Page 1

MINIATURE SIGNAL RELAYS

EC2 SERIES (DIP TYPE)

EE2 SERIES (SMD TYPE)

TECHNICAL DATA

Document No. 0170EMDD03VOL01E

Date Published July 2002 P

Printed in Japan

Page 2

MINIATURE SIGNAL RELAYS

EC2 SERIES (DIP TYPE)

EE2 SERIES (SMD TYPE)

TECHNICAL DATA

Page 3

No part of this document may be copied or reproduced in any form or by any means without the

prior written consent of NEC/TOKIN Corporation. NEC/TOKIN Corporation assumes no resposibility

for any errors which may appear in this document.

NEC/TOKIN Corporation does not assume any liability for infringement of patents, copyrights or

other intellectual property rights of third parties by or arising from use of a device described herein

or any other liability arising from use of such device. No license, either express, implied or

otherwise, is granted under any patents, copyrights or other intellectual property rights of NEC

/TOKIN Corporation or others.

While NEC/TOKIN Corporation has been making continuous effort to enhance the reliability of its

electronic components, the possibility of defects cannot be eliminated entirely. To minimize risks

of damage or injury to persons or property arising from a defect in an NEC/TOKIN electronic component,

customers must incorporate sufficient safety measures in its design, such as redundancy,firecontainment, and anti-failure features. NEC/TOKIN devices are classified into the following three

quality grades:

"Standard," "Special," and "Specific". The Specific quality grade applies only to devices

developed based on a customer designated "quality assurance program" for a specific

application. The recommended applications of a device depend on its quality grade, as indicated

below. Customers must check the quality grade of each device before using it in a particular

application.

Standard: Computers, office equipment, communications equipment, test and measurement

equipment, audio and visual equipment, home electronic appliances, machine tools,

personal electronic equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems,

anti-disaster systems, anti-crime systems, safety equipment and medical

equipment (not specifically designed for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control

systems, life support systems or medical equipment for life support, etc.

The quality grade of NEC/TOKIN devices is "Standard" unless otherwise specified in NEC/TOKIN’s

Data Sheets or Data Books. If customers intend to use NEC/TOKIN devices for applications other

than those specified for Standard quality grade, they should contact an NEC/TOKIN sales representative

in advance.

(Note)

(1) "NEC/TOKIN" as used in this statement means NEC/TOKIN Corporation and also includes

its majority-owned subsidiaries.

(2) "NEC/TOKIN electronic component products" means any electronic component product developed

or manufactured by or for NEC/TOKIN (as defined above).

DE0202

Page 4

CONTENTS

1. Preface ........................................................................................................................................... 1

2. Structure ........................................................................................................................................ 2

3. Basic Characteristics ................................................................................................................... 3

3.1 Switching power ..................................................................................................................................... 3

3.2 Life curve ................................................................................................................................................ 3

3.3 Maximum coil voltage ............................................................................................................................. 4

3.4 Coil temperature rise .............................................................................................................................. 4

3.5 Driving power vs. timing ......................................................................................................................... 5

3.6 Driving pulse width vs. set & reset voltages ........................................................................................... 6

3.7 Thermal characteristics .......................................................................................................................... 7

3.8 Magnetic interference ............................................................................................................................. 8

3.9 High-frequency characteristics ............................................................................................................... 9

3.10 Coil inductance ....................................................................................................................................... 10

3.10.1 Measurement by LCR meter .................................................................................................... 10

3.10.2 Measurement by coil current waveform ................................................................................... 10

3.11 Capacitance ........................................................................................................................................... 11

3.12 Resistance to surge voltage ................................................................................................................... 12

3.13 Current surge interrupt test .................................................................................................................... 13

3.14 Resistance to carrying current ................................................................................................................ 13

4. Distribution of Characteristics .................................................................................................... 14

4.1 Operate & release voltages (set & reset voltages) ................................................................................. 14

4.2 Operate & release times (set & reset times) .......................................................................................... 15

4.3 Transfer time .......................................................................................................................................... 16

4.4 Timing and details .................................................................................................................................. 17

4.5 Contact resistance.................................................................................................................................. 21

4.6 Breakdown voltage ................................................................................................................................. 22

4.7 Thermal Electromotive Force (EMF) (offset voltage between contacts) ................................................ 22

5. Test Data ....................................................................................................................................... 23

5.1 Environmental tests ................................................................................................................................ 24

5.1.1 High-temperature test ................................................................................................................. 24

5.1.2 Low-temperature test ................................................................................................................. 27

5.1.3 Moisture resistance test ............................................................................................................. 29

5.1.4 Heat shock test ........................................................................................................................... 31

5.1.5 Vibration test .............................................................................................................................. 33

5.1.6 Shock test ................................................................................................................................... 35

5.1.7 Resistance to solder heat test (only EC2 series) ....................................................................... 37

5.1.8 Resistance to reflow solder heat test (only EE2 series) ............................................................. 38

5.1.9 Terminal strength test (only EC2 series) .................................................................................... 40

- i -

Page 5

5.2 Contact life tests ..................................................................................................................................... 41

5.2.1 Non-load test A (Mechanical life test, Ta = 25˚C) ....................................................................... 41

5.2.2 Non-load test B (Mechanical life test, T

5.2.3 Resistive load test A (10 m Vdc, 10

a = 85˚C) ....................................................................... 42

µ

A, Ta = 25˚C) ................................................................... 42

5.2.4 Resistive load test B (10 Vdc, 10 mA, Ta = 85˚C) ...................................................................... 43

5.2.5 Resistive load test C (28 Vdc, 100 mA, T

5.2.6 Resistive load test D (50 Vdc, 100 mA, T

a = 85˚C) .................................................................... 43

a = 25˚C) .................................................................... 44

5.2.7 Resistive load test E (50 Vdc, 100 mA, Ta = 85˚C) .................................................................... 44

5.2.8 Inductive load test (48 Vdc, 110 mA, Ta = 25˚C) ........................................................................ 45

5.2.9 Resistive load test F (220 Vdc, 0.14 A, Ta = 25˚C) .................................................................... 45

5.2.10 Resistive load test G (125 Vdc, 0.5 A, T

5.2.11 Resistive load test H (30 Vdc, 1 A, T

a = 25˚C) ...................................................................... 46

a = 25˚C) ........................................................................... 46

- ii -

Page 6

1. Preface

Miniature signal relays are used in a wide range of application fields including communication, measurement, and

factory automation. This document gives the basic characteristics and test data of NEC’s EC2 and EE2 series

miniature signal relays.

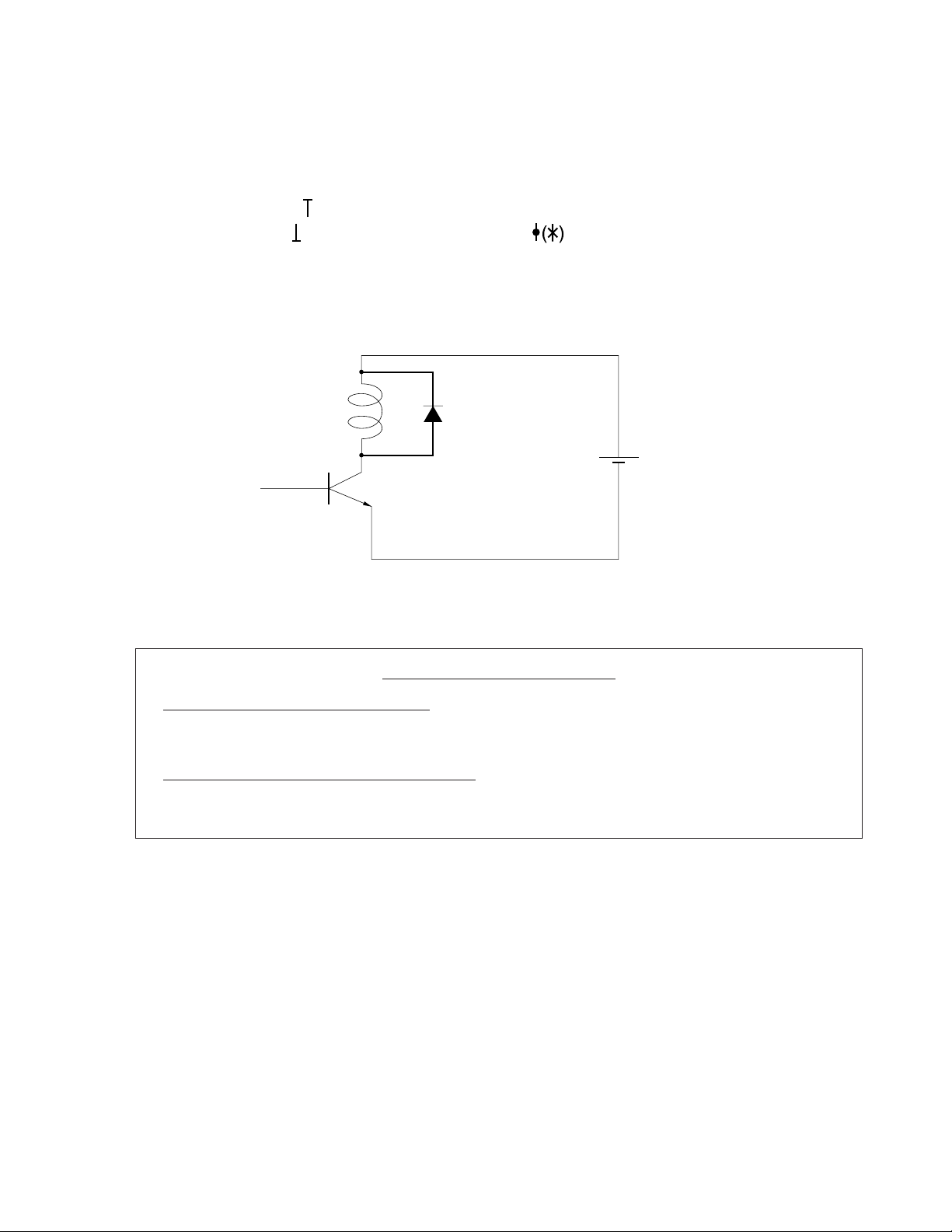

Notes 1. The symbol

shown in the graphs throughout this document indicates the maximum value of the data.

Likewise, indicates the minimum value, and indicates the mean value.

2. When a relay is driven by an IC, a protective element such as a diode may be connected in parallel

with the relay coil to protect the IC from damage caused by the counter-electromotive force (EMF) due

to the inductance of the coil. However, unless otherwise specified, the operate time and release time

(set and reset times) shown in this document are measured without such a protective element.

Relay Coil

Tr

Diode

Power Supply

For Right Use of Miniature Relays

DO NOT EXCEED MAXIMUM RATINGS.

Do not use relays under exceeding conditions such as over ambient temperature, over voltage and over

current. Incorrect use could result in abnormal heating, damage to related parts or cause burning.

READ CAUTIONS IN THE SELECTION GUIDE.

Read the cautions described in NEC/TOKIN’s “Miniature Relays” (0123EMDD03VOL01E) when you choose

relays for your application.

1

Page 7

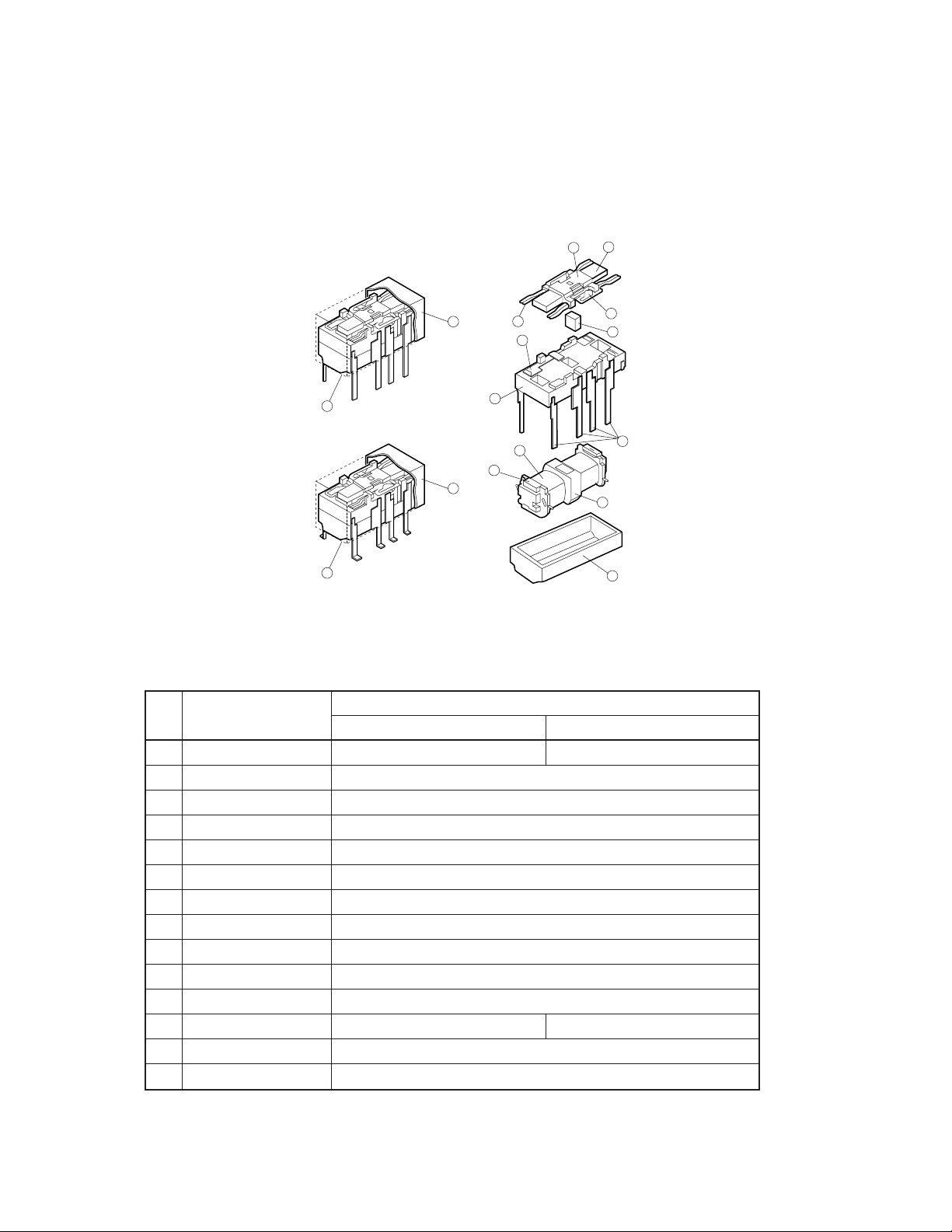

2. Structure

Figure 2.1 shows the structures of the EC2 and the EE2 series relays. EC2 series relay has a terminal configuration

called dual in-line leads (DIL), and EE2 series relay has a resistibility to solder heat, and a terminal configuration that

conforms to surface mounting. Table 2.1 lists the parts constituting relay.

EC2 series and EE2 series relays have a common structure except difference of a terminal configuration and some

parts.

11

[EC2 series]

12

10

13

7

5

3

14

[EE2 series]

14

1

1

8

9

2

4

6

Figure 2.1 Structure of the EC2/EE2 Series Relay

Table 2.1 Parts of EC2/EE2 Series Relay

No. Parts

EC2 Series EE2 Series

1 Cover Polybutylene telephthalate

2 Base Liquid crystalline polymer

3 Base pad Liquid crystalline polymer

4 Coil wire Polyurethane copper wire

5 Coil spool Polyphenylene sulfide

#

6 Core Pure iron

7 Terminal Phosphor bronze (surface is treated with preparatory solder)

8 Moving contact Au-alloy + AgNi

9 Stationary contact Au-alloy + AgNi

*

*

10 Contact spring Phosphor bronze

11 Armature Pure iron

12 Armature block mold Polyethersulfone Liquid crystallene polymer

13 Magnet Cobalt magnet

14 Sealing material Epoxy resin

Material

*

*

*

Liquid crystalline polymer

*

Note: *: Standard type

#: Conforms to UL94V-0

2

Page 8

3. Basic Characteristics

)

This section provides data necessary for designing an external circuit that uses the relay.

EC2 and EE2 series relays are designed with common specifications. So, this section shows common

characteristics of EC2 and EE2 series.

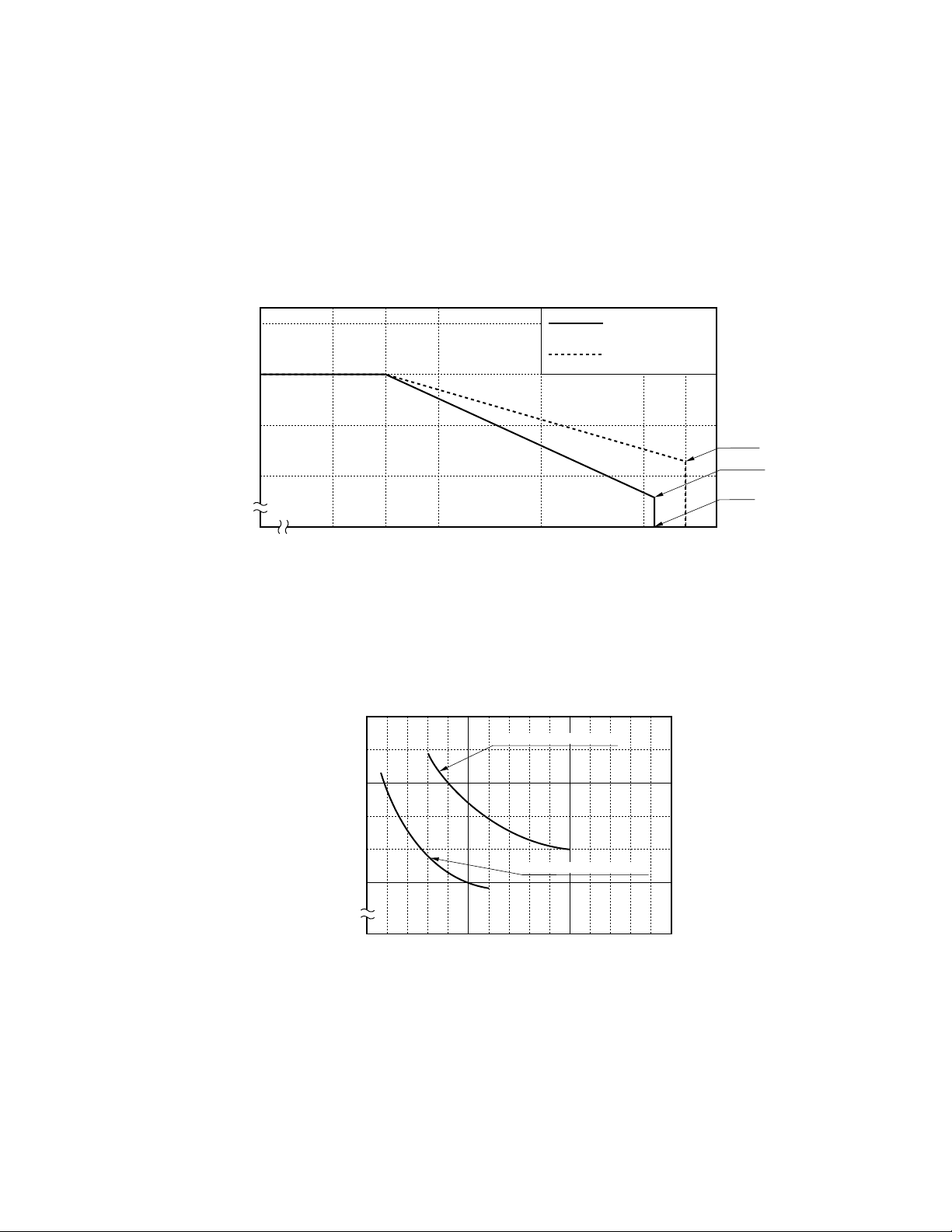

3.1 Switching power

If the contact load voltage and current of the relay are in the region enclosed by the solid and dotted lines in the

figure below, the relay can perform stable switching operation. If the relay is used at a voltage or current exceeding

this region, the life of the contacts may be significantly shortened.

2.0

1.0

0.5

Load Current (A)

0.2

20 30 50 100 200 250

Load Voltage (V

DC Resistive Load

AC Resistive Load

0.25 A

0.136 A

220 V

Figure 3.1 Switching Power

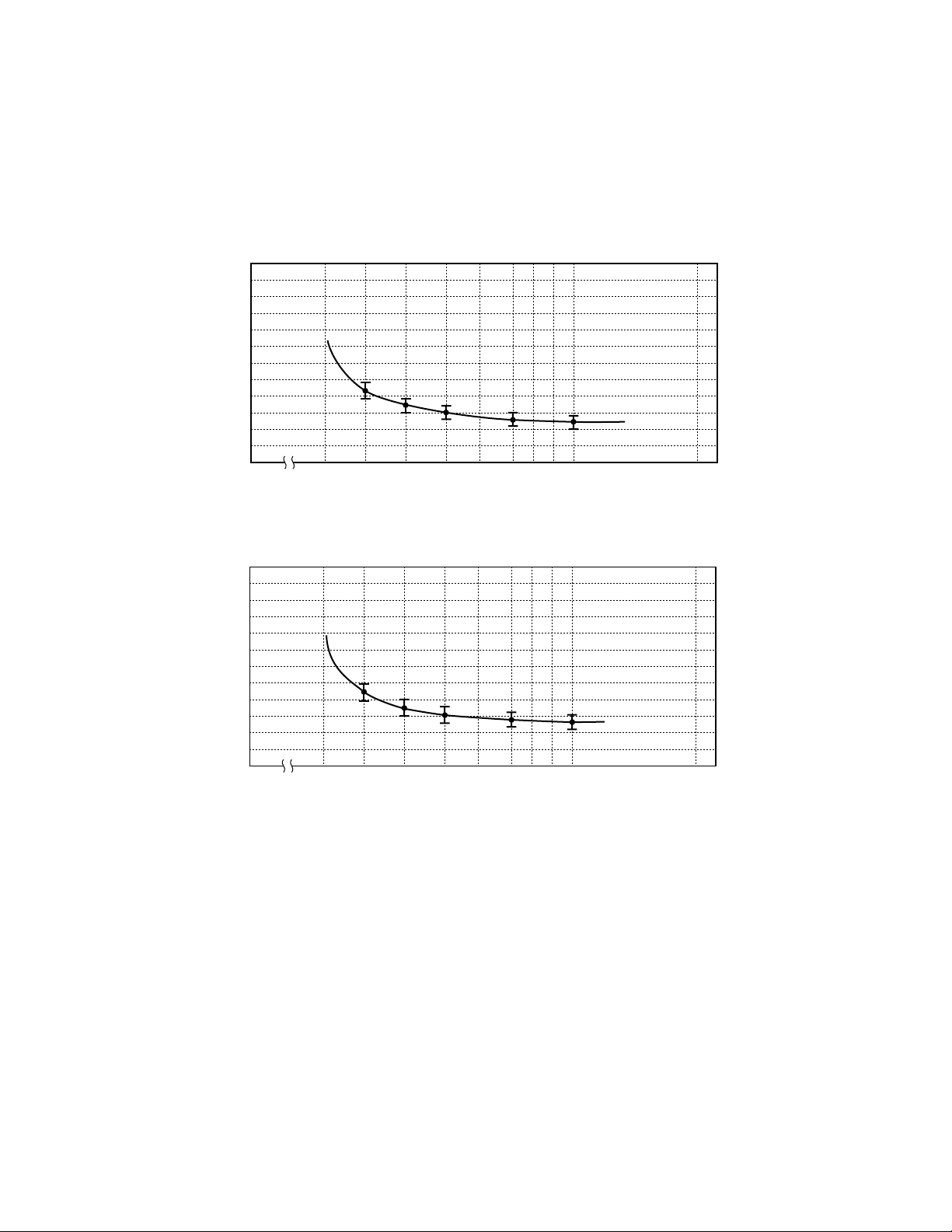

3.2 Life curve

The life expectancy of the relay can be roughly estimated from the switching voltage and current of the contact

load shown in Figure 3.2.

200

30 Vdc Resistive Load

100

50

operations)

4

20

Life (×10

10

0 0.5 1.0

Switching Current (A)

125 Vac Resistive Load

Figure 3.2 Life Curve

3

Page 9

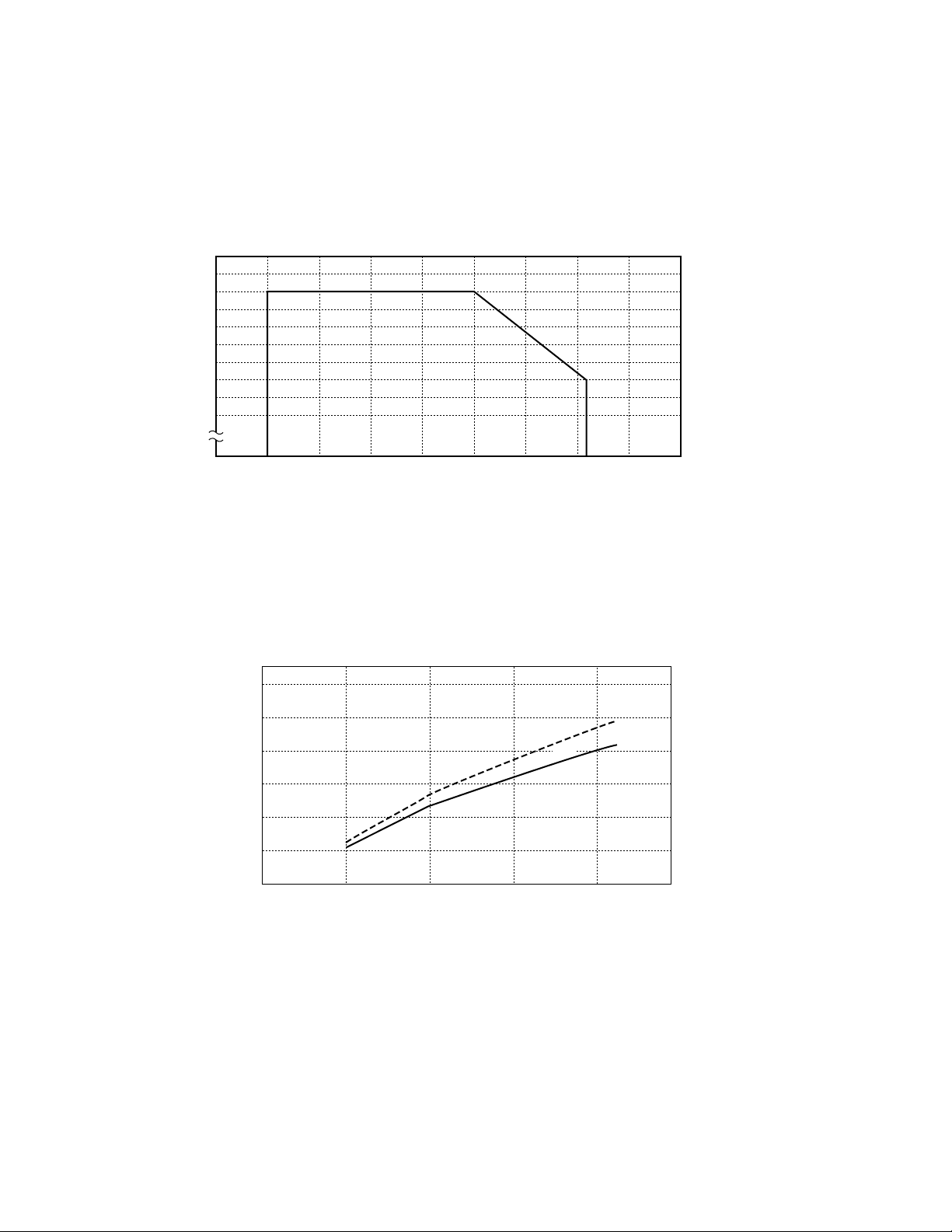

3.3 Maximum coil voltage

)

)

Figure 3.3 shows the ratio of maximum voltage that can be continuously applied to the coil of the relay to the nominal

voltage. As long as the relay is used in the enclosed region in this figure, the coil is not damaged due to burning

and the coil temperature does not rise to an abnormally high level.

(* Rated Coil Voltage: 3 to 24 Vdc)

(Rated of decrease in maximum voltage: 50%/45˚C)

150

100

Ratio of maximum applied voltage

to nominal voltage (%)

0 – 40 –200 20406080100

Ambient temperature (˚C

85˚C

Figure 3.3 Maximum Voltage Applied to Coil

3.4 Coil temperature rise

Figure 3.4 shows the relation between the rise in coil temperature and the power (product of the coil voltage and

current) dissipated by the coil. This figure shows the difference between the temperature before the power is applied

to the coil and the saturated temperature after application of power to the coil.

60

50

40

30

20

2 A

0 A

Carrying

Current

Temperature Rise (˚C)

10

0 100 200 300 400

Applied Power (mW

Figure 3.4 Coil Temperature Rise

4

Page 10

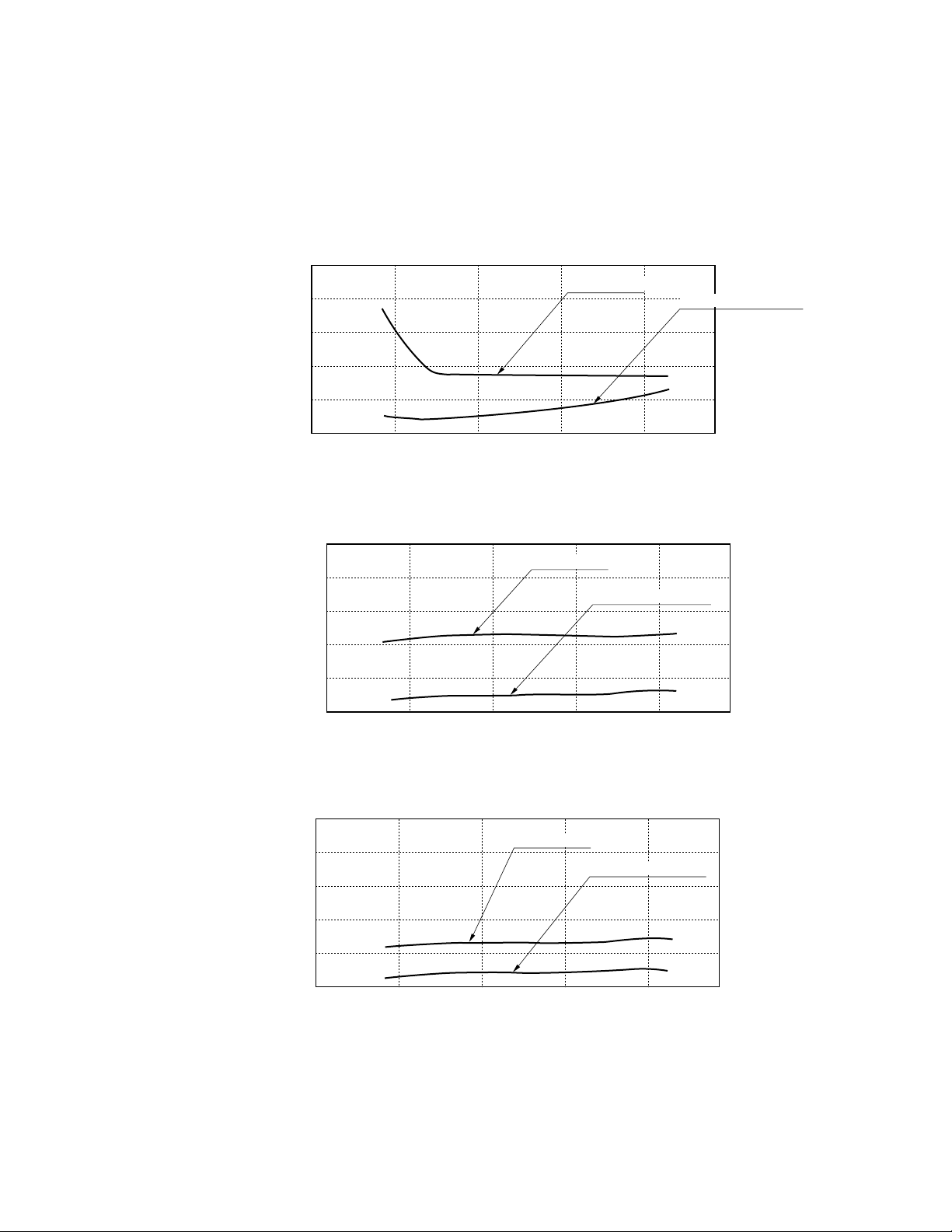

3.5 Driving power vs. timing

Figure 3.5 (1) shows the relations among the power applied to drive the relay, the operate time, and the bounce

time. Figure 3.5 (2) shows the relations among the supplied power, the release time, and the bounce time, and Figure

3.5 (3) shows the relations among the supplied power, the release time, and the bounce time when a diode is not

connected to the coil to absorb surges.

(1) Operate time

4

3

2

1

Operate Time

Operate Bounce Time (ms)

0 100 200 300 400

(2) Release time (with diode)

4

3

2

1

Release Bounce Time (ms)

(with diode)

Release Time

0 100 200 300 400

Operate time

Operate bounce time

Applied Power (mW)

Release time

Release bounce time

Applied Power (mW)

(3) Release time

4

3

2

1

Release Time

Release Bounce Time (ms)

0 100 200 300 400

Applied Power (mW)

Release time

Release bounce time

Figure 3.5 Driving Power vs. Timing

5

Page 11

3.6 Driving pulse width vs. set & reset voltages

Because the latching type relay can be driven on a pulse voltage, it can save power. However, if the pulse width

is too narrow, the relay does not operate correctly.

Figure 3.6 shows the relations among the width of the pulse voltage applied to the coil, the set voltage, and the

reset voltage of the latching type relay.

(1) Set voltage

200

100

Ratio of set voltage to

nominal voltage (%)

0

2345678910 20

Driving Pulse Width (ms)

(2) Reset voltage

200

100

Ratio of reset voltage to

nominal voltage (%)

0

2345678910 20

Driving Pulse Width (ms)

Figure 3.6 Driving Pulse Width vs. Set & Reset Voltages

(Hints on correct use)

If the driving pulse width is too narrow, the relay cannot be driven at the nominal voltage. Hence, in actual

applications, apply a pulse with a width of 10 ms or more to the relay.

6

Page 12

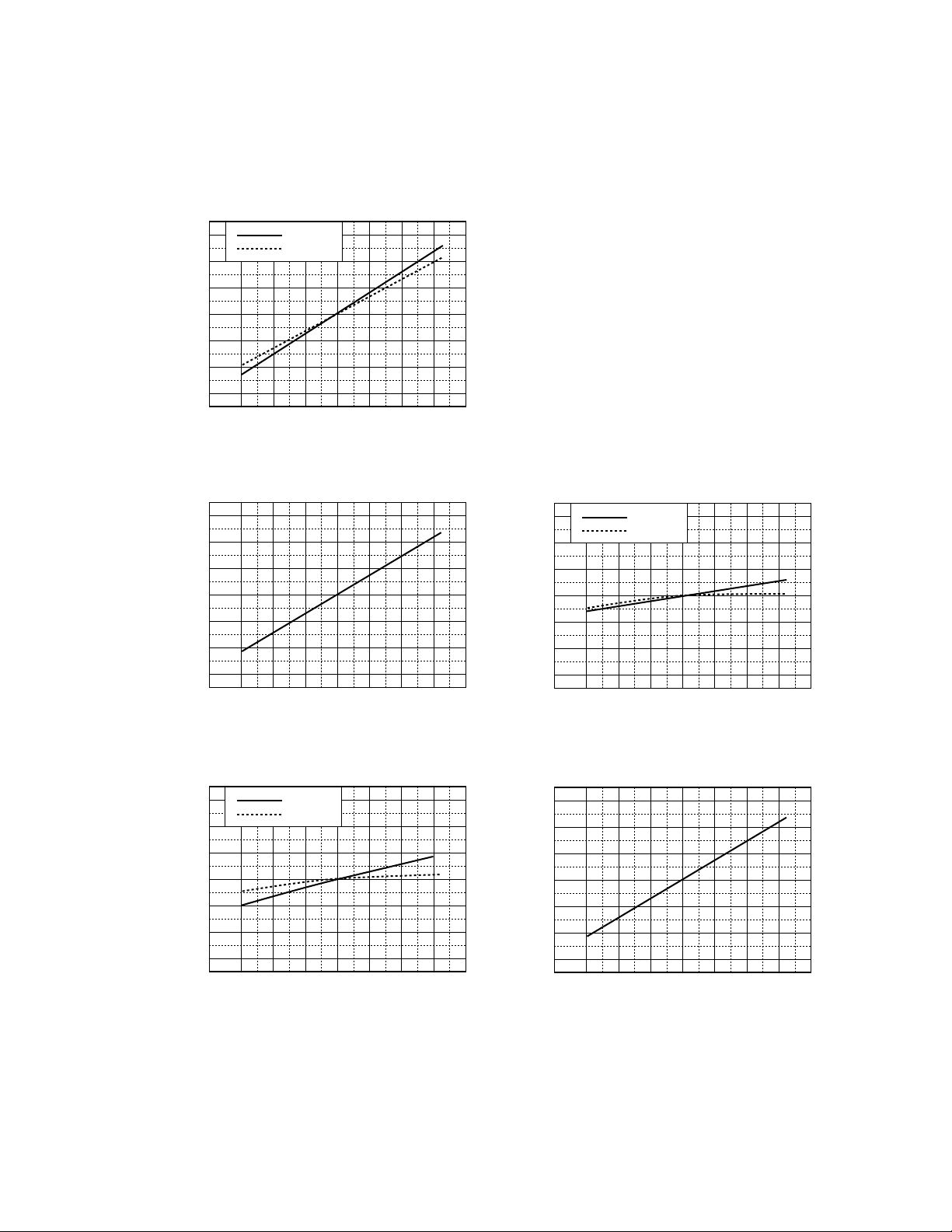

3.7 Thermal characteristics

p

p

)

p

)

p

)

p

)

The general characteristics of a relay gradually change with the ambient temperature. Figure 3.7 shows the typical

characteristics of the EC2 series relay.

(1) Operate & release voltages

130

120

110

100

90

80

70

Change in Must Operate and Must

Release Voltages (%)

– 40 –20 0 20406080100

Operate

Release

Ambient Tem

rature Ta (˚C)

(2) Contact resistance* (4) Transfer times

130

120

110

100

90

80

70

Changes in Contact Resistance (%)

– 40 –20 0 20406080100

Ambient Tem

rature Ta (˚C

130

120

110

100

90

80

Cange in Transfer Time (%)

70

– 40 –20 0 20406080100

Operate

Release

Ambient Tem

rature Ta (˚C

(3) Operate & release times (5) Coil resistance

130

120

110

100

90

80

70

Change in Must Operate and Must

Release Times (%)

– 40 –20 0 20406080100

Operate

Release

Ambient Tem

rature Ta (˚C

130

120

110

100

90

80

70

Change in Coil Resistance (%)

– 40 –20 0 20406080100

Ambient Tem

rature Ta (˚C

Figure 3.7 Temperature Characteristics

* The contact resistance includes the conductive resistance of the terminals. It is this conductive resistance

component that changes with the temperature.

7

Page 13

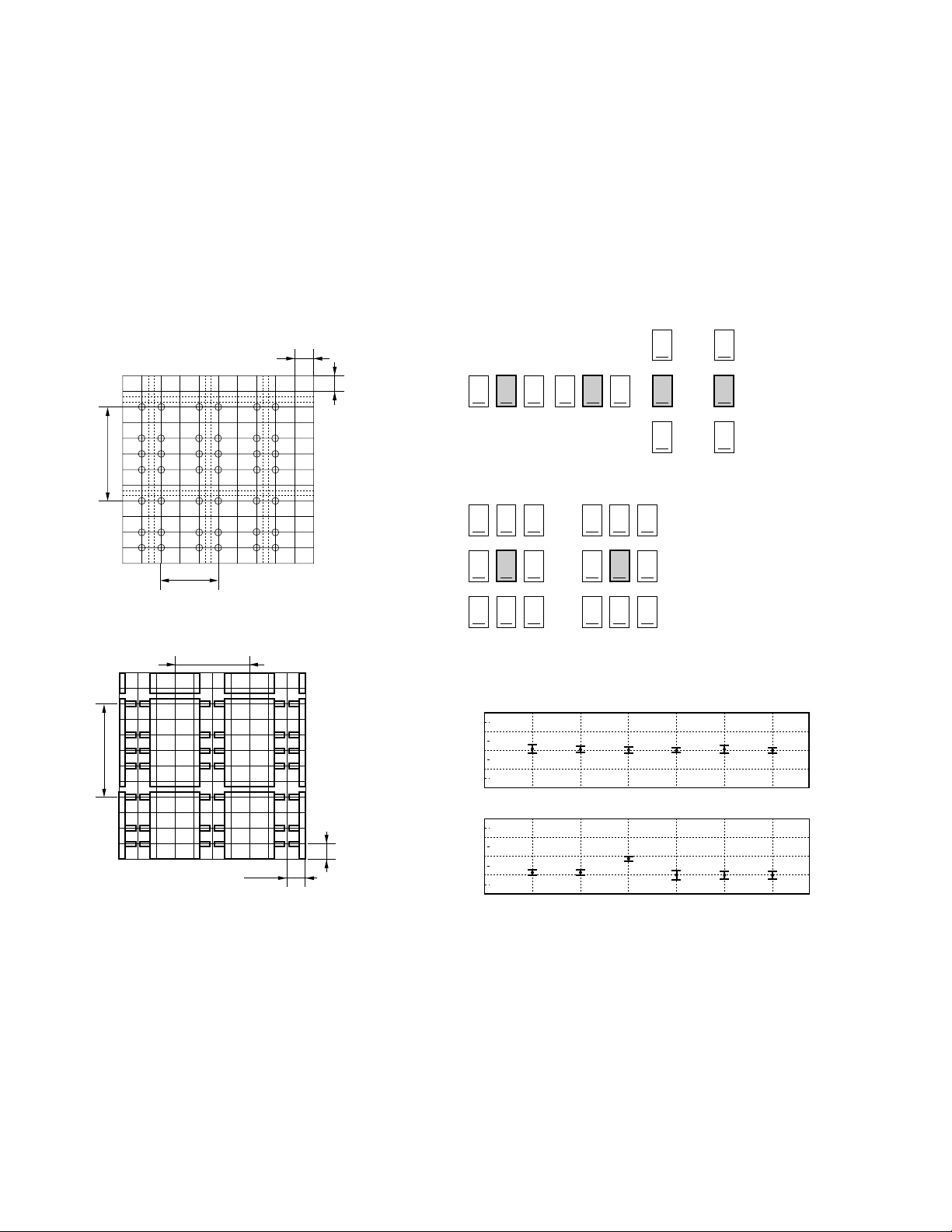

3.8 Magnetic interference

This section describes changes in the operate voltage caused by mutual magnetic interference when several relays

are closely mounted on a printed circuit board (PCB). Figure 3.8 (1) shows the distance among the relays mounted

on the PCB. As shown, the pin pitch of each relay is 2.54 mm. Figure 3.8 (2) shows the relay that is subject to

interference. In this figure, the hatched relay shown in the center of each relay arrangement is subject to interference,

and the surrounding relays influence the center relay. The condition under which the center relay suffers interference

and the surrounding relays affect the center relay differs depending on whether power is supplied to each relay. Figure

3.8 (3) shows the deviation in percent of the operate and release voltages of the center relays in Figure 3.8 (2).

(1) Mounting pitch (mm) (2) Relay arrangement

[EC2 series]

6 × 2.54

[EE2 series]

6 × 2.54

3 × 2.54

2.54

2.54

10.16

2.54

2.54

ON

ON

ON OFF OFF

OFF

Condition1 Condition2

ON

OFF

Condition3 Condition4

ON

ON

ON

OFF

OFF

OFF

Condition5 Condition6

(3) Deviation of must operate and must release voltages

+20

+10

0

–10

–20

Deviation of Must

Operate Voltage (%)

+20

+10

0

–10

–20

Deviation of Must

Release Voltage (%)

123456

123456

Condition

Condition

Figure 3.8 Magnetic Interference

8

Page 14

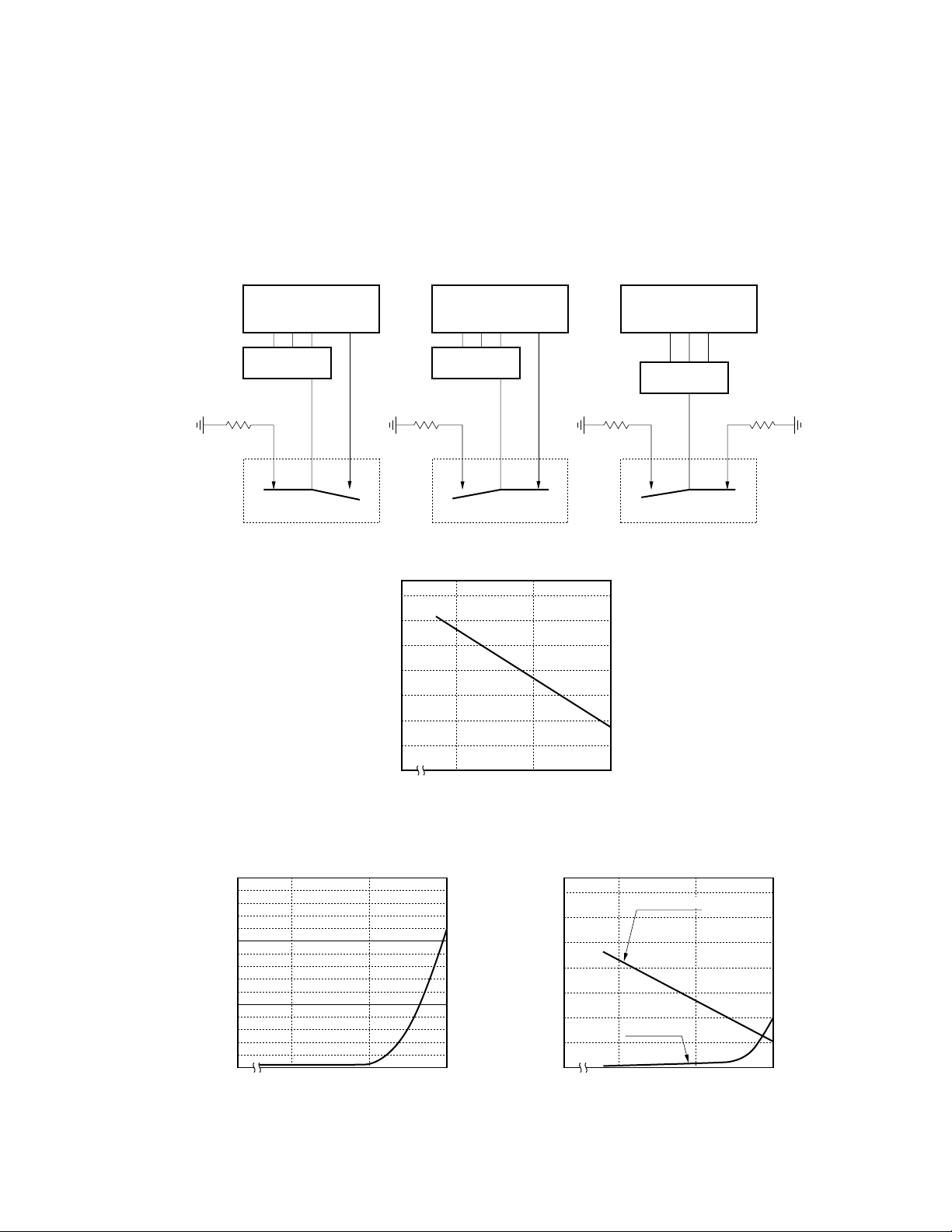

3.9 High-frequency characteristics

Figure 3.9 shows the performance of the EC2 and the EE2 series relays when a high-frequency signal is switched

by the contacts of the relay. Figure 3.9 (1) shows the test circuit. Figure 3.9 (2) shows the isolation loss of the relay.

Figure 3.9 (3) and Figure 3.9 (4) respectively show the insertion loss and return loss.

(1) Test circuit

Test equipment: HP8505A Network Analyzer (characteristic impedance: 50 Ω)

50 Ω

(2) Isolation loss

Isolation Loss

Network Analyzer

Test Set

IN

OUT

50 Ω

70

60

50

40

30

Isolation Loss (dB)

20

10

0

Insertion Loss

Network Analyzer

OUT

Test Set

IN

50 Ω

10 100 1000

Frequency (MHz)

Return Loss

Network Analyzer

IN

Bridge

OUT

50 Ω

(3) Insertion loss (4) Return loss

1.5

1.0

0.5

Insertion Loss (dB)

0

10 100 1000

Frequency (MHz)

70

60

50

40

30

Return Loss (dB)

20

10

0

Figure 3.9 High-frequency characteristics

Return Loss

V. S. W. R.

10 100 1000

Frequency (MHz)

3

2

V. S. W. R.

1

9

Page 15

3.10 Coil inductance

The control input of a relay is the coil. The coil inductance can be measured using the following two methods.

Either method may be used based on preference.

Table 3.1.1 and 3.1.2 show the results of measurement.

3.10.1 Measurement by LCR meter

Table 3.1.1 Coil Inductance

(Unit: mH)

Part Number Part Number Part Number

Non-latching type Inductance Single coil Inductance Double coil Inductance

(Standard type) Latching type Latching type

EC2/EE2-3 30 EC2/EE2-3S 14 EC2/EE2-3T 10

EC2/EE2-4.5 48 EC2/EE2-4.5S 32 EC2/EE2-4.5T 21

EC2/EE2-5 64 EC2/EE2-5S 40 EC2/EE2-5T 26

EC2/EE2-6 83 EC2/EE2-6S 56 EC2/EE2-6T 38

EC2/EE2-9 180 EC2/EE2-9S 130 EC2/EE2-9T 78

EC2/EE2-12 340 EC2/EE2-12S 220 EC2/EE2-12T 135

EC2/EE2-24 868 EC2/EE2-24S 1450 EC2/EE2-24T 825

(Measurement frequency: 1 kHz)

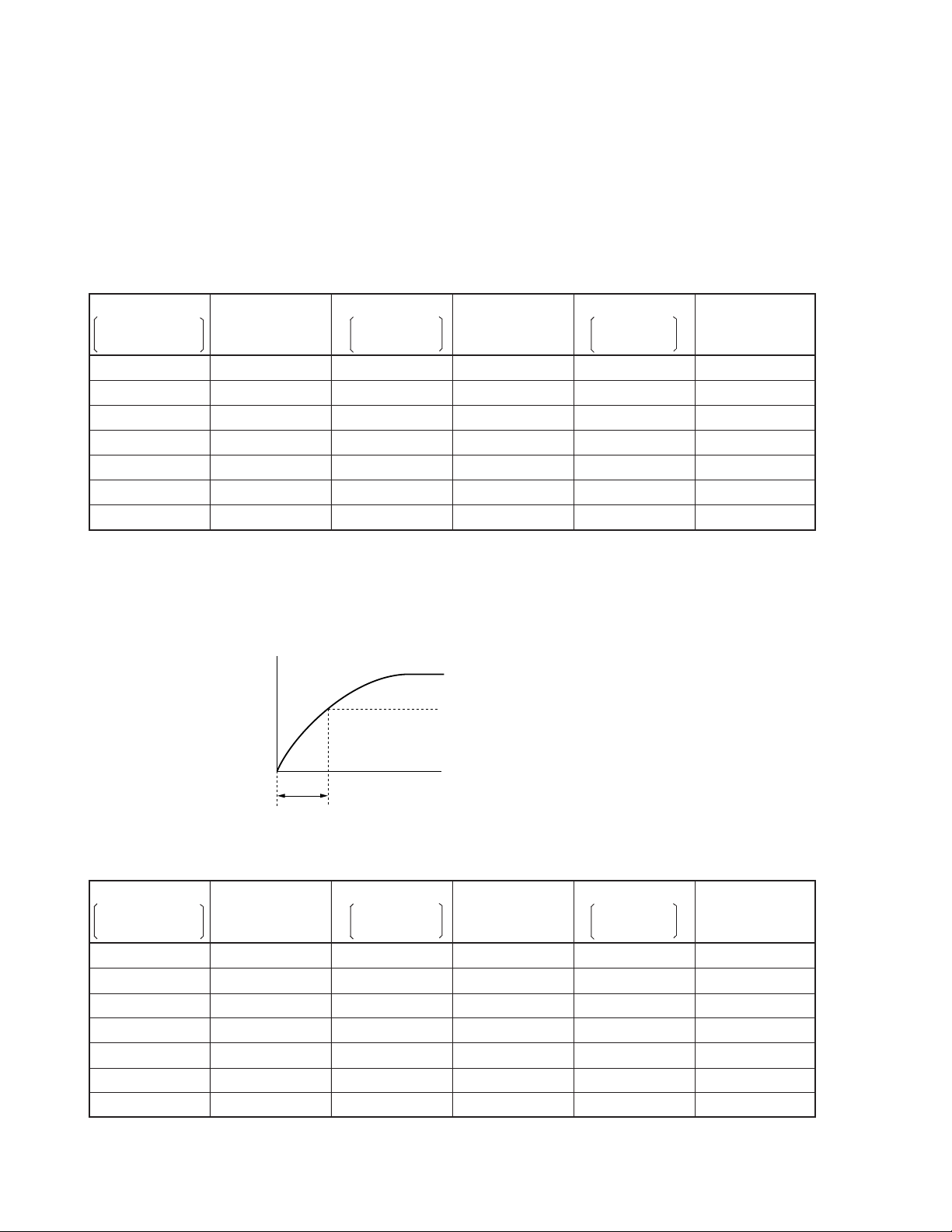

3.10.2 Measurement by coil current waveform

τ

The inductance is calculated by observation of

τ

: Determined by current waveform I = Imax (1 – e

Coil Current

τ

equaling 63.2 % of max value

-t/τ

).

100 %

63.2 %

τ

= × R

L

= Coil resistance

R

= Coil current

I

Time (t)

Table 3.1.2 Coil Inductance

(Unit: mH)

Part Number Part Number Part Number

Non-latching type Inductance Single coil Inductance Double coil Inductance

(Standard type) Latching type Latching type

EC2/EE2-3 19 EC2/EE2-3S 11 EC2/EE2-3T 7

EC2/EE2-4.5 46 EC2/EE2-4.5S 27 EC2/EE2-4.5T 20

EC2/EE2-5 54 EC2/EE2-5S 34 EC2/EE2-5T 23

EC2/EE2-6 88 EC2/EE2-6S 51 EC2/EE2-6T 36

EC2/EE2-9 206 EC2/EE2-9S 120 EC2/EE2-9T 85

EC2/EE2-12 392 EC2/EE2-12S 241 EC2/EE2-12T 151

EC2/EE2-24 983 EC2/EE2-24S 1100 EC2/EE2-24T 820

10

(Applied voltage = Nominal D.C. voltage)

Page 16

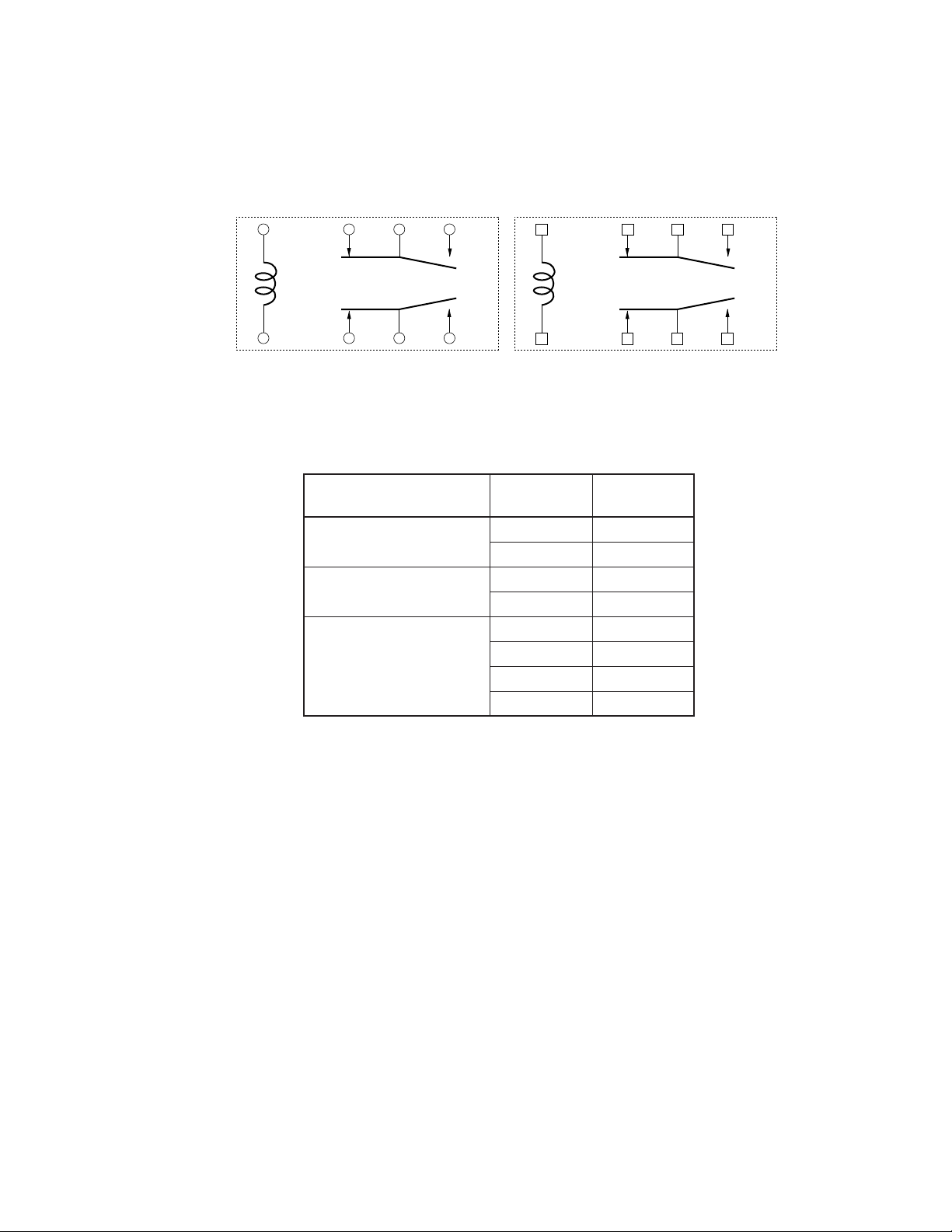

3.11 Capacitance

Table 3.2 shows the capacitance between terminals of the EC2 and the EE2 series relay.

Note that the terminals not tested are left open.

[EC2 series] [EE2 series]

1 345

1 345

12 10 9 8

Internal Connection of Relay (Bottom View)

Table 3.2 Capacitance

Parameter

Between Coil and Contact 1, 4 1.44

Between Opening Contacts 4, 5 0.56

Between Adjacent Contacts 4, 8 0.34

12 10 9 8

(Unit: pF)

Terminal

Number

9, 12 1.45

8, 9 0.57

4, 9 0.64

5, 8 0.19

5, 9 0.34

Capacitance

11

Page 17

3.12 Resistance to surge voltage

When a relay is used in a communication circuit, it may be subjected to a lightning surge via the circuit or due to

induction. A surge voltage test is conducted to measure the resistance of the EC2 and the EE2 series relays to surge

voltage.

(1) Test condition 1

The voltage waveform used for this test is specified by the Federal Communications Commission (FCC) Standard

Part 68.

The EC2 series relay can withstand even if the surge voltage shown in Figure 3.10 is applied (1) between opening

contacts, (2) between coil and contacts, or (3) between adjacent contacts.

MAX

. = 1500 V

V

µ

10 s

V

MAX

.

V

MAX

./2

Voltage (V)

0

µ

160 s

Time

Figure 3.10 Surge Voltage Waveform

(2) Test condition 2

The voltage waveform used for this test is specified by the Bellcore Standard. The EC2 and the EE2 series relay

can withstand even if the surge voltage shown in Figure 3.11 is applied between coil and contact.

2500

2250

1250

250

Voltage (V)

0

2 s

µ

10 s

Time

µ

12

Figure 3.11 Surge Current Waveform

Page 18

3.13 Current surge interrupt test

This test is conducted for the relay used in a communication circuit to evaluate the resistance to abnormally high

current appeared in the case of a touch between the communication circuit and an electric power line.

[Test conditions]

1. Voltage : 700 Vac (50 Hz)

2. Current : 4.2 A

3. Switching times : 4 times (At N.C. contact)

3.14 Resistance to carrying current

If an abnormally high current flows continuously through the closed contacts of the relay for a long time, meltdown

of inner mold of the relay, and large deviation of characteristics may occur.

Figure 3.12 shows the relation between the value of the carrying current at which the relay can operate normally

and time.

100

Meltdown of Inner Mold

50

<Destruction Region>

20

Large Deviation of Characteristics

10

Carrying Current (A)

5

2

10 s 20 s 30 s 40 s 50 s 1 m 2 m 5 m

Time

After Test

Figure 3.12 Resistance to Carrying Current

(Hints on correct use)

Limit the carrying current of the contacts to a maximum of 2 A to maintain the reliability of the relay.

13

Page 19

4. Distribution of Characteristics

This chapter presents the distribution data of the general characteristic values of the EC2 series relay on behalf

of the EC2 and the EE2 series relays, because they are designed with common specifications. The data shown in

this chapter are sampled from a certain production lot, and do not necessarily guarantee the characteristics of any

particular lot that is shipped. The number of samples is 40 relays for each test.

4.1 Operate & release voltages (set & reset voltages)

This section shows the distribution of the voltage at which the relay operates.

(1) Non-latching, 5-V type (EC2-5)

10

5

Number of Samples

0

2.5 3.0

Operate Voltage (V)

(2) Non-latching, 12-V type (EC2-12)

10

5

Number of Samples

0

58

Operate Voltage (V)

10467 9

10

5

Number of Samples

0

10

5

Number of Samples

0

1.0 2.0

Release Voltage (V)

32.5 4.543.5 5

Release Voltage (V)

(3) Latching of single-wound coil, 5-V type (EC2-5S)

10

5

Number of Samples

0

2.0 2.5

Set Voltage (V)

3.0 3.0

Figure 4.1 Operate & Release Voltages

14

10

5

Number of Samples

0

2.0 2.5

Reset Voltage (V)

Page 20

4.2 Operate & release times (set & reset times)

p

)

(ms)

)

)

This section shows the operate time that elapses from the time when the relay coil is energized until the relay

contacts close, and the release time that elapses from the time when the relay coil is deenergized until the closed

contacts open.

The number of samples used for each measurement is 40.

(1) Non-latching, 5-V type (EC2-5)

20

10

Number of Samples

0

O

erate Time (ms

(2) Non-latching, 12-V type (EC2-12)

20

10

Number of Samples

0

2.0 2.5 3.0

Operate Time (ms)

20

10

Number of Samples

0

20

10

Number of Samples

0

2.0 2.5 3.02.0 2.5 3.0

Release Time

2.0 2.5 3.0

Release Time (ms)

(3) Latching of single-wound coil, 5-V type (EC2-5S)

20

10

Number of Samples

0

1.5 2.0 2.5

Set Time (ms

Figure 4.2 Operate & Release Times

20

10

Number of Samples

0

1.5 2.0 2.5

Reset Time (ms

15

Page 21

4.3 Transfer time

p

)

(ms)

)

)

(ms)

(ms)

This section gives data on the transfer time, which is the total time between the breaking of one set of contacts

and the making of another. The number of samples used for each measurement of the transfer time is 40.

(1) Non-latching, 5-V type (EC2-5)

20

10

Number of Samples

0

0.5 1 1.5

O

erate Transfer Time (ms

(2) Non-latching, 12-V type (EC2-12)

20

10

Number of Samples

20

10

Number of Samples

0

Release Transfer Time

20

10

Number of Samples

10.5 1.5

0

0.5 1 1.5 0.5 1 1.5

Operate Transfer Time (ms

(3) Latching of single-wound coil, 5-V type (EC2-5S)

20

10

Number of Samples

0

Set Transfer Time

Figure 4.3 Transfer Times

16

0

Release Transfer Time (ms

20

10

Number of Samples

0

0.5 1.510.5 1.51

Reset Transfer Time

(without diode)

Page 22

4.4 Timing and details

The EC2 and the EE2 series relays have two sets of transfer contacts. This section shows the movements of each

contact, which are not included in the timing specifications, using the timing chart shown in Figure 4.4A.

Coil Voltage

Normally Open

Contact No. 1

Normally Close

Contact No. 1

Normally Open

Contact No. 2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

TOB

Energized

Not Energized

1 THM1 TRM1

TOM

1

TTO1

TOM2 THM2 TRM2

TRB1

THB1

TTR1

Normally Close

Contact No. 2

ON

OFF

TOB2

TRB2 THB2

TTR2

TTO2

COR

COO

Figure 4.4A Timing Chart of Coil and Contacts

(Test results)

The timing specifications show the greater of the values of the two sets of contacts. The time difference between

the two contact sets, however, is almost negligible as shown in data (1) through (8) on the following pages. Practically,

therefore, the time difference can be ignored.

17

Page 23

The following charts show the distribution of timing. Twenty EC2-5’s are used as the samples.

)

)

)

)

(1) On times of make contacts at operation (TOM)

Contact #1

20

10

Number of Samples

0

2.0 2.5

TOM

1

(ms)

(2) Off times of break contacts at operation (TOB)

Contact #1

20

20

10

Number of Samples

0

2.0 2.5

20

Contact #2

TOM

2

(ms)

Contact #2

10

Number of Samples

0

1.0 1.5 2.0 1.0 1.5 2.0

TOB

1

(ms

(3) Off times of make contacts at release (TRM)

Contact #1 Contact #2

20

10

Number of Samples

0

1.0 1.5

TRM

1

(ms

10

Number of Samples

0

20

10

Number of Samples

0

TOB

2

(ms

1.0 1.5

TRM

2

(ms

18

Figure 4.4B Timing

Page 24

(4) On times of break contacts at release (TRB)

)

)

)

)

Contact #1

20

10

Number of samples

0

1.5 2.0 2.5 1.5 2.0 2.5

TRB

1

(ms)

(5) Bounce times of make contacts at operation (THM)

Contact #1

20

20

10

Number of samples

0

20

Contact #2

2

(ms)

TRB

Contact #2

10

Number of samples

0

0.5 1.0

THM1 (ms

(6) Bounce times of break contacts at release (THB)

Contact #1

20

10

Number of samples

0

0.5 1.0

1

(ms

THB

10

Number of samples

0

20

10

Number of samples

0

0.5 1.0

THM2 (ms

Contact #2

0.5 1.0

2

(ms

THB

Figure 4.4C Timing

19

Page 25

(7) Operate transfer times (TTO)

)

)

Contact #1

20

10

Number of Samples

0

1.0 1.5 1.0 1.5

TTO

1

(8) Release transfer times (TTR)

Contact #1

20

(ms)

20

10

Number of Samples

0

20

Contact #2

TTO

2

(ms)

Contact #2

10

Number of Samples

0

(9) Common open times

20

10

Number of Samples

0

10

Number of Samples

0

TTR1 (ms

At operation

20

10

1.0 1.51.0 1.5

TTR2 (ms

At release

Number of Samples

1.0 1.5 1.00.50.5 1.5

COO (ms)

0

COR (ms)

20

Figure 4.4D Timing

Page 26

4.5 Contact resistance

This section gives data on the resistance of the contacts when the contacts are closed. The number of sample

used for measurement of the contact resistance is 40 each.

(1) Non-latching, 5-V type (EC2-5)

20

10

Number of Samples

0

35 40 45

Contact Resistance (mΩ)

(N.O. Contact)

(2) Non-latching, 24-V type (EC2-24)

20

10

Number of Samples

20

10

Number of Samples

0

35 40 45

Contact Resistance (mΩ)

(N.C. Contact)

20

10

Number of Samples

0

35 40 45

Contact Resistance (mΩ)

(N.O. Contact)

(3) Latching of single-wound coil, 5-V type (EC2-5S)

20

10

Number of Samples

0

35 40 45

Contact Resistance (mΩ)

(N.O. Contact)

Figure 4.5 Contact Resistance

0

35 40 45

Contact Resistance (mΩ)

(N.C. Contact)

20

10

Number of Samples

0

35 40 45

Contact Resistance (mΩ)

(N.C. Contact)

21

Page 27

4.6 Breakdown voltage

)

)

µµ

This section gives data on the breakdown voltage between terminals of the EC2 series relay.

(Sample: EC2-5, n = 10 pcs.)

(a) Between open contacts (n = 20)

10

5

Number of Samples

0

1.0 1.5 2.0

10

5

Breakdown Voltage (kV)

(c) Between coil and contacts (n = 20)

(b) Between adjacent contacts (n = 10)

10

5

Number of Samples

0

2.0 2.5 3.0

Breakdown Voltage (kV)

Number of Samples

0

1.5 2.0 2.5

Breakdown Voltage (kV)

Figure 4.6 Breakdown Voltage

4.7 Thermal Electromotive Force (EMF) (offset voltage between contacts)

This section gives data on the thermal EMF which is a voltage that appears when the contacts are closed.

(Sample: EC2-5, number of samples = 10 pcs., number of data = 20)

(a) N.C. contact (not energized)

10

5

Number of Samples

10

5

Number of Samples

(b) N.O. contact (energized)

22

0

0.5 1.0

Thermal EMF ( V

0

0.5 1.0

Thermal EMF ( V

Figure 4.7 Thermal EMF

Page 28

5. Test Data

This chapter shows examples of the results of environmental tests (refer to 5.1 for details) and contact life tests

(refer to 5.2). The table below lists the types of tests, conditions, and data. As the sample, the EC2/EE2-5 and EC2/

EE2-5S are used for the environmental tests, and the EC2-5 is used for the contact life tests.

Table 5 Types of Tests, Conditions, and Data

Test Test Conditions Refer to Page:

Environ- High-temperature test Ambient temperature: +105˚C 24 to 26

mental Duration: 672 hours

test

Contact Non-load test A 25˚C 41

life

test

Low-temperature test Ambient temperature: –40˚C 27, 28

Duration: 672 hours

Moisture resistance test Ambient temperature: –10˚C to +65˚C 29, 30

Humidity: 95% RH, test cycles: 10

Heat shock test Ambient temperature: –55˚C/+85˚C 31, 32

Test cycles: 100

Vibration test

Shock test Waveform: Half sine wave, 75 G max. 35, 36

Resistance to solder Solder temperature: 260 ± 10˚C37

heat test Immersion time: 10 seconds

Resistance to reflow Maximum temperature: 235 ˚C 38, 39

solder heat test Refer to Figure 5.8

Terminal strength Ambient temperature: 25˚C, Tensile strength: 1.36 kg 40

Non-load test B 85˚C 42

Resistive load test A 10 mV, 10 µA, 25˚C42

Amplitude: 1.52 mm, Test time: 2 hours each in X, Y, and Z directions

Frequency: 10 Hz to 500 Hz, Peak acceleration: 20 G

6 Times each in X, Y, and Z directions, totaling 36 times

Number of times of bending: 2

33, 34

Resistive load test B 10 Vdc, 10 mA, 85˚C43

Resistive load test C 28 Vdc, 100 mA, 85˚C43

Resistive load test D 50 Vdc, 100 mA, 25˚C44

Resistive load test E 50 Vdc, 100 mA, 85˚C44

Inductive load test 48 Vdc, 110 mA, 25˚C45

Resistive load test F 220 Vdc, 0.14 A, 25˚C45

Resistive load test G 125 Vdc, 0.5 A, 25˚C46

Resistive load test H 30 Vdc, 1 A, 25˚C46

23

Page 29

5.1 Environmental tests

This section shows the results of environmental tests to be conducted to evaluate the performance of the relay

under specific storage and operating environmental conditions. No abnormality was found after all the tests had been

conducted.

* The operate and release voltages, contact resistance, operate and release times, and transfer time of the sample

before and after each test were compared, but no major change in these parameters was observed, and the sample

still satisfied the initial standard values of the parameters after the test. For details, refer to the graph for each

test.

9

* The initial standard value of the insulation resistance of 10

* The initial standard value of two breakdown voltages of 1500 Vac (between coil and contact), and of 1000 Vac

(between opening contacts, and between adjacent contacts) were satisfied for 1 minute after the test.

* After each test, no abnormality was found in the appearance. The cover of the relay was removed and the internal

mechanism was also inspected visually for dirt, deformation, and other abnormalities, but no such abnormalities

was found.

* After each test, a sealability test was conducted to examine the sealability of the relay by immersing the relay into

a fluorocarbon solution and checking to see if the internal gas of the relay leaked out. No abnormality was observed

as a result of this sealability test.

5.1.1 High-temperature test (test conditions: temperature: +105˚C, duration: 672 hours, sample: 10 pcs. each)

This test was conducted to check whether the performance of the relay is degraded after the relay has been left

at the upper-limit value of the rated ambient temperature for the specified duration.

Ω or higher was still satisfied after the test.

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages

5

4

3

2

1

0

Operate & Release Voltages (V)

Before Test

(c) Operate & release times (d) Transfer times

3

2.5

2

Operate Voltage

Release Voltage

After Test

Operate Time

Release Time

Contact Resistance (mΩ)

200

100

50

20

1.5

1

1

(b) Contact resistances

Before Test

Normally Open (N.O.) Contact

Normally Close (N.C.) Contact

After Test

At Operation

At Release

24

1.5

Operate & Release Times (ms)

0

Before Test

0.5

Transfer Time (ms)

0

After Test After Test

Before Test

Figure 5.1 (1) High-temperature Test

Page 30

(2) Latching of single-wound coil, 5-V type

(a) Set & reset voltages

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

(b) Contact resistances

Set Voltage

Reset Voltage

After Test

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After Test

At Set

At Reset

Figure 5.1 (2) High-temperature Test

25

Page 31

[EE2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages

5

4

3

2

1

0

Operate & Release Voltages (V)

Before Test

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

Operate & Release Times (ms)

0

Before Test

(b) Contact resistances

Operate Voltage

Release Voltage

After Test

Operate Time

Release Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

1

1.5

1

0.5

Transfer Time (ms)

0

Before Test

Normally Open (N.O.) Contact

Normally Close (N.C.) Contact

After Test

At Operation

At Release

Figure 5.1 (3) High-temperature Test

(2) Latching of single-wound coil, 5-V type

(a) Set & reset voltages

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

After Test

Set Time

Reset Time

After Test After Test

Figure 5.1 (4) High-temperature Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

(b) Contact resistances

N.O. Contact

N.C. Contact

After Test

At Set

At Reset

26

Page 32

5.1.2 Low-temperature test (test conditions: temperature: –40˚C, duration: 672 hours, sample: 10 pcs. each)

This test is conducted to check whether the performance of the relay is degraded after the relay has been left at

the lower-limit value of the rated ambient temperature for the specified duration.

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.2 (1) Low-temperature Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

1

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

Figure 5.2 (2) Low-temperature Test

27

Page 33

[EE2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.2 (3) Low-temperature Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

1

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

Figure 5.2 (4) Low-temperature Test

28

Page 34

5.1.3 Moisture resistance test (test conditions: temperature: –10 ˚C to 65˚C, humidity: 90 to 98% RH, test cycles:

10, sample: 10 pcs. each)

This test is conducted to check whether the performance of the relay is degraded after the relay has been left in

a highly humid atmosphere for the specified duration.

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

1

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.3 (1) Moisture Resistance Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

Figure 5.3 (2) Moisture Resistance Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

29

Page 35

[EE2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

1

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.3 (3) Moisture Resistance Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

Figure 5.3 (4) Moisture Resistance Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

30

Page 36

5.1.4 Heat shock test (test conditions: temperature: –55˚C to 85˚C, test cycles: 100, sample: 10 pcs, each)

This test is to check whether the performance of the relay is degraded if the ambient temperature abruptly changes.

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.4 (1) Heat Shock Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

1

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

Figure 5.4 (2) Heat Shock Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

After Test

31

Page 37

[EE2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.4 (3) Heat Shock Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

1

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

Figure 5.4 (4) Heat Shock Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

After Test

32

Page 38

5.1.5 Vibration test (test conditions: amplitude: 1.52 mm, frequency: 10 Hz to 500 Hz, 20 G peak, test time:

2 hours each in X, Y, and Z directions, totaling 6 hours, sample: 10 pcs. each)

This test is conducted to check whether the performance of the relay is degraded after vibration is continuously

applied to the relay while the relay is being transported.

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

(2) Latching of single-wound coil, 5-V

N.O. Contact

200

100

50

20

Contact Resistance (mΩ)

Before Test

Operate Time

Release Time

After Test After Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.C. Contact

After TestAfter Test

At Operation

At Release

Figure 5.5 (1) Vibration Test

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

2

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

1

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

Figure 5.5 (2) Vibration Test

33

Page 39

[EE2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

(2) Latching of single-wound coil, 5-V

N.O. Contact

200

100

50

20

Contact Resistance (mΩ)

Before Test

Operate Time

Release Time

After Test After Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.C. Contact

After TestAfter Test

At Operation

At Release

Figure 5.5 (3) Vibration Test

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

2

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

1

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

Figure 5.5 (4) Vibration Test

34

Page 40

5.1.6 Shock test (test conditions: waveform: half sine wave, peak acceleration: 75 G, 6 times each in X, Y, and

Z directions, totaling 36 times, sample: 10 pcs. each)

This test is conducted to check whether the performance of the relay is degraded after an abrupt shock is applied

to the relay while the relay is being transported.

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2

1

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.6 (1) Shock Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

1

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Set

At Reset

Figure 5.6 (2) Shock Test

35

Page 41

[EE2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2

1

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.6 (3) Shock Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

1

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Set

At Reset

Figure 5.6 (4) Shock Test

36

Page 42

5.1.7 Resistance to solder heat test (test conditions: solder temperature = 260 ± 10˚C, immersion time: 10

seconds, sample: 10 pcs. each)

This test is conducted to check whether the performance of the relay is degraded after the relay has been exposed

to heat when it is soldered to a printed circuit board (PCB).

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times

3

2.5

2

1.5

1

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.7 (1) Resistance to Solder Heat Test

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

(d) Transfer times

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

3

2.5

2

1.5

Set & Reset Times (ms)

0

Before Test

Figure 5.7 (2) Resistance to Solder Heat Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

37

Page 43

5.1.8 Resistance to reflow solder heat test

This test is conducted to check whether the performance of the relay is degraded after the relay has been exposed

to heat when it is soldered to a printed circuit board (PCB).

Test condition:

<1> Soldering method: IRS (Infrared Ray Soldering)

<2> PCB: Material epoxy-glass

Thickness 1.6 mm

Size 25 × 30 cm

<3> Temperature measurement point: Printed circuit board surface near the relay terminals

<4> Temperature profile: Refer to Figure 5.8

Tmax.: 235

200

175

150

Temperature (˚C)

30 sec.

200 sec.

80 sec.

Figure 5.8 Temperature Profiles

38

Page 44

[EE2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Before Test

(c) Operate & release times (d) Transfer times

3

2

1

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.8 (1) Resistance to Reflow Solder Heat

(2) Latching of single-wound coil, 5-V type

100

50

20

10

Contact Resistance (mΩ)

Before Test

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

2

1

Set & Reset Times (ms)

0

Before Test

Figure 5.8 (2) Resistance to Reflow Solder Heat

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

100

50

20

10

Contact Resistance (mΩ)

Before Test

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Set

At Reset

39

Page 45

5.1.9 Terminal strength test (test conditions: ambient temperature: 25˚C, tensile strength: 1.36 kg, number of

times of bending: 2, sample: 10 pcs. each)

The purpose of this test is to check whether the performance of the relay is degraded after an excessive force

is applied to the terminals of the relay when the relay is mounted on a PCB.

[EC2 series]

(1) Non-latching, 5-V type

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Before Test

Operate & Release Voltages (V)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Before Test

Operate Voltage

Release Voltage

Operate Time

Release Time

After Test After Test

Figure 5.9 (1) Terminal Strength

(2) Latching of single-wound coil, 5-V type

200

100

50

20

Contact Resistance (mΩ)

Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N. O. Contact

N. C. Contact

After TestAfter Test

At Operation

At Release

40

(a) Set & reset voltages (b) Contact resistances

5

4

3

2

1

Set & Reset Voltages (V)

0

Before Test

(c) Set & reset times (d) Transfer times

2

2.5

1

1.5

Set & Reset Times (ms)

0

Before Test

Set Voltage

Reset Voltage

Set Time

Reset Time

After Test After Test

200

100

50

20

Contact Resistance (mΩ)

Before Test

1

1.5

1

0.5

Transfer Time (ms)

0

Before Test

N.O. Contact

N.C. Contact

After TestAfter Test

At Operation

At Release

Figure 5.9 (2) Terminal Strength

Page 46

5.2 Contact life tests

p

This section shows the results of tests conducted to examine the service life of the contacts, which has a significant

influence on the life of the relay.

To test the service life of the contacts, the operate and release voltages, contact resistance, operate and release

times, and transfer time of each relay is measured each time the relay has performed the specified number of

operations under the specified conditions.

The service life of contacts of the EC2 series relay is equal to the one of the EE2 series relay, because they have

common structure.

For changes in the characteristics, refer to the graphs shown below.

5.2.1 Non-load test A (driving frequency: 50 Hz, ambient temperature: +25˚C, sample: 10 non-latching types

(rated at 5 V))

The cleanness of the contact surfaces influences the result of this test because no electric load is applied to the

relay.

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Number of Operations (×107 Times)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

1

Operate & Release Times (ms)

Number of Operations (×107 Times)

Operate Voltage

Release Voltage

510Before Test

510Before Test

200

100

50

20

Contact Resistance (mΩ)

0

Number of Operations (×10

Operate Time

Release Time

2

1.5

1

0.5

Transfer Time (ms)

0

Number of O

Figure 5.10 Non-load Test A

N.O. Contact

N.C. Contact

510Before Test

510Before Test

erations (×107 Times)

7

Times)

At Operation

At Release

41

Page 47

5.2.2 Non-load test B (driving frequency: 50 Hz, ambient temperature: +85˚C, sample: 10 non-latching types

p

)

(rated at 5 V))

The conditions of this test are more stringent than those of the test in 5.2.1 because the relay is exposed to a higher

ambient temperature and consequently organic gas is more likely to be generated inside the relay housing.

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Number of Operations (×107 Times)

Operate Voltage

Release Voltage

510Before Test

200

100

50

20

Contact Resistance (mΩ)

0

Number of Operations (×10

(c) Operate & release times (d) Transfer times

3

2

1

0

Operate & Release Times (ms)

Number of Operations (×107 Times)

Operate Time

Release Time

510Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Number of O

N.O. Contact

N.C. Contact

510Before Test

510Before Test

erations (×107 Times

7

Times)

At Operation

At Release

Figure 5.11 Non-load Test B

µ

5.2.3 Resistive load test A (contact load: 10 mVdc, 10

A, resistive, driving frequency: 25 Hz, ambient

temperature: +25˚C, sample: 10 non-latching types (rated at 5 V))

This test is conducted with the relay under the minimum applied load condition.

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Number of Operations (×107 Times)

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Number of Operations (×107 Times)

Operate Voltage

Release Voltage

510Before Test

Operate Time

Release Time

510Before Test

200

100

50

20

Contact Resistance (mΩ)

0

Number of Operations (×10

2

1.5

1

0.5

Transfer Time (ms)

0

Number of Operations (×10

N.O. Contact

N.C. Contact

510Before Test

At Operation

At Release

510Before Test

7

Times)

7

Times)

42

Figure 5.12 Resistive Load Test A

Page 48

5.2.4 Resistive load test B (contact load: 10 Vdc, 10 mA, resistive, driving frequency: 2 Hz, ambient temperature:

p

)

+85˚C, sample: 10 non-latching types (rated at 5 V))

This test is conducted with a load equivalent to the signal level of an IC applied to the relay.

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Number of Operations (×105 Times)

Operate Voltage

Release Voltage

510Before Test

(c) Operate & release times (d) Transfer times

3

2.5

2

1.5

0

Operate & Release Times (ms)

Number of Operations (×105 Times)

510Before Test

Operate Time

Release Time

200

100

50

20

Contact Resistance (mΩ)

0

Number of Operations (×10

1

1.5

1

0.5

Transfer Time (ms)

0

Number of Operations (×10

N.O. Contact

N.C. Contact

510Before Test

At Operation

At Release

510Before Test

5

Times)

5

Times)

Figure 5.13 Resistive Load Test B

5.2.5 Resistive load test C (contact load: 28 Vdc, 100 mA, resistive, driving frequency: 2 Hz, ambient tempera-

ture: +85˚C, sample: 10 non-latching types (rated at 5 V))

This test is conducted with a load of medium level applied to the relay contacts.

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Number of Operations (×105 Times)

Operate Voltage

Release Voltage

25Before Test

100

50

20

10

Contact Resistance (mΩ)

0

Number of Operations (×10

(c) Operate & release times (d) Transfer times

Operate Time

3

2.5

2

1.5

0

Operate & Release Times (ms)

Number of Operations (×105 Times)

Release Time

25Before Test

1

1.5

1

0.5

Transfer Time (ms)

0

Number of O

N.O. Contact

N.C. Contact

25Before Test

25Before Test

erations (×105 Times

5

Times)

At Operation

At Release

Figure 5.14 Resistive Load Test C

43

Page 49

5.2.6 Resistive load test D (contact load: 50 Vdc, 100 mA, resistive, driving frequency: 5 Hz, ambient tempera-

p

)

ture: +25˚C, sample: 10 non-latching types (rated at 5 V))

The load conditions of this test are equivalent to the voltage and current levels of a public telephone circuit.

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Number of Operations (×105 Times)

Operate Voltage

Release Voltage

510Before Test

200

100

50

20

Contact Resistance (mΩ)

0

Number of Operations (×10

(c) Operate & release times (d) Transfer times

Operate Time

3

2.5

2

1.5

0

Operate & Release Times (ms)

Number of Operations (×105 Times)

Release Time

510Before Test

2

1.5

1

0.5

Transfer Time (ms)

0

Number of Operations (×10

N.O. Contact

N.C. Contact

510Before Test

At Operation

At Release

510Before Test

5

Times)

5

Times)

Figure 5.15 Resistive Load Test D

5.2.7 Resistive load test E (contact load: 50 Vdc, 100 mA, resistive, driving frequency: 5 Hz, ambient temperature:

+85˚C, sample: 10 non-latching types (rated at 5 V))

The conditions of this test are more stringent for the relay than those in 5.2.6 above because the ambient

temperature is higher.

(a) Operate & release voltages (b) Contact resistances

5

4

3

2

1

0

Operate & Release Voltages (V)

Number of Operations (×105 Times)

Operate Voltage

Release Voltage

510Before Test

(c) Operate & release times (d) Transfer times

3

2.5

1

1.5

0

Operate & Release Times (ms)

Number of Operations (×105 Times)

510Before Test

Operate Time

Release Time

200

100

50

20

Contact Resistance (mΩ)

0

Number of Operations (×10

2

1.5

1

0.5

Transfer Time (ms)

0

Number of O

N.O. Contact

N.C. Contact

510Before Test

510Before Test

erations (×105 Times

5

Times)

At Operation

At Release

44

Figure 5.16 Resistive Load Test E

Page 50

5.2.8 Inductive load test (contact load: 48 Vdc, 110 mA, inductive load by wire spring relay, driving frequency:

p

)

2 Hz, ambient temperature: +25˚C, sample: 10 non-latching types (rated at 5 V))