DATA SHEET

BIPOLAR ANALOG INTEGRATED CI RCUIT

PC8105GR

µµµµ

400 MHz QUADRATURE MODULATOR

FOR DIGITAL MOBILE COMMUNICATION

DESCRIPTION

The µPC8105GR is a sillicon monolithic integrated circuit designed as quadrature modulator for digital mobile

communication systems. This modulator housed in a 16 pin plastic SSOP that is easy to install and contributes to

miniaturizing the system.

The device has power save function and can operates 2.7 to 5.5 V supply voltage to realize low power

consumption.

FEATURES

•

Internal 90° phase shifter is accurate over an IF range from 100 MHz to 400 MHz.

•

Wide supply voltage range: VCC = 2.7 to 5.5 V.

•

Low operation current: ICC = 16 mA (typ.).

•

16 pin plastic SSOP suitable for high density surface mounting.

•

Low current in sleep mode

APPLICATION

•

IF modulator for Digital cellular phone (PDC, IS-54, GSM etc..)

•

IF modulator for Digital cordless phone (PHS, PCS etc..)

ORDERING INFORMATION

PART NUMBER PACKAGE SUPPLYING FORM

µ

PC8105GR-E1 16 pin plastic SSOP (225 m i l ) Carrier tape width 12 mm. Q’ty 2. 5 kp/Reel

Pin 1 indicated pull-out direc tion of tape.

To order evaluation samples, please contact your local NEC sales office. (Part number for sample order:

PC8105GR)

µ

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. P10807EJ3V0DS00 (3rd edition)

Date Published October 1999 N CP(K)

Printed in Japan

Caution electro-static sensitive device

The mark shows major revised points.

©

1995, 1999

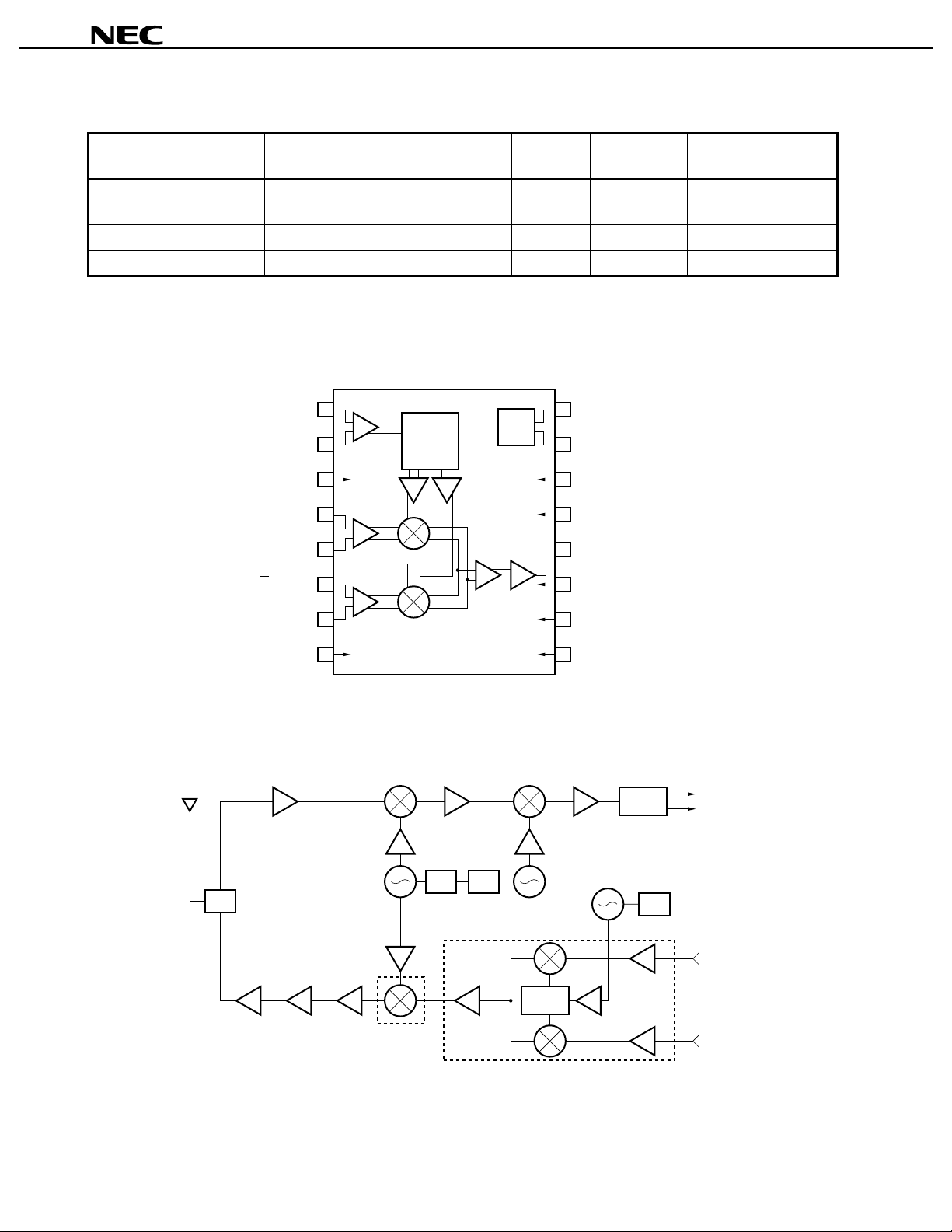

SERIES PRODUCTS

µµµµ

PC8105GR

SERIES TYPE

150 MHz Quadrature MOD

Up-Con + Quadrature MOD

400 MHz Quadrature MOD

Remark:

As for detail information of series products, please refer to each data sheet.

PART

NUMBER

PC8101GR 100 to

µ

PC8104GR 100 to 400 DC to 10 800 to 1900 Digital Comm.

µ

PC8105GR 100 to 400 DC to 10 External Digital Comm.

µ

f LO1 in

(MHz)

300

f MODout

(MHz)

50 to 150 DC to 0.5 External CT2, Digital Comm.

f I/Q

(MHz)

INTERNAL BLOCK DIAGRAM AND PIN CONNECTIONS (Top View)

LO

LO

GND

I-INPUT

I-INPUT

Q-INPUT

1

in

90˚

in

2

3

4

5

6

Phase

Sifter

REG.

V

16

CC

15

Power Save

14

GND

13

GND

12

MOD

11

N.C.

Up-Converter

f RFout (MHz)

out

APPLICATIONS

Q-INPUT

GND

APPLICATION EXAMPLE

[Digital cellular hand-held phone]

Low-noise transistor

RX

SW

TX

PA

10

7

8

÷N

VCO

PLL

µ

Phase

shifter

µ

PC8106T

N.C.

9

N.C.

PC8105GR

0˚

90˚

DEMO

PLL

I

Q

I

Q

2

Data Sheet P10807EJ3V0DS00

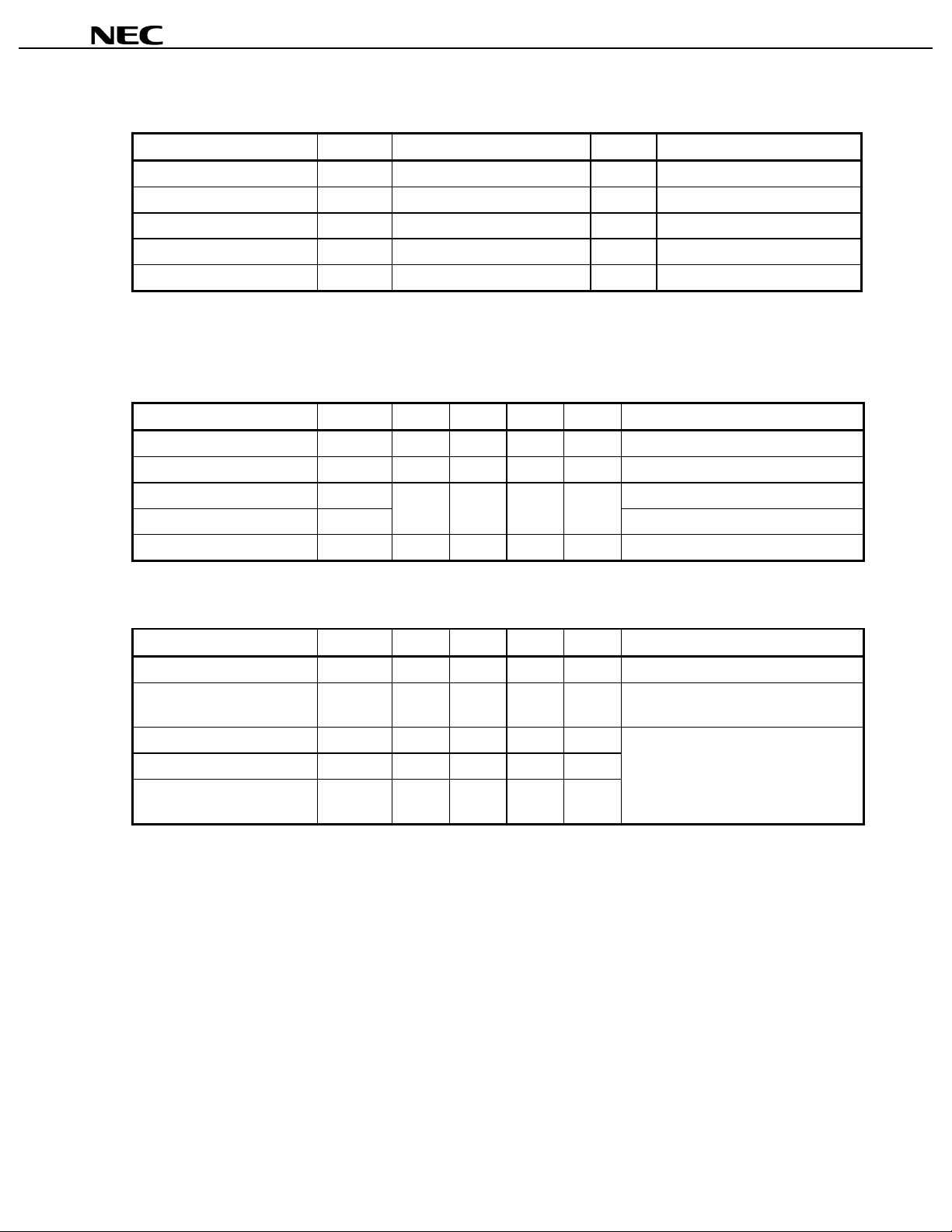

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL RATING UNIT TEST CONDITIONS

µµµµ

PC8105GR

Supply Voltage V

Power Save Voltage V

Power Dissipation P

Operating Temperature T

Storage Temperature T

: Mounted on 50 × 50 × 1.6 mm double copper clad epoxy glass board

*1

CC

PS

D

op

stg

6.0 V TA = +25 °C

6.0 V TA = +25 °C

310 mW

40 to +85

−

55 to +150

−

RECOMMENDED OPERATING CONDITIONS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

Supply Voltage V

Operating Temperature T

Modulator Output Frequency f

LO1 Input Frequency f

I/Q Input Frequency f

ELECTRICAL CHARACTERISTICS (TA = +25

CC

A

MODout

LO1in

I/Qin

2.7 3.0 5.5 V

40 +25 +85

−

100 400 MHz

DC 10 MHz P

C, VCC = 3.0 V, Unless Otherwise Specified VPS

°°°°

A

T

= +85 °C

C

°

C

°

C

°

LOin

P

= −10 dBm

I/Qin

= 600 mV

*1

p-p

MAX (Single ended)

1.8 V)

≥≥≥≥

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

Circuit Current I

Circuit Current at Power

CC

10 16 21 m A No input signal

ICC(PS) 0.1 5

AVPS ≤ 1.0 V

µ

Save Mode

Output Power P

LO Carrier Leak LOL

Image Rejection

MODout

ImR

−

21.0

−

16.5

40

−

40

−

12.0 dBm

−

30 dBc

−

30 dBc

−

I/Q DC = 1.5 V

I/Qin

= 500 mV

P

(Side Band Leak)

p-p

(Single ended)

Data Sheet P10807EJ3V0DS00

3

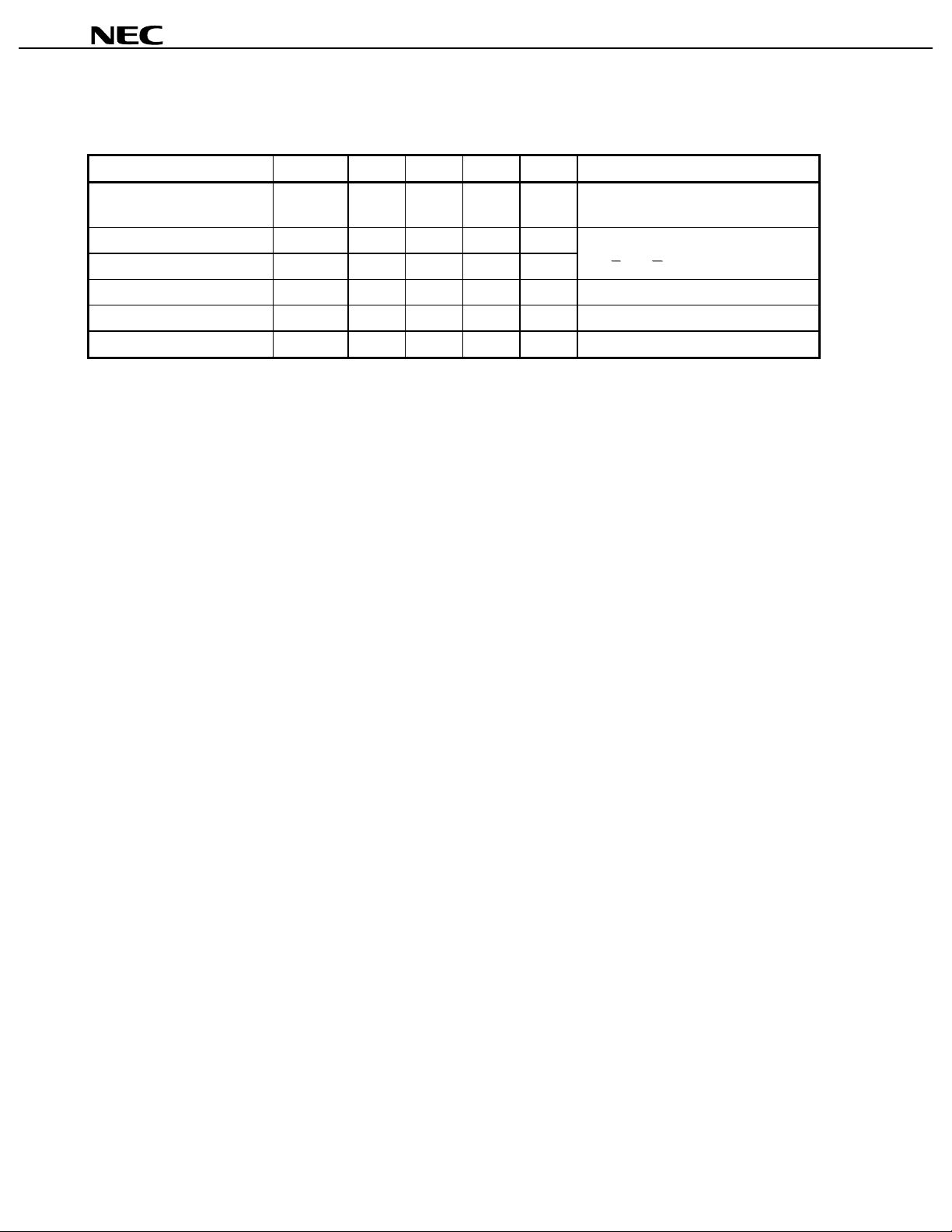

STANDARD CHARACTERISTICS FOR REFERENCE

(TA = +25

C, VCC = 3.0 V, Unless Otherwise Specified VPS

°°°°

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITIONS

1.8 V)

≥≥≥≥

µµµµ

PC8105GR

I/Q 3rd Order

IM

Intermodulation Distort i on

I/Q Input Impedance Z

I/Q Bias Current I

LO1 Input VSWR Z

Power Save Rise Time T

Power Save Fall Time T

3I/Q

I/Q

I/Q

LO

PS(RISE)

PS(FALL)

50

−

30 dBc I/Q DC = 1.5 V

−

20 k

5

1.2:1

25

25

Ω

A

µ

I/Qin

= 500 mV

P

I/Q DC = 1.5 V

I/Qin

= 500 mV

P

(I → I, Q → Q)

p-p

p-p

−

sVPS(OFF) → VPS(ON)

µ

sVPS(ON) → VPS(OFF)

µ

(Single ended)

(Single ended)

4

Data Sheet P10807EJ3V0DS00

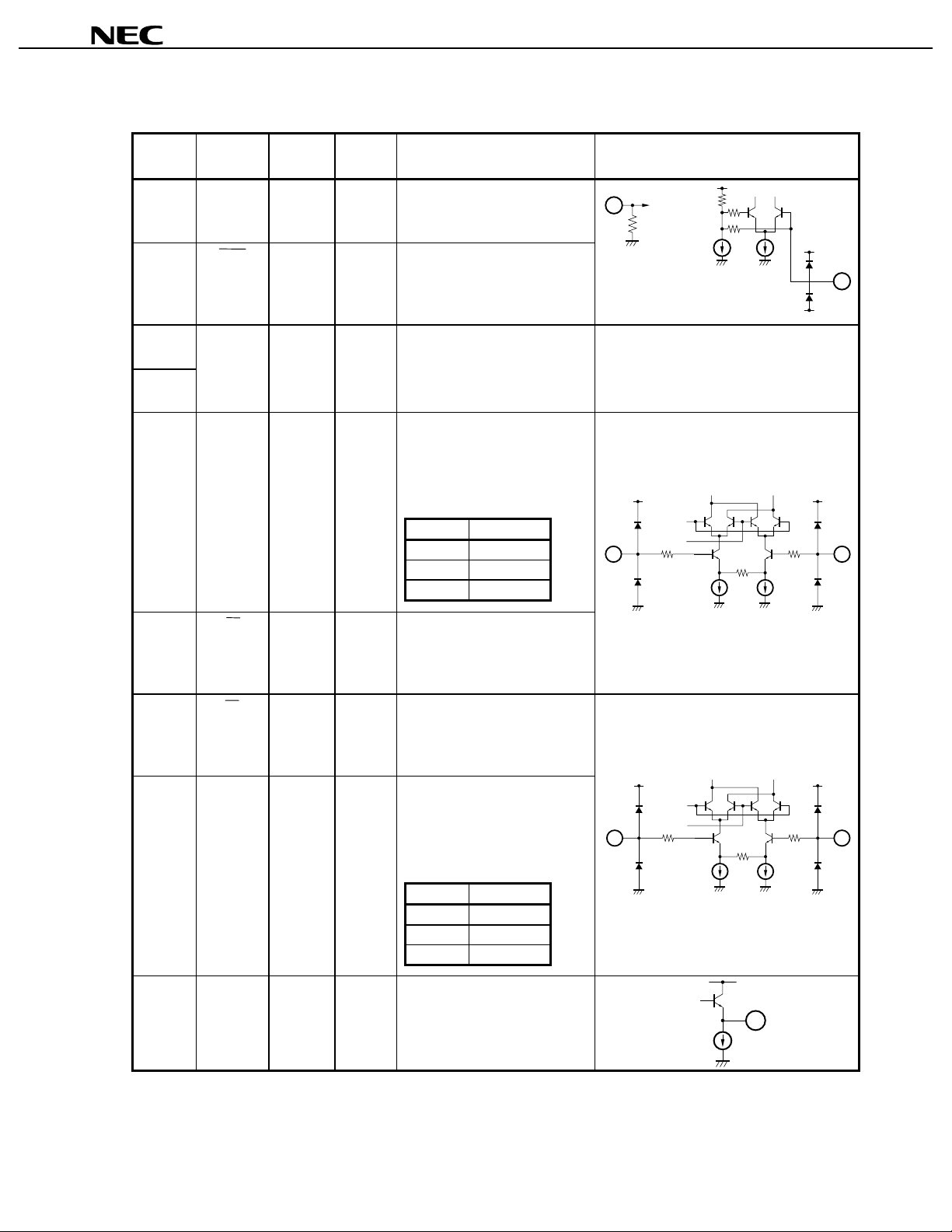

PIN EXPLANATION

µµµµ

PC8105GR

PIN NO.

ASSIGNMENT

1LOin

2LOin

SUPPLY

VOL. (V)

−

−

3GND0

8

4IV

CC

PIN

VOL.(V)

FUNCTION AND APPLICATION EQUIPMENT CIRCUIT

0 LO input for phase shifter.

This input impedance is 50

matched internally.

Ω

1

50 Ω

2.4 Bypass of LO input.

This pin is grounded through

2

internal capacitor.

Open in case of single ended.

−

Connect to the ground with

minimum inductance.

Track length should be kept as

short as possible.

/2

Input for I signal. This in put

−

impedance is larger than 20 kΩ.

Relations between amplitude and

CC

/2 bias of input signal are

V

following.

VCC/2 (v) Amp. (mV

1.35 400

≥

1.5 600

≥

1.75 1000

≥

p-p

)

*1

4 5

5IV

6QV

7QV

12 MODout

CC

/2

CC

/2

CC

/2

−

Input for I signal. This in put

−

impedance is larger than 20 kΩ.

CC

/2 biased DC signal should be

V

input.

Input for Q signal. This i n put

−

impedance is larger than 20 kΩ.

CC

/2 biased DC signal should be

V

input.

Input for Q signal. This i n put

−

impedance is larger than 20 kΩ.

Relations between amplitude and

CC

/2 bias of input signal are

V

following.

VCC/2 (v) Amp. (mV

1.35 400

≥

1.5 600

≥

1.75 1000

≥

1.5 Output from modulator.

This is emitter follower output.

7 6

p-p

)

*1

12

In case of that I/Q input signals are single ended.

*1:

Of course, I/Q signal inputs can be used either single endedly or differentially with proper terminations.

Data Sheet P10807EJ3V0DS00

5

×2

from LO

in

÷2 F/F

I

I

Q

Q

to MOD

out

PIN EXPLANATION

15

µµµµ

PC8105GR

PIN NO.

13 GND 0

14

15 Power

16 V

ASSIGNMENT

Save

SUPPLY

VOL. (V)

VP/S

CC

2.7 to

5.5

PIN

VOL.(V)

−

−

−

FUNCTION AND APPLICATION EQUIPMENT CIRCUIT

Connect to the ground with

minimum inductance.

Track length should be kept as

short as possible.

Power save control pin can be

controlled ON/SLEEP state with

bias as follows;

VP/S (v) STATE

1.8 to 5.5 ON

0 to 1.0 SLEEP

Supply voltage pin for modulator.

Internal regulator can be kept

stable condition of suppl y bias

against the variable temperat ure

CC

.

or V

EXPLANATION OF INTERNAL FUNCTION

BLOCK FUNCTION/OPERATI ON BLOCK DIAGRAM

90° PHASE

SHIFTER

BUFFER AMP. Buff er am pl i f i ers for each phase signals to

MIXER Each signals from buffer amp. are

ADDER Output signals from each mixers are added

Input signal from LO is s end to digital

circuit of T-type f l i p-flop through frequency

doubler. Output signal from T-ty pe F/ F i s

changed to same frequency as LO i nput

and that have quadrature phase shift, 0°,

90°, 180°, 270°. These circuits hav e

function of self phas e correction to make

correctly quadrature signals.

send to each mixers.

quadrature modulated with two doublebalanced mixers.

High accurate phase and amplitude i nput s

are realized to good performance for im age

rejection.

with adder and send to final amplif i er.

6

Data Sheet P10807EJ3V0DS00

µµµµ

PC8105GR

TYPICAL CHARACTERISTICS (TA = +25

CC

Unless otherwise specified V

(single ended), P

LOin

= −10 dBm, (continuous wave)

= VPS = 3 V, I/Q DC offset = I/Q DC offset = 1.5 V, I/Q Input Signal = 500 mV

SUPPLY VOLTAGE vs CIRCUIT CURRENT

40

35

30

25

20

- Circuit Current - mA

15

CC

I

C)

°°°°

p-p

Lo INPUT POWER vs OUTPUT POWER,

LOCAL LEAK, IMAGE REJECTION,

I/Q 3RD ORDER INTERMODULATION

DISTORTION

10

0

I/Q - dBc

3

–10

–20

–30

–40

(PHS)

384 Kbps

RNYQ

α = 0.5

(0000)

All zero

Pout

LOL(ISO(LO))

ImR

–10

–20

–30

- Modulator Output Power - dBm

10

5

0

0123456

CC

- Supply Voltage - V

V

VCC = VPS = 3 V

RF None

) - Local Leak, ImR - Image Rejection, IM

–50

LO

LOL (ISO

–60

–70

–30 –20 –10 0 +10

P

Loin

- Lo Input Power - dBm

IM

3I/Q

–40

–50

MODout

P

Data Sheet P10807EJ3V0DS00

7

µµµµ

PC8105GR

I/Q INPUT SIGNAL vs OUTPUT POWER,

LOCAL LEAK, IMAGE REJECTION,

I/Q 3RD ORDER INTERMODULATION

DISTORTION

10

(PHS)384 Kbps

RNYQ α = 0.5

(0000) All zero

0

–10

–20

–30

–40

–50

LOL (ISOLO) - Local Leak, ImR - Image Rejection, IM3 I/Q - dBc

–60

ImR

Pout

LOL(ISO(LO))

IM3I/Q

Lo INPUT FREQUENCY vs OUTPUT POWER,

LOCAL LEAK, IMAGE REJECTION, I/Q 3RD,

ORDER INTERMODULATION DISTORTION

–10

–20

–30

PMODout - Modulator Output Power - dBm

–40

–10

–20

–30

–40

–50

–60

LOL(ISOLO) - Local Leak, ImR - Image Rejection, IM3 I/Q - dBC

–70

P

out

ImR

LOL(ISO(LO))

IM

3I/Q

50 100 200 500

fLO - Lo Input Frequency - MHz

–10

–20

–30

–40

–50

MODout - Modulator Output - Power - dBm

P

–60

–70

–70

0 0.5 1

P

I/Qin - I/Q Input Signal - Vp-p

I/Q INPUT SIGNAL vs PHASE ERROR,

MAGNITUDE ERROR, VECTOR ERROR

VCC = 3 V

Lo: 240 MHz

10

–10 dBm

I/Q DC: 1.5 V

Single ended

<PHS>

384 Kbps

7

RNYQ α = 0.5

PN9

5

φ

∆ - Phase Error - deg.

∆A - Magnitude Error - % rms

∆M - Vector Error - % rms

3

2

1

0

0 0.5 1

I/Qin - I/Q Input signal - mVp-p

P

∆M

∆A

∆

–50

Lo INPUT FREQUENCY vs VECTOR ERROR,

MAGNITUDE ERROR, PHASE ERROR

VCC = 3 V

Lo: 15 dBm

I/Q DC 1 500 mV

10

AC 430 mV

<PHS>384 Kbps

RNYQ α = 0.5

PN9

7

5

φ

∆ - Phase Error - deg.

∆A - Magnitude Error - % rms

∆M - Vector Error - % rms

φ

3

2

1

0

0 200 400

p-p

∆M

∆A

φ

∆

100 300 500

LO - Lo Input Frequency - MHz

f

8

Data Sheet P10807EJ3V0DS00

TYPICAL SINE WAVE MODULATION

OUTPUT SPECTRUM

µµµµ

PC8105GR

10 dB/

RBW

1 kHz

VBW

1 kHz

SWP

2.0 s

ATT 10 dBREF 0.0 dBm

CENTER 240.0000 MHz

<PHS>384 kbps, RNYQ α = 0.5, MOD Pattern<000>, all zero

SPAN 200.0 kHz

TYPICAL π/4 DQPSK MODULATION OUTPUT SPECTRUM

<PHS>384 kbps, RNYQ α = 0.5, MOD Pattern (PN9)

TYPICAL π/4 DQPSK MODULATION OUTPUT SPECTRUM

<PDC>42 kbps, RNYQ α = 0.5, MOD Pattern<PN9>

REF –10.0 dBm

10 dB/

ADJ BS

192 kHz

DL –10.0 dBm

RBW 3 kHz

VBW 10 kHz

SWP 5.0 s

1

CENTER 240.000 MHz SPAN 2.000 MHz

ATT 0 dB

MARKER

239.100 MHz

68.75 dB

2

∗∗∗ Multi Marker List ∗∗∗

No.1: 239.100 MHz –68.75 dB

No.2: 239.400 MHz –68.25 dB

No.3: 240.600 MHz –68.25 dB

No.4: 240.900 MHz –69.00 dB

3

REF –10.0 dBm

10 dB/

ADJ BS

21.0 kHz

4

DL –10.0 dBm

RBW 3 kHz

VBW 3 kHz

SWP 5.0 s

CENTER 240.0000 MHz SPAN 500 kHz

ATT 0 dB

MARKER

289.9000 MHz

76.50 dB

23

1

∗∗∗ Multi Marker List ∗∗∗

No.1: 239.9000 MHz –76.50 dB

No.2: 239.9500 MHz –70.50 dB

No.3: 240.0500 MHz –71.00 dB

No.4: 240.1000 MHz –75.75 dB

4

Data Sheet P10807EJ3V0DS00

9

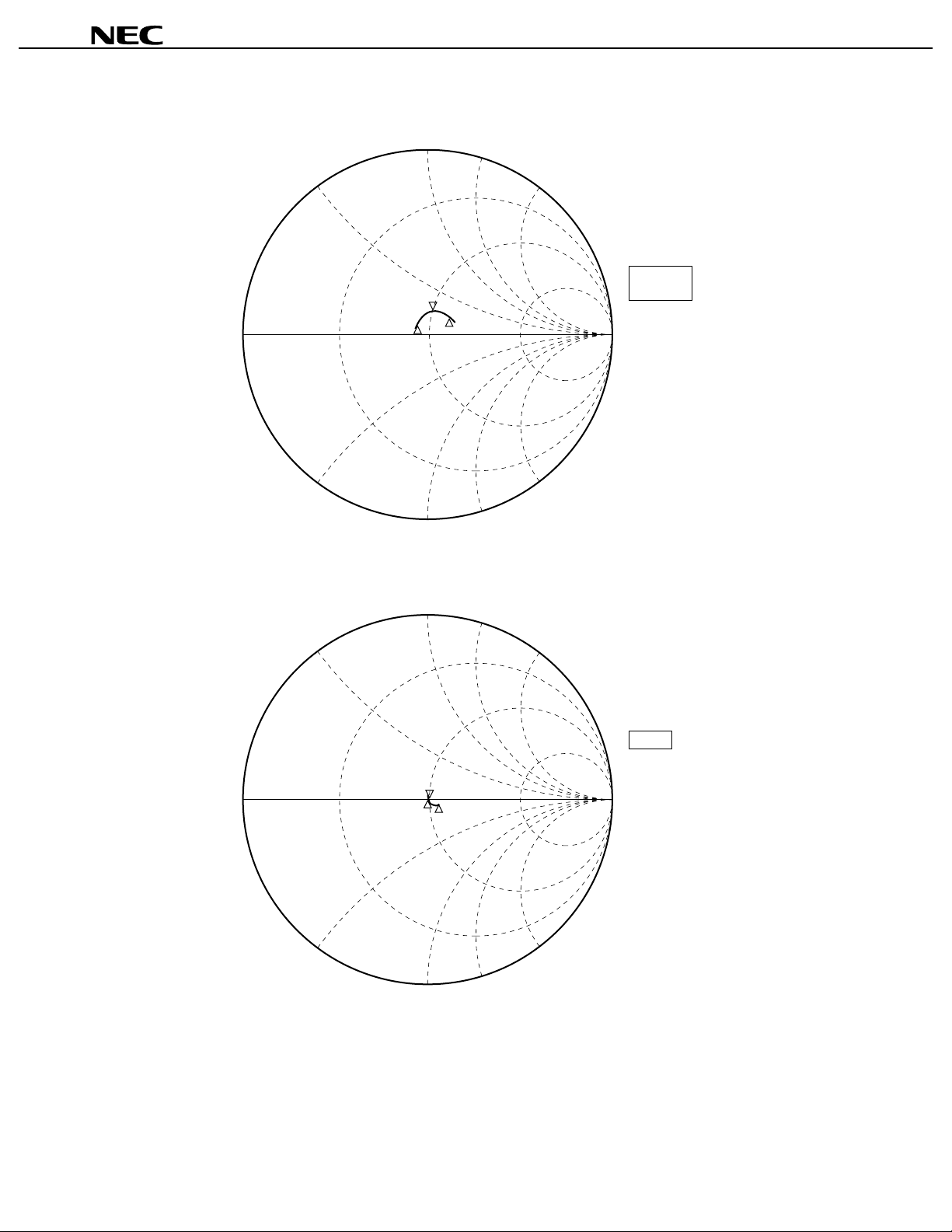

MODout OUTPUT IMPEDANCE

MARKER 2

240 MHz

2; 49.244 Ω 13.58 Ω 9.0056 nH

240.000 000 MHz

µµµµ

PC8105GR

LOin INPUT IMPEDANCE

MARKER 2

240 MHz

2

3

1

STOP 500.000 000 MHzSTART 50.000 000 MHz

2; 51.727 Ω –2.0059 Ω 330.5 pF

240.000 000 MHz

MOD out

Marker

1. 100 MHz

2. 240 MHz

3. 400 MHz

10

2

3

1

STOP 500.000 000 MHzSTART 50.000 000 MHz

Data Sheet P10807EJ3V0DS00

Lo in

Marker

1. 100 MHz

2. 240 MHz

3. 400 MHz

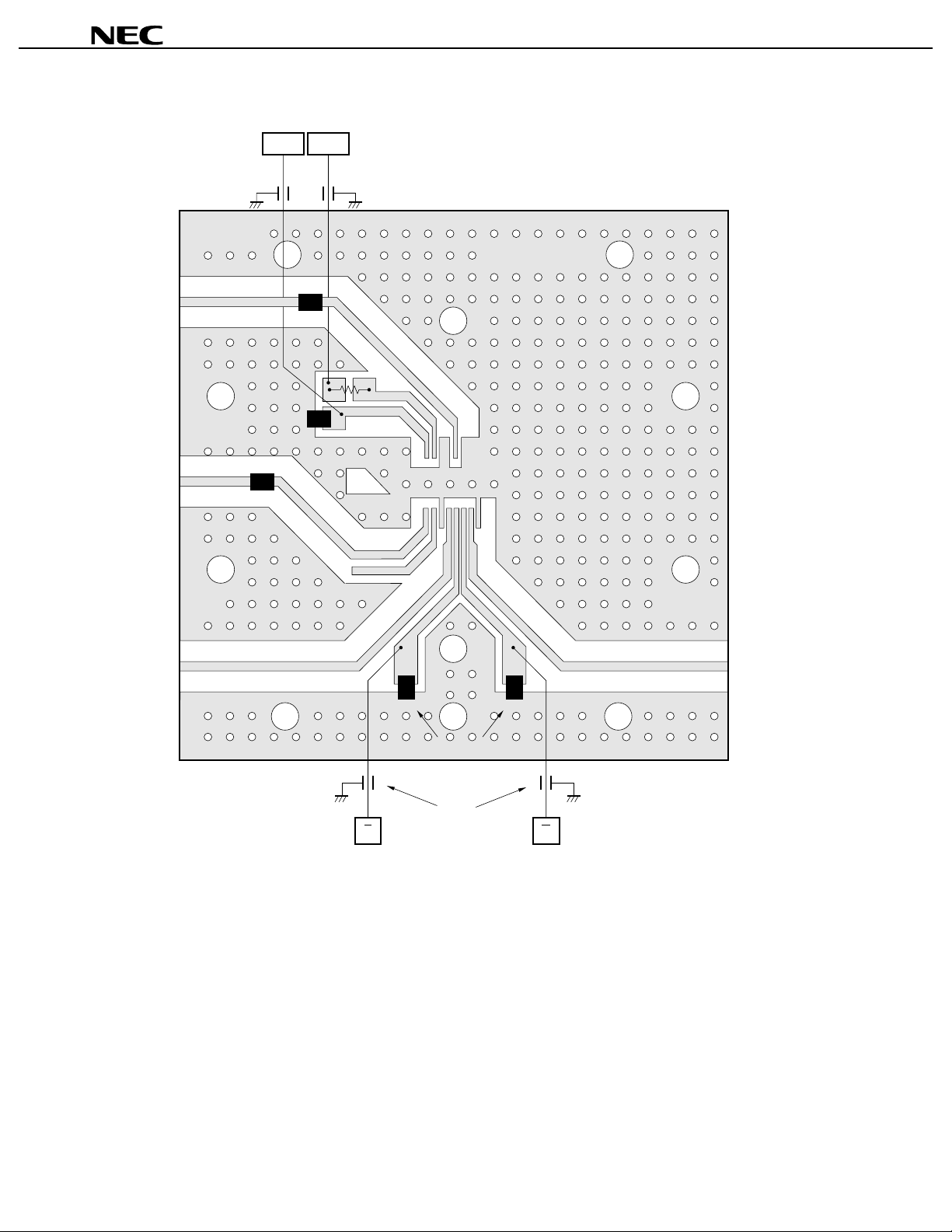

TEST CIRCUIT

fMOD out = 100 ~ 400 MHz

S.P.A

µµµµ

PC8105GR

V

CC

LO

S.G

f

LO

= 100 ~ 400 MHz

IN

= –10 dBm

P

GND

I

1 000 pF

MOD out

I

p-p

(I, Q only)

NC

Q

10 kΩ

16 15 14 13 12 11 10 9

CC

V

Lo in

12345678

Open

1 000 pF

GND

Power Save

Lo in

GND

IIQQ

I/Q Signal Generator

f : DC to hundreds kHz

A : 0.5 V

V : 1.5 V (I, I, Q, Q)

NC

Q

NC

GND

Data Sheet P10807EJ3V0DS00

11

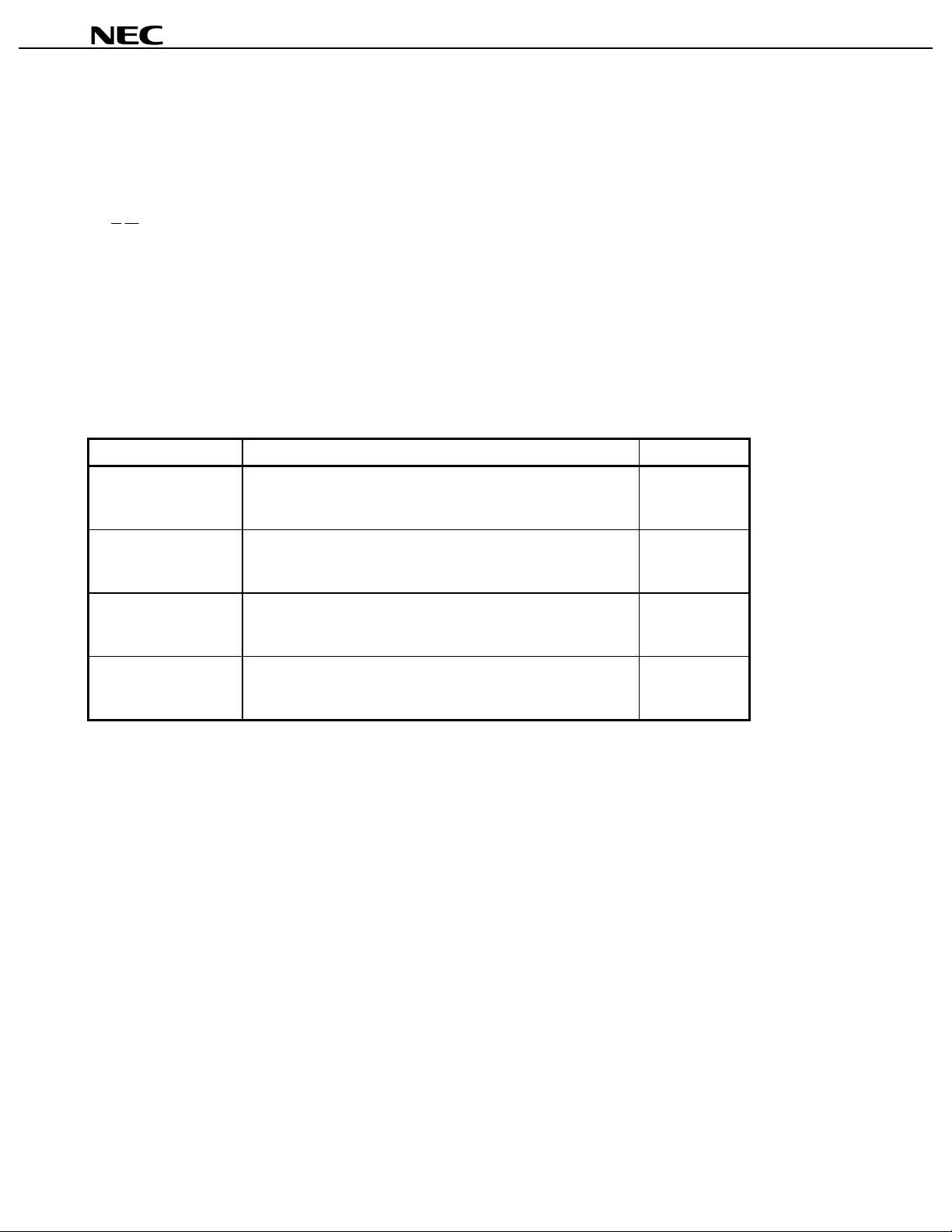

TEST BOARD

I F OUT

CC

1 000 pF

µµµµ

PC8105GR

P. S.V

10 000 pF10 000 pF

µ

PC8105GR

10 kΩ

LO IN

1 000 pF

1

1 000 pF

I IN Q IN

10 000 pF

IQ

10 000 pF

12

Data Sheet P10807EJ3V0DS00

PACKAGE DIMENSIONS

16 PIN PLASTIC SHRINK SOP (225 mil) (UNIT: mm)

16 9

detail of lead end

5° ± 5°

µµµµ

PC8105GR

18

1.565 ± 0.235

1.44

0.125 ± 0.075

NOTE Each lead centerline is located within 0.10 mm of its true position (T.P.) at maximum material condition.

5.2 ± 0.3

0.65

0.22 ± 0.08

0.475 MAX.

M

0.10

6.2 ± 0.3

4.4 ± 0.2

S

0.5 ± 0.2

+0.08

0.17

−0.07

0.9 ± 0.2

0.10

S

Data Sheet P10807EJ3V0DS00

13

µµµµ

PC8105GR

NOTE ON CORRECT USE

(1) Observe precautions for handling because of electrostatic sensitive devices.

(2) Form a ground pattern as widely as possible to minimize ground impedance (to prevent undesired oscillation).

(3) Keep the track length of the ground pins as short as possible.

CC

(4) Connect a bypass capacitor (e.g. 1 000 pF) to the V

pin.

(5) I, Q DC offset voltage should be same as the I, Q DC offset voltage (to prevent changing the local leak level with

power save control.)

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered in the following recommended conditions. Other soldering methods and

conditions than the recommended conditions are to be consulted with our sales representatives.

PC8105GR

µµµµ

Soldering process Soldering Conditions Symbol

Infrared ray reflow Peak package’s surface temperature: 235 °C or below,

Reflow time: 30 seconds or bel ow (210 °C or higher),

Number of reflow process: 3, Exposure limit

VPS Peak package’s surface temperature: 215 °C or below,

Reflow time: 30 seconds or bel ow (200 °C or higher),

Number of reflow process: 3, Exposure limit

Wave soldering Solder temperature: 260 °C or below

Flow time: 10 seconds or below,

Number of reflow process: 1, Exposure limit

Partial heating method Terminal temperature: 300 °C or below

Flow time: 3 seconds/pi n or bel ow,

Exposure limit

Exposure limit before soldering after dry-pack package is opened.

*:

*

: None

*

: None

*

: None

*

: None

IR35-00-3

VP15-00-3

WS60-00-1

Storage conditions: 25 °C and relative humidity at 65 % or less.

Apply only a single process at once, except for “Partial heating method”.

Note:

For details of recommended soldering conditions for surface mounting, refer to information document

SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL (C10535E).

The application circuits and their parameters are for reference only and are not intended for use in actual design-ins.

14

Data Sheet P10807EJ3V0DS00

[MEMO]

µµµµ

PC8105GR

Data Sheet P10807EJ3V0DS00

15

µµµµ

PC8105GR

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98. 8

Loading...

Loading...