Neoprobe 2000, 2100 User manual

neo2000®Gamma Detection System

6

Service Manual

Models 2000 & 2100

Manufacturer:

Neoprobe Corporation

425 Metro Place North, Suite 300

Dublin, Ohio 43017-1367 USA

Tel: +1 (614) 793 7500

Fax: + 1 (614) 793 7531

008

Medical Electrical Equipment

With respect to electrical shock,

fire, and mechanical hazards.

only.

00-0059 Rev B © 2001 Neoprobe Corporation

Authorized representative:

AR-MED, Ltd.

Runnymede Malthouse

Egham TW20 9BD, UK

Tel: +44 (0) 1748 497851

Fax: +44 (0) 1748 497801

“neo2000” is a registered trademark of Neoprobe Corporation.

“BlueTip” is a trademark of Neoprobe Corporation.

Table of Contents

1. Introduction 1-1

1.1 System Warnings, Cautions and Notes 1.1-1

2. Specifications 2-1

3. Technical Overview 3-1

4. Diagnostic Troubleshooting 4-1

5. Disassembly, Service Part Installation and Re-assembly 5-1

6. Performance Verification 6-1

7. Disclaimers 7-1

8. Service Policy 8-1

i

Table of Contents (continued)

9. Warranty 9-1

10. Notices 10-1

Appendix A

A.1 neo2000

A.2 neo2000 Grounding & Isolation Diagram A.2-1

A.2 Front Housing Assembly A.3-1

A.3 Rear Housing Assembly A.4-1

Appendix B Neoprobe Authorized Service Parts B-1

Appendix C Service Checklist C-1

®

Functional Schematic A.1-1

ii

Introduction

1

Purpose

This manual provides the necessary

information for an experienced biomedical

instrumentation technician to perform

routine service operations on the Neoprobe

neo2000® Gamma Detection System

(neo2000) in Model 2000 and 2100

configurations.

Scope

This manual gives instructions for the

servicing of the neo2000, including

diagnostic sequences to troubleshoot and

isolate failures, assembly sequences

required to remove and replace suspect

service parts, and performance verification

sequences to ensure that the performance

of the repaired unit meets Neoprobe

specifications. This manual does not

include any servicing capability for the

Neoprobe gamma detection probes, cables

or accessories. These items are not

serviceable in the field. This manual does

not provide detailed repair procedures and

technical documentation to isolate failures

to the lowest possible level. It

also does not discuss how to

perform surgery and procedures

for nuclear medicine.

The intent of this manual is not

to support the remanufacture

and resale of the neo2000 by

third parties.

Servicing Personnel

This manual is intended for use

by biomedical instrumentation

technicians and other

individuals who are familiar

with the routine servicing and maintenance

of medical electronic instrumentation. (For

additional information see Chapter 7.)

Those individuals should also be

thoroughly familiar with the neo2000

Operation Manual.

Customers are not authorized to perform

service during the initial one (1) year

period.

Training

This manual in conjunction with the

neo2000 Operation Manual provides all

the information that should be necessary

for a competent biomedical

instrumentation technician to perform the

authorized servicing operations. Neoprobe

does not provide any supplemental training

in the servicing of the neo2000.

1-1

Introduction (continued)1

Customer Feedback

Neoprobe understands the importance of

feedback to continual quality

improvement, and encourages users and

servicing personnel to provide any

suggestions for improving the products

and this manual. Please forward any

suggestions to:

Neoprobe Corporation

425 Metro Place North, Suite 300

Dublin, OH 43017-1367

Attn: Technical Support

or telephone:

(800) 793 0079 (USA only) or

+1 (614) 793 7500

or email:

service@neoprobe.com.

Note: In the unlikely event of a malfunction or failure,

Neoprobe recommends that owners of neo2000

instruments contact Neoprobe for service.

®

1-2

1.1

Warnings, Cautions and Notes

Overview

Read this section before servicing

the neo2000®. Included below are

warnings, cautions and notes for

safe service of the neo2000.

Definitions

Service Part: Component used in

the neo2000 that is available as a

replacement part for order from

Neoprobe by registered owners of

Neoprobe neo2000 products.

Warning: Specific information

provided to the service technician to

advise of improper servicing of the

device that could present potential

harm to the service technician, user

or patient and/or could result in

irreparable damage to the device or

property.

Caution: Specific information

provided to the service technician to

prevent the incorrect servicing of the

device which may affect performance

or safety of the device.

Note: General information provided

to the service technician to further

explain or clarify the proper servicing

of the device.

Warnings

• Only biomedical instrumentation

technicians or other individuals who

are familiar with the routine servicing and maintenance of medical

grade electronic instrumentation

should service the neo2000.

• Neoprobe shall have no liability for

any incident resulting from improper

servicing of the neo2000, or from the

use of any service parts that are not

obtained by authorized Neoprobe

sources of supply. (see chapter 9)

• Before servicing, complete the

necessary cleaning and inspection

process. (see chapter 4.2 of the

neo2000 Operation Manual)

• Disconnect the power cord from the

power outlet before opening.

• Do not open in the presence of

fluids, flammable anesthetics or

other explosive gases.

• The internal electronics of the

neo2000 are sensitive to damage

from electrostatic discharge (ESD).

Use appropriate precaution when

opening and servicing the unit.

• Neoprobe Corporation does not

support the remanufacture and

resale of the neo2000 by third

parties.

• Returned products must be properly

decontaminated in accordance with

all applicable regulations for

biohazardous material.

• Proper configuration of grounding

required for safety.

Cautions

• Replace wire ties and reroute wires

as they were initially found.

• Do not leave loose hardware inside

the console.

• Conduct normal in-house product

safety testing for the neo2000 after

servicing and before returning the

unit for use on patients.

1.1-1

Warnings, Cautions and Notes (continued)1.1

Notes

• The volume knob may be damaged

by mechanical shock.

• In the unlikely event of a malfunc-

tion or failure, Neoprobe recommends that owners of neo2000

instruments contact Neoprobe for

service.

• Calibration & Preventive Mainte-

nance: The neo2000 is shipped

set to factory specifications.

Preventive maintenance is limited

to external cleaning of the

neo2000, fuse replacements and

functional diagnostics.

®

• Replacement of certain items will

require reprogramming of the unit.

Contact Neoprobe to arrange for

reprogramming of the unit.

• Regarding Year 2000 compliance,

the neo2000 Gamma Detection

System does not use a Real Time

Clock, and subsequently is not

adversely affected by Year 2000.

• “Error 1” or “Error No Probe” is a

normal operating message when

no probe is present. Check probe

and cable connections.

1.1-2

Specifications2

Product Specifications

The neo2000® complies with

the following specifications.

Service replacement parts

ordered through Neoprobe also

comply with the appropriate

specifications listed. Personnel

performing service on the

neo2000 must understand

these specifications and must

ensure that all servicing

activities performed on the

neo2000 do not compromise

any of these specifications.

Product Classification Standard or Regulation

System: Class I, Exempt USA, 21 CFR § 892.1320

Class IIa Europe, Medical Device Directive

Class II Canada, Therapeutic Device Regulation

Class II Australia, Therapeutic Device Regulation

Model 2000 Type B EN 60601-1/2

Model 2100 Type BF EN 60601-1/2

(1)(2)

(2)

Console: Explosion Equipment not suitable for use in the

presence of Flammable ANASTHETIC

MIXTURE WITH AIR or OXYGEN or

NITROUS OXIDE

Fluid Ingress Ordinary Equipment

Mode of Operation Continuous Operation

Degree of Mobility Stationary, non-mobile

Protection against Fused and removable power cable

electrical shock

BlueTip

TM

Fluid Ingress IPX4

Probes

(1)

The degree of protection from electrical shock is based on the system configured with

reusable metal encased probes (Model 1017). When used with the BlueTipTM Probes (Model

2001, 2002, & 2003), the system is Type BF due to the mechanical isolation barrier the

plastic material provides.

2)

Product safety testing of the initial design is certified through laboratory testing conducted

by a certified third party testing laboratory. Ongoing production testing assures that each

device continues to comply with these criteria.

2-1

2 Specifications (continued)

IPX4

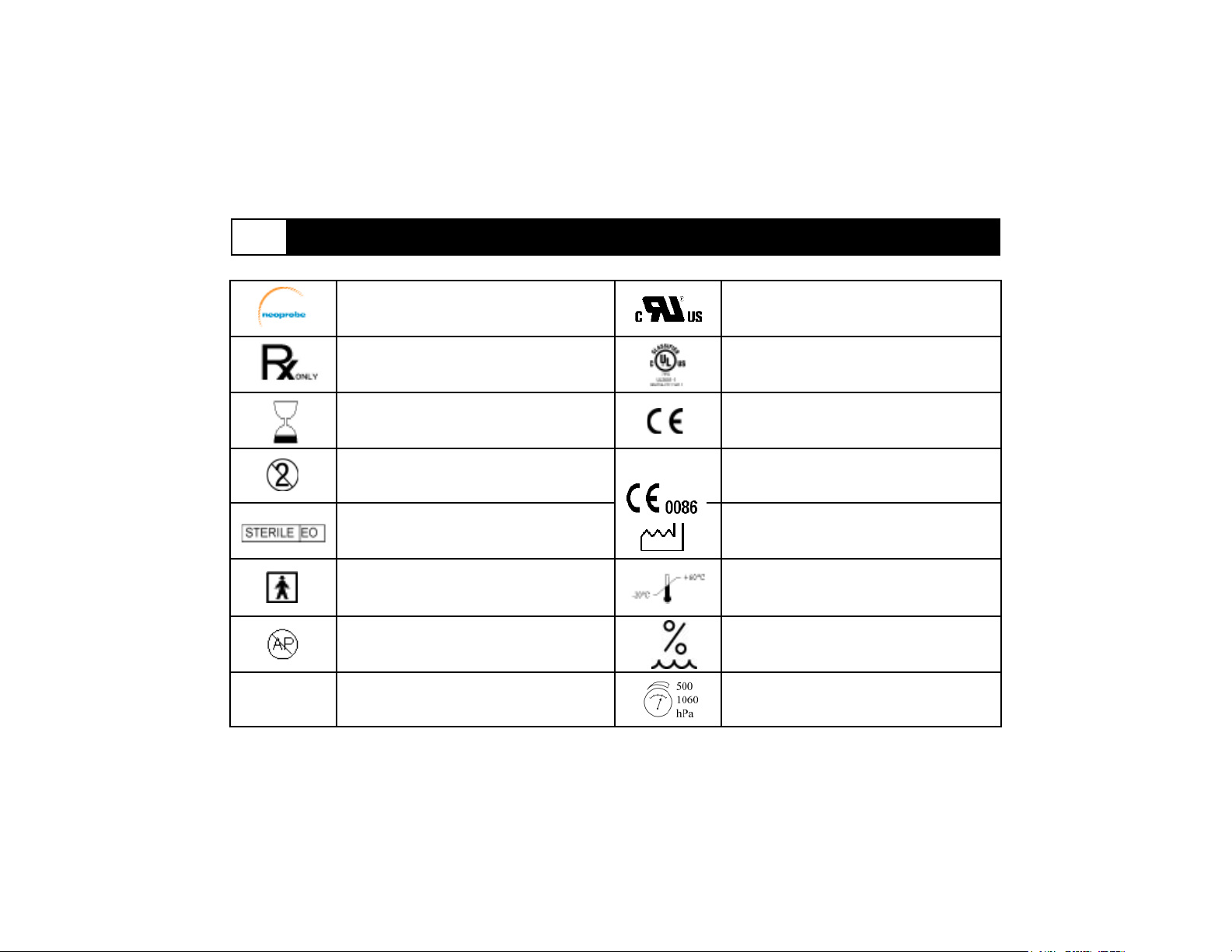

Neoprobe Corporation logo

In the U.S.A., Caution: Federal Law

restricts this device to sale by or on the

order of a physician

Use by

Do not reuse

Sterile using Ethylene Oxide

Type BF

Not for use in the presence of flammable

anesthetics

Splash-proof equipment

Underwriters Laboratory (UL) recognized

symbol component

UL Classified device

CE Mark, Class I

CE Mark, Class II, Class I Sterile

Date of manufacture

Storage and Transit Temperature

Storage and Transit Pressure

Storage and Transit Humidity

2-2

2 Specifications (continued)

Serial number

Batch code

Catalog number

Alternating current

Caution: consult accompanying

documents

Consult instructions for use

Standby (push-push) (power on:

connections to mains; power off:

disconnection from mains)

Equipotentiality

2-3

Technical Overview

3

Overview

This section describes the basic technical

features of the neo2000® console. Refer

to Appendix A.

Processing Architecture

The neo2000® contains two processors

with distinct functions: the central

processing unit (CPU) and the digital signal

processor (DSP). The CPU controls the

operator interface and some higher level

processing functions. The DSP performs a

majority of the processing of the probe

input signals including many of the

formatting and statistical processes

associated with counting input pulses. The

processors are located on separate circuit

boards and use a standard bus structure

with the CPU as the master of the bus.

Operator Inputs

Operator control over the console is

accomplished through the use of momentary pushbuttons. Most buttons have only

one function within a single operating mode.

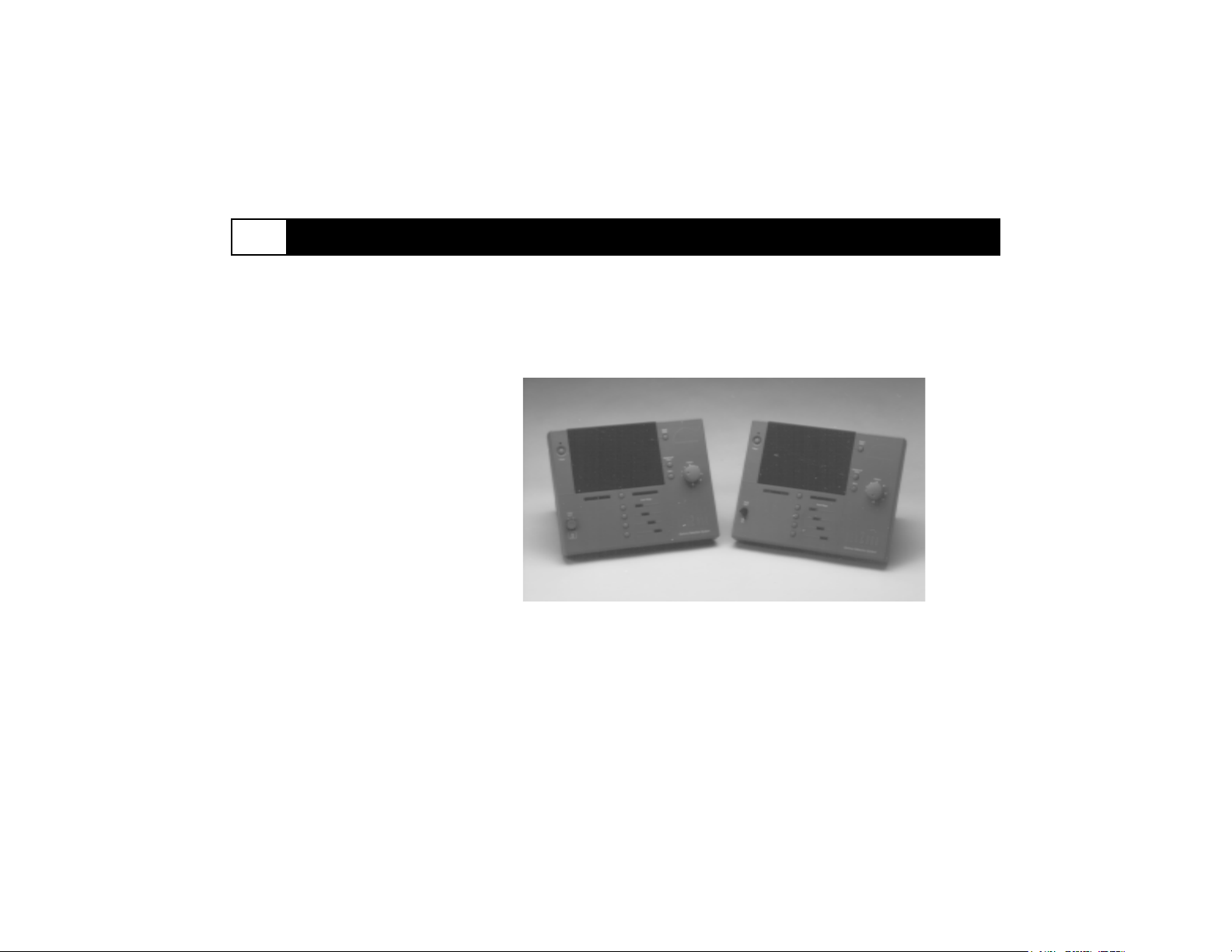

Figure 3-1. neo2000 Console (Left: Model 2100; Right: Model 2000)

3-1

Technical Overview (continued)

3

Volume control is accomplished

through use of a rotary input. To

maximize flexibility, this rotary input

is readable by the software and does

not directly control the audible

output level. Audible feedback of

button presses is provided electronically rather than mechanically.

Operator Outputs

Data from the console is presented to the

operator using both visual and audible

means. Operational state indicators are

provided to clearly indicate the operating

mode of the system to the user. Numeric

displays present quantitative data for

evaluation by the operator. A graphics

display and an audio speaker present

information in a qualitative manner.

Audible data is presented in order to allow

the surgeon to keep visually focused on

the patient. The audible output produces

data and status information simultaneously.

Electronic Input/Output (I/O) Ports

There are two serial I/O ports on the rear

of the console. These are used at the

factory to program the unit and for future

expansion.

Enclosure

The

enclosure

design

complies

with the

following

regulatory

requirements: 1)

EN 60601-11 drop test; 2)

EN 60601-1-2

electromagnetic

susceptibility and

emissions tests. To meet these

design requirements, a two piece

clamshell enclosure is used.

The enclosure has interlocking ribs

combined with a tongue and groove joint

to provide strength to pass the drop test.

Rigidity of the housing is obtained by

screwing the front and rear housings

together.

The walls of the housings are

angled to allow fluids to flow off

of the console. The tongue and

groove allows the placement of

a gasket to prevent liquid

ingress at the location of the

seam. The buttons are

designed to prevent liquid

entry without sacrificing

tactile feedback. External

components are resistant to

most common disinfectants used

to clean devices outside of the sterile

field.

Connectors and Cabling

The console contains both externally

accessible connectors as well as internal

cabling. Connectors and cables meet

applicable regulatory requirements and

environmental conditions.

3-2

Technical Overview (continued)

3

A

E

B

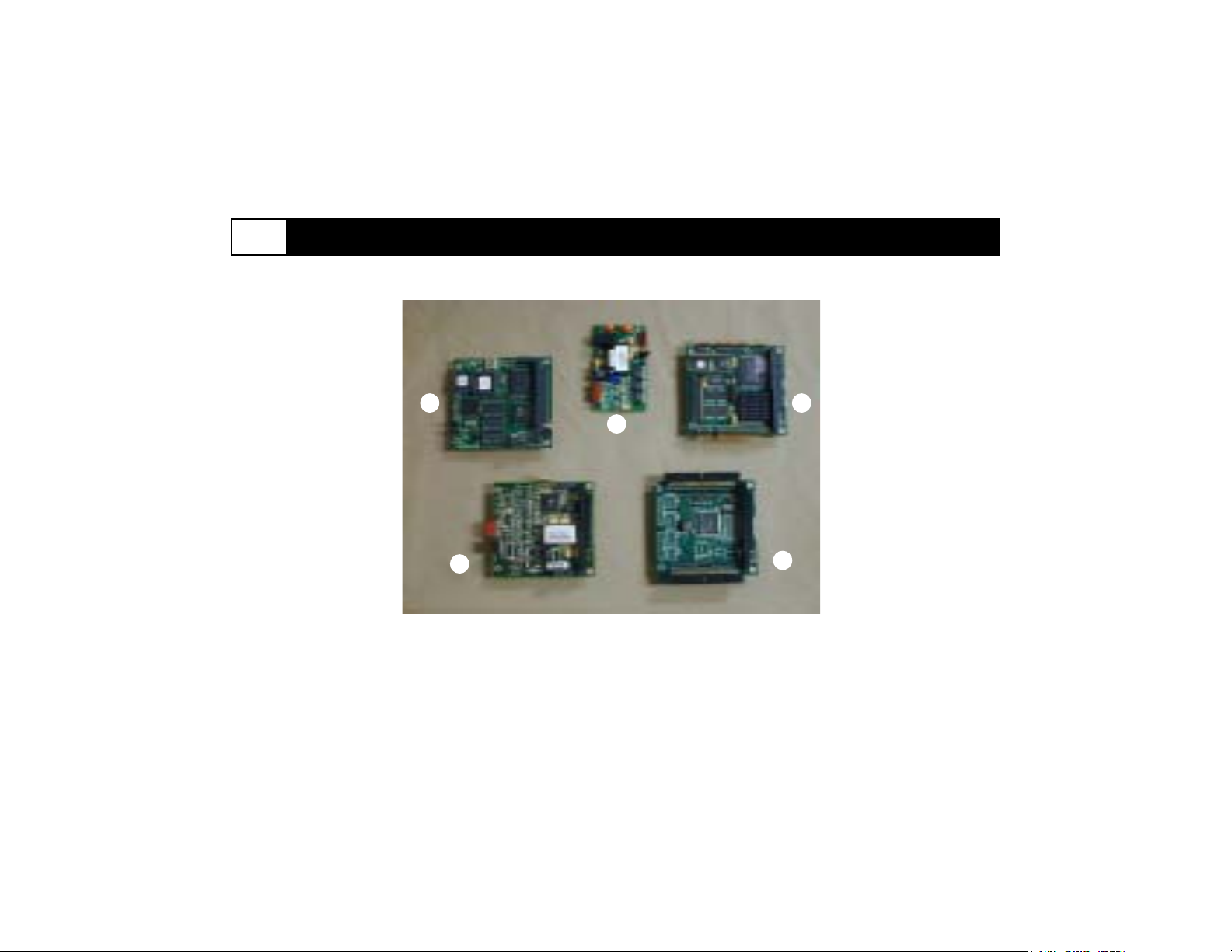

Figure 3-2. A. DSP Board B. PDM Board C. I/O Board D. CPU Board

E. PIM Board(Model 2100 only)

D

C

3-3

Technical Overview (continued)

3

Technical Overview (continued)

neo2000® Components

CPU Board (P101)

The main CPU board is a 100/133 MHz

486DX based PC/104 board with onboard

programming of Flash memory, floppy/IDE

interface, serial ports, parallel port, and

serial boot loader capability.

I/O Board (P105)

The I/O board provides digital expansion

channels to meet the total I/O requirements for the neo2000.

DSP Board (P102)

The DSP is a Starburst DSP board

containing a DSP running at 32 MHz. This

processor is capable of both 32-bit

floating point and 32-bit fixed point

operations and has two timers. This board

also provides the necessary analog and

discrete I/O channels to control and

interface with the probe input circuitry.

PDM Board (P103* or P104**)

The pulse descriminator module (PDM)

board contains the interface circuitry for

the external probe. The major components

of the PDM board are the signal conditioning circuitry, the power circuitry and the

Pulse Discriminator.

PIM Board (P107**)

The probe isolation module (PIM) board

provides isolation circuits for the interface

to the external probe.

Main Board (P100)

The Main board serves as a mounting point

for most of the displays and switches in

the console and also serves as the

motherboard for the console.

Auxiliary Board (P106)

The auxiliary board serves as a junction

box for the rear enclosure half and acts as

a mounting point for the I/O connectors

and the radionuclide switch.

Power Supplies (P140, P141)

The +5V and +12V power supplies are

medical grade universal input supplies

which accept single phase power between

85 and 264 VAC and 47 to 63 Hz.

Cabling

There are a total of eleven cables and four

ground wires in the console. Refer to A.3.

The cables consist of:

Serial port cables (P120, P121)

I/O cables (2) (P122)

Auxiliary board cable (P132)

Line Filter cable (P124)

Power converter cable (P126)

Probe input cable (P128* or P129**)

PIM to PDM cable (P123**)

Speaker cable (P131)

Fan cable assembly (P150)

Line filter ground cable (P125)

Power converter ground cable (2 xP127)

Probe input ground cable (P130*)

* Specific to Model 2000

** Specific to Model 2100

3-4

Loading...

Loading...