Page 1

Chapter 6

Installing and Using Utilities

This section describes how to use the NEC EXPRESSBUILDER DVD that comes with your server

and to install the utilities stored on the NEC EXPRESSBUILDER.

Page 2

6-2 Installing and Using Utilities

NEC EXPRESSBUILDER

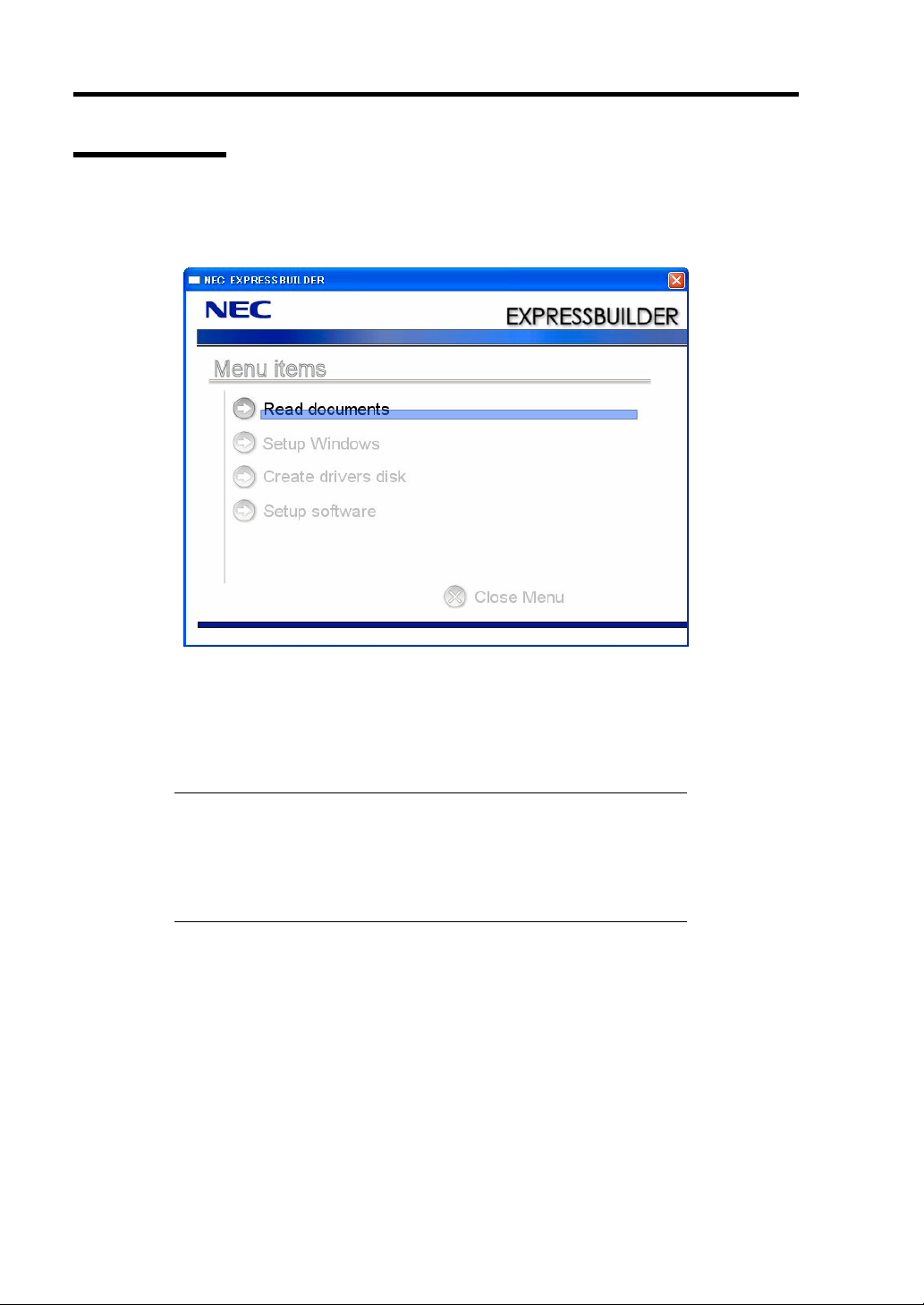

The NEC EXPRESSBUILDER (referred to as "EXPRESSBUILDER" hereinafter) helps you install

the Operating system/the Management software or use the maintenance utilities.

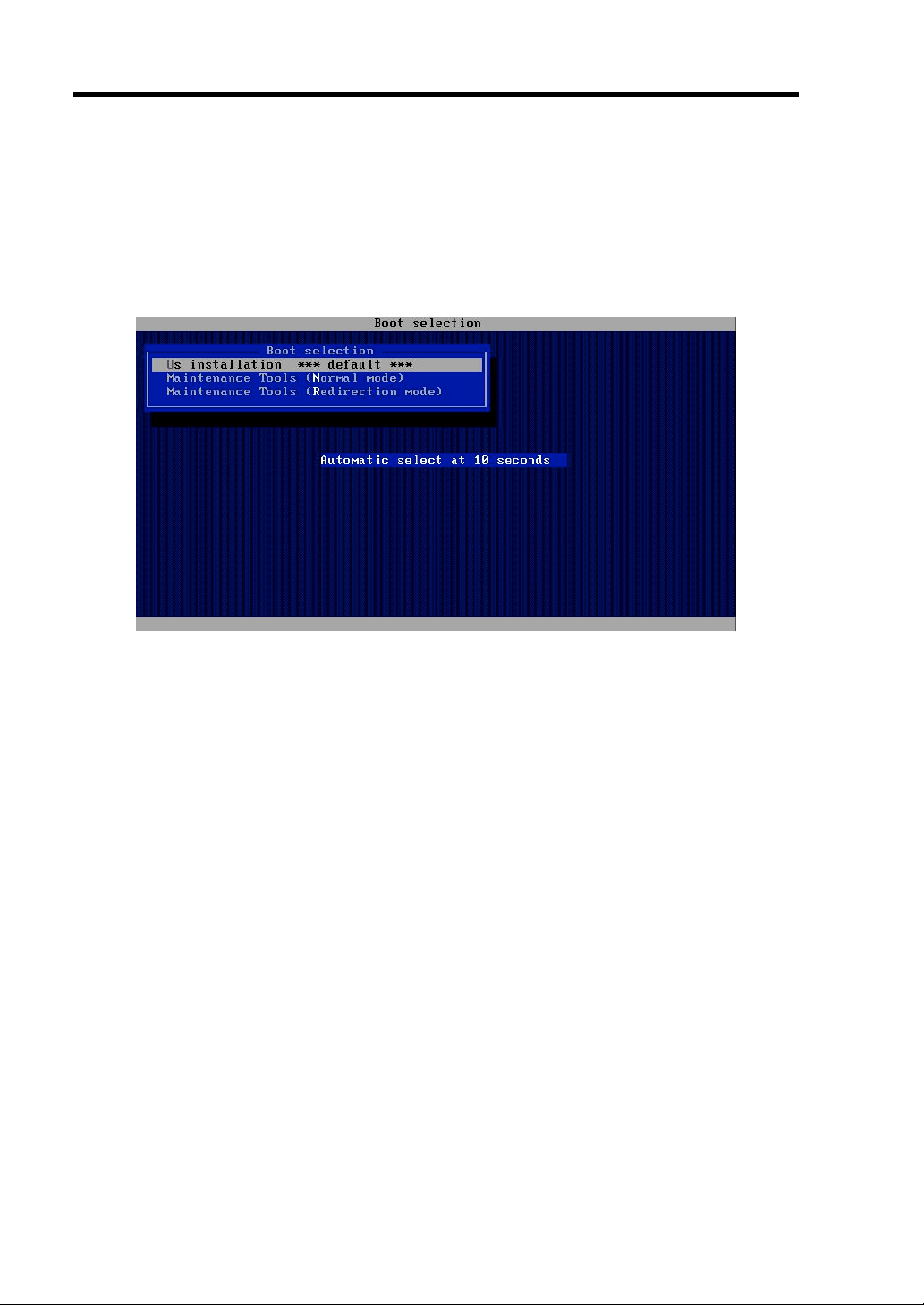

When you insert the EXPRESSBUILDER disk into the DVD drive and reboot the system, the

following menu appears.

Page 3

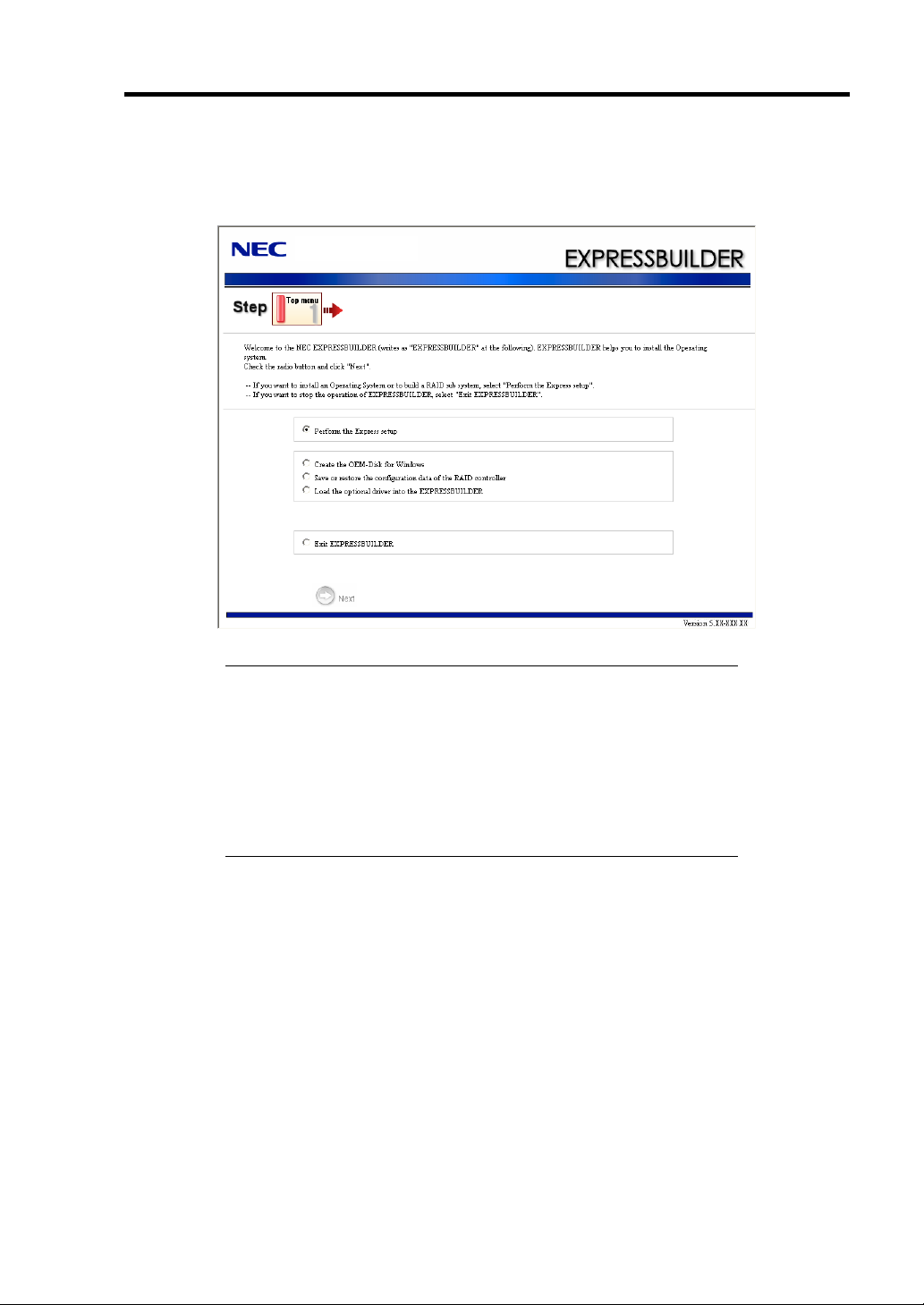

OS installation

If you select this item, the Top menu appears.

Installing and Using Utilities 6-3

IMPORTANT:

This tool is Configuration Tool that built on Windows PE 2.0

technology.

Pay attention to the automatic reboot that occurs after 72 hours

from start.

The configuration with Windows PE 2.0 supports Windows Server

2003 (32bit) and Windows Vista Business (32-bit (x86)), but the

other operation is not supported.

You can use the Express Setup (see Chapter 5) or the following functions from this menu.

– Create the OEM-Disk

You can create the Windows OEM-Disk to use at the Windows manual setup.

– Load the driver

This function is not usually used. If you add the new device to the server, this function

may use. (See Chapter 5.)

Page 4

6-4 Installing and Using Utilities

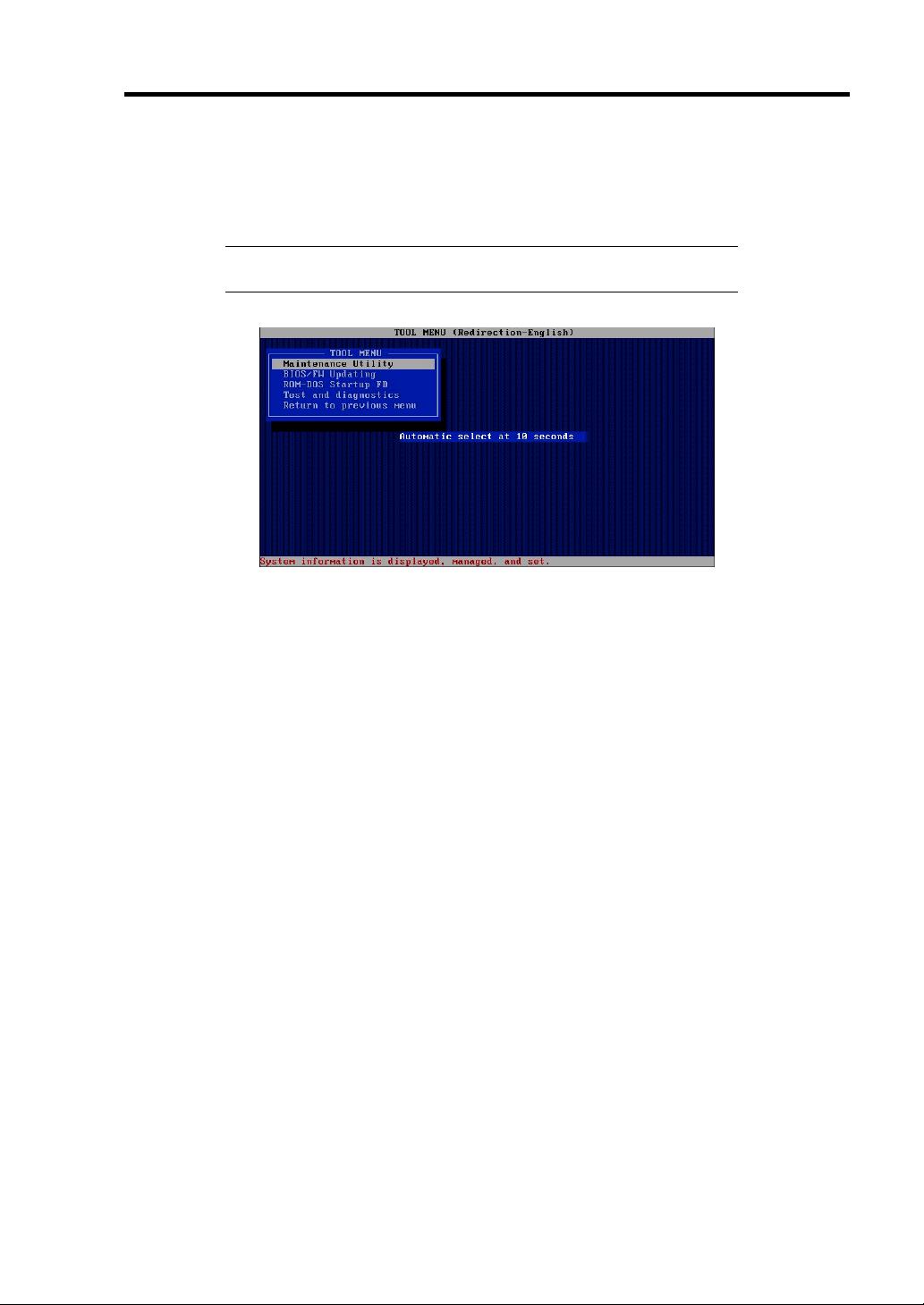

Maintenance Tools (Normal Mode)

If you select this item, the Tool menu appears.

You can use the below functions for maintenance.

– Maintenance Utility

The Maintenance Utility is usually used by the service representative. (See Chapter 7.)

– BIOS/FW Updating

You can update the system BIOS by using the floppy disk (prepare a 3.5" floppy disk).

– ROM-DOS Startup FD

The ROM-DOS Startup FD is used for starting the ROM-DOS system.

– Test and diagnostics

This function allows you to diagnose this computer. (See Chapter 7.)

Page 5

Installing and Using Utilities 6-5

Maintenance Tools (Redirection Mode)

If you want to operate this computer via the BIOS redirection (the console-less function),

select this item.

NOTE: If you operate this computer via the Remote KVM function,

select the "Maintenance Tools (Normal mode)".

The menu's functions are the same as the "Maintenance Tools (Normal Mode)".

Page 6

6-6 Installing and Using Utilities

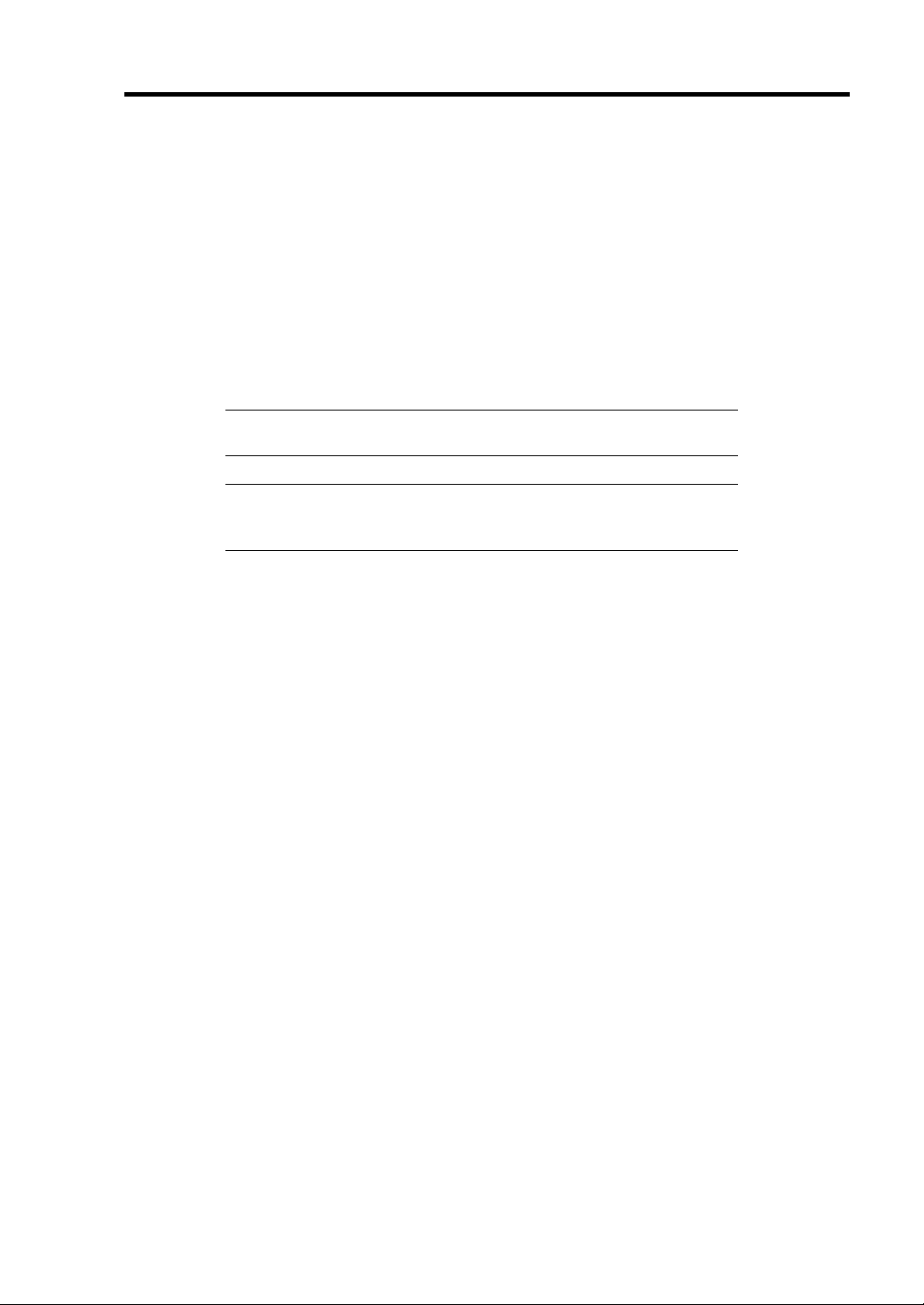

Autorun Menu

When the EXPRESSBUILDER disk is inserted into the DVD drive, Windows automatically

launches the menu as shown below.

This menu is used to,

Read the User's Guide or the other documents,

Update the server system (Windows drivers), and

Install the management software.

NOTES:

This menu requires Microsoft Windows XP, Vista or Windows

Server 2003 (or later).

Some documents are provided in PDF format. Use the Adobe

Reader to view or print these documents.

If the menu does not appear, select "My computer" by using the Explorer, and double-click the icon

of the DVD drive that contains the EXPRESSBUILDER DVD.

Some menu items are grayed-out when the logon user does not have the authority of the

administrator or the menu item is not available for your system.

To use the menu,

Click on the menu items, or

Click the right mouse button on the menu window.

Page 7

Installing and Using Utilities 6-7

PARAMETER FILE CREATOR

"Parameter File Creator" is a tool to create [Parameter file] that is used for configuring the server

with the Express Setup (see Chapter 5 for details).

If you use the Parameter file created by the Express Setup and Parameter File Creator to operate the

setup, you can setup from the installation of OS to several utilities automatically except for a few

key input to confirm the specification. Also, you can install the system with the same specification

as before when re-installing the system. We recommend you to create [Parameter file] to setup the

servers from NEC EXPRESSBUILDER.

When using a floppy disk, a USB floppy disk drive is required.

IMPORTANT: You can not create [Parameter file] for Microsoft

Windows Server 2003 x64 Editions.

NOTE: You can install Windows Server 2003 without [Parameter file].

Also, you can modify/newly create [Parameter file] during the setup

with NEC EXPRESSBUILDER.

Page 8

6-8 Installing and Using Utilities

Parameter File

This section describes about specifying setup information that is necessary for OS installation and

creating [Parameter file].

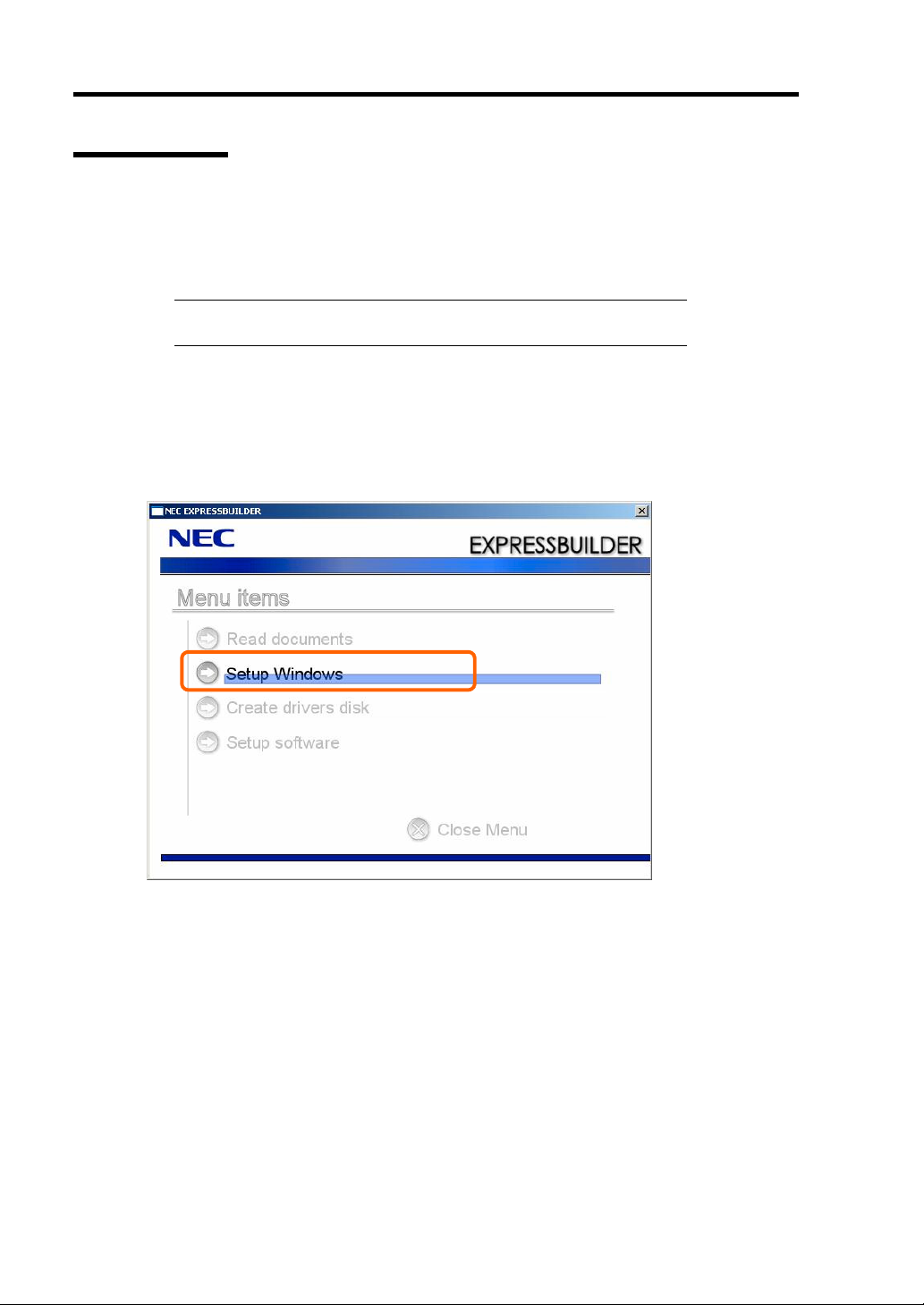

Follow the procedure below.

IMPORTANT: Do not remove NEC EXPRESSBUILDER DVD from

drive during a parameter file creation.

1. Start the OS.

2. Insert the NEC EXPRESSBUILDER DVD into the optical disk drive.

The menu will appear.

3. Right-click on the screen or left-click [Setup Windows]. The menu will appear.

Page 9

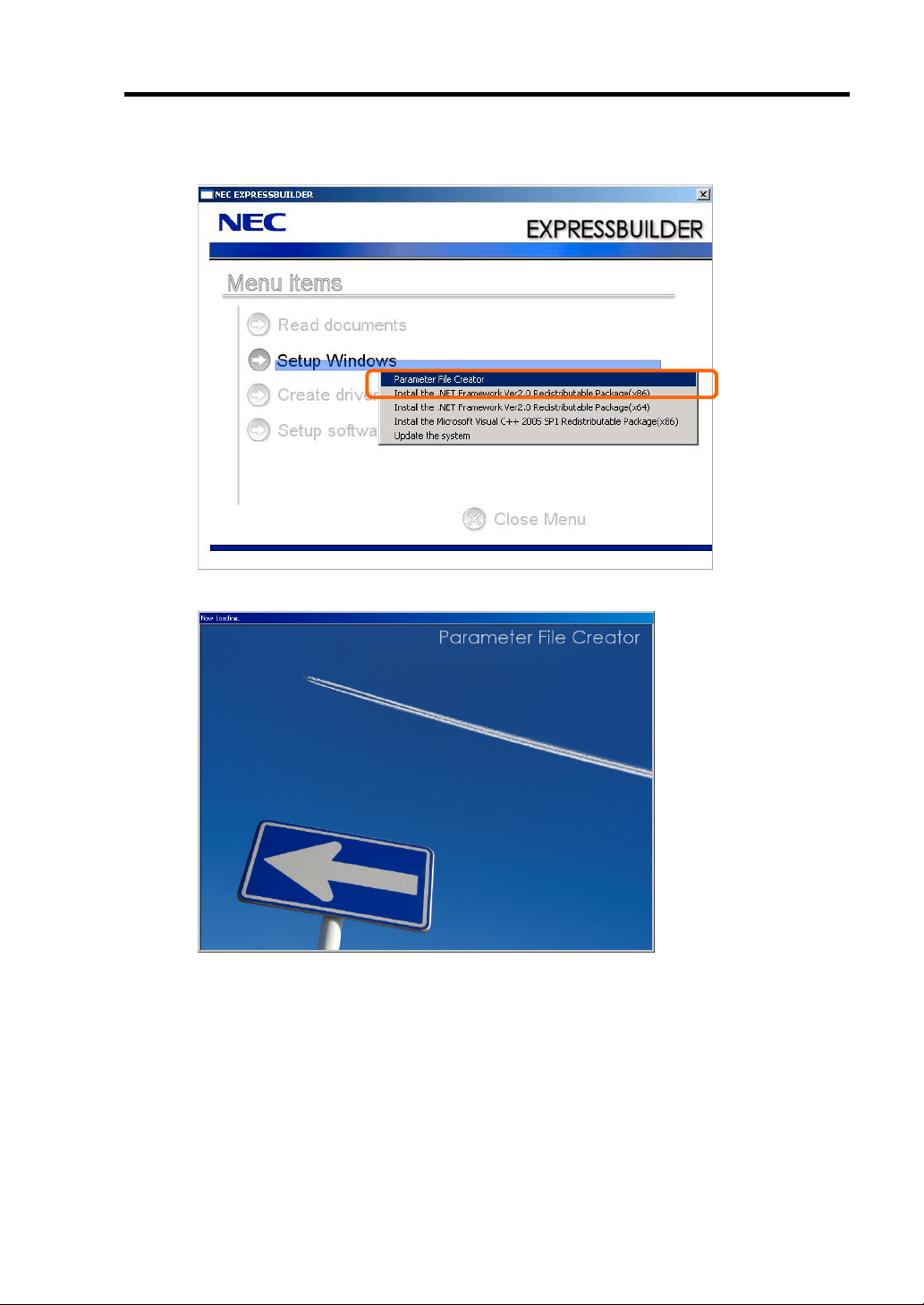

4. Click [Parameter File Creator].

Parameter File Creator will appear.

Installing and Using Utilities 6-9

Page 10

6-10 Installing and Using Utilities

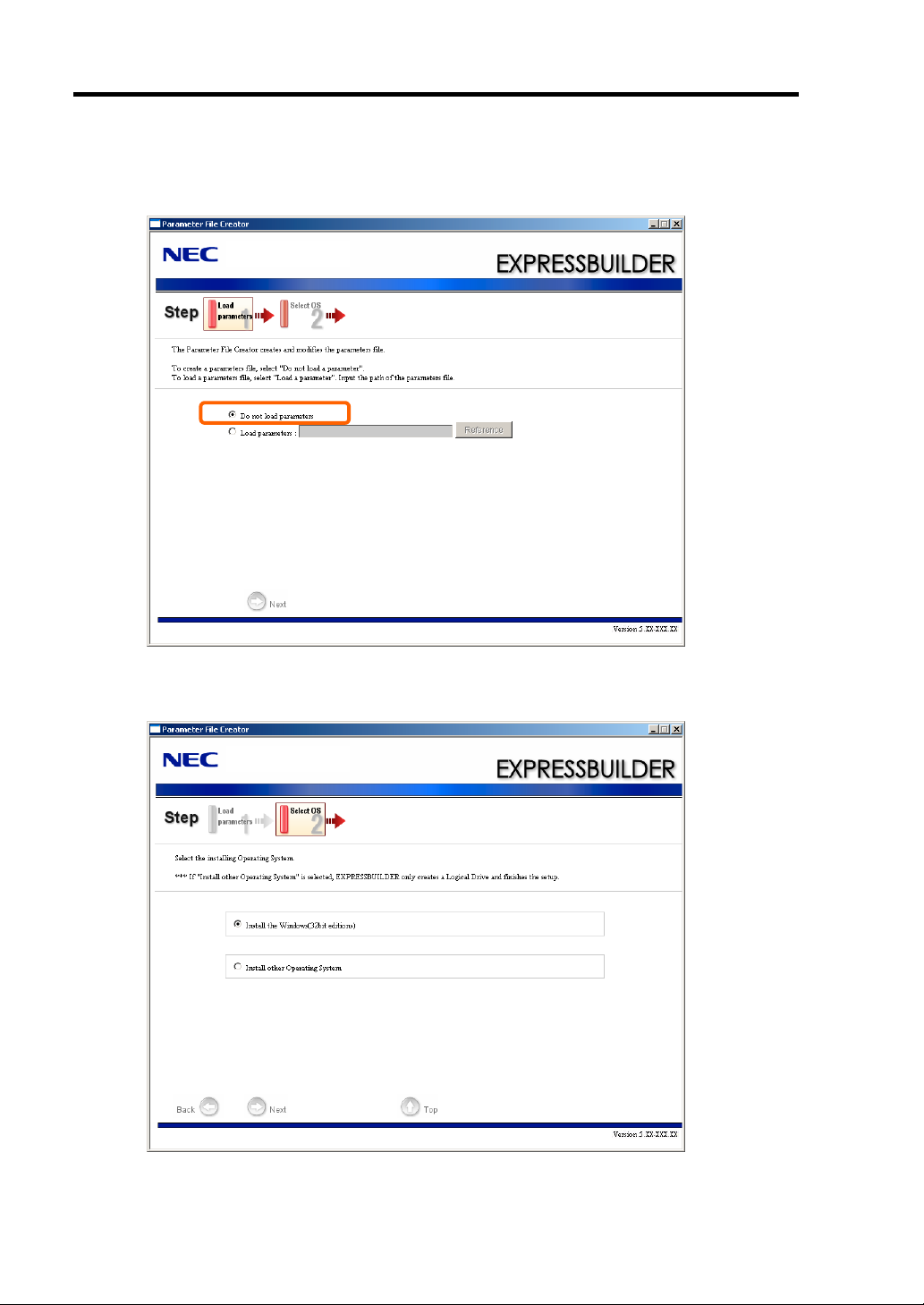

5. [Load Parameters] step is displayed.

Select [Do not load parameters] from the menu, click [Next].

6. Select the installing Operating System.

Select [Install the Windows (32bit editions)] from the menu, click [Next].

Page 11

Installing and Using Utilities 6-11

7. Enter the setting of a logical drive.

[Enter RAID setting] steps are displayed. Confirm the parameters, modify if necessary,

and then click [Next].

IMPORTANT: At "The number of the total physical devices",

Parameter File Creator displays upper limit that the RAID controller

can support.

The total of "The number of physical devices used to create the logical

drive" and "The number of the physical devices specified as the hot

spare" must not exceed "The number of the total physical devices"

which connected to the target system.

NOTE: You can use only the physical devices that have same model

number to configure logical drive.

Page 12

6-12 Installing and Using Utilities

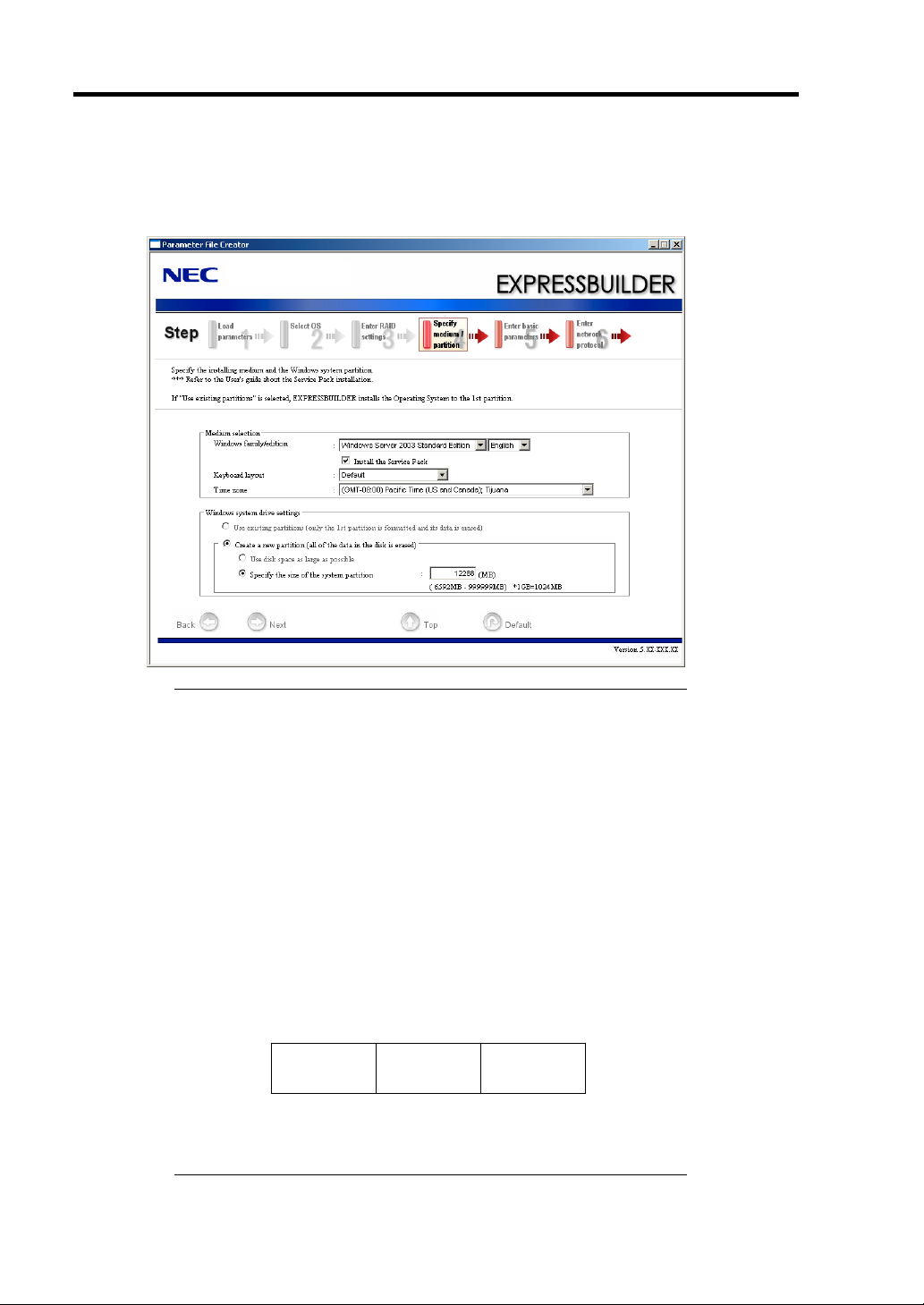

8. Specify the installing medium and the Windows system partition.

[Specify medium / Partition] steps are displayed. Confirm the parameters, modify if

necessary, and then click [Next].

IMPORTANT:

About partition size

– Specify the partition size larger than required minimum size for

OS installation.

– Do not specify larger partition size than the capacity of

connected hard disk drive.

– You can not specify the partition size larger than 2,097,152MB

(2TB) at RAID system.

If you select "Create a new partition" at "Windows system drive

settings", the contents of the hard disk will be all deleted.

If "Use existing partitions" is selected, EXPRESSBUILDER

installs the Operating System to the 1st partition (1st partition is

deleted). The data in the other partition is kept if the system has

two or more partitions. (See the figure below.)

First

Partition

Deleted

You can not re-install the system with the existing partition that is

Second

Partition

Retained

Third

Partition

Retained

upgraded to Dynamic Disk remained. Do not select "Use existing

partitions" at "Windows system drive settings".

Page 13

Installing and Using Utilities 6-13

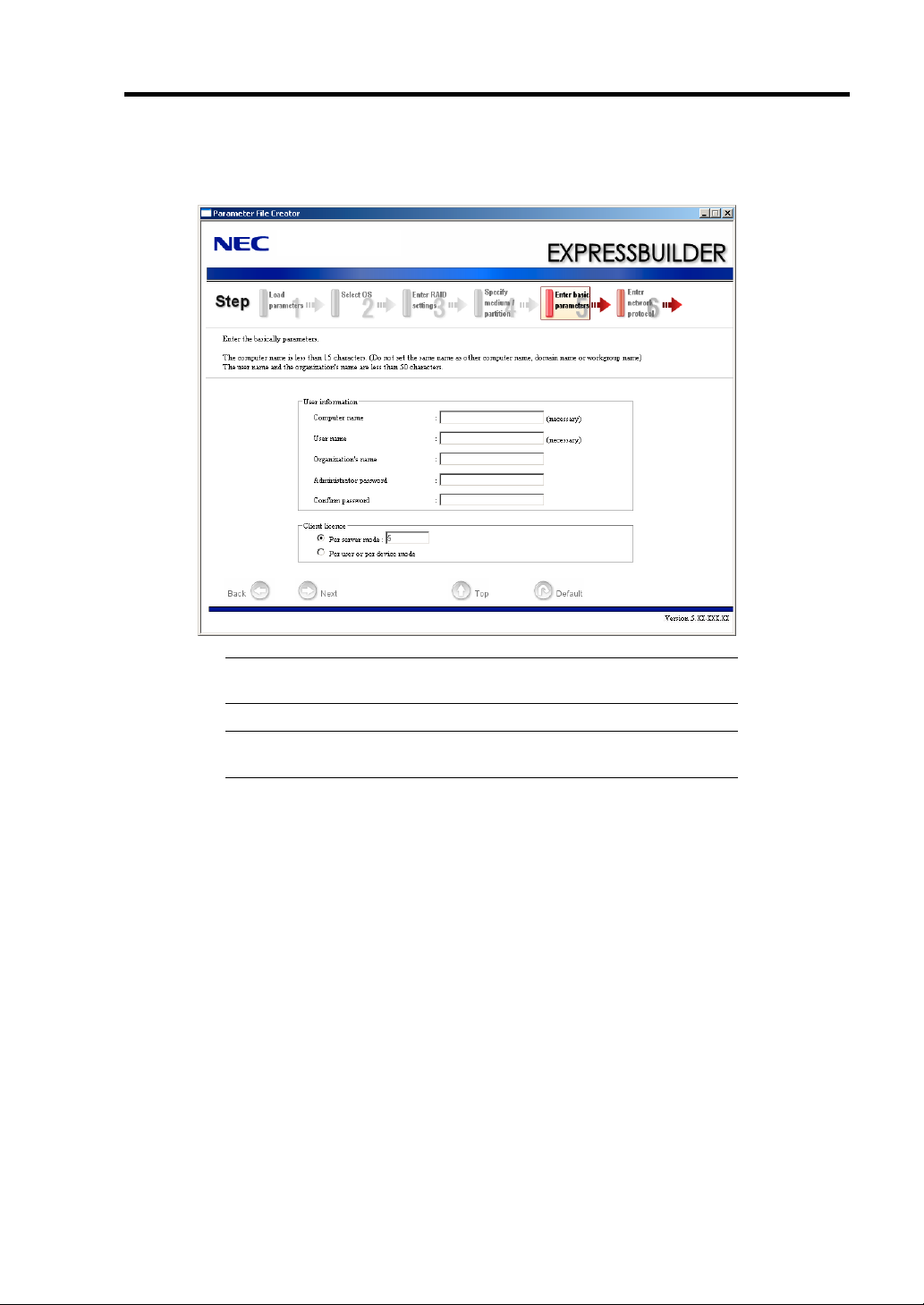

9. Enter the user information and client license mode. [Enter basic parameters] steps are

displayed. Confirm the parameters, modify if necessary, and then click [Next].

IMPORTANT: Computer name and User name are required

parameters.

NOTE: Even if you do not input value into "Administrator password",

"Confirm password", "zzzzzz" is displayed.

Page 14

6-14 Installing and Using Utilities

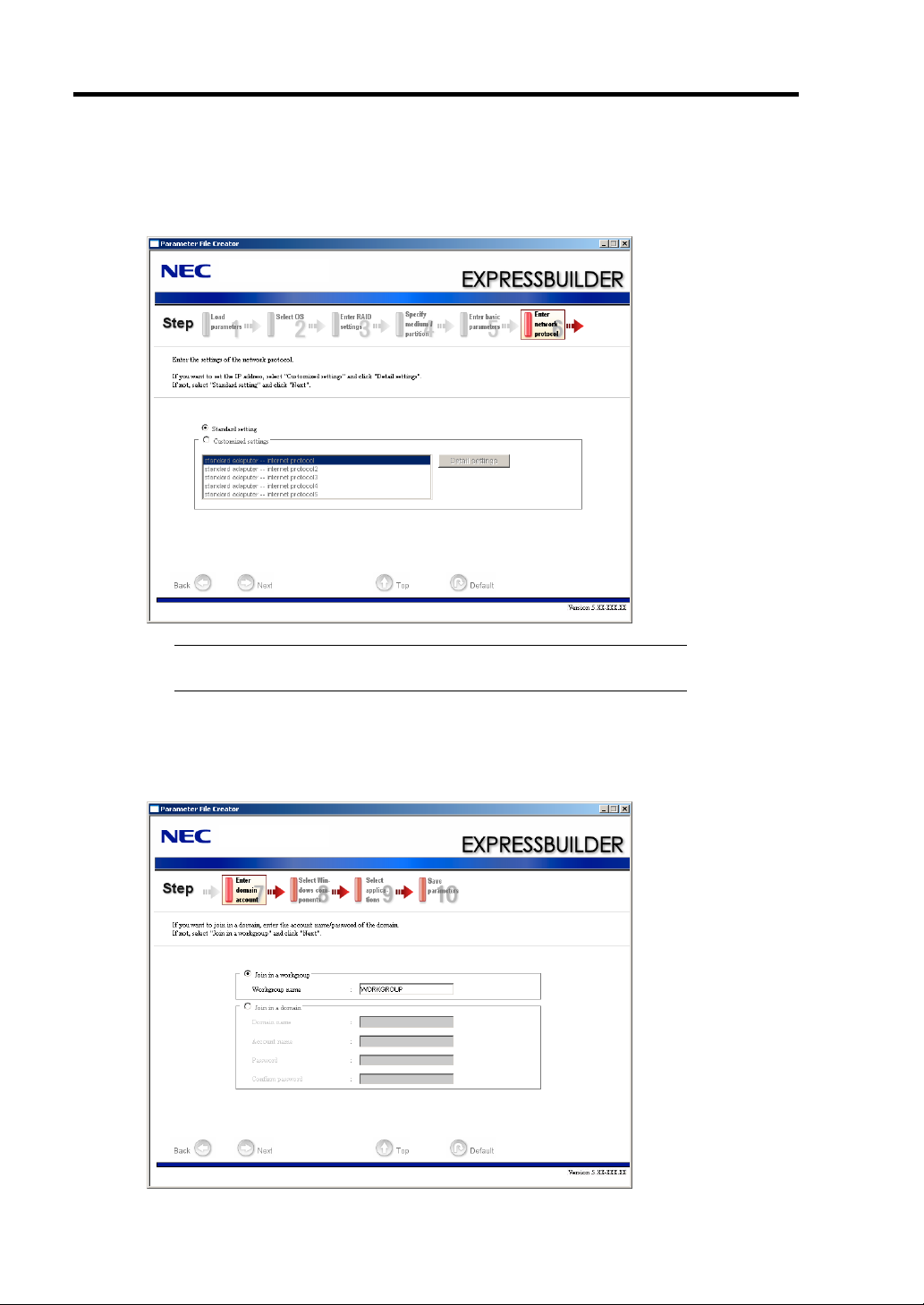

10. Enter the setting of the network protocol.

[Enter network protocol] steps are displayed. Confirm the parameters, modify if necessary,

and then click [Next].

NOTE: The order of entry in custom setting may differ from the

numbering of LAN port.

11. Enter the domain or workgroup name to be used.

[Enter domain account] steps are displayed. Confirm the parameters, modify if necessary,

and then click [Next].

Page 15

Installing and Using Utilities 6-15

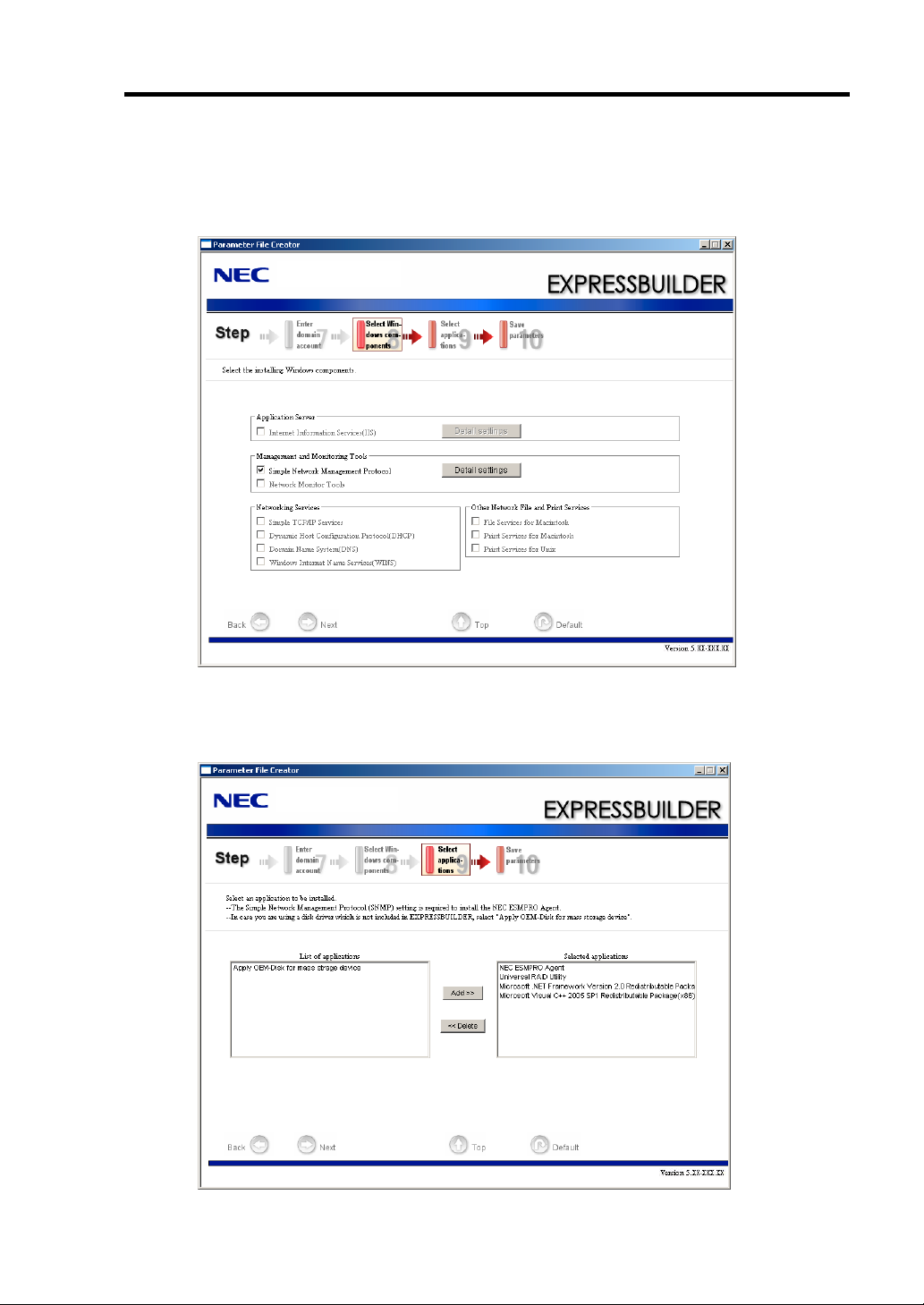

12. Select the installing components.

[Select Windows components] steps are displayed. Confirm the parameters, modify if

necessary, and then click [Next]

13. Select the installing applications.

[Select applications] steps are displayed. Confirm the parameters, modify if necessary, and

then click [Next].

Page 16

6-16 Installing and Using Utilities

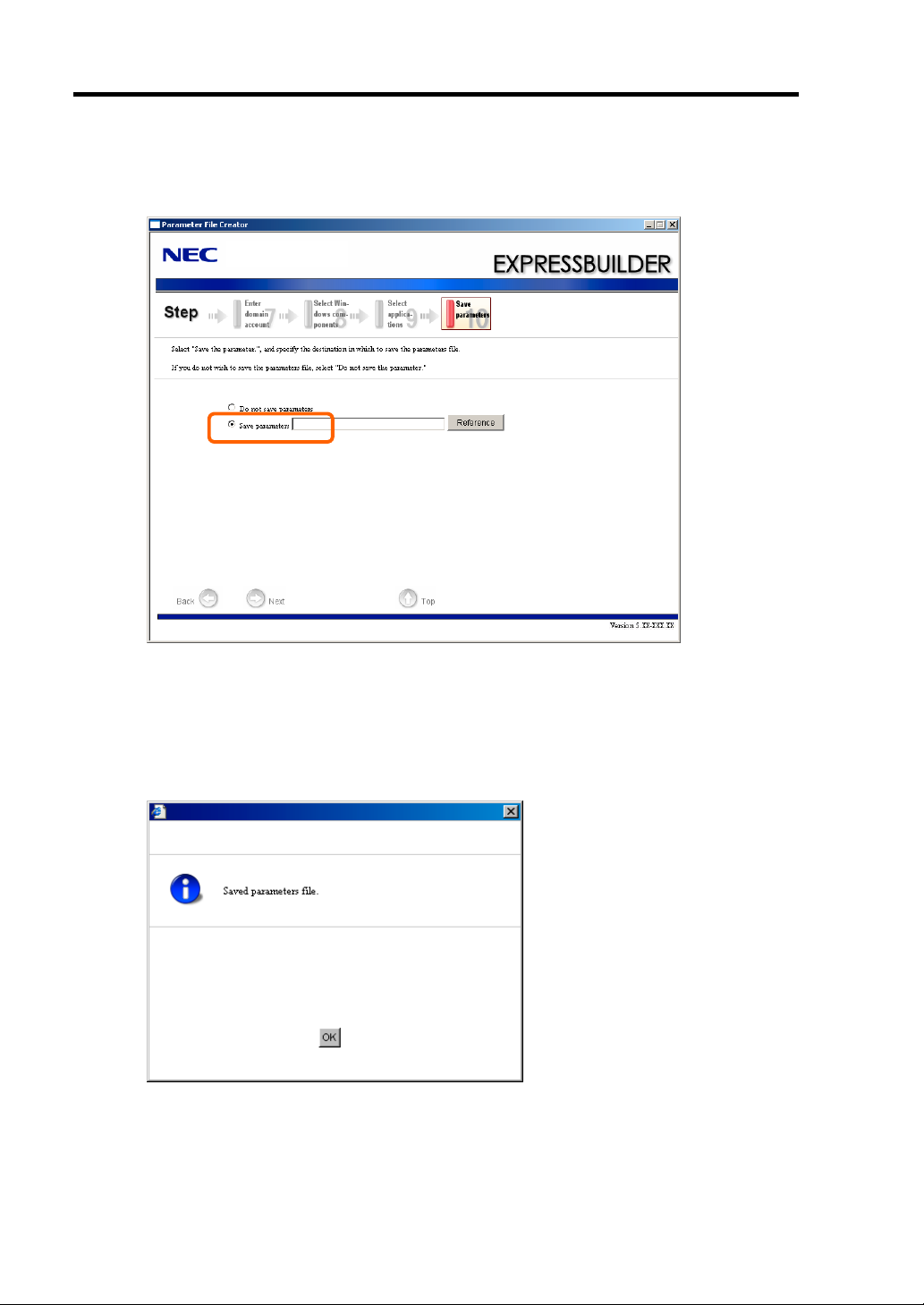

14. Save the parameters.

[Save parameters] steps are displayed.

If you want to save the parameters, set the free formatted floppy disk.

Select [Save parameters], enter the file path of the parameters files into the text box and

click [Next].

If not, select [Do not save parameters].

15. Saved to a floppy disk.

Page 17

Installing and Using Utilities 6-17

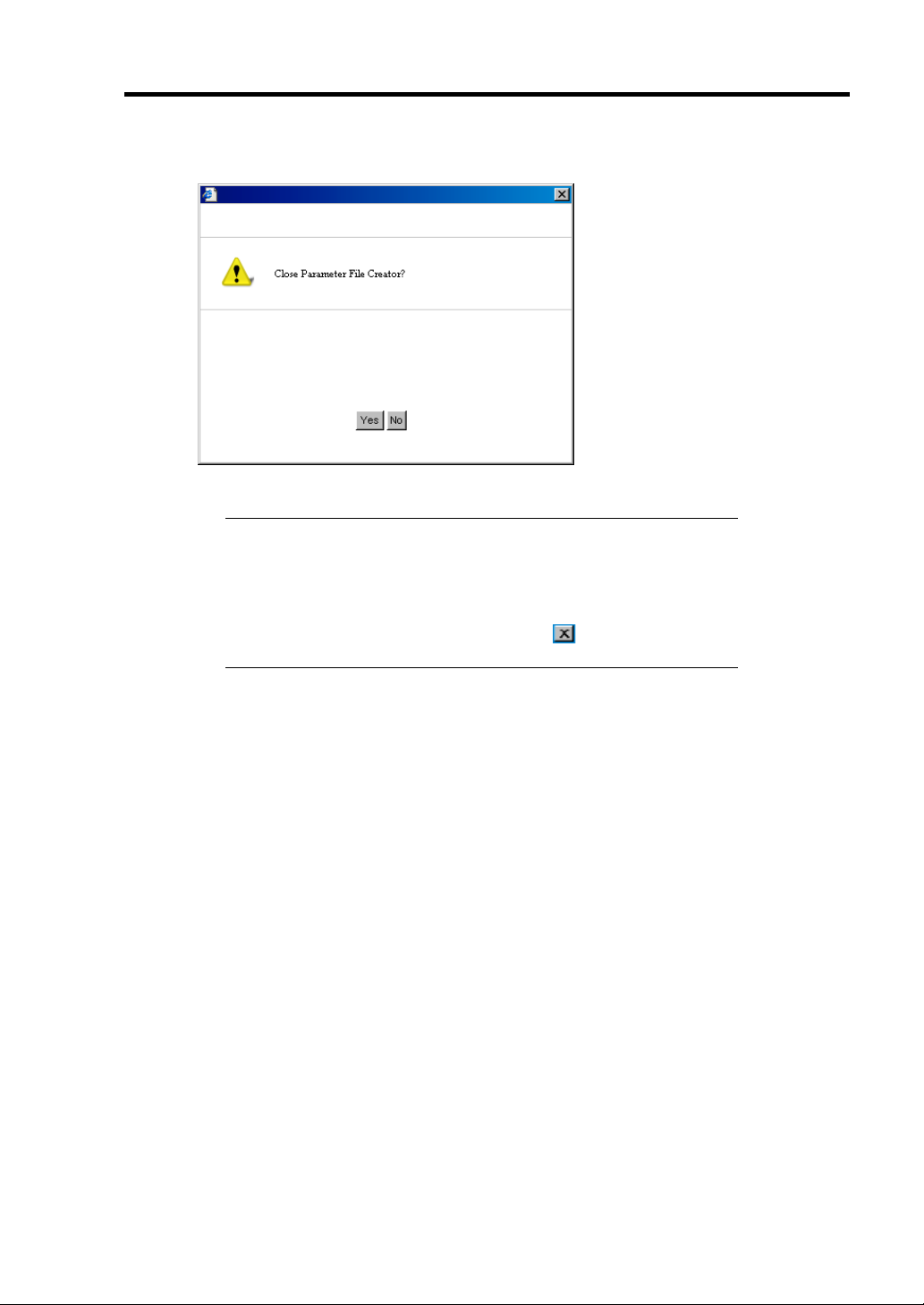

Now [the floppy disk containing the parameters file] has been created.

Click [Yes] to exit Parameter File Creator.

NOTES:

If you modify existing information file (parameter file), click

"Load Parameters" at [Load Parameters] screen. Refer to help to

modify information file.

If you cancel operation on the way, click at the upper-right

corner of the screen.

Page 18

6-18 Installing and Using Utilities

NEC ESMPRO

The NEC ESMPRO lets a system administrator manage remote servers across a network. NEC

ESMPRO monitors server hardware and software configurations, failures, and performance. With

log data collected by NEC ESMPRO, a system administrator can track long-term and short-term

performance, monitor server usage, create graphs to record trends, and check server failure rates.

The administrator can use the information collected to create more efficient data routing procedures

and optimize server usage.

Functions and Features

NEC ESMPRO offers many functions and features for managing remote servers across a network.

These features help the system administrator perform daily system operation, system extension, and

transfer tasks. Some features of NEC ESMPRO Manager include:

Hardware and software server configuration

– Hardware resources mounted in servers, such as the CPU, memory, disks, RAID

System, and LAN boards.

– Software resources, such as operating system information and drivers running on each

server.

Server failures

– On-screen real-time displays provide the system administrator with the failure type,

location, cause, and suggested corrective action.

– Failure data includes hardware failure information such as system board temperature,

memory failure, crashes, and software failure information.

Performance

– NEC ESMPRO monitors server performance and displays server usage on the screen

and displays information, such as the rate of CPU load, memory usage, disk usage, and

LAN traffic. Usage threshold values can help the system administrator monitor and

prevent server overloads.

For installation procedure and detailed explanations on NEC ESMPRO, refer to the online

document in the NEC EXPRESSBUILDER DVD.

Page 19

Installing and Using Utilities 6-19

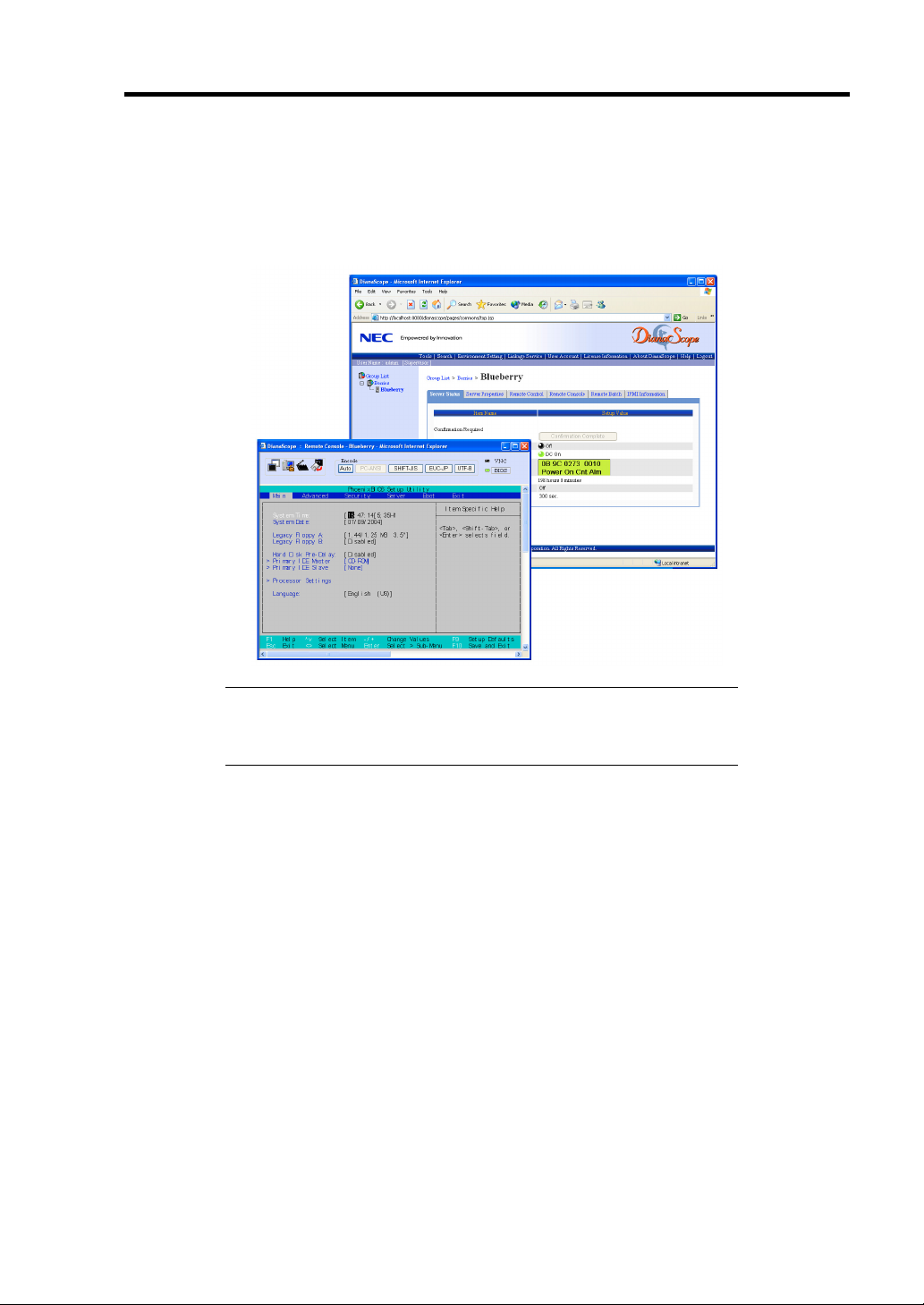

NEC DianaScope

NEC DianaScope is software for the remote management of the server.

See the online documents for details on the functions and installation of NEC DianaScope.

NOTE: You need the server license to activate DianaScope for this

product. The server license below is attached to this product.

DianaScope Additional Server License (1)

Page 20

6-20 Installing and Using Utilities

Universal RAID Utility

Universal RAID Utility is an application to manage or monitor the following RAID Controllers.

Internal RAID Controller (equivalent to N8103-116)

N8103-90 Disk Array Controller (External SAS HDD)

Before attempting to operate Universal RAID Utility, read the "Universal RAID Utility User's

Guide" included in NEC EXPRESSBUILDER DVD. The manual explains the installation

procedure and notes on operating Universal RAID Utility.

Setup with Express Setup

You can install Universal RAID Utility with Express Setup contained in NEC EXPRESSBUILDER

DVD. When you start the Express Setup, a dialog to specify an application appears. Select

[Universal RAID Utility] on the dialog.

Page 21

Installing and Using Utilities 6-21

Manual Setup

Windows

You can start the setup program of Universal RAID Utility from [Autorun Menu].

Click to [Setup Software] → [Universal RAID Utility] in [Autorun Menu].

You need to install the following software.

Microsoft .NET Framework 2.0

The Runtime component of the Microsoft Visual C++ 2005 SP1

You can install these software from [Autorun Menu] too.

Click [Setup Windows] → [Install the .NET Framework Ver 2.0 Redistributable Package (x86)] (If

CPU architecture is x64, [Install the .NET Framework Ver2.0 Redistributable Package (x64)]) in

[Autorun Menu] for the setup of Microsoft.NET Framework 2.0.

Click [Setup Windows] → [Install the Microsoft Visual C++ 2005 SP1 Redistributable Package

(x86)] (Use the x86 package whatever the CPU architecture may be.) for the setup of the Runtime

component of the Microsoft Visual C++ 2005 SP1.

Linux

You need to run the setup.sh in the install image of Universal RAID Utility

There is the install image of Universal RAID Utility in the following directory of

EXPRESSBUILDER.

/BBB/lnx/pp/uraidutl

The part of BBB is BBB of the medium number (5.AA-BBB.CC) of EXPRESSBUILDER

Page 22

6-22 Installing and Using Utilities

Using Universal RAID Utility via Network

Universal RAID Utility doesn't have the function of management to computer installed RAID

Controller via network. If you want to manage it via network, please use the function of remote

console (ex. Remote Desktop of Windows).

Creating Logical Drive of RAID 6

You must use four or larger Physical Devices for creating the Logical Drive of RAID 6 by Universal

RAID Utility. If you want to create the Logical Drive from three Physical Devices, you need to use

WebBIOS.

Page 23

Chapter 7

Maintenance

This chapter describes the daily maintenance of the server and precautions when relocating or

storing the server.

MAKING BACKUP COPIES

NEC recommends you make backup copies of your valuable data stored in hard disk drives of the

server on a regular basis. For backup storage devices suitable for the server and backup tools,

consult with your service representative.

When you have changed the hardware configuration or BIOS configuration, select "System

Information Management" and then "Save" of the Off-line Maintenance Utility to make a backup

copy of the system information.

Also make a backup copy of the RAID System configuration data if your system is in the RAID

System configuration. When your hard disk drives have been auto-rebuilt due to a failure, it is

recommended to make a backup copy of the configuration data. To make a backup copy of the

configuration data, use the configuration utility that is resident in the FLASH memory on the

optional RAID Controller. Refer to the manual supplied with the board.

Page 24

7-2 Maintenance

CLEANING

Clean the server on a regular basis to keep the server in a good shape.

WARNING

Observe the following instructions to use the server safely. Failure to follow

these instructions may result in death or serious personal injury. See pages 13 to 1-8 for details.

Do not disassemble, repair, or alter the server.

Do not remove the lithium battery.

Disconnect the power plug before working with the server.

CAUTION

Observe the following instructions to use the server safely. Failure to follow

these instructions may cause a fire, personal injury, or property damage. See

pages 1-3 to 1-8 for details.

Avoid installation in extreme temperature conditions.

Make sure to complete board installation.

Page 25

Maintenance 7-3

Cleaning the Server

For daily cleaning, wipe the external surfaces of the server with a dry soft cloth. Follow the

procedure below if stains remain on the surfaces:

IMPORTANT:

To avoid altering the material and color of the server, do not use

volatile solvents such as thinner and benzene to clean the server.

The power receptacle, the cables, the connectors on the rear panel of

server, and the inside of the server must be kept dry. Do not moisten

them with water.

1. Make sure that the server is off-powered (the POWER/SLEEP LED goes off).

2. Unplug the power cord of the server from a power outlet.

3. Wipe off dust from the power cord plug with a dry cloth.

4. Soak a soft cloth in neutral detergent that is diluted with cold or lukewarm water, and

squeeze it firmly.

5. Rub off stains on the server with the cloth prepared in Step 4.

6. Soak a soft cloth in water, squeeze it firmly, wipe the server with it once again.

7. Wipe the server with a dry cloth.

8. Wipe off dust from the fan exhaust opening on the rear of the server with a dry cloth.

Page 26

7-4 Maintenance

Cleaning the Interior

One of the most important items in a good maintenance program is regular and thorough cleaning of

the interior of the server, especially around the mother board.

Dust buildup inside the server can lead to several problems. As dust acts as a thermal insulator, a

buildup can prevent proper system cooling. Excessive heat will shorten the life of server

components. Also, dust may contain conductive or corrosive materials that can cause short circuits

or corrosion of electrical contacts.

How often you should clean the interior of the server depends on the environment in which it is

located. For most office environments, you probably should clean the server every 12 months. For

more severe environments, clean the interior every 6 months.

Cleaning the interior of the server entails powering off the server and removing the left side cover.

You will need a small vacuum cleaner (with plastic tipped nozzle and electrostatic protection),

computer grade canned air, and a small brush for cleaning the interior.

Follow the procedure below to clean the interior of the server.

WARNING

Unplug all power cords.

Unplug all power cords before performing any maintenance. Voltage is present

inside the server and display unit even after the power is turned off. All voltage is

removed only when the power cord is unplugged.

1. Turn off the server and unplug all power cables.

2. Remove the logic cover and drive cover. (See Chapter 9.)

3. Use a small brush to loosen any dust and debris on the mother board.

4. Use computer grade canned air to blow dust off components on the mother board.

5. Use a small vacuum cleaner with plastic tip to vacuum out dust and debris from the

interior of the server.

6. Reinstall the covers. (See Chapter 9.)

7. Reconnect all power cables and turn on the server.

Page 27

Maintenance 7-5

Cleaning the Keyboard/Mouse

Make sure that the server and peripheral devices are all off-powered (the POWER/SLEEP LED

goes off), and then wipe the keyboard surface with a dry cloth.

The mouse operation depends on the degree of smoothness of the internal ball rotation. To keep the

mouse ball clean, use the mouse in a place with little dust. Follow the steps below to clean the

mouse regularly:

1. Prepare cold or lukewarm water, neutral detergent, alcohol, two dry soft clothes, and

cotton swabs.

2. Make sure that the server is off-powered (the POWER/SLEEP LED goes off).

3. Turn the mouse upside down, and rotate the mouse ball cover counterclockwise to remove

it.

4. Take out the ball from the mouse. Cover the bottom of the mouse with your hand, and turn

your hand holding the mouse (the mouse is on your palm with the button upward). The

mouse ball is released onto your palm.

Mouse ball

Mouse ball cover

Bottom View

Roller

5. Soak a soft cloth in neutral detergent that is diluted with cold or lukewarm water, and

squeeze it firmly.

6. Rub off stains on the mouse ball. Softly wipe the mouse ball with the cloth prepared in

Step 5.

7. Wipe the mouse ball with a dry soft cloth.

8. Wipe three small rollers inside the mouse with a cotton swab soaked with alcohol. Wipe

stains slowly and carefully by rotating rollers with the tip of the cotton swab.

9. Blow out any dust from the mouse. Protect your eyes from the dust.

10. Put the mouse ball back into the mouse.

11. Place the mouse ball cover, and rotate it clockwise until it is locked.

Page 28

7-6 Maintenance

Cleaning Disc

A dusty disc or dust-accumulated tray causes the device to fail to read data correctly.

Follow the procedure below to clean the tray and disc regularly:

1. Make sure that the server is powered (the POWER/SLEEP LED is lit).

2. Press the CD tray Open/Close button on the front of the optical disk drive.

The tray opens.

3. Hold the disc lightly and take it out from the tray.

NOTE: Do not touch the signal side of the disc with your hand.

4. Wipe the tray with a dry soft cloth.

IMPORTANT: Do not wipe the lens of the optical disk drive. Doing

so may damage the lens and may cause a malfunction of the drive.

5. Push on the tray front to close the tray.

6. Wipe the signal side of the disc with a dry soft cloth.

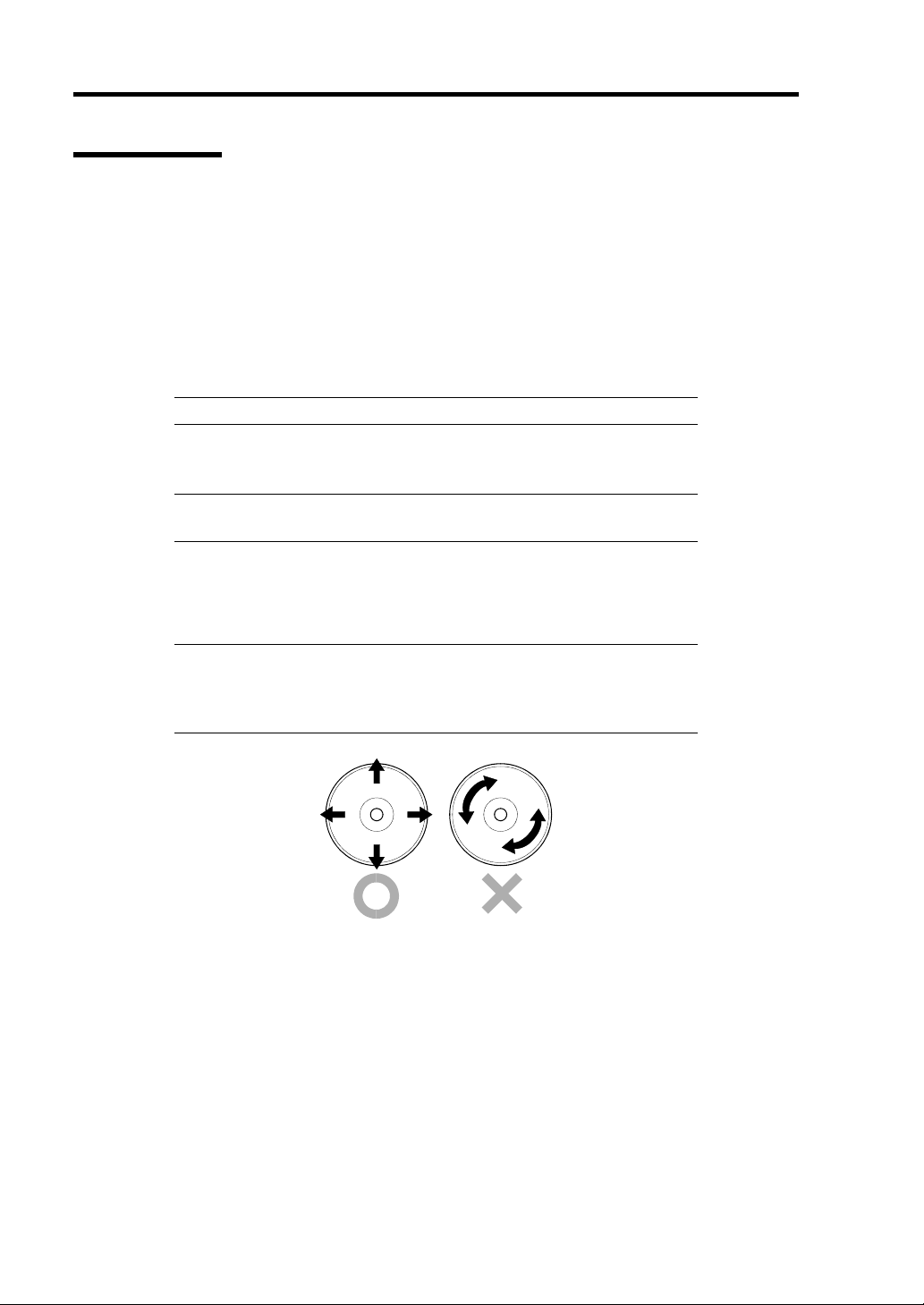

IMPORTANT: Wipe disc from the center to the outside. Use only disc

cleaner if necessary. Cleaning a disc with record spray/cleaner, benzene,

or thinner causes damage to the disc contents. At worst, inserting the

disc into the server may cause failure.

Page 29

Maintenance 7-7

SYSTEM DIAGNOSTICS

The System Diagnostics runs several tests on the server.

Select [Maintenance Tools] - [Test and diagnostics] in the NEC EXPRESSBUILDER to diagnose

the system.

Test Items

The following items are tested in system diagnostics.

Memory

CPU cache memory

Hard disk drive used as a system

IMPORTANT: When executing the system diagnostics, make sure to

disconnect the LAN cable. Executing the system diagnostics with the

LAN cable connected, the network may be influenced.

NOTE: On checking the hard disk drive, no data is written into the

disk.

Page 30

7-8 Maintenance

Startup and Exit of System Diagnostics

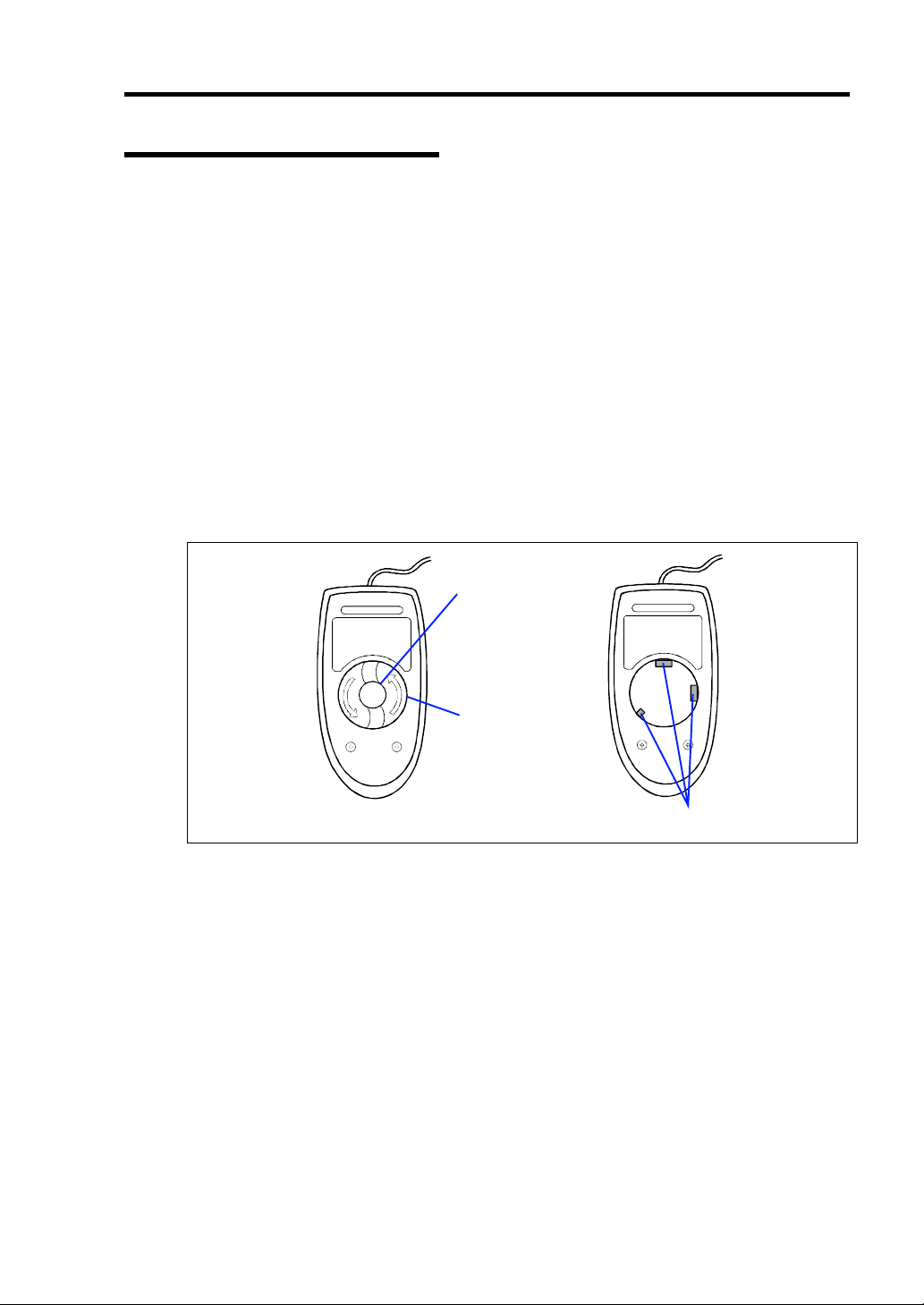

There are two ways to diagnose the server: to use the local console (keyboard) of the server itself,

and to use the management PC via serial port (remote console).

IMPORTANT: Two methods of LAN and the serial port are mentioned

in "MAINTENANCE TOOLS" of Chapter 8 "Troubleshooting" in the

way of communicating in remote console.

Use the serial port to execute System Diagnostics with remote console.

The LAN connection is not for System Diagnostics.

Procedures to start the diagnostics program are as follows:

1. Shutdown the OS, and power off the server. Then, unplug the power cord.

2. Disconnect all the LAN cables from the server.

3. Plug the power cord and power on the server.

4. Use the NEC EXPRESSBUILDER DVD to start the system.

5. Select [Maintenance Tools (Normal mode)] when local console of the server is used for, or

select [Maintenance Tools (Redirection mode)] when remote console is used for.

NOTE: If the system displays the [Language selection] menu, select

[English].

The following menu is displayed on the screen.

Local console Remote console

Page 31

Maintenance 7-9

T

T

6. Select [Test and diagnostics].

Select [End-User Mode] and the system diagnostics starts. The diagnostics will be

completed in approximately three minutes. When the diagnostics is completed, the screen

of the display changes as shown below:

Diagnostics tool title

eDoLi (TEst & Diagnosis On Linux) Ver001.00 (Build020901.1.1m)

Start 10:06:58 End 10:09:58 Pass 000:03:00 TestTime 000:03:00

est End : NormalEnd 03 AbnormalEnd 00 ForceEnd 00

<System>

MEM Memory 16 count NormalEnd

CACHE Cache 49 count NormalEnd

<SCSI>

HDD_02:000 DK32DJ-36W 89 count NormalEnd

[Enter] Detail Information [ESC] Return to Enduser Menu

Guide line

Test window title

Test End

Test result

Test summary

window

– Diagnostics tool title

Shows the name and version of the diagnostic tool.

– Test window title

Shows the progress of the diagnostics. "Test End" is displayed when the diagnostics

completes.

– Test result

Shows the start, end, and elapsed time and completion status of the diagnostics.

– Guide line

Shows the details of the keys to operate window.

– Test summary window

Shows the results of each test that executed the diagnostics. Move the cursor and

press the Enter key on the cursor line to display the details of the test.

When an error is detected by the system diagnostics, the relevant test result in the test

Summary window is highlighted in red, and "Abnormal End" is displayed in the result on

the right side.

Move the cursor to the test that detected the error, and press the Enter key. Record the

error message that has been output to the Detail Information screen and contact your

service representative.

Page 32

7-10 Maintenance

7. Follow the guide line shown at the bottom of the screen, and press the Esc key.

The [Enduser Menu] below is displayed.

TeDoLi (TEst & Diagnosis On Linux) Ver001.00 (Build020901.1.1m)

Enduser Menu

Enduser Menu

<Test Result>

<Device List>

<Log Info>

<Option>

<Reboot>

Please choose a function by the arrow key and push Enter key.

<Test Result> Shows the diagnostics completion screen of the above diagnostics.

<Device List> Shows a list of connected devices.

<Log Info> Shows the log information of the diagnostics. It can be saved on a floppy

disk.

To save it on a floppy disk, insert a formatted floppy disk to the floppy

disk drive, and select <Save(F)>.

<Option> Optional features can be used from this menu.

<Reboot> Reboots the system.

8. Select <Reboot> in the [Enduser Menu] above.

The server restarts and the system is started from the NEC EXPRESSBUILDER.

9. Exit the NEC EXPRESSBUILDER, and remove the DVD-ROM from the optical disk

drive.

10. Power off the server and unplug the power cord from the receptacle.

11. Reconnect all the LAN cables that have been disconnected in Step 2 to the server.

12. Plug in the power cord.

This completes the system diagnostics.

Page 33

RELOCATING/STORING THE SERVER

Follow the procedure below to relocate or store the server:

CAUTION

Observe the following instructions to use the server safely. Failure to follow

these instructions may cause a fire, personal injury, or property damage. See

pages 1-3 to 1-8 for details.

Never attempt to lift the server only by yourself.

Do not install the server in any place other than specified.

Do not connect/disconnect any interface cable with the power cord of the

server plugged to a power source.

IMPORTANT:

If the server needs to be relocated/stored due to a change in the floor

layout to a great extent, contact the service representative.

Maintenance 7-11

Make sure to make a backup copy of your valuable data in the hard

disk drive, if any.

Make sure not to apply a shock to hard disk drives to relocated the

server if the contains any.

1. Take a media out of the server, if any.

2. Power off the server (the POWER/SLEEP LED goes off).

3. Unplug the power cord of the server from a power outlet.

4. Remove all the cables from the server.

5. Hold the server by its bottom with at least three persons to carry the server.

IMPORTANT: Do not hold the front door to lift the server. The front

door may be disengaged from the server, causing personal injury.

6. Protect the server with the shock-absorbing materials, and pack it securely.

Page 34

7-12 Maintenance

(This page is intentionally left blank.)

Page 35

Chapter 8

Troubleshooting

If your server does not operate as expected, read this chapter before assuming a failure.

NOTE: For provision against an unexpected failure, it is

recommended to install the maintenance utility, NEC ESMPRO, to the

server and client computers.

Page 36

8-2 Troubleshooting

SYSTEM VIEWERS

Monitor the occurrence of fault by NEC ESMPRO during the system operation.

Especially take note on whether any alert is reported to NEC ESMPRO Manager on the

management PC. Check whether any alert is reported on the Operation Window, DataViewer, or

AlertViewer of NEC ESMPRO Manager.

[Example]

NEC ESMPRO Manager

Page 37

Troubleshooting 8-3

LEDS

The server includes LEDs to indicate the server states by a variety of colors and display patterns on

the front panel, hard disk drive, and power supply.

Chapter 2 "Status Indicators" lists the LED displays and their meanings and the actions taken at

occurrences of failures.

ERROR MESSAGES

If an error occurs in the server, an error message appears on the display unit connected to the server.

Error Messages after Power-on

Powering on the server automatically starts the self-diagnostic program, POST (Power On SelfTest). When the POST detects any error, it displays an error message and its measure on the display

unit.

Follow the table below to troubleshoot such errors. However, even when there is no hardware

failure, use of the keyboard or mouse at the following timing causes the POST to assume a

keyboard controller error and stop processing.

Immediately after the server is powered

Immediately after the system is rebooted in response to a keyboard instruction

(simultaneous key entry of Ctrl + Alt + Delete)

Immediately after the system is rebooted in response to an OS instruction

During hardware initialization following restart of the POST

When the POST detects a hardware failure due to the above reason, restart the server once again. If

the same error message reappears, you may assume there is no hardware error. To ensure normal

operation of the server, however, make sure to follow the following restrictions.

Do not make any keyboard entry or use the mouse before the memory count appears on

the screen following the server power-on.

Do not make any keyboard entry or use the mouse before the start-up message of the SCSI

Configuration Utility appears on the screen following the server reboot.

IMPORTANT: Take a note on the on-screen message before

contacting your service representative. The alarm indication would be a

great help for maintenance.

Page 38

8-4 Troubleshooting

POST Error Messages

When POST detects an error, it displays an error message on the display unit screen. The following

table lists error messages and actions to take.

IMPORTANT: Take a note on the messages displayed before

consulting with your service representative. Alarm messages are useful

information for maintenance.

Error

code

0200 Failure Fixed Disk. Contact your service representative.

0210 Stuck Key. Disconnect the keyboard and connect it

0211 Keyboard error Disconnect the keyboard and connect it

0213 Keyboard locked - Unlock key switch.

0220

0230 System RAM Failed at offset.

0231 Shadow Ram Failed at offset.

0232 Extended RAM Failed at address line.

0250

0251

0252

0260 System timer error.

0270 Real time clock error.

0271 Check date and time setting.

0280

0281

02D0 System cache error - Cache disabled.

Error message Recommended Action

again.

again. If the error cannot be corrected,

contact your service representative.

Release the lock of the key switch. If the

error cannot be corrected in spite of the

release of the lock, contact your service

representative.

Monitor type does not match CMOS - Run

SETUP.

System battery is dead - Replace and run

SETUP.

System CMOS checksum bad - Default

configuration used.

Password checksum bad - Passwords

cleared.

Previous boot incomplete - Default

configuration used.

Memory size found by POST differed from

EISA CMOS.

Start the SETUP. If the error cannot be

corrected in spite of the start of SETUP,

contact your service representative.

Contact your service representative.

Contact your service representative to

replace the battery. (After restarting the

computer, start the SETUP to provide the

setting again.)

The default values have just been set. Start

the SETUP to provide the setting again. If

the error cannot be corrected, contact your

service representative.

The password has just been cleared. Start

the SETUP to provide the setting again.

Start the SETUP to set the date and time

again. If the same error occurs

successively in spite of the resetting,

contact your service representative.

Start the SETUP to provide the setting

again.

Initialize EISA CMOS.

The cache cannot be used. Contact your

service representative.

Page 39

Troubleshooting 8-5

Error

code

02D1 System Memory exceeds the CPU's caching

02F4 EISA CMOS not write able.

02F5 DMA Test Failed.

02F6 Software NMI Failed.

02F7 Fail-safe Timer NMI Failed.

0B22 Processors are installed out of order. Request the maintenance to replace the

0B28 Unsupported CPU detected on CPU socket

0B29 Unsupported CPU detected on CPU socket

0B30 FAN1 Alarm occurred.

0B31 FAN2 Alarm occurred.

0B32 FAN3 Alarm occurred.

0B33 FAN4 Alarm occurred.

0B34 FAN5 Alarm occurred.

0B35 FAN6 Alarm occurred.

0B36 FAN7 Alarm occurred.

0B37 FAN8 Alarm occurred.

0B42 Resource Conflict

0B43 Warning: IRQ not configured

0B45 System configuration Data Write Error

0B50 Processor #1 with error taken off line.

0B51 Processor #2 with error taken off line.

0B5F Forced to use Processor with error

0B60 DIMM group #1 has been disabled

0B61 DIMM group #2 has been disabled

0B62 DIMM group #3 has been disabled

0B63 DIMM group #4 has been disabled

0B64 DIMM group #5 has been disabled

0B65 DIMM group #6 has been disabled

0B70 The error occurred during temperature

0B71 System Temperature out of the range. Contact your service representative to

0B74 The error occurred during voltage sensor

0B75 System voltage out of the range.

0B80 BMC Memory Test Failed.

0B81 BMC Firmware Code Area CRC check failed.

0B82 BMC core Hardware failure.

0B83 BMC IBF or OBF check failed.

0B8A BMC SEL area full

0B8B BMC progress check timeout.

0B8C BMC command access failed.

0B8D Could not redirect the console - BMC Busy 0B8E Could not redirect the console - BMC Error -

Error message Recommended Action

Contact your service representative.

limit.

CPU.

Make sure that the server supports the

1.

2.

sensor reading.

reading.

CPU. If you are not sure, contact your

service representative to request the

maintenance.

Clean the internal cooling fans.

Contact your service representative to

replace the fan.

Contact your service representative.

Because an error is detected in every CPU,

the system is forcibly started. Contact your

service representative.

Contact your service representative.

Contact your service representative.

replace the fan.

Contact your service representative.

Turn off the power once and then on again

to start the server. If the error cannot be

corrected, contact your service

representative.

Clear the system event logs by using the

BIOS SETUP utility (see Chapter 4).

Turn off the power once and then on again

to start the server. If the error cannot be

corrected, contact your service

representative.

Page 40

8-6 Troubleshooting

Error

code

0B8F

0B90 BMC Platform Information Area corrupted.

0B91 BMC update firmware corrupted.

0B92 Internal Use Area of BMC FRU corrupted.

0B93 BMC SDR Repository empty.

0B94 IPMB signal lines do not respond.

0B95 BMC FRU device failure.

0B96 BMC SDR Repository failure.

0B97 BMC SEL device failure.

0B98 BMC RAM test error.

0B99 BMC Fatal hardware error.

0B9A BMC not responding.

0B9B Private I2C bus not responding.

0B9C BMC internal exception.

0B9D BMC A/D timeout error.

0B9E SDR repository corrupt.

0B9F SEL corrupt.

0BB0 SMBIOS – SROM data read error.

0BB1 SMBIOS – SROM data checksum bad.

8068 Unsupported Processor Speed detected on

8069 Unsupported Processor Speed detected on

8100 Memory Error detected in DIMM group #1.

8101 Memory Error detected in DIMM group #2.

8102 Memory Error detected in DIMM group #3.

8103 Memory Error detected in DIMM group #4.

8104 Memory Error detected in DIMM group #5.

8105 Memory Error detected in DIMM group #6.

8160 Mismatch Processor Type/Speed detected

8161 Mismatch Processor Type/Speed detected

Error message Recommended Action

Could not redirect the console - BMC

Parameter Error -

CPU Slot 1.

CPU Slot 2.

on Processor 1.

on Processor 2.

Turn off the power once and then on again

to start the server. If the error cannot be

corrected, contact your service

representative.

This is not a fatal error. Turn off the power

once and then on again to restart the

server. If the error cannot be corrected,

contact your service representative.

Turn off the power once and then on again

to restart the server. If the error cannot be

corrected, contact your service

representative.

This is not a fatal error. Turn off the power

once and then on again to restart the

server. If the error cannot be corrected,

contact your service representative.

This is not a fatal error. Turn off the power

once and then on again to restart the

server. If the error cannot be corrected,

contact your service representative.

Turn off the power once and then on again

to start the server. If the error cannot be

corrected, contact your service

representative.

Update the RMC firmware. If the error

cannot be corrected, contact your service

representative.

Turn off the power once and then on again

to start the server. If the error cannot be

corrected, contact your service

representative.

Contact your service representative.

Contact your service representative.

Contact your service representative to

replace the DIMM in the relevant group.

Contact your service representative.

Page 41

Troubleshooting 8-7

Error

code

None Expansion ROM not initialized – PCI Mass

Error message Recommended Action

Storage Controller in slot n (n: slot number)

H/W Configuration of BMC is corrupted.

!! Update BMC F/W Configuration by

configuration tool !!

!! Refer to BMC configuration manual !!

Disable initialization of the optional device

expansion ROM by using the BIOS SETUP

utility (see Chapter 4).

Use the NEC EXPRESSBUILDER to

configure the remote management card

(see Chapter 6).

Page 42

8-8 Troubleshooting

Beep Codes

If an error occurs during the POST, the server beeps, indicating the type of error.

Each number indicates the number of short beeps, and a hyphen indicates a pause. For example, the

beep interval 1-5-2-2 indicates 1 beep, pause, 2 beeps, pause, 2 beeps, pause, and 3 beeps notifying

that no processor is detected on the mother board.

Beep code Description Recommended action

1-2 Option ROM initialization

error

3-3

1-2-2-3

1-3-1-1 DRAM refresh test error 1. Check if the DIMM is properly installed.

1-3-1-3 Keyboard controller error 1. Check if the keyboard is properly connected.

1-3-3-1 No memory or capacity

1-3-4-1 DRAM address error

1-3-4-3 DRAM test Low Byte

1-4-1-1 DRAM test High Byte

1-5-1-1 CPU startup error

1-5-2-2 No CPU installed

1-5-4-2 AC power interrupted The AC power supply is interrupted due to power

1-5-4-4 Abnormal voltage Replace the mother board.

2-1-2-3 BIOS ROM copyright test

2-2-3-1 Unexpected interrupt test

ROM checksum error Replace the mother board.

check error

error

error

error

error

1. Check if the optional add-in card is properly

installed.

2. Run the BIOS SETUP utility to check the IRQ

assignment.

3. Ask your service representative to replace the addin card or mother board..

2. Remove the DIMM once, and then re-install it to

check if it operates normally.

3. Ask your service representative to replace the failed

DIMM or mother board.

2. Replace the mother board.

1. Check if the DIMM is properly installed.

2. Remove the DIMM once, and then re-install it to

check if it operates normally.

3. Ask your service representative to replace the failed

DIMM or mother board..

1. Check if the CPU is properly installed.

2. Remove the CPU once, and then re-install it to

check if it operates normally.

3. Ask your service representative to replace the failed

CPU.

failure or momentary voltage drop and the system is

restarted. This is not an error.

Replace the mother board.

Page 43

Troubleshooting 8-9

Error Messages on Virtual LCD

NEC EXPRESSSCOPE Engine 2 (Remote Management Controller) on your server board allows

you to monitor the server status on the WEB browser-based screen of the client PC via network.

The virtual LCD (16 digits x 2 lines) in the "Host Information" area displays the POST codes and

status message.

When POST detects an error, the POST error code is displayed on the virtual LCD upon completion

of POST. See the table for POST error codes for details.

Example:

Virtual LCD

Status i ndic ators

Message send from BIOS

Message send from B MC

POWER ON

ATTENTION

Messages displayed on upper line (BIOS message)

On-screen message Description Action

XX BIOS Rev YYYY

CPU Reconfigured

Mem Reconfigured POST completes with memory

POST in progress.

XX: POST code, YYYY: BIOS version

POST completes with processor

degraded.

degraded.

This is not an error.

Contact your service

representative.

Try the following steps to cancel

the error.

1. Start BIOS SETUP.

2. Select [Main] - Processor

Settings] - [Processor Retest] [Yes].

3. Select [Exit] - [Exit Saving

Changes].

Contact your service

representative.

Try the following steps to cancel

the error.

1. Start BIOS SETUP.

2. Select [Advanced] - [Memory

Configuration] - [Memory

Retest] - [Yes].

3. Select [Exit] - [Exit Saving

Changes].

Page 44

8-10 Troubleshooting

On-screen message Description Action

Memory C-Err XX A correctable error frequently occurs in DIMM

#XX.

Memory U-Err XX An uncorrectable error has occurred in DIMM

#XX.

PCI Bus PERR XX A PERR has occurred in the PCI bus XX.

PCI Bus SERR XX A SERR has occurred in the PCI bus XX.

Mem Err Disable A correctable memory error frequently

occurred.

Prepare To Boot POST completes normally. This is not an error.

Contact your service

representative.

Messages displayed on lower line (BMC message)

When the following messages are displayed on the virtual LCD, restart your server by turning off

and on. If an error still occurred, contact your service representative for maintenance.

On-screen message Description

240VA Power Down Power supply failure occurred.

BB +1.5v Alm XX

BB +1.8v Alm XX

BB +3.3v Alm XX

BB +5.0v Alm XX

BB +12v Alm XX

BB P_Vtt Alm XX

BB Temp1 Alm XX Mother board thermal error occurred.

DUMP Request ! Dump switch is pressed.

OS shutdown Alm OS shutdown alarm occurred.

Power On Cnt Alm Power supply failure occurred.

Power Unit 1 Alm Power unit #1 Failure occurred.

Power Unit 2 Alm Power unit #2 Failure occurred.

Proc Missing Processor is not found.

Proc 1 T-Trip

Proc 2 T-Trip

Proc1 Therm % XX

Proc2 Therm % XX

Proc1 VccpAlm XX

Proc2 VccpAlm XX

Processor 1 IERR

Processor 2 IERR

SMI timeout SMI timeout occurred.

Voltage alarm occurred on the mother board.

XX=09: high voltage (fetal)

XX=07: high voltage (warning)

XX=02: low voltage (warning)

XX=00: low voltage (fetal)

XX=09: high voltage (fetal)

XX=07: high voltage (warning)

XX=02: low voltage (warning)

XX=00: low voltage (fetal)

Thermal Trip occurred on processor #1 or #2. The system is forcibly

turned off.

Processor #1 or #2 thermal error occurred.

XX=09: high temperature (fetal)

XX=07: high temperature (warning)

XX=02: low temperature (warning)

XX=00: low temperature (fetal)

Voltage alarm occurred on processor #1 or #2.

XX=09: high voltage (fetal)

XX=07: high voltage (warning)

XX=02: low voltage (warning)

XX=00: low voltage (fetal)

IERR occurred on processor #1 or #2.

Page 45

On-screen message Description

Sys Fan 1 Alarm FAN#1 alarm occurred.

Sys Fan 2 Alarm FAN#2 alarm occurred.

Sys Fan 3 Alarm FAN#3 alarm occurred.

Sys Fan 4 Alarm FAN#4 alarm occurred.

Sys Fan 5 Alarm FAN#5 alarm occurred.

Sys Fan 6 Alarm FAN#6 alarm occurred.

Sys Fan 7 Alarm FAN#7 alarm occurred.

Sys Fan 8 Alarm FAN#8 alarm occurred.

VBAT Alm XX Voltage alarm in lithium battery occurred.

XX=09: high voltage (fetal)

XX=07: high voltage (warning)

XX=02: low voltage (warning)

XX=00: low voltage (fetal)

WDT timeout Watchdog timer timeout error occurred.

Troubleshooting 8-11

Page 46

8-12 Troubleshooting

SOLVING PROBLEMS

When the server fails to operate as expected, see the following to find out your problem and follow

the instruction given before asking for repair.

If the server still fails to operate successfully after solving your problem, take a note on the onscreen message and contact your service representative.

Problems with the Server

Fail to power on the server:

T Is the server is properly supplied with power?

→ Check if the power cord is connected to a power outlet (or UPS) that meets the

power specifications for the server.

→ Make sure to use the power cord provided with the server. Check the power cord

for broken shield or bent plugs.

→ Make sure the power breaker for the connected power outlet is on.

→ If the power cord is plugged to a UPS, make sure the UPS is powered and it

outputs power. See the manual that comes with the UPS for details.

Power supply to the server may be linked with the connected UPS using the BIOS

setup utility of the server.

<Menu to check: [Server] - [AC-LINK]>

T Did you press the POWER switch?

→ Press the POWER switch on the front of the server to turn on the power (the

POWER LED lights).

Fail to power off the server:

T Is the POWER switch enabled?

→ Restart the server and start the BIOS setup utility.

<Menu to check: [Security] - [Power Switch Inhibit]>

T Is the server running in the Secure Mode?

→ The POWER switch is disabled in the Secure Mode. (Forced shutdown is also not

available.) To release the Secure Mode, enter the password specified with the

BIOS SETUP utility.

Page 47

No screen display appears with beep:

→ Check whether DIMMs are connected to the mating connectors firmly.

→ Check whether DIMMs of different specifications are installed in the specific bank.

See Chapter 9 for the specifications of DIMMs.

→ DIMMs must be populated in pairs and in the following order:

11 and 21, 31 and 41, 12 and 22, 32 and 42, 13 and 23, and 33 and 43.

→ Installed DIMMs must be the same speed and must all be registered.

→ Take a note of beep code pattern, and take appropriate action according to the table

listed earlier in "Beep Codes".

POST fails to complete:

T Is the DIMM board installed?

→ At least two DIMM boards are required for operation.

→ DIMMs must be populated in pairs and in the following order:

11 and 21, 31 and 41, 12 and 22, 32 and 42, 13 and 23, and 33 and 43.

Troubleshooting 8-13

→ Installed DIMMs must be the same speed and must all be registered.

T Is the memory size large?

→ The memory check may take a few seconds if the memory size is large. Wait for a

while.

T Did you perform any keyboard or mouse operation immediately after you started the

server?

→ If you perform any keyboard or mouse operation immediately after start-up, POST

may accidentally detect a keyboard controller error and stops proceeding. In such

a case, restart the server once again. Do not perform any keyboard or mouse

operation until the BIOS start-up message appears when you restart the server.

T Does the server have contains appropriate memory boards or PCI devices?

→ Operation of the server with unauthorized devices is not guaranteed.

Page 48

8-14 Troubleshooting

Fail to access to internal or external devices (or such devices fail to operate):

T Are cables properly connected?

→ Make sure that the interface cables and power cord are properly connected. Also

make sure that the cables are connected in the correct order.

T Is the power-on order correct?

→ When the server has any external devices connected, power on the external

devices first, then the server.

T Did you install drivers for connected optional devices?

→ Some optional devices require specific device drivers. Refer to the manual that

comes with the device to install its driver.

T Is BIOS configuration correct?

→ When the server has PCI devices connected, make sure to set the PCI device

interrupt and others with the BIOS SETUP utility of the server. (Most PCI devices

generally do not require any change to the configuration, but some boards do

require specific settings. Refer to the manual that comes with the board for details

to make correct settings.

<Menus to check: [Advanced] - [PCI Configuration] - [PCI Slot xx ROM]

x: PCI slot number>

→ Some devices connected to the serial or parallel port may require I/O port address

or operation mode settings. Refer to the manual that comes with the board for

details to make correct settings.

<Menu to check: [Advanced] - [Peripheral Configuration]>

The POWER switch and sleep feature are disabled:

T Is the POWER switch masked by the BIOS feature?

→ The BIOS can disable power-off with the POWER switch after the operating

system is started (including shutdown by pressing the POWER switch for at least

four seconds).

Run the BIOS SETUP utility to change settings (see Chapter 4).

Page 49

The keyboard or mouse fails to operate:

T Is the cable properly connected?

→ You must use the provided keyboard/mouse branch cable (Y cable) for this server.

Make sure that the provided cable is connected to the correct connector on the rear

of the server.

→ The keyboard or mouse does not operate if it is connected when the server is

powered (not applicable to USB devices). Power of the server first and connect it

properly.

T Is BIOS configuration correct?

→ The keyboard and mouse may be disabled with the BIOS SETUP utility of the

server. Check the settings with the BIOS SETUP utility.

<Menus to check: [Advanced] - [Numlock]>

T Are the server drivers installed?

→ Refer to the manual that comes with your OS to check that the keyboard and

mouse drivers are installed. (These drivers are installed along with the OS.)

Some OS's allow you to change the keyboard and mouse settings. Refer to manual

that comes with your OS to check that the keyboard and mouse settings are

correct.

Troubleshooting 8-15

Fail to access to the disc:

T Is the disc properly set in the optical disk drive tray?

→ The tray is provided with a holder to secure the disc. Make sure that the disc is

placed properly in the holder.

T Is the disc applicable to the server?

→ The disc for Macintosh is not available for use.

T Is the CD/FDD bay installed correctly?

→ Reinstall the CD/FDD bay (see Chapter 9).

Inserted the correct disc but the message like the following is displayed:

The CD-ROM is not inserted or the wrong CD-ROM is inserted.

Please insert the correct CD-ROM.

OK

T Is the data side of the disc dirty or injured?

→ Take the disc out of the optical disk drive, confirm that it is not dirty or injured,

reset and click [OK].

Page 50

8-16 Troubleshooting

Fail to access the hard disk drive:

(Refer to the documentation supplied with the RAID Controller.)

T Is the hard disk drive applicable to the server?

→ Operation of any device that is not authorized by NEC is not guaranteed.

T Is the hard disk drive properly installed?

→ Make sure to lock the hard disk drive with the lever on its handle. The hard disk

drive is not connected to the internal connector when it is not completely installed

(see Chapter 9).

Fail to access the (internal or external) SCSI devices:

T Is the SCSI device applicable to the server?

→ Operation of any SCSI device that is not authorized by NEC is not guaranteed.

T Are SCSI devices properly configured?

→ When the server has external SCSI devices connected, hard disk drive settings,

including SCSI ID and terminator, are required. Refer to the manual that comes

with the SCSI device for details.

T Are the SCSI controllers (including optional controllers) properly configured?

→ Use the SCSI BIOS setup utility for proper configuration of SCSI devices

connected to the SCSI connector on the mother board. When the server has an

optional SCSI controller installed and SCSI devices connected to it, use the SCSI

BIOS setup utility that comes with the optional SCSI controller for proper

configuration. See the manual that comes with the optional SCSI controller for

details.

Page 51

The server is not found on the network:

T Is the LAN cable connected?

→ Make sure to connect the LAN cable to the network port on the rear of the server.

Also make sure that the LAN cable to use conforms with the network interface

standard.

T Is BIOS configuration correct?

→ The internal LAN controller may be disabled with the BIOS SETUP utility of the

server. Check the setting with the BIOS SETUP utility.

<Menus to check:

[Advanced] - [PCI Configuration] - [Onboard LAN] - [LAN Controller]>

T Have the protocol and service already configured?

→ Install the distinctive network driver for the server. Make sure that the protocol,

such as TCP/IP, and services are properly specified.

T Is the transfer speed correct?

→ Open the network property dialog box in control panel to specify the "Link Speed

& Duplex" value the same as the value specified for HUB.

Troubleshooting 8-17

Wake on LAN does not start from standby state.

T Is Hub set to Auto-Negotiation? Or, Is the client set to Auto-Negotiation/optimum

speed?

→ For both hub and client, Wake on LAN does not start from the standby state if the

speed is fixed to 1000Mbps.

Page 52

8-18 Troubleshooting

Event logs in using Intel Network adapter teaming

Event Type: Warning

Event Source: IANSMiniport

Event Category: None

Event ID: 11

Description: Adapter link down: Intel(R)PRO/1000 ----

Event Type: Warning

Event Source: IANSMiniport

Event Category: None

Event ID: 13

Description: Intel(R)PRO/1000 ---- has been deactivated from the team.

Event Type: Error

Event Source: IANSMiniport

Event Category: None

Event ID: 16

Description: Team #0: The last adapter has lost link.

Team network connection has been lost.

Event Type: Warning

Event Source: IANSMiniport

Event Category: None

Event ID: 22

Description: Primary Adapter does not sense any Probes:

Intel(R)PRO/1000 ---- Possible reason: partitioned Team.

Above-mentioned event log will appear when the system starts.

There is no problem in LAN driver operation.

Page 53

Troubleshooting 8-19

Problems with RAID System Configuration

Check the following if the server configuring a RAID System does not operate properly or a

management utility does not operate correctly. If a relevant item is found, follow the processing

method.

Fail to install the OS:

T Is the RAID Controller configured?

→ Provide proper configuration for the RAID Controller by using the WebBIOS.

Fail to start the OS:

T Is the BIOS of the RAID Controller changed?

→ Set the BIOS correctly by using the WebBIOS.

T Does POST recognize the RAID Controller?

→ After making sure that the RAID Controller is connected correctly, then power on

the server.

If the RAID Controller is not recognized correctly despite correct connection, the

RAID Controller may be failed. Contact your service representative.

Rebuild fails:

T Is the capacity of the hard disk drive to be rebuilt sufficient?

→ The hard disk drive to be rebuilt should have the same capacity of the failed had

disk drive.

T Is RAID0 configured?

→ RAID0 has no data redundancy, therefore, Rebuild is disabled in the RAID0

configuration. Replace the failed hard disk drive, create the configuration data

again and initialize the hard disk drives. Then recover the data by using backup

data.

Auto rebuild fails:

T Was a sufficient time taken for hot swap of hard disk drives?

→ To allow the auto rebuild to operate correctly, it should take 90 seconds or longer

for the interval between the removal of the failed hard disk drive and the

installation of a new hard disk drive.

A hard disk drive fails:

Contact your service representative.

Page 54

8-20 Troubleshooting

Problems with Windows

There are some cases that an event log is registered as follows when you install

Windows Server 2003 x64 Editions.

Source: DCOM

Category: Error

Event ID: 10016

Description: The application-specific permission settings do not grant Local Activation

permission for the COM server application with CLSID {555F3418-D99E4E51-800A-6E89CFD8B1D7} to the user {NT AUTHORITY\LOCAL

SERVICE} SID {S-1-5-19}.

This security permission can be modified using the component Services

administrative tool.

→ It is not a problem in operating the system.

There are some cases that an event log is registered as follows when you install

Windows Server 2003 x64 Editions.

Event Source: Service Control Manager

Event Type: Error

Event ID: 7011

Description: Timeout (30000 milliseconds) waiting for a transaction response from the

IMAP4Svc service.

→ When this event is not registered by rebooting the system, it is not a problem in

operating the system.

Page 55

Troubleshooting 8-21

There are some cases that an event log is registered as follows when you operate

Windows Server 2003 R2.

Source: IPMIDRV

Type: Error

Event ID: 1001

Description: The IPMI device driver attempted to determine if the system supported an IPMI BMC

device. The driver attempted to detect the presence of the IPMI BMC by searching the

SMBIOS for Type 38 record. But either no record was found or the record was not

compatible with the version of the device driver.

If a SMBIOS Type 38 record was detected, the Dump Data field of the event contains

a binary representation of the record.

→ If you use "Hardware Management" which is provided by Windows Server 2003

R2, above-shown event log will be registered.

For more details, refer to "Enabling Microsoft Windows Server 2003 R2

Hardware Management" on the following site.

[NEC Express5800 Web Site]

http://www.nec.co.jp/express/download/W2K3_R2

The system displays the message below and fails to log on.

Windows Product Activation

This copy of Windows must be activated with Microsoft before you can

continue. You cannot log on until you activate Windows.

To shut down the computer, click Cancel.

YES NO Cancel

→ In Windows Server 2003, the above message will be displayed if you use the

operating system without executing the license authentication. Select "Yes", and

execute the procedure for license authentication.

Cannot install the operating system correctly.

T Did you confirm the notes on installing the operating system?

→ See Chapter 6.

Page 56

8-22 Troubleshooting

Fail to start the OS with the /3GB switch

→ System often fails to start the OS with the /3GB switch.

In this case, please adjust the capacity of the user mode area using the /userva

switch in reference to the following URL.

http://support.microsoft.com/kb/316739/en

During installation, the following warning is registered in the System Log of the

Event Viewer:

Error detected on the device \Device\CdRom0

during the paging operation.

→ There is no problem on this issue.

Fail to start the OS:

T Is a floppy disk in the floppy disk drive?

→ Take out the floppy disk and restart the server.

T Is the NEC EXPRESSBUILDER DVD in the optical disk drive?

→ Take out the NEC EXPRESSBUILDER DVD and restart the server.

T Is the OS broken?

→ Use recovery process to recover the system.

The OS presents unstable operation:

T Did you update the system?

→ Installing a network drive after installation of the OS may cause unstable

operation. Use the NEC EXPRESSBUILDER DVD to update the system. (See

Chapter 6.)

The system does not restart automatically when a stop error occurs, though the

system is adjusted to automatically restarting:

→ When the system does not restart automatically, restart it manually.

The system restarts automatically when a stop error occurs, though the system is

NOT adjusted to automatically restarting:

→ There is no problem about this issue.

Check the System Event Log to confirm that STOP error occurred.

Page 57

Troubleshooting 8-23

Cannot turn the power OFF at the blue screen:

→ If you want to turn off the power at the blue screen, execute forced shutdown

(forced shutdown: continue to press POWER/SLEEP switch for 4 seconds). The

power will not be turned off if you press the switch for less than 3 seconds.

The PXE boot (network boot) fails or the server is not found on the network:

T Is the cable connected properly?

→ Connect the proper cable to the network port on the rear of the Express server. In

addition, make sure that the used cable conforms to the network interface standard.

T Is BIOS configuration correct?

→ The internal LAN controller may be disabled with the BIOS SETUP utility of the

server. Check the setting with the BIOS setup utility.

T Have the protocol and service already configured?

→ Install the distinctive network driver for the server. Make sure that the protocol,

such as TCP/IP, and services are properly specified.

T Is the transfer speed correct?

→ Open the network property dialog box in control panel to specify the link speed

and duplex value the same as the value specified for HUB.

The Telnet Service is not installed.

→ Adjust the computer name to 14 characters or less, and then install the Telnet Service

according to <How to install the Telnet Service>.

<How to install the Telnet Service>

1. Click [Run] on Start menu.

2. Type "tlntsvr /service" in the [Open] box, and click [OK].

3. Click Start menu, point to [Control Panel] and click [Computer Management] and then

click the [Services] to specify whether the Telnet Service is registered.

* When the installation of Telnet Service is finished, there is no problem if the computer

name is set to 15 characters or more.

Power ON/OFF (Wake On LAN) feature does not work:

→ Immediately after the AC power is turned on, the Remote Power ON/OFF feature

(Wake ON LAN) is disabled. Start Windows 2003 once, provide settings as shown

below, then shutdown the system. After restart, the Remote Power On/Off feature is

available unless the AC power is turned off.

Select [Start] → [Administrative Tools] → [Computer Management].

Select Device Manager, double-click [Intel(R) PRO/1000EB Network Connection

with I/O Acceleration #n] under Network Adapter, and specify as follows in [Detail]

tab.

PME: [ON]

Wake On: [Magic Packet]

Page 58

8-24 Troubleshooting

Problems with NEC EXPRESSBUILDER

When the server is not booted from the NEC EXPRESSBUILDER DVD, check the following:

T Did you set the NEC EXPRESSBUILDER during POST and restart the server?

→ If you do not set the NEC EXPRESSBUILDER during POST and restart the

server, an error message will appear or the OS will boot.

T Is BIOS configuration correct?

→ The boot device order may be specified with the BIOS SETUP utility of the server.

Use the BIOS SETUP utility to change the boot device order to boot the system

from the optical disk drive first.

<Menu to check: [Boot]>

If [OS installation ***default***] is selected at BOOT Selection screen, following message is

displayed.

After this message appears, check the error and take the appropriate corrective action according to

the message listed in the table below.

Message Cause

This EXPRESSBUILDER version was not designed

for this computer.

Insert the correct version and click [OK]. (When you

click [OK], the computer reboots.)

EXPRESSBUILDER could not get the hardware

parameters written in this motherboard.

This version is not designed for this computer or the

motherboard may be broken. (When you click [OK],

the computer reboots.)

The hardware parameters written in this

motherboard are incorrect.

This version is not designed for this computer or the

motherboard may be broken.

This NEC EXPRESSBUILDER

version is not designed for this server.

Execute the NEC EXPRESSBUILDER

on the compliant server.

This message is shown when NEC

EXPRESSBUILDER could not find

system-specific information because

of mother board exchange and so on.

Page 59

Troubleshooting 8-25

Problems with Express Setup

The system partition is created by size smaller than specified value.

→ In ExpressSetup, there are some cases that the system partition is created by size

about 8MB smaller than specified size.

It is not a problem in operating the system.

Following message appeared when you tried to install Express Setup to the hard disk drive

that has smaller capacity than the specified partition size:

The creating of the partition was failed.

The process can not be continued. The process was stopped.

OK

→ Cannot continue the setup.

Specify smaller partition size than the capacity of connected hard disk drive, and then

retry the setup.

Specified to join the Domain, but the system is installed as Workgroup.

→ When the setup fails to join the Domain during the installation, it will install the

system as Workgroup. Open [System] in Control Panel to specify joining the Domain.

Unable to specify the details of Network adapter.

→ In Express Setup, you can not specify the details of Network adapter. Specify them

from Control Panel after starting Windows.

Fail to start Parameter File Creator:

T Parameter File Creator requires to run by "Microsoft® HTML Application host".

→ If Parameter File Creator does not start, associate the file type with "Microsoft®

HTML Application host" via following process.

1) Click [Run] on Start menu.

2) Type "%windir%\system32\mshta.exe /register" in the [Open] box, and click

[OK].

Page 60

8-26 Troubleshooting

Problems with Windows Autorun Menu

Cannot read online document:

T Do you have Adobe Reader installed correctly in your system?

→ Some online documents are supplied with PDF format. To read the document of

PDF format, Adobe Reader is required in your system.

T Is the operating system Windows XP SP2?

→ With Windows XP SP2, the following information may appear in browser.

"To help protect your security, Internet Explorer has restricted this file from

showing active content that could access your computer. Click here for options..."

1. Click the Information Bar.

The shortcut menu appears.

2. Click [Allow blocked content].

The security alert dialog box appears.

3. Click [Yes] on dialog box.

The menu fails to appear:

T Is your system Windows XP or later, or Windows 2003 or later?

→ The Windows Autorun menu is supported by Windows XP/Windows 2003 or

later.

→ If your system runs on Windows Autorun Menu on Windows 2000 system, you

need to setup IE6.0 before using Windows Autorun Menu.

T Is Shift pressed?

→ Setting the DVD/CD-ROM with Shift pressed down cancels the Autorun feature.

T Is the system in the proper state?

→ The menu may not appear depending on the system registry setting or the timing

to set the DVD/CD-ROM. In such a case, start the Explorer and double-click the

icon of the optical disk drive.

Some menu items are grayed-out:

T Is your system environment correct?

→ The menu items are grayed-out when the logon user does not have the authority of

the Administrator or the system does not meet the requirements to install the

application. Login with the user having the proper authority on the proper system,

and try again.

Page 61

Troubleshooting 8-27

COLLECTING DR. WATSON DIAGNOSTIC INFORMATION

Dr. Watson collects diagnostic information related to application errors. The location to save the

information can be specified as you like. For more information, refer to Chapter 5.

MEMORY DUMP

If an error occurs, the dump file should be saved to acquire necessary information.

If you saved the dump to DAT, write down that it is saved as "NTBackup" or "ARCServe" on the

label. You can specify the location to save the diagnostic information as you like.. For more

information, refer to "Specifying Memory Dump (Debug Information (refer to Chapter 5 for

detail)".

IMPORTANT:

Consult with your service representative before dumping the

memory. Dumping the memory while the server is in the successful

operation may affect the system operation.

Restarting the system due to an error may display a message

indicating insufficient virtual memory. Ignore this message and

proceed. Restarting the system may result in dumping improper

data.

Preparing for Memory Dumping

Memory dumping with the DUMP switch may disable the server to restart. In such a case, it is

required to force the server to shut down. This forced shutdown, however, is not available if

"Enable" is selected for "Power Switch Inhibit" on the Security menu of the BIOS setup utility,

SETUP, because this setting disables POWER switch operation.

Follow the procedure below to change the setting to enable the forced shutdown and restart of the

server.

1. Power on the server and start the BIOS setup utility, SETUP.

2. Select "Disable" for "Power Switch Inhibit" in the Security menu.

3. Save the configuration data and exit the SETUP.

Page 62

8-28 Troubleshooting

Saving the Dump File

Press the DUMP switch to save the dump file when an error occurs. Insert a metal pin (a

straightened large paper clip will make a substitute) into the switch hole to press the DUMP switch.

DUMP

switch

0

1

2

3

4

5

Pressing the DUMP switch saves the dump file in the specified directory. (Memory dumping may

not be available when the CPU stalls.)

IMPORTANT: Do not use a toothpick or plastic stick that is easy to

break.

Page 63

Troubleshooting 8-29

RECOVERY FOR WINDOWS SERVER 2003 X64 EDITIONS AND WINDOWS SERVER 2003

If the system fails to start by some reasons, recover the system with the recovery console. However,

recovery using this method should be performed only by system administrator or a user who has an

expert knowledge.

See Online Help for details.

Page 64

8-30 Troubleshooting

Maintenance Tools

The Maintenance Tools is a tool of this product prevention to maintain, and to analyze the trouble.

Starting Maintenance Tools

The Maintenance Tools is started according to the following procedure.

1. Turn on peripheral devices and the server in this order.

2. Insert the NEC EXPRESSBUILDER DVD supplied with your server into the optical disk

drive of your server.

3. Press Ctrl, Alt, and Delete to reboot the server from the NEC EXPRESSBUILDER.

(You may also turn off and then on again to reboot the server.)

System boots up displaying Boot Selection menu.

IMPORTANT: An initial selection of the menu is "Os installation".

"Os installation" starts by the automatic after the Boot Selection menu

is displayed.

4. When a local console is used, "Maintenance Tools (Normal mode)" is selected.

Moreover, "Maintenance Tools (Redirection mode)" is selected when using it with remote

console. The Language selection menu is displayed.

Page 65

IMPORTANT: An initial selection of the menu is "Japanese".

"Japanese" starts by the automatic operation when the operation is not

done for five seconds after the Language Selection menu is displayed.

5. "English" is selected.

The tool menu is displayed.

Troubleshooting 8-31

When you use a local console

When you use a remote console

6. Each tool is selected, and it starts.

Page 66

8-32 Troubleshooting

Function of Maintenance Tools

The following functions can be executed in the Maintenance Tools.

Maintenance Utility

The Off-line Maintenance Utility is started in Maintenance Utility. The Off-line

Maintenance Utility is an OS-independent maintenance program. When you are unable to

start the OS-dependent NEC ESMPRO to troubleshoot a problem, the Off-line

Maintenance Utility can be used.

IMPORTANT:

The Off-line Maintenance Utility is intended for use of your service

representative. The NEC EXPRESSBUILDER DVD you have

created contain a file that describes operation of the utility, but do

not attempt to use the utility by yourself. Contact your service

representative and follow instructions.

See the on-line help for details of the Off-line Maintenance Utility.

For further information, ask your service representative.

The Off-line Maintenance Utility provides the following features.