Page 1

DV1000

ZERO CLEARANCE DIRECT VENT GAS FIREPLACE

WITH L.P. (Liquid Propane) or Natural Gas/ Millivolt System

This appliance is not convertible for use with other gases, unless a certified kit is used.

Approved By:

WARNING: If the information in these instructions are not followed exactly, a fire

or explosion may result causing property damage, personal injury or loss of life.

⎯ Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

⎯ WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas suppli-

ers instructions.

• If you cannot reach your gas supplier, call the fire department.

⎯ Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

This appliance may be installed in an aftermarket, permanently located, manufactured

home (USA only) or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This

appliance is not convertible for use with other gases, unless a certified kit is used.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

JULY 2006

New Buck Corporation

P.O. Box 69

8000 South 226 Highway

Spruce Pine, NC 28777

Page 2

Page 3

TABLE OF CONTENTS

Introduction .......................................................................................................................... 2

Firebox Cover Door Removal……………………………………………………………..3

Specifications……………………………………………………………………………...5

Minimum Framing Dimensions……………………………………………………………6

Vent Terminal Clearance…………………………………………………………………..7

Determining The Location…………………………………………………………………8

Minimum Clearances To Combustible Material…………………………………………..8

Direct Vent Termination Installation Instruction………………………………………….9

Pre Installation Instructions………………………………………………………………10

Pipe Installation…………………………………………………………………………...10

Connecting The Venting System To The DV1000……………………………………….11

Optional Rear Horizontal Vent Termination Fireplace Installation…………….………...12

Standard Horizontal Termination Installation…………………………………………….13

Standard Vertical Chase Termination Installation………………………………………..14

Removable Inner Bottom Instructions……………………………………………………15

Gas Supply Connection……………………………………………………………….…..16

Log Placement…………………………………………………………………………….18

Lighting Instructions……………………………………………………………………...20

Wire Diagram (Optional Blower)………………………………………………………...23

Repair Parts/ Manufacturers Address…………………………………………………….24

Cleaning And Maintenance……………………………………………………………….25

Trouble Shooting………………………………………………………………………….27

Replacement Parts………………………………………………………………….30 & 32

Parts Identification………………………………………………………………………..31

Warranty………………………………………………………………………………….33

Page 4

DANGER: Carbon monoxide poisoning may lead to death!

Page 1

This appliance is a vented product. This appliance will not produce any gas leakage into

your home if properly installed. This appliance must be properly installed by a qualified service person. The glass door must be properly seated and sealed. If this unit is not properly

installed by a qualified service person with glass door properly seated and sealed, gas leakage can occur.

Carbon Monoxide Poisoning: Early signs of carbon monoxide poisoning resemble the flu,

with headaches, dizziness, or nausea. If you have any of these signs, the cast stove with

burner system may not have been installed properly. Get fresh air at once! Have this appliance and venting system inspected and serviced by a qualified service person. Some people

are more affected by carbon monoxide than others. These include pregnant women, people

with heart or lung disease or anemia, those under influence of alcohol, and those at high altitudes.

Propane/LP gas and natural gas are both odorless. An odor-making agent is added to each of

these gases. The odor helps you detect a gas leak. However, the odor added to these gases

can fade. Gas may be present even though no odor exists.

Make certain you read and understand all warnings. Keep this manual for reference. It is

your guide to safe and proper operation of this cast stove and burner system.

The Model DV1000 Direct Vent Fireplace must be vented using only Magnaflex venting

system (Type: DV4-F.

A manufactured home (USA only) or mobile home OEM installation must confirm

with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part

3280, or, when such a standard is not applicable, the Standard for Manufactured Home

Installations, ANSI/NCSBCS A225.1, or Standard for Gas Equipped Recreational Vehicles and Mobile Housing, CSA Z240.4.

NOTE: If you have a standard ON/OFF Remote Control or an Optional Thermostat

Remote Control System follow the installation instructions provided with the individual package.

Page 5

INTRODUCTION AND SAFETY FOR

Page 2

INSTALLATION AND OPERATION

This instruction manual will help you obtain a safe, efficient, dependable installation for your appliance

and vent system. Please read and understand these instructions before beginning your installation.

The model DV1000 is a sealed combustion, air circulating gas appliance designed for residential and

mobile home applications. The appliance must be installed with Magnaflex DV4-F vent system that is

routed to outside atmosphere. It is also listed for bedroom installations.

This appliance is designed to operate on natural or propane gas. A millivolt gas control valve with piezo

ignition system provides safe, efficient operation. No external electrical power is required to operate the

gas valve and burner. 115V AC is required to operate the room air fan.

This appliance complies with National Safety Standards and is tested and listed to ANSI Z21.88-2005

and CSA 2.33-2005.

Installation must conform to local codes. In the absence of local codes, installation must comply with

the current

Installation Code, CSA b149.1...

National Fuel Gas Code, ANSI Z223.1/NFPA54, or the National gas and Propane

“WARNING”: Improper installation, adjustment, alteration, service or maintenance can

cause injury or property damage.

SPECIFICATIONS - MODEL DV1000

RATE: NAT. L.P.

MAX. 25,000 BTU 24,000 BTU

MIN. 20,000 BTU 20,000 BTU

GAS SUPPLY PRESSURE: NAT. L.P.

MAX. INPUT 10.5" W.C. 13.0" W.C.

MIN. INPUT *4.0" W.C. 11." W.C.

MANIFOLD PRESSURE: NAT. L.P.

3.5" W.C. 10.0" W.C.

EFFICIENCY:(With Blower “ON”)

NATURAL GAS 88%

L.P. GAS 88%

FLUE VENT 4" INNER, 7" OUTER; Magnaflex

SAFETY CSA CERTIFIED PILOT GENERATOR, MILLIVOLT

SYSTEM ACTIVATED WITH SWITCH OR THERMOSTAT.

“WARNING”: This appliance must not be connected to a chimney flue serving a separate

solid-fuel burning appliance.

“Do not use this appliance if any part has been under water. Immediately call a qualified

service technician to inspect the appliance and to replace any part of the control system

and any gas control which has been under water.”

NOTE: the appliance are be kept clear and free from combustible materials, gasoline and

other flammable vapors and liquids.

The flow of combustible and ventilation air not be obstructed.

Page 6

Page 3

NOTE: Installation and repair should be performed by a qualified service person. The

appliance should be inspected before use and at least annually by a professional service

person. More frequent cleaning may be required due to excessive lint from carpeting,

bedding material, et cetera. It is imperative that control compartments, burners and

circulating air passageways of the appliance be kept clean.

When choosing a location for your DV1000 in your home be sure to provide the following:

Adequate accessibility clearances for servicing and proper operation.

Children and adults should be alerted to the hazards of high surface temperature and

should stay away to avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the same room as the

appliance.

Clothing or other flammable material should not be placed on or near the appliance.

“WA RN I N G: Do not operate appliance with the glass front removed, cracked or

broken. Replacement of the glass should be done by a licensed or qualified service

person.”

“WARNING: Only Logs and Embers supplied with this appliance may be used. No

substitute materials may be used at any time.”

“WARNING: Do not use abrasive cleaners on this appliance. Abrasive

cleaners can damage the painted and glass surfaces of the appliance.”

DV1000 FIREBOX COVER DOOR

REMOVAL INSTRUCTIONS

Glass Care: This appliance has a large cover door bolted to the front area of the firebox. This

cover door must be in place at all times when the appliance is in operation. For the most visual

performance with your appliance it is good to maintain a clean glass on the cover door. To

clean the glass first make sure the glass is cool (not hot), trying to clean the glass when it is hot

can cause personal injury, or damage your cleaning device and the glass. With the glass at room

temperature and the door attached to the appliance, spray the glass are with household glass

cleaner and wipe clean with a lint-free towel. If the inside of the glass needs cleaning follow the

directions on page 4 for removing the cover door, and then clean as you did the front side of the

glass.

“WARNING: Do not abuse the glass cover door such as striking or slamming

shut. The glass can break and cause personal injury.”

CAUTION: If the glass in your appliance becomes broken or cracked,

remove the glass with caution. Wear safety glasses, gloves, shoes and other

protective clothing as needed. See your dealer or the manufacturer for replacement glass cover door.

Page 7

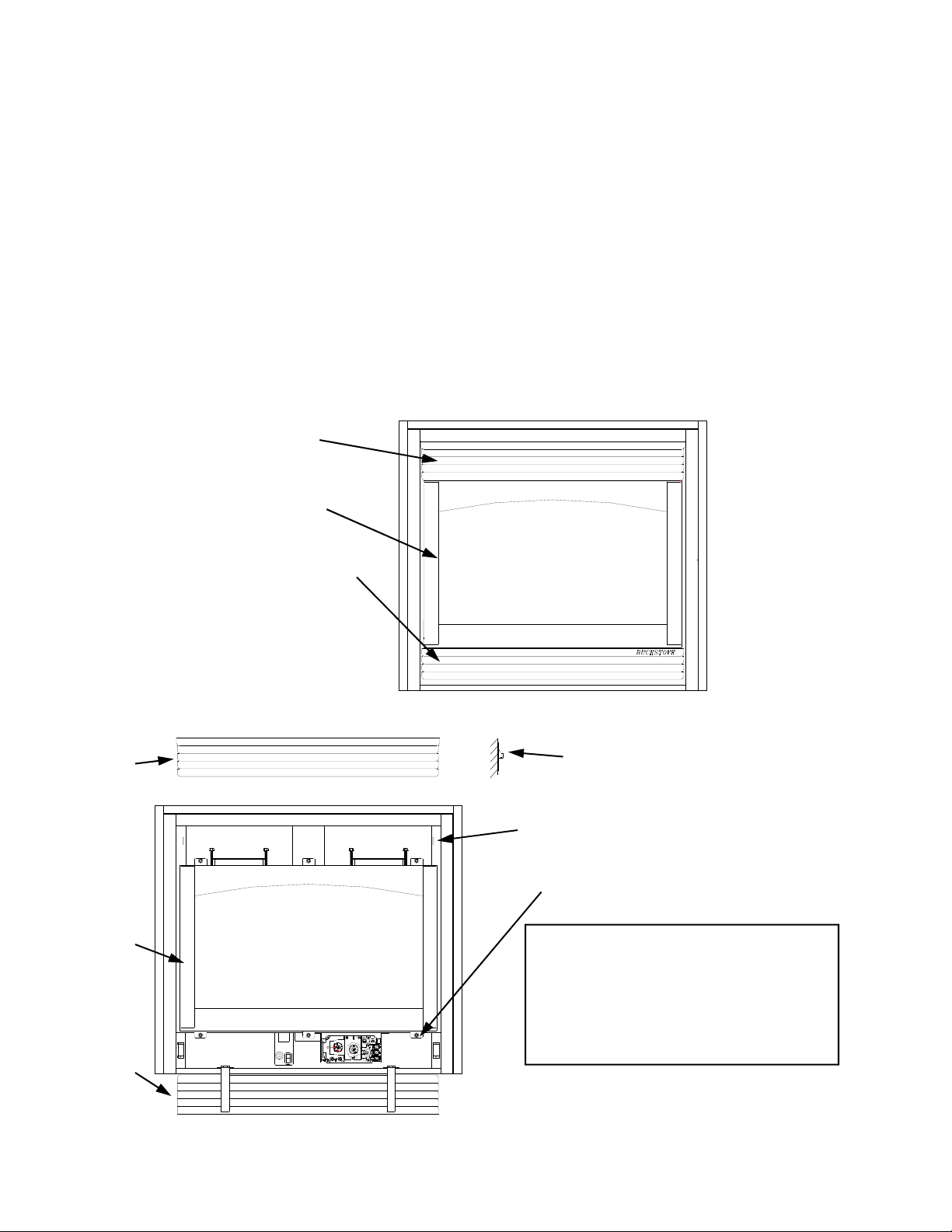

1. The top louver assembly must be removed first. To remove the top louver assembly you must

Page 4

place your hands one at the bottom left corner and the other at the bottom right corner of the louver assembly. Then with both hands lift up and outwards to release the louver clips from the

stove body. After removing the louver assembly place it in a safe place until time to reinstall.

2. The bottom louver assembly must be in the open position to access the firebox cover door fasteners. The bottom louver assembly is hinged to the bottom of the stove. Place one hand on the

center of the top louver and pull slowly out and downward to open.

3. Before removing the firebox cover door you must remove the six (6) 1/4-20 nuts located across

the top of the door and the bottom of the door. After removing the nuts you must slowly pull the

door outward and completely off the studs. Place the door in a safe place until time to reinstall,

the glass is breakable.

NOTE: The Firebox Cover Door must be removed to access the pilot assembly located in the right

rear corner of the firebox area, and to access the burner pan located in the bottom center of the

firebox area. The door must also be removed when placing the logs and embers.

4. To replace the cover door, reverse steps 3 thru 2.

1. TOP LOUVER ASSEMBLY

3. FIREBOX COVER DOOR

2. BOTTOM LOUVER ASSEMBLY

FIGURE 1

LEFT SIDE

#1

#3

#2

RIGHT SIDE

FRONT

#1 SIDE VIEW OF

LOUVER ASSEMBLY

AND CLIP.

SLOT IN STOVE BODY FRONT FOR LOUVER ASSEMBLY CLIP TO SECURE TO

STOVE BODY.

1/4-20 NUTS

WARNING: “Do not operate

appliance with the glass front

removed, cracked or broken.

Replacement of the glass should be

done by a licensed or qualified

service person.”

Replace the entire cover door assembly if glass

becomes defective with part # PO COVDOR1.

Page 8

Page 5

DV1000 SPECIFICATIONS

38-1/8”

36”

33-1/2”

2-1/2”

16-15/16”

6”

TOP STANDOFF(S)

SIDE STANDOFF(S)

27-1/8”

13-9/16”

10-5/32”

24-1/4”

FIGURE 2

REAR STANDOFF

16-1/2”

15-1/8”

NOTE: When the appliance is installed directly on carpeting, tile or

other combustible material other than wood flooring, the appliance

shall be installed on a metal or wood panel extending the full width

and depth of the appliance.

Page 9

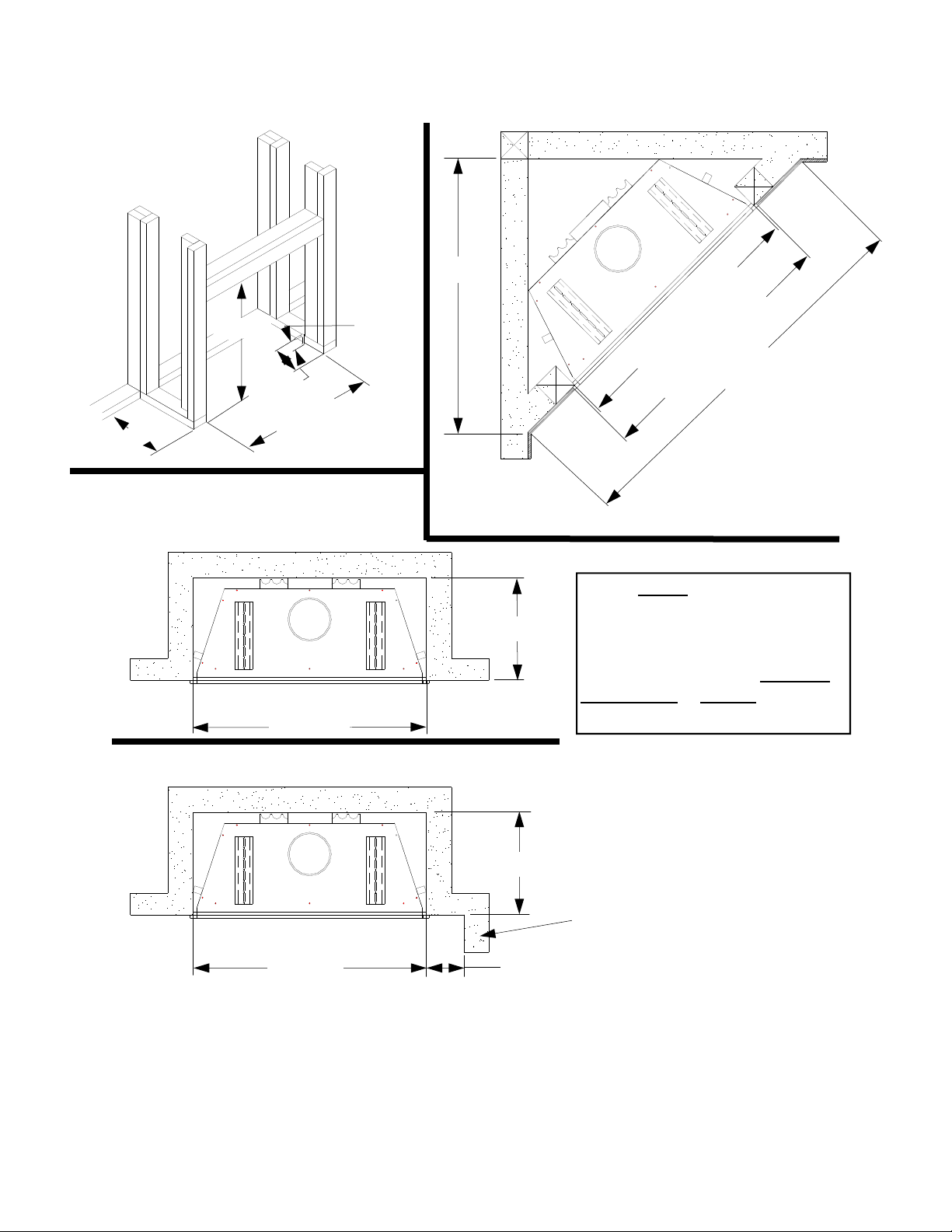

MINIMUM FRAMING DIMENSIONS

Page 6

40-1/8”

”

7

1

RIGHT

SIDE *

16

2-1/2”

37-7/16” (Framing*)

”

38-1/8” (Fi

ished) *

n

56-

3/4”

”

/8

1

-

6

3

”

2

/

1

-

6

/

7

-

7

3

Note: “Front side and top standoff (s) are permanently attached

17” *

to the front trim panels. The

front trim panels are attached by

the manufacturer and must not

FRONT *

37-7/16” *

LEFT

SIDE *

be removed or altered in anyway

for any reason.”

17” *

Combustible Adjacent

Side Wall.

37-7/16”*

FIGURE 3

6”

Note: “Only trim kit(s) supplied by the manufacturer shall be used in the installation of

this appliance.”

Page 10

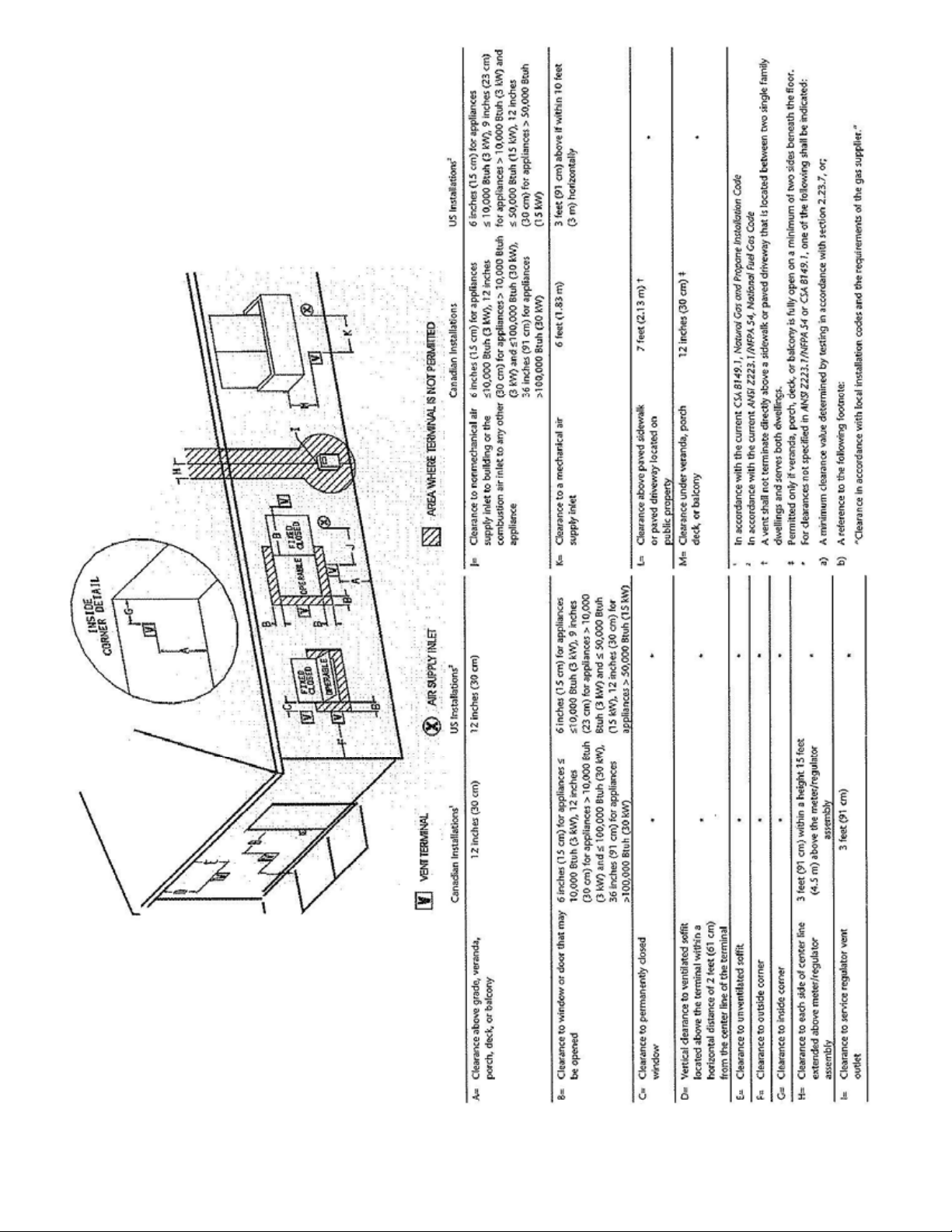

VENT TERMINAL CLEARANCES

Page 7

FIGURE 4

Page 11

DETERMINING THE LOCATION FOR DV1000

Page 8

Note: The installation must conform with local codes or, in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Instal-

lation Code, CSA B149.1.

This appliance may be installed in an aftermarket, permanently located, manufactured

home (USA only) or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use with other gases, unless a certified kit is used.

Due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies.

The appliance, when installed, must be electrically grounded in accordance with local codes

or, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code CSA C22.1.

The Model DV1000 Direct Vent Fireplace must be vented using only Magnaflex DV4-F venting

system. All warranties will be voided and tech service suspended and serious fire, health or

safety hazards may result from using any other venting system than the tested and approved

Magnaflex DV4-F system with this appliance.

You must check the Vent Termination Clearance requirements from decks, windows, soffits, gas

regulators, air supply inlets, and public walkways, etc. as shown in these instructions and specified by local building codes (see figure 4, page 7). This gas appliance must be vented directly to

the outside of the building. This gas appliance must not be connected to a chimney flue serving a

separate solid-fuel burning appliance. Preparation for electrical connection and gas supply must

be made before the appliance is located. (see figure 3, page 6 for framing dimensions)

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIAL FROM FIREPLACE AND

VENT SURFACES:

Sides, Back, Bottom and Top of appliance (standoffs) 0 inch

Recessed depth to back of front trim 17 inches

Recessed depth to front of front trim 17-1/2 inches

Diameter of vent pipe 2 inches

Top of appliance to ceiling 54 inches

MANTEL CLEARANCES……

DRYWALL

WALL BOARD

W

STUD

H

STANDOFF

DV1000

W=Width (@) H=Height

3/4” ——————–2”

2”———————–2”

4”———————–10”

6”———————–12”

8”———————–14”

10”———————16”

12”———————18”

TOP EDGE OF

UNITS TRIM

NOTE: Adequate clearances around air openings

into the combustion chamber. Do Not cover any of

the louvered areas on this

appliance front, or the glass

cover door.

FIGURE 5

Page 12

DV1000

Page 9

DIRECT VENT TERMINATION

INSTALLATION INSTRUCTIONS

(MAGNAFLEX)

Read the instructions in this manual completely before installing the DV1000 appliance with

the Magnaflex vent system. Magnaflex Venting systems are packaged with installation instructions, the instructions must be followed exactly for your safety and to prevent voiding the war-

ranty of your appliance and venting system.

The DV1000 will operate safely when installed in accordance with this instruction manual.

Read all instructions before starting installation, then follow these instructions carefully to

maximize fireplace performance and safety. Report damaged parts to your dealer.

Any common venting of the gas appliance using DV vent kit with other gas appliances is not

allowed. Do not connect this appliance to a chimney flue serving a separate solid fuel-burning

appliance.

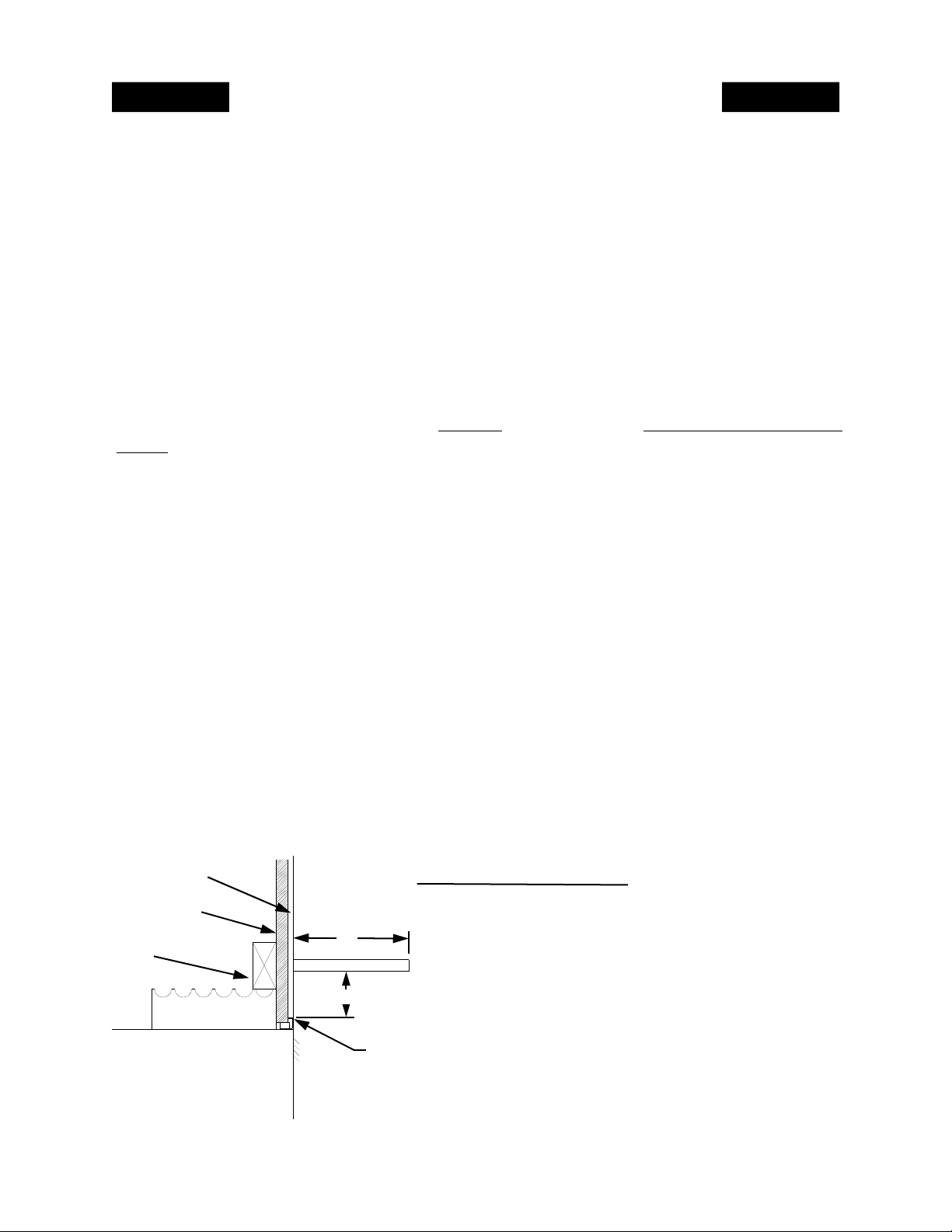

WA RN I N G: Always maintain minimum clearances around vent systems. The minimum

clearance to combustibles for horizontal vent pipe is 3 inches at the top and 1 inch at the

bottom of the vent system until the flue penetrates the nearest vertical wall.

FOR WALL FIRESTOPS AND VERTICAL RUNS ONLY, maintain a 1 inch minimum

clearance from all sides of the vent. Do not pack the open air spaces around the fireplace

or flue with insulation or other materials. Any horizontal run must have a 1/4” rise for

every one (1) foot of run towards the vent termination. Never install the vent level or

downward.

WA RN I N G: Contact your Local Building and Fire Officials about restrictions and in-

stallation inspections in your area.

IMPORTANT SAFETY INFORMATION

∗ The termination cap MUST be vented directly to the outside. The termination kit MUST

NEVER be connected to a chimney flue(s) servicing a separate solid-fuel burning appliance

or any other appliance.

∗ Termination cap MUST NOT be recessed into a wall or siding.

∗ The flexible vent pipe cannot be intermingled with any of the rigid vent pipe section. DO

NOT connect two sections of flexible vent pipe together to achieve a longer length without

approved connectors.

∗ Horizontal runs must be supported every 3 feet using wall straps. Vertical runs must be sup-

ported every 8 feet using wall straps. Slip wall straps loosely on to pipe. Attach straps to

framing members using nails or screws. Tighten nut/bolt to secure pipe.

∗ The fireplace and venting system should be inspected before initial use and at least annually

by a qualified field service person. Inspect external vent cap on a regular basis to make sure

that no debris is interfering with the airflow. Inspect entire venting system to ensure proper

function.

∗ Vent connections should overlap a minimum of 1” for proper sealing.

∗ Always stretch and secure venting with metal strapping secured with nails (nails and strap-

ping not supplied) to ensure that the horizontal runs remain true.

Page 13

∗ The termination cap must be positioned so that the embossed arrow is pointed up.

Page 10

∗ Ensure that the venting system exits the structure through a sidewall or similar structure and

does not terminate less than 12 inches (305mm) above the ground.

∗ Ensure that the venting system is located above the snow line in geographical areas where snow

accumulates.

PRE-INSTALLATION INFORMATION:

Items Required For Installation:

Tools Building Supplies

Phillips Screwdriver Measuring Tape Framing Materials

Hammer Electric Drill and Bits Wall Finishing Materials

Saw and/or saber saw Pliers Caulking Material (Noncombustible)

Level Square Silicone Sealant (High Temp.)

PIPE INSTALLATION:

Note: If you haven’t read pages 1 thru 9 completely “STOP”, and read them “NOW”.

1. Unpack vent components and check all items for shipping damage.

2. Locate Magnaflex DV4-F Installation Instructions and follow them exactly.

3. If Wall Straps are needed for your installation, determine the number of straps needed and ob-

tain them before beginning the installation process.

4. The pipe assembly consist of (2) two pipes. The enter pipe is the 4” flue pipe, and the outer pipe

is the 7” vent pipe. The (2) two pipes are separated by spacer springs, if any of the spacer

springs should come off while installing the pipe you must replace the before continuing (see

figure 6).

5. Follow the vent manufactures instruction for placing the Spacer Springs onto the 4” flue pipe.

6. The flexible vent pipe cannot be intermingled with any rigid vent pipe section. DO NOT connect two sections of flexible vent pipe together to achieve a longer length without approved

connectors.

7. Use the 4” Clamps provided with your kit to attach the flue pipe to the appliance and to the ter-

mination cap. Also use the 7” Clamps provided with your kit to attach the vent pipe to the adaptor collar after it has been attach to the appliance and to the termination cap also. (see page 11,

figure 7)

FIGURE 6

7” FLEX

OUTER VENT

PIPE

CLAMP

CLAMP

SPACER

SPRING

4” FLEX FLUE

PIPE

Page 14

8. Plan your installation. Set the appliance in place and survey how best to vent the appliance. Se-

Page 11

lect the appropriate termination kit for the installation. Read the vent pipe manufacturers instructions and the appliance manufacturers instruction manual before either. After vent configuration has been decided, stretch the flex components out, then trim off what will not be needed.

A temporary fit up will determine this. Once the vent length has been determined and the necessary parts are obtained for the installation you can begin installing the venting system.

• Follow the Installation Instructions provided with the Magnaflex DV4-F venting kit.

CONNECTING OR RECONNECTING THE VENTING SYSTEM TO THE Model DV1000

∗ After following the venting manufactures instructions, and you have installed the piping up

to the area of the appliance. Continue with the installation using the vent manufactures instructions and the instructions and illustrations in this manual.

A. Add High temperature

sealant (caulk) to the

inside (inner) edge of

the 4” flexible flue

pipe.

B. Place the 4” flexible

flue pipe through the

center of the flex

adapter collar w/

gasket , leaving the

adapter collar unattached to the appliance

and pulled up the pipe

out of the way. With

the 4” clamp also over

the 4” flex flue and

loose, push the 4” flex

flue pipe onto (over)

the 4” flue adapter collar until it is properly

seated (about 1” to 11/4”).

OUTER 7” VENT PIPE

INNER 4” FLUE PIPE

SELF TAPPING SCREWS

FLEX ADAPTER COLLAR WITH

GASKET (Gasket may come attach

to the collar from the manufacturer)

APPLIANCE 4” FLUE ADAPTOR

COLLAR (FLUE EXIT). PREINSTALLED BY THE APPLIANCE

MANUFACTURER.

C. Place the 4” clamp over the section of 4” flex flue

pipe that is pushed onto the flue adapter and

tighten the clamp.

D. Seat the flex flue adapter collar with gasket on to

the appliance centering around the flue adapter

and secure it to the appliance using (4) four of the

self tapping screws provided with the venting kit.

E. Next place the 7” clamp over the end of the 7” flex

vent pipe and leave it loose for now.

F. With both hands pull the 7” flex vent pipe onto

(over) the flex flue adapter and push it onward

until it is properly seated.

G. Place the 7” clamp over the section of 7” flex vent

pipe you just seated and tighten.

NOTE: TOP VENT INSTALLATION SHOWN ABOVE. FOLLOW THE SAME INSTRUCTIONS FOR OPTIONAL REAR

VENT INSTALLATION.

FIGURE 7

Page 15

OPTIONAL DV1000 REAR HORIZONTAL VENT TERMINATION FIREPLACE

Page 12

This appliance has a rear vent termination option. (you must purchase a DV1000 with this option from your dealer) Use termination kit #PP-DVVK-4F-1 only. This installation option can

only be used exactly as shown in figure 5. Follow the direction provided with the termination

kit. (see Horizontal Air Termination Installation page )

* 20” “From the rear

of the unit to the outside wall.”

3/4” WALL BOARD

2” x 4” WALL STUD

3/4” BLACK EXTERIOR WALL BOARD

2” x 4” x 8” BRICK EXTERIOR SURFACE

DV1000

* 8”

1” min.

* 24-1/4”

Flex Pipe

FIGURE 8/ OPTIONAL REAR VENT TERMINATION EXAMPLE

.

3” min.

FILL ANY CRACKS OR GAPS

WITH HIGH TEMPERATURE

CAULK

NOTE: This is only an example.

Walls may vary in materials and

construction type.

9-1/2” WALL

CORNER TERMINATION WITH OPTIONAL REAR VENT

DEFLECTOR SHIELD

HORIZONTAL

TERMINATION CAP

* “DIMENSION(S) MUST

BE EXACTLY

IN THIS EXAMPLE.”

AS SHOWN

20”

The maximum length for a

corner installation is 20”,

with a minimum 8” rise.

FIGURE 9

20”

8”

Page 16

DV1000 STANDARD HORIZONTAL TERMINATION INSTALLATIONS

Page 13

HORIZONTAL

TERMINATION CAP

ASSEMBLY

10-1/2” From Rear

Standoff To Outside

Wall.

12”

45-1/2”

MINIMUM INSTALLATION

53” Max. & 11” Min.

From Rear Standoff To

Outside Wall.

56”Max. & 49-1/2” Min.

MAXIMUM INSTALLATION

NOTE: Horizontal pipe installations must be

supported with Wall Straps every 3 feet.

WALL STRAPS

*16”

FIGURE 10

Page 17

DV1000 STANDARD VERTICAL CHASE TERMINATION

Page 14

INSTALLATIONS

VERTICAL TERMINATION CAP

ASSEMBLY

30 FT.

MAX.

WALL STRAPS

NOTE: Vertical pipe installations must

be supported with Wall Straps every

8 feet.

3 FT.

MIN.

FLEX PIPE (ONLY)

DV1000 FRONT

FIGURE 11

Page 18

DATE

REV

E

REMOVABLE INNER BOTTOM PAN ASSEMBLY

Page 15

The DV1000 is equip with a removable Inner Bottom Pan Assembly for service purposes only. The burner

control assembly should only be accessed by this procedure by a qualified service technician, or by the

manufacturer. Follow the instructions and diagrams below.

1. Turn gas OFF at equipment shut OFF

valve, and disconnect union located at

Right side of control valve. Remove

Cover Door, see pages 3 & 4.

2. Remove the 4 screws located on top of

the Burner Pan area which attach the

Burner Pan to the Firebox Deck.

3. Remove the 4 screws located at the

back of the Firebox area which attach

the Firebox Deck to the back of the

Firebox.

4. Lift the Firebox Deck upward and outwards. And then gently lift the Burner

and Ventura assembly upward from

top of the Orifice assembly.

5. Next locate the 26 screws pattern

around the edge of the Inner Bottom

Pan Assembly and remove them.

6. Push upward from the bottom of the

Inner Bottom Pan ( do not

5

2

3

4

.

DAT

6

FIGURE 12

push on the gas valve control or any of the other components).

7. A gasket is located on the bottom edges of the Inner Bottom

Pan assembly. If this gasket is damaged during this process it

must be replaced with a gasket from the manufacture and

resealed with high-temperature caulk weather damaged or

7

Page 19

GAS SUPPLY CONNECTION

Page 16

CHECK GAS TYPE

Use proper gas type for the burner system you are installing. If you have conflicting gas types, do

not install burner system. See dealer where you purchased the stove and burner system for proper

burner system according to your gas type.

INSTALLING GAS PIPING TO APPLIANCE

Installation Items Needed

Before installing the appliance make sure you have the items listed below.

• External regulator (supplied by installer)

• Piping (check local codes)

• Sealant (resistant to propane/LP gas)

• Equipment shutoff valve *

• Test gauge connection *

• Sediment trap

• Tee joint

• Pipe wrench

Warning: A qualified installer or

service person must connect burner

system to gas supply. Follow all local

codes.

∗ An CSA design-certified equipment shutoff valve with 1/8" NPT tap is an acceptable alternative

to test gauge connection. Purchase the CSA design-certified equipment shutoff valve from your

dealer.

CAUTION: For propane/LP units, never connect burner system directly to the propane/LP

supply. This burner system requires an external regulator (not supplied). Install the external

regulator between the burner system and propane/LP supply.

CAUTION: Use only new, black iron or steel pipe. Internally-tinned copper tubing may be

used in certain areas. Check your local codes. Use pipe of 1/2" diameter or greater to allow

proper gas volume to burner system. If pipe is too small, undue loss of pressure will occur.

For propane/LP connections only, the installer must supply an external regulator. The external

regulator will reduce incoming gas pressure. You must reduce incoming gas pressure to between

11 and 14 inches of water. If you do not reduce incoming gas pressure, burner system regulator

damage could occur. Install external regulator with the vent pointing down as shown in. Pointing

the vent down protects it from freezing rain or sleet.

Installation must include an equipment shutoff valve, union, and plugged 1/8" NPT tap. Locate

NPT tap within reach for test gauge hook up. NPT tap must be upstream from burner system.

IMPORTANT: Install main gas valve (equipment shutoff valve) in an accessible location. The

main gas valve is for turning on or shutting off the gas to the appliance.

Check your building codes for any special requirements for locating equipment shutoff valve to

stoves.

Apply pipe joint sealant lightly to male threads. This will prevent excess sealant from going into

pipe. Excess sealant in pipe could result in clogged burner system valves.

We recommend that you install a sediment trap/drip leg in supply line. Locate sediment trap/drip

leg where it is within reach for cleaning. Install in piping system between fuel supply and burner

system. Locate sediment trap/drip leg where trapped matter is not likely to freeze. A sediment trap

traps moisture and contaminants. This keeps them from going into burner system gas controls. If

sediment trap/drip leg is not installed or is installed wrong, burner system may not run properly.

Page 20

Pressure Testing Gas Supply Piping System

Page 17

Note: The appliance and its appliance main valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psi. (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its equipment shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 psi. (3.5 kPa).

Test Pressures In Excess of 1/2 PSIG (3.5 kPa)

1. Disconnect appliance with its appliance main gas valve (control valve) and equipment shutoff

valve from gas supply piping systems. Pressures in excess of 1/2 psig (3.5 kPa) will damage

burner system gas regulator.

2. Cap off open end of gas pipe where equipment shutoff valve was connected.

3. Pressurize supply piping system by either opening propane/LP supply tank valve for propane/LP

gas burner system or opening main gas valve located on or near gas meter for natural gas burner

system, or using compressed air.

4. Check all joints of gas supply piping system. Apply commercial leak test solution to all gas

joints. Bubbles forming show a leak. Correct all leaks at once.

5. Reconnect burner system and equipment shutoff valve to gas supply. Check reconnected fittings

for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve.

2. Pressurize supply piping system by either opening propane/LP supply tank valve for propane/LP

gas burner system or opening main gas valve located on or near gas meter for natural gas burner

system, or using compressed air.

3. Check all joints from propane/LP supply tank or gas meter to equipment shutoff valve (see

Figure 34, page 17 for propane/LP or Figure 35, page 17 for natural). Apply commercial leak test

solution to all gas joints. Bubbles forming show a leak. Correct all leaks at once.

Warning: Test all gas piping and

connections for leaks after

installing or servicing. Correct all

leaks at once.

WARNING: Never use an open

flame to check for a leak. Apply

commercial leak test solution to all

gas joints. Bubbles forming show a

leak. Correct all leaks at once.

NOTE: The minimum inlet gas supply

pressure for the purpose of input adjustment.

NOTE: The maximum inlet gas supply

pressure.

LP NATURAL

PRESSURE: 10.0" W.C. 3.5" W.C.

*MIN. INLET 11.0" W.C. 4" W.C.

MAX. INLET 13.0" W.C. 10.5" W.C.

Union

CSA/AGA DesignCertified Equipment

Shutoff Valve With

1/8" NPT Tap

Gas Control

EQUIPMENT

SHUTOFF

VALVE

OPEN

CLOSED

FIGURE 13

EQUIPMENT SHUTOFF VALVE

Page 21

CAUTION

Page 18

Hot while in operation. Do Not Touch severe burns may result. Keep children, clothing,

furniture, gasoline, and other liquids having flammable vapors away.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, personal injury, or loss of life. Refer to owner’s information manual

provided with this appliance. Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

IMPORTANT: Always operate the appliance at the completely ON or the completely OFF

positions. Never use the heater at a setting between these positions as this can result in

improper combustion and excessive carbon monoxide emissions.

Keep burner and control compartment clean. See installation and operating instructions

accompanying heater.

DV1000 LOG PLACEMENT

Before placing the Logs and Embers you must first remove the Firebox Cover Door from the

appliance, see pages 3 and 4. After removing the cover door follow the instructions below and

on the following page. (The log placement is exactly the same for the Pine log set as for the

Oak log set.

1. Carefully open the box containing the logs. Remove the #1 log (Rear Log) and place it in

the rear center of the firebox behind the log holders located on the left and right sides.

2. Next remove the #2 log (Left Middle Log) and place it on the 2 pins (screws) located on the

left hand side of the burner.

3. Now remove the #3 log (Right Middle Log) and place it on the pins (screws) located on the

right hand side of the burner.

4. Locate the #4 log (Left Front Log) and place it on the pin (screw) located on the left front

bottom corner of the firebox. Next place the other end of the log on the pin (pins) located on

the left side of the top of the #1 log.

5. Place the large end of the #5 log (Front Center Log) on the pin (screw) located in the front

bottom center of the firebox. Place the other end of the #5 log on the pin located at the top

center of the #1 log.

6. Next place the #6 log (Right Front Bottom Log) on the pins (screws) located on the left

hand side of the bottom of the firebox.

7. Place the #7 log (Right Front Top Log) on to the pins located in the top of the #6 log.

8. Provided with your log set is a package of Glowing Embers (rock wool). Open the package

and tare off small pieces of the wool material and place it over the small holes (ports) located on the front burner pan in front of logs #5 and #6. Cover the entire section of holes

(ports). *Replacement of loose (Glowing Embers) must be purchased from the original

manufacturer and application of excess loose material may adversely affect performance of the heater.

NOTE: “Wash your hands immediately after coming in contact with the wool material.

The wool can cause slight itching or burning in some cases, avoid any contact with eyes.”

Page 22

Page 19

FIGURE 14

“Apply loose material per instructions manual. DO NOT apply extra material or material not supplied with the heater. Replace only with material from your Buck Stove dealer or from New Buck

Corporation.

WARNING: Failure to position the parts in accordance with these diagrams or failure to use

only parts specifically approved with this heater may result in property damage or personal

injury.

This appliance must be installed in accordance with local codes if any. If none, then follow the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Natural Gas and Propane Installation

Codes, CSA -B149.1.

“CAUTION: Do not operate the appliance with glass removed, cracked or broken. Re-

placement of the panel(s) should be done by a licensed or qualified service person.”

Page 23

FOR YOUR SAFETY READ BEFORE

Page 20

LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

A. This appliance has a pilot which must be lighted by hand. When lighting the pilot, follow

these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air and will settle to the floor.

WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electric switch; do not use any phone in your building.

* Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

* If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never use tools. If the knob

will not push in or turn by hand, don’t try to repair it, call a qualified service technician. Force

or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualified

service technician to inspect the appliance and to replace any part of the control system and any

gas control which has been under water.

Page 24

LIGHTING INSTRUCTIONS

Page 21

1. STOP! Read the safety information on this label.

2. “Set the thermostat to lowest setting.”

3. “Turn off all electric power to the appliance.”

4. Open access cover door.

5. Turn control knob clockwise to the “OFF” position.

T

T

U

U

O

O

I

I

N

N

P

P

I

I

T

T

L

O

L

O

NOTE: Knob cannot be turned from “PILOT” to “OFF” unless knob is pushed in slightly.

DO NOT FORCE.

6. “Wait five (5) minutes” to clear out any gas. Then smell for gas, including near the floor.

If you smell gas, STOP! Follow “B” in the safety information label. If you don’t smell gas,

go to the next step.

7. Pilot is located between the front and rear burner.

8. Turn control knob counter clockwise to the “Pilot” position.

9. Press in control knob. With control knob pressed in, immediately push and release ignitor

button. This will light the pilot.

NOTE: * If the knob does not pop up when released, “Stop” and immediately call your

service technician or gas supplier.

* “If the pilot will not stay lit after several tries, turn the gas control knob to “OFF”

and call your service technician or gas supplier.”

10. Continue to hold the control knob pressed in for one (1) minute after the pilot is lit.

Release the control knob and it will pop back up. Pilot should remain lit. If it goes out,

repeat steps 5 thru 10.

11. Turn control knob counter clockwise to “ON” position.

12. Close access cover door.

13. Turn on all electric power to the appliance.

CONTROL KNOB

Page 25

14. If using unit without wall thermostat place (AUTO/OFF/MANUAL) switch

Page 22

in the “MANUAL” position. If using wall thermostat place (AUTO/OFF/

MANUAL) switch in the “AUTO” position, and place wall thermostat to a

setting higher than the room temperature.

PIEZO IGNITOR BUTTON LOCATED TO THE LEFT, BESIDE

THE SIDE OF THE GAS VALVE

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting (if used).

2. Turn off all electric power to the appliance if service is to be performed.

3. Open access cover door.

4. Push in gas control knob slightly and turn clockwise to “OFF.” Do not

force.

5. Close access cover door.

Page 26

WIRING DIAGRAM

Page 23

JUMPER

THERMOSTAT

MOTOR

JUMPER

JUMPER

WHITE

GREEN

BLACK

RHEOSTAT

BLACK

POWER CORD

Optional Blower Kit: #MA DV1000714. (Standard with XL package.)

NOTE: “If any of the original wire as supplied with the gas appliance must be replaced, it

must be replaced with a wire of at least a 105o C. temperature rating.”

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation.

Verify proper operation after servicing.

WARNING:

ELECTRICAL GROUNDING INSTRUCTION:

THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG (GROUNDING) PLUG

FOR YOUR PROTECTION AGAINST SHOCK HAZARD AND SHOULD BE

PLUGGED DIRECTLY INTO A PROPERLY GROUNDED THREE-PRONG

RECEPTACLE.

WARNING: DO NOT USE A BLOWER INSERT , HEAT EXCHANGER OR OTHER

ACCESSORY NOT APPROVED FOR USE WITH THIS HEATER.

FOR YOUR SAFETY : DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Page 27

BURNER ORIFICES SIZES:

Page 24

“For natural gas when equipped with No. 46 drill size orifice.”

“For propane when equipped with No. 1.50mm drill size orifice.”

NOTE: “This appliance equipped only for altitudes 0-2000 feet (0-610m).”

SERVICING

Repair and replacement work should only be performed by a qualified service technician.

Always shut off the gas supply and make sure heater is cool before beginning any service

operation. Check for gas leaks after servicing.

REPAIR PARTS

A parts list with exploded view follows. Always include correct name, part number, and model

number of the heater when ordering service parts. Please contact your local dealer or distributor

when ordering . If one is not available, you may contact.

New Buck Corporation

8000 Highway 226 South

Spruce Pine, NC 28777

Page 28

CLEANING AND MAINTENANCE

Page 25

Glass Care: This appliance has a large cover door bolted to the front area of the firebox. This cover

door must be in place at all times when the appliance is in operation. For the most visual performance with your appliance it is good to maintain a clean glass on the cover door. To clean the glass

first make sure the glass is cool (not hot), trying to clean the glass when it is hot can cause personal

injury, or damage your cleaning device and the glass. With the glass at room temperature and the

door attached to the appliance, spray the glass are with household glass cleaner and wipe clean with

a lint-free towel. If the inside of the glass needs cleaning follow the directions on page 4 for removing the cover door, and then clean as you did the front side of the glass.

During start-up it is normal for condensation to form on the inside of the glass causing lint, dust, and

other airborne particles to cling to the glass surface. During initial start-up a slight film may form on

the glass due to paint curing. The glass should be cleaned several times with a non-ammonia, nonabrasive household cleaner and warm water after the first two weeks of operation. Thereafter, clean

the glass two or three times during each heating season, depending on the usage and circumstances

present.

“WARNING: Do not abuse the glass cover door such as striking or slamming shut. The glass

can break and cause personal injury.”

Any safety screen or guard removed for servicing an appliance must be replaced prior to operating the appliance.

CAUTION: If the glass in your appliance becomes broken or cracked, remove the glass with

caution. Wear safety glasses, gloves, shoes and other protective clothing as needed. See your

dealer or the manufacturer for replacement glass.

PILOT AND BURNERS

Periodic visual check of pilot and burner flames

• Burner and controls should be cleaned with compressed air to remove dust, dirt, or lint.

Use a vacuum cleaner or small, soft bristled brush to remove excess dust, dirt, or lint.

Pilot Burner

PILOT

Thermocouple

Thermopile

Burner Flame Pattern

Ignitor Electrode

BURNER/ AIR SHUTTER

Incorrect flame patterns

Flame should

engulf the tip end

of the Thermopile and the Thermocouple, and

should be constant. The flame

should be

Blue in color.

And 3/4” to 1” in height.

Correct flame pattern

Page 29

LOGS:

Page 26

• If you remove logs for cleaning, refer to Installing Logs, page 18 to properly replace logs.

• Use a vacuum cleaner to remove any carbon buildup on logs.

Replace logs if broken. See Replacement Parts on page 29.

• Also use a vacuum cleaner to remove any particles on the Burner Pan.

EMBERS:

“Apply loose material per instructions manual. DO NOT apply extra material or material not

supplied with the heater. Replace only with material from your Buck Stove dealer or from New

Buck Corporation.

BURNER PAN ASSEMBLY

BURNER PAN

BURNER PORTS

Philllips Head Screw

AIR SHUTTER

(To Gain Access To The Air Shutter, Remove

The Cover Plate On The Orifice Box Located In

The Burner Control Compartment Directly Under The Center Of The Burner Pan)

VENTURA ASSEMBLY

Air Shutter Slot (Opening)

VENTING SYSTEM

Periodic examination of venting systems by a qualified agency.

1. Check areas of venting system that are exposed to the weather for corrosion (rust spots or streaks

and, in extreme cases, holes). Have these items replaced immediately by a qualified service person.

2. Remove the vent cap and shine a flashlight into the vent. Remove any foreign material.

3. Check for evidence of excessive condensation. Continuous condensation can cause corrosion of

caps, pipes, and fittings and can be caused by having excessive lateral runs, too many elbows, or

exterior portions of the system being exposed to cold weather.

4. Inspect joints to verify that no pipe section or fitting has been disturbed and loosened. Check mechanical supports such as wall straps for rigidity.

Page 30

TROUBLESHOOTING

Page 27

Note: All troubleshooting items are listed

in order of operation.

WARNING: Turn off burner system

and let cool before servicing. Only a

qualified service person should service

and repair burner system or stove.

CAUTION: Never use a wire, needle,

or similar object to clean pilot. This

can damage pilot unit.

OBSERVED PROBLEM

When ignitor button is pressed, there is no

spark at pilot

When ignitor button is pressed, there is

spark at pilot but no ignition

Pilot lights but flame goes out when

control knob is released

POSSIBLE CAUSE

1. Ignitor electrode not connected to

ignitor cable

2. Ignitor cable pinched or wet

3. Piezo ignitor nut is loose

4. Broken ignitor cable

5. Bad piezo ignitor

6. Ignitor electrode broken

7. Ignitor electrode positioned wrong

1. Gas supply turned off or equipment

shutoff valve closed

2. Gas control knob not in PILOT

position

3. Gas control knob not pressed in

while in PILOT position

4. Air in gas lines when installed

5. Depleted gas supply (propane/LP

models only)

6. Pilot is clogged

7. Gas regulator setting is not correct

1. Gas control knob not fully pressed in

2. Gas control knob not pressed in long

enough

3. Equipment shutoff valve not fully

open

4. Pilot flame not touching

thermocouple, which allows

thermocouple to cool, causing pilot

flame to go out. This problem could

be caused by one or both of the

following:

A. Low gas pressure

B. Dirty or partially clogged pilot

5. Thermocouple connection loose at

control valve

6. Thermocouple damaged

7. Control valve damaged

REMEDY

1. Reconnect ignitor cable

2. Free ignitor cable if pinched by any

metal or tubing. Keep ignitor cable

dry

3. Tighten nut holding piezo ignitor.

Nut is located behind the mounting

bracket

4. Replace ignitor cable

5. Replace piezo ignitor

6. Replace pilot assembly

7. Replace pilot assembly

1. Turn on gas supply or open

equipment shutoff valve

2. Turn gas control knob to PILOT

position

3. Press in gas control knob while in

PILOT position

4. Continue holding down gas control

knob. Repeat igniting operation until

air is removed

5. Contact local propane/LP gas

company

6. Clean pilot (see Cleaning and

Maintenance, page 25 or replace

pilot assembly

7. Replace gas control

1. Press in gas control knob fully

2. After pilot lights, keep gas control

knob pressed in 30 seconds

3. Fully open equipment shutoff valve

4. A) Contact local gas company

B) Clean pilot (see Cleaning and

Maintenance, page 25) or replace

pilot assembly

5. Hand tighten until snug, then tighten

1/4 turn more

6. Replace thermocouple

7. Replace control valve

24

Page 31

OBSERVED PROBLEM

Page 28

Burner does not light after pilot is lit

Delayed ignition burner

Burner backfiring during combustion

Slight smoke or odor during initial

operation

Burner system produces a whistling noise

when burner is lit

Glass soots

Burner system produces a clicking/ticking

noise just after burners are lit or shut off

Remote does not function

POSSIBLE CAUSE

1. Burner orifice clogged

2. Inlet gas pressure is too low

3. Thermopile leads disconnected or

improperly connected

4. Thermopile is defective

1. Manifold pressure is too low

2. Burner porting or orifice clogged

1. Burner orifice is clogged or damaged

2. Damaged burner

3. Gas regulator defective

1. Residues from manufacturing

processes and logs curing

1. Turning gas control knob to HI

position when burner is cold

2. Air in gas line

3. Dirty or partially clogged burner

orifice

1. Flame impingement on logs

2. Debris around burner air mixer

1. Metal expanding while heating or

contracting while cooling

1. Battery is not installed or battery

power is low

REMEDY

1. Clean burner (see Cleaning and

Maintenance, page 25 or replace

burner orifice

2. Contact local propane/LP or natural

gas company

3. Reconnect leads (see Wiring

Diagram, page 30

4. Replace thermopile

1. Contact local propane/LP or natural

gas company

2. Clean burner (see Cleaning and

Maintenance, page 25 or replace

burner orifice

1. Clean burner (see Cleaning and

Maintenance, page 25) or replace

burner orifice

2. Replace damaged burner

3. Replace gas control

1. Problem will stop after a few hours

of operation

1. Turn gas control knob to LO

position and let warm up for a

minute

2. Operate burner until air is removed

from line. Have gas line checked by

local propane/LP or natural gas

company

3. Clean burner (see Cleaning and

Maintenance, page 25) or replace

burner orifice

1. Adjust the log set so that the flame

does not excessively impinge on it

2. Inspect the opening at the base of the

burner to see that it is NOT packed

with any type of material

1. This is common. If noise is

excessive, contact qualified service

person.

1. Replace 9-volt batteries in receiver

and remote control

Page 32

TROUBLESHOOTING

Page 29

Continued

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

OBSERVED PROBLEM

Burner system produces unwanted odors

Burner system shuts off in use

Gas odor even when control knob is in OFF

position

Gas odor during combustion

Dark residue on logs or inside of burner

system

POSSIBLE CAUSE

1. Gas leak. See Warning statement

above

1. High or gusting winds

2. Low line pressure

3. Pilot is partially clogged

4. Inner vent pipe leaking exhaust

gasses into system

5. Glass too loose and air tight gasket

leaks in corners after usage

6. Bad thermopile or thermocouple

7. Improper vent cap installation

1. Gas leak. See Warning statement

above

2. Control valve defective

1. Gas leak. See Warning statement

above

1. Improper log placement

2. Air holes at burner inlet blocked

3. Burner flame holes blocked

REMEDY

1. Locate and correct all leaks (see

Checking Gas Connections, pages 15

thru 17

1. Burner system has been tested for up

to 40 mph winds. However, extreme

conditions may occur. See Lighting

Instructions on page 21-22

2. Contact local propane/LP or natural

gas company

3. Clean pilot (see Cleaning and

Maintenance, page 25)

4. Locate and correct all leaks (see

Checking Gas Connections, pages 16

thru 17)

5. Tighten glass

6. Replace faulty component

7. Check for proper installation and

freedom from debris or blockage

1. Locate and correct all leaks (see

Checking Gas Connections, pages 16

thru 17)

2. Replace control valve

1. Locate and correct all leaks (see

Checking Gas Connections, pages 16

thru 17)

1. Properly locate logs ( see Installing

Logs, page 19)

2. Clean out air holes at burner inlets.

Periodically repeat as needed

3. Remove blockage or replace burner

Page 33

SERVICING

Page 30

Repair and replacement work should only be done by a qualified service person.

Always shut off the gas supply and make sure that heater is cool before beginning any

service operation. Always check for gas leaks after servicing.

REPLACEMENT PARTS

A parts list with exploded view follows. Always include correct name, part number, and model

number of the heater when ordering service parts.

KEY# PART DESCRIPTION PART NUMBER

1. S.I.T. PILOT (L.P.) ASSEMBLY PE 199615

1. S.I.T. PILOT (NAT) ASSEMBLY PE 199616

2. GENERATOR PE 240002

3. 1/8" PILOT TUBE MF 1812 ALMTUB

4. GENERATOR WIRE

5. BURNER PAN MA DV1000-BP

6. ORIFICES

L.P. PO 150MVORF

N.G. PO 046MVORF

7. 3/8" COMPRESSION NUT W/ SLEEVE PH 616 & PH 606

8. 3/8" FLEXIBLE BURNER SUPPLY TUBE

1 piece 6" PO T6-06

9. 12" SWITCH WIRES PE 12JUMPER

10. CARLING SWITCH

(AUTO/OFF/MANUAL) PE RC211RB

11. PIEZO STRIKER PE 124461

12. S.I.T. 24" IGNITOR WIRE PE 028515

13 VENTURA ASSEMBLY PO DVVEN1

14. THERMO-COUPLE PE 290136

16. 820 S.I.T. MV. VALVE LP - PE 820633

NAT - PE 820634

17. BALL VALVE PO 110-553

18. BLACK IRON UNION PO 124BINIP

19. PINE LOG SET (FIBER) PO DV1000LG-PINE

20. OAK LOG SET (CERAMIC) PO DV1000LG-OAK

Page 34

PARTS IDENTIFICATION AND GAS CONTROL WIRING DIAGRAM

Page 31

11

ON/OFF/MANUAL

9

10

12

1

7

8

3

2

13

6

17

16

18

5

“CAUTION: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause improper and dangerous operation.”

Figure 43

Page 35

ADDITIONAL

Page 32

REPLACEMENT PARTS

PART DESCRIPTION PART NUMBER

*RHEOSTAT PE BC204

*RHEOSTAT KNOB PE BC204A

*THERMOSTAT 140 DEG. PE 400130

*THERMOSTAT WIRES PE 30JUMPER

*** DOOR GLASS PG DV1G01

*** DOOR GLASS GASKET

TAD POLE (W/ADHESIVE) RP GT716B11

** FIREBOX COVER DOOR ASSEMBLY PE COVDOR1

INNER BOTTOM PAN GASKET POIBPG60

* OPTIONAL

** CONSUMERS MUST USE PE COVDOR1 ONLY.

*** FOR CERTIFIED SERVICE TECHNICIANS ONLY.

*MOTOR PE SBR084

Page 36

WARRANTY

Page 33

LIMITED FOUR YEAR WARRANTY

FOR THE BUCK STOVE AND RELATED PRODUCTS

PLEASE READ THIS WARRANTY CAREFULLY

This warranty covers your new heating unit, so long as it is owned by the original purchaser,

including optional and standard accessories purchased at the same time, subject to terms,

limitations, and conditions herein set out. To make a claim under this warranty the Bill of Sale

or Cancelled check must be presented.

This warranty will not cover any damage and/or failure caused by abuse or improper installation of the products covered.

WARRANTY

For a four (4) year period from the date of purchase, as long as the heater is owned by the

original purchaser, NBC will repair or replace, at its option, any part defective in materials

or workmanship, with the exception of: optional and standard accessories, glass, gaskets and

all parts not permanently attached to the heating unit. Parts not permanently attached to the

heating unit are defined as those items designed to be removed from the stove, including

those removable with common hand tools. The cost of parts only are included. The customer

pays any labor or transportation charges required.

Electrical motors, wiring, switches, gas components and all parts not permanently attached are

warranted for one (1) year from date of purchase. Customer pays any transportation charges.

PROCEDURE

Should you feel that your heater is defective, you should contact any NBC dealer for the name

of your nearest authorized heater service representative, who will instruct you on the proper

procedure.

CONDITIONS AND EXCLUSIONS

(A) Replacement of parts may be in the form of new or fully reconditioned parts, at NBC's

option.

(B) There are no other warranties express or implied including warranties of Merchantability,

Fitness for Purpose, or Otherwise except those warranties expressly stated herein.

(C) NBC is not liable for indirect, incidental, or consequential damages in connection with the

use of the product including any cost or expense of providing substitute equipment or

service during periods of malfunction or non-use.

Some states do not allow the exclusion of incidental or consequential damages, so the above

exclusion may not apply to you.

35

Page 37

Page 34

(D) All warranty repairs under this warranty must be performed by an authorized Buck Stove

service representative. Repairs or attempted repairs by anyone other than an authorized service representative are not covered under this warranty. In addition, these

unauthorized repairs may result in additional malfunctions, the correction of which is not

covered by warranty.

OTHER RIGHTS

This warranty gives you specific legal rights, and you may also have other rights, which vary

from state to state.

Page 38

Page 35

Loading...

Loading...