TFT COLOR LCD MODULE

NL2432HC22-41K

8.9cm (3.5 Type)

QVGA

DATA SHEET

DOD-PP-0307 (2nd edition)

This DATA SHEET is updated document from

DATA SHEET DOD-PP-0184(1).

All information is subject to change without notice.

Please confirm the sales representative before

starting to design your system.

Document Number: DOD-PP-0307 (2nd edition)

Published date: July 2007 CP(N)

1

© NEC LCD Technologies, Ltd.

2007 All rights reserved.

NL2432HC22-41K

INTRODUCTION

The Copyright to this document belongs to NEC LCD Technologies, Ltd. (hereinafter called "NEC").

No part of this document will be used, reproduced or copied without prior written consent of NEC.

NEC does and will not assume any liability for infringement of patents, copyrights or other intellectual

property rights of any third party arising out of or in connection with application of the products

described herein except for that directly attributable to mechanisms and workmanship thereof. No license,

express or implied, is granted under any patent, copyright or other intellectual property right of NEC.

Some electronic parts/components would fail or malfunction at a certain rate. In spite of every effort to

enhance reliability of products by NEC, the possibility of failures and malfunction might not be avoided

entirely. To prevent the risks of damage to death, human bodily injury or other property arising out

thereof or in connection therewith, each customer is required to take sufficient measures in its safety

designs and plans including, but not limited to, redundant system, fire-containment and anti-failure.

The products are classified into three quality grades: "Standard", "Special", and "Specific" of the

highest grade of a quality assurance program at the choice of a customer. Each quality grade is designed

for applications described below. Any customer who intends to use a product for application other than

that of Standard quality grade is required to contact an NEC sales representative in advance.

The Standard quality grade applies to the products developed, designed and manufactured in

accordance with the NEC standard quality assurance program, which are designed for such application as

any failure or malfunction of the products (sets) or parts/components incorporated therein a customer uses

are, directly or indirectly, free of any damage to death, human bodily injury or other property, like general

electronic devices.

Examples: Computers, office automation equipment, communications equipment, test and measurement

equipment, audio and visual equipment, home electronic appliances, machine tools, personal

electronic equipment, industrial robots, etc.

The Special quality grade applies to the products developed, designed and manufactured in accordance

with an NEC quality assurance program stricter than the standard one, which are designed for such

application as any failure or malfunction of the products (sets) or parts/components incorporated therein a

customer uses might directly cause any damage to death, human bodily injury or other property, or such

application under more severe condition than that defined in the Standard quality grade without such

direct damage.

Examples: Control systems for transportation equipment (automobiles, trains, ships, etc.), traffic control

systems, anti-disaster systems, anti-crime systems, medical equipment not specifically

designed for life support, safety equipment, etc.

The Specific quality grade applies to the products developed, designed and manufactured in accordance

with the standards or quality assurance program designated by a customer who requires an extremely

higher level of reliability and quality for such products.

Examples: Military systems, aircraft control equipment, aerospace equipment, nuclear reactor control

systems, medical equipment/devices/systems for life support, etc.

The quality grade of this product is the "Standard" unless otherwise specified in this document.

DATA SHEET DOD-PP-0307 (2nd edition)

2

NL2432HC22-41K

CONTENTS

INTRODUCTION ..........................................................................................................................................

1. OUTLINE....................................................................................................................................................

1.1 STRUCTURE AND PRINCIPLE...........................................................................................................

1.2 APPLICA TION.......................................................................................................................................

1.3 FEATURES.............................................................................................................................................

2. GENERAL SPECIFICATIONS ................................................................................................................5

3. BLOCK DIAGRAM...................................................................................................................................

4. DETAILED SPECIFICATIONS...............................................................................................................

4.1 MECHANICAL SPECIFICATIONS......................................................................................................

4.2 ABSOLUTE MAXIMUM RATINGS....................................................................................................

4.3 ELECTRICAL CHARACTERISTICS...................................................................................................

4.4 SETTING OF THE INTERNAL RESISTER.......................................................................................

4.5 INTERFACE PIN CONNECTIONS ....................................................................................................

4.6 DISPLAY COLORS AND INPUT DATA SIGNALS ..........................................................................

4.7 DISPLAY POSITIONS.........................................................................................................................

4.8 SCANNING DIRECTIONS.................................................................................................................

4.9 INPUT SIGNAL TIMINGS..................................................................................................................

4.9.1 RGB interface (Ta= 25°C, VCC= 3.0V)......................................................................................

4.9.2 Serial interface (Ta= 25°C, VCC= 3.0V).....................................................................................

4.10 OPTICAL CHARACTERISTICS ......................................................................................................

5. RELIABILITY TESTS.............................................................................................................................

6. PRECAUTIONS .......................................................................................................................................

6.1 MEANING OF CAUTION SIGNS......................................................................................................

6.2 CAUTIONS..........................................................................................................................................

6.3 A TTENTI ONS......................................................................................................................................

6.3.1 Handling of the product...............................................................................................................

6.3.2 Environment.................................................................................................................................

6.3.3 Characteristics..............................................................................................................................

6.3.4 Other............................................................................................................................................

7. OUTLINE DRAWINGS...........................................................................................................................

8. RECOMMENDED DESIGN OF FRONT BEZEL................................................................................

2

4

4

4

4

6

8

8

8

9

11

14

16

17

17

18

18

21

22

25

26

26

26

26

26

27

27

27

28

29

DATA SHEET DOD-PP-0307 (2nd edition)

3

1. OUTLINE

1.1 STRUCTURE AND PRINCIPLE

Color LCD module NL2432HC22-41K is composed of the amorphous silicon thin film transistor liquid

crystal display (a-Si TFT LCD) panel structure with driver LSIs for driving the TFT (Thin Film

Transistor) array, touch panel (T/P) and a backlight.

The a-Si TFT LCD panel structure is injected liquid crystal material into a narrow gap between the TFT

array glass substrate and a color-filter glass substrate.

Color (Red, Green, Blue) data signals from a host system (e.g. signal generator, etc.) are modulated into

best form for active matrix system by a controller, and sent to the driver LSIs which drive the individual

TFT arrays.

The TFT array as an electro-optical switch regulates the amount of transmitted light from the backlight

assembly, when it is controlled by data signals. Color images are created by regulating the amount of

transmitted light through the TFT array of red, green and blue dots.

1.2 APPLICATION

• PDAs

1.3 FEATURES

• Adoption of SR-NLT (Super-Reflective Natural Light TFT) (Transflective type)

• Backlight and touch panel attached

• High luminance

• High contrast

• Including LCD controller and power supply

• 6-bit digital RGB signals

• Compliance with the European RoHS directive (2002/95/EC)

NL2432HC22-41K

DATA SHEET DOD-PP-0307 (2nd edition)

4

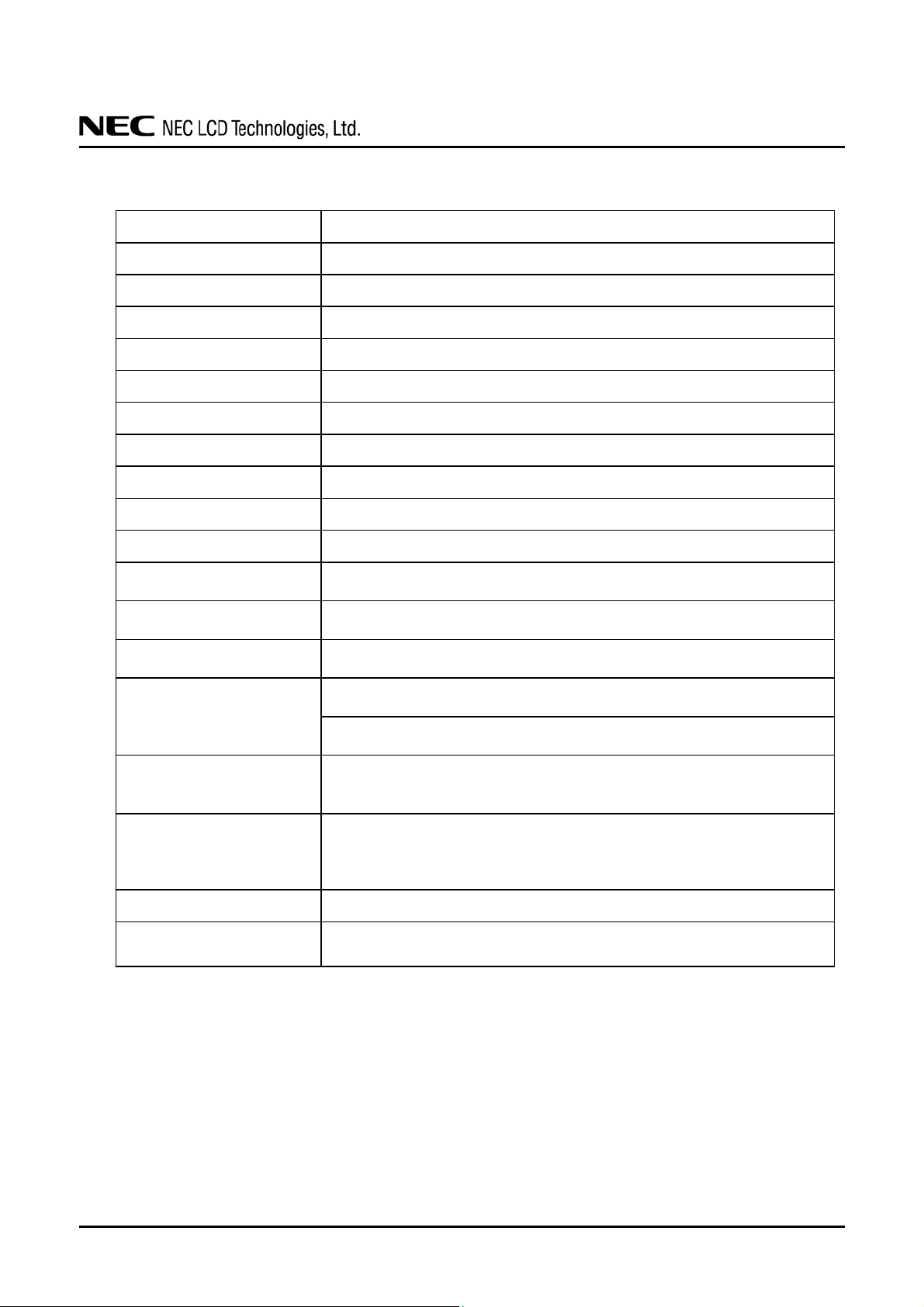

2. GENERAL SPECIFICAT IONS

Display area

NL2432HC22-41K

53.64 (W) × 71.52 (H) mm

Diagonal size of display

Drive system

Display color

Pixel

Pixel arrangement

Dot pitch

Pixel pitch

Module size

Weight

Touch panel surface

Touch panel

pencil-hardness

Luminance

Reflection ratio

Contrast ratio

Response time

Signal system

Supply voltage

8.9 cm (3.5 inches)

a-Si TFT active matrix

262,144 colors

240 (H) × 320 (V) pixels

RGB (Red dot, Green dot, Blue dot) vertical stripe

0.0745 (H) × 0.2235 (V) mm

0.2235 (H) × 0.2235 (V) mm

63.5 (H) × 85.0 (V) × 4.2 (D) mm (typ.)

43g (typ.)

Clear

3H (min.) [by JIS K5400]

At IL= 20mA, with Touch panel

200cd/m

2

(typ.)

With Touch panel

15% (typ.)

At transmissive mode, IL= 20mA, with Touch panel

150:1 (typ.)

At reflective mode, with Touch panel

15:1 (typ.)

←→

Ton+Toff (10%

90%)

30 ms (typ., at transmissive mode)

16 ms (typ., at reflective mode)

6-bit digital signals for data of RGB colors, Dot clock (CLK),

Horizontal synchronous signal (HSYNC),

Vertical synchronous signal (VSYNC)

Serial interface (SPI correspondence) (/CS, SCL, SI)

VCC: 3.0V (typ.)

Power consumption

LCD panel: 50 mW (typ.)

Backlight: 384mW (typ., at IL=20mA)

DATA SHEET DOD-PP-0307 (2nd edition)

5

r

t

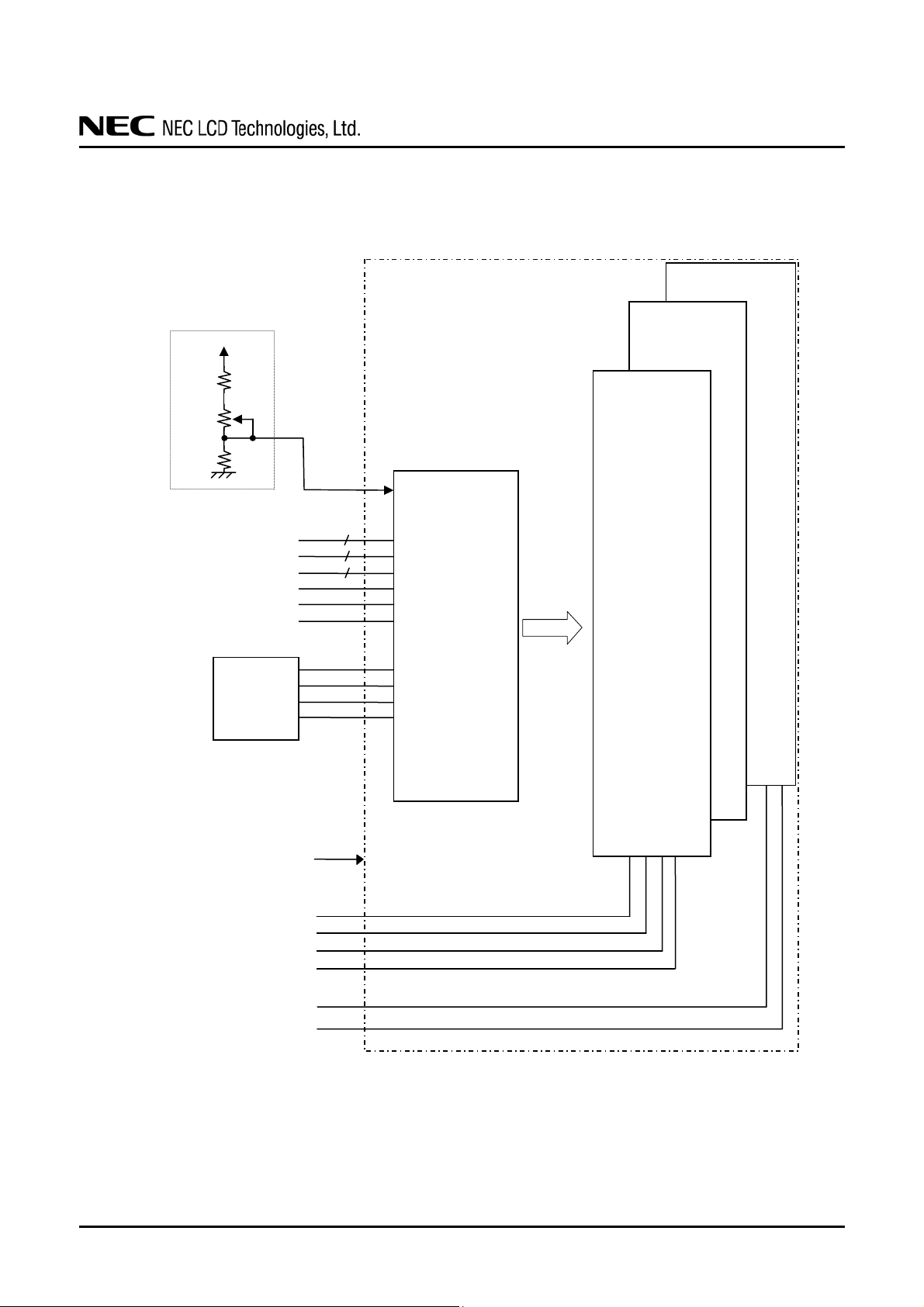

3. BLOCK DIAGRAM

COM circuit diagram

(Example of connection)

Power supply

Input

CPU

/RESET

/CS

SCL

SI

Touch panel

Backligh

NL2432HC22-41K

Product (LCD panel + Driver + Backlight + Touch panel (T/P))

Backlight

LCD panel

Touch panel

(T/P)

VCOMIN

D20 to D25

D10 to D15

D00 to D05

CLK

VSYNC

HSYNC

/RESET

/CS

SCL

SI

Anode

VCC

Drive

XL

YD

XR

YU

Cathode

DATA SHEET DOD-PP-0307 (2nd edition)

6

NL2432HC22-41K

FPC I/F

Pin No.

13 to 18

19 to 24

25 to 30

10

9

11

8

35

32

33

36

3, 4, 5, 6

1, 2, 7, 12,

31, 38, 43

39, 40,

41, 42

44

45

Reference design of COM circuit

6220kΩ

100kΩ

56

68kΩ

D00 to D05

D10 to D15

D20 to D25

VSYNC

HSYNC

CLK

/RESET

/CS

SCL

SI

VCOMIN

VCC

GND

XL, YD

XR, YU

ANODE

CATHODE

5

3V

Symbol

720 lines

LCD panel

320 lines

H: 240 × 3 (R, G, B)

V: 320

Driver

Touch panel

+3.0V

Backlight

VCOMIN

DATA SHEET DOD-PP-0307 (2nd edition)

7

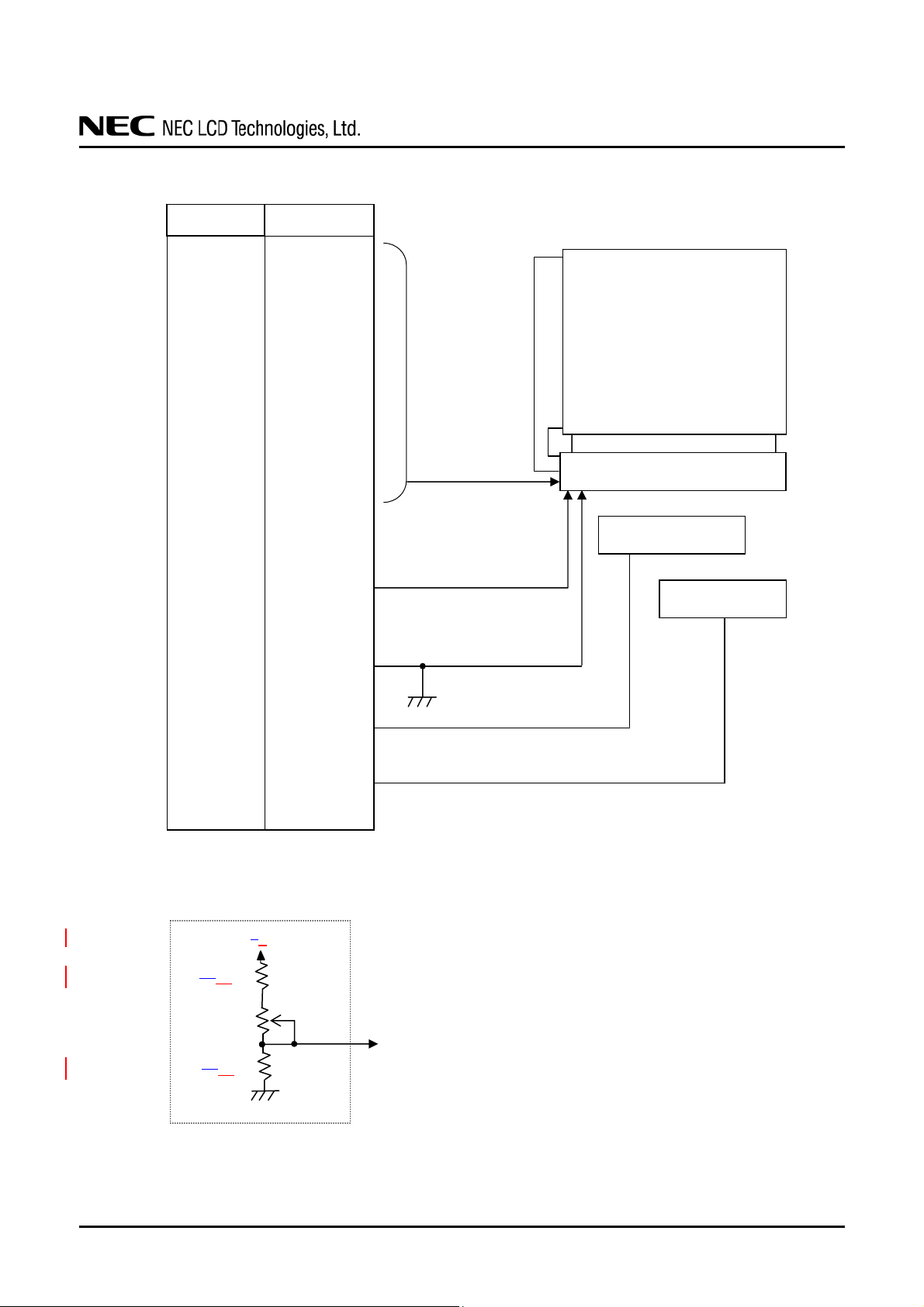

4. DETAILED SPECIFICATIONS

4.1 MECHANICAL SPECIFICATIONS

Parameter Specification Unit

Module size

Display area 53.64 (H) × 71.52 (V) Note2 mm

Weight 43 (typ.), 45 (max.) g

Note1: Excluding FPC

Note2: See "7. OUTLINE DRAWINGS".

4.2 ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Rating Unit Remarks

63.5 ± 0.3 (W) × 85.0 ± 0.3 (H) × 4.2 ± 0.2 (D)

Note1

NL2432HC22-41K

Note2 mm

Supply voltage VCC -0.5 to +6.0 V

Logic input voltage VI -0.5 to VCC+0.5 V Logic signals

Reverse voltage VR

Power dissipation PD

Backlight

Storage temperature Tst -30 to +80 Operating temperature Top -20 to +70

Relative humidity

Absolute humidity

Storage altitude

Operating altitude

Forward current IL Note1 mA

Pulse forward current IFP 100 mA

Note3

Note3

RH

AH

≤ 30

≤ 738

≤ 95 Ta≤ 40°C

≤ 85 40°C <Ta≤ 50°C

≤ 70

≤ 73

Note4

≤ 13,600

≤ 4,850

V

mW

°C

%

g/m

m

m

3

Ta= 25°C

Ta= 25°C

Pulse width ≤ 10ms,

Duty ≤ 1/10

Product surface Note2

50°C <Ta≤ 55°C

Ta> 55°C

-30°C ≤ Ta ≤ 80°C

-20°C ≤ Ta ≤ 70°C

Note1: Allowable forward current

40

35

30

25

20

15

10

5

0

Allowable forward current [mA]

0 20 40 60 80 100

Ambient temperature Ta [

°C

]

℃

35mA (27°C)

8.5m

Note2: Measured at display area

Note3: No condensation

Note4: Water amount at Ta= 55°C and RH= 70%

DATA SHEET DOD-PP-0307 (2nd edition)

8

NL2432HC22-41K

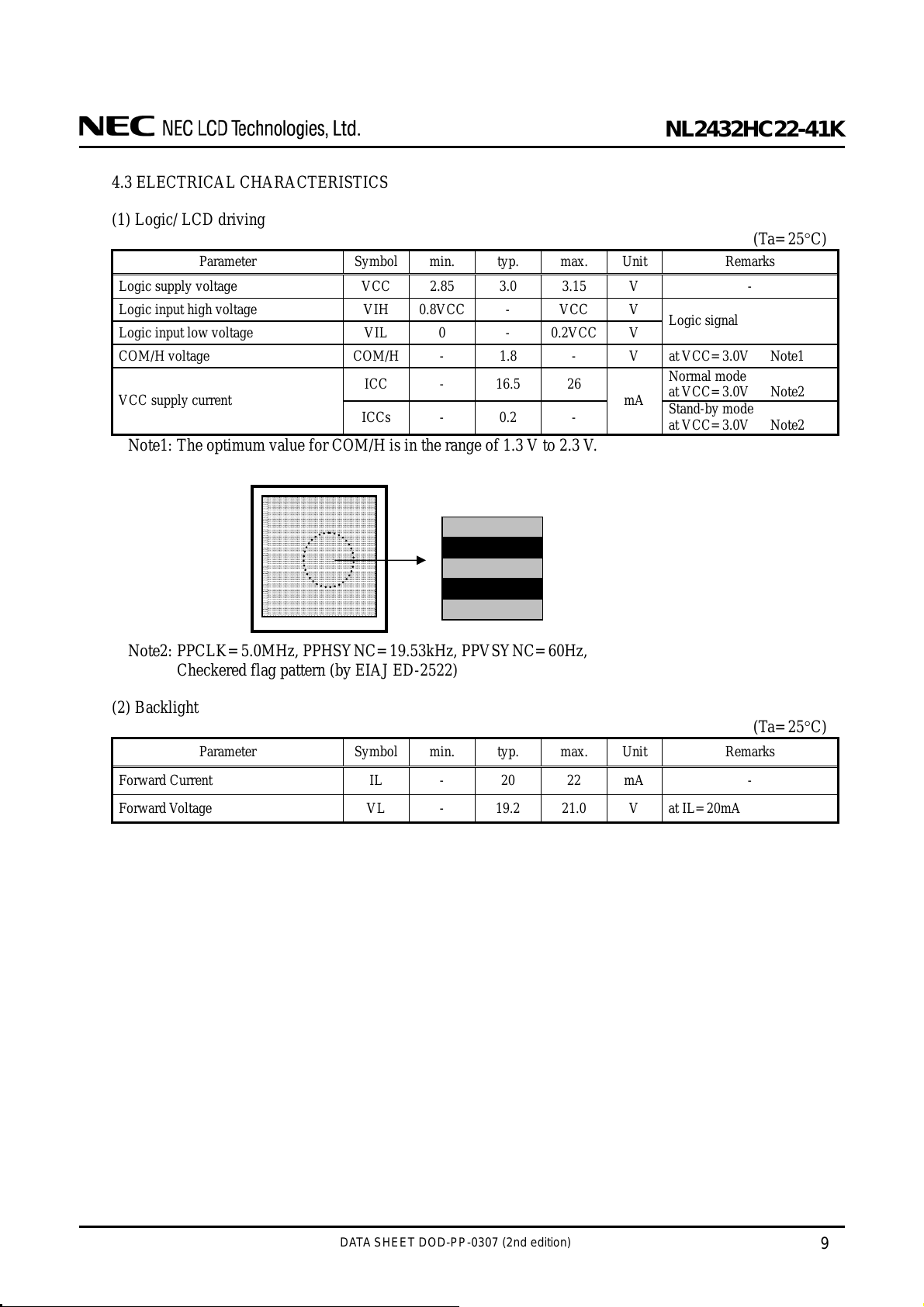

4.3 ELECTRICAL CHARACTERISTICS

(1) Logic/ LCD driving

(Ta= 25°C)

Parameter Symbol min. typ. max. Unit Remarks

Logic supply voltage VCC 2.85 3.0 3.15 V -

Logic input high voltage VIH 0.8VCC - VCC V

Logic input low voltage VIL 0 - 0.2VCC V

COM/H voltage COM/H - 1.8 - V at VCC= 3.0V Note1

ICC - 16.5 26

VCC supply current

ICCs - 0.2 -

Note1: The optimum value for COM/H is in the range of 1.3 V to 2.3 V.

Recommended adjustment display for COM/H

Half tone display (32/63 gray scale)

Full black display (0/63 gray scale)

Half tone display (32/63 gray scale)

Full black display (0/63 gray scale)

Half tone display (32/63 gray scale)

Note2: PPCLK= 5.0MHz, PPHSYNC= 19.53kHz, PPVSYNC= 60Hz,

Checkered flag pattern (by EIAJ ED-2522)

(2) Backlight

Parameter Symbol min. typ. max. Unit Remarks

Logic signal

Normal mode

at VCC= 3.0V Note2

mA

Stand-by mode

at VCC= 3.0V Note2

(Ta= 25°C)

Forward Current IL - 20 22 mA -

Forward Voltage VL - 19.2 21.0 V at IL= 20mA

DATA SHEET DOD-PP-0307 (2nd edition)

9

NL2432HC22-41K

(3) T ouch panel

(Ta= 25°C)

Parameter Symbol min. typ. max. Unit Remarks

Touch panel input voltage Vtp - - 5.5 V Resistor between pins(XL-XR) Rx 190 - 500

Resistor between pins(YU-YD) Ry 140 - 540

Line linearity (X direction) Xlin - - 1.5 % Note1

Line linearity (Y direction) Ylin - - 1.5 % Note1

Insulation resistance Rins 20 - Static Capacitance Ctp - - 100 nF Chattering Chat - - 10 ms Note1

Operation starting force Ost - Surface hardness Hs 3 - - H Pencil hardness

Lhp 1,000,000 - - times

Point hitting life

Lhr 1,000,000 - - times

Line writing life Lwl 50,000 - - times

0.78 N

80 gf

Ω

Ω

at DC 25V

MΩ

Note1, Note2

Polyacetal stylus pen: R0.8mm

Load: 2.45N(250gf)

Silicon rubber:

R8mm, Hardness 60°

Load: 2.94N(300gf)

Polyacetal stylus pen: R0.8mm

Load: 2.45N(250gf), 35mm

Note1: Input methods are a Finger or R0.8mm Polyacetal Stylus Pen

Note2: Test condition

Resistance between X and Y axis must be 2kΩ or less, and the test voltage is 5V DC.

-

-

DATA SHEET DOD-PP-0307 (2nd edition)

10

y

4.4 SETTING OF THE INTERNAL RESISTER

Initial setting of the internal Resister is undefined data. So the Resister Data must be written in the Resister,

after initialization by the /RESET pin. The Resister Data can be written from serial interface pins (/CS, SCL

and SI). The setting method is as follows.

(1) Command Byte Function

Bits Functions Discription

A7 - A6 - A5 Read / Write 0:Write 1:Read

A4 - A3 - A2 - A1 - A0 Register Number / Data 0:Register Number 1:Register Data

(2) Timing chart

/CS

SCL

SI

A7 A6 A5 A4 A3

Command Byte Data Byte

Ex) When data 55h is written to Register R26 (R1Ah)

1st byte 2nd byte

/CS

SCL

SI

X X 0 X

Specify to transfer of the resister

number value at the next transfer

te 4th byte

/CS

SCL

SI

X X 0 X X

3rd b

Specify to transfer of the resister data

value at the next transfer

Note1: During 32-bit transfer of the Resister Data, /CS pin (Pin No.35) must be maintained active.

Note2: "X" is set in accordance with the usage conditions.

DATA SHEET DOD-PP-0307 (2nd edition)

A2 A1

XX

XX

A0 D7 D6 D5

MSB LSB

D4

- Register Number or Register Data

000011

MSB LSB

Transfer of the resister number value

1010

MSB LSB

Transfer of the resister data value

11

NL2432HC22-41K

D3

D2

0

D1 D0

1 0 X

0 0

1

11

(3) Command sequence

①Power On

Sequence

1 Power On 26 R76 01h

2 1ms min. wait. 27 R77 01h 3 Reset by the /RESET pin (Pin No. 8). 28 R80 00h 4 1ms min. wait after /RESET↑. 29 R81 00h 5 R3 01h - 30 R82 2Eh 6 R1 00h - 31 R83 C4h 7 R100

8 R101

9 R102

10 R103

11 R104

12 R105

13 R106

14 R107

15 R108

16 R109

17 R110

18 R111

19 R112

20 R113

21 R114

22 R115

23 R116

24 R2 40h

25 R75 04h

②Power Off

Sequence

1 R0 08h 2

3 R24 00h 4

5 R1 08h 6 Data Off

7 Power Off

Register

Number

Register

Number

25 ms min. wait.

20 ms min. wait.

Data Comment Sequence

0Fh

3Fh

3Fh

00h

00h

30h

04h

37h

17h

00h

40h

30h 04h 37h 17h

00h 40h -

Data Comment

- 32 R86 15h -

- 33 R87 EDh -

- 34 R95 3Fh -

- 35 R96 22h

- 36 R25 76h

- 37 R26 54h

- 38 R27 67h -

- 39 R28 60h -

- 40 R29 04h

- 41 R30 1Ch

- 42 R31 A9h

43 R32 00h

44 R33 20h

45 R24 77h

- 46

47

48 R59 01h

-

-

49

50

Register

Number

30 μs min. wait.

Data input start

20 ms min. wait.

R0 00h -

NL2432HC22-41K

Data Comment

-

-

-

-

-

-

-

-

-

-

DATA SHEET DOD-PP-0307 (2nd edition)

12

③Standby

④Wake Up

NL2432HC22-41K

Sequence

1 R0 08h 2

3 R24 00h 4

5 R1 08h -

Sequence

1 R1 00h 2 R24 FFh 3

4 R0 00h -

Register

Number

25 ms min. wait.

20 ms min. wait.

Register

Number

30 μs min. wait.

Note1: Be sure to perform reset by the /RESET pin (Pin No. 8) every power-on

Note2: Write the Resister Data every power-on, because the data are not stored in the product.

Note3: Due to influence such as static electricity from the outside, data in the register may transform. Data

is recommended to be written in the register regularly.

Data Comment

Data Comment

DATA SHEET DOD-PP-0307 (2nd edition)

13

4.5 INTERFACE PIN CONNECTIONS

CN1 (FPC)

Adaptable socket: FH23-45S-0.3SHW(05) (Hirose Electric Co., Ltd.(HRS))

Pin No. Symbols Functions Pin No. Symbols Functions

1 GND Ground Note1 25 D20 Red data (LSB)

2 GND Ground Note1 26 D21 Red data

3 VCC 27 D22 Red data

4 VCC 28 D23 Red data

5 VCC 29 D24 Red data

6 VCC

7 GND Ground Note1 31 GND Ground Note1

8 /RESET Reset 32 SCL Serial clock

9 HSYNC Horizontal synchronous signal 33 SI Serial input

10 VSYNC Vertical synchronous signal 34 RSVD Keep this pin Open.

11 CLK Dot clock 35 /CS Chip selection

12 GND Ground Note1 36 VCOMIN COM high voltage input

13 D00 Blue data (LSB) 37 N.C. Keep this pin Open.

14 D01 Blue data 38 GND Ground Note1

15 D02 Blue data 39 XL Horizontal terminal (Left side)

16 D03 Blue data 40 YD Vertical terminal (Down side)

17 D04 Blue data 41 XR Horizontal terminal (Right side)

18 D05 Blue data (MSB) 42 YU Vertical terminal (Up side)

19 D10 Green data (LSB) 43 GND Ground Note1

20 D11 Green data 44 ANODE LED voltage (Anode)

21 D12 Green data 45 CATHODE LED voltage (Cathode)

22 D13 Green data

23 D14 Green data

24 D15 Green data (MSB)

Power supply Note1

Note1: All GND terminals should be used without any non-connected lines.

Note2: Do not fold the FPC. When folding the FPC, pattern disconnection may occur. In case of bending

FPC, the minimum curvature (R) must be more than 1.0 mm.

NL2432HC22-41K

30 D25 Red data (MSB)

DATA SHEET DOD-PP-0307 (2nd edition)

14

Description of terminals

Terminals Description

When /RESET is L, an internal reset is performed.

/RESET

/CS

SCL This pin is clock input of serial interface.

SI This pin is data input of serial interface.

VCOMIN

YU,XR,YD,XL Refer to the below “Circuits of touch panel”.

ANODE,

CATHODE

XL

The reset operation is executed at the /RESET signal level.

Be sure to perform reset via this pin at power application.

This pin is used for chip select signals. When /CS= L, the chip is active and can

perform data I/O operations including command and data I/O.

This pin is the Common high voltage. The voltage needs to be adjusted.

The details are explained the above.

See "3 BLOCK DIAGRAM - Reference design of COM circuit".

Refer to the below “Circuits of backlight”.

YU

XR

YD

XL, YD, XR, YU

Circuits of touch panel

NL2432HC22-41K

Anode

Cathode

Circuits of backlight

DATA SHEET DOD-PP-0307 (2nd edition)

15

4.6 DISPLAY COLORS AND INPUT DATA SIGNALS

This product can display in equivalent to 262,144 colors in 64 gray scales. Also the relation

between display colors and input data signals is as the following table.

Display colors

Black

Blue

Red

Magenta

Green

Basic colors

Red gray scale

Green gray scale

Blue gray scale

Cyan

Yellow

White

Black

dark

bright

Red

Black

dark

bright

Green

Black

dark

bright

Blue

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

000000

000000

111111

111111

000000

000000

111111

111111

000000

000001

000010

↑

↓

111101

111110

111111

000000

000000

000000

↑

↓

000000

000000

000000

000000

000000

000000

↑

↓

000000

000000

000000

:

:

:

:

:

:

Data signal (0: Low level, 1: High level)

000000

000000

000000

000000

111111

111111

111111

111111

000000

000000

000000

000000

000000

000000

000000

000001

000010

111101

111110

111111

000000

000000

000000

000000

000000

000000

NL2432HC22-41K

000000

111111

000000

111111

000000

111111

000000

111111

000000

000000

000000

:

:

000000

000000

000000

000000

000000

000000

:

:

000000

000000

000000

000000

000001

000010

:

:

111101

111110

111111

:

:

:

:

:

:

DATA SHEET DOD-PP-0307 (2nd edition)

16

4.7 DISPLAY POSITIONS

The following table is the coordinates per pixel (See figure of "4.8 SCANNING DIRECTIONS".).

C (0, 0) C (1, 0)

NL2432HC22-41K

R G B

R G B

C( 0, 0) C( 1, 0)

C( 0, 1) C( 1, 1)

•

•

•

C( 0, Y) C( 1, Y)

•

•

•

C( 0, 318) C( 1, 318)

C( 0, 319) C( 1, 319)

•

•

•

•

•

•

• • •

• • •

•

• • •

•

• • •

•

• • •

•

• • •

• • •

C( X, 0)

C( X, 1)

•

•

•

C( X, Y)

•

•

•

C( X, 318)

C( X, 319)

• • •

• • •

•

• • •

•

• • •

•

• • •

•

• • •

• • •

C(238, 0) C(239, 0)

C(238, 1) C(239, 1)

•

•

•

C(238, Y) C(239, Y)

•

•

•

C(238, 318) C(239, 318)

C(238, 319) C(239, 319)

4.8 SCANNING DIRECTIONS

The following figures are seen from a front view. Also the arrow shows the direction of scan.

C (0, 0)

D (0, 0)

C (239, 0)

D (239, 0)

FPC

C (0, 319)

D (0, 319)

C (239, 319)

D (239, 319)

Note1: Meaning of C (X, Y) and D (X, Y)

C (X, Y): The coordinates of the display position (See "4.7 DISPLAY POSITIONS".)

D (X, Y): The data number of input signal for LCD panel

•

• • •

•

•

•

•

DATA SHEET DOD-PP-0307 (2nd edition)

17

4.9 INPUT SIGNAL TIMINGS

4.9.1 RGB interface (Ta= 25°C, VCC= 3.0V)

(1) Timing characteristics

Parameter Symbol min. typ. max. Unit Remarks

Frequency 1/tc 4.81 5.0 5.12 MHz 200ns (typ.)

CLK

DATA

(D00-05)

(D10-15)

(D20-25)

HSYNC

VSYNC

Duty tcd 0.4 0.5 0.6 Rise time, Fall time tcrf - - 15 ns

CLK-DATA

Rise time, Fall time tdrf - - 15 ns

Cycle th

Display period thd 240 CLK

Front-porch thf 4 CLK

Pulse width thp 2 8 - CLK

Back-porch thb 4 CLK

CLKHSYNC

Rise time, Fall time thrf - - 15 ns

Cycle tv

Display period tvd 320 H

Front-porch tvf 1 H

Pulse width tvp 1 2 - H

Back-porch tvb 1 H

VSYNC-HSYNC timing tvh 15 - - ns

Rise time, Fall time tvrf - - 15 ns

Setup time tds 15 - - ns

Hold time tdh 15 - - ns

Setup time ths 15 - - ns

Hold time thh 15 - - ns

Note1: Definition of parameters is as follows.

tc= 1CLK, tcd= tch/tc, th= 1H

Note2: All parameters should be kept within the specified range.

NL2432HC22-41K

-

-

50.0 51.2 53.2

256 CLK

16.2 16.59 17.24 ms 60Hz (typ.)

324 H

μs

19.53kHz (typ.)

-

-

DATA SHEET DOD-PP-0307 (2nd edition)

18

NL2432HC22-41K

(2) Input signal timing chart

VSYNC

tvp

tvb tvd

3H (fixed)

HSYNC

3

1

2

HSYNC

DATA

(D00-05)

(D10-15)

(D20-25)

INVALID

D(X,0)

HSYNC

DATA

(D00-05)

(D10-15)

(D20-25)

INVALID

D(0,Y)D(1,Y) D(X,Y) D(238,Y)D(239,Y)

HSYNC

thp

thb

12CLK (fixed)

CLK

DATA

(D00-05)

(D10-15)

(D20-25)

1

2

INVALID

Note1: Unless otherwise specified, the input level is defined to be VIH= 0.8VCC, VIL= 0.2VCC.

tv

1H

320H (fixed)

D(X,Y)

D(0,Y)D(1,Y) D(239,Y)

D(X,318)D(X,319)

th

1CLK

240CLK (fixed)

tvf

1H (fixed)

1

thd

INVALID

(Note: X=0 to 239)

INVALID

thf

4CLK (fixed)

1

INVALID

(Note: Y=0 to 319)

DATA SHEET DOD-PP-0307 (2nd edition)

19

NL2432HC22-41K

tvrf

tc

tdrf

thrf thrf

tvh

tds

ths

tdh

tdrf

thh

tch

CLK

0.8VCC

0.2VCC

tcrf tcrf

DATA

(D00-05)

(D10-15)

(D20-25)

0.8VCC

0.2VCC

INVALID

CLK

0.8VCC

0.2VCC

HSYNC

0.8VCC

0.2VCC

HSYNC

0.8VCC

0.2VCC

VSYNC

0.8VCC

0.2VCC

Note1: Unless otherwise specified, the input level is defined to be VIH= 0.8VCC, VIL= 0.2VCC.

DATA SHEET DOD-PP-0307 (2nd edition)

20

NL2432HC22-41K

4.9.2 Serial interface (Ta= 25°C, VCC= 3.0V)

(1) Timing characteristics

Parameter Symbol Condition min. typ. max. Unit Remarks

Serial clock cycle tSCYC

SCL high level pulse width tSHW

SCL low level pulse width tSLW

/CS rise time, fall time tcsrf /CS - - 15 ns -

SCL rise time, fall time tscrf SCL - - 15 ns -

SI rise time, fall time tsirf SI - - 15 ns -

/CS setup time tCSS /CS 50 - - ns -

/CS hold time tCSH /CS 30 - - ns -

Data setup time tSDS SI 30 - - ns -

Data hold time tSDH SI 15 - - ns -

Reset pulse width tRW /RESET 2 - - μs -

/RESET↑ to /CS time tRCS /RESET↑ to /CS 1 - - ms -

Note1: All parameters should be kept within the specified range.

/RESET

0.8VCC

0.5VCC

0.2VCC

/CS

0.8VCC

0.5VCC

0.2VCC

SCL

0.8VCC

0.5VCC

0.2VCC

SI

0.8VCC

0.5VCC

0.2VCC

Note2: Unless otherwise specified, the input level is defined to be VIH= 0.8VCC, VIL= 0.2VCC.

READ 450 - - ns WRITE 100 - - ns READ 210 - - ns WRITE 40 - - ns READ 210 - - ns WRITE 40 - - ns -

tRW

tRCS

tCSS

tcsrf

tSCYC

tSHW tSLW

tscrf tscrf

tSDS

tsirf

tSDH

tsirf

tCSH

tcsrf

DATA SHEET DOD-PP-0307 (2nd edition)

21

NL2432HC22-41K

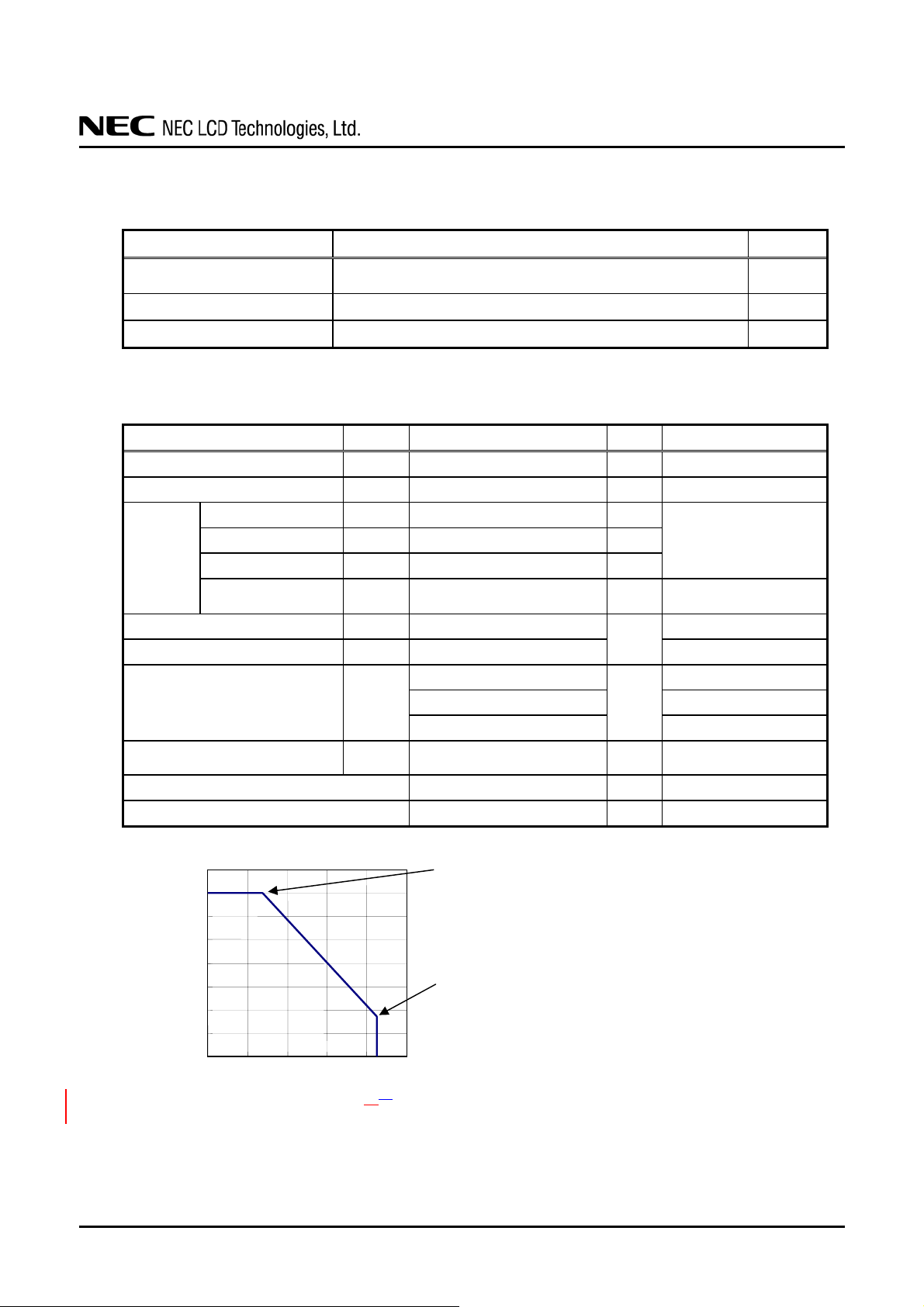

4.10 OPTICAL CHARACTERISTICS

<Backlight turning OFF>

(Note1, Note3, Note4)

Parameter Condition Symbol min. typ. max. Unit Remarks

Reflection ratio White, at center RE 8 15 - % Note6

Contrast ratio White/Black, at center CR 10 15 -

Reference data

Parameter Condition Symbol min. typ. max. Unit Remarks

Chromaticity

coordinates

Color gamut at center, against NTSC color space C - 5 - %

White to black

Response time

Black to white

White

90%→ 10%

10%→ 90%

Wx - 0.32 - Wy - 0.34 - -

Ton - 7 14

Toff

-

9 18

<Backlight turning ON>

Parameter Condition Symbol min. typ. max. Unit Remarks

Luminance

Contrast ratio

Luminance

uniformity

θR= 0°, θL= 0°, θU= 0°, θD= 0°

θR= 0°, θL= 0°, θU= 0°, θD= 0°

θR= 0°, θL= 0°, θU= 0°, θD= 0°

White at center

White/Black at center

White

Maximum luminance: 100%

L 150 200 - cd/m

CR 75 150 -

LU 60 70 - % Note11

Reference data

Parameter Condition Symbol min. typ. max. Unit Remarks

Note7

-

(Note1, Note3, Note4)

Note8

ms

Note9

Note10

(Note2, Note3, Note5)

2

-

Note7

-

(Note2, Note3, Note5)

Chromaticity

coordinates

Color gamut

Response time

Right

Viewing

angle

Left

Up

Down

White

θR= 0°, θL= 0°, θU= 0°, θD= 0°

at center, against NTSC color space

White to black

Black to white

θU= 0°, θD= 0°, CR≥ 5 θR

θU= 0°, θD= 0°, CR≥ 5 θL

θR= 0°, θL= 0°, CR≥ 5 θU

θR= 0°, θL= 0°, CR≥ 5 θD

90%→ 10%

10%→ 90%

DATA SHEET DOD-PP-0307 (2nd edition)

Wx 0.25 0.30 0.35 Wy 0.27 0.32 0.37 -

C - 40 - %

Ton - 7 14

Toff

-

-

-

-

-

23 46

30 30 30 35 -

ms

°

°

°

°

Note8

Note9

Note10

-

22

NL2432HC22-41K

(

)

(

)

N

Note1: Measurement conditions are as follows.

Ta= 25 °C, VCC= 3.0V, with touch panel

Note2: Measurement conditions are as follows.

Ta= 25 °C, VCC= 3.0V, IL= 20mA, with touch panel

Note3: Definition of viewing angles

12 o’clock

Upper

Note4: In reflective mode (Backlight turning OFF), Reflection ratio, Contrast ratio, Chromaticity

coordinates and Color gamut are measured as follows.

Light source

Product or Standard diffused reflector

Note5: In transmissive mode (Backlight turning ON), Luminance, Contrast ratio, Chromaticity coordinates

and Color gamut are measured as follows.

Upper Lower

ormal axis (Perpendicular)

θU

θL

Left

LCD5200 or SR-3

30°

Upper Lower

Photodetector

LCD5200 or SR-3

Product

Right

θR

θD

FPC

Photo-detector

10°

Lower

DATA SHEET DOD-PP-0307 (2nd edition)

23

NL2432HC22-41K

×

Note6: Definitions of reflection ratio

The reflection ratio is calculated by using the following formula.

Reflection (RE) =

Note7: Definition o f cont rast ratio

The contrast ratio is calculated by using the following formula.

Contrast ratio (CR) =

Note8: The White chromaticity coordinates are deviated by the LED deviation in addition to color filter

deviation.

Note9: Definition o f response times

Response time is measured, the luminance changes from "white" to "black", or "black" to "white"

on the same screen point, by photo-detector. Ton is the time it takes the luminance change from

90% down to 10%. Also Toff is the time it takes the luminance change from 10% up to 90% (See

the following diagram.).

White

100%

90%

Luminance

Black

10%

0%

Note10: Product surface temperature: Top= 25°C

Note11: Definition of luminance uniformity

Luminance uniformity is calculated by using the following formula.

Luminance uniformity (LU) =

Luminance of reflected light at white screen

Luminance of standard diffused reflector

Luminance of white screen

Luminance of black screen

Ton

Minimum lumina nce from A to I

Maximum lumina nce from A to I

1/6 1/2 5/6

ABC

DEF

GH I

1/6

1/2

5/6

×100

Toff

100

DATA SHEET DOD-PP-0307 (2nd edition)

24

5. RELIABILITY TESTS

Test item Condition Judgment Note1

NL2432HC22-41K

High temperature and humidity

(Operation)

Heat cycle

(Operation)

Thermal shock

(Non operation)

Low pressure

(Non operation)

Low pressure

(Operation)

ESD

(Operation)

Dust

(Operation)

Vibration

(Operation)

Mechanical shock

(Non operation)

① 55 ± 2°C, RH = 85%, 240 hours

② Display data is black.

① -20 ± 3°C…1 hour

70 ± 3°C…1 hour

② 50 cycles, 4 hours/cycle

③ Display data is black.

① -30 ± 3°C…30 minutes

80 ± 3°C…30 minutes

② 100 cycles, 1 hour/cycle

③ Temperature transition time is within 5 minutes.

① 15kPa

② -30 ± 3°C…24 hours

③ 80 ± 3°C…24 hours

① 53.3 kPa

② -20 ± 3°C…24 hours

③ 70 ± 3°C…24 hours

① 150pF, 150Ω, ±10kV

② 3 places on a panel surface

③ 10 times each places at 1 sec interval

① Sample dust: No. 15 (by JIS-Z8901)

② 15 seconds stir

③ 8 times repeat at 1 hour interval

① 30 to 100Hz, 19.6m/s

② 30 minutes/cycle

③ X, Y, Z direction

④ 1 times each directions

① 3,920m/ s

② ±X, ±Y, ±Z direction

③ 1 times each directions

2

, 2.5ms

2

No display malfunctions

No display malfunctions

No physical damages

Note1: Display and appearance are checked under environmental conditions equivalent to the inspection

conditions of defect specifications.

DATA SHEET DOD-PP-0307 (2nd edition)

25

!

6. PRECAUTIONS

6.1 MEANING OF CAUTION SIGNS

The following caution signs have very important meaning. Be sure to read "6.2 CAUTIONS" and

"6.3 ATTENTIONS", after understanding these contents!

This sign has the meaning that customer will be injured by himself or the product will

sustain a damage, if customer has wrong operations.

This sign has the meaning that customer will get an electrical shock, if customer has wrong

operations.

This sign has the meaning that customer will be injured by himself, if customer has wrong

operations.

6.2 CAUTIONS

∗ Do not touch the working backlight. There is a danger of an electric shock.

NL2432HC22-41K

∗ Do not touch the working backlight. There is a danger of burn injury.

∗ Do not shock and press the LCD panel and the backlight! There is a danger of breaking,

because they are made of glass. (Shock: To be not greater 3,920m/s

2.5ms)

6.3 ATTENTIONS

6.3.1 Handling of the product

① Take hold of both ends without touching the FPC when the product (LCD module) is picked up from

the tray .

② Do not hook nor pull the FPC in order to avoid any damage.

③ When the product is put on the table temporarily, display surface must be placed downward.

④ When handling the product, take the measures of electrostatic discharge with such as earth band,

ionic shower and so on, because the product may be damaged by electrostatic.

⑤ The product must be installed and/or handled without any stress such as bends or twist. Bends, twist

or any stress to any portion may cause display failures. And also do not put heavy or hard materials

on the product.

⑥ Do not hit or rub the surface of touch panel with hard materials, because it is easily scratched.

(Touch panel pencil-hardness: 3H)

⑦ When cleaning the T/P surface, wipe it with a soft dry cloth.

⑧ Do not push nor pull the FPC while the product is working.

⑨ Do not fold the FPC. When the FPC is folded, pattern disconnection may be caused. In case of

bending FPC, the minimum curvature (R) must be more than 1.0 mm.

⑩ When installing the product, do not contact a conductor such as a metal to the FPC excluding the

terminal area. There is a risk of short circuit which is caused by breakage of insulation layer of the

FPC.

⑪ When installing the product, apply the waterproof design to avoid going of water into the product.

!

2

and to be not greater

DATA SHEET DOD-PP-0307 (2nd edition)

26

6.3.2 Environment

① Do not operate or store in high temperature, high humidity, dewdrop atmosphere or corrosive gases.

② In order to prevent dew condensation occurring by temperature difference, the product packing box

③ Do not operate in high magnetic field. Circuits may be broken down by it.

④ This product is not designed as radiation hardened.

6.3.3 Characteristics

The following items are neither defects nor failures.

① Response time, luminance and color may be changed by ambient temperature.

② Display mura, flicker, vertical seam or small spot may be observed depending on display patterns.

③ Do not display the fixed pattern for a long time because it may cause image sticking.

④ Optical characteristics may be changed depending on input signal timings.

⑤ Touch panel film has polarizing characteristic. And the polarizer characteristics differ among

6.3.4 Other

① All GND terminals should be used without any non-connected lines.

② Do not disassemble the product.

③ Pack the product with original shipping package, in order to avoid any damages during transportation,

④ When installing the product to customer equipment, do not apply any stress to the rear side of the

NL2432HC22-41K

Keep the product in packing box with antistatic pouch in room temperature to avoid for dusts and

sunlight, when storing the product.

should be opened after enough time being left under the environment of an unpacking room.

Evaluate the leaving time sufficiently because a situation of dew condensation occurring is changed

by the environmental temperature and humidity. (Recommended leaving time: 6 hours or more with

packing state)

products. Therefore, when seeing the displays through the other polarizing material (for example

polarizing sunglasses), some displays can not be seen and some displays look different color darker

because of polarizer characteristic mismatching between touch panel film and the other polarizing

material.

when returning the product to NEC.

product, FPC, A area, Soldering Area and Mounting Area. If not, it may cause display un-uniformity

or LCD panel separation or break down of the product.

DATA SHEET DOD-PP-0307 (2nd edition)

27

7. OUTLINE DRAWINGS

Note1: The values in parentheses are for reference.

Note2: When installing the product to customer equipment, do not apply any stress to the rear side of the product, FPC, A area, Soldering Area and Mounting

Area.

If not, it may cause display un-uniformity or LCD panel separation or break down of the product.

Note3: While the product is working, do not contact a conductor such as a metal to the Soldering Area and Mounting Area of the FPC.

NL2432HC22-41K

Pin No. Symbols Pin No. Symbols

1 GND 25 D20

2 GND 26 D21

3 VCC 27 D22

4 VCC 28 D23

5 VCC 29 D24

6 VCC 30 D25

7 GND 31 GND

8 /RESET 32 SCL

9 HSYNC 33 SI

10 VSYNC 34 RSVD

11 CLK 35 /CS

12 GND 36 VCOMIN

13 D00 37 N.C.

14 D01 38 GND

15 D02 39 XL

16 D03 40 YD

17 D04 41 XR

18 D05 42 YU

19 D10 43 GND

20 D11 44 ANODE

21 D12 45 CATHODE

22 D13

23 D14

24 D15

Unit: mm

DATA SHEET DOD-PP-0307 (2nd edition)

28

8. RECOMMENDED DESIGN OF FRONT BEZEL

T/P Viewing area

T/P Response area

Electrode

0.2 - 0.7

Touch Panel

1.0

(4 .55 )

62 .74 (TO U CH P ANEL OUTL INE )

(BEZEL OPEN ING )

55 .64

53 .64

(LCD ACT IVE AREA )

LCD A c t i v e a r e a

Beze l open ing

Front Bezel opening design

NL2432HC22-41K

Front Bezel

Spacer

PET Film

Double-sided adhesive tape

Design guidance for the front bezel and the spacer

1. Front Bezel opening design

a. Please place the front bezel opening to maintain the operation by a stylus pen inside the T/P response area.

b. Any pressures in the area between T/P response area and T/P viewing area are prohibited.

Please use the appropriate material as the front bezel.

2. Spacer design

a. Please put the spacer, a cushion, on the front bezel. Do not use a double-sided adhesive tape because it adheres on

the touch panel surface.

b. Please position the spacer over the Spacer area to avoid a “short”.

Glass

62 .74 (TOU CH PANEL OUTL I NE )

1.25(Max.) 1.25(Max.)

(4 .24 )

1.0

(LCD ACT IVE AREA )

71 .52

(BEZEL OPE N I NG )

73 .52

(T OUC H PANEL OUTL INE )

84 .2

(4 .55 )

53 .64

(LCD ACT IVE AREA )

LCD A c t i v e a r ea

Spacer area

1.2

(4 .24 )

(LCD ACT IVE AREA )

71 .52

(Max.)

(T OUC H PANEL OUTL INE )

84 .2

Spacer design

2.00(Max.)

Unit: mm

DATA SHEET DOD-PP-0307 (2nd edition)

29

Loading...

Loading...