Page 1

Page 2

© 2003 Nedap Retail Support Netherlands

Parallelweg 2d, 7141 DC Groenlo

The software / hardware described in this book / file is furnished under a license agreement and may be used only in accordance with the

terms of the agreement.

Documentation version 1.0

Copyright Notice

All Rights Reserved.

Any technical documentation that is made available by Nedap Retail Support is the

copyrighted work of Nedap Retail Support and is owned by Nedap Retail Support.

NO WARRANTY. The technical documentation is being delivered to you AS-IS and

Nedap Retail Support makes no warranty as to its accuracy or use. Any use of the

technical documentation or the information contained therein is at the risk of the user.

Documentation may include technical or other inaccuracies or typographical errors.

Nedap Retail Support the right to make changes without prior notice.

No part of this publication may be copied without the express written permission of

Nedap Retail Support, Parallelweg 2d, 7141 DC Groenlo, Netherlands

Trademarks

Nedap, the Nedap logo, Nedap EASi/Net and the Nedap EASi/Net are registered trademarks of Nedap N.V. Groenlo.

Other product names mentioned in this manual may be trademarks or registered

trademarks of their respective companies and are hereby acknowledged.

Printed in the Netherlands

OS/T Course 2003 © NEDAP Retail Support 2003

2

Page 3

Technical Support:

- E-mail:support-rs@nedap.nl

- H. Hammer

+31 (0) 544 47 15 19

h.hammer@nedap.nl

- H. Broekhuis

+31 (0) 544 47 15 02

h.broekhuis@nedap.nl

- Fax:

+31 (0) 544 46 58 14

Visitor’s address:

Nedap Retail Support

Parallelweg 2d

Groenlo

Netherlands

Postal address:

Nedap Retail Support

Postbus 102

7140 AC Groenlo

Netherlands

OS/T Course 2003 © NEDAP Retail Support 2003

3

Page 4

Table of contents

Technical Support: .................................................................................................................................... 3

BQ PCB ............................................................................................................................................. 5

EQ PCB ............................................................................................................................................. 7

EQ3E PCB......................................................................................................................................... 9

IQ PCB............................................................................................................................................. 11

IQ3E PCB ........................................................................................................................................ 13

Attenuation....................................................................................................................................... 15

IO Connector K23 ............................................................................................................................ 16

IO Connector K24 ............................................................................................................................ 16

System configurations ..................................................................................................................... 17

BQ System , 1 aisle, Deactivatorunit ............................................................................................... 18

EQ System , 3 aisles ....................................................................................................................... 19

IQ System , 7 aisles, MD CC........................................................................................................... 21

Checklist modem settings iNCC ...................................................................................................... 20

Connecting a PC to a XQ or EQ/IQ Unit ......................................................................................... 28

Connecting a XQ or EQ/IQ unit to a modem ................................................................................... 29

Connecting to an ISDN line using the DeTeWe TA33 terminal adapter ......................................... 30

OS/T Course 2003 © NEDAP Retail Support 2003

4

Page 5

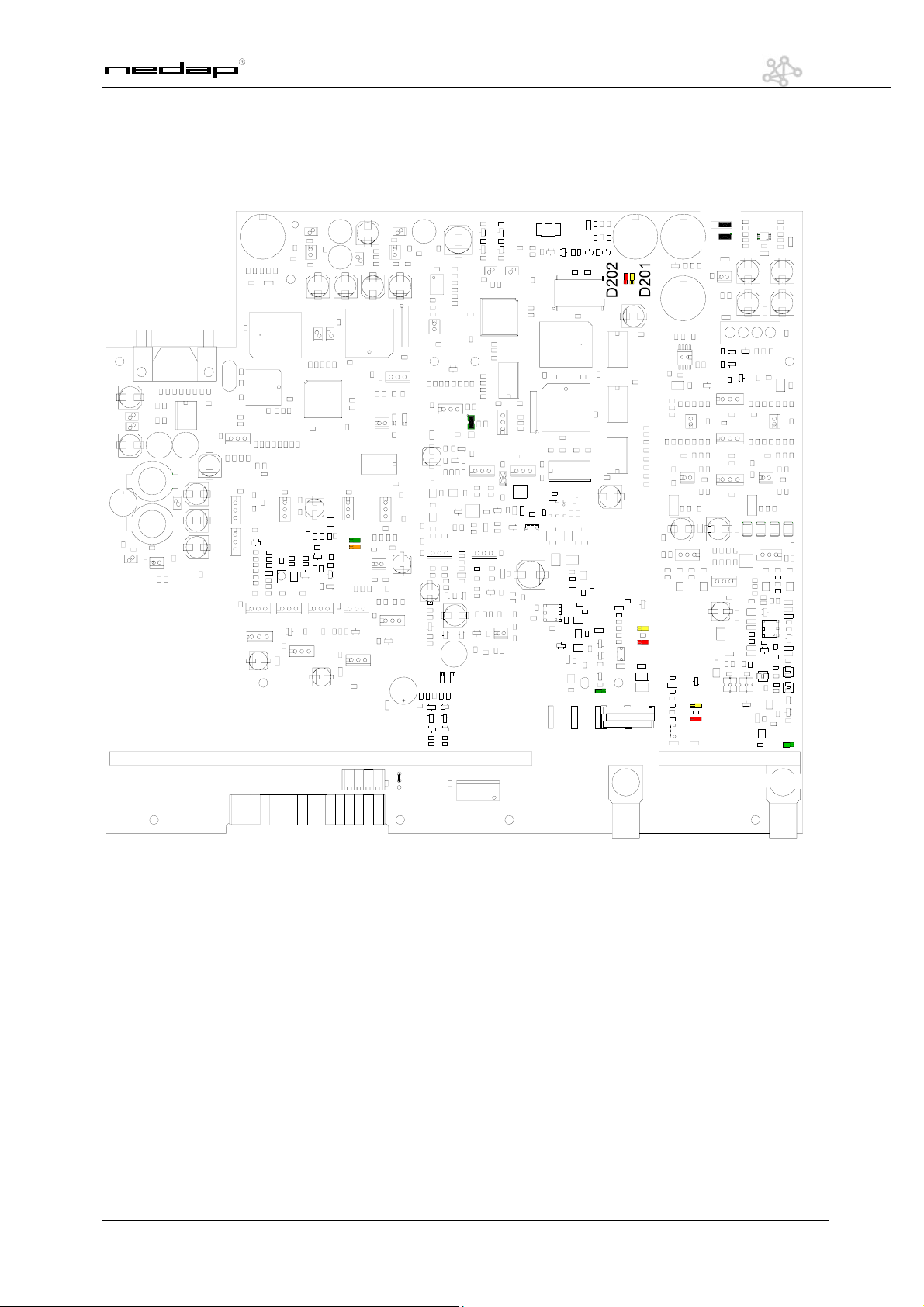

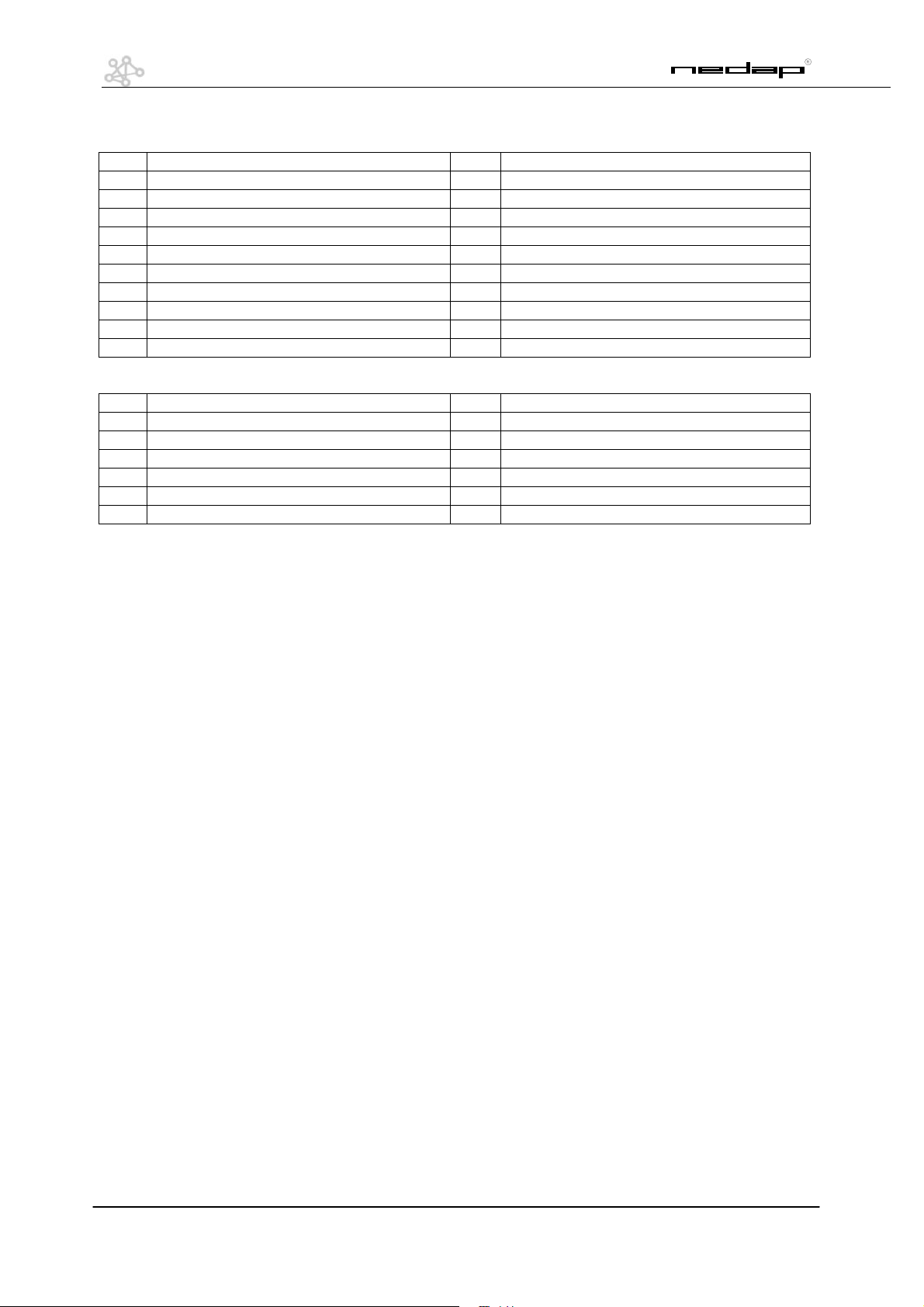

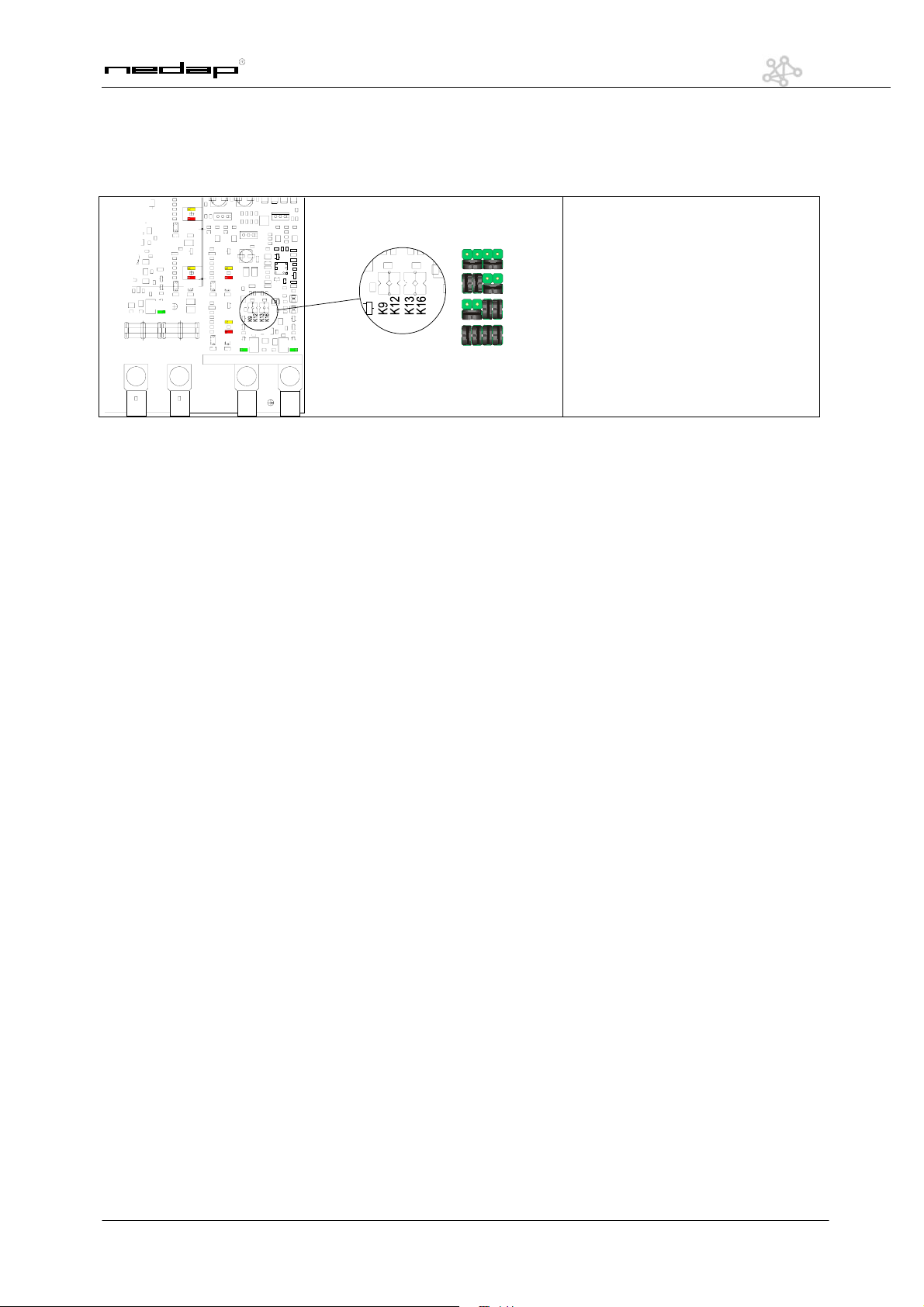

BQ PCB

K203

K205 K201

K16

K19

D25

D26

K202

K204

K3

P3

K23

K24

K11

K5

D19

D16

D301

D300

D311

K300

OS/T Course 2003 © NEDAP Retail Support 2003

5

Page 6

The following points can be used:

K3 Oscilloscope Tx K201 Handheld terminal RxTx

K5 Output Tx (connector 3) K202 Oscilloscope Rx

K9 Jumper Attenuation K203 Jumper

K11 Power Input K204 Jumper

K12 Jumper Attenuation K205 Handheld terminal NCC

K13 Jumper Attenuation K300 Output Rx (connector 1)

K15 Jumper Attenuation P1 PA Drive Adjustment

K16 RS232 Interface Connector P2 Phase Adjustment Tx

K21 Connector FCI P3 Mixer Bias Adjustment

K23 IO Connector P4 Slave Data communication Rx

K24 IO Connector P5 Master Data communication Rx

Indicator leds:

D11 Mux Connector 1 TX D48 Customer Counting: Led on = active

D12 Mux Connector 2 TX D202 Communication Error RxTx

D16 Lamp On Connector 3 D220 Label Detection Alarm NCC on = detection

D19 Lamp Overload Connector 3 D221 Communication Error NCC

D25 Sweep Lock D300 Lamp Overload Connector 1

D26 Center Lock D301 Lamp On Connector 1

D201 Label Alarm RxTx D311 Mux Connector 1 RX

D47 Customer Counting: Led on = active D202 Communication Error RxTx

OS/T Course 2003 © NEDAP Retail Support 2003

6

Page 7

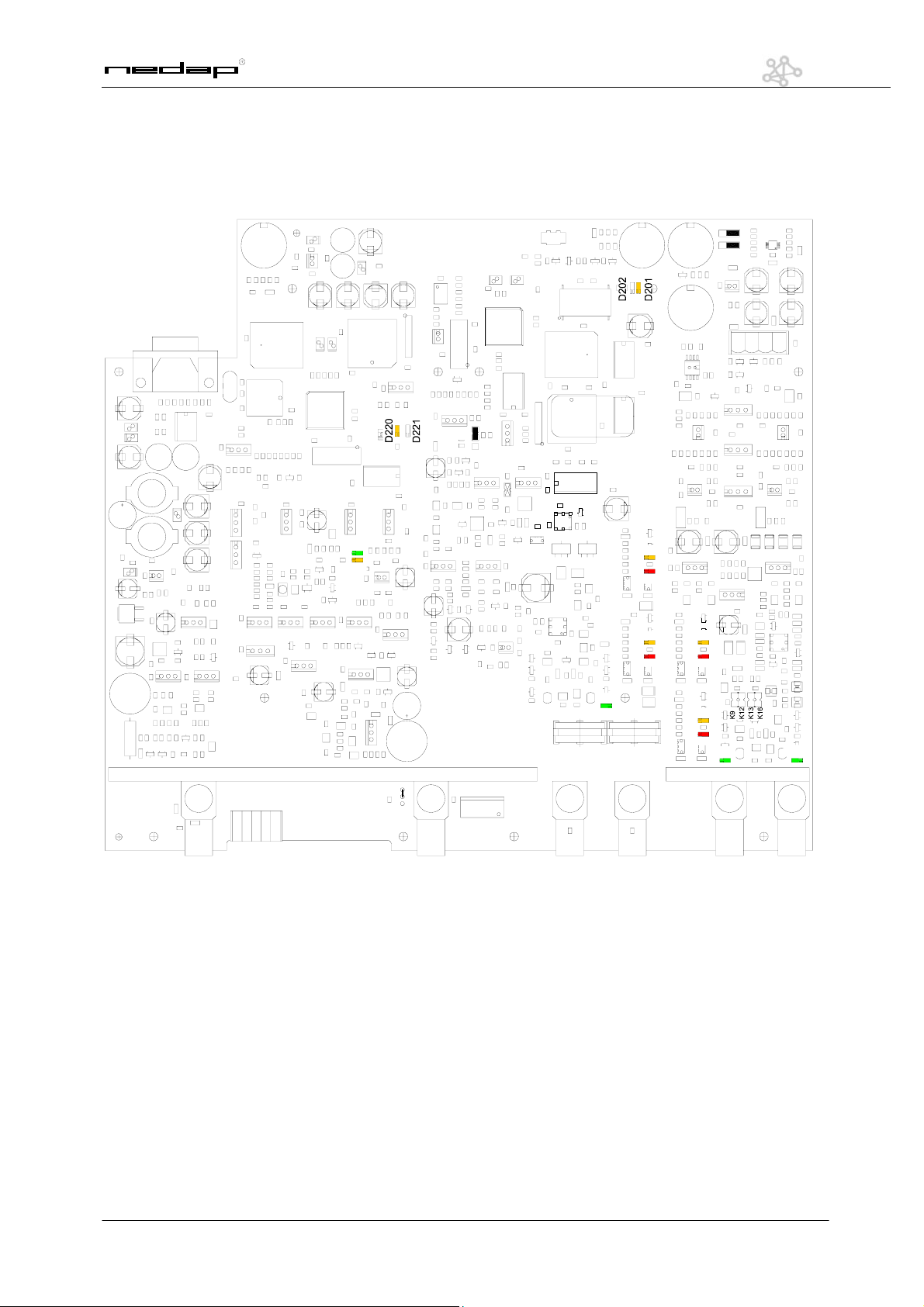

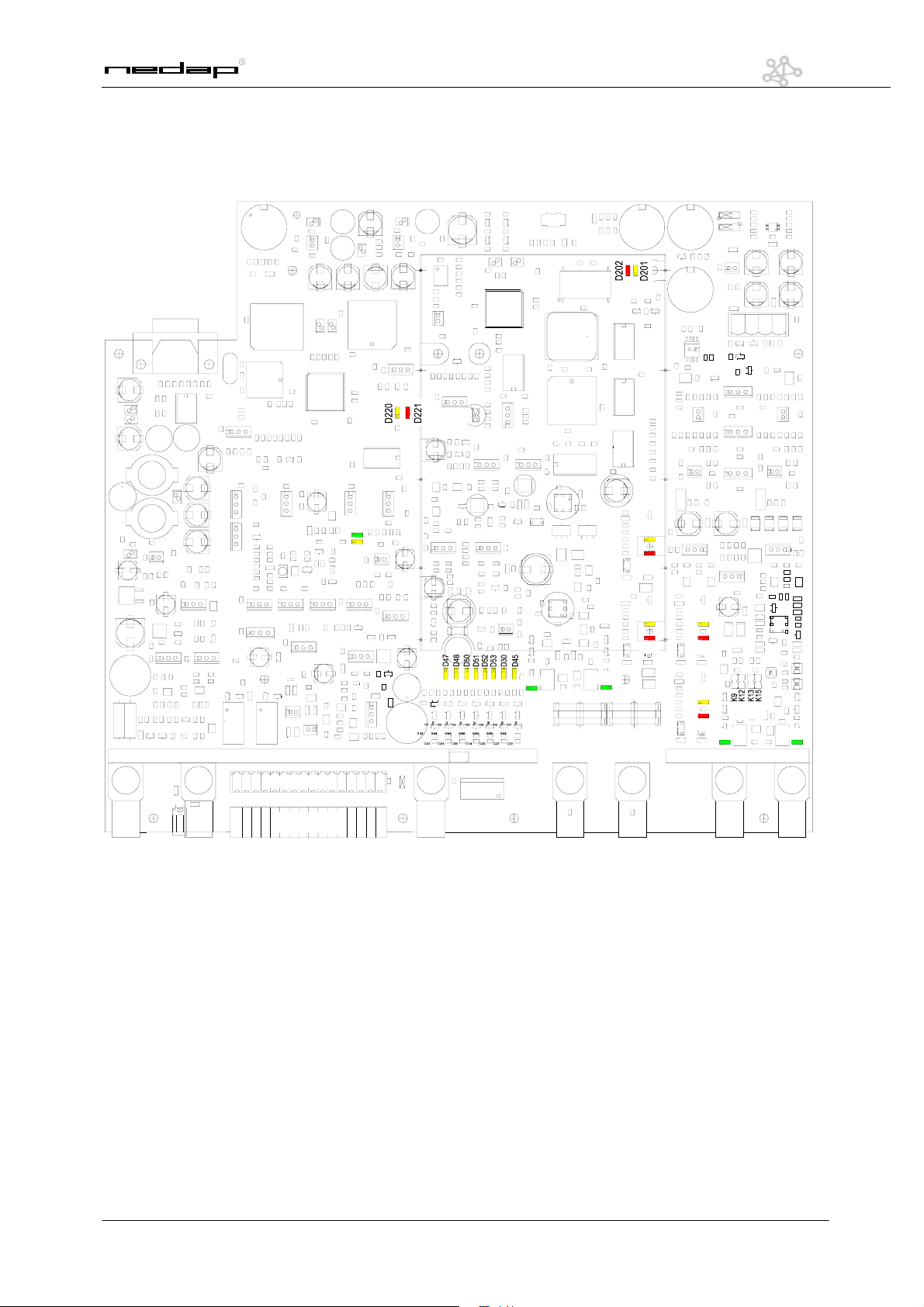

EQ PCB

P1

K21

K201 K202

D18

D17

K205

K16

K19

P2

D25

D26

K203

K204

K3

P3

P4

P5

K6

K23

15

K10

K4

D19

D16

D11

K5

D303

D302

D301

D300

K301

D311D312

K300

7

OS/T Course 2003 © NEDAP Retail Support 2003

Page 8

The following points can be used:

K3 Oscilloscope Tx K201 Handheld terminal RxTx

K4 Output Tx (connector 4) K202 Oscilloscope Rx

K5 Output Tx (connector 3) K203 Jumper

K6 Synchronization In K204 Jumper

K9 Jumper Attenuation K205 Handheld terminal NCC

K10 Master connector K300 Output Rx (connector 1)

K11 Power Input K301 Output Rx (connector 2)

K12 Jumper Attenuation P1 PA Drive Adjustment

K13 Jumper Attenuation P2 Phase Adjustment Tx

K15 Jumper Attenuation P3 Mixer Bias Adjustment

K16 RS232 Interface Connector P4 Slave Data communication Rx

K21 Connector FCI P5 Master Data communication Rx

K23 IO Connector

Indicator leds:

D11 Mux Connector 1 TX D202 Communication Error RxTx

D12 Mux Connector 2 TX D220 Label Detection Alarm NCC on = detection

D16 Lamp On Connector 3 D221 Communication Error NCC

D17 Lamp On Connector 4 D300 Lamp Overload Connector 1

D18 Lamp Overload Connector 4 D301 Lamp On Connector 1

D19 Lamp Overload Connector 3 D302 Lamp Overload Connector 2

D25 Sweep Lock D303 Lamp On Connector 2

D26 Center Lock D311 Mux Connector 1 RX

D201 Label Alarm RxTx D312 Mux Connector 2 RX

OS/T Course 2003 © NEDAP Retail Support 2003

8

Page 9

EQ3E PCB

K

P1

P2

K201 K202

K203

K204

K3

D18

D312

K301

P3

D11D11D11D11D11

D311

K300

D17

P4

D12

K6

K7

1

K23

16

K11

K4

D19

D16

D11

K5

D303

D302

D301

D300

9

OS/T Course 2003 © NEDAP Retail Support 2003

Page 10

The following points can be used:

K3 Oscilloscope Tx K24 IO Connector

K4 Output Tx (connector 4) K201 Handheld terminal RxTx

K5 Output Tx (connector 3) K202 Oscilloscope Rx

K6 Synchronization In K203 Jumper

K7 Synchronization In K204 Jumper

K9 Jumper Attenuation K300 Output Rx (connector 1)

K11 Power Input K301 Output Rx (connector 2)

K12 Jumper Attenuation P1 PA Drive Adjustment

K13 Jumper Attenuation P2 Phase Adjustment Tx

K15 Jumper Attenuation P3 Mixer Bias Adjustment

K21 Connector FCI

Indicator leds:

D11 Mux Connector 1 TX D202 Communication Error RxTx

D12 Mux Connector 2 TX D300 Lamp Overload Connector 1

D16 Lamp On Connector 3 D301 Lamp On Connector 1

D17 Lamp On Connector 4 D302 Lamp Overload Connector 2

D18 Lamp Overload Connector 4 D303 Lamp On Connector 2

D19 Lamp Overload Connector 3 D311 Mux Connector 1 RX

D201 Label Alarm RxTx D312 Mux Connector 2 RX

OS/T Course 2003 © NEDAP Retail Support 2003

10

Page 11

IQ PCB

K203

K204

K3

P3

K16

K205

D25

D26

K

P1

P2

K201 K202

D18

D17

P4

K6

P4

P5

K7

116

116

K24

K23

K10

K11

D12

K4

D19

D16

D11

K5

D303

D302

D301

D300

D312

K301

D311

K300

11

OS/T Course 2003 © NEDAP Retail Support 2003

Page 12

The following points can be used:

K3 Oscilloscope Tx K23 IO Connector

K4 Output Tx (connector 4) K24 IO Connector

K5 Output Tx (connector 3) K201 Handheld terminal RxTx

K6 Synchronization In K202 Oscilloscope Rx

K7 Synchronization In K203 Jumper

K9 Jumper Attenuation K204 Jumper

K10 Master connector K205 Handheld terminal NCC

K11 Power Input K300 Output Rx (connector 1)

K12 Jumper Attenuation K301 Output Rx (connector 2)

K13 Jumper Attenuation P1 PA Drive Adjustment

K15 Jumper Attenuation P2 Phase Adjustment Tx

K16 RS232 Interface Connector P3 Mixer Bias Adjustment

K19 Jumper P4 Slave Data communication Rx

K21 Connector FCI P5 Master Data communication Rx

Indicator leds:

D11 Mux Connector 1 TX D51 Customer Counting: Led on = active

D12 Mux Connector 2 TX D52 Customer Counting: Led on = active

D16 Lamp On Connector 3 D53 Customer Counting: Led on = active

D17 Lamp On Connector 4 D201 Label Alarm RxTx

D18 Lamp Overload Connector 4 D202 Communication Error RxTx

D19 Lamp Overload Connector 3 D220 Label Detection Alarm NCC on = detection

D25 Sweep Lock D221 Communication Error NCC

D26 Center Lock D300 Lamp Overload Connector 1

D30 Customer Counting: Led on = active D301 Lamp On Connector 1

D45 Customer Counting: Led on = active D302 Lamp Overload Connector 2

D47 Customer Counting: Led on = active D303 Lamp On Connector 2

D48 Customer Counting: Led on = active D311 Mux Connector 1 RX

D50 Customer Counting: Led on = active D312 Mux Connector 2 RX

OS/T Course 2003 © NEDAP Retail Support 2003

12

Page 13

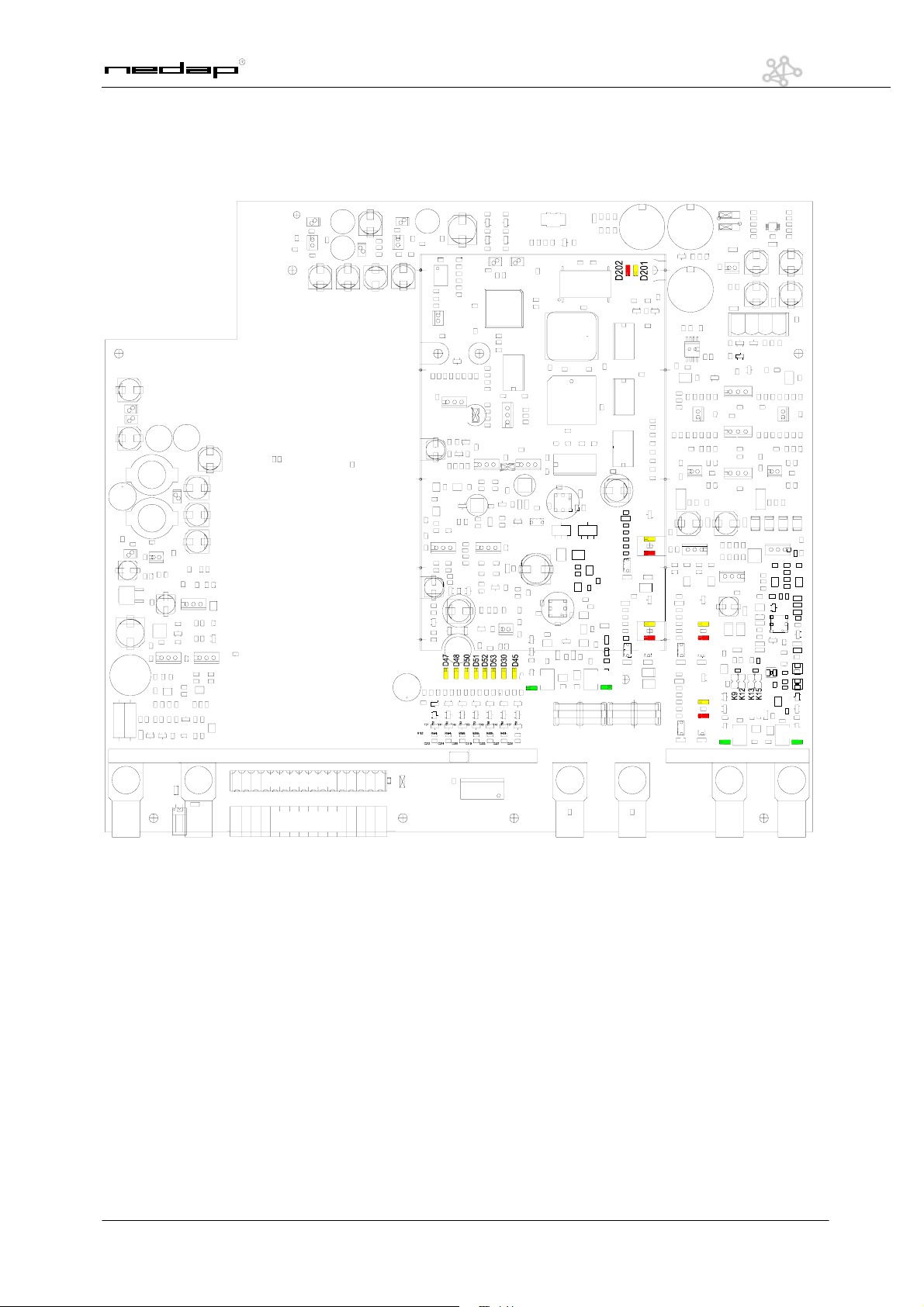

IQ3E PCB

K

P1

P2

K201 K202

D18

D17

K203

K204

K3

P3

P4

D12

K6

K7

116

1

K24

K23

16

K11

K4

D19

D16

D11

K5

D303

D302

D301

D300

D312

K301

D311

K300

13

OS/T Course 2003 © NEDAP Retail Support 2003

Page 14

The following points can be used:

K3 Oscilloscope Tx K23 IO Connector

K4 Output Tx (connector 4) K24 IO Connector

K5 Output Tx (connector 3) K201 Handheld terminal RxTx

K6 Synchronization In K202 Oscilloscope Rx

K7 Synchronization In K203 Jumper

K9 Jumper Attenuation K204 Jumper

K11 Power Input K300 Output Rx (connector 1)

K12 Jumper Attenuation K301 Output Rx (connector 2)

K13 Jumper Attenuation P1 PA Drive Adjustment

K15 Jumper Attenuation P2 Phase Adjustment Tx

K19 Jumper P3 Mixer Bias Adjustment

K21 Connector FCI

Indicator leds:

D11 Mux Connector 1 TX D51 Customer Counting: Led on = active

D12 Mux Connector 2 TX D52 Customer Counting: Led on = active

D16 Lamp On Connector 3 D53 Customer Counting: Led on = active

D17 Lamp On Connector 4 D201 Label Alarm RxTx

D18 Lamp Overload Connector 4 D202 Communication Error RxTx

D19 Lamp Overload Connector 3 D300 Lamp Overload Connector 1

D30 Customer Counting: Led on = active D301 Lamp On Connector 1

D45 Customer Counting: Led on = active D302 Lamp Overload Connector 2

D47 Customer Counting: Led on = active D303 Lamp On Connector 2

D48 Customer Counting: Led on = active D311 Mux Connector 1 RX

D50 Customer Counting: Led on = active D312 Mux Connector 2 RX

OS/T Course 2003 © NEDAP Retail Support 2003

14

Page 15

Attenuation

K4

D18

D17

P3

Jumpers

D19

D303

D302

D16

D11

D301

D300

D312

K5

K301

D311

K300

= 0 dB

= 6 dB

= 12 dB

= 18 dB

It is possible to attenuate the

receiver input sensitivity with 6, 12

or 18dB. In this way the receiver is

capable of accepting the high level

of the coupled transmitter signal

when the panels are too close to

eachother. When the distance

between the antenna’s is below 1.5

metre the attenuator should be

used to avoid overloading of the

receiving input.

15

OS/T Course 2003 © NEDAP Retail Support 2003

Page 16

IO Connector K23

1 = DRF2b count in2

2 = DRF2b count in1

3 = DRF2b enable burst

4 = DRF2b sync 150 Hz

5 = Gnd general

6 = +33V

7 = Gnd Customer Counting

8 = sensor in 8

9 = sensor in 7

10 = sensor in 6

11 = sensor in 5

12 = sensor in 4

13 = sensor in 3

14 = sensor in 2

15 = sensor in 1

16 = +15V Customer Counting

IO Connector K24

1 = Ry1 C

2 = Ry1 NO

3 = Ry1 NC

4 = Ry2 C

5 = Ry2 NO

6 = Ry2 NC

7 = opto in 1

8 = opto in 2

9 = common opto inputs

10 = opto out 2

11 = opto out 1

12 = common opto outputs

13 = I2C Sda

14 = I2c Scl

15 = + 6Volt

16 = Gnd

116

1

116

1

K24

K23

K24

K23

16

16

OS/T Course 2003 © NEDAP Retail Support 2003

16

Page 17

System configurations

1. Shown configurations are examples

2. Settings may differ from the store you are installing - programming

3. Shown firmware is version 1.406 X and 1.407 X, used for these examples, your version may be different!

OS/T Course 2003 © NEDAP Retail Support 2003

17

Page 18

BQ System , 1 aisle, Deactivatorunit

BQ - Unit

MM

tidE7

sevalSC

krowteN1

Deactivator DRF2B

RX TX

To deactivator

A

K3

S1

J1

K5

rettimsnarTSM

31-20-3002tidE7

45:35:11tseT4

A/604.1MMsutatS1

03E5QEtoobeRC

hsalF9peewS7

medoM6mralA4

tuOnI3krowteN1

03E5sserddA

FFFFsevalstceteDC

sevalstceteDC

03E5sserddA

FFFFsevalstceteDC

tidE7

XT4

xuM7

mralA4

rewoP1

xuM7

31-20-3002tidE7

45:35:11tseT4

A/604.1SMsutatS1

C5B41QItoobeRC

hsalF9XR7

tuOnI6XT4

1deL7nO<1xxuM

DCBAesahP

1111nnoC

1111puorG

tidE7

xuM7

revieceRSM

31-20-3002tidE7

45:35:11tseT4

A/604.1SMsutatS1

C5B41QItoobeRC

hsalF9XR7

tuOnI6XT4

tidEXR7

StuM8xuM7

tucM5mrlA4

omdA3lgiS2sneS1

pocS0qerFC

1deL7nO<1xuM

DCBAesahP

1111nnoC

1111puorG

tuOnISM

31-20-3002tidE7

45:35:11tseT4

A/604.1SMsutatS1

C5B41QItoobeRC

tidE7

<1egasU

hsalF9XR7

tuOnI6XT4

tidEtuOnI6

)1/0(tcaed/eerF7

)*(oCuC4

)4/2(lateM1

tcaed/eerF7

<1elbanEtcaeD

00tuOnI

s1tuo1niesluP

03emiT05lvL

hsalF9peewS7

medoM6mralA4

sevalSC

sevalSC

hsalF9

tuOnI3krowteN1

)kcehc(sevalSC

000000000000<C5B4

000000000000<0000

000000000000<0000

000000000000<0000

hsalF9peewS7

medoM6mralA4

tuOnI3krowteN1

sgnittesevaS7

erotseR4

sgnittesevaS7

enoD

)eunitnocotcsE(

xuM7

mralA4

rewoP1

mralA4

ruobhgienmralA

DCBA

0000000003E5<03E5

000000000000<0000

xuM7

mralA4

rewoP1

rewoP1

DCBAesahP

111<21rewoP

1cgA

xuM7

mralA4

rewoP1

hsalF9

erotseR4

0011lautcA

hsalF9XR7

tuOnI6XT4

sgnittesevaS7

sgnittesevaS7

enoD

)eunitnocotcsE(

StuM8xuM7

tucM5mrlA4

omdA3lgiS2sneS1

pocS0qerFC

sneS1

tluafeD0

omdA3

hsalF9

erotseR4

45BniaG<54AniaG

45DniaG<45CniaG

04WPxaM8hserT

StuM8xuM7

tucM5mrlA4

omdA3lgiS2sneS1

pocS0qerFC

01deepS<1edoMdA

000xfuBdA

020202<32xaM

000xtnerruC

StuM8xuM7

tucM5mrlA4

omdA3lgiS2sneS1

pocS0qerFC

hsalF9XR7

tuOnIXT4

6

sgnittesevaS7

sgnittesevaS7

enoD

)eunitnocotcsE(

<1egasU

hsalF9

)1/0(tcaed/eerF7

)*(oCuC4

)4/2(lateM1

hsalF9XR7

tuOnI6XT4

sgnittesevaS7

erotseR4

sgnittesevaS7

enoD

)eunitnocotcsE(

OS/T Course 2003 © NEDAP Retail Support 2003

18

Page 19

EQ System, 3 aisles

EQ - Unit

K205

K16

K201 K202

K3

AB C

4 3 2 1

K4

K5

K300

K6

15

K10

K23

K301

MM

7 Edit 2003-02-13

4 Test 11:53:54

1 Status MM 1.406/A

C Reboot EQ 5E30

7 Edit

7 Sweep 9 Flash

4 Alarm 6 Modem

1 Network 3 InOut

C Slaves

1 Network

Address 5E30

C Detect slaves FFFF

C Detect slaves

Address 5E30

C Detect slaves FFFF

7 Sweep 9 Flash

4 Alarm 6 Modem

1 Network 3 InOut

C Slaves

C Slaves (check)

4B5C<0000 0000 0000

0000<0000 0000 0000

0000<0000 0000 0000

0000<0000 0000 0000

7 Sweep 9 Flash

4 Alarm 6 Modem

1 Network 3 InOut

C Slaves

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

MS Transmitter

7 Edit 2003-02-13

4 Test 11:53:54

1 Status MS 1.406/A

C Reboot EQ3 4B5C

7 Edit

7 RX 9 Flash

4 TX 6 InOut

4 TX

7 Mux

4 Alarm

1 Power

7 Mux

Mux x 4< On 7 Led 1

Phase A B C D

Conn 3 3 4 4

Group 1 1 1 1

7 Mux

4 Alarm

1 Power

4 Alarm

Alarm neighbour

A B C D

4B5C<4B5C 4B5C 0000

0000 0000 0000 0000

7 Mux

4 Alarm

1 Power

1 Power

Phase A B C D

Power 12< 12 12 12

Actual 12 12 12 12

Agc 1

7 Mux

4 Alarm

1 Power

MS Receiver

7 Edit 2003-02-13

4 Test 11:53:54

1 Status MS 1.406/A

C Reboot EQ3 4B5C

7 Edit

7 RX 9 Flash

4 TX 6 InOut

7 RX Edit

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

7 Mux

Mux 4< On 7 Led 1

Phase A B C D

Conn 1 2 2 2

Group 1 1 1 1

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

1 Sens

GainA 54< GainB 54

GainC 54 GainD 54

Tresh 8 MaxPW 40

0 Default

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

4 Alarm

Ext Rel 0< 0 0 0

AlrmEna 1 1 1 0

Buzzer Ena 1 Mode 0

Lvl 0 Time 0

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

7 RX 9 Flash

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

7 RX 9 Flash

7 RX 9 Flash

4 TX 6 InOut

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

19

OS/T Course 2003 © NEDAP Retail Support 2003

Page 20

IQ System, 7 aisles, Customer Counting, Metal

Detection

See last page for an

extended view

OS/T Course 2003 © NEDAP Retail Support 2003

20

Page 21

Checklist modem settings iNCC

PRE -INSTALLATION

Is there an analog

line present?

YES

NO

Install

telephoneline

When is the

line ready?

CAUTION:

ISDN connections to the

internet are

supported at this moment.

Connecting to an ISDN-line

is possible with a DeTeWe TA33

converter, but is

supported by Nedap

__ - __ - _____

NOT

NOT

Date ready

Is the line available at

the place of the

installation?

YES

Phone number of

this line

___________________

Prefix for calling

outside the store

NO

Is it possible to call

interlocal?

YES / NO

NO

Will this be arranged

by third party?

YES

When is the

line ready?

Is the line ready before

the installation of

the OS/T system?

YES

YES

Prefix: ___

NO

Will this be arranged

by Nedap?

YES

Date ready

__ - __ - _____

NO

Problems?

extra visit

Date visit

__ - __ - _____

Is it possible to call

international?

YES / NO

Next page

21

OS/T Course 2003 © NEDAP Retail Support 2003

Page 22

Is this line blocked for

special phonenumbers?

NO

YES

Blocked for:

________________

________________

________________

Can this line be

approached through a

telephonecentral?

YES

Can this line be

used for

data-transport?

YES

Is this a shared line?

NO

Is there an ISP present

at the customer?

YES

Did you enquire

a Store-ID?

YES

NO

NO

YES

NO

NO

YES

Arrange connecting

through the cental

YES

Arrange

data-transport

At what time can there

be called In or OUT

YES

Arrange an ISP

Mail/Fax Nedap for a

Store-ID by filling in

the applicationform

Times to call:

example: 02 h 15m

____ h ____ m

____ h ____ m

____ h ____ m

ISP stettings:

Provider:_________________

Phonenumber:____________

IP: ______________________

Password:________________

Store-ID: ___

YES

On-site installation

22

OS/T Course 2003 © NEDAP Retail Support 2003

Page 23

INSTALLATION ON SITE

What brand and type

is the modem?

Test the line with an

analog telephone

Call with this telephone

the ISP

Connect the modem of

the iNCC to the

laptop / pc

Test the modem by

calling the ISP

OK

Modem:

Brand:__________

Type:___________

You will hear a sound

like you are calling a fax

YES

FAIL

Solve problem

OK

NO

CAUTION:

Nedap recommends

NOT

use a US Robotics modem

Check your

telephoneline

to

Save the configuration

as AT&W

AT&W setting:

Go to Control panel, modem,

modemproperties, advanced

Extra initialization commands:

AT& W

Next page

OS/T Course 2003 © NEDAP Retail Support 2003

23

Page 24

Connect the PC with

the iNCC

Program the ISP

settings and the

Store-ID into the iNCC

Disconnect the PC and

connect the modem

Next page

XQ EQ / IQ

F

M

F

M

GENDER CHANGER

M

F

Direct

modem cable

M

F

Direct

modem cable

MODEM MODEM

OS/T Course 2003 © NEDAP Retail Support 2003

24

Page 25

Place the handterminal

in the MM part of the

Check if "Connect" = 0

0= Modem recognized

unit

Press "6"

7 Modem

4 Internet

Store 19<

Press "7"

Modem 3<Auto 0

Connect 0 Logon 0

Baud 38400 Pin 0000

Bits 8 Par N Stop 1

Your StoreID

Press " "

7 Modem

4 Internet

Store 19<

Press "4"

Dial interval 1440<

Max connect 30

Syslog free 796

High 320 Low 64

Check and / or

change these settings

Next page

25

OS/T Course 2003 © NEDAP Retail Support 2003

Page 26

Press "ESC"

7 Edit 2002-09-06

4 Tests 10:18:04

1 Status MM 1.406/A

C Reboot EQ 7862

Press "1"

7 Alarm

4 Bridging 6 Modem

1 Network 3 InOut

C Timer

Press "6"

Ival 1412 Con 118

Wait 0 DialNow 0

Attempt 0 Modem 0

Ppp 00.00 0 0

Press "C"

(Clearing the statusview)

Press "E"

(pressing E will

start dialing)

"DialNow" will get "1"

Con will get 4

minutes higher

Next page

OS/T Course 2003 © NEDAP Retail Support 2003

26

Page 27

When the modem is

switching from

"0" > "-1" > "0" it is

starting to call out of

the store

Modem "2", starts

calling and is getting

"3"

Take a look at the

PPP status: When PPP

is "3F" then data will

be send to the database

Connection OK

When data is send, PPP

status will be FF or BF

Make a drawing of the

systemconfiguration

Modem

-1 = No modem - Wrong cable / modem

switched off / wrong modem

0 = Modem found - default value

1 = Modem connected - someone is

connecting to the NCC

2 = Modem is trying to connect

3 = Connection present- NCC is connected

to the other side

Ppp = Point to Point Protocol

(when modem status is 3)

00 = No PPP - No modem connection / provider

does not understand the options

01 = LCP ISP is ready - NCC can not handle

the provider options

03 = LCP NCC is ready- Wrong name or Password

07 = PAP NCC is ready- Provider does not

understand IPCP options

0F = IPCP ISP is ready- NCC does not understand

IPCP options

1F = IPCP NCC is ready- TOP-server can not be

found / wrong IP-number and/or provider

does not support protocol

3F = TOP started- Default value

7F = TOP execute- Default value (very rare)

FF = Hangup- Default value (very rare)

and mail / fax it to the

Nedap in Groenlo

OS/T Course 2003 © NEDAP Retail Support 2003

27

Page 28

Connecting a PC to a XQ or EQ/IQ Unit

XQ EQ / IQ

PC

M

F

RS232

9P SUB-D

Extension cable

F

M

M

F

NULL MODEM

M

F

GENDER CHANGER

F

M

RS232

9P SUB-D

Extension cable

F

M

PC

RS232

F = Female, M = Male

RS232

28

OS/T Course 2003 © NEDAP Retail Support 2003

Page 29

Connecting a XQ or EQ/IQ unit to a modem

XQ EQ / IQ

F

M

F

M

GENDER CHANGER

M

F

Direct

modem cable

MODEM MODEM

M

F

Direct

modem cable

F = Female, M = Male

OS/T Course 2003 © NEDAP Retail Support 2003

29

Page 30

Connecting to an ISDN line using the DeTeWe TA33

terminal adapter

At the moment this manual is written, connecting a ISDN modem to a XQ or an EQ/IQ Unit is NOT supported. The

connection shown below can be used in case of an ISDN telephone line.

XQ EQ / IQ

M

F

M

GENDER CHANGER

M

ANALOG

MODEM

TA33

ISDN

A/B A/B

F

F

Direct

modem cable

DeTeWe TA33

Terminal Adapter

Analog -> ISDN

DeTeWe

Direct

modem cable

ANALOG

MODEM

TA33

ISDN

A/B A/B

M

F

DeTeWe

ISDN

F = Female, M = Male

ISDN

30

OS/T Course 2003 © NEDAP Retail Support 2003

Page 31

K205

K201 K202

K3

K205

K201 K202

K3

RX

MDRX

TX

MDTX

RX

MDRX

TX

MDTX MDRX

RX

TX

MDTX

RX

MDRX

TX

MDTX

IQ3

16

K10

16

4 3 2 1

K4 K5

K300

K301

1

K24

K6

1

K23

Buzzer for Metal Detection on relay 1

IQ3

MM

7 Edit 2003-02-13

4 Test 10:26:15

1 Status MM 1.407/A

C Reboot IQ 52C5

7 Edit

7 Sweep 9 Flash

4 Alarm 6 Modem

1 Network 3 InOut

C Slaves

1 Network

Address 52C5

C Detect slaves FFFF

C Detect slaves

Address 52C5

C Detect slaves FFFF

7 Sweep 9 Flash

4 Alarm 6 Modem

1 Network 3 InOut

C Slaves

C Slaves (check)

6288<72C5 0000 0000

0000 0000 0000 0000

7 Sweep 9 Flash

4 Alarm 6 Modem

1 Network 3 InOut

C Slaves

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

MS Transmitter

7 Edit 2003-02-13

4 Test 11:33:39

1 Status MS 1.406/B

C Reboot IQ3 72C5

7 Edit

7 RX 9 Flash

4 TX 6 InOut

4 TX

7 Mux

4 Alarm

1 Power

7 Mux

Mux x 4< On 7 Led 1

Phase A B C D

Conn 3 3 4 4

Group 1 1 1 1

7 Mux

4 Alarm

1 Power

4 Alarm

Alarm neighbour

A B C D

72C5<72C5 72C5 6288

0000 0000 0000 0000

7 Mux

4 Alarm

1 Power

1 Power

Phase A B C D

Power 12< 12 12 12

Actual 12 12 12 12

Agc 1

7 Mux

4 Alarm

1 Power

7 RX 9 Flash

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

1

K24

K6

1

K23

IQ4E

4 3 2 1

16

K10

16

K4 K5

K300

K301

MS Receiver

7 Edit 2003-02-13

4 Test 11:33:39

1 Status MS 1.406/B

C Reboot IQ3 72C5

7 Edit

7 RX 9 Flash

4 TX 6 InOut

7 RX

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

7 Mux

Mux 4< On 7 Led 1

Phase A B C D

Conn 1 2 2 1

Group 1 1 1 1

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

1 Sens

GainA 54< GainB 54

GainC 54 GainD 20

Tresh 8 MaxPW 40

0 Default

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

4 Alarm

Ext Rel 0< 0 0 0

AlrmEna 1 1 1 0

Buzzer Ena 1 Mode 0

Lvl 0 Time 0

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

7 RX 9 Flash

7 RX 9 Flash

4 TX 6 InOut

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

13241324

CC & MD

7 Edit 2003-02-13

4 Test 11:33:39

1 Status MS 1.406/B

C Reboot IQ3 72C5

7 Edit

7 RX 9 Flash

4 TX 6 InOut

6 InOut

Usage 4<

7 Free/Deact (0/1)

4 CuCo (*)

1 Metal (2/4)

4 CuCo

7 Counting

4 Direction

7 Counting

Single/Double 2<

MinPuls 60 TO 15

WA 1:0 2:0 3:0 4:0

Lvl 25 Time 5

7 Counting

4 Direction

4 Direction

1:72C5<A 2:72C5 B

3:72C5 C 4:6288 D

Window 2000 ms

LvL 1 Time 5

7 Counting

4 Direction

Usage 4<

7 Free/Deact (0/1)

4 CuCo (*)

1 Metal (2/4)

1 Metal (2/4)

Action 1< 0 0 0

Mode 0 0 0 0

Pulse in 5 s

Lvl 25 Time 5

Usage 4<

7 Free/Deact (0/1)

4 CuCo (*)

1 Metal (2/4)

7 RX 9 Flash

7 RX 9 Flash

4 TX 6 InOut

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

AB C

IQ4E

MS Transmitter

7 Edit 2003-02-13

4 Test 11:33:39

1 Status MS 1.406/B

C Reboot IQ4E 6288

7 Edit

7 RX 9 Flash

4 TX 6 InOut

4 TX

7 Mux

4 Alarm

1 Power

7 Mux

Mux x 4< On 7 Led 1

Phase A B C D

Conn 3 3 4 4

Group 1 1 1 1

7 Mux

4 Alarm

1 Power

4 Alarm

Alarm neighbour

A B C D

6288<6288 6288 0000

0000 0000 0000 0000

7 Mux

4 Alarm

1 Power

1 Power

Phase A B C D

Power 12< 12 12 6

Actual 12 12 12 0

Agc 1

7 Mux

4 Alarm

1 Power

7 RX 9 Flash

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

MS Receiver

7 Edit 2003-02-13

4 Test 11:33:39

1 Status MS 1.406/B

C Reboot IQ4E 6288

7 Edit

7 RX 9 Flash

4 TX 6 InOut

7 RX

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

7 Mux

Mux 4< On 7 Led 1

Phase A B C D

Conn 1 2 2 1

Group 1 1 1 1

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

1 Sens

GainA 54< GainB 54

GainC 54 GainD 54

Tresh 8 MaxPW 40

0 Default

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

4 Alarm

Ext Rel 0< 0 0 0

AlrmEna 1 1 1 1

Buzzer Ena 1 Mode 0

Lvl 0 Time 0

7 Mux 8 MutS

4 Alrm 5 Mcut

1 Sens 2 Sigl 3 Admo

C Freq 0 Scop

7 RX 9 Flash

7 RX 9 Flash

4 TX 6 InOut

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

DA BC

CC & MD

7 Edit 2003-02-13

4 Test 11:33:39

1 Status MS 1.406/B

C Reboot IQ4E 6288

7 Edit

7 RX 9 Flash

4 TX 6 InOut

6 InOut

Usage -1<

7 Free/Deact (0/1)

4 CuCo (*)

1 Metal (2/4)

4 CuCo

7 Counting

4 Direction

7 Counting

Single/Double 2<

MinPuls 60 TO 15

WA 1:0 2:0 3:0 4:0

Lvl 1 Time 5

7 Counting

4 Direction

4 Direction

1:6288<A 2:6288 B

3:6288 C 4:0000 0

Window 2000 ms

LvL 25 Time 5

7 Counting

4 Direction

Usage -1<

7 Free/Deact (0/1)

4 CuCo (*)

1 Metal (2/4)

7 RX 9 Flash

7 RX 9 Flash

4 TX 6 InOut

4 TX 6 InOut

9 Flash

7 Save settings

4 Restore

7 Save settings

Done

(Esc to continue)

CCTX

CCRX

Filter

7 Save settings

Done

(Esc to continue)

Page 32

Page 33

NEDAP RETAIL SUPPORT

Metal Detection

Manual MD4 including 62,75 MHz

Page 34

Caution!

This document is made for Adobe Acrobat Reader 5.0 or higher.

You can download this version of the reader at www.adobe.com

Technical Support:

- support-rs@nedap.nl

- H. Hammer

+31 (0) 544-47 15 19

h.hammer@nedap.nl

- H. Broekhuis

+31 (0) 544-47 15 02

h.broekhuis@nedap.nl

Visitor’s address:

Nedap Retail Support

Parallelweg 2d

Groenlo

Netherlands

Postal address:

Nedap Retail Support

Postbus 102

7140 AC Groenlo

Netherlands

2

Manual MD4 V1.3 © NEDAP Retail Support 2003

Page 35

Table of content

Technical Support: 2

Modification of the OS/T Metal Detection operating frequency from 66 kHz to 62.75 kHz. 4

1 General 5

2 Block diagram 6

2.1 Explanation of the diagram 7

3 Printed Circuit Board 8

4 Metal Detection PCB in XQ unit 9

5 Metal Detection PCB in EQ/IQ unit 9

6 Handheld terminal settings 10

Manual MD4 V1.3 © NEDAP Retail Support 2003

3

Page 36

Modification of the OS/T Metal Detection

operating frequency from 66 kHz to 62.75 kHz.

In DSP3 systems the Metal Detection (MD) had an operating frequency of 48 kHz, independent of the

8.2 MHz sweep generation system. It could run as a stand-alone system.

In the OS/T system, it is possible to set up a system including MD with internal electronics in the panels

and a single coax connection between the panels.

To realize that, the operating frequency of the OS/T MD had to be derived from the OS/T sweep

frequency. The required modification also gave the opportunity to choose a higher operating frequency.

That was desired because of an enhanced detectability of metal-lined bags with a very thin aluminum

layer, like used in certain types of “Cool Bags”.

The new operating frequency was chosen at 66 kHz, 8 kHz above the Acousto-Magnetic (AM)

operating frequency of Sensormatic, in stead of 10 kHz below it, but still within a frequency band where

the same level of fieldstrength (72 dBµA/m) is allowed, and not on the frequency’s of several

positioning systems, time standards and submarine communications.

Unfortunately this carefully chosen frequency appeared to be exactly the listen frequency of Security

Tag or Xpondr frequency divider EAS systems. The transmitter frequency of Xpondr is 132 kHz, so the

Nedap MD does not suffer from any interference of a Xpondr system.

When installed in neighbor shops, an Xpondr system appeared to be completely deaf.

Therefore we had to modify the operating frequency to a nominal 62.75 kHz in stead of 66 kHz.

This small frequency shift has the least impact in the modification of several filter components.

With the sweep-extend of the OS/T system on position 3, this frequency shifts down to 60.57 kHz.

This range is sufficiently below 66 kHz to prevent interference problems with both digital and older

analog Xpondr systems.

The drawback unfortunately is that 62.75 kHz is closer to the AM frequency. A Nedap MD system can

function on a distance of about 20 m away from an AM system. This minimum distance now should be

at least 25 m.

4

Manual MD4 V1.3 © NEDAP Retail Support 2003

Page 37

1 General

The OST combination NCC4 and external RX4/TX4 can be fitted with up to 8 antenna’s making it

possible to guard up to 4 entrance separately.

This MD4 pcb also makes it possible for the Metal Detection to connect and process up to 4 different

entrances separately.

Like the FCI (Flat Cable Interface) pcb this MD4 pcb is also connected to the feature connector on the

OST RX4 or TX4. The MD4 pcb does not need tuning and holds no jumpers.

In addition to the 4 Metal Detection in/outputs the pcb is fitted with 4 extra inputs. Floating contacts can

be connected to these inputs, for instance to count tag decouplings or shop open/closed.

Manual MD4 V1.3 © NEDAP Retail Support 2003

5

Page 38

2 Block diagram

/start

BST82

+33V

74HC573 74HC4052

600Hz

74HC123

1-shot

74HC123

1-shot

+24V +15V +5V

LM2672

74HC4046

VCO

132Kc

74HC74

D - FF

78M15 78M05

600Hz

BST82

74HC4040

Deler

BC807

BC817

66Kc

6

in

buffer

2 x 4mux

latch

74HC573

Manual MD4 V1.3 © NEDAP Retail Support 2003

ext_clk(I/0)

ext_io(I/0)

+

mute_3

Page 39

2.1 Explanation of the diagram

On the OST feature connector a 600Hz repeated signal is available from which the flat cable

interface produces the 66 kHz which is used on the metal detection PCB’s.

The /start pulse from the feature connector are infect two very narrow pulses about120uSec

apart and repeated in a more or less 600 Hz rhythm.

On every first pulse a 1 shot 74HC123) is triggered to produce a more or less 600 Hz block

signal used a reference signal for a PLL (74HC4046). The VCO of the PLL block oscillates on

132 kHz which by means of a programmable divider divides this signal to around 600 Hz.

This signal is then used on the Comp In. of the PLL and the 132 kHz is locked. Another 1 shot

triggers a divider by 2 circuit to output the 66 kHz signal which is available on the 4 data cable

outputs.

An alarm from the MD RX is shaped and buffered (74hc573) and presented on one of the

inputs of a 2 x 4mux (74hc4052). Dependent on the mute_3 signal, ext_clk and ext_i/o are

used to address the latch (74hc573) or read the output of the mux.

Manual MD4 V1.3 © NEDAP Retail Support 2003

7

Page 40

3 Printed Circuit Board

connection to feature

conn. OST

extra conn.

8

gnd

66kc

alarm

gnd

gnd

24Vdc

24Vdc

gnd

gnd

extra IN

MD

Manual MD4 V1.3 © NEDAP Retail Support 2003

gnd

24Vdc

gnd

gnd

24Vdc

Page 41

4 Metal Detection PCB in XQ unit

4.1 Circuit board in unit XQ

The MD4 pcb is intended to be placed on top of the TX-PCB* inside the external unit shown above.

A CC4 pcb can be placed inside the unit as well.

bottom entry

conn.

MD4-CC4 PCB

board stacker

feature conn.

OST-PCB

Connecting the MD4 PCB to a NR4 on a external NRT4 Unit will decrease EAS performance

*

Manual MD4 V1.3 © NEDAP Retail Support 2003

9

Page 42

5 Metal Detection PCB in EQ/IQ unit

K205

K16

41K

7K

1K

31K

5K4K3K2K

P4

K6

K7

116

1

K201 K202

1

2L

D25

D26

21K

11K

P5

K23

K24

16

P2

K10

K11

K21

P1

D18

D17

D19

D16

D12

D11

K5

K4

K203

K204

K3

P3

D303

D302

D301

D300

D312

K301

D311

K300

The MD4 PCB will be mounted on the metal plate on top of the IQ unit.

It will be connected with a flat-cable to connector K21 (FCI) of the IQ PCB.

See the drawing for the right polarity.

6 Handheld terminal settings

For the handheld-terminal settings see the manual of the handheld-terminal (version 1.300 or higher).

10

Manual MD4 V1.3 © NEDAP Retail Support 2003

Page 43

7 Wiring examples

MD4 pcb

Filter

Entrance 1

3 Panel

3 x MD Rx TX RX

Entrance 2

2 Panel

2 x MD RX TX

11

Manual MD4 V1.3 © NEDAP Retail Support 2003

Page 44

MD4 pcb

Filter

Entrance 1

2 Panel

2 x MD Rx TX

12

Entrance 3

2 Panel

2 x MD RX TX

Entrance 2

2 Panel

2 x MD RX TX

Manual MD4 V1.3 © NEDAP Retail Support 2003

Page 45

MD4

gnd

24Vdc

gnd

gnd

66kc

MD-TX

EQ45 Panel 1

gnd

alarm

66kc

+24V

alarm

gnd

gnd

gnd

24Vdc

gnd

24Vdc

gnd

24Vdc

MD-RX

EQ45 Panel 2

gnd

alarm

66kc

+24V

13

Manual MD4 V1.3 © NEDAP Retail Support 2003

Page 46

MD4

gnd

gnd

gnd

24Vdc

66kc

MD-TX

EQ45 Panel 1

alarm

gnd

gnd

gnd

gnd

24Vdc

24Vdc

gnd

24Vdc

gnd

alarm

66kc

+24V

MD-RX

EQ45 Panel 2

gnd

alarm

66kc

+24V

MD-TX

EQ45 Panel 3

gnd

alarm

66kc

+24V

MD-RX

EQ45 Panel 4

gnd

alarm

66kc

+24V

MD-TX

EQ45 Panel 5

14

Manual MD4 V1.3 © NEDAP Retail Support 2003

+24V

gnd

alarm

66kc

Page 47

The MD4 is designed to be used in combination with the OST external TX unit.

Metal detection now can be used in the same entrance configuration as you connect your OST external

RX/TX. As on the OST unit, 4 independent Metal Detection connectors are available with independent

alarming. (alarming is per entrance not per aisle).

As you see there is no change in how to loop the Metal Detection pcb’s together.

Only be sure to connect only one entrance per connector on the MD4 pcb.

This MD4 is also fitted with 4 additional “alarm-inputs” which can be used for a variety of options. Only

a floating contact is needed. One can use the contacts for instance as detection “shop open/closed” –

guard on watch – alarm cause – etc etc.

MD4

gnd

gnd

gnd

24Vdc

66kc

MD-TX

EQ45 Panel 1

alarm

gnd

gnd

24Vdc

push button

door switch

gnd

24Vdc

gnd

24Vdc

gnd

gnd

alarm

66kc

+24V

MD-RX

EQ45 Panel 2

gnd

alarm

66kc

+24V

15

Manual MD4 V1.3 © NEDAP Retail Support 2003

Loading...

Loading...