()

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

EXPRESS5800/140Rc-4

User's Guide

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

Proprietary Notice and Liability Disclaimer

The information disclosed in this document, including all designs and related materials, is

the valuable property of NEC Solutions (America), Inc. and/or its licensors. NEC Solutions

(America), Inc. and/or its licensors, as appropriate, reserve all patent, copyright and other

proprietary rights to this document, including all design, manufacturing, reproduction, use,

and sales rights thereto, except to the extent said rights are expressly granted to others.

The NEC Solutions (America), Inc. product(s) discussed in this document are warranted in

accordance with the terms of the Warranty Statement accompanying each product.

However, actual performance of each product is dependent upon factors such as system

configuration, customer data, and operator control. Since implementation by customers of

each product may vary, the suitability of specific product configurations and applications

must be determined by the customer and is not warranted by NEC Solutions (America), Inc.

To allow for design and specification improvements, the information in this document is

subject to change at any time, without notice. Reproduction of this document or portions

thereof without prior written approval of NEC Solutions (America), Inc. is prohibited.

Trademarks

Windows 2000 is a registered trademark of Microsoft Corporation.

Intel is a registered trademark of Intel Corporation.

Xeon is a trademark of Intel Corporation.

All other product, brand, or trade names used in this publication are the trademarks or registered

trademarks of their respective trademark owners.

PN: 456-01678-000 March 2003

Copyright 2003

NEC Solutions (America), Inc

10850 Gold Center Drive, Suite 200,

Rancho Cordova, CA 95670

All Rights Reserved

Contents

Proprietary Notice

Using This Guide

Text Conventions.................................................................................................................. x

Related Documents .............................................................................................................. xi

Safety Notices.....................................................................................................................xii

General Notices..............................................................................................................xii

Safety Notices for Users Outside of the U.S.A. and Canada........................................xiii

Fire Related Notices...................................................................................................... xiv

Shock Related Notices................................................................................................... xv

Rack-mount Related Notices ........................................................................................ xvi

Care and Handling.............................................................................................................xvii

1. System Overview

Overview............................................................................................................................ 1-2

System Chassis................................................................................................................... 1-4

Top View ......................................................................................................................1-4

Front View (Bezel Installed).........................................................................................1-5

Front View (Bezel Removed) .......................................................................................1-6

Front Panel Switches, Connectors and LED Indicators................................................1-7

Rear View ..................................................................................................................... 1-8

Internal View .............................................................................................................. 1-10

Electronics Bay........................................................................................................... 1-11

Status LED Indicator Descriptions .............................................................................1-12

System Board Set............................................................................................................. 1-15

System Board Set Features...............................................................................................1-18

Intel Xeon Processor...................................................................................................1-18

System Memory..........................................................................................................1-18

I/O Expansion Slots ....................................................................................................1-18

Real-Time Clock/Calendar .........................................................................................1-18

BIOS ........................................................................................................................... 1-18

Controllers...................................................................................................................1-19

IDE Controller.....................................................................................................1-19

Keyboard and Mouse Controller......................................................................... 1-19

Network Interface Controller..............................................................................1-19

SCSI Controller...................................................................................................1-20

Video Controller..................................................................................................1-20

Peripheral Controller........................................................................................... 1-20

System Board Management Controller (BMC) .................................................. 1-20

External Device Connectors........................................................................................1-21

System Power................................................................................................................... 1-22

Peripheral Bays................................................................................................................1-22

Disk Array........................................................................................................................1-23

Automatic Rebuilding Function..................................................................................1-24

Expand Capacity Function..........................................................................................1-24

System Functions.............................................................................................................1-25

Hot Swapping..............................................................................................................1-25

Hot Plug PCI............................................................................................................... 1-25

Contents iii

Fans .............................................................................................................................1-25

Sleep Mode..................................................................................................................1-26

ACPI............................................................................................................................1-26

AC Link Mode.............................................................................................................1-26

Remote Power-On (Wake On LAN) Function............................................................1-27

Reconfiguration...........................................................................................................1-27

SAF-TE Logic.............................................................................................................1-27

System Security................................................................................................................1-27

Security with Mechanical Locks and Monitoring.......................................................1-28

Software Locks via the BIOS Setup Utility ................................................................1-28

2. Setting Up the System

Overview ............................................................................................................................2-2

Selecting a Site...................................................................................................................2-2

Unpacking the System........................................................................................................2-3

Rack-Mount Subsystem Assembly.....................................................................................2-4

Unpacking the Rack Mounting Hardware.....................................................................2-4

Before You Begin..........................................................................................................2-5

Static Precautions..........................................................................................................2-6

Assembly.......................................................................................................................2-6

Mounting the Server in the Rack Cabinet...................................................................2-14

Installing the Cable Arm Assembly ............................................................................2-16

Removing the Server from the Rack ................................................................................2-22

Making Connections.........................................................................................................2-24

Connection to External SCSI Devices..............................................................................2-26

Connecting Power Cord....................................................................................................2-27

Turning On the Server......................................................................................................2-29

Resetting the Server..........................................................................................................2-30

Forced Shutdown..............................................................................................................2-31

3. Configuring Your System

Configuring Your System...................................................................................................3-2

BIOS Setup Utility..............................................................................................................3-3

Using the BIOS Setup Utility........................................................................................3-3

BIOS Setup Configuration Settings...............................................................................3-4

Main Menu....................................................................................................................3-5

Processor Settings Submenu..................................................................................3-6

Primary IDE Master/Primary IDE Slave Submenu...............................................3-7

Advanced Menu ............................................................................................................3-8

Memory Configuration Submenu..........................................................................3-9

PCI Configuration Submenu.................................................................................3-9

Hot-plug PCI Control Submenu..........................................................................3-10

Empty Bus Default Speed Submenu....................................................................3-10

Embedded SCSI/Embedded NIC/Embedded Video Controller Submenu..........3-10

PCI Slot 1 – PCI Slot 8 Submenu........................................................................3-11

I/O Device Configuration Submenu....................................................................3-12

Advanced Chipset Control Submenu...................................................................3-13

PCI Device Submenu...........................................................................................3-13

Security Menu.............................................................................................................3-14

Security Menu (continued)..........................................................................................3-15

Server Menu................................................................................................................3-16

Server Menu (continued).............................................................................................3-17

iv Contents

System Management Submenu...........................................................................3-18

Console Redirection Submenu............................................................................3-19

Boot Menu .................................................................................................................. 3-20

Exit Menu....................................................................................................................3-21

SCSISelect Utility............................................................................................................ 3-22

Running the SCSISelect Utility..................................................................................3-22

Adaptec SCSI Utility Configuration Settings............................................................. 3-23

Exiting Adaptec SCSI Utility......................................................................................3-24

Configuring Optional SCSI Controller Boards...........................................................3-24

SCSI Disk Utilities........................................................................................................... 3-25

Configuring the RAID Controller.................................................................................... 3-26

Configuring System Jumpers...........................................................................................3-27

Before You Begin.......................................................................................................3-27

System Board Jumper Block.......................................................................................3-27

Moving System Jumpers............................................................................................. 3-28

Clearing CMOS .......................................................................................................... 3-29

Clearing the Password.................................................................................................3-30

4. Upgrading Your System

Precautions......................................................................................................................... 4-3

Preparing Your System for Upgrade..................................................................................4-5

Equipment Log...................................................................................................................4-5

Preparing for Installation and Removal..............................................................................4-5

Hard Disk Drives................................................................................................................4-7

Installation.....................................................................................................................4-8

Removal......................................................................................................................4-11

Considerations.............................................................................................................4-11

Power Supply Unit........................................................................................................... 4-12

Installation...................................................................................................................4-12

Replacing a Failing Power Supply Unit...................................................................... 4-14

Extending the Server from the Rack................................................................................4-16

Front Access Cover..........................................................................................................4-18

Removal......................................................................................................................4-18

Installation...................................................................................................................4-19

5.25-inch Peripheral Device............................................................................................. 4-19

Installation Considerations..........................................................................................4-19

Installation...................................................................................................................4-20

Removal......................................................................................................................4-22

Rear Access Cover........................................................................................................... 4-23

Removal......................................................................................................................4-23

Installation...................................................................................................................4-23

CPU Access Cover...........................................................................................................4-24

Removal......................................................................................................................4-24

Installation...................................................................................................................4-25

PCI Board......................................................................................................................... 4-26

RAID Controller Considerations................................................................................4-27

Optional Devices and Available Slots ........................................................................4-28

Onboard LAN Controller Considerations...................................................................4-28

Non-hot-plug PCI Boards...........................................................................................4-29

Installation...........................................................................................................4-29

Removal ..............................................................................................................4-31

Hot-plug PCI Board.................................................................................................... 4-31

Requirements for Hot Add..................................................................................4-32

Contents v

Status Lamps .......................................................................................................4-32

Hot Add...............................................................................................................4-33

Hot Remove.........................................................................................................4-36

Hot Replace.........................................................................................................4-40

Memory Board..................................................................................................................4-46

Removal.......................................................................................................................4-46

Installation...................................................................................................................4-47

DIMMs.............................................................................................................................4-48

Installation...................................................................................................................4-49

Removal.......................................................................................................................4-51

Processor Board Air Duct.................................................................................................4-52

Removal.......................................................................................................................4-52

Installation...................................................................................................................4-53

Processor Board................................................................................................................4-54

Removal.......................................................................................................................4-54

Installation...................................................................................................................4-55

Processor (CPU)...............................................................................................................4-56

Installation...................................................................................................................4-57

Removing a Processor.................................................................................................4-61

5. Problem Solving

Problem Solving.................................................................................................................5-2

Static Precautions ...............................................................................................................5-2

Troubleshooting Checklists................................................................................................5-3

Initial System Startup....................................................................................................5-3

Running New Application Software .............................................................................5-4

After System Has Been Running Correctly...................................................................5-5

Diagnostic Procedures........................................................................................................5-6

Error Checking..............................................................................................................5-6

Troubleshooting Guide..................................................................................................5-6

Preparing the System for Diagnosing Problems....................................................5-6

Monitoring POST..................................................................................................5-7

Verifying Proper Operation of Key System Indicators.........................................5-8

Confirming Loading of the Operating System......................................................5-8

Specific Problems and Corrective Actions.........................................................................5-9

Power LED Does Not Light..........................................................................................5-9

Incorrect or No Beep Code............................................................................................5-9

No Characters Appear on Screen................................................................................5-10

Characters are Distorted or Incorrect ..........................................................................5-10

System Cooling Fans Do Not Rotate...........................................................................5-10

Diskette Drive Activity LED Does Not Light.............................................................5-11

CD-ROM Drive Activity Light Does Not Light .........................................................5-11

Problems with Application Software...........................................................................5-11

Bootable CD-ROM Is Not Detected............................................................................5-12

Problems with the Network..............................................................................................5-12

Plug and Play Installation Tips.........................................................................................5-12

Error Messages.................................................................................................................5-13

POST Error Codes and Messages................................................................................5-13

Fans......................................................................................................................5-24

Processors (CPUs)...............................................................................................5-24

Memory ...............................................................................................................5-24

How to Identify BIOS and BMC Revision Levels...........................................................5-25

vi Contents

A. Technical Specifications

Server Unit........................................................................................................................A-2

B. Interrupt Request/ PCI IRQ Device/ I/O Port Address Assignment

Interrupt Request Assignments ......................................................................................... B-2

PCI IRQ Device Assignments........................................................................................... B-3

I/O Port Address Assignments.......................................................................................... B-5

Glossary

Equipment Log

Contents vii

Using This Guide

The Express5800/140Rc-4 Server User’s Guide provides a quick reference to information

about your server system. Its goal is to familiarize you with your system and the tasks

necessary for system configuring and upgrading.

This guide contains the following information:

! Chapter 1, “System Overview” provides an overview of your system and describes your

system’s major system components. See this chapter to familiarize yourself with your

system.

! Chapter 2, “Setting Up Your System” tells you how to select a site, unpack the system,

make cable connections, and how to use your system.

! Chapter 3, “Configuring Your System” tells you how to configure the system and

provides instructions for running the BIOS Setup Utility and the SCSISelect

Configuration Utility, which is used to configure SCSI devices in your system. This

chapter also provides information on system board jumper settings.

! Chapter 4, “Upgrading Your System” provides you with instructions for upgrading your

system with additional processors, optional memory, options cards, peripheral devices,

and redundant power supply.

! Chapter 5, “Problem Solving” contains helpful information for solving problems that

might occur with your system.

! Appendix A, “Technical Specifications” provides specifications for your server system.

! Appendix B, “Interrupt Request/PCI IRQ Device/I/O Port Address Assignments"

provides the Interrupt Requests (IRQs), PCI IRQ device, and I/O port addresses that are

assigned by the factory for this system. These values can be used for reference when

installing an optional device.

! “Glossary” defines the standard acronyms and technical terms used in this manual.

! “Equipment Log” provides you with a sample equipment log for documenting the

system configuration and future updates you may make to your system.

Using This Guide ix

Text Conventions

This guide uses the following text conventions.

Warnings, cautions, and notes have the following meanings:

Warnings alert you to situations that could result in serious personal injury or loss

of life.

Cautions indicate situations that can damage the system hardware or software.

Note: Notes give important information about the material being described.

! Names of keyboard keys are printed as they appear on the keyboard. For example, Ctrl,

Alt, or Enter.

!

WARNING

!

CAUTION

! Text or keystrokes that you enter appear as boldface type. For example, type abc123 and

press ENTER.

! File names are printed in uppercase letters. For example, AUTOEXEC.BAT.

x Using This Guide

Related Documents

In addition to this guide, the following system documentation is included with your server

either as electronic files on EXPRESSBUILDER or as paper copy shipped with your server.

! System Release Notes

Release Notes provide you with the latest information about your system. This

information was not available to be included in your user's guide at the time it was

developed and released.

! Getting Started Sheet

The Getting Started Sheet provides several easy-to-follow steps to become familiar with

your server documentation and to complete your installation successfully.

! Network Operating System Configuration Guide

This guide contains supplemental instructions needed to install and configure your

server Windows 2000, Windows NT 4.0, Novell NetWare v5.0, Santa Cruz Operation

(SCO) OpenServer Release 5.05, and UNIXWare 7.1.1 Network Operating Systems.

This document is intended to complement the more detailed procedural documents

available from the vendor of the network operating system.

Using This Guide xi

Safety Notices

General Notices

Lithium batteries can be dangerous. Improper handling of lithium batteries may

result in an explosion. Dispose of lithium batteries as required by local ordinance.

Replace only with the same or equivalent type battery.

The CD-ROM drive uses a laser beam. Do not look or insert a mirror inside while

the system is on. A laser beam is invisible; if your eyes get exposed to it, there is

a risk of losing your eyesight.

This equipment uses 3-wire, grounded power cords. To prevent electrical

hazards, do not remove or defeat the ground prong on the power cords. Replace

a power cord if it gets damaged. The detachable power supply cords are intended

to serve as the disconnect devices. Contact your dealer for an exact replacement.

The DC push-button on/off switch does not turn off the system AC power. Also,

+5vdc is present within the system whenever the AC power cords are connected

between the system and an AC outlet. Before doing the procedures in this

manual, make sure that your system is powered off and unplug the AC power

cords from the back of the chassis. Failure to disconnect power before opening

your system can result in personal injury and/or equipment damage.

!

WARNING

Under no circumstances should you attempt to disassemble a power supply. The

power supply has no user-replaceable parts. Inside the power supply are

hazardous voltages that can cause serious personal injury. A defective power

supply must be returned to your dealer.

Never connect the ground wire to a gas pipe. There is a risk of a gas explosion.

The equipment weighs around 60 to 70 kg (depending on its hardware

configuration). If you carry it alone, injuries may result. It takes at least four

people to carry it; hold the equipment firmly by its bottom. Do not hold the front

bezel, or it may become detached, causing an injury.

Immediately after powering off the system, components such as CPU processor

heat sinks and hard disk drives may be very hot. Wait for the server to cool down

completely before adding/removing components.

Do not attempt to remove a device while it is in operation. Device malfunction or

personal injury may result.

Be careful not to get your fingers or hair caught in cooling fans located in the back

of a running server.

! Be sure to power off the equipment and unplug its power cords from the wall outlet

before installation/relocation. All voltage is removed only when the power cords are

unplugged.

! Turn off your cellular phone or pager when you use the equipment. Their radio waves

may cause the equipment to malfunction.

xii Using This Guide

! Do not use damaged power cords. (Replace it with a new one of the same type.)

! In the U.S.A. and Canada, the power cord must be a UL-listed detachable power cord (in

Canada, CSA-certified), type ST or SJT, 16 AWG, 3-conductor, provided with a

molded-on NEMA type 5-15 P plug cap at one end and a molded-on cord connector

body at the other end. The cord length must not exceed 9 feet (2.7 meters).

! Outside the U.S.A. and Canada, the plug must be rated for 250 VAC, 10 amp minimum,

and must display an international agency approval marking. The cord must be suitable

for use in the end-user country. Consult your dealer or the local electrical authorities if

you are unsure of the type of power cord to use in your country. The voltage change

occurs via a switch in the power supply.

Safety Notices for Users Outside of the U.S.A. and Canada

! PELV (Protected Extra-Low Voltage) Integrity: To ensure the extra-low voltage

integrity of the equipment, connect only equipment with mains-protected electricallycompatible circuits to the external ports.

! Remote Earths: To prevent electrical shock, connect all local (individual office)

computers and computer support equipment to the same electrical circuit of the building

wiring. If you are unsure, check the building wiring to avoid remote earth conditions.

! Earth Bonding: For safe operation, only connect the equipment to a building supply

that is in accordance with current wiring regulations in your country. In the U.K., those

regulations are the IEE.

Using This Guide xi ii

Fire Related Notices

To prevent fires, and damage to the equipment and supply wiring, make sure that

the rated load of the power branch circuit is not exceeded. Equipment nameplate

ratings should be used when addressing this concern. For more information on

installation and wiring of power-related facilities, contact your electrician or local

power company.

If the equipment emits smoke, odor, or noise, immediately turn off the POWER

switch, unplug the cord, and contact your sales agent. There may be a risk of a

fire.

Use a wall outlet with the specified voltage rating and power type. Otherwise,

there is a risk of a fire or current leakage.

Avoid installing the equipment where you may need to use an extension cord. If

you use a cord that does not meet power specifications, there is a risk of

overheating that could lead to a fire.

Insert the plug firmly into an outlet. Otherwise, there is a risk of heat or fire due to

poor contact. If dust settles on the slots and it absorbs moisture, there is also a

risk of heat or fire.

!

CAUTION

Use only the supplied power cords. If the rated current of the power cord is

exceeded, there is a risk of a fire. Also observe the following prohibitions to

prevent damage to cords:

Do not pull on the cord.

Do not pinch the cord.

Do not bend the cord.

Keep chemicals away from the cord.

Do not twist the cord.

Do not place any object on the cord.

Do not bundle several cords.

Do not alter, modify, or repair the cord.

Do not staple the cord.

Use only interface cables designed for your server. Identify which component or

connector to attach beforehand. If you use a wrong cable or make a wrong

connection, there is a risk of short-circuit that could lead to a fire. You also have

to observe the following prohibitions about handling and connecting interface

cables:

Do not use any damaged cable connector.

Do not step on the cables.

Disconnect the power plug from the outlet occasionally and clean the plug with a

dry cloth. Heat will be generated if condensation is formed on a dusty plug, which

may cause a fire.

Firmly install all power cords, interface cables and/or boards. An incompletely

installed component may cause a contact failure, resulting in fire and/or smoke.

xiv Using This Guide

Shock Related Notices

Do not insert a wire or metal objects into a vent or disk drive slot. There is a risk

of an electric shock.

Do not let water or foreign objects (e.g., pins or paper clips) enter the equipment.

There is a risk of a fire, electric shock, and breakdown. When such objects

accidentally enter the equipment, immediately turn off the power and unplug the

cord. Contact your sales agent instead of trying to disassemble it yourself.

Do not plug/unplug a power cord with a wet hand. There is a risk of an electric

shock.

Make sure to power off the server and unplug the power cord from a power outlet

before installing/removing any optional internal device or

connecting/disconnecting any interface cable to/from the server. If the server is

powered off, but its power cord is plugged to a power source, touching an internal

device, cable, or connector may cause an electric shock or a fire.

Unless described herein, never attempt to disassemble, repair, or alter the

equipment. There is a risk of an electric shock or fire as well as malfunction.

You may want to unplug the equipment if a thunderstorm is eminent. Do NOT

touch the equipment and cables during a thunderstorm in your area. There is a

risk of a fire or electric shock.

!

WARNING

Make sure to power off the server and disconnect the power plug from a power

outlet before cleaning or installing/removing internal optional devices. Touching

any internal device of the server with its power cord connected to a power source

may cause an electric shock even of the server is off-powered.

Using This Guide xv

Rack-mount Related Notices

To avoid a risk of injuries, users should not attempt to install the equipment into a

rack. Installation should be performed by trained maintenance personnel.

It takes at least two people to carry or maneuver a rack. Otherwise, it may be

dropped and cause injuries or damage to physical assets. A tall rack (such as

44U rack) is quite unstable, especially when not fixed by stabilizers.

For stability and to distribute the weight, attach stabilizers or install two or more

racks together. Otherwise, the rack may topple over and cause injuries.

It takes at least two people to mount doors and trays to a rack. Otherwise, parts

may be dropped causing breakage or injuries.

If you extend two or more devices from the rack at the same time, the rack may

topple over on you. Extend only one device from the rack at a time.

Install the equipment into a 19-inch rack conforming to EIA standards. Do not use

the equipment without a rack or install it on a nonconforming rack. Otherwise, the

equipment may not function properly, and there is a risk of equipment damage or

personal injury. For suitable racks, contact your sales agent.

!

WARNING

Exercise great care not to hurt your fingers on the rail when you mount/dismount

the equipment into/from the rack.

! Elevated Operating Ambient Temperature – If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may be greater

than the room ambient environment. Therefore, consideration should be given to

installing the equipment in an environment compatible with the a maximum rated

ambient temperature of 35°C. Refer to Chapter 2 on this manual for more details on

room ambient temperature.

! Reduced air Flow – Installation of the equipment in a rack should be such that the

amount of air flow required for safe operation of the equipment is not compromised.

! Before pulling a server or device out of a rack, make sure that the rack is secured by

stabilizers.

! To prevent fires, and damage to rack equipment and supply wiring, make sure that the

rated load of the power branch circuit is not exceeded. Equipment nameplate ratings

should be used when addressing this concern. For more information on installation and

wiring of power-related facilities, contact your electrician or local power company.

! To prevent electrical shock, connect all rack and rack support equipment to the same

electrical circuit of the building wiring. If you are unsure, check the building wiring to

avoid remote earth conditions.

! For safe operation, only connect the equipment to a building supply that is in accordance

with current wiring regulations in your country. In the U.K., those regulations are the

IEE.

xvi Usi ng Thi s Guide

Care and Handling

Use the following guidelines to properly handle and care for your system.

Protect the system from extremely low or high temperatures. Let

the system warm (or cool) to room temperature before using it.

Keep the system away from magnetic forces.

Keep the system dry. Do not wash the system with a wet cloth or

pour fluid into it.

Protect the system from being bumped or dropped.

Check the system for condensation. If condensation exists, allow it

to evaporate before powering on the system.

Keep the system away from dust, sand, and dirt.

Using This Guide xvii

System Overview

! Overview

! System Chassis

! System Board Set

! System Board Set Features

! System Power

! Peripheral Bays

! Disk Array

! System Functions

1

! System Security

Overview

Your server is a highly reliable, high-powered, fault-tolerant, high-capacity,

multiprocessing server based on the Intel Xeon™ Processor MP. It is a solid performer

and offers the latest technology. The combination of compute performance, memory

capacity, and integrated I/O provides a high performance environment for many server

market applications. These range from large corporations supporting remote offices to

small companies looking to obtain basic connectivity capability such as file and print

services, e-mail, web access, web site server, etc. See Figure 1-1. Your server is housed

and available as a rack-mount system. Your server conveniently installs into a standard

EIA 19-inch rack cabinet.

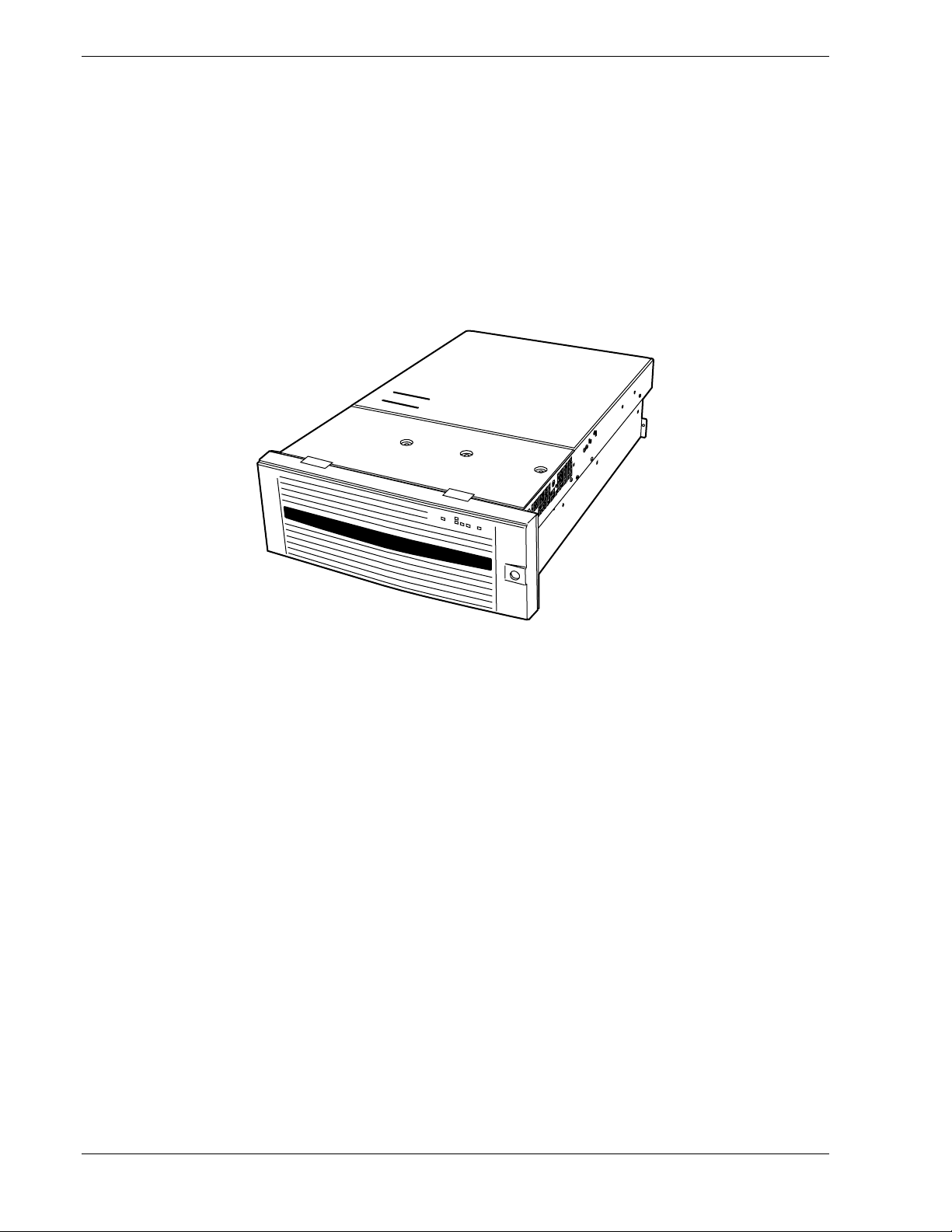

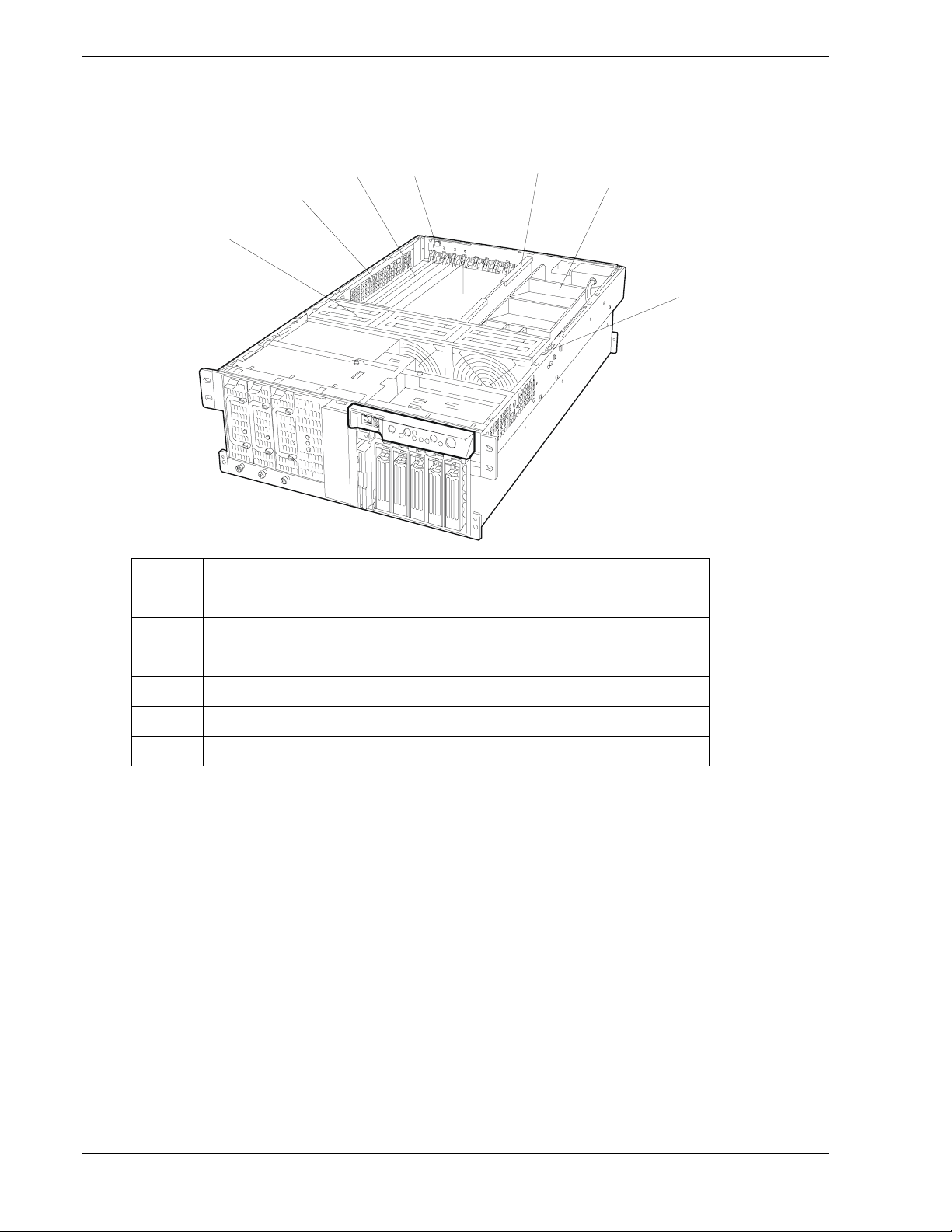

Figure 1-1. Express5800/140Rc-4 Server

Your server includes a 3.5-inch diskette drive, a CD-ROM drive, a 3.5-inch hard disk

bay, and removable media device bay. The 3.5-inch hard disk bay supports up to five

1.0-inch SCSI hard disk drives that can be swapped in or out of the system without

powering it down, if RAID functionality is configured in the system.

As application requirements increase, you can expand your server with an additional

processor, additional memory, add-in boards and peripheral devices: tape devices,

CD-ROM, and hard disk drives.

The combination of superior computing performance, high memory capacity, and

integrated I/O provides a high performance environment for the many sophisticated

applications available to network servers. The server system is designed for use in

applications where advanced technology, high performance, and high levels of

reliability and compatibility are expected at all times.

1-2 System Overview

Your server is designed for minimum downtime. To this end, the server includes or has

the option to include the following:

! A chassis that supports up to three self-contained power supplies (two are standard

power supplies). An additional power supply can be added to provide redundant

power (i.e., the system will continue to operate with a single power supply failure).

If optional power system redundancy is installed, the power supply units are then

hot-swappable and can be easily installed or removed from the chassis without

turning the system power off.

! Fan modules that can be easily installed or removed from the top of the system. The

fan modules contain a total of six fans for effective cooling. An additional fan cools

the disk drive bay and each power supply contains a fan.

! Cooling system redundancy where the system will continue to operate in the event of

a fan failure or having cabinet temperatures approaching the threshold limit, the

redundant fans will switch to maximum operating speed.

! Up to five SCSI drive bays accessible from the front of the cabinet.

! Hot-swap SCSI disk drive backplane; a failed drive can be removed and replaced

with a new drive without system power being turned off (if an optional Redundant

Array of Independent Disks (RAID) controller is installed.)

! High degree of SCSI disk fault tolerance and advanced disk array management

features through the use of RAID technology, if an optional RAID controller is

installed.

! Hardware monitors (temperature and voltage) and software monitors to indicate

failures.

As application requirements increase, you can expand your server system with

additional processors, additional memory, add-in boards and peripheral devices.

Your server system features the following major components:

! Up to four high-performance Intel Xeon processors.

! Up to 12GB of DDR200 SDRAM four way interleaved memory.

! Eight full-length PCI expansion slots of which four supports 64-bit hot-plug PCI-X

boards, two support 64-bit non-hot-plug PCI-X boards and two support 32-bit nonhot-plug PCI boards. The hot-plug PCI feature is useable only when operating

system support is available.

! Embedded PC-compatible support (serial, parallel, mouse, keyboard, diskette, IDE,

USB, LAN, and video).

! Integrated onboard ATI RAGE XL PCI 64-bit Super Video Graphics Array (SVGA)

controller with 4 MB of video memory.

! Adaptec® AIC7902 SCSI controller providing dual channel Ultra320/160 SCSI

interfaces for the hot swap hard disk drives. This controller also supports Ultra2 and

Ultra Wide SE SCSI devices.

System Overview 1-3

! Two Integrated onboard Network Interface Controllers (NIC), an Intel 82550 NIC

that supports 10Base-T and 100Base-TX networks and an Intel 82544 NIC that

supports 10Base-T, 100Base-TX and 1000Base-T networks.

! Single channel Ultra ATA100 enhanced IDE controller.

! Chassis that holds up to 8 drives; five hot-swap bays for Ultra SCSI hard disk drives;

a 5.25-inch media device bay, a CD-ROM drive installed; and a 3.5-inch diskette

drive installed.

! Five hot-swap SCSI hard disk drive bays accessible from the front of the chassis.

The drives can be swapped in or out of the system without powering down, if RAID

is configured in the system.

! SCSI backplane is Ultra320 capable.

! Integrated triple Universal Serial Bus (USB) ports.

! Two standard power supplies. When an additional power supply is installed, both the

standard and additional redundant power supplies become hot swappable.

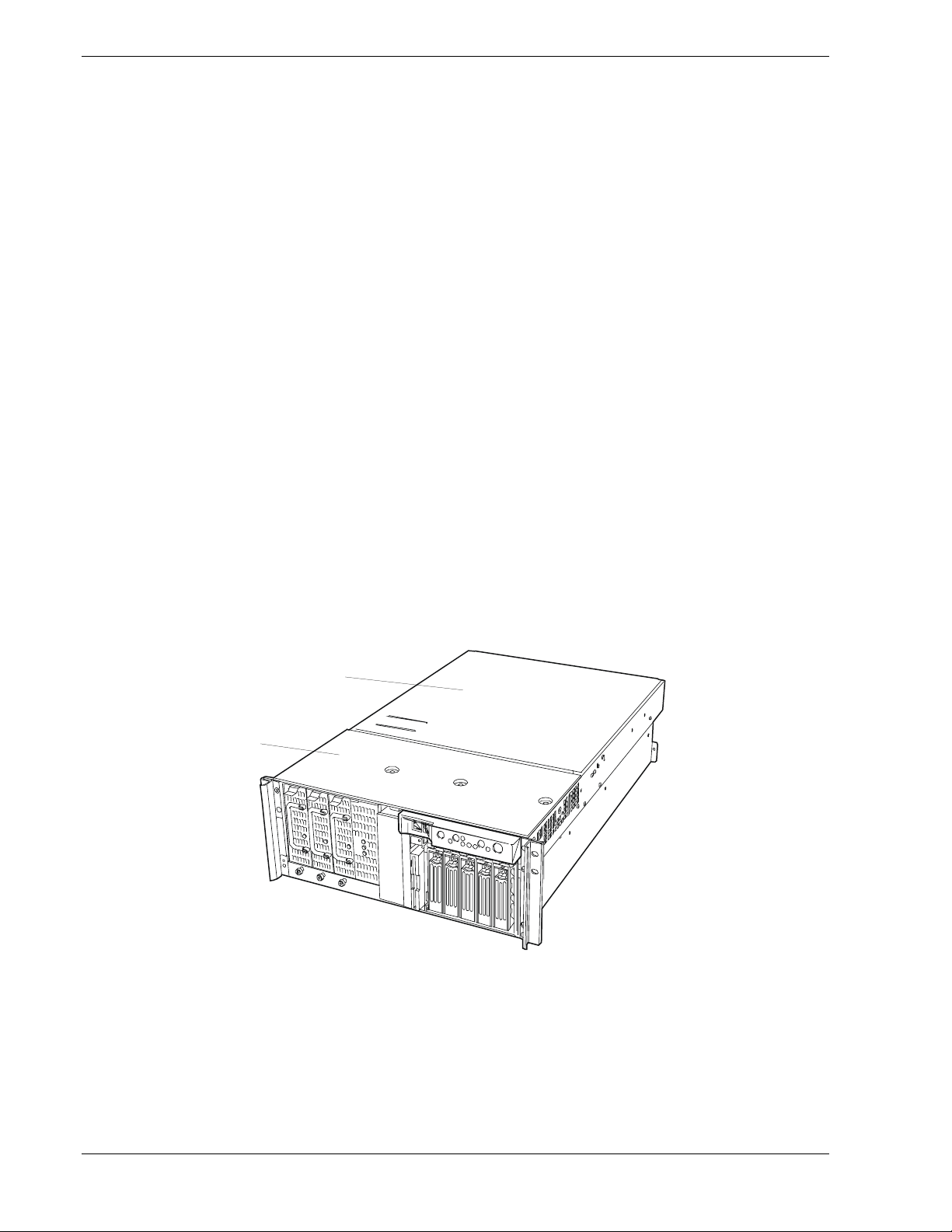

System Chassis

The system chassis (Figure 1-2) is an easy-to-access, fabricated metal structure. The

following subsections describe the main system components, the electronics bay

components, the front panel controls and indicators and the rear panel connectors and

indicators.

Top View

B

A

Front access cover – remove to replace defective fans and to

A

install or remove optional 5.25-inch devices.

Rear access cover – remove to install or remove optional PCI

B

boards, optional processors and DIMMs.

1-4 System Overview

Figure1-2. System Chassis

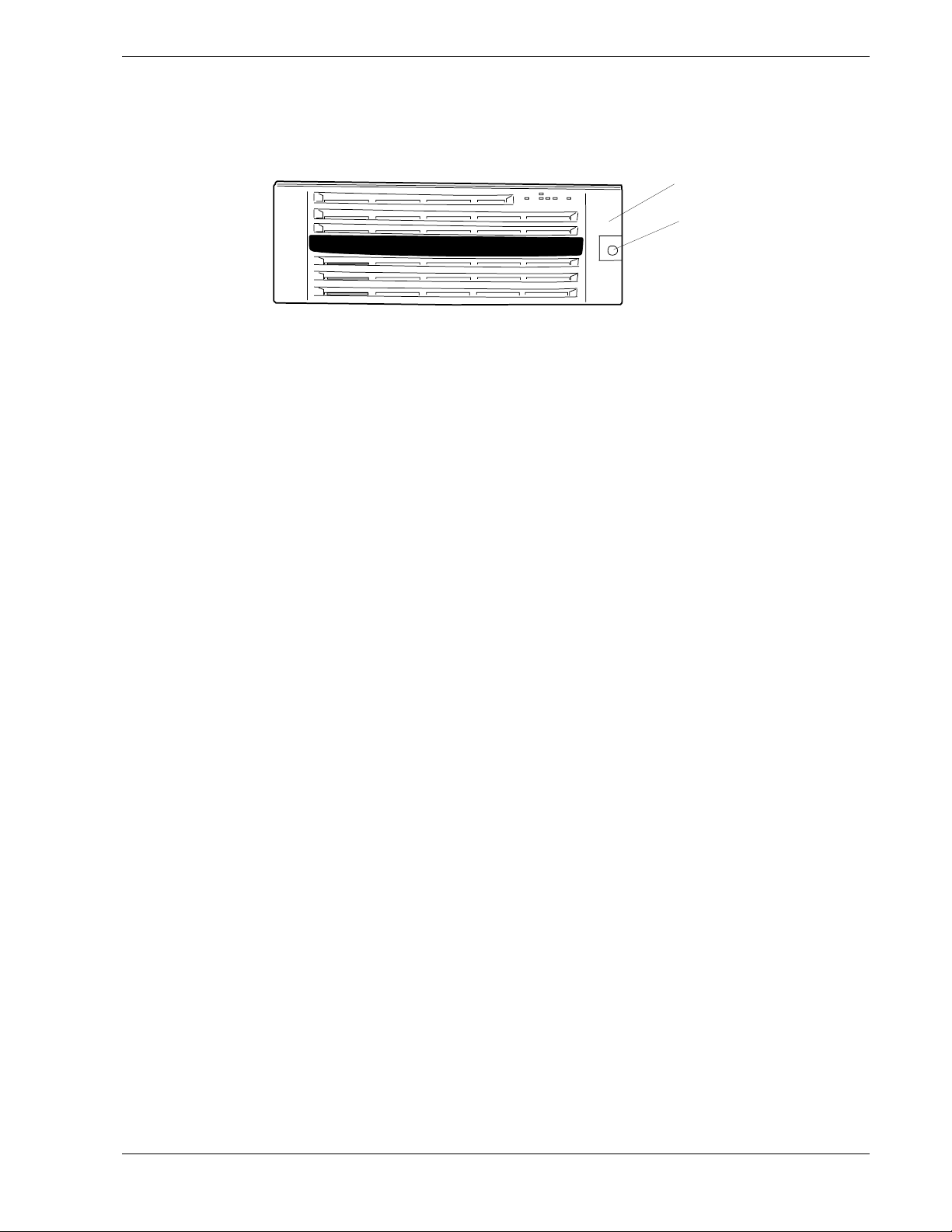

Front View (Bezel Installed)

Figure 1-3 shows the front bezel and keylock.

A Front bezel

Remove the front bezel when you need access to the POWER/SLEEP switch, the CD-ROM

drive, or the floppy disk drive or install or remove a hard disk drive from the 3.5-inch hard

disk bay. The front bezel can be locked by using the attached security key.

BKeylock

Insert the security key to lock/unlock the front bezel.

Figure 1-3. Front View (Bezel Installed)

A

B

System Overview 1-5

Front Vi ew (Bezel Remo ved)

Figure 1-4 shows the front chassis features and controls visible with the front bezel

removed.

-1BA

-2

A

-3

C D G

A

A Power Unit The power unit supplies DC powers to the server. The slot A-

E

-1

E

-2

E

-3

F

-1F-2F-3

3 is optional power unit slot.

H

B Power lamp Solid green indicates the presence of DC power in the server.

C AC Standby lamp If the power cord is connected to the AC inlet to supply AC

power to the power unit, these lamps are lit green except for

the lamp labeled AC_R. If the power system of the server is

in the redundant mode, after turning on the server, the lamp

indicated AC_R is also lit green. See Table 1-3.

D 5.25-inch device bay Backup tape drives may be installed in the 5.25-inch device

bay.

E CD-ROM drive The CD-ROM drive reads data from the inserted CD-ROM.

E-1: Access lamp (lit orange during accessing)

E-2: CD tray eject button

E-3: Emergency hole

F 3.5-inch floppy disk

drive

G 3.5-inch hard disk bay The 3.5-inch hard disk bay contains additional hard disk slots.

H Disk lamp

(green/amber)

Insert a 3.5-inch floppy disk to the 3.5-inch floppy disk drive

to read data from the disk or write data to the disk.

F-1: Disk inserting section

F-2: Floppy disk access lamp (lit green during accessing)

F-3: Eject button

Hard disks having the thickness of 1 inch can be inserted into

the slots. The SCSI IDs are defined as follows: ID0 to ID4

from right to left.

The disk lamp is lit green if a hard disk installed in the server

is accessed. If a hard disk is defective, the lamp is lit amber.

During the rebuild processing, the lamp is lit green or amber

alternately. (This occurs only in the disk array configuration.)

1-6 System Overview

Figure 1-4. Front View (Bezel Removed)

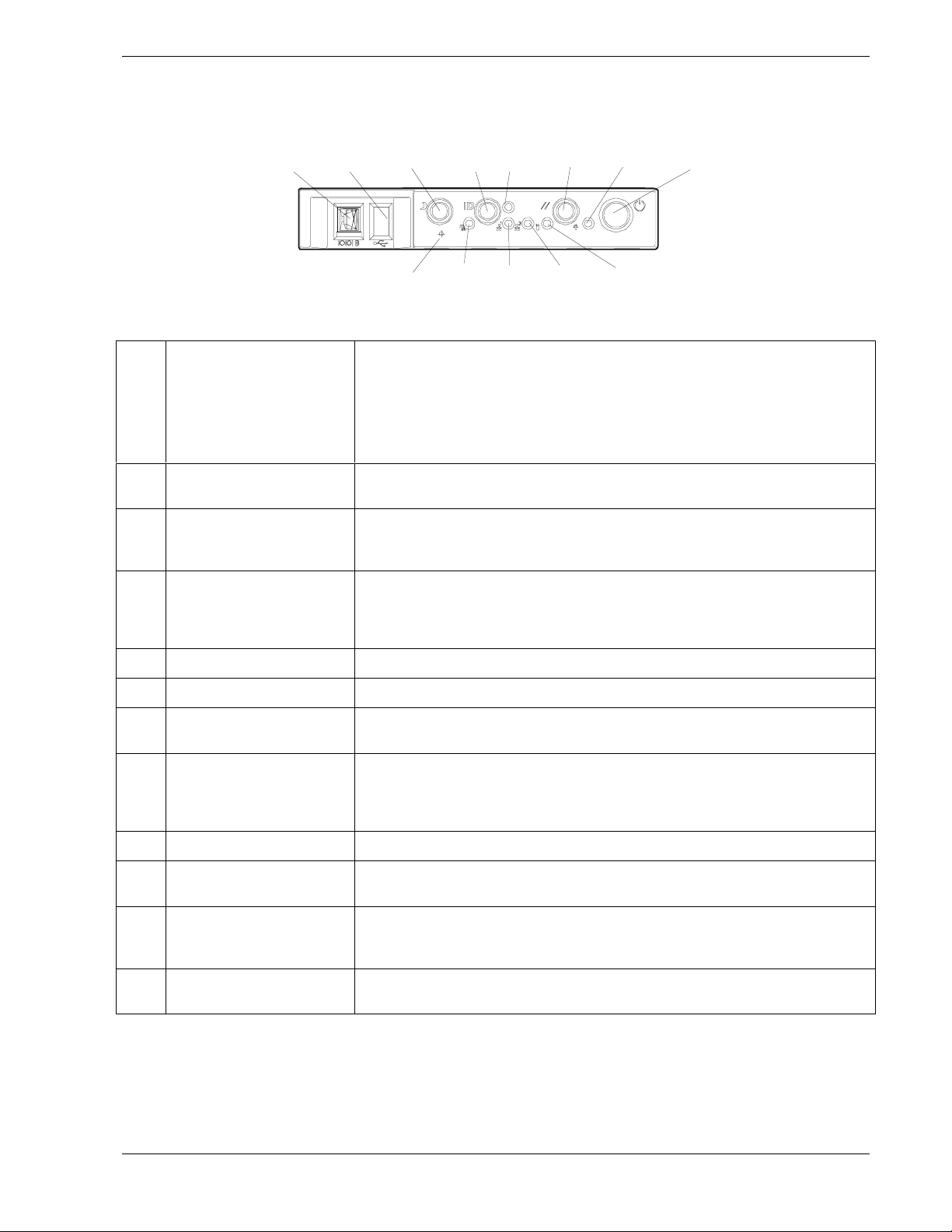

Front Panel Switches, Connectors and LED Indicators

Figure 1-5 shows the front panel switches, connectors and LED indicators

A B C D E F G H

I J K K L

A Serial port B connector The serial port B connector is used to connect the server to a device with the

serial interface.

The server cannot be directly connected to a leased line through the connector.

IMPORTANT: Only the RJ-45 serial interface cable can be connected to this port.

Do not connect any other interface cables such as the Ethernet cable. Doing so

could damage the device, your server, or both.

B USB3 connector The USB3 connector allows the server to be connected to a device accepting the

USB interface.

C SLEEP switch Pressing the sleep switch once causes the server to enter into the sleep state

(power saving mode). Pressing the power switch in the sleep state recovers the

machine to the normal state. (This function is supported by Windows 2000.)

D UID (Unit ID) switch Pressing the UID switch turns UID lamp (blue) located on the front panel and the

rear panel on and off. The UID lamp located on the rear panel is visible through

the rear of the chassis and allows you to locate the server you're working on from

the rear of the servers on a rack.

E UID lamp (blue) Lights blue when the ID switch is pressed.

F RESET switch The reset switch is used to reset the server.

G POWER/SLEEP lamp

(green)

H POWER switch The power switch is used to turn power on/off. If you press the switch once, then

I Dump switch The dump switch is used to collect the event log data.

J STATUS lamp

(green/amber)

K LAN1/LAN2 ACCESS lamp

(green)

L DISK ACCESS lamp

(green/amber)

Lights green when the server is powered on. Goes off when the server is

powered off. Blinks when the system is placed in the sleep mode.

the POWER/SLEEP lamp goes on and the power is turned on. If you press the

switch again, the power is turned off. The system is forcibly shut down when the

power switch is pressed continuously for four seconds or longer.

Lights green while the server is in successful operation. When any error is

detected, this lamp lights or blinks amber.

Lights green while the server is connected to the network. Blinking green

indicates the network activity. Numbers printed near the lamps indicate the LAN

port number.

Lights green while the internal hard disk is in access. When any one of the

internal hard disks fails, this lamp lights amber.

Figure 1-5. Front Panel Switches, Connectors and LED Indicators

System Overview 1-7

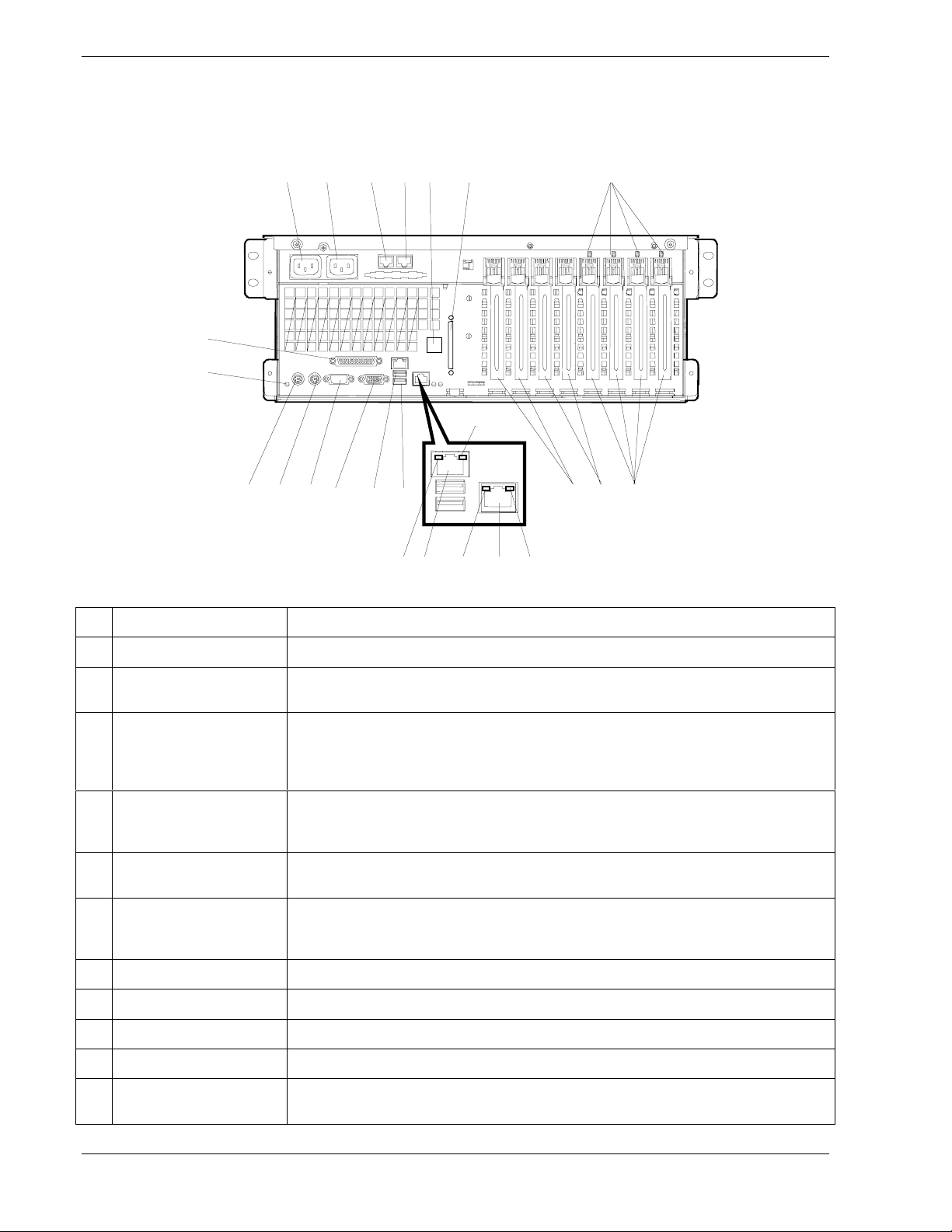

Rear View

Figure 1-6 shows the rear chassis features and controls.

AB C2DE

C1

F

G

H

I J K L M1 N O P

A AC inlet 1 The AC inlet 1 is connected with the power cord coming with the server.

M2

QR STUQ

B AC inlet 2 The AC inlet 2 is used when the additional power unit is installed in the server.

C ICMB-1 (left) ICMB-2

(right) connector

D Serial port B connector The serial port B connector is used to connect the server to a device with the serial

E External SCSI connector The external SCSI connector is used to connect the server to external SCSI devices.

F PCI slot power lamp

(green) (upper)

F PCI slot fault lamp

(amber) (lower)

G Printer port connector The printer port B is used to connect a printer to the system.

H UID lamp (blue) This lamp is lit when the UID switch is pressed.

I Keyboard connector The keyboard connector is used with PS/2 type keyboard.

J Mouse connector The mouse connector is used with the PS/2 type mouse.

K Serial port A connector The serial port A connector is connected with a device having the serial interface. The

The ICMB connector is connected to a device having the ICMB interface.

interface. The server cannot be directly connected to a leased line through the

connector. For using this port, the rear serial cable that comes with your server

should be connected to this connector.

For connection, attached SCSI cable is necessary and some cable connections must

be changed on the system board.

The PCI slot power lamp is lit when the power of the PCI slot is turned on.

PCI slot fault lamp blinks when the hot plug PCI function is enabled with Windows

2000. This lamp also goes on if a fault occurs in the PCI board installed into the slot

or the slot itself.

server can't directly be connected to a leased line through the connector.

1-8 System Overview

L Monitor connector The monitor connector is connected with the display unit.

M USB-1 - USB-2

connectors

N Additional PCI board

slots

O Additional PCI board

slots

P Additional PCI hot-plug

board slots

Q LINK/ACT lamp The LINK/ACT lamp shows the LAN access status.

R LAN1 connector The LAN1 connector is connected with a network system on LAN. This port can be

S LAN2 connector The LAN2 connector is connected with a network system on LAN. This port can be

T 100/10 lamp The 100/10 lamp indicates the LAN transfer rate.

U 1000/100/10 lamp The 1000/100/10 lamp indicates the LAN transfer rate.

The USB-1 (upper) and USB-2 (lower) connectors are connected with devices

accepting the USB interface.

Optional PCI boards (32-bit/33MHz) may be inserted into the slots.

Optional PCI boards (64-bit/100 MHz) may be inserted into the slots.

Optional PCI hot-plug boards (64-bit/100 MHz) may be inserted into the slots.

operated through 100BASE-TX or 10BASE-T interface.

operated through 1000BASE-T, 100BASE-TX or 10BASE-T interface.

Figure 1-6. Rear View

System Overview 1-9

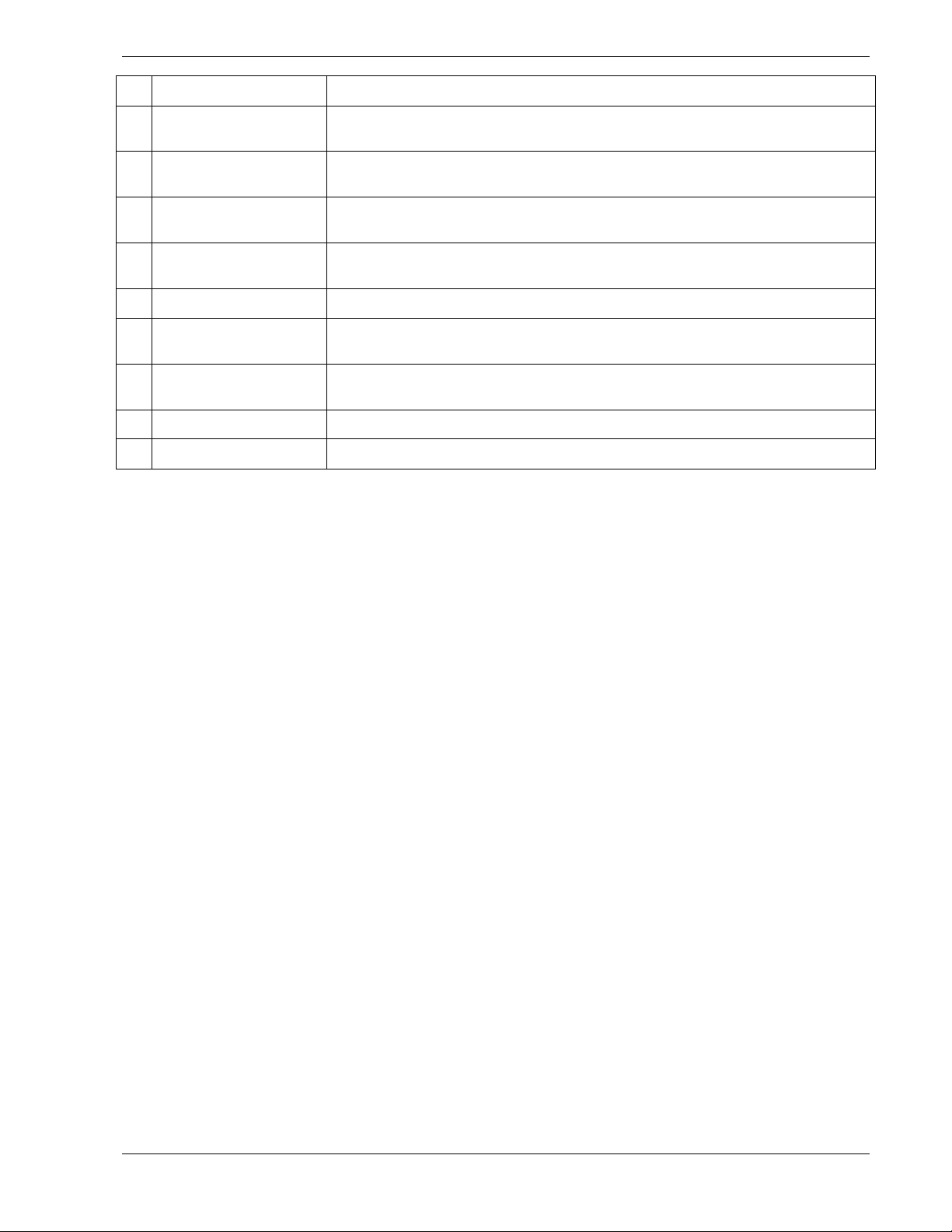

Internal View

Figure 1-7 shows an internal view of the server.

C

D

B

A

A Fan bay (6 Cooling fans are located in this bay.)

B Electronics bay

E

F

G

C Additional PCI board slots (8 slots)

D Hot Plug PCI LED Board

E Memory board

F Processor board air duct

G Cover open sensor

Figure 1-7. Internal View

1-10 System Overview

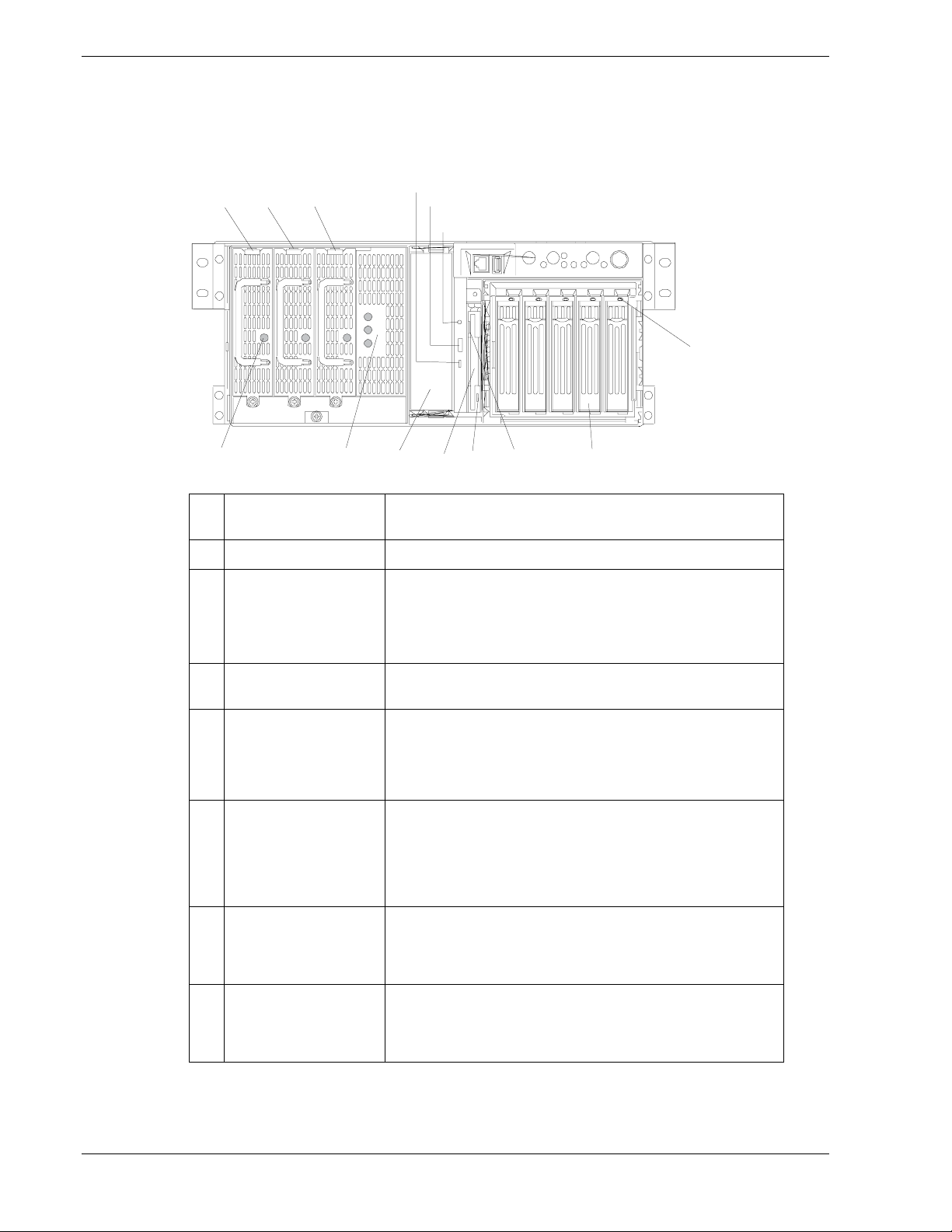

Electronics Bay

Figure 1-8 shows the electronics bay.

A

B

C

D

A Hot-plug PCI board slots

B Non-hot-plug PCI board slots

C Dummy sponge

D Processor board

E System board

E

Figure 1-8. Electronics Bay

System Overview 1-11

Status LED Indicator Descriptions

Table 1-1 lists the system status LED indicators along with a description of each LED

indicator. Table 1-2 lists the disk drive status LED panel indicators along with a

description of each LED indicator. Table 1-3 lists the power supply status LED panel

indicators along with a description of each LED indicator. Table 1-4 lists system status

abnormal conditions.

The access LED indicators for the CD-ROM drive and the diskette drive light when

access is being made to the media in the drive.

Table 1-1. System Status LED Indicators (Figure 1-5)

LED Status Description Response

Power Off Power OFF None required (normal)

Green Power ON None required (normal)

(Flashing

green)

Status Off

(Turns off after

lighting in

amber)

Green

(Steady light)

(Flashing light)

Amber Abnormal condition

Disk Off Not accessing disk

Amber Internal disk drive

Green Accessing disk

LAN1/LAN2 Off Server not

Power saving mode

(Sleep mode)*

Power OFF

Abnormal condition

(see Table 1-4)

No alarms

Abnormal condition

(see Table 1-4)

(see Table 1-4)

drives

failure

drives

connected to a LAN

None required (normal)

None required (normal)

Check condition

None required (normal)

Check condition

Check condition

None required (normal)

Check disk drive status LEDs

None required (normal)

None required (normal)

UID (unit ID) OFF/ON (blue) Turn on to identify

* Requires a operating system support.

1-12 System Overview

Green Server connected to

a LAN

(Flashing

green)

Server accessed

through a LAN

the server you are

working on. Visible

from the front and

rear of the server.

None required (normal)

None required (normal)

None required (convenience LED)

Table 1-2. Disk Drive Status LED Panel Indicators (Figure 1-4)

LED Status Description Response

Disk Drive

Power/access

/error

*Disk array configuration only

Off Disk drive

power off

Green Disk drive

power on

Flashing

green

Amber Disk drive failure* Replace disk drive

(Alternating

between

amber and

green)

Accessing disk drive None required (normal)

Rebuilding* LED

goes off when

rebuilding is

complete.

Remount the disk drive

None required (normal)

None required (normal)

Table 1-3. Power Supply Power and Status LED Indicators (Figure 1-4)

LED Status Description Response

PWR Off Power off None required (normal)

On (green) Power on None required (normal)

SB1/SB2 Off Power not

connected to AC

inlets.

On (green) Power connected to

AC inlets.

AC_R Off Non-redundant

power configuration

On (green) Three power

supplies installed.

Redundant power

configuration.

Connect power cords to AC inlets 1

and 2.

None required (normal)

None required (normal)

None required (normal).

System Overview 1-13

Table 1-4. System Status Abnormal Conditions (Figure 1-5)

Status LED Description Response

Off POST is in progress. Wait for a while. It lights green a few seconds after

completion of POST.

CPU error is detected. Turn the server off and then back on. If an error

message appears during POST, take note of the error

message and contact your technical support

representative.

Green

(Flashing light)

Amber

(Steady light)

Amber

(Flashing light)

CPU temperature error is detected.

(Thermal-Trip)

Watchdog timer has timed out. Same

Uncorrectable error is detected in the

memory.

PCI system error is detected. Same

PCI parity error is detected. Same

CPU bus error is detected. Same

Memory dump request is being

issued.

Memory or CPU is degraded. Use the BIOS setup utility, SETUP, to locate the

Critical temperature error is detected. Check if any fan inside the server has dust on it. Make

Critical voltage error is detected. Contact your technical support representative.

Power supply failed. Contact your technical support representative.

A power alarm was detected in each

power system.

Same

Same

Wait until the memory dump finishes.

degraded device and replace it as soon as possible.

sure that fan cables are firmly connected.

If the lamp indication still does not change, contact

your technical support representative.

Identify the failed power supply unit and contact your

technical support representative.

Fan alarm is detected. Make sure fan cables are firmly connected.

Temperature alarm is detected. Check if any fan inside the server has dust on it. Make

Voltage alarm is detected. Contact your technical support representative.

1-14 System Overview

If they are and the lamp indication still does not

change, contact your technical support representative.

sure that fan cables are firmly connected.

If the lamp indication still does not change, contact

your technical support representative.

System Board Set

The system board set inside the server includes the system board, memory board, and

processor board.

Figures 1-9, 1-10, and 1-11 show the major components on the system board, memory

board, and processor board. Table 1-5 summarizes the features of the board set.

Table 1-5. Features of the Board Set

Feature Description

Multiple processor

slots

Four processor sockets on the system board.

Upgradeable

memory

Hot Plug PCI slots Four hot-plug PCI-X add-in board slot locations (Figure 1-6, A), two non-hot-

SCSI controller Adaptec AIC7902 SCSI controller providing dual channel Ultra320/160 SCSI

BIOS Flash memory-based BIOS (Basic Input/Output System) and Setup utilities.

Video Integrated super SVGA controller ships with 4 MB of video memory.

External device

connectors

Clock Real-time clock/calendar (RTC).

System hardware

monitoring

Twelve DIMM sockets on a single memory board, supporting up to 12GB

memory using 1GB DIMMs. Must use four sticks (4-way interleaving)

double-sided buffered type only.

plug PCI-X add-in board slot locations (Figure 1-6, B) and two non-hot-plug

PCI add-in board slot locations (Figure 1-6, C). The four hot-plug PCI-X

board slot locations are dedicated 64-bit, 100 MHz PCI-X bus slots. The two

non-hot-plug PCI-X board slot locations are dedicated 64-bit, 100 MHz

PCI-X bus slots. And the two non-hot-plug PCI board slot locations are

dedicated 33-bit, 33MHz PCI bus slots.

interfaces for the hot swap hard disk drives. This controller also supports

Ultra2 SCSI devices.

Connectors for two serial ports, parallel printer port, wide SCSI port, three

USB connectors, one 10/100 BaseTX connector and one 10/1 00/1 000

BaseT connector, two optional ICMB port connectors, PS/2-compatible

keyboard and mouse, and SVGA monitor.

Contains power interlock switch and sensors for temperature, voltage, and

fan failure.

Configuration

utilities

BIOS Setup and SCSISelect Configuration Utility.

System Overview 1-15

CC DDEE

FF

GG

HH

JJ

KK

LL

BB

A

B

AA

Z

Y

X

W

V

C

D

E

F

U

N

QRST

M

P

A 64-bit, 100-MHz, hot-plug PCI-X slots U 14-pin Power Control connector (P35)

B 64-bit, 100-MHz, non-hot-plug PCI-X slots V 24-pin Power connector (P32)

C 32 bit, 33-MHz, non-hot-plug PCI slots W 20-pin Power connector (P28)

D Intelligent Chassis Management Bus

(ICMB) connector (P24)

E Hot-Plug Indicator Board Connector (P23) Y USB #3 Header (P18)

F Back Panel I/O connectors Z Front Panel Header (P19)

G Intel ® 82550 Ethernet controller AA IDE Connector (P13)

H ATI Rage XL 2D/3D graphics accelerator BB SCSI LVD connectors (P4 and P7)

J Intel ® 82544 Ethernet controller CC Intelligent Platform Management Bus (IPMB)

K Video RAM (VRAM) (4 MB total) DD Adaptec 7902 SCSI controller

L Processor board connectors (P21 and

P22)

M ServerWorks South Bridge Controller FF ServerWorks PCI-X Bus Bridge Controller

N BMC component GG ServerWorks PCI-X Bus Bridge Controller

P BIOS Flash component HH RAID LED connectors (P1 and P2)

Q PC87417 Super I/O controller JJ Hot-swap backplane (HSBP) connector (P16)

R BMC Flash component KK HSBP connector (P15)

S Battery LL Jumper block JP4

T Chassis Intrusion Detect connector (P36)

X Serial port B connector (P17)

connector (P12)

EE Fan connector (P11)

GHJKL

Figure 1-9. System Board Component Locations

1-16 System Overview

DIMM Group 3

DIMM Group 2

DIMM Group 1

11

9

7

5

3 4

1 2

A

Note: DIMMs are grouped into four and must be installed in

multiples of four. Group 1 DIMMs are installed in the system. When

adding DIMMs, install DIMMs into Group 2, then Group 3. When

removing DIMMs, remove DIMMs in Group 3 first, followed by Group

2, and lastly Group 1.

Group #1 DIMM sockets (DIMM slots 1, 3, 2, 4)

Group #2 DIMM sockets (DIMM slots 5, 7, 6, 8)

Group #3 DIMM sockets (DIMM slots 9, 11, 10, 12)

A = System board connector

12

10

8

6

DIMM Group 3

DIMM Group 2

DIMM Group 1

Figure 1-10. Memory Board Component Locations

C

D

AB

A Processor (CPU) #1

B Processor (CPU) #2

C Processor (CPU) #3

D Processor (CPU) #4

Figure 1-11. Processor Board Component Locations

System Overview 1-17

System Board Set Features

The following subsections provide a description of the system board set features.

Intel Xeon Processor

Depending on system configuration, your server includes from one to four Intel Xeon

processors. Available processor speeds are 1.5GHz, 1.9GHz, and 2.0GHz. Each Intel

Xeon processor plugs into a ZIF (Zero Insertion Force) socket on the system board. The

processor includes a numeric coprocessor, a 1MB or 2MB L3 cache, and operates at a

bus speed of 400MHz. Up to four optional processors enhance performance and enables

symmetric multiprocessing (SMP).

System Memory

The memory board contains twelve 168-pin DIMM slots each supporting 72-bit ECC

(64-bit main memory plus ECC) registered PC-200 Double Data Rate (DDR) DIMMs.

Memory is partitioned in three banks. You may install a minimum of 512 MB

(128 MB x 4) or as much as 12 GB. The controller automatically detects, sizes, and

initializes the memory array, depending on the type, size, and speed of the installed

DIMMs, and reports memory size and allocation to the server via configuration

registers.

Note: Only use DIMMs approved for use in this server system.

Call your customer service representative for information.

I/O Expansion Slots

The server's expansion capabilities meet the needs of file and application servers for

high performance I/O by providing a combination of 32-bit and 64-bit PCI expansion

slots.

The system board has four full-length hot-plug 64-bit, 100 MHz PCI-X connectors, two

non-hot-swap full-length 64-bit, 100 MHz PCI-X connector slots and two non-hot-swap

32-bit 33 MHz PCI connector slots. See Table 1-5.

Real-Time Clock/Cale ndar

The real-time clock provides system clock/calendar information stored in a non-volatile

memory (NVRAM). The real-time clock battery provides power backup for the realtime clock.

BIOS

The BIOS and Setup Utility are located in the Flash EPROM on the system board and

include support for system setup and legacy device configuration. A number of security,

reliability, and management features also have been incorporated to meet vital server

needs.

1-18 System Overview

Controllers

The following provides a description of the controllers.

IDE Controller

The system includes a single channel enhanced IDE 32 bit interface. The IDE controller

provides support for the internally mounted CD-ROM.

The device controls:

! PIO and DMA transfer modes

! Mode 4 timings

! Transfer rates up to 100 MB/s

! Buffering for PCI/IDE burst transfers.

Keyboard and Mouse Controller

The keyboard and mouse controller are PS/2 compatible.

Network Interface Controller

The system board includes two network interface controllers (NICs):

! Intel 82550 NIC that supports 10Base-T and 100Base-TX networks

! Intel 82544 NIC that supports 10Base-T, 100Base-TX networks, and 1000BASE-T

networks.

The 82550 controller supports the following features:

! 32-bit PCI, CardBus master interface

! Integrated IEEE 802.3 10Base-T and 100Base-TX compatible PHY

! IEEE 820.3u auto-negotiation support

! Chained memory structure similar to the 82559, 82558, 82557 and 82596

! Full duplex support at both 10 Mbps and 100 Mbps operation

! Low power +3.3 V device

! IP checksum off-loading.

NIC 1 can be used as both a network interface and server management interface.

The 82544 controller supports the following features:

! Direct 32/64-bit, 33/66-MHz interface to the PCI bus

! Integrated IEEE 802.3 1000BASE-T, 100BASE-TX, and 10BASE-T

! Integrated third-generation MAC and proven IEEE 803.3ab compatible PHY

! Full duplex support for 10-Mbps, 100-Mbps, and 1000 Mpbs operation

System Overview 1-19

! Descriptor ring management architecture optimized to deliver both high performance

and PCI/PCI-X bus efficiency

! Low power +3.3 V device

! IP and TCP/UDP checksum off-loading.

SCSI Controller

The system board includes an embedded Adaptec 7902 SCSI controller, which contains

two independent SCSI channels. You can disable the SCSI controller in BIOS Setup.

Both channels support 16-bit SE or LVD SCSI operations at the following speeds:

! Ultra320 (320 MB/sec)

! Ultra160 (160 MB/sec)

! Ultra2 (80 MB/sec)

! Ultra Wide SE (40 MB/sec)

The system board provides active terminators, termination voltage, resettable fuses, and

protection diodes for both SCSI channels. You can disable the onboard terminators in

BIOS Setup.

Video Controller

The system board incorporates an ATI RAGE XL PCI graphics accelerator with 4 MB

of video SDRAM that supports all standard IBM VGA modes. The embedded SVGA

video subsystem supports:

! Pixel resolutions up to 1024 x 768

! CRT and LCD monitors up to 100 Hz vertical refresh rate

The system board supports disabling of the onboard video through BIOS Setup or when

a plug-in video card is installed in any of the PCI slots.

Peripheral Controller

The advanced integrated peripheral controller supports two serial ports, three universal

serial bus ports, one parallel port, diskette drive, PS/2-compatible keyboard and mouse,

and integrated Real Time Clock (RTC). The system provides the connector interface for

each port.

System Board Management Controller (BMC)

Server management is concentrated in the System Board Management Controller

(BMC). The BMC and associated circuitry are powered from a 5Vdc standby voltage,

which remains active when system power is switched off, but the ac power source is

still on and connected.

The BMC supports the Management Workstation Application (MWA), which allows

remote server management via a modem, LAN, or direct connection to a manager

system. Events monitored by the manager system include over-temperature and overvoltage conditions, fan failure, or chassis intrusion.

1-20 System Overview

One major function of the BMC is to autonomously monitor system management

events, and log their occurrence in the nonvolatile System Event Log (SEL). The events

being monitored include overtemperature and overvoltage conditions, fan failure, or

chassis intrusion. To enable accurate monitoring, the BMC maintains the nonvolatile

Sensor Data Record (SDR), from which sensor information can be retrieved. The BMC

provides an ISA host interface to SDR sensor information, so that software running on

the server can poll and retrieve the server's current status.

The BMC performs the following:

! Monitors server board temperature and voltage

! Monitors processor presence and controls Fault Resilient Boot (FRB)

! Detects and indicates system board fan failure

! Manages the SEL interface

! Manages the SDR Repository interface

! Monitors the SDR/SEL timestamp clock

! Monitors the system management watchdog timer

! Monitors the periodic SMI timer

! Monitors the event receiver

! Controls secure mode, including video blanking, diskette write-protect monitoring,

and front panel lock/unlock initiation

! Controls Wake On LAN via Magic Packet support.

External Device Connectors

The external I/O connectors provide support for a PS/2 compatible mouse and a

keyboard, a SVGA monitor, 2 serial port connectors, a parallel port connector, two

LAN ports, two USB ports, and one external-SCSI connector.

System Overview 1-21

System Power

The system contains two auto-sensing 430 watt power supplies at an operating

frequency of 50/60 Hz. A third optional power supply may be added as part of a faulttolerant hot-swap design. With three power supplies installed, in the unlikely event of a

power supply failure, the load is transferred to the remaining power supply without

interruption to normal operation. In this case the faulty power supply can be replaced

without powering down the system.

Note: The power supplies are not hot-swappable unless there

are three supplies installed.

The power supplies are designed to comply with existing emission standards and

provide sufficient power for a fully loaded system configuration.

Peripheral Bays

The system supports a variety of standard PC AT-compatible peripheral devices. The

chassis includes these peripheral bays:

! A 3.5-inch front panel bay for mounting the standard 3.5" diskette drive (supports

720 KB and 1.44 MB diskette media)

! A 5.25-inch removable media front panel bay for mounting half-height 5.25-inch

peripheral devices: optional tape drives and optional additional CD ROM drive, etc.

! A front panel bay for mounting the standard CD-ROM drive.

! A SCSI hard disk drive bay for mounting up to five SCSI hard disk drives in easily

removable drive carriers. Each drive has one LED to indicate a fault or other status:

power-on/activity (green LED), and fault (amber LED). The SCSI disk drives can be

easily installed or removed. The drive carrier allows you to access disk drives from

the front of the system. If disk drives are used in a RAID configuration within the