Page 1

NDA-24300

ISSUE 1

STOCK # 200787

®

System Operations and Maintenance Manual

OCTOBER, 2000

NEC America, Inc.

Page 2

LIABILITY DISCLAIMER

NEC America, Inc. reserves the right to change the specifications,

functions, or features, at any time, without notice.

NEC America, Inc. has prepared this document for use by its

employees and custome rs. The information contained herein is

the property of NEC America, Inc. and shall not be reproduced

without prior written approval from NEC America, Inc.

NEAX and D

term

are registered trademarks of NEC Corporation.

Copyright 2000

NEC America, Inc.

Printed in U.S.A.

Page 3

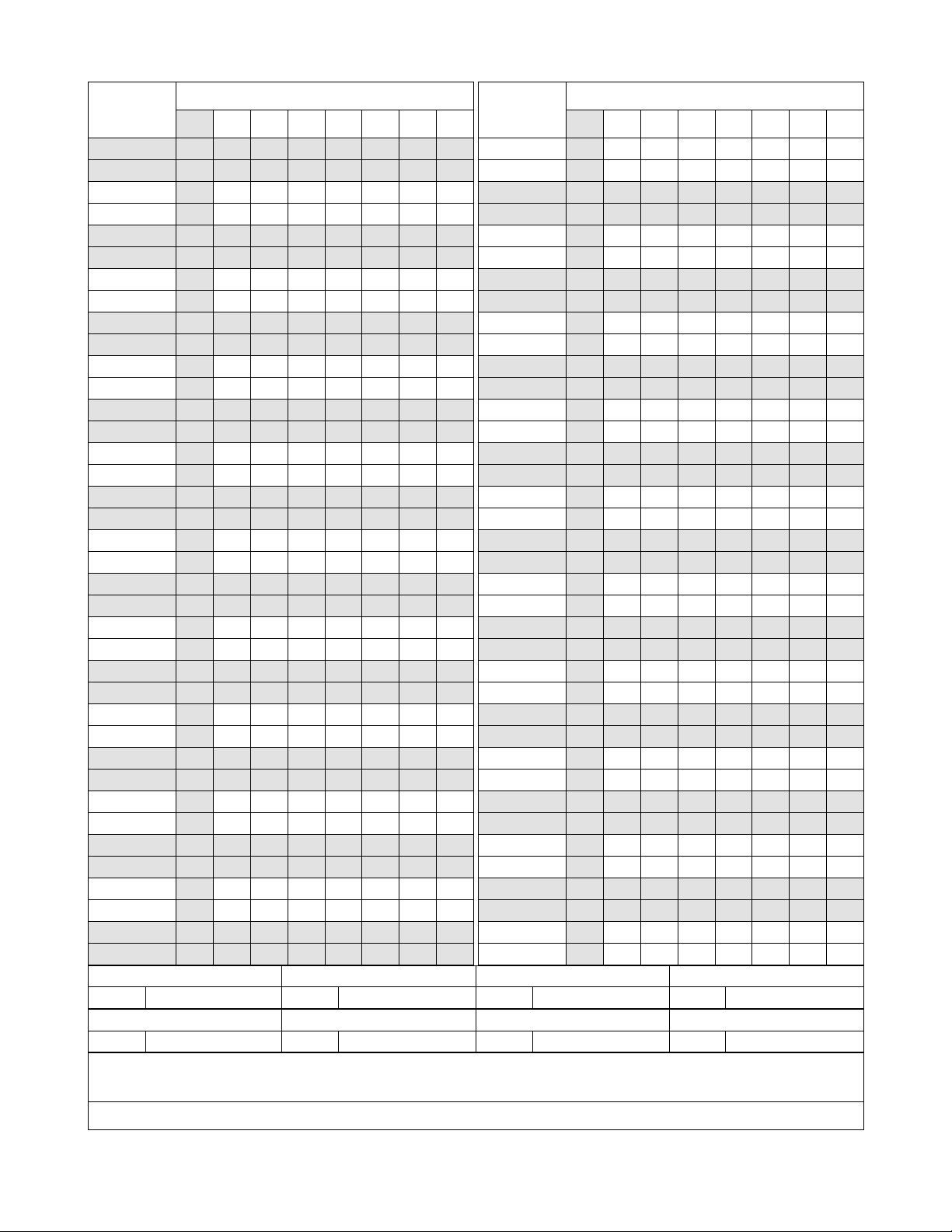

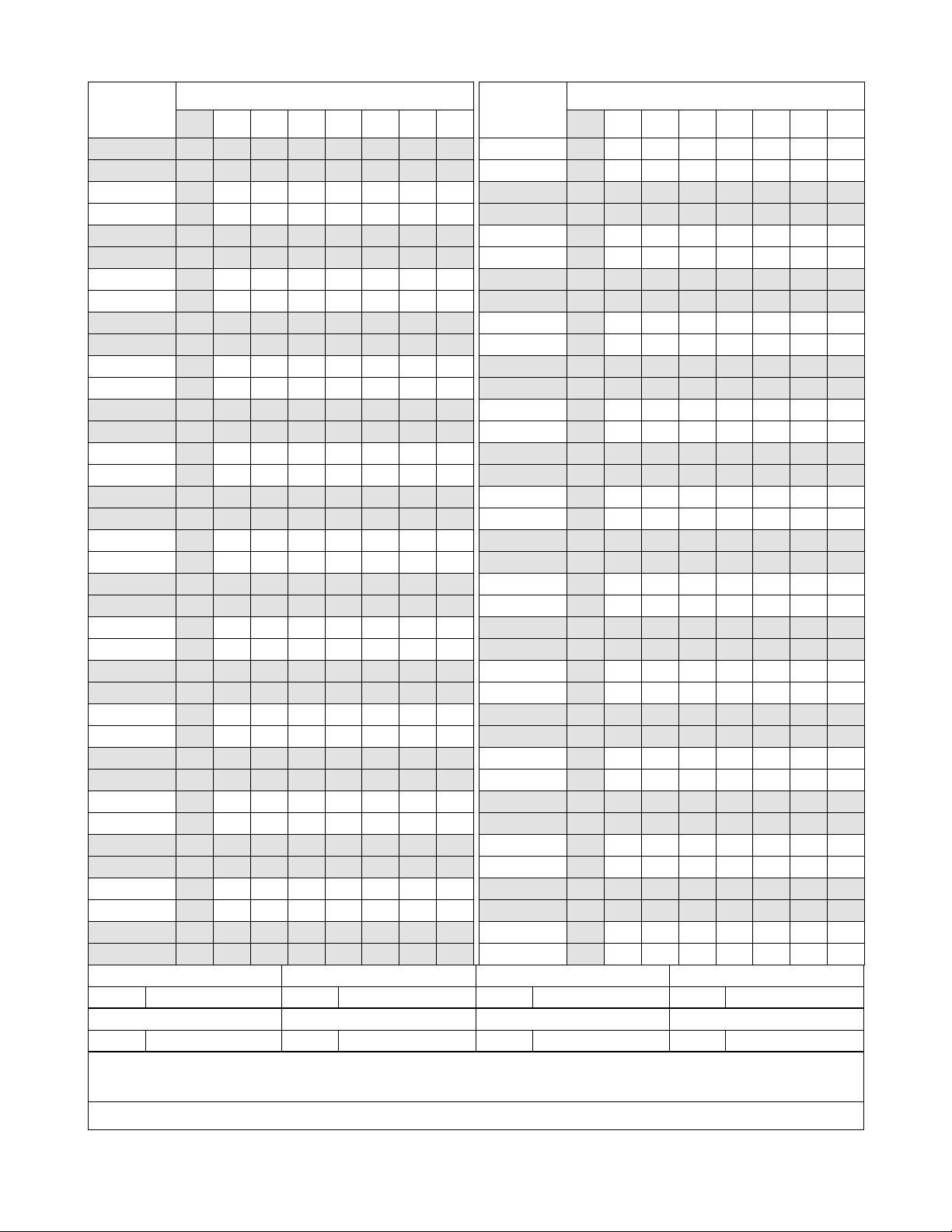

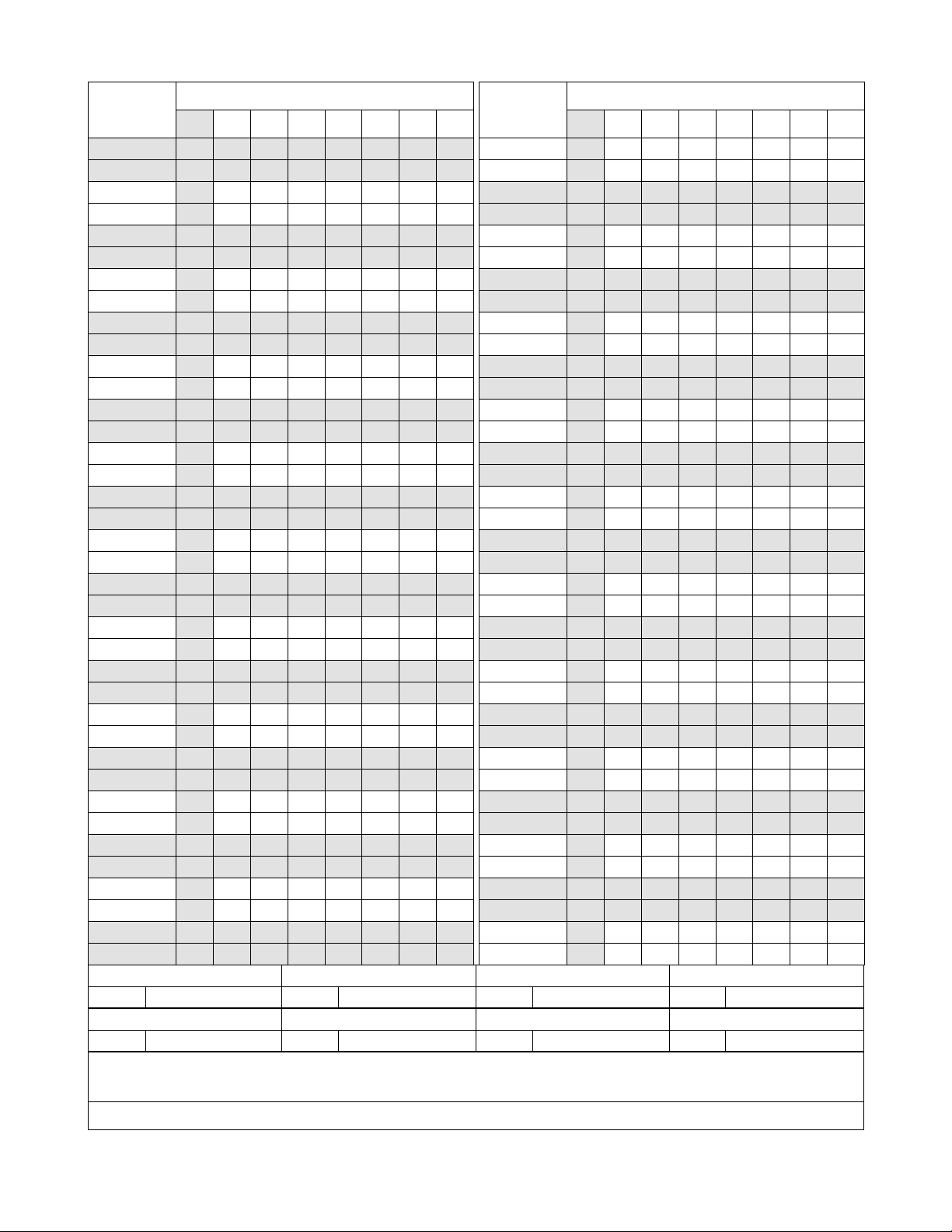

PAGE No.

i 1

ii 1

iii 1

iv

v 1

vi 1

vii 1

viii

ix 1

x 1

xi 1

xii

xiii 1

xiv 1

xv 1

xvi

1 1

2 1

3 1

4

5 1

6 1

7 1

8

9 1

10 1

11 1

12

13 1

14 1

15 1

16

17 1

18 1

19 1

20

21 1

22 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

23 1

24

25 1

26 1

27 1

28

29 1

30 1

31 1

32

33 1

34 1

35 1

36

37 1

38 1

39 1

40

41 1

42 1

43 1

44

45 1

46 1

47 1

48

49 1

50 1

51 1

52

53 1

54 1

55 1

56

57 1

58 1

59 1

60

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 1/9

NDA-24300

Page 4

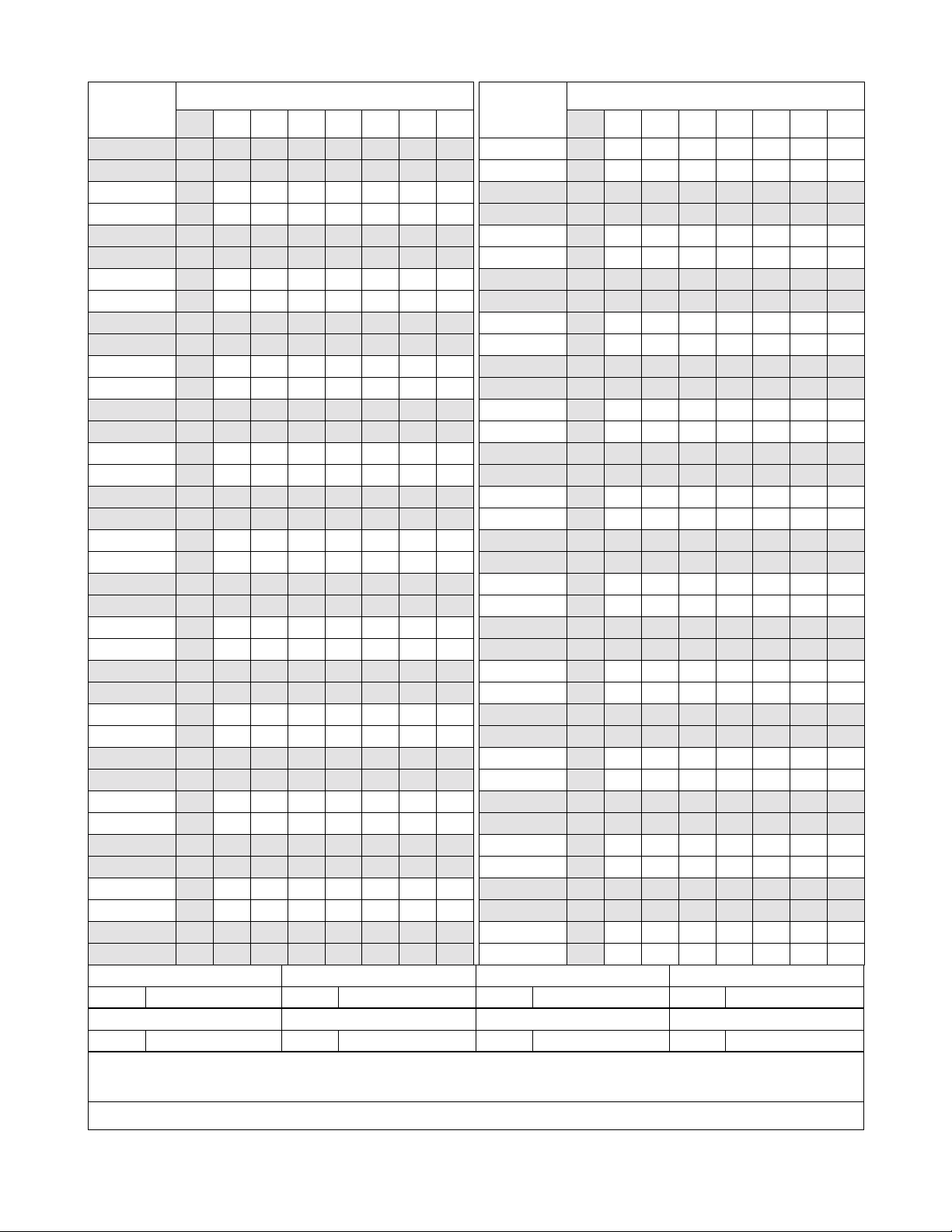

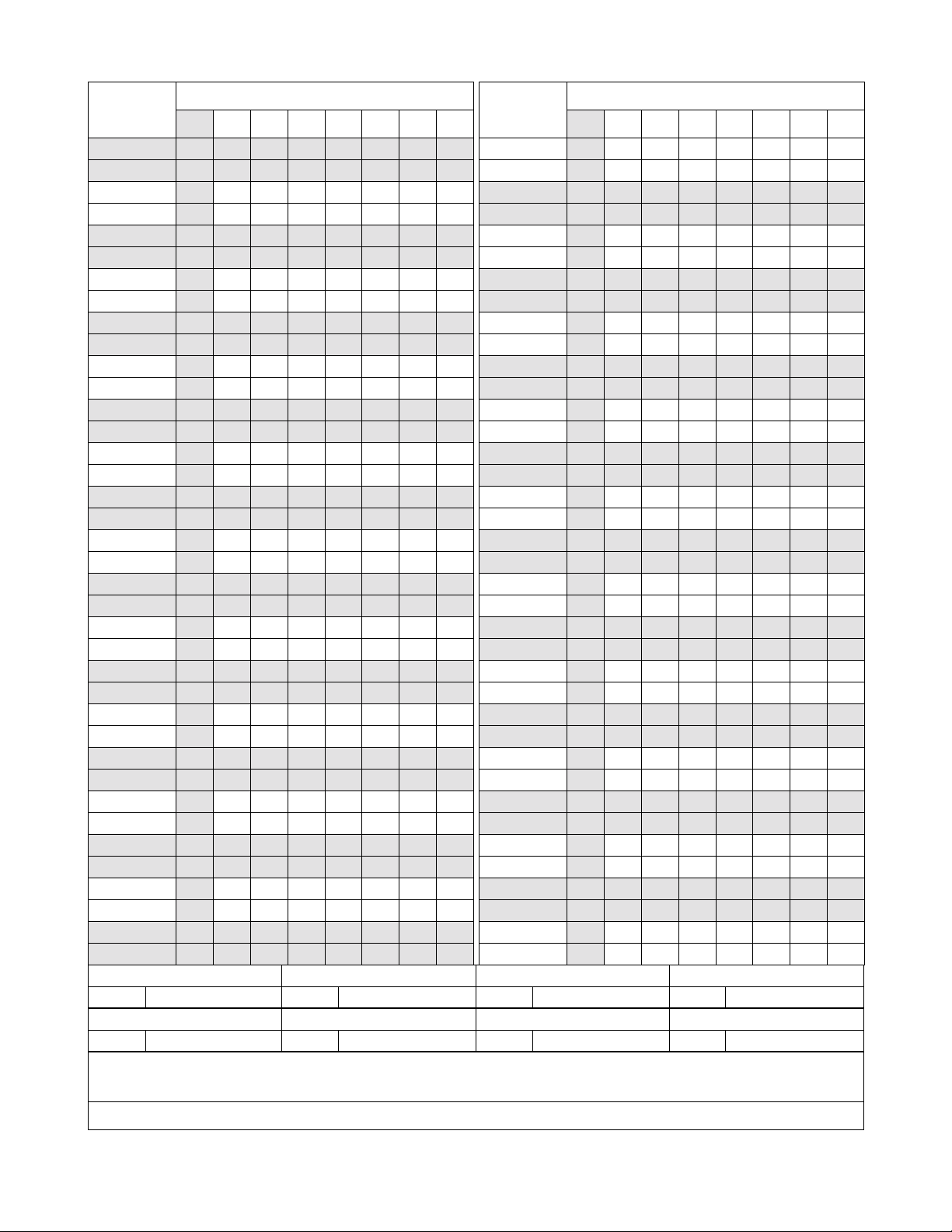

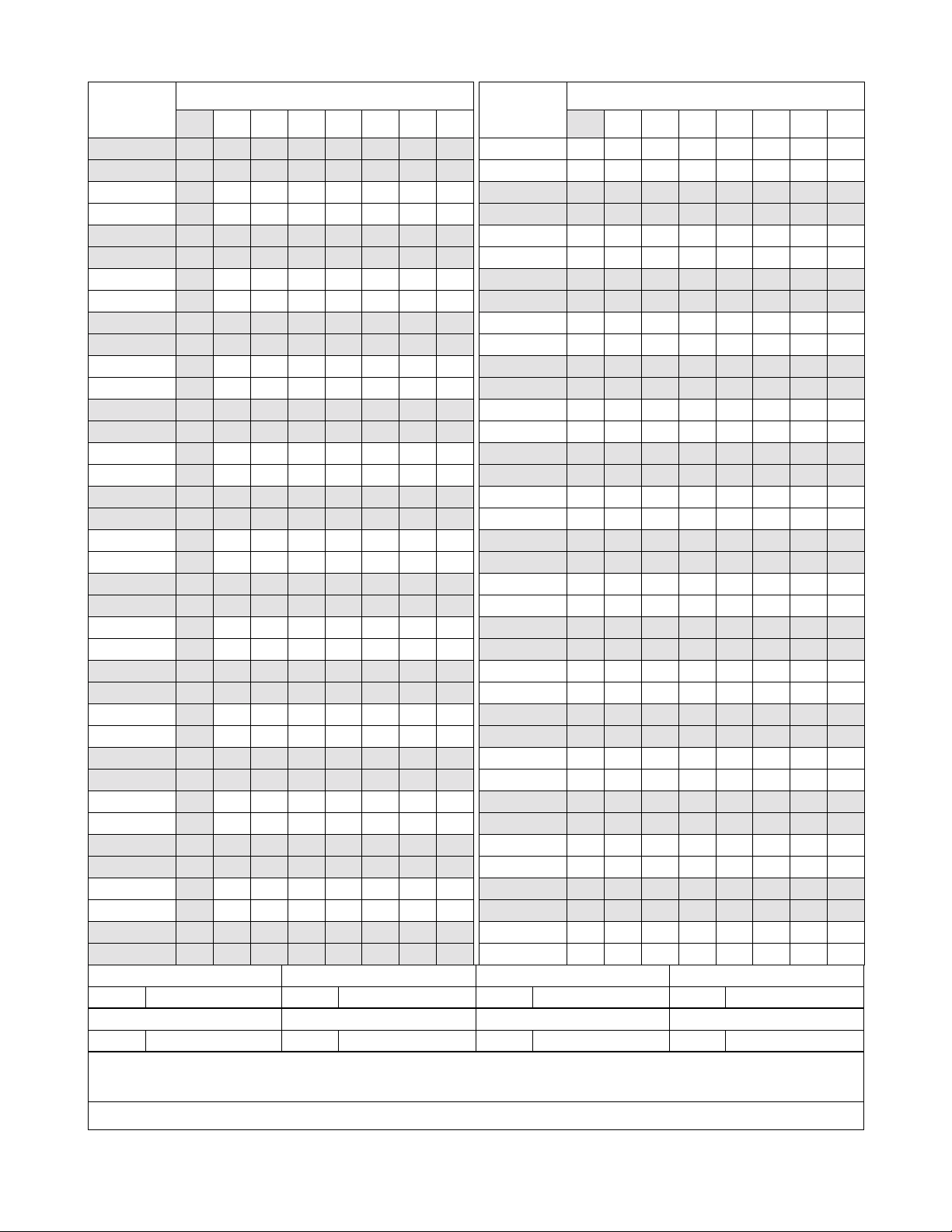

PAGE No.

61 1

62 1

63 1

64

65 1

66 1

67 1

68

69 1

70 1

71 1

72

73 1

74 1

75 1

76

77 1

78 1

79 1

80

81 1

82 1

83 1

84

85 1

86 1

87 1

88

89 1

90 1

91 1

92

93 1

94 1

95 1

96

97 1

98 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

99 1

100

101 1

102 1

103 1

104

105 1

106 1

107 1

108

109 1

110 1

111 1

112

113 1

114 1

115 1

116

117 1

118 1

119 1

120

121 1

122 1

123 1

124

125 1

126 1

127 1

128

129 1

130 1

131 1

132

133 1

134 1

135 1

136

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 2/9

NDA-24300

Page 5

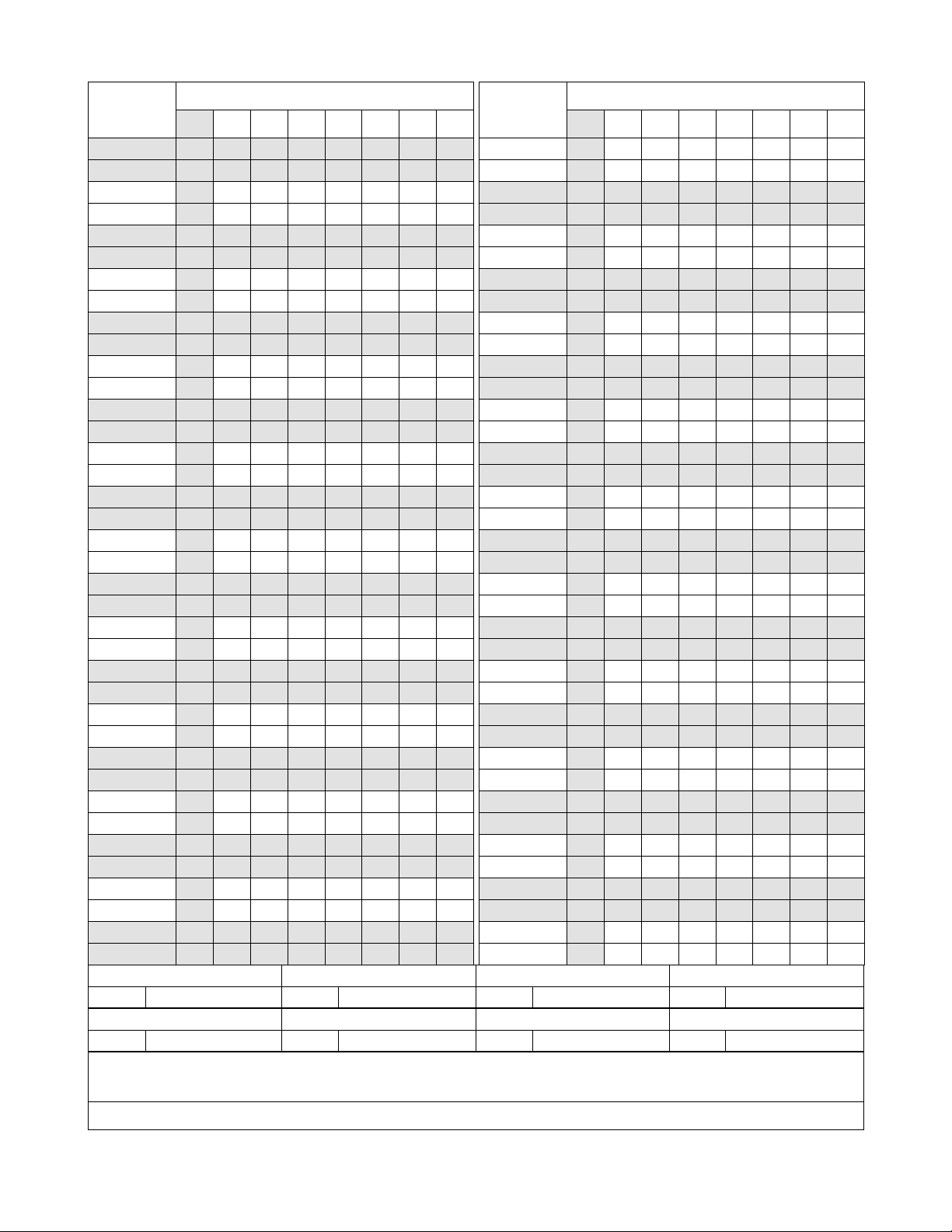

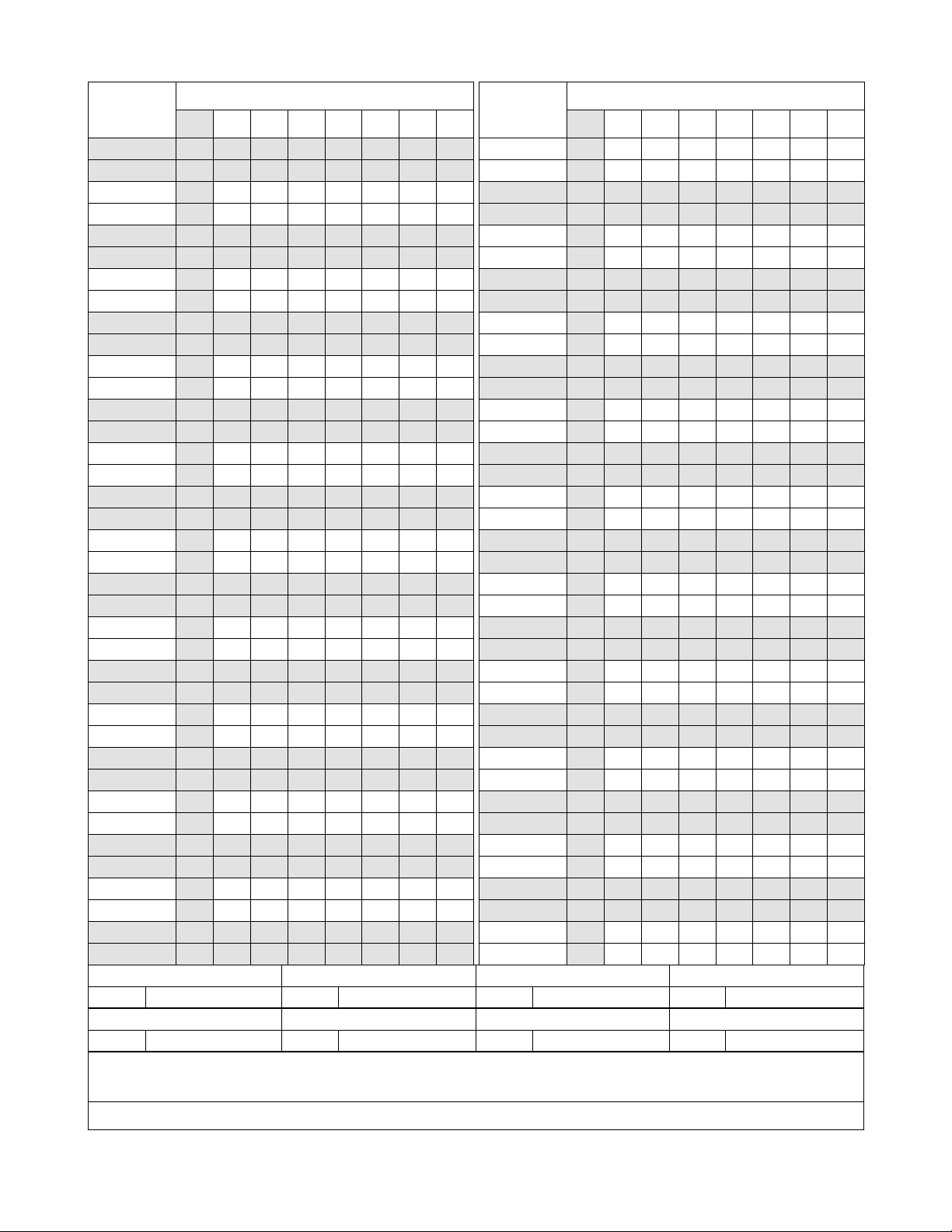

PAGE No.

137 1

138 1

139 1

140

141 1

142 1

143 1

144

145 1

146 1

147 1

148

149 1

150 1

151 1

152

153 1

154 1

155 1

156

157 1

158 1

159 1

160

161 1

162 1

163 1

164

165 1

166 1

167 1

168

169 1

170 1

171 1

172

173 1

174 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

175 1

176

177 1

178 1

179 1

180

181 1

182 1

183 1

184

185 1

186 1

187 1

188

189 1

190 1

191 1

192

193 1

194 1

195 1

196

197 1

198 1

199 1

200

201 1

202 1

203 1

204

205 1

206 1

207 1

208

209 1

210 1

211 1

212

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 3/9

NDA-24300

Page 6

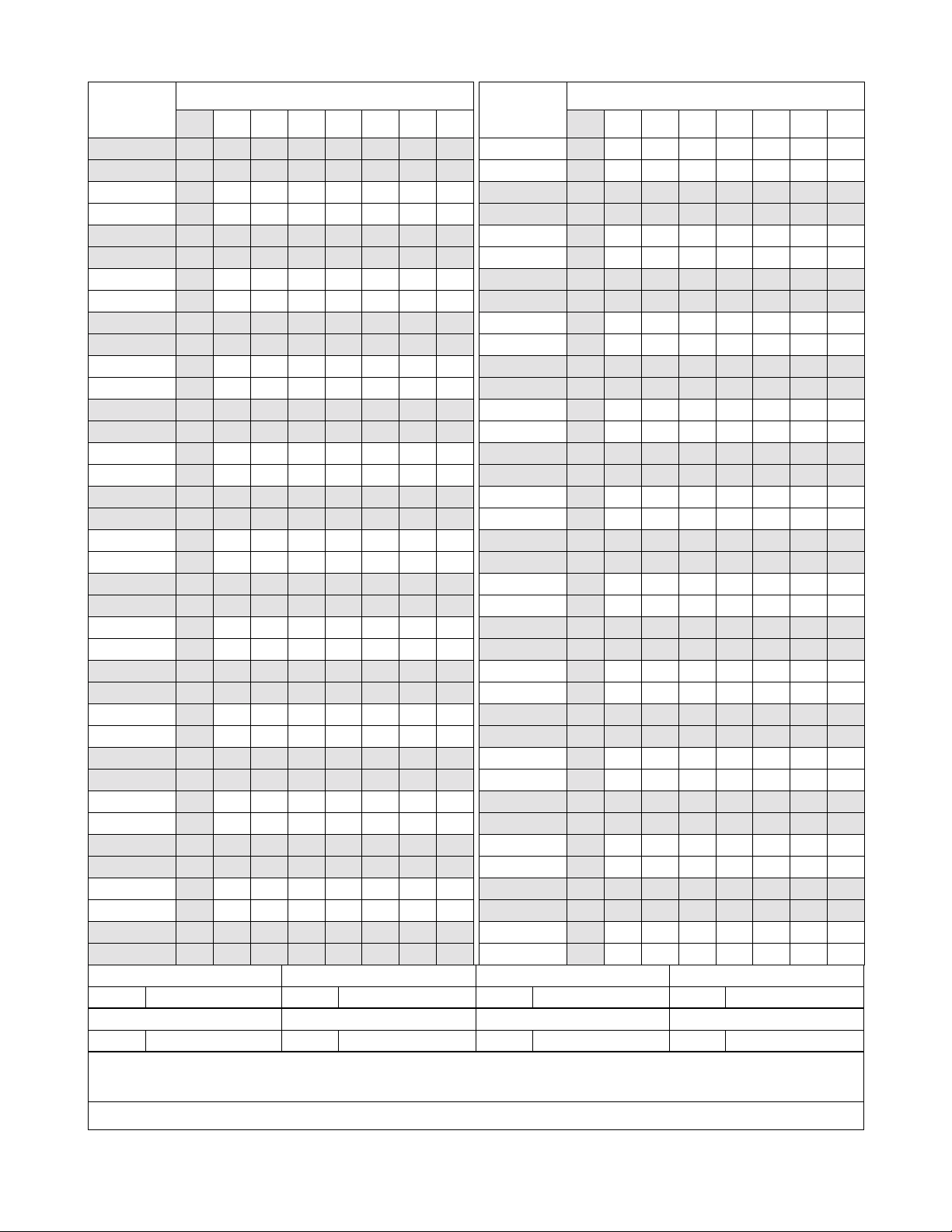

PAGE No.

213 1

214 1

215 1

216

217 1

218 1

219 1

220

221 1

222 1

223 1

224

225 1

226 1

227 1

228

229 1

230 1

231 1

232

233 1

234 1

235 1

236

237 1

238 1

239 1

240

241 1

242 1

243 1

244

245 1

246 1

247 1

248

249 1

250 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

251 1

252

253 1

254 1

255 1

256

257 1

258 1

259 1

260

261 1

262 1

263 1

264

265 1

266 1

267 1

268

269 1

270 1

271 1

272

273 1

274 1

275 1

276

277 1

278 1

279 1

280

281 1

282 1

283 1

284

285 1

286 1

287 1

288

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 4/9

NDA-24300

Page 7

PAGE No.

289 1

290 1

291 1

292

293 1

294 1

295 1

296

297 1

298 1

299 1

300

301 1

302 1

303 1

304

305 1

306 1

307 1

308

309 1

310 1

311 1

312

313 1

314 1

315 1

316

317 1

318 1

319 1

320

321 1

322 1

323 1

324

325 1

326 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

327 1

328

329 1

330 1

331 1

332

333 1

334 1

335 1

336

337 1

338 1

339 1

340

341 1

342 1

343 1

344

345 1

346 1

347 1

348

349 1

350 1

351 1

352

353 1

354 1

355 1

356

357 1

358 1

359 1

360

361 1

362 1

363 1

364

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 5/9

NDA-24300

Page 8

PAGE No.

365 1

366 1

367 1

368

369 1

370 1

371 1

372

373 1

374 1

375 1

376

377 1

378 1

379 1

380

381 1

382 1

383 1

384

385 1

386 1

387 1

388

389 1

390 1

391 1

392

393 1

394 1

395 1

396

397 1

398 1

399 1

400

401 1

402 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

403 1

404

405 1

406 1

407 1

408

409 1

410 1

411 1

412

413 1

414 1

415 1

416

417 1

418 1

419 1

420

421 1

422 1

423 1

424

425 1

426 1

427 1

428

429 1

430 1

431 1

432

433 1

434 1

435 1

436

437 1

438 1

439 1

440

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 6/9

NDA-24300

Page 9

PAGE No.

441 1

442 1

443 1

444

445 1

446 1

447 1

448

449 1

450 1

451 1

452

453 1

454 1

455 1

456

457 1

458 1

459 1

460

461 1

462 1

463 1

464

465 1

466 1

467 1

468

469 1

470 1

471 1

472

473 1

474 1

475 1

476

477 1

478 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

479 1

480

481 1

482 1

483 1

484

485 1

486 1

487 1

488

489 1

490 1

491 1

492

493 1

494 1

495 1

496

497 1

498 1

499 1

500

501 1

502 1

503 1

504

505 1

506 1

507 1

508

509 1

510 1

511 1

512

513 1

514 1

515 1

516

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 7/9

NDA-24300

Page 10

PAGE No.

517 1

518 1

519 1

520

521 1

522 1

523 1

524

525 1

526 1

527 1

528

529 1

530 1

531 1

532

533 1

534 1

535 1

536

537 1

538 1

539 1

540

541 1

542 1

543 1

544

545 1

546 1

547 1

548

549 1

550 1

551 1

552

553 1

554 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

555 1

556

557 1

558 1

559 1

560

561 1

562 1

563 1

564

565 1

566 1

567 1

568

569 1

570 1

571 1

572

573 1

574 1

575 1

576

577 1

578 1

579 1

580

581 1

582 1

583 1

584

585 1

586 1

587 1

588

589 1

590 1

591 1

592

12345678

1

1

1

1

1

1

1

1

1

1

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 8/9

NDA-24300

Page 11

PAGE No.

593 1

594 1

595 1

596

597 1

598 1

599 1

600

601 1

602 1

603 1

604

605 1

606 1

607 1

608

609 1

610 1

611 1

612

613 1

614 1

615 1

616

617 1

618 1

619 1

620

621 1

622 1

623 1

624

625 1

626 1

627 1

628

629 1

630 1

DATE OCTOBER, 2000 DATE DATE DATE

DATE DATE DATE DATE

12345678

1

1

1

1

1

1

1

1

1

ISSUE 1 ISSUE 2 ISSUE 3 ISSUE 4

ISSUE 5 ISSUE 6 ISSUE 7 ISSUE 8

ISSUE No.

PAGE No.

12345678

NEAX2400 IPX

System Operatio ns a nd Maintenance Manual

ISSUE No.

Revision Sheet 9/9

NDA-24300

Page 12

NDA-24300

ISSUE 1

OCTOBER, 2000

NEAX2400 IPX

System Operations and Maintenance Manual

TABLE OF CONTENTS

Page

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

CHAPTER 1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. HOW TO FOLLOW THIS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2 SYSTEM MAINTENANCE OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Administrative Management Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Summary of This Manual’s Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. BASIC KNOWLEDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Line Equipment Numbers (LENS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Module Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.3 Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.4 Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Local Partition (LP) Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 System Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Fault Detecting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Range of Faults Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7 Explanation of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3. HOW TO READ PRECAUTIONS, DIAGNOSTIC, AND FAULT REPAIR INFORMATION . . . . . . . . . 26

3.1 Precaution about Diagnostic Procedure/Fault Repair Procedure. . . . . . . . . . . . . . . . . . . . . . . . 26

3.2 How to Follow Diagnostic Procedure/Fault Repair Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4. REPORTING FAULT TO NEC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Fault Reporting Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2 Forwarding Faulty Circuit Card Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

CHAPTER 3 SYSTEM MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

0-C Reset Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

0-D CPU Clock Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

0-E C-Level Infinite Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

0-F Memory Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

0-G B1-Level Infinite Loop (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

0-H B1-Level Infinite Loop (Temporary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

NDA-24300 TABLE OF CONTENTS

Page i

Issue 1

Page 13

TABLE OF CONTENTS (CONTINUED)

Page

0-I Mate CPU Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

0-J Abnormal Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1-A Both TSW Failure (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1-B TSW Failure (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1-C Both TSW Write Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1-D TSW Write Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1-E Both TSW Clock Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1-F TSW Clock Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1-O Both PLO Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1-P PLO Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1-S Module Group Down Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1-T TSW ACT Change Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1-U DLKC Data Transfer Failure (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1-V DLKC Data Transfer Failure (Temporary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1-W PLO Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3-B C-Level Infinite Loop (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3-C C-Level Infinite Loop (Temporary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3-D Lock-Up Failure (Permanent). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3-E Lock-Up Failure (Temporary). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3-F -48V Over Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3-G Ground Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3-H Digital Line Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3-I Digital Line Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3-J Digital Line Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4-C Both TSW Ready Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4-D TSW Ready Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4-Q DLKC Ready Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4-S MUX Ready Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4-T Both MUX Ready Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4-U PCI Card Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4-V PCI Card Failure Recovered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6-A System Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6-B RGU & Howler Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6-C Line Load Control Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6-D Line Load Control Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6-H Bad Call Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6-I STA-Test Connection Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6-J Emergency Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6-L Emergency Control Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6-M Emergency Control Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6-N Abnormal Call Duration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6-O SMDR Output Buffer Overflow Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6-P SMDR Output Buffer Overflow Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7-A System Initialize With Data Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7-B System Initialize. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

7-C CPU MBR Key Turn ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

7-D CPU MBR Key Turn OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7-E TSW MBR Key Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

7-F TSW MBR Key Turn OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

TABLE OF CONTENTS NDA-24300

Page ii

Issue 1

Page 14

TABLE OF CONTENTS (CONTINUED)

Page

7-G TSW PLO Key Turn ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7-H TSW PLO Key Turn OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7-I ALMC MB Key Turn ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

7-J ALMC MB Key Turn OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7-K PM MB Key Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7-L PM MB Key Turn OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

7-M NCU MB Key Turn ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7-N NCU MB Key Turn OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

7-O Cyclic Diagnosis Normal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7-P Cyclic Diagnosis Information (Error Detected). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7-U PLO MB Key Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

7-V PLO MB Key Turn OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

13-A CCH Clock Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

13-B CCH C-Level Infinite Loop Failure (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

13-C CCH C-Level Infinite Loop Failure (Temporary). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

13-D CCH Lock-Up Failure (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

13-E CCH Lock-Up Failure (Temporary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

13-F CCH B-Level Infinite Loop Failure (Permanent). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

13-G CCH B-Level Infinite Loop Failure (Temporary). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

13-H CCS Link Failure (Permanent). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

13-I CCS Link Failure (Temporary). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

13-J Restoration From CCS Link Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

13-K CCH Reset Interrupt Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

13-N Digital Line Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

13-O Digital Line Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

13-P Digital Line Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

13-Q DRU Battery Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

13-R DRU Line Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

13-Z Power Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

15-A VPS Failure (Temporary). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

15-B VPS Failure (Permanent). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

15-C VPS Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

16-A Inside Trunk All Busy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

16-B Virtual Tie Line Set Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

16-C Virtual Tie Line Cancel Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

16-E Virtual Tie Line Set Time Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

16-F Sender Start Time Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

16-K I/O Port Line OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

16-L I/O Port Line Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

16-M Hard Clock Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

16-N Hard Clock Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

16-T IOC Failure (Temporary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

16-U IOC Failure (Permanent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

16-X Station Exchanged Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

17-A CCH MBR Key Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

17-B CCH MBR Key Turn OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

17-C CCH MB Key Turn ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

17-D CCH MB Key Turn OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

17-H Day/Night Change Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

NDA-24300 TABLE OF CONTENTS

Page iii

Issue 1

Page 15

TABLE OF CONTENTS (CONTINUED)

Page

17-O IOC MB Key Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

17-P IOC MB Key Turn OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

17-Q IOC MBR Key Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

17-R IOC MBR Key Turn OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

23-P DCH Back-Up Automatic Change Start/End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

23-Q DCH Back-Up Manual Change Start/End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

23-Y MUX Clock Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

23-Z Both MUX Clock Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

26-N MAT Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

26-R Call Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

26-V LAN Interface Error Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

26-W LAN Interface Release Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

33-A MUX Clock Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

33-B SDT Alarm Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

33-C SDT Alarm Trouble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

33-D SDT Alarm Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

33-E SDT Interface Change Notify. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

CHAPTER 4 UNIT/CIRCUIT CARD REPLACEMENT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

1. LPM ACCOMMODATING UNIT/CIRCUIT CARD REPLACEMENT PROCEDURE . . . . . . . . . . . . . . 239

1.1 Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

1.2 Circuit Card Mounting Face Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

1.3 Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

1.3.1 CPR Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

1.3.2 EMA Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

1.3.3 IOC Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

1.3.4 Power Supply Unit Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

1.3.5 MISC Card Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

2. TSWM ACCOMMODATING CIRCUIT CARD REPLACEMENT PROCEDURE . . . . . . . . . . . . . . . . . 266

2.1 Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

2.2 Circuit Card Mounting Face Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

2.3 Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

2.3.1 GT Card Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

2.3.2 TSW Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

2.3.3 DLKC Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

2.3.4 PLO Card Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

2.3.5 PWR SW Card Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

2.3.6 MISC Card Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

3. PIM ACCOMMODATING CIRCUIT CARD REPLACEMENT PROCEDURE . . . . . . . . . . . . . . . . . . . 283

3.1 Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

3.2 Circuit Card Mounting Face Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

3.3 Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

3.3.1 LC/TRK Circuit Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

3.3.2 MUX Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

3.3.3 SDT Card Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

3.3.4 PWR Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

4. FAN UNIT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

5. CPR COOLING FAN REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

TABLE OF CONTENTS NDA-24300

Page iv

Issue 1

Page 16

TABLE OF CONTENTS (CONTINUED)

Page

6. FUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

CHAPTER 5 FAULT REPAIR PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

1. LINE FAULT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

1.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

1.2 Line Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

1.3 Line Fault - When Dial Tone (DT) Cannot Be Heard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

1.4 Line Fault - When Dialing Results in Wrong Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

1.5 Line Fault - When Bell Does Not Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

1.6 When Call Cannot Be Answered and Speech Cannot Be Made . . . . . . . . . . . . . . . . . . . . . . . . 317

1.7 D

2. TRUNK FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

2.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

2.2 Trunk Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

2.3 Trunk (ORT, SND, CFT) Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

2.4 Trunk (COT, TLT, DTI) Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

3. ATTCON/DESKCON FAULT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

3.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

3.2 ATTCON/DESKCON Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

3.3 ATTCON/DESKCON Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

4. UNIT FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

4.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

4.2 Unit Fault - Fault Related to Speech . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

4.3 Unit Fault - When Dial Tone (DT) Cannot Be Heard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

4.4 Unit Fault - ACT-Side MUX Card Is Faulty and System Has Changed Over. . . . . . . . . . . . . . . 344

5. SPEECH PATH (TSW) SYSTEM FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

5.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

5.2 Speech Path System Fault - Fault Related to Speech. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

5.3 Speech Path System Fault - When Dial Tone (DT) Cannot Be Heard. . . . . . . . . . . . . . . . . . . . 353

5.4 Speech Path System Fault - STBY Side Has Become Faulty . . . . . . . . . . . . . . . . . . . . . . . . . . 354

6. CONTROL SYSTEM FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

6.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

6.2 Control System Fault - Fault Occurs Intermittently. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

6.3 Control System Fault - STBY Side Is Faulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

7. ALARM INDICATION FAULT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

7.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

7.2 Fault of Alarm Indicating Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

7.3 Fault That Cannot Be Detected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

8. POWER SUPPLY FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

8.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

8.2 Fuse Blown Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

8.3 Circuit Breaker OFF Fault in PWR Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

8.4 Fault of Alarm Lamps on PWR Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

9. FAN UNIT FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

9.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

9.2 Fan Unit Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

term

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

NDA-24300 TABLE OF CONTENTS

Page v

Issue 1

Page 17

TABLE OF CONTENTS (CONTINUED)

Page

10. TONE FAULT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

10.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

10.2 Tone Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

11. SYSTEM DOWN FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

11.1 When Cause for Fault Cannot Be Identified. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

11.2 When Faulty Circuit Cards Can Be Assumed From System Message . . . . . . . . . . . . . . . . . . . 382

12. COMMON CHANNEL INTEROFFICE SIGNALING (CCIS) LINE FAULT . . . . . . . . . . . . . . . . . . . . . . 383

12.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

12.2 CCIS Line Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

12.3 Specific CCH/CCT Card Is Faulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

12.4 Fault of CCH, DTI and Related Flat Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

13. INTEGRATED SERVICE DIGITAL NETWORK (ISDN) LINE FAULT . . . . . . . . . . . . . . . . . . . . . . . . . 386

13.1 Check Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

13.2 ISDN Line Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

13.3 Specific DCH/PRT Card Is Faulty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

13.4 Fault of DCH, DTI, and Related Flat Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

14. HARD TIME CLOCK FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

CHAPTER 6 SYSTEM OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

1. ALARM INDICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

1.1 Kinds of Alarm Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

1.2 How to Stop Alarm Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

1.3 Alarm Indications on TOPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

1.4 Variable Alarm Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

2. COLLECTION OF SYSTEM MESSAGES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

2.1 Automatic Printout to System Message Dedicated Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

2.2 Display on MAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

3. INDICATION OF LOCKOUT STATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

3.1 Indicating Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

3.2 Recovery Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

4. LINE LOAD CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

5. IOC LINE MONITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

6. LINE MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

6.1 Make-Busy/Make-Busy Cancel of Station and Data Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . 401

6.2 Class Change and Number Change of Station and Data Terminal . . . . . . . . . . . . . . . . . . . . . . 402

6.3 Make-Busy/Make-Busy Cancel of C.O. Line/Tie Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

6.4 Line Management Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

7. STATION MESSAGE DETAIL RECORDING SYSTEM (SMDR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

7.1 Transmission Data to SMDR Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

7.2 Details on Transmission Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

7.2.1 Calling Party Information/Called Party Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

7.2.2 Call Start/Call End Time Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

7.2.3 Called Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

7.2.4 Account Code/Authorization Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

7.2.5 Route Advance Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

7.2.6 Condition B Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

TABLE OF CONTENTS NDA-24300

Page vi

Issue 1

Page 18

TABLE OF CONTENTS (CONTINUED)

Page

7.2.7 Call Metering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

7.2.8 Office Code of Calling (Called) Party and Billing Process Office . . . . . . . . . . . . . . . . . 414

7.2.9 Text Format of Centralized Billing - Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

7.2.10 Text Format of SMDR - TCP/IP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

8. TRAFFIC MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

8.1 Kind of Traffic Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

8.2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

9. OFFICE DATA MANAGEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

9.1 Office Data Stored Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

9.2 Office Data Preservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

9.3 Office Data Management Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

9.4 Call Forwarding Data/Individual Speed Calling Data Management . . . . . . . . . . . . . . . . . . . . . . 437

9.5 One-Touch Speed Call Memory Data Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

9.6 Data Management Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

10. TEST OPERATIONS OF VARIOUS KINDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

10.1 Designated Connection Test (Station) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

10.2 Designated Connection Test (DESKCON/ATTCON). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

10.3 Bad Call Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

11. ROUTINE DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

11.1 Related System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

11.2 Routine Diagnosis Result. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

12. SYSTEM CONTROL PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

12.1 Changeover/Make-Busy/Make-Busy Cancel of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

12.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

12.1.2 How to Control CPU Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

12.1.3 Manual System Changeover of CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

12.1.4 Forced Changeover of CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

12.1.5 How to Control Switching Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

12.1.6 Manual System Changeover of Speech Path System . . . . . . . . . . . . . . . . . . . . . . . . . 467

12.1.7 Manual System Changeover of PLO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 472

12.2 Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

12.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

12.2.2 System Initialization by Turning ON Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

12.2.3 System Initialization by Key Operations on TOPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 476

12.2.4 System Initialization by Keys on CPU Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

12.2.5 System Initialization by SINZ Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

12.2.6 Peripheral Equipment Initialization (Line/Trunk Initialization) . . . . . . . . . . . . . . . . . . . . 486

12.3 How to Turn ON/OFF Whole System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

12.3.1 How to Turn On Whole System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

12.3.2 How to Turn OFF Whole System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

12.4 System Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 489

CHAPTER 7 ROUTINE MAINTENANCE PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

1.1 Flow of Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

1.2 Required Test Equipment and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 496

2. ROUTINE MAINTENANCE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

NDA-24300 TABLE OF CONTENTS

Page vii

Issue 1

Page 19

TABLE OF CONTENTS (CONTINUED)

Page

2.1 Ambient Conditions in Switch Room Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

2.2 Alarm Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 499

2.3 MAT/Printer Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

2.4 Collection of System Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

2.5 Display of Locked-out Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 502

2.6 Fan Unit Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 503

2.7 Alarm Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 504

2.8 Main Power System Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

2.9 Trunk RGU Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

2.10 ATTCON/DESKCON Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 507

2.11 System Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

3. ROUTINE MAINTENANCE CHECK LISTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 510

CHAPTER 8 MAINTENANCE COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 519

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 519

ALLC Assignment of Line Load Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 522

ALMG Assignment of Alarm Grade Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 523

ATRF Assignment of Traffic Measurement Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 524

ATRFN Assignment of Traffic Measurement Order for Fusion Network. . . . . . . . . . . . . . . . . . . . . 525

BOSD Back Up One-Touch Speed Call Memory Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 526

CADSD Continuous Assignment of Station Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

CATK Continuous Assignment of Trunk Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530

CBCN Control of Broadcasting for NDM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 537

CCSE Change of Common Signaling Channel Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 538

CDBU Change of Dch Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 539

CMOD Change of System Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540

CMWL Control Message Waiting Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 541

CMWL_T Control Message Waiting Lamps – Telephone Number . . . . . . . . . . . . . . . . . . . . . . . . . . 542

CPRS Controlled Alternate PRSCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543

CSCL Continuous Change of Station Class. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

CSTN Continuous Change of Station Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 545

DCBD Display of Call Block Entry Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 546

DCEN Display of Connection Trunk LENS Data for LDM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 548

DCON Display of Connection Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 549

DFTD Display of System Message Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

DISS Display of Program Issue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

DLEN Display of LENS Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .552

DLSL Display of Lockout Station - LENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 554

DLSS Display of Lockout Station - Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 555

DLSS_T Display of Lock Out Station – Number – Telephone Number . . . . . . . . . . . . . . . . . . . . . . 556

DLTEL Display of Telephone Number from LENS for LDM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 557

DNTEL Display of Telephone Number from LENS for NDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 558

DPKG Display of Setting Port Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 559

DPSW Display Package Switch Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 560

DSTN Display of Station Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .561

DTELN Display of Telephone Number Data for NDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 562

DTF101 Display of Terminal Traffic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 564

DTF102 Display of Route Traffic Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .565

DTF103 Display of Station Peg Count Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

TABLE OF CONTENTS NDA-24300

Page viii

Issue 1

Page 20

TABLE OF CONTENTS (CONTINUED)

Page

DTF104 Display of Attendant Peg Count Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 567

DTF105 Display of Route Peg Count Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 568

DTF201 Display of Service Peg Count Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 569

DTF301 Display of UCD Route Peg Count Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 570

DTF302 Display of UCD Group Peg Count Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 571

DTF303 Display of Station Peg Count Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 572

DTF501 Display of Attendant Answering Peg Count Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 573

DTF601 Display of Connection Route Peg Count Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 574

DTF602 Display of Connection Route Traffic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 575

DTF101N Display of Terminal Traffic Data for Fusion Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 576

DTF102N Display of Route Traffic Data for Fusion Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 577

DTF103N Display of Station Peg Count Data for Fusion Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 578

DTF104N Display of Attendant Peg Count Data for Fusion Network. . . . . . . . . . . . . . . . . . . . . . . . . 579

DTF105N Display of Route Peg Count Data for Fusion Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 580

DTF201N Display of Service Peg Count Data for Fusion Network . . . . . . . . . . . . . . . . . . . . . . . . . . 581

DTF301N Display of UCD Route Peg Count Data for Fusion Network . . . . . . . . . . . . . . . . . . . . . . . 582

DTF302N Display of UCD Group Peg Count Data for Fusion Network . . . . . . . . . . . . . . . . . . . . . . . 583

DTF303N Display of UCD Station Peg Count Data for Fusion Network . . . . . . . . . . . . . . . . . . . . . . 584

DTF501N Display of Attendant Answering Peg Count Data for Fusion Network. . . . . . . . . . . . . . . . 585

DTF601N Display of Connection Route Peg Count Data for Fusion Network . . . . . . . . . . . . . . . . . . 586

DTF602N Display of Connection Route Traffic Data for Fusion Network . . . . . . . . . . . . . . . . . . . . . 587

FLINST File Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 588

HDD_FDD Data Control Between HDD and FDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 589

HDD_MAT Data Control Between HDD and MAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 591

HDD_MAT_N Data Control Between HDD and MAT for NDM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 592

HDFP HDD Format of PBX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 593

MBCT Make Busy of Connection Trunk for LDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 594

MBLE Make Busy of LENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 595

MBPM Make Busy of Port Microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 596

MBRT Make Busy of Route . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .597

MBSM Make Busy of System Message Printout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 598

MBST Make Busy of Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .599

MBST_T Make Busy of Station – Telephone Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

MBTC Make Busy of Trunk-Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

MBTK Make Busy of Trunk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .602

MEM_HDD Data Control Between Memory and HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603

MEM_HDD_N Data Control Between Memory and HDD for NDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

MFCH Make Busy of FCCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 605

PMBU Port Microprocessor Back Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

RALM Release Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 607

RALMN Release Alarm for NDM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

RLST Release Station/Trunk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .609

RLST_T Release of Station/Trunk – Telephone Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 610

SINZ System Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612

SPTS Scanning of Port Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .613

SRTS Scanning of Route Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 618

XHFD X-RAY HD or FDD Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 619

NDA-24300 TABLE OF CONTENTS

Page ix

Issue 1

Page 21

LIST OF FIGURES

Figure Title Page

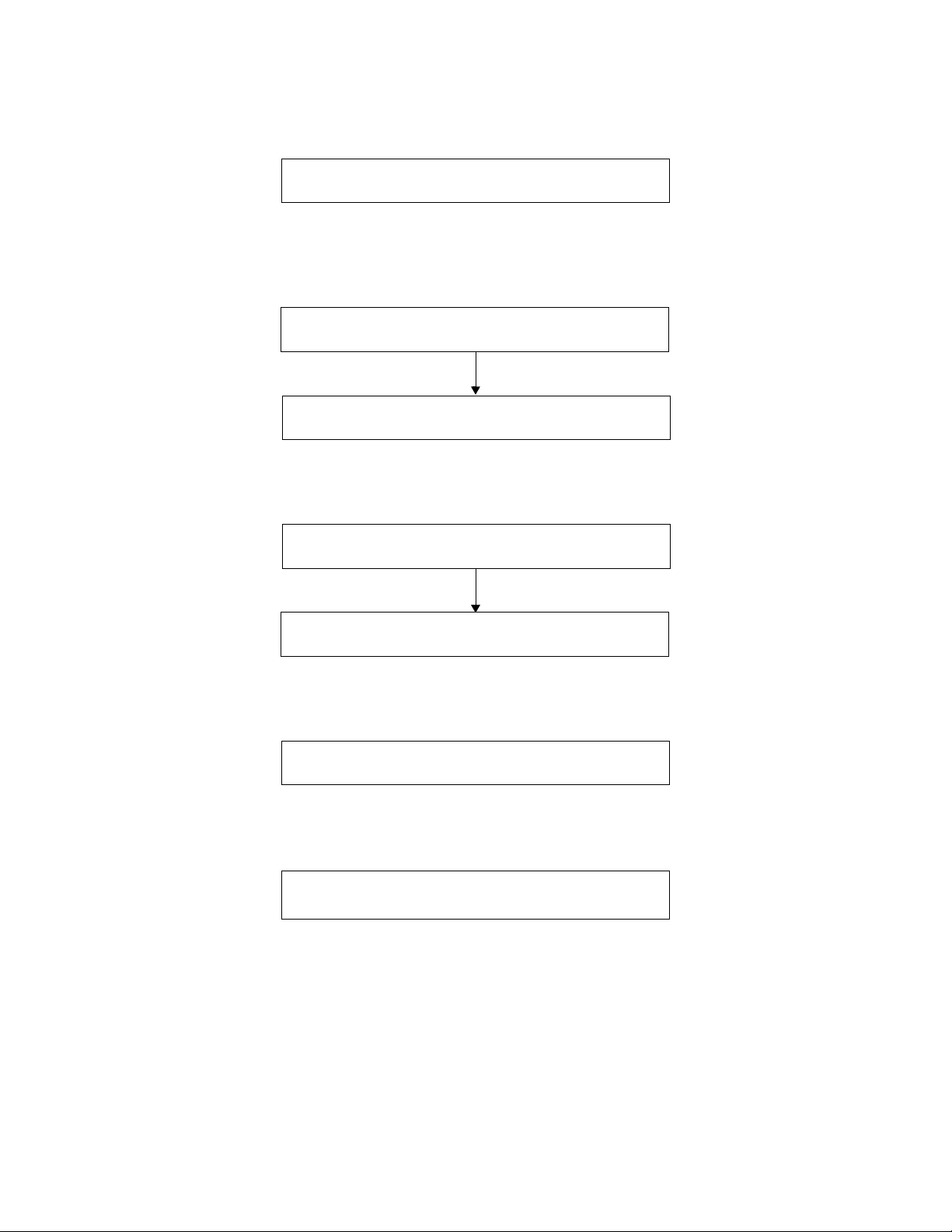

Figure 2-1 Flow of Administrative Management Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 2-2 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2-3 Face Layout of IMG0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2-4 Face Layout of IMG1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2-5 Face Layout of IMG2/3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2-6 LENS Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2-7 Module Group Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2-8 Unit Number Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2-9 Group Number Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-10 Level Number Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2-11 LP Number Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 2-12 System Message Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

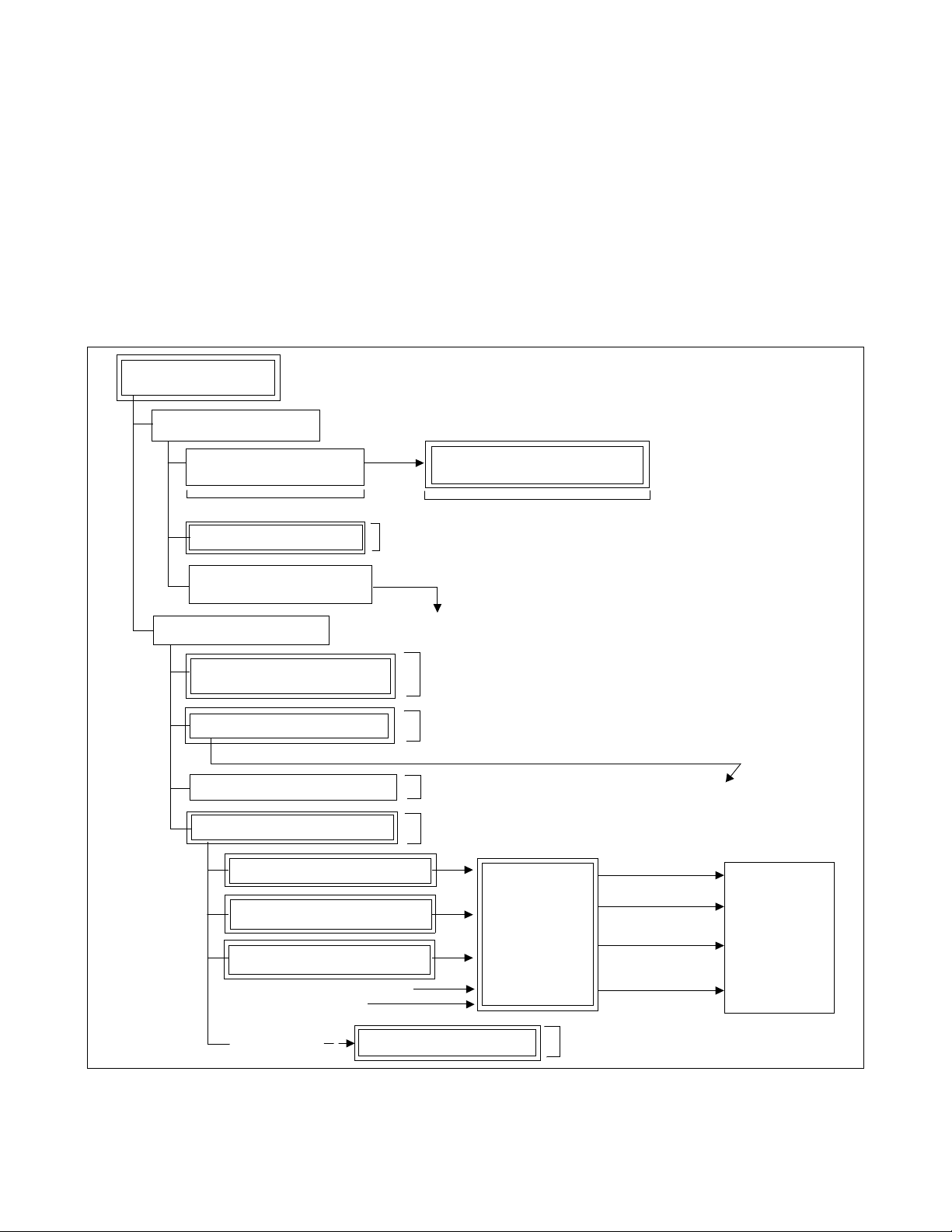

Figure 2-13 Fault Detection General Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2-14 Fault Detection Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2-15 General System Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2-16 CPU Controlling Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-17 Speech Path Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2-18 Speech Path Range of Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 2-19 3M

Figure 2-20 How to Hold a Circuit Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-21 How to Set the ROM in IC Socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-22 How to Clean the Connector Portion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-23 How to Clean Gold-Plated Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-24 Diagnostic Work Items and Symbols Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 2-25 Recovery Procedure Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 2-26 Circuit Card Version Number, Program Name, and Program Package Version Number . . . . 34

Figure 4-1 Circuit Card Mounting Face Layout of LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Figure 4-2 CPR Face Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Figure 4-3 How to Replace the CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Figure 4-4 Removal of Front Panel and Top Cover from CPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Figure 4-5 Insertion of ISAGT and LANI Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Figure 4-6 Reattachment of CPR Top Cover and Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Figure 4-7 Accommodation of New CPR into LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Figure 4-8 Insertion of New HFD into CPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Figure 4-9 Removal of Front Panel and Top Cover From CPR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Figure 4-10 Insertion of ISAGT and LANI Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Figure 4-11 Reattachment of CPR Top Cover and Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Figure 4-12 Location of New CPR Into LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Figure 4-13 Insertion of New HFD Into CPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Figure 4-14 Circuit Card Mounting Face Layout of TSWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Figure 4-15 System Block Diagram (Connections Between GT and CPU). . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 4-16 System Block Diagram (TSW and Other Speech Path Echelons). . . . . . . . . . . . . . . . . . . . . . 273

Figure 4-17 LEDs and Switches for TSW Changeover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Figure 4-18 Circuit Card Mounting Face Layout of PIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Figure 4-19 FANU Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Figure 4-20 Preparation for FANU Replacement (Fans on TOPU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Figure 4-21 How to Replace FANU (Fans on TOPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Figure 4-22 Preparation for FANU Replacement (Fans in Fan Box). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Figure 4-23 How to Replace FANU (Fans in Fan Box) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

®

Model 8012 Portable Field Service Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

LIST OF FIGURES NDA-24300

Page x

Issue 1

Page 22

LIST OF FIGURES (CONTINUED)

Figure Title Page

Figure 4-24 CPR Face Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Figure 4-25 Extraction of CPR from LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Figure 4-26 Rear View of CPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Figure 4-27 How to Remove the Cooling FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Figure 4-28 Fuses Used by System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Figure 4-29 Blown Fault Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Figure 4-30 Fuse Locations Within System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Figure 4-31 Fuse Location Within TSWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Figure 4-32 RGU Fuse Blown Fault Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Figure 4-33 DC -48V Fuse Blown Fault Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Figure 5-1 Controlling LC/ELC Circuit Cards and Speech Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312