Page 1

Page 2

Page 3

SP-A310

Service & Parts Manual

September 1996

Revision C-02

+-’

Page 4

Page 5

WARNING LABELS

-

i

Page 6

SAFETY

ALL Areas

INFORMATlON

.

INTERNAL LASER RADIATION

Maximum radiation power: 8.8 x

lo4 (W)

Wavelength: 770-8 10 MI

This is a Class

Bib

Laser Diode Assy. that has an invisible Laser Beam. The Print Head

Unit is NOT A FIELD SERVICE ITEM. Therefore, the Print Head Unit should not be

opened under any circumstances.

U.S.A. Only

LASER SAFETY

This LBP printer is certified as a Class 1 laser product under the U.S. Department of Health

and Human Services

(DHHS)

Radiation Performance Standard according to the Food, Drug

and Cosmetic Act of 1990. This means that the LBP printer does not produce hazardous laser

radiation.

Since radiation emitted inside the LBP printer is completely confined within protective

housing and external covers, the laser beam cannot escape from the LBP printer during

any phase of user operation.

CDRH REGULATIONS

The Center for Devices and

R&ological

Health (CDRH) of the U.S. Food and Drug

Administration implemented regulations for laser products on August 2, 1976. These

regulations apply to laser products manufactured from August 1, 1976. Compliance is

mandatory for products marketed in the United States. The label shown in the figure

indicates compliance with the CDRH regulations and must be attached to laser products

marketed in the United States-.

CLASSIFICATION OF THE LASER PRODUCT

This product is classified as a Class 1 Laser Product under the CDRH Regulations U.S.A..

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Discard

used

batteries according to manufacture’s instructions.

ii

Page 7

Denmark Only

Norway Only

Sweden Only

-.

(

.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved

Udskifining m4

kun ske med

batteri af samme

Lever det brugte batter-i tilbage

fejlagtig

til leverandoren.

ADVARSEL

Lithiumbatteri-Bksplosjonsfare.

Ved

utskifting

Brukt batteri

benyttes kun batter-i som anbefalt av apparatfabrikanten.

retumeres

apparatleverand@ren.

VARNING

Explosionsfara

AMind samma

typ

som rekommenderas av

Kassera anvXnt

vid felaktigt

batterityp

bat&byte.

eller

en ekvivalent

apparativerkaren.

batter-i enligt fabrikantens

VARNING!

Osynlig

Behakta ej

laserstr&ting

St&en.

n3r denna de1 ar oppnad

hhdtering.

fabrikat og type.

in&&ion.

och

sp&-ren 2r

urkopplad.

.,

1-

Finland Only

VAROITIJS

Pristo voi

Vaihda

tyyppiin. H&vita tiytetty paristo valmistajan

r&jahM

jos se on

virheellisesti asennettu.

paristo ainoastaan laitevalmistajan suosittelemaan

ohjeiden

mukaisesti.

VARO!

Avattaessa ja suojalulcitus

&4

katso

sateeseen.

ohitettasessa

olet

ahtiina n&ymatt(lmtie lasersateilylle.

New Zealand Only

Warning

“Immediately disconnect the equipment should it become physically damaged, and arrange

for its disposal or repair before reconnecting.”

“Disconnect the Telecom Network connection before disconnecting the Power connection

prior to relocating the equipment, and reconnect the Poker first.”

User Instruction (For all users)

The outlet should be located near the printer and should be easily accessible.

. . .

III

Page 8

>,.--

)‘ 1

_-

.

Please read the following for your own protection.

C

A

I

Opening the cover indicated by the

harmful laser radiation which could cause damage or loss of eyesight. Do

Open the Cover

when the power is on.

Caution

Caution

label below may expose you to

1

not

iv

Page 9

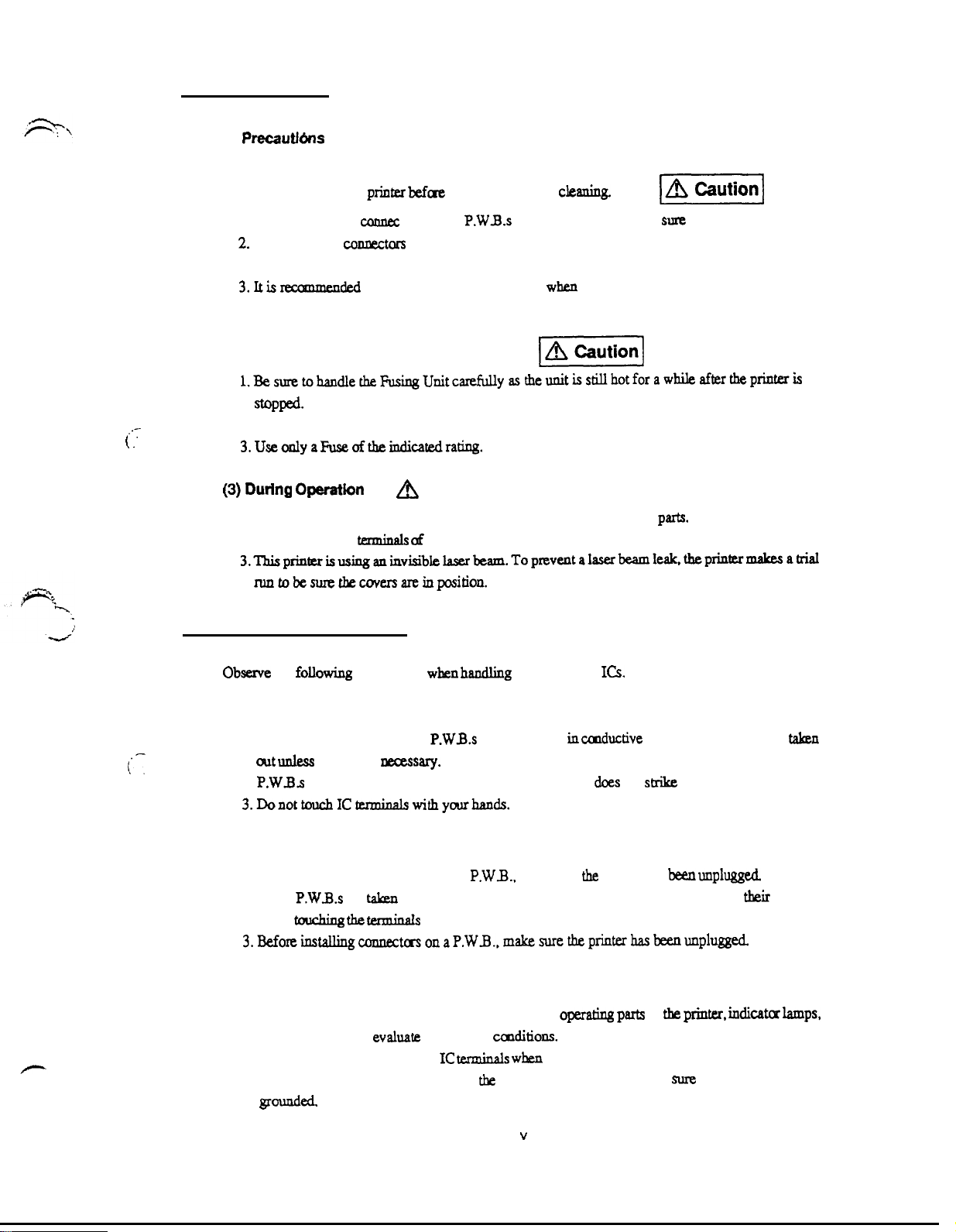

PRECAUTIONS

(1)

Precautlbns

Refer to D: DISASSEMBLY/

Be sure to unplug the

1. When unplugging

2.

Always unplug conrxctors by holding the connector housing. Pulling on the power cord can lead

printer

ccumec

CLEANING for the Disassembly procedure.

befcre disassembling and

cleauing.

pczzi&q

tors on the P.WI3.s themselves, always make

sum

the power is OFF first.

to problems with poor contact.

3.Itisrec

canmended

that a body ground not be used when carrying out any trouble-shooting

procedure. Be sure to ground DC lines to a ground test point on the P.W.B.

(2) At Replacement/ Adjustment/ Cleaning

pGiq

l.BesuretohandletheFusingUnitcarefullyastheunitisstillhotforawhileafbertheprinteris

stopped-

2.

;-

t

:

Do not disassemble the Imaging Cartridge or the Print Head Unit

3.UseonlyaPuseoftheindicatedrating.

(3) During

Operation

A

Caution

1. Keep your hands. clothing, etc. well away from operating or rotating

2.

Never touch the

temhals d

electrical parts or high voltage parts.

parts.

3.Thisprinbuisusinganinvisiblelaserbeam.Topleventalaserbeamleak.theprintermaLesatri~

runtobesurethecoversarein@tion.

HANDLING THE P.W.B.

Observe

(1)

i:

the folIowing precautions when handling a P.W.B. with

ICs.

During Transportation/ Storage

1. During transport and storage,

out

lmkss

2.

P.WBs

absolutely

should be stored in a place where direct sunlight

rEce.ssary.

P.WB.s

should be kept

incarductive

does

not

bags or on mats and not

strike

3.Don0ttouch1Ctermin&withyourhands.

(2) At Replacement

1. Before removing connectors from a

2. When

P.WB.s

avoid touching

are

taken

the term&Is

out of their conductive bags or off their mats, hold them by

or the patterned surfaces.

P.WB..

make sure

the

printer has been ~npluggcd

3.BeforeinstallingumnectcrsonaP.WB..makesuretheprinterhasbeenunplugged.

(3)

At Inspection

1. Avoid checking a P.WB. with testers; instead, use

and other means to evaluate operational

2.

Be careful not to short-circuit IC

3. If it is necessary to touch elements on

umditions.

terminals when

the

P.W.B. with your hand, make

operating pa.tQ

of

using metal instruments or screws.

5&d

them.

t&sir

the

printer. mdicatrx

sure

your body is properly

taken

edges to

ktrps,

V

Page 10

CONTENTS

A: PRODUCT INSTALLATION

1.

PRECAUITON FOR INSTALLATION ......................................................................................

l-l. Installation Site

1-2.

Ekonmental

l-3.

Power

Rquirements ...........................................................................................................

...................................................................................................................

Requirementi

.............................................................................................

A- 1

A-l

A-l

A-l

2.

INSTALLATION .........................................................................................................................

2-l.

cannectioa

2-2.

space Requirements

..........................................................................................................................

............................................................................................................

A- 1

A-l

A-2

B: GENERAL INFORMATION

1.

SPECIFICATIONS

2.

PARTS IDENTIFICATION ......................................................................................................... B-3

3. COMPONENT LAYOUT ............................................................................................................ B-4

4. GEARS/ ROLLERS ASSIGNMENT .......................................................................................... B-5

5.

ELECTRICAL CfX4POMENT

6.

CONNEcroRs

7.

SWlXElES/

8.

ELECl.RlCAL

9.

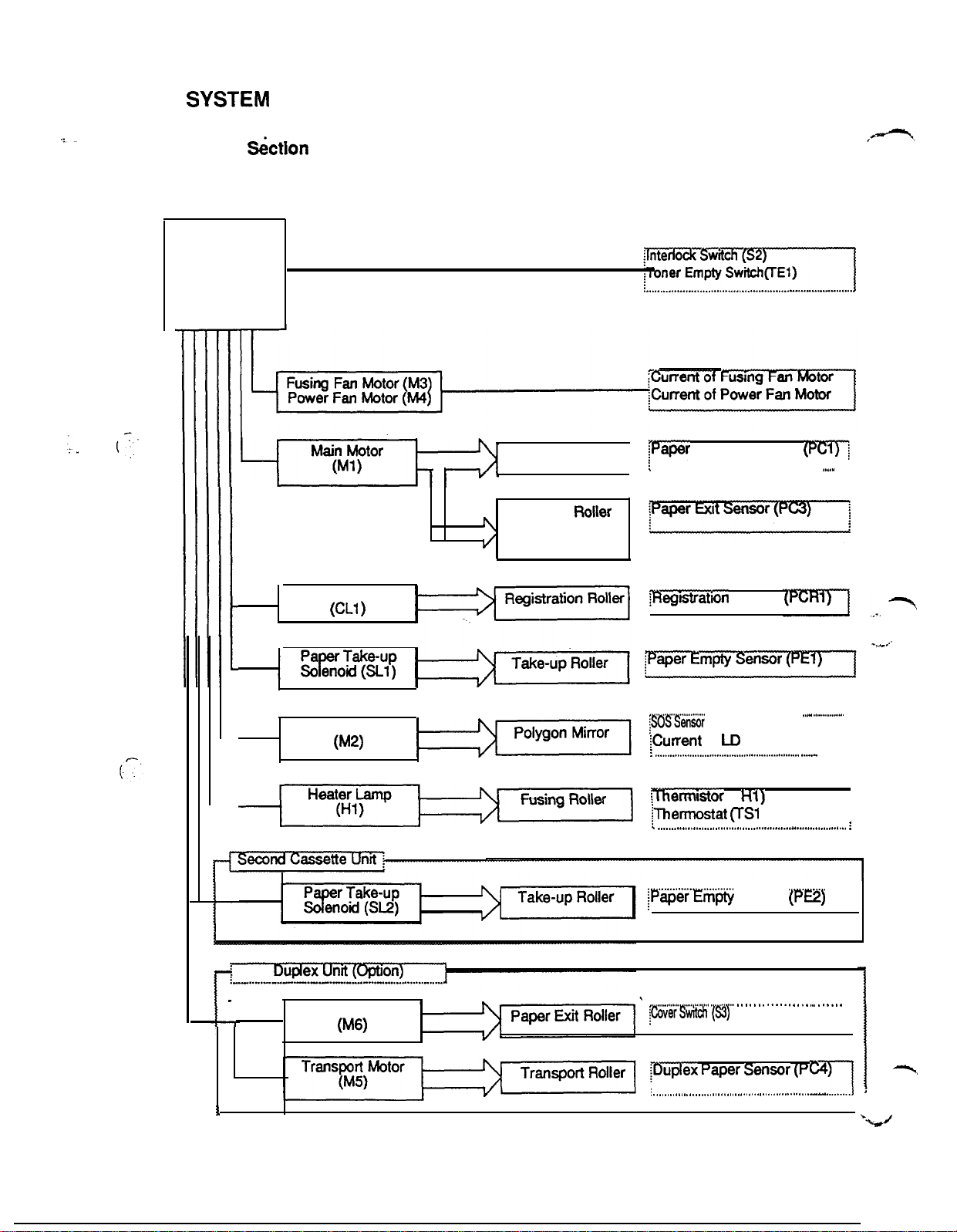

SYSTEM

9-l. Drive Se&m

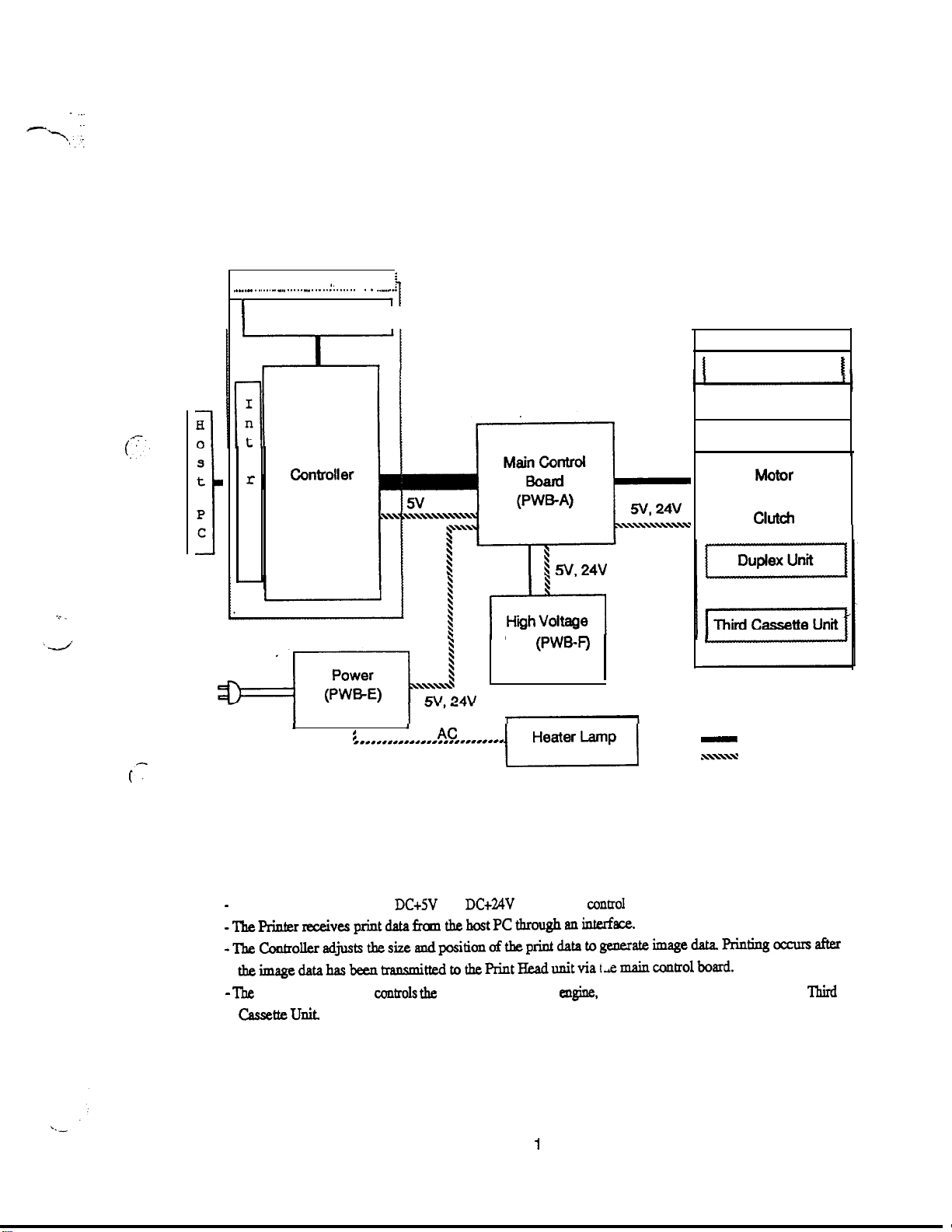

9-2.ElectridSection

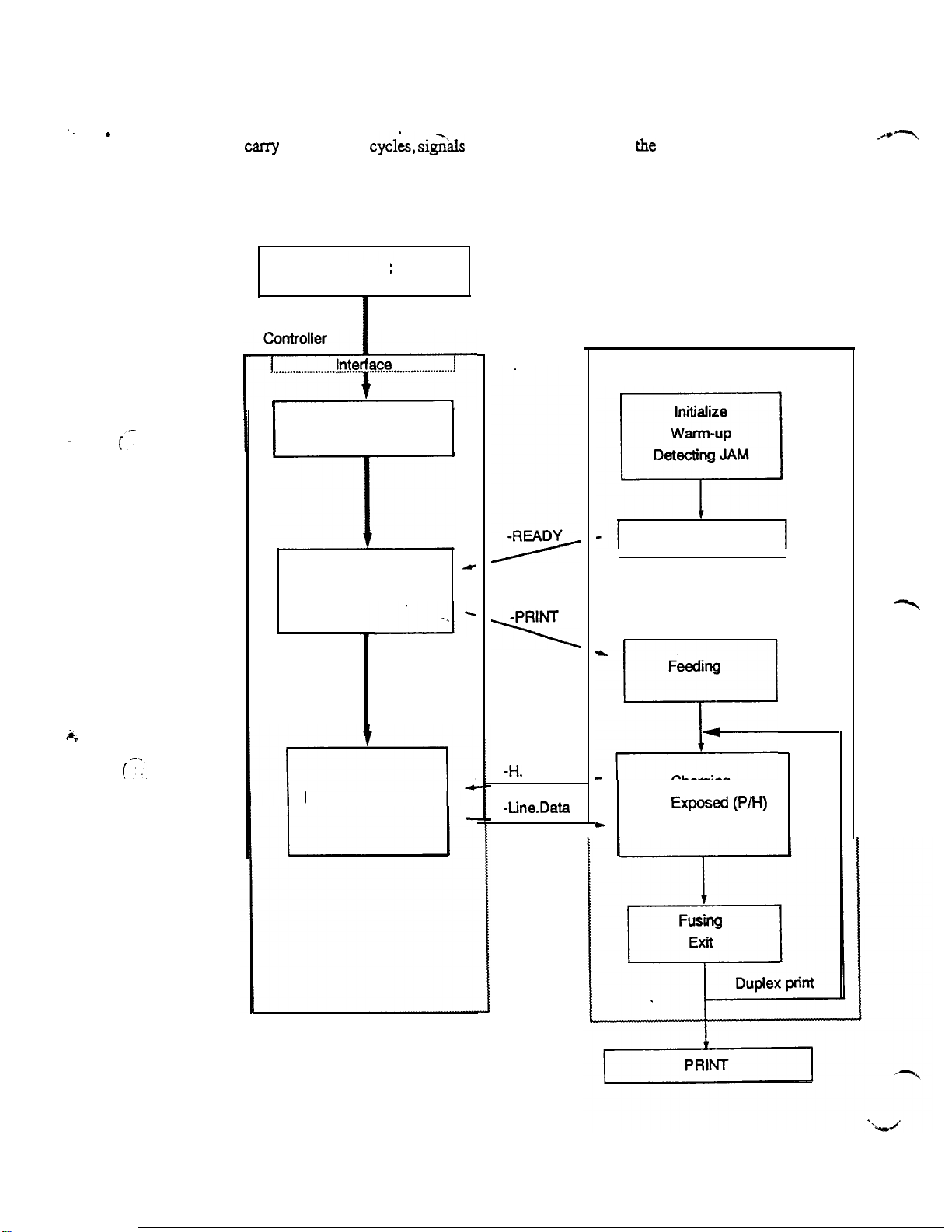

10. SEQUENCE FLOW

SENSORS IDEN’IlFICA&N

LAYOUT

......................................................................................................................

LAYOUT

LAYOUT

SERVICE

........................................

PARTS

...................................................................................................................

....................................................................................................................

................................................................

.................................................................................................................. B-12

..................................................................................

ON P. W.

.

.................................................................

....................................................... ........... B-8

BOARDS

..............................................................

..-

.......................................... B-11

$. _,

:a..

B-l

B-6

B-7

B-9

B-10

B-10

11.

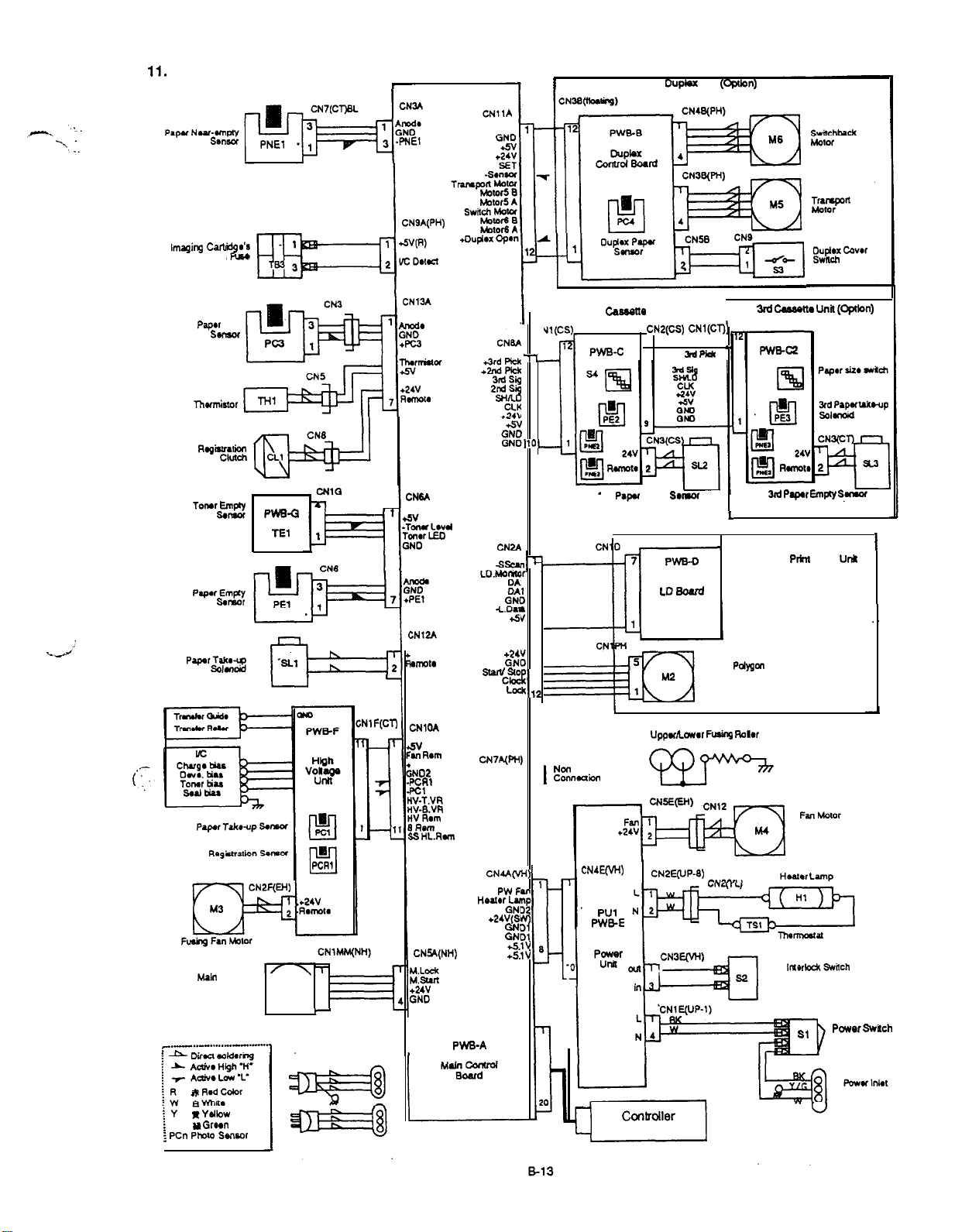

CIRCUITDIAGRAM ..............................................................................................................

vi

B-13

Page 11

C: MECHANICAL/ ELECTRICAL

1.

PRINTING

2.

PAPER

PROCESS

FEfZDlNG

2-1. Multi-purpose Tray

2-2.

second

Cassette

3. IMAGING CARTRIDGE

4. CHARGING

5.

ExPosuRE cP/Hl

6.

DEVELOPMENT

7.TRANsFER

8.

FUSING

.................................................................................................................................

..................................................................................................................................

........................................................................................................................................

9. PAPER EXIT/ DUPLEX

.-

(

:

9.1. Paper Exit

9-2. Duplex (Option)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................................................................................................................

.............................................................................................................

..........................................................................................................

Tray

............................................................................................................

........................................................................................................................

.........................................................................................................................

..............................................................................................................

............................................................................................................................

..................................................................................................................

10. PRINTING SEQUENCE ...................................................

l&l. sriuting seqmnce

10-2.

Multiple sequence .............................................................................................................

10-3.

Fkdiug sequeuce ...............................................................................................................

104.

Duplex SeqEnce

10-S.

PowerONsequence

..............................................................................................................

.............................................................................................................

........................................................................................................

.

C-l

,*

C-2

c-2

c-3

C4

c-5

c-5

C-6

C-6

c-7

C-8

C-8

C-8

’

.........................................................

c-9

c-9

C-9

-

c-9

c-10

c-10

D: DISASSEMBLY/ CLEANING

1.

MAINTENANCE/ INSPECTION ...............................................................................................

l-l.

Replacement

1-2.

cbauiug Parts

1-3. Required

s-

(

2.

DISASSDlBLY PROCE5DURE

2-1.

Outer

2-2. Fusing unit

2-3.

Image Traasfer Unit

24. High Voltage Unit

2-5. Power unit

2-6. Print Head Unit

2-7.

Paper Empty

2-8. Paper Take-up Roll Assy.

2-9. Registration Roller

2-

10. Drive Unit

2-11.Dup1exunit

of Parts

..........................................................................................................

.....................................................................................................................

Send

.......................................................................................................

Tools

..................................................................................................

........................................................................................................................

cover

........................................................

...........................................

..”

................

.

............................................................................................................

...............................................................................................................D-6

..........................................................................................................................

...................................................................................................................

Sensor

Assy. ..................................................................................................

...................................................................................................

......................................................................................................

by

.......................................................................................................................

......................................................................................................................

D-l

D-l

D-l

D-l

D-2

D-2

D-2

D-6

D-7

D-7

D-8

D-8

D-8

D-9

D-9

vii

Page 12

E: ADJUSTMENT

1. IMAGE REGISTRATION . . . . . . . . . . . . . . . . .

.

,~,,.......,“,.............................,..............................................

E-l

F: TROUBLE-SHOOTING

1.

TROUBLE DETECTION

l-l. JAMDetection

1-2.

Fusing

unit

nlaanaion

l-3.W mahnction

l-4. Polygon Motor malfimction

............................................................................................................

.....................................................................................................................

.....................................................................................................

................................................................................................................

................................................................................................F-2

l-5. Fan Motar malfunction .......................................................................................................

l-6. Main Motor malfunction

2. AClTON FOR

2-1. JAM1

-.

t

”

2-2. JAM2 ..................................................................................................................................

2-3. JAh43

2-4.

JAM4

2-S.

Fusing

2-6. Laser

2-7.

Polygon

DETECTED

..................................................................................................................................

..................................................................................................................................

.................................................................................................................................

unit

IIlahndal

malfuoctoo

Motcx

malfunction

2-8. Fan Motor malfunction

2-9. Main Motor

m-on

....................................................................................................

JAM OR

MALILJNCI’ION ............................................................

.

.....................................................................................................

...............................................................................................................

...............................................................................................

..-

................................................................

...................................

-....................................................................................................

.F-

F-l

E2

F-2

P2

z-2

F-3

F-3

J?-3

.F4

.F4

ES

ES

s-5

T-5

J-5

1

(.--

3. Ol-HER

..

DETECTED TROUBLE

3-1.

3-2.

NoPower

Skew

.............................

........................................

4. IMAGE QUALlTY TROUBLE

Black/ White lines

IJtdmlltal

lines

LowimageDensity

Fogsyb=kground

No Image

(Hank/

.....................................................................................................................

......................................................................................

...................................................................................................................

...................................................................................................................

Black)

................................................................................................

.“.....:

..........................................................................................F-6

.

.............................................................................

...................................................................................................

.;.

................................

...........................................................................................................

Offset Image .............................................................................................................................

F-6

F-6

.F-7

“F-7

P-7

.F-7

F-7

F-8

.F-8

VIII

. . .

Page 13

A: PRODUCT INSTALLATION

(-

1.

PREC]AlJTION

l-l.

Jnstallation

l-2.lzLwirm

l-3.

Power Req

2. INSTALLATION

2-1.

Gmuection

2-2. space

FOR

Site

td

uirements

.........................................................................................................................

..........................................................................................................................

Requirements

NjlXlLATION

...................................................................................................................

llequireme~ts

...........................................................................................................

...........................................................................................................

......................................................................................

.............................................................................................

A- 1

A-l

A-l

A-l

A-l

A-l

A-2

Page 14

1. PRECAUTION FOR INSTALLATION

-Y

l-l. Installation Site

’

-

.- .:

.

( -..

When installing the printer, please avoid

considerations and to avoid breakdowns.

-

Which is exposed to direct sunlight.

-

Which is damp or dusty.

-

Where it may be splashed with water.

-

Which is tilted or subject to undue vibratlon.

-

Where it will be subject to extremely high or low temperature or humidity.

-

Where it will be subject to sudden fluctuations In either temperature or humidlty.

-

Which is near volatile flammables or corrosive gas

-

Which is in the

-

Which Is near a IV set or radio.

direct

air stream of an air conditioner, heater, or ventilator.

the

1-2. Environmental Requirements

In order to make sure

saiis6esthefollawingn4uirements:

TemperahUt?

Humidity

Height

the

printer functions in good

lOto350C

15to85%RH

o-2500m

-..

types of locations listed

conditi~

Temperaturektuation rtl~Cperhourculess

Humidity fluctuation of r2090 RH per hour or less

Atmospheric pressure

please make

below.

760

hPa or more

both for safety

sme

the

ambii enviraunent

-

.

”

l-3.

Power Requirements

Do not plug the Power Cord into a power outlet via an extension cord supplying electricity to more than

onelmk

120v

Power

Voltage fluctuaticm

I-

-.

;.

‘.

l3-qmcyfluchlation

When any other electric appliance is

the outlet is not exceeded.

-

Ensure that the power outlet is not hidden

power cord

-

The power cord

whennecessary.

should

sourced

not be cracked or scratched.

6oHz

*lO%

*3Hz

from the same power outlet make sure

bebind

any object, allowing the user to immediately unplug the

22ov-24ovsoHi

tb.at th:

current capacity of

2. INSTALLATION

2-1. Connection

The following

- Connea

-

Connect the Power Cord

items

should be connected before use.

the

Intezface

Cable.

A-l

Page 15

-

-Y

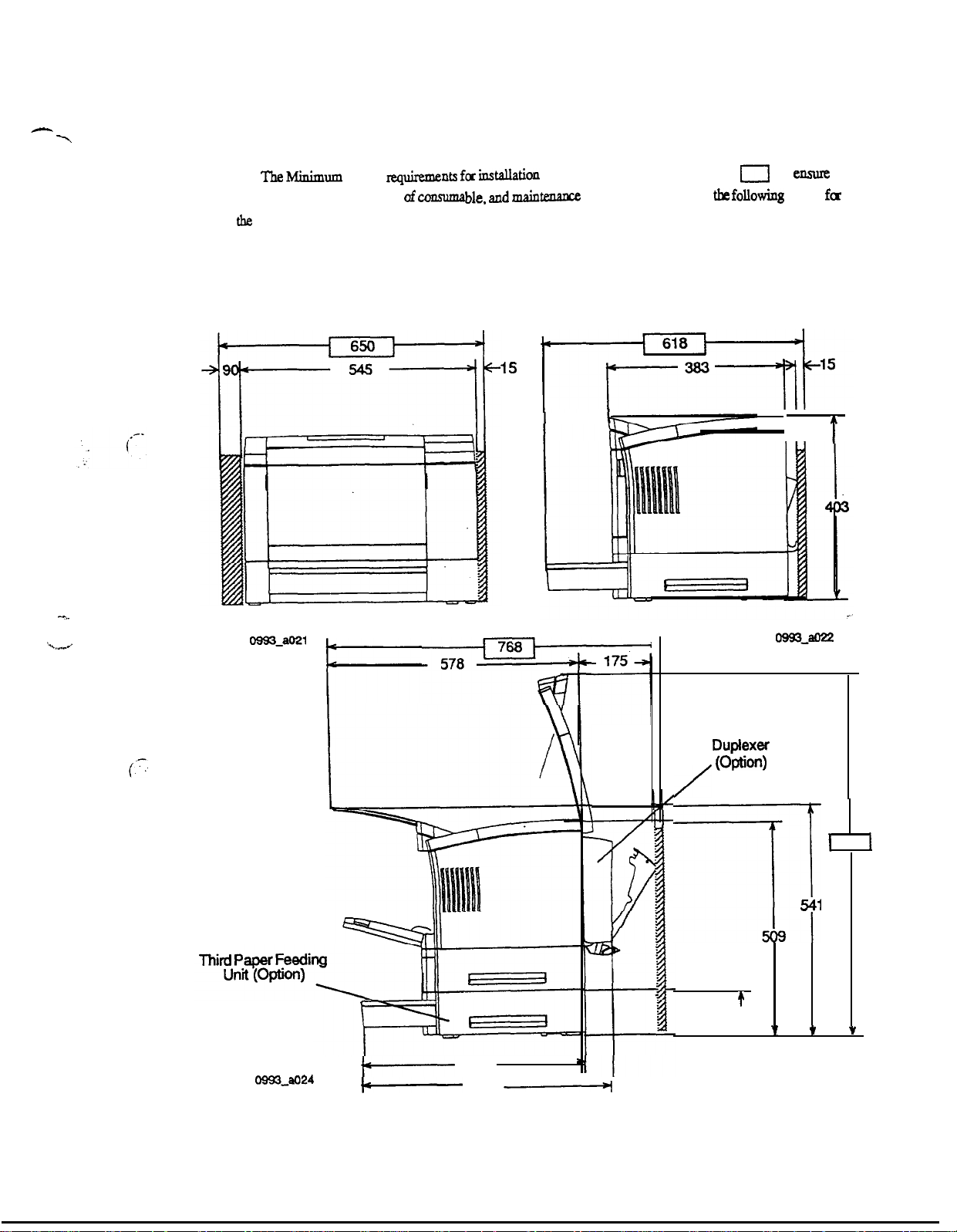

2-2. Space Requirements

Note:

The htinimum

easy operation, replacement of

the

installation of the printer.

Space

requireme

n$ for indhion

comma

ble, and main-

of the printer are enclosed in a

service jobs, provide

15

I

a

TO ensure

the fotiowing

space

iii

fa

t

-,.

‘.,,/

OSS~aO21

175

-15

0993--

ns

7

Dupiexer

Kwon)

/

1

880

1

541

=p

f

106

v

Y

Y

0993maO24

+------

-

521

593

______Ff

A-2

Unit: mm

Page 16

c’

.

B: GENERAL INFORMATION

SPECIFICATIONS

1.

2.

PARTSIDENTIFICATION

3.

COMhENT

4.

GEARS/ ROLLERS ASSICXMENT

5. ELECTRICAL COMPONENT LAYOUT

6.

CO-ORS

7.

SWlTCBE.S/

8.

FXECIRIW

SENSORS

9. SYSTEM LAYOUT

9-l. Drive Section

Ele&cal section

9-2.

10. SEQUENCE FLOW

11.

URCUlTDL4GRAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-l

.k

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

IAYOUT

............................................................................................................

...........................................................................................

LAYOUT

........................................................................................................ .B-7

IDENTIPICATION

SERVICE PARTS

ONP.W.

...................................................................................................................

....................................................................................................................

..............................................................................................................

.................................................................................................................

..............................................................................................................

-

...................................................................................

..............................................................................

BOgRDS

..............................................................

B-4

B-5

B-6

B-8

B-9

B-10

B-10

B-l 1

B-12

B-13

-.

_T-

.._I

Page 17

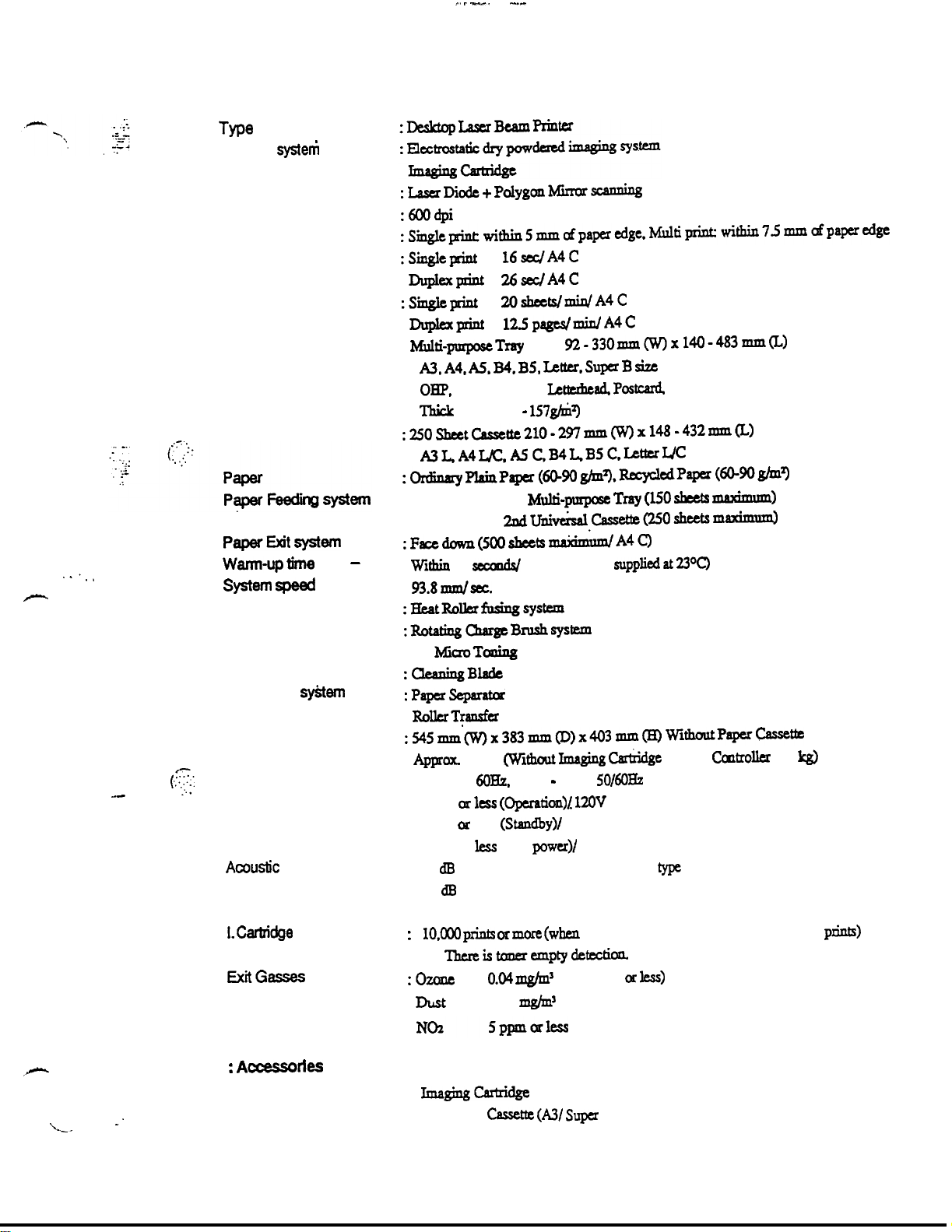

1. SPECIFICATIONS

TYPe

Printing

systerri

,(, * -....

,-*,..

Exposure system

Print density

Print Image

Printing time

Multi printing time

Paper size

:LascIDiodc+PolygcnlMimxscanning

:64Xldpi

:S~~~within5mmcdpa~edge,Multiprint:within75mmafpaper~ge

:SblgkpKiIlt

Dupkxpiint

:shgleprint

Duplexpint

:

h-fdti-purposeTray

A3. A4. M. B4. BS. Lettet.

OBP,

Transparency,

Thick

Paper (91 -

16saiA4C

26sec/A4C

2Osh1xtslmip/A4C

125pagcs/min/A4C

!92-33Omm(w)x14O-483mm(L)

Supa B

Letterbead F’o~tcard

157gM)

size

Label

:25oSheet~tte210-2~mm(W)x148-432mmQ

ML,A4LK.A5C,B4L.B5C.kttu~C

:ordiMlyPlainPapcr(6Woghn%lkWJ~Paper(6o-~g/m3

: 2 way system

Multi-~

Tray (150 sheets a)

1st

2nduIli~~cassette(250~~-

PaperExitsystem

..‘.,

/----

. . .

. . .

.+e

. .

CT::

Wamwptime

Svstem speed

Fusing system.

Charging system

Development

Drum deaning’

Separating

image Transfer system

Dimensions

Weight

Power supply

Power Consumption

AaxMic

Monthly Duty Cycle

I. CafMge

system

Noise

operating life

-

:Faccdown(5OOshtx~~A4O

: within 70

:

93.8mdscc.

sttaldd (when power

supplied ti zoo

:Eteat~llerfusiIlgsystem

:RotatiqhrgcBxuhsysIem

:

Fine

system

:CkmingBlade

:papaseparatar

:

RcLkT~ansfer

system

:545mm(w)x383mm~)x403mm~~~Paper~~

:

Approx.

24 kg (miloutlmagiJlg

: AC 120V

: 750 w or

200 w or less

30 w or

:

53 dB (A) or less (Operation)/ standard

38

: 50,000 prints

10,~ pr;nts 0~ IIXUX (when

:

6OEx.

220V - 240V

less (opcratioll)f 12ov

(stanciby)/

less

(low

power)/

cIB

(A) or less (Standby)

120v

cardridge

1.9 kg.

50/60&

120v

type

the

black-to-white ratio is 5% on multi

Caltroller

0.5

W

pints)

ThueiStOWUnpty&tif=

EXiiGtE3.%5

:ozinlc

Dust

0.04 mgh?

mghl’ or less

0.25

(0.02 ppm or

less)

,-

: Accessories

: Power cord

Imagingcartridge

\--*

_’

250 Sheet

cassette (A3/ Super

B)

B-l

Page 18

!--‘

:

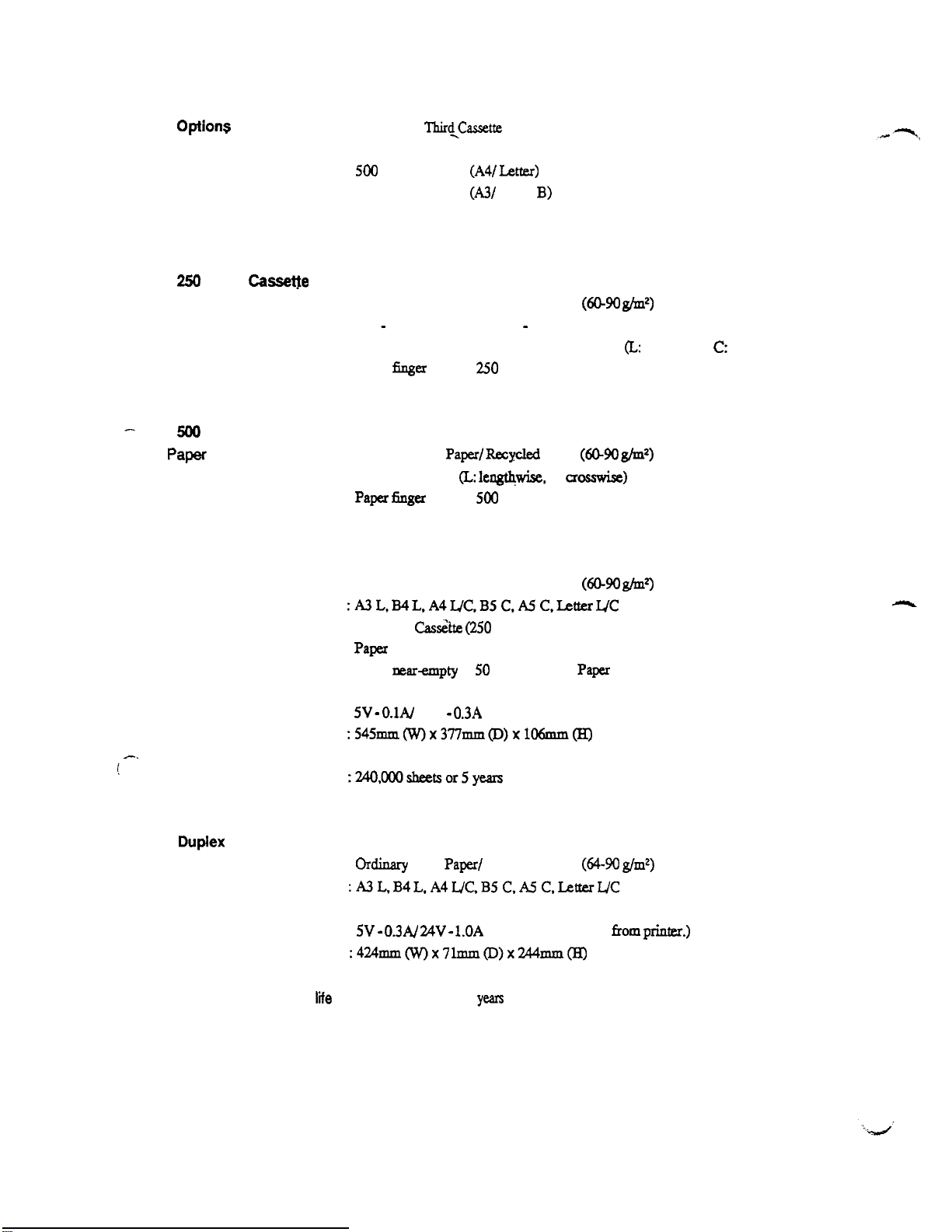

Options

:

250

Sheet

Paper

Paper size

Paper Feeding system

:

500

Sheet Cassette

Paper

Paper size

Paper Feeding system

: Third Cassette Unit

Paper

Paper size

Paper Feeding

Detecting Paper

System speed

Power supply

Dimensions

Weight

Third C. Unit operating life

Cassetje

: 500 Sheet

: Ordinary Plain Paper/ Recycled Paper (6WO

: 210 - 297 mm (width) x 148 - 432 mm (length)

: Paper Snger system.

: Ordinary Plain

: A4 C or Letter C

:

: Ordinary Plain Paper/ Recycled Paper

:A3L.B4L.A4UC.B5C.A5C,LetterUC

: 250 sheet

:

: 95.6 mm/ sec.

: 5V -

:545mm(w)x377mm(D)x1O6mm(H)

: Approx. 5.4 kg (Third Cassette Unit 3.3 kg + 250 Sheet Cassette 2.1 kg)

:24QOOGsheetsor5years

Thir<cassette

250 Sheet Third Cassette Unit

500

Sheet Cassette (A4/Letter)

250 Sheet Cassette

Duplex Unit

A3 L, A4 WC. A5 C. B4 C. B5 C, Letter L/C

Paper/

PaF

finger system,

Cat&e (250

Paper

empty: 0 sheet

Paper

nearempty

O.lA/

24V -

0.3A

unit

(A3/

Super

B)

g/mz)

(L:

250

sheets

Recycled Paper

(L:

lengthwise. C:

500

sheets

sheets maximum)

1: 50 sheets or less.

maximum (Supplied from printer.)

(aCr90 gim2)

uosswise)

(60-90 g/m?

Paper

near-empty 2: 250 sheets

lengthwise. c: crosswise)

:

Duplex

Unit

Paper

Paper size

System speed

Power supply

Dimensions

Weight

Duplex Unit operating

life

: Ordinary Plain Paper/ Recycled Paper

:A~L,B~L.A~L/C.B~C.~C.L~~~~XL/C

: 95.7 mm/ sec.

: 5V -

0.3N 24V - l.OA

:424mm(w)x7lmm(D)x244mm0

: Approx. 2.1 kg

: 150,000 sheets

maximum (Supplied

or 5

years

B-2

(64-90 g/m2)

itom prinrer.)

Page 19

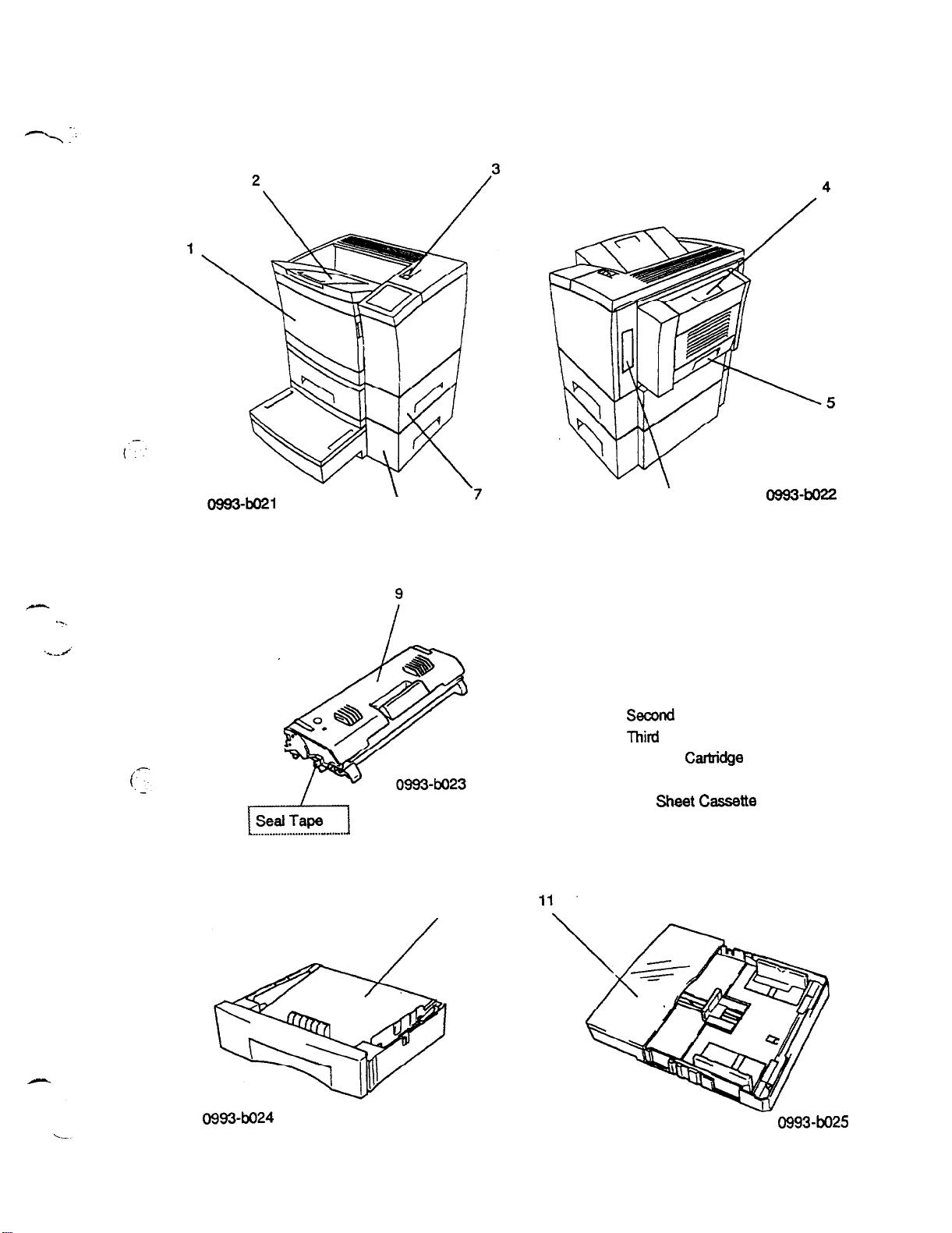

2. PARTS IDENTIFICATION

OSS3-bo21

8

10

-6

1. Paper Feed Tray

2. Paper Exit Tray

3. Upper Unit Lock Release Lever

4. Duplex Unit (Option)

5. Duplex Lower Cover

6. Interface Connector

7.

!33cod Cassette Unit

8.

Third

Cassette Unit (Option)

9. Imaging

10.500 Sheet Letter Cassette (Option)

11.250

Shset

Cartridge

Cassette

oss34022

OSS3-b024

OS93W25

B-3

Page 20

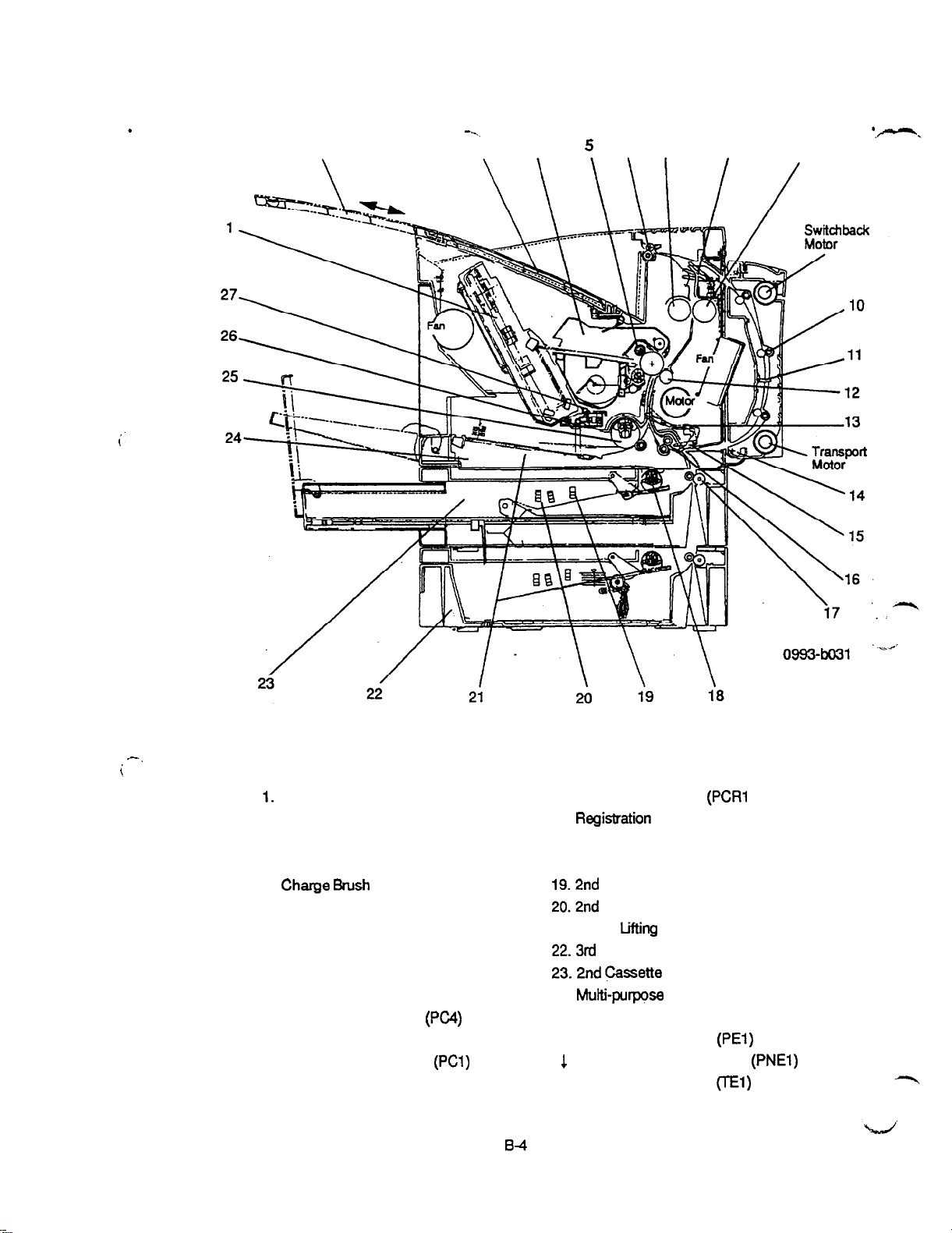

3. COMPONENT LAYOUT

.

5

2

i.

3

4

6 7

8

9

-.

i,

1.

Print Head Unit

2. A3 Exit Tray (stored type)

3. Paper Exit Tray

4. Imaging Cartridge

5.

Charge f3rush

6. Paper Exit Roller

7. Upper Fusing Roller

8. Paper Exit Sensor (PC3)

9. Lower Fusing Roller

10. Duplex Transport Roller (Option)

11. Duplex Paper Sensor

12. Image Transfer Roller

13. Paper Take-up Sensor (PCl)

14. Duplex Cover Switch (Option)

(PC4)

15. Registration Sensor

16.

17. 2nd Transport Roller

18. 2nd Paper Take-up Roller

19.2nd Paper Empty Sensor (PE2)

20.2nd Paper Near-empty Sensor (PNE2)

21. Paper

22.3rd Cassette Unit (Option)

23.2nd

24. ML&purpose Tray

25. Paper Take-up Roll

26. Paper Empty Sensor

27. Toner Empty Sensor

Regislration

1

Paper Near-empty Sensor

Roller

Lifting

Cassette

Plate

Unit

(PCRl

(PEl)

(TEI)

)

(PNEl)

Page 21

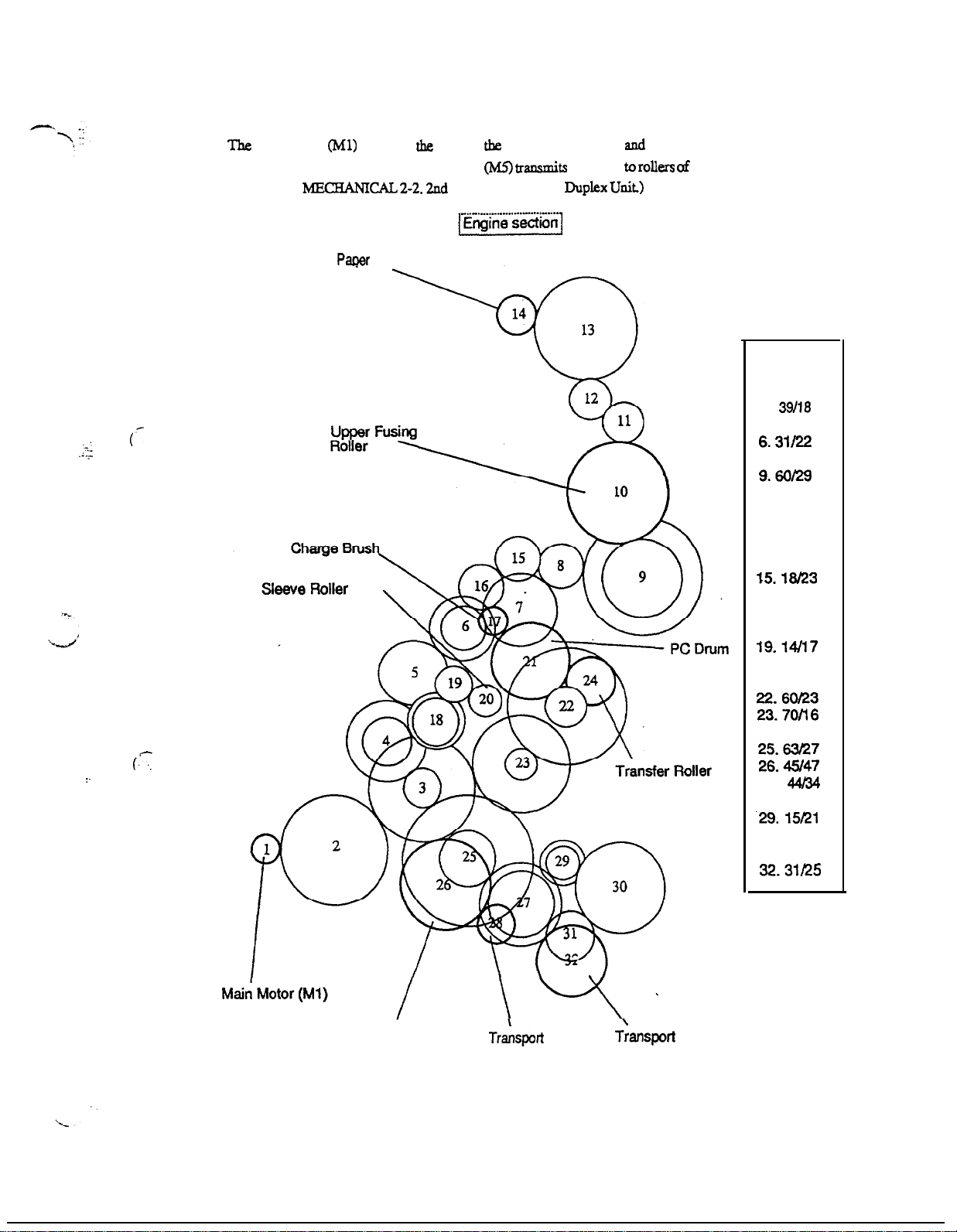

4. GEARS/ ROLLERS ASSIGNMENT

The Main Motor (Ml) transmits

each gear. The duplex unit Transport Motor

(Refer to C: MECHANICAL

the

drive to

2-2.2nd

the

rollers of the printer

(M5) fnnsmiti

Cassette Unit, 9-2.

the drive to

Duplex Utit)

and

the optional 3rd Cassette Unit via

rollers aE

the Duplex Unit.

.

Exit

Roller

Gear Ratios

1.20

2. 77

3. 75

4.

39/18

5.33

6.31/22

7.38

9.6oR3

10.39

11.15

1.2. 15

13.39

14.14

15.18R3

16.24

17.14

18.20

19.14/17

20.16

21.44

22.601'23

23.7Otl6

24.18

25.63/27

26.45/47

27.

44.134

28.18

.29.

15Rl

30.44

31.25

32.31R5

Pam

(.--y

:-

Paper Take-up Roll

Trahqm?

B-5

Roller

T\ransport

Gear

Page 22

(.-.

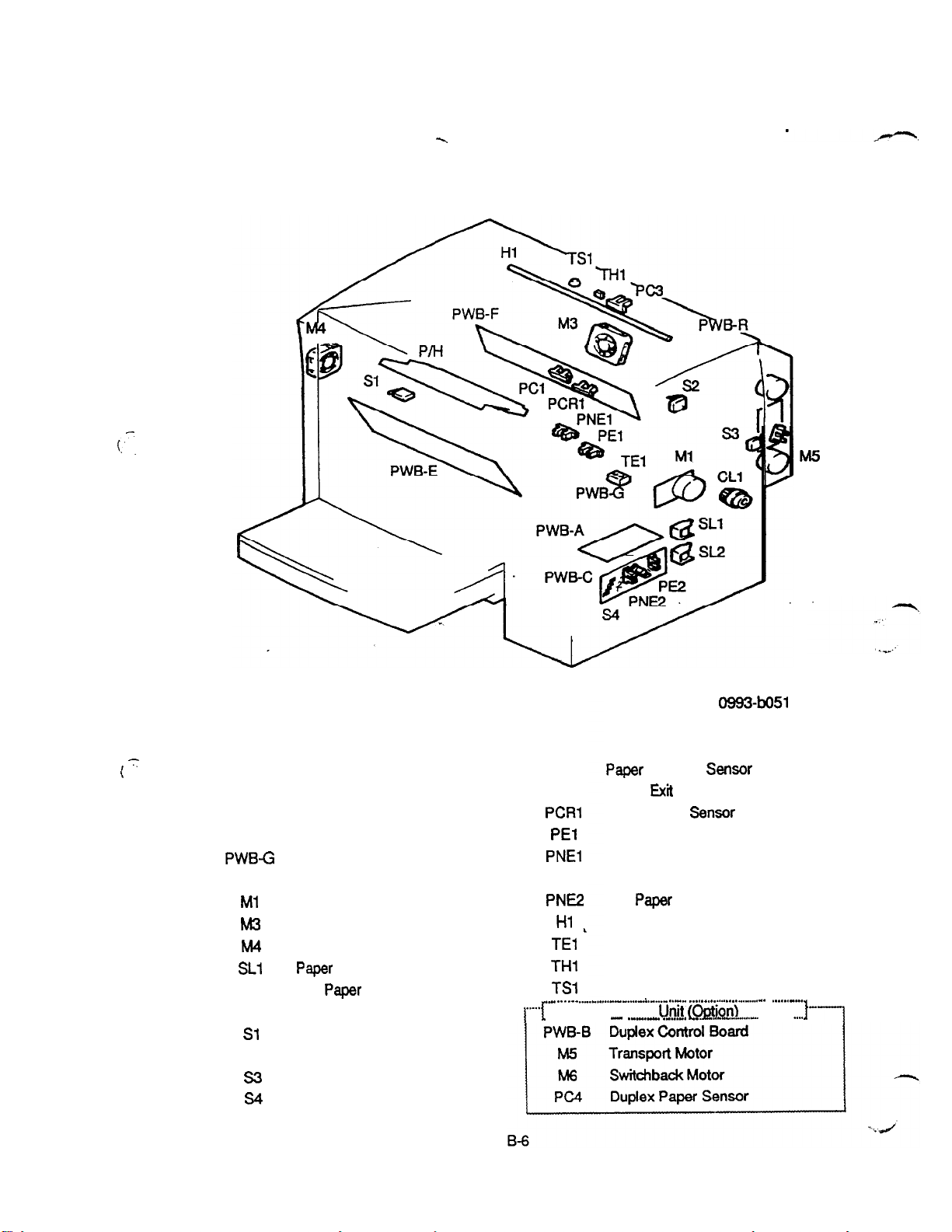

5. ELECTRICAL COMPONENT LAYOUT

M6

PWB-B

PC4

h-l5

0963~bO51

7

i

PWB-A

PWB-C

PWB-E

PWB-F

PWBG

PWB-R

Ml

M3

M4

SLI

SL2

CL1

Sl

s2

s3

s4

Main control Board

2nd Cassette Unit Board

Power Unit

High Voltage Unit

Toner Empty Board

Resistor Board

Main Motor

Fusing Fan Motor

Power Fan Motor

Paper

Take-up Solenoid

2nd

Papar

Take-up Solenoid

Registration Clutch

Power Switch

Interlock Switch

Duplex Cover Switch

2nd Paper Size Switch

PC1

PC3

PCRI

PEl

PNEI

PE2

PNE2

H’

TEI

THI

TSI

..” . . . . . . ..“.“....._ “.“.^.i.“...” ..*-”

. . .._..“..... . .

r-l

Papar

Take-up

Paper

Exit

Registration

Sensor

Sensor

Sensor

Paper Empty Sensor

Paper Near-empty Sensor

2nd Paper Empty Sensor

2nd

Papar

Near-empty Sensor

Heater Lamp

L

Toner Empty Sensor

Thermistor

Thermostat

Duplex

...“-

.-...... .“...“.

Unit

. . . . . . . . .

:‘”

. . . .

(@bon)

”

-..““. .“.....,...--

...“.... .

.

.

.. ...“...

. . . . .

-..

~---I

Page 23

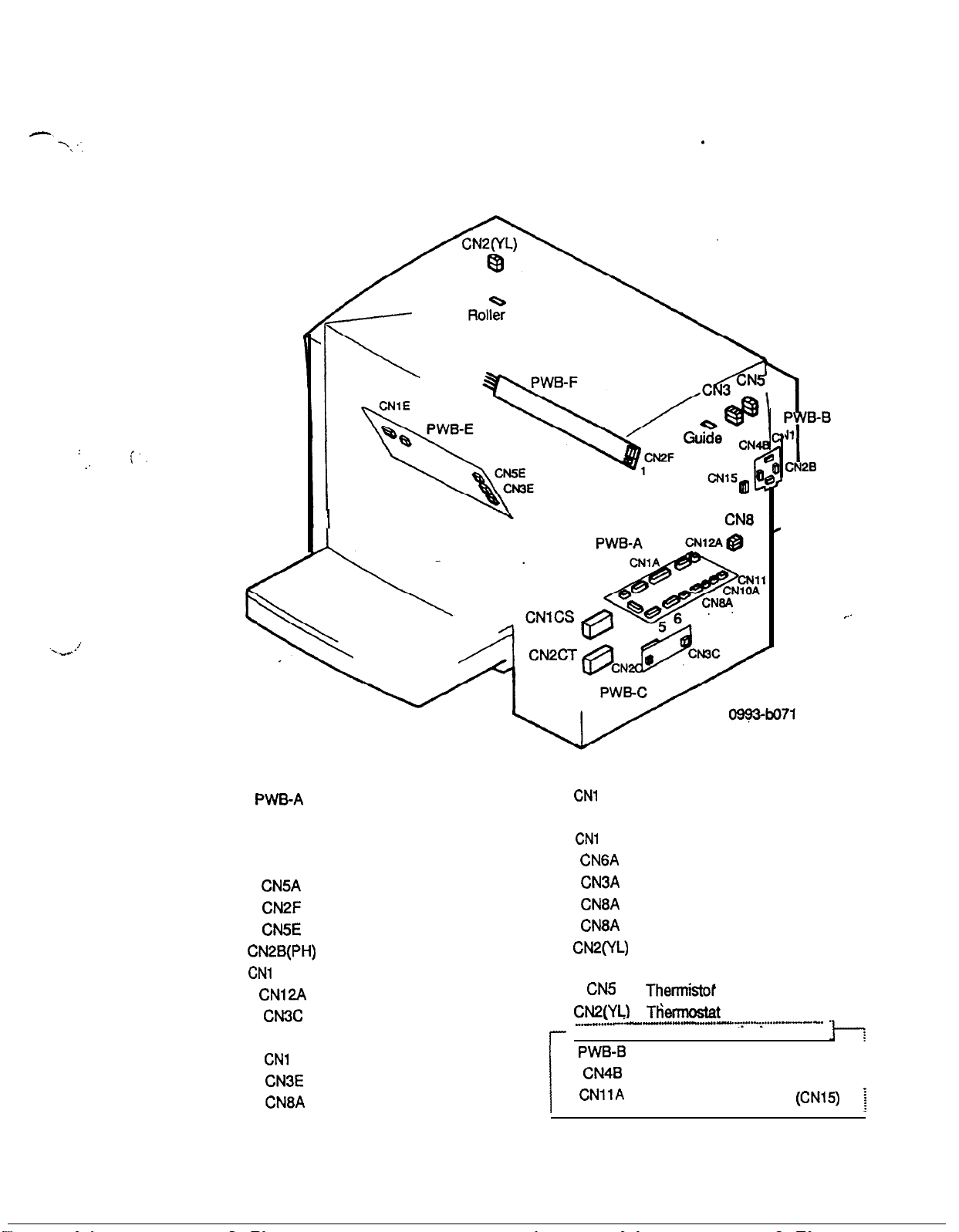

6. CONNECTORS LAYOUT

.

:

(..

:

I

CN8

I

CN2B

J

,.I

(I-

41

/’

PWEA

PWB-C

PWB-E

PWB-F

CN5A

CN2F

CNSE

CN2B(PH)

CNI

B(PH)

CN12A

cN3c

CN8

CNl

CN3E

CN8A

Main Control Board

2nd Cassette Unit Board

Power Unit

High Voltage Unit

Main Motor

Fusing Fan Motor

Power Fan Motor

Transport Motor

Switch back Motor

Paper Take-up Solenoid

2nd Paper Take-up Solenoid

Registration Clutch

Power Switch

E

Interlock Switch

2nd Paper Size Switch

CNI

OA

CN3

CNl

CNGA

CN3A

CN8A

CN8A

CN2(YL)

CNEA

CN5

CIWYL)

“.S”...“.

PWB-B

CN4B

CN11A

Paper Take-up Sensor

Paper Exit Sensor

OA

Registration Sensor

Paper Empty Sensor

Paper Near-empty Sensor

2nd Paper Empty Sensor

2nd Paper Near-empty Sensor

Heater Lamp

Toner Empty Sensor

Therm&of

Ttkmostat

.

. . . . --.--.-_-..

Duplex Unit (Option)

Duplex Control Board

.

Duplex Cover Switch

, Duplex Paper Sensor,

-

..“~............... I . . . . . ...“. “.

(CN15)

i

B-7

Page 24

. . .

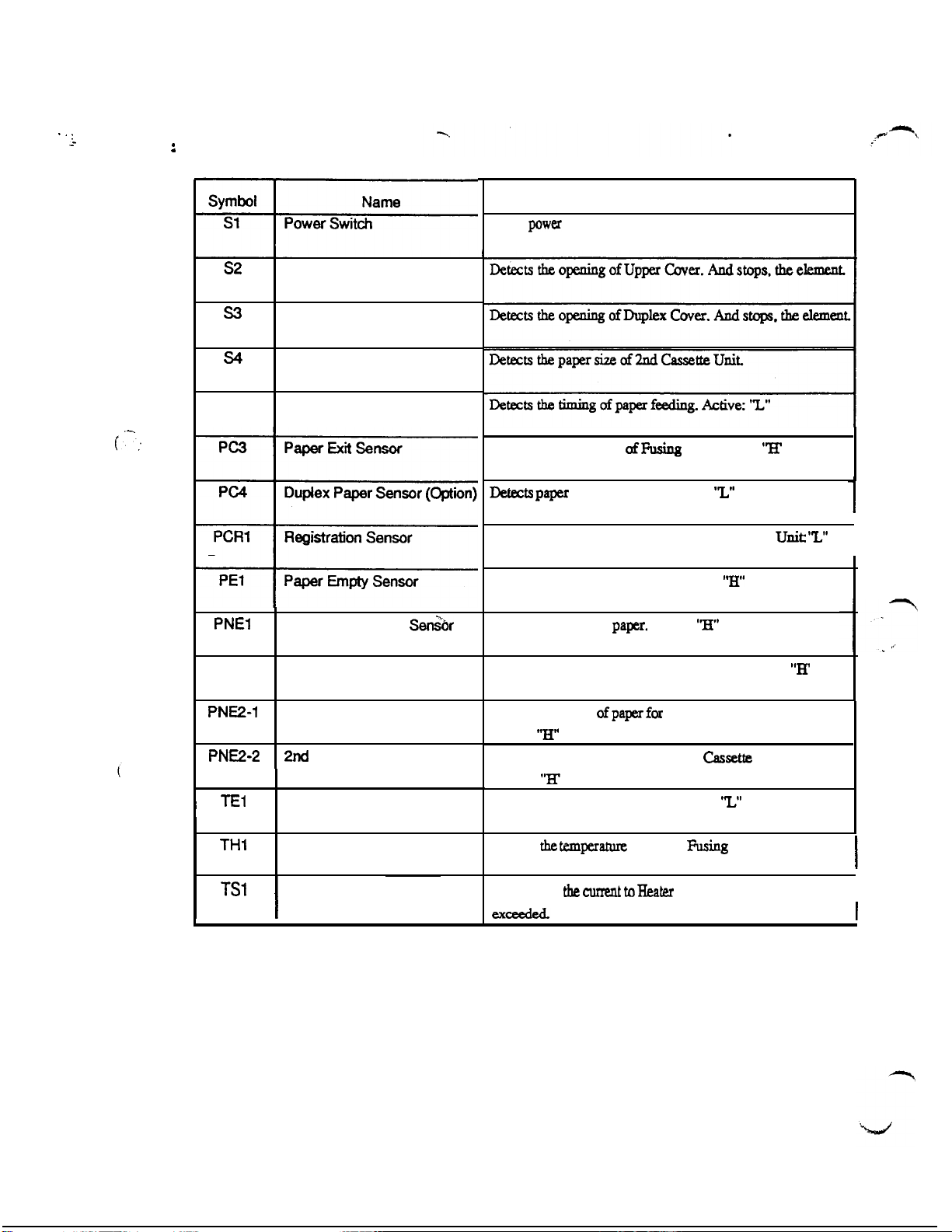

7. SWITCHES/ SENSORS IDENTIFICATION

1

*

Printer, Duplex Unit.

.

Turns

powex

ON and OFF.

Function

s2

!33

s4

PC1

PNEl

PE2

PNE2-1

PNE2-2

i

TEI

Interlock Switch

Duplex Cover Switch (Option)

2nd Paper Size Switch

Paper Take-up Sensor

Paper Near-empty

2nd Paper Empty Sensor

2nd Paper Near-empty

Sensor

2nd

Paper Near-empty

Sensor

Toner Empty Sensor

Se&&r

Detects the paper exit

De&da paper in Duplex Unit. Active:

Defects the timing of 2nd Cassette Unit. Duplex Unit:

Detects paper empty condition. Active:

Detects 50 sheets of

Detects paper empty of 2nd Cassette Unit. Active:

Detects 50 sheets

Active:

‘33”

Detects 250 sheets of paper for 2nd Cassette Unit

Active:

Detects toner empty condition. Active:

“ET

ofFus&

paper.

Active:

ofpapesfor

Unit Active:

‘z”

‘H”

2nd Cassette Unit.

‘WY

‘H”

‘z”

“E

‘z”

I

THl

TSl

I

Thermistor

Thermostat

I

Detects

Cuts

OFF

E-8

the

kmperature of Upper Fusing Roller.

the current to Heater

Lamp when

temperature is

I

Page 25

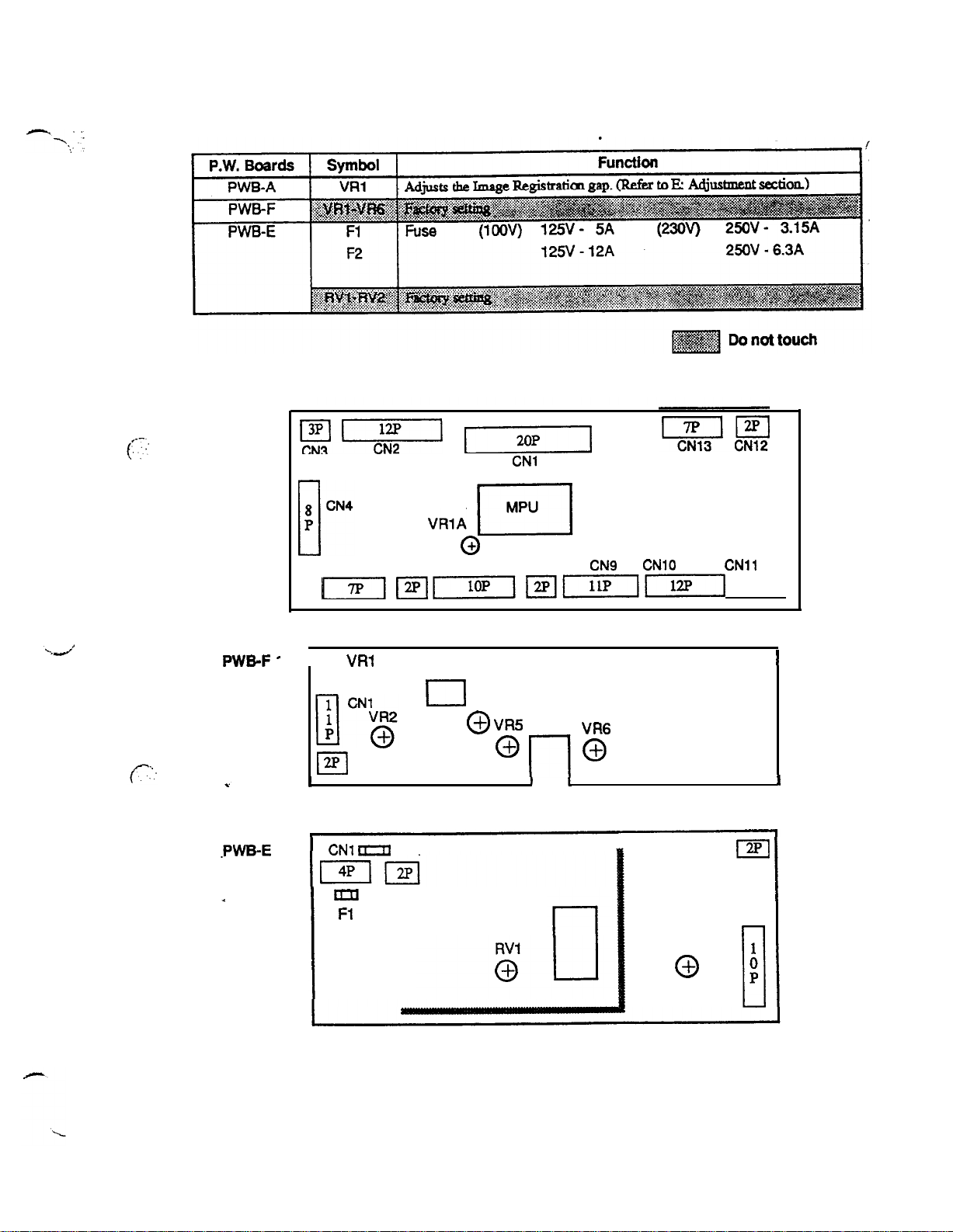

8. ELECTRICAL SERVICE PARTS ON P.W. BOARDS

PWB-A

PWB-F -

.PWB-E

mw

CN3

VRlA

CN5

r-q

j-7q7p1[2p1~1op1)2pll1Ip]

I

VRl

+

0

2P CN2

0

I

CNl

CN6

I

VR3 @

rl

F2

y2op

CNl

0

VR5

0

CN8

r-l

I

1

CN7

CN9

VR6

@

CNlO

CN5

CNll

I

m

cm

Fl

CN2

B-9

RV2

@

CN4

CN3 q

:,

P

c

Page 26

9.

SYSTENl

LAYOUT

9-1. Drive

S&on

: Mechanical Control and Sensor Layout

Main Control

Board

(PWB-A)

Transport Roller

I\

Fusing Roller

/

Paper Exit Roller

Registration Clutch

a-1 1

Transfer

Roller

/Paper

Take-up Sensor

I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

piin

Sensor

m!

..-.... I

. . . . .

I<

I

;sas.sgtiG.

Polygon Motor

uw

.

Switchback Motor

w3)

iCurrent

! ,.......................................................... e......

Themstor

khemwstat (X31

1 ,...............,...,.........,,.......................,...,..........

jt%$‘i’Empty

\

iEg..sa* .@$. . . . . . . . . . . . . . . . . . *.. . . . . . .

duplex Paper Sen=r VJ

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . .

B-10

. . . . . . . . . . . . . . . . . .

of

LD

(I

Hi)

.............................

Sensor

)

..#” .*...............

. . . .

..............

(Pl2)

c4)1

1

i

‘.*/

T

’

Page 27

9-2. Electrical Section

: Power Supply and Signal Transmission

(7’.

(7

OEM Setup

,....” .. .. . . .. “..” . . . . . ...” . . . . . . . . . . . . .. .

I

Control Panel

I

e

Is

f

a

C

e

I

:

._-_--...._.._._1..1.~..---

b

..a.....

s

II

lAC

Unit

1

(PWB-F)

1

Print Head Unit

Imaging Cartridge

MOtW

Solenoid

Cllltdl

-

Signal line

AX~XXV

Power line

1

-

The Power source supplies

-ThePrinterreceivesprintdataframthehostPCthroughaninterface.

-‘Zhe~olleradjus$thesizeandpositionoftbeprint&tatogenerateimage~Printingoccursafter

theimagedatahasbeentransmittedtothePrintHeadunitviat~emain~olbosrd.

- The

main control board

Gw&teuniL

DC+SV

controls the

and

DC+24V

various parts of the

to the main

qine.

B-1

1

control

board and AC to the Heater Lamp.

Print Head unit, and Duplex Unit.

l%ird

Page 28

. . .

IO. Sequence Flow

.

To

can-y

out printing

engine as shown below.

cyclks, s&&Is

Host PC

are transferred between

the

Controller, main control and

-d-+7

Controller

f!.z+cT

. . . . . . . . . . . . . . . . . .

I

T

k

I.-

(-:..

I I

Interface

..-....

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Command Processor

Command Processor

Image ProcessingImage Processing

Image Line Memory

I

I

I

-H.

SYNC

-Line.Data

Main Control

Standby

Feeding

yl?

Charging

Exposed (PM

w

Transfer

B-l 2

Page 29

11.

CIRCUIT DIAGRAM

Imaging

Carlr

Parts

Pq.w

Thumistor

i

Ragiul~tbn

““‘FS

s-

Y*

Exit

CMCh

I I

CNSA(PH)

lx4

Ul(CS)

1

1

‘;

dr

N0l-l

COllt-lbClbll

I

2nd Cas9etlo Unit

PWB-c

2nd

Papu

CN

0

PM-Q

TEl

:NlF(CTI

I

Cl

T--

I

I

110,

CN6A

“T

I,

2

:

:

:N12A

24V

kmm

1

CNlM

sv

‘m Ram

24V

tuo2

PCRl

EVR

iv-B.VR

xm

is

HL.Run

+24

GNI

stall/St0

CbC

CN7A(PH

La:

Yl

L

)

2

Duplex unit (oprron)

CNZ(CS)

-i-l

Empty sotwar

7

1

tip** ‘.

PWB-0

LD Board

Uppwhoww Fusiq Fwlrr

CNl(Cl-)’

I

1

-I

Pdygon Motor

3rd

cw9atlo

3rd

Pqxr Empty s,mwr

Prinl Head utdl

Urtil

(opa)

I

. .

h4aln

Motor

iY

tY.lbw

;

G

yGrwn

i Pal Photo serlwr

CN4ACJ

W

1

PWF

!i

Heafrr&

+24V(S

r!

3j

CNSA(NH)

Ml

4

I

PWB-A

4.

CN’

‘V 8

1V

IA

I

:NIE&H)

PlJl

PWB-E

CNPE(UP-(I)

Hmahl

Lamp

Power Svrlch

Page 30

-._

C: MECHANICAL/ ELECTRICAL

-

1.

PRINTINGPROCESS

2. PAPER FEEDING

2-1. Multi-purpose

2-2.

Secmd

Cassette

3. IMAGING CARTRIDGE

4.

CHARGlNG.................................................................................................................................

5.

ExEmmRE

6.

DEVELOPMENT

7.

TIUNSFER

8.

FUSING

9. PAPER

9-1.Paper Exit

9-2.Duplex

10. PRINTING SEQUENCE

l0-l.Starting

10-2.Multiple

10-3,

loA.

10-5.

(p/-H)

.................................................................................................................................

.......................................................................................................................................

EXJT/DUPLEX

(Option)

millg

Duplex

Power ON

.................................................................................................................

.....................

Tray

Tray

.......................................................................................................................

........................................................................................................................

...........................................................................................................................

.................................................................................................................

sequence

sequence

sequence

seqmce

Print

sequence

.I..

.............................................................................................

.............................................................................................................

.........................................................................................................

.....................................................................................................

.............................................................................................................

...........................................................................................................

..............................................................................................................

.............................................................................................................

..*...

....................................................................

....................................................................................................

.......................................................................................................

.....................................

.:.

....

C-l

c-2

C-2

C-3

c-4

c-5

c-5

C-6

c-6

C-7

C-8

C-8

C-8

c-9

c-9

C-9

c-9

c-10

C-10

Page 31

,> : . .

I.

PRINTING PROCESS

.

I

9. Paper Exit/ Duplex

C-l

: Sensor

I

Page 32

2. PAPER FEEDING

-

Paper is fed from either the multi-purpose tray (holding up to 150 sheets of paper) or the

commanlycalledtheuniversalcasse~fholdingupto25Osbeetsafpaper).~optianalThirdcassetteUnit

may be installed to

serve

as a

fixed

cassette capable of holding 500 sheets of paper (1 a

capable of holding 250 sheets of paper.)

-ThePapatake-uprolltakesupasheetafpaperandthe~~rollerfeedsittothePC~.

-Thesignalindicatingthatthepapertake-upsensorIPCl)isactivatedisusedto&terminethestamngpositian

oftheimage.

- Tke

paper

nearempty

sensor

(PNEl)

detects a

umdition ia

which the amount of paper still available for use

ia50sheetsor1ess.

2-1.

Multl-purpose

- The

drive is

take-up

roll, and the push-down cam.

-

When the

complete turn. As the

t&

up one sheet of paper. The friction

Tray

trauami#ed

paper

from the main drive motor

take-up solenoid

push-down

(SLl)

cam

(Ml)

to the paper take-up clutch (one-way clutch), paper

is

eneqixd.

turns.

the paper lifting plate is raised so that the paper tak-up roll can

with the

the paper take-up roll and push-down cam

separator pad ensures

thatonlyoaesheetcxfpaperistaktn

upatatimebythepapertake-uproll.

2nd

univenal

paper tray.

cassette

turn

one

Pushdown Cam

Paper Near-empty Sensor (PNEl)

Transport Roll

Paper Empty Sensor

Paper

Paper Take-up Sensor (PCl)

\

Paper Take-up Roll

(PEI)

/

Paper Take-up Clutch

Paper

Take-up Solenoid

(SLl)

c-2

\<

Paper

lifting Plate

Page 33

2-2.

Second Cassette Tray

- The

drive for the

paper take-up roll, and

- The secad

secmd

paper tray is transmitted from the printer to the intermediary

paper tray is

the tmqxxt rollex.

cmtrolled

by the main control board

@WB-A)

gear.

paper take-up Clut4

via the control board

-whenthepapertake-upsolenoid(sL2)isene~tbepapertahe-uprollisturnedonecamplete~totakeup

a sheet of

paper

and the transport roller feeds it to

the PC

drum.

The

paper separator

fingers

andsubsequentsheetsdpaperfranbeingtaLenupwiththefirstane.

-Thepapersizeswitches(S4-1.2.3,and4)anthecontrolboard~-c)&tectthesizeofthepaperloadedin~~

~ay.‘Ihecambinatiansinwhich~switcbesarehrmedaoandoffarelistedbelowtorepresent~

.

- k~~~kr+mpty sensor (PNE2)

sheets cr less or 250 ar less.

detects a

(J%e

optional Third Cassette Unit is

cmdition

in

which

the amount of paper still available for

conligured

in tbe same way.)

: Paper size Switch

(FWB-C).

prevent

f.

the-secmd

use

is 50

’

Paper

Note: 0:

ON, 1: OFF

Paper

5ize

Contn

Plate

(PL-v,

I

Paper’Size

Transport Roller

Switch

(S4-1,2,3,4)

Intermediary

Gear

,-

c-3

Page 34

3. IMAGING CARTRIDGE

-

The illustration below shows the

c&&ction

of the PC drum charge unit and developing

Charse

Brush

tit

Cleaning Blade

/

.<

i-

Agitator Blade

Pa&

/

Toner Hopper

Cleaner Mirror/

Fuse

Toner

J

eed

Roller

S&eve

Roller

window

Page 35

4. CHARGING

n

.

:

1 t

-

A rotary brush is

directly to the PC Drum at a low voltage and tkrefore the

used

to charge tbe PC Drum by static electricity

Bmouat

More

laser exposure. It applies

of ozone produced is only

negligiile.

&arg(’

(

_,-

Laser

5. EXPOSURE

(P/H)

Charge Brush

\

Charge bias

-..

t.

Laser Diie

Polygon Mirror

\

PC Drum

Page 36

6. DEVELOPMENT

--.

- The developiug

visible toner image.

-WbentbeprintcycleisstartedandtheMaindrivemotor(Ml)isenergized.theslafacepotentialafthePCdrum

is approx.

-~LEDonPWB-Gemitslightwhichisthen~fl~tedoffthemirroainsidethetonerhopperforuseinthe

detection of a

PWB-F

unit feeds

OV.

The

tauz

sleeve

roller voltage is made positive to

tfmer-empty ccndilion.

to the electrostatic latent image on the surface of the

prevent @leI fram stiCkiUg to

Readings are taken while the Main drive

motoI

PC drum to

the OV

*isturning.

+leeve Roller

produce a

alEaS.

.

F+-.

Hiih Volt-

age Unit

t

7. TRANSFER

Drum

PC

\

seal

kas

Toner

\

Ern@Se&or (TEl)

\

Ton\er

Feed Roller

Needle

/

PC Drum

0693-CO62

pole

PC Drum

L

Transfer bias

AOOOV

Transfer guide

I

ocEE-co71

\-Transfer roller

‘1

OSS461

Page 37

8. FUSING

-Thefusingunitpennanen

upper

fusing roller, which is heated by a

fusingrolkspressthemeltitcmerintothepaper.

-

The thermistor

- Ibe

thermostat

Heater Lamp

ml)

(IX)

021).

tly fixes the toner image onto

Hater

L&p

built into it, melts the toner and then

detects the temperature of the

turns OFF as it

senses

an

upper

abnamally

fusing

high

: Fusing Temperature Control Circuit

-

The

tbamistor

analog voltage. to

-TheHeaterLamp~l)istumedONorOFFbyasignalfromMPUou~accardingtothetemperature

detected by the

- Whn

the thermistor detects

(TEl) detects

MIPU.

tbermistar. thereby controlling

the suface tan-

~JI

abnormally high temperature.

of

the

the tempenture of the upper

the

paper.

rok

for fusing tcmpemture controL

temperatunz. these&y

upper fusing roller and inputs the carrespanding

MKJ

forces

.

This

is accomplished by a

the upper

cutting

fusing roller.

the

Heater Lamp OFF.

he&d roller.

and lower

oEcmnnt

The

to the

_

(‘Y

c-.

t

.

PWEA

Thermistor (THl) Detects Analog

in

: Fusing Unit Temperature Control

1. During warm-up

2. During print

3.

During

standby

4. Energy saving

The

@T@I

ssvitchistmnedON.

cycle On

receiving

uppa

fusing rollix temperature at approx.

‘I& uppex

The

contxoller sigrk turns

starts

fusing

w&m-up

a

print camman& the printez

rokr temperatute

to

attah

a temperature of approx.

starts a temperature control cycle to keep the

MPC

is maintained at approx.

OFF the. Heater Lamp.

Voltagje

Thermistor

190°C

when the power

1WC.

Temperature Curve

.

. . . . .

. . . . . . . . . ..." . . . . . . . . . . .

blower

;

b

6N

2 min.i 5 min. I 5 min.

-I- - I-

!

I

. . . . . . . . . . . . . .

I

. . . .

lhrmostat

I

I

I

‘i

AHeater

i

, Time

I

c-7

OFF

Thermistor

Lower Fusing Roller

Page 38

9. PAPER EXIT/ DUPLEX

i.,?’

9-t. EXIT

-

TIE paper

the

-.

exit

roller receives its drive from

exit tray with its printed side down

1

Paper Exit

I - I

Paper

1

/

Upper Fusing

.

the

Main Drive Motor (Ml) via a gear train. The

Exit

Roller

Paper Exit Sensor

/

e-----r:--

Roller

n---

paper

switchback

is fed onto

.e-

.

.*-

t

\

Registration Roller

--m-

9-2. Duplex (Option)

-

When the duplex unit is mounted on the printer,

way of

the

coupling lever and gear.

1. When the printing cycle is completed for l-sided printing,

the printer by

2.

When the printing cycle is completed for the front side in

the

exit roller until it moves past the exit sensor. When the paper

motor

(M5) then transports

ad

then the registration roller feeds the paper to the image transfer section far printing to the back side. The

paper, having gone through the second print cycle, is fed out of the printer by the exit

(M6)

the

exit roller.

is

turned

backward feeding the paper back to the duplex paper take-up area The transport motor

the paper up to the registration roller. Skew in paper is

t&e

exit roller is

C-8

co-ted

the

paper, moving past the exit sensor, is fed out

24ded

printing, the paper is fed towards the exit by

move3

to the switchback motor

past the exit sensor,

corrected

by

rokr.

the switchback

the

registration

(MC)

senscx

by

of

Page 39

IO. PRINTING SEQUENCE

1 O-1.

Starting sequecznt

,

Polygon Motor

(tvl2)

Take-up Solenoid

(SLl/SU)

Paper Take-up

Sensor(PC1)

_ .. . . .

il$

-7 *

.

f

!

f

;

10000

hd3

Continuous

.

9

d .’

[m =-I

I

1 O-2. Multiple sequence

10-3.

Ending sequence

vExit Sensor OFF

VPtint

Print ends v

[m sec.]

Page 40

1 O-4. Duplex sequence

-..

.

-:

I.

10-5.

Power ON sequence (Trouble Check)

vPower ON

R ist.!Sensor

(hl, Pc4)

Note: Error check

sequen&

C-l 0

Page 41

,A

:’

1..

.

.

D: DISASSEMBLY/ CLEANING

-

,-

L.2’

1.

htAIMENANQE/ llWTXITON

l-l.

ReplAlcemeIlt

1-2.

Cleaning

1-3.

Requkd

2.

DISASSEMBLYPROCEDURE

2-l.

Outer

2.2. Fusiug

of Part

Parts.....................................................................................................................

ServiceTools......................................................................................................

cover

unit

s

........................................................................................................................

.............................................................................

2-3. Image Transfer Unit

24.

High Voltage Unit

2.5. Power

2-6.

2-7.

Unit

Print

Head

Paper Empty

Unit

2.8.Paper Take-up

2-9.

Regismion

2-10.

Drive

Unit

2-11. Duplex Unit

..............................................................................................................

..........................................................................................................................

..................................................................................................................

Sensor

Roll

Assy.

Roller Assy.

.........................................................................................................................

......................................................................................................................

...............................................

i..

.......................................................................................................

.................................................................................................

...........................................................................................................

Assy.

.................................................................................................

...................................................................................................

...................................................................................................

....................................

.‘......:.

..I

........................................

D-l

Dl

Dl

D-l

D2

D-2

D-2

Ix

D4

D7

.07

D-8

D-8

D-8

D9

D-9

Page 42

1. MAINTENANCE/ INSPECTION

. . .

c

l-l. Replacement of Parts

Parts Name

Imaging Cartridge

Paper Take-up Roll

Fusing Unit

Image Transfer Unit

1-2. Cleaning Parts

Parts Name

Paper Take-up Roll

Fusing Roller

Image Transfer Roller

*

Note: Do not touch the surface of the Image Transfer Roller with the hand.

l-3. Required Service Tools

.

Replacement Cyde

Multi printing:

At

&wion

At

de.tection

At detection

wipetheduat&withasoftclothdampenedtithacahal.

Wipethe&st&witha.dtclothdampUXdwithaldd.

Wipethesurfacewithadrypieceofsoftcloth.

N

of fault,

-

10,ooO; intermiaent:

of fault, or,

off&f

Cleaning Procedure

12O.ooO sheets of multi prhting

ar.

120,000

or, 120,000 sheets of multi printing

8,000 sheets

sheets

of multi printing

Ir-

~ . .

-,’

T

I’ ..‘.

+Driver (No.2)

Tools

use

Note: Grease: For the Drive Section:

Generally use

I

-Driver

1

MOLYCORT

E-ring

EMBOL

Needle Nose Pliers

I

I

E-ring

D-l

Page 43

F--x”.

1:.

2. DISASSEMBLY PROCEDURE

Before

king

the disassembly

ranove the

Imaging Cartridge.

2-1. Outer Cover

p~ccedure.

press the upper

kit

lock release button to

open

the Upper Unit.

6.

. .

.: :

Upper Unit Lock Release Button

1. Remove the Left Cover. (2

screws)

2. Remove the Right Cover. (3 screws)

3. Remove the Upper Unit. (2 screws)

4. Remove the Right Front Cover. (1 screw)

5. Remove the Front Cover. (6 screws)

6. Remove the Rear Cover. (2 screws)

-,

I

‘I

-9!33-d021

2-2.

Fusing Unit

1. Remove the Outer Cover. (Refer to section

2-l.)

2. Remove the Fusing Unit. (4 screws, 3

CoMectors)

0993-d0226

D-2

Note: When reassembling the Fusing

Unit, adjust the position of the Image

Transfer Unit.

\

Pin

Page 44

: Heater Lamp Cover

.

<-

..:

C-:

Left Heater Lamp

Riiht

Heater Lamp Cover

Cover

0993-d0222

3. Remove the Left

I

Note: When removing the Left Heater Lamp

Cover, turn the Cover in the clockwise

direction.

4. Remove the Right Heater

Note: When removing the Right Heater Lamp

Cover, turn the Cover in the counter

clockwiie

Heater

direction.

Lamp Cover. (1 screw)

Lamp

Cover. (1

screw)

.- ---Y

(. ‘..

: Heater Lamp

-do221

5.HoldingtherightendoftheHeate.rLamp,takeout

the stopper and

6.

Pressing

the Heater Lamp in the direction indicate

spring.

by the arrow, remove it from the heater saket.

-6’

D-3

Page 45

-

\. ‘.

.

.

: Paper Exit Sensor

1.

Remove tbei Paper

2. Remove

Exit Sensor. (1 connector)

tlie achmtor.

(1 spring)

::

!.

: Lower Fusing Roller

09S34026

1.

F&move the

Rear

Fusing Cover.

(2

scows)

2.PushtheAodrstopperinthedirectionindiuttedby

the

arrow

and remove the Lower Fusing Roller.

1. Release the stoppers of

tJle

separator.

2. Pulling and sliding remove the stoppers.

_--

D-4

Note: The two paper separator finger stoppers

on the right face the opposite direction to the

two on the left.

,

Page 46

: Thermistor

: Thermostat

- .

1. Remove the front Fusing Cover. (2 screws, 1

harness)

2. Remove

the

Thermistor. (1 screw)

09934272

: Upper Fusing Roller, Gear, G-ring, E-ring

r

1. Remove the

1.

Remove the G-ring.

2. Remove

3. Remove

IYbe.rmostat.

the

Gear, Ring. Bushing.

the

Upper

(2

saws)

Fusing

Roller as indicated by

the arrow.

4. Remove the Gear. (1 E-ring)

-.

.,. ,

*..-’

D-5

Page 47

n

\ .:.

...

Note: When disassembling/ reassembling the Transfer Unit, High Voltage Unit, Registration

.

Roller Assy. and Paper Take-up Roller Unit, please note

a hole in the

m

Release each unit from the Drive Unit

Right

Frame and a screw that secures the unit in the Left Frame.

that

each has a peg that fits into

when removing the unit.

2-3.

Image Transfer Unit

1. Remove the Outer Cover. (Refer to sect. 2- 1)

2.

Remove the Fusing Unit. (Refer to sect. 2-2)

3. Remove

the

Rear Frame. (6 screws, 1

connector)

Inter-face Plate

24.

High Voltage Unit

High Voltage Unit

Image Transfer Unit

Left Frame

4. Remove

the

Image Transfer Unit. (1 scriw)

Note: With the Left Frame open, release

the Transfer Unit. Pulling the Transfer

Unit in the direction indicated by

the

arrow, remove it.

Note: Don’t touch the surface of the

Transfer Roller with the hand.

1. Remove the Outer Cover. (Refer to sect. 2- 1)

2. Remove

3.

Remove the Transfer Unit. (Refer to sect. 2-

the

Fusing Unit. (Refer to sect. 2-2)

3)

4.

Remove the High Voltage Unit. (1 screw, 1

couxctor)

-. _..

Note: Pulling the High Voltage Unit in the

direction indicated by the arrow,

remove it.

D-6

Page 48

2-5. Power Unit

1. Remove the Outer Cover. (Refer to sect. 2-l)

2. Remove the Power Unit. (6 screws,

CoMectors)

5

_.

i-

0993dOS12

2-6. Print Head Unit

1. Remove the Outer Cover. (Refer to sect. 2- 1)

2.

Remove

the

Harness Cover. (2 screws)

Note: Pulling the harness cover to the

right, remove it.

0993doE22

3.

Remove the Print Head Unit. (3

screws, 1

connector)

D-7

Page 49

2-7. Paper Empty Sensor Assy.

(7’

2-8.

Paper Take-up Roll Assy.

Take-up Roll Assy.

OS93dO72

Transport Guide

1.Removefheoutercwtr.(Referto~2-1)

2.

Remove the

3. Remove

Harness

Cover.

the

Paper Empty Sensor

(Resfa

Assy.

to sect

(3

245)

stxws.

Connectors)

Note: After reinstallation, Secure the harness

in the wire saddle.

1.RemovethePeperEmptySensorAssy.(Referto

sect.

2-7)

2.Pulhgup.removetheTranspatGGk

3.

Remove

the

Paper Take-up Roll

Assy.

(1 screw)

;

2

5.

(. :

2-9. Registration Roller

Assy.

0993dO822

1.RemovetbeOuterCmx.@efkrtosect.2-1)

2.

Remove

the Fusing Unit (Refer to sect 2-2)

3.

Remove

the

4.

Remove the High Voltage Unit. (Refer to sect.

5.

llemwe

sect.

2-7)

6. Remove the Paper

Note: Move the printer Left Frame in the

direction of the arrow to unlock the

the

7.

Rmove

Note:

to unlock it from the tight drive unit of the

printer.

D-8

Transk

the Paper Empty

frame.

the Paper

Side

Unit.

(Refer to sect

Sensor Assy. (Refer

Lifting

Plate. (1 screws)

T&e-up

Roller Unit. (1

the unit in the direction of

2-3)

p&e

the

24)

to

from

screw)

arrow

Page 50

.

8. Remove

i

099311102

the

Registration Roller

Assy.

(3

screws)

2-10. Drive Unit

,-

(

1. Remove

2. Remove

3. Remove

4. Remove the High Voltage Unit

5.RemovethePapezE.nptySensorAssy.@eferto

sect. 2-7)

6.RemovetheRegistr~Roll~hsy.Wertosect

,243

7. Remove the Drive Unit (5 screws, 7 cumectm)

the Outer

the Pusing

the

Cover.

Transfer Unit (R&x to sect 2-3)

(R&s

to

sect.

Unit (Refer to sect

(Refer

to

2-l)

2-2)

sect. 2-4)

2-l 1. Duplex Unit

D-9

1.

Loosen

2

SLxews.

2. Remove

Note: At reinstallation, position the two

the

Duplex Unit

positioning pins, coupling gear, and coupling

amnector correctly.

Page 51

E: ADJUSTMENT

1.

IMAGE REGISTRATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

;

E - 1

Page 52

-,

Page 53

1. IMAGE REGISTRATION

: After the Main

below.

1

t

Gapd

Paper Reading

Registration position

ControlBoard

(PWB-A)

Edge

~replaced.

PWB-A

adjust

1. Remove

the

gap by

Disassembly/ Clean@

fouo*g the pr-

the

Light

Fret

Cover.

item

2-l)

hbd

@efex

to the

7

Dz

E-l

3.

Another

Adjust

between

adjustment.

the

VRlA so

VRlA

and ground terminal.

that the

Voltage is 250V

Page 54

i-

F: TROUBLESHOOTING

1.TROUBLEDEIECI’JON

l-l.

JAMDetection

1-2.

Fusing

unit

malfuncrion

1-3.

Laser malflmcti0r.l

1-Q.

Folygon

Motor ma&n&on

l-5.

Fan M&r

l-6.

Main

2. ACTION FOR

2-1. JAM1

2-2. JAM2...................................................................................................................................

i:

2-3.JAM3

2-4. JAM4...................................................................................................................................

2-5. Fusing Unit

2-6.

Laser

2-7. Polygon Motor malfunction

2-8.

FanMotor malfunction

2-9. Main Motor

3.OTHERDETECIXD

3-1.

NoPower

3-2. Skew

4.

IMAGE QU-

BklC.WWhikl.iIleS

Horizantal

Low Image Density

Foggy background

No

Image(Blank/ Black)

Offset Image

malfunction

Motor

DElTCTED

..........................

...................................................................................................................................

malfunction

............................................................................................................................

...................................................................................................................................

lines

..............................................................................................................................

.............................................................................................................

....................................................................................................................

.....................................................................................................

...................................

malfunction...........................................

malfixuztion

................................................................................................................

maH%nction

TROUBLE

TROUBLE

.....................................................................................................................

.........................................................................................................................

...................................................................................................................

.....................................................................................................................

-

................................................................................................

.......................................................................................................

JAM OR

..~.......................-.............................................................................

.....................................................................................................

.......................................................................................................

...........................................................................................................

MAJXUNCI’ION

................................................................................................

.....................................................................................................

................................................................................................

...................................................................................................

........................................................................

..eT

.........................................................

.

...........................................................

F-l

F-l

F-2

F-2

F-2

F-2

F-2

F-3

F-3

F-3

F-4

F-4

F-5

F-5

F-5

F-5

F-5

F-6

Fd

F-6

F-7

F-7

F-7

F-7

F-7

F-8

F-8

Page 55

1. JAM DETECTION

Note: This printer detects the following

conditions is detected, all printer elements are brought to a stop except the fan motor.

l-l. JAM Detection

A

misfeed

may be

1. When paper is fed

approx. 1.6 sec. after the Paper Take-up Roll has started

2.

When paper is fed from the 2nd paper tray, the Registration

approx. 1.4 sec. (approx. 2.5 sec. for the

turning

3. when paper is fed

approx. 1.0 sec. after the leading edge of

4.‘IIePaperTake-upSensor(PC1)

is closed a Duplex Cover ia closed

S.ThePaperTalre-upSensat(PCl)isintbeactivatedstatettbeperioddtimeequivalenttotbepapersize

plus 2.8 sec.

6.ThePaper~tSensor(P(33)isinthedeactivatedstateapprox.2.3sec.afterthe~edgeofthepaper

has

cla&ied

(JAhll).

reached the Papet Takeq

into one of four categories,

from

the Multi-purpose tray, the Paper Take-up Sensor

from

after

the

leading

misfeeds

the 2nd paper

isintbeactivatedstatew~tbePow~is tumedON.artheUpper~t

(JAM2).

edge of the

Sensor

and malfunctions. When any of these trouble

JAMl. JAM2. JAM3,

Third

Cassette Unit) after

tray. the

Paper Take-up Sensor

the

paper has reached

paper

has

nz&ed the Paper

(Xl>

(JAFM).

turning

Sensa

and JAM4, as detailed below.

(PCl)

is in the deactivated state

(JAN).

(PCRl)

is in the deactivated state

the

Paper Take-up Roll has started

@Cl)

is in tk deactivated state

the,&gistration

Take-up Sensor

Sensor

@‘CXi)

(Xl)

(JAW).

(JAMl).

7.ThePaper~tSensor~)isintheactivatedstateapprox.2.3sec.afferthetrairingedgedthep

has-moved past the

8.ThePaperEjcitSensor(PC3)isintheactivatedstatewheathePwerisRrrnedON.ortheUpperuaitis

closed a Duplex cover is closed

9. The Duplex Paper

the Duplex unit has been eneqized

1O.TheRegistrationsenSar~1)isinthedeactivatedstate~~ox l.lsec.aftertheleadingedgeofthe

paper has reached the Duplex Paper Sensor

11. When paper is fed

1.0 sec. after

12.

The Duplex Paper

is closed a Duplex cover is closed