NEC NL256204AM15-01 Specification

Global LCD Panel Exchange Center

TFT MONOCHROME LCD MODULE

NL256204AM15-01

www.panelook.com

NL256204AM15-01A

51cm (20.1 Type)

QSXGA

LVDS Interface (4 ports)

DATA SHEET

DOD-PD-0887 (4th edition)

This DATA SHEET is updated document from

DOD-PD-0561(3).

All information is subject to change without notice.

Please confirm the sales representative before

starting to design your system.

Document Number: DOD-PD-0887 (4th edition)

Published date: March 2005 CP(N)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

1

¤ NEC LCD Technologies, Ltd.

2003- 2005 All rights reserved.

www.panelook.com

Global LCD Panel Exchange Center

No part of this document shall be copied in any form or by any means without the prior written consent

of NEC LCD Technologies, Ltd. (hereinafter called "NEC").

NEC does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a product described herein or any other liability arising

from use of such application. No license, express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC or of others.

While NEC has been making continuous effort to enhance the reliability of its products, the possibility

of failures cannot be eliminated entirely. To minimize risks of damage to property or injury to person

arising from a failure in an NEC product, customers must incorporate sufficient safety measures in their

design, such as redundancy, fire-containment and anti-failure features.

www.panelook.com

NL256204AM15-01/01A

INTRODUCTION

NEC products are classified into the following three quality grades:

"Standard", "Special", "Specific"

The "Specific" quality grade applies only to applications developed based on a customer designated

"quality assurance program" for a specific application. The recommended applications of a product

depend on its quality grade, as indicated below. Customers must check the quality grade of each

application before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically

designed for life support)

Specific: Military systems, aircraft, aerospace equipment, submersible repeaters, nuclear reactor control

systems, life support systems (medical equipment, etc.) and any other equipment

The quality grade of this product is "Standard" unless otherwise specified in this document. If

customers intend to use this product for applications other than those specified for "Standard" quality

grade, they should contact NEC sales representative in advance.

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

2

www.panelook.com

Global LCD Panel Exchange Center

INTRODUCTION ..........................................................................................................................................2

1. OUTLINE....................................................................................................................................................4

1.1 STRUCTURE AND PRINCIPLE...........................................................................................................4

1.2 APPLICATION.......................................................................................................................................4

1.3 FEATURES.............................................................................................................................................4

2. GENERAL SPECIFICATIONS ................................................................................................................5

3. BLOCK DIAGRAM ................................................................................................................................... 6

4. DETAILED SPECIFICATIONS ............................................................................................................... 7

4.1 MECHANICAL SPECIFICATIONS......................................................................................................7

4.2 ABSOLUTE MAXIMUM RATINGS ....................................................................................................7

4.3 ELECTRICAL CHARACTERISTICS................................................................................................... 8

4.3.1 LCD panel signal processing board ............................................................................................... 8

4.3.2 Inverter........................................................................................................................................... 9

4.3.3 Inverter current wave ..................................................................................................................... 9

4.3.4 Power supply voltage ripple.........................................................................................................10

4.3.5 Fuse.............................................................................................................................................. 10

4.4 POWER SUPPLY VOLTAGE SEQUENCE ........................................................................................ 11

4.4.1 LCD panel signal processing board ............................................................................................. 11

4.4.2 Inverter......................................................................................................................................... 11

4.5 CONNECTIONS AND FUNCTIONS FOR INTERFACE PINS.........................................................12

4.5.1 LCD panel signal processing board ............................................................................................. 12

4.5.2 Inverter......................................................................................................................................... 15

4.5.3 Positions of socket .......................................................................................................................15

4.6 LUMINANCE CONTROL................................................................................................................... 16

4.6.1 Luminance control methods.........................................................................................................16

4.6.2 Detail of PWM timing ................................................................................................................. 17

4.7 METHOD OF CONNECTION FOR LVDS TRANSMITTER............................................................18

4.8 DISPLAY GRAY SCALE AND INPUT DATA SIGNALS .................................................................. 20

4.9 INPUT SIGNAL TIMINGS.......................................................................................................

iming characteristics..................................................................................................................21

4.9.1 T

4.9.2 Input signal timing chart ..............................................................................................................21

4.10 LVDS DATA TRANSMISSION MODE ............................................................................................ 22

4.11 DISPLAY POSITIONS.......................................................................................................................23

4.12 PIXEL ARRANGNMENT .................................................................................................................24

4.13 TEN-bit LOOK UP TABLE FOR GAMMA ADJUSTMENT............................................................25

4.14 LUT SERIAL COMMUNICATION TIMINGS .................................................................................28

4.15 OPTICS...............................................................................................................................................30

4.15.1 Optical characteristics................................................................................................................30

4.15.2 Definition of contrast ratio......................................................................................................... 32

4.15.3 Definition of luminance uniformity...........................................................................................32

4.15.4 Definition of response times ...................................................................................................... 32

4.15.5 Definition of viewing angles......................................................................................................32

5. RELIABILITY TESTS.............................................................................................................................33

6. PRECAUTIONS .......................................................................................................................................34

6.1 MEANING OF CAUTION SIGNS ...................................................................................................... 34

6.2 CAUTIONS ..........................................................................................................................................34

6.3 ATTENTIONS ......................................................................................................................................34

6.3.1 Handling of the product ............................................................................................................... 34

6.3.2 Environment.................................................................................................................................35

6.3.3 Characteristics..............................................................................................................................36

6.3.4 Other ............................................................................................................................................36

7. OUTLINE DRAWINGS ........................................................................................................................... 37

www.panelook.com

NL256204AM15-01/01A

CONTENTS

...........21

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

3

www.panelook.com

Global LCD Panel Exchange Center

1. OUTLINE

1.1 STRUCTURE AND PRINCIPLE

Monochrome LCD module NL256204AM15-01 and NL256204AM15-01A are composed of the

amorphous silicon thin film transistor liquid crystal display (a-Si TFT LCD) panel structure with driver

LSIs for driving the TFT (Thin Film Transistor) array and a backlight.

The a-Si TFT LCD panel structure is injected liquid crystal material into a narrow gap between the TFT

array glass substrate and a monochrome-filter glass substrate.

Grayscale data signals from a host system (e.g. PC, signal generator, etc.) are modulated into best form

for active matrix system by a signal processing board, and sent to the driver LSIs which drive the

individual TFT arrays.

The TFT array as an electro-optical switch regulates the amount of transmitted light from the backlight

assembly, when it is controlled by data signals. Monochrome images are created by regulating the

amount of transmitted light through the TFT array.

www.panelook.com

NL256204AM15-01/01A

1.2 APPLICATION

x Monochrome monitor system

1.3 FEATURES

x Ultra-wide viewing angle (Adoption of Super Advanced -Super Fine TFT (SA-SFT))

x High luminance

x High contrast

x Low reflection

x High resolution

x 256 gray scales per 1 sub-pixel

x LVDS interface

x Adjustable gamma characteristics by using built-in 10-bit LUT (look up table)

x Selectable LVDS data input map

x Selectable LVDS data transmission mode

x Small foot print

x Incorporated direct type backlight

x Replaceable backlight unit and inverter

x Differences between NL256204AM15-01 and NL256204AM15-01A

Item NL256204AM15-01 NL256204AM15-01A

White chromaticity Wx, Wy = (0.255, 0.310) (typ.) Wx, Wy = (0.280, 0.304) (typ.)

Backlight unit

(Replaceable part)

DATA SHEET DOD-PD-0887 (4th edition)

201LHS07 201LHS08

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

4

www.panelook.com

Global LCD Panel Exchange Center

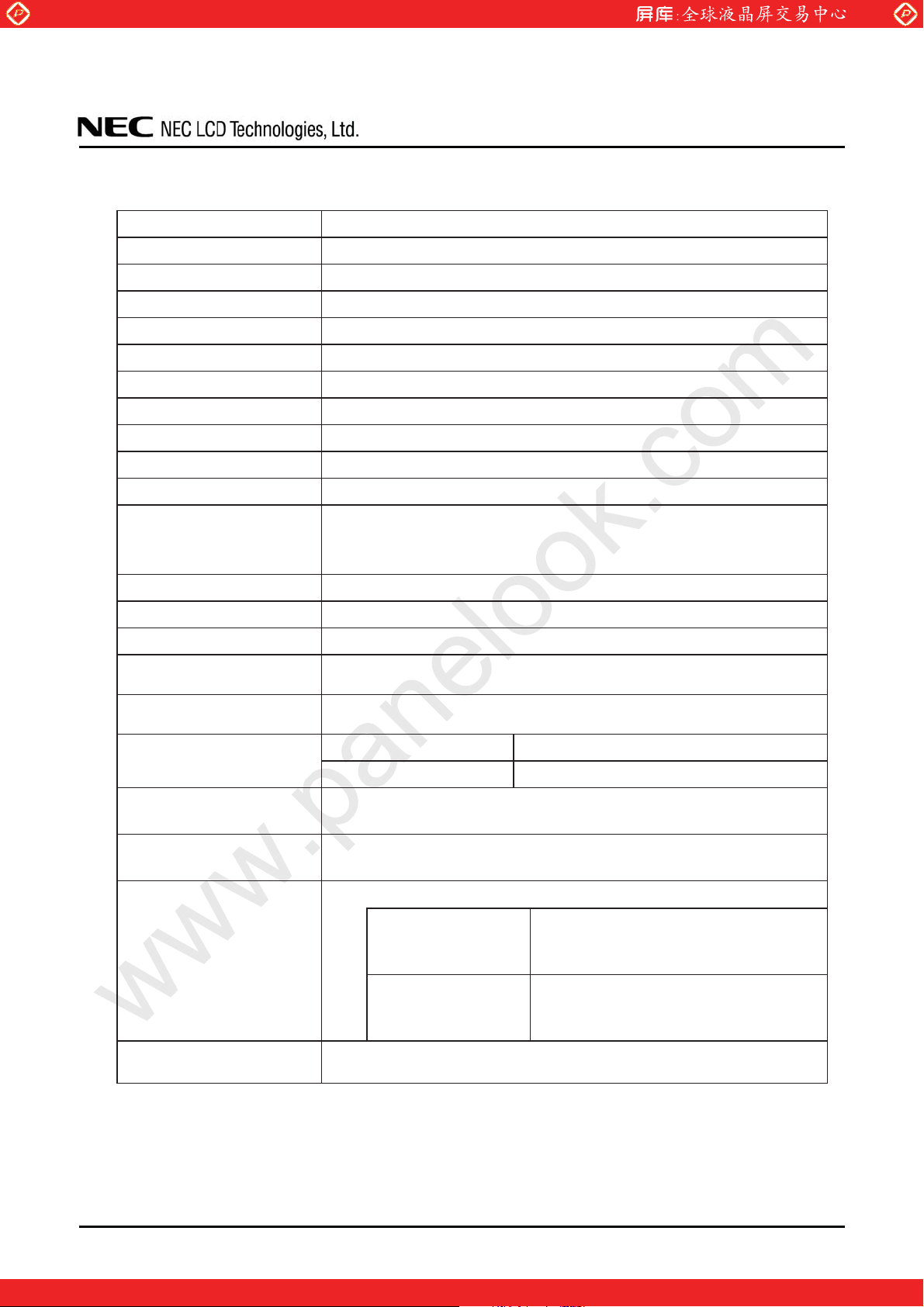

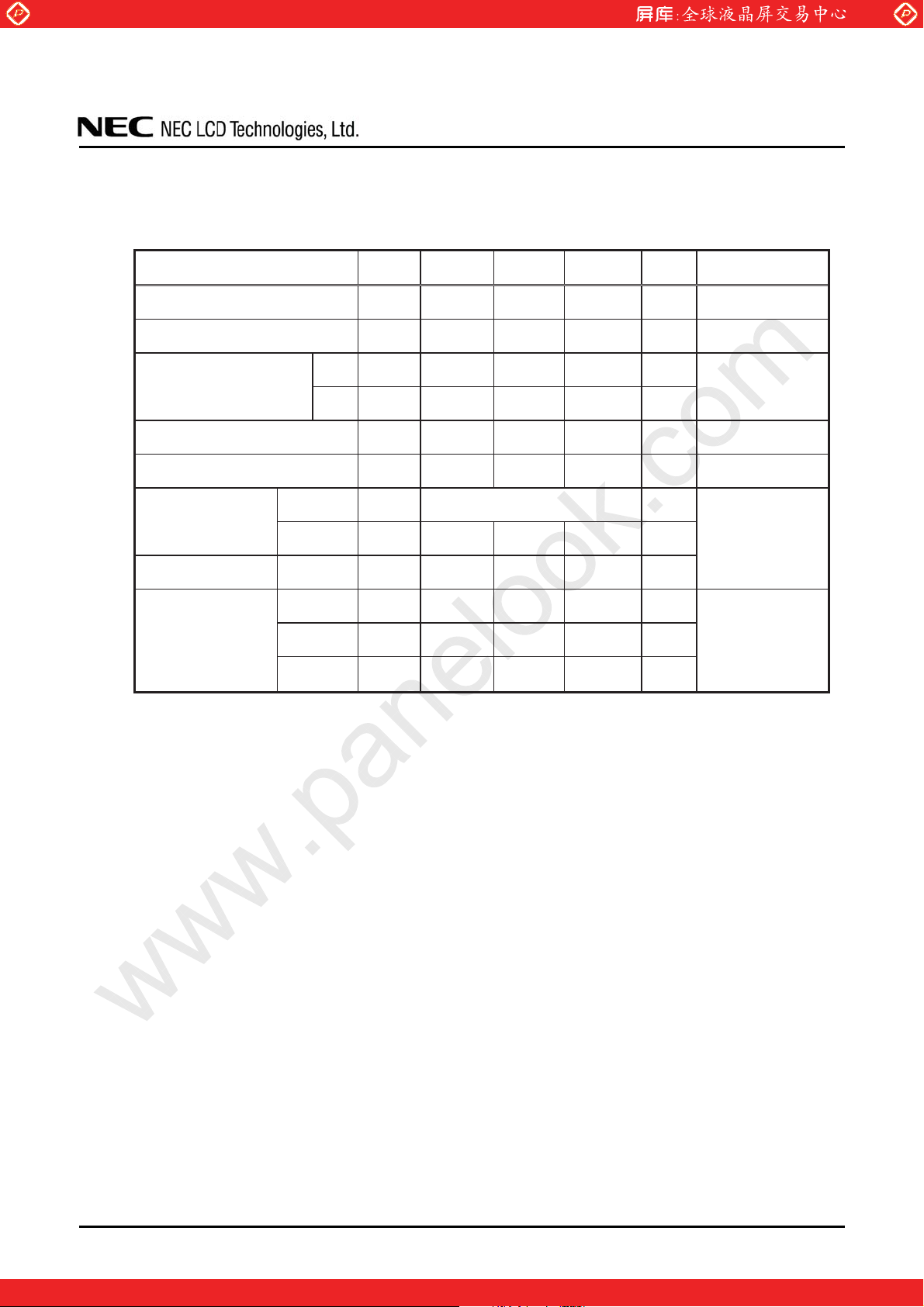

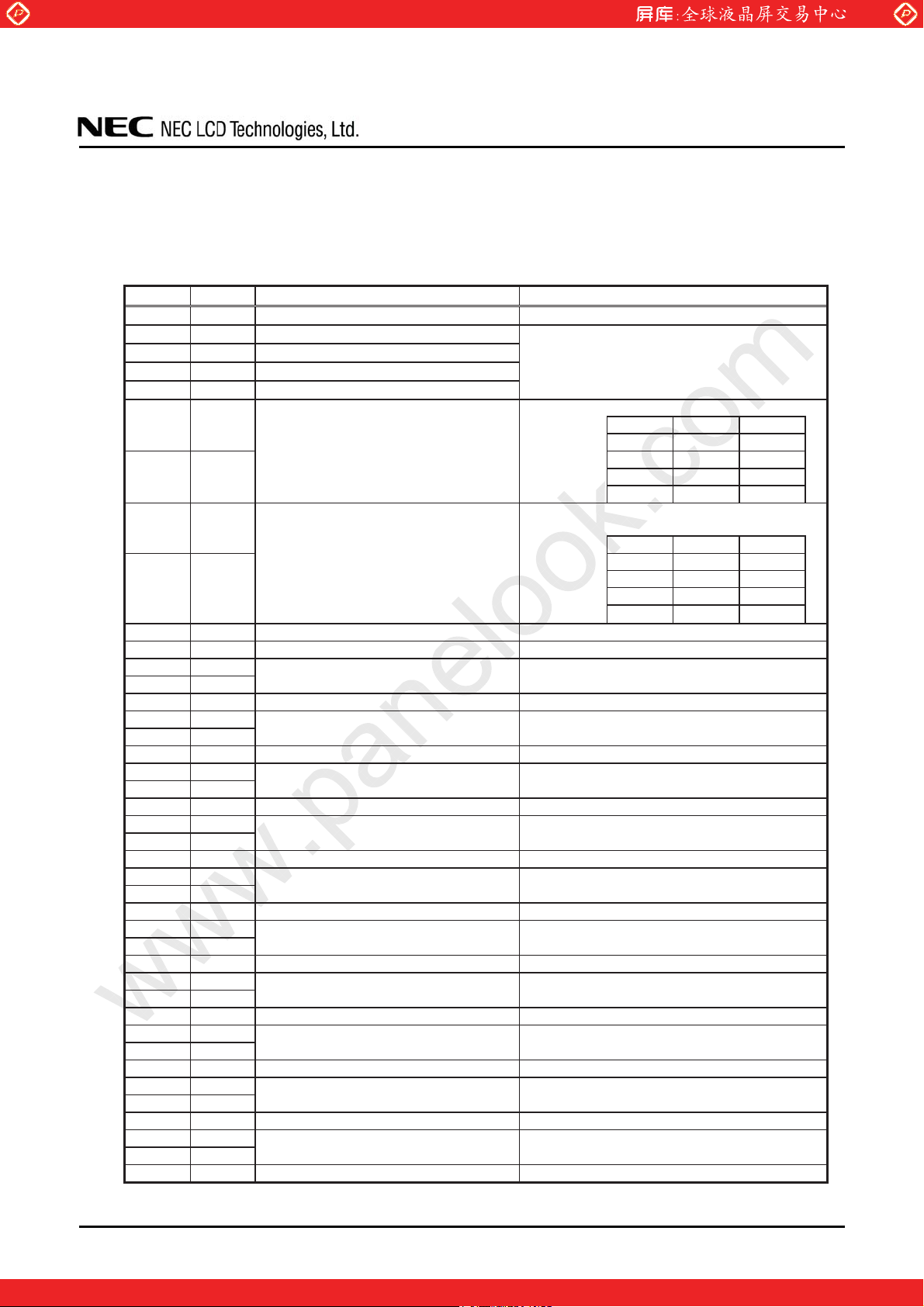

2. GENERAL SPECIFICATIONS

www.panelook.com

NL256204AM15-01/01A

Display area

Diagonal size of display

Drive system

Display gray scale

Pixel

Pixel arrangement

Sub-pixel pitch

Pixel pitch

Module size

Weig ht

Contrast ratio

Viewing angle

Designed viewing direction

Polarizer surface

Polarizer pencil-hardness

Response time

Luminance

White chromaticity

399.36 (H) u 319.488 (V) mm

51 cm (20.1 inches)

a-Si TFT active matrix

256 gray scales per 1 sub-pixel (8-bit) (766 gray scales per 1 pixel)

2,560 (H) u 2,048 (V) pixels (1 pixel consists of 3 sub pixels (LCR))

LCR Vertical stripe

0.052 (H) u 0.156 (V) mm

0.156 (H) u 0.156 (V) mm

423.4 (W) u 343.5 (H) u 43.5 (D) mm (typ.)

2,440 g (typ.)

600:1 (typ.)

t

At the contrast ratio

10:1

x Horizontal: Right side 85q (typ.), Left side 85q (typ.)

x Vertical: Up side 85q (typ.), Down side 85q (typ.)

Viewing angle with optimum grayscale (J=DICOM): normal axis Note1

Antiglare

2H (min.) [by JIS K5400]

Ton + Toff (10%

mo

90%)

30 ms (typ.)

At the maximum luminance control

850 cd/m

2

(typ.)

NL256204AM15-01 Wx, Wy = (0.255, 0.310) (typ.)

NL256204AM15-01A Wx, Wy = (0.280, 0.304) (typ.)

Signal system

Power supply voltage

4 ports LVDS interface

LCR 8-bit signals, Data enable signal (DE), Dot clock (CLK)

LCD panel signal processing board: 12.0V

Inverter: 12.0V

Direct light type: 12 cold cathode fluorescent lamps with an inverter

NL256204AM15-01

Backlight

NL256204AM15-01A

Power consumption

At checkered flag pattern and the maximum luminance control

49.2 W (typ.)

Note1: When the product luminance is 850cd/m

DATA SHEET DOD-PD-0887 (4th edition)

Replaceable parts

x Backlight unit: Type No.: 201LHS07

x Inverter: Type No.: 201PW121

Replaceable parts

x Backlight unit: Type No.: 201LHS08

x Inverter: Type No.: 201PW121

2

, the gamma characteristic is designed to J=DICOM.

5

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

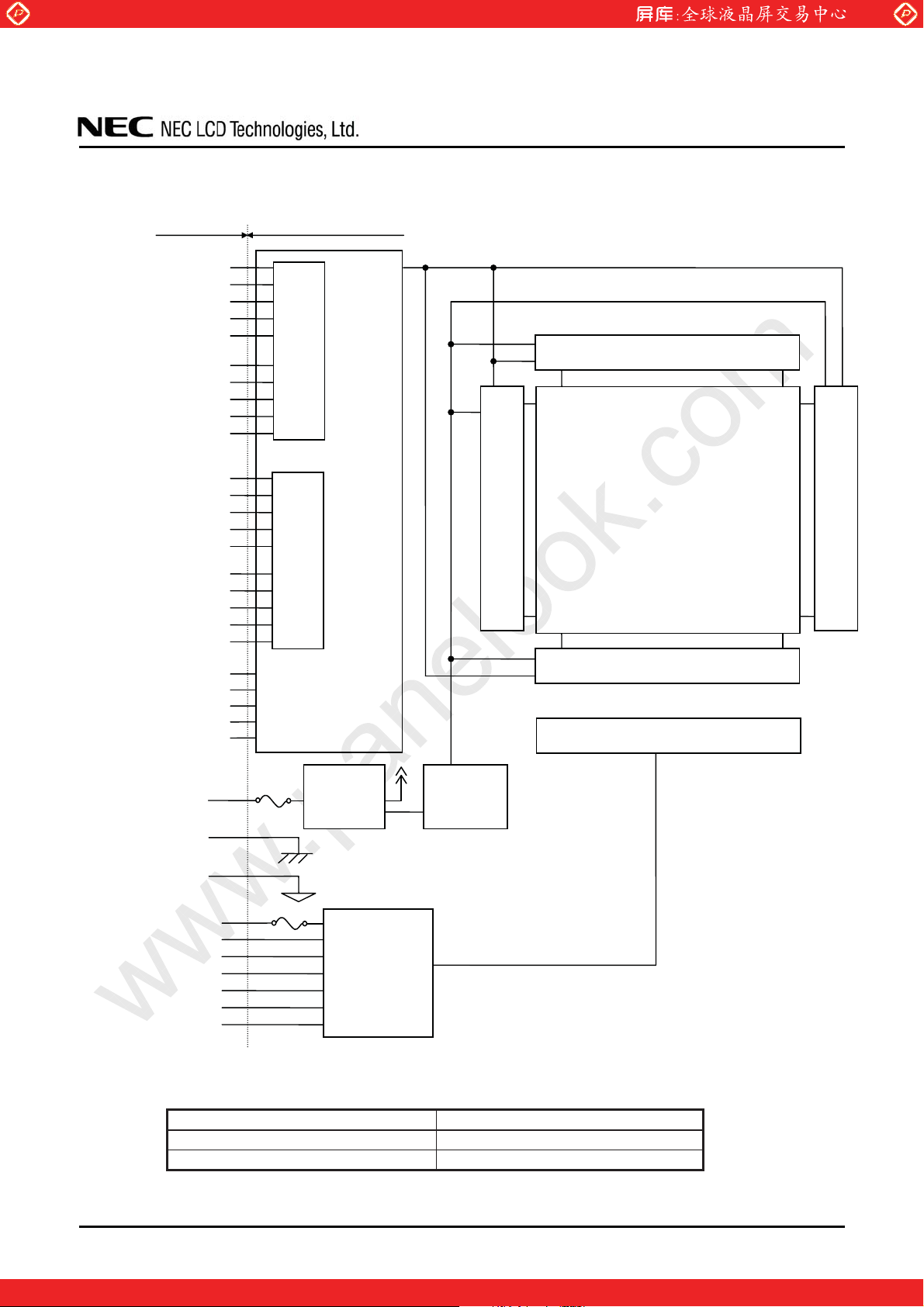

3. BLOCK DIAGRAM

Host LCD module (product)

DA0+/DA1+/DA2+/CKA+/DA3+/-

DB0+/DB1+/DB2+/CKB+/DB3+/-

DC0+/DC1+/DC2+/CKC+/DC3+/-

LVDS receiver

www.panelook.com

Controller

V-driver

2,048 lines

NL256204AM15-01/01A

H-driver

7,680 lines

TFT LCD panel

H: 2,560 u 3 (L, C, R)

V: 2,048

V-driver

DD0+/DD1+/DD2+/CKD+/DD3+/-

MOD>0:1@

BSEL>0:1@

CSR, CSL

SCLK

SDAT

VDD

GND

Note1, Note2

FG

Note1, Note2

VDDB

BRTC

BRTH

BRTI

BRTP

PWSEL

GNDB

Note1, Note2

Fuse

Fuse

LVDS receiver

Converter

DC/DC

H-driver

Backlight (Direct light type)

Power

supply for

drivers

Inverter

Note1: Connections between GND (Signal ground), FG (Frame ground) and GNDB (Inverter ground) in the

LCD module

GND - FG Not connected

GND - GNDB Not connected

FG - GNDB Not connected

Note2: GND, FG and GNDB must be connected to customer equipment’s ground, and it is recommended that

these grounds are connected together in customer equipment.

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

6

www.panelook.com

Global LCD Panel Exchange Center

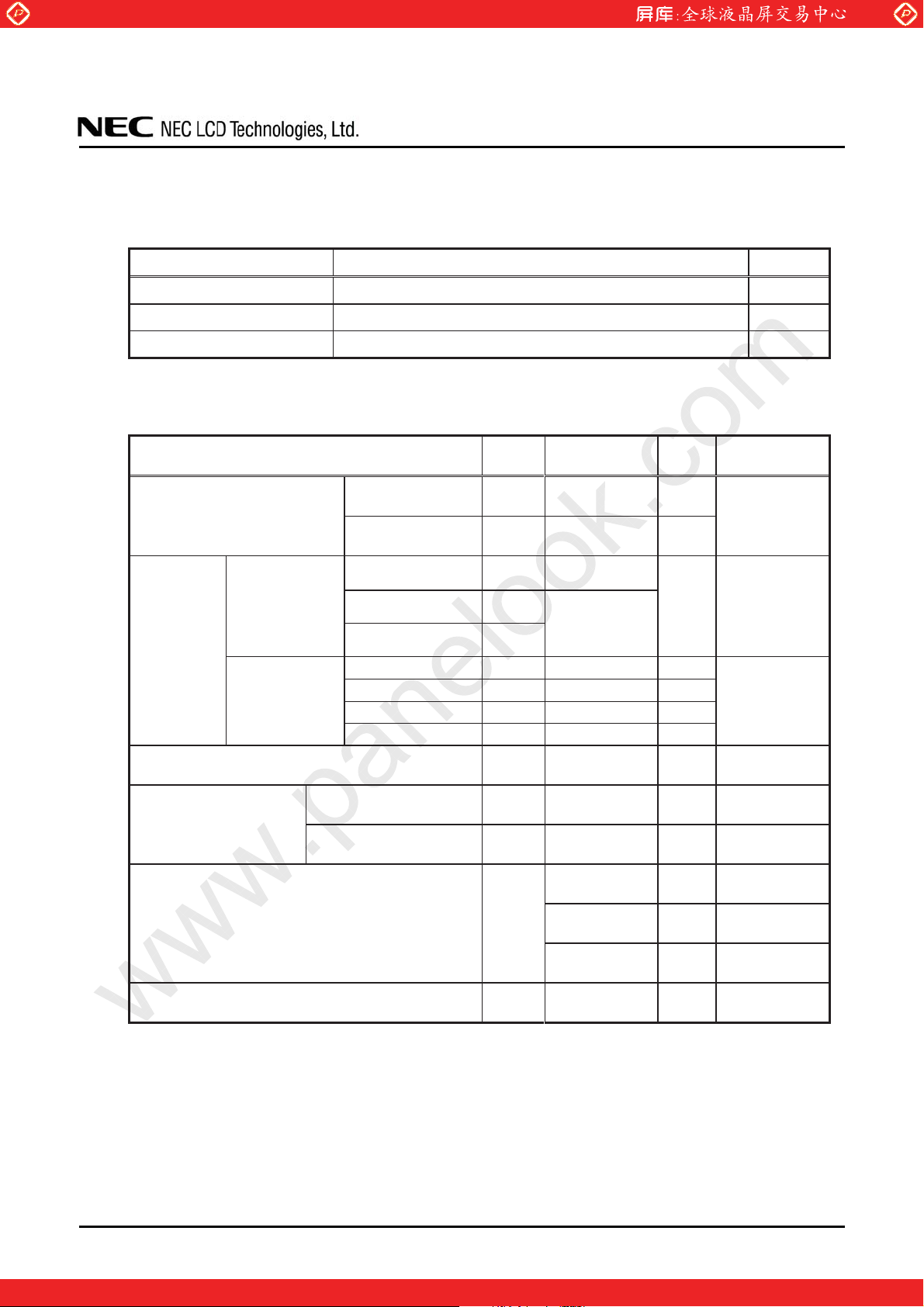

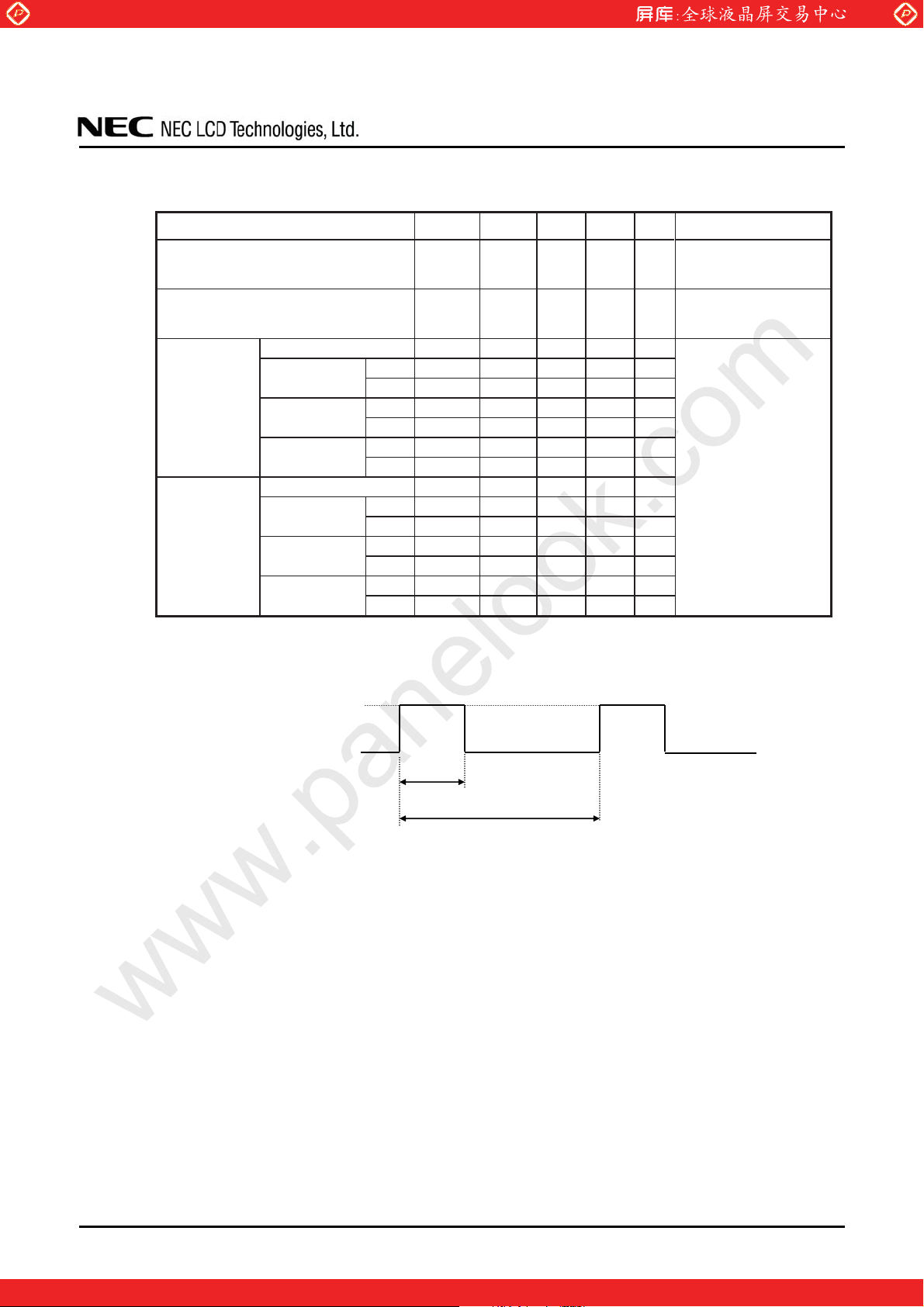

4. DETAILED SPECIFICATIONS

4.1 MECHANICAL SPECIFICATIONS

Parameter Specification Unit

www.panelook.com

NL256204AM15-01/01A

Module size

Display area

Weight 2,440 (typ.), 2,600 (max.) g

423.4 r 1.0 (W) u 343.5 r 1.0 (H) u 43.5 r 1.0 (D)

Note1: See "7. OUTLINE DRAWINGS".

4.2 ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Rating Unit Remarks

LCD panel signal

Power supply voltage

LCD panel signal

processing board

Input voltage

for signals

Inverter

processing board

Display signals

Function signal 1

Function signal 2

PWSEL signal VPSL -0.3 to +5.5 V

399.36 (H) u 319.488 (V)

VDD -0.3 to +15.0 V

Inverter VDDB -0.3 to +15.0 V

Note1

Note2

Note3

BRTI signal VBI -0.3 to +1.5 V

BRTP signal VBP -0.3 to +5.5 V

BRTC signal VBC -0.3 to +5.5 V

VD -0.3 to +3.6

VF1

-0.3 to +3.9

VF2

V

Note1 mm

Note1 mm

Ta = 25qC

Ta = 25qC

VDD=12.0V

Ta = 25qC

VDDB = 12.0V

Storage temperature Tst -20 to +60

Operating temperature

Relative humidity

Absolute humidity

Note6

Note6

Front surface TopF 0 to +55

Rear surface TopR 0 to +55

d 95

RH

AH

d 85

d 70

d 73

Note7

qC

qC

qC

%

%

%

g/m

3

-

Note4

Note5

Ta d 40qC

40 < Ta d 50qC

50 < Ta d 55qC

Ta > 55qC

Note1: DA0+/-, DA1+/-, DA2+/-, DA3+/-, CKA+/-, DB0+/-, DB1+/-, DB2+/-, DB3+/-, CKB+/-, DC0+/-,

DC1+/-, DC2+/-, DC3+/-, CKC+/-, DD0+/-, DD1+/-, DD2+/-, DD3+/-, CKD+/Note2: MOD0, MOD1, BSEL0, BSEL1

Note3: CSR, CSL, SCLK, SDAT

Note4: Measured at center of LCD panel surface (including self-heat)

Note5: Measured at center of LCD module's rear shield surface (including self-heat)

Note6: No condensation

Note7: Water amount at Ta = 55°C and RH = 70%

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

7

www.panelook.com

Global LCD Panel Exchange Center

4.3 ELECTRICAL CHARACTERISTICS

4.3.1 LCD panel signal processing board

Parameter Symbol min. typ. max. Unit Remarks

Power supply voltage VDD 10.8 12.0 13.2 V -

Power supply current IDD -

Differential input threshold

voltage for Display signals

Input voltage swing VI 0 - 2.4 V Note4

www.panelook.com

NL256204AM15-01/01A

900

Note1

High VTH - - +100 mV

Low VTL -100 - - mV

1,800

Note2

mA

(Ta = 25qC)

at VDD = 12.0V,

Mode 0 is selected.

at VCM= 1.2V

Note3, Note4

Terminating resistance RT - 100 -

Input voltage for

Function signal 1

Input current for

Function signal 1

Input voltage for

Function signal 2

High VFH1 High must be Open. -

Low VFL1 0 - 0.8 V

Low IFL1 -10 - 10

High V+ - - 2.3 V

Low V- 0.5 - - V

Hysteresis VH 0.4 - - V

:

Note5

PA

Note6

Note1: Checkered flag pattern [by EIAJ ED-2522]

Note2: Pattern for maximum current

Note3: Common mode voltage for LVDS receiver

Note4: DA0+/-, DA1+/-, DA2+/-, DA3+/-, CKA+/-, DB0+/-, DB1+/-, DB2+/-, DB3+/-, CKB+/-,

DC0+/-, DC1+/-, DC2+/-, DC3+/-, CKC+/-, DD0+/-, DD1+/-, DD2+/-, DD3+/-, CKD+/-.

Note5: MOD0, MOD1, BSEL0, BSEL1

Note6: CSR, CSL, SCLK, SDAT

-

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

8

www.panelook.com

Global LCD Panel Exchange Center

4.3.2 Inverter

Parameter Symbol min. typ. max. Unit Remarks

Power supply voltage VDDB 11.4 12.0 12.6 V -

Power supply current IDDB - 3,200 4,000

BRTI signal VBI 0 - 1.0 V

BRTP signal

Input voltage

for signals

Input current

for signals

BRTC signal

PWSEL signal

BRTI signal IBI -130 - -

BRTP signal

BRTC signal

PWSEL signal

www.panelook.com

NL256204AM15-01/01A

VDDB = 12.0V,

At the maximum

m$

luminance control

High VBPH 2.0 - 5.25 V

Low VBPL 0 - 0.8 V

High VBCH 2.0 - 5.25 V

Low VBCL 0 - 0.8 V

High VPSLH 2.0 - 5.25 V

Low VPSLL 0 - 0.8 V

P$

High IBPH - - 3.5 mA

Low IBPL -1.6 - - mA

High IBCH - - 440

Low IBCL -610 - -

High IPSLH - - 440

Low IPSLL -610 - -

P$

P$

P$

P$

(Ta = 25qC)

-

4.3.3 Inverter current wave

3,200 (mA) typ.

0 (A)

Duty

Luminance control frequency

Maximum luminance control: 100%

Minimum luminance control: 20%

Luminance control frequency: 285Hz (typ.)

Note1: Luminance control frequency indicate the input pulse frequency, when select the external pulse

control. See "4.6.2 Detail of PWM timing".

Note2: The power supply lines (VDDB and GNDB) have large ripple voltage (See "4.3.4 Power

supply voltage ripple".) during luminance control. There is the possibility that the ripple

voltage produces acoustic noise and signal wave noise in audio circuit and so on. Put a

capacitor (5,000 to 6,000PF) between the power supply lines (VDDB and GNDB) to reduce the

noise, if the noise occurred in the circuit.

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

9

www.panelook.com

Global LCD Panel Exchange Center

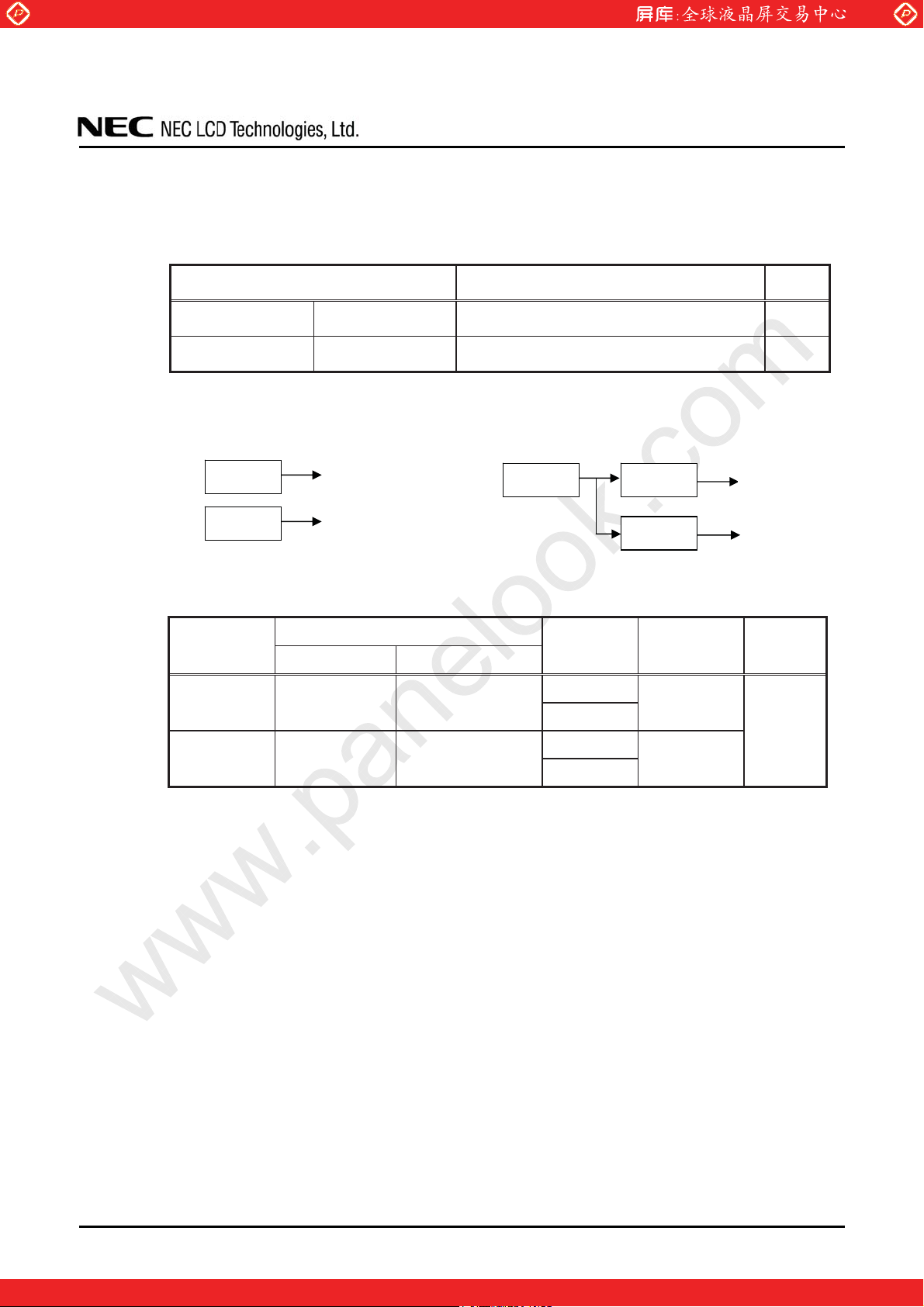

4.3.4 Power supply voltage ripple

This product works, even if the ripple voltage levels are beyond the permissible values as following

the table, but there might be noise on the display image.

www.panelook.com

NL256204AM15-01/01A

Power supply voltage

VDD 12.0 V

VDDB 12.0 V

Note1: The permissible ripple voltage includes spike noise.

Example of the power supply connection

a) Separate the power supply b) Put in the filter

Power

Power

VDD

VDDB

4.3.5 Fuse

Parameter

VDD

VDDB 0453007 Littelfuse Inc.

Type Supplier

FHC20 502AD

Note1: The power supply capacity should be more than the fusing current. If it is less than the fusing

current, the fuse may not blow in a short time, and then nasty smell, smoke and so on may

occur.

(Measure at input terminal of power supply)

Fuse

KAMAYA ELECTRIC

Co., Ltd.

Ripple voltage Note1

d 100

d 200

Power

Rating Fusing current Remarks

5A

24V

7A

125V

Filter

Filter

12.5A,

5s max.

14A,

5s max.

Unit

mVp-p

mVp-p

VDD

VDDB

Note1

ყ

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

10

www.panelook.com

Global LCD Panel Exchange Center

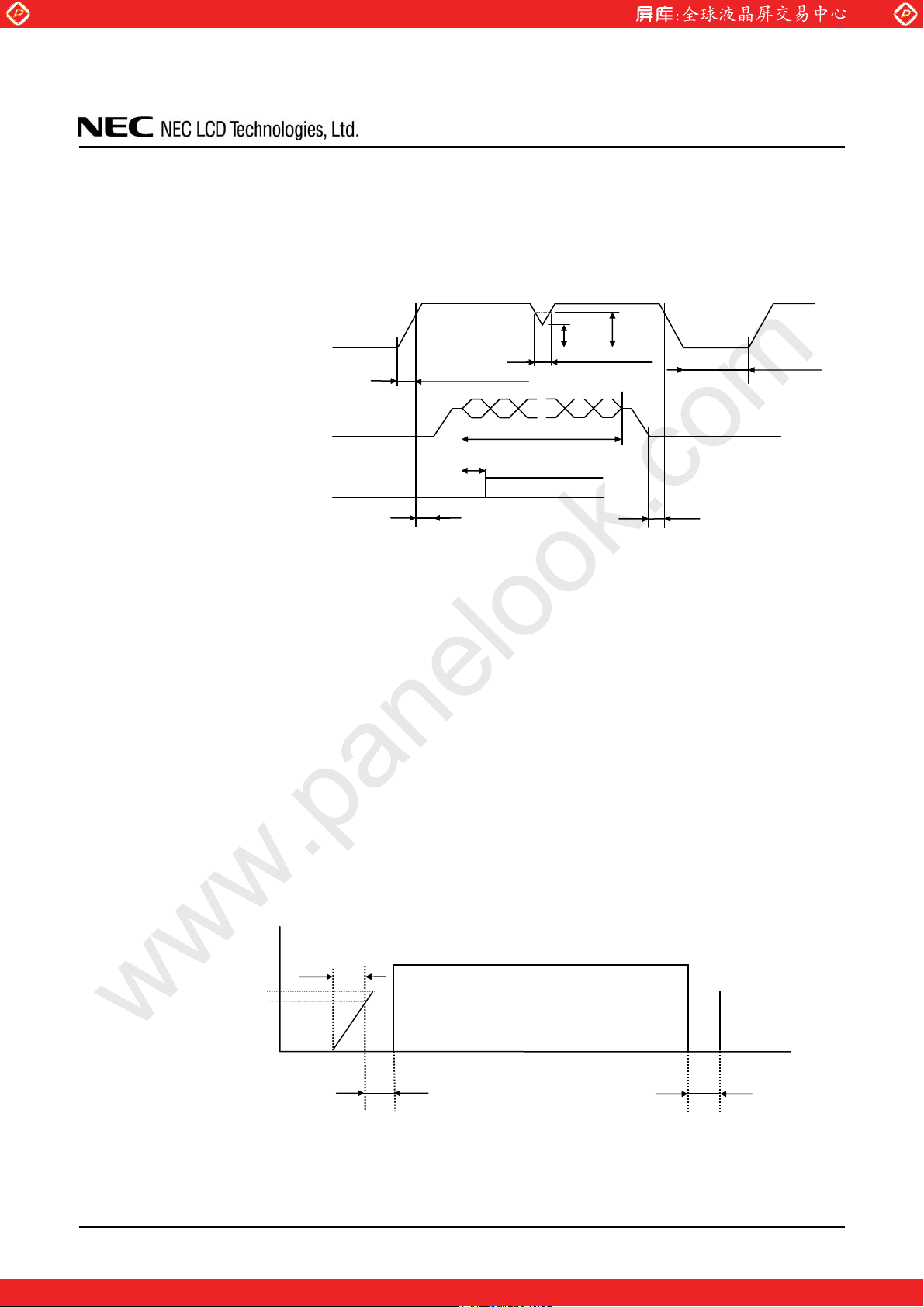

4.4 POWER SUPPLY VOLTAGE SEQUENCE

4.4.1 LCD panel signal processing board

www.panelook.com

NL256204AM15-01/01A

VDD

Note1, Note2

0V

VDD ON

10.8V

9.6V

VDD dip < 20ms

5ms < Tr < 80ms

VDD OFF

10.8V

VDD ON

10.8V

Tof f > 50ms

LVDS Signals *1,*2

Note3

0V

CSR, CSL, SCLK, SDAT

Note3

0V

10ms < t < 35ms

VALID period

tt20ms Note4

VALID period

0ms < t < 35ms

*1: DA0+/-, DA1+/-, DA2+/-, DA3+/-, CKA+/-, DB0+/-, DB1+/-, DB2+/-, DB3+/-, CKB+/-,

DC0+/-, DC1+/-, DC2+/-, DC3+/-, CKC+/-, DD0+/-, DD1+/-, DD2+/-, DD3+/-, CKD+/-

*2: LVDS signals should be measured at the terminal of 100: resistance.

Note1: In terms of voltage variation (voltage drop) while VDD rising edge is below 10.8V, a protection

circuit may work, and then this product may not work.

Note2: VDD should be 10.8V or more during VDD ON period.

Note3: LVDS signals and CSR, CSL, SCLK, SDAT must be Low or High-impedance, exclude the

VALID period (See above sequence diagram), in order to avoid that internal circuits is

damaged.

If some of signals are cut while this product is working, even if the signal input to it once again,

it might not work normally. If customer stops the display and function signals, they should be

cut VDD.

Note4: At the beginning of the serial communication mode, take 20ms or more after the LVDS signal

input.

4.4.2 Inverter

Voltage

12.0V

td800ms

BRTC

VDDB

11.4V

0<t

Note1: The inverter power supply voltage (VDDB) should be inputted within the valid period of LVDS

signals, in order to avoid unstable data display.

Note2: If tr is more than 800ms, the backlight will be turned off by a protection circuit for inverter.

Note3: When VDDB is 0V or BRTC is Low, PWSEL must be set to Low or Open.

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Time

0<t

11

www.panelook.com

Global LCD Panel Exchange Center

4.5 CONNECTIONS AND FUNCTIONS FOR INTERFACE PINS

4.5.1 LCD panel signal processing board

CN1 socket (LCD module side): FI-W41P-HF (Japan Aviation Electronics Industry Limited (JAE))

Adaptable plug: FI-W41S (Japan Aviation Electronics Industry Limited (JAE))

Pin No. Symbol Signal Remarks

1 GND Signal ground Note1

2 CSR Chip selection R

3 CSL Chip selection L

4 SCLK Serial Clock

5 SDAT Serial Data

6 MOD0

Selection of LVDS Data Transmission Mode

(Pull-up 25k:)

7 MOD1

8 BSEL0

Selection of LVDS data input map

(Pull-up 25k:)

9 BSEL1

10 RSVD Reserved Keep this pin Open.

11 GND Signal ground Note1

12 DB3+

13 DB314 GND Signal ground Note1

15 CKB+

16 CKB17 GND Signal ground Note1

18 DB2+

19 DB220 GND Signal ground Note1

21 DB1+

22 DB123 GND Signal ground Note1

24 DB0+

25 DB026 GND Signal ground Note1

27 DA3+

28 DA329 GND Signal ground Note1

30 CKA+

31 CKA32 GND Signal ground Note1

33 DA2+

34 DA235 GND Signal ground Note1

36 DA1+

37 DA138 GND Signal ground Note1

39 DA0+

40 DA041 GND Signal ground Note1

Pixel data B3 LVDS differential data input Note2

Pixel clock B LVDS differential clock input Note2

Pixel data B2 LVDS differential data input Note2

Pixel data B1 LVDS differential data input Note2

Pixel data B0 LVDS differential data input Note2

Pixel data A3 LVDS differential data input Note2

Pixel clock A LVDS differential clock input Note2

Pixel data A2 LVDS differential data input Note2

Pixel data A1 LVDS differential data input Note2

Pixel data A0 LVDS differential data input Note2

www.panelook.com

NL256204AM15-01/01A

LUT communication control signal

See "4.13 TEN-bit LOOK UP TABLE FOR

GAMMA ADJUSTMENT".

See "4.10 LVDS DATA TRANSMISSION MODE".

MOD0 MOD1 Mode

Open Open 0

Open Low 1

Low Open Reserved

Low Low 0

See "4.7 METHOD OF CONNECTION FOR

LVDS TRANSMITTER".

BSEL0 BSEL1 Mode

Open Open A

Open Low B

Low Open C

Low Low A

DATA SHEET DOD-PD-0887 (4th edition)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

12

www.panelook.com

Loading...

Loading...