Page 1

FR202/-RP

Flashlink 2RU frame

User manual

Rev. A

Nevion

Nordre Kullerød 1

3241 Sandefjord

Norway

Tel: +47 33 48 99 99

nevion.com

Page 2

FR-2RU-20-2 Rev. A

Nevion Europe

P.O. Box 1020

3204 Sandefjord, Norway

Support phone 1: +47 33 48 99 97

Support phone 2: +47 90 60 99 99

Nevion USA

1600 Emerson Avenue

Oxnard, CA 93033, USA

Toll free North America: (866) 515-0811

Outside North America: +1 (805) 247-8560

E-mail: support@nevion.com

See http://www.nevion.com/support/ for service hours for customer support globally.

Rev.

Repl.

Date

Sign

Change description

A - 2014-12-03

MR

Initial release

Nevion Support

Revision history

Current revision of this document is the uppermost in the table below.

nevion.com | 2

Page 3

FR-2RU-20-2 Rev. A

Contents

Revision history ........................................................................................................ 2

1 Product overview ................................................................................................... 5

2 Specifications ........................................................................................................ 6

2.1 General specifications ................................................................................................... 6

2.2 Front view ..................................................................................................................... 6

2.3 Rear view ...................................................................................................................... 7

2.4 Power consumption ....................................................................................................... 8

3 Configuration ......................................................................................................... 9

3.1 Address setting on each frame ...................................................................................... 9

3.2 PSU redundancy mode selection .................................................................................10

4 Connections ........................................................................................................ 11

4.1 Power connection .........................................................................................................11

4.2 GPI Power Supply Status outputs ................................................................................11

4.3 RS-422 connection .......................................................................................................12

4.3.1 Pin-out RS-422 (RJ45) ..............................................................................................12

4.3.2 Connecting several frames together ..........................................................................13

4.4 Sync input/output. ........................................................................................................14

5 Frame operation ................................................................ .................................. 15

5.1 Removing the front panel ................................................................ .............................15

5.2 Backplane insertion ................................................................................................ ......16

5.3 Main module insertion ..................................................................................................18

5.4 Card removal ...............................................................................................................21

5.5 PSU insertion ...............................................................................................................22

5.6 PSU removal ................................................................................................................22

5.7 Attaching the front panel ..............................................................................................23

5.8 Frame status (LEDs) ....................................................................................................24

5.8.1 Multicon .....................................................................................................................24

5.9 Fans ................................ ............................................................................................. 25

5.9.1 Fan operation ............................................................................................................25

5.9.2 Replacing defective fans ...........................................................................................25

6 Fiber optics .......................................................................................................... 26

6.1 Laser safety precautions ..............................................................................................26

6.2 Handling of optical fibers ..............................................................................................27

6.3 Optical connectors .......................................................................................................27

7 Flashlink control protocol ..................................................................................... 28

7.1 Document conventions .................................................................................................28

7.2 Hardware interface .......................................................................................................28

7.3 Addressing ...................................................................................................................28

7.4 General command structure .........................................................................................28

7.5 Card detection (hot swap) ............................................................................................28

7.6 Hello command ............................................................................................................29

7.7 Electrical to optical converters ......................................................................................29

7.7.1 Hello command ................................................................ .........................................29

7.7.2 Info command ...........................................................................................................29

7.8 Optical to electrical converters .....................................................................................30

7.8.1 Hello command ................................................................ .........................................30

7.8.2 Info command ...........................................................................................................30

Product Warranty.................................................................................................... 32

nevion.com | 3

Page 4

FR-2RU-20-2 Rev. A

Appendix A Materials declaration and recycling information .................................. 33

A.1 Materials declaration ....................................................................................................33

A.2 Recycling information ...................................................................................................33

nevion.com | 4

Page 5

FR-2RU-20-2 Rev. A

1 Product overview

The FR202 (-RP) frame, is a compact frame, providing space for up to 20 Flashlink

modules, in addition to two fixed positions for power supply modules and one fixed position

for a possible future control board.

The frame features maximum flexibility as every module comes with a dedicated backplane module, which takes up n x 7TE spacing. The 3.5TE distance between card positions

opens for connection of two Flashlink modules to one 7TE backplane. The number of

backplanes with 3.5TE module distance (utilizing all 20 positions) is currently limited, but

will be expanded in the future. Each frame can be controlled by a Multicon System

Controller card , together with up to 7 other frames.

The sync function makes it possible to provide a common sync signal to all card positions.

Power consumption

The current draw in the Flashlink frame is limited by the power supplies.

Overloading the power supplies will cause the power units to malfunction. Please

read chapter 2.4 for further details!

Heat dissipation

The heat dissipation is based on convection as well as cooling by fans, and it is

therefore very important not to block the warm air exhaust perforations in the

chassis.

nevion.com | 5

Page 6

FR-2RU-20-2 Rev. A

AC Power:

PWR-AC-160W

AC power supply module 100-240VAC.

Redundant Power

(optional):

PWR-AC-160W

Dimensions:

19’’ width 2RU height

Card slots:

20 for Flashlink modules, 1 allocated for a possible future

board

Power Supply slots

2.

Internal voltages:

Sync:

GPI:

+5V, +15V, -15V.

Return loss; typical <14dB, 0-5MHz (dependent of the

quality of the termination at Power C5)

Open drain output from each power supply which turns low

ohmic in an alarm situation.

To withstand +10VDC (open) and 100mADC (at less than

50mOhm) (closed)

2 Specifications

2.1 General specifications

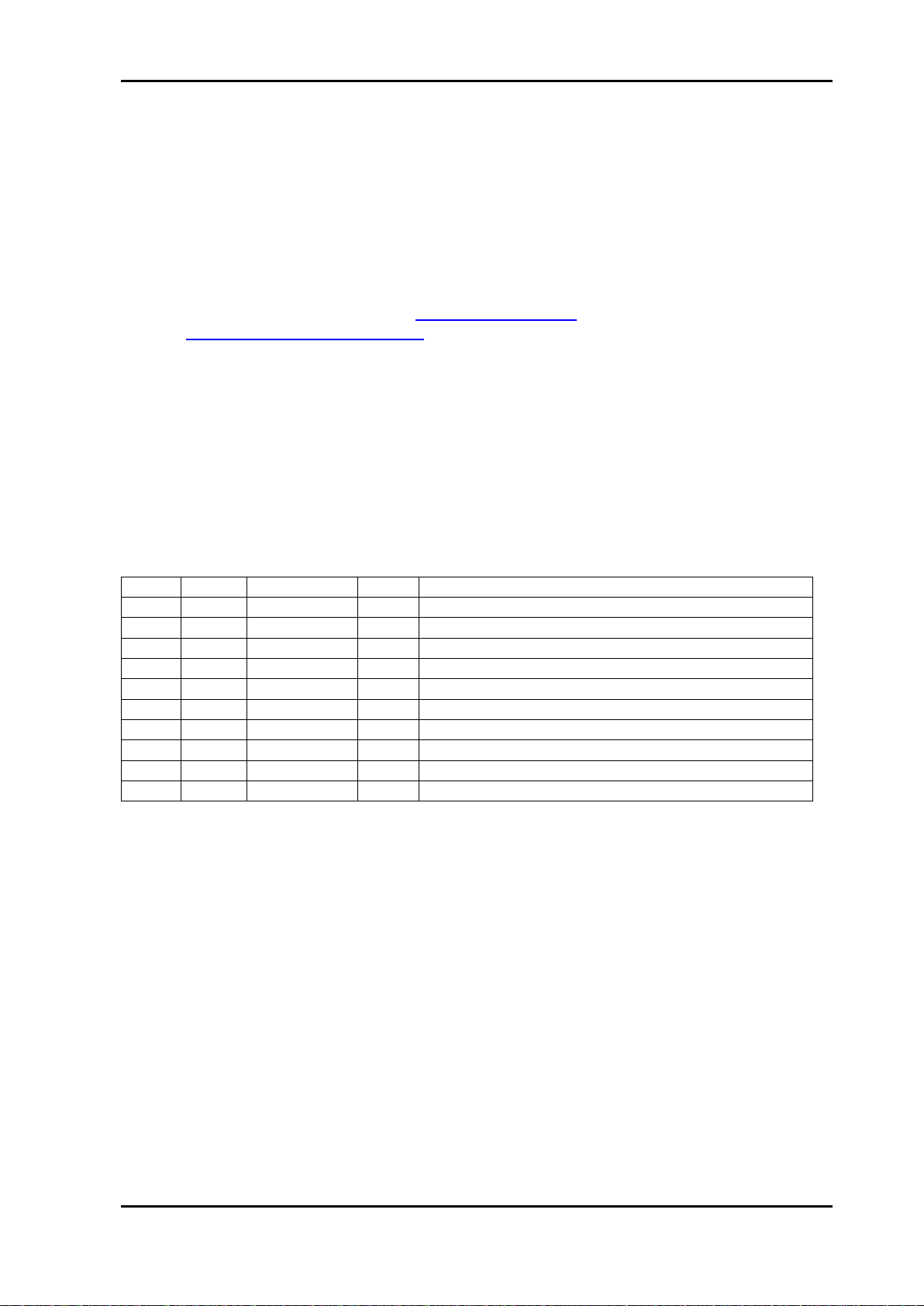

2.2 Front view

The front view of the frame shows status LEDs for the power supply modules.

Figure 1:Front view of the Flashlink frame.

The two LEDs at the front have the following functions:

Upper LED: Voltage and current alarm, internal voltages

Lower LED: Fan and temperature alarm

nevion.com | 6

Page 7

FR-2RU-20-2 Rev. A

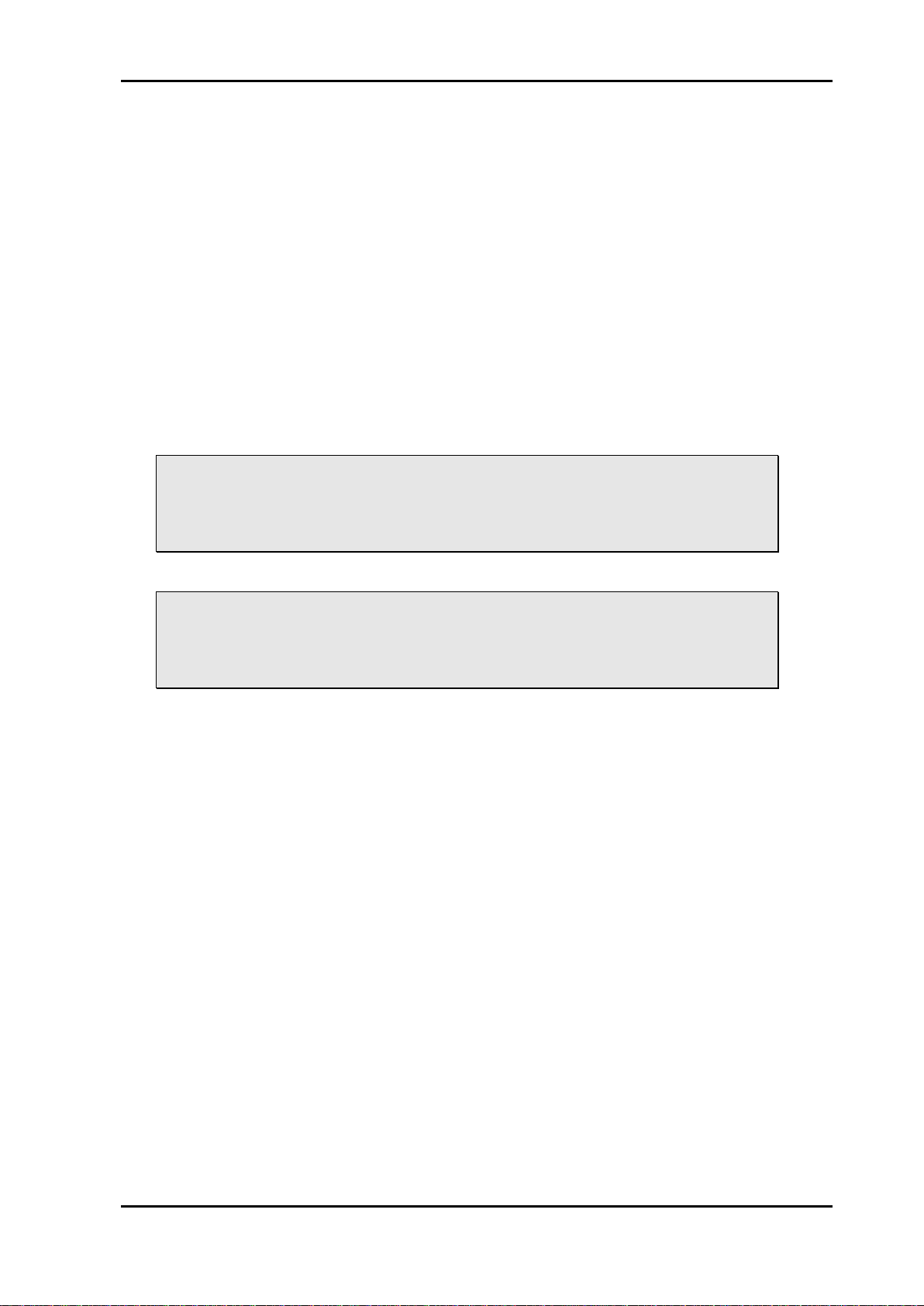

2.3 Rear view

Figure 2 shows an example of a fully equipped Flashlink frame, seen from the rear side.

The outer left and outer right modules are backplanes for the power supplies and contain

connections as follows;

- Left backplane;

o IEC-C14 AC mains inlet

o BNC, sync in

- Right backplane;

o IEC-C14 AC mains inlet

o BNC, sync out

o 2pcs. RJ-45 for RS-422 in/out

o Rotary switch for programming frame number to be read by Multicon

o 4 pin connector, GPI out

*The other connector modules are described in their respective user manuals.

Figure 2: Illustration of fully equipped Flashlink frame.

Figure 3: Flashlink frame equipped with blanks.

nevion.com | 7

Page 8

FR-2RU-20-2 Rev. A

Remark:

The power supplies support load sharing giving them extended life time. Though the total

potential power supply capacity is actually doubled in a redundant coupling, the above listed

maximum power limits for the frame shall never be exceeded.

2.4 Power consumption

The current draw in the Flashlink frame is limited by the power supplies. Overloading the

power supplies will cause them to malfunction.

The power and current limits for the frame, even with two active power supplies, are as

follows:

Total: 130W (Remaining available 30W up to 160W is dedicated for Fanboard and

fans)

+5V: 20A

+15V: 8.7A

-15V: 2A

The power consumption can be drawn from the three voltages in any combination, though

not exceeding 130W in total.

The sum of power for all cards on each rail must not be higher than the above listed limits.

The power consumption for each of the power supply rails is found in the user manual for

each Flashlink card, as this is not the same for all Flashlink cards.

nevion.com | 8

Page 9

FR-2RU-20-2 Rev. A

Valid positions: 0-7

3 Configuration

3.1 Address setting on each frame

Each frame can be assigned an address through the rotary switches on the rear. Maximum

8 frame addresses (0-7) are available, this means that pos. “8” and “9” on the rotary switch

are not valid

This address setting only applies when the frame is used in combination with a GYDA-SC

Rack System Controller.

If you have more than 8 frames together, you need several GYDA-SC Rack System

Controller cards.

In order to ensure proper operation of the system, it is important that no frames

controlled by the same GYDA-SC Rack System Controller card have the same

address set.

Reset the frame after reconfiguring the frame system, by turning the power off

and on again.

Figure 4: Rotary switch

More detailed information on the RS-422 configuration can be found in a separate

document and at our web site: http://www.nevion.com/

nevion.com | 9

Page 10

FR-2RU-20-2 Rev. A

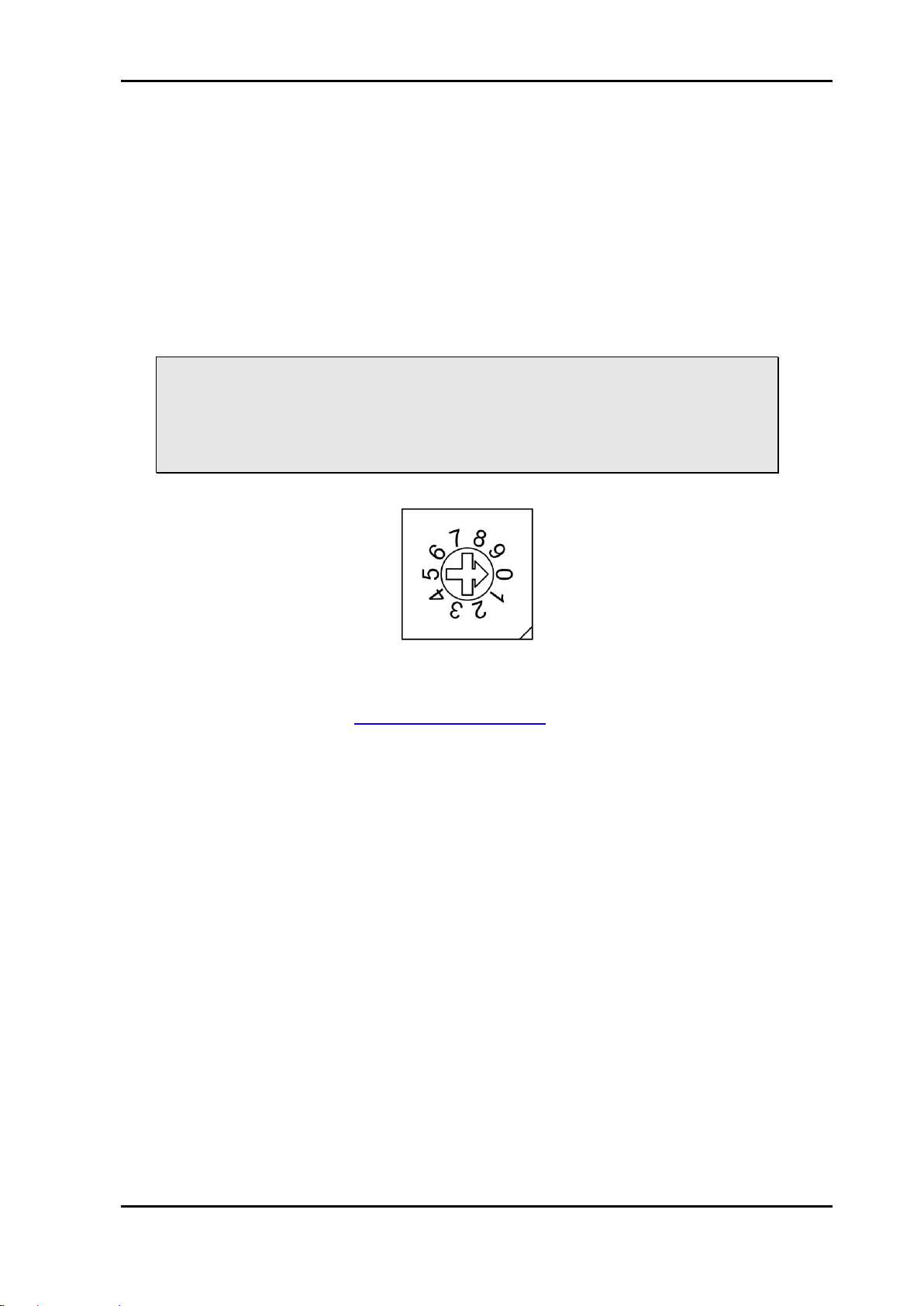

3.2 PSU redundancy mode selection

The frame comes equipped with a jumper mounted at the programming header at the

Fanboard.

Depending on the desired mode the jumper shall be mounted as described in the figure

below.

Figure 5: Location of jumper for redundancy mode selection

nevion.com | 10

Page 11

FR-2RU-20-2 Rev. A

GND

Not connected

GPI from nearest power supply

GPI from farthest power supply

4 Connections

4.1 Power connection

Figure 3 shows the power connections of the frame as well as the RS-422 connections and

the rotary-switch for address setting of the frame.

Figure 6: Connector module for the power supply.

AC: Connect mains to the frame with a mains cord with an IEC 320 connector.

To ensure a safe connection a cable with IEC-lock connector should be used.

Such cables can be ordered from Nevion.

A green LED will light on the front when the power supply is in operation mode.

For a faulty power supply LED will have red light or no light.

4.2 GPI Power Supply Status outputs

The GPI module status outputs can be used for wiring up alarms for third party control

systems.

Figure 7: GPI connector

In an alarm situation the GPI output is connected low ohmic to GND.

nevion.com | 11

Page 12

FR-2RU-20-2 Rev. A

Pin #1

Rx A (+)

Pin #2

Rx B (-)

Pin #3

Tx A (+)

Pin #4

Reserved

Pin #5

Reserved

Pin #6

Tx B (-)

Pin #7

Not Connected

Pin #8

Not Connected

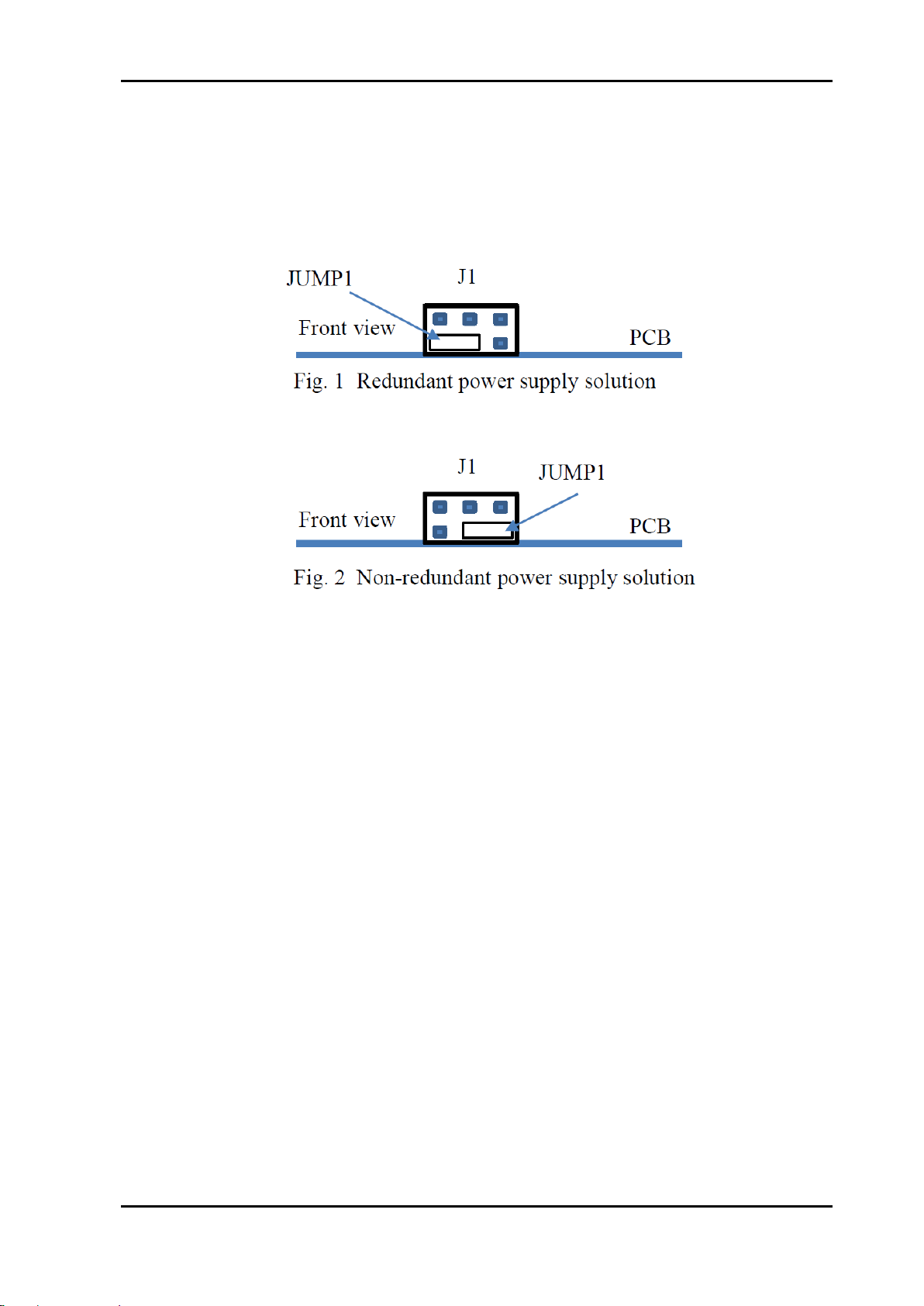

4.3 RS-422 connection

At the rear end of the frame is an RS-422 bus. When used in combination with the Multicon

Rack System Controller, up to 8 frames can be controlled. On the rear end of the frame is a

rotary switch by witch each frame can be assigned its own address (see figure 3).

The RS-422 interface is shown in figure 8.

4.3.1 Pin-out RS-422 (RJ45)

Figure 8: RS-422 pin-out.

nevion.com | 12

Page 13

FR-2RU-20-2 Rev. A

1 2 3 6

4.3.2 Connecting several frames together

Several frames can be connected to each other through the RS-422 ports on the rear of

each frame.

One GYDA-SC controller can control maximum 8 frames.

You start with the frame containing the GYDA-SC Rack System Controller, and use 1 RS422 port to loop through to the next.

The last frame connected must be terminated with 110 in order to ensure proper

operation. The other port of the rack containing the GYDA-SC controller must be left open,

and cannot be connected to other frames.

Figure 5 shows an example of how to connect 8 frames together as seen from the rear end.

By using the RS-422 interface at the GYDA-SC controller card, we control 8 frames via one

RS-422 bus.

Figure 9: Control of 8 frames with GYDA-SC.

The 110 termination plug used is a standard RJ45 plug with the following internal wiring:

Figure 10: RS-422 termination.

In the figure above, Pin 1 is connected to Pin 2 with a 110 resistor, and Pin 3 is connected

to Pin 6 with a 110 resistor.

nevion.com | 13

Page 14

FR-2RU-20-2 Rev. A

4.4 Sync input/output.

An analog sync signal may be applied to the frame via the “Sync in” BNC connector .Which

Flashlink modules that can utilize the sync signal, is described in user manual for the actual

modules.

While sync is applied, the sync termination switch must be switched to “on” (upper)

position).

nevion.com | 14

Page 15

FR-2RU-20-2 Rev. A

5 Frame operation

In order to reconfigure or expand the number of modules within a frame, the front panel

must be removed. Each module has a corresponding connector module at the rear, and is

hot swappable.

Use safety goggles when hot-swapping module cards.

If a receiver card is removed from the frame, an invisible laser beam may be

emitted inside the frame from the laser at the other end. The laser beam might

be harmful to your eyes.

5.1 Removing the front panel

Pull here Pull here

"Left circle" "Right circle"

Figure 11: Removing the front panel.

nevion.com | 15

Page 16

FR-2RU-20-2 Rev. A

Figure 12: Removing the front panel (continued).

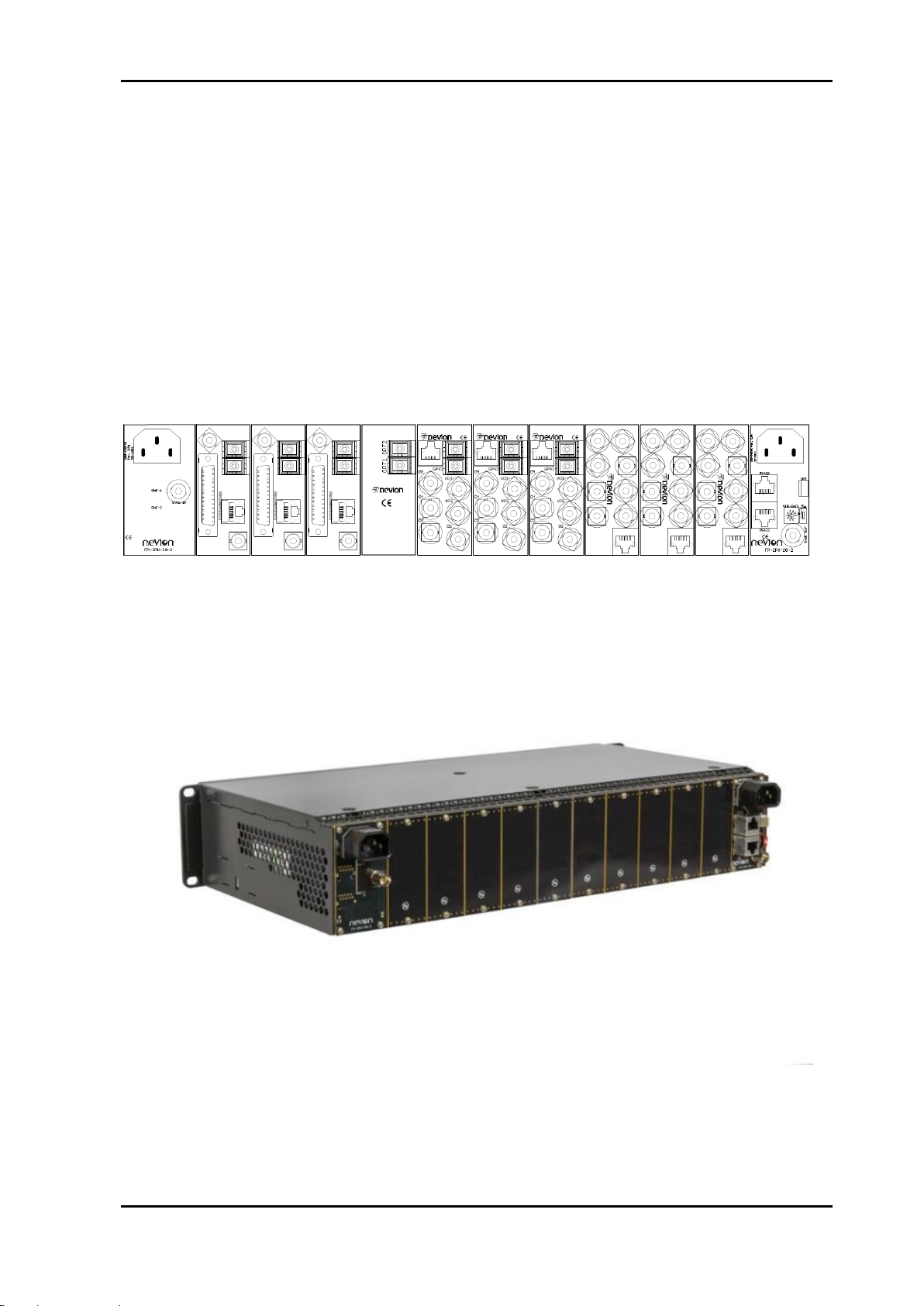

5.2 Backplane insertion

Before installing a new Flashlink main module, the accompanying back plane must be

mounted.

Switch off the power-supply. The LED on the power module is then off. With a redundant

solution, make sure that both power supplies are switched off.

Remove all screws holding the back plane to be replaced. Remove the backplane by lifting

it straight out from the rear of the frame.

The backplanes with an optical interface have a rubber plug inside each fiber adapter to

protect from dust. This rubber plug must be removed before the backplane is inserted.

.

Figure 13: Removing the rubber plug from module cards.

nevion.com | 16

Page 17

FR-2RU-20-2 Rev. A

When mounting a backplane, the backplane connector shall always be aligned at the left

and upper corner pin, see figure 13 below.

Alignment pin

+

Figure 14: Alignment pin

If the backplane to be mounted has an EMC gasket of newest type (see fig. 14),

the procedure described below does not apply.

Figure 15: Newest EMC gasket solution

Remove the screws on the back plane to the left of where the new back plane is to be

installed (seen from the back of the frame). Lift the right hand side of it slightly.

Insert the new back plane. Carefully place the right hand-side of the back plane into the slot

first (this is the side without the EMC shielding.) Then, use your business card (or another

suitable card), and insert the left edge of the back plane as shown in Figure 15 below. This

will help avoid damage to the EMC shield when inserting the new back plane.

Figure 16: Inserting a new back plane.

After the backplanes are mounted, the main module can be inserted as described in

section 5.3

nevion.com | 17

Page 18

FR-2RU-20-2 Rev. A

5.3 Main module insertion

After the fan front is removed, full access to the card modules inside the frame is given.

Switch off the power with the power switch at the power-supply modules. The green light -at the power module is now switched off. If the power supply is redundant, make sure that

both power supplies are off.

The frames are equipped with plastic guide rails to align the module cards into their

respective positions 1 to 20. Just before a card is inserted, one should remove the plastic

cap from the fiber ferrule as shown in figure 11. Do not touch the ferrule tip with your fingers

(see chapter Error! Reference source not found. - fig. 21).

Remove plastic cap before inserting module cards

a) b)

Figure 17: Removal of plastic cap

Figure 18: Open frame.

nevion.com | 18

Page 19

FR-2RU-20-2 Rev. A

Figure 19: Overview of card positions inside a frame

Be careful when inserting the card into the frame.

The ferrule of the fiber may be damaged if it touches the frame walls. Do not

touch the ferrule tip with your fingers.

Figure 20: Marking of main module locations.

Figure 21: Inserting module cards.

nevion.com | 19

Page 20

FR-2RU-20-2 Rev. A

Card locking clip

Figure 22: Inserting module cards (continued)

Slide the card into the plastic guide rails inside the frame by pushing at the card edge until

the rear edge of the card is locked by the card lock at the end of the card rail. Then push

the card handle into vertical position. See sketches below for detailed description.

Make sure that the connector on the module card fits with the connector on the back plane

card when inserting a new module card for the first time.

nevion.com | 20

Figure 23: Inserting module cards (continued)

It should not be necessary to use any force when entering the module card into

the accompanying back plane connector.

Page 21

FR-2RU-20-2 Rev. A

5.4 Card removal

To remove a module from the frame, push the spring loaded card lock downwards and

below the lower edge of the card. Then, simultaneously with the other hand, move the card

handle from vertical to nearly horizontal position and pull the card entirely out of the rack.

When removing a receiver card from the frame (hot swapping), the laser beam

may be present inside the frame (transmitted through the fiber). To avoid

damaging your eyes, never look directly into the frame unless you are 100% sure

that no laser beam is present inside the frame.

Figure 24: Card removal

nevion.com | 21

Page 22

FR-2RU-20-2 Rev. A

5.5 PSU insertion

Figure 25: PSU insertion.

The outer left and outer right positions are allocated for PSUs.

With exception for the lacking card handle the procedure for mounting is similar to main

module insertion procedure.

In a non-redundant configuration any PSU position may be used.

5.6 PSU removal

Figure 26: PSU removal

To remove a PSU from the frame, push the spring loaded card lock downwards. Be aware

of the PSU connector release force.

Then, simultaneously with the other hand, move the metal handle from vertical to nearly

horizontal position and pull the PSU entirely out of the rack.

nevion.com | 22

Page 23

FR-2RU-20-2 Rev. A

5.7 Attaching the front panel

To attach the front panel, we invert the process described in section 5.1. Start by switching

on the power supplies.

Then move the front to upright position and push it carefully into the frame until it stops.

When correctly mounted, both LEDs at the fan front will go through a short start-up

sequence before they both provide stable light.

Figure 27: Attaching the front panel.

nevion.com | 23

Page 24

FR-2RU-20-2 Rev. A

Symbol

Green LED

Yellow LED

Red LED

No LED

PSU module

none

Power is OK

Voltage or

current alarm

Power

off

Frame front

Power is OK

Communication

problem with

fan front*

Voltage or

current alarm

Power

off**

Temperature

/fans are OK

Communication

problem with

fan front*

Temperature

/fans alarm

Power

off**

5.8 Frame status (LEDs)

PSU status is presented in the following ways:

* Lack of communication with PSU in non-RP mode or one of the PSU’s in RP mode.

(In both situations the fans will have permanent maximum speed)

** PSU in non-RP mode or both of the PSU’s in RP mode

5.8.1 Multicon

- Multicon GUI which presents the following information

o Measured voltages

o Measured currents at each frame voltage

o Total provided power

o Internal PSU temperature

o Alarm status for;

voltages

currents

total provided power

temperature

Defect fan

Figure 28: Example of PSU interface in Multicon

- GPI

o See description in chapter “GPI Power Supply Status outputs”.

nevion.com | 24

Page 25

FR-2RU-20-2 Rev. A

5.9 Fans

5.9.1 Fan operation

The fans at the front provide sufficient cooling for modules and power supplies in every

allowed load situation. Their speed is controlled by control circuits in the power supplies

based on their internal temperature. The fan speed is individually and continuously

checked, and if a fan has a speed outside expected limits, it will be reported to Multicon as

being defective and the lower LED at the fan front will change to red.

Having one defective fan in the frame shall not be considered as an emergency situation

since the total needed air flow will be maintained by an increase in speed for the remaining

fans.

Removing the fan front in a live frame may cause malfunction or damage to modules due to

excessive heat and should, as a rule, never be done.

To maintain optimal cooling, all air flow openings in the chassis must be kept uncovered.

5.9.2 Replacing defective fans

Changing a defective fan should be performed at a non-live frame.

Procedure; Please contact Nevion’s customer support department.

nevion.com | 25

Page 26

FR-2RU-20-2 Rev. A

6 Fiber optics

6.1 Laser safety precautions

Guidelines to limit hazards from laser exposure.

All the available EO units in the Flashlink range include a laser.

Therefore this note on laser safety should be read thoroughly.

The lasers emit light at 1270 nm or 1610 nm. This means that the human eye cannot see

the beam, and the blink reflex cannot protect the eye. (The human eye can see light

between 400 nm to 700 nm).

A laser beam can be harmful to the human eye (depending on laser power and exposure

time), therefore:

Be careful when connecting / disconnecting fiber pigtails (ends).

Never look directly into the pigtail of the laser/fiber.

Never use microscopes, magnifying glasses or eye loupes to look into a fiber end.

Use laser safety goggles blocking light between 1270 nm and at 1610 nm.

Instruments exist to verify light output power: Power meters, IR-cards etc.

Dette er vel ikke helt oppdatert:

Flashlink features:

The FR202(-RP) is classified as Class 1 laser product according to EN 60 8251:94/A11:96, and CFR Ch1(1997) Part 1040.10.

If the front panel is removed, the FR202(-RP) is classified as Class 1 laser product

according to EN 60 825-1:94/A11:96, and class IIIb according to

CFR Ch1(1997) Part 1040.10.

Sjekk angående denne spec:

Maximum output power: 5 mW.(Egentlig 10mW?)

Operating wavelengths: 1270 to 1610 nm

Figure 29: Laser class label

nevion.com | 26

Page 27

FR-2RU-20-2 Rev. A

6.2 Handling of optical fibers

When handling fiber optical cables and interconnections, these precautions must be taken

to ensure reliable operation:

- Do not bend the fiber too much, all fiber optical cables have a minimum bend

radius. Follow manufactures datasheet recommendation for each cable or use

40 mm as a general guideline.

- Do not apply excessive mechanical stress on the fiber optical cables or

connectors.

- Keep the connectors clean from dust. Good practice is to clean the ferrule each

time a new connection is made between two optical connectors. Always use

special fiber optical ferrule cleaner made for this purpose.

- Never touch the ferrule or make the tip of the ferrule come in contact with other

objects. Always protect ferrules on optical connectors with protective cap when

not in use.

If the above precautions are not taken, the optical signal may be degraded or even lost

completely and the equipment will not function properly.

6.3 Optical connectors

The Flashlink product range utilizes among others SC/PC connectors.

An illustration of the different parts of the fiber optical connector are shown below.

Figure 30: The different parts of an SC/PC Connector.

Clean connectors are of crucial for reliable operation.

nevion.com | 27

Page 28

FR-2RU-20-2 Rev. A

Byte 0

Rack ID (0-7); Destination

Byte 1

Card position (0-19); Destination

Byte 2

Rack ID (0-7); Source

Byte 3

Card position (0-19); Source

Byte 4 – n

Command or command response

Byte n+1

Linefeed (10 decimal, 0x0A hex)

7 Flashlink control protocol

7.1 Document conventions

All commands sent to the card are printed in italics.

This is a command sent to a card.

All responses sent from a card to the controller are printed in bold.

This is a response sent from a card to the controller.

7.2 Hardware interface

The hardware interface is basically RS-422, a serial communication standard much like RS232 but with balanced lines. You can use a simple (dumb) RS-232 to RS-422 converter if

you want to use a standard RS-232 port (eg. a PC COM port).

The receive and transmit lines can be connected to make a true RS-485 bus, but this

requires special care from the PC side, since you have to control the bus direction (e.g.

using a dedicated RS-485 board with RS-485 drivers). We recommend using RS-422 for

control.

Data rate: 115200 bps, 8 bits, with one stop bit and no parity.

All data is 8 bit ASCII (ISO8859-1 encoding, but currently any ASCII encoding will do since

no special ASCII characters are used).

7.3 Addressing

Each card has a unique identifier called card position, which is assigned (trough hardware

pinning) automatically when a card is inserted into a subrack. The card positions are

numbered from 1 to 20 from a user point of view. From a protocol (or software) point of

view, the cards are numbered 0-19. When we refer to card position in this document, we

refer to this "low level id" numbered 0-19, but the user should always see positions 1-20 in

menus, etc.

Each frame (if you use more than one) should have a unique frame id, numbered 0-7 (user

and protocol/software wise). The id is set by rotary switches on the rear of the rack, behind

the power supply at the left side.

7.4 General command structure

Each command is built up of a sequence of ASCII characters terminated by linefeed. The

first two characters are the source address (source frame id and the source card position).

Frame structure:

If the command or command response contains a line feed, it is preceded by a backslash

(\).

7.5 Card detection (hot swap)

The controller must send a "hello" command to gain control over a board, this is to make

sure that the control software is aware of any card changes. After a power up or hot swap,

the card does not respond to any other command than hello.

nevion.com | 28

Page 29

FR-2RU-20-2 Rev. A

7.6 Hello command

This command establishes communication with a new unit. An example of communication

with SDI-EO and SDI-OE is shown in the following. The command is short (a single

question mark) to save bandwidth. The card will respond with card info. If the card is not

present, the command times out.

A typical response would be:

0409?

0904EO/SDI/1310nm,-7.5dBm\

hw rev 1.0\

sw rev 1.0\

protocol ver 1.0

This is an electrical to optical converter for SDI, with a -7.5dBm 1310nm laser. The

hardware revision is ver 1.0, and the software version is ver 1.0. The protocol version is 1.0.

7.7 Electrical to optical converters

7.7.1 Hello command

An EO converter will respond to a hello command with:

0409?

0904EO/SDI/1310nm,-7.5dBm\

hw rev 1.0\

sw rev 1.0\

protocol ver 1.0

or

0409?

0904EO/T140/1310nm,-7.5dBm\

hw rev 1.0\

sw rev 1.0\

protocol ver 1.0

7.7.2 Info command

The card will respond to the command string "info" by sending the card status. This is a

typical example.

0409info

0904laser on\

SDI signal strength = 81 %\

vcc = 5.04 V\

laser fail: no

nevion.com | 29

Page 30

FR-2RU-20-2 Rev. A

7.8 Optical to electrical converters

7.8.1 Hello command

An OE converter will respond to a hello command with:

0409?

0904OE/SDI/reclocking, not calibrated\

hw rev 1.0\

sw rev 1.0\

protocol ver 1.0

or

0409?

0904OE/T140/reclocking, not calibrated\

hw rev 1.0\

sw rev 1.0\

protocol ver 1.0

"Not calibrated" refers to the optical power measurement which is not calibrated.

7.8.2 Info command

The card will respond to the command string "info" by sending the card status. This is a

typical example.

0409info

0904signal = -12.2 dBm\

optical signal: yes\

reclocker locked: yes\

vcc = 4.97V

Note that since the optical signal strength is not calibrated, the measurement will be wrong

(typ. +/- 5 dB).

nevion.com | 30

Page 31

FR-2RU-20-2 Rev. A

1.

The equipment will meet the guaranteed performance specification under the

following environmental conditions:

-

Operating room temperature range:

0°C to 45°C

-

Operating relative humidity range:

< 90% (non-condensing)

2.

The equipment will operate without damage under the following environmental

conditions:

-

Temperature range:

-10°C to 55°C

-

Relative humidity range:

< 95% (non-condensing)

General environmental requirements for Flashlink equipment

nevion.com | 31

Page 32

FR-2RU-20-2 Rev. A

Product Warranty

The warranty terms and conditions for the product(s) covered by this manual follow the

General Sales Conditions by Nevion, which are available on the company web site:

www.nevion.com

nevion.com | 32

Page 33

FR-2RU-20-2 Rev. A

組成名稱

Part Name

Toxic or hazardous substances and elements

鉛

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr(VI))

多溴联苯

Polybrominated

biphenyls

(PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

<Product>

O O O O O

O

<Power supply, if

delivered with unit>

O O O O O

O

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials used

for this part is above the limit requirement in SJ/T11363-2006.

Appendix A Materials declaration and recycling

information

A.1 Materials declaration

For product sold into China after 1st March 2007, we comply with the “Administrative Measure

on the Control of Pollution by Electronic Information Products”. In the first stage of this

legislation, content of six hazardous materials has to be declared. The table below shows

the required information.

This is indicated by the product marking:

A.2 Recycling information

Nevion provides assistance to customers and recyclers through our web site

http://www.nevion.com/. Please contact Nevion’s Customer Support for assistance with

recycling if this site does not show the information you require.

Where it is not possible to return the product to Nevion or its agents for recycling, the following

general information may be of assistance:

Before attempting disassembly, ensure the product is completely disconnected from

power and signal connections.

All major parts are marked or labeled to show their material content.

Depending on the date of manufacture, this product may contain lead in solder.

Some circuit boards may contain battery-backed memory devices.

nevion.com | 33

Loading...

Loading...