New Holland L213, 200, L223, L215, L225 Owner's Manual

...

ORIGINAL INSTRUCTIONS

OPERATOR’S MANUAL

L213 L223

L215 L225

L218 L230

L220

Tier 3

200 Series Skid Steer Loader

PIN NHM435463 and above

C227

C232

C238

Tier 3

200 Series Compact Track Loader

PIN NHM435463 and above

Part number 48065346

st

edition English

1

August 2017

Contents

1GENERALINFORMATION

Notetotheowner...........................................................................1-1

Electro-MagneticCompatibility(EMC).....................................................1-3

Productidentication.......................................................................1-4

Operator'smanualstorageonthemachine................................................1-8

Machineorientation.........................................................................1-9

Machinecomponents......................................................................1-10

2SAFETYINFORMATION

Safetyrulesandsignalwords..............................................................2-1

Safetyrules.................................................................................2-2

Utilitysafety.................................................................................2-8

Properentryandexit.......................................................................2-9

Startingandstoppingprecautions.........................................................2-11

Seatbeltprecautions......................................................................2-12

Specicprecautionstothismachine......................................................2-14

Fireextinguisher...........................................................................2-14

RollOverProtectiveStructure(ROPS)....................................................2-15

Weldingonthemachine...................................................................2-17

Loaderarmlockandcabtiltprocedure-radialliftmachines..............................2-18

Loaderarmlockandcabtiltprocedure-verticalliftmachines............................2-22

Noenginepower-loaderarmupanddowncontrol......................................2-26

Emergencyexit............................................................................2-27

Ecologyandtheenvironment.............................................................2-28

Safetysigns...............................................................................2-29

3CONTROLSANDINSTRUMENTS

ACCESSTOOPERATOR'SPLATFORM

Doorlatches,cab.......................................................................3-1

Windowglass,cab.....................................................................3-2

Windshieldwiperandwashercontrols.................................................3-3

Cabairlouvers.........................................................................3-4

OPERATOR'SSEAT

Standardseat...........................................................................3-5

Mechanicalsuspensionseat...........................................................3-5

Airseat.................................................................................3-5

Seatbeltoperation.....................................................................3-6

Shoulderbelt...........................................................................3-7

Restraintbar(ifequipped)..............................................................3-7

MECHANICALHYDRAULICCONTROLS

Steeringandtravel.......................................................................3-8

Movingthemachine....................................................................3-8

Turningthemachine....................................................................3-9

Liftarmandbucketcontrols.............................................................3-10

Handcontrols..........................................................................3-10

Footpedals............................................................................3-11

ELECTROHYDRAULICCONTROLS

Controlpatternoverview................................................................3-12

StandardHcontrolpattern............................................................3-12

StandardISOcontrolpattern..........................................................3-13

Electro-hydrauliccontrolhandleadjustment..........................................3-13

Hcontrolpatternsteeringandtravel....................................................3-14

Handcontrols..........................................................................3-14

Movingthemachine...................................................................3-15

Turningthemachine...................................................................3-16

Hcontrolpatternliftarmandbucketcontrols...........................................3-17

Liftarmraise/lowercontrol............................................................3-17

Bucketcurl/dumpcontrol..............................................................3-18

ISOcontrolpatternsteeringandtravel..................................................3-19

Movingthemachine...................................................................3-19

Turningthemachine...................................................................3-20

ISOcontrolpatternliftarmandbucketcontrols.........................................3-22

Liftarmandbucketcontrols...........................................................3-22

CONTROLHANDLES

Switchcongurations..................................................................3-23

Two-speedfunction....................................................................3-28

AUXILIARYHYDRAULICS

Standardauxiliaryhydraulics..........................................................3-29

Highowauxiliaryhydraulics..........................................................3-31

EnhancedHighFlow(EHF)auxiliaryhydraulics......................................3-33

INSTRUMENTCLUSTER

ElectronicInstrumentCluster(EIC)...................................................3-35

AdvancedInstrumentCluster(AIC)...................................................3-42

Instrumentcluster.....................................................................3-49

InstrumentclusterSETUPmenu......................................................3-50

Instrumentclusterdisplaysetting......................................................3-51

Electro-Hydraulic(EH)controllabilityselection........................................3-52

Temperaturedisplayselection.........................................................3-57

VieworresetJobTimer(JTIME)......................................................3-58

Anti-theftprotection....................................................................3-59

Left-handcolumnswitchidentication.................................................3-65

ISOorHpatterncontrolswitch........................................................3-68

Machinelights.........................................................................3-69

4OPERATINGINSTRUCTIONS

COMMISSIONINGTHEUNIT

OperatingInstructions..................................................................4-1

STARTINGTHEUNIT

Engineoperation.......................................................................4-3

Operatinginextremetemperatures....................................................4-5

Throttle.................................................................................4-6

Boosterbatteryprocedure..............................................................4-7

STOPPINGTHEUNIT

Parkingthemachineandstoppingtheengine.........................................4-8

MOVINGTHEUNIT

Machineoperation......................................................................4-9

5TRANSPORTOPERATIONS

SHIPPINGTRANSPORT

Transportingthemachine..............................................................5-1

RECOVERYTRANSPORT

Movingadisabledmachine...........................................................5-13

6WORKINGOPERATIONS

GENERALINFORMATION

Mechanicalattachmentmountingsystems.............................................6-1

Hydraulicattachmentmountingsystems...............................................6-4

Fieldoperation..........................................................................6-6

7MAINTENANCE

GENERALINFORMATION

Generalsafetybeforeyouservice......................................................7-1

Lubricationanalysisprogram...........................................................7-3

Plasticandresinparts..................................................................7-3

Machinecleaning.......................................................................7-4

Cabdoorremovalandinstallation......................................................7-5

Batterysafety-checkandcleaning....................................................7-6

Batterydisconnectswitch..............................................................7-8

Fireextinguisher........................................................................7-8

Enginehourmeter......................................................................7-9

Fluidsandlubricants..................................................................7-10

Engineoils.............................................................................7-11

Hydraulicoilviscosity..................................................................7-12

Biodieselfuel..........................................................................7-13

OrganicAcidTechnology(OA T)coolant...............................................7-14

Lubricationandmaintenanceaccess..................................................7-16

Fusesandrelays......................................................................7-18

MAINTENANCECHART

Maintenancechart.....................................................................7-25

INITIAL10HOURS

Tracktensioncheckandadjustment..................................................7-26

Tirepressureandwheelhardwaretorque.............................................7-27

Alternatorandairconditioningcompressor(ifequipped)belttension................7-29

EVERY10HOURSOREACHDAY

Cleantracksandcomponents.........................................................7-30

Engineandhydrauliccoolers..........................................................7-30

Enginecoolantlevel...................................................................7-32

Engineoillevel........................................................................7-34

Loaderarmpivotpoints,couplerpins,andcylinderpins..............................7-35

Hydraulicoillevel......................................................................7-36

Loaderarmandbuckethydraulicinterlock............................................7-37

INITIAL50HOURS

Engineoilandlter....................................................................7-38

RollOverProtectiveStructure(ROPS)mechanismandhardwarecheck............7-42

EVERY50HOURS

Cabintakelter........................................................................7-43

Tracktensioncheck...................................................................7-44

Seatbelt...............................................................................7-45

INITIAL100HOURS

Finaldriveoil(trackmodels)..........................................................7-46

EVERY250HOURS

Fuellter...............................................................................7-47

In-linefuellter........................................................................7-48

Wheelsandtires......................................................................7-50

Drivechaintensioncheck.............................................................7-52

EVERY500HOURS

Aircleanerelements...................................................................7-53

Engineoilandlter....................................................................7-55

Finaldrivechaintankoil...............................................................7-59

Primaryfuellter......................................................................7-60

Hydraulicoillter......................................................................7-61

Finaldriveoil(trackmodels)..........................................................7-62

RollOverProtectiveStructure(ROPS)mechanismandhardwarecheck............7-63

Cabdoor-Grease.....................................................................7-64

8TROUBLESHOOTING

EVERY1000HOURS

Hydraulicuidandlter................................................................7-65

Finaldrivechaintankoil...............................................................7-70

Enginevalveclearance................................................................7-72

EVERY2000HOURS

Radiatordrainandush...............................................................7-73

ASREQUIRED

Hardware-looseordamaged.........................................................7-75

Windowremovalandcleaning........................................................7-76

STORAGE

Storingthemachine...............................................................7-83

FAULTCODERESOLUTION

Errorcodeindex....................................................................8-1

9SPECIFICATIONS

Fluidsandlubricants.......................................................................9-1

Generalspecication.......................................................................9-2

Productidentication–attachments......................................................9-18

Materialweights...........................................................................9-25

Unitsofmeasureandconversion.........................................................9-26

Torquecharts-Minimumtighteningtorquesfornormalassembly.......................9-28

10ACCESSORIES

Telematics-OverviewwithNewHollandFleetForce™...................................10-1

1-GENERALINFORMATION###_1_###

Notetotheowner

1-GENERALINFORMATION

9310026591

Thismanualcontainsimportantinformationaboutthesafeoperation,adjustment,andmaintenanceofyourmachine.

RefertothedetailedINDEXattheendofthismanualforlocatingspecicitemsaboutyourmachine.Yourmachine

conformstocurrentsafetyregulations.Usethismanualasaguide.Y ourmachinewillremainareliableworkingtool

aslongasitiskeptingoodworkingconditionandservicedproperly .

Thismachine,withstandardequipmentandauthorizedattachments,isintendedforabovegroundmaterialhandling.

Useonlyapprovedaccessoriesandattachmentsdesignedforyourmachine.

CNHIndustrialAmerica

LLC

P .O.Box9228

Wichita,Kansas

U.S.A

67277

DEALER'SSTAMPOR

CARD

1-1

1-GENERALINFORMATION

Theinformationinthismanualisprovidedonthebasisofinformationthatwasavailableatthetimethatthemanual

waswritten.Settings,procedures,partnumbers,software,andotheritemscanchange.Thesechangescanaffect

theservicethatisgiventothemachine.Ensurethatyouhavecompleteandcurrentinformationfromyourdealer

beforeyoustartanymachineoperation.

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

Throughoutthismanualandonmachinedecals,youwillndthesignalwordsDANGER,WARNING,andCAUTION

followedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworking

withyou.

DONOToperateorpermitanyonetooperateorservicethismachineuntilyouortheotherpersonshavereadand

understandthesafety,operation,andmaintenanceinstructionsinthismanual.Useonlytrainedoperatorswhohave

demonstratedtheabilitytooperateandservicethismachinecorrectlyandsafely.Allpersonswhowillbeoperating

thismachineshallpossessavalidlocalvehicleoperatingpermitand/orotherapplicablelocalageworkpermit.The

informationinthismanualisprovidedonthebasisofinformationthatwasavailableatthetimethatthemanualwas

written.Settings,procedures,partnumbers,software,andotheritemscanchange.Thesechangescanaffectthe

servicethatisgiventothemachine.Ensurethatyouhavecompleteandmostcurrentinformationfromyourdealer

beforeyoustartyourmachineoperation.

Allpersonswhowillbeoperatingthismachineshallpossessavalidlocalvehicleoperatingpermitand/orotherapplicablelocalageworkpermits.

Useonlyapprovedaccessoriesandattachmentsdesignedforyourmachine.Consultyourdealeronchanges,additions,ormodicationsthatmayberequiredforyourmachine.Donotmakeanyunauthorizedmodicationstoyour

machine.Anyonemakingsuchunauthorizedmodicationsisresponsiblefortheconsequences.

DONOTusethismachineforanypurposeorinanymannerotherthanasdescribedinthemanual,decals,orother

productsafetyinformationprovidedwiththemachine.Thesematerialsdenethemachine'sintendeduse.

ATTENTION:Theengineandfuelsystemonyourmachineisdesignedandbuilttogovernmentemissionsstandards.

Tamperingbydealers,customer,operators,andendusersisstrictlyprohibitedbylaw.Failuretocomplycouldresult

ingovernmentnes,reworkchargesinvalidwarranty,legalaction,andpossibleconscationofthemachineuntil

reworktooriginalconditioniscompleted.Engineserviceandorrepairsmustbedonebyacertiedtechnicianonly!

1-2

1-GENERALINFORMATION

Electro-MagneticCompatibility(EMC)

Interferencemayariseasaresultofadd‐onequipmentthatmaynotnecessarilymeettherequiredstandards.As

suchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobserve

thefollowing:

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine

Theadd‐onequipmentmustnotinterferewiththefunctioningoftheonboardelectronics

•

FailuretocomplywiththeseruleswillrendertheNEWHOLLANDCONSTRUCTIONwarrantynullandvoid.

1-3

1-GENERALINFORMATION

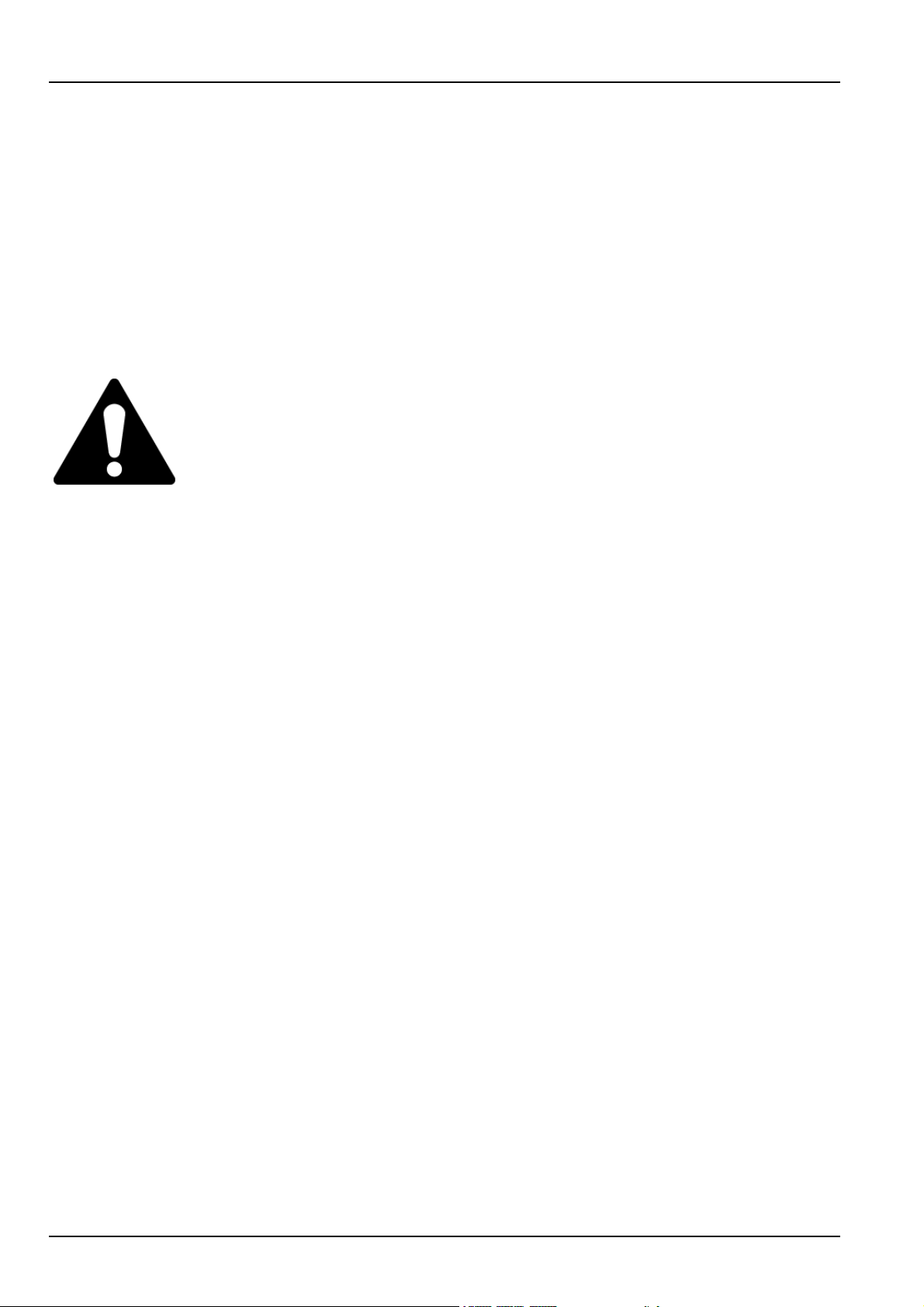

Productidentication

Writeyourmachinemodelnumber,ProductIdenticationNumber(PIN),andserialnumbersonthelinesprovided

below.Alwaysgivethesenumbersandcomponentplatenumberstoyourdealerwhenyouneedpartsorinformation

foryourmachine.

Makearecordofthenumbers.Keepthisrecordandyourmanufacturer’sstatementoforigininasafeplace.Ifthe

machineisstolen,reportthenumberstoyourlocallawenforcementagency.

MACHINE

MachineModelandType

ProductIdenticationNumber

YearofBuild

EngineSerialNumber

HydrostaticPumpSerialNumber

BucketPartNumber

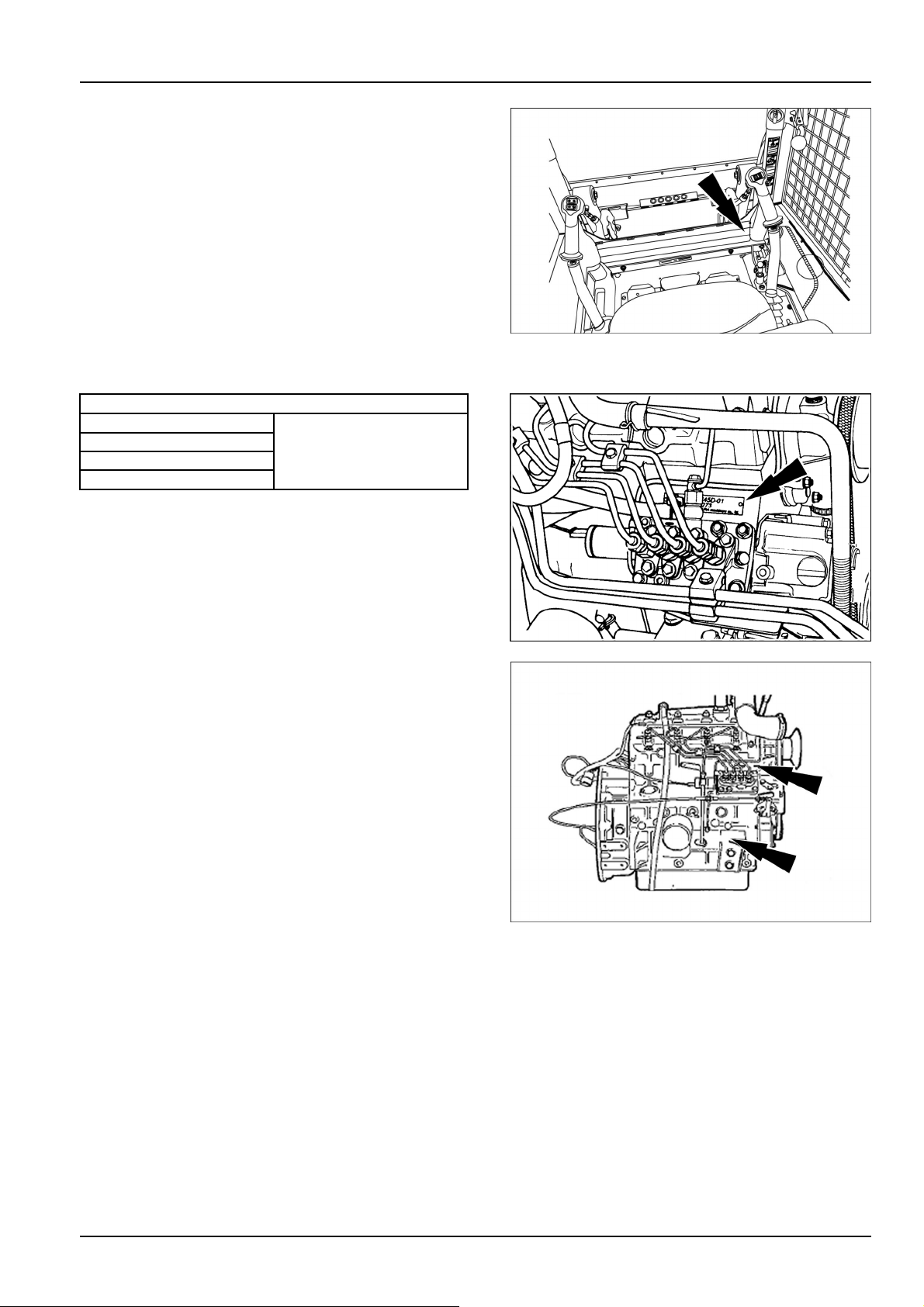

ProductIdenticationNumber(PIN).

Outsideright-handsideofchassis-verticallift.

•

Insideleft-handsideloaderarmtower-radiallift.

•

93107486111

931002296A2

1-4

1-GENERALINFORMATION

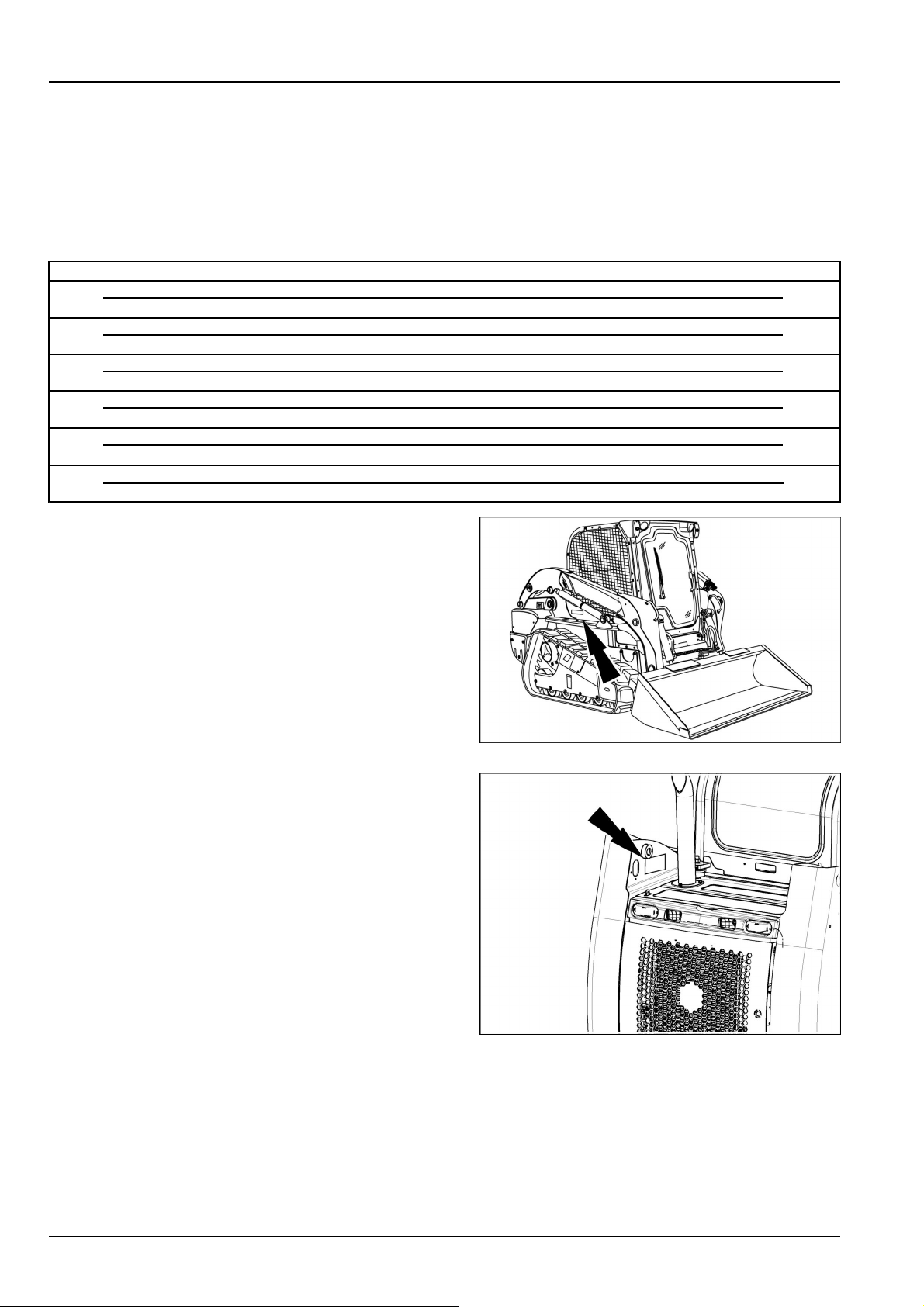

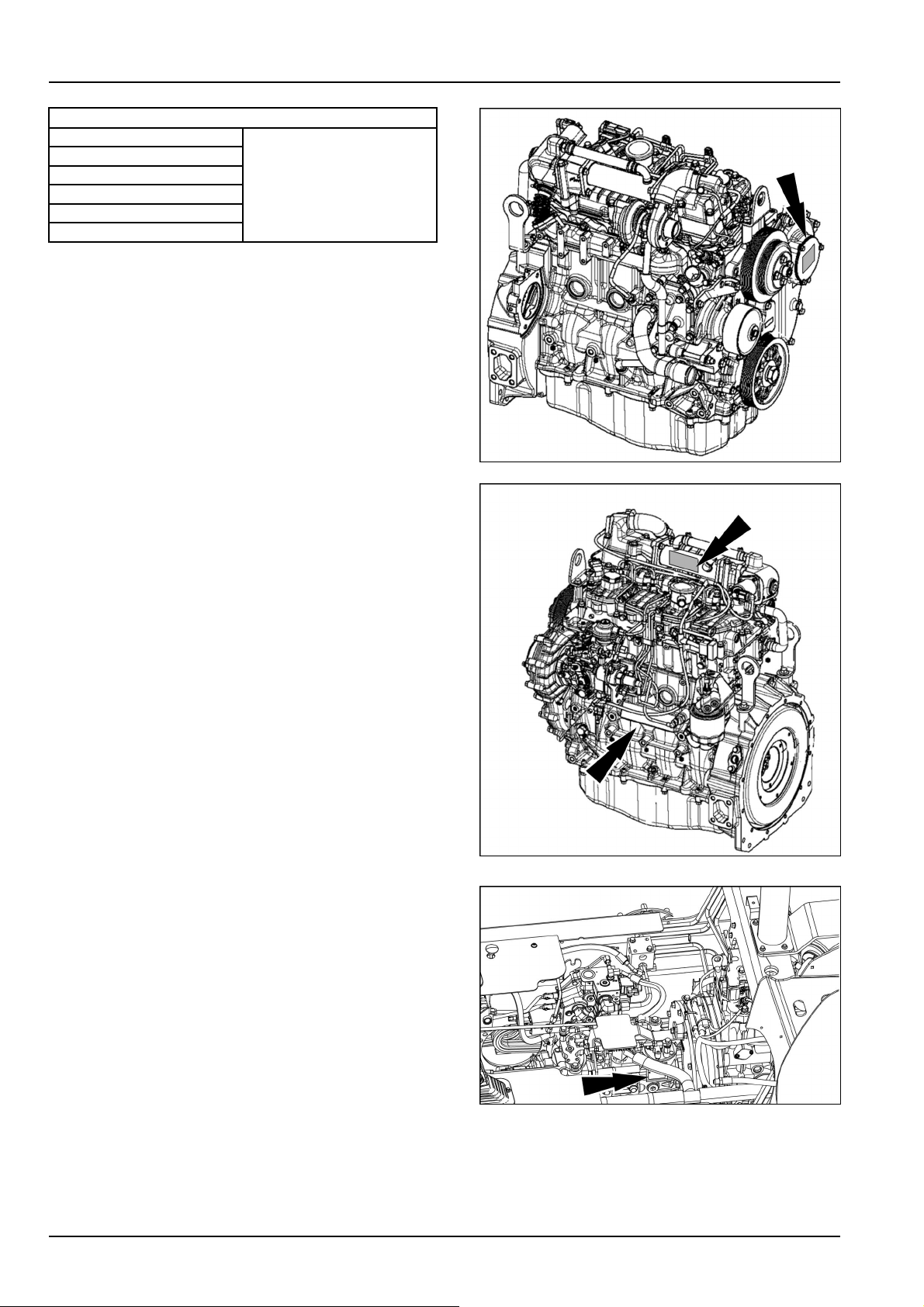

RollOverProtectiveStructure(ROPS)certicationplate.

Frontedge(lower)insidecab.

•

Engineserialnumberplate

Onthefuelinjection-ISMengines.

L213

L215

L218

ISMengine

L220

931007505A3

760757564

RCPH11SSL004AAD5

1-5

Locatedattheendoftheenginethatisfacingrearward

L223

L225

L230

C227

C232

C238

1-GENERALINFORMATION

FPTengines

9310022366

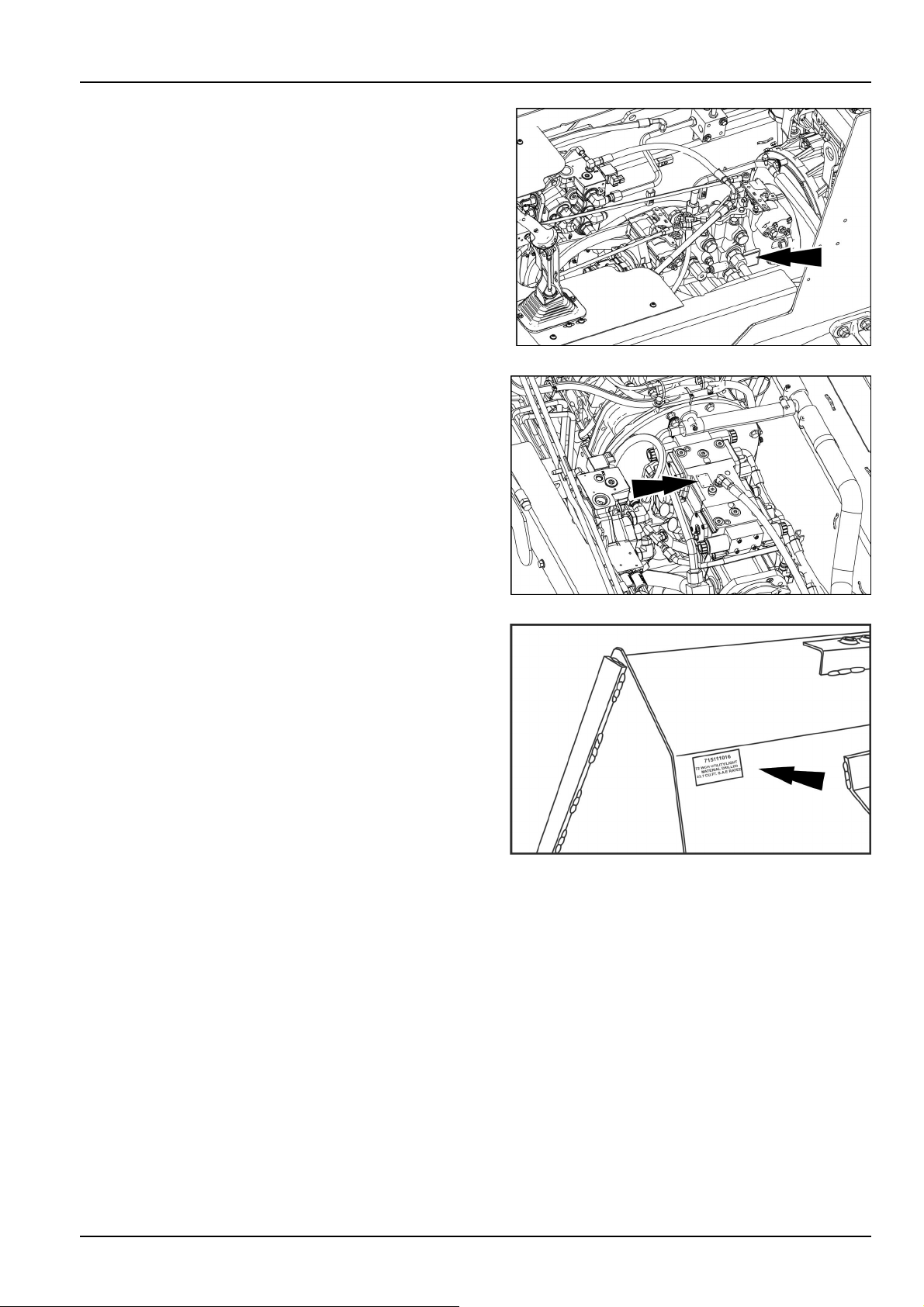

Hydrostaticpump

Mechanical(Manual)hydrostaticpump

•

NOTE:Youmusttiltthecabforwardtoviewthehydrostaticpump.Someitemsnotshownforclarity .

9310022377

RAIL15SSL0134BA8

1-6

1-GENERALINFORMATION

Mechanical(Servo)hydrostaticpump

•

NOTE:Youmusttiltthecabforwardtoviewthehydrostaticpump.Someitemsnotshownforclarity .

Electro-Hydraulic(EH)hydrostaticpump

•

NOTE:Youmusttiltthecabforwardtoviewthehydrostaticpump.Someitemsnotshownforclarity .

RAIL15SSL0133BA9

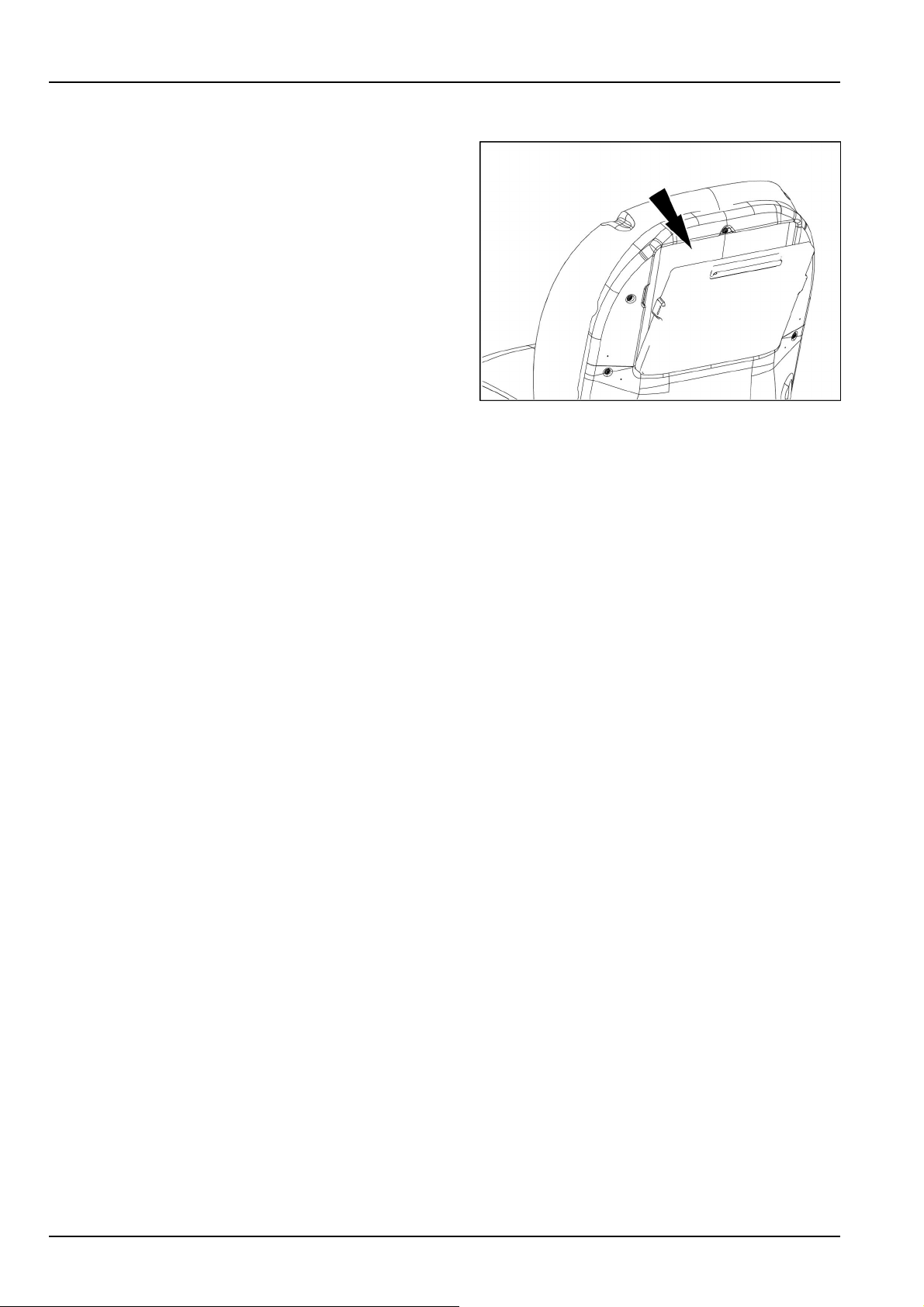

Bucketidenticationplate(partnumberanddescription)

RAIL15SSL0135BA10

BT04F026-0111

1-7

1-GENERALINFORMATION

Operator'smanualstorageonthemachine

KeeptheOperator'smanualinthestoragecompartment

behindtheoperator’sseat.TheOperator'smanualmust

beavailableforusebyalloperators.

RAIL15SSL0131BA1

1-8

1-GENERALINFORMATION

Machineorientation

RAPH12SSL0057BA1

Thetermsfront(1),right-handside(2),rear(3),andleft-handside(4)areusedinthismanualtoindicatethe

directionasseenfromtheoperator'sseat.

1-9

1-GENERALINFORMATION

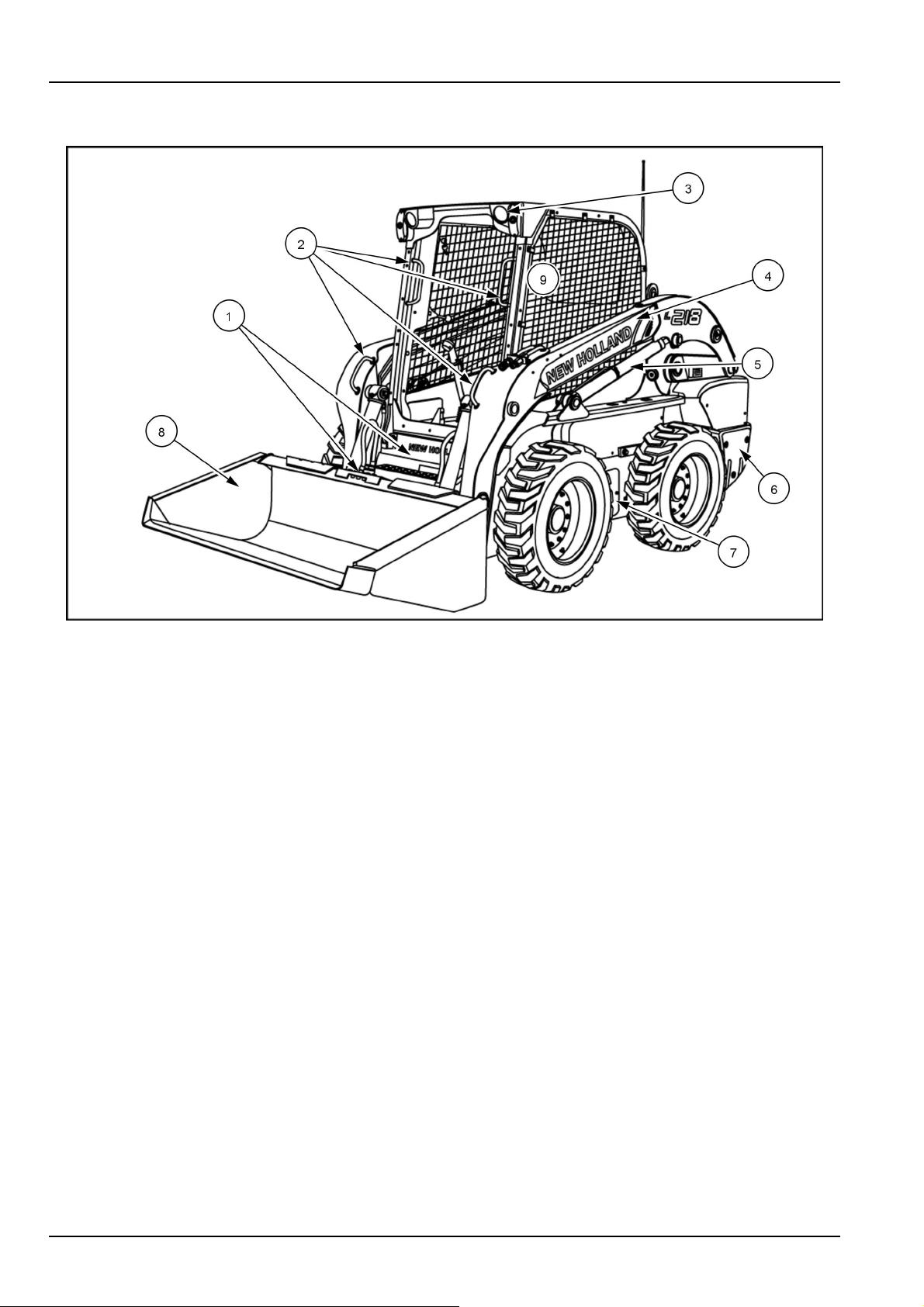

Machinecomponents

931074441

(1)Steps(6)Serviceaccesscover

(2)Hand-holds(7)Chaincompartmentaccess

(3)Frontlights(8)Bucket

(4)Loaderarm(9)Operator'scompartment

(5)Loaderarmcylinder

1-10

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalwords

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

ThroughoutthismanualyouwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworkingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury .

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury .

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY.

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachineorpropertydamage.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

Safetyrules

2-SAFETYINFORMATION

Generalsafetyrules

Usecautionwhenyouoperatethemachineonslopes.

Raisedequipment,fulltanksandotherloadswillchange

thecenterofgravityofthemachine.Themachinecan

tiporrolloverwhennearditchesandembankmentsor

unevensurfaces.

Neverpermitanyoneotherthantheoperatortorideon

themachine.

Neveroperatethemachineundertheinuenceofalcohol

ordrugs,orwhileyouareotherwiseimpaired.

Whendiggingorusingground-engagingattachments,be

awareofburiedcables.Contactlocalutilitiestodetermine

thelocationsofservices.

Payattentiontooverheadpowerlinesandhangingobstacles.Highvoltagelinesmayrequiresignicantclearance

forsafety.

Hydraulicoilordieselfuelleakingunderpressurecan

penetratetheskin,causingseriousinjuryorinfection.

DONOTuseyourhandtocheckforleaks.Useapiece

•

ofcardboardorpaper.

Stoptheengine,removethekey(ifapplicable),and

•

movethecontrolhandlesaroundtorelievethepressure

beforeyouconnectordisconnectuidlines.

Makesurethatallcomponentsareingoodcondition.

•

Tightenallconnectionsbeforeyoustarttheengineor

pressurizethesystem.

Ifhydraulicuidordieselfuelpenetratestheskin,seek

•

medicalattentionimmediately .

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Keepclearofmovingparts.Looseclothing,jewelry,

watches,longhair,andotherlooseorhangingitemscan

becomeentangledinmovingparts.

DONOTattempttoremovematerialfromanypartofthe

machinewhileitisbeingoperatedorwhilecomponents

areinmotion.

Makesurethatallguardsandshieldsareingoodconditionandproperlyinstalledbeforeyouoperatethemachine.Neveroperatethemachinewithshieldsremoved.

Alwayscloseaccessdoorsorpanelsbeforeyouoperate

themachine.

Dirtyorslipperysteps,ladders,walkways,andplatforms

cancausefalls.Makesurethesesurfacesremainclean

andclearofdebris.

Apersonorpetwithintheoperatingareaofamachinecan

bestruckorcrushedbythemachineoritsequipment.DO

NOTallowanyonetoentertheworkarea.

Raisedequipmentand/orloadscanfallunexpectedlyand

crushpersonsunderneath.Neverallowanyonetoenter

theareaunderneathraisedequipmentduringoperation.

Neveroperatetheengineinenclosedspacesasharmful

exhaustgasesmaybuildup.

Beforeyoustartthemachine,besurethatallcontrolsare

inneutralorparklockposition.

Starttheengineonlyfromtheoperator’sseat.Donot

connectorshortacrossterminalsonthestartersolenoid.

Attachjumpercablesasdescribedinthemanual.Starting

ingearmaycausedeathorseriousinjury.

Alwayskeepwindows,mirrors,alllighting,and

Slow-MovingVehicle(SMV)emblemcleantoprovidethe

bestpossiblevisibilitywhileyouoperatethemachine.

Operatecontrolsonlywhenseatedintheoperator’sseat,

exceptforthosecontrolsexpresslyintendedforusefrom

otherlocations.

Wearprotectiveequipmentwhenappropriate.

2-2

2-SAFETYINFORMATION

Beforeyouleavethemachine:

1.Parkthemachineonarm,levelsurface.

2.Lowertheloaderarmsandattachmentstothe

ground.

3.Placeallcontrolsintheneutralposition.

4.PresstheOperatebuttonontheinstrumentpanel,

thisshoulddisablethegrounddriveandtheloader

hydrauliccontrols.

5.Engagetheparkbrake.

6.Checkthattheinterlocksystemisfunctioningby

movingthecontrolsoutoftheneutralposition.Ifany

movementoccursdonotoperatethemachine.Park

themachine,turnofftheengine,andcontactyour

authorizeddealerforassistance.

7.Turnofftheengineandifapplicableremovethekey.

8.Exitthemachine.

9.Usewheelchocksifrequired.

Generalmaintenancesafety

When,duetoexceptionalcircumstances,youwould

decidetokeeptheenginerunningafteryouleave

theOperator’sstation,thenyoumustfollowthese

precautions:

1.Bringtheenginetolowidlespeed.

2.Lowertheloaderarmsandattachmentstotheground.

3.Placeallcontrolsintheirneutralposition.

4.PresstheOperatebuttonontheinstrumentpanel,this

shoulddisablethegrounddriveandtheloaderhydrauliccontrols.

5.Engagetheparkbrake.

6.Checkthattheinterlocksystemisfunctioningbymovingthecontrolsoutoftheneutralposition.Ifany

movementoccursdonotoperatethemachine.Park

themachine,turnofftheengine,andcontactyourauthorizeddealerforassistance.

7.Exitthemachine.

Keeptheareausedforservicingthemachinecleanand

dry.Cleanupspilleduids.

Servicethemachineonarm,levelsurface.

Installguardsandshieldsafteryouservicethemachine.

Closeallaccessdoorsandinstallallpanelsafterservicing

themachine.

Donotattempttoclean,lubricate,clearobstructions,or

makeadjustmentstothemachinewhileitisinmotionor

whiletheengineisrunning.

Alwaysmakesurethatworkingareaisclearoftools,

parts,otherpersonsandpetsbeforeyoustartoperating

themachine.

Unsupportedhydrauliccylinderscanlosepressureand

droptheequipment,causingacrushinghazard.Donot

leaveequipmentinaraisedpositionwhileparkedorduringservice,unlesstheequipmentissecurelysupported.

Jackorliftthemachineonlyatjackorliftpointsindicated

inthismanual.

Incorrecttowingprocedurescancauseaccidents.When

youtowadisabledmachinefollowtheprocedureinthis

manual.Useonlyrigidtowbars.

Stoptheengine,removethekey,andrelievepressure

beforeyouconnectordisconnectuidlines.

Stoptheengineandremovethekeybeforeyouconnect

ordisconnectelectricalconnections.

Scaldingcanresultfromincorrectremovalofcoolant

caps.Coolingsystemsoperateunderpressure.Hot

coolantcansprayoutifyouremoveacapwhilethesystemishot.Allowthesystemtocoolbeforeyouremove

thecap.Whenyouremovethecap,turnitslowlytoallow

pressuretoescapebeforeyoucompletelyremovethe

cap.

Replacedamagedorworntubes,hoses,electricalwiring,

etc.

Theengine,transmission,exhaustcomponents,andhydrauliclinesmaybecomehotduringoperation.T akecare

whenyouservicesuchcomponents.Allowsurfacesto

coolbeforeyouhandleordisconnecthotcomponents.

Wearprotectiveequipmentwhenappropriate.

Whenwelding,followtheinstructionsinthemanual.Alwaysdisconnectthebatterybeforeyouweldonthemachine.Alwayswashyourhandsafteryouhandlebattery

components.

Makesurethattiresarecorrectlyinated.Donotexceed

anyrecommendedloadorpressure.Followtheinstructionsinthemanualforpropertireination.

Wheelsandtires

Tiresareheavy.Handlingtireswithoutproperequipment

couldcausedeathorseriousinjury.

2-3

2-SAFETYINFORMATION

Alwayshaveaqualiedtiretechnicianservicethetires

andwheels.Ifatirehaslostallpressure,takethetireand

wheeltoatireshoporyourdealerforservice.Explosive

separationofthetirecancauseseriousinjury.

DONOTweldtoawheelorrimuntilthetireiscompletely

removed.Inatedtirescangenerateagasmixturewith

Drivingonpublicroadsandgeneraltransportationsafety

Complywithlocallawsandregulations.

Useappropriatelightingtomeetlocalregulations.

MakesurethattheSMVemblemisvisible.

Liftimplementsandattachmentshighenoughabove

groundtopreventaccidentalcontactwithroad.

Whenyoutransportequipmentoramachineonatransporttrailer,makesurethatitisproperlysecured.Besure

theSMVontheequipmentormachineiscoveredwhile

beingtransportedonatrailer.

theairthatcanbeignitedbyhightemperaturesfromweldingproceduresperformedonthewheelorrim.Removing

theairorlooseningthetireontherim(breakingthebead)

willNOTeliminatethehazard.Thisconditioncanexist

whethertiresareinatedordeated.ThetireMUSTbe

completelyremovedfromthewheelorrimpriortoweldingthewheelorrim.

Beawareofoverheadstructuresorpowerlinesandmake

surethatthemachineand/orattachmentscanpasssafely

under.

Travelspeedshouldbesuchthatyoumaintaincomplete

controlandmachinestabilityatalltimes.

Slowdownandsignalbeforeturning.

Pullovertoallowfastertrafctopass.

Fireandexplosionprevention

Fueloroilthatisleakedorspilledonhotsurfacesorelectricalcomponentscancauseare.

Cropmaterials,trash,debris,birdnests,orammable

materialcanigniteonhotsurfaces.

Alwayshaveareextinguisheronornearthemachine.

Makesurethatthereextinguisher(s)ismaintainedand

servicedaccordingtothemanufacturer’sinstructions.

Atleastonceeachdayandattheendoftheday,remove

alltrashanddebrisfromthemachineespeciallyaround

hotcomponentssuchastheengine,transmission,exhaust,battery,etc.Morefrequentcleaningofyourmachinemaybenecessarydependingontheoperatingenvironmentandconditions.

Atleastonceeachday,removedebrisaccumulation

aroundmovingcomponentssuchasbearings,pulleys,

Generalbatterysafety

belts,gears,cleaningfans,etc.Morefrequentcleaning

ofyourmachinemaybenecessarydependingonthe

operatingenvironmentandconditions.

Inspecttheelectricalsystemforlooseconnectionsand

frayedinsulation.Repairorreplacelooseordamaged

parts.

Donotstoreoilyragsorotherammablematerialonthe

machine.

Donotweldoramecutanyitemsthatcontainammable

material.Cleanitemsthoroughlywithnon-ammablesolventsbeforeweldingorame-cutting.

Donotexposethemachinetoames,burningbrush,or

explosives.

Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringoperationofthemachine.

Alwaysweareyeprotectionwhenyouworkwithbatteries.

Donotcreatesparksorhaveopenamenearabattery.

Ventilatetheareawhenyouchargeabatteryorusea

batteryinanenclosedarea.

Disconnectthenegative(-)terminalrstandreconnect

thenegative(-)terminallast.

Whenyouweldonthemachine,disconnectbothterminalsofthebattery.

Donotweld,grind,orsmokenearabattery .

Whenyouuseauxiliarybatteriesorconnectjumpercablestostarttheengine,usetheprocedureshowninthe

operator’smanual.Donotshortacrossterminals.

2-4

2-SAFETYINFORMATION

Followthemanufacturer’sinstructionswhenyoustore

andhandlebatteries.

Batterypost,terminals,andrelatedaccessoriescontain

leadandleadcompounds.Washhandsafterhandling.

ThisisaCaliforniaProposition65warning.

Batteryacidcausesburns.Batteriescontainsulfuricacid.

Avoidcontactwithskin,eyes,orclothing.Antidote(exter-

Operatorpresencesystem

Yourmachineisequippedwithanoperatorpresencesystemtopreventtheuseofsomefeatureswhiletheoperator

isnotintheoperator’sseat.

Reectorsandwarninglights

Youmustuseashingamberwarninglightswhenyou

operateequipmentonpublicroads.

nal):Flushwithwater.Antidote(eyes):ushwithwater

for15minutesandseekmedicalattentionimmediately.

Antidote(internal):Drinklargequantitiesofwaterormilk.

Donotinducevomiting.Seekmedicalattentionimmediately.

Keepoutofreachofchildrenandotherunauthorizedpersons.

Neverdisconnectorbypasstheoperatorpresencesystem.

Iftheoperatorpresencesystemisinoperable,thenitmust

berepaired.Followthetestprocedure(7-37).

Air-conditioningsystem

Theair-conditioningsystemisunderhighpressure.Do

notdisconnectanylines.Thereleaseofhighpressure

cancauseseriousinjury.

PersonalProtectiveEquipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchashard

hat,eyeprotection,heavygloves,hearingprotection,protectiveclothing,etc.

DoNotOperatetag

Beforeyoustartservicingthemachine,attacha‘DoNot

Operate’warningtagtothemachineinanareathatwill

bevisible.

Theair-conditioningsystemcontainsgasesthatare

harmfultotheenvironmentwhenreleasedintotheatmosphere.Donotattempttoserviceorrepairthesystem.

Onlytrainedservicetechnicianscanservice,repair,or

rechargetheair-conditioningsystem.

Operatorprotectivestructure

Yourmachineisequippedwithanoperatorprotective

structure,suchas:aRollOverProtectiveStructure

(ROPS),FallingObjectsProtectiveStructure(FOPS),

oracabwithaROPS.AROPSmaybeacanframe

oratwo-postedorfour-postedstructureusedforthe

protectionoftheoperatortominimizethepossibilityof

seriousinjury .Themountingstructureandfasteners

formingthemountingconnectionwiththemachineare

partoftheROPS.

Theprotectivestructureisaspecialsafetycomponentof

yourmachine.

2-5

2-SAFETYINFORMATION

DONOTattachanydevicetotheprotectivestructurefor

pullingpurposes.DONOTdrillholestotheprotective

structure.

Theprotectivestructureandinterconnectingcomponents

areacertiedsystem.Anydamage,re,corrosion,or

modicationwillweakenthestructureandreduceyour

protection.Ifthisoccurs,THEPROTECTIVESTRUCTUREMUSTBEREPLACEDsothatitwillprovidethe

sameprotectionasanewprotectivestructure.Contact

yourdealerforprotectivestructureinspectionandreplacement.

Afteranaccident,re,tipover,orrollover,thefollowing

MUSTbeperformedbyaqualiedtechnicianbefore

returningthemachinetoeldorjob-siteoperations:

TheprotectivestructureMUSTBEREPLACED.

•

Hazardouschemicals

Ifyouareexposedtoorcomeincontactwithhazardous

chemicalsyoucanbeseriouslyinjured.Theuids,lubricants,paints,adhesives,coolant,etc.requiredforthe

functionofyourmachinecanbehazardous.Theymay

beattractiveandharmfultodomesticanimalsaswellas

humans.

MaterialSafetyDataSheets(MSDS)provideinformation

aboutthechemicalsubstanceswithinaproduct,safe

handlingandstorageprocedures,rstaidmeasures,and

procedurestotakeintheeventofaspilloraccidental

release.MSDSareavailablefromyourdealer.

BeforeyouserviceyourmachinechecktheMSDSfor

eachlubricant,uid,etc.usedinthismachine.Thisinformationindicatestheassociatedrisksandwillhelpyou

servicethemachinesafely.Followtheinformationinthe

Themountingorsuspensionfortheprotectivestruc-

•

ture,operator’sseatandsuspension,seatbeltsand

mountingcomponents,andwiringwithintheoperator’s

protectivesystemMUSTbecarefullyinspectedfor

damage.

AlldamagedpartsMUSTBEREPLACED.

•

DONOTWELD,DRILLHOLES,A TTEMPTTO

STRAIGHTEN,ORREPAIRTHEPROTECTIVESTRUCTURE.MODIFICATIONINANYWAYCANREDUCE

THESTRUCTURALINTEGRITYOFTHESTRUCTURE,

WHICHCOULDCAUSEDEATHORSERIOUSINJURY

INTHEEVENTOFFIRE,TIPOVER,ROLLOVER,

COLLISION,ORACCIDENT .

Seatbeltsarepartofyourprotectivesystemandmustbe

wornatalltimes.Theoperatormustbeheldtotheseat

insidetheframeinorderfortheprotectivesystemtowork.

MSDS,andonmanufacturercontainers,aswellastheinformationinthismanual,whenyouservicethemachine.

Disposeofalluids,lters,andcontainersinanenvironmentallysafemanneraccordingtolocallawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

Storeuidsandltersinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthestorageofchemicalsorpetrochemicalsubstances.

Keepoutofreachorchildrenorotherunauthorizedpersons.

Appliedchemicalsrequireadditionalprecautions.Obtain

completeinformationfromthemanufacturerordistributor

ofthechemicalsbeforeyouusethem.

Electricalstormsafety

Donotoperatemachineduringanelectricalstorm.

Ifyouareonthegroundduringanelectricalstorm,stay

awayfrommachineryandequipment.Seekshelterina

permanent,protectedstructure.

Liftingandoverheadloads

Neveruseloaderbuckets,forks,etc.orotherlifting,handling,ordiggingequipmenttoliftpersons.

Donotuseraisedequipmentasaworkplatform.

Ifanelectricalstormshouldstrikeduringoperation,remaininthecab.Donotleavethecaboroperator’splatform.Donotmakecontactwiththegroundorobjects

outsidethemachine.

Knowthefullareaofmovementofthemachineandequipmentanddonotenterorpermitanyonetoenterthearea

ofmovementwhilethemachineisinoperation.

Neverenterorpermitanyonetoentertheareaunderneathraisedequipment.Equipmentand/orloadscanfall

unexpectedlyandcrushpersonsunderneathit.

2-6

2-SAFETYINFORMATION

Donotleaveequipmentinraisedpositionwhileparked

orduringservice,unlesssecurelysupported.Hydraulic

cylindersmustbemechanicallylockedorsupportedif

theyareleftinaraisedpositionforserviceoraccess.

Loaderbuckets,forks,etc.orotherlifting,handling,or

diggingequipmentanditsloadwillchangethecenterof

gravityofthemachine.Thiscancausethemachinetotip

onslopesorunevenground.

Loaditemscanfallofftheloaderbucketorliftingequipmentandcrushtheoperator.Caremustbetakenwhen

liftingaload.Useproperliftingequipment.

Donotliftloadhigherthannecessary.Lowerloadsto

transport.Remembertoleaveappropriateclearanceto

thegroundandotherobstacles.

Equipmentandassociatedloadscanblockvisibilityand

causeanaccident.Donotoperatewithinsufcientvisibility.

2-7

2-SAFETYINFORMATION

Utilitysafety

YOUMUSTFOLLOWsafetyprecautionswhenyouwork

nearburiedutilitylines.

Duringoperationitislikelythatyouwillbeworking

aroundornearburiedutilitylinesthatmayinclude,but

arenotlimitedto:

Electricalpowerline

•

Gasline

•

Waterline

•

Communicationline-telephoneorcabletelevision

•

Sewerline

•

NOTICE:Beforeconstructionworkbeginsitisyourresponsibilitytobeawareofallutilitylinesintheareaof

yourprojectandtoavoidthem.

ALWAYShavealllocalutilitycompaniesmarkthelocation

oftheirlines.

NOTICE:Checkwithlocalauthoritiesforlaws,regulations,and/orstrictpenaltiesrequiringyoutolocateand

avoidexistingutilities.

Callallutilitycompaniesbeforeyouperform

anymachineoperation

Afteryoulocateanyburiedutilitylines,carefullydigahole

totheutilitylinebyhandand/orwithautomaticvacuum

equipment.Verifythelocationanddepthoftheline.

Whereapplicable,knowtheutilitycolorcode.

ElectricRed

Gas,Oil,orPetroleum

Communication,T elephone,T elevisionOrange

WaterBlue

SewerGreenor

ProposedExcavationWhite

Surveying

ReclaimedWaterandSlurry

Coordinateallexcavationactivitywiththeproperauthoritiesandprofessionalsbeforebeginning.

Yellow

Brown

Pink

Purple

2-8

2-SAFETYINFORMATION

Properentryandexit

DANGER

Crushinghazard!

Donotenterorexittheoperator'scompartmentwhiletheloaderarmsareraisedorunsupported.Rest

theloaderarmsonthegroundorverifythatloaderarmisbeingsupportedbytheloaderarmstrutor

loaderarmlockpinbeforeenteringorexitingtheoperator'scompartment.

Failuretocomplywillresultindeathorseriousinjury.

WARNING

Fallhazard!

Jumpingonoroffthemachinecouldcauseaninjury.Alwaysfacethemachine,usethehandrails

andsteps,andgetonoroffslowly.Maintainathree-pointcontacttoavoidfalling:bothhandsonthe

handrailsandonefootonthestep,oronehandonthehandrailandbothfeetonthesteps.

Failuretocomplycouldresultindeathorseriousinjury.

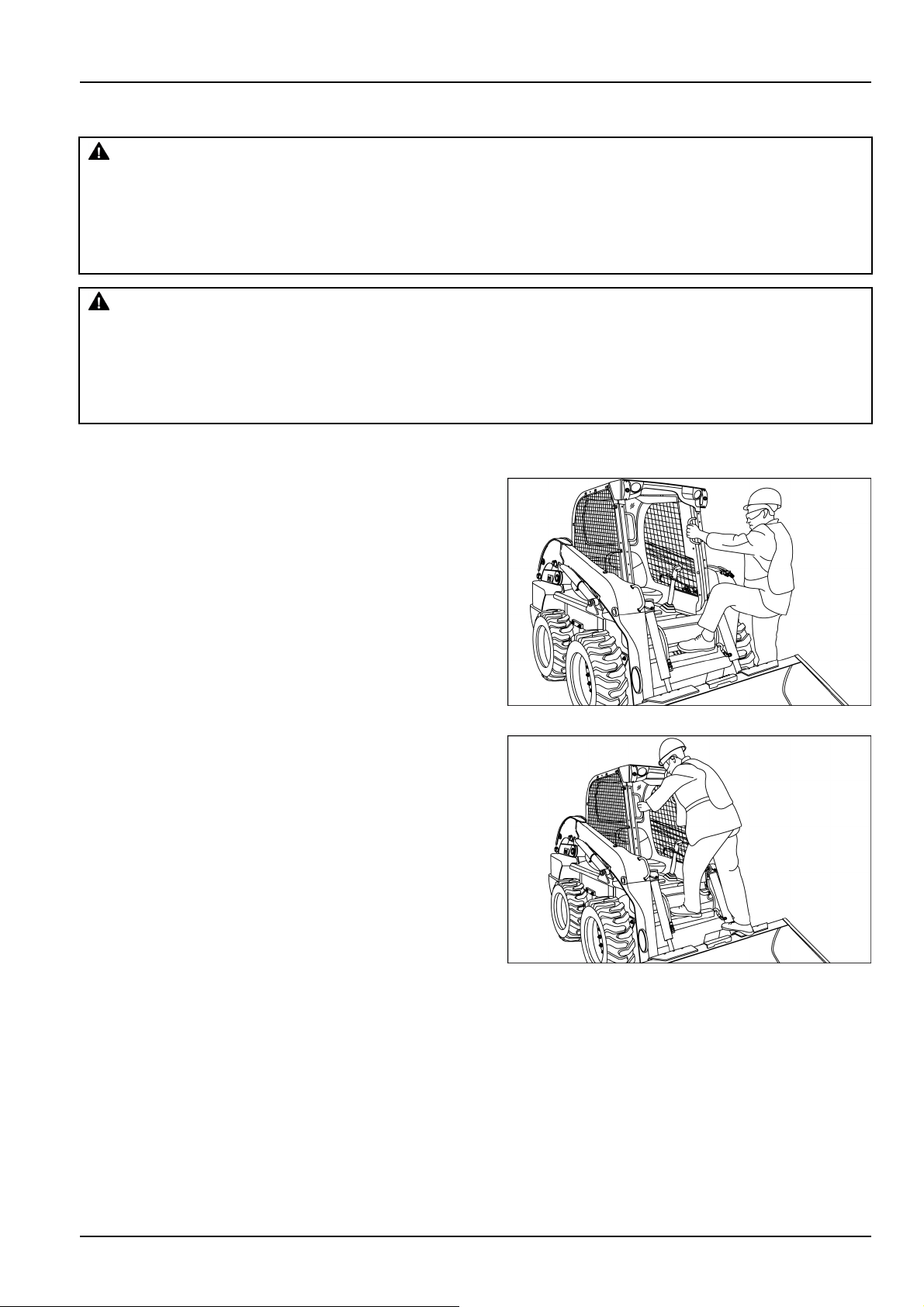

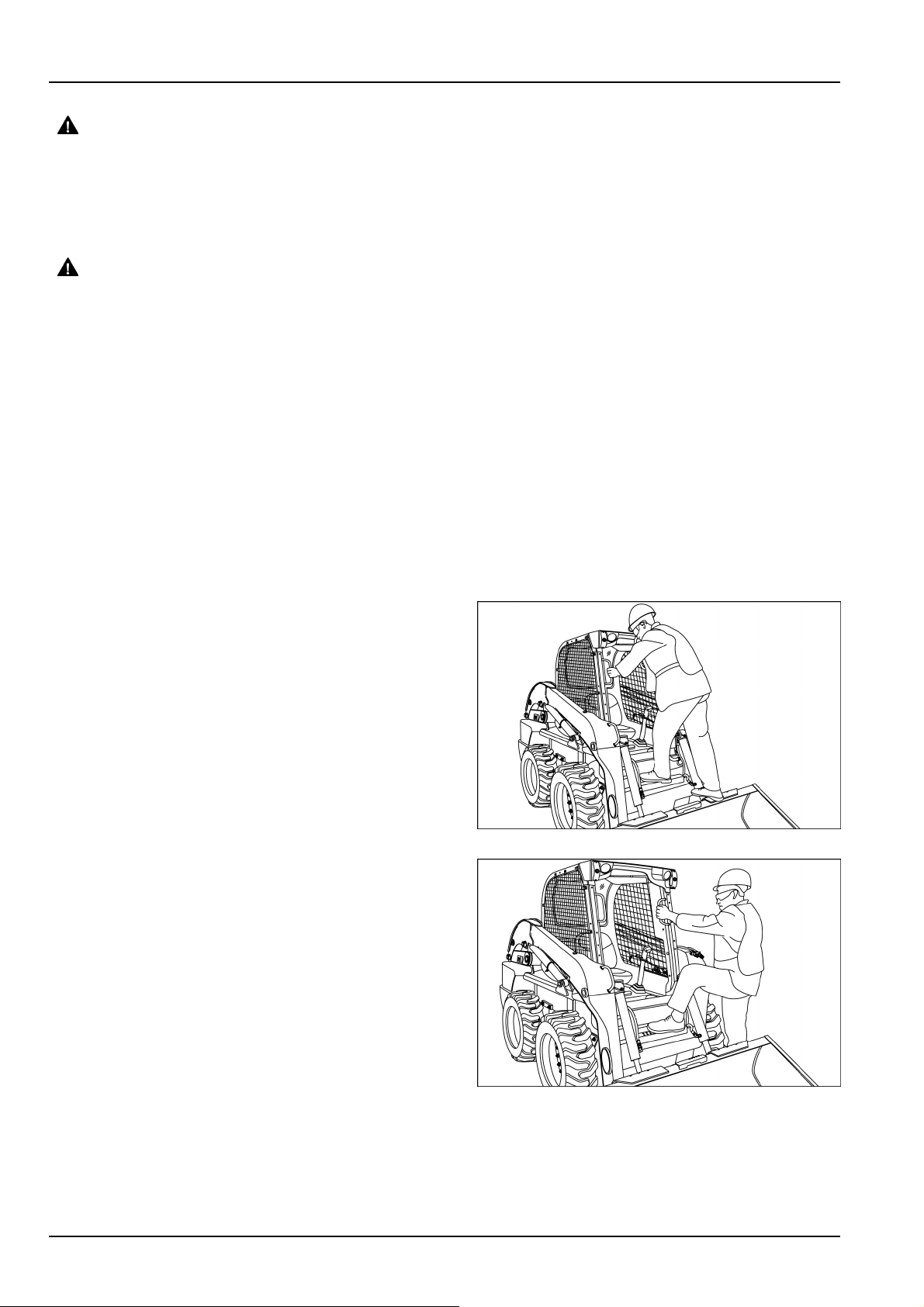

Enterthemachine

1.Facethecabentrypoint.

2.Ifapplicable,openthecabdoor.

3.Handholdsareprovidedontheloaderarm,frontcab

posts,orontheinsideofthecabdoor.Grabthehand

holds.

4.Placeonefootontheloaderarmcouplersteporon

thebucketstep.

D0168A

W0141A

5.Pullyourselfup,facethemachine,andstandonthe

step(s).

6.Positionyourhandssothatyouarecomfortablewith

steppingintothecab.

7.Placeonefootintothecenterareaofthecab.Astep

areaisprovidedbetweenthefootpedals,ifequipped.

8.Stepintothecab,turnyourbody,andsitintheoperator’sseat.

9310022861

9310022852

2-9

2-SAFETYINFORMATION

DANGER

Crushinghazard!

Donotenterorexittheoperator'scompartmentwhiletheloaderarmsareraisedorunsupported.Rest

theloaderarmsonthegroundorverifythatloaderarmisbeingsupportedbytheloaderarmstrutor

loaderarmlockpinbeforeenteringorexitingtheoperator'scompartment.

Failuretocomplywillresultindeathorseriousinjury.

WARNING

Fallhazard!

Jumpingonoroffthemachinecouldcauseaninjury.Alwaysfacethemachine,usethehandrails

andsteps,andgetonoroffslowly.Maintainathree-pointcontacttoavoidfalling:bothhandsonthe

handrailsandonefootonthestep,oronehandonthehandrailandbothfeetonthesteps.

Failuretocomplycouldresultindeathorseriousinjury.

Exitthemachine

1.Lowertheloaderarmandorattachmentstothe

ground.

2.Stoptheengine.Theparkingbrakeisautomatically

set.

3.Removetheseatbelt.Ifequipped,raisetherestraint

bar.

D0168A

W0141A

4.Ifapplicable,openthecabdoor.

5.Grabthehandholds.

6.Pullyourselfupandplaceonefootontheloaderarm

couplersteporonthebucketstep.

7.Positionyourhandsonthehandholdssothatyouare

comfortablewithsteppingoutofthecab.

8.Stepoutofthemachineandturnyourbodysothatyou

facethemachine.

9.Lookandmakesurethatthegroundareaisclearto

stepoffofthemachine.

10.Positionyourhandssothatyouarecomfortablewith

steppingoffofthemachine.

11.Placeonefootontheground.

12.Placetheotherfootonthegroundandsafelymove

awayfromthemachine.

9310022853

9310022864

2-10

Startingandstoppingprecautions

2-SAFETYINFORMATION

Walkaroundthemachineandattachmentstowarnall

•

personnelwhomaybeservicingthemachineorarein

themachinepathpriortostarting.Donotstartuntilall

personnelareclearlyawayfromthemachine.Sound

thehorn,ifequipped,beforestarting.

Walkaroundthemachineandattachment.Ensurethat

•

allsafetyprecautions/warningsareupheldandall

safetydevicesareworkingastheattachmentmanufacturestatesintheirsafetyinformation.

Checkthattheparkingdeviceisapplied,placeallcon-

•

trolsinneutralorparkasspeciedbythemanufacturer,

beforestartingthemachine.

Adjust,secure,andlatchtheseatbelt.Ifequipped,

•

lowertherestraintbarbeforestartingthemachine.

Toavoidpotentialseriousinjurybycontactwiththema-

•

chine’smovingattachment,DONOTrewiretobypass

theseat,seatbeltswitches,orrestraintbarswitches(if

equipped).

Startandoperatethemachineonlyfromtheoperator’s

•

seat.

Usejumpercablesonlyintherecommendedmanner.

•

Improperusecanresultinbatteryexplosionorunex-

pectedmachinemotion.V entilatethebatteryareabeforeusingjumpercables.Makesurethatusingjumper

cableswillnotinterfereorharmelectronicdevices.

DONOToperatetheengineinanenclosedareawith-

•

outadequateventilation.

Parkthemachineonlevelgroundwheneverpossible

•

andapplytheparkingbrake.Ongrades/slope,park

themachinewiththewheelsortracksecurelyblocked.

Beforeleavingtheoperatorstation,lowertheequip-

•

menttothegroundandshutofftheengine.

Removethestarterkeyorlocktheinstrumentpanel,

•

orturnthemasterdisconnectswitch(ifequipped)to

theOFFpositionwhenleavingthemachineparkedor

unattended.

2-11

2-SAFETYINFORMATION

Seatbeltprecautions

Seatbelts

Seatbeltsmustbewornatalltimes.

Seatbeltinspectionandmaintenance:

Keepseatbeltsingoodcondition.

•

Keepsharpedgesanditemsthancancausedamage

•

awayfromthebelts.

Periodicallycheckbelts,buckles,retractors,tethers,

•

slacktake-upsystem,andmountingboltsfordamage

andwear.

Replaceallpartsthathavedamageorwear.

•

Replacebeltsthathavecutsthatcanmakethebelt

•

weak.

WARNING

Avoidinjury!

Beforestartingtheengine,securelyfastenthe

seatbelt.Theseatbeltcanhelpensureyour

safetyifitisproperlyusedandmaintained.

Neverwearaseatbeltlooselyorwithslack

inthebeltsystem.Neverwearthebeltifit

istwistedorpinchedbetweentheseatstructures.

Failuretocomplycouldresultindeathorseriousinjury .

Checkthatboltsaretightontheseatbracketormount-

•

ing.

Ifbeltisattachedtoseat,makesureseatorseatbrack-

•

etsaremountedsecurely.

Keepseatbeltscleananddry.

•

Cleanbeltsonlywithsoapsolutionandwarmwater.

•

Donotusebleachordyeonthebeltsbecausethiscan

•

makethebeltsweak.

W0142A

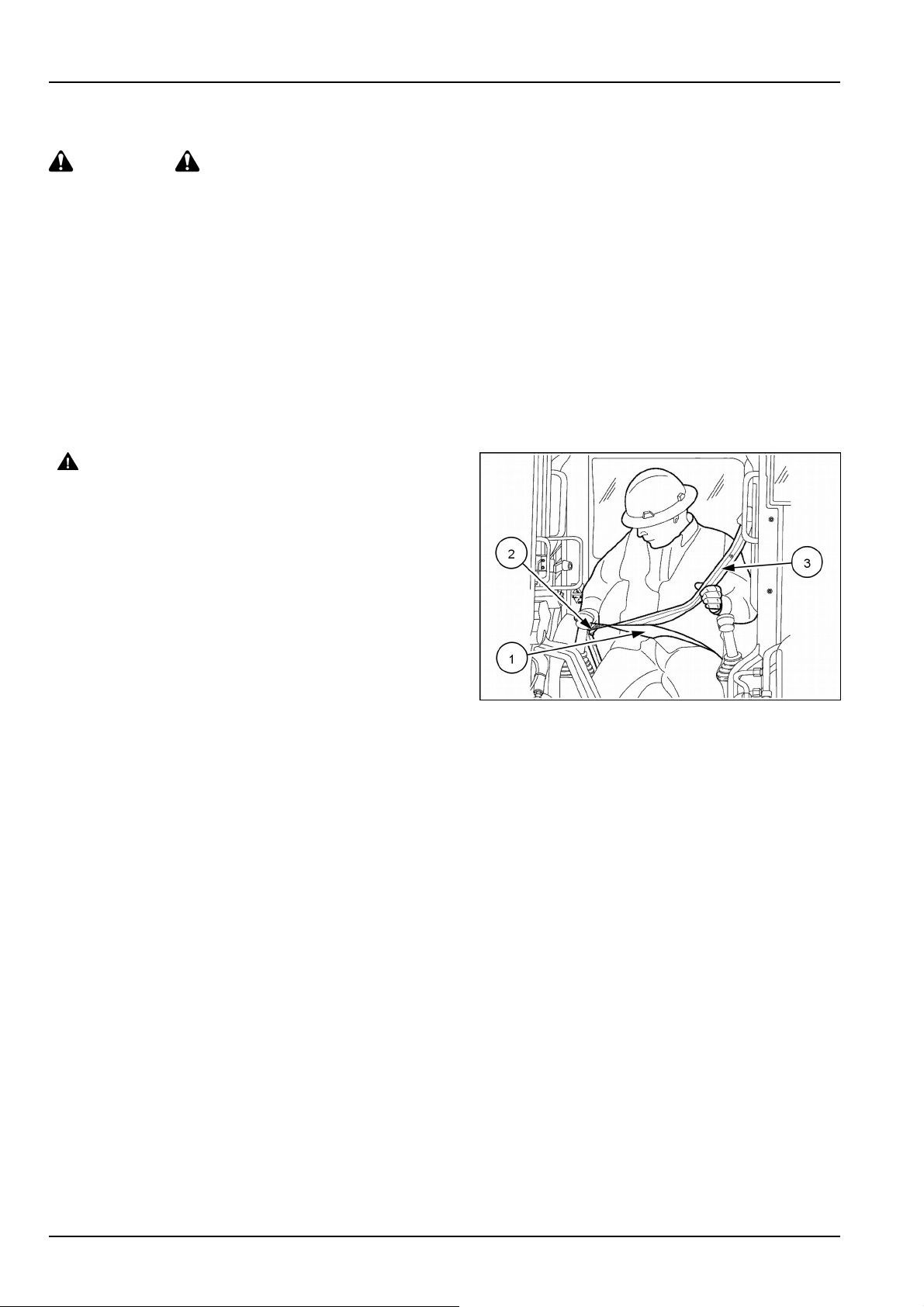

1.Pulltheseatbeltretractablehalf(1)acrossandbuckle

securelywiththebucklehalf(2).

2.Ashoulderbelt(3)isavailablefromyourdealer.Some

machinecongurationsareequippedwithashoulder

belt.

NOTE:StateorLocalregulationsmayrequirea

7.6cm(3in)webbingseatbeltavailablethrough

DealerServiceParts.Thisbeltmaybenecessaryin

someindustrialapplications.Checkyourlocalcodes.

BD07C132I-31

2-12

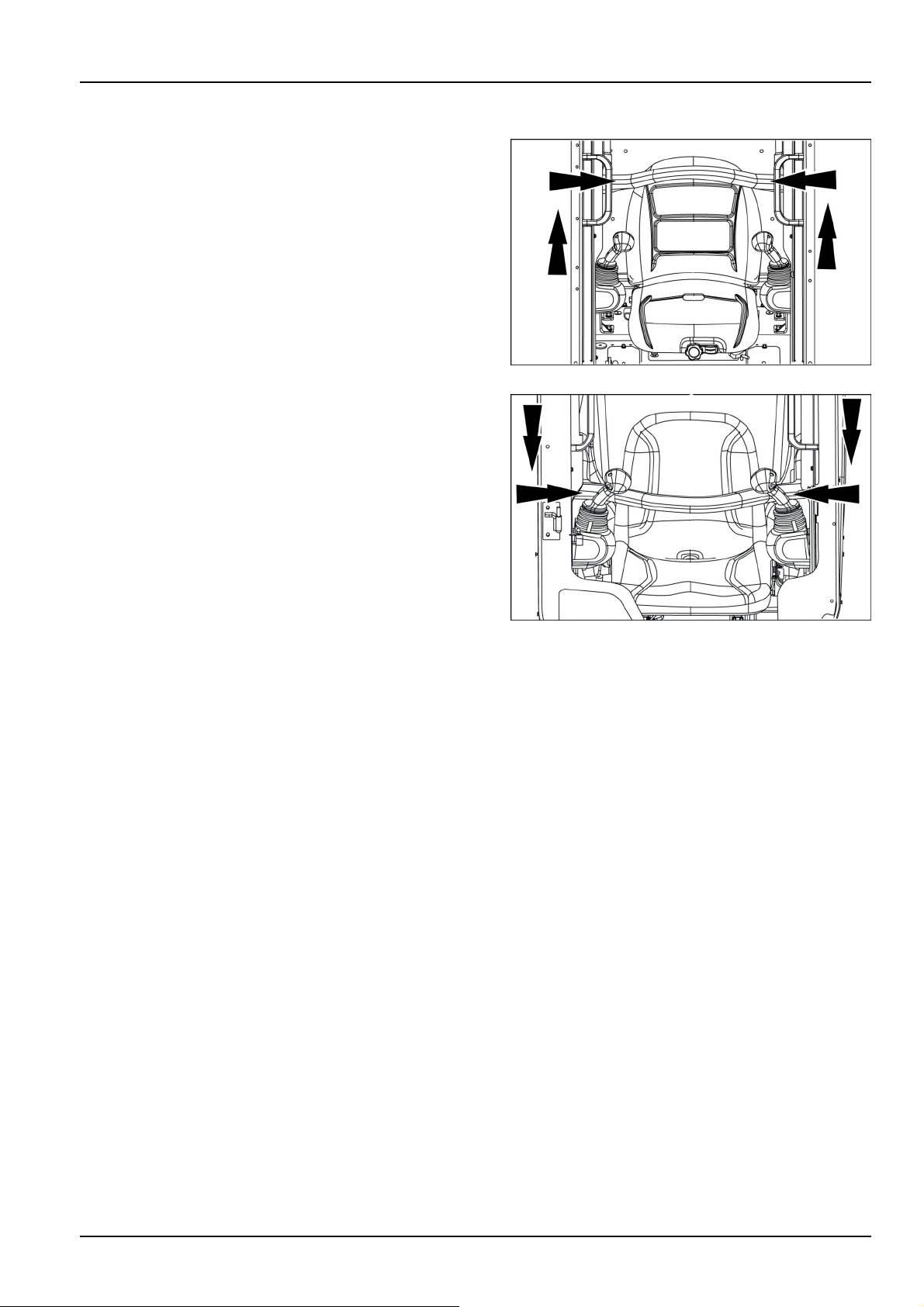

Seatrestraintbar(ifequipped)

Therestraintbarmustbedownintheoperatingposition

beforestarting.

Seatrestraintbarintheraisedposition.

Seatrestraintbarintheoperatingposition.

2-SAFETYINFORMATION

931093332

931093073

2-13

2-SAFETYINFORMATION

Specicprecautionstothismachine

DANGER

Crushinghazard!

Donotenterorexittheoperator'scompartmentwhiletheloaderarmsareraisedorunsupported.Rest

theloaderarmsonthegroundorverifythatloaderarmisbeingsupportedbytheloaderarmstrutor

loaderarmlockpinbeforeenteringorexitingtheoperator'scompartment.

Failuretocomplywillresultindeathorseriousinjury.

Allmachinesareequippedwithsafetysupportfeatureswhenserviceormaintenanceofthemachineisrequired.

•

Youmaysecuretheloaderarminaraisedpositionandsecurethecabinatiltposition.Thesefeaturesallow

greateraccesstotheinternalcomponentsofthemachine.Readandunderstandthe“Loaderarmlockandcabtilt

procedure-radialliftmachines”page2-18or“Loaderarmlockandcabtiltprocedure-verticalliftmachines”page

2-22inthismanual.

Placeallcontrolsinneutralbeforeleavingthecabandbecarefulnottoengagethemaccidentlywhenenteringor

•

exitingthecab.

Beforeleavingtheoperatorscompartmentchecktheinterlocksystemsomovementofcontrolsdonotresultin

•

machinemovement.Followthe“Loaderarmandbuckethydraulicinterlock”procedureonpage7-37.

Keeptheloadortoolaslowaspossiblewhilemovingthemachinearoundthejobsite.

•

Conrmthatthecouplerlockpinsareengagedwiththebucketorattachmentretainingtabs.

•

Donotoverllthebucket.Dirt,rocksanddebriscanentertheoperatorarea.

•

D0168A

Fireextinguisher

Itisrecommendedthatyouhaveareextinguisheronyourmachine.Contactyourdealerforthetypeandlocation

ofareextinguisheronthismachine.

2-14

Loading...

Loading...