Instruction Manual

NC-103D

Important safety instructions

When using an electrical appliance, basic safety should always be followed,

including the following:

Read all instructions before using this sewing machine.

DANGER

1. An appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the electric outlet immediately after using

and before cleaning.

WARNING

- To reduce the risk of electric shock:

- To reduce the risk of burns, re, electric shock,

or injury to persons:

1. Read the instruction carefully before you use the machine

2. Keep the instructions at a suitable place close to the machine and hand it

over if you give the machine to a third party.

3. Use the machine only in dry locations.

4. Never leave the machine unattended with children or elderly people as they

may not be able to estimate the risk.

5. This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards

involved.

6. Children shall not play with the appliance.

7. Cleaning and user maintenance shall not be made by children without

supervision.

8. Always switch off the machine if you carry out preparation for work (change

the needle, feed the yarn through the machine, change the footer, etc.).

9. Always unplug the machine if you leave it unattended, to avoid injury by

expediently switch on the machine.

10. Always unplug the machine if you carry out maintenance (oiling, cleaning).

11. Don't use the machine if it’s wet or in humid environment.

12. Never pull at the cord, always unplug the machine by gripping the plug.

13. If the LED lamp is damaged or broken, it must be replaced by the

manufacturer or it's service agent or a similarly qualied person, in order to

avoid a hazard.

14. Never place anything on the pedal.

I

15. Never use the machine if the air vents are blocked, keep the air vents of the

machine and the foot pedal free from dust, fusel and leftovers.

16. The machine must only be used with designated foot controller, in order

to avoid a hazard. If the foot controller is damaged or broken, it must be

replaced by the manufacturer or its service agent or a similarly qualied

person.

17. The sound pressure level at normal operation is smaller than 75dB(A).

18. Do not dispose of electrical appliances as unsorted municipal waste, use

separate collection facilities.

19. Contact your local government for information regarding the collection

systems available.

20. If electrical appliances are disposed of in landlls or dumps, hazardous

substances can leak into the groundwater and get into the food chain,

damaging your health and well-being.

21. When replacing old appliances with new ones, the retailer is legally obligated

to take back your old appliance for disposal at least for free of charge.

22. The appliance is not to be used by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction. (For outside Europe)

23. Children being supervised not to play with the appliance. (For outside

Europe)

SAVE THESE INSTRUCTIONS

This sewing machine is intended for household use only.

Be sure to use the sewing machine in the temperature range from 5ºC to 40ºC.

If the temperature is excessively low, the machine can fail to operate normally.

To carry the sewing machine, hold the carrying handle with your hand, and

support the sewing machine with the other hand.

II

Contents

Machine Introduction

Principal parts of the machine ...............................................................................................1

Accessories .............................................................................................................................. 2

Standard ................................................................................................................................................. 2

Optional .................................................................................................................................................. 2

Connecting machine to power source ................................................................................... 3

Polarized plug information ..................................................................................................................... 3

Foot control ........................................................................................................................................... 3

Foot controller with needle up and down feature ................................................................................... 3

Machine Setup

Sewing table .............................................................................................................................5

Free arm ................................................................................................................................................. 5

Two-step presser foot lifter .................................................................................................... 5

Install the extension table ....................................................................................................... 6

Adjust presser foot pressure .................................................................................................. 6

Winding the bobbin ................................................................................................................. 7

Inserting the bobbin ................................................................................................................ 9

Threading the upper thread .................................................................................................. 10

Bringing up the bobbin thread ............................................................................................. 13

Replacing the needle ............................................................................................................. 14

Matching needle/fabric/thread ............................................................................................. 15

Changing the presser foot .................................................................................................... 16

Remove the presser foot ...................................................................................................................... 16

Attach the presser foot ......................................................................................................................... 16

Remove and insert the presser foot holder.......................................................................................... 16

Insert the edge/quilting guide ............................................................................................................... 16

To raise or drop the feed dogs ............................................................................................. 17

Thread tension ....................................................................................................................... 18

Instruction

LCD screen ............................................................................................................................. 20

Operation buttons .................................................................................................................. 21

Selecting stitch ...................................................................................................................... 27

Memory function buttons ..................................................................................................... 28

Memory program.................................................................................................................... 29

Combine stitches.................................................................................................................................. 29

Recalling and sewing the memorized stitches ..................................................................................... 30

Inserting stitches .................................................................................................................................. 30

Editing stitches ..................................................................................................................................... 31

Clearing stitches .................................................................................................................................. 31

Repeat setting ...................................................................................................................................... 32

Stitch Chart

Stitch chart ............................................................................................................................. 34

A-Direct Pattern Group ....................................................................................................................... 34

B-Regular Pattern Groups .................................................................................................................. 34

C-Alphabet Group-Block style ............................................................................................................ 36

D-Alphabet Group-Script style ........................................................................................................... 36

III

Sewing Basics

Straight stitch ......................................................................................................................... 38

Changing the needle position .............................................................................................................. 38

Zigzag stitch ........................................................................................................................... 39

Starting to sew .......................................................................................................................40

Useful skills ............................................................................................................................ 42

Reverse sewing .................................................................................................................................... 42

Sewing curves ...................................................................................................................................... 42

Sewing corners .................................................................................................................................... 43

Sewing stretch fabrics .......................................................................................................................... 43

Sewing thin fabrics ............................................................................................................................... 43

Sewing heavy fabric ............................................................................................................................. 44

Utility Stitches

Stretch stitch .......................................................................................................................... 46

Straight stretch stitch ........................................................................................................................... 46

Zigzag stretch stitch ............................................................................................................................. 46

Sewing stretch fabrics and elastic tape .............................................................................. 47

Overcasting stitch .................................................................................................................. 48

Using the all purpose foot .................................................................................................................... 48

Using the overcasting foot ................................................................................................................... 48

Blind Hem ............................................................................................................................... 49

Buttonhole stitch ................................................................................................................... 50

Making a buttonhole on stretch fabrics ................................................................................................ 52

Bar tack stitch ........................................................................................................................ 53

Darning stitch ......................................................................................................................... 54

Eyelet stitch ............................................................................................................................ 56

Button sewing ........................................................................................................................57

Zipper insertion ...................................................................................................................... 58

Inserting a centered zipper .................................................................................................................. 58

Inserting a side zipper .......................................................................................................................... 59

Satin stitch sewing ................................................................................................................60

Gathering ................................................................................................................................ 61

Gathered fabric .................................................................................................................................... 61

To gather and attach gathered fabric in one step ................................................................................ 61

Smocking ................................................................................................................................ 62

Free motion darning, embroidery and monogramming .................................................... 63

Preparation for embroidering and monogramming .............................................................................. 63

Darning ................................................................................................................................................. 64

Embroidery ........................................................................................................................................... 64

Monogramming .................................................................................................................................... 64

Quilting ................................................................................................................................... 65

Using the edge/quilting guide ............................................................................................................... 65

Joining the pieces of the fabric ............................................................................................................ 65

Patchwork stitching .............................................................................................................................. 66

Applique .................................................................................................................................. 67

Fagoting .................................................................................................................................. 67

Scallop stitch .......................................................................................................................... 68

Scallop edging...................................................................................................................................... 68

IV

Scallop hem ......................................................................................................................................... 68

Cording.................................................................................................................................... 69

Single cording ...................................................................................................................................... 69

Striple cording ...................................................................................................................................... 69

Narrow hemming .................................................................................................................... 70

Twin need le ............................................................................................................................. 71

Maintenance and Trouble shooting

Maintenance ........................................................................................................................... 74

Clean the hook ......................................................................................................................................74

Clean the machine surface ...................................................................................................................74

Warning Function ...................................................................................................................75

Warning beeping sound ....................................................................................................................... 75

Trouble shooting guide ......................................................................................................... 76

V

Machine Introduction

Principal parts of the machine

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

⑰

⑱

⑲

⑳

㉑

㉒

㉓

㉔

㉕

㉖

㉗

㉘

㉙

㉚

Take-up lever

Presser foot pressure dial

Operation buttons

Thread cutter

Sewing table and accessory box

Tension dial

Speed adjustment slide

Bobbin winder spindle

Bobbin winder stopper

LCD screen

Operation buttons

Pattern group switch button

Quick reference plate

Buttonhole lever

Needle threader

Needle plate

Needle clamp screw

Presser foot

Bobbin cover

Horizontal spool pin

Second spool pin hole

Handwheel

Main power switch

Power cord socket

Foot control connector

Bobbin thread guide

Upper thread guide

Handle

Presser foot lifter

Drop feed lever

1

Accessories

Most accessories are stored in

the accessory box. The extension

table and soft cover can be found

aside of the packing styrofoam.

vStandard

All purpose foot (already installed)

①

Zipper foot

②

Buttonhole foot

③

Satin stitch foot

④

Button sewing foot

⑤

Blind hem foot

⑥

Overcasting foot

⑦

Hemmer foot

⑧

Gathering foot

⑨

Cording foot

⑩

Quilting foot

⑪

Darning/embroidery foot

⑫

Bobbin (4x) (1x already installed)

⑬

Spool holder (Large)

⑭

Spool holder (Small)

⑮

Spool pin felt

⑯

Second spool pin

⑰

L-screwdriver

⑱

Edge/quilting guide

⑲

Pack of Needle: 3x single needles

⑳

(75/11, 90/14, 100/16)

Seam ripper/brush

㉑

Twin needle (80/12, 2.5mm

㉒

distance)

Extension table

㉓

Soft cover

㉔

vOptional

Walking foot

㉕

Note

To purchase optional accessories,

please consult your local dealer

for further information.

2

Connecting machine to power source

nAttention

Always make sure that the machine is

unplugged from power source and the main

switch is off ("O"), when the machine is not

in use and before inserting or removing

parts.

Before connecting the power supply, make

1

2

ONOFF

sure that the voltage shown on the rating

plate is conforming with your main power.

Put the machine on a stable table.

1. Connect the machine to a power source

as illustrated.

2. Turn the power switch to on ("I").

The sewing lamp will light up when the switch

is turned on.

vPolarized plug information

This appliance has a polarized plug (one

blade is wider than the other), to reduce the

risk of electrical shock; this plug will t in a

polarized outlet only one way. If the plug does

not t fully in the outlet, reverse the plug. If it

still does not t, contact a qualied electrician

to install the proper outlet. Do not modify the

plug in any way.

vFoot control

When the machine is off, insert the foot

control plug into its connector on the machine.

Turn on the machine, and then slowly press

down the foot control to start sewing. Release

the foot control to stop the machine.

vFoot controller with needle up

and down feature

User can quickly press one step on the foot

controller to change the needle position go up

or down into the fabric.

Note

Consult a qualied electrician if in doubt

as to connect the machine to the power

source.

3

Machine Setup

Sewing table

Hold the sewing table horizontally, then pull

toward the left to remove it from the machine.

Attach the sewing table, and then push it to

the right.

The inside space of the sewing table is used

as an accessory box.

vFree arm

Free-arm sewing is convenient for sewing

tubular areas such as pant hems and cuffs.

Two-step presser foot lifter

The presser foot lifter is to raise or lower your

presser foot.

When sewing multi-layers or thick fabrics, the

presser foot can be further raised up manually

to allow enough space for your sewing work.

The needle must always be at the highest

position.

Note

5

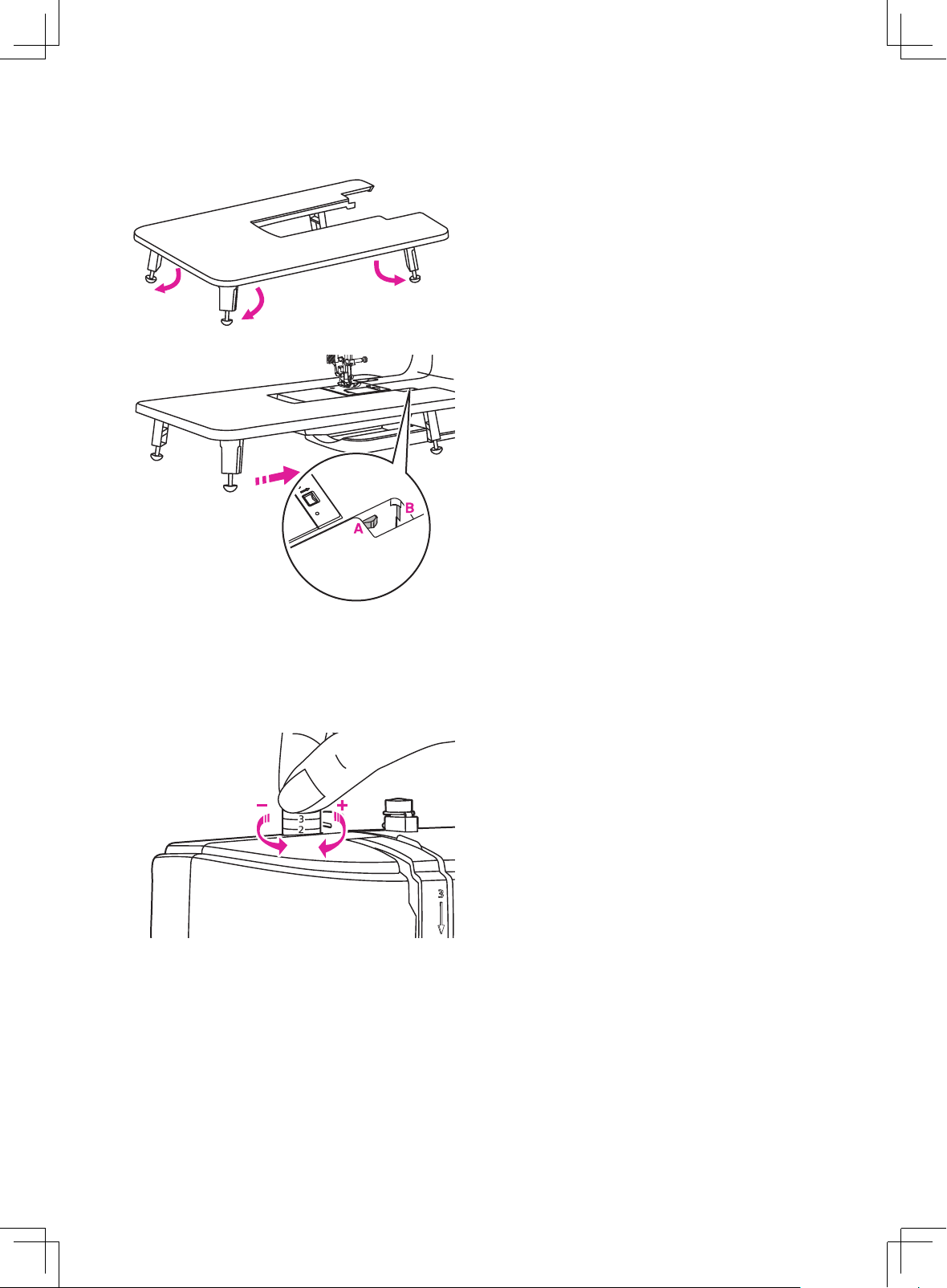

Install the extension table

Pull the sewing table and accessory box off

by sliding it to the left.

Follow the arrow, and stretch the foot of the

extension table.

Snap (A) of the extension table into (B) of the

machine.

Adjust presser foot pressure

The presser foot pressure dial is on the top

left of the face plate.

The presser foot pressure of the machine

has been pre-set and requires no particular

adjustment for general sewing.

Basic presser foot pressure setting: "2".

For sewing with very thin fabric, reduce

the pressure by turning the dial counterclockwise. If kept turning the dial, it could

be take out. By that time, just turn the screw

clockwise, it could be locked back and

readjust the pressure.

For heavy fabric, increase the pressure by

turning it clockwise. Once dial could not be

moved any further, it has been reached the

bottom, please do not turn any more.

6

Winding the bobbin

Please following the number order and see the corresponding illustrations below.

1. Place the thread and spool holder onto

the spool pin. For better sewing quality,

choose a proper size of the spool holder

for the thread and attach it next to the

spool.

Large spool holder

①

1

2

Small spool holder

②

2. Draw the thread from the spool and place

the thread in between the upper thread

guide.

3. Wind the thread clockwise around the

tension discs.

1

2

4. Place the thread end through one of

the inner holes as illustrated and place

the empty bobbin on the bobbin winder

spindle. Then align the notch with bobbin

winder spindle spring.

Notch

①

Bobbin winder spindle spring

②

5. Push the bobbin to the right. When the

bobbin winder spindle is pushed to the

right, the screen will display the gure.

7

6. Hold the thread tail securely in one hand.

Step on the foot control or press the start/

stop button to start winding the bobbin.

7. After the bobbin has wound a few rounds,

stop the machine and cut the thread near

the hole of the bobbin. Continue lling

the bobbin until it is full. Once the bobbin

is full, it rotates slowly. Release the foot

control or press the start/stop button to

stop the machine, then push the bobbin

winder spindle to the left.

8. Cut the thread and then remove the

bobbin.

Note

When the bobbin winder spindle is pushed

to the right position, it’s in "bobbin winding"

mode and the machine is not allowed to

sew and the handwheel will not be able

to turn. To start sewing, push the bobbin

winder spindle back to the left.

Note

Use a bobbin that has been correctly

wound with thread, otherwise the needle

may break or the thread tension will be

incorrect.

8

Inserting the bobbin

nAttention

Turn the power switch to off ("O").

When inserting or removing the bobbin, the

needle and the presser foot must be fully

raised.

Open the bobbin cover by pushing the release

button to the right.

Release button

①

Insert the bobbin in the bobbin case with

the thread running in a counter-clockwise

1

direction (arrow).

Pull the thread through the slit (A).

With a nger hold gently on top of the bobbin,

please follow the arrow markings and draw

the thread into the bobbin thread guide from

(A) to (B).

Pull the thread at the arrow markings into the

stitch plate thread guide from (B) to (C).

To cut off excessive thread, pull it back to the

cutter at point (C).

Close the bobbin cover.

9

Threading the upper thread

Please following the number order and see the corresponding illustrations below. It is

important to carry out the threading correctly to get a quality sewing. Otherwise several

problems will occur.

1. Turn the power switch to on ("I"). Raise

the presser foot lifter.

ONOFF

2. Press the needle up/down position button

to bring the needle and take-up lever to

highest position.

3. Place the thread and spool holder onto

the spool pin. For better sewing quality,

choose a proper size of the spool holder

for the thread and attach it next to to the

thread.

Large spool holder

①

1

2

10

Small spool holder

②

4. Draw the thread from the spool and place

the thread in between the upper thread

guide.

5. Guide the thread ahead and pull the

thread through the pre-tension spring as

illustrated.

6. Continue to guide the thread into the silver

discs to keep the thread in proper tension.

7. Pass the thread under the take-up spring

then pull it upwards as arrow marks

illustrated.

8. Pull the thread to the top then pass the

thread through the slotted eye of the

take-up lever. Guide the thread down

afterwards.

9. Pass the thread behind the at, horizontal

thread guide. Use the needle threader to

thread the needle.

11

10. Lower the presser foot lifter.

11. Lower the needle threader lever slowly

and draw the thread through the thread

guide as illustrated and then to the right.

Lever

①

Hook pin

②

12. The needle threader automatically turns

to the threading position and the hook pin

passes through the needle eye.

Hook pin

①

Needle

②

1

2

13. Take the thread in front of the needle.

Hook pin

①

1

14. Hold the thread loosely and release the

lever slowly. The hook turns and passes

the thread through the needle eye forming

a loop.

Pull the thread through the needle eye.

Note

our machine is threaded and ready for

Y

sewing, follow the instructions on "Starting

to sew" chapter to start sewing. (Page 40)

12

Bringing up the bobbin thread

When sewing gathering or smocking stitch, bring up the bobbin thread rst as below

instruction.

Hold the upper thread with your left hand.

Turn the handwheel towards you (counterclockwise) to lower the needle down below

the needle plate then raise it to bring the

bobbin thread up.

Gently pull on the upper thread to bring the

bobbin thread up through the needle plate

hole. The bobbin thread will come up in a

loop.

Pull both threads to the back under the

presser foot.

13

Replacing the needle

Change the needle regularly, especially when it shows signs of wear or if it causes

problems.

nAttention

Turn the power switch to off ("O") when

carrying out below operations!

1

2

1

Turn the handwheel toward you to raise the

needle then loosen the needle clamp screw to

remove the needle.

Needle clamp screw

①

When inserting a new needle, keep the at

side of the shaft to the back.

Push the needle into the clamp until it touches

the pin and stops. Then secure it by tightening

the needle clamp screw.

Flat side of the shaft

①

Pin

②

Needles must be in perfect condition.

1

2

3

Problems can occur with:

Bent needles

①

Blunt needles

②

Damaged points

③

14

Matching needle/fabric/thread

NEEDLE SIZE FABRICS THREAD

65/9 - 75/11

80/12

90/14

100/16

1. In general, ne threads and needles are used for sewing ne fabrics, thicker threads and

needles are used for sewing heavy fabrics.

2. Always test thread and needle size on a small piece of fabric which will be used for actual

sewing.

3. Use the same thread for needle and bobbin.

4. Use a stabilizer or place a backing for ne or stretchy fabrics, and select the correct

presser foot.

5. It is recommended that a 90/14 needle should be used when embroidering on heavyweight

fabrics or stabilizing products (for example, denim, puffy foam, etc.). A 75/11 needle may

bend or break, which could result in injury.

6. For transparent nylon thread, always use needle 90/14 - 100/16. The same thread is

usually used for the bobbin thread and upper threading.

Lightweight fabrics-

thin cottons, voile, serge, silk, muslin,

Qiana, interlocks, cotton knits, tricot,

jerseys, crepes, woven polyester,

shirt & blouse fabrics.

Medium weight fabrics-

cotton, satin, kettleclote, sailcloth,

double knits, lightweight woolens.

Medium weight fabrics-

cotton duck, woolen, heavier knits,

terrycloth, denims.

Heavyweight fabrics-

canvas, woolens, outdoor tent and

quilted fabrics, denims, upholstery

material (light to medium).

Note

Light-duty thread in cotton, nylon,

polyester or cotton wrapped

polyester.

Most threads sold are medium

size and suitable for these fabrics

and needle sizes.

Use polyester threads on

synthetic materials and cotton

on natural woven fabrics for best

results.

Always use the same thread on

top and bottom.

15

Changing the presser foot

1

Turn the power switch to off ("O").

Always use the proper foot for the selected

stitch. The wrong foot can cause the

needle to break.

vRemove the presser foot

1

Raise the presser foot lifter. Press the back

lever to release the presser foot.

①

vAttach the presser foot

Lower the presser foot lifter until the cut-out

meets the pin.

nAttention

Lever

The presser foot will attach to the presser foot

1

2

holder automatically.

Cut-out

①

Pin

②

vRemove and insert the presser

1

2

foot holder

Raise the presser foot lifter. Align the presser

foot holder with the lower left side of the

presser bar. Hold the presser foot holder,

then tighten the screw using the enclosed

screwdriver.

Presser foot bar

①

Presser foot holder

②

vInsert the edge/quilting guide

Insert the edge/quilting guide in the slot as

illustrated. Adjust the needed width according

to your sewing applications.

Slot

16

①

Edge/quilting guide

②

2

To raise or drop the feed dogs

3

The drop feed lever can be seen on the base

at the back side of the sewing machine.

Sliding the drop feed lever to lower or raise

the feed dogs. When lever is in raised

position, the feed dog will arise automatically

when you are sewing.

Drop feed lever

①

Lowered position

②

Raised position

1

③

2

When you nish the work, (e.g. button

sewing, free motion darning, embroidery

and monogramming), please move the drop

feed lever to raised position for general

sewing purpose.

Note

17

Thread tension

Proper tension setting is important for sewing. There is no single tension setting

appropriate for all the stitch functions and fabrics.

Basic thread tension setting: "4".

Normal thread tension for straight stitch

1

3

2

4

sewing.

Upper thread

①

Bobbin thread

②

Surface

③

Wrong side

④

Thread tension is too loose for straight stitch

sewing. To increase the tension, press the "+"

button.

Thread tension is too tight for straight stitch

sewing. To reduce the tension, press the "–"

button.

Normal thread tension for zig zag and

decorative sewing.

For all decorative sewing you will always

obtain a nicer stitch and less fabric puckering.

Correct thread tension is when a small

number of the upper thread appears on the

bottom side of fabric.

18

Instruction

Loading...

Loading...