0.001 J

BAR GRAPH ON

TONE OFF

GPIB ADDR 05

BAUD RATE 9600

RS-232 ECHO OFF

These parameters adopt the following default values at power up and are not

affected by recalling a configuration or by setting the configuration to default.

Local Lockout OFF

Display Brightness NORMAL

Table 10. below lists the menu commands effecting the saving and recalling of

meter configurations.

Table 10 – Meter Configuration Operations

Menu Operation Keypad Commands Associated Remote Commands

SAVE CONFIG Adjust SAVE TO d, *SAV

and ENTER

RECALL CONFIG Adjust RECALL d, *RCL,*RST

and ENTER

2.4.4 AUTO CAL

The AUTO CAL command causes the 2835-C to perform A/D conversions of

amplifier offset voltages (zero errors) arising from aging and temperature

effects. These conversions are then used in subtracting the appropriate error

voltage from each reading during normal operation. The 2835-C automatically

performs this procedure every time it powers up (or is reset). To achieve

stable reading at the specified accuracy, AUTO CAL should be executed for

each channel after a minimum 60 minute warm-up period from power-up.

Executing AUTO CAL with High Power (Thermopile) detectors:

1. With the detector connected to the 2835-C, remove the detector from the

radiation source and allow a minimum of 60 seconds for the detector

surface temperature to stabilize.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

18

Page 35

2. Press ENTER when AUTO CAL is displayed. The display message area will

display “ONE MOMENT”, followed by a buzzer sound indicating that AUTO

CAL is complete.

NOTE:

Although at Power up, an AUTOCAL is performed, the above method is

necessary for proper calibration when the 2835-C is used with voltage sources.

Executing AUTO CAL with Low Power (Photodiode) or Energy

detectors:

Simply press ENTER when AUTO CAL is displayed. The display message area

will display “ONE MOMENT”, followed by a buzzer sound indicating that

AUTO CAL is complete. Low Power and Energy detectors do not have to be

connected to the 2835-C or removed from the radiation source to effectively

execute AUTO CAL.

2.4.5 Attenuator

The Attenuator selects the responsivity value, Rλ, to be the value for the

detector alone or the value for the detector-with-attenuator. When ATTN is

ON the ATTN annunciator is lit and the responsivity of the detector-withattenuator is used. When ATTN is OFF, the annunciator is off and the detectoralone responsivity is used. If the detector does not have an attentuator, or if

USR CAL is on (Section 2.4.6) the ATTN setting has no effect.

2.4.6 User Calibration

The Model 2835-C allows one to create a detector responsivity which overrides the responsivities obtained from the detector’s calibration module. This

allows one to account for the effects of additional optics and filters in the

measurement path. When USR CAL is on, the USR CAL annunciator is lit and

the meter adopts the responsivity value displayed by the editable USR RESP

value. Use the PRESENT RESP function to display the current calibration

module responsivity.

The USR RESP units are the same as the PRESENT RESP units. Table 11 lists

the possible user calibration operations.

Table 11 – User Calibration Operations

Menu Operation Keypad Commands Associated Remote Commands

USR CALIB ON, OFF Edit USR CALIB USRCAL_n, USRCAL_n?

ON, OFF

USR RESP Edit d.dddE±dd A/W* USRRESP_n, USERRESP_n?

PRESENT RESP ENTER to view RESP_n?

d.dddE±dd A/W*

*Units of A/W, V/W or V/J may be displayed. These units are not editable.

NOTE

n in a remote command stands for A (channel A) or B (channel B).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

19

Page 36

2.4.7 DC Sampling

The Model 2835-C incorporates two analog-to-digital, (A/D) converters, one

with 20,000 count resolution and a second with 4096 count resolution. The

user may select which A/D will be used for both channels during DC CONT

and DC SNGL acquisition modes. All other modes use the 4096 count A/D.

The 20,000 count A/D converter can operate at sample rates up to 25 Hz.

When two detector calibration modules are plugged into the meter, the 4,096

count A/D converter can operate at sample rates up to 500 Hz. When one

detector calibration module is plugged into the meter, the 4,096 count A/D

converter can operate at sample rates up to 1000 Hz.

The SAMPLE PREC menu command, Table 12, selects which analog-to-digital

converter is used for both channels. The sampling frequency for both channels can be adjusted within the limits imposed by the SAMPLE PREC state, see

Table 13. When the SAMPLE PREC state changes, the sampling frequency

defaults to 25 Hz if the existing SAMPLE FREQ is incompatible with the new

SAMPLE PREC state. The SAMPLE FREQ and the SAMPLE PREC settings affect

both channels, not just the the display channel.

Table 12 – SAMPLE PREC States and Limits.

SAMPLE PREC A/D Accuracy Sample Frequency Range

20000 CNT 20,000 counts 0.001 Hz to 25.0 Hz

4096 CNT 4,096 counts 0.001 Hz to 500.0 Hz or 1000.0 Hz

Table 13 – DC SAMPLING Operations.

Menu Function Keypad Commands Associated Remote Commands

SAMPLE PREC Edit PREC= 20,000, SPREC, SPREC?

4096 CNT

SAMPLE FREQ Edit FREQ= SFREQ, SFREQ?

ddd.ddd HZ

2.4.8 Trigger Output

The Model 2835-C’s rear panel TTL trigger output allows it to coordinate

activities among other instruments. The trigger output can operate in several

ways: conversion complete, periodic output, comparator output and integrating comparator output. In addition, the polarity of the trigger output can be

specified.

In TRIG ON CMPLT mode, a pulse is output after each reading has been

acquired and completely processed from either channel. When acquiring on

one channel, it indicates that the 2835-C is ready to take another reading. The

width of this pulse is at least 8 µS.

In TRIG AT FREQ mode, a pulse is output at a user defined frequency or rate.

Each pulse width is at least 8 µS and the programmable frequency range of the

pulses is 0.001 Hz to 1000.0 Hz.

In TRIG ON LEVEL mode, each measurement is compared to a programmable

trigger level. The units of the trigger level always equal Watts for power

detectors or Joules for energy detectors. If a measurement is less than the

specified value, then the trigger output is inactive. If the measurement

exceeds the specified value then the trigger output becomes active. The TRIG

ON LEVEL output is a shift in level rather than a pulse.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

20

Page 37

In TRIG ON INTG mode, continuous measurements from a power detector are

integrated and compared against a programmable value. The units of the

programmable value are Joules. If the calculated integral is less than the

specified value, then the trigger output is active. If the calculated integral

exceeds the specified value, then the trigger output becomes inactive. The

TRIG ON INTG trigger is a shift in level rather than a pulse.

If both channels are sampling when this function is initiated, the time lag

between subsequent triggers is less than 700 µsec. If a R/S A or R/S B is

initiated twice, then the separation between TTL OUTPUTS is relative to the

RUN command initialization, giving a time lag up to one sample period between channel triggers (depending on sample frequency chosen).

The polarity of the trigger output is programmable as active high or active

low. If the polarity is active high then the output will idle low. If the polarity is

active low then the line will idle high.

Table 14 – TRIGGER OUT Operations.

Menu Function Keypad Commands Associated Remote Commands

TRIGGER OUT Edit TRIG ON CMPLT TRIGOUT, TRIGOUT?

TRIG AT FREQ

TRIG ON LEVEL

TRIG ON INTG

TRIG OUT OFF

TRIG POLARITY Edit ACTIVE HI, LO TRIGOUTPOL, TRIGOUTPOL?

TRIGGER FREQ Edit FREQ= ddd.ddd Hz TRIGOUTFREQ, TRIGOUTFREQ?

TRIGGER LEVEL Edit LVL= d.dddE±dd W* TRIGOUTLVL, TRIGOUTLVL?

TRIGGER INTG Edit INTG= d.dddE±dd J TRIGOUTINTG, TRIGOUTINTG?

*Displayed units may be W or J depending upon the detector in use.

2.4.9 Trigger Input

The Model 2835-C’s rear panel TTL external trigger input can be enabled or

disabled, Section 2.3.17, and have its edge polarity set. The edge polarity is

accessed via the EXT TRIGGER IN menu function and can be set to rising or

falling edge triggering.

The external trigger affects both channels and, like the R/S key, acts like an