New Buck Corporation DV23ZC User Manual

OPERATIONS MANUAL FOR THE MODEL DV23ZC

DIRECT VENT ZERO CLEARANCE GAS FIREPLACE

APPROVED FOR MOBILE HOME INSTALLATION

WARNING:

explosion may result causing property damage, personal injury, or loss of life.

-DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

-WHAT TO DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use any phone in your building.

* Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

* If you cannot reach the gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer, service agency, or the gas

supplier.

-Save this manual for future reference.

New Buck Corporation Revised Aug/2008

P.O. Box 69

200 Ethan Allen Drive

Spruce Pine, NC 28777

If the following information in this manual is not followed exactly, a fire or

TABLE OF CONTENTS

Introduction .......................................................................................................................... 3

Specifications ....................................................................................................................... 3

Installation ........................................................................................................................... 5

Location and Clearance ....................................................................................................... 5

Assembly Steps-Overview ................................................................................................... 5

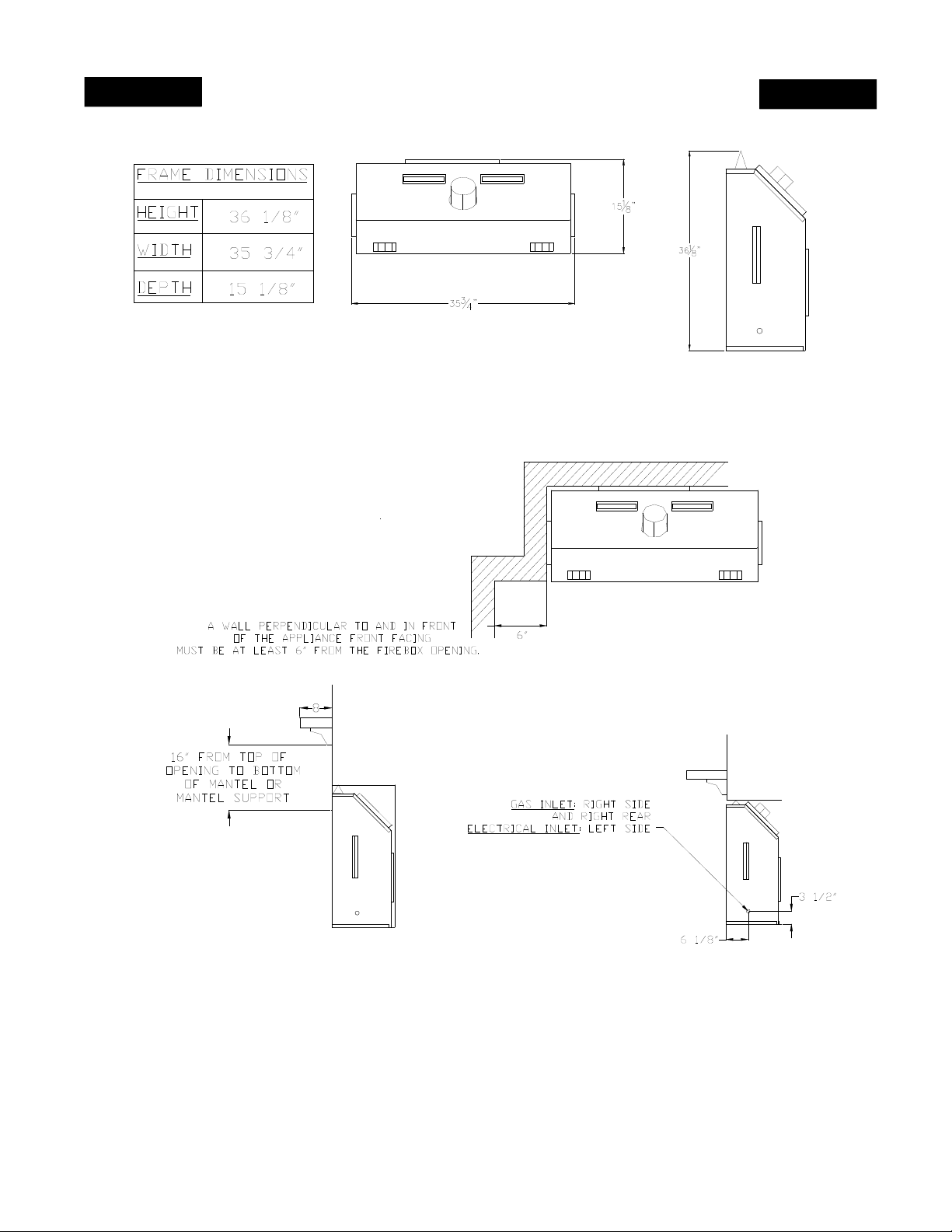

Appliance and Framing Dimensions ................................................................................... 6

Exterior Vent Locations and Restrictions ............................................................................ 9

Minimum-Maximum Vent Length Requirement ............................................................... 10

Vent Assembly ................................................................................................................... 11

Horizontal Termination ..................................................................................................... 11

Vertical Termination .......................................................................................................... 14

High Altitude ..................................................................................................................... 17

Gas Valve Connection ....................................................................................................... 18

Gas Pressure Checks .......................................................................................................... 18

Operating Instructions ....................................................................................................... 19

Lighting Instructions .......................................................................................................... 19

Shut Off Procedure ........................................................................................................... 21

Log Installation .................................................................................................................. 22

Pilot and Flame .................................................................................................................. 23

Glass Door Installation ...................................................................................................... 23

Wiring Diagrams ............................................................................................................... 24

Accessories or Options ...................................................................................................... 25

Maintenance ....................................................................................................................... 26

General Maintenance ......................................................................................................... 26

Replacement Parts ............................................................................................................. 27

Warranty ............................................................................................................................ 30

1

2

This instruction manual will help you obtain a safe, efficient, dependable installation for your appliance

and vent system. Please read and understand these instructions before beginning your installation.

The model DV23ZC is a sealed combustion, air circulating gas appliance designed for residential and

mobile home applications. The appliance must be installed with Dura-Vent GS vent system that is

routed to outside atmosphere. It is also listed for bedroom installations.

This appliance is designed to operate on natural or propane gas. A millivolt gas control valve with piezo

ignition system provides safe, efficient operation. No external electrical power is required to operate the

gas valve and burner. 120VAC is required to operate the room air fan.

This appliance complies with National Safety Standards and is tested and listed by (ITS) Intertek Testing

Services (Warnock Hersey) to ANSI Z21.88-2002 and CSA 2.33-2002 ISA CAN/CGA-2.17-M91Appliance for use at high altitudes. Installation must conform to local codes. In the absence of local

codes, installation must comply with the current

(In Canada, installation must comply with the current CAN-1B149 installation code.)

Approved for manufactured (Mobile) home installation. For mobile housing, Title 24 CFR, Part

3280 or when such a standard is not applicable, the standard for manufactured home installation, ANSI /

NCBS A225.1 or standard for gas equipped recreation vehicles and mobile housing, CSA Z240.4.

INTRODUCTION

National Fuel Gas Code, ANSI Z223.1/NFPA54..

DO NOT ATTEMPT TO ALTER OR MODIFY THE CONSTRUCTION OF THE

APPLIANCE OR ITS COMPONENTS. ANY MODIFICATION OR ALTERATION

MAY VOID THE WARRANTY, CERTIFICATION AND LISTINGS OF THIS UNIT.

SPECIFICATIONS - MODEL DV23ZC

GAS: NAT. L.P.

HIGH FIRE 22,000 BTU 22,000 BTU

LOW FIRE 14,000 BTU 17,600 BTU

GAS INLET PRESSURE: NAT. L.P.

MAX. INPUT 10.5" W.C. 14.0" W.C.

MIN. INPUT *5.0" W.C. 10.5" W.C.

*5.0" W.C. is minimum inlet gas supply pressure for the purpose of input adjustment.

MANIFOLD PRESSURE: NAT. L.P.

3.5" W.C. 10.0" W.C.

STEADY STATE EFFICIENCY:

NATURAL GAS 77.10%

L.P. GAS 77.10%

FLUE VENT 4" INNER, 6" OUTER; DURA-VENT MODEL GS

SAFETY AGA CERTIFIED PILOT GENERATOR, MILLIVOLT

SYSTEM ACTIVATED WITH SWITCH OR THERMOSTAT.

3

NOTE: Installation and repair should be performed by a qualified service person. The

appliance should be inspected annually by a qualified professional service person. More

frequent inspections and cleanings may be required due to excessive lint from carpeting,

bedding material, pet hair, etc. It is imperative that the control compartment, burners and

circulating air passage ways of the appliance be kept clean.

Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct the front openings of the appliance.

This appliance is designed to operate on natural or propane gas only. The use of other fuels or

combination of fuels will degrade the performance of this system. The gas input of this

appliance is 22,000 BTU/HR for natural gas and 22,000 BTU/HR for propane gas models.

Children and adults should be alerted to the hazards of high surface temperatures and

should stay away to avoid burns or clothing ignition. Young children should be carefully

supervised when they are in the same room as the appliance. Clothing or other flammable

material should not be placed on or near the appliance.

Any safety screen or guard removed for servicing this appliance must be replaced prior to

operating the appliance.

WARNING

Do not operate with the glass door removed, cracked, or broken. Replacement of the glass

should be done by a licensed or qualified service person.

Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the appliance and to replace any parts of the control system and any gas

controls which have been under water.

Minimum inlet gas pressure is 5" Water Column for natural gas and 10.5" Water Column for

propane for the purpose of input adjustment.

Maximum inlet gas supply pressure is 10.5" Water Column for natural gas and 14" Water

Column for propane.

The appliance must be isolated from the gas supply piping system (by closing its individual

manual shut-off valve) during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5kPa).

This appliance and its individual shut-off valve must be disconnected from the gas supply

piping system during any pressure testing of that system at pressures in excess of 1/2 psig

(3.5kPa).

4

GENERAL INFORMATION

LOCATION AND CLEARANCE

Make sure your installation location provides adequate combustion and ventilation air.

In selecting the location, the aesthetic and functional uses of the appliance are primary concerns.

However, vent system routing to the exterior and access to the fuel supply are also important.

Consideration should be given to traffic ways, furniture, draperies, etc., due to elevated surface

temperatures. The location should also be free of electrical, plumbing or other heating/air conditioning ducts. Be sure to maintain adequate clearances around air openings into combustion

chamber.

The appliance should be mounted on a fully supported base extending the full width and depth

of the unit. The appliance may be located on or near conventional construction materials.

However, if installed on combustible materials, such as carpeting, vinyl tile, etc., a metal or

wood barrier covering the entire bottom surface must be used.

Right and left sides of the unit are determined when standing in front of the unit.

Minimum clearance to combustibles: sides and back - 0", floor - 0" , adjacent wall to Front 6".

Minimum clearance to combustibles for the vent system is 2" when passing through a wall or

chase.

ASSEMBLY STEPS—OVERVIEW

The typical sequence of installation follows. However, each installation is unique resulting in

variations to those described.

1. Construct framing and position the appliance.

2. Route gas supply line and bring in electrical service line to appliance location.

3. Install vent system.

4. Make connection to gas supply and electrical service.

5. Install the log assembly.

6. Install the remote thermostat (optional).

7. Test fire the burner.

8. Install glass panel.

9. Finish enclosure walls and trim.

5

INSTALLATION

Figure 1

6

*

SUPPLIED BY MANUFACTURER

INTERIOR HORIZONTAL

MINIMU M INSTALLATION

NOTE:

NOTE:

NOTE: You may replace or

*

cover this piece of material with a

more decorative non-combustible

material when the unit is installed.

Figure 2

*

SUPPLIED BY MANUFACTURER

INTERIOR VERTICAL

INSTALLATION WITH

A MAXIMU M 42' RISE .

7

INSTALLATION

GENERAL INFORMATION

Remove the shipping carton. Make sure the unit is not damaged. Lift the top louver and remove

three (3) nuts at the upper left, right, and center of the glass frame. Also, open louver at bottom

and remove the three (3) nuts. Set the door aside and protect from inadvertent damage. Retain

nuts for reassembly. Next, carefully remove the box of logs inside the appliance and set these

aside.

1. Framing - Maintain dimensions for the appliance enclosure as illustrated in Figure 1.

2. Gas Supply - These units are equipped with pipe supply access holes at the right side and

right rear facing unit.

3. Position appliance into framing - DO NOT secure with nails at the nailing tabs at top front

corners until venting installation is complete.

4. Vent system — NOTE: (The Model No. DV23ZC must be vented using the Simpson-DuraVent Direct Vent Gas 4" inside 6" venting system.) All warranties will be voided and

serious fire, health, or other safety hazards may result from any of the following actions:

Installation of any damaged components not manufactured or approved by Simpson-DuraVent; failure to meet all clearance requirements; failure to properly twist-lock and seal all

components.

Each section of Dura-Vent-GS flue system must be properly sealed to prevent the possibility of

leakage. This is accomplished by using high temperature silicone sealant. Apply a bead of

sealant around the bell section of the inner pipe prior to joining the pieces together. The outer

pipe joint may be sealed with metal foil tape or with silicone sealant.

WARNING

Always maintain required clearances (air spaces) to combustibles to prevent a fire hazard. Do

not fill air spaces with insulation. Check installation instructions for minimum clearance

requirements between the outer walls of the vent pipe and nearby combustible surfaces. Be sure

to check the vent termination clearance requirements from decks, windows, soffits, gas

regulators, air supply inlets, and public walkways, as specified in these installation instructions

and local building codes. (See page 9.) The gas appliance and vent system must be vented

directly to the outside of the building, and never attached to a chimney serving separate solid

fuel or gas burning appliances. Each direct vent gas appliance must have its own separate vent

system. Common vent systems are prohibited.

5. Remote Wall Switch or Thermostat or Remote Control - This appliance can be switched on

or off using one of several devices: 1). Appliance ON/OFF switch, 2) Wall Mounted Remote

Wall Switch, 3) Remote Wall Thermostat, or 4) Wireless Remote Control.

6. Connecting gas line — make gas line connections. All codes require a shut-off valve

mounted in the supply line. See Figure 15.

The flex line method is acceptable in the United States. However, Canadian requirements vary

depending upon locality. Installation must be in compliance with local codes.

8

Loading...

Loading...