Page 1

GammaCompMD QA Client Version 5

User Manual

Version 5.1.50

Page 2

GammaCompMD QA Client User Manual

Copyright © NEC Display Solutions Ltd. 2006 - 2015

This document contains proprietary information from NEC Display Solutions, Ltd. This information

may not be reproduced or transmitted, in whole or in part, without a written agreement from NEC

Display Solutions, Ltd. No patent or other license is granted to this information. The software, if any,

described in this document is furnished under license agreement. The software may not be used or

copied except as provided in the license agreement.

NEC Display Solutions, Ltd. provides this publication “as is” without warranty of any kind, either

express or implied, including but not limited to the implied warranties of merchantability or fitness

for a particular purpose. NEC Display Solutions, Ltd. may revise this document from time to time

without notice. Some states or jurisdictions do not allow disclaimer of express or implied warranties

in certain transactions; therefore, this statement may not apply to you. Information in this document

about products not manufactured by NEC Display Solutions, Ltd. is provided without warranty or

representation of any kind, and NEC Display Solutions, Ltd. will not be liable for any damages resulting

from the use of such information.

NEC and the NEC logo are registered trademarks. Microsoft, Windows, Windows XP, Windows 7 and

Windows 8 / 8.1 are trademarks of Microsoft Corporation.

Manufacturer:

NEC Display Solutions, Ltd. 4-28, 1-chome, Minato-ku, Tokyo, 108-0023 Japan

Importer into the United States of America:

NEC Display Solutions of America, Inc., 500 Park Blvd., Suite 1100, Itasca, Illinois 60143, USA

European Representative:

NEC Display Solutions Europe GmbH, Landshuter Allee 12-14, 80367 Muenchen, Germany

World Wide Web sites:

USA: www.necdisplay.com/medical

Europe: www.medical.nec-display-solutions.com

Sales information:

USA: www.necdisplay.com/medical

Europe: med-info@nec-displays.com

Technical support:

USA: techsupport@necdisplay.com

Europe: med-support@nec-displays.com

Copyright © NEC Display Solutions Ltd., 2006 -2015 2

Page 3

GammaCompMD QA Client User Manual

Table of contents

About GammaCompMD QA Client ............................................................................. 7

1. System Environment .......................................................................................... 10

1.1. Before you start ......................................................................................................10

1.2. Operating System Environment ..............................................................................10

1.3. Workstation Hardware .............................................................................................10

1.4. Display Sensors ......................................................................................................10

1.5. External Sensors ....................................................................................................10

1.6. Pre-requisite Software ............................................................................................ 11

1.7. Supported Display Models ...................................................................................... 11

2. Checking System Dependencies ........................................................................ 14

2.1. External Sensors ....................................................................................................14

2.2. Attaching MD-N2M5B Sensors and External Sensors .............................................14

2.3. Updating GammaCompMD QA Client with MD-N2M5B sensor(s) ...........................14

2.4. Using the CA-210 Color Analyzer ................................................................ ............14

2.5. Using the IBA LXplus instrument .............................................................................14

2.6. Using the IBA LXcan or LXchroma instrument ........................................................15

2.7. Using the Unfors Luxi (new product name: Raysafe Solo Light) instrument ............15

2.8. Using the Windows Power Management Option .....................................................15

2.9. Using Displays without PIP Support ........................................................................15

2.10. Calibration, Test, Level Measurements, and QA Testing ......................................16

2.11. Lost Password .....................................................................................................16

2.12. Using NEC MD215MG ........................................................................................16

2.13. Using NEC MD211G5 ..........................................................................................16

2.14. Using NEC MD302C6 ..........................................................................................16

2.15. Using NEC X651UHD/X841UHD/X981UHD ........................................................17

2.16. Using NEC MD212G3 .........................................................................................17

2.17. Using M-Series Display Controllers from Matrox .................................................17

2.18. ECO mode, Auto brightness, and Human sensing function ..................................17

2.19. Using Windows 8 / 8.1 .........................................................................................17

2.20. Common Dialog Box Conventions .......................................................................18

2.21. Using PIP Enabled Displays ................................................................................19

3. Installation .......................................................................................................... 26

3.1. Setup ......................................................................................................................27

Copyright © NEC Display Solutions Ltd., 2006 -2015 3

Page 4

GammaCompMD QA Client User Manual

3.2. Installation of the internal database ................................................................ .........30

3.3. Finishing the installation ..........................................................................................31

3.4. Options to consider during installation .....................................................................31

3.5. Un-installation .........................................................................................................32

3.6. Database Backup ....................................................................................................32

3.7. Version Upgrades ...................................................................................................33

4. Firewall Settings ................................................................................................. 35

4.1. Windows XP ................................ ................................................................ ...........35

4.2. Windows 7 and Windows 8 / 8.1 .............................................................................39

5. First Start ............................................................................................................ 44

5.1. Start-up and shutdown of GammaCompMD QA Client ............................................44

5.2. User Password Setup .............................................................................................45

5.3. Changing the Display Configuration ................................ ........................................46

5.4. Changing the Sensor ..............................................................................................46

5.5. Change of Installation Location or Ambient Light Environment ................................46

6. Main Display ....................................................................................................... 47

7. GammaCompMD QA Main Menu Structure ....................................................... 49

7.1. Display Overview ....................................................................................................50

7.1.1. Rearrange Displays ................................................................................................ 51

7.1.2. Alert Log ............................................................................................................... 51

7.1.3. Refreshing Display Information .............................................................................. 52

7.1.4. Calibration Reports ................................................................................................ 52

7.1.5. Conformance Test Reports ..................................................................................... 53

7.1.6. QA Test Reports ..................................................................................................... 53

7.2. Calibration ..............................................................................................................54

7.2.1. Perform a Calibration ............................................................................................ 54

7.2.2. Rearrange Displays ................................................................................................ 56

7.2.3. Calibration Reports ................................................................................................ 56

7.2.4. Schedule Setup ...................................................................................................... 60

7.2.5. Calibration Setup ................................................................................................... 64

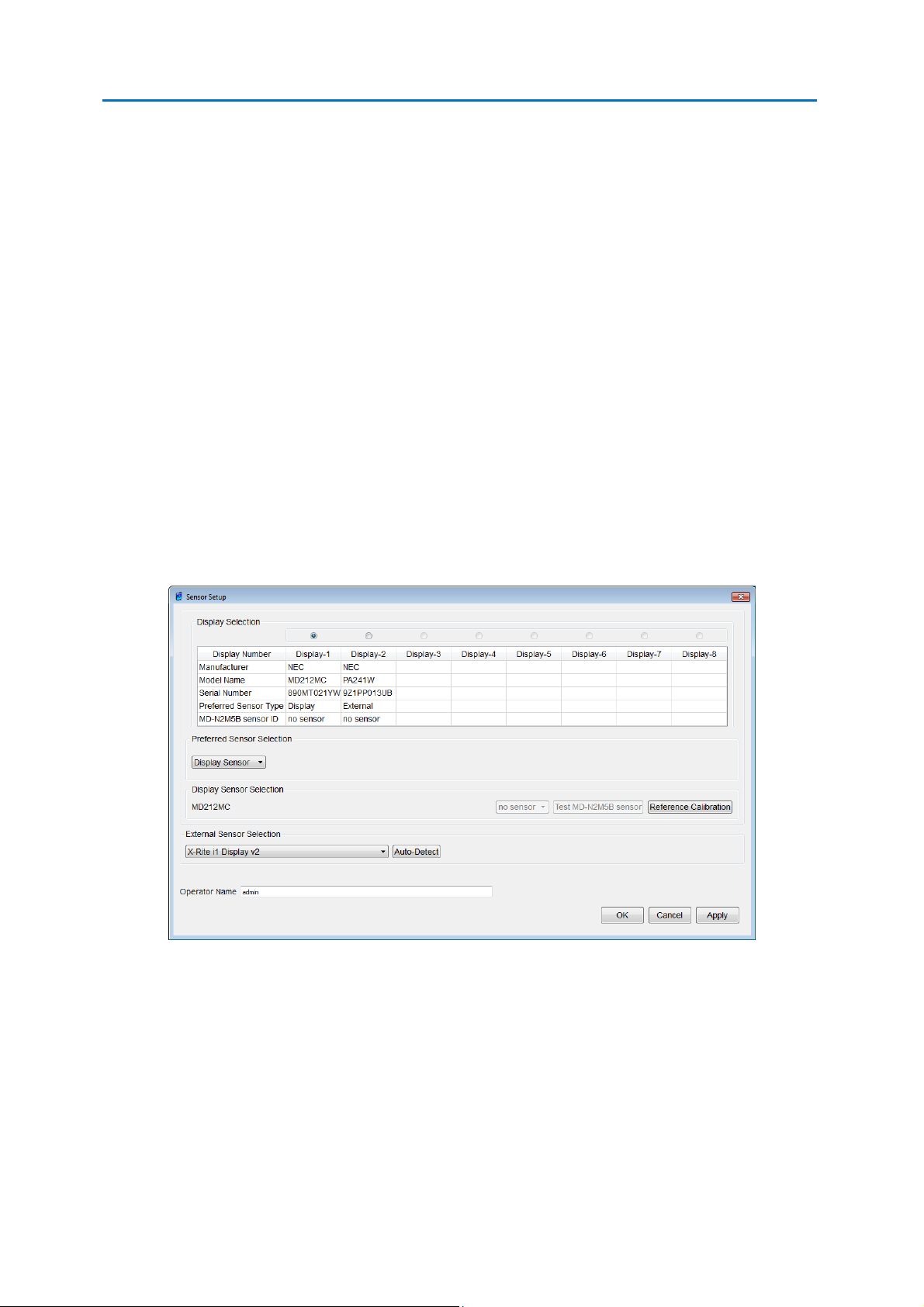

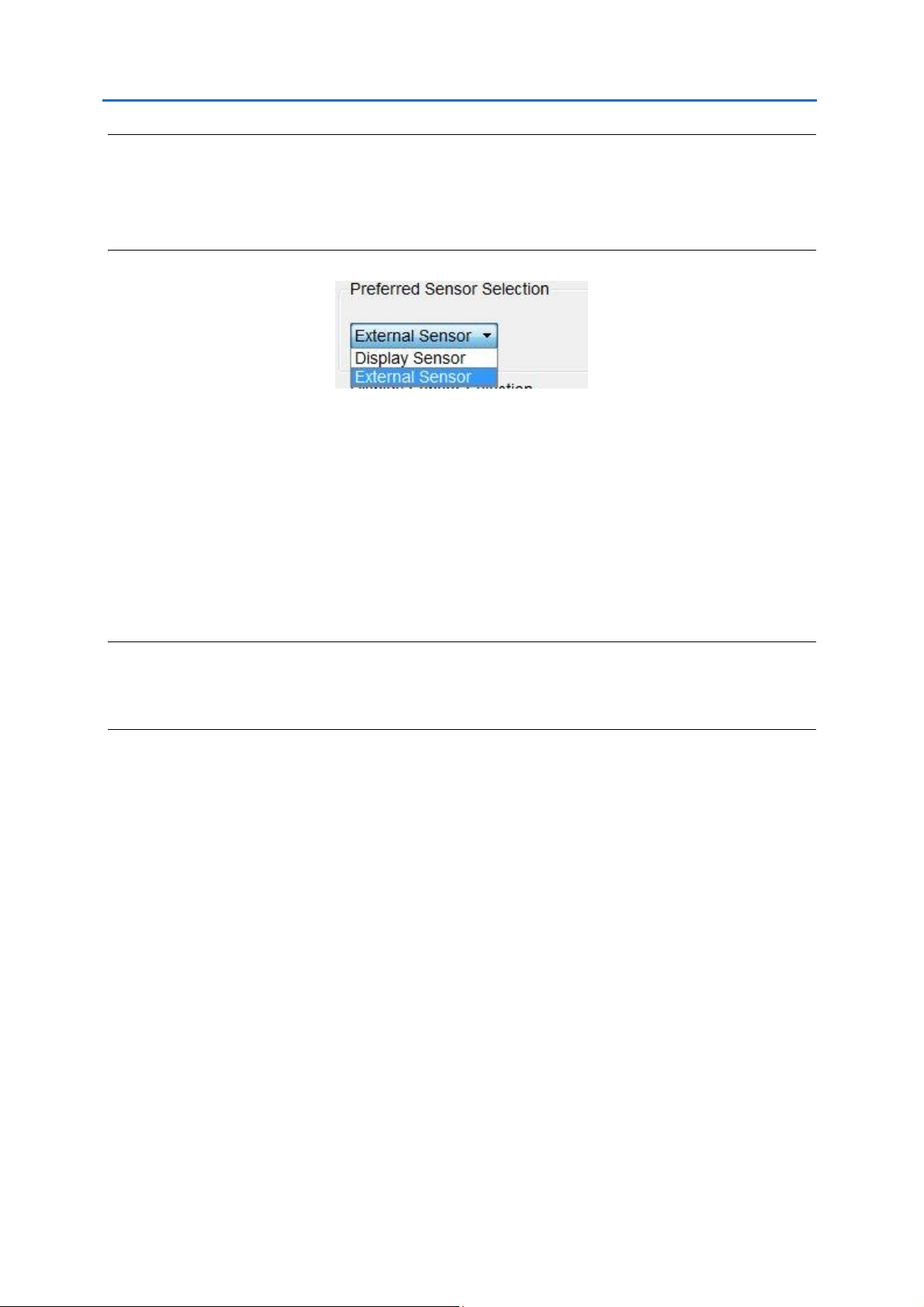

7.2.6. Sensor Setup ......................................................................................................... 77

7.3. Conformance Tests .................................................................................................83

7.3.1. Perform a Conformance Test .................................................................................. 83

7.3.2. Rearrange Displays ................................................................................................ 85

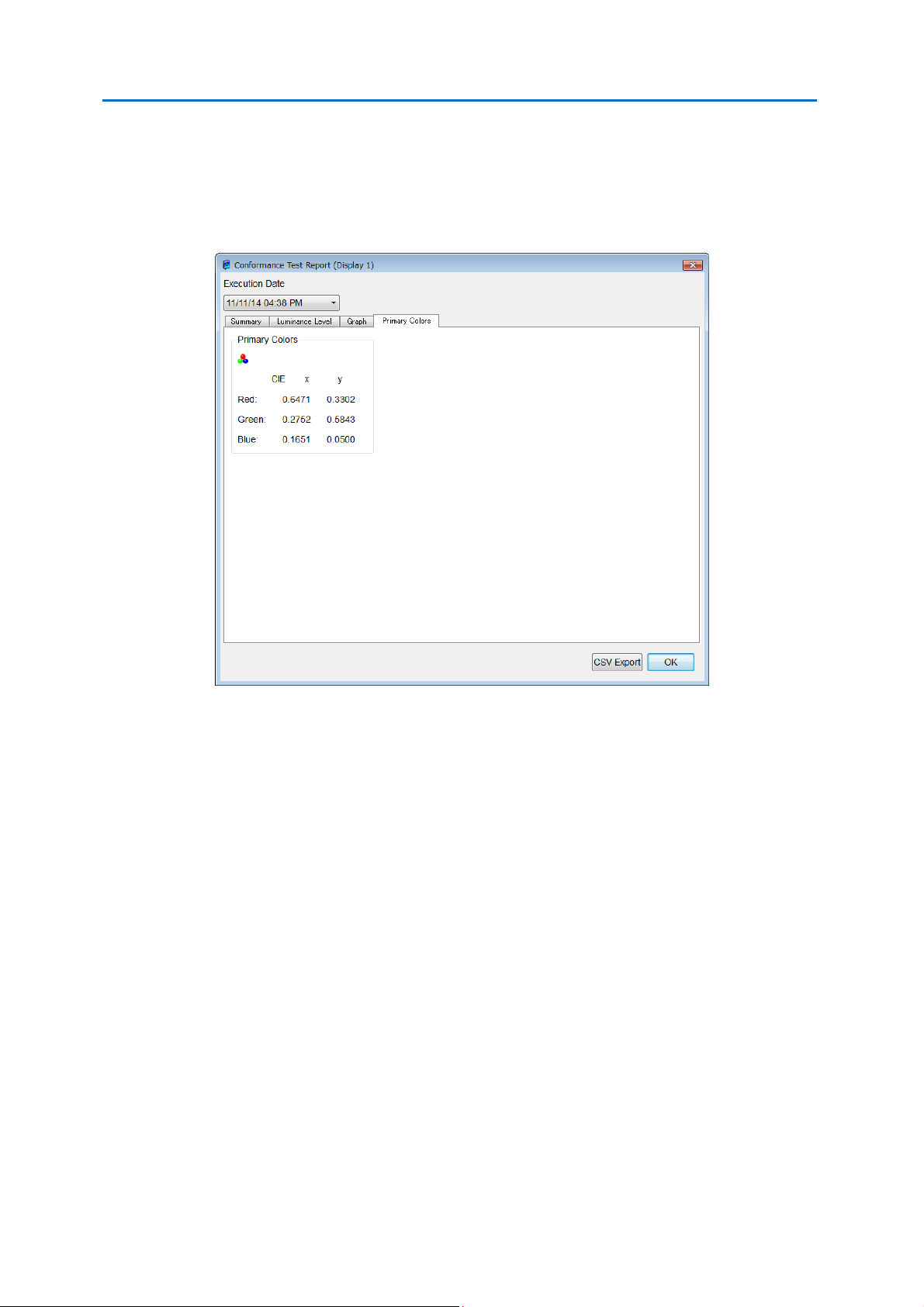

7.3.3. Conformance Test Reports ..................................................................................... 85

Copyright © NEC Display Solutions Ltd., 2006 -2015 4

Page 5

GammaCompMD QA Client User Manual

7.3.4. Schedule Setup ...................................................................................................... 89

7.3.5. Sensor Setup ......................................................................................................... 89

7.3.6. Historical Trend View ............................................................................................ 89

7.4. QA Test ...................................................................................................................90

7.4.1. QA Test Start ......................................................................................................... 90

7.4.2. Rearrange Displays ................................................................................................ 95

7.4.3. QA Test Reports ..................................................................................................... 95

7.4.4. QA Test Setup .........................................................................................................97

7.5. Test Pattern.............................................................................................................99

7.5.1. Display the Test pattern ......................................................................................... 99

7.5.2. Rearrange Displays ............................................................................................... 100

7.5.3. Test Pattern Setup ................................................................................................ 100

7.6. Stand Alone Calibration ......................................................................................... 102

7.6.1. How to get the results of Stand Alone Calibration. ................................................. 102

7.7. Administrator ......................................................................................................... 105

7.7.1. System Setup ....................................................................................................... 105

7.7.1.1. Re-initialization of Display Configuration .............................................................................................. 105

7.7.1.2. Reinitialize System Configuration ......................................................................................................... 108

7.7.1.3. Language Setup .................................................................................................................................... 114

7.7.1.4. Asset ID Setup (Optional) ..................................................................................................................... 115

7.7.1.5. Alert Setup ........................................................................................................................................... 116

7.7.1.6. Network Execution Setup ..................................................................................................................... 122

7.7.1.7. Backup Schedule Setup ........................................................................................................................ 125

7.7.2. User Setup ........................................................................................................... 127

7.7.2.1. Access Rights Setup for Quality Assurance ............................................................................................ 127

7.7.2.2. User Password Setup ............................................................................................................................ 131

7.7.2.3. Startup User Level ................................................................................................................................ 133

7.7.3. Extra Features ...................................................................................................... 134

7.7.3.1. White Luminance Measurement .......................................................................................................... 134

7.7.3.2. Black Luminance Measurement ............................................................................................................ 135

7.7.3.3. Uniformity Test ..................................................................................................................................... 137

7.7.3.4. Display Matching .................................................................................................................................. 139

7.7.3.5. Create Modification Log Entry .............................................................................................................. 141

7.7.3.6. Display Control Button Lock ................................................................................................................. 141

7.7.4. Special Reports ..................................................................................................... 143

7.7.4.1. White and Black Luminance Measurement Reports .............................................................................. 143

7.7.4.2. Uniformity Test Reports ........................................................................................................................ 145

Copyright © NEC Display Solutions Ltd., 2006 -2015 5

Page 6

GammaCompMD QA Client User Manual

7.7.4.3. Latest Results List ................................................................................................................................. 147

7.7.4.4. Display Information .............................................................................................................................. 148

7.7.4.5. System Information .............................................................................................................................. 149

8. Help .................................................................................................................. 151

9. Alert and Warning Popup Windows .................................................................. 152

10. Log Viewer .................................................................................................... 153

11. Trend Viewer ................................................................................................. 156

12. Troubleshooting ............................................................................................. 158

13. MD215MG EDID Serial Number Update Tool ............................................... 168

13.1. Overview ........................................................................................................... 168

13.2. Hardware Setup ................................................................................................ 169

13.3. Software Installation .......................................................................................... 169

13.4. Starting the Software ......................................................................................... 169

13.5. Writing Serial Number(s) to EDID Data .............................................................. 169

13.6. Calibration ......................................................................................................... 171

13.7. Troubleshooting ................................................................................................. 171

14. Notes ............................................................................................................. 172

14.1. Restrictions........................................................................................................ 172

14.2. Copyright Information ........................................................................................ 172

15. Appendix ....................................................................................................... 173

15.1. ACR AAPM SIIM Default Rank .......................................................................... 173

15.2. Saved Settings for Upgrade ............................................................................... 177

15.3. How important is Reference Calibration? ........................................................... 179

Copyright © NEC Display Solutions Ltd., 2006 -2015 6

Page 7

GammaCompMD QA Client User Manual

About GammaCompMD QA Client

GammaCompMD QA is a Display Maintenance and Quality Assurance system specifically

developed to maintain Diagnostic Imaging Displays in a Medical Environment and ensure

compliance with Digital Imaging and Communications in Medicine Grayscale Standard

Display Function (DICOM GSDF).

GammaCompMD QA Client is the part of this system which is installed and used on

workstations with NEC diagnostic imaging displays and review display in PACS environments.

GammaCompMD QA Client can be used stand-alone as well as in a networked Display

Maintenance and Quality Assurance environment and allows a user to:

Check display status – current luminance, active backlight hours and remaining backlight

lifetime, display temperature and other hardware status information

Check PACS display information - serial number and asset ID, DICOM conformance and

historical status data of the connected displays

Perform conformance check and re-calibration to DICOM

Check luminance uniformity across the display surface

Match pairs of displays - Luminance and Color matching to other displays in the field

Copy display performance settings from one display to another

Automate maintenance - schedule calibrations and conformance tests

Generate reports of QC tests performed - following AAPM TG18, ACR AAPM SIIM,

and JESRA X-0093 guidelines as well as regional support for DIN V 6868-57, DIN

6868-157 and IEC 62563-1.

Different user levels

GammaCompMD QA Client features an intuitive user interface with three different

customizable user levels. The Advanced user level contains access to the complete menu and

configuration structure, and is aimed at expert users, PACS administrators and Service

Providers. A second Technician user level has slightly restricted menu options, which are

suited to medical physicists and radiographers who need to carry out conformance checks

and QA tests. The final Radiologist user level is aimed at Radiologists with visual tests, to

confirm the DICOM compliance of the display quickly.

Automated Procedures

GammaCompMD QA Client provides a high level of automated procedures. While the Auto

Mode for a simplified calibration routine and Scheduled Tests ensure a more productive

work process, automated data backup increases data safety and QA peace of mind.

Copyright © NEC Display Solutions Ltd., 2006 -2015 7

Page 8

GammaCompMD QA Client User Manual

Full network capability

With various supported network protocols, NEC displays can be easily integrated and

configured into a PACS network infrastructure. The GammaCompMD QA network system

performs network communication between GammaCompMD QA Server and associated

GammaCompMD QA Client workstations. These workstations can be either diagnostic

imaging workstations or client clinical referral workstations as part of a PACS system.

The GammaCompMD QA network system uses a low bandwidth TCP/ IP socket protocol for

communication between Client workstations (maximum 1000) and the Server for display

status information, remotely initiated calibrations and conformance tests and central

retrieval of calibration and QA test results.

The control center of the GammaCompMD QA Server is HTTP web browser based and

therefore the server can be managed from any workplace within the LAN environment on

the same site. VPN concepts may be used to manage a network over several physical sites, as

long as routing schemes as well as Network Security policies allow the communication.

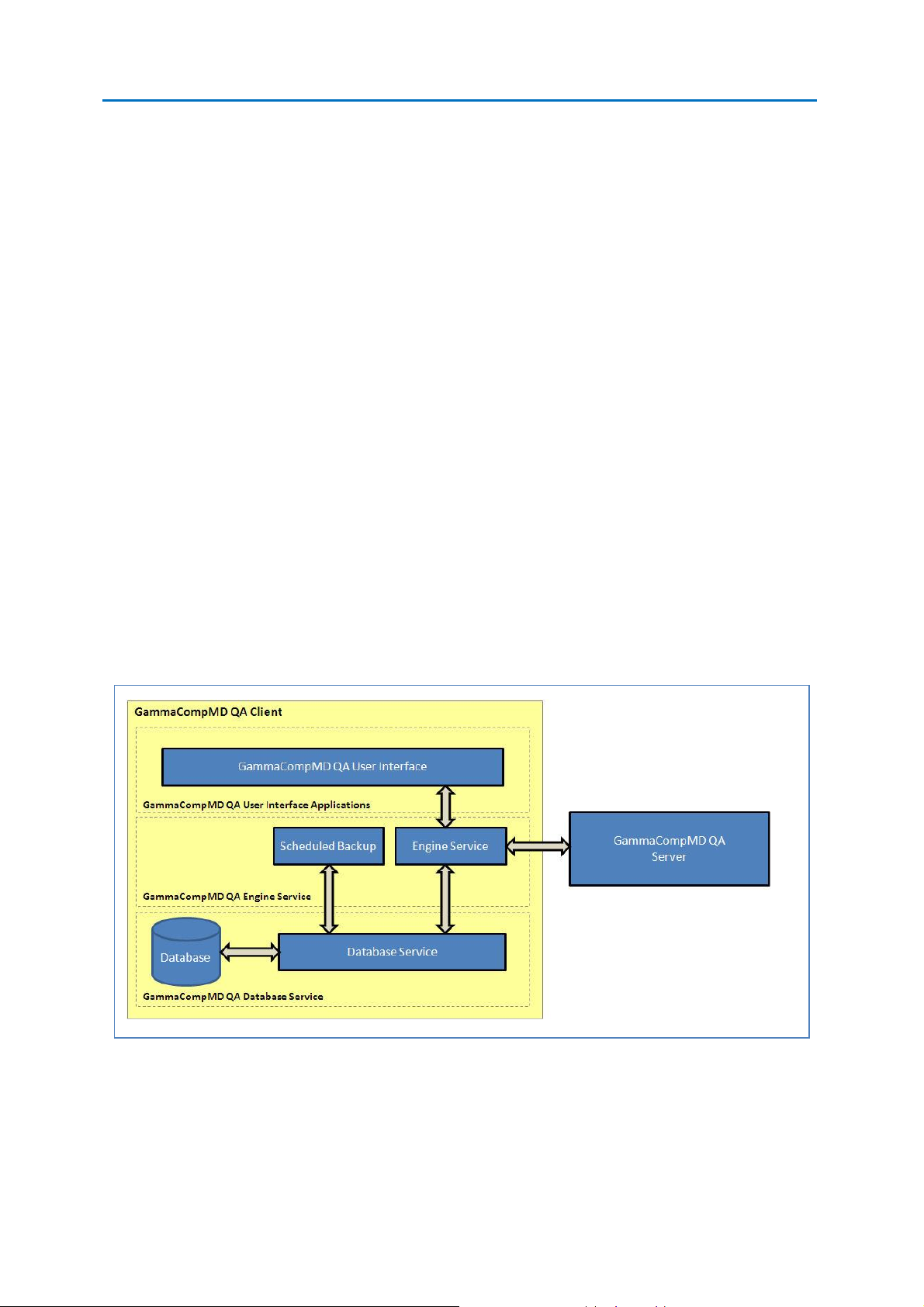

The following drawing shows the structure of the GammaCompMD QA Client software,

when installed on a workstation.

Figure 1: GammaCompMD QA Client software structure

GammaCompMD QA Client consists of several Graphical User Interface (GUI) Applications

and several System Services running in the background, even when no user is logged in.

Copyright © NEC Display Solutions Ltd., 2006 -2015 8

Page 9

GammaCompMD QA Client User Manual

The Applications are called up from a taskbar icon, where a user - depending on user level -

checks display status, does calibrations, conformance tests, QA tests or visual tests.

The three most important System Services are:

The QAEngine Service

Communicating with the connected displays and sensors, the Applications, the Database

Service and - when connected - with the GammaCompMD QA Server.

The Database Service

Controlling a local database system to save all events and results and communicating with

the Applications via the QAEngine Service.

The Scheduled Backup Service

Taking care of automated backups of the database contents, when enabled and maintained

active schedules. During installation of GammaCompMD QA, a GCMDQABackupUser

account is created to manage the background operation of this service.

The communication of these system services with the Applications and the GammaCompMD

QA Server is managed using different IP addresses and different TCP Port addresses.

Therefore it is crucial for successful installation and operation of GammaCompMD QA Client

that these addresses are not blocked, firewalled or run in conflict with other applications on

the workstation. GammaCompMD QA Client is installed with the following IP addresses and

TCP Port addresses (numbers) by default:

- System Service (including QAEngine service and Backup service):

- IP: Localhost, TCP Port: 53250

- Database Service:

IP: Localhost, TCP Port: 5432

If required, these TCP Port addresses may be modified later with the 7.7.1.2 Reinitialize

System Configuration (page 108) menu.

NOTE: An additional Event Logger system service will be used to communicate with the

GammaCompMD QA Server, using the server’s target IP address and HTTPS protocol with

default TCP Port address: 443. This service however is not enabled during Installation. See

7.7.1.2 Reinitialize System Configuration (page 108) to configure the server connection.

Copyright © NEC Display Solutions Ltd., 2006 -2015 9

Page 10

GammaCompMD QA Client User Manual

1. System Environment

1.1. Before you start

This manual contains instructions for using GammaCompMD QA Client software.

GammaCompMD QA Client is designed to run in the following operating environment.

Please check the system environment before installing GammaCompMD QA Client software.

1.2. Operating System Environment

Windows XP professional SP2 or later, 32/64bit (32-bit compatibility mode)

Japanese/English/German/French/Spanish/Italian

Windows 7 professional SP1 or later, 32/64bit (32-bit compatibility mode)

Japanese/English/German/French/Spanish/Italian

Windows 8 / 8.1 professional , 32/64bit (32-bit compatibility mode)

Japanese/English/German/French/Spanish/Italian

An IPv4 / IPv6 based network

1.3. Workstation Hardware

CPU Minimum: Pentium 4, 1.6 GHz

Recommended: Core2Duo, 2.1 GHz or greater

HDD 300MB+ of free space

Memory Minimum: 512MB

Recommended: 1GB or greater

LAN Minimum: 100 Mbps

Recommended: 1000 Mbps or above

1.4. Display Sensors

Front Sensors: MD212MC, MD213MC, MD210C2, MD211C2, MD242C2,

MD210C3, MD211C3, MD302C4, MD302C6, MD213MG, MD211G3,

MD212G3, MD215MG, MD211G5

Retractable Sensor: MD-N2M5B

1.5. External Sensors

MDSVSENSOR3 by NEC (USB)

i1 Display version 2 by X-Rite (GretagMacbeth) (USB)

Chroma 5 Colorimeter by X-Rite (USB)

i1Display Pro by X-Rite (USB)

ColorMunki by X-Rite (USB)

Copyright © NEC Display Solutions Ltd., 2006 -2015 10

Page 11

GammaCompMD QA Client User Manual

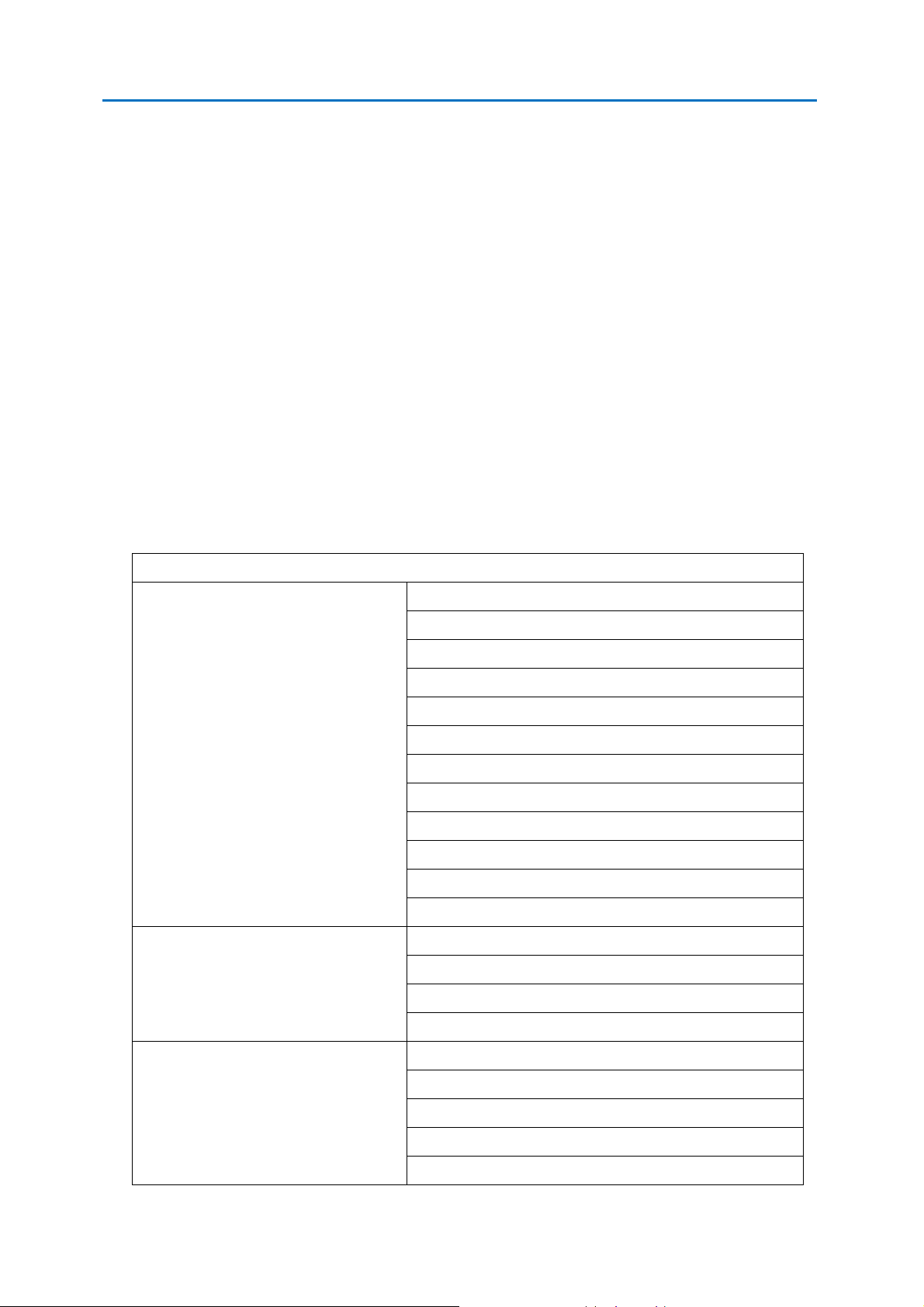

Supported Display Models

NEC MultiSync 90 Series

LCD1990SXi

LCD1990SX

LCD2090UXi

LCD2190UXi

LCD2190UXp

LCD2190UXi

LCD2490WUXi

LCD2490WUXi2

LCD2690WUXi

LCD2690WUXi2

LCD3090WQXi

LCD1990SXp

NEC MD Series (Grayscale)

MD21GS-2MP

MD21GS-3MP

MD205MG

MD205MG-1

NEC MD Series (Display Sensor

Model / Grayscale)

MD213MG

MD215MG (USB cable required)

MD211G3

MD212G3 (USB cable required)

MD211G5 (USB cable required)

i1Pro by X-Rite (USB)

Spyder3 by Colorvision (USB)

Konica Minolta CA-210 (RS-232C/USB)

IBA LXplus (RS-232C) - Color measurement not supported

Unfors Luxi (RS-232C) - Color measurement not supported

IBA LXcan(USB) - Color measurement not supported

IBA LXchroma(USB)

1.6. Pre-requisite Software

Adobe Reader (Version 7.0 or later) – To display the Help file

An internet browser – To read exported QA Test HTML files (i.e. Internet Explorer 7

or later, Firefox 6 or later).

1.7. Supported Display Models

GammaCompMD QA Client supports the following display models

Copyright © NEC Display Solutions Ltd., 2006 -2015 11

Page 12

GammaCompMD QA Client User Manual

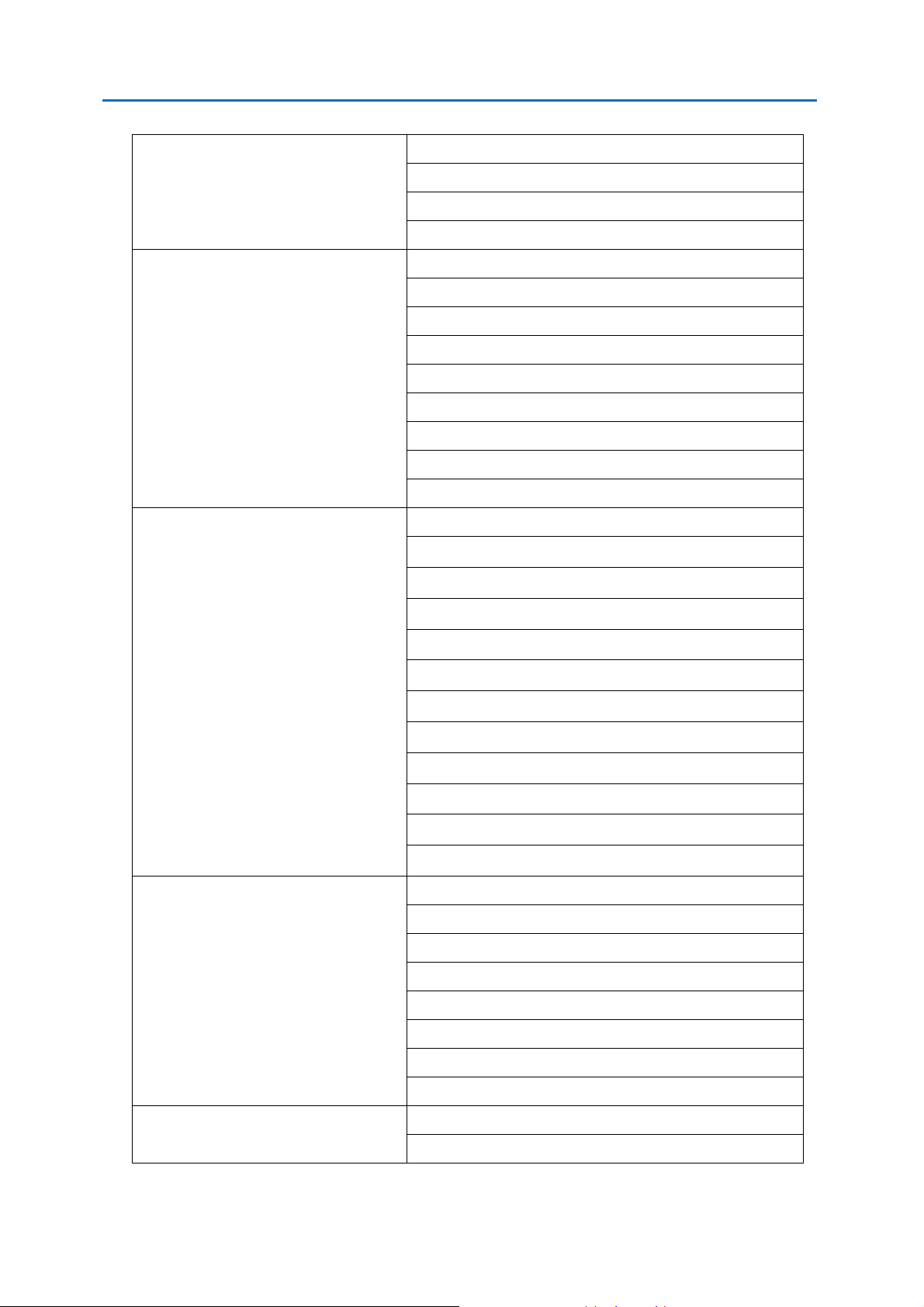

NEC MD Series (Color)

MD21M

MD304MC

MD301C4

MD322C8

NEC MD Series (Display Sensor

Model / Color)

MD212MC

MD213MC

MD210C2

MD211C2

MD242C2

MD210C3

MD211C3

MD302C4

MD302C6 (USB cable required)

NEC EA Series

EA193Mi

EA224WMi

EA234WMi

EA244WMi

EA244UHD

EA273WMi

EA274WMi

EA275WMi

EA275UHD

EA294WMi

EA304WMi

EA305WMi

NEC MultiSync PA Series

PA231W

PA241W

PA271W

PA301W

PA242W

PA272W

PA302W

PA322UHD

NEC MultiSync P Series

P241W

P232W

Copyright © NEC Display Solutions Ltd., 2006 -2015 12

Page 13

GammaCompMD QA Client User Manual

P242W

NEC Public Display Series

(For displaying medical images)

X651UHD

X841UHD

X981UHD

NEC large format models

Note:

Gamma correction only, manual

adjustment of luminance is

required

Multeos M40

Multeos M46

Multeos LCD M401

Multeos LCD M461

LCD 4020

LCD 4620

LCD 5220

LCD 6520L

LCD 6520P

LCD X461UN

LCD X461HB

LCD P401

LCD P461

LCD S401

LCD S461

LCD S521

LCD P521

LCD P402 *Using DVI connection only

LCD P462 *Using DVI connection only

Copyright © NEC Display Solutions Ltd., 2006 -2015 13

Page 14

GammaCompMD QA Client User Manual

2. Checking System Dependencies

2.1. External Sensors

External sensor drivers are included with the GammaCompMD QA Client. Please install

GammaCompMD QA Client before connecting any external sensor to the system. If

multiple external sensors are connected simultaneously, they will not be correctly

identified. Please connect only one external sensor.

2.2. Attaching MD-N2M5B Sensors and External Sensors

The NEC MD-N2M5B external sensor can be used to perform automated calibrations

on some display models. Some MD-N2M5B sensors and external sensors cannot be

stopped by the operating system (the [Safely Remove Hardware] icon is not shown in

the taskbar). To remove a sensor that does not have this icon, only remove it after

checking that the sensor is not in use. It is recommended that the sensor be removed

after stopping the GammaCompMD QA Client.

2.3. Updating GammaCompMD QA Client with MD-N2M5B sensor(s)

If updating from GammaCompMD QA Client Version 4.0.10, the settings of MD-N2M5B

sensor will be discarded. Set it up again after upgrading. For more information about

sensor settings, refer to 7.2.6 Sensor Setup (page 77).

2.4. Using the CA-210 Color Analyzer

If connecting with serial communication, set the baud rate for the sensor unit to

9600bps. The sensor will not be detected if it is set at another baud rate. Settings are

not necessary when connecting with USB communications. Also, special modes set at

the CA-210 (MEAS or 0-CAL) will not be recognized by GammaCompMD QA Client.

Please follow the instructions displayed at the start of calibration and startup to

properly set the mode. You cannot use a CA-210 which supports two or more

measuring probes. Only one probe connection is supported. Please refer to detailed

instructions how to use this instrument in the CA-210 user manual.

2.5. Using the IBA LXplus instrument

For ambient light measurement, the optional lux sensor needs to be attached to the

LXplus instrument. Please turn the LXplus power to OFF when attaching / detaching the

Lux sensor. At this time, be careful to not pull out the USB cable when performing USB

communications with a USB - serial conversion adapter. Please refer to detailed

instructions how to use this instrument in the LXplus user manual.

Copyright © NEC Display Solutions Ltd., 2006 -2015 14

Page 15

GammaCompMD QA Client User Manual

2.6. Using the IBA LXcan or LXchroma instrument

For ambient light measurement, the optional LxLs lux sensor needs to be attached to

the LXcan or LXchroma instrument. Please turn the LXcan or LXchroma power to OFF

when attaching / detaching the Lux sensor. Please refer to detailed instructions how to

use this instrument in the LXcan or LXchroma user manual.

The screen contact mask is needed for measuring directly on screens.

The distance mode requires a distance of about 50 cm for measuring, an ultrasound

range finder is integrated in the LXcan or LXchroma. On the display, the distance is

shown as an arrow indicating in which direction the device must be moved to reach the

right measurement distance.

2.7. Using the Unfors Luxi (new product name: Raysafe Solo Light) instrument

It is equipped with a light detector which can be used for both measuring display

luminance and ambient light. Please turn the sensor's power OFF when enabling /

disabling the ambient light detector. Be careful to not pull out the USB cable when

performing USB communications with a USB - serial conversion cable.

NOTE: Only Unfors Luxi instruments equipped with firmware version 5.05 or later are

supported by GammaCompMD QA Client software. Please refer to detailed instructions

in the Unfors Luxi (XI Kit) User Manual.

2.8. Using the Windows Power Management Option

When the power management option is used in Windows XP (or when the Microsoft

“Windows PC Automatic Energy-Saving Program” is used), an external sensor may not

be recognized after the system returns from standby or sleep mode. If a sensor is not

recognized, remove it, reconnect it, and check that the external sensor automatic

detection and calibration are working normally.

2.9. Using Displays without PIP Support

With a display model not supporting PIP MODE, GammaCompMD QA Client cannot be

used when the display is connected using multiple inputs (e.g. DVI input + DisplayPort

input) through cables to one or more workstations. Please make sure that only one

input is connected to the display before using GammaCompMD QA Client. Also, please

perform a re-initialization of the display configuration when you disconnect/reconnect

display cables to change connection.

Copyright © NEC Display Solutions Ltd., 2006 -2015 15

Page 16

GammaCompMD QA Client User Manual

2.10. Calibration, Test, Level Measurements, and QA Testing

Do not turn off power, enter the power management manually (from OS side), unplug

cables, or remove external sensors’ USB cables during calibration, conformance test,

uniformity test, white/black level measurements or QA tests, as doing so will have a

negative effect on accuracy. If re-initialization is necessary, follow the instructions in

7.7.1.1 Re-initialization of Display Configuration (page 105).

2.11. Lost Password

User passwords must be set by a user with (local) administrator rights.

GammaCompMD QA will need to be reinstalled if the Advanced User password is lost.

2.12. Using NEC MD215MG

When using the MD215MG model, some additional action is required to support this

model within GammaCompMD QA Client, including connecting a USB cable from the

computer to the monitor. Please refer to 13 MD215MG EDID Serial Number Update

Tool (page 168).

2.13. Using NEC MD211G5

When using the MD211G5 model, connecting a USB cable from the computer to the

monitor is required for communication.

2.14. Using NEC MD302C6

When using the MD302C6 model, connecting a USB cable from the computer to the

monitor is required for communication.

When you use external sensor, use a color sensor.

If a signal cable is changed after installation or calibration, please execute

re-initialization of the display configuration and execute re-calibration. Regarding

how to operate, refer to 7.7.1.1 Re-initialization of Display Configuration (page 105)

and 7.2 Calibration (page 54).

If an external sensor was used for the calibration, the actually calibrated luminance

will be slightly lower than the selected target luminance.

This effect will happen under the following conditions:

OS: Windows7 or later

Display controller: Display Port 10-bit output is enabled.

Countermeasure: Disable 10-bit support (NVIDIA Quadro Series factory default:

Enabled) or keep 10-bit support disabled (AMD Firepro Series factory default:

Disabled).

Copyright © NEC Display Solutions Ltd., 2006 -2015 16

Page 17

GammaCompMD QA Client User Manual

2.15. Using NEC X651UHD/X841UHD/X981UHD

If GCMDQA has not recognized the NEC model X651UHD, X841UHD and X981UHD,

check the following using the ON-SCREEN-DISPLAY (OSD) menu of this large format

display

SPECTRAVIEW ENGINE is’ ON’.

DDC/CI is ’ENABLE’.

(Refer to the display's documentation for details.)

2.16. Using NEC MD212G3

When using the MD212G3 model, connecting a USB cable from the computer to the

monitor is required for communication.

2.17. Using M-Series Display Controllers from Matrox

When using M-Series display controllers from Matrox while the system is logged off,

any scheduled executions will not function. Also, when logging on to Windows after it

was once logged off, there may be cases where the displays are not correctly

recognized by GammaCompMD QA Client. In this case, please execute re-initialization

of the display configuration. Regarding how to operate, refer to 7.7.1.1 Re-initialization

of Display Configuration (page 105).

2.18. ECO mode, Auto brightness, and Human sensing function

When using EA Series model, please turn off the above functions manually before the

calibration.(Refer to the display's documentation for details.)

When using MD211C3, MD210C3, MD211C2, MD210C2, MD242C2 or MD302C4

models, Human Sensing is turned OFF automatically while each function runs. Human

Sensing returns to original setting after each function runs. If a display entered into

power saving mode by Human Sensing, a display will return form power saving mode

before running each function.

When the calibration will be started, the display will perform a warm-up after having

returned from power saving mode.

2.19. Using Windows 8 / 8.1

If you want to upgrade from Windows 7 to Windows 8 / 8.1, and GammaCompMD

QA was installed, a seamless operation of GammaCompMD QA cannot be

guaranteed. For this case, the following operation is recommended:

(1) Backup data before an upgrade to Windows 8 / 8.1. Refer to 3.6 Database

Backup (page 32).

Copyright © NEC Display Solutions Ltd., 2006 -2015 17

Page 18

GammaCompMD QA Client User Manual

(2) Uninstall GammaCompMD QA.

(3) Upgrade to Windows 8 / 8.1.

(4) Re-Install GammaCompMD QA.

(5) Restore Backup data. Refer to 7.7.1.2 Reinitialize System Configuration (page

108).

If restoring backup data (history) is not desired, only perform step (2), (3) and (4).

GammaCompMD QA Client performs as Desktop Application.

If Start Screen (Figure 2) and/or Modern UI Application (Windows Store apps) are

shows, the execution of network and/or schedule tests are suspended. You need to

close the Start Screen or Windows Store apps. When the Desktop is shown, the

execution of network and/or schedule tests starts.

While the schedule test and/or the execution of network performs, a Main Screen can’t

be started. If you need to operate a Main Screen, complete, cancel or postpone the

execution of network and/or the schedule test before operating a Main Screen.

Figure 2: Start Screen of Windows 8 / 8.1

Do not change to the Start Screen and Windows Store apps during execution of

GammaCompMD QA Client.

Do not show the charm bar during execution of GammaCompMD QA Client.

Launch GammaCompMD QA Client after canceling a snap view.

LXcan and LXchroma are not supported on Windows8.1.

When using MD215MG, MD211G5, MD212G3 or MD302C6 on Windows8.1, it may

cause GammaCompMD QA Client to malfunction. In this case, disable [USB Selective

Suspend] in Windows 8 / 8.1.

2.20. Common Dialog Box Conventions

GammaCompMD QA Client displays separate dialog boxes for each of its features. The

following describes the function of buttons and checkboxes in the dialog boxes.

Copyright © NEC Display Solutions Ltd., 2006 -2015 18

Page 19

GammaCompMD QA Client User Manual

Dialog boxes with only an OK button

Clicking OK closes the dialog box. When displaying a dialog box with display selection

buttons again, the previous selections are cleared. Make the selections again.

Dialog boxes with OK and Cancel buttons

Clicking OK performs the intended action (enables setting / start calibration / view

report). Clicking Cancel closes dialog box without applying any changes.

Dialog boxes with OK, Cancel, and Apply buttons

Clicking OK enables settings and closes the dialog box. Clicking Cancel cancels any

change and closes the dialog box. However, the settings that were applied by clicking

the Apply button will not be changed back. Clicking Apply applies settings but does

not close the dialog box.

Dialog boxes with OK and View buttons

Clicking OK closes the dialog box. Clicking View will cause all changes to be lost in

dialog boxes with checkboxes. Clicking View will show the test pattern.

Checkboxes

Select All/Deselect All Checkboxes

Checking these will check all available items in dialog box.

Un-checking this will deselect all available items in the dialog box.

NOTE: When the checkbox is in a tab such as in 7.7.1.5 Alert Setup (page 116), it

affects only those checkboxes in the currently selected tab.

Windows Commands, Menus and Messages

All instructions and menu references related to the Windows operating system are

shown within brackets.

Example: Select the [General] tab on the [Windows Firewall] screen.

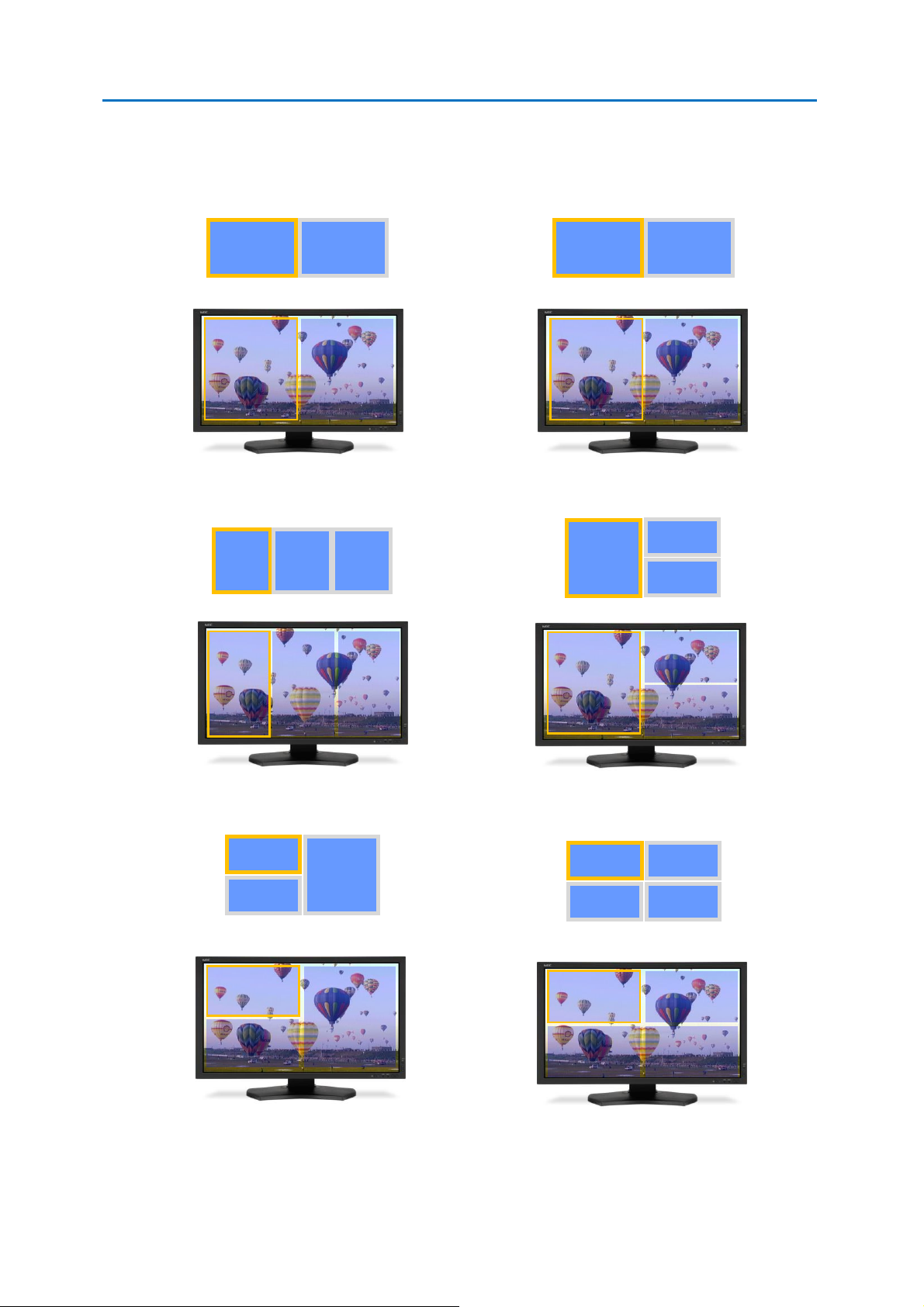

2.21. Using PIP Enabled Displays

PIP MODE supported display models are able to display information from more than

one input on one screen at the same time. Please refer to the display’s user manual for

details.

GammaCompMD QA Client can handle configurations where two or more inputs are

Copyright © NEC Display Solutions Ltd., 2006 -2015 19

Page 20

GammaCompMD QA Client User Manual

displayed on one screen. Set up the input sequence, screen order in Windows and the

display area according to the example settings shown on the next page.

Copyright © NEC Display Solutions Ltd., 2006 -2015 20

Page 21

GammaCompMD QA Client User Manual

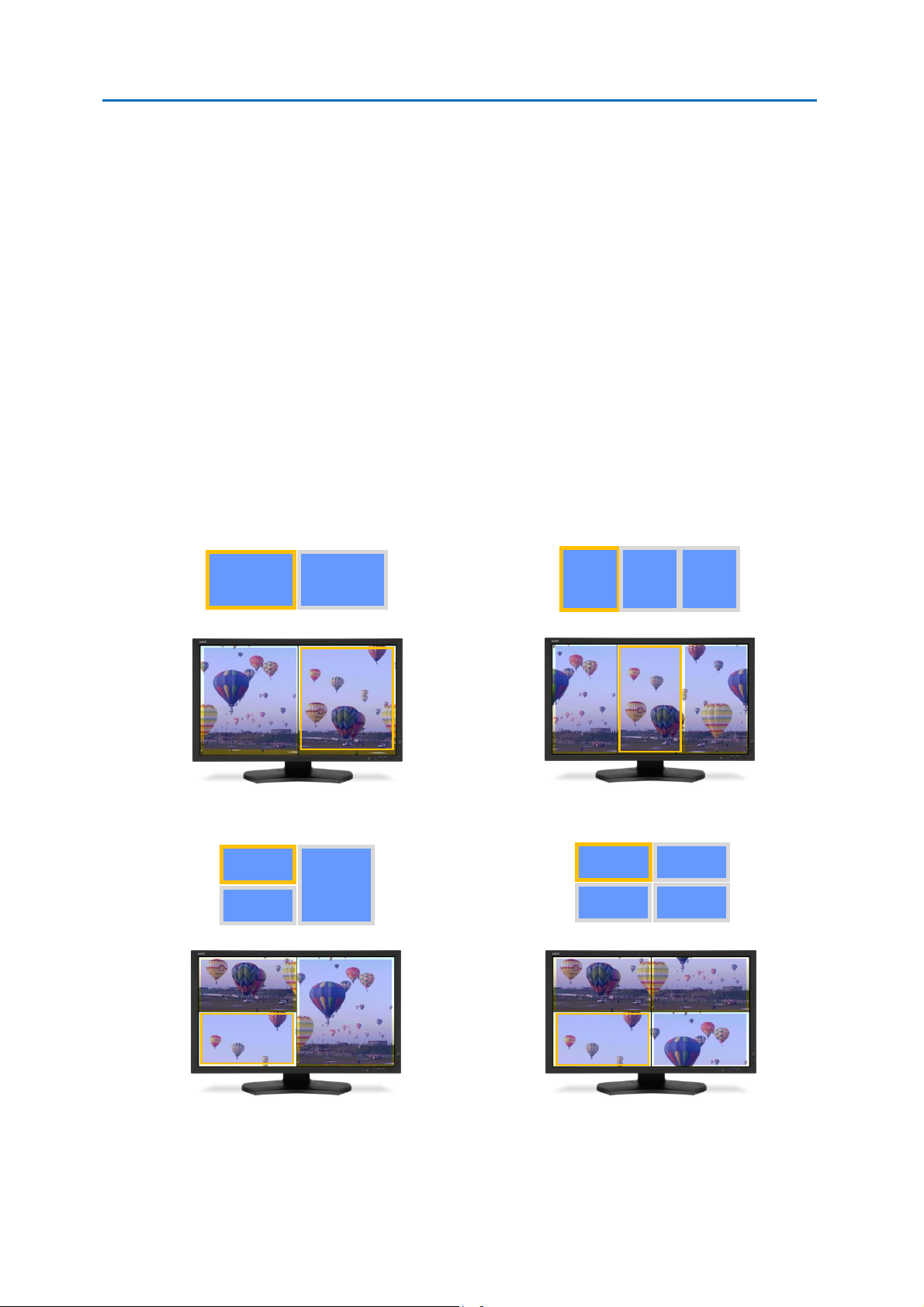

Screen setting in Windows

Screen setting in Windows

Screen setting on display

1

2

1

2

1

2

1

2

(c) Correct example 3

(d) Correct example 4

Screen setting in Windows

Screen setting on display

Screen setting on display

1

1

3

2

3

1 2 3

Screen setting in Windows

Screen setting in Windows

Screen setting on display

Screen setting on display

1

3 2 4

1 2 3

4

2

1

3

2

1

2

3

1

2

3

Screen setting in Windows

(a) Correct example 1

(b) Correct example 2

(e) Correct example 5

(f) Correct example 6

Examples for correct setup

Screen order in Windows setting view and actual display screen should be the same.

Copyright © NEC Display Solutions Ltd., 2006 -2015 21

Figure 3: Examples of correct display settings when using PIP MODE

Page 22

GammaCompMD QA Client User Manual

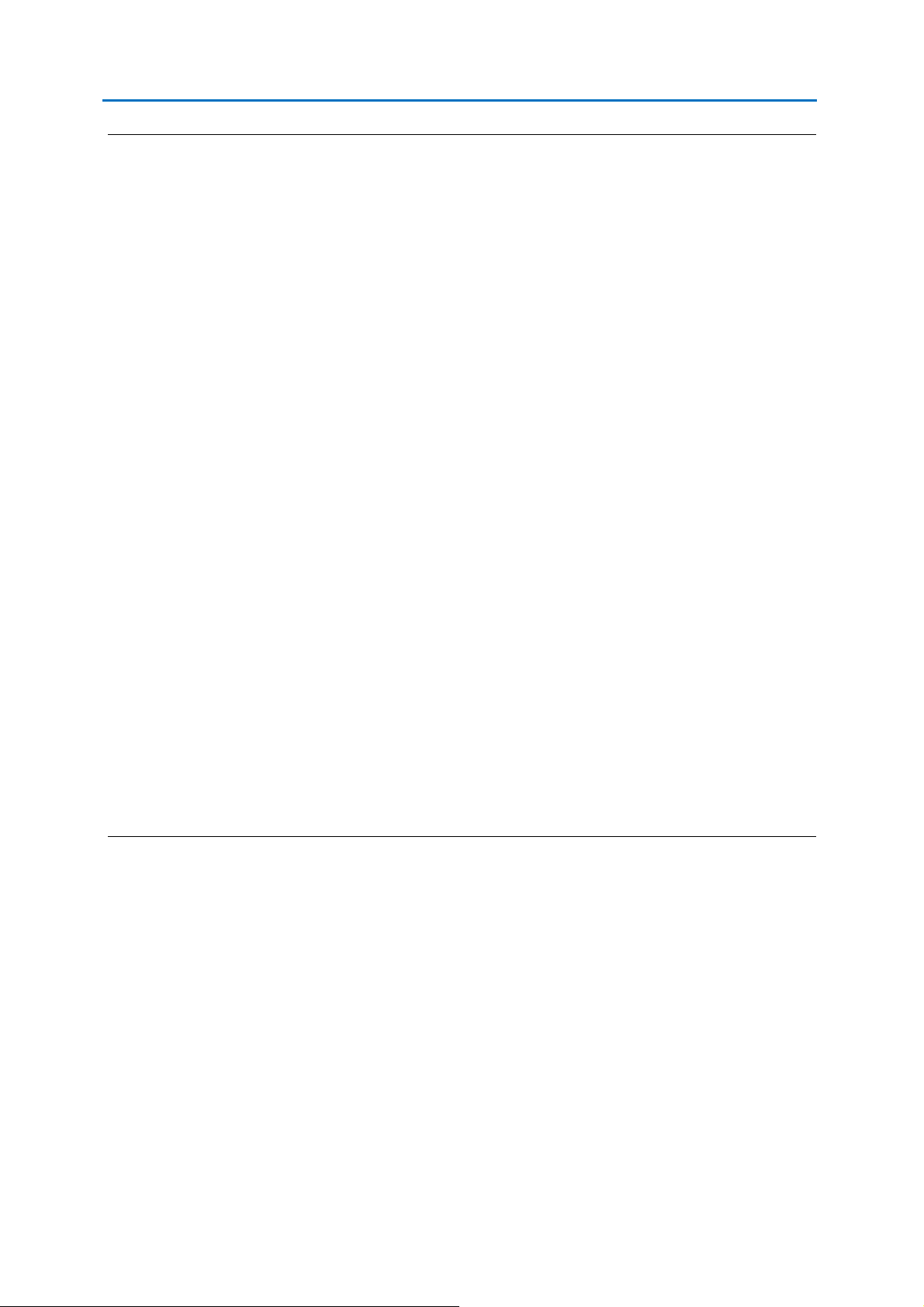

Screen setting in Windows

(a) Incorrect example 1

Screen setting on display

1

2

Screen setting in Windows

Screen setting on display

2

1

3

1 2 3

2

1

(b) Incorrect example 2

Screen setting in Windows

Screen setting in Windows

Screen setting on display

3 1 4

2

1 2 3

4

Screen setting on display

2

1

3

1

2

3

(d) Incorrect example 3

(f) Incorrect example 4

When you perform a calibration, luminance measurement or QA test, PIP MODE will

be turned off automatically. You can test the correct input, using the following:

1. Manually turn “PIP MODE” OFF on the display via control button.

2. For case (a), (c), (e) and (f), you should only see the image of display area #1,

otherwise changes in connection sequence are required. For case (b) and (d),

change some settings to see the image of display area #2 image as well.

3. Turn ON “PIP MODE (PbP) (hereinafter referred to as PbP)” and reconfirm the

screen order.

4. Refer to the display's documentation for PIP MODE. The identification of the

display within Windows can be changed by settings of the screen resolution.

Perform procedure 1 to 3 if you changed settings.

Examples of incorrect setup (I.e. changing the settings via the OSD’s SWAP function)

Screen order in Windows setting view and actual display screen are mismatched.

Copyright © NEC Display Solutions Ltd., 2006 -2015 22

Figure 4: Example of incorrect display setting when using PIP MODE

Page 23

GammaCompMD QA Client User Manual

If the main screen setting is correctly done, Sensor Contact Position Guide (Figure

57) will be shown before calibration or taking other measurements starts. If QA Test

starts, the following message (Figure 5) will be shown before calibration or taking

other measurements starts.

When the circle and the rectangle are displayed correctly related to the center of

screen, the user is allowed to continue the operation.

If the circle and the rectangle are displayed incorrectly, click the cancel button. In this

case, execute 7.7.1.1 Re-initialization of Display Configuration (page 105) after

setting according to the correct example.

Figure 5: Continue Operation dialog

When the main screen setting is not correctly done, the following message (Figure 6)

may be shown. In this case, please check and redo the setting.

Figure 6: Abort Operation dialog

Copyright © NEC Display Solutions Ltd., 2006 -2015 23

Page 24

GammaCompMD QA Client User Manual

IMPORTANT NOTES:

・Unlike other sensors, retractable sensor executes calibration automatically when connected

to the system. As long as PIP MODE main screen setting is correctly done, calibration will be

completed properly without showing Sensor Contact Position Guide (Figure 57) or Continue

Operation dialog (Figure 5). If the screen is not correctly set, calibration will stop with an

error message. Please set up PIP MODE correctly again and re-execute the calibration.

・If the buttons of the Sensor Contact Position Guide (Figure 57) or Continue Operation

dialog (Figure 5) are not shown, push the ESC key to cancel the operation.

・When displaying two or more inputs on one screen, it is necessary that both inputs are

connected to the same display controller. Displays cannot be managed properly when each

input is connected to a different display controller.

・When displaying two or more inputs on one screen, please connect the signal cables of

same connector type (Display Port/DVI/HDMI) to the display.

・Any change of Windows display settings or display controller or input or connection of a

different display typically requires an update of configuration settings. In such a case, please

execute “Re-initialization of the Display Configuration” in GammaCompMD QA Client.

・Executing QA Test with PIP MODE equipped displays will always show Continue Operation

dialog (Figure 5) regardless of PIP MODE setting (ON/OFF). If the screen configuration is

correct, press “Continue” to continue your operation.

・If using this function on a display with PIP MODE (PbP), you need to input the appropriate

resolution on the screen to perform correctly the visual test. When you change the

resolution manually, please return to the original settings after the visual test.

・When the display sensor (Front sensor model or Retractable sensor) is used, be sure to set

the both the EXPANSION mode and the PIP MODE to “FULL” in the ON-SCREEN-DISPLAY

(OSD) of the display.

・Please set the PIP MODE not to "Picture in Picture" but to "Picture by Picture".

Copyright © NEC Display Solutions Ltd., 2006 -2015 24

Page 25

GammaCompMD QA Client User Manual

・If the operation with the PIP MODE (PbP) goes wrong, connect the PC with the display using

an USB cable. This is an alternative way of communication between PC and Display.

Refer to the display's documentation for details.

・If the restoration of PIP MODE (PbP) from OFF to ON takes unusually long time, connect the

PC with the display using an USB cable. Refer to the display's documentation for details.

・After the calibration, the BLACK LEVEL value may return to the value before the calibration

when PIP MODE (PbP) is set to OFF or ON. In this case, please set the value of BLACK LEVEL

to 50.0% by the OSD menu.

・In MD302C6, when two inputs of INPUT1+INPUT2 will be displayed, both inputs should use

the same type of connector, and set up to the same resolution. Set up coordinates according

to correct example.

・If the calibration with the PIP MODE(PbP) goes wrong, execute 7.7.1.1 Re-initialization

Display Configuration after setting PIP MODE to OFF. Execute calibration again after

re-initialization.

・When displaying two or more inputs on one screen, please unify Picture Mode setting,

Luminance setting, Contrast setting, and Black level setting via the ON-SCREEN-DISPLAY

(OSD) menu.

Refer to the display's documentation for details.

・When an upgrade installation was done while PIP MODE (PbP) has been in ON state, please

execute 7.7.1.1 Re-initialization of Display Configuration (page 105).

Copyright © NEC Display Solutions Ltd., 2006 -2015 25

Page 26

GammaCompMD QA Client User Manual

3. Installation

Administrator privileges are required in order to install this software. If the user does not

have administrator rights, a prompt will appear requesting an administrator’s username and

password. Follow the on-screen instructions to continue with the installation.

Selecting Only for me in Select Options dialog box (Figure 8) will set the input ID as the

current user and a desktop shortcut will be created for the [Administrator] account.

Selecting the Anyone who uses this computer (all users) option will allow also [Standard

User] accounts to run GammaCompMD QA Client.

External sensor drivers are included in the GammaCompMD QA Client package as described

in 1.5 External Sensors (page 10). Install GammaCompMD QA Client before connecting

sensors to the computer. GammaCompMD QA Client can be installed by double clicking

setup.exe from your GammaCompMD QA Client installation media or download package.

NOTE:

・GammaCompMD QA Version 5 cannot be installed on a system which has GammaCompMD

Version 2, GammaCompMD QA Version 3, or SpectraView II installed as well. The installation

will stop, notifying the user of the conflicting software.

Un-install these applications, as required.

You may re-install GammaCompMD QA Version 3 or SpectraView II to use them after

GammaCompMD QA Client Version 5 has been installed.

Please do not use GammaCompMD QA Client Version 5, GammaCompMD QA Client Version

3 and SpectraView II concurrently, because connected displays may not be set up correctly,

as these programs work with the same access method to control the displays, resulting in

access conflicts.

Copyright © NEC Display Solutions Ltd., 2006 -2015 26

Page 27

GammaCompMD QA Client User Manual

3.1. Setup

NOTE: If GammaCompMD Version 2 or GammaCompMD QA Version 3 Client is still installed

on the system, these need to be un-installed manually before this setup.

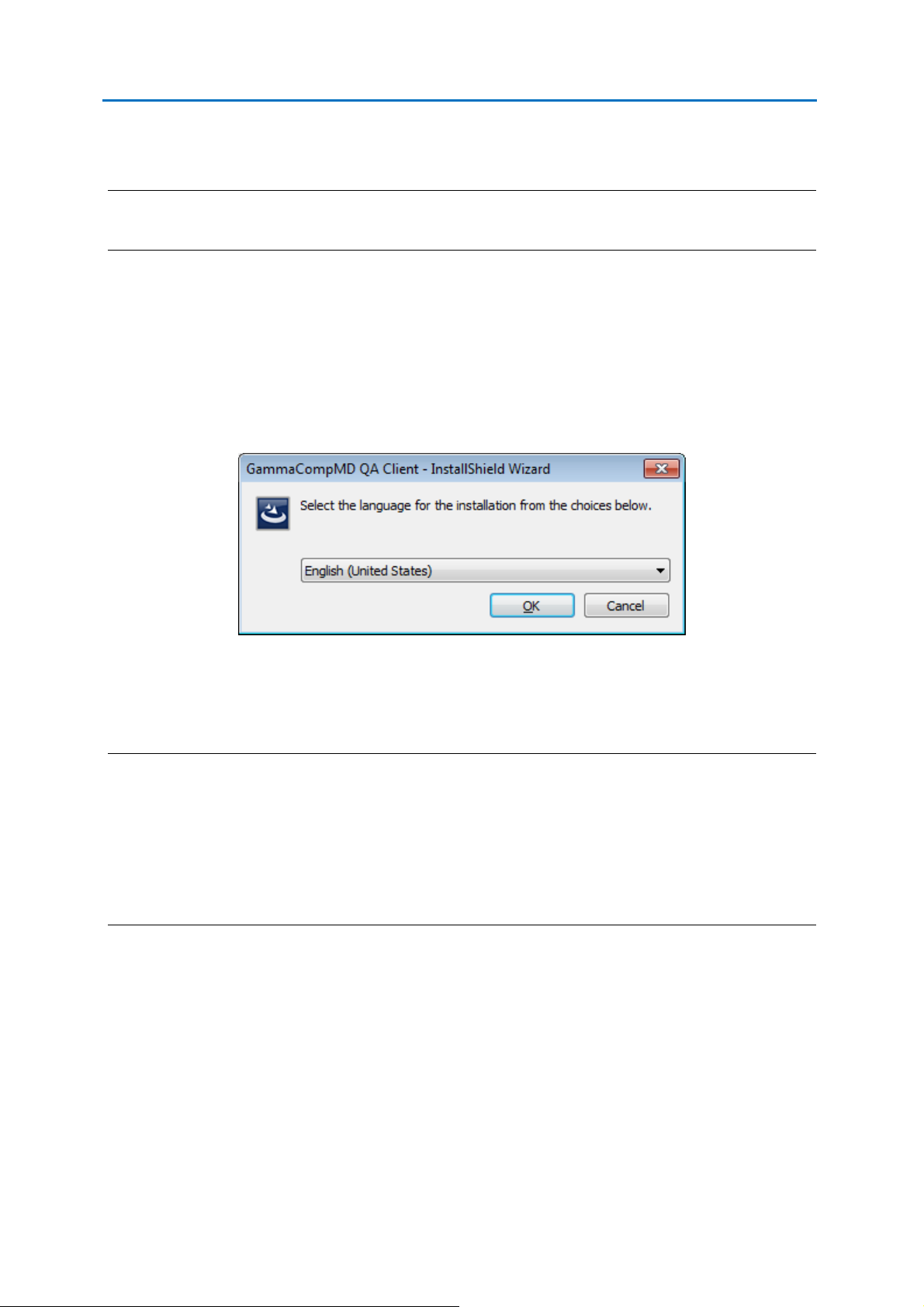

When installation begins, a Choose Setup Language (Figure 7) and then an Options

Selection (Figure 8) dialog box will be displayed. Follow the instructions accordingly for any

other dialog boxes that may appear. In addition, a Readme file is shown. After reading the

contents, click on the x to exit.

Language Selection

Figure 7: Choose Setup Language dialog box

Select your language for the installation from the Choose Setup Language dialog box.

NOTE:

・If you select Japanese during installation in other than Japanese version of Windows XP, you

need to insert “East Asian languages” in advance. Please set up “East Asian Languages” from

the “Region and Language” in “Control Panel” before the installation.

・If you perform an upgrade, it will be executed in the same language which you selected

during first installation.

Copyright © NEC Display Solutions Ltd., 2006 -2015 27

Page 28

Options Selection

GammaCompMD QA Client User Manual

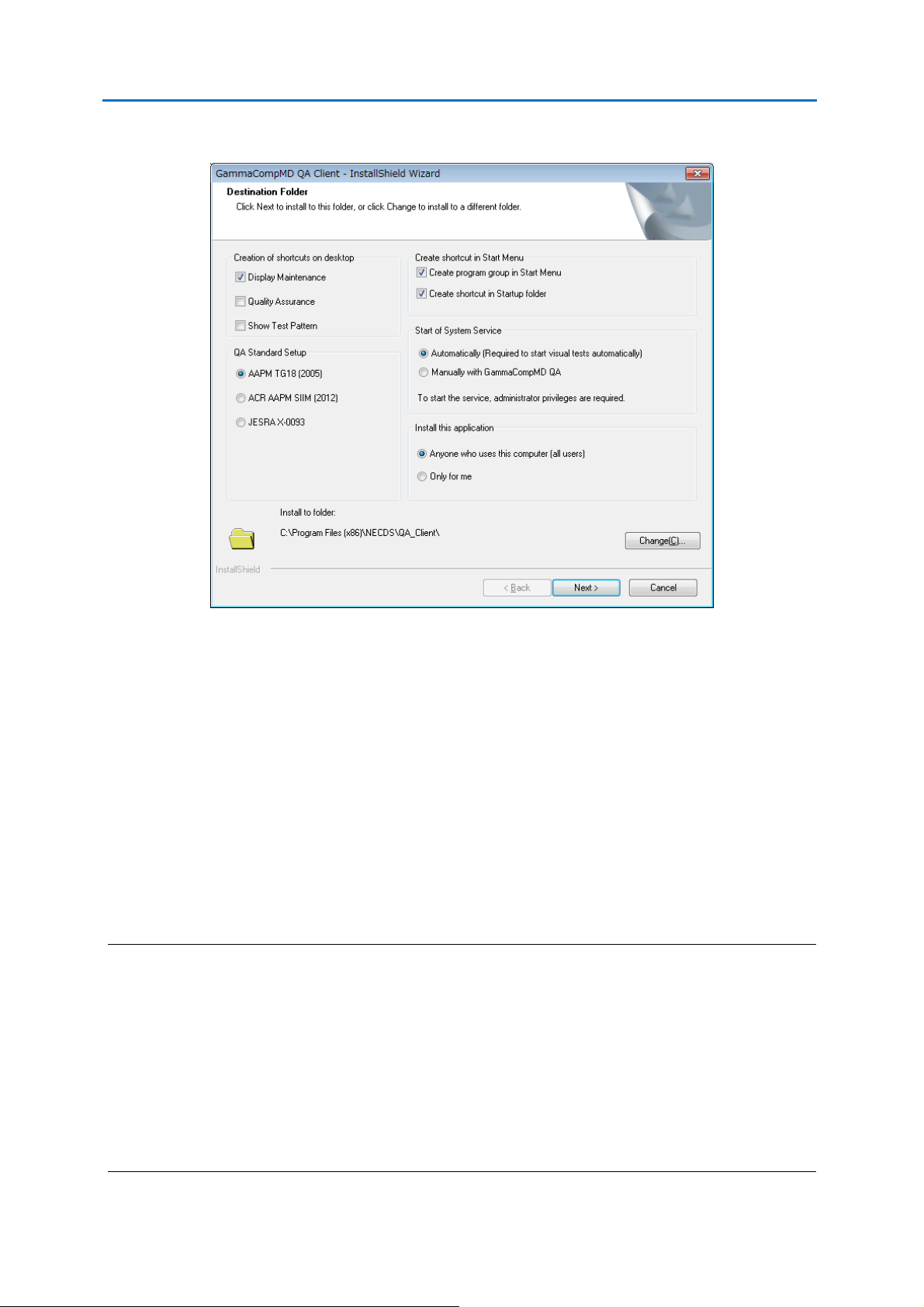

Figure 8: Options Selection dialog box

This box is available to select the following installation options.

Creation of desktop shortcuts

Display Maintenance / Quality Assurance / Show Test Pattern)

QA Standard Setup

(AAPM TG18 / ACR AAPM SIIM / JESRA X-0093)

Create shortcut in Start Menu

(Start Menu / Startup Menu)

Start of System Service

(Automatically / Manually)

NOTE: System Service refers to installed Windows System Services. These system services

access the database, control the display and communicate with a GammaCompMD QA

Server.

If Automatically is selected, these services are started at boot up time of the system and run

permanently in the background, even if no user is logged in.

If Manually with GammaCompMDQA is selected, these services must be manually started,

using the following steps: Open Display Maintenance menu, then enter:

System Setup Reinitialize System Configuration

Copyright © NEC Display Solutions Ltd., 2006 -2015 28

Page 29

GammaCompMD QA Client User Manual

Install this application

(Anyone who uses this computer (all users) / Only for me)

Install to folder:

By default, GammaCompMD QA will be installed in the following folder:

Windows 32-bit versions C:\[Program Files]\NECDS\QA_Client

Windows 64-bit versions C:\[Program Files(x86)]\NECDS\QA_Client

NOTE: In the following, this user manual refers to these folders as [Installation Folder].

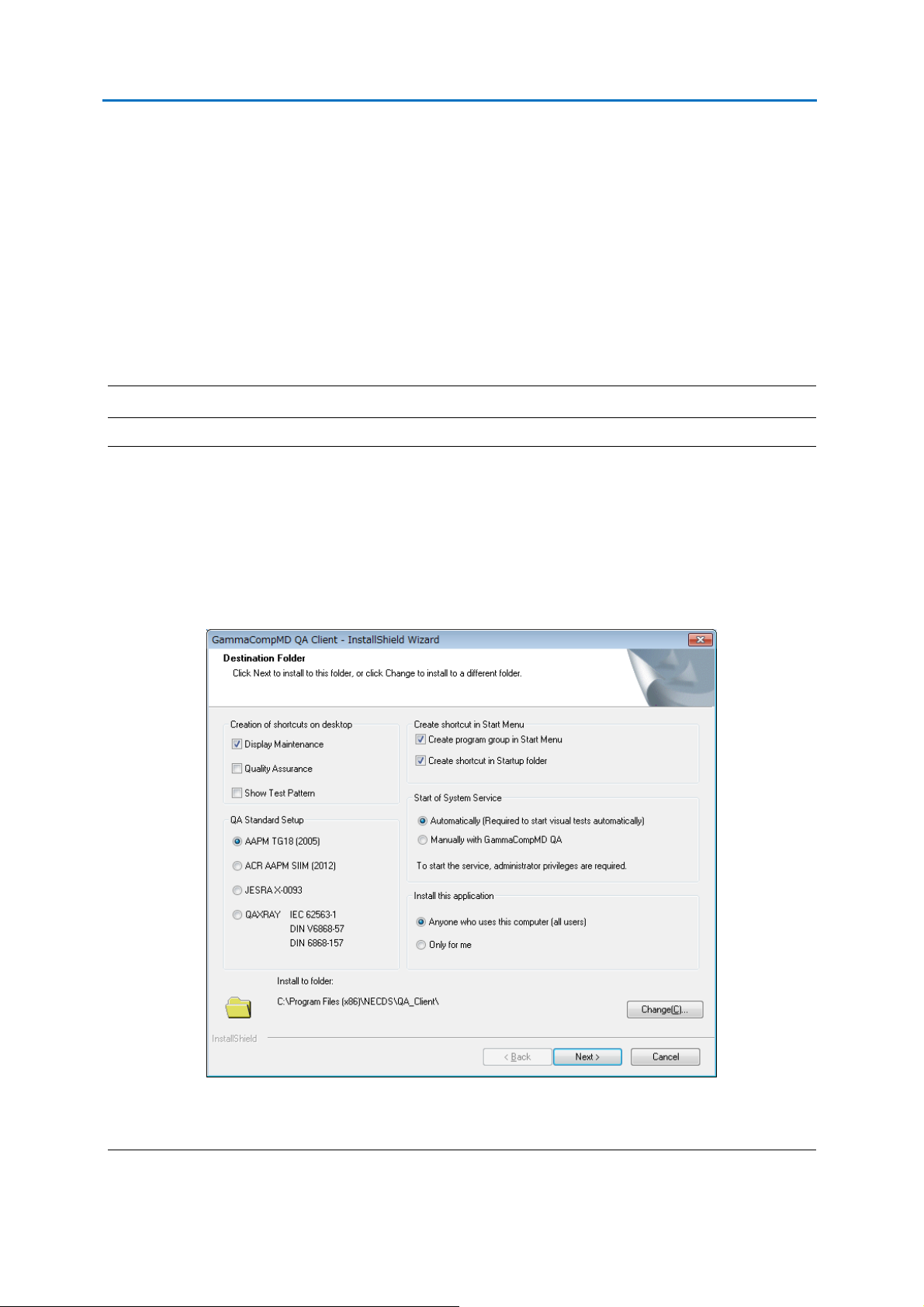

EU Limited Edition:

If you are using GammaCompMD QA Client for EU, you can select QAXRAY (IEC 62563-1/DIN

V 6868-57/DIN 6868-157) at the time of installation. (Figure 9). When you select QAXRAY, the

installation dialog box for QAXRAY will be displayed during the installation. Install QAXRAY

according to the message of the dialog box. Please note: If the installation of QAXRAY is

canceled, the installation of GammaCompMD QA Client will be canceled as well.

Figure 9:Options Selection dialog box (EU Limited Edition)

Copyright © NEC Display Solutions Ltd., 2006 -2015 29

Page 30

GammaCompMD QA Client User Manual

Error Code

Description

8

Database connection error

13

Cancelled by another process

26

Database initialization error

33

Exceptional error in database

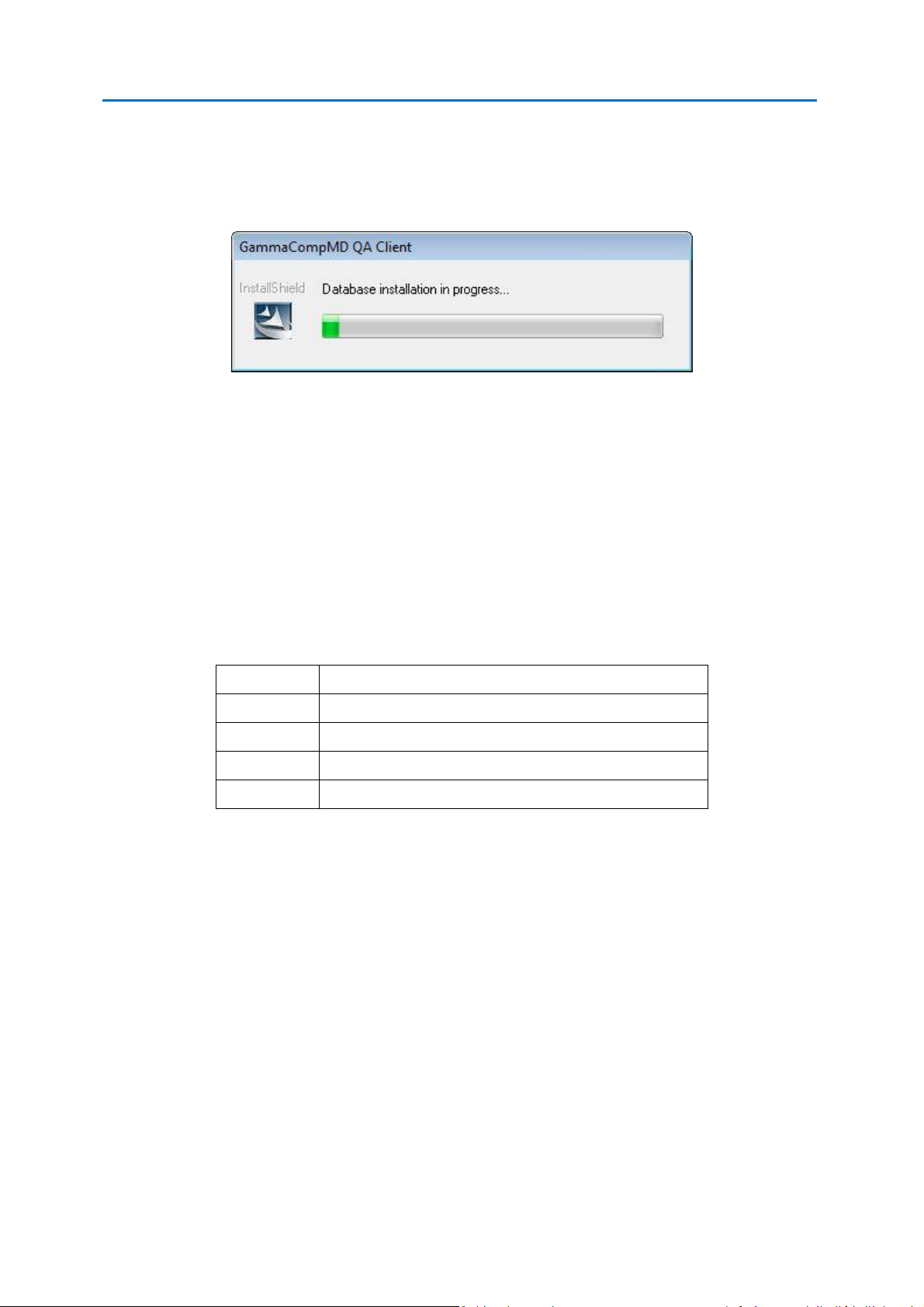

3.2. Installation of the internal database

During the installation process, GammaCompMD QA also installs a PostgreSQL database, as

shown in Figure 10.

Figure 10: Database installation in progress…

This database is used to save all calibration actions, measurement data, QA tests and alerts

and to build a history of the status of the connected display over time.

In addition, the database is used for providing actual and historical data, when the Client

communicates with a GammaCompMD QA Server in a networked environment.

In case that a problem occurs during database installation or initialization, a message pops up

with an error code. Below find a small list of error codes and a short description related to

the installation/initialization of the GammaCompMD QA Client internal database during

installation.

GammaCompMD QA Client assumes that the user installing this application has full

(local) administration rights.

The database communicates with the main application and with other system services via

IP address (127.0.0.1; localhost) and TCP port number: 5432.

To find the cause of an installation failure, please check (among other possible causes):

Are there any limitations to the local administrator rights, or is an automatic creation of

an account blocked, i.e. via Microsoft’s advanced group policy management?

Any TCP port conflicts with other applications, or any firewall port blocking?

Does the system run another PostgreSQL or other database installation?

Copyright © NEC Display Solutions Ltd., 2006 -2015 30

Page 31

GammaCompMD QA Client User Manual

Sensor Model

Driver Install Location

ColorMunki

[Installation Folder]\drivers\ColorMunki

Chroma5

[Installation Folder]\drivers\GretagMacbeth

Spyder3

[Installation Folder]\drivers\Spyder3

Xrite i1 Series

[Installation Folder]\drivers\XriteEyeone

CA-210

[Installation Folder]\drivers\CA-210

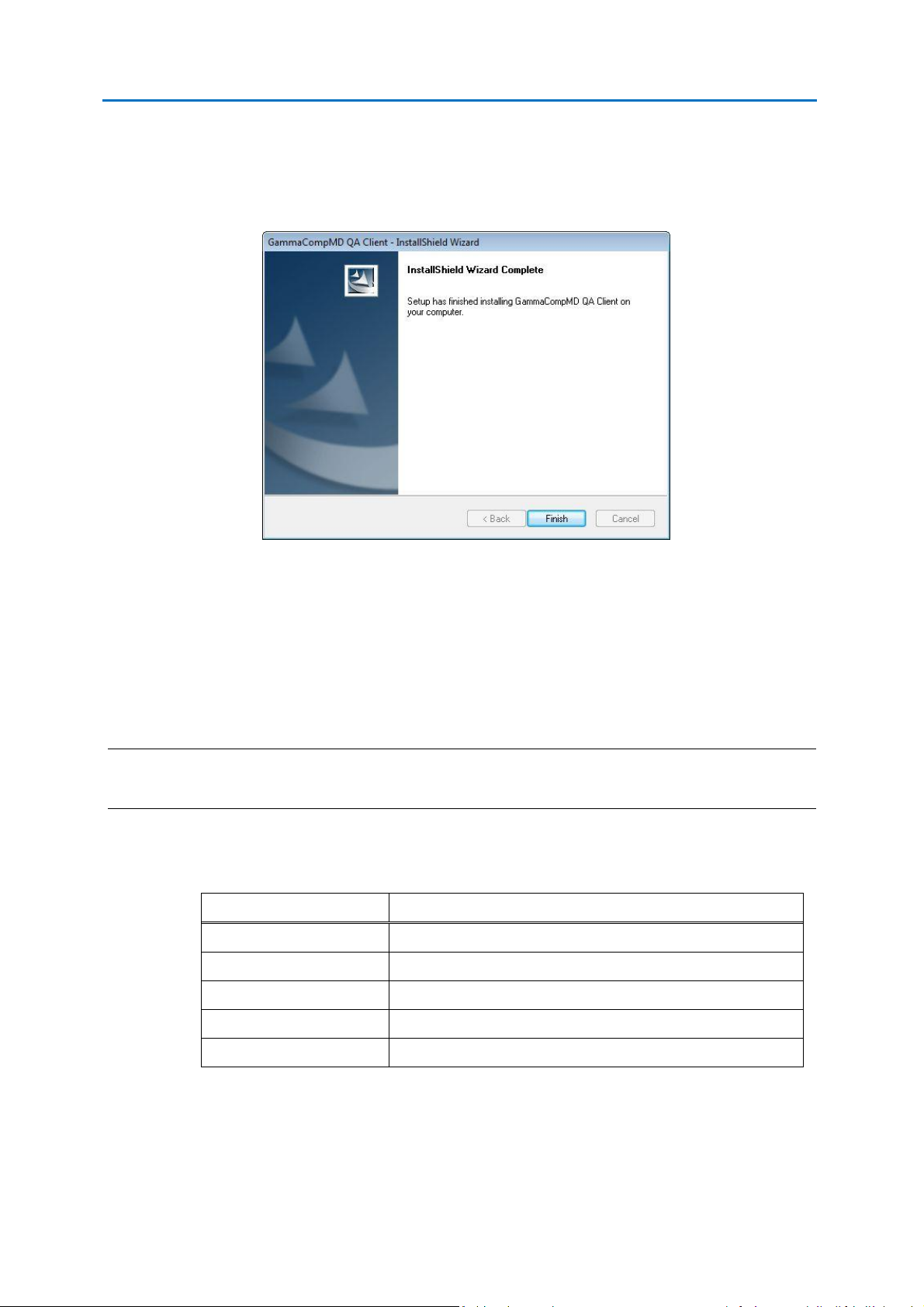

3.3. Finishing the installation

A dialog box will appear indicating the installation has finished, Installation Complete dialog

box (Figure 11) is displayed.

Figure 11: Installation Complete dialog box

3.4. Options to consider during installation

Backup User Account

GammaCompMD QA Client automatically creates the following account:

"GCMDQABackupUser” account for backup features

[WARNING] Do not edit the account. It may cause GammaCompMD QA Client to

malfunction.

Installation Location for USB Sensor Drivers

USB sensor models which are not listed above, will use the standard USB driver

included in the OS.

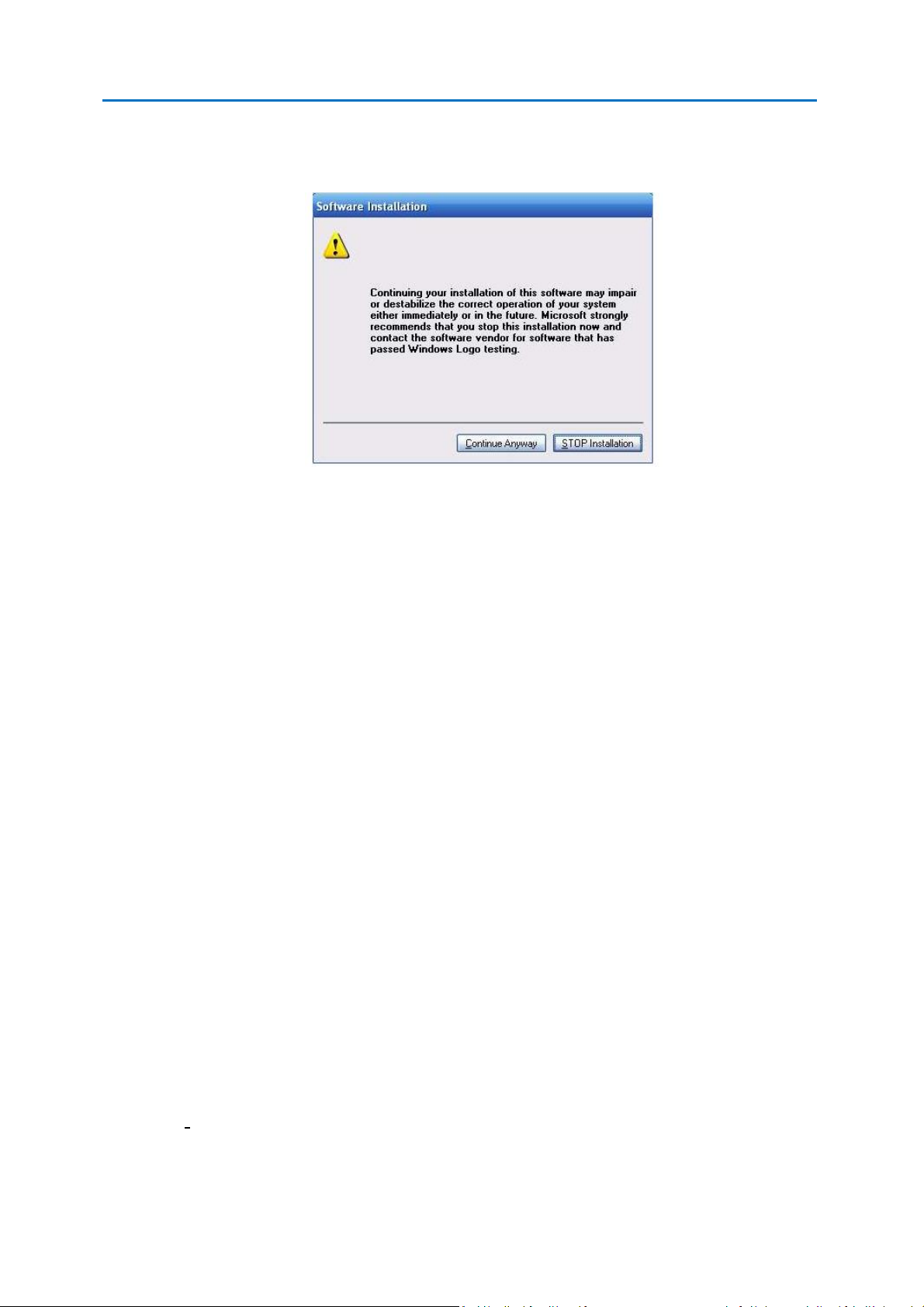

Installation Confirmation Dialog for Sensor Drivers

The software installation confirmation dialog in Figure 12 may be displayed during the

Copyright © NEC Display Solutions Ltd., 2006 -2015 31

Page 32

GammaCompMD QA Client User Manual

GammaCompMD QA Client installation. If this dialog is displayed, click on the Continue

button.

Figure 12: Software Installation confirmation dialog

3.5. Un-installation

This application can be un-installed in two different ways:

Using the Windows Control Panel

Windows XP: [Start Menu] [Control Panel] [Add or Remove Programs] and

double-click on GammaCompMD QA Client to un-install.

Windows 7: [Start Menu] [Control Panel] [Category View] [Uninstall a

program] and double-click on GammaCompMD QA Client to un-install.

Windows 8/ 8.1: Press the [Windows key] and the [X key] are simultaneously, then go to

[Control Panel] [Category View] [Uninstall a program] and

double-click on GammaCompMD QA Client to un-install.

Using the GammaCompMD QA Installer

Double-click on setup.exe in your GammaCompMD QA Client Installer source (CD-ROM,

DVD-ROM, stored locally or on a network drive.

3.6. Database Backup

Backup display information, calibration, and QA test results can be viewed by re-installing

GammaCompMD QA Client and restoring from the backup, using the 7.7.1.2 Reinitialize

System Configuration (page 108) option.

During un-installation, a dialog box will be displayed, asking if existing QA data should be

backed up, as shown in Figure 13.

Copyright © NEC Display Solutions Ltd., 2006 -2015 32

Page 33

GammaCompMD QA Client User Manual

Figure 13: Backup confirmation

Click Yes to create a backup. Click No to continue without making a backup.

Backed up files are saved as follows:

Windows XP: C:\[Documents and Settings]\[ALL Users]\[Documents]

Windows 7 and windows 8 / 8.1: C:\[Users]\[Public]\[Documents]

NOTES:

The backup filename is created in the following format:

[Computer Name] Year Month Day Hour Minute Second.gcmddat

Example: The filename for a backup made at 1:15:30 p.m. on September 1, 2011 under the

computer name Medical would be: MEDICAL20110901131530.gcmddat.

Database restoration is only possible using the same GammaCompMD QA Client version

which was used to create the backup. Restoration with a newer version leads to inconsistent

data in the database. The restore operation with a newer version will actually be aborted.

An installation folder may not be deleted after un-installation. If necessary, you can

delete it manually.

3.7. Version Upgrades

Older versions of GammaCompMD QA Client will be upgraded when installing a newer

version. Do not un-install the previously installed version of GammaCompMD QA before an

upgrade, if you want to keep history data. All database content (history data) of the

previous version will be converted (if required) and then read into the new version’s

database to keep all history data.

Copyright © NEC Display Solutions Ltd., 2006 -2015 33

Page 34

GammaCompMD QA Client User Manual

NOTE:

If you connected a NEC display that is not supported by GammaCompMD QA, it will be

recognized as "StdDisplay". In that case, Initial target luminance will be set to 200cd/m2, and

the grade of quality assurance test will be set to match to the target luminance. If this display

is supported by a future version of GammaCompMD QA and you install this new version as

an upgrade, the following configuration information will be kept.

Calibration configurations

Alert configurations

Grade of quality assurance test

Please check and re-configure this Information manually, if required.

Refer to 15.2 Saved Settings for Upgrade (Page 177) for the saved settings by upgrade

installation.

Copyright © NEC Display Solutions Ltd., 2006 -2015 34

Page 35

GammaCompMD QA Client User Manual

4. Firewall Settings

An active firewall may block network communication between a GammaCompMD QA Client

and a GammaCompMD QA Server, if a firewall is enabled. The following description refers to

the integrated firewall within Windows.

4.1. Windows XP

Opening the Windows Firewall

Click [Start] on the task bar, then click [Control Panel] [Windows Firewall].

The [Windows Firewall] screen is displayed.

Enabling the Firewall

Select the [General] tab on the [Windows Firewall] screen. The Windows Firewall general

screen, as shown in Figure 14, is displayed. Select [ON] and do not check the [Do Not Allow

Exceptions] box.

Figure 14: Windows Firewall - General

Copyright © NEC Display Solutions Ltd., 2006 -2015 35

Page 36

GammaCompMD QA Client User Manual

Setting Firewall Exceptions

Select the [Exceptions] tab on the [Windows Firewall] screen. The [Windows Firewall

Exception Program List] menu, see Figure 17, is shown. If QAInitialize and QAEngineService

have already been added to the Exception Program List, the following procedure is

unnecessary. If it has not yet been added, click [Add a Program].

The [Add a Program] menu, see Figure 15, is displayed. Click [Browse].

The [Browse] menu, see Figure 16, is displayed. Select the following applications in the

installation folder and click [Open].Set for every applications.

[Installation Folder]\QAInitialize.exe (initialization of application)

[Installation Folder]\ QAEngineService.exe (Service)

The screen returns to the [Windows Firewall Exception Program List] screen, see Figure 17.

Verify that the tick box for QAInitialize and QAEngineService, which now has been added to

the Exception List, are checked, and click [OK].

Figure 15: Add a Program

Copyright © NEC Display Solutions Ltd., 2006 -2015 36

Page 37

GammaCompMD QA Client User Manual

Figure 16: Browse programs to add

Figure 17: Windows Firewall - Exceptions program list

Copyright © NEC Display Solutions Ltd., 2006 -2015 37

Page 38

GammaCompMD QA Client User Manual

Setting Firewall Advanced

Select the [Advanced] tab on the [Windows Firewall] screen. The [Windows Firewall –

Advanced], see Figure 18, is shown. Choose from a [Network Connection Settings] list the

connection used for communication with a server, and click a [Settings…] button.

Figure 18 Windows Firewall – Advanced

Select the [ICMP] tab on the [Advanced Settings] screen, see Figure 19, is shown. Select tick

box [Allow incoming echo request], and click a [OK] button.

Figure 19 Windows Firewall - Advanced – Advanced Settings

Copyright © NEC Display Solutions Ltd., 2006 -2015 38

Page 39

GammaCompMD QA Client User Manual

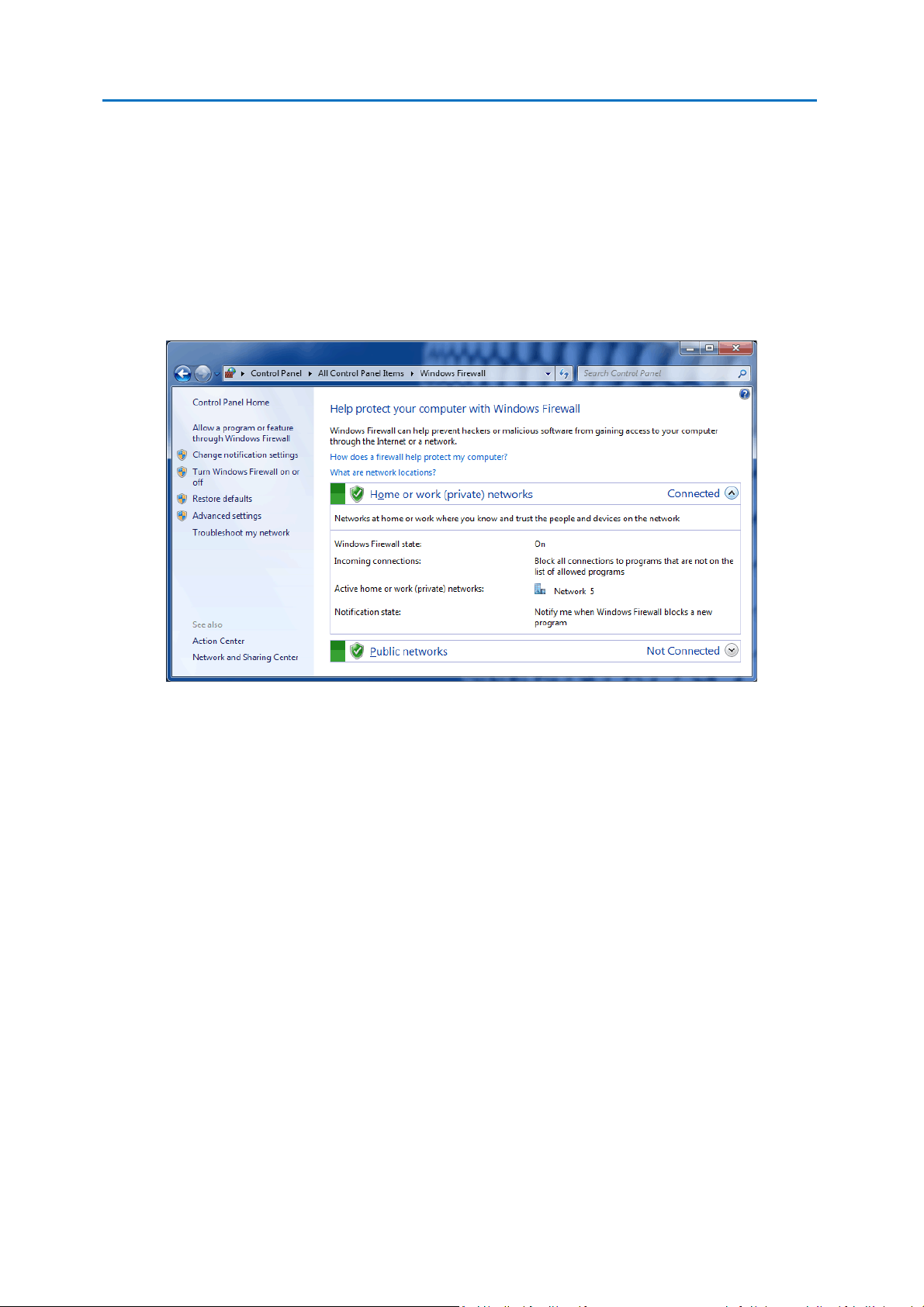

4.2. Windows 7 and Windows 8 / 8.1

Opening the Windows Firewall

Click on [Start] in the taskbar, and select [Control Panel].(Windows 7)

The [windows key] and the [X key] are pressed simultaneously, and select [Control

Panel].(Windows 8 / 8.1)

Click on [System and Security] [Windows Firewall].

The [Help protect your computer with Windows Firewall] menu, see Figure 20, will appear.

Figure 20: Help protect your computer with Windows Firewall

Enabling the Firewall

Click [Turn Windows Firewall on or off] on the left side of this menu, see Figure 20. The

[Customize settings for each type of network] menu, see Figure 21, will now be shown.

Select [Turn on Windows Firewall] and uncheck [Block all incoming connections, including

those in the list of allowed programs]. Repeat this action in the [Public network location

settings] area.

Click on the [OK] button to return to the [Help protect your computer with Windows

Firewall] menu, see Figure 20.

Copyright © NEC Display Solutions Ltd., 2006 -2015 39

Page 40

GammaCompMD QA Client User Manual

Figure 21: Customize settings for each type of network

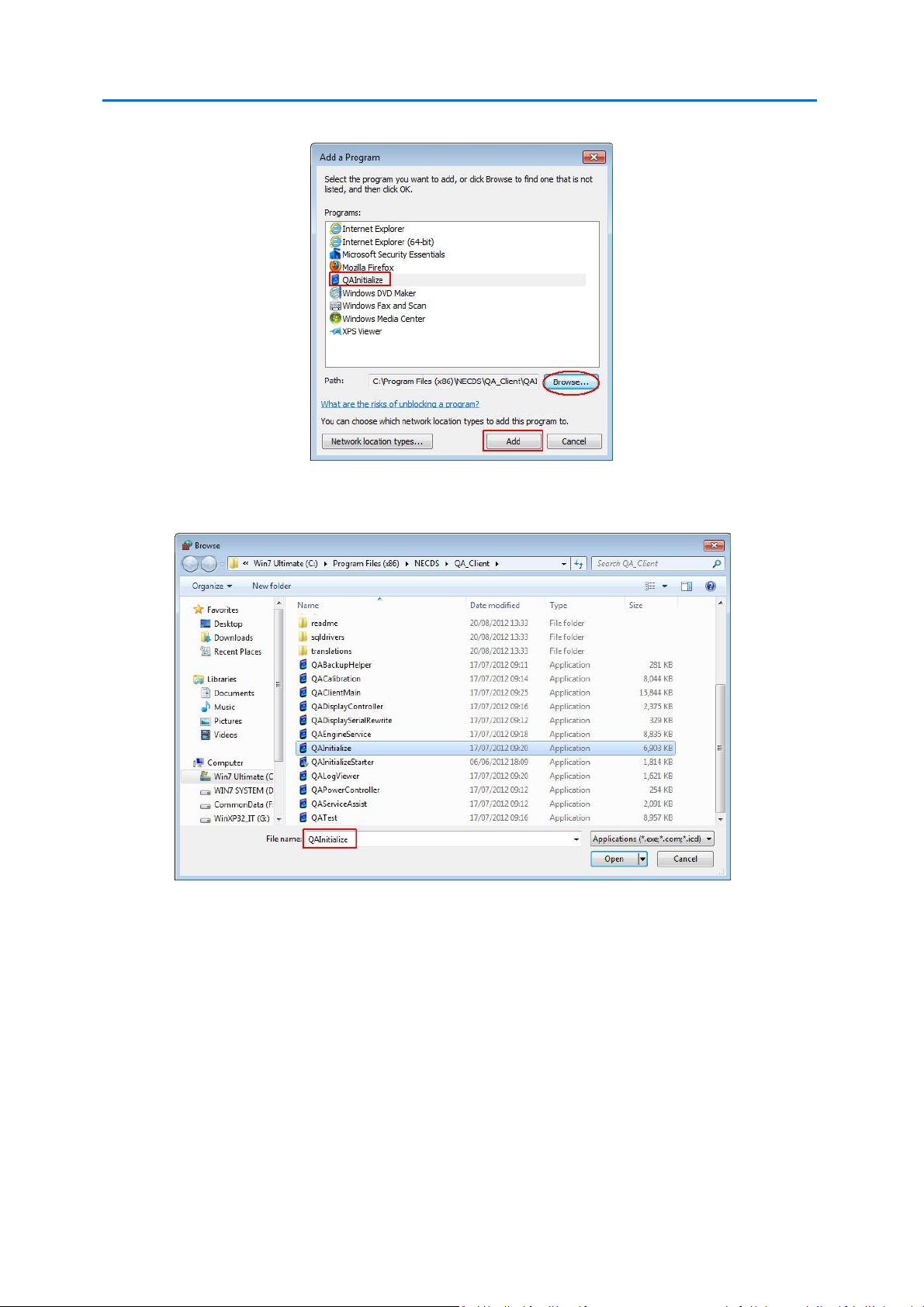

Setting Firewall Exceptions

Click on [Allow a program or feature through Windows Firewall] on the left side of this

menu, see Figure 20. The [Allowed programs to communicate through Windows Firewall]

menu, see Figure 24, is displayed. If QAInitialize and QAEngineService are already added,

the procedures below are unnecessary. If it is not added, click on [Allow another program…].

The [Add a Program] menu, see Figure 22, is displayed. Click on [Browse...].

The [Browse] menu, see Figure 23, is displayed. Select the following applications in the

Installation Folder, and then click [Open]. Set for every applications.

[Installation Folder]\QAInitialize.exe (initialization of application).

[Installation Folder]\ QAEngineService.exe (Service)

The screen returns to Figure 22. Click on QAInitialize with the mouse (select it) and then

click [Add].

Copyright © NEC Display Solutions Ltd., 2006 -2015 40

Page 41

GammaCompMD QA Client User Manual

Figure 22: Add a Program menu

Figure 23: Select (Browse) programs to add screen

The Menu, as shown in Figure 24, allows programs to communicate through the Windows

Firewall. Verify that the QAInitialize and QAEngineService are checked.

Copyright © NEC Display Solutions Ltd., 2006 -2015 41

Page 42

GammaCompMD QA Client User Manual

Figure 24: Allow programs to communicate through Windows Firewall Screen

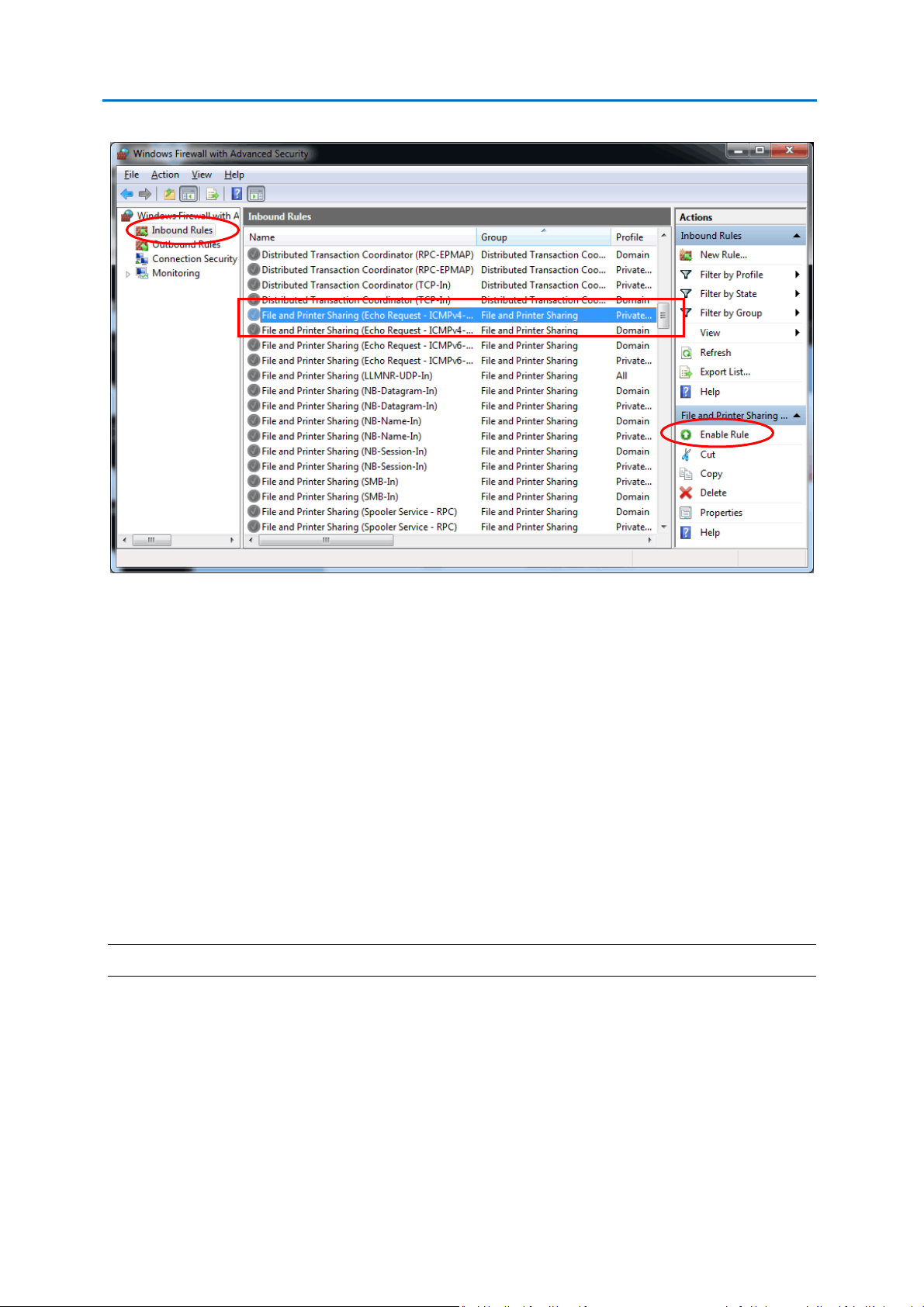

Inbound Rules of the Firewall

Click [Advanced Setting] on the left side of the [Help protect your computer with Windows

Firewall] menu, see Figure 20.

The [Windows Firewall with Advanced Security] menu, see Figure 25, will now be shown.

Copyright © NEC Display Solutions Ltd., 2006 -2015 42

Page 43

GammaCompMD QA Client User Manual

Figure 25 Windows Firewall with Advanced Security

Select [Inbound Rules] from the tree on the left, and select [File and Printer Sharing (Echo

Request - ICMPv4-In)] and [File and Printer Sharing (Echo Request – ICMPv6-In)] in the

center pane. Two or more [File and Printer Sharing (Echo Request - ICMPv4-In)] and [File

and Printer Sharing (Echo Request – ICMPv6-In)] are listed, please see the "Profile" column

of the "Inbound Rules" and choose a profile (Public, Private, or Domain) suitable for

network composition.

Then please click [Enable Rule] in the right column. If the [File and Printer Sharing (Echo

Request - ICMPv4-In)] and [File and Printer Sharing (Echo Request – ICMPv6-In)] icons have

changed to green, the operation is complete.

NOTE: Be sure to adjust security settings when behind a software firewall.

Copyright © NEC Display Solutions Ltd., 2006 -2015 43

Page 44

GammaCompMD QA Client User Manual

5. First Start

5.1. Start-up and shutdown of GammaCompMD QA Client

If you selected Create shortcut in Startup folder during installation, GammaCompMD QA

Client is started automatically when you start Windows. If you do not have created a shortcut

on the Startup menu or the user have terminated GammaCompMD QA Client manually,

please select GammaCompMD QA Client in the startup menu then active GammaCompMD

QA Client manually.

All four methods actually place the GammaCompMD QA Client icon into the taskbar.

With a mouse right-click on this icon, a Popup Menu is displayed, see Figure 26.

Figure 26: Popup Menu

The Popup Menu and User Levels are related to the user levels as follows:

Display Maintenance = Advanced Mode (Expert level)

Quality Assurance = Technician Mode (Standard level)

Show Test Pattern = Radiologist Mode (Visual test level)

Log Viewer

If you double click on the GammaCompMD QA Client icon, you can perform one of the three

(Display Maintenance, Quality Assurance or Show Test Pattern) directly.

NOTE: If you see a communication failure message during the start of the Display

Maintenance menu, it is likely due to a change in the Display configuration that was made

between the GammaCompMD QA installation and first start of the application.

GammaCompMD QA retrieves the display configuration from the Windows registry,

therefore may not identify the displays correctly anymore. The following actions may solve

the issue:

- Rebooting the system will read in the latest display configuration, which is then used

by GammaCompMD QA.

- If this does not help, re-install GammaCompMD QA.

Copyright © NEC Display Solutions Ltd., 2006 -2015 44

Page 45

GammaCompMD QA Client User Manual

Level

Description

Advanced Mode

(Expert level)

Assumes a user who is typically a PACS system administrator or

third party Service Provider. All features of Display Maintenance

are available. Since the user at this level can set password and/or

access rights for the Technician Mode level, this level may also be

able to execute all Display Maintenance functions.

The Advanced Mode user should have local system administrator

rights, to be able to restart system services and set backup

schedules.

Technician Mode

(Standard level)

Assumes a user who is typically a Medical Physicist or Biomedical

Engineer who does not make any adjustments to the displays.

Depending on the password setting, only Quality Assurance may be

executed. The available features are limited to the items as

specified with 7.7.2.1 Access Rights Setup for Quality Assurance

(page 127). (Note: The Access Rights Setup for Quality Assurance

can only be modified by an Advanced Mode user.)

Radiologist Mode

(Visual test level)

Assumes a user who performs visual tests. Typically this is a

Radiologist or a Radiographer. Depending on the password setting,

only viewing of test patterns may be executed.

5.2. User Password Setup

As shown in User levels, GammaCompMD QA Client provides the following three user levels:

Advanced Mode Display Maintenance (Expert level)

Technician Mode Quality Assurance (Standard level)

Radiologist Mode Show Test Patterns (Visual test level)

The functionality is different for each level. By default, all users can execute operations at all

levels from Advanced to Radiologist without a password, as no passwords are initially set.

To place restrictions on features that can be used in Technician and Radiologist level, an

Advanced Mode user must set passwords within 5.2 User Password Setup (page 45).

For the Advanced Mode (Expert level), it is recommended to set up a password to operate

GammaCompMD QA Client in a secure way. For further information about setting passwords,

refer to 7.7.2.2 User Password Setup (page 131).

Copyright © NEC Display Solutions Ltd., 2006 -2015 45

Page 46

GammaCompMD QA Client User Manual

Figure 27: User authentication dialog

5.3. Changing the Display Configuration

If the screen orientation, resolution, logical display position, the number of connected

displays or PIP MODE has changed, the Reinitialize Display Configuration is required. See

7.7.1.1 Re-initialization of Display Configuration (page 105) for the re-initialization

procedure.

5.4. Changing the Sensor

When clicking on Auto-Detect, the sensor connection is recognized. Also, a display sensor or

external sensor can be selected from the Preferred Sensor Selection listbox. This function is

only active for either a display with a front sensor or a display for which a retractable sensor

has been set up.

5.5. Change of Installation Location or Ambient Light Environment

If the location or indoor lighting environment has changed, please complete an Ambient

Light Measurement. Ambient light measurements may either be performed manually with a

professional illuminance meter or as described in Ambient Light Measurement (page 68).

Then execute the QA test as described in 7.4.1 QA Test Start (page 90).

Copyright © NEC Display Solutions Ltd., 2006 -2015 46

Page 47

Icon

Description

A color display is being used in landscape mode

A color display is being used in portrait mode

①

②

③

④

⑤

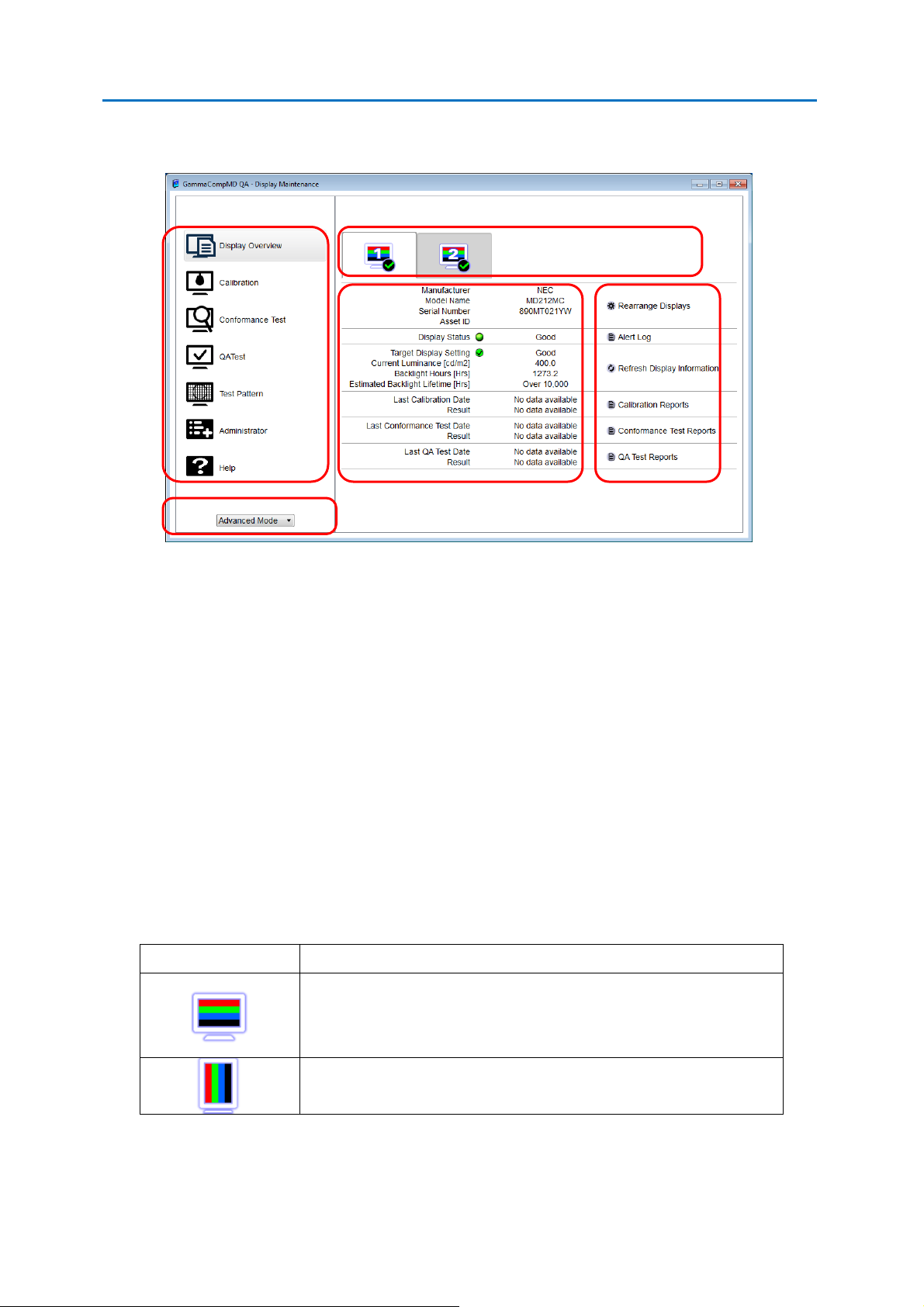

6. Main Display

GammaCompMD QA Client User Manual

Figure 28:Main Display and each Information Area

① Main Menu Area

The contents of ④Display Information Area and ⑤Sub Menu will change by selecting

each item of the main menu.

② User Level Area

The current User Level is shown. The User Level will change by selecting a User Level in the

listbox. You will be prompted to enter the password if a User Password has been set for this

level.

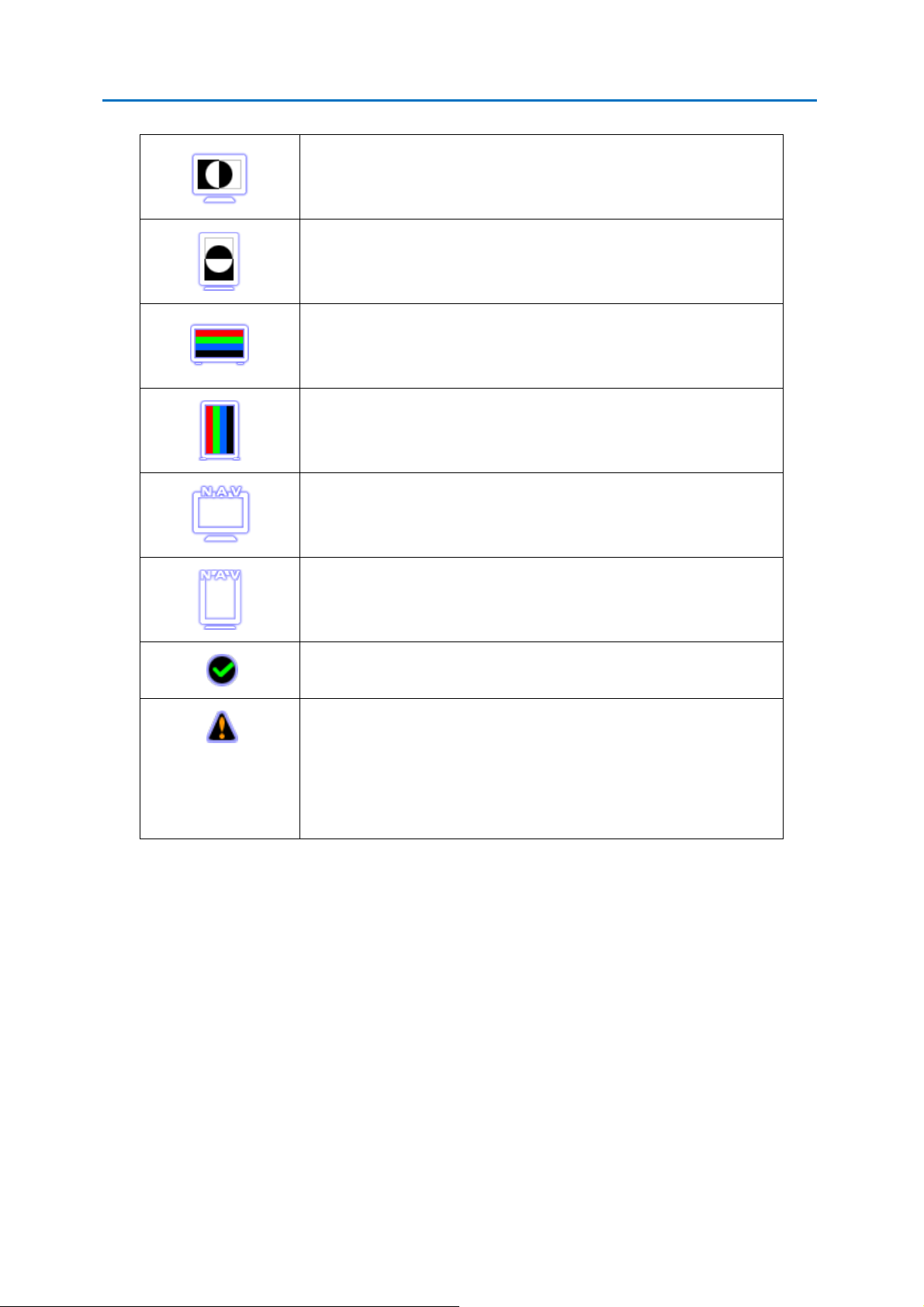

③ Display Icon Area

Various types of available display icons are shown below:

Copyright © NEC Display Solutions Ltd., 2006 -2015 47

Page 48

GammaCompMD QA Client User Manual

A grayscale display is being used in landscape mode

A grayscale display is being used in portrait mode

A large screen display (example: Multeos) is being used in landscape

mode

A large screen display (example: Multeos) is being used in portrait mode

A navigation display (a display that is not subject to any action) is being

used in landscape mode

A navigation display (a display that is not subject to any action) is being

used in portrait mode

The display is recognized correctly.

If any errors are detected on the connected display.

・The display has not been recognized correctly.

・An error occurred in the connected display during QA test or calibration.

・A display has been detected, which is different from the original display

since the last re-initialization of display configuration.

④ Display Information Area

Shows information according to the selected item in the main menu.

⑤ Sub Menu Area

The sub menu is shown according to the selected item in the main menu. Perform specific

functions by selecting an item in this sub menu.

Copyright © NEC Display Solutions Ltd., 2006 -2015 48

Page 49

GammaCompMD QA Client User Manual

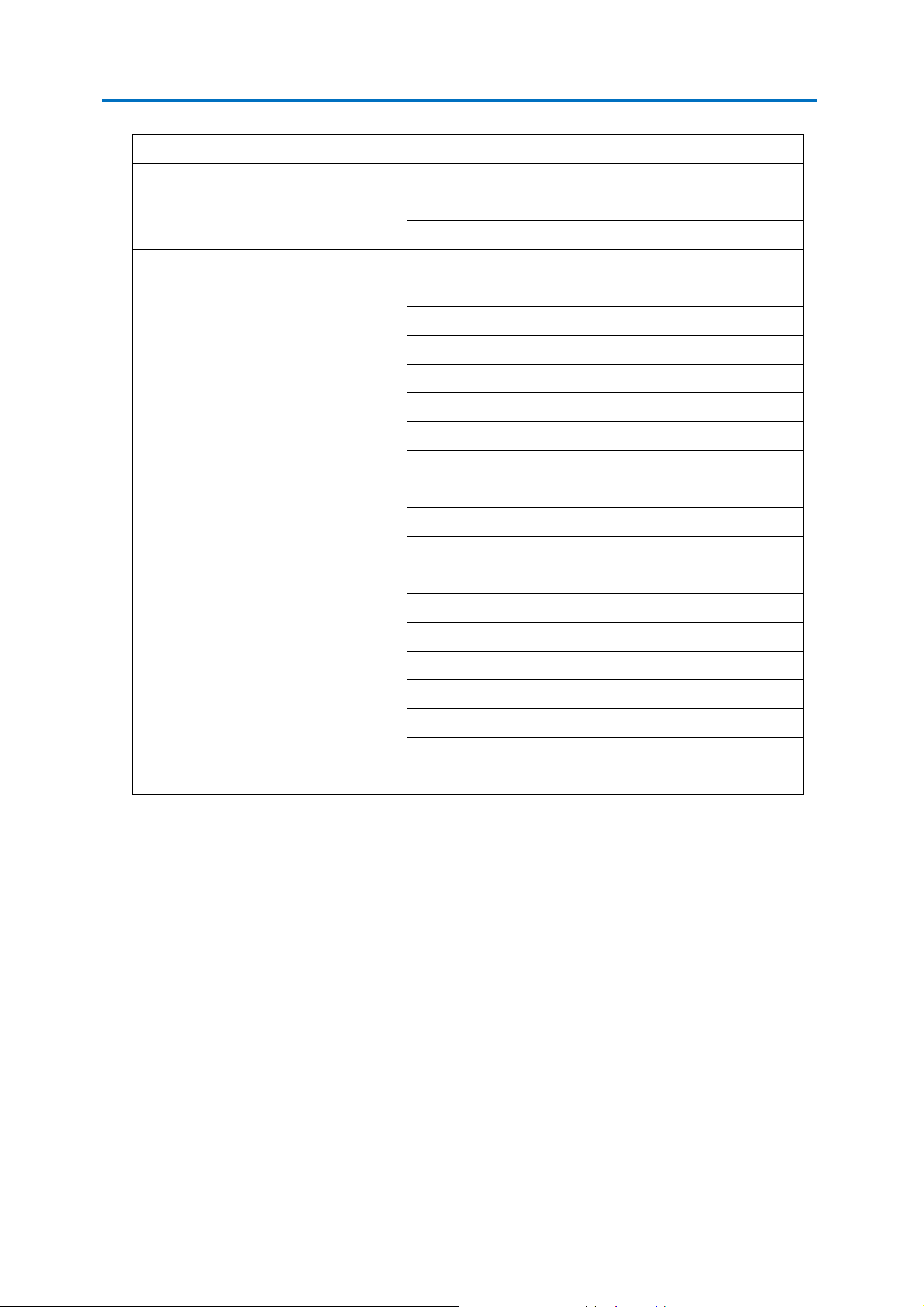

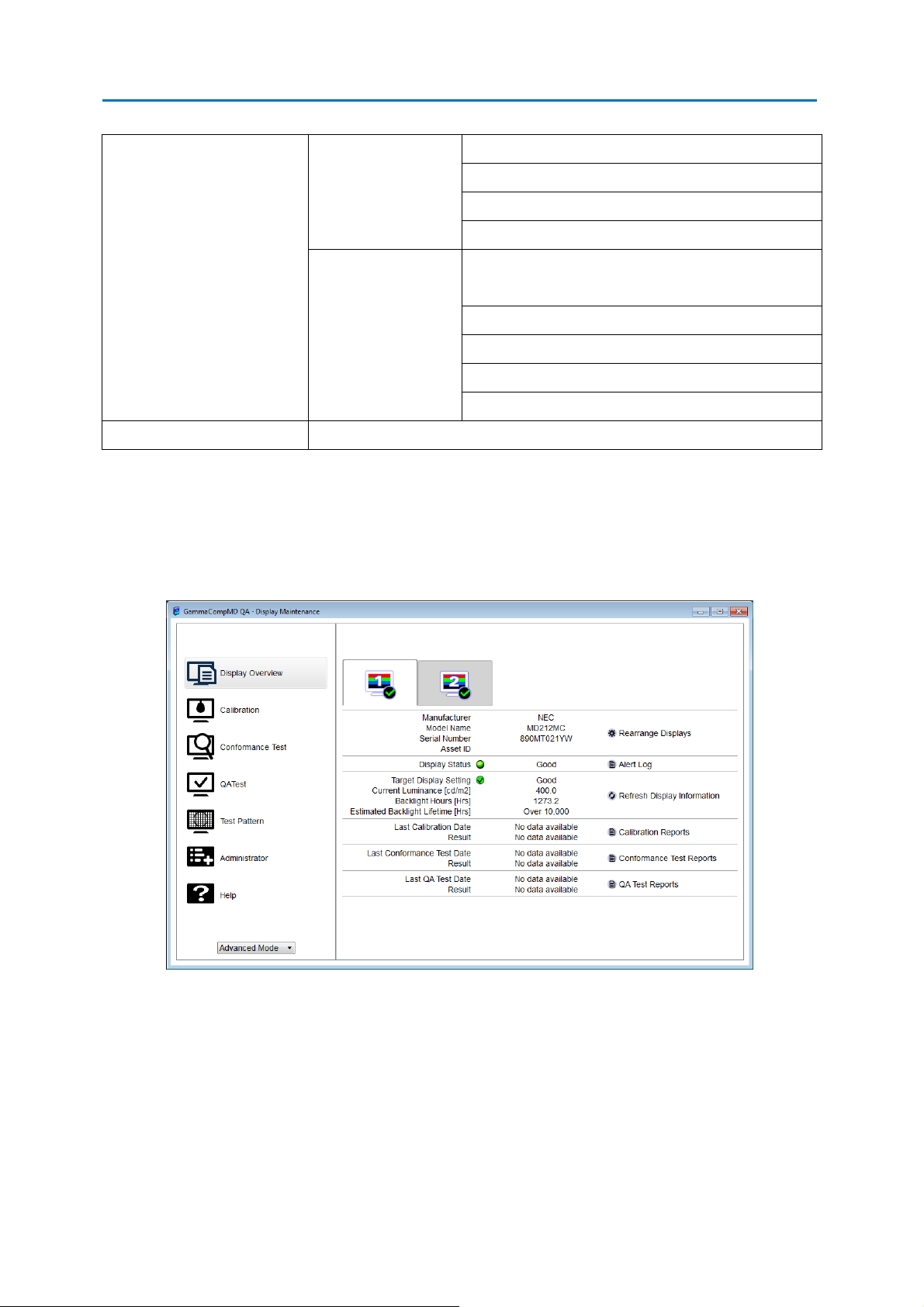

Main Menu

Sub Menu

Display Overview

Rearrange Displays

Alert Log

Refreshing Display Information

Calibration Reports

Conformance Test Reports

QA Test Reports

Calibration

Rearrange Displays

Calibration Reports

Schedule Setup

Calibration Setup

Sensor Setup

Conformance Tests

Rearrange Displays

Conformance Test Reports

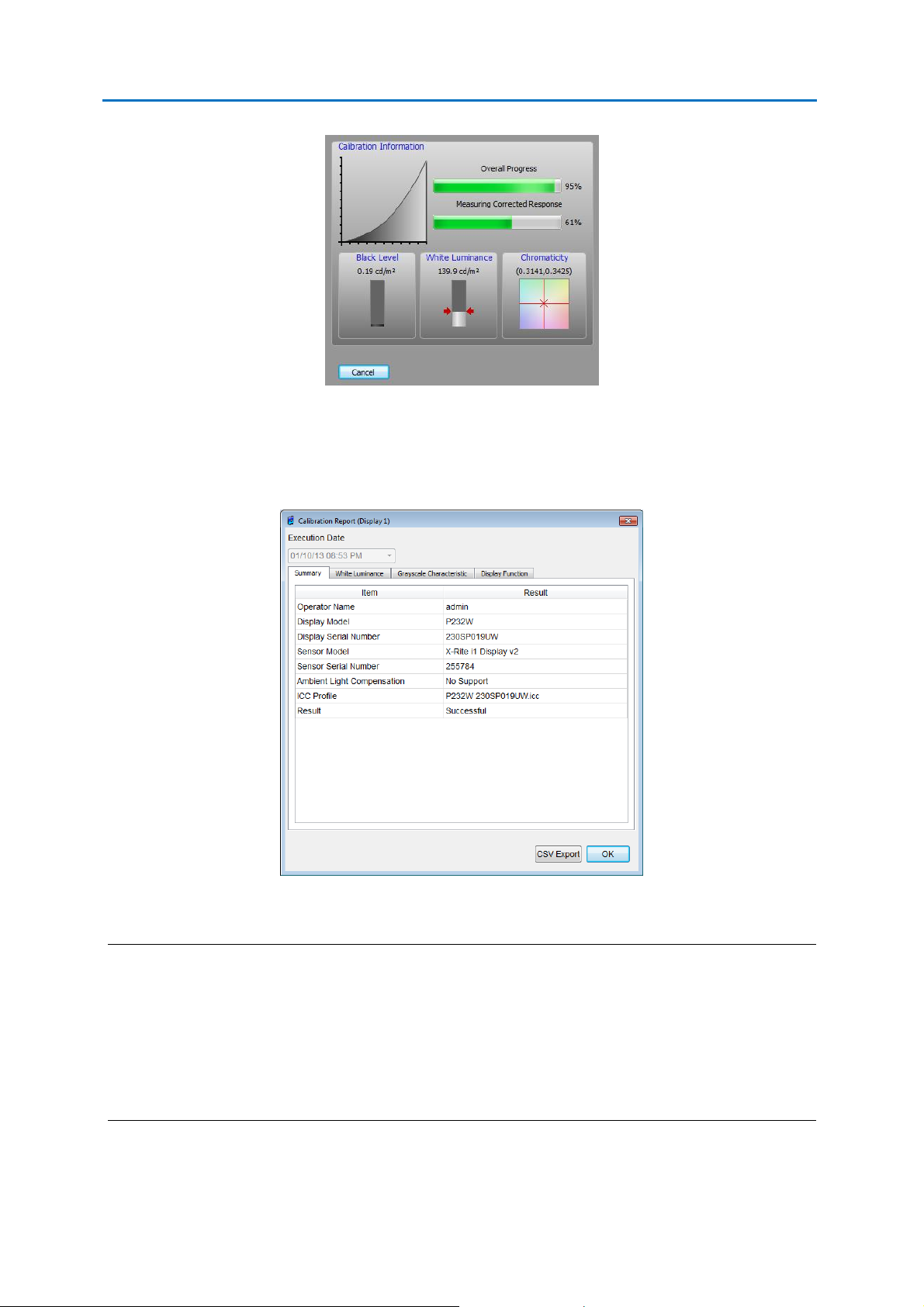

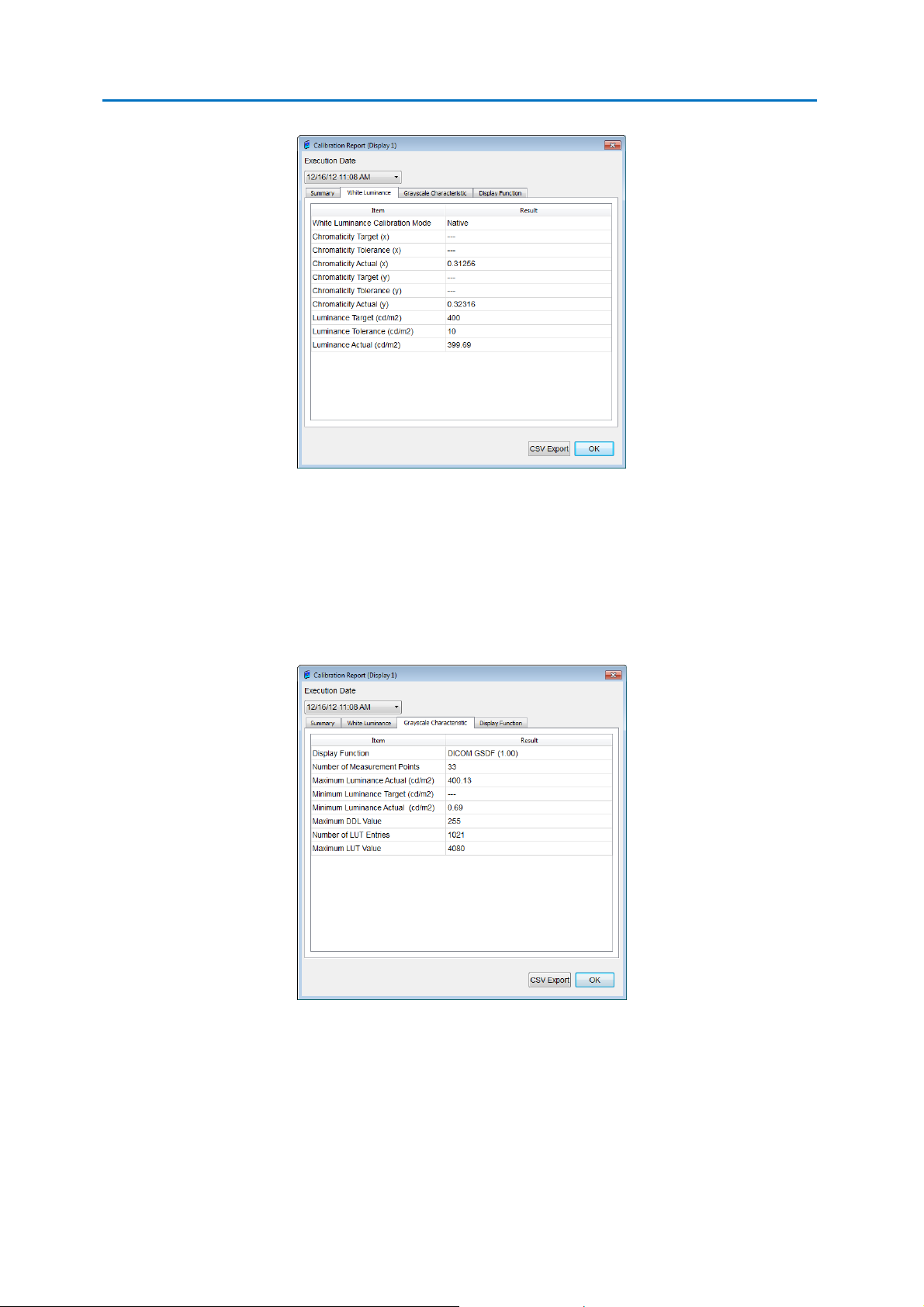

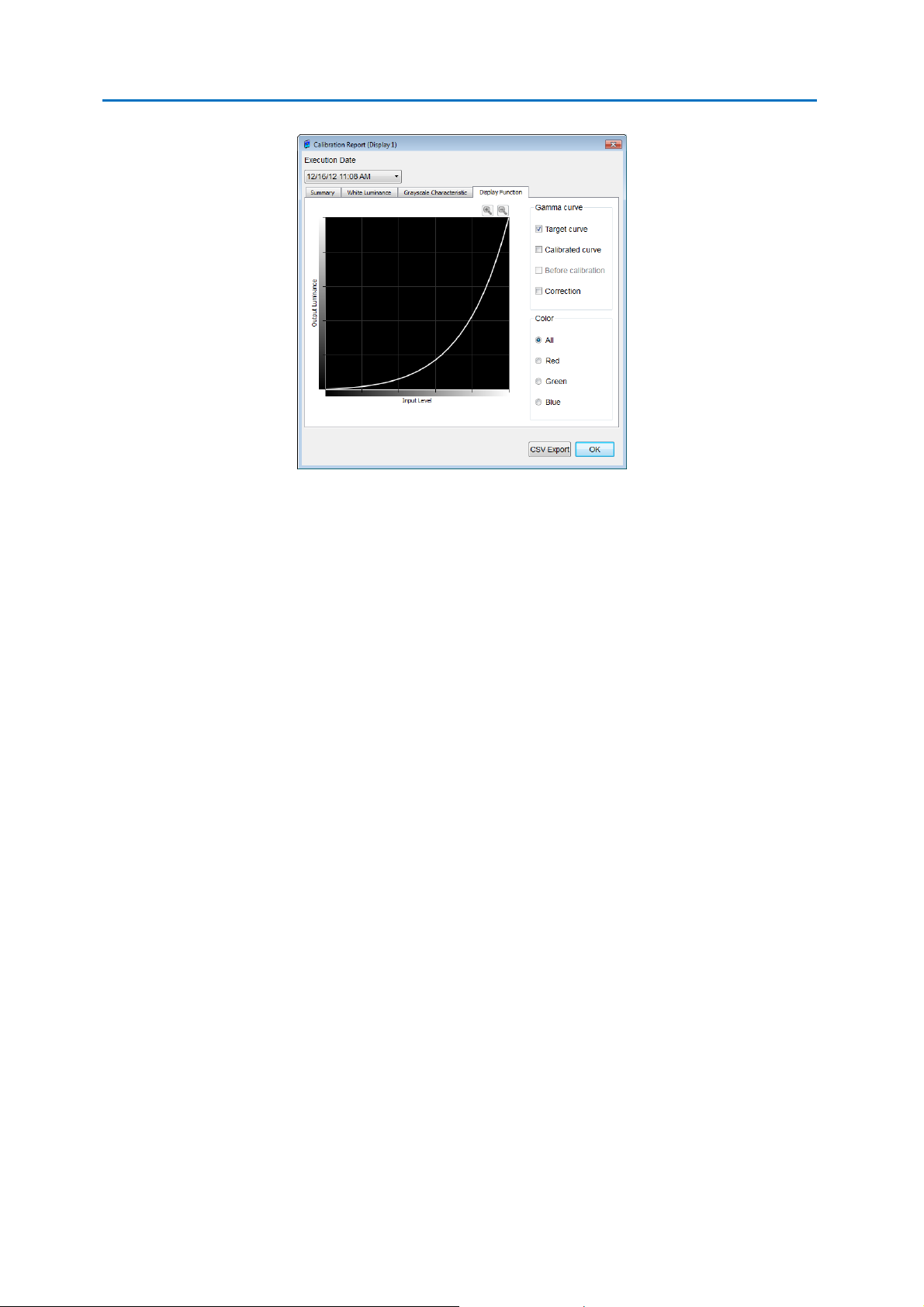

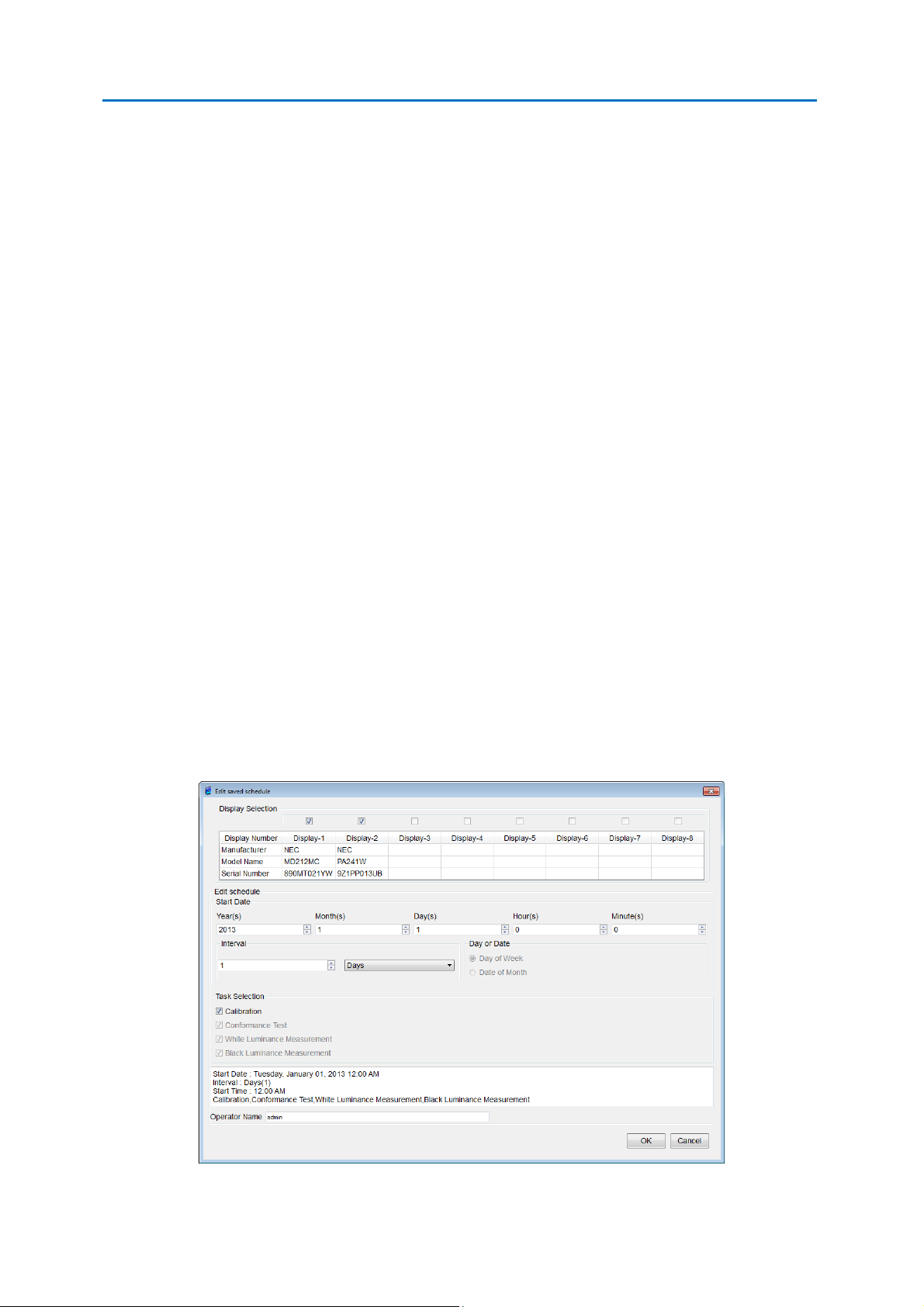

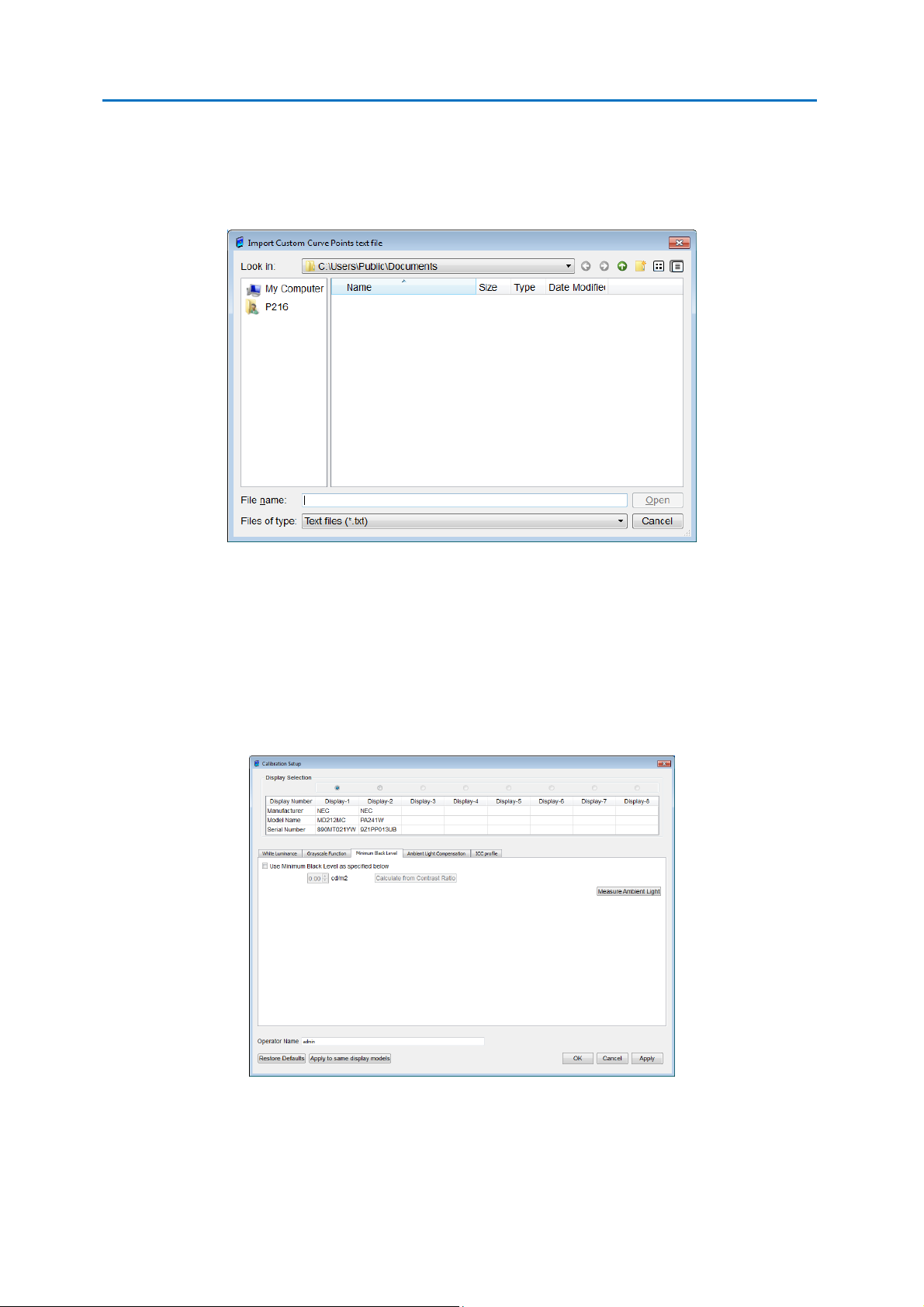

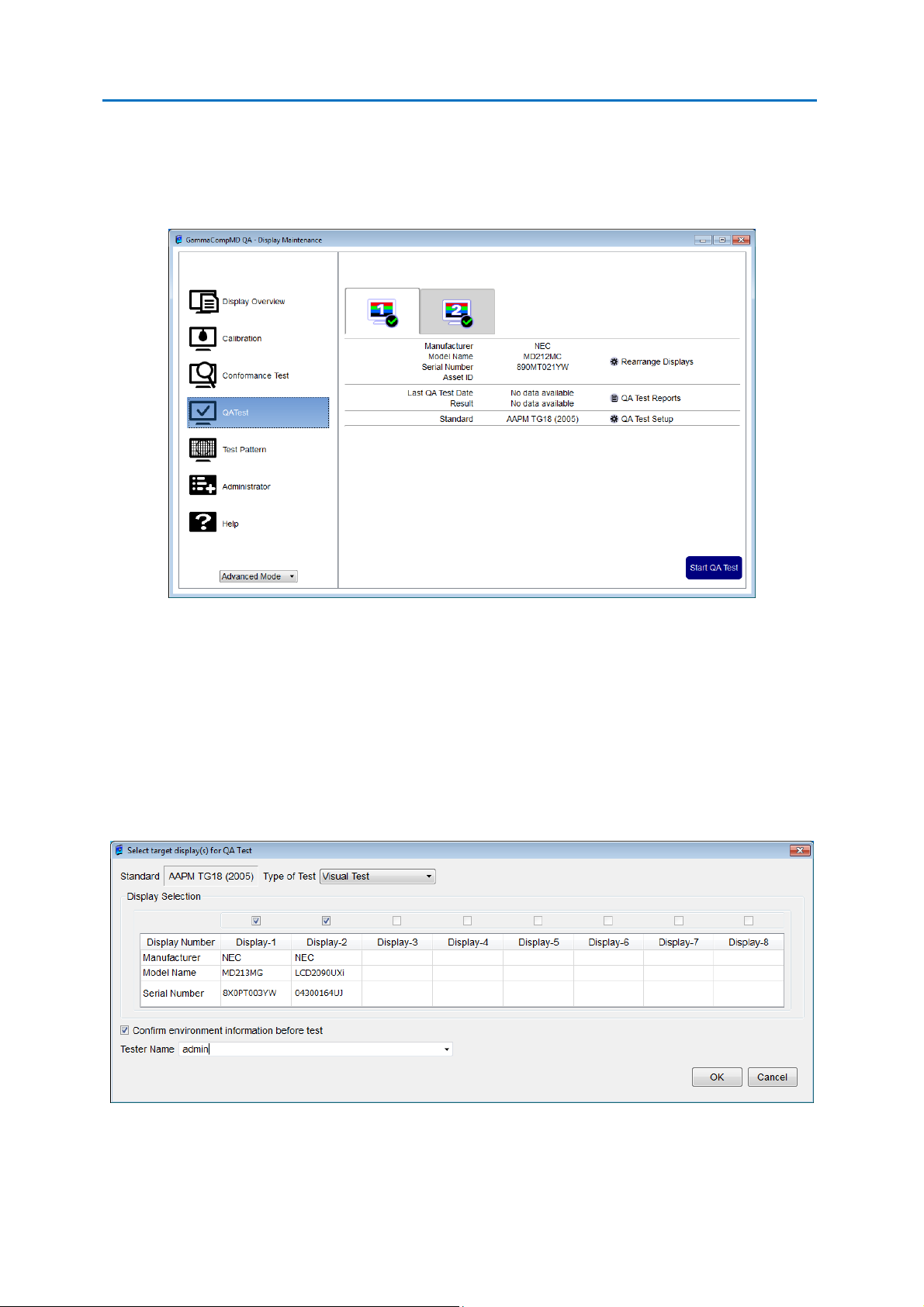

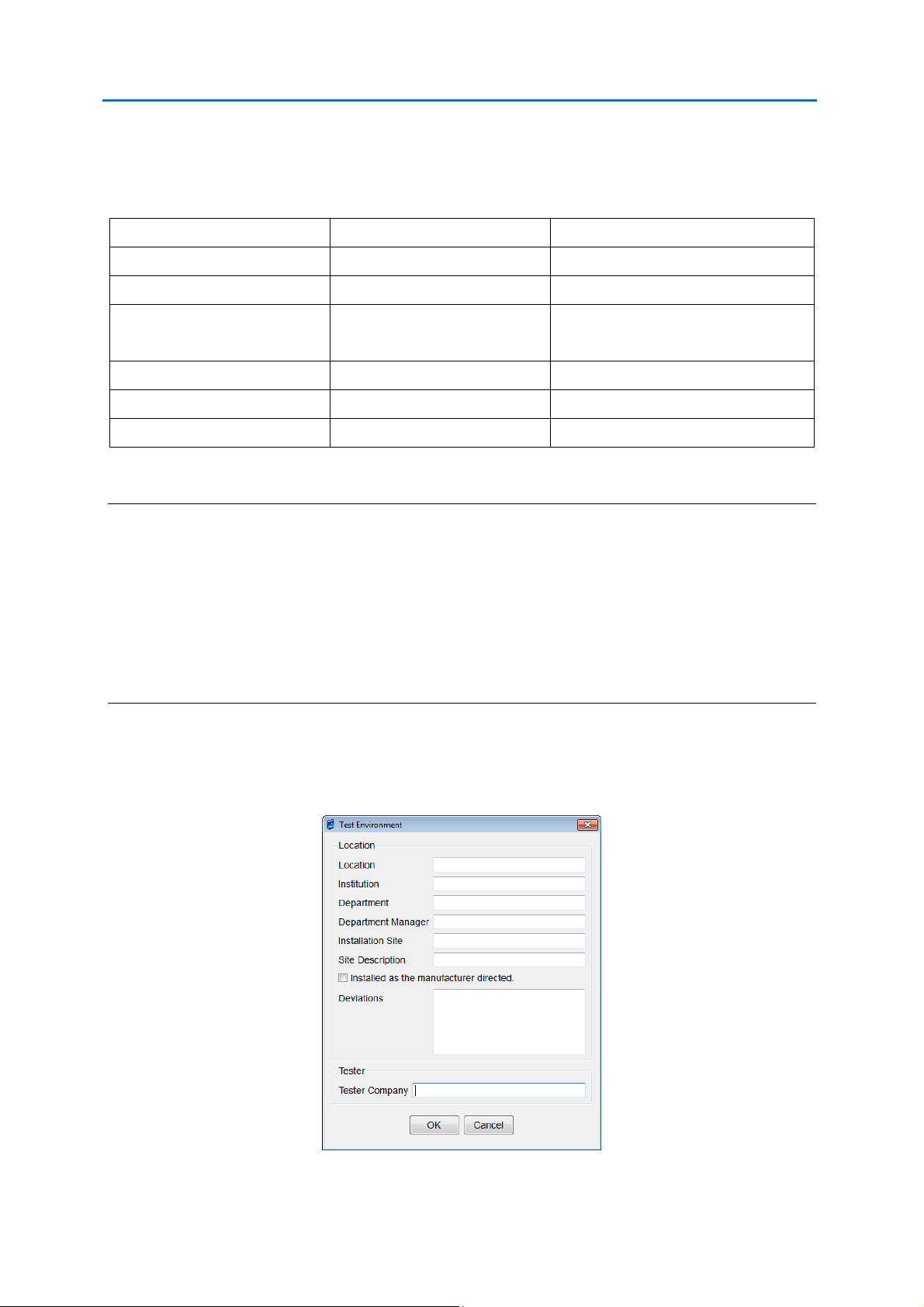

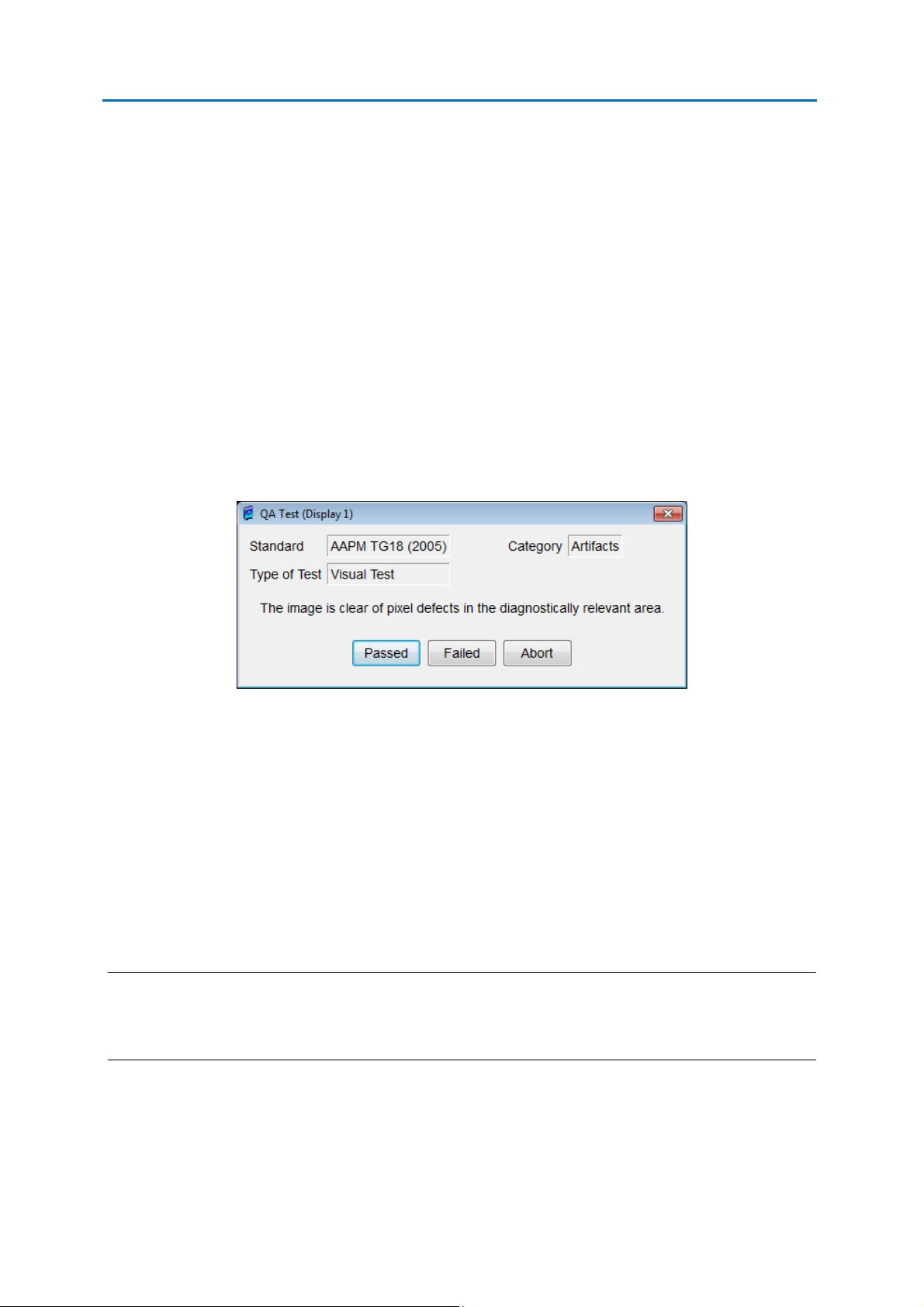

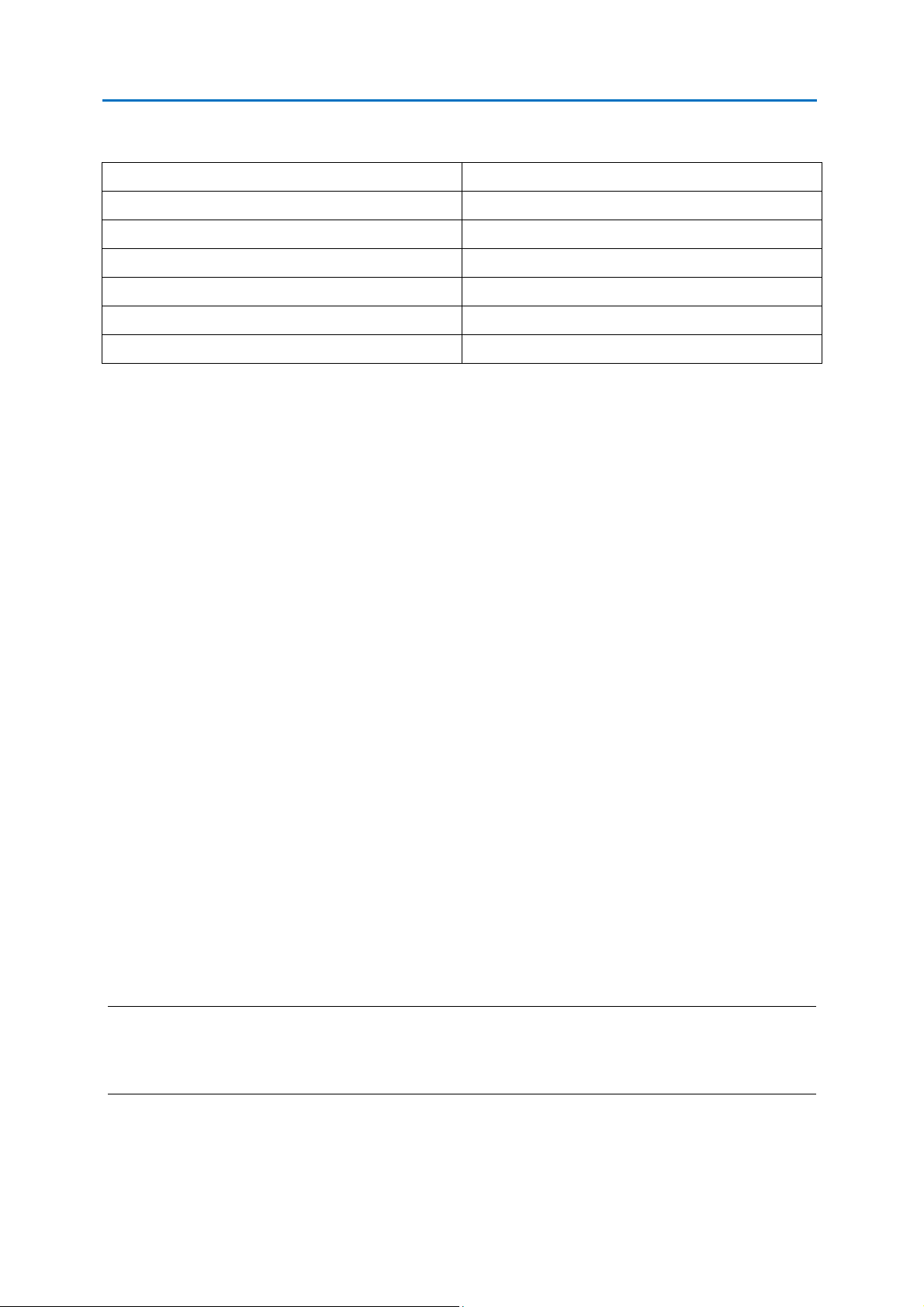

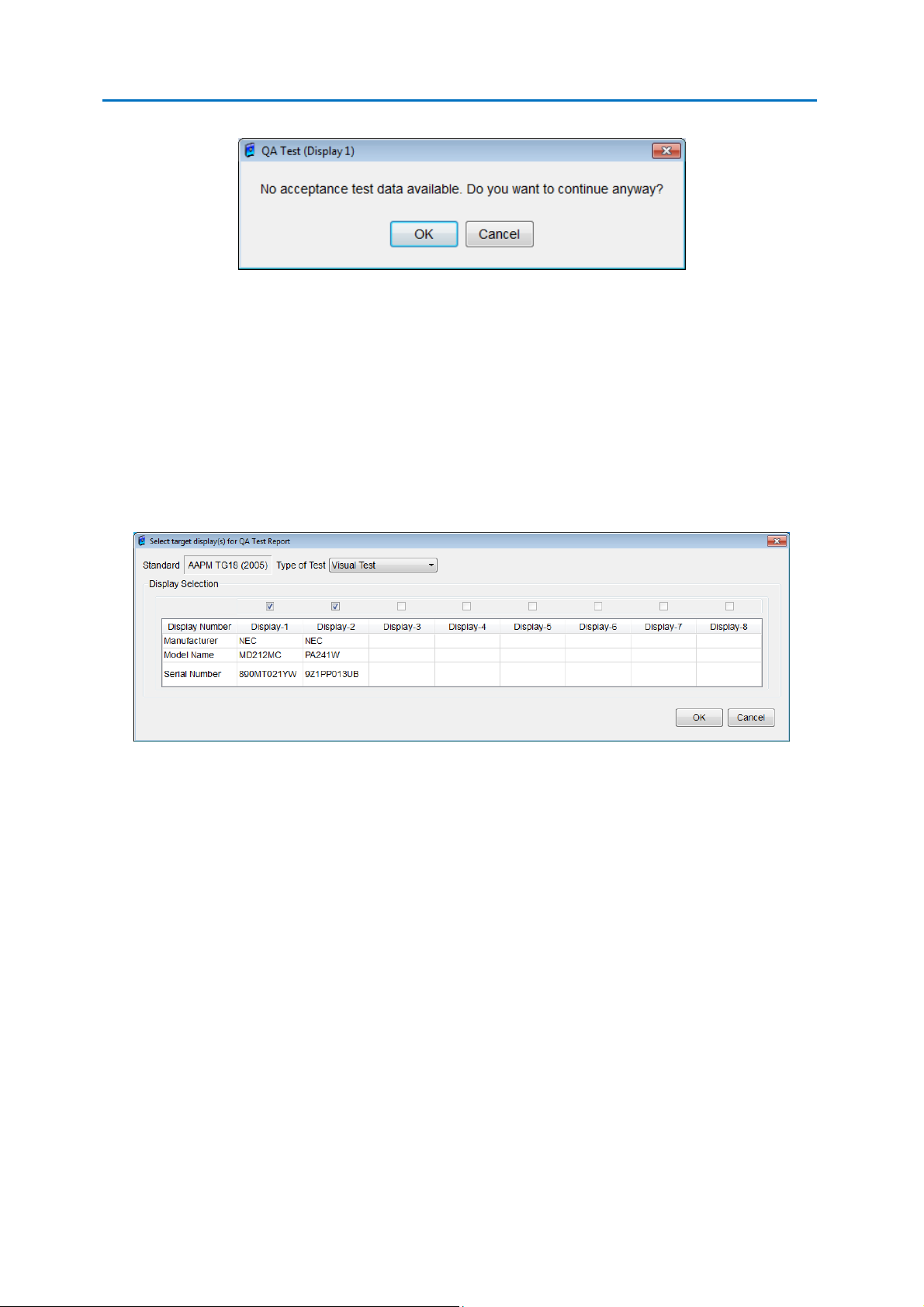

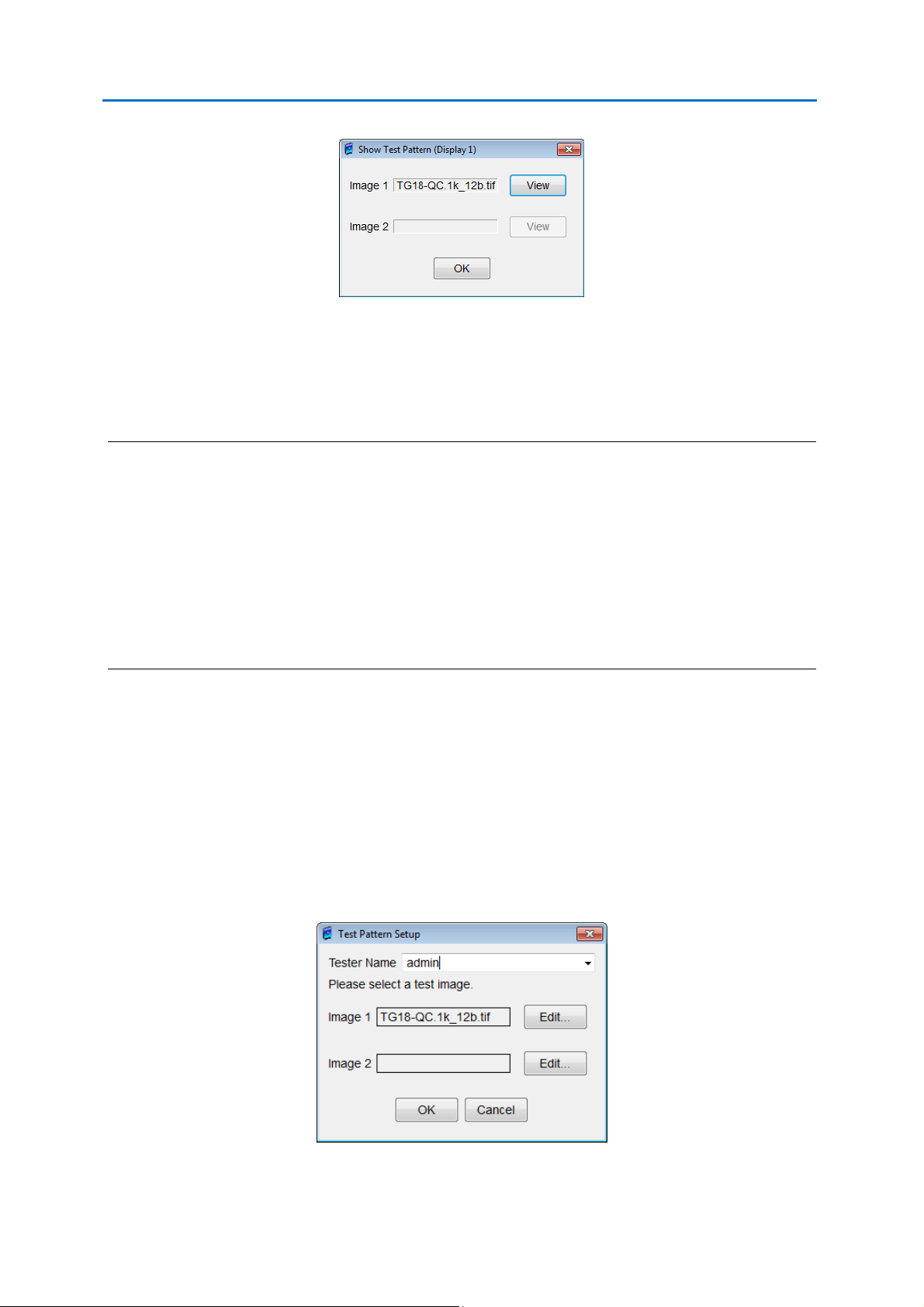

Schedule Setup